Page 1

AN-2241 SM72445 Evaluation Board

User's Guide

Literature Number: SNVA649

May 2012

Page 2

Contents

1 Introduction ........................................................................................................................ 5

2 System Overview ................................................................................................................ 5

3 SM72445 Evaluation module Design Specification .................................................................. 6

4 Schematic .......................................................................................................................... 9

5 Bill of Material ................................................................................................................... 11

2

Table of Contents SNVA649–May 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

1 Evaluation Board Simplified Diagram .................................................................................... 5

2 Panel Mode Operation Using Converter's FET (“Boost” waveform is taken at drain of Q3, “Buck”

3 Slew Rate Limit (between the two markers) and Soft OVP (after the second marker)............................ 7

4 Start-Up Pattern With Unloaded Output ................................................................................. 7

5 Load Connect and Stand-By Sequence After Start-Up................................................................ 8

6 Circuit Schematic ........................................................................................................... 9

7 Top Assembly Diagram................................................................................................... 10

8 Bottom Assembly Diagram............................................................................................... 11

List of Figures

waveform was taken at drain of Q4.)..................................................................................... 6

All trademarks are the property of their respective owners.

SNVA649–May 2012 List of Figures

Submit Documentation Feedback

3

Copyright © 2012, Texas Instruments Incorporated

Page 4

User's Guide

SNVA649–May 2012

AN-2241 SM72445 Evaluation Board

The SolarMagic™ SM72445 Evaluation Board is designed to demonstrate the operation and the

capabilities of the SM72445 MPPT controller. The board consists of a high efficiency, four-switch BuckBoost DC/DC converter and a bidirectional FET based switch designed to bypass the DC/DC converter for

cases when DC/DC conversion is not needed and during failure of the DC/DC converter (over-current

protection, over-temperature, and so forth). The board also includes auxiliary circuits such as driver,

current sensor, temperature sensor and additional OVP circuitry.

4

AN-2241 SM72445 Evaluation Board SNVA649–May 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

DC/DC converter

Panel Mode

Bi-directional switch

SM72445

SM72295

Curr.

Sense amp.

Comparator

Temp. sensor

PV

Panel

LOAD

PWM signal

Gate Drive

Current

sense

Input

Current

sense

Input voltage

sense

Output voltage

sense

Protection trigger

Out current sense

Protection

trigger

www.ti.com

1 Introduction

The SM72445 is designed to maximize the energy production of a photovoltaic panel through the control

of a four switch buck-boost converter as well as an optional FET bi-directional switch (two FETs) designed

to maximize the efficiency at 1:1 conversion ratios. The maximum voltage and power transferred depend

on the component choice (driver, passive components, FET, and so forth). The SM72445 performs

optimization of the operating point of the solar panel through a high speed Perturb&Observe algorithm.

The input voltage and current are sampled at a high rate and digitally filtered while the algorithm updates

the output PWM waveform at a rate up to 1.2ms/step. The PWM waveforms include dead-time and can be

directly fed to the drivers controlling the DC/DC converter’s switches. The SM72445 is designed to

operate at 110kHz, 137kHz and 220kHz depending on the operating mode set. The SM72445 includes

and I2C slave module with 8 address settings to communicate monitoring information and to allow remote

shut-down and configuration modifications.

The SolarMagic™ SM72445 Evaluation Board is based off of the SM3320-1A1 power optimizer, and

shares all of its best-in-class power optimization features. This includes its ability to mitigate real-world

mismatch, its 99.5% peak efficiency, and its Panel-Mode operation. In addition, the same ultra-low profile

form factor of the original SM3320-1A1 is maintained so that it can be integrated into the same junction

box designs.

This Evaluation module is fully operational and can be used with panels from 15V up to 50V (absolute)

operating voltage and up to 300W of power. Proper heat-sinking of the Power FETs must be achieved for

power levels above 50W at room temperature.

