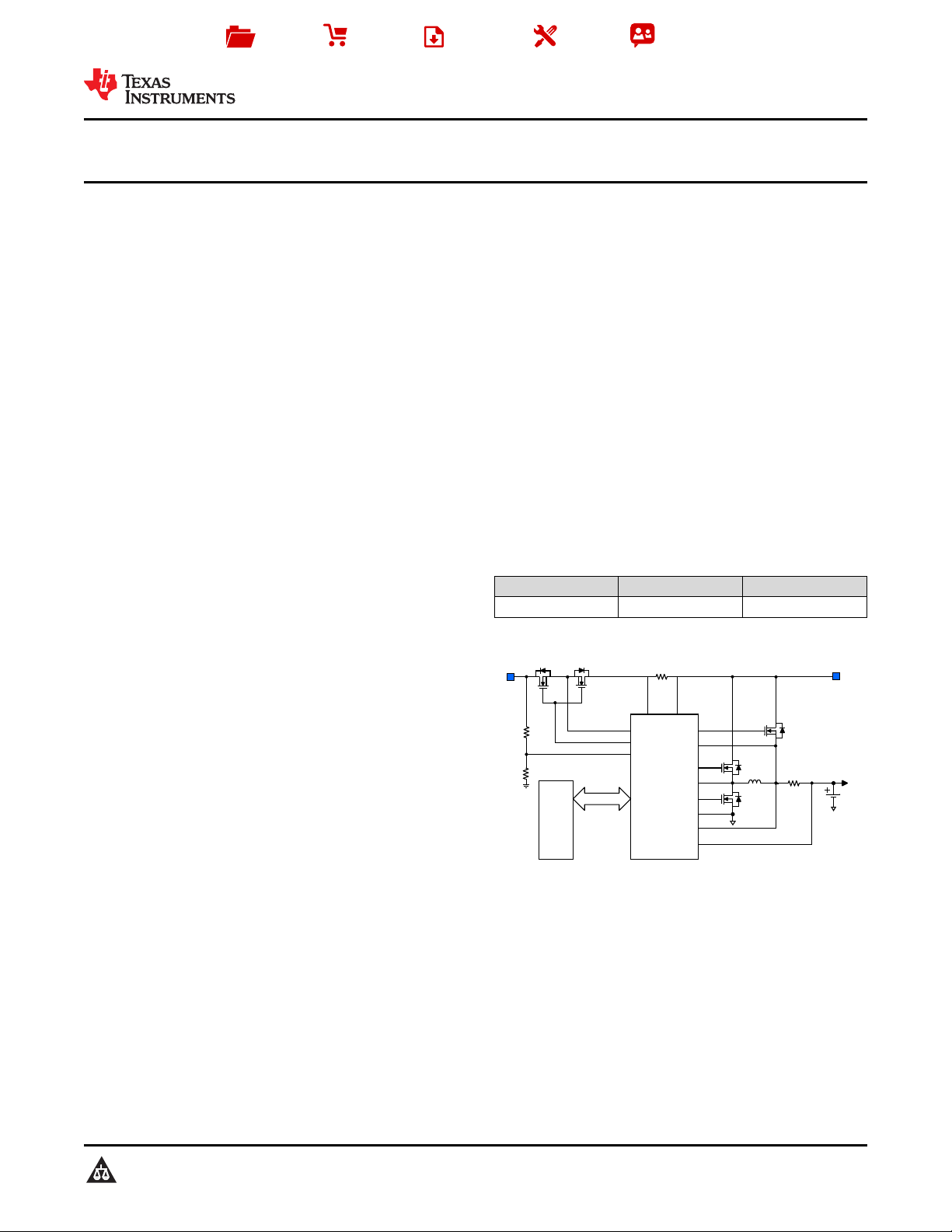

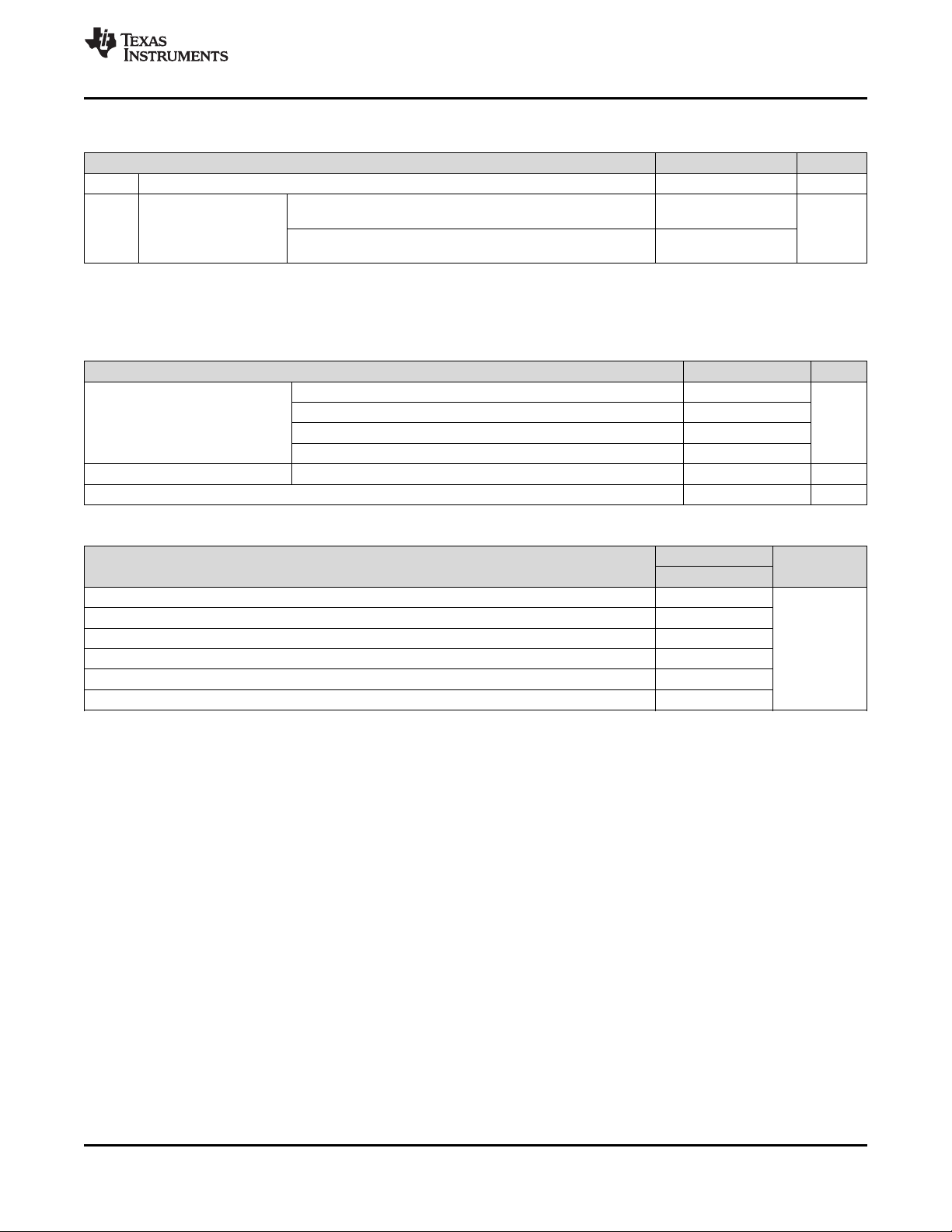

R

SR

Adapter

4.5-24V

HOST

bq24725A

Hybrid Power

Boost Charge

Controller

SYS

Battery

Pack

N-FET Driver

N-FET Driver

1S-4S

SMBus

SMBus Controls V & I

with high accuracy

Adapter Detection

Enhanced Safety:

OCP,OVP, FET Short

Integration:

Loop Compensation; Soft-Start

Comparator

R

AC

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

bq24725A 1-4 Cell Li+ Battery SMBus Charge Controller with N-Channel Power MOSFET

Selector and Advanced Circuit Protection

1 Features 3 Description

1

• SMBus Host-Controlled NMOS-NMOS

Synchronous Buck Converter with Programmable

615kHz, 750kHz, and 885kHz Switching

Frequencies

• Automatic N-channel MOSFET Selection of

System Power Source from Adapter or Battery

Driven by Internal Charge Pumps

• Enhanced Safety Features for Over Voltage

Protection, Over Current Protection, Battery,

Inductor and MOSFET Short Circuit Protection

• Programmable Input Current, Charge Voltage,

Charge Current Limits

– ±0.5% Charge Voltage Accuracy up to 19.2V

– ±3% Charge Current Accuracy up to 8.128A

– ±3% Input Current Accuracy up to 8.064A

– ±2% 20x Adapter Current or Charge Current

Amplifier Output Accuracy

• Programmable Battery Depletion Threshold, and

Battery LEARN Function

• Programmable Adapter Detection and Indicator

• Integrated Soft Start

• Integrated Loop Compensation

• Real Time System Control on ILIM pin to Limit

Charge Current

• AC Adapter Operating Range 4.5V-24V

• 5µA Off-State Battery Discharge Current

• 0.65mA (0.8mA max) Adapter Standby Quiescent

Current

• 20-pin 3.5 x 3.5 mm2VQFN Package

The bq24725A is a high-efficiency, synchronous

battery charger, offering low component count for

space-constraint, multi-chemistry battery charging

applications.

The bq24725A utilizes two charge pumps to

separately drive n-channel MOSFETs (ACFET,

RBFET and BATFET) for automatic system power

source selection.

SMBus controlled input current, charge current, and

charge voltage DACs allow for very high regulation

accuracies that can be easily programmed by the

system power management micro-controller.

The bq24725A uses internal input current register or

external ILIM pin to throttle down PWM modulation to

reduce the charge current.

The bq24725A charges one, two, three or four series

Li+ cells.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

bq24725A VQFN (20) 3.50mm x 3.50mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

(1)

2 Applications

• Portable Notebook Computers, UMPC, Ultra-Thin

Notebook, and Netbook

• Handheld Terminal

• Industrial and Medical Equipment

• Portable Equipment

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Pin Configuration and Functions......................... 3

6 Specifications......................................................... 4

6.1 Absolute Maximum Ratings ...................................... 4

6.2 Handling Ratings....................................................... 5

6.3 Recommended Operating Conditions....................... 5

6.4 Thermal Information.................................................. 5

6.5 Electrical Characteristics........................................... 6

6.6 Timing Characteristics............................................. 10

6.7 Typical Characteristics............................................ 10

7 Parameter Measurement Information ................ 12

8 Detailed Description ............................................ 13

8.1 Overview................................................................. 13

8.2 Functional Block Diagram....................................... 14

8.3 Feature Description................................................. 15

8.4 Device Functional Modes........................................ 16

8.5 Register Maps......................................................... 22

9 Application and Implementation ........................ 28

9.1 Application Information............................................ 28

9.2 Typical Application .................................................. 28

9.3 Application Curves .................................................. 35

9.4 System Examples .................................................. 35

10 Power Supply Recommendations ..................... 36

11 Layout................................................................... 37

11.1 Layout Guidelines ................................................. 37

11.2 Layout Example ................................................... 38

12 Device and Documentation Support ................. 39

12.1 Third-Party Products Disclaimer ........................... 39

12.2 Trademarks........................................................... 39

12.3 Electrostatic Discharge Caution............................ 39

12.4 Glossary................................................................ 39

13 Mechanical, Packaging, and Orderable

Information........................................................... 39

4 Revision History

Changes from Original (September 2011) to Revision A Page

• Changed the format to the new TI standard .......................................................................................................................... 1

• Added the Device Information table ...................................................................................................................................... 1

• Added LODRV, HIDRV, and PHASE (2% duty cycle) to the Abs Max Table........................................................................ 4

• Added the Handling Ratings table.......................................................................................................................................... 5

2 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

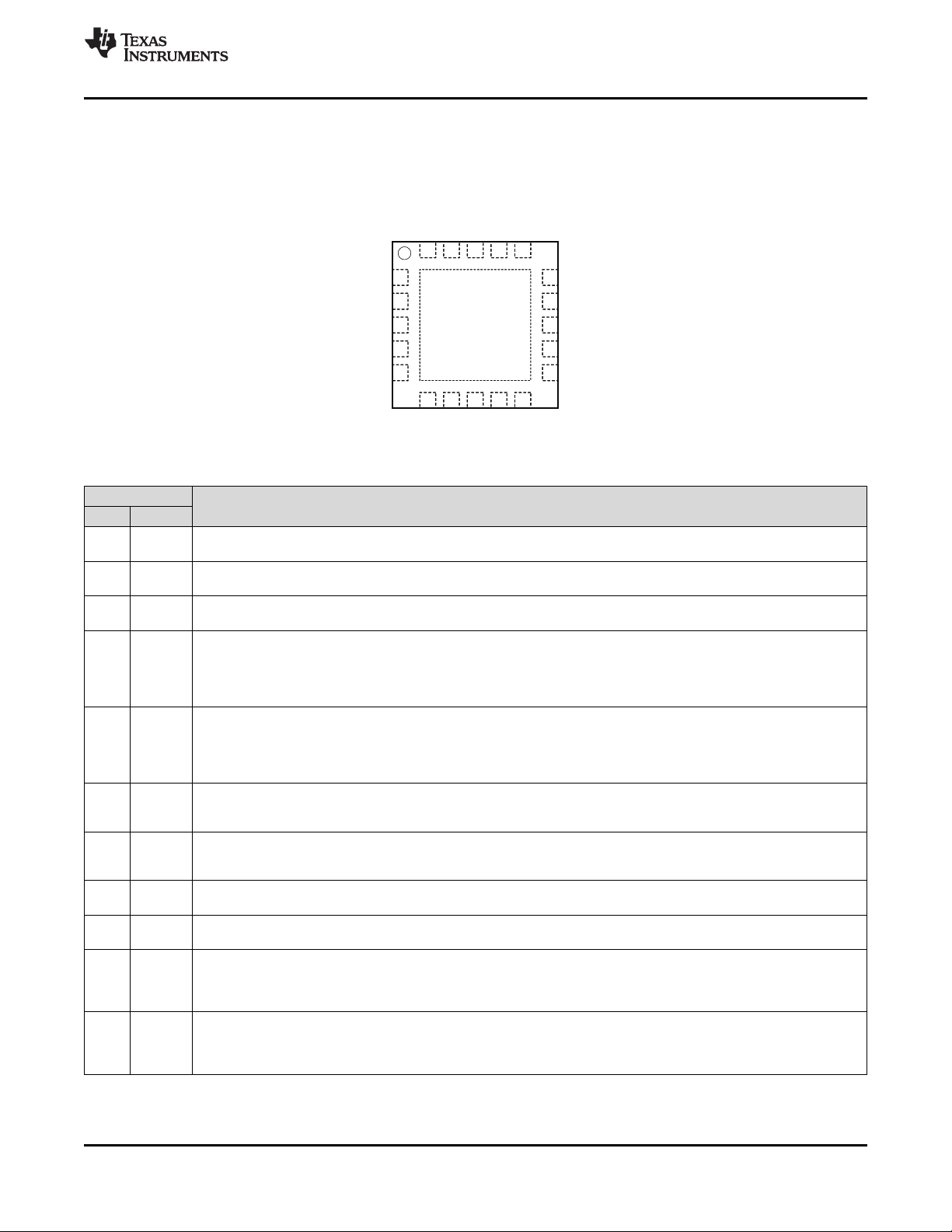

1

2

3

4

5

6 7 8 9 10

15

14

13

12

11

20 19 18 17 16

ACN

ACP

CMSRC

ACDRV

ACOK

ACDET

IOUT

SDA

SCL

ILIM

BATDRV

SRN

SRP

GND

LODRV

REGN

BTST

HIDRV

PHASE

VCC

bq24725A

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

5 Pin Configuration and Functions

RGR Package

Top View

Pin Functions

PIN

NO. NAME

1 ACN Input current sense resistor negative input. Place an optional 0.1µF ceramic capacitor from ACN to GND for common-

mode filtering. Place a 0.1µF ceramic capacitor from ACN to ACP to provide differential mode filtering.

