Page 1

testo 480 · Climate measuring instrument

Instruction manual

Page 2

2

Page 3

1 Contents

1 Contents

1 Contents ................................................................................................... 3

2 Safety and the environment .................................................................... 5

2.1. About this document ........................................................................ 5

2.2. Ensure safety ................................................................................... 6

2.3. Protecting the environment .............................................................. 7

3 Specifications .......................................................................................... 8

3.1. Use .................................................................................................. 8

3.2. Technical data ................................................................................. 8

4 Product description ............................................................................... 11

4.1. Overview........................................................................................ 11

4.1.1. Hand instrument ............................................................................................ 11

4.1.2. Instrument connections and interfaces ........................................................... 12

4.1.3. Controls ......................................................................................................... 13

4.1.4. Display ........................................................................................................... 14

5 First steps .............................................................................................. 16

5.1. Commissioning .............................................................................. 16

5.2. Getting to know the product ........................................................... 19

5.2.1. Navigating in the menu .................................................................................. 19

5.2.2. Calling up a function ...................................................................................... 20

5.2.3. Exit the menu ................................................................................................. 20

5.2.4. Switching to another tab ................................................................................ 20

5.2.5. Entering values .............................................................................................. 20

5.2.6. Saving values ................................................................................................ 21

6 Using the product .................................................................................. 22

6.1. Performing settings ........................................................................ 22

6.2. Setting the measurement display .................................................. 23

6.2.1. Calculated measurement parameters ............................................................ 24

6.3. Favourites tab ................................................................................ 25

6.4. Probe menu ................................................................................... 26

6.5. Explorer menu ............................................................................... 27

3

Page 4

1 Contents

6.6.

Measurements & Measuring programs ......................................... 30

6.6.1. Retaining (“holding”) measurement values .................................................... 31

6.6.2. Quick back-up ................................................................................................ 31

6.6.3. Measuring program ........................................................................................ 31

6.6.4. Grid measurement ......................................................................................... 34

6.6.5. Turbulence measurement .............................................................................. 38

6.6.6. Pitot tube measurement ................................................................................. 39

6.6.7. Measurement with the funnel ......................................................................... 40

6.6.8. Pressure measurement ................................................................................. 40

6.6.9. CO2 measurement ......................................................................................... 41

6.6.10. WBGT measurement ..................................................................................... 41

6.6.11. PMV/PPD measurement ................................................................................ 43

6.6.12. Saving measurement values .......................................................................... 47

6.6.13. Printing measurement values ........................................................................ 49

6.6.14. Display measuring values graphically ............................................................ 49

6.6.15. Transferring measurement values ................................................................. 51

7 Maintaining the product ....................................................................... 52

7.1.1. Battery care ................................................................................................... 52

7.1.2. Carrying out humidity adjustment................................................................... 52

7.1.3. Carrying out a firmware update ...................................................................... 54

8 Tips and assistance .............................................................................. 55

8.1. Questions and answers ................................................................ 55

8.2. Accessories and spare parts ......................................................... 56

4

Page 5

2 Safety and the environment

2 Safety and the environment

2.1. About this document

Symbols and writing standards

Representation Explanation

Warning advice, risk level according to the

signal word:

Warning! Serious physical injury may occur.

Caution! Slight physical injury or damage to

the equipment may occur.

> Implement the specified precautionary

measures.

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be

followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu Elements of the instrument, the instrument

display or the program interface.

[OK] Control keys of the instrument or buttons of

the program interface.

... | ... Functions/paths within a menu.

“...” Example entries

Warnings

Always pay attention to information that is marked by the following

warnings with warning pictograms. Implement the specified

precautionary measures.

Representation Explanation

CAUTION

NOTICE

indicates circumstances that may lead to

damage to the products

indicates potential minor injuries

5

Page 6

2 Safety and the environment

2.2. Ensure safety

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

use any force.

> The objects to be measured or the measurement environment

may also pose risks: Note the safety regulations valid in your

area when performing the measurements.

> Do not perform contact measurements on non-insulated, live

parts.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Testo.

> Temperatures given on probes relate only to the measuring

range of the sensors. Do not expose handles and feed lines to

temperatures in excess of 40 °C (104 °F), unless they are

expressly permitted for higher temperatures.

> After the final measurement, allow probes and probe shafts to

cool down sufficiently in order to avoid burns from the hot

sensor tip or the probe shaft.

> Improper use of rechargeable batteries can lead to destruction

or injuries by means of current surges, fire or escaping

chemicals. The following instructions must be observed to avoid

such hazards:

• Only use in accordance with the directions in the instruction

manual.

• Do not short, take apart or modify.

• Do not expose to heavy impacts, water, fire or temperatures

above 60 °C.

• Do not store in the proximity of metal objects.

• Do not use leaky or damaged rechargeable batteries. In the

event of contact with battery acid: Thoroughly wash affected

area with water and consult a doctor, if necessary.

6

Page 7

• Only charge in the instrument or the recommended charging

station.

• Immediately stop the charging process if this is not

completed in the given time.

• In the event of improper function or signs of overheating,

immediately remove the rechargeable battery from the

measuring instrument/charging station. Caution:

Rechargeable battery may be hot!

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

2.3. Protecting the environment

product.

> Dispose of faulty rechargeable batteries/spent batteries in

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to Testo for disposal.

2 Safety and the environment

7

Page 8

3 Specifications

3 Specifications

3.1. Use

The testo 480 is a measuring instrument for measuring climaterelated parameters. The testo 480 is ideal for comfort level

measurements for the workplace evaluation and flow

measurements in and at ventilation and air-conditioning systems.

The instrument is only to be used by qualified expert personnel.

3.2. Technical data

Then product must not be used in explosive environments!