The absolute maximum output voltage is 50V. The maximum operating current is 11A

Introduction

2 System Overview

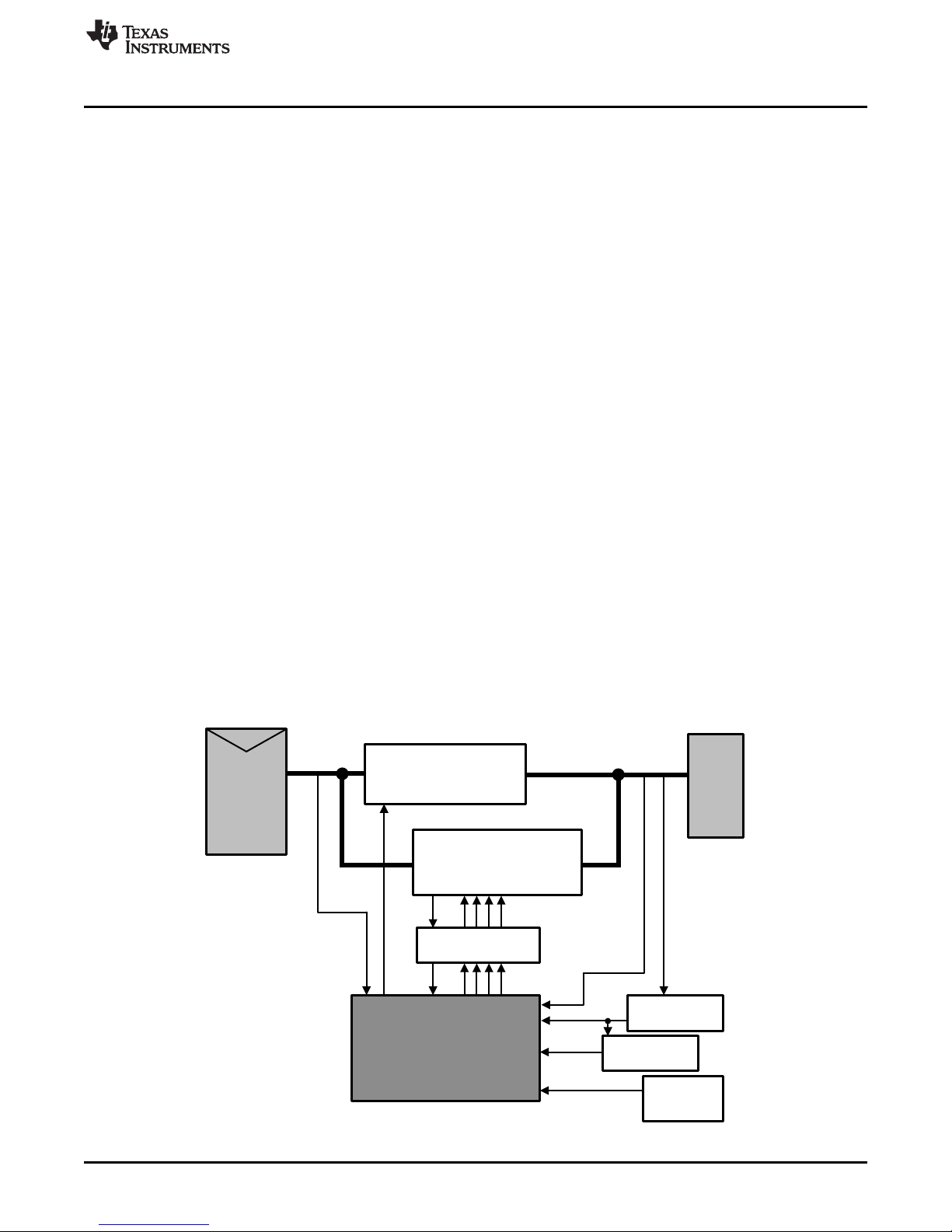

Figure 1 depicts how the SM72445 design would be implemented in its intended application. In this

example, the SM72445 senses the input and output voltages and currents, filters them digitally and

calculates power. It then issues four PWM pulses to the gate drivers to control the converter's switches.

The SM72445 also operates an additional switch (called Panel-Mode or PM switch) to optimize efficiency

when operating close to a 1:1 conversion ratio. Optionally, the switch can be omitted for reduced cost. The

SM72445 then utilizes the converter at a 1:1 conversion ratio and increases efficiency by reducing the

