Page 1

User’s Guide

Using the bq241xx (bqSWITCHERE)

User’ s Gu ide

Page 2

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION

PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED,

IMPLIED, OR S TA TUTOR Y, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not b e r e gulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

2

Page 3

DYNAMIC WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input voltage range of 4.5 V to 16 V.

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM.

If there are questions concerning the input range, please contact a TI field representative prior to connecting

the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible

permanent damage to the EVM. Please consult the EVM User’s Guide prior to connecting any load to the EVM

output. If there is uncertainty as to the load specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 50°C. The EVM

is designed to operate properly with certain components above 50°C as long as the input and output ranges are

maintained. These components include but are not limited to linear regulators, switching transistors, pass

transistors, and current sense resistors. These types of devices can be identified using the EVM schematic

located in the EVM User’s Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

3

Page 4

SLUU200 − July 2004

r

Using the bq241xx (bqSWITCHERE)

.

Portable Powe

Contents

1 Introduction 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Test Summary 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Schematic 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Physical Layouts 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 List of Materials 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 References 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction

This user’s guide describes the bq241xxEVM (bqSWITCHER) Evaluation Module. The EVM provides a

convenient method for evaluating the performance of a charge management solution for portable applications

using the bq241xx product family. A complete designed and tested charger is presented. The charger is

designed to deliver up to 2.0 A of continuous output current. The charger is programmed from the factor to deliver

1.33 A of charging current. Follow the instructions in this user’s guide that pertain to the specific bq241xxEVM

to be evaluated (one-, two- or three-cell). Please refer to the bqSWITCHER data sheet (SLUS606) prior to

evaluation for detailed information on the bqSWITCHER device.

1.1 Background

The bqSWITCHER series are highly integrated Li-Ion and Li-Pol switch-mode charge management devices

targeted at a wide range of portable applications. The bqSWITCHER series offer integrated synchronous PWM

Controller and PowerFETs, high-accuracy current and voltage regulation, charge conditioning, charge status,

and charge termination, in a small thermally enhanced QFN package. The system-controlled version provides

additional input for full charge management under system control.

The bqSWITCHER charges the battery in three phases: conditioning, constant current and constant voltage.

Charge is terminated based on user-selectable minimum current level. A programmable charge timer provides

a backup safety for charge termination. The bqSWITCHER automatically restarts the charge if the battery

voltage falls below an internal threshold. The bqSWITCHER automatically enters sleep mode when V

is removed.

CC

supply

4

Using the bq241xx (bqSWITCHERE)