Hand-held instrument

Feature Values

Measurement

parameters

• Temperature (°C, °F, difference-°C,

difference-°F)

• Humidity (%RH, td°C, td°F, wet bulb °C,

wet bulb °F, g/m

3

, g/ft3, g/kg, g/lb, kJ/kg,

BTU/lb, ppm, Vol%)

• Flow velocity (m/s, ft/m)

• Pressure (Pa, hPa, mbar, kPa, bar, psi,

inH2O, inHg, mmH2O, Torr)

• CO

(ppm, Vol%)

2

• Lux (Lux, footcandle)

Sensor connections • 2x temperature (TC type K)

• 1x differential pressure

• 3x digital probes (flow, humidity,

temperature, CO

, Lux, absolute

2

pressure)

Interfaces • Mini USB

• Infrared for testo report printer

• SD card

• Mains connection

Internal memory

capacity

Rechargeable battery

life

1.8 GB (approx. 60,000,000 measuring

values)

Approx. 17 h (hand instrument without

probe with 50% display brightness)

8

Page 9

Feature Values

Measuring cycle 0.5 s

Operating

0 to +40 °C

temperature

Storage temperature -20 to +60 °C

Dimensions 81 mm x 235 mm x 39 mm

Housing material ABS, TPE, PMMA

Weight Approx. 435 g

IP protection class 30 (with connected probes)

Integrated measurement (at 22 °C, ±1 digit)

Feature Values

Temperature (TC

type K; internal

reference point

measurement:

measuring range 0 to

+40 °C, accuracy

±0.5 °C)

Measuring range: -200.0 to +1370.0 °C

Accuracy: ±(0.3 °C + 0.1 % of meas. val.)

Resolution: 0.1 °C

The accuracy information applies in

a similar, stable temperature state.

Plugging in the main unit, charging

the battery or adding digital probes

can distort this temporarily, and

additional errors may occur.

3 Specifications

Differential pressure Measuring range: -25 to +25 hPa

Accuracy1: ±(0,3 Pa + 1% of meas. val.)

Resolution: 0.001 hPa

The accuracy specification applies

immediately after zeroing of the

sensor. For long-term

measurements, mains operation

with fully-charged battery is

recommended.

Temperature coefficient: <0.01%

FS/K typical

1

Source: DIN EN ISO 7726

9

Page 10

3 Specifications

Feature Values

Absolute pressure Measuring range: +700 to +1100 hPa

Accuracy: ±3 hPa

Resolution: 0.1 hPa

Standards, tests, warranty

Feature Values

EU Directive 2004/108/EC

Vibration IEC 60068-2-6

Warranty

2 years, warranty conditions: see

www.testo.com/warranty

Mains unit (0554 8808) for continuous measurements and

battery charging

Feature Values

Output voltage 5 V / 4 A

EU Directive 2004/108/EC

Warranty period

2 years, warranty conditions: see

www.testo.com/warranty

Lithium battery

Feature Values

Charging option In instrument

Charging current Max. 2.5 A per battery

Discharge current Max. 1.5 A per battery

Charge time Approx. 8 h

Battery life

Approx. 17 h (hand instrument without

probe with 50% display brightness)

Ambient temperature 0 – 40 °C / 32 – 104 °F

Long-term storage

<23 °C / <73 °F

temperature

EU Directive 2004/108/EC

Warranty period

2 years, warranty conditions: see

www.testo.com/warranty

10

Page 11

4 Product description

4.1. Overview

4.1.1. Hand instrument

4 Product description

1 Display

2 Mini USB interface (right-hand side of instrument)

3 Control buttons and trackpad (navigation field)

4 SD card slot (right-hand side of instrument)

5 Magnetic holder (on back)

CAUTION

Damage to other equipment caused by strong magnets!

> Keep well away from products that could be damaged by the

effects of magnetism (e.g. pacemakers, monitors, computers or

credit cards).

