Page 1

1 General Description

The evaluation board (Figure 1) is designed to help the evaluation of the LMH2190 Quad Channel 26 MHz

Clock Tree Driver with I2C™ interface. The LMH2190 provides a digital system clock to peripheral devices

in mobile handsets. It provides a solution to clocking issues such as limited drive capability for fanout or

longer traces, protection of the master clock from varying loads and frequency pulling effects, isolation

buffering from noisy modules, and crosstalk isolation. It has very low phase noise which enables it to drive

sensitive modules such as Wireless LAN and Bluetooth.

User's Guide

SNAA068B–July 2009–Revised May 2013

AN-1966 LMH2190 Evaluation Board

I2C is a trademark of Philips Semiconductor Corp.

All other trademarks are the property of their respective owners.

SNAA068B–July 2009–Revised May 2013 AN-1966 LMH2190 Evaluation Board

Submit Documentation Feedback

Figure 1. LMH2190 Evaluation Board

1

Copyright © 2009–2013, Texas Instruments Incorporated

Page 2

Basic Operation

2 Basic Operation

The LMH2190 evaluation board is designed such that it gives maximum flexibility in evaluating the

LMH2190 in various configurations. The schematic, Bill of material and board layout can be found at the

end of this document. In the following sections a description will be given on how to setup the

measurement bench. For the factory default jumper setting, refer to Section 3.

2.1 Supply

The common ground of the evaluation board is connected via Connector CON3. The LMH2190 is

powered via V

BAT

In the factory default configuration the ENABLE voltage is supplied externally via connector CON7 and

should be 1.8V. Three on-board buffers are separately powered through Connector CON18 (+5V) and

CON 19 (-5V). If they are not used for evaluation they can be left un-powered when jumper locations J7,

J16 and J17 are open.

2.2 Applying Clock

In factory default configuration the clock to the LMH2190 is supplied by the on-board TCXO. Alternatively

the clock can be applied externally either in DC mode via CON12 or in AC mode via CON10. The clock

source can be selected by J13. Note that for DC mode, the I2C registers also need to be changed.

The LMH2190 distributes the clock to a maximum of 4 outputs, CLK1 to CLK4, that are accessible via

CON1, CON5, CON6 and CON8. An additional capacitive load can be connected between CLK to GND to

simulate the load in the actual application via J1, J2, J14 and J15.

There is also a possibility to measure the clocks as well as the TCXO clock via a buffer. This buffer can

drive 50 ohm making them excellent for connecting to measurement equipment, like a Signal Source

Analyzer. This analyzer can for instance measure the Phase noise and Jitter. The three buffers can be

connected to the clock's by J7, J16 and J17. When the buffers are not used it is recommended to

disconnect them, since they increase the capacitive load on the clocks slightly.

(CON2). The typical supply voltage for V

www.ti.com

is 3.5V, but it may range from 2.5V to 5.5V.

BAT

2.3 Clock Request

The CLK's can be enabled by their appropriate CLK_REQ's. The CLK_REQ pin can be connected to a

logic Low or High level via J6, J8, J10 and J12. The level of the Logic High can be selected by J5, either

V

, V

BAT

or V

ENABLE

OUT

CON11, CON13 and CON14. Make sure that the jumpers are removed in this case. In factory default

configuration only CLK1 is enabled. The other clocks can simply be enabled by placing the jumper on J8,

J10 and J12 in the other position.

2.4 I2C Interface

The LMH2190 can be controlled by an I2C host device that can be connected via J4. It can configure the

registers inside the LMH2190 to change the default configuration. According to the I2C specification one

set of pull-up resistors needs to be present on the I2C bus. If they are not present elsewhere in the system

they can be connected on the evaluation board via J19. The evaluation board can be used without I2C

host device connected. It will then work in its default configuration.