2 ACP Input current sense resistor positive input. Place a 0.1µF ceramic capacitor from ACP to GND for common-mode

filtering. Place a 0.1µF ceramic capacitor from ACN to ACP to provide differential-mode filtering.

3 CMSRC ACDRV charge pump source input. Place a 4kΩ resistor from CMSRC to the common source of ACFET (Q1) and

RBFET (Q2) limits the in-rush current on CMSRC pin.

4 ACDRV Charge pump output to drive both adapter input n-channel MOSFET (ACFET) and reverse blocking n-channel MOSFET

(RBFET). ACDRV voltage is 6V above CMSRC when voltage on ACDET pin is between 2.4V to 3.15V, voltage on VCC

pin is above UVLO and voltage on VCC pin is 275mV above voltage on SRN pin so that ACFET and RBFET can be

turned on to power the system by AC adapter. Place a 4kΩ resistor from ACDRV to the gate of ACFET and RBFET

limits the in-rush current on ACDRV pin.

5 ACOK AC adapter detection open drain output. It is pulled HIGH to external pull-up supply rail by external pull-up resistor when

voltage on ACDET pin is between 2.4V and 3.15V, and voltage on VCC is above UVLO and voltage on VCC pin is

275mV above voltage on SRN pin, indicating a valid adapter is present to start charge. If any one of the above

conditions can not meet, it is pulled LOW to GND by internal MOSFET. Connect a 10kΩ pull up resistor from ACOK to

the pull-up supply rail.

6 ACDET Adapter detection input. Program adapter valid input threshold by connecting a resistor divider from adapter input to

ACDET pin to GND pin. When ACDET pin is above 0.6V and VCC is above UVLO, REGN LDO is present, ACOK

comparator and IOUT are both active.

7 IOUT Buffered adapter or charge current output, selectable with SMBus command ChargeOption(). IOUT voltage is 20 times

the differential voltage across sense resistor. Place a 100pF or less ceramic decoupling capacitor from IOUT pin to

GND.

8 SDA SMBus open-drain data I/O. Connect to SMBus data line from the host controller or smart battery. Connect a 10kΩ pull-

up resistor according to SMBus specifications.

9 SCL SMBus open-drain clock input. Connect to SMBus clock line from the host controller or smart battery. Connect a 10kΩ

pull-up resistor according to SMBus specifications.

10 ILIM Charge current limit input. Program ILIM voltage by connecting a resistor divider from system reference 3.3V rail to ILIM

pin to GND pin. The lower of ILIM voltage or DAC limit voltage sets charge current regulation limit. To disable the

control on ILIM, set ILIM above 1.6V. Once voltage on ILIM pin falls below 75mV, charge is disabled. Charge is enabled

when ILIM pin rises above 105mV.

11 BATDRV Charge pump output to drive Battery to System n-channel MOSFET (BATFET). BATDRV voltage is 6V above SRN to

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 3

turn on BATFET to power the system from battery. BATDRV voltage is SRN voltage to turn off BATFET to power

system from AC adapter. Place a 4kΩ resistor from BATDRV to the gate of BATFET limits the in-rush current on

BATDRV pin.

Product Folder Links: bq24725A

DESCRIPTION

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

www.ti.com

Pin Functions (continued)

PIN

NO. NAME

12 SRN Charge current sense resistor negative input. SRN pin is for battery voltage sensing as well. Connect SRN pin to a 7.5

Ω resistor first then from resistor another terminal connect a 0.1µF ceramic capacitor to GND for common-mode filtering

and connect to current sensing resistor. Connect a 0.1µF ceramic capacitor between current sensing resistor to provide

differential mode filtering. See application information about negative output voltage protection for hard shorts on battery

to ground or battery reverse connection by adding small resistor.

13 SRP Charge current sense resistor positive input. Connect SRP pin to a 10 Ω resistor first then from resistor another terminal

connect to current sensing resistor. Connect a 0.1µF ceramic capacitor between current sensing resistor to provide

differential mode filtering. See application information about negative output voltage protection for hard shorts on battery

to ground or battery reverse connection by adding small resistor.

14 GND IC ground. On PCB layout, connect to analog ground plane, and only connect to power ground plane through the power

pad underneath IC.

15 LODRV Low side power MOSFET driver output. Connect to low side n-channel MOSFET gate.

16 REGN Linear regulator output. REGN is the output of the 6V linear regulator supplied from VCC. The LDO is active when

voltage on ACDET pin is above 0.6V and voltage on VCC is above UVLO. Connect a 1µF ceramic capacitor from

REGN to GND.

17 BTST High side power MOSFET driver power supply. Connect a 0.047µF capacitor from BTST to PHASE, and a bootstrap

Schottky diode from REGN to BTST.

18 HIDRV High side power MOSFET driver output. Connect to the high side n-channel MOSFET gate.

19 PHASE High side power MOSFET driver source. Connect to the source of the high side n-channel MOSFET.

20 VCC Input supply, diode OR from adapter or battery voltage. Use 10Ω resistor and 1µF capacitor to ground as low pass filter

to limit inrush current.

PowerPAD™ Exposed pad beneath the IC. Analog ground and power ground star-connected only at the PowerPAD plane. Always

solder PowerPad to the board, and have vias on the PowerPAD plane connecting to analog ground and power ground

planes. It also serves as a thermal pad to dissipate the heat.

DESCRIPTION

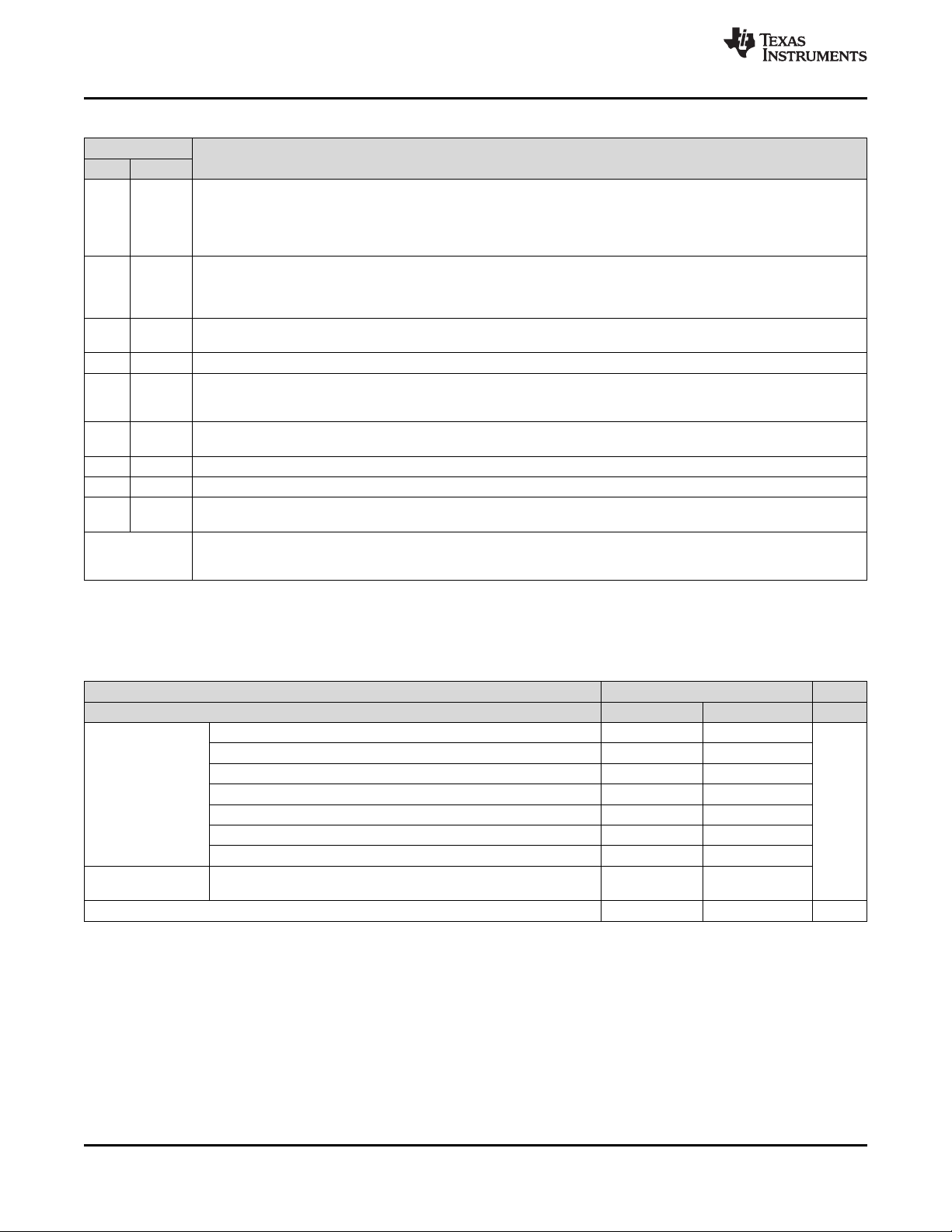

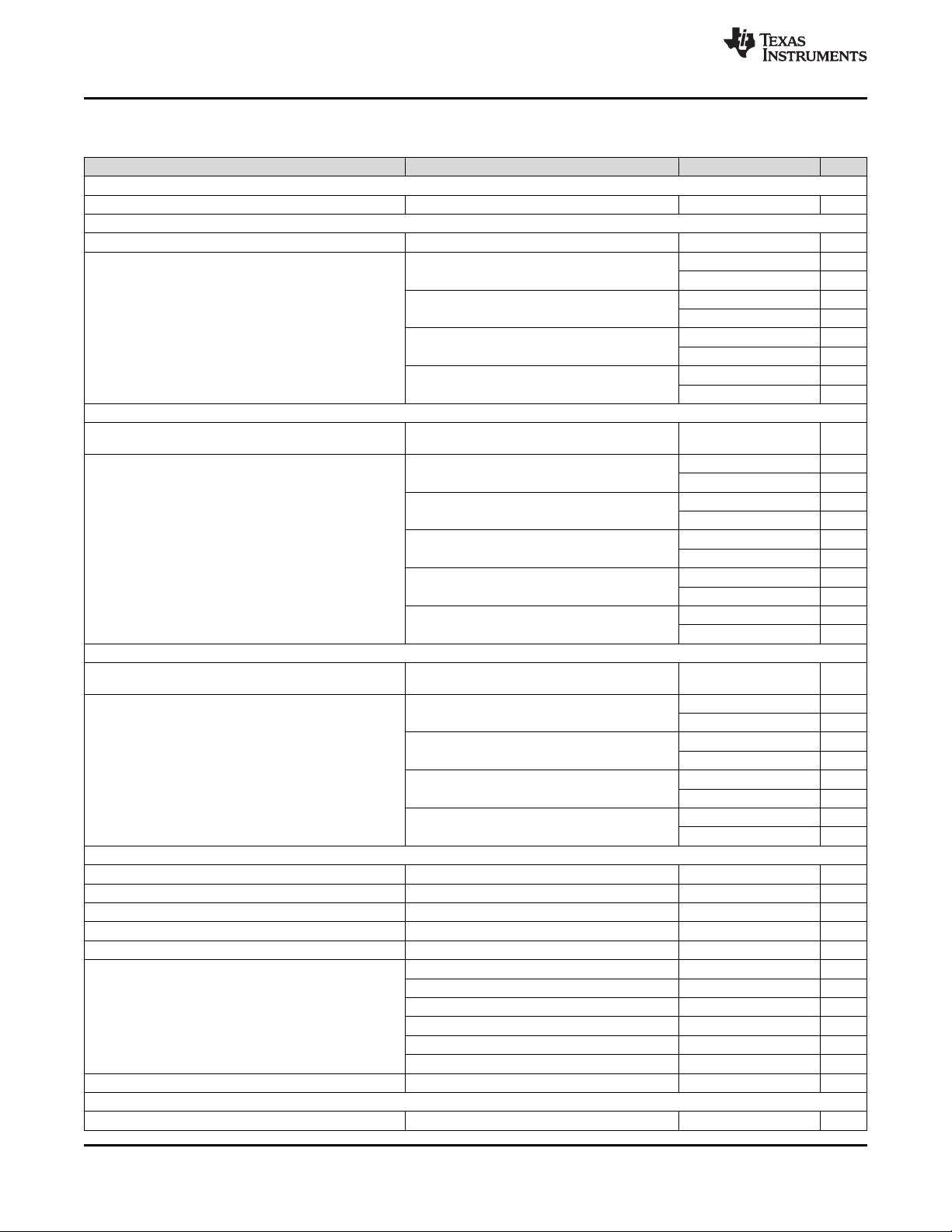

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

SRN, SRP, ACN, ACP, CMSRC, VCC –0.3 30

PHASE –2 30

ACDET, SDA, SCL, LODRV, REGN, IOUT, ILIM, ACOK –0.3 7

Voltage range BTST, HIDRV, ACDRV, BATDRV –0.3 36

LODRV (2% duty cycle) –4 7

HIDVR (2% duty cycle) –4 36

PHASE (2% duty cycle) –4 30

Maximum difference SRP–SRN, ACP–ACN –0.5 0.5

voltage

Junction temperature range, T

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to GND if not specified. Currents are positive into, negative out of the specified terminal. Consult Packaging

Section of the data book for thermal limitations and considerations of packages.