11

Page 12

4 Product description

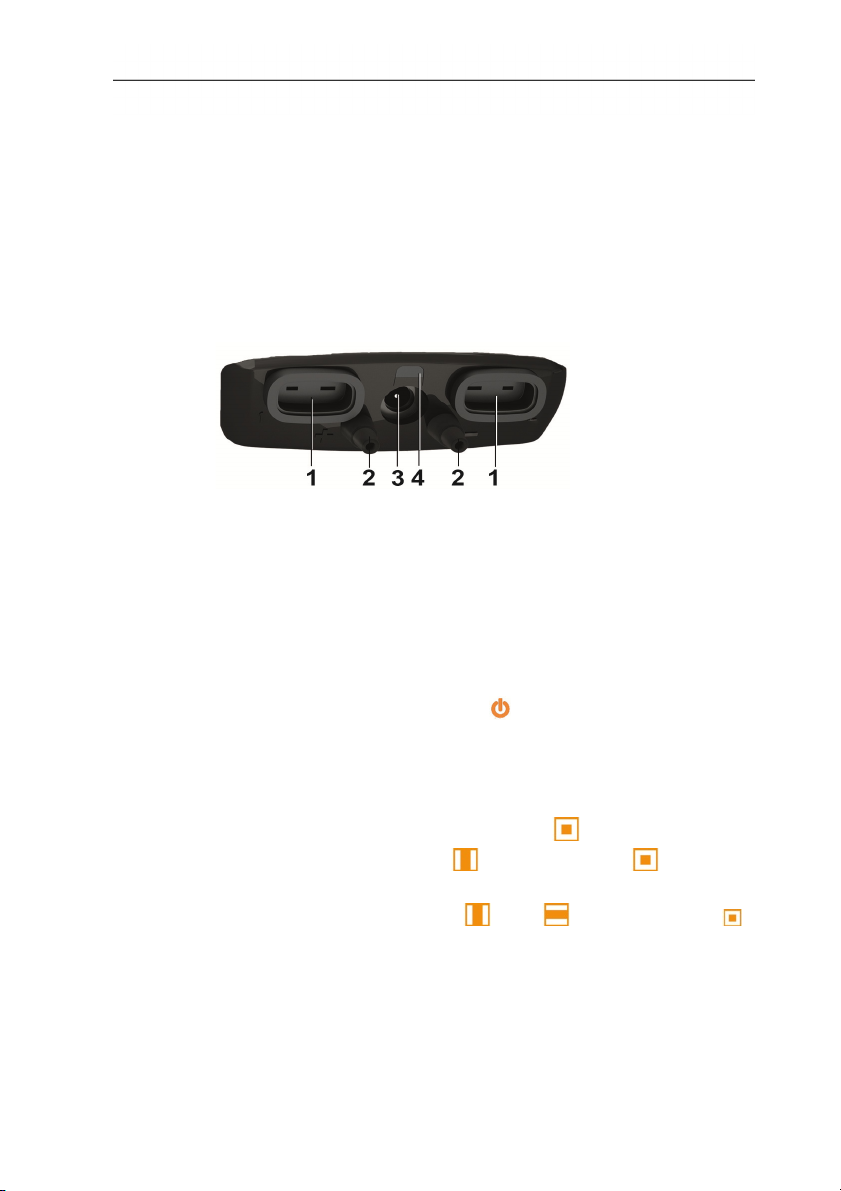

4.1.2. Instrument connections and interfaces

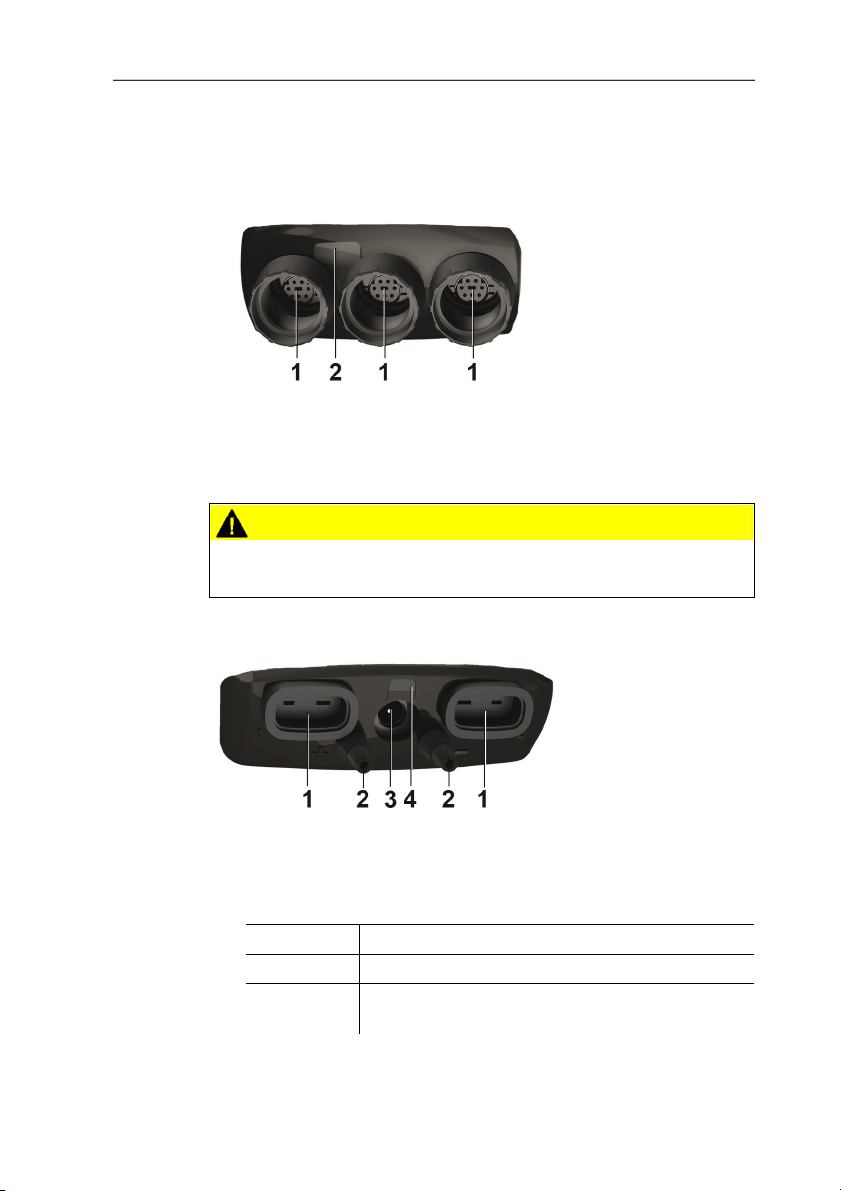

Top

1 Probe sockets for digital probes

2 IR interface for printouts with testo report printer (art. no. 0554

0549)

CAUTION

Risk of injury from infrared beam!

> Do not direct infrared beam at human eyes!

