Page 1

查询BGA供应商

Design Summary for

56GQL (48- and 56-pin functions)

MicroStar Junior

PCB Design Guidelines

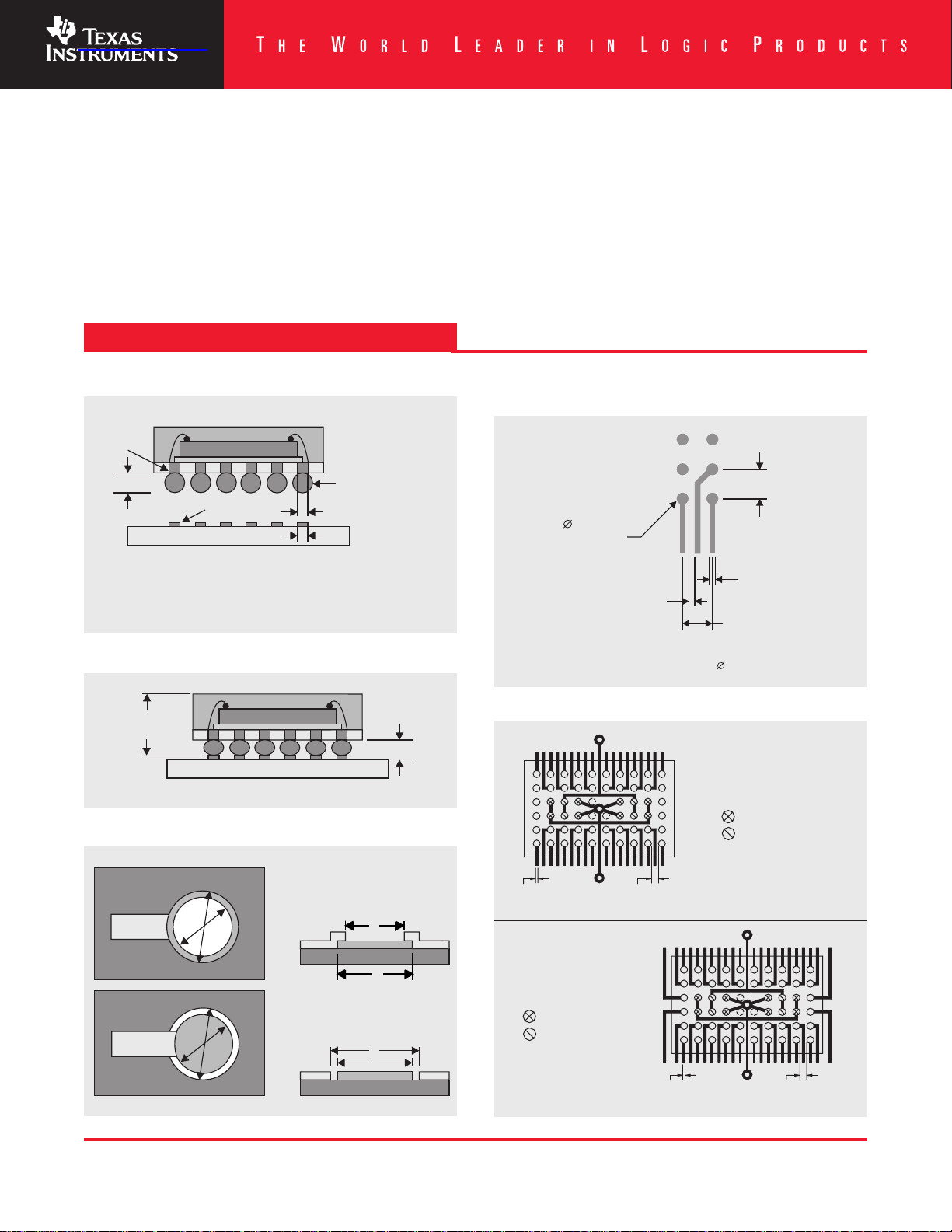

Package Via to Board Land Area Configuration

Package

ball via

0.2±0.05mm

(Not to scale)

Ratio A/B should equal 1.0 for optimum reliability

Overall Height

< 1.0 mm

MicroStar Junior Package

Land on PCB

PCB

A = Via diameter on package = 0.33 mm (for 0.65-mm pitch)

B = Land diameter on PCB

Solder Ball Collapse

PCB

(Not to scale)

VFBGA Recommended Land Pad Design

TM

BGA

Near-Sn/Pb

eutectic solder

with liquidus

temperature of

178°C to 210°C

A

B

0.2 mm

typical

Trace Width/Spacing Dimensions (mm [in.])