switching frequency of the converter

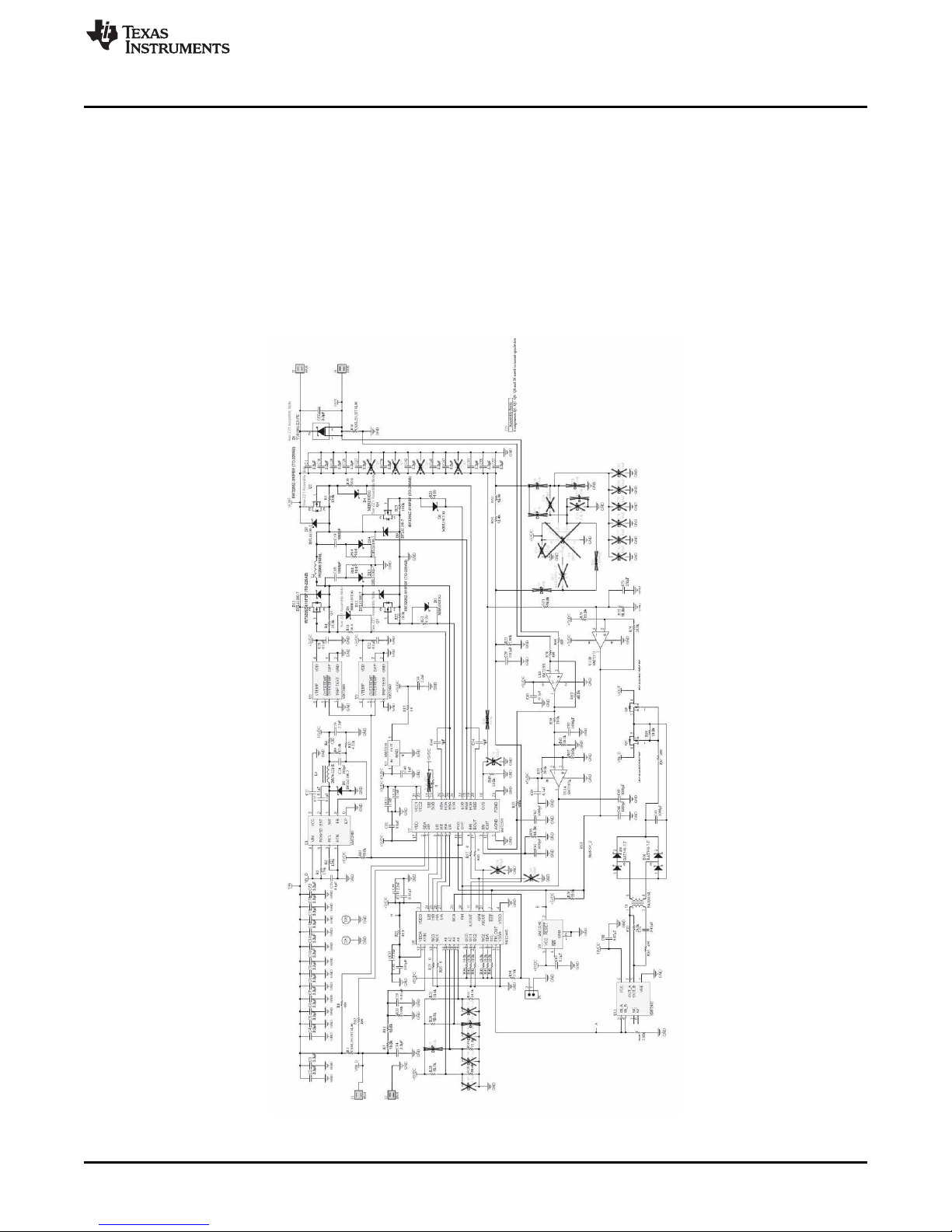

Figure 6 shows the detailed schematic with component references.

Figure 1. Evaluation Board Simplified Diagram

SNVA649–May 2012 AN-2241 SM72445 Evaluation Board

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

5

Page 6

Buck

Boost

SM72445 Evaluation module Design Specification

3 SM72445 Evaluation module

Design Specification

Symbol Parameter Min Typ Max

V

MPP

P

MPP

V

OC

I

SC

V

OUT

I

OUT

OVP Overvoltage Protection Threshold 45V

OTP Overtemperature Protection Threshold 125oC

MPP

EFF

PM

EFF

CONFIGURATION MODES

The SM72445 is configured through I2C communication or through resistor settings on pin A0, A2, A4 and

A6. The default configuration setting on the board is:

Pin name Pin Voltage Description

A0 3.0V “Soft” output voltage limit of 40V (AVOUT=3V)

A2 0V 220kHz operation, uses dedicated FET switch for higher efficiency

A4 5.0V Internal current protection not used

A6 1.56V Long slew rate limit, 60s in a 1:1 conversion ratio at start-up before enabling

PV Module MPP Voltage 15 Vdc 40Vdc

PV Module Power 10 W 350 W

PV Module Open Circuit Voltage 50 Vdc

PV Module Short-Circuit Current 11A

Output Voltage 0 Vdc 43 Vdc

Output Current 12.5A

MPP Efficiency 98.5%

Panel-Mode Efficiency 99.5%

www.ti.com

optimization

Modifications to the configuration can be performed by changing the resistor settings. The change in

configuration will only happen at start-up and during reset of the IC.

“PANEL MODE” OPERATION

The board is configured to use “Panel Mode” FETs to reach the highest possible efficiency at a 1:1

conversion ratio. The SM72445 will disconnect the DC/DC converter and turn on this switch whenever it

detects that the panel is matched to the load. The detail of this operation can be found in the SM72445

datasheet. Alternatively, the SM72445 can be configured to run the DC/DC converter in a Panel-Mode

behavior instead, driving the high-side FETs of the converter in a mostly ONstate (Figure 2) and achieving

the same function as the dedicated Panel-Mode FETs. This option optimizes the component count and the

cost of the solution but slightly reduces the efficiency of the system in the band close to a 1:1 conversion

ratio. To configure the board in this mode, the resistor couple R29 and R39 can be changed to modify the

voltage at pin A2. In addition, T1 should be removed. Check the SM72445 datasheet for additional details

on the different configuration settings.

Figure 2. Panel Mode Operation Using Converter's FET (“Boost” waveform is taken at drain of Q3,

“Buck” waveform was taken at drain of Q4.)

6

AN-2241 SM72445 Evaluation Board SNVA649–May 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

“SOFT” OUTPUT VOLTAGE LIMIT

The soft output voltage limit of “Soft OVP” is designed to prevent the output voltage from reaching

dangerous level when the system is running the converter in boost mode. This mechanism works by

reducing the duty cycle of the converter when the voltage at pin AVOUT is increasing above the voltage at

pin A0.

SLEW RATE LIMIT

The slew rate limit is designed to limit the rate of rise of the output voltage when and only when the

converter is running in boost mode. The rise of the duty cycle will be limited to ensure that the output

voltage will rise in a controlled manner, especially during transients such as when the load is reduced or

gets removed (before the SM72445 returns in stand-by mode). To test the slew rate limit, start-up the

system with a current load at 1.5A and with an input that has a maximum power point above 3A. The

output voltage will increase very rapidly until it reaches the input voltage. The output voltage will then

increase slowly above the input voltage as limited by the slew rate setting programmed.

SM72445 Evaluation module Design Specification

Figure 3. Slew Rate Limit (between the two markers) and Soft OVP (after the second marker)

STARTUP

When starting up at no load, the SM72445 will increase the duty cycle until a 1:1 conversion ratio is

reached. The system will then enter a stand-by mode and wait for the detection of power by sensing the

output current. When the voltage on AIOUT rises above the internal threshold, the system will wait for a

typical period of 64 seconds and exit the stand-by mode. This is to allow the proper start-up of a potential

inverter connected to the string of panels in which the SM72445 based optimizer would be inserted. Upon

exiting stand-by mode, the system will enter “PM mode” (see SM72445 datasheet for further explanation).