Page 5

SLUU200 − July 2004

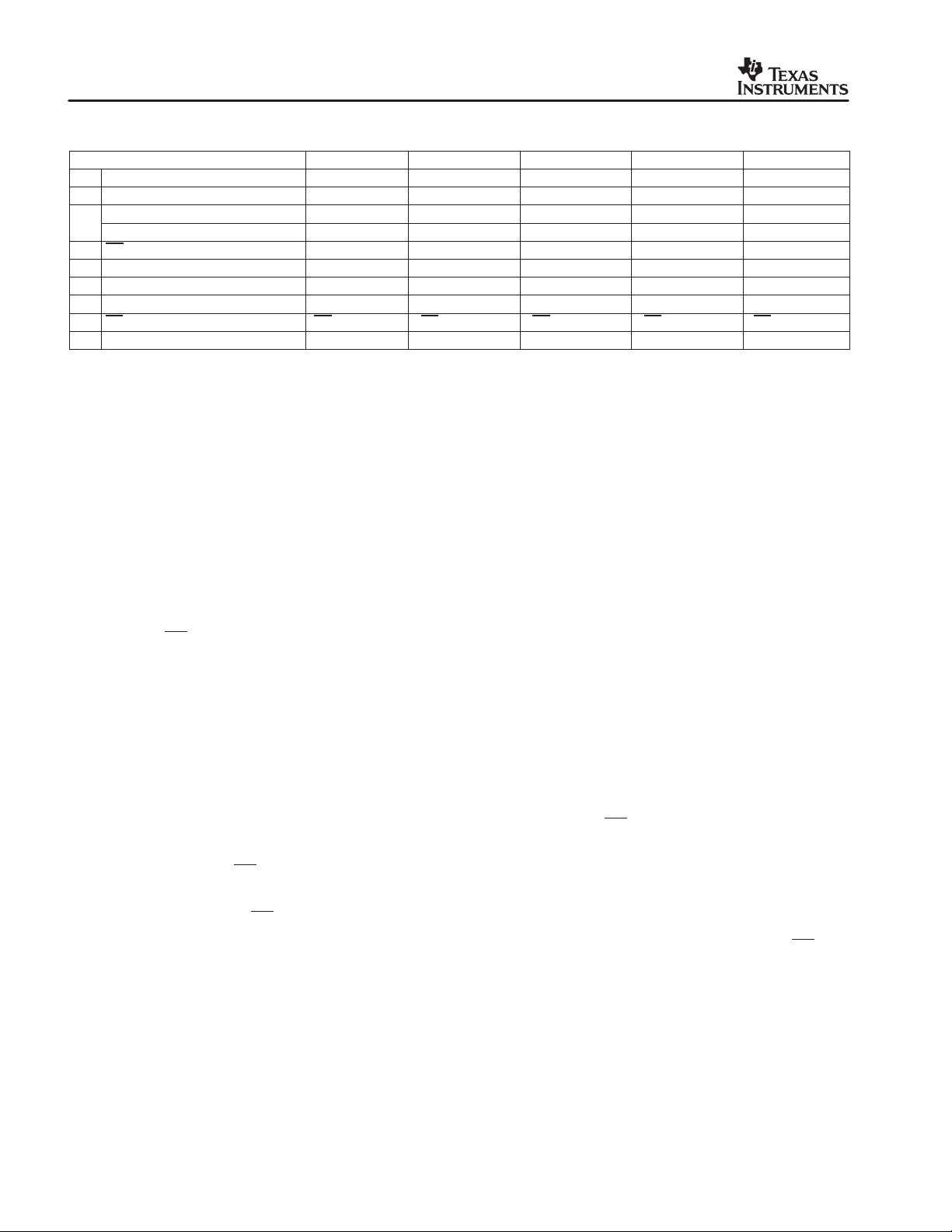

1.2 Performance Specification Summary

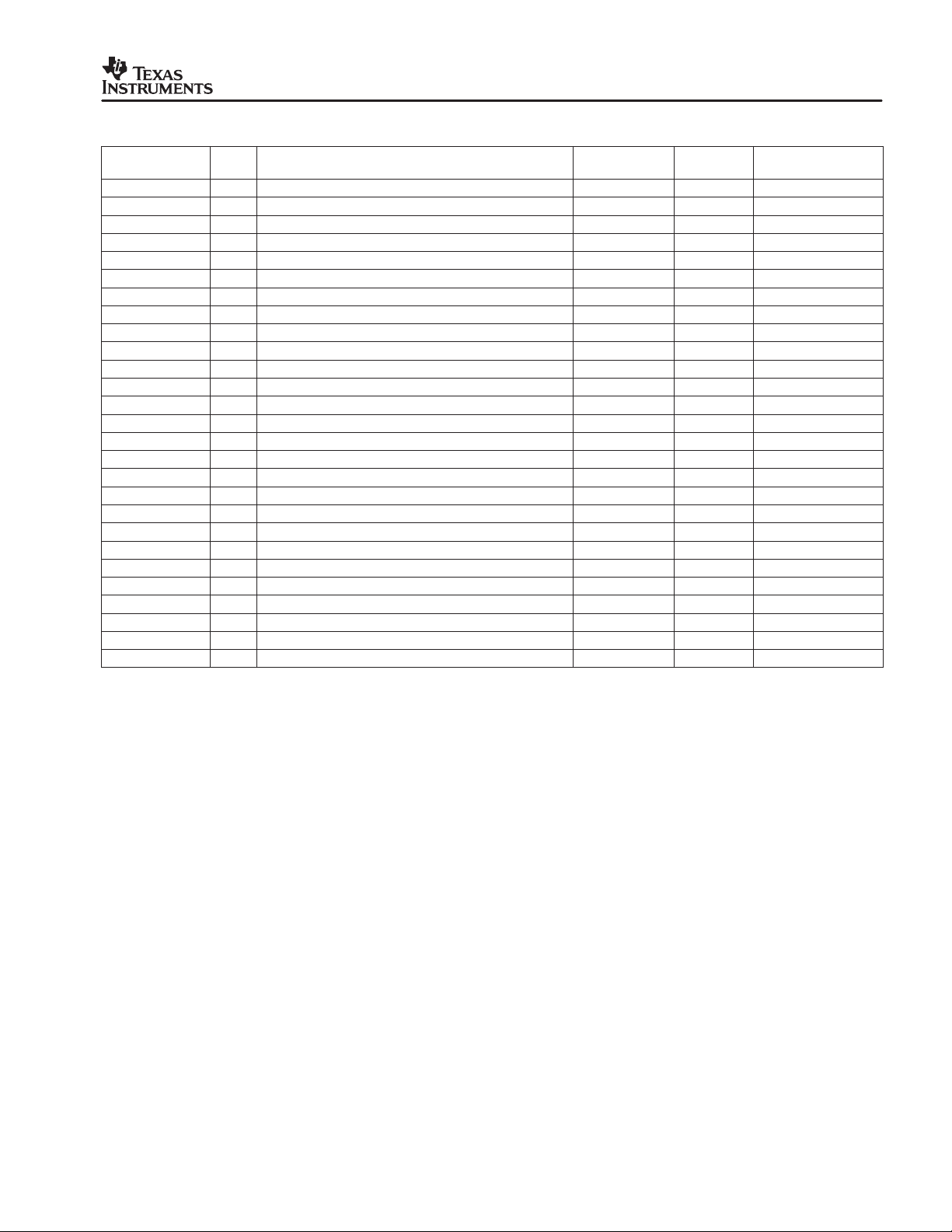

This section summarizes the performance specifications of the EVM. Table 1 gives the performance