J

(1) (2)

VALUE UNIT

MIN MAX

V

–40 155 °C

4 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

6.2 Handling Ratings

MIN MAX UNIT

T

V

stg

(ESD)

Storage temperature range –55 155 °C

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all

(1)

Electrostatic discharge V

pins

Charged device model (CDM), per JEDEC specification

JESD22-C101, all pins

(2)

–2000 2000

–500 500

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

SRN, SRP, ACN, ACP, CMSRC, VCC 0 24

Voltage range V

Maximum difference voltage SRP–SRN, ACP–ACN –0.2 0.2 V

Junction temperature range, T

PHASE -2 24

ACDET, SDA, SCL, LODRV, REGN, IOUT, ILIM, ACOK 0 6.5

BTST, HIDRV, ACDRV, BATDRV 0 30

J

0 125 °C

6.4 Thermal Information

(1)

R

R

R

ψ

ψ

R

θJA

θJCtop

θJB

JT

JB

θJCbot

THERMAL METRIC

Junction-to-ambient thermal resistance 46.8

Junction-to-case (top) thermal resistance 56.9

Junction-to-board thermal resistance 46.6

Junction-to-top characterization parameter 0.6

Junction-to-board characterization parameter 15.3

Junction-to-case (bottom) thermal resistanc 4.4

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

bq24725A

RGR (20 PIN)

UNIT

°C/W

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: bq24725A

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

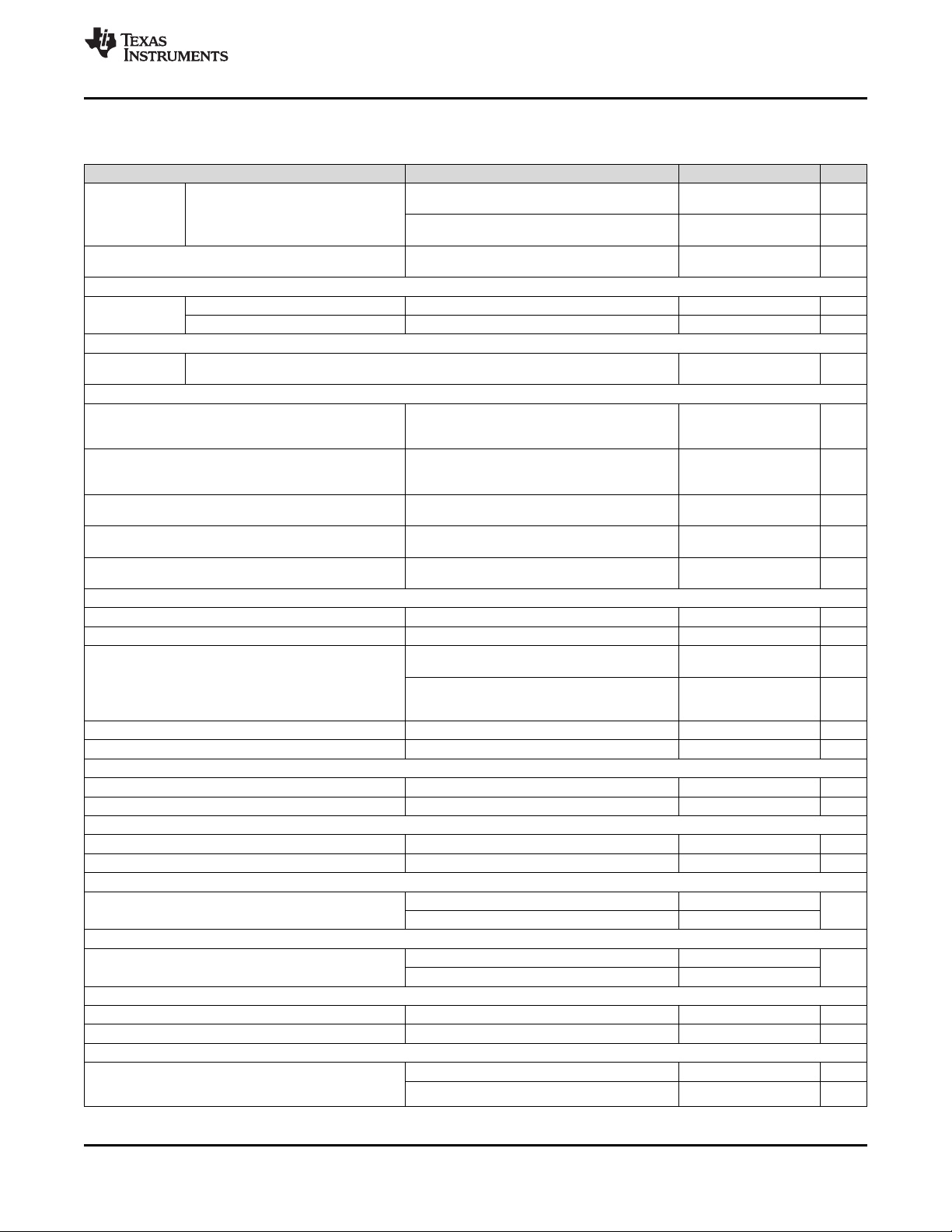

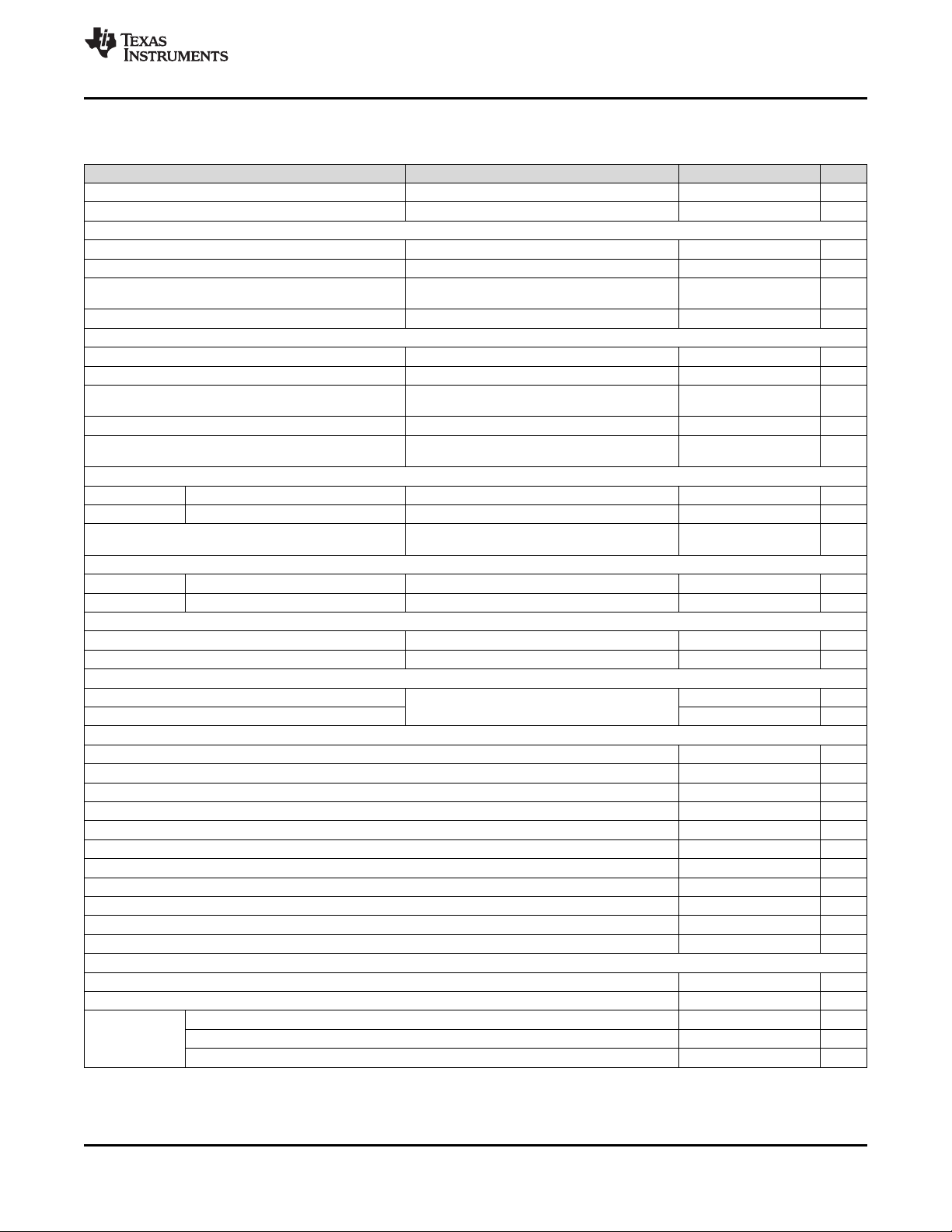

6.5 Electrical Characteristics

4.5 V ≤ V

OPERATING CONDITIONS

V

VCC_OP

CHARGE VOLTAGE REGULATION

V

BAT_REG_RNG

V

BAT_REG_ACC

CHARGE CURRENT REGULATION

V

IREG_CHG_RNG

I

CHRG_REG_ACC

INPUT CURRENT REGULATION

V

IREG_DPM_RNG

I

DPM_REG_ACC

INPUT CURRENT OR CHARGE CURRENT SENSE AMPLIFIER

V

ACP/N_OP

V

SRP/N_OP

V

IOUT

I

IOUT

A

IOUT

V

IOUT_ACC

C

IOUT_MAX

REGN REGULATOR

V

REGN_REG

≤ 24 V, 0°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VCC Input voltage operating range 4.5 24 V

Battery voltage range 1.024 19.2 V

Charge voltage regulation accuracy

Charge current regulation differential

voltage range

Charge current regulation accuracy 10mΩ

current sensing resistor

Input current regulation differential voltage

range

Input current regulation accuracy 10mΩ

current sensing resistor

Input common mode range Voltage on ACP/ACN 4.5 24 V

Output common mode range Voltage on SRP/SRN 0 19.2 V

IOUT output voltage range 0 3.3 V

IOUT output current 0 1 mA

Current sense amplifier gain V

Current sense output accuracy

Maximum output load capacitance For stability with 0 to 1mA load 100 pF

REGN regulator voltage V

ChargeVoltage() = 0x41A0H

ChargeVoltage() = 0x3130H

ChargeVoltage() = 0x20D0H

ChargeVoltage() = 0x1060H

V

IREG_CHG

= V

SRP

- V

SRN

ChargeCurrent() = 0x1000H

ChargeCurrent() = 0x0800H

ChargeCurrent() = 0x0200H

ChargeCurrent() = 0x0100H

ChargeCurrent() = 0x0080H

V

IREG_DPM

= V

ACP

– V

ACN

InputCurrent() = 0x1000H

InputCurrent() = 0x0800H

InputCurrent() = 0x0400H

InputCurrent() = 0x0200H

or V

or V

or V

or V

or V

or V

or V

(ACP-ACN)

= 40.96mV –2% 2%

(ACP-ACN)

= 20.48mV –4% 4%

(ACP-ACN)

= 10.24mV –15% 15%

(ACP-ACN)

= 5.12mV –20% 20%

(ACP-ACN)

= 2.56mV –33% 33%

(ACP-ACN)

= 1.28mV –50% 50%

(ACP-ACN)

> 0.6V (0-45mA load) 5.5 6 6.5 V

ACDET

(ICOUT)/V(SRP-SRN)

V

(SRP-SRN)

V

(SRP-SRN)

V

(SRP-SRN)

V

(SRP-SRN)

V

(SRP-SRN)

V

(SRP-SRN)