MPPT will be enabled if power variation is detected. If no power variation is detected such as when the

system is connected to a DC Electronic load for example, MPPT will be enabled only after the “PM mode”

timer expires after an additional period of 64 seconds.

Figure 4. Start-Up Pattern With Unloaded Output

SNVA649–May 2012 AN-2241 SM72445 Evaluation Board

Submit Documentation Feedback

7

Copyright © 2012, Texas Instruments Incorporated

Page 8

SM72445 Evaluation module Design Specification

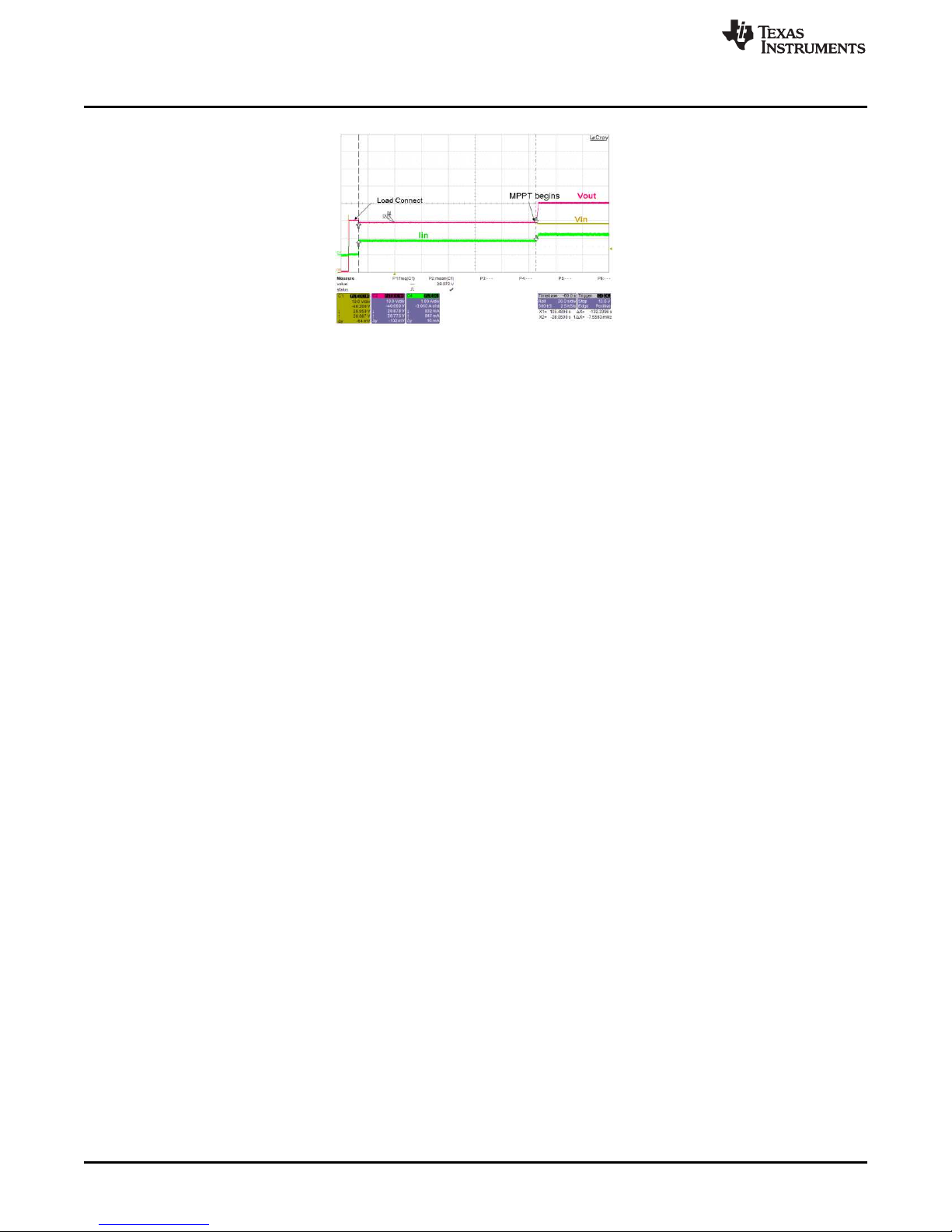

Figure 5. Load Connect and Stand-By Sequence After Start-Up

When a load is already present on the output of the board, the SM72445 will increase the duty cycle and

immediately enable MPPT operation when the voltages on AIOUT and AIIN rise above the internal

threshold.

INTERNAL CURRENT PROTECTION

If the voltage at AIOUT rises above the value set in A4, the system will reset. If AIOUT is set at or above

VDDA, this feature will be de-activated. The default setting for this board has this feature de-activated.

Current protection is performed using an external comparator

BOARD CURRENT PROTECTION

The board features a current protection circuit with U11A activating the PM pin of the SM72445 and

forcing the PM mode bypass switch to turn on (or the bridge to switch to 1:1 operation if the board is

reconfigured) when the output current reaches 13.5A. The output current will then be limited by the input

(solar panel) current. It is important to verify that the maximum solar panel current does not exceed the

rating of the components.

TEMPERATURE PROTECTION

U2 and U3 are strategically placed near the highest source of heat in the system (Q1 and Q4). When the

temperature reaches the tripping point (120 C), the ICs will activate the PM mode of the SM72445 by

forcing the PM pin low.

OVER-VOLTAGE PROTECTION

U11B forces the SM72445 to reset if the output voltage rises above 44V.