specifications of the EVM. The TS pin has been disabled, for easier charging evaluation, by fixing its voltage

to a set value. See EVM schematic and data sheet for information on how to change R10 and R11 values to

use with an external thermistor

SPECIFICATION

Input DC voltage, V

Battery charge current

Power dissipation

I(DC)

(1)

, I

O(CHG)

2 Test Summary

Table 1. Performance Specification Summary

TEST CONDITIONS MIN TYP MAX UNIT

bq24100

(1 cell)

bq24103

bq24113

(1 cell)

bq24103

bq24113

(2 cell)

bq24105

bq24115

(1 cell)

bq24105

bq24115

(2 cell)

bq24105

bq24115

(3 cell)

5 V ≤ VIN ≤ 16 V, V

5 V ≤ VIN ≤ 16 V, V

9 V ≤ VIN ≤ 16 V, V

5 V ≤ VIN ≤ 16 V, V

9 V ≤ VIN ≤ 16 V, V

13.5 V ≤ VIN ≤ 16 V, V

(BAT)

(BAT)

(BAT)

(BAT)

(BAT)

(BAT)

= 4.2 V, I

= 4.2 V, I

= 8.4 V, I

= 4.2 V, I

= 8.4 V, I

= 12.6 V , I

= 1.33 A 0.6

OUT

= 1.33 A 0.6

OUT

= 1.33 A 0.85

OUT

= 1.33 A 0.6

OUT

= 1.33 A 0.85

OUT

= 1.33 A 1.17

OUT

(1)

V

+ 0.6 5.0 16 V

REG

1.33 2.0

(1)

A

W

This chapter covers the test setups and tests performed, in evaluating the EVM.

2.1 Equipment

D

Power Source: Current limited 15-V lab supply with its current limit set to 25% above the programmed

charging current (1.7 A for setup from factory). This is basically a safety limit. The actual DC input current

should be less than the charging current.

D Two Fluke 75: (optional) To measure input and output voltage and drop across current sense resistor.

2.2 Setup

The bq241xx EVM board requires a regulated supply approximately 0.3 V minimum above the regulated voltage

of the battery pack (1-cell pack: 4.2 V; 2-cell pack: 8.4 V; 3-cell pack: 12.6 V) to a maximum input voltage of

16 V

A one- to three-cell battery pack is needed for EVM evaluation. The EVM should be chosen and set up to charge

the same numbers of cells as the battery pack to be evaluated. See Table 2.

Setup the EVM as shown in Table 2. Preset the input supply to the desired voltage, turn off supply and then

connect supply to J1. Set the supply’s current limit 25% above the programmed charging current. The test setup

connections and jumper setting selections are configured for a stand-alone evaluation but can be changed to

interface with external hardware such as a microcontroller. Refer to schematic and data sheet for additional

functional information on other optional connections.

DC

.

Using the bq241xx (bqSWITCHERE)

5

Page 6

SLUU200 − July 2004

J2

Table 2. I/O and Jumper Connections (Factory Jumper Selections are shown in BOLD):

ASSEMBLY −001 −002 −003 −004 −005

U1 Device bq24100 bq24105

J1 DC+/DC−:Input voltage range (V) 5 to 16 V

BAT+/BAT−No. cell in series 1 1 1 1 1

Output regulation voltage (V) 4.2 4.2

J5 PG LED or EXT LED or EXT LED or EXT LED or EXT LED or EXT

J6 STAT1 LED or EXT LED or EXT LED or EXT LED or EXT LED or EXT

J7 STAT2 LED or EXT LED or EXT N/C no jumper N/C no jumper LED or EXT

J8 TTC or CMOD TTC no jumper TTC no jumper CMOD jumper HI CMOD jumper HI TTC no jumper

J9 CE CE jumper LO CE jumper LO CE jumper LO CE jumper LO CE jumper LO

J10 Cells or FB No jumper No jumper Cells jumper LO No jumper Cells jumper low

(1)

R5 and R7 can be changed to regulate output between approximately 3.2 V to 15.5 V. Adjust the input voltage as required. Output set to operate

at 4.2 VDC from the factory.

