Page 1

BOOSTXL-ULN2003 Dual Stepper Motor Driver

BoosterPack Hardware

User's Guide

Literature Number: SLCU002

September 2016

Page 2

Contents

1 Introduction......................................................................................................................... 5

1.1 BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Overview ........................................ 5

2 Hardware Description ........................................................................................................... 6

2.1 Top and Bottom View.................................................................................................... 6

2.2 Board Overview .......................................................................................................... 6

2.3 Block Diagram ............................................................................................................ 7

2.4 Connector, Switch, and LED Descriptions............................................................................ 8

2.5 Powering the BOOSTXL-ULN2003................................................................................... 11

2.6 Other Hardware Highlights ............................................................................................ 13

3 Interfacing With External Hardware ...................................................................................... 15

3.1 Connecting to a LaunchPad........................................................................................... 15

3.2 Connecting a Motor or Other Peripherals ........................................................................... 15

3.3 Connecting to Other Development Boards.......................................................................... 16

4 Functional Modes............................................................................................................... 17

4.1 Modes of Operation Overview ........................................................................................ 17

4.2 3-pin Serial Mode....................................................................................................... 18

4.3 8-pin Parallel Mode..................................................................................................... 19

5 Additional Information ........................................................................................................ 20

5.1 Design Files ............................................................................................................. 20

5.2 Software.................................................................................................................. 20

5.3 Hardware Change Log................................................................................................. 20

5.4 Schematic................................................................................................................ 21

2

Table of Contents

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 3

www.ti.com

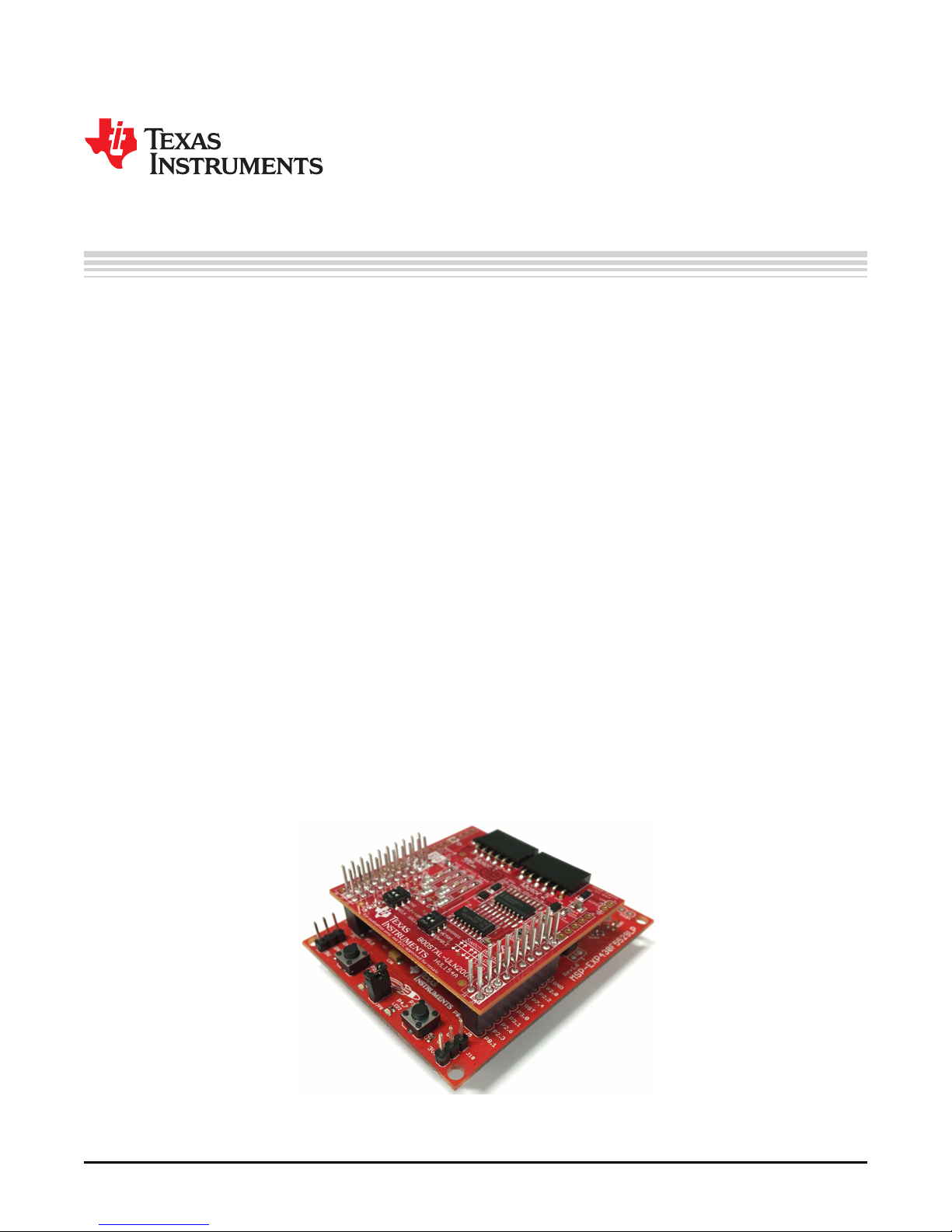

1 BOOSTXL-ULN2003 Connected to MSP-EXP430F5529LP........................................................... 5

2 Top View of BOOSTXL-ULN2003 ......................................................................................... 6

3 Bottom View of BOOSTXL-ULN2003 ..................................................................................... 6

4 BOOSTXL-ULN2003 Top Side Overview................................................................................. 6

5 BOOSTXL-ULN2003 Block Diagram...................................................................................... 7

6 BOOSTXL-ULN2003 2x20 Header Description.......................................................................... 8

7 Board Image of Switches ................................................................................................... 9

8 Schematic View of Switches ............................................................................................... 9

9 Board Image of LEDs...................................................................................................... 10

10 Schematic View of LEDs.................................................................................................. 10

11 External Supply Connected to Motor Supply Pins..................................................................... 11

12 On-Board Power OR-ing .................................................................................................. 11

13 USB Powering a Single Motor (See NOTE) ............................................................................ 12

14 BoosterPack With ULN2003A ............................................................................................ 13

15 BoosterPack With ULN2803A ............................................................................................ 13

16 Board Image of LED Section ............................................................................................. 14

17 LED Section With R5 Depopulated ...................................................................................... 14

18 Board Image of COM Diode Section .................................................................................... 14

19 COM Diode Section With R14 Depopulated............................................................................ 14

20 BoosterPack Connected to MSP430F5529 LaunchPad .............................................................. 15

21 BoosterPack With Two Stepper Motors ................................................................................. 15

22 BoosterPack with Motor and Male Expansion Header ................................................................ 16

23 BOOSTXL-ULN2003 Mode Overview ................................................................................... 17

24 3-Pin Mode Abbreviated Schematic (Zoom for Higher Resolution).................................................. 18

25 8-Pin Mode Abbreviated Schematic (Zoom for Higher Resolution).................................................. 19

26 BOOSTXL-ULN2003 Schematic (Zoom for Higher Resolution)...................................................... 21

List of Figures

SLCU002–September 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

List of Figures

3

Page 4

www.ti.com

List of Tables

1 J1 and J2 Connector Pinout Description ................................................................................. 8

2 Dip Switch Description ...................................................................................................... 9

3 LED Description ............................................................................................................ 10

4 Description of Hardware Changes ....................................................................................... 20

4

List of Tables

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 5

BOOSTXL-ULN2003 Dual Stepper Motor Driver

BoosterPack Hardware

1 Introduction

1.1 BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Overview

The BOOSTXL-ULN2003 provides an easy-to-use development board to interface with up to two unipolar

stepper motors using any Launchpad in the Launchpad Ecosystem. This user’s guide details a hardware

description of the BoosterPack, how to interface the BoosterPack with external hardware, various modes

of operation, and additional features.