PANEL MODE SWITCH

Q5 and Q6 form a bi-directional switch controlled by the SM72445 and driven by U13 through T1. The

SM72445 supplies a 440kHz square waveform to turn on the switch.

GATE DRIVER

U7 is a quad 3A gate driver (two high and two low). It contains high-side operational amplifiers and buffers

used to sense the input current for MPPT purposes.

HEATSINKING

SM72445 evaluation board does not come with a heatsink. Therefore, in order to run the evaluation board

at elevated power ratings, an appropriate heatsink should be added on Q1, Q2, Q3 and Q4 as well as

diode D1. Care must be taken to prevent electrical contact between the drains of the MOSFETs in the

process of proper heatsinking. At elevated power operation please note the increase in temperature

across these semiconductor devices.

TEST SETUP

To perform an evaluation on the SM72445 evaluation board, it is suggested that the user connect the

input to a SAS (Solar Array Simulator) and the output to a load bank, preferably in Current mode (Voltage

mode sometimes causes regulation issues with some electronic load when used with the evaluation

board). The following sequence can be used to verify the operation of the board:

www.ti.com

8

AN-2241 SM72445 Evaluation Board SNVA649–May 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

• Connect S.A.S. to input.

• Connect Electronic load to output.

• Turn on SAS Verify proper startup pattern (see Figure 4).

• Set Electronic load to 2A and turn on Electronic load.

• Wait two minutes and verify that SAS is operating at Maximum Power Point. If output voltage is

close to 40V, increase Electronic load current.

• Vary Electronic load current and verify that the SAS is operating at Maximum Power Point in

step-up (lower load current) and step-down (higher load current) operation.