(2)

To operate as a two cell version (8.4V), replace battery with a two-series cell pack, set J10 to High and adjust the Input voltage between

9.2 V to 16 V.

REG

(1)

+0.8 t o 1 6

(1)

(1)

bq24113

(2)

5 to 16 V

(2)

4.2

bq24115

REG

(1)

+0.8 t o 1 6

(1)

4.2

(1)

bq24103

5 to 16

(2)

4.2

(2)

(2)

2.3 Test Procedure

Setup the evaluation board as described above, by making the necessary I/O connections and jumper

selections. Prior to test and evaluation, it is important to verify that the EVM selected is setup correctly

for the battery pack to be charged (several evaluation modules have a CELLs option that can be

programmed for two different size − number of series cells). It is highly recommended that the battery

pack to be charged has internal proteciton as a safety backup.

1. Turn on the power supply, preset to the suggested value in Table 2, and approximately 1.7 A for the current

limit setting.

2. The PG

3. The bq241xx enters pre-conditioning mode if the battery is below the V

bq241xx pre−charges the battery with a low current programmed by the ISET2 pin. If the R

resistors are the same value then the precharge is one tenth the fast charge current (I

= 133 mA) until the battery voltage reaches the V

LED should turn on along with STAT1, if the battery is charging.

(LOWV)

(LOWV)

threshold or until the precharge timer expires. If

threshold. In this mode, the

SET1

PRE−CHG

the timer expires then the charge current is terminated and the bq241xx enters fault mode. STAT1 and

STAT2 (if available) LEDs turns off when in fault mode. Note that there are several non-charging modes that

share this status state. Toggling input power or battery replacement resets fault mode.

4. Once the battery voltage is above the V

(LOWV)

is programmed for approximately 1.3 A of fast charging current. The PG

threshold, the battery enters fast charge mode. This EVM

and STAT1 LEDs should be on.

5. Once the battery reaches voltage regulation (4.2 V) the current tapers down as the battery reaches its full

capacity. The PG

6. When the current reaches the taper termination threshold, set by the R

terminated. The PG

and STAT1 LEDs should be on.

resistor, the charge is

SET2

LED should still be on and the STAT1 LED should turn off and STAT2 LED turn on.

7. If the battery discharges down to the recharge threshold, the charger starts fast charging. The PG

should still be on and the STAT2 LED should turn off and STAT1 LED turn on.

An alternative method of testing the EVM is with a source meter, that can sink or source current. This can easily

be adjusted to test each mode, in place of a battery.

3 Schematic

and R

SET2

= 1.33 A/10

LED

Figure 1 shows the schematic diagram for the EVM.

6

Using the bq241xx (bqSWITCHERE)

Page 7

SLUU200 − July 2004

Figure 1. bq241xxEVM Top Layer

Using the bq241xx (bqSWITCHERE)