Non-Solder Mask Defined Pad

0.65 [.0256]

0.30 [.0118]

Solder Pad

0.117 [.0046] Trace

0.117 [.0046] min. space

0.65 [.0256]

Trace width/spacing for non-solder mask defined = 0.1167 [.0046]

Trace width/spacing for solder mask defined with 0.33 solder pad = 0.0733 [.0029]

Recommended Board Routing

V

CC

Recommended Routing

for VFBGA-48

GND

V

CC

Solder Mask Defined Pad

A

B

B

A

A = 0.43 mm

B = 0.33 mm

Non Solder M ask Defined Pad

A = 0.30 mm

B = 0.45 mm

B

A

B

A

0.117 MAX

[.0042]

Recommended Routing

for VFBGA-56

GND

V

CC

Note: Typical for most devices.

Refer to data sheet for

specific applications.

GND

0.320 MAX

[.0126]

Note: Typical for most devices.

Refer to data sheet for

specific applications.

0.117 MAX

[.0042]

GND

V

CC

0.320 MAX

[.0126]

Page 2

Geometric Dimensional Tolerances

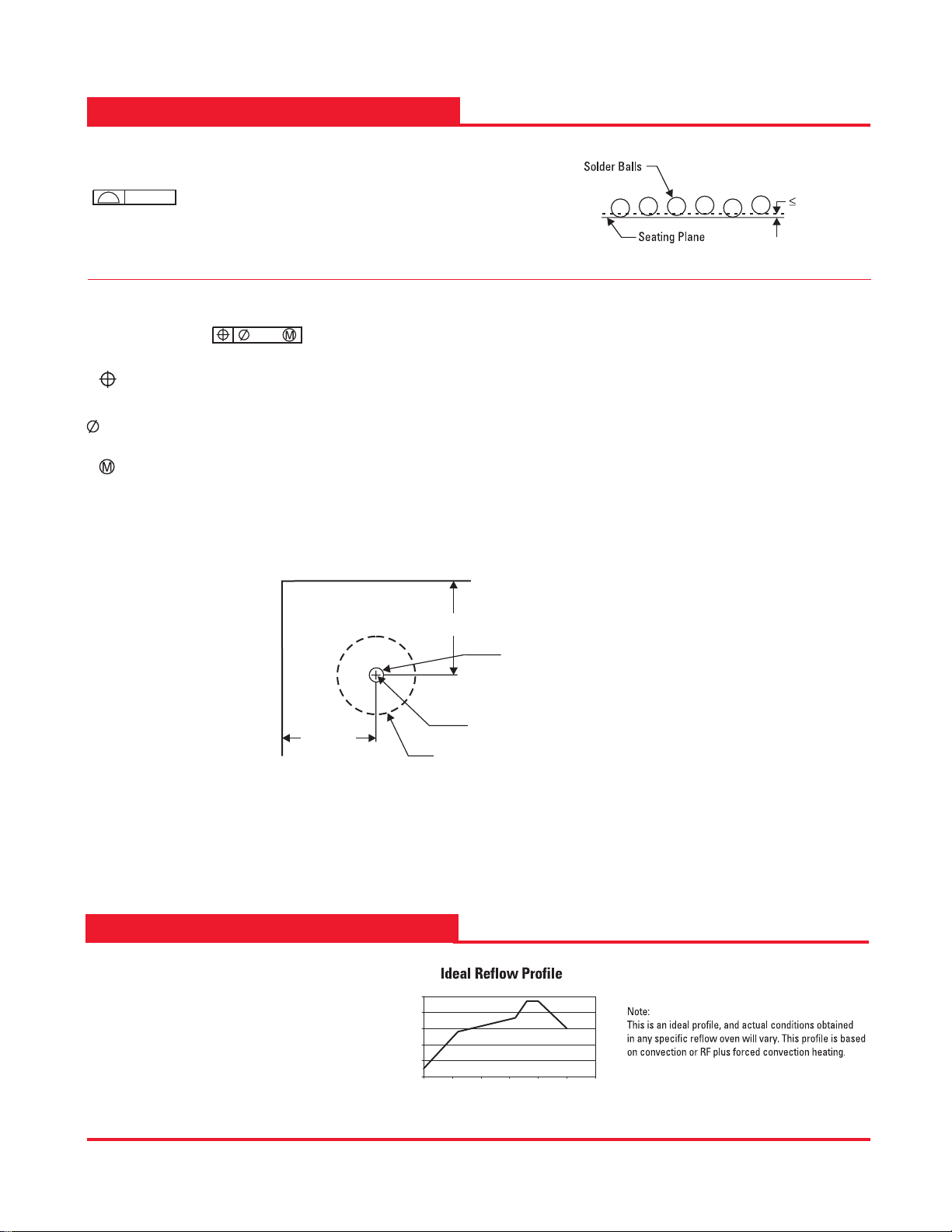

Coplanarity

This geometric dimensioning and tolerancing (GD & T) term

means that this package meets a coplanarity of 0.08 mm

0,08 mm

as shown below. Coplanarity is defined as a unilateral tolerance zone

measured upward from the seating plane. (Reference ASME Y14.5-

1994).

Position Tolerance

0.08 mm

This GD & T term is described below:

0,05

This is the symbol for true position.

True position is defined as the theoretically exact centerline location of the solder ball(s).

This symbol/number represents how much the centerline of the solder ball(s) is allowed to vary from it's true position.

0,05

This symbol/letter is defined as the maximum material condition of the solder ball(s) which is 0.45 mm DIA.

The graphic representation is shown below for the top, left solder ball of this package.

Package End

*0.575 mm

Pattern locating boundary for the

centerline of the solder ball.

Package Side

* These two dimensions are calculated

based on a package with nominal

body width and length dimensions.

*0.625 mm

Pattern locating boundary containing the collective dimensions of the maximum size of

the solder ball (0.45 mm) and the maximum variance of the centerline of the solder