The BOOSTXL-ULN2003 allows for the control of eight high-current (up to 500 mA per channel), high

voltage (up to 30 V), sink outputs. These outputs are controlled either through a serial (3-pin) or parallel

(8-pin) mode. Using the BOOSTXL-ULN2003 in serial 3-pin mode allows for control of two unipolar

stepper motors while only requiring 3 General-Purpose Input/Output (GPIO) pins, ultimately allowing for

flexibility in design and reduction in the number of GPIO pins required.

The BOOSTXL-ULN2003 can not only be used to provide an interface to unipolar stepper motors, but also

can be used in the following applications.

• Relay Driving

• Solenoid Driving

• LED Driving

• High-Voltage Logic Level Shifting

For additional information regarding these applications, see What is a Peripheral Driver? Applications and

Design Considerations.

The Boosterpack is not limited to one specific application at a time, but can be used for all of these

applications simultaneously. For example, one BoosterPack could enable driving one stepper motor,

driving one relay, driving two LEDs, and shifting a 3.3-V logic signal to a 24-V logic signal at the same

time.

User's Guide

SLCU002–September 2016

Figure 1. BOOSTXL-ULN2003 Connected to MSP-EXP430F5529LP

SLCU002–September 2016

Submit Documentation Feedback

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

5

Page 6

J1, J3 Standard

BoosterPack Header

J

2

,

J

4

Standard

BoosterPack Header

Header for Other Dev Board Compatibility

Dev Board

Hardware Description

2 Hardware Description

2.1 Top and Bottom View

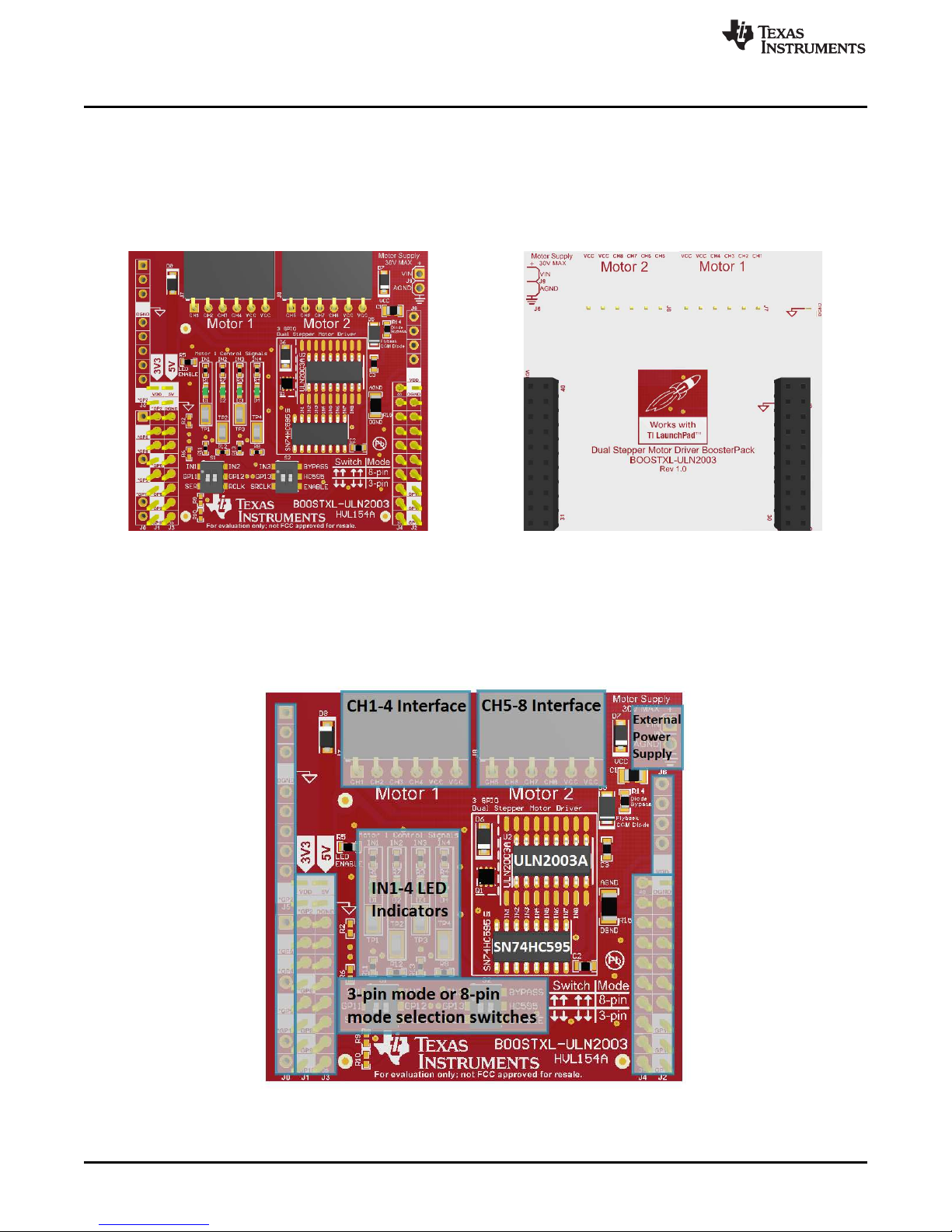

Figure 2 is a top view of the BOOSTXL-ULN2003, and Figure 3 is a bottom view of the

BOOSTXL-ULN2003.

www.ti.com

Figure 2. Top View of BOOSTXL-ULN2003 Figure 3. Bottom View of BOOSTXL-ULN2003

2.2 Board Overview

Figure 4 shows an overview of the BOOSTXL-ULN2003 BoosterPack. The main features such as devices,

switches, connectors, and LEDs are highlighted.

See Section 2.4 for additional details regarding each section.