7

Page 8

SLUU200 − July 2004

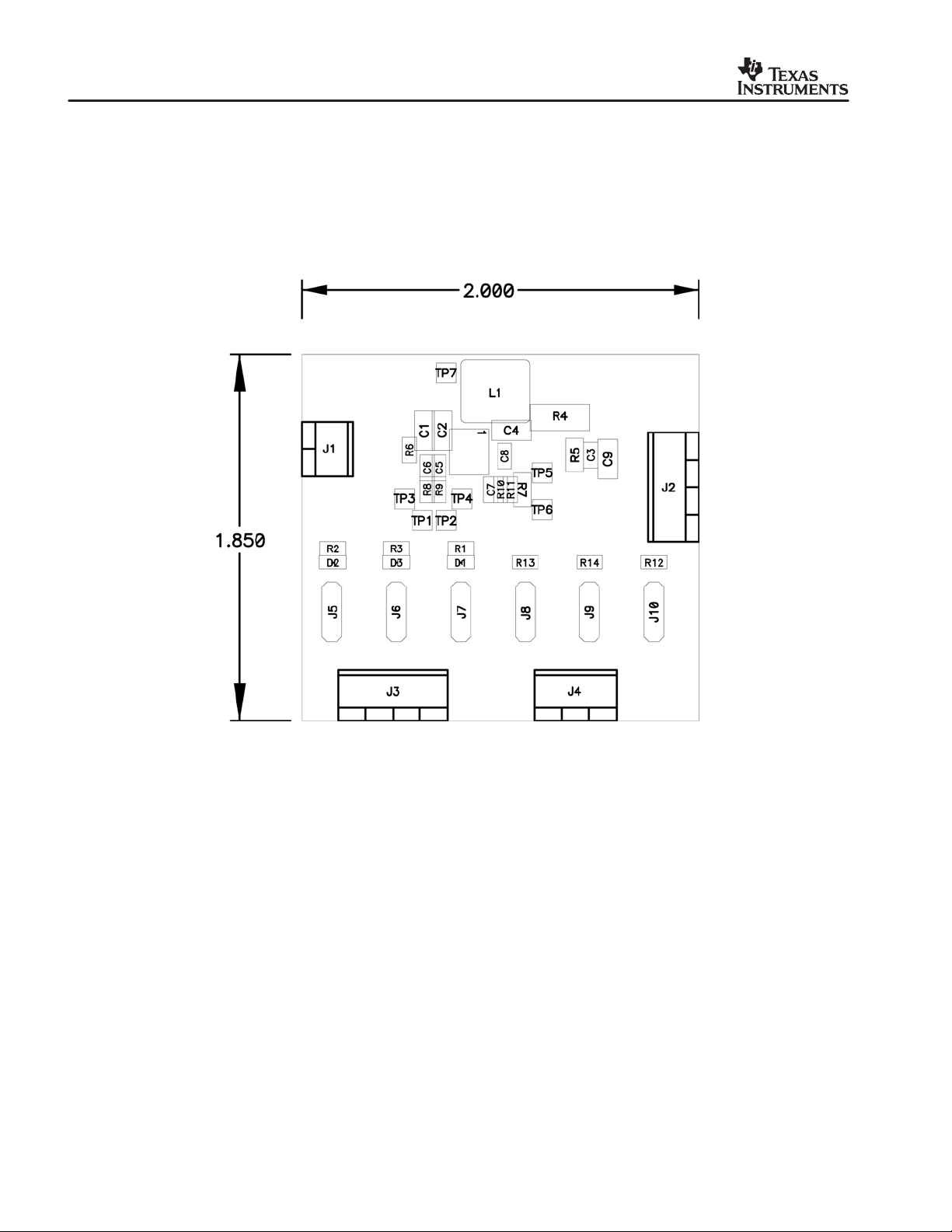

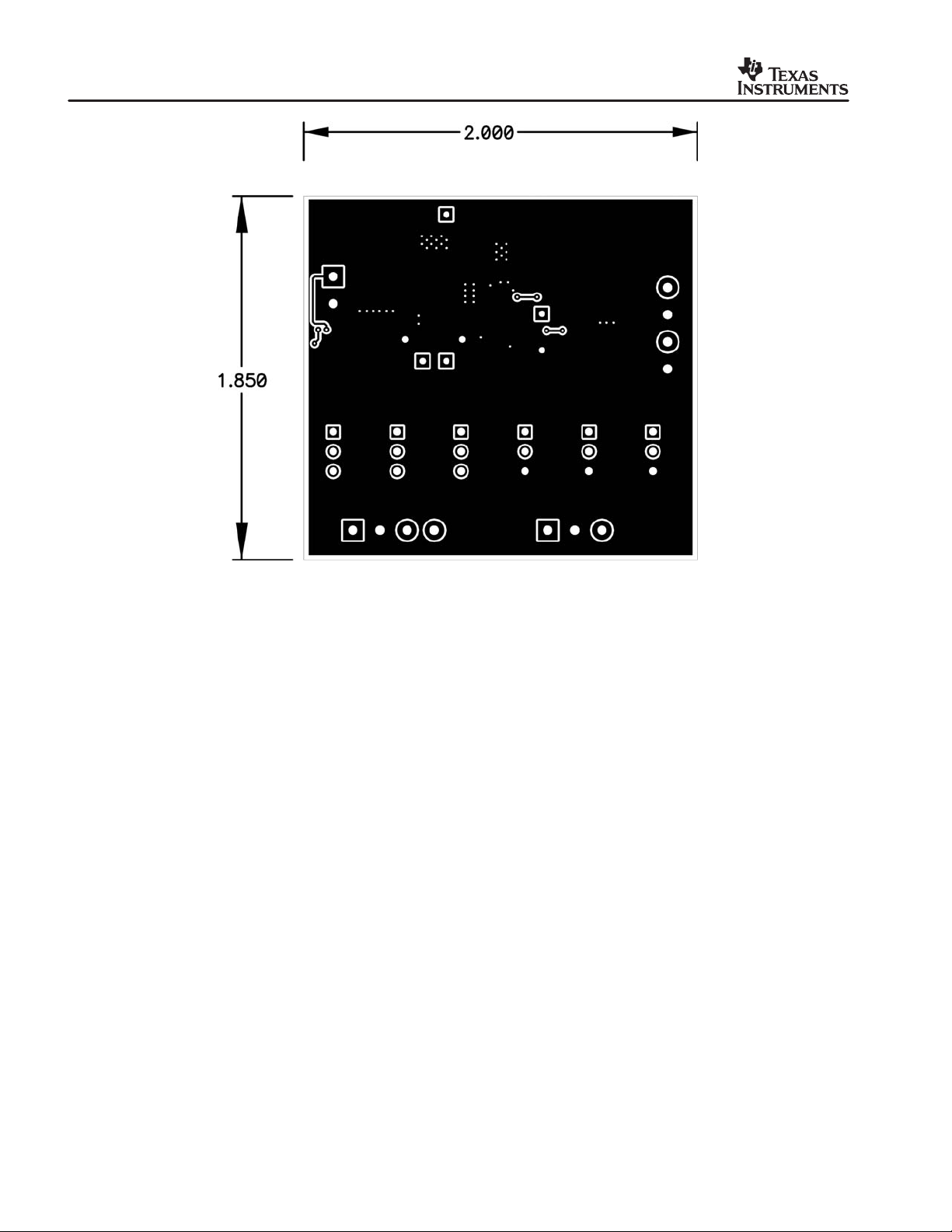

4 Physical Layouts

This chapter contains the board layout and assembly drawings for the EVM.