> 6.5V, V

VCC

www.ti.com

16.716 16.8 16.884 V

-0.5% 0.5%

12.529 12.592 12.655 V

–0.5% 0.5%

8.350 8.4 8.45 V

–0.6% 0.6%

4.163 4.192 4.221 V

–0.7% 0.7%

0 81.28 mV

3973 4096 4219 mA

–3% 3%

1946 2048 2150 mA

–5% 5%

410 512 614 mA

–20% 20%

172 256 340 mA

–33% 33%

64 128 192 mA

–50% 50%

0 80.64 mV

3973 4096 4219 mA

–3% 3%

1946 2048 2150 mA

–5% 5%

870 1024 1178 mA

–15% 15%

384 512 640 mA

–25% 25%

20 V/V

6 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

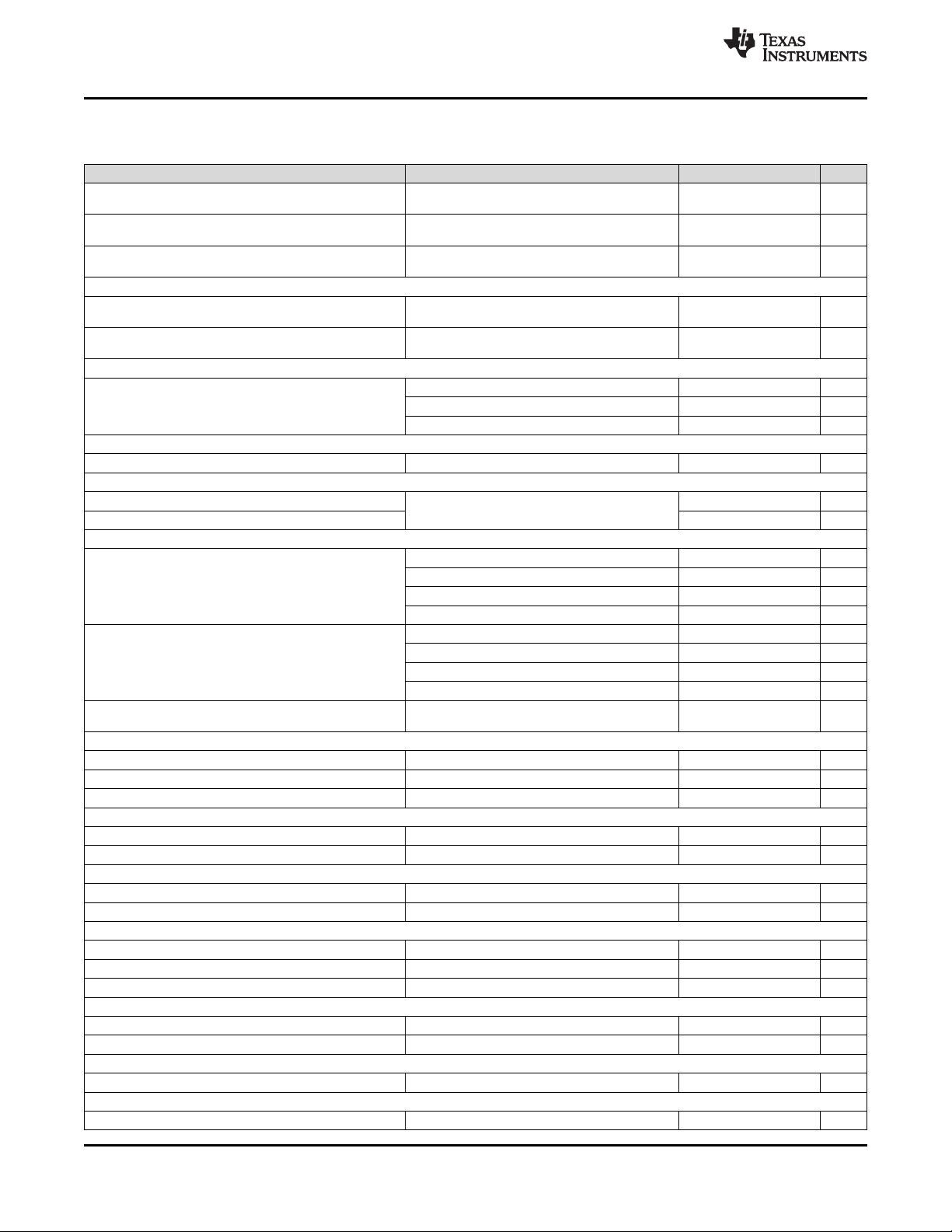

www.ti.com

Electrical Characteristics (continued)

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

4.5 V ≤ V

≤ 24 V, 0°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

REGN_LIM

C

REGN

REGN current limit

REGN output capacitor required for I

stability

INPUT UNDERVOLTAGE LOCKOUT COMPARATOR (UVLO)

UVLO

Under voltage rising threshold V

Under voltage hysteresis, falling V

FAST DPM COMPARATOR (FAST_DPM)

V

FAST_DPM

Fast DPM comparator stop charging rising threshold with respect to input current limit, voltage

across input sense resistor rising edge

QUIESCENT CURRENT

Battery BATFET OFF STATE Current,

I

BAT_BATFET_OFF

BATFET off,

I

+ I

SRP

SRN

+ I

PHASE

+ I

ACP

+ I

ACN

Battery BATFET ON STATE Current,

I

BAT_BATFET_ON

I

STANDBY

I

AC_NOSW

I

AC_SW

BATFET on,

I

+ I

+ I

+ I

+ I

VCC

ACP

+ I

+ I

ACN

ACP

SRP

SRN

PHASE

VCC

Standby quiescent current, I

I

ACN

Adapter bias current during charge, V

I

+ I

ACP

+ I

ACN

VCC

Adapter bias current during charge, V

I

+ I

ACP

+ I

ACN

VCC

ACOK COMPARATOR

V

ACOK_RISE

V

ACOK_FALL_HYS

V

ACOK_RISE_DEG

V

WAKEUP_RISE

V

WAKEUP_FALL

ACOK rising threshold V

ACOK falling hysteresis V

ACOK rising deglitch (Specified by design)

WAKEUP detect rising threshold V

WAKEUP detect falling threshold V

VCC to SRN COMPARATOR (VCC_SRN)

V

VCC-SRN_FALL

V

VCC-SRN _RHYS

VCC-SRN falling threshold V

VCC-SRN rising hysteresis V

ACN to SRN COMPARATOR (ACN_SRN)

V

ACN-SRN_FALL

V

ACN-SRN_RHYS

HIGH SIDE IFAULT COMPARATOR (IFAULT_HI)

V

IFAULT_HI_RISE

LOW SIDE IFAULT COMPARATOR (IFAULT_LOW)

V

IFAULT_LOW_RISE

ACN to BAT falling threshold V

ACN to BAT rising hysteresis V

(1)

ACP to PHASE rising threshold mV

(1)

PHASE to GND rising threshold mV

INPUT OVER-VOLTAGE COMPARATOR (ACOV)

V

ACOV

V

ACOV_HYS

INPUT OVER-CURRENT COMPARATOR (ACOC)

ACDET over voltage rising threshold V

ACDET over voltage falling hysteresis V

(1)

Adapter over current rising threshold with ChargeOption() bit [1] = 1 (Default) 300% 333% 366%

V

ACOC

respect to input current limit, voltage

across input sense resistor rising edge

V

= 0V, V

REGN

TSHUT

V

= 0V, V

REGN

TSHUT

= 100µA to 50mA 1

LOAD

rising 3.5 3.75 4 V

VCC

falling 340 mV

VCC

> UVLO charge enabled and not in 50 75

VCC

> UVLO charge disabled or in 7 14

VCC

103% 107% 111%

V

= 16.8V, VCC disconnect from battery, BATFET

VBAT

charge pump off, BATFET turns off, TJ= 0 to 85°C

V

= 16.8V, VCC connect from battery, BATFET

VBAT

charge pump on, BATFET turns on, TJ= 0 to 85°C

+ V

> UVLO, V

VCC

TJ= 0 to 85°C

> UVLO, 2.4V < V

VCC

charge enabled, no switching, TJ= 0 to 85°C

> UVLO, 2.4V < V

VCC

charge enabled, switching, MOSFET Sis412DN

> UVLO, V

VCC

> UVLO, V

VCC

V

> UVLO, V

VCC

First time OR ChargeOption() bit [15] = 0

V

> UVLO, V

VCC

(NOT First time) AND ChargeOption() bit [15] = 1 0.9 1.3 1.7 s

> 0.6V, charge disabled,

ACDET

< 3.15V,

ACDET

< 3.15V,

ACDET

rising 2.376 2.4 2.424 V

ACDET

falling 35 55 75 mV

ACDET

rising above 2.4V,

ACDET

rising above 2.4V,

ACDET

0.65 0.8 mA

1.5 3 mA

10 mA

100 150 200 ms

(Default)

> UVLO, V

VCC

> UVLO, V

VCC

falling towards V

VCC

rising above V

VCC

falling towards V

ACN

rising above V

ACN

rising 0.57 0.8 V

ACDET

falling 0.3 0.51 V

ACDET

SRN

SRN

SRN

SRN

70 125 200 mV

100 150 200 mV

120 200 280 mV

40 80 120 mV

ChargeOption() bit [8] = 1 (Default) 450 750 1200

ChargeOption() bit [8] = 0 Disable function

ChargeOption() bit [7] = 0 (Default) 70 135 220

ChargeOption() bit [7] = 1 140 230 340

rising 3.05 3.15 3.25 V

ACDET

falling 50 75 100 mV

ACDET

ChargeOption() bit [1] = 0 Disable function

mA

mA

µF

5 µA

25 µA

(1) User can adjust threshold via SMBus ChargeOption() REG0x12.

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: bq24725A

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

Electrical Characteristics (continued)

www.ti.com

4.5 V ≤ V

≤ 24 V, 0°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

ACOC_min

V

ACOC_max

t

ACOC_DEG

Min ACOC threshold clamp voltage 40 45 50 mV

Max ACOC threshold clamp voltage 135 150 165 mV

ACOC deglitch time (Specified by design) 2.3 4.2 6.6 ms

BAT OVER-VOLTAGE COMPARATOR (BAT_OVP)

V

OVP_RISE

V

OVP_FALL

Over voltage rising threshold as V

percentage of V

BAT_REG

Over voltage falling threshold as V

percentage of V

BAT_REG

CHARGE OVER-CURRENT COMPARATOR (CHG_OCP)

Charge over current rising threshold,

V

OCP_RISE

measure voltage drop across current ChargeCurrent()=0x1000H – 0x17C0H 80 90 100 mV

sensing resistor

CHARGE UNDER-CURRENT COMPARATOR (CHG_UCP)

V

UCP_FALL

Charge under-current falling threshold V

LIGHT LOAD COMPARATOR (LIGHT_LOAD)

V

LL_FALL

V

LL_RISE_HYST

Light load falling threshold 1.25 mV

Light load rising hysteresis 1.25 mV

BATTERY DEPLETION COMPARATOR (BAT_DEPL) [1]

Battery depletion falling threshold,

V

BATDEPL_FALL

V

BATDEPL_RHYST

t

BATDEPL_RDEG

percentage of voltage regulation limit, V

falling

Battery depletion rising hysteresis, V

rising

Battery Depletion Rising Deglitch Delay to turn off ACFET and turn on BATFET during

(Specified by design) LEARN cycle

BATTERY LOWV COMPARATOR (BAT_LOWV)

V

BATLV_FALL

V

BATLV_RHYST

I

BATLV

Battery LOWV falling threshold V

Battery LOWV rising hysteresis V

Battery LOWV charge current limit 10 mΩ current sensing resistor 0.5 A

THERMAL SHUTDOWN COMPARATOR (TSHUT)

T

SHUT

T

SHUT_HYS

Thermal shutdown rising temperature Temperature rising 155 °C

Thermal shutdown hysteresis, falling Temperature falling 20 °C

ILIM COMPARATOR

V

ILIM_FALL

V

ILIM_RISE

ILIM as CE falling threshold V

ILIM as CE rising threshold V

LOGIC INPUT (SDA, SCL)

V

IN_ LO

V

IN_ HI

I

IN_ LEAK

Input low threshold 0.8 V

Input high threshold 2.1 V

Input bias current V = 7 V –1 1 μA

LOGIC OUTPUT OPEN DRAIN (ACOK, SDA)

V

OUT_ LO

I

OUT_ LEAK

Output saturation voltage 5 mA drain current 500 mV

Leakage current V = 7 V –1 1 μA

ANALOG INPUT (ACDET, ILIM)

I

IN_ LEAK

Input bias current V = 7 V –1 1 μA

PWM OSCILLATOR

F

SW

PWM switching frequency ChargeOption () bit [9] = 0 (Default) 600 750 900 kHz

ChargeOption() Bit [1] = 1 (333%),

InputCurrent () = 0x0400H (10.24mV)

ChargeOption() Bit [1] = 1 (333%),

InputCurrent () = 0x1F80H (80.64mV)

Voltage across input sense resistor rising to disable

charge

rising 103% 104% 106%

SRN

falling 102%

SRN

ChargeCurrent()=0x0xxxH 54 60 66 mV

ChargeCurrent()=0x1800 H– 0x1FC0H 110 120 130 mV

falling towards V

SRP

SRN

1 5 9 mV

Measure the voltage drop across current sensing

resistor

ChargeOption() bit [12:11] = 00 55.53% 59.19% 63.5%

ChargeOption() bit [12:11] = 01 58.68% 62.65% 67.5%

SRN

ChargeOption() bit [12:11] = 10 62.17% 66.55% 71.5%

ChargeOption() bit [12:11] = 11 (Default) 66.06% 70.97% 77%

ChargeOption() bit [12:11] = 00 225 305 400 mV

ChargeOption() bit [12:11] = 01 240 325 430 mV

SRN

ChargeOption() bit [12:11] = 10 255 345 450 mV

ChargeOption() bit [12:11] = 11 (Default) 280 370 490 mV

600 ms

falling 2.4 2.5 2.6 V

SRN

rising 200 mV

SRN

falling 60 75 90 mV

ILIM

rising 90 105 120 mV

ILIM

8 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

www.ti.com

Electrical Characteristics (continued)

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

4.5 V ≤ V

≤ 24 V, 0°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

F

SW+

F

SW–

PWM increase frequency ChargeOption() bit [10:9] = 11 665 885 1100 kHz

PWM decrease frequency ChargeOption() bit [10:9] = 01 465 615 765 kHz

BATFET GATE DRIVER (BATDRV)

I

BATFET

V

BATFET

R

BATDRV_LOAD

R

BATDRV_OFF

BATDRV charge pump current limit 40 60 µA

Gate drive voltage on BATFET V

Minimum load resistance between

BATDRV and SRN

BATDRV

- V

SRN

when V

> UVLO 5.5 6.1 6.5 V

SRN

500 kΩ

BATDRV turn-off resistance I = 30 µA 5 6.2 7.4 kΩ

ACFET GATE DRIVER (ACDRV)

I

ACFET

V

ACFET

R

ACDRV_LOAD

R

ACDRV_OFF

V

ACFET_LOW

ACDRV charge pump current limit 40 60 μA

Gate drive voltage on ACFET V

Minimum load resistance between ACDRV

and CMSRC

ACDRV–VCMSRC

when V

> UVLO 5.5 6.1 6.5 V

VCC

500 kΩ

ACDRV turn-off resistance I = 30 µA 5 6.2 7.4 kΩ

ACDRV Turn-Off when Vgs voltage is low

(Specified by design)

5.9 V

PWM HIGH SIDE DRIVER (HIDRV)