Figure 4. BOOSTXL-ULN2003 Top Side Overview

6

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 7

VCC

3V3

MSP430

Launchpad

40-pin

BoosterPack

Interface

ULN2003A

+

CSD17571Q2

SN74HC595

CH1-4 + Vcc

[Motor 1]

[4 Relays]

[4 LEDs]

CH5-8 + Vcc

[Motor 2]

[4 Relays]

[4 LEDs]

3-Pin

Mode

Dip Switches (x4)

8-Pin

Mode

Dual Stepper Motor Driver BoosterPack

BOOSTXL-ULN2003

Inputs

Outputs

Motor Supply

-

+

AGND

VIN

+

5V+3V3

-

DGND

VIN

5V

Power

OR-ing

VCC

VCC

VCC

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

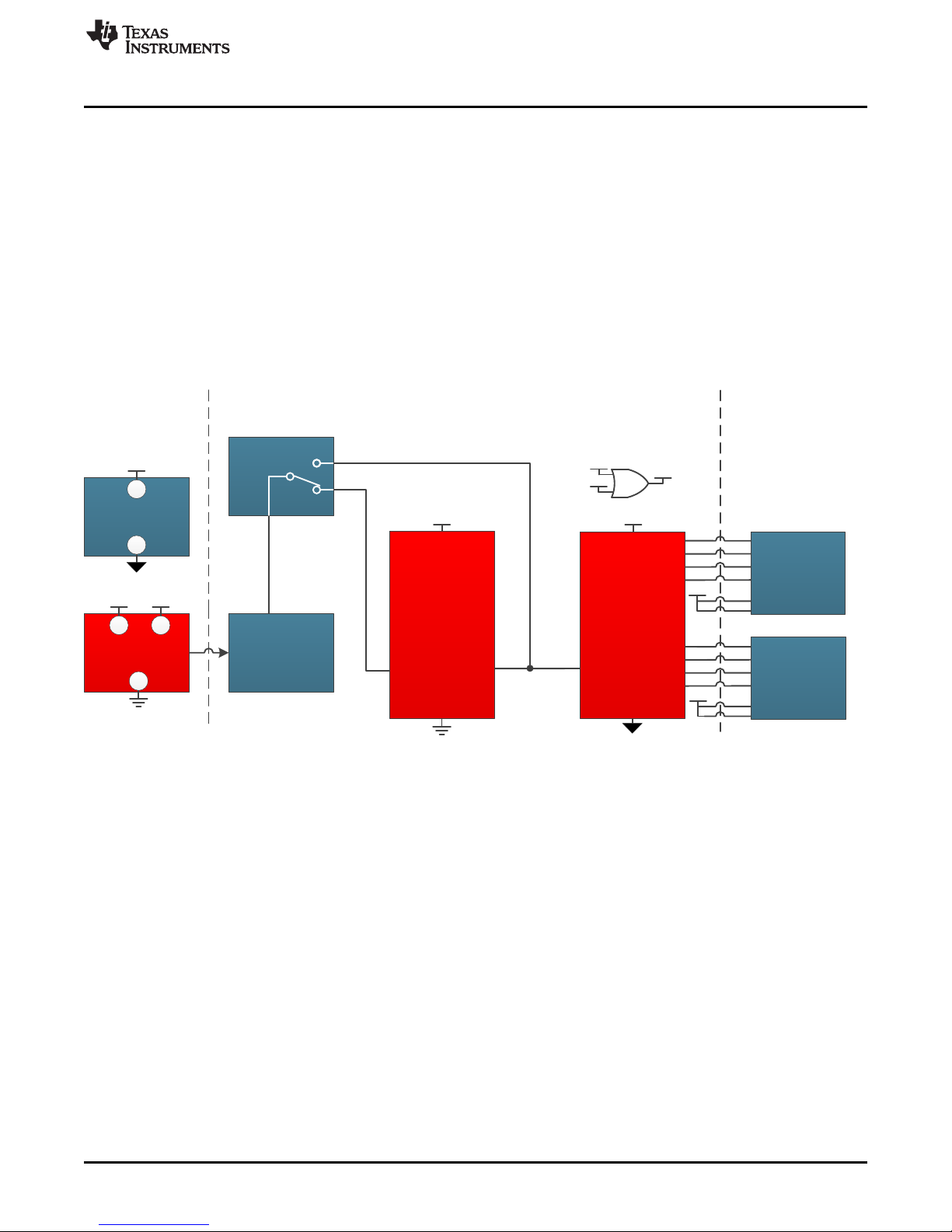

2.3 Block Diagram

Figure 5 details a block diagram of the BOOSTXL-ULN2003 BoosterPack. The 40-pin BoosterPack

header allows the BoosterPack to be interfaced with any LaunchPad in the MSP430 LaunchPad

ecosystem. See ti.com/launchpad for a list of all available MSP430 LaunchPads. A row of four switches

allow the user to choose between a parallel, direct-drive (8-pin) mode and a serial (3-pin) mode of control

of the ULN2003A.

The ULN2003A is a 7-channel Darlington pair array that is used to drive motors, solenoids, LEDs, or

relays. See the ULN2003A product folder for additional overview regarding this device. The CSD17571Q2

is a TI N-Channel NexFET Power MOSFET that is paired with the ULN2003A in order to enable an eighth

output channel. See the CSD17571Q2 product folder for additional overview regarding this device. The

SN74HC595 shift register enables the 3-pin control mode, ultimately reducing the number of GPIOs

required for driving eight output channels. See the SN74HC595 product folder for additional overview

regarding this device. See Section 4 for additional information on how to select between 3-pin mode and

8-pin mode.