4.1 Board Layout

Figure 2 shows the top assembly of the EVM. Figure 3 shows the top silk screen. The bq24103 may also be

evaluated on this evaluation board. Figure 4 shows the top layer. Figure 5 shows the bottom layer view.

Figure 2. bq241xxEVM Top Assembly

8

Using the bq241xx (bqSWITCHERE)

Page 9

SLUU200 − July 2004

Figure 3. bq241xxEVM Top Silk Screen

Figure 4. bq241xx Top Layer

Using the bq241xx (bqSWITCHERE)

9

Page 10

SLUU200 − July 2004

Figure 5. bq241xxEVM Top Asembly

10

Using the bq241xx (bqSWITCHERE)

Page 11

SLUU200 − July 2004

5 List of Materials

Tables 3 through 7 list the components used in this design. With minor component adjustments this design could

be modified to meet a wide range of applications.

Table 3. bq24100EVM−001 List of Materials

REFERENCE

DESIGNATOR

C1, C2, C4 3 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C9 0 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C3 0 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C5, C7, C8 3 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C6 1 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

D1 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D2 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D3 1 Diode, LED, red, 1.8 V, 20 mA, 20 mcd 603 Liteon 160−1181−1−ND

J1 1 Terminal block, 2-pin, 6 A, 3.5 mm 75525 OST ED1514

J2, J3 2 Terminal block, 4-pin, 6 A, 3.5 mm 0.55 × 0.25 OST ED1516

J4 1 Terminal block, 3-pin, 6 A, 3.5 mm 0.41 × 0.25 OST ED1515

J5, J6, J8, J9 4 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J7 1 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J10 0 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

5 Shunt, 100 mil, black 0.100 3M 929950−00

L1 1 Inductor, SMT, 10 µH, 1.84 A, 49 mΩ 0.315 × 0.287 Sumida CDRH74−100

R1 1 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R10 1 Resistor, chip, 4.99 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−4991−F

R11, R13, R14 3 Resistor, chip, 10 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1002−F

R12 0 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−0000−F

R2, R3 2 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R4 1 Resistor, chip, 0.1 Ω, ½ W, 1% 2010 Vishay CRCW1210−0R10F

R5, R7 0 Resistor, chip, 200 kΩ, 1/8−W, 1% 805 Vishay CRCW0805−2003−F

R6 1 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−00R0−F

R8, R9 2 Resistor, chip, 7.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−7501−F

U1 1 IC, advanced Li-Ion and Li-Pol charge management RHL−20 TI bq24100RHL

−− 1 PCB, 2.0 In x 1.9 In x .031 In Any HPA040

(1)

These assemblies are ESD sensitive, ESD precautions shall be observed.

(2)

These assemblies must be clean and free from flux and all contaminants. Use of no clean flux is not acceptable.

(3)

These assemblies must comply with workmanship standards IPC−A−610 Class 2.

(4)

C9 can be installed by the customer if using long cables (inductive load)

(5)

Place shunts as follows (Jumper pin orientation: pin 1: top (toward RD), pin 2: center, pin 3−bottom). Place shunts on J5, J6, J7−1/2 (LED);

J9−2/3 (LOW); J8−2 (optional)

QTY DESCRIPTION SIZE MFR PART NUMBER

Using the bq241xx (bqSWITCHERE)

11

Page 12

SLUU200 − July 2004

Table 4. bq24105EVM−002 List of Materials

REFERENCE

DESIGNATOR

C1, C2, C4 3 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C9 0 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C3 1 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C5, C7, C8 3 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C6 1 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

D1 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D2 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D3 1 Diode, LED, red, 1.8 V, 20 mA, 20 mcd 603 Liteon 160−1181−1−ND

J1 1 Terminal block, 2-pin, 6 A, 3.5 mm 75525 OST ED1514

J2, J3 2 Terminal block, 4-pin, 6 A, 3.5 mm 0.55 × 0.25 OST ED1516

J4 1 Terminal block, 3-pin, 6 A, 3.5 mm 0.41 × 0.25 OST ED1515

J5, J6, J8, J9 4 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J7 1 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J10 0 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

5 Shunt, 100 mil, black 0.100 3M 929950−00

L1 1 Inductor, SMT, 10 µH, 1.84 A, 49 mΩ 0.315 × 0.287 Sumida CDRH74−100

R1 1 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R10 1 Resistor, chip, 4.99 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−4991−F

R11, R13, R14 3 Resistor, chip, 10 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1002−F

R12 0 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−0000−F

R2, R3 2 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R4 1 Resistor, chip, 0.1 Ω, ½ W, 1% 2010 Vishay CRCW1210−0R10F

R5, R7 2 Resistor, chip, 200 kΩ, 1/8−W, 1% 805 Vishay CRCW0805−2003−F

R6 1 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−00R0−F

R8, R9 2 Resistor, chip, 7.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−7501−F

U1 1 IC, Advanced Li −Ion and Li−Pol Charge Management RHL−20 TI bq24105RHL

−− 1 PCB, 2.0 In × 1.9 In × 0.031 In Any HPA040

(1)

These assemblies are ESD sensitive, ESD precautions shall be observed.