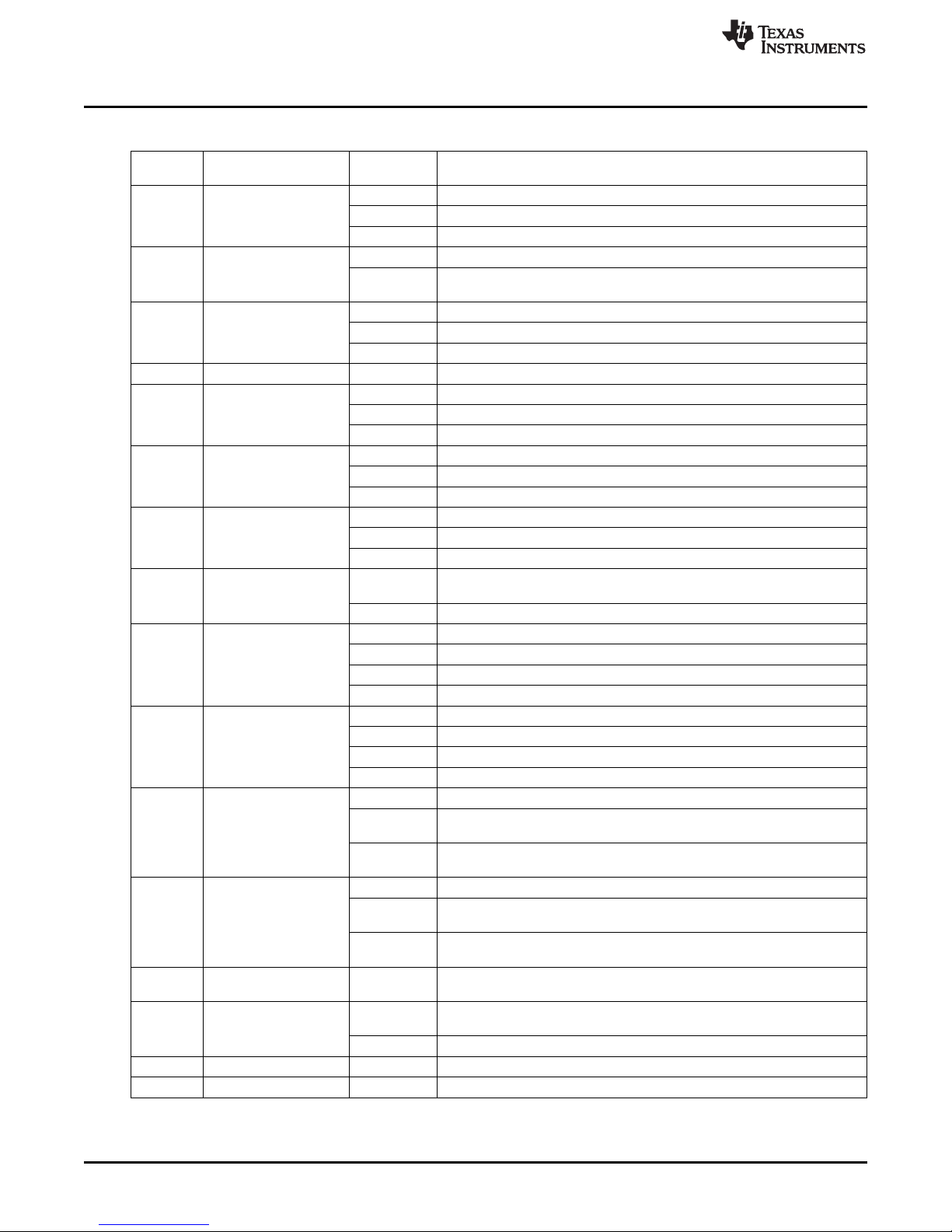

3 Configuration

The LMH2190 evaluation board can be configured via jumper settings. An overview of the various jumper

positions on the board is given in Figure 2. The settings of these jumpers and their functions are listed in

Table 1.

. Instead of via the jumpers, the CLK_REQ's can also be controlled via CON9,

2

AN-1966 LMH2190 Evaluation Board SNAA068B–July 2009–Revised May 2013

Copyright © 2009–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

Configuration

Figure 2. Jumper Positions

Table 1. Jumper and Header Overview

Jumper Function Jumper Desription

J1 CLK1 Capacitive load 1-2 Connects 10 pF from CLK1 to GND

J2 CLK2 Capacitive load 1-2 Connects 10 pF from CLK2 to GND

J3 ENABLE 1-2 ENABLE = V

J4 I2C Header Header to connect I2C signals

J5 CLK_REQx Logic High 1-2 CLK_REQx

Level

(1)

Bold face jumper settings refer to the factory default configuration.

Position

3-4 Connects 22 pF from CLK1 to GND

5-6 Connects 33 pF from CLK1 to GND

7-8 Connects 47 pF from CLK1 to GND

3-4 Connects 22 pF from CLK2 to GND

5-6 Connects 33 pF from CLK2 to GND

7-8 Connects 47 pF from CLK2 to GND

OUT

3-4 ENABLE is supplied by CON7

5-6 ENABLE is supplied by I2C conector J4 pin 4

7-8 ENABLE = GND

= V

HIGH

OUT

3-4 CLK_REQx

5-6 CLK_REQx

HIGH

HIGH

= V

= V

BAT

ENABLE

(1)

SNAA068B–July 2009–Revised May 2013 AN-1966 LMH2190 Evaluation Board

Submit Documentation Feedback

3

Copyright © 2009–2013, Texas Instruments Incorporated

Page 4

Configuration

www.ti.com

Table 1. Jumper and Header Overview

(1)

(continued)

Jumper Function Jumper Desription

Position

J6 CLK_REQ1 Open CLK_REQ1 can be controlled externally via CON9

1-2 CLK_REQ1 = GND

2-3 CLK_REQ1 = High. Level is determined by J5

J7 Connects Buffer to Open No buffer connected to measure TCXO Clock

TCXO OUT

1-2 Buffer LMH6559MA (U2) is connected to measure TCXO Clock. Buffer can

drive 50 Ohm.