4 Schematic

Schematic

SNVA649–May 2012 AN-2241 SM72445 Evaluation Board

Submit Documentation Feedback

Figure 6. Circuit Schematic

9

Copyright © 2012, Texas Instruments Incorporated

Page 10

Schematic

www.ti.com

10

AN-2241 SM72445 Evaluation Board SNVA649–May 2012

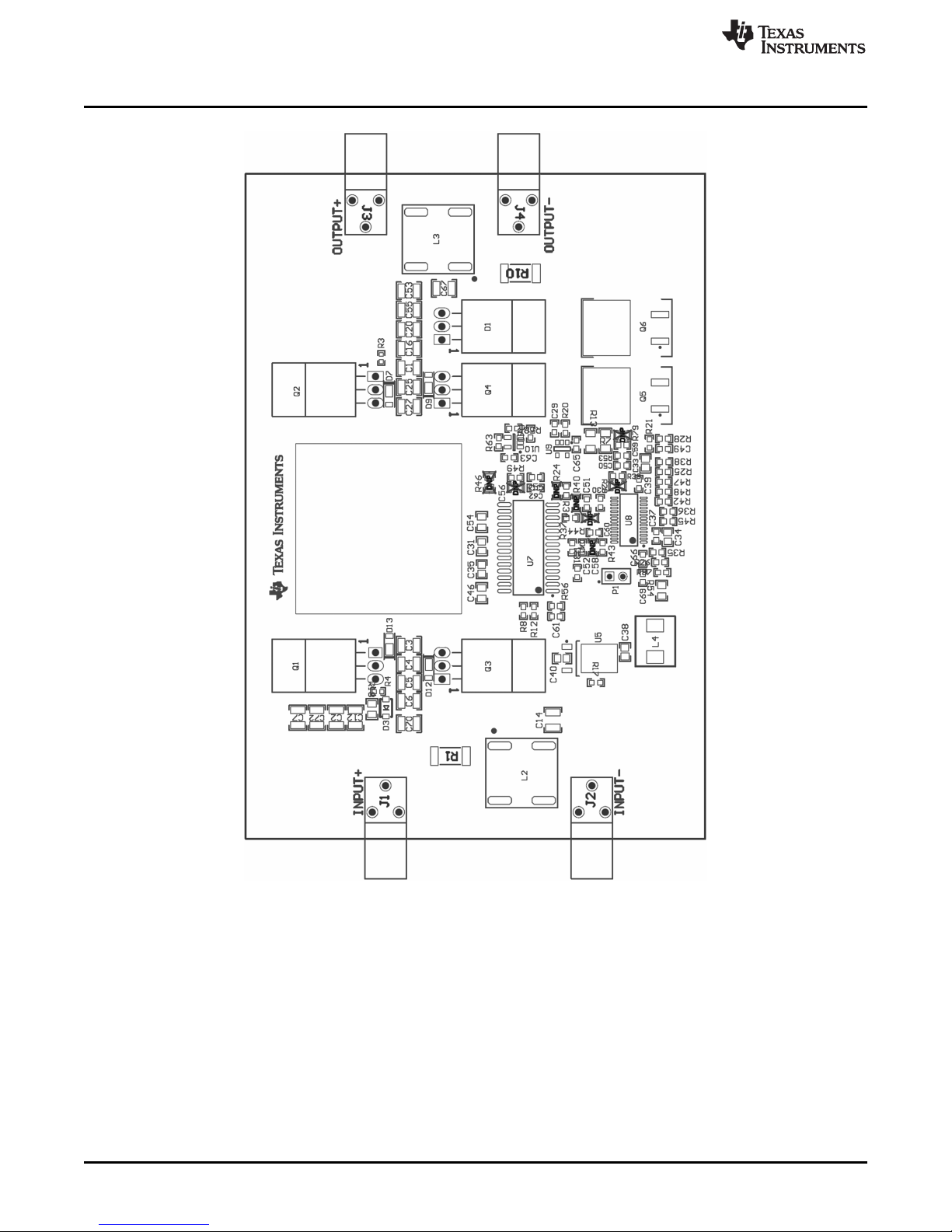

Figure 7. Top Assembly Diagram

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

Bill of Material

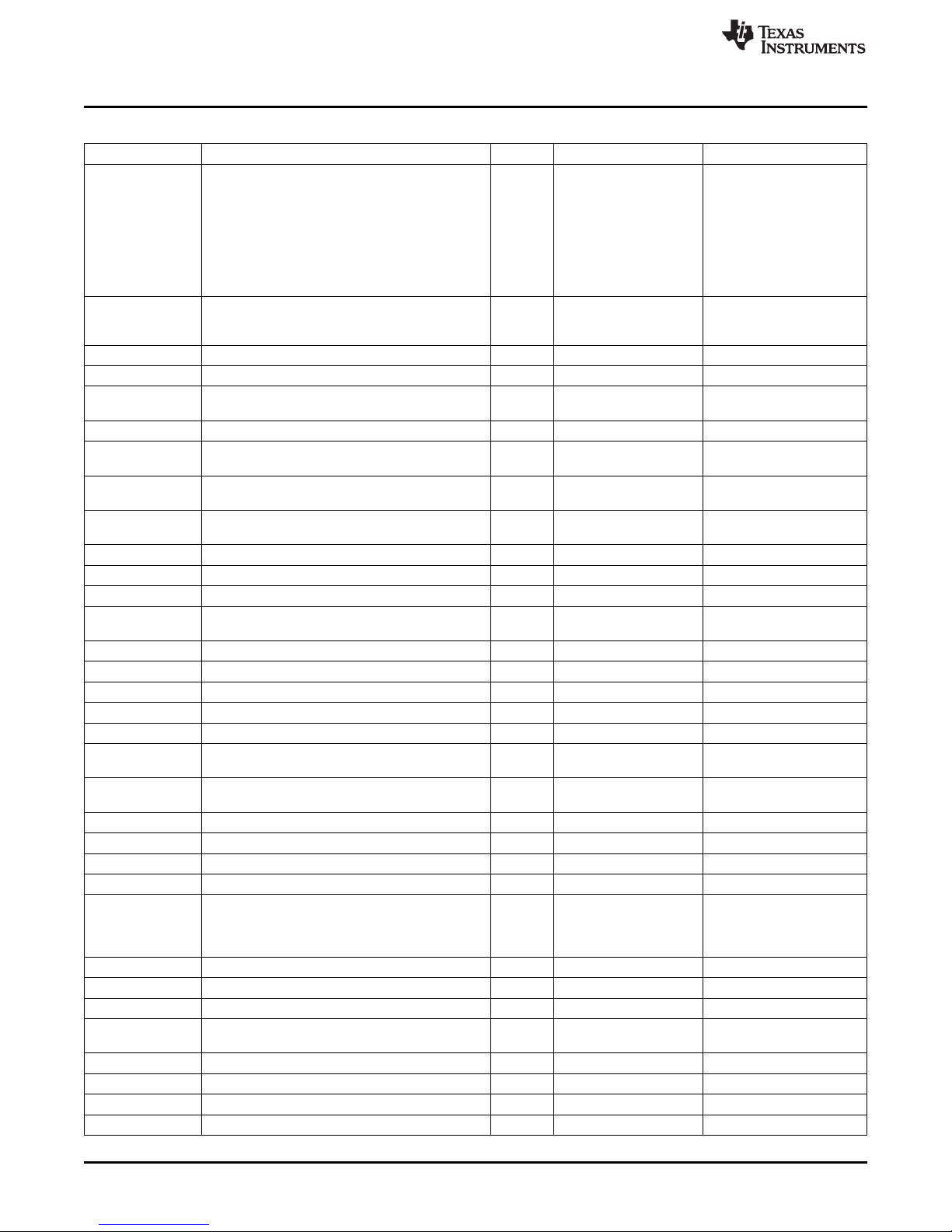

5 Bill of Material

SNVA649–May 2012 AN-2241 SM72445 Evaluation Board

Submit Documentation Feedback

Figure 8. Bottom Assembly Diagram

11

Copyright © 2012, Texas Instruments Incorporated

Page 12

Bill of Material

www.ti.com

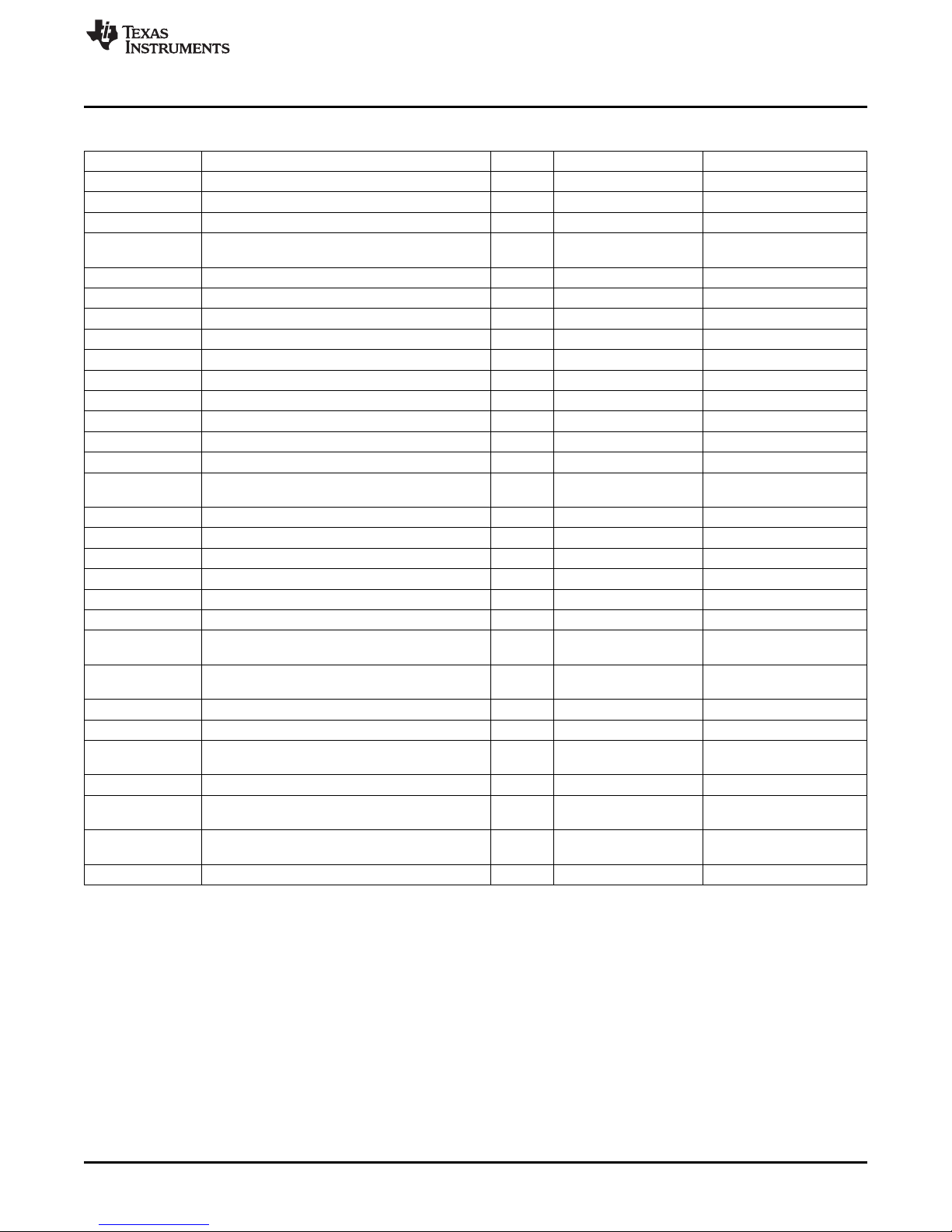

Table 1. Bill of Material

Designator Part Description Qty. Manufacturer Part number