ball (0.05 mm) for a total boundary of 0.50 mm DIA.

I.E., the solder ball, regardless of size, must fall within this boundary. (Defined as

virtual condition per ASME standard Y14.5 - 1994).

Please note that a smaller diameter solder ball will have more tolerance in this

boundary than the maximum diameter solder ball.

(0.05 mm DIA.)

True position of the solder ball.

IR Reflow Profile

Ideal (1st and 2nd) Reflow Profile

Room Temp to 140°C: 60 - 90 sec.

140°C to 160°C: 90 - 120 sec.

Time above 200°C: 30 - 60 sec.

Peak Temp: 235°C ±5°C

Time within 5°C Peak Temp: 10-20 sec.

Ramp down rate: 1 - 3°C/sec. max.

250

200

150

100

50

Temperature (°C)

0

0 50 100 150 200 250 300

Time (seconds)

Page 3

Stencil Vitals

0.33 mm

0

.3

3

m

m

Packaging Tape and Reel

icrons

icrons

125 to 150 m

125 to 150 m

Solder Paste

TI recommends the use of paste when mounting MicroStar

Junior BGAs. The use of paste offers the following

advantages:

It acts as a flux to aid wetting of the solder ball to the PCB

land.

The adhesive properties of the paste will hold the

component in place during reflow.

Paste contributes to the final volume of solder in the joint,

and thus allows this volume to be varied to give an

optimum joint.

Paste selection is normally driven by overall system

assembly requirements. In general, the "no clean"

compositions are preferred due to the difficulty in cleaning

under the mounted components.

45

°

K

Quantity per reel = 1,000

Dimensions in millimeters

T

0.30 ± 0.05

0

B

6.3

0

A

0

B

0

K

0

F 7.50 ± 0.1

P

1

W 16.00 ± 0.3

(Not to scale)

D

1.55 ± 0.05

D

1

1.6 ± 0.1

R

0.3 Typical

4.80 ± 0.1

7.30 ± 0.1

1.50 ± 0.1

8.00 ± 0.1

P

2

0

Y

Y

2.0 ± 0.1

P

1

0.2

1.21.2

P

0

4.0 ± 0.1

3.8

A

0

Pin 1 Quadrant

F

Balls face down in pocket

Dimensions in millimeters

E

1.75 ± 0.1

W

Feed Direction

Reel Width

16.0

Reel Diameter

330

Cover Tape Width

13.5

Page 4

Package Outline

48/56GQL (4.5 x 7.0 mm, 0.65 mm pitch)