R

DS_HI_ON

R

DS_HI_OFF

V

BTST_REFRESH

High side driver turn-on resistance V

High side driver turn-off resistance V

Bootstrap refresh comparator threshold V

voltage

– VPH= 5.5 V, I = 10 mA 6 10 Ω

BTST

– VPH= 5.5 V, I = 10 mA 0.65 1.3 Ω

BTST

– VPHwhen low side refresh pulse is requested

BTST

3.85 4.3 4.7 V

PWM LOW SIDE DRIVER (LODRV)

R

DS_LO_ON

R

DS_LO_OFF

Low side driver turn-on resistance V

Low side driver turn-off resistance V

= 6 V, I = 10 mA 7.5 12 Ω

REGN

= 6 V, I = 10 mA 0.9 1.4 Ω

REGN

PWM DRIVER TIMING

t

LOW_HIGH

t

HIGH_LOW

Driver dead time from low side to high side 20 ns

Driver dead time from high side to low side 20 ns

INTERNAL SOFT START

I

STEP

t

STEP

Soft start current step 64 mA

Soft start current step time 240 μs

In CCM mode 10mΩ current sensing resistor

SMBus TIMING CHARACTERISTICS

t

R

t

F

t

W(H)

t

W(L)

t

SU(STA)

t

H(STA)

t

SU(DAT)

t

H(DAT)

t

SU(STOP)

t

(BUF)

F

S(CL)

SCLK/SDATA rise time 1 μs

SCLK/SDATA fall time 300 ns

SCLK pulse width high 4 50 μs

SCLK Pulse Width Low 4.7 μs

Setup time for START condition 4.7 μs

START condition hold time after which first clock pulse is generated 4 μs

Data setup time 250 ns

Data hold time 300 ns

Setup time for STOP condition 4 µs

Bus free time between START and STOP condition 4.7 μs

Clock Frequency 10 100 kHz

HOST COMMUNICATION FAILURE

t

timeout

t

BOOT

t

WDI

SMBus bus release timeout

Deglitch for watchdog reset signal 10 ms

Watchdog timeout period, ChargeOption() bit [14:13] = 01

Watchdog timeout period, ChargeOption() bit [14:13] = 10

Watchdog timeout period, ChargeOption() bit [14:13] = 11

(2)

(3)

(3)

(3)

(Default) 140 175 210 s

25 35 ms

35 44 53 s

70 88 105 s

(2) Devices participating in a transfer will timeout when any clock low exceeds the 25ms minimum timeout period. Devices that have

detected a timeout condition must reset the communication no later than the 35ms maximum timeout period. Both a master and a slave

must adhere to the maximum value specified as it incorporates the cumulative stretch limit for both a master (10ms) and a slave (25ms).

(3) User can adjust threshold via SMBus ChargeOption() REG0x12.

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: bq24725A

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

www.ti.com

6.6 Timing Characteristics

4.5 V ≤ V

SMBus TIMING CHARACTERISTICS

t

R

t

F

t

W(H)

t

W(L)

t

SU(STA)

t

H(STA)

t

SU(DAT)

t

H(DAT)

t

SU(STOP)

t

(BUF)

F

S(CL)

HOST COMMUNICATION FAILURE

t

timeout

t

BOOT

t

WDI

(1) Devices participating in a transfer will timeout when any clock low exceeds the 25ms minimum timeout period. Devices that have

detected a timeout condition must reset the communication no later than the 35ms maximum timeout period. Both a master and a slave

must adhere to the maximum value specified as it incorporates the cumulative stretch limit for both a master (10ms) and a slave (25ms).

(2) User can adjust threshold via SMBus ChargeOption() REG0x12.

≤ 24 V, 0°C ≤ TJ≤ 125°C, typical values are at TA= 25°C, with respect to GND (unless otherwise noted)

VCC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SCLK/SDATA rise time 1 μs

SCLK/SDATA fall time 300 ns

SCLK pulse width high 4 50 μs

SCLK Pulse Width Low 4.7 μs

Setup time for START condition 4.7 μs

START condition hold time after which first clock pulse is generated 4 μs

Data setup time 250 ns

Data hold time 300 ns

Setup time for STOP condition 4 µs

Bus free time between START and STOP condition 4.7 μs

Clock Frequency 10 100 kHz

SMBus bus release timeout

(1)

25 35 ms

Deglitch for watchdog reset signal 10 ms

Watchdog timeout period, ChargeOption() bit [14:13] = 01

Watchdog timeout period, ChargeOption() bit [14:13] = 10

Watchdog timeout period, ChargeOption() bit [14:13] = 11

(2)

(2)

(2)

(Default) 140 175 210 s

35 44 53 s

70 88 105 s

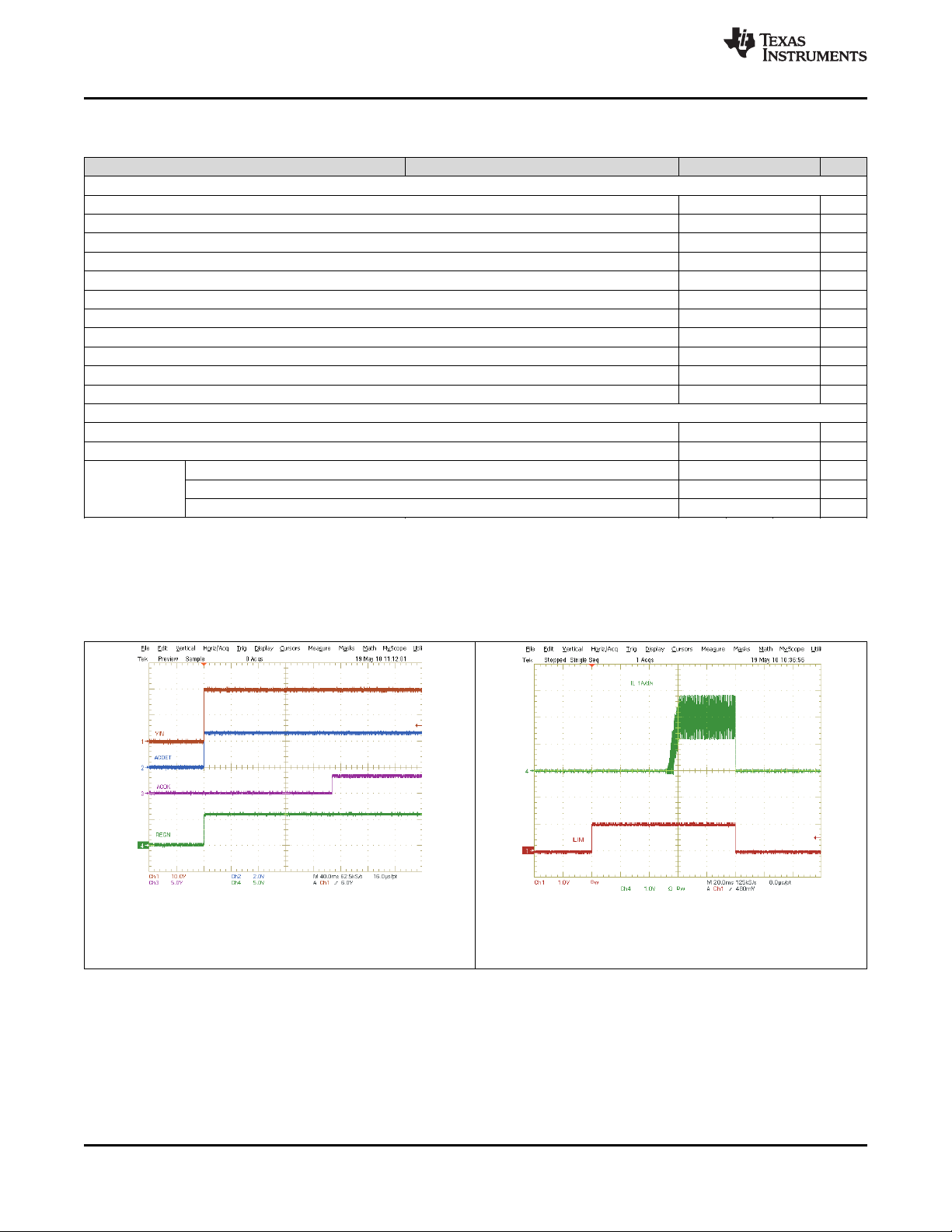

6.7 Typical Characteristics

,

CH1: VCC, 10V/div, CH2: ACDET 2V/div, CH3: ACOK, 5V/div

CH4: REGN, 5V/div, 40ms/div

Figure 1. VCC, ACDET, REGN and ACOK Power Up

CH1: ILIM, 1V/div

CH4: inductor current 1A/div, 20ms/div

Figure 2. Charge Enable by ILIM

10 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

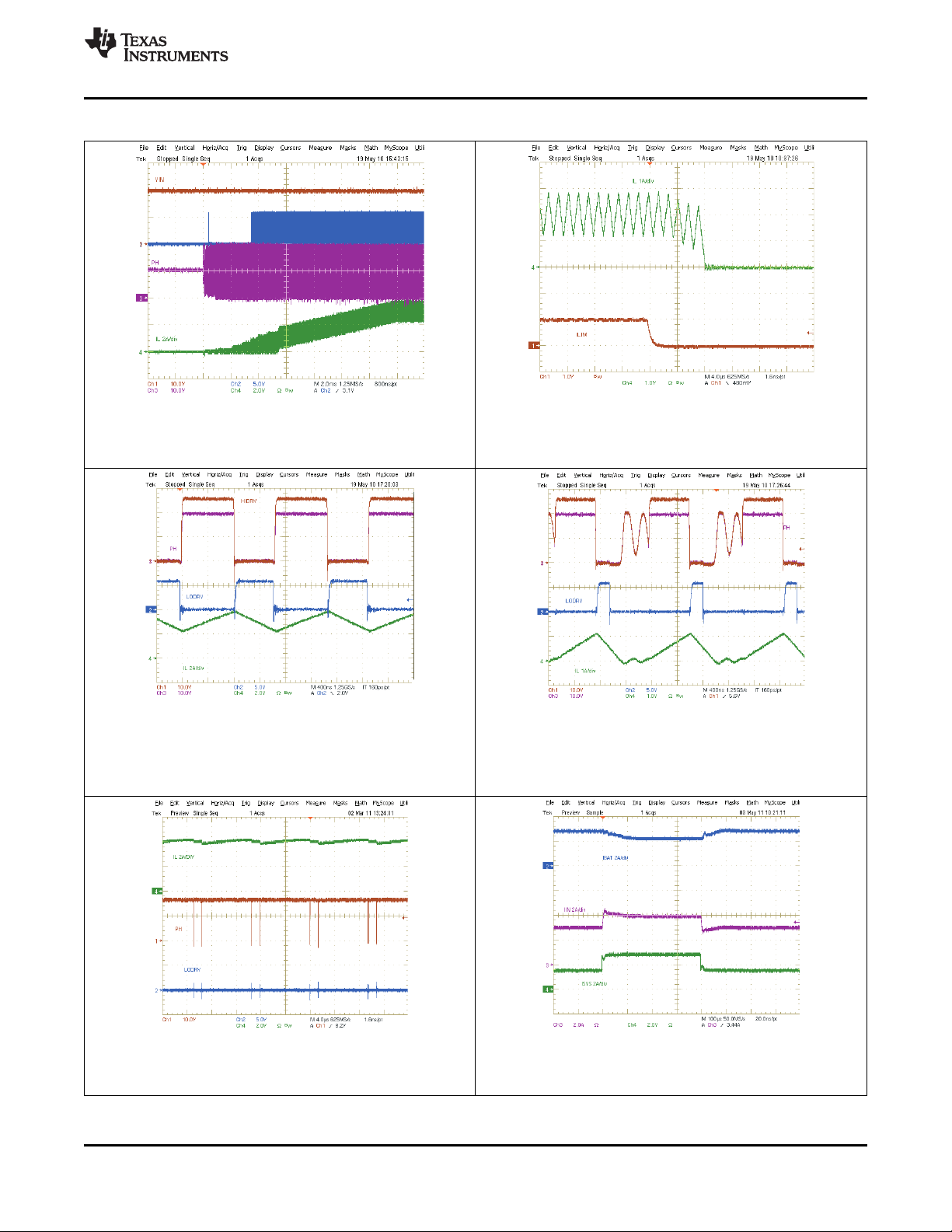

www.ti.com

Typical Characteristics (continued)

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

CH1: Vin, 10V/div , CH2: LODRV, 5V/div, CH3: PHASE, 10V/div

CH4: inductor current, 2A/div, 2ms/div

Figure 3. Current Soft-Start

CH1: PHASE, 10V/div, CH2: LODRV, 5V/div

CH3: HIDRV, 10V/div

CH4: inductor current, 2A/div, 400ns/div

Figure 5. Continuous Conduction Mode Switching

Waveforms

,

CH1: ILIM, 1V/div

CH4: inductor current, 1A/div, 4us/div

Figure 4. Charge Disable by ILIM

CH1: PHASE, 10V/div, CH2: LODRV, 5V/div

CH3: HIDRV, 10V/div

CH4: inductor current, 1A/div, 400ns/div

Figure 6. Cycle-by-Cycle Synchronous to Non-synchronous

CH1: PHASE, 10V/div, CH2: LODRV, 5V/div CH2: battery current, 2A/div, CH3: adapter current, 2A/div

CH4: inductor current, 2A/div, 4us/div CH4: system load current, 2A/div, 100us/div

Figure 7. 100% Duty and Refresh Pulse Figure 8. System Load Transient (Input DPM)