Hardware Description

Figure 5. BOOSTXL-ULN2003 Block Diagram

SLCU002–September 2016

Submit Documentation Feedback

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

7

Page 8

Hardware Description

2.4 Connector, Switch, and LED Descriptions

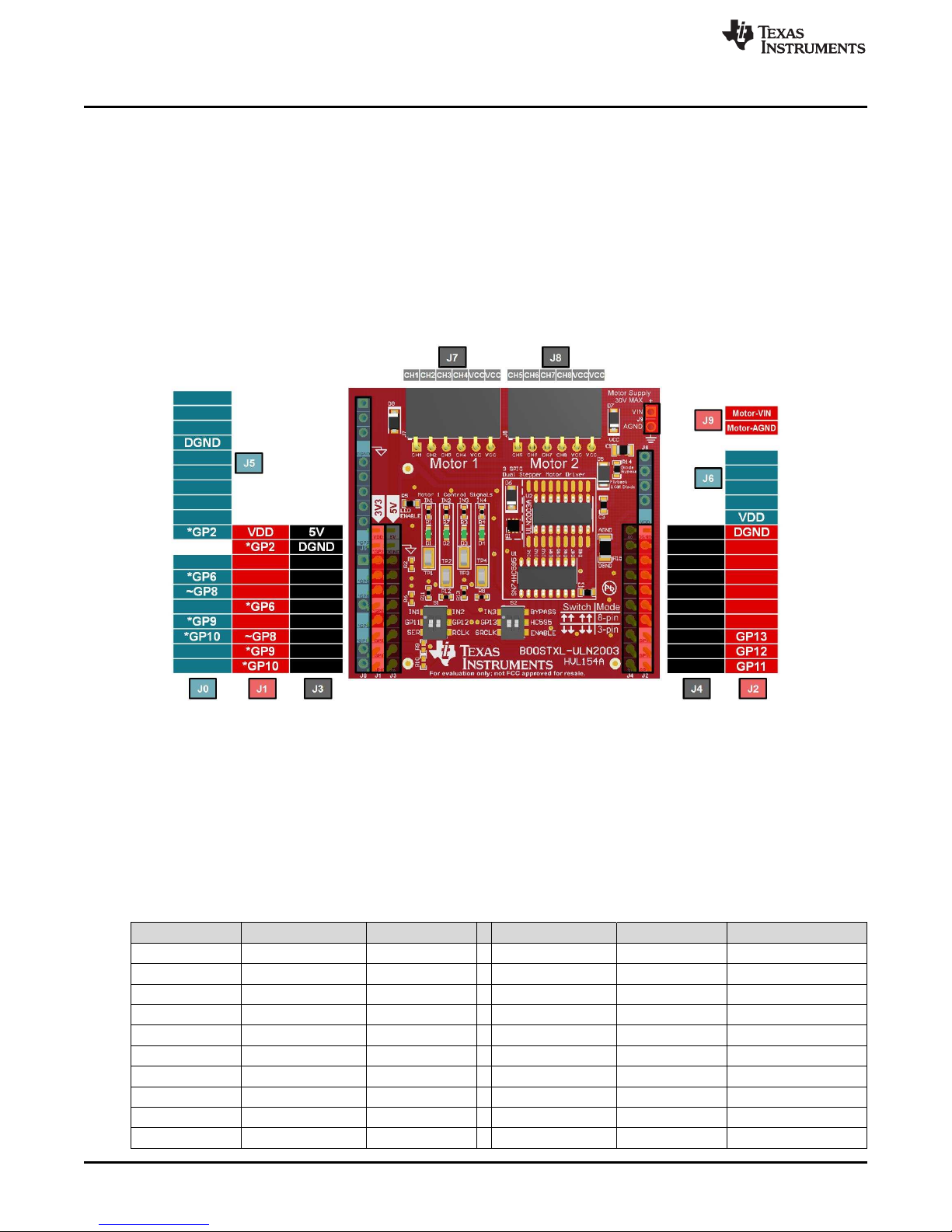

2.4.1 Connectors

The signal assignment on the BoosterPack pin connectors is shown in Figure 6. The J1-J4 descriptions on

the BoosterPack follow the J1-J4 convention for the Launchpad ecosystem. See ti.com/launchpad for

further description of the 40-pin BoosterPack standard.

Only the outer two pin columns, J1 and J2 (highlighted in red below) are required for BoosterPack

operation, the inner 2 columns, J3 and J4, are provided to pass signals from any 40-pin Launchpad to

other BoosterPack boards that may require these pins. The additional headers, J0, J5, and J6 are for

interfacing with other development boards. See Section 3.3 for details regarding connecting to other

development boards.

www.ti.com

(1) Pins with no name/description are not connected. Pins with the same name/description are shorted together.

(2) *~ These pins are not required for BoosterPack operation.

(3) * These pins are not connected out of the box. To enable control of this board through these pins, see

Section 4.3.1.

(4) ~ This pin is connected to IN4 out of the box. This allows for channels IN1-IN4 to be driven directly using 8-

pin parallel mode. A resistor is connected to protect the line from bus contention if 3-pin mode is being used

and this pin is being used for another purpose.

Figure 6. BOOSTXL-ULN2003 2x20 Header Description

Table 1. J1 and J2 Connector Pinout Description

Direction Pin Name Pin Number Pin Number Pin Name Direction

POWER VDD J1.1 J2.20 DGND POWER

INPUT GP2* J1.2 J2.19

INPUT GP6* J1.6 J2.15

INPUT GP8~ J1.8 J2.13 GP13 INPUT

INPUT GP9* J1.9 J2.12 GP12 INPUT

INPUT GP10* J1.10 J2.11 GP11 INPUT

8

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

J1.3 J2.18

J1.4 J2.17

J1.5 J2.16

J1.7 J2.14

SLCU002–September 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

Page 9

GP11 GP12 GP13

SRCLK

IN3

RCLK

IN2

SER

IN1

OE

DGND

3V3

3

1

2

6

4

5

S2

3

1

2

6

4

5

S1

560

R11

560

R12

560

R13

www.ti.com

2.4.2 Switches

The four on-board dip switches are used to select between 3-pin mode and 8-pin mode operation of the

BoosterPack. Descriptions for each of the switches are provided in Table 2.

Hardware Description

Figure 7. Board Image of Switches

Figure 8. Schematic View of Switches

Table 2. Dip Switch Description

Reference Description

This SPDT switch directs the signal from BoosterPack header input GP11. If the switch

is down, it connects GP11 to the SER input of the SN74HC595. If the switch is up, it

S1 - GP11

S1 - GP12

S2 - GP13

S2 - HC595

connects GP11 directly to IN1 – ultimately connected to the gate of the CSD17571Q2

FET.

Switch Down = 3-pin Serial Mode

Switch Up = 8-pin Parallel Mode

This SPDT switch directs the signal from BoosterPack header input GP12. If the switch

is down, it connects GP12 to the RCLK input of the SN74HC595. If the switch is up, it

connects GP12 directly to IN2 – ultimately connected to 1B of the ULN2003A device.

Switch Down = 3-pin Serial Mode

Switch Up = 8-pin Parallel Mode

This SPDT switch directs the signal from BoosterPack header input GP13. If the switch

is down, it connects GP13 to the SRCLK input of the SN74HC595. If the switch is up, it

connects GP13 directly to IN3 – ultimately connected to the 2B of the ULN2003A

device.

Switch Down = 3-pin Serial Mode

Switch Up = 8-pin Parallel Mode

This SPDT switch connects the OE pin either to 3V3 or DGND. This determines

whether or not the SN74HC595 outputs are enabled or are in high-impedance (Hi-Z)

mode. If the switch is down, it enables the SN74HC595 outputs. If the switch is up, it

disables the SN74HC595 outputs. Disabling these outputs is required for 8-pin Parallel

Mode to avoid bus contention at the inputs of the ULN2003A and the CSD17571Q2

FET.

Switch Down = 3-pin Serial Mode

Switch Up = 8-pin Parallel Mode

SLCU002–September 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

9

Page 10

Green

12

D1

Green

12

D2

Green

12

D3

Green

12

D4

DGND

IN1 IN2 IN3 IN4

0

R5

1.0k

R1

1.0k

R7

1.0k

R3

1.0k

R4

Hardware Description

2.4.3 LEDs

The four on-board LEDs provide visual feedback for the IN1 through IN4 signals. When operating in 3-pin

mode these LEDs are driven by the SN74HC595, and when operating in 8-pin mode these LEDs are

being driven directly by the MSP430 GPIO pins.

If the user wants to disable the onboard LEDs, resistor R5 can be removed. Additional details are found in

Section 2.6.2.

www.ti.com

Figure 9. Board Image of LEDs Figure 10. Schematic View of LEDs

Reference Description

D1

D2

D3

D4

Table 3. LED Description

D1 is connected to the signal IN1. D1 is on when IN1 is high, and is off when IN1 is low.

When IN1 is high, M1_CH1 is activated – ultimately being pulled to AGND as the CSD17571Q2

inverts the logic signal.

D2 is connected to the signal IN2. D2 is on when IN2 is high, and is off when IN2 is low.

When IN2 is high, M1_CH2 is activated – ultimately being pulled to AGND as the ULN2003A inverts

the logic signal.

D3 is connected to the signal IN3. D3 is on when IN3 is high, and is off when IN3 is low.

When IN3 is high, M1_CH3 is activated – ultimately being pulled to AGND as the ULN2003A inverts

the logic signal.