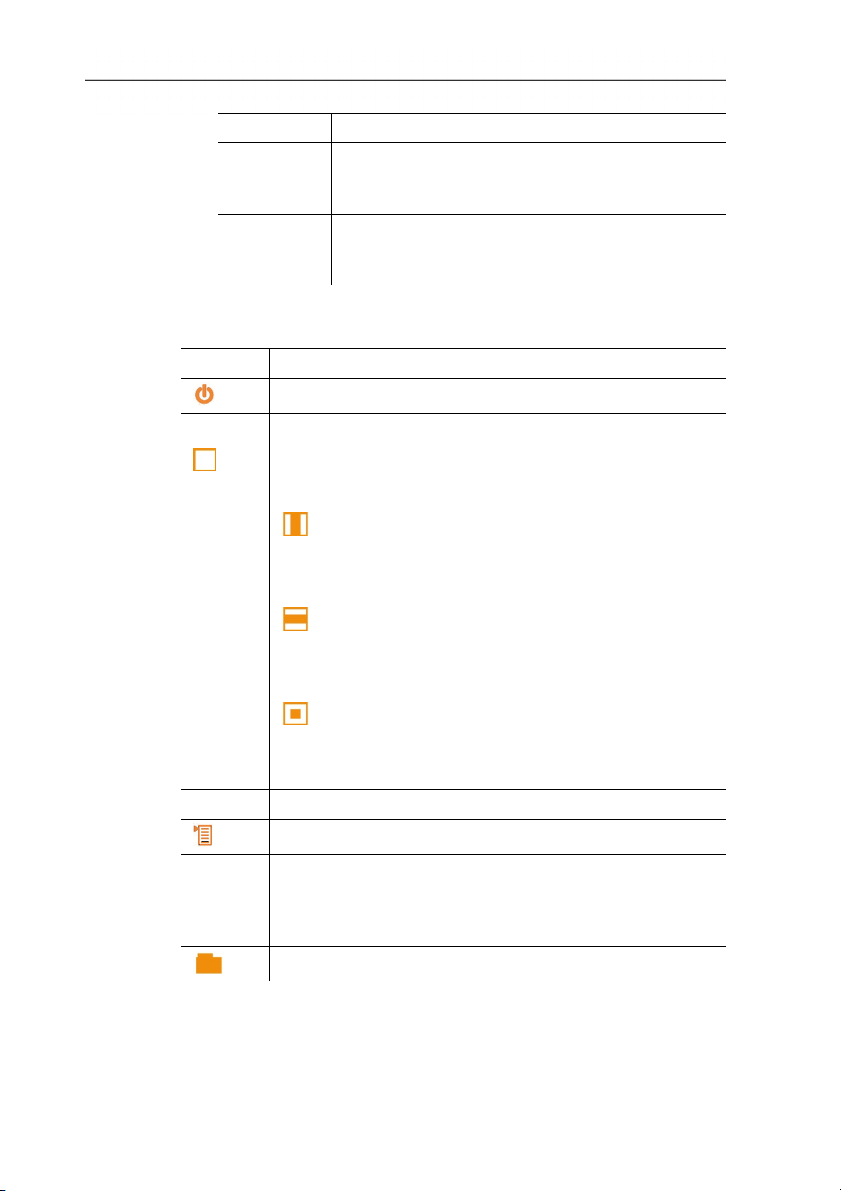

Bottom

12

1 TC connection for temperature probe type K

2 Connections for differential pressure (+/- sign on the instrument)

3 Mains socket

4 Status LED, mains socket

Status Explanation

LED off Rechargeable battery is not charging

LED on,

Rechargeable battery is charging

lights up

Page 13

Status Explanation

LED on,

flashes

slowly

LED on,

flashes

quickly

4.1.3. Controls

Button Functions

[]

[]

[Esc]

[]

[–]

[]

4 Product description

Rechargeable battery is not charging,

instrument/battery temperature too high

Rechargeable battery is not charging, battery

faulty

Switch measuring instrument on / off

The following symbols are used to operate the trackpad.

see Navigating in the menu, page 19.

Move your finger on the trackpad to scroll up or down

on the screen.

Move your finger smoothly over the trackpad

[]

from top to bottom: scrolls down.

Move your finger smoothly over the trackpad

from bottom to top: scrolls up.

Move your finger smoothly over the trackpad

[]

from left to right: scrolls right.

Move your finger smoothly over the trackpad

from right to left: scrolls left.

Briefly touch the trackpad with your finger to

[]

confirm the selection. When confirming, you

should notice a click similarly to pressing a

button.

Back, cancel function

Open main menu, save settings

Configurable button for quick access to a frequently

used function. The button is not preassigned at the

factory. Configure button, see Performing settings, page

22.

Explorer is opened, see Explorer menu, page 27.

13

Page 14

4 Product description

4.1.4. Display

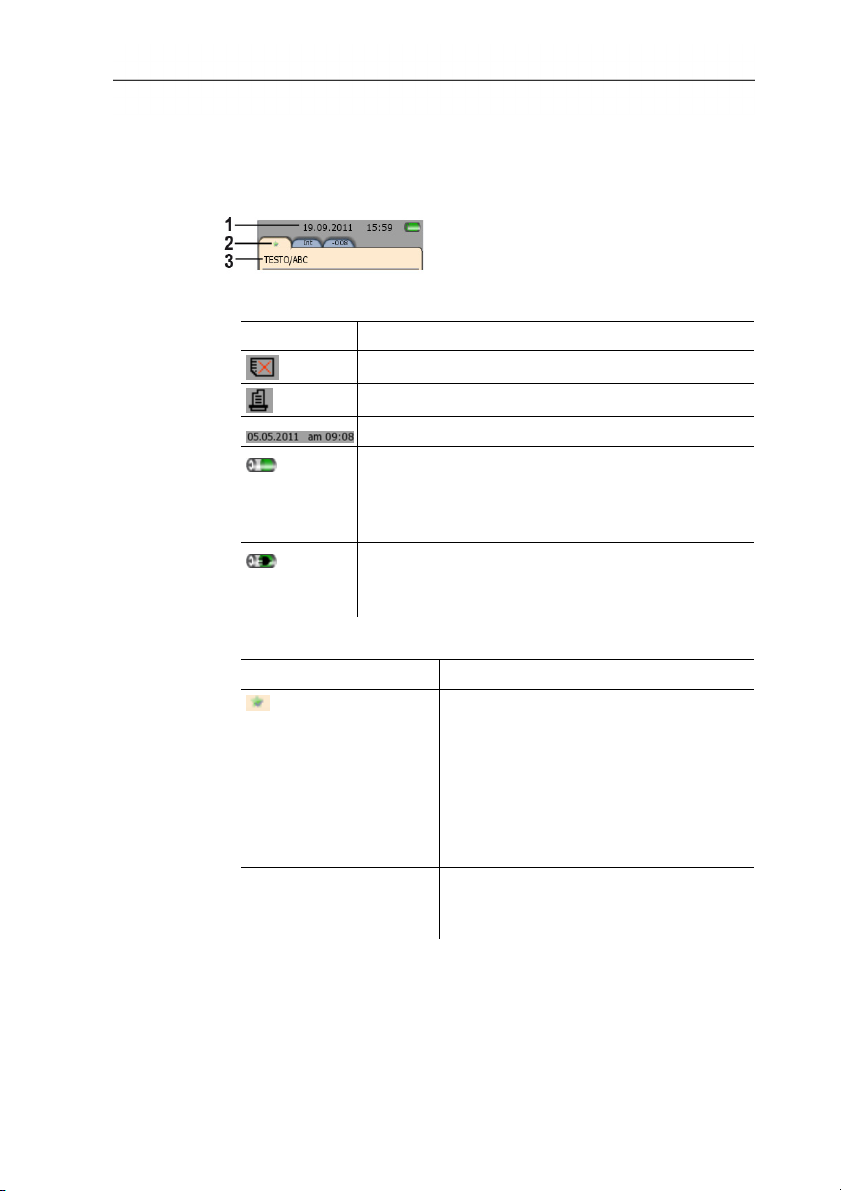

Status line and tabs

1 Status bar (dark grey background):

Icon Explanation

2 Tabs:

Tab name Explanation

(Favourites tab)

Int Measurement values of the internal

There is no SD card in the instrument

Printing

Date and time

Battery operation

Indication of remaining capacity of the rech. batt.

by the colour and fill level of the battery symbol

(green = 5-100%, red = < 5%)

Mains operation

Indication of remaining capacity of rech. batt:

see above

The Favourites tab is the actual work

area for the instrument see Favourites

tab, page 25.

Here, measurement values of various

probes can be combined into one

measurement, and measuring

programs can be run, saved and

printed.

sensors and connected TC probes

are displayed.

14

Page 15

4 Product description

Tab name Explanation

-881 (Example; the last

three digits of the serial

number of the probe

are displayed. The full

serial number of the

probe is shown on a

label on the probe.)

An additional tab is displayed for each

connected probe with the

measurement values of the probe and

the calculated parameters. The tabs

are displayed in the order in which the

probes were connected to the

instrument.