Pinout

4,60

4,40

3X Via Hole

Without

Ball

7,10

6,90

DEVICE

YMLLLLS

0,45

0,35

M

0,05

1,00 MAX

0,25

0,15

Missing Vi a

Hole Indicates

Pin A1

Quadrant

Seating Plane

0,08

0,65

K

J

H

G

F

E

D

C

B

A

123 645

Electrical Characteristics

R(ohms) L(nH) C(pF)

Min. 0.048 1.470 0.182

Mean 0.066 2.257 0.264

Max. 0.116 3.965 0.430

Thermal Characteristics

6.00

5.50

5.00

4.50

4.00

3.50

3.00

Power Dissipation (W)

2.50

2.00

1.50

20 30 40 50 60 70 80 90

4.50

4.00

3.50

3.00

2.50

Power Dissipation (W)

2.00

1.50

20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95

Eight Thermal Vias, High K

Ambient Temperature (ºC)

Without Thermal Vias, High K

Ambient Temperature (ºC)

Daisy Chain Net List

56GQL TOP VIEW

A1-B3 J4-K6

A2-A3 K4-K5

6

5

4

3

2

1

A

BCDEFGHJ K

A4-A5 K2-K3

A6-B4 J3-K1

B5-B6 J1-J2

C6-D5 G2-H1

C4-C5 H2-H3

D4-D6 G1-G3

E5-E6 F1-F2

F5-F6 E1-E2

G4-G6 D1-D3

H4-H5 C2-C3

G5-H6 C1-D1

J5-J6 B1-B2

3,25 TYP

0,325

0 lfm @ Tj=150ºC

150 lfm @ Tj=150ºC

250 lfm @ Tj=150ºC

500 lfm @ Tj=150ºC

0 lfm @ Tj=150ºC

150 lfm @ Tj=150ºC

250 lfm @ Tj=150ºC

500 lfm @ Tj=150ºC

0,325

0,65

5,85 TYP

Pinout for 48-pin functions

6 A48 A46 A43 A40 A37 A36 A33 A30 A27 A25

5 NC A47 A44 A41 A38 A35 A32 A29 A26 NC

4 NC *A45 A42 *A39 *A34 A31 *A28 NC

3 NC *A4 A7 *A10 *A15 A18 *A21 NC

2 NC A2 A5 A8 A11 A14 A17 A20 A23 NC

1 A1 A3 A6 A9 A12 A13 A16 A19 A22 A24

ABCDEFGHJK

Contr ol *GND V

Note: This is a topside view

CC

Pinout for 56-pin functions

6 A54 A51 A48 A45 A43 A42 A40 A37 A34 A31

5 A55 A52 A49 A47 A44 A41 A38 A36 A33 A30

4 A56 A53 A50 *A46 *A39 A35 *A32 A29

3 A1 A4 A7 *A11 *A18 A22 *A25 A28

2 A2 A5 A8 A10 A13 A16 A19 A21 A24 A27

1 A3 A6 A9 A12 A14 A15 A17 A20 A23 A26

ABCDEFGHJK

Contr ol *GND V

Note: This is a topside view

Package Reliability Data

Test Chip: ALVCH16501, 'B' Die Revision, 85 x 107 mils

Preconditioning: JEDEC Level 2 (85°C/60% 168 hr + 3IRR 220°C)