D4 is connected to the signal IN4. D4 is on when IN4 is high, and is off when IN4 is low.

When IN4 is high, M1_CH4 is activated – ultimately being pulled to AGND as the ULN2003A inverts

the logic signal.

10

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 11

VCC

AGND DGND

0

R15

1µF

C1

D7

VIN

1

2

J9

5V

D8

www.ti.com

2.5 Powering the BOOSTXL-ULN2003

2.5.1 Powering the On-Board Devices

The BoosterPack is designed to accept power from a connected Launchpad. The 3.3 V line from the

Launchpad is required to power the SN74HC595 device. The 3.3 V line from the LaunchPad cannot

source enough current to power motors, relays, or LEDs, so an additional source of power is required as

described in Section 2.5.2.

2.5.2 Powering the Motor or Other Peripherals

The method of powering the external peripherals is dependent upon the LaunchPad being used in addition

to the output current requirements.

For higher current or voltage applications, the external motor supply pins should be connected to an

external supply as shown in Figure 11. The maximum voltage supplied through these pins should not

exceed 30 V, or permanent damage to components may occur. While there is some protection against

reverse polarity included on the board, note the correct orientation of the motor supply pins to avoid

permanent damage to the board.

Hardware Description

Figure 11. External Supply Connected to Motor Supply Pins

As shown in Figure 12, the VCC connected to the motor peripheral to provide power is created by using

power OR-ing diodes.

• If there is no 5-V line available from the LaunchPad, the motor supply is required to power the external

peripherals.

• If there is a 5-V line connected, and no motor supply is connected, the VCC pins provide a voltage

close to 5 V.

• If there is a 5-V line connected, and the motor supply voltage is connected and greater than 5 V, the

motor supply is used to power any external peripherals.

SLCU002–September 2016

Submit Documentation Feedback

Figure 12. On-Board Power OR-ing

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

11

Page 12

Hardware Description

Some LaunchPad boards have a 5-V supply pin, which is powered directly from the USB port. This supply

can be used to power peripherals, as shown in Figure 13, but there are some exceptions to when this can

be used (See the following NOTE). The 5-V stepper motor used in Figure 13 below has the following DigiKey Part Number: 1528-1366-ND. A 12-V version of this stepper motor has the following Digi-Key Part

Number: 1528-1367-ND.

www.ti.com

Figure 13. USB Powering a Single Motor (See NOTE)

NOTE: When using the 5-V pin (USB Power) to provide power to an external peripheral, TI does not

recommend to exceed 250 mA, and further caution should be taken when powering

additional BoosterPacks. TI does not recommend to power more than one stepper motor

from this board when using the 5-V LaunchPad power pin.

12

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 13

ULN2803A

ULN2003A

www.ti.com

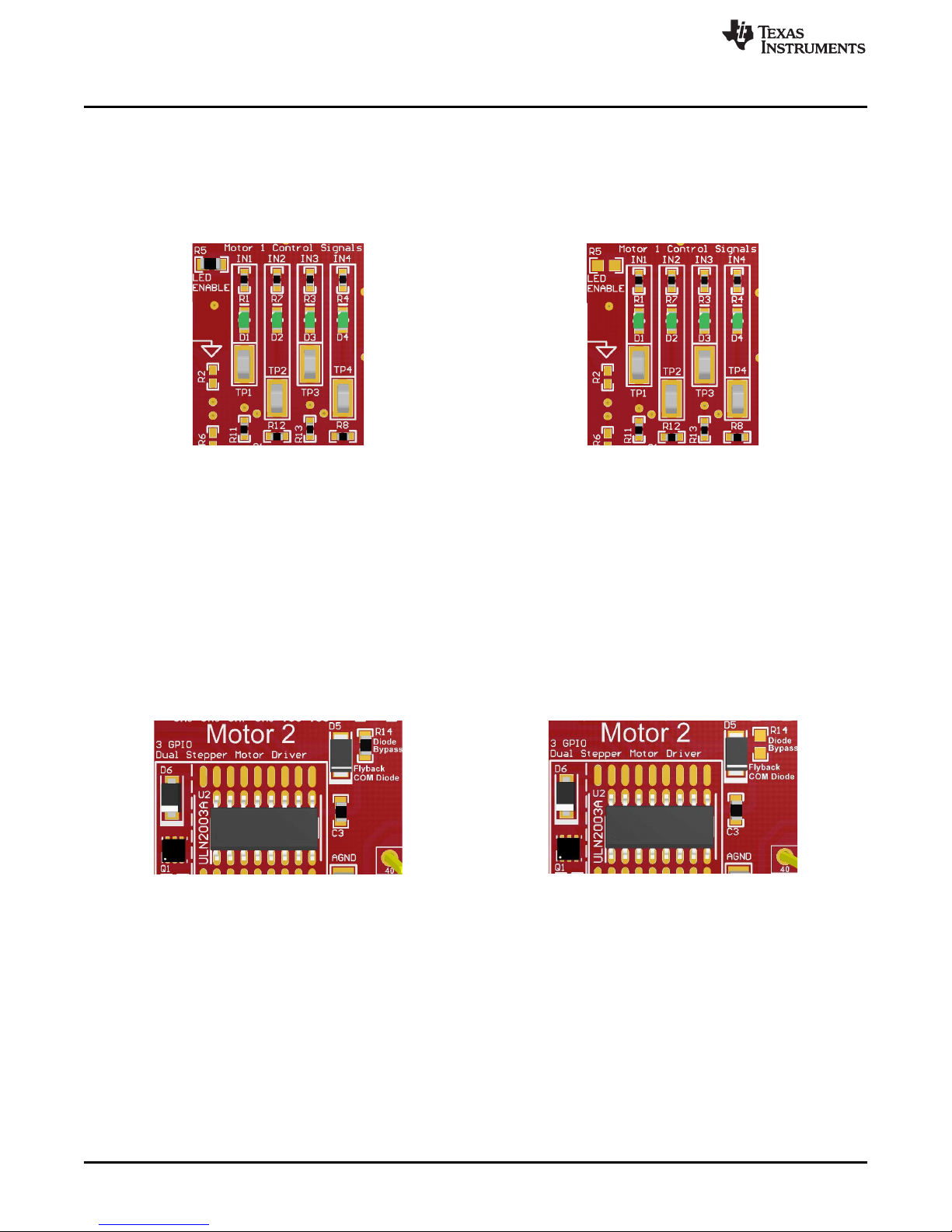

2.6 Other Hardware Highlights

2.6.1 Additional Device Compatibility

While the board initially comes populated with a ULN2003A device, this board is compatible with many

other pin-to-pin devices that perform a similar function. As shown in Figure 14, the Boosterpack has the

landing pattern for both the 16-pin D (SOIC) as well as the 18-pin DW (WIDE SOIC) package. Figure 15

shows the Boosterpack populated with the ULN2803A device.

If the ULN2003A device is depopulated, the following list of devices can be populated in order to be

evaluated.