3 Info field of register tabs: display of the selected measuring

location/measuring point. The displayed measuring point can be

selected in Explorer, see Explorer menu, page 27.

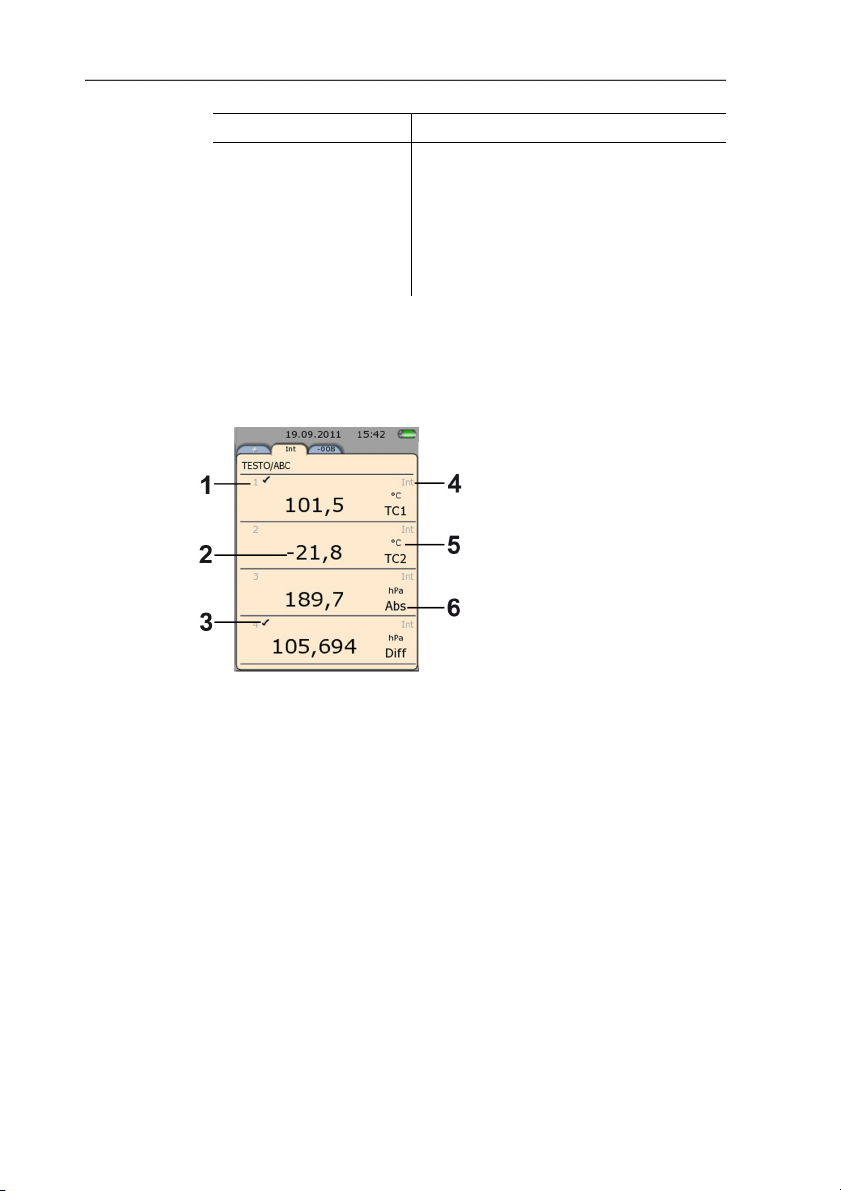

Measuring view

1 Line number

2 Measurement value

3 Indication that the measurement value is also displayed in the

Favourites tab.

4 Probe designation

5 Unit

6 Measurement parameter

The measuring view can be changed individually for each tab, see

Setting the measurement display, page 23.

15

Page 16

5 First steps

5 First steps

5.1. Commissioning

Initial charging of rechargeable battery

The testo 480 is delivered with a partially charged battery. Charge

the battery fully before using it for the first time.

1. Connect the mains unit to the mains socket (3).

2. Connect the mains plug to a power socket.

- Battery charging is started: status LED (4) lights up.

- The battery is fully charged: status LED (4) is off.

3. Disconnect instrument from the mains unit.

- After initial charging of the rech. battery, the instrument is ready

for use.

Switching on

1. Switch the instrument on with [].

- The start screen appears.

For initial commissioning or after a factory reset, the Initial

operation menu is opened automatically. Set the required menu

language:

> Call up the required selection list with [].

2. Select the language with [] and confirm with [].

- Instrument language is changed.

3. Set the date and time with [] and [] and confirm with [].

16

Page 17

5 First steps

4. Select ISO/US units with [] and confirm with [].

The setting only relates to the measured values and can be

individually adjusted for each measurement value if

required.

5. [] → Save and close.

- The current measurement values are displayed. The instrument

is now operational.

Switching off

Unsaved measurement values are lost when the

instrument is switched off.

> Switch the instrument off with [].

Connecting probes / sensors

Probes are detected automatically by the instrument.

Make sure the connections are secure, but do not use force!

> Insert the probe connector into the probe socket:

• Bottom of the instrument: TC probe (type K)

• Top of the instrument: digital probe:

Push/pull plug-in connections protect digital probes from

being unintentionally disconnected from the instrument.

> Connect pressure tubes to + and -.

Caution! Danger of injury caused by the pressure tube

jumping away from the connection socket!

> Ensure correct connection.

17

Page 18

5 First steps

Removing probes

Thermocouple (TC) probe:

> Unplug connector from the socket.

Digital probe:

1. Pull back outer sleeve to release the push/pull plug-in

connection.

2. Unplug connector from the socket.

Connecting the mains unit

If the mains unit is connected, the instrument is powered

automatically via the mains unit.

When power is supplied via the mains unit, the instrument

may heat up. This may increase the measurement

uncertainty during TC measurement.

1. Plug the mains unit instrument connector (art. no. 0554 8808)

into the mains socket on the bottom of the instrument.

2. Plug the mains unit plug into a mains socket.

- The instrument is supplied with power via the mains unit and

battery charging begins automatically.

18

Page 19

5.2. Getting to know the product

5.2.1. Navigating in the menu

1. Press [].

- The Options menu is opened. Selected function is highlighted

white.

2. Select navigation/function:

• [] Move the trackpad down to select the menu item.

• [] Briefly touch the trackpad with your finger to confirm

the selection.

• Press [Esc] to cancel the action and switch to measuring

mode.