(2)

These assemblies must be clean and free from flux and all contaminants. Use of no clean flux is not acceptable.

(3)

These assemblies must comply with workmanship standards IPC−A−610 Class 2.

(4)

C9 can be installed by the customer if using long cables (inductive load)

(5)

Place shunts as follows (Jumper pin orientation: pin 1: top (toward RD), pin 2: center, pin 3−bottom). Place shunts on J5, J6, J7−1/2 (LED);

J9−2/3 (LOW); J8−2 (optional)

QTY DESCRIPTION SIZE MFR PART NUMBER

12

Using the bq241xx (bqSWITCHERE)

Page 13

Table 5. bq24113EVM−003 List of Materials

SLUU200 − July 2004

REFERENCE

DESIGNATOR

C1, C2, C4 3 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C9 0 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C3 0 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C5, C7, C8 3 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C6 0 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

D1 0 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D2 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D3 1 Diode, LED, red, 1.8 V, 20 mA, 20 mcd 603 Liteon 160−1181−1−ND

J1 1 Terminal block, 2-pin, 6 A, 3.5 mm 75525 OST ED1514

J2, J3 2 Terminal block, 4-pin, 6 A, 3.5 mm 0.55 × 0.25 OST ED1516

J4 1 Terminal block, 3-pin, 6 A, 3.5 mm 0.41 × 0.25 OST ED1515

J5, J6, J8, J9 4 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J7 0 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J10 1 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

5 Shunt, 100 mil, black 0.100 3M 929950−00

L1 1 Inductor, SMT, 10 µH, 1.84 A, 49 mΩ 0.315 × 0.287 Sumida CDRH74−100

R1 0 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R10 1 Resistor, chip, 4.99 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−4991−F

R11, R13, R14 3 Resistor, chip, 10 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1002−F

R12 1 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−0000−F

R2, R3 2 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R4 1 Resistor, chip, 0.1 Ω, ½ W, 1% 2010 Vishay CRCW1210−0R10F

R5, R7 0 Resistor, chip, 200 kΩ, 1/8−W, 1% 805 Vishay CRCW0805−2003−F

R6 1 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−00R0−F

R8, R9 2 Resistor, chip, 7.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−7501−F

U1 1 IC, Advanced Li-Ion and Li-Pol Charge Management RHL−20 TI bq24113RHL

−− 1 PCB, 2.0 In × 1.9 In × 0.031 In Any HPA040

(1)

These assemblies are ESD sensitive, ESD precautions shall be observed.

(2)

These assemblies must be clean and free from flux and all contaminants. Use of no clean flux is not acceptable.

(3)

These assemblies must comply with workmanship standards IPC−A−610 Class 2.

(4)

C9 can be installed by the customer if using long cables (inductive load)

(5)

Place shunts as follows (Jumper pin orientation: pin 1: top (toward RD), pin 2: center, pin 3−bottom). Place shunts on J8−1/2 (Hi), J5 & J6−1/2

(LED), J9−2/3 (LOW). Place shunts on J10−2/3 (LOW)

QTY DESCRIPTION SIZE MFR PART NUMBER

Using the bq241xx (bqSWITCHERE)

13

Page 14

SLUU200 − July 2004

Table 6. bq24115EVM−004 List of Materials

REFERENCE

DESIGNATOR

C1, C2, C4 3 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C9 0 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C3 1 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C5, C7, C8 3 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C6 0 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

D1 0 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D2 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D3 1 Diode, LED, red, 1.8 V, 20 mA, 20 mcd 603 Liteon 160−1181−1−ND

J1 1 Terminal block, 2-pin, 6 A, 3.5 mm 75525 OST ED1514

J2, J3 2 Terminal block, 4-pin, 6 A, 3.5 mm 0.55 × 0.25 OST ED1516

J4 1 Terminal block, 3-pin, 6 A, 3.5 mm 0.41 × 0.25 OST ED1515

J5, J6, J8, J9 4 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J7 0 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J10 0 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

4 Shunt, 100 mil, black 0.100 3M 929950−00

L1 1 Inductor, SMT, 10 µH, 1.84 A, 49 mΩ 0.315 × 0.287 Sumida CDRH74−100

R1 0 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R10 1 Resistor, chip, 4.99 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−4991−F