• ULQ2003A - –40°C to +105°C Temperature Range

• ULQ2003-Q1 - Automotive Qualified Variant

• ULN2003LV - FET based variant

• ULN2003V12 - Wider-Voltage FET based variant

• ULN2803 - 8 channel variant

• TPL7407L - FET based variant with 40V outputs and drive circuitry to decrease power dissipation

Hardware Description

Figure 14. BoosterPack With ULN2003A Figure 15. BoosterPack With ULN2803A

SLCU002–September 2016

Submit Documentation Feedback

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

13

Page 14

Hardware Description

2.6.2 Disabling the On-Board LEDs

Figure 16 shows the section of the board with the LEDs. The R5 resistor is labeled LED ENABLE because

when a 0-Ω resistor is populated here, it allows a path for current flow through the LEDs. The on-board

LEDs can be disabled easily by depopulating this R5 resistor. Figure 17 shows the resistor depopulated,

so there is no longer a path for current to flow through the LEDs, thereby disabling them.

Figure 16. Board Image of LED Section Figure 17. LED Section With R5 Depopulated

2.6.3 Enabling Quick Inductor Discharge

The ULN2003A has internal flyback diodes to suppress voltage spikes due to inductive kickback. Stepper

Motors and relays have inductive kickback that is suppressed by these internal diodes. The rate of

discharge of the inductor is also directly proportional to the voltage across the inductor when discharging.

Figure 18 shows the section of the board near the COM pin of the ULN2003A device. Diode D5, also

labeled Flyback COM diode, is a 12-V Zener diode that is in series with the internal flyback diodes of the

ULN2003A. Normally there is a 0-Ω resistor (R14) in parallel with this Zener diode, also labeled Diode

Bypass, effectively bypassing the Zener diode. To enable the quick inductor discharge, the Diode Bypass

resistor (R14) should be depopulated. Figure 19 shows the board with this resistor depopulated, ultimately

enabling quick inductor discharge.

www.ti.com

Figure 18. Board Image of COM Diode Section Figure 19. COM Diode Section With R14 Depopulated

14

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 15

www.ti.com

3 Interfacing With External Hardware

3.1 Connecting to a LaunchPad

The BoosterPack is ready to connect to any LaunchPad out of the box. Figure 20 shows the correct

orientation of the BoosterPack on the LaunchPad.

The connectors should be aligned carefully as misalignment could cause

permanent damage to the BoosterPack.

Interfacing With External Hardware

CAUTION

Figure 20. BoosterPack Connected to MSP430F5529 LaunchPad

3.2 Connecting a Motor or Other Peripherals

The Boosterpack provides two standard 100 mil spacing female receptacles to interface two unipolar

stepper motors or other peripherals such as relays, solenoids, or LEDs.

Each receptacle provides a six-pin interface. Four pins are dedicated to the outputs of the ULN2003A and

CSD17571Q2 to drive the peripheral, and two pins are connected to the motor supply that is connected to

the board. These two VCC pins allow for connection to both 5-pin and 6-pin type Unipolar stepper motors.

Figure 21 shows two 5-pin unipolar motors connected to the BoosterPack.

Figure 21. BoosterPack With Two Stepper Motors

SLCU002–September 2016

Submit Documentation Feedback

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

15

Page 16

Interfacing With External Hardware

As shown in Figure 22, a male to male header can also be added to the receptacle to help interface with

standard 5-pin or 6-pin unipolar stepper motors with female receptacles.

Figure 22. BoosterPack with Motor and Male Expansion Header

www.ti.com

3.3 Connecting to Other Development Boards

The BoosterPack is compatible with Arduino development boards, but some additional hardware is

required beyond what is supplied in the box. The following list shows the additional required materials.

These must be populated on the BoosterPack to enable a hardware interface with the development board.

• J0 Male Pin Header

• J5 Male Pin Header

• J6 Male Pin Header

Once the additional headers are populated, the BoosterPack can be connected to the development board.

NOTE: The BoosterPack must be placed on the development board upside down for the pins to

align properly.

16

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 17

www.ti.com

4 Functional Modes

4.1 Modes of Operation Overview

Figure 23 provides a brief overview of how the Boosterpack pins are connected to either the SN74HC595

or the ULN2003A based on the selected mode of operation. Additional details for 3-pin mode and 8-pin

mode can be found in Section 4.2 and Section 4.3 respectively.

Functional Modes

(1) *There are NO resistors populated for pins GP6, GP2, GP9, and GP10, therefore there will be no direct

connection to IN5, IN6, IN7, and IN8 respectively. 0 Ohm or solder bridge connections can be made to

connect these pins in order to enable the full functionality of 8 pin mode. See Section 4.3.1 for additional

details

(2) ~There IS a resistor populated for pin IN4, therefore it can be used in 8-pin mode without bus contention;

however, in 3-pin mode it will draw current if GP8 is set low. The resistor allows IN4 and GP8 to be different

voltage levels when GP8 is being used for another purpose while the Boosterpack is in 3-pin mode. See

Section 4.2.1 for additional details.

Figure 23. BOOSTXL-ULN2003 Mode Overview

SLCU002–September 2016

Submit Documentation Feedback

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

17

Page 18

GP12

DGND

GP13

GP11

QB

1

QC

2

QD

3

QE

4

QF

5

QG

6

QH

7

GND

8

QH'

9

SRCLR

10

SRCLK

11

RCLK

12

OE

13

SER

14

QA

15

VCC

16

U1

SN74HC595DR

VCC

AGND

Green

12

D1

Green

12

D2

Green

12

D3

Green

12

D4

VCC

AGND

AGND

VCC

3

5,6,84,7

1,2,

Q1

CSD17571Q2

DGND

0.1 µF

C3

IN1

0

R14

DGND

TP1

TP2

TP3

TP4

0.1 µF

C2

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

IN1 IN2 IN3 IN4

3V3

DGND

1B

1

2B

2

3B

3

4B

4

5B

5

6B

6

7B

7

GND

8

COM

9

7C

10

6C

11

5C

12

4C

13

3C

14

2C

15

1C

16

U2

ULN2003ADR

1

2

3

4

5

6

J7

1

2

3

4

5

6

J8

M1_CH1

M1_CH2

M1_CH3

M1_CH4

M2_CH5

M2_CH6

M2_CH7

M2_CH8

COM

AGND

VCC

0

R5

DGND

0

R15

COM

1µF

C1

D7

DB2W40200L

D6

DB2W40200L

VIN

1

2

J9

12V

D5

5V

D8

DB2W40200L

1.0k

R1

1.0k

R7

1.0k

R3

1.0k

R4

Copyright © 2016, Texas Instruments Incorporated

Launchpad Inputs

Motor/Peripheral Outputs

Functional Modes

4.2 3-pin Serial Mode

4.2.1 Enabling 3-pin Mode

The BoosterPack has all of the required components to run 3-pin Mode out of the box. To enable this

mode of operation, the four dip switches should be in the lower position. Each switch works as defined in

Table 2.