C1, C2, C3, C4, CAP, CERM, 3.3µF, 50V, ±20%, X7R, 1210 28 TDK C3225X7R1H335M

C5, C6, C7, C8,

C9, C10, C11,

C12, C13, C14,

C16, C20, C25,

C27, C30, C42,

C45, C47, C53,

C55, C57, C67,

C70, C72

C15, C17, C22, CAP, CERM, 0.1µF, 16V, ±10%, X7R, 0603 8 Taiyo Yuden EMK107B7104KA-T

C26, C32, C63,

C64, C65

C18, C19 CAP, CERM, 1000pF, 100V, ±10%, X7R, 0805 2 Kemet C0805C102K1RACTU

C21 CAP, CERM, 0.1µF, 100V, ±10%, X7R, 0805 1 Kemet C0805C104K1RACTU

C23, C33, C34, CAP, CERM, 2.2µF, 16V, ±10%, X7R, 0805 4 Taiyo Yuden EMK212B7225KG-T

C38

C24 CAP, CERM, 330pF, 50V, ±10%, X7R, 0603 1 Kemet C0603C331K5RACTU

C29, C37, C39, CAP, CERM, 0.01µF, 50V, ±10%, X7R, 0603 4 Kemet C0603C103K5RACTU

C59

C31, C35, C40, CAP, CERM, 1µF, 16V, ±10%, X7R, 0805 5 Taiyo Yuden EMK212B7105KG-T