5 First steps

Short form

This document uses a short form for describing operating steps

(e.g. calling up a function).

Example: calling up Min/Max

Short form

Steps

required

[] →

1. Open Main

menu: [].

function

Display → Min/Max.

2. Select

Display

4. Select

menu: [].

3. Confirm

5. Confirm

selection: [

].

Min/Max

menu: [].

selection: [

].

19

Page 20

5 First steps

5.2.2. Calling up a function

1. Select function: [].

- A box appears around the selected function.

2. Confirm selection: [].

- The selected function is opened.

5.2.3. Exit the menu

> Press [Esc].

Before the entered data or measurement data may be lost,

a confirmation prompt always appears, which must be

confirmed with [].

Or

5.2.4. Switching to another tab

> [] → Save and close.

> Select the required tab: [].

- Required tab is activated and all other tabs are greyed out.

5.2.5. Entering values

Some functions require values (numbers, units, characters) to be

entered. Depending on the function that is chosen, the values are

entered via either a list field or an input editor.

20

List field

1. Select the value to be changed (numerical value, unit): [], [

] (depending on the selected function).

2. Press [].

3. Set value: [], [] (depending on the selected function).

Page 21

4. Confirm the entry: [].

5. Repeat steps 1 and 4 as required.

6. Save the entry: [] → Save and close.

Input editor

1. Select the value to be changed (character): [], [].

2. Accept value: [].

Options:

> Toggle between upper / lower case characters:

Select

> Toggle between characters and numbers: select or

.

> Insert space: select

.

> Delete character in front of cursor:

select .

3. Repeat steps 1 and 2 as required.

4. Save the entry: select .

5 First steps

5.2.6. Saving values

21

> [] → Save and close.

Page 22

6 Using the product

6 Using the product

6.1. Performing settings

1. Press [].

- The configuration menu is opened.

2. Select Settings and set parameters:

Symbol Explanation

Energy brightness The brightness of the display can be

adapted to suit ambient conditions.

Trackpad It is possible to set the response time of

the trackpad.

Speed-dial keys Functions that are frequently required can

be assigned to one of the two function

keys [–].

Energy

management

It is possible to set the time frame for

automatically switching off the instrument

or the display illumination to preserve the

battery.

Date/time

Password

Various displays can be selected.

When password protection is enabled, all

these functions can only be carried out by

entering the password:

• Instrument factory reset

• Probe reset

• Firmware update

• Change/deactivate password

• Probe name

22

If you forget the password, it can

only be reset by Testo Service

Password protection is not set as default.

Units It is possible to toggle between ISO and

US units. The setting only relates to the

unit of the measured parameters, not to

the calculated parameters.

Page 23

6 Using the product

Symbol Explanation

Norm data The temperature and absolute pressure

values for the internal calculation of the

standard flow rate can be changed.

Factory-set: 25 °C, 1013.25 hPa

Pressure settings Selection of the additional information

that should be included on a

measurement value printout.

Language The instrument language is set. Select a

language that you can understand well.

Factory reset The instrument is reset to the factory

settings:

• Settings

• Adjustment data

• Password deactivated

• Favourites tab is blank

> After a factory reset, switch off the

instrument with [] and then switch it

on again.

3. []→ Save and close.

- Instrument switches to the measuring view.

6.2. Setting the measurement display

The measurement display can be set individually for each probe

tab. These settings are saved in the probe and also apply when the

probe is next connected.

✓ Tab for which the measurement display should be changed is

selected.

1. Press [].

- The configuration menu is opened.

23

2. Select Display function and set parameters:

Adjustable parameters

Representation Explanation

Min/max

When the function is activated, each

line shows: average value, min value and

max value.

To deactivate: select function again.

Page 24

6 Using the product

Representation Explanation

Parameter display The individual lines can be changed in

the parameter display:

• Changing measurement parameters

and units: Select line [].

• Move/delete/insert lines [].

• Copy lines to Favourites tab [].

Lines displayed on the Favourites tab

are indicated with a tick.

Number of lines Selects how many lines should be

displayed at the same time.

If not all lines can be displayed at the

same time, a scrollbar appears on the

right. The remaining lines can be

displayed with [].

- Instrument switches to the selected measuring view.

see Calculated measurement parameters, page 24

6.2.1. Calculated measurement parameters

The following calculated measurement parameters can –

depending on the connected probes – also be included in the

measurement value display for the measured parameters.

24

Operating flow rate

Value calculated from measured air velocity multiplied by the crosssection under the prevailing conditions in the application (e.g.

56 °C, 920 hPa).

Standard flow rate

Value calculated from the operating flow rate relating to the values

entered under norm data (e.g. 25 °C, 1013 hPa).

Dampness degree (pressure-dependent)

Unit g/kg: Describes how many grams of water are contained in a

kg of dry air. It is used to calculate the absolute pressure entered

under norm data.

Water content

Indicates the volume percentage of water vapour in the measured

gas. Unit is not absolute (ppm or %).

Page 25

Dewpoint

Temperature at which condensation of the water vapour in the gas

occurs.

Psychrometer temperature (pressure-dependent)

Wet-bulb temperature of a psychrometer. It is used to calculate the

absolute pressure entered under norm data

Enthalpy

Heat content of the measured gas. Unit kJ/kg or BTU/lb.

Absolute humidity

Describes how many grams of water are contained in a cubic metre

of the currently measured gas. Unit g/m³.

6.3. Favourites tab

The Favourites tab is the actual work area for the instrument.

Here, measurement values of various probes can be combined into

one measurement, and measuring programs can be run, saved and

printed.

Only the measurement values displayed on the Favourites tab are

saved in the measurement protocol.

> [] → Display → Parameter display → [] → Add line to

Favorites.

When the probe is first connected, all measurable parameters are

transferred over to the Favourites tab. Calculated measurement

parameters must be added manually on the Favourites tab.

6 Using the product

Adjusting the displayed measurement parameters

25

> [] → Display → Parameter display → []

Page 26

6 Using the product

6.4. Probe menu

Call up function:

> [] → Probe menu.

Adjustable parameters

Symbol Explanation

Damping (moving

average)

Probe info Probe name, serial number and probe

Probe name

Adjustment info The probe-specific adjustment data saved

Damping type and duration can be

individually adjusted.

Damping can be activated/deactivated.

type are displayed.

Probe name can be edited.

on the probe can be displayed.