J8 CLK_REQ2 Open CLK_REQ2 can be controlled externally via CON11

1-2 CLK_REQ2 = GND

2-3 CLK_REQ2 = High. Level is determined by J5

J9 TCXO Supply 1-2 TCXO is supplied by V

OUT

J10 CLK_REQ3 Open CLK_REQ3 can be controlled externally via CON13

1-2 CLK_REQ3 = GND

2-3 CLK_REQ3 = High. Level is determined by J5

J11 SCLK_REQ Pull Up / Open No Pull-up or Pull-down connected to SCLK_REQ

Pull Down

1-2 100 kΩ Pull-down resistor connected from SCLK_REQ to GND

2-3 100 kΩ Pull-up resistor connected from SCLK_REQ to V

BAT

J12 CLK_REQ4 Open CLK_REQ4 can be controlled externally via CON14

1-2 CLK_REQ4 = GND

2-3 CLK_REQ4 = High. Level is determined by J5

J13 SCLK_IN Source 1-2 SCLK_IN is connected to External Source, either through CON10 (AC-

Coupled) or CON12 (DC-Coupled)

3-4 SCLK_IN is connected to on-board TCXO

J14 CLK3 Capacitive load 1-2 Connects 10 pF from CLK3 to GND

3-4 Connects 22 pF from CLK3 to GND

5-6 Connects 33 pF from CLK3 to GND

7-8 Connects 47 pF from CLK3 to GND

J15 CLK4 Capacitive load 1-2 Connects 10 pF from CLK4 to GND

3-4 Connects 22 pF from CLK4 to GND

5-6 Connects 33 pF from CLK4 to GND

7-8 Connects 47 pF from CLK4 to GND

J16 Connects Buffer to Open No buffer connected to CLK1/2

CLK1/2

1-2 Buffer LMH6559MA (U3) is connected to measure CLK2. Buffer can drive

50 Ohm.

2-3 Buffer LMH6559MA (U3) is connected to measure CLK1. Buffer can

drive 50 Ohm.

J17 Connects Buffer to Open No buffer connected to measure TCXO Clock

CLK3/4

1-2 Buffer LMH6559MA (U4) is connected to measure CLK4. Buffer can drive

50 Ohm.

2-3 Buffer LMH6559MA (U4) is connected to measure CLK3. Buffer can drive

50 Ohm.

J18 TCXO Supply Header Header can be used to provide an (external) TCXO supply instead of the

on-board V

supply. Header J9 should be open in this case.

OUT

J19 I2C Pull-up Resistors Open No Pull-up resistor connected to SDA and SCL line. Elsewhere should be

pull-up resistors present on SDA and SCL

1-2 Pull-up resistors connected on SDA and SCL

J20 SCLK_REQ Header Header to monitor SCLK_REQ.

J21 Future purpose Not Assembled

4

AN-1966 LMH2190 Evaluation Board SNAA068B–July 2009–Revised May 2013

Submit Documentation Feedback

Copyright © 2009–2013, Texas Instruments Incorporated

Page 5

SCLK_IN

CLK1

CLK2

CLK3

CLK4

TIME (5 ns/DIV)

0.5 V/DIV

SCLK_IN

CLK1

LMH2190TM

Eval Board

V

BAT

GND

GND

+3.5V

Power

Supply

Oscilloscope

Volt Meter

+1.8V

ENABLE

V

OUT

CLK1

CLK2

CLK3

CLK4

GND

Power

Supply

(Optional)

+5V

-5V

V+

V-

GND

GND

CON3

CON2

CON7

CON4

CON18

CON19

TP1

TP5

TP9

TP11

SCLK_IN

J13-4

www.ti.com

4 Measurement Setup

The performance of the LMH2190 can be measured with the setup shown in Figure 3.

Measurement Setup

Figure 3. Measurement Setup

The +5V and -5V to connector CON18 and CON19 don't need to be applied unless buffers U2, U3 and/or

U4 are used for the measurements. In factory default configuration, only CLK1 is enabled. With an

oscilloscope and Hi-impedance probes the TCXO (J13–4) and CLK1 (TP1) can be measured. This should

result in a measurement as depicted in Figure 4. Other CLK's can be enabled by connecting the

appropriate CLK_REQ to V

BAT

depicted in Figure 5. It can be seen that the CLK's are skewed from each other.