4.2.2 3-pin Mode of Operation

Figure 24 shows the effective schematic for the 3-pin mode of operation. Inputs GP11, GP12, and GP13

from the microcontroller are used to drive the inputs of the SN74HC595 device. This 8-bit shift register

converts the serial input data to parallel output data to control the ULN2003A channels. For example

software to drive the SN74HC595, see Section 5.2.

www.ti.com

18

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Figure 24. 3-Pin Mode Abbreviated Schematic (Zoom for Higher Resolution)

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 19

GP13

GP12

GP11

VCC

AGND

Green

12

D1

Green

12

D2

Green

12

D3

Green

12

D4

VCC

AGND

AGND

VCC

3

5,6,84,7

1,2,

Q1

CSD17571Q2

DGND

0.1 µF

C3

IN1

0

R14

TP1

TP2

TP3

TP4

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

IN1 IN2 IN3 IN4

1B

1

2B

2

3B

3

4B

4

5B

5

6B

6

7B

7

GND

8

COM

9

7C

10

6C

11

5C

12

4C

13

3C

14

2C

15

1C

16

U2

ULN2003ADR

1

2

3

4

5

6

J7

1

2

3

4

5

6

J8

M1_CH1

M1_CH2

M1_CH3

M1_CH4

M2_CH5

M2_CH6

M2_CH7

M2_CH8

COM

AGND

VCC

0

R5

DGND

0

R15

COM

1µF

C1

D7

DB2W40200L

D6

DB2W40200L

VIN

1

2

J9

12V

D5

5V

D8

DB2W40200L

1.0k

R1

1.0k

R7

1.0k

R3

1.0k

R4

Copyright © 2016, Texas Instruments Incorporated

GP10

GP9

GP8

GP6

GP2

560

R8

0

R6

0

R2

0

R9

0

R10

560

R13

560

R12

560

R11

Launchpad Inputs

Motor/Peripheral Outputs

X

X

X

X

DNP

DNP

DNP

DNP

www.ti.com

4.3 8-pin Parallel Mode

4.3.1 Enabling 8-pin Mode

The BoosterPack has the required components to run ONLY 4 pins of the 8-pin Mode out of the box.

Ultimately, this allows control of a single stepper motor in a parallel control mode, so additional

components are required to enable control of all 8 outputs in parallel mode. To use 8-pin mode, the four

dip switches should be in the upper position. Each switch works as defined in Table 2.

To enable all 8 pins for this mode of operation, a 0-Ω resistor or solder bridge should be populated on the

pads for resistors R6, R2, R9, and R10 to enable IN5, IN6, IN7, and IN8 respectively.

NOTE: The 560-Ω resistors exist on IN1, IN2, IN3, and IN4 to help protect against bus contention if

the IN1, IN2, IN3, and IN4 pins are being driven by both the SN74HC595 and the

microcontroller. This should only happen if the dip switches are in the wrong position. If the

intent is to use the device in the 8-pin mode, and the switches are set properly, then there

should be no potential for bus contention, and therefore 560-Ω resistors are not required for

R6, R2, R9, and R10.

4.3.2 8-pin Mode of Operation

Figure 25 shows the effective schematic for the 8-pin mode of operation. Inputs GP11, GP12, GP13, GP8,

GP6, GP2, GP9, and GP10 from the microcontroller are used to drive the inputs of the ULN2003A device

directly. For example software to drive unipolar stepper motors using the ULN2003A, see Section 5.2.

Functional Modes

SLCU002–September 2016

Submit Documentation Feedback

Figure 25. 8-Pin Mode Abbreviated Schematic (Zoom for Higher Resolution)

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

19

Page 20

Additional Information

5 Additional Information

5.1 Design Files

All design files including schematics, layout, Bill of Materials (BOM), Gerber files, and documentation are

made available in the Texas Instruments Resource Explorer:

dev.ti.com/tirex

The schematic for the design is also attached as Figure 26 to the end of the document for quick reference.

5.2 Software

For software examples including the out-of-box experience, 3-pin mode driving, and 8-pin mode driving,

see dev.ti.com/BOOSTXL-ULN2003.

For additional information regarding stepper motor driving patterns, including half-step, full-step, and wave

drive, see Stepper Motor Driving with Peripheral Drivers (Driver ICs)

5.3 Hardware Change Log

PCB Revision Description of Changes

Rev 1.0

www.ti.com

Table 4. Description of Hardware Changes

• Initial Release

20

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

SLCU002–September 2016

Submit Documentation Feedback

Page 21

QB

1

QC

2

QD

3

QE

4

QF

5

QG

6

QH

7

GND

8

QH'

9

SRCLR

10

SRCLK

11

RCLK

12

OE

13

SER

14

QA

15

VCC

16

U1

SN74HC595DR

COM

10

1B

1

2B

2

3B

3

4B

4

5B

5

6B

6

7B

7

8B

8

GND

9

8C

11

7C

12

6C

13

5C

14

4C

15

3C

16

2C

17

1C

18

U3

ULN2803ADW

GPIO !

31

GPIO !

32

GPIO !

33

GPIO !

34

Timer_Cap/GPIO !

35

Timer_Cap/GPIO !

36

PWM/GPIO !

37

PWM/GPIO !

38

PWM/GPIO !

39

PWM/GPIO !

40

GPIO !

11

SPI_CS/GPIO !

12

SPI_CS/GPIO !

13

SPI_MISO

14

SPI_MOSI

15

RST

16

GPIO

17

GPIO !

18

PWM/GPIO !

19

GND

20

J2/J4

SSQ-110-03-T-D

+3.3V

1

Analog_In

2

LP_UART_RX

3

LP_UART_TX

4

GPIO !

5

Analog In

6

SPI_CLK

7

GPIO !

8

I2C_SCL

9

I2C_SDA

10

+5V

21

GND

22

Analog_In

23

Analog_In

24

Analog_In

25

Analog_In

26

Analog_In/I2S_WS

27

Analog_In/I2S_SCLK

28

Analog_Out/I2S_SDout

29

Analog_Out/I2S_SDin

30

J1/J3

SSQ-110-03-T-D

VCC

AGND

Green

12

D1

Green

12

D2

Green

12

D3

Green

12

D4

GP8

GP13

GP12

GP11

GP10

GP11 GP12 GP13

DGND

VCC

AGND

AGND

VCC

3

5,6,84,7

1,2,

Q1

CSD17571Q2

DGND

3V3

0.1µF

C3

IN1

0

R14

DGND

TP1

TP2

TP3

TP4

GP2

GP10

GP9

GP6

GP9

GP8

GP6

GP2

SRCLK

IN3

RCLK

IN2

SER

IN1

SER

SRCLK

RCLK

5

4

1

2

3

6

7

8

J0

5

4

1

2

3

J6

0.1µF

C2

IN4 IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

IN1 IN2 IN3 IN4

IN6

IN5

IN7

IN8

3V3

DGND

OE

OE

DGND

3V3

1B

1

2B

2

3B

3

4B

4

5B

5

6B

6

7B

7

GND

8

COM

9

7C

10

6C

11

5C

12

4C

13

3C

14

2C

15

1C

16

U2

ULN2003ADR

5

4

1

2

3

6

7

8

9

10

J5

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

AGND

COM

M2_CH8

M2_CH7

M2_CH6

M2_CH5

M1_CH4

M1_CH3

M1_CH2

M1_CH1

1

2

3

4

5

6

J7

1

2

3

4

5

6

J8

M1_CH1

M1_CH2

M1_CH3

M1_CH4

M2_CH5

M2_CH6

M2_CH7

M2_CH8

COM

AGND

VCC

3

1

2

6

4

5

S2

3

1

2

6

4

5

S1

0

R5

DGND

DGND

DGND

3V3

0

R15

GP10

GP9

GP8

GP6

GP2

COM

1µF

C1

3V3

D7

DB2W40200L

D6

DB2W40200L

VIN

1

2

J9

12V

D5

5V

5V

D8

DB2W40200L

1.0kR11.0kR71.0kR31.0k

R4

560

R11

560

R12

560

R13

560

R8

560

R6

560

R2

560

R9

560

R10

Copyright © 2016, Texas Instruments Incorporated

X

DNP

X

DNP

X

DNP

X

DNP

X

DNP

X

DNP

X

DNP

X

DNP

www.ti.com

Additional Information

21

SLCU002– September 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

5.4 Schematic

Figure 26. BOOSTXL-ULN2003 Schematic (Zoom for Higher Resolution)

NOTE: DNP is an abbreviation for do not populate. Components highlighted as DNP in the schematic are not populated out of the box.