The digital probes allow direct

measurement and signal

conversion in the probe. This

technology means that

measurement uncertainty caused

by the instrument is no longer an

issue.

The probe can be calibrated

without a hand instrument.

Entering the adjustment data via

the EasyClimate software

generates a zero-error display.

26

Humidity

adjustment

Humidity adjustment is possible with the

following probes:

• Humidity probe

• IAQ probe

• Thermal air flow measuring head and

humidity probe

When a thermal air flow

measuring head and humidity

probe is used, the probe must be

deactivated before the

adjustment.

Page 27

Symbol Explanation

Probe reset

6.5. Explorer menu

In Explorer, all saved measurement values are displayed with the

assigned data like the measuring program and customer data in a

set structure.

Measurement values that were not saved are lost when the

measuring instrument is switched off!

Calling up the Explorer view

> Press [].

- Explorer structure is displayed.

6 Using the product

Probe is reset to the factory settings:

• Measurement value display

• Probe name

• Adjustment table

• Humidity adjustment

• Damping

Icon Feature

The root folder is a default folder, which

cannot be deleted, moved or renamed.

The folder is used to structure data and is where

all elements (such as folders, measuring

locations, measuring points, etc.) are saved.

27

Selection collapses sub-tree.

Selection expands sub-tree.

Page 28

6 Using the product

Factory-set measuring point under which the

measuring programs are saved if no specific

measuring location is created.

Measuring location documenting the name and

address of the customer. A measuring location

can have several measuring points.

Measuring point (e.g. ventilation shaft 1)

documenting the location description with

measurement-related parameters, e.g. crosssections. A measuring point can have several

measuring programs.

Measuring program documenting the measuring

process and the start and stop criteria for the

measurement (e.g. continuous or punctual

measurement).

Grid measurement (standards-compliant air flow

and volumetric flow rate measurement in

ventilation and air-conditioning systems) see Grid

measurement, page 34.

Turbulence measurement (standards-compliant

measurement of comfort) see Turbulence

measurement, page 38.

Report of the saved measurement data

All settings configured in the Explorer

structure before measurement are stored

in the protocol and cannot be

subsequently changed.

The Explorer structure can also be edited via the

EasyClimate software and re-imported into the instrument.

28

Creating a new folder

A folder is always created in another folder.

1. Select the (root) folder in which the new folder is to be created.

2. [] → New folder.

3. Enter name.

4. Finalise the entry: [] → Save and close.

Page 29

6 Using the product

Other folder options

• [] → New measuring location: create new measuring

location in the selected folder.

• [] → Edit folder: change the name of an existing folder.

• [] → Delete folder: delete an existing folder, including the

locations created therein.

Creating a new location

A location is always created in a folder.

1. Select the folder in which the location is to be created.

2. [] → New measuring location.

3. Enter values.

4. Finalise the entry: [] → Save and close.

Other measuring location options

> [] → New measuring point: create new measuring point in

the selected measuring location.

> [] → Edit measuring location: make changes to an existing

location.

> [] → Delete measuring location: delete an existing

measuring location, including the measuring points created

therein.

Creating a new measuring point

A measuring point is always created under a measuring location.

1. Select the measuring location in which the measuring point is to

be created.

2. [] → New measuring point.

3. Enter values.

4. Finalise the entry: [] → Save and close.

29

Page 30

6 Using the product

Other measuring point options

> [] → Select measuring point: measuring point is selected

> [] → Edit measuring point: make changes to an existing

> [] → Delete measuring point: delete an existing measuring

> [] → New measuring program: determine parameters for a

> [] → New grid measurement: carry out grid measurement,

> [] → New turbulence measurement: carry out turbulence

> [] → New PMV/PPD measurement: Carrying out a

> [] → New WBGT measurement: Carrying out a WBGT

For creating a new measuring program, see PMV/PPD

measurement, page 43.

see WBGT measurement, page 41

see Measuring program, page 31

and displayed in the status line in the measuring view. Reports

are saved under the selected measuring point.

measuring point.

point, including the measurement protocols saved for it.

new individual measurement.

see Grid measurement, page 34.

measurement, see Turbulence measurement, page 38.

PMV/PPD measurement, see PMV/PPD measurement, page

43.

measurement, see WBGT measurement, page 41.

6.6. Measurements & Measuring programs

General measurement information

• Depending on the measurement parameter to be measured,

certain probes must be plugged into the instrument.

• Some (thermal) probes require a warming-up phase until they

are ready to measure.

Adjustment phase

• For some measurement parameters, additional calculation

parameters must be set to ensure correct measurement results,

see Performing settings, page 22

30

Page 31

6 Using the product

6.6.1. Retaining (“holding”) measurement values

Displayed measurement values can be held on the Favourites or

Probe tabs and printed out. The measurement values cannot be

saved in one measurement protocol.

> [] →Hold.

- The measurement value is retained. is displayed.

> Cancel Hold: [] →Hold.

Held measurement values can be printed see Measuring program,

page 31

The measuring values can be saved in one measurement protocol.

6.6.2. Quick back-up

With quick back-up, the current measuring values are saved to the

folder selected for the measurement.

If no measuring point has been selected, the measurement

protocols are saved under "Default Point".

> [] → Quick back-up.

- Measuring values are saved.

see Printing measurement values, page 49

6.6.3. Measuring program

You can customise measuring programs to match the relevant

measuring task (e.g. continuous or punctual measurement). These

measuring programs are linked to a specific measuring point. After

the measurement, the relevant measurement protocols are saved

under the measuring program.

For creating a new measuring program,

A measuring program is always created under a measuring point.

1. Press [].

- Explorer structure is displayed.

2. Select a measuring point for which the measuring program

should be created.

3. [] → New measuring program.

31

Page 32

6 Using the product

4. Determine parameters.

Parameter Explanation

Name Name under which the measuring program is

saved in Explorer.

Measuring point Measuring point to which the measuring

program is assigned.

Measuring type

• Continuous: Mean calculation across a

specific period

• Punctual: Mean calculation across

individual current values buffered via []

or button on probe handle.

• Continuous/Punctual: At each point a

mean value is calculated according to the

end criterion set (Duration or Number of

values). At the end of the measurement,

an overall mean value is calculated.

Measuring rate Interval at which the measurement values are

recorded.

Start criterion

• Manual: Measurement is triggered via [

].

• Date/Time: Measurement starts at a set

time.

End criterion

• Manual: Measurement is ended via []

→ End.