Simultaneous Switching Life Test

(SSLT), 150°C, 300 Hours

Highly Accelerated Life Test (HAST),

130°C, 85% RH, 100 Hours

Temperature Cycle Test, -65°C to

150°C, 1000 Hours

Autoclave, 121°C, 96 Hours 77 / 0 77 / 0

Solderability, 8 Hours 8 / 0 8 / 0

Flammability (UL) 5 / 0 5 / 0

Flammability (IEC) 5 / 0 5 / 0

Thermal Shock 26 / 0 26 / 0

X-Ray, Top View Only 5 / 0 5 / 0

Physical Dimensions 15 / 0 15 / 0

Manufacturability pass pass

Sample Size /

Board Level Reliability Data

56 GQL Package

Sample Size = 32

Temp Cycle Range -40°C to 125°C

No Underfill

Board Thickness (mm) 1.6 0.8 0.8, no Au

0 cycle 000

250 cycle 000

500 cycle 000

750 cycle 000

1000 cycle 2* 0 0

1250 cycle 15 1 0

1500 cycle 19 8 0

1750 cycle N/A 20 1

2000 cycle N/A N/A 0

* First failure at 951 cycles

t = 0.8 mm, with Au, 50% failure = 1733 cycles

CC

Required

ALVCH16501GQL

Actual Sample Size /

#Fails

39 / 0 39 / 0

39 / 0 39 / 0

77 / 0 77 / 0

# Fails

Page 5

Sockets

Yamaichi Socket Numbers:

VFBGA-56 PN# IC280-056-237

Questions and Answers

Board Design/Electrical Issues

Q. Where can the decoupling capacitors go for the VFBGA package?

A. The recommended capacitance value and number of capacitors for decoupling

is a 0.1 mF capacitor for each VCC on the VFBGA package. The decoupling

capacitors should be connected as close as possible to the GROUND and VCC

planes.

Q. Any EMI concerns for traces under the package and how can customers

design their board to minimize EMI?

A. EMI can be controlled by minimizing any complex current loops on the PCB

trace. Some helpful hints include:

Solid ground and power planes be used in the design. Partitioned ground

and power planes must be avoided. These ground and power partitions

may create complex current loops increasing radiation.

Avoid right angles or "T" crosses on the trace. Right angles can cause

impedance mismatch and increase trace capacitance causing signal

degradation.

Minimize power supply loops by keeping power and ground traces parallel

and adjancent to each other. Significant package EMI can be reduced by

using this method.

Use decoupling capacitors as described in the previous question.

Lead-Free

Q. Should I use underfill?

A. No, the package qualification results show that this is not necessary and is only

an added process expense.

Q. Can the boards be repaired?

A. Yes, there are rework and repair tools and profiles available (see references 4

and 7). We strongly recommend that removed packages be discarded.

Q. How do the board assembly yields of MicroStar Junior BGAs compare to

TSSOPs?

A. Many customers are initially concerned about assembly yields. However, once

they had MicroStar Junior BGAs in production, most of them report improved

process yields compared to TSSOPs. This is due to the elimination of bent and

misoriented leads, the wider terminal pitch than with 0.5-mm pitch TSSOPs,

and the ability of these packages to self align during reflow. The collapsing

solder balls also mean that the coplanarity is improved over leaded

components.

Q. What alignment accuracy is possible?

A. Alignment accuracy for the 0.65-mm pitch package is dependent upon board

level pad tolerance, placement accuracy, and solder ball position tolerance.

Nominal ball position tolerances are specified at ±50 microns. These packages

are self-aligning during solder reflow, so final alignment accuracy may be better

than placement accuracy.

Q. Are there specific recommendations for SMT processing?

A. Texas Instruments recommends alignment with the solder balls for the CSP

package, although it is possible to use the package outline for alignment. Most

customers have found they do not need to change their reflow profile.

Q. Can the solder joints be inspected after reflow?

A. Process yields of 5-ppm rejects are typically seen, so no final inline inspection

is required. Some customers are achieving satisfactory results during process

setup with lamographic X-ray techniques.

Package (Incoming Inspection)

Q. Is package repair possible? Are tools available?

A. Yes, some limited package repair is possible, and there are some semi-auto

M/C tools available. However, TI does not guarantee the reliability of repaired

packages.

Q. Do the solder balls come off during shipping?

A. No, this has never been observed. The balls are 100 percent inspected for

coplanarity, diameter and other physical properties prior to packing for

shipment. Because solder is used during the ball attachment process, uniformly

high ball attachment strengths are developed. Also, the ball attachment

strength is monitored frequently in the assembly process to prevent ball loss

from vibration and other shipping forces.

Q. Is TI developing a lead-free version of MicroStar Junior BGAs?

A. Yes, Texas Instruments is working toward eliminating lead in the solder balls to

comply with lead-free environmental policies. The lead-free solder is in final

evaluation. Only the solder will change, not the package structure or the

mechanical dimensions. The solder system under development is based on

Sn-Cu-Ag metallurgy. Check with your local TI Field Sales representative for

sample availability.

Assembly Process/Yield Considerations

Q. What size land diameter for these packages should I design on my

board?