Page 22

22

SLCU002– September 2016

Submit Documentation Feedback

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Page 23

www.ti.com

Additional Information

IMPORTANT NOTICE FOR TI DESIGN INFORMATION AND RESOURCES

Texas Instruments Incorporated (‘TI”) technical, application or other design advice, services or information, including, but not limited to,

reference designs and materials relating to evaluation modules, (collectively, “TI Resources”) are intended to assist designers who are

developing applications that incorporate TI products; by downloading, accessing or using any particular TI Resource in any way, you

(individually or, if you are acting on behalf of a company, your company) agree to use it solely for this purpose and subject to the terms of

this Notice.

TI’s provision of TI Resources does not expand or otherwise alter TI’s applicable published warranties or warranty disclaimers for TI

products, and no additional obligations or liabilities arise from TI providing such TI Resources. TI reserves the right to make corrections,

enhancements, improvements and other changes to its TI Resources.

You understand and agree that you remain responsible for using your independent analysis, evaluation and judgment in designing your

applications and that you have full and exclusive responsibility to assure the safety of your applications and compliance of your applications

(and of all TI products used in or for your applications) with all applicable regulations, laws and other applicable requirements. You

represent that, with respect to your applications, you have all the necessary expertise to create and implement safeguards that (1)

anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood of failures that

might cause harm and take appropriate actions. You agree that prior to using or distributing any applications that include TI products, you

will thoroughly test such applications and the functionality of such TI products as used in such applications. TI has not conducted any

testing other than that specifically described in the published documentation for a particular TI Resource.

You are authorized to use, copy and modify any individual TI Resource only in connection with the development of applications that include

the TI product(s) identified in such TI Resource. NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO

ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY TECHNOLOGY OR INTELLECTUAL PROPERTY

RIGHT OF TI OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

regarding or referencing third-party products or services does not constitute a license to use such products or services, or a warranty or

endorsement thereof. Use of TI Resources may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

TI RESOURCES ARE PROVIDED “AS IS” AND WITH ALL FAULTS. TI DISCLAIMS ALL OTHER WARRANTIES OR

REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING TI RESOURCES OR USE THEREOF, INCLUDING BUT NOT LIMITED TO

ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL

PROPERTY RIGHTS.

TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY YOU AGAINST ANY CLAIM, INCLUDING BUT NOT

LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF PRODUCTS EVEN IF

DESCRIBED IN TI RESOURCES OR OTHERWISE. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL,

COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR

ARISING OUT OF TI RESOURCES OR USE THEREOF, AND REGARDLESS OF WHETHER TI HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES.

You agree to fully indemnify TI and its representatives against any damages, costs, losses, and/or liabilities arising out of your noncompliance with the terms and provisions of this Notice.

This Notice applies to TI Resources. Additional terms apply to the use and purchase of certain types of materials, TI products and services.

These include; without limitation, TI’s standard terms for semiconductor products http://www.ti.com/sc/docs/stdterms.htm), evaluation

modules, and samples (http://www.ti.com/sc/docs/sampterms.htm).

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

SLCU002–September 2016

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

BOOSTXL-ULN2003 Dual Stepper Motor Driver BoosterPack Hardware

Copyright © 2016, Texas Instruments Incorporated

23

Page 24

IMPORTANT NOTICE FOR TI DESIGN INFORMATION AND RESOURCES

Texas Instruments Incorporated (‘TI”) technical, application or other design advice, services or information, including, but not limited to,

reference designs and materials relating to evaluation modules, (collectively, “TI Resources”) are intended to assist designers who are

developing applications that incorporate TI products; by downloading, accessing or using any particular TI Resource in any way, you

(individually or, if you are acting on behalf of a company, your company) agree to use it solely for this purpose and subject to the terms of

this Notice.

TI’s provision of TI Resources does not expand or otherwise alter TI’s applicable published warranties or warranty disclaimers for TI

products, and no additional obligations or liabilities arise from TI providing such TI Resources. TI reserves the right to make corrections,

enhancements, improvements and other changes to its TI Resources.

You understand and agree that you remain responsible for using your independent analysis, evaluation and judgment in designing your

applications and that you have full and exclusive responsibility to assure the safety of your applications and compliance of your applications

(and of all TI products used in or for your applications) with all applicable regulations, laws and other applicable requirements. You

represent that, with respect to your applications, you have all the necessary expertise to create and implement safeguards that (1)

anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood of failures that

might cause harm and take appropriate actions. You agree that prior to using or distributing any applications that include TI products, you

will thoroughly test such applications and the functionality of such TI products as used in such applications. TI has not conducted any

testing other than that specifically described in the published documentation for a particular TI Resource.

You are authorized to use, copy and modify any individual TI Resource only in connection with the development of applications that include

the TI product(s) identified in such TI Resource. NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO

ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY TECHNOLOGY OR INTELLECTUAL PROPERTY

RIGHT OF TI OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

regarding or referencing third-party products or services does not constitute a license to use such products or services, or a warranty or

endorsement thereof. Use of TI Resources may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

TI RESOURCES ARE PROVIDED “AS IS” AND WITH ALL FAULTS. TI DISCLAIMS ALL OTHER WARRANTIES OR

REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING TI RESOURCES OR USE THEREOF, INCLUDING BUT NOT LIMITED TO

ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL

PROPERTY RIGHTS.

TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY YOU AGAINST ANY CLAIM, INCLUDING BUT NOT

LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF PRODUCTS EVEN IF

DESCRIBED IN TI RESOURCES OR OTHERWISE. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL,

COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR

ARISING OUT OF TI RESOURCES OR USE THEREOF, AND REGARDLESS OF WHETHER TI HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES.

You agree to fully indemnify TI and its representatives against any damages, costs, losses, and/or liabilities arising out of your noncompliance with the terms and provisions of this Notice.

This Notice applies to TI Resources. Additional terms apply to the use and purchase of certain types of materials, TI products and services.

These include; without limitation, TI’s standard terms for semiconductor products http://www.ti.com/sc/docs/stdterms.htm), evaluation

modules, and samples (http://www.ti.com/sc/docs/sampterms.htm).

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2017, Texas Instruments Incorporated

Loading...

Loading...