SNAA068B–July 2009–Revised May 2013 AN-1966 LMH2190 Evaluation Board

Submit Documentation Feedback

Figure 4. CLK1 Response, CL= 22 pF Figure 5. Clock Outputs Skewed

(J8, J10, J12). A schematic representation of the TCXO and all the CLKs is

Copyright © 2009–2013, Texas Instruments Incorporated

5

Page 6

Schematic

5 Schematic

www.ti.com

6 Bill of Material

The Bill of Material (BOM) of the evaluation board is in Table 2.

Designator Description Comment

C1, C4, C11, C13 0603 Capacitor 10 pF

C2, C5, C19, C22 0603 Capacitor 22 pF

C3, C8, C20, C23 0603 Capacitor 33 pF

C6 Case A Capacitor NC

C7, C28, C31 Case A Capacitor 10 µF

C9, C10, C25, C29, C30 0603 Capacitor 100 nF

C12, C16 0603 Capacitor 10 nF

C14, C15 0603 Capacitor 470 pF

C17, C18, C21, C24 0603 Capacitor 47 pF

C26, R9, R10, R13, R15 0603 Capacitor / Resistor NC

C27 Case A Capacitor 2.2 µF

CON1 Connector SMA

Figure 6. Evaluation Board Schematic

Table 2. Bill of Material

6

AN-1966 LMH2190 Evaluation Board SNAA068B–July 2009–Revised May 2013

Submit Documentation Feedback

Copyright © 2009–2013, Texas Instruments Incorporated

Page 7

www.ti.com

Designator Description Comment

CON2 Connector Banana

CON3 Connector Banana

CON4 Connector Banana

CON5 Connector SMA

CON6 Connector SMA

CON7 Connector Banana

CON8 Connector SMA

CON9 Connector SMA

CON10 Connector SMA

CON11 Connector SMA

CON12 Connector SMA

CON13 Connector SMA

CON14 Connector SMA

CON15 Connector SMA

CON16, CON17 Connector SMA

CON18 Connector Banana

CON19 Connector Banana

J1, J2, J14, J15 Header 2x4

J3 Header 2x4

J4 Header 2x5

J21 Header 2x7

J5 Header 2x3

J6, J8, J10, J11, J12 Header 1x3

J7, J9, J19, J20 Header 1x2

J13 Header 2x2

J16, J17 Header 1x3

J18 Header 1x2

R1, R2, R3, R4, R5, R6, R12, R17, R18, R19 0603 Resistor 0Ω

R7, R11, R14 0603 Resistor 100 kΩ

R8 0603 Resistor 4.7 kΩ

R16 0805 Resistor 4.7 kΩ

R20, R21, R22 0603 Resistor 51Ω

U1 DSBGA LMH2190

U2, U3, U4 SOIC LMH6559

X1 small TCXO 26.0MHz

Board Layout

Table 2. Bill of Material (continued)

7 Board Layout

As with any other device, careful attention must be paid to the board layout. If the board is not properly

designed, the performance of the device can be less than might be expected. Especially the input clock

trace (SCLK_IN) and output traces (CLK1/2/3/4) should be as short as possible to reduce the capacitive

load observed by the clock outputs. Also proper decoupling close to the device is necessary. Beside a

capacitor in the µF range, a capacitor of 100 nF on V

equivalent series resistance (ESR) of the capacitors should be sufficiently low. A standard capacitor is

usually adequate. The copper layers of the evaluation board are depicted in Figure 9, Figure 10, and

Figure 11.

SNAA068B–July 2009–Revised May 2013 AN-1966 LMH2190 Evaluation Board

Submit Documentation Feedback

and V

BAT

Copyright © 2009–2013, Texas Instruments Incorporated

is recommended close to device. The

OUT

7

Page 8

Board Layout

www.ti.com

8

AN-1966 LMH2190 Evaluation Board SNAA068B–July 2009–Revised May 2013

Figure 7. Component Locations Top Side

Copyright © 2009–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

Board Layout

Figure 8. Component Locations Bottom Side (Bottom View)

SNAA068B–July 2009–Revised May 2013 AN-1966 LMH2190 Evaluation Board

Submit Documentation Feedback

9

Copyright © 2009–2013, Texas Instruments Incorporated

Page 10

Board Layout

www.ti.com

Figure 9. Top Layer of Evaluation Board

Figure 10. Inner Layer of Evaluation Board

Figure 11. Bottom Layer of Evaluation Board

10

AN-1966 LMH2190 Evaluation Board SNAA068B–July 2009–Revised May 2013

Copyright © 2009–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...