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: bq24725A

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

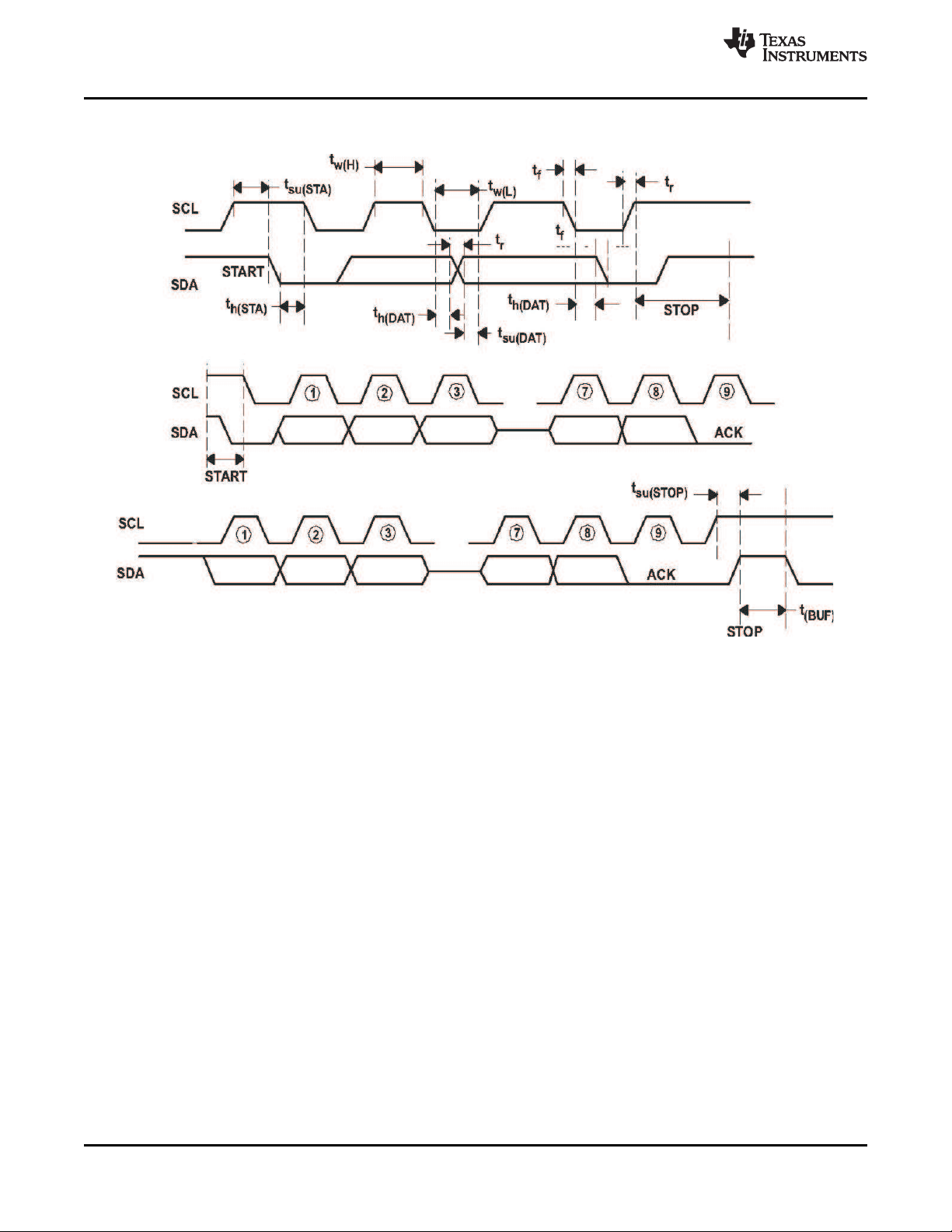

7 Parameter Measurement Information

www.ti.com

Figure 9. SMBus Communication Timing Waveforms

12 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

8 Detailed Description

8.1 Overview

The bq24725A is a 1-4 cell battery charge controller with power selection for space-constrained, multi-chemistry

portable applications such as notebook and detachable ultrabook. It supports wide input range of input sources

from 4.5V to 24V, and 1-4 cell battery for a versatile solution.

The bq24725A supports automatic system power source selection with separate drivers for n-channel MOSFETS

on the adapter side and battery side.

The bq24725A features Dynamic Power Management (DPM) to limit the input power and avoid AC adapter overloading. During battery charging, as the system power increases, the charging current will reduce to maintain

total input current below adapter rating.

The SMBus controls input current, charge current and charge voltage registers with high resolution, high

accuracy regulation limits.

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: bq24725A

bq24725A

135mV

1.07

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

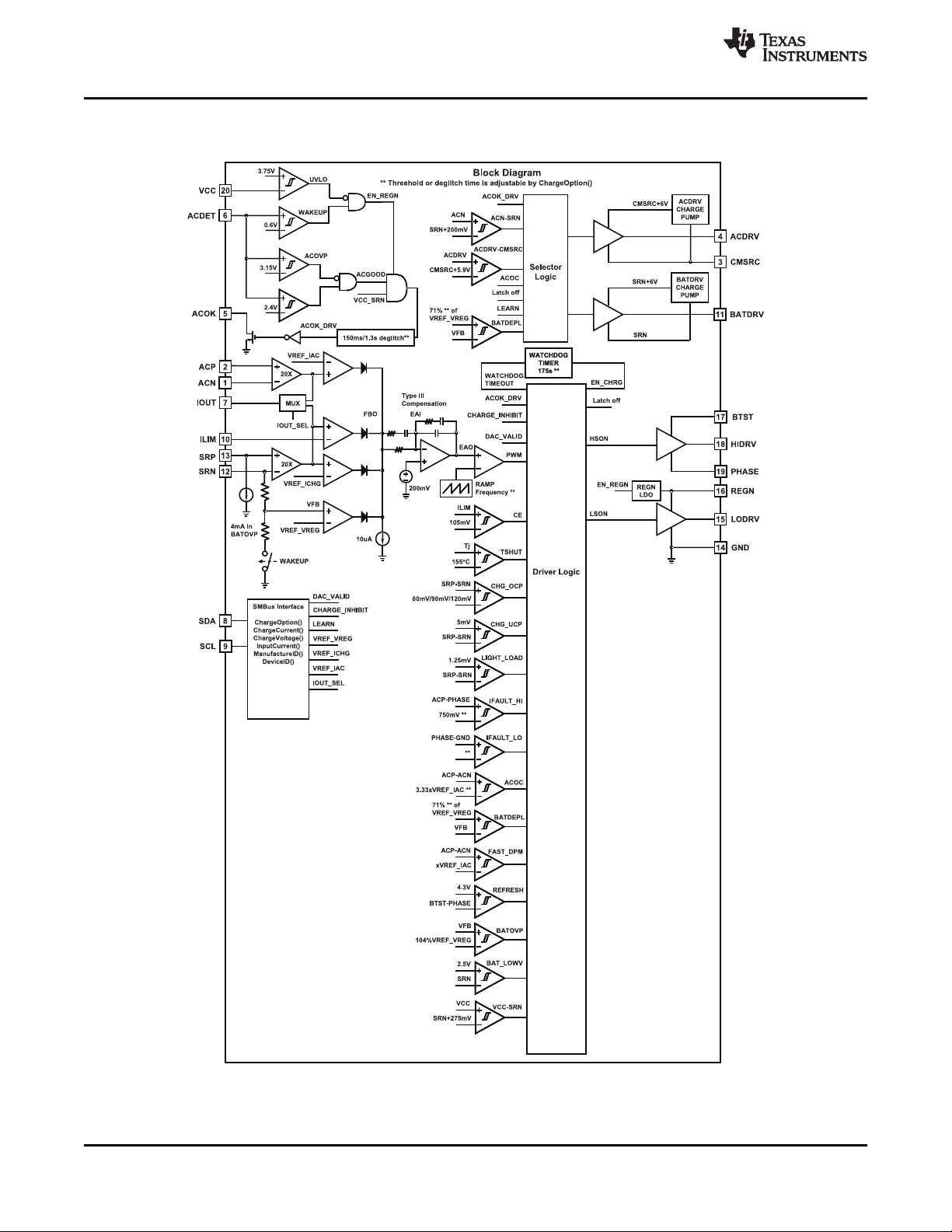

8.2 Functional Block Diagram

www.ti.com

Figure 10. Functional Block Diagram for bq24725A

14 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

S

SLAVE

ADDRESS

W ACK

COMMAND

BYTE

ACK

LOW DATA

BYTE

ACK

HIGH DATA

BYTE

ACK P

7 BITS 1b 1b 8 BITS 1b 8 BITS 1b 8 BITS 1b

MSB LSB 0 0 MSB LSB 0 MSB LSB 0 MSB LSB 0

a) Write-Word Format

S

SLAVE

ADDRESS

W ACK

COMMAND

BYTE

ACK S

SLAVE

ADDRESS

R ACK

LOW DATA

BYTE

ACK

HIGH DATA

BYTE

NACK P

7 BITS 1b 1b 8 BITS 1b 7 BITS 1b 1b 8 BITS 1b 8 BITS 1b

MSB LSB 0 0 MSB LSB 0 MSB LSB 1 0 MSB LSB 0 MSB LSB 1

Preset to 0b0001001 DeviceID() = 0xFFH Preset to D7 D0 D15 D8

ManufactureID() = 0xFEH 0b0001001

ChargeCurrent() = 0x14H

ChargeVoltage() = 0x15H

InputCurrent() = 0x3FH

ChargeOption() = 0x12H LEGEND:

S = START CONDITION OR REPEATED START CONDITION P = STOP CONDITION

ACK = ACKNOWLEDGE (LOGIC-LOW) NACK = NOT ACKNOWLEDGE (LOGIC-HIGH)

W = WRITE BIT (LOGIC-LOW) R = READ BIT (LOGIC-HIGH)

b) Read-Word Format

MASTER TO SLAVE

SLAVE TO MASTER

Preset to 0b0001001

ChargeOption() = 0x12H

D7

D0 D15 D8

ChargeCurrent() = 0x14H

ChargeVoltage() = 0x15H

InputCurrent() = 0x3FH

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

8.3 Feature Description

8.3.1 SMBus Interface

The bq24725A operates as a slave, receiving control inputs from the embedded controller host through the

SMBus interface. The bq24725A uses a simplified subset of the commands documented in System Management

Bus Specification V1.1, which can be downloaded from www.smbus.org. The bq24725A uses the SMBus ReadWord and Write-Word protocols (see Figure 11) to communicate with the smart battery. The bq24725A performs

only as a SMBus slave device with address 0b00010010 (0x12H) and does not initiate communication on the

bus. In addition, the bq24725A has two identification registers a 16-bit device ID register (0xFFH) and a 16-bit

manufacturer ID register (0xFEH).

SMBus communication is enabled with the following conditions:

• V

• V

The data (SDA) and clock (SCL) pins have Schmitt-trigger inputs that can accommodate slow edges. Choose

pull-up resistors (10kΩ) for SDA and SCL to achieve rise times according to the SMBus specifications.

Communication starts when the master signals a START condition, which is a high-to-low transition on SDA,

while SCL is high. When the master has finished communicating, the master issues a STOP condition, which is a

low-to-high transition on SDA, while SCL is high. The bus is then free for another transmission. Figure 12 and

Figure 13 show the timing diagram for signals on the SMBus interface. The address byte, command byte, and

data bytes are transmitted between the START and STOP conditions. The SDA state changes only while SCL is

low, except for the START and STOP conditions. Data is transmitted in 8-bit bytes and is sampled on the rising

edge of SCL. Nine clock cycles are required to transfer each byte in or out of the bq24725A because either the

master or the slave acknowledges the receipt of the correct byte during the ninth clock cycle. The bq24725A

supports the charger commands as described in Table 2.

is above UVLO;

VCC

is above 0.6V;

ACDET

Figure 11. SMBus Write-Word and Read-Word Protocols

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: bq24725A

A =START CONDITION E=SLAVEPULLSSMBDATA LINELOW I= ACKNOWLEDGECLOCKPULSE

B=MSBOF ADDRESSCLOCKEDINTOSLAVE F= ACKNOWLEDGEBIT CLOCKEDINTOMASTER J=STOP CONDITION

C=LSBOF ADDRESSCLOCKEDINTOSLAVE G=MSBOFDATA CLOCKEDINTOMASTER K=NEWSTART CONDITION

D=R/WBIT CLOCKEDINTOSLAVE H=LSBOFDATA CLOCKEDINTOMASTER

A B C D EF G H IJK

t

LOWtHIGH

SMBCLK

SMBDATA

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

Feature Description (continued)

Figure 12. SMBus Write Timing

www.ti.com

Figure 13. SMBus Read Timing

8.4 Device Functional Modes

8.4.1 Adapter Detect and ACOK Output

The bq24725A uses an ACOK comparator to determine the source of power on VCC pin, either from the battery

or adapter. An external resistor voltage divider attenuates the adapter voltage before it goes to ACDET. The

adapter detect threshold should typically be programmed to a value greater than the maximum battery voltage,

but lower than the maximum allowed adapter voltage.

The open drain ACOK output requires external pull up resistor to system digital rail for a high level. It can be

pulled to external rail under the following conditions:

• V

• 2.4V < V

• V

The first time after IC POR always gives 150ms ACOK rising edge delay no matter what the ChargeOption

register value is. Only after the ACDET pin voltage is pulled below 2.4V (but not below 0.6V, which resets the IC

and forces the next ACOK rising edge deglitch time to be 1.3s) and the ACFET has been turned off at least one

time, the 1.3s (or 150ms) delay time is effective for the next time the ACDET pin voltage goes above 2.4V. To

change this option, the VCC pin voltage must above UVLO, and the ACDET pin voltage must be above 0.6V

which enables the IC SMBus communication and sets ChargeOption() bit[15] to 0 which sets the next ACOK

rising deglitch time to be 150ms. The purpose of the default 1.3s rising edge deglitch time is to turn off the

ACFET long enough when the ACDET pin is pulled below 2.4V by excessive system current, such as over

current or short circuit.

> UVLO;

VCC

ACDET

VCC–VSRN

< 3.15V (not in ACOVP condition, nor in low input voltage condition);

> 275mV (not in sleep mode);

16 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

Device Functional Modes (continued)

8.4.2 Adapter Over Voltage (ACOVP)

When the ACDET pin voltage is higher than 3.15V, it is considered as adapter over voltage. ACOK will be pulled

low, and charge will be disabled. ACFET will be turned off to disconnect the high voltage adapter to system

during ACOVP. BATFET will be turned on if turns on conditions are valid. See the System Power Selection

section for details.