A. Land size is the key to board-level reliability, and Texas Instruments strongly

recommends following the design rules included in this bulletin.

Q. Can customers mount MicroStar Junior BGA packages on the bottom

side of the PCB board?

A. Yes, they can and the ideal 2nd reflow profile is the same as the 1st (IR profile

is recommended in the bulletin). The root causes for solder ball off are:

Excess amount of solder paste during customers board assembly. TI

recommends minimizing the amount of solder paste on the bottom side by

using a stencil thickness of 0.15 mm with 0.33-mm aperture opening.

Moisture absorption also affects the ball off issue. The package was

qualified at Moisture Level 2, and has been released at Moisture Level 2A.

The first and second reflow must be completed within 4 weeks.

References

Recommended References:

1. MicroStar BGA Packaging Reference Guide - SSYZ015

2. 96 and 114 ball LFBGA Application Note - IDT, Philips Semiconductor and Texas

Instruments

3. Board Level Reliability Evaluations of 40, 32 and 30 Mil Pitch Ball Grid Array

Packages Over -40 to 125°C - Puligandla Viswanadham, Steve Dunford and

Ted Carper, Circuit Card Assemblies Center of Excellence Raytheon Systems

Co.

4. Comprehensive User's Guide for µBGA*Packages www.intel.com/design/flcomp/packdata/297846.htm

5. Solder Paste Printing Guidelines for BGA and CSP Assemblies - Donald C. Burr,

published in SMTJanuary 1999.

6. Maintaining BGA Reliability During Rework - Stuart Downes and Robert Farrell,

published in SMT January 1999.

7. BGA Rework Considerations - Jennie S. Hwang, published in SMT November

1998.

Page 6

TI Worldwide Technical Support

Internet

TI Semiconductor Home Page

www.ti.com/sc

MicroStar Junior BGA Home Page

www.ti.com/sc/msjunior

TI Distributors

www.ti.com/sc/docs/general/distrib.htm

Product Information Centers

Americas

Phone +1(972) 644-5580

Fax +1(214) 480-7800

Internet www.ti.com/sc/ampic

Europe, Middle East, and Africa

Phone

Belgium (English) +32 (0) 27 45 55 32

France +33 (0) 1 30 70 11 64

Germany +49 (0) 8161 80 33 11

Israel (English) 1800 949 0107

Italy 800 79 11 37

Netherlands (English) +31 (0) 546 87 95 45

Spain +34 902 35 40 28

Sweden (English) +46 (0) 8587 555 22

United Kingdom +44 (0) 1604 66 33 99

Fax +44 (0) 1604 66 33 34

Email epic@ti.com

Internet www.ti.com/sc/epic

Logic Overview Page

www.ti.com/sc/logic

Phone

International +886-2-23786800

Domestic Local Access Code TI Number

Australia 1-800-881-011 -800-800-1450

China 10810 -800-800-1450

Hong Kong 800-96-1111 -800-800-1450

India 000-117 -800-800-1450

Indonesia 001-801-10 -800-800-1450

Korea 080-551-2804 Malaysia 1-800-800-011 -800-800-1450

New Zealand 000-911 -800-800-1450

Philippines 105-11 -800-800-1450

Singapore 800-0111-111 -800-800-1450

Taiwan 080-006800 Thailand 0019-991-1111 -800-800-1450

Fax 886-2-2378-6808

Email tiasia@ti.com

Internet www.ti.com/sc/apic

Japan

Phone

International +81-3-3344-5311

Domestic 0120-81-0026

Fax

International +81-3-3344-5317

Domestic 0120-81-0036

Internet

International www.ti.com/sc/jpic

Domestic www.tij.co.jp/pic

Asia

MicroStar BGA and MicroStar Junior are trademarks of

Texas Instruments Incorporated

© Copyright 2000 Texas instruments Incorporated

Important Notice: The products and services of Texas

Instruments and its subsidiaries described herein are sold

subject to TIs standard terms and conditions of sale. Customers

are advised to obtain the most current and complete information

about TI products and services before placing orders. TI

assumes no liability for applications assistance, customers

applications or product designs, software performance, or

infringement of patents. The publication of information regarding

any other companys products or services does not constitute

TIs approval, warranty or endorsement thereof.

SCET004

Loading...

Loading...