R11, R13, R14 3 Resistor, chip, 10 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1002−F

R12 0 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−0000−F

R2, R3 2 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R4 1 Resistor, chip, 0.1 Ω, ½ W, 1% 2010 Vishay CRCW1210−0R10F

R5, R7 2 Resistor, chip, 200 kΩ, 1/8−W, 1% 805 Vishay CRCW0805−2003−F

R6 1 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−00R0−F

R8, R9 2 Resistor, chip, 7.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−7501−F

U1 1 IC, Advanced Li-Ion and Li-Pol Charge Management RHL−20 TI bq24115RHL

−− 1 PCB, 2.0 In × 1.9 In × 0.031 In Any HPA040

(1)

These assemblies are ESD sensitive, ESD precautions shall be observed.

(2)

These assemblies must be clean and free from flux and all contaminants. Use of no clean flux is not acceptable.

(3)

These assemblies must comply with workmanship standards IPC−A−610 Class 2.

(4)

C9 can be installed by the customer if using long cables (inductive load)

(5)

Place shunts as follows (Jumper pin orientation: pin 1: top (toward RD), pin 2: center, pin 3−bottom). Place shunts on J8−1/2 (Hi), J5 & J6−1/2

(LED), J9−2/3 (LOW)

QTY DESCRIPTION SIZE MFR PART NUMBER

14

Using the bq241xx (bqSWITCHERE)

Page 15

Table 7. bq24103EVM−005 List of Materials

SLUU200 − July 2004

REFERENCE

DESIGNATOR

C1, C2, C4 3 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C9 0 Capacitor, ceramic, 10 µF, 25 V, X5R, 20% 1206 Panasonic ECJ−3YB1E106M

C3 0 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C5, C7, C8 3 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

C6 1 Capacitor, ceramic, 0.1 µF, 16 V, X7R, 10% 603 Panasonic ECJ−1VB1C104K

D1 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D2 1 Diode, LED, green, 2.1 V, 20 mA, 6 mcd 603 Liteon 160−1183−1−ND

D3 1 Diode, LED, red, 1.8 V, 20 mA, 20 mcd 603 Liteon 160−1181−1−ND

J1 1 Terminal block, 2-pin, 6 A, 3.5 mm 75525 OST ED1514

J2, J3 2 Terminal block, 4-pin, 6 A, 3.5 mm 0.55 × 0.25 OST ED1516

J4 1 Terminal block, 3-pin, 6 A, 3.5 mm 0.41 × 0.25 OST ED1515

J5, J6, J8, J9 4 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J7 1 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

J10 1 Header, 3−pin, 100 mil spacing, (36-pin strip) 34100 Sullins PTC36SAAN

6 Shunt, 100 mil, black 0.100 3M 929950−00

L1 1 Inductor, SMT, 10 µH, 1.84 A, 49 mΩ 0.315 × 0.287 Sumida CDRH74−100

R1 1 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R10 1 Resistor, chip, 4.99 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−4991−F

R11, R13, R14 3 Resistor, chip, 10 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1002−F

R12 1 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−0000−F

R2, R3 2 Resistor, chip, 1.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−1501−F

R4 1 Resistor, chip, 0.1 Ω, ½ W, 1% 2010 Vishay CRCW1210−0R10F

R5, R7 0 Resistor, chip, 200 kΩ, 1/8−W, 1% 805 Vishay CRCW0805−2003−F

R6 1 Resistor, chip, 0 Ω, 1/16−W, 1% 603 Vishay CRCW0603−00R0−F

R8, R9 2 Resistor, chip, 7.5 kΩ, 1/16−W, 1% 603 Vishay CRCW0603−7501−F

U1 1 IC, Advanced Li-Ion and Li-Pol Charge Management RHL−20 TI bq24103RHL

−− 1 PCB, 2.0 In × 1.9 In × 0.031 In Any HPA040

(1)

These assemblies are ESD sensitive, ESD precautions shall be observed.

(2)

These assemblies must be clean and free from flux and all contaminants. Use of no clean flux is not acceptable.

(3)

These assemblies must comply with workmanship standards IPC−A−610 Class 2.

(4)

C9 can be installed by the customer if using long cables (inductive load)

(5)

Place shunts as follows (Jumper pin orientation: pin 1: top (toward RD), pin 2: center, pin 3−bottom). Place shunts on J5, J6, J7−1/2 (LED);

J9−2/3 (LOW); J8−2 (optional). Place shunts on J10−2/3 (LOW)

QTY DESCRIPTION SIZE MFR PART NUMBER

6 References

1. bq241xx Synchronous Switchmode Li−Ion and Li−Pol Charge Management IC With Integrated PowerFETs

(bqSWITCHER) datasheet (SLUS606)

Using the bq241xx (bqSWITCHERE)

15

Page 16

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...