When ACDET pin voltage falls below 3.15V and above 2.4V, it is considered as adapter voltage returns back to

normal voltage. ACOK will be pulled high by external pull up resistor. BATFET will be turned off and ACFET and

RBFET will be turned on to power the system from adapter. The charge can be resumed if enable charge

conditions are valid. See the Enable and Disable Charging section for details.

8.4.3 System Power Selection

The bq24725A automatically switches adapter or battery power to system. The battery is connected to system at

POR if battery exists. The battery is disconnected from system and the adapter is connected to system after

default 150ms delay (first time, the next time default is 1.3s and can be changed to 150ms) if ACOK goes HIGH.

An automatic break-before-make logic prevents shoot-through currents when the selectors switch.

The ACDRV drives a pair of common-source (CMSRC) n-channel power MOSFETs (ACFET and RBFET)

between adapter and ACP (see Figure 18 for details). The ACFET separates adapter from battery or system, and

provides a limited di/dt when plugging in adapter by controlling the ACFET turn-on time. Meanwhile it protects

adapter when system or battery is shorted. The RBFET provides negative input voltage protection and battery

discharge protection when adapter is shorted to ground, and minimizes system power dissipation with its low

R

When the adapter is not present, ACDRV is pulled to CMSRC to keep ACFET and RBFET off, disconnecting

adapter from system. BATDRV stays at V

valid:

• V

• V

• V

Approximately 150ms (first time; the next time default is 1.3s and can be changed to 150ms) after the adapter is

detected (ACDET pin voltage between 2.4V and 3.15V), the system power source begins to switch from battery

to adapter if all the following conditions are valid:

• Not in LEARN mode or in LEARN mode and V

• ACOK high

The gate drive voltage on ACFET and RBFET is V

20ms, and the voltage across gate and source is still less than 5.9V, ACFET and RBFET will be turned off. After

1.3s delay, it resumes turning on ACFET and RBFET. If such a failure is detected seven times within 90

seconds, ACFET/RBFET will be latched off and an adapter removal and system shut down is required to force

ACDET < 0.6V to reset the IC. After IC reset from latch off, ACFET/RBFET can be turned on again. After 90

seconds, the failure counter will be reset to zero to prevent latch off. With ACFET/RBFET off, charge is disabled.

To turn off ACFET/RBFET, one of the following conditions must be valid:

• In LEARN mode and V

• ACOK low

To limit the in-rush current on ACDRV pin, CMSRC pin and BATDRV pin, a 4kΩ resistor is recommended on

each of the three pins.

To limit the adapter inrush current when ACFET is turned on to power system from adapter, the Cgs and Cgd

external capacitor of ACFET must be carefully selected. The larger the Cgs and Cgd capacitance, the slower turn

on of ACFET will be and less inrush current of adapter. However, if Cgs or Cgd is too large, the ACDRV-CMSRC

voltage may still go low after the 20ms turn on time window is expired. To make sure ACFET will not be turned

on when adapter is hot plugged in, the Cgs value should be 20 times or higher than Cgd. The most cost effective

way to reduce adapter in-rush current is to minimize system total capacitance.

compared to a Schottky diode.

DS(on)

> UVLO;

VCC

> UVLO;

SRN

< 200mV above V

ACN

+ 6V to connect battery to system if all the following conditions are

SRN

(ACN_SRN comparator);

SRN

is lower than battery depletion threshold;

SRN

CMSRC

is above battery depletion threshold;

SRN

+ 6V. If the ACFET/RBFET have been turned on for

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: bq24725A

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

www.ti.com

Device Functional Modes (continued)

8.4.4 Battery LEARN Cycle

A battery LEARN cycle can be activated via SMBus command (ChargeOption() bit[6]=1 enable LEARN cycle,

bit[6]=0 disable LEARN cycle). When LEARN is enabled with ACFET/RBFET connected, the system power

selector logic is over-driven to switch to battery by turning off ACFET/RBFET and turning on BATFET. LEARN

function allows the battery to discharge in order to calibrate the battery gas gauge over a complete

discharge/charge cycle. The controller automatically exits LEARN cycle when the battery voltage is below battery

depletion threshold, and the system switches back to adapter input by turning off BATFET and turning on

ACFET/RBFET. After LEARN cycle, the LEARN bit is automatically reset to 0. The battery depletion threshold

can be set to 59.19%, 62.65%, 66.55%, and 70.97% of voltage regulation level via SMBus command

(ChargeOption() bit[12:11]).

8.4.5 Enable and Disable Charging

In Charge mode, the following conditions have to be valid to start charge:

• Charge is enabled via SMBus (ChargeOption() bit [0]=0, default is 0, charge enabled);

• ILIM pin voltage higher than 105mV;

• All three regulation limit DACs have valid value programmed;

• ACOK is valid (See the Adapter Detect and ACOK Output section for details);

• ACFET and RBFET turns on and gate voltage is high enough (See the System Power Selection section for

details);

• V

• IC Temperature does not exceed TSHUT threshold;

• Not in ACOC condition (See the Input Over Current Protection (ACOC) section for details);

One of the following conditions will stop on-going charging:

• Charge is inhibited via SMBus (ChargeOption() bit[0]=1);

• ILIM pin voltage lower than 75mV;

• One of three regulation limit DACs is set to 0 or out of range;

• ACOK is pulled low (See the Adapter Detect and ACOK Output section for details);

• ACFET turns off;

• V

• TSHUT IC temperature threshold is reached;

• ACOC is detected (See the Input Over Current Protection (ACOC) section for details);

• Short circuit is detected (See the Inductor Short, MOSFET Short Protection section for details);

• Watchdog timer expires if watchdog timer is enabled (See the Charger Timeout section for details);

does not exceed BATOVP threshold;

SRN

exceeds BATOVP threshold;

SRN

8.4.6 Automatic Internal Soft-Start Charger Current

Every time the charge is enabled, the charger automatically applies soft-start on charge current to avoid any

overshoot or stress on the output capacitors or the power converter. The charge current starts at 128mA, and the

step size is 64mA in CCM mode for a 10mΩ current sensing resistor. Each step lasts around 240µs in CCM

mode, till it reaches the programmed charge current limit. No external components are needed for this function.

During DCM mode, the soft start up current step size is larger and each step lasts for longer time period due to

the intrinsic slow response of DCM mode.

8.4.7 High Accuracy Current Sense Amplifier

As an industry standard, high accuracy current sense amplifier (CSA) is used to monitor the input current or the

charge current, selectable via SMBUS (ChargeOption() bit[5]=0 select the input current, bit[5]=1 select the

charge current) by host. The CSA senses voltage across the sense resistor by a factor of 20 through the IOUT

pin. Once VCC is above UVLO and ACDET is above 0.6V, CSA turns on and IOUT output becomes valid. To

lower the voltage on current monitoring, a resistor divider from IOUT to GND can be used and accuracy over

temperature can still be achieved.

A 100pF capacitor connected on the output is recommended for decoupling high-frequency noise. An additional

RC filter is optional, if additional filtering is desired. Note that adding filtering also adds additional response delay.

18 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

o

o o

1

=

2 L Cp

¦

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

Device Functional Modes (continued)

8.4.8 Charge Timeout

The bq24725A includes a watchdog timer to terminate charging if the charger does not receive a write

ChargeVoltage() or write ChargeCurrent() command within 175s (adjustable via ChargeOption() command). If a

watchdog timeout occurs all register values keep unchanged but charge is suspended. Write ChargeVoltage() or

write ChargeCurrent() commands must be re-sent to reset watchdog timer and resume charging. The watchdog

timer can be disabled, or set to 44s, 88s or 175s via SMBus command (ChargeOption() bit[14:13]). After

watchdog timeout write ChargeOption() bit[14:13] to disable watchdog timer also resume charging.

8.4.9 Converter Operation

The synchronous buck PWM converter uses a fixed frequency voltage mode control scheme and internal type III

compensation network. The LC output filter gives a characteristic resonant frequency

(1)

The resonant frequency fo is used to determine the compensation to ensure there is sufficient phase margin and

gain margin for the target bandwidth. The LC output filter should be selected to give a resonant frequency of

10–20 kHz nominal for the best performance. Suggest component value as charge current of 750kHz default

switching frequency is shown in Table 1.

Ceramic capacitors show a dc-bias effect. This effect reduces the effective capacitance when a dc-bias voltage is

applied across a ceramic capacitor, as on the output capacitor of a charger. The effect may lead to a significant

capacitance drop, especially for high output voltages and small capacitor packages. See the manufacturer's data

sheet about the performance with a dc bias voltage applied. It may be necessary to choose a higher voltage

rating or nominal capacitance value in order to get the required value at the operating point.

Table 1. Suggest Component Value as Charge Current of Default 750kHz

Switching Frequency

Charge Current 2A 3A 4A 6A 8A

Output Inductor Lo (µH) 6.8 or 8.2 5.6 or 6.8 3.3 or 4.7 3.3 2.2

Output Capacitor Co (µF) 20 20 20 30 40

Sense Resistor (mΩ) 10 10 10 10 10

The bq24725A has three loops of regulation: input current, charge current and charge voltage. The three loops

are brought together internally at the error amplifier. The maximum voltage of the three loops appears at the

output of the error amplifier EAO. An internal saw-tooth ramp is compared to the internal error control signal EAO

(see Figure 10) to vary the duty-cycle of the converter. The ramp has offset of 200mV in order to allow 0% dutycycle.

When the battery charge voltage approaches the input voltage, EAO signal is allowed to exceed the saw-tooth

ramp peak in order to get a 100% duty-cycle. If voltage across BTST and PHASE pins falls below 4.3V, a refresh

cycle starts and low-side n-channel power MOSFET is turned on to recharge the BTST capacitor. It can achieve

duty cycle of up to 99.5%.

8.4.10 Continuous Conduction Mode (CCM)

With sufficient charge current the bq24725A’s inductor current never crosses zero, which is defined as

continuous conduction mode. The controller starts a new cycle with ramp coming up from 200mV. As long as

EAO voltage is above the ramp voltage, the high-side MOSFET (HSFET) stays on. When the ramp voltage

exceeds EAO voltage, HSFET turns off and low-side MOSFET (LSFET) turns on. At the end of the cycle, ramp

gets reset and LSFET turns off, ready for the next cycle. There is always break-before-make logic during

transition to prevent cross-conduction and shoot-through. During the dead time when both MOSFETs are off, the

body-diode of the low-side power MOSFET conducts the inductor current.

During CCM mode, the inductor current is always flowing and creates a fixed two-pole system. Having the

LSFET turn-on keeps the power dissipation low, and allows safely charging at high currents.

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: bq24725A

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

www.ti.com

8.4.11 Discontinuous Conduction Mode (DCM)

During the HSFET off time when LSFET is on, the inductor current decreases. If the current goes to zero, the

converter enters Discontinuous Conduction Mode. Every cycle, when the voltage across SRP and SRN falls

below 5mV (0.5A on 10mΩ), the under current-protection comparator (UCP) turns off LSFET to avoid negative

inductor current, which may boost the system via the body diode of HSFET.

During the DCM mode the loop response automatically changes. It changes to a single pole system and the pole

is proportional to the load current.

Both CCM and DCM are synchronous operation with LSFET turn-on every clock cycle. If the average charge

current goes below 125mA on 10mΩ current sensing resistor or the battery voltage falls below 2.5V, the LSFET

keeps turn-off. The battery charger operates in non-synchronous mode and the current flows through the LSFET

body diode. During non-synchronous operation, the LSFET turns on only for a refreshing pulse to charge the

BTST capacitor. If the average charge current goes above 250mA on 10mΩ current sensing resistor, the LSFET

exits non-synchronous mode and enters synchronous mode to reduce LSFET power loss.

8.4.12 Input Over Current Protection (ACOC)

The bq24725A cannot maintain the input current level if the charge current has been already reduced to zero.

After the system current continues increasing to the 3.33X of input current DAC set point (with 4.2ms blank out

time), ACFET/RBFET is latches off and an adapter removal and system shutdown is required to force ACDET <

0.6V to reset IC. After IC reset from latch off, ACFET/RBFET can be turned on again.

The ACOC function threshold can be set to 3.33x of input DPM current or disable this function via SMBus

command (ChargeOption() bit [1]).

8.4.13 Charge Over Current Protection (CHGOCP)

The bq24725A has a cycle-by-cycle peak over current protection. It monitors the voltage across SRP and SRN,

and prevents the current from exceeding of the threshold based on the DAC charge current set point. The highside gate drive turns off for the rest of the cycle when the over current is detected, and resumes when the next

cycle starts.

The charge OCP threshold is automatically set to 6A, 9A, and 12A on a 10mΩ current sensing resistor based on

charge current register value. This prevents the threshold to be too high which is not safe or too low which can

be triggered in normal operation. Proper inductance should be selected to prevent OCP triggered in normal

operation due to high inductor current ripple.

8.4.14 Battery Over Voltage Protection (BATOVP)

The bq24725A will not allow the high-side and low-side MOSFET to turn-on when the battery voltage at SRN

exceeds 104% of the regulation voltage set-point. If BATOVP last over 30ms, charger is completely disabled.

This allows quick response to an over-voltage condition – such as occurs when the load is removed or the

battery is disconnected. A 4mA current sink from SRP to GND is on only during BATOVP and allows discharging

the stored output inductor energy that is transferred to the output capacitors. Set ChargeVoltage() register value

to 0V will not trigger BATOVP function.

8.4.15 Battery Shorted to Ground (BATLOWV)

The bq24725A will limit inductor current if the battery voltage on SRN falls below 2.5V. After 1ms charge is reset.

After 4-5 ms the charge is resumed with soft-start if all the enable conditions in the “Enable and Disable

Charging” sections are satisfied. This prevents any overshoot current in inductor which can saturate inductor and

may damage the MOSFET. The charge current is limited to 0.5A on 10mΩ current sensing resistor when

BATLOWV condition persists and LSFET keeps off. The LSFET turns on only for a refreshing pulse to charge

BTST capacitor.

8.4.16 Thermal Shutdown Protection (TSHUT)

The QFN package has low thermal impedance, which provides good thermal conduction from the silicon to the

ambient, to keep junctions temperatures low. As added level of protection, the charger converter turns off for selfprotection whenever the junction temperature exceeds the 155°C. The charger stays off until the junction

temperature falls below 135°C. During thermal shut down, the REGN LDO current limit is reduced to 16mA.