C46, C54

C43, C61, C62, CAP, CERM, 1000pF, 50V, ±10%, X7R, 0603 6 Kemet C0603C102K5RACTU

C66, C69, C82

C68, C71 CAP, CERM, 0.47µF, 16V, ±10%, X7R, 0805 2 TDK C2012X7R1C474K

C73 CAP, CERM, 150pF, 50V, ±5%, C0G/NP0, 0603 1 Kemet C0603C151J5GACTU

D1 DIODE SCHOTTKY 30A 100V TO-220AB 1 Vishay-Semiconductor V30100S-E3/4W

D2, D7, D9, D12, Diode, Schottky, 100V, 1A, PowerDI123 7 Diodes Inc. DFLS1100-7

D13, D14, D15

D3, D4, D5, D6 Diode, Schottky, 30V, 1A, SOD-123 4 ON Semiconductor MBR130T1G

D8, D10 Diode, Schottky, 30V, 0.2A, SOT-23 2 Diodes Inc. BAT54S-7-F

J1, J2, J3, J4 PC Quick-Fit 0.250 Horizontal Tab 4 Keystone Electronics 4910

L1 Inductor 20 µH EFD-30 core 1 Pulse Electronics PA2965.203NL

L2, L3 Choke, Filter 2 Pulse PA2972NL

L4 Inductor, Shielded Drum Core, Ferrite, 220 µH, 1 Coiltronics DR74-221-R

P1 Header, TH, 100mil, 1x2, Tin plated, 230 mil 1 Samtec Inc. TSW-102-07-T-S

Q1, Q2, Q3, Q4 MOSFET 55V, 6.5m Ω 4 International Rectifier IRF3205Z-010PBF

Q5, Q6 MOSFET 60V, 2.4m Ω 2 International Rectifier IRFS3206TRRPBF

R1, R10 RES .004 Ω 2W 1% 2512 SMD 2 Stackpole Electronics Inc CSNL2512FT4L00

R2, R54 RES, 174k Ω, 1%, 0.125W, 0805 2 Vishay-Dale CRCW0805174KFKEA

R3, R4, R22, R23, RES, 10.0k Ω, 1%, 0.1W, 0603 13 Vishay-Dale CRCW060310k0FKEA

R36, R42, R43,

R45, R47, R48,

R49, R64, R72

R5 RES, 124k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW0603124kFKEA

R6 RES, 1.00 Ω, 1%, 0.125W, 0805 1 Vishay-Dale CRCW08051R00FNEA

R7, R13 RES, 10.0k Ω, 1%, 0.25W, 1206 2 Vishay-Dale CRCW120610K0FKEA

R8, R12, R16, RES, 499 Ω, 1%, 0.1W, 0603 6 Vishay-Dale CRCW0603499RFKEA

R58, R60, R67

R9 RES, 12.4k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060312k4FKEA

R11, R14 RES, 10.0 Ω, 1%, 1W, 1218 SMD 2 Vishay-Dale CRCW121810R0FKEK

R15 RES, 4.22k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW06034k22FKEA

R17 RES, 1.0 Ω, 1%, 0.1W, 0603 1 Panasonic ERJ3RQF1R0V

0.56A, 0.907 Ω, SMD

above insulator

12

AN-2241 SM72445 Evaluation Board SNVA649–May 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

Bill of Material

Table 1. Bill of Material (continued)

Designator Part Description Qty. Manufacturer Part number

R18, R19 RES, 10.0 Ω, 1%, 0.125W, 0805 2 Vishay-Dale CRCW080510R0FKEA

R20, R53, R69 RES, 2.00k Ω, 1%, 0.1W, 0603 3 Vishay-Dale CRCW06032k00FKEA

R21 RES, 49.9 Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060349R9FKEA

R25, R34, R35, RES, 0 Ω, 5%, 0.1W, 0603 5 Vishay-Dale CRCW06030000Z0EA

R37, R44

R26, R87 RES, 59.0k Ω, 1%, 0.1W, 0603 2 Vishay-Dale CRCW060359K0FKEA

R28, R30 RES, 19.1k Ω, 1%, 0.1W, 0603 2 Vishay-Dale CRCW060319K1FKEA

R31 RES, 31.6k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060331K6FKEA

R32, R33 RES, 4.99 Ω, 1%, 0.125W, 0805 2 Vishay-Dale CRCW08054R99FNEA

R38 RES, 29.4k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060329K4FKEA

R39 RES, 15.8k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060315K8FKEA

R41 RES, 14.3k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060314K3FKEA

R51, R52 RES, 12.4k Ω, 1%, 0.25W, 1206 2 Vishay-Dale CRCW120612K4FKEA

R55 RES, 100k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW0603100KFKEA

R56 RES, 45.3k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060345K3FKEA

R57, R59, R62, RES, 20.0k Ω, 1%, 0.1W, 0603 5 Vishay-Dale CRCW060320K0FKEA

R70, R74

R61 RES, 26.1k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060326K1FKEA

R63 RES, 40.2k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060340K2FKEA

R71 RES, 76.8k Ω, 1%, 0.125W, 0805 1 Vishay-Dale CRCW080576K8FKEA

R73 RES, 23.2k Ω, 1%, 0.1W, 0603 1 Vishay-Dale CRCW060323K2FKEA

T1 SMT GATE TRANS 1:1 1500V 403 uH 0.60R 1 Pulse Electronics PA2001NL

TP1, TP2 Test Point, SMT, Miniature 2 Keystone Electronics 5015

U1 100V, 150 mA Constant On-Time Buck Switching 1 National Semiconductor SM72485

U2, U3 1.6V, LLP-6 Factory Preset Temperature Switch 2 National Semiconductor SM72480

U5 5V Micropower Voltage Regulator 1 National Semiconductor SM72238

U7 Photovoltaic Full Bridge Driver 1 National Semiconductor SM72295

U8 Programmable Maximum Power Point Tracking 1 Texas Instruments SM72445

U9 5-Pin Microprocessor Reset Circuits 1 National Semiconductor SM72240

U10 Precision, CMOS Input, RRIO, Wide Supply 1 National Semiconductor SM72501

U11 Dual Micropower Rail-To-Rail Input CMOS 1 National Semiconductor SM72375

U13 Dual 5A Compound Gate Driver 1 National Semiconductor SM72482

Regulator

and Temperature Sensor

Controller With Adjustable PWM Frequency

Range Amplifier

Comparator with Open Drain Output

SNVA649–May 2012 AN-2241 SM72445 Evaluation Board

Submit Documentation Feedback

13

Copyright © 2012, Texas Instruments Incorporated

Page 14

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2012, Texas Instruments Incorporated

Page 15

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

SM72445EVM/NOPB

Loading...

Loading...