Once the temperature falls below 135°C, charge can be resumed with soft start.

20 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

8.4.17 EMI Switching Frequency Adjust

The charger switching frequency can be adjusted ±18% to solve EMI issue via SMBus command.

ChargeOption() bit [9]=0 disable the frequency adjust function. To enable frequency adjust function, set

ChargeOption() bit[9]=1. Set ChargeOption() bit [10]=0 to reduce switching frequency, set bit[10]=1 to increase

switching frequency.

If frequency is reduced, for a fixed inductor the current ripple is increased. Inductor value must be carefully

selected so that it will not trig cycle-by-cycle peak over current protection even for the worst condition such as

higher input voltage, 50% duty cycle, lower inductance and lower switching frequency.

8.4.18 Inductor Short, MOSFET Short Protection

The bq24725A has a unique short circuit protection feature. Its cycle-by-cycle current monitoring feature is

achieved through monitoring the voltage drop across R

of the MOSFETs after a certain amount of blanking

DS(on)

time. In case of MOSFET short or inductor short circuit, the over current condition is sensed by two comparators

and two counters will be triggered. After seven times of short circuit events, the charger will be latched off and

ACFET and RBFET are turned off to disconnect adapter from system. BATFET is turned on to connect battery

pack to system. To reset the charger from latch-off status, the IC VCC pin must be pulled below UVLO or the

ACDET pin must be pulled below 0.6V. This can be achieved by removing the adapter and shut down the

operation system. The low side MOSFET short circuit voltage drop threshold can be adjusted via SMBus

command. ChargeOption() bit[7] =0, 1 set the low side threshold 135mV and 230mV respectively. The high side

MOSFET short circuit voltage drop threshold can be adjusted via SMBus command. ChargeOption() bit[8] = 0, 1

disable the function and set the threshold 750mV respectively.

Due to the certain amount of blanking time to prevent noise when MOSFET just turn on, the cycle-by-cycle

charge over-current protection may detect high current and turn off MOSFET first before the short circuit

protection circuit can detect short condition because the blanking time has not finished. In such a case the

charger may not be able to detect short circuit and counter may not be able to count to seven then latch off.

Instead the charger may continuously keep switching with very narrow duty cycle to limit the cycle-by-cycle

current peak value. However, the charger should still be safe and will not cause failure because the duty cycle is

limited to a very short of time and MOSFET should be still inside the safety operation area. During a soft start

period, it may takes long time instead of just seven switching cycles to detect short circuit based on the same

blanking time reason.

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: bq24725A

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

www.ti.com

8.5 Register Maps

8.5.1 Battery-Charger Commands

The bq24725A supports six battery-charger commands that use either Write-Word or Read-Word protocols, as

summarized in Table 2. ManufacturerID() and DeviceID() can be used to identify the bq24725A. The

ManufacturerID() command always returns 0x0040H and the DeviceID() command always returns 0x000BH.

Table 2. Battery Charger Command Summary

REGISTER ADDRESS REGISTER NAME READ/WRITE DESCRIPTION POR STATE

0x12H ChargeOption() Read or Write Charger Options Control 0xF902H

0x14H ChargeCurrent() Read or Write 7-Bit Charge Current Setting 0x0000H

0x15H ChargeVoltage() Read or Write 11-Bit Charge Voltage Setting 0x0000H

0x3FH InputCurrent() Read or Write 6-Bit Input Current Setting 0x1000H

0XFEH ManufacturerID() Read Only Manufacturer ID 0x0040H

0xFFH DeviceID() Read Only Device ID 0x000BH

8.5.2 Setting Charger Options

By writing ChargeOption() command (0x12H or 0b00010010), bq24725A allows users to change several charger

options after POR (Power On Reset) as shown in Table 3.

Figure 14. Charge Options Register (0x12H)

15 14 13 12 11 10 9 8

ACOK Deglitch WATCHDOG Timer Adjust BAT Depletion Comparator EMI Switching EMI Switching IFAULT_HI

Time Adjust Threshold Adjust Frequency Frequency Comparator

R/W R/W R/W R/W R/W R/W R/W

7 6 5 4 3 2 1 0

IFAULT_LOW LEARN Enable IOUT Selection AC Adapter Not in use Not in use ACOC Charge Inhibit

Comparator Indication Threshold

Threshold (Read Only) Adjust

Adjust

R/W R/W R/W R/W R/W R/W R/W R/W

LEGEND: R/W = Read/Write; R = Read only; -n = value after reset

Adjust Enable Threshold

Adjust

Table 3. Charge Options Register (0x12H)

Bit Field Type Reset Description

[15] ACOK Deglitch Time Adjust R/W Adjust ACOK deglitch time.

After POR, the first time the adapter plug in occurs, deglitch time

is always 150ms no matter if this bit is 0 or 1. This bit only sets

the next ACOK deglitch time after ACFET turns off at least one

time. To change this option, VCC pin voltage must be above

UVLO and ACDET pin voltage must be above 0.6V to enable IC

SMBus communication.

0: ACOK rising edge deglitch time 150ms

1: ACOK rising edge deglitch time 1.3s <default at POR>

[14:13] WATCHDOG Timer Adjust R/W Set maximum delay between consecutive SMBus Write charge

voltage or charge current command. The charge will be

suspended if IC does not receive write charge voltage or write

charge current command within the watchdog time period and

watchdog timer is enabled.

The charge will be resumed after receive write charge voltage or

write charge current command when watchdog timer expires and

charge suspends.

00: Disable Watchdog Timer

01: Enabled, 44 sec

10: Enabled, 88 sec

11: Enable Watchdog Timer (175s) <default at POR>

22 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

Table 3. Charge Options Register (0x12H) (continued)

Bit Field Type Reset Description

[12:11] BAT Depletion Comparator R/W This is used for LEARN function battery over discharge

[10] EMI Switching Frequency Adjust R/W 0: Reduce PWM switching frequency by 18% <default at

[9] EMI Switching Frequency Enable R/W 0: Disable adjust PWM switching frequency <default at

[8] IFAULT_HI Comparator Threshold R/W Short circuit protection high side MOSFET voltage drop

[7] IFAULT_LOW Comparator R/W Short circuit protection low side MOSFET voltage drop

[6] LEARN Enable R/W Set this bit 1 start battery learn cycle. IC turns off ACFET and

[5] IOUT Selection R/W 0: IOUT is the 20x adapter current amplifier output <default

[4] AC Adapter Indication (Read Only) R/W 0: AC adapter is not present (ACDET < 2.4V) <default at

[3] Not in use R/W 0 at POR

[2] Not in use R/W 0 at POR

[1] ACOC Threshold Adjust R/W 0: function is disabled

[0] Charge Inhibit R/W 0: Enable Charge <default at POR>

Threshold Adjust protection. During LEARN cycle, when the IC detects battery

voltage is below depletion voltage threshold, the IC turns off

BATFET and turned on ACFET to power the system from AC

adapter instead of the battery. The rising edge hysteresis is

340mV. Set ChargeVoltage() register value to 0V will disable

this function.

00: Falling Threshold = 59.19% of voltage regulation limit

(~2.486V/cell)

01: Falling Threshold = 62.65% of voltage regulation limit

(~2.631V/cell)

10: Falling Threshold = 66.55% of voltage regulation limit

(~2.795V/cell)

11: Falling Threshold = 70.97% of voltage regulation limit

(~2.981V/cell) < default at POR>

POR>

1: Increase PWM switching frequency by 18%

POR>

1: Enable adjust PWM switching frequency

Adjust comparator threshold.

0: function is disabled

1: 750mV <default at POR>

Threshold Adjust comparator threshold.

0: 135mV <default at POR>

1: 230mV

turns on BATFET to discharge battery capacity. When battery

voltage reaches threshold defined in bit [12;11], the BATFET is

turned off and ACFET is turned on to finish battery learn cycle.

After finished learn cycle, this bit is automatically reset to 0. Set

this bit 0 will stop battery learn cycle. IC turns off BATFET and

turns on ACFET.

0: Disable LEARN Cycle <default at POR>

1: Enable LEARN Cycle

at POR>

1: IOUT is the 20x charge current amplifier output

POR>

1: AC adapter is present (ACDET > 2.4V)

1: 3.33x of input current regulation limit <default at POR>

1: Inhibit Charge

bq24725A

8.5.3 Setting the Charge Current

To set the charge current, write a 16bit ChargeCurrent() command (0x14H or 0b00010100) using the data format

listed in Table 4. With 10mΩ sense resistor, the bq24725A provides a charge current range of 128mA to 8.128A,

with 64mA step resolution. Sending ChargeCurrent() below 128mA or above 8.128A clears the register and

terminates charging. Upon POR, charge current is 0A. A 0.1µF capacitor between SRP and SRN for differential

mode filtering is recommended, 0.1µF capacitor between SRN and ground for common mode filtering, and an

optional 0.1µF capacitor between SRP and ground for common mode filtering. Meanwhile, the capacitance on

SRP should not be higher than 0.1µF in order to properly sense the voltage across SRP and SRN for cycle-bycycle under-current and over current detection.

Copyright © 2011–2014, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: bq24725A

( )

ILIM SRP SRN CHG SR

V = 20 × V V = 20 I R- ´ ´

bq24725A

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

www.ti.com

The SRP and SRN pins are used to sense RSRwith default value of 10mΩ. However, resistors of other values

can also be used. For a larger sense resistor, a larger sense voltage is given, and a higher regulation accuracy;

but, at the expense of higher conduction loss. If the current sensing resistor value is too high, it may trigger an

over current protection threshold because the current ripple voltage is too high. In such a case, either a higher

inductance value or a lower current sensing resistor value should be used to limit the current ripple voltage level.

A current sensing resistor value no more than 20mΩ is suggested.

To provide secondary protection, the bq24725A has an ILIM pin with which the user can program the maximum

allowed charge current. Internal charge current limit is the lower one between the voltage set by

ChargeCurrent(), and voltage on ILIM pin. To disable this function, the user can pull ILIM above 1.6V, which is

the maximum charge current regulation limit. Equation 2 shows the voltage set on ILIM pin with respect to the

preferred charge current limit:

(2)

Figure 15. Charge Current Register (0x14H), Using 10mΩ Sense Resistor

15 14 13 12 11 10 9 8

Not in use Not in use Not in use Charge Charge Charge Charge Charge

R/W R/W R/W R/W R/W R/W R/W

7 6 5 4 3 2 1 0

Charge Charge Not in use Not in use Not in use Not in use Not in use Not in use

Current, Current,

DACICHG 1 DACICHG 0

R/W R/W R/W R/W R/W R/W R/W R/W

LEGEND: R/W = Read/Write; R = Read only; -n = value after reset

Current, Current, Current, Current, Current,

DACICHG 6 DACICHG 5 DACICHG 4 DACICHG 3 DACICHG 2

Table 4. Charge Current Register (0x14H), Using 10mΩ Sense Resistor

Bit Field Type Reset Description

[15] Not in use R/W Not used.

[14] Not in use R/W Not used.

[13] Not in use Not used.

[12] Charge Current, DACICHG 6 R/W 0 = Adds 0mA of charger current.

[11] Charge Current, DACICHG 5 R/W 0 = Adds 0mA of charger current.

[10] Charge Current, DACICHG 4 R/W 0 = Adds 0mA of charger current.

[9] Charge Current, DACICHG 3 R/W 0 = Adds 0mA of charger current.

[8] Charge Current, DACICHG 2 R/W 0 = Adds 0mA of charger current.

[7] Charge Current, DACICHG 1 R/W 0 = Adds 0mA of charger current.

[6] Charge Current, DACICHG 0 R/W 0 = Adds 0mA of charger current.

[5] Not in use R/W Not used.

[4] Not in use R/W Not used.

[3] Not in use R/W Not used.

[2] Not in use R/W Not used.

[1] Not in use R/W Not used.

[0] Not in use R/W Not used.

1 = Adds 4096mA of charger current.

1 = Adds 2048mA of charger current.

1 = Adds 1024mA of charger current.

1 = Adds 512mA of charger current.

1 = Adds 256mA of charger current.

1 = Adds 128mA of charger current.

1 = Adds 64mA of charger current.

24 Submit Documentation Feedback Copyright © 2011–2014, Texas Instruments Incorporated

Product Folder Links: bq24725A

bq24725A

www.ti.com

SLUSAL0A –SEPTEMBER 2011–REVISED AUGUST 2014

8.5.4 Setting the Charge Voltage

To set the output charge regulation voltage, write a 16bit ChargeVoltage() command (0x15H or 0b00010101)

using the data format listed in Table 5. The bq24725A provides charge voltage range from 1.024V to 19.200V,

with 16mV step resolution. Sending ChargeVoltage() below 1.024V or above 19.2V clears the register and

terminates charging. Upon POR, charge voltage limit is 0V.

The SRN pin is used to sense the battery voltage for voltage regulation and should be connected as close to the

battery as possible, and place a decoupling capacitor (0.1µF recommended) as close to the IC as possible to

decouple high frequency noise.

Figure 16. Charge Voltage Register (0x15H)

15 14 13 12 11 10 9 8

Not in use Charge Charge Charge Charge Charge Charge Charge

R/W R/W R/W R/W R/W R/W R/W

7 6 5 4 3 2 1 0

Charge Charge Charge Charge Not in use Not in use Not in use Not in use

Voltage, DACV Voltage, DACV Voltage, DACV Voltage, DACV

3 2 1 0

R/W R/W R/W R/W R/W R/W R/W R/W

LEGEND: R/W = Read/Write; R = Read only; -n = value after reset

Voltage, DACV Voltage, DACV Voltage, DACV Voltage, DACV Voltage, DACV Voltage, DACV Voltage, DACV

10 9 8 7 6 5 4

Table 5. Charge Voltage Register (0x15H)

Bit Field Type Reset Description

[15] Not in use R/W Not used.

[14] Charge Voltage, DACV 10 R/W 0 = Adds 0mV of charger voltage.

[13] Charge Voltage, DACV 9 R/W 0 = Adds 0mV of charger voltage.