• Date/Time: Measurement ends at a set

time.

• Duration: measurement ends after a set

duration has lapsed.

• Number of values: measurement ends

after a sequence of measured values.

The measuring program only applies to the Favourites tab.

Only the values displayed on the Favourites tab are saved

in the measurement protocol.

32

Page 33

6 Using the product

5. Save setting and navigate to the measuring program: select [

] → Save and start measurement.

> If you do not want the measurement to start immediately: select

[] → Save and close.

Another way to create a measuring program in the

Favourites tab under the selected measuring point:

> [] → Application → Measuring program.

Starting a measuring program

If a start date has been set, the program starts

automatically. In the case of a manual start, the

measurement must be triggered as described.

1. Select required measuring program.

2. [] → Start measuring program.

> Depending on the selected start criterion, the measurement

must be started via [].

Other measuring program options

> [] → Edit measuring program: make changes to an existing

measuring program.

> [] → Delete measuring program: delete an existing

33

measuring program.

Page 34

6 Using the product

6.6.4. Grid measurement

There are various options for measuring the air and volumetric flow

rate in ventilation and air-conditioning systems. These are

distinguishable by the measuring range in particular. For the testo

480, there are three different flow probes:

• Thermal probes (incl. temperature measurement and possibly

humidity measurement) for low flow speeds

• 16 mm wheel measuring head (incl. temperature measurement)

for average flow velocities

• Pitot tube for measurements at high velocities and in heavily

contaminated flows with a high percentage of particles

Detailed background information on grid measurement and

carrying it out can be found in the Testo Ambient Air

Measurement for Practical Users field guide. You can

request a free copy or download it from www.testo.com.

Selecting a suitable measuring point

The main prerequisite for accurate measurement is the suitability of

the measuring point. Minimum distances from points of

discontinuity must be observed:

• From points of discontinuity upstream of the flow, observe a

clearance of at least six times the hydraulic diameter Dh = 4A/U

(A: channel cross-section, U: channel circumference).

• From points of discontinuity downstream of the flow, observe a

clearance of at least twice the hydraulic diameter Dh = 4A/U (A:

channel cross-section, U: channel circumference).

34

Preparing for measurement

✓ 16 mm wheel measuring head, thermal air flow measuring head

and humidity probe or Pitot tube is connected.

1. Switch the instrument on.

2. Create a new measuring point in Explorer under the required

measuring location.

3. Set the following parameters:

Page 35

6 Using the product

Parameter Values

Temperature,

Relative humidity

and Absolute

pressure

The parameters must be correctly entered or

measured. This affects the measurement

with Pitot tube.

Thermal probe has an internal absolute

pressure sensor. No entry is required here.

Flow rate

correction factor

Pitot factor

Must be 1.00 (has a proportional effect on

the flow rate).

Only has to be entered for measurement with

Pitot tube, see Pitot tube measurement, page

39.

Channel geometry

Profile and dimensions of the channel. Select

channel geometry with []:

Electric power

Manual input value, only used for logging.

4. In Explorer, under the created measuring point, create a new

grid measurement, see Explorer menu, page 27.

5. Make the following settings to suit the measuring point:

Parameter Values

Measuring type

Punctual or Continuous/Punctual

The end criterion can be defined individually

depending on the selection.

Nominal

volumetric flow

Information value for the nominal volumetric

flow. The unit can be freely selected, this

value appears in the protocol and on the

printout as supplementary information.

Probe

Select probe via serial number with [].

If a Pitot tube is connected, the

differential pressure is measured

when INT is selected.

Layout Measuring

points

The number of measuring points depends on

the distance from the point of discontinuity

and irregularities in the profile. More

information can be found in the Testo

"Ambient Air Measurement for Practical

Users" field guide.

35

Page 36

6 Using the product

Parameter Values

Measuring type

Nominal

volumetric flow

Hole position

Edge spacing

Uncertainties

Channel

Uncertainties

Density (air

density, only for

Pitot tube

measurement)

6. Save setting and navigate to the measuring program: select [

> If you do not want the measurement to start immediately: select

Punctual or Continuous/Punctual

The end criterion can be defined individually

depending on the selection.

Information value for the nominal volumetric

flow. The unit can be freely selected, this

value appears in the protocol and on the

printout as supplementary information.

Select any hole position with [] depending

on channel accessibility.

For example, damping of the channel wall

can be taken into consideration. Entered

values influence the coordination of the

measuring points.

Estimated uncertainty of the channel

dimensions. Entered value is taken into

account in the flow rate calculation.

When all relevant measurement parameters

(temperature, relative humidity, absolute

pressure) are measured, the value can be set

to 0.

] → Save and start measurement.

[] → Save and close.

36

Page 37

6 Using the product

Performing the measurement

✓ All points under "Preparing for measurement" have been carried

out.

1. Position the probe at the grid measurement point shown in the

form of a chart on the display.

2. With [] or the integrated measurement button on the probe,

transfer the measured value, or start the continuous/punctual

measurement.

- The measured point is indicated with a tick.

- The position of the measuring point is automatically moved to

the next point on the display and the new immersion depth

required is displayed. The immersion depth of the probe can be

found on the scale of the probe shaft.

3. Repeat steps 1 and 2 until all points have been measured.

- The individual velocity measurement values are used to

calculate the mean flow velocity, from which the volumetric air

flow is then calculated.

If high differences in flow velocities are ascertained over

the cross-section, the number of measuring points is to be

increased.

The number of measuring points is then adequate if the

measurement value for each area is representative for its

immediate surroundings, i.e. if it can be regarded as a

genuine mean value for its portion of the area.

37

Page 38

6 Using the product

4. Before the measurement is completed, any measured point can

> Select [] → Save and close.

- Measurement protocol is saved in Explorer under the selected

The HVAC protocol contains multiple views, which can be changed

via[].

• Values Result: End result (mean value) and deviation of the

• Graphic Result: Channel view with the results per measuring

• HVAC program parameters: preset parameters for the

• Density parameters: preset values for calculating the density

be approached. If this point needs to be remeasured → []→

Repeat measurement.

As soon as all measuring points have been input,

"Measurement completed" is displayed. The whole

measurement can be repeated → []→ Repeat HVAC

measurement.

measuring point.

flow velocity and volumetric flow parameters.

point.

measurement (e.g. channel geometry).

(temperature, humidity, absolute pressure).

6.6.5. Turbulence measurement

A connected turbulence probe 0628 0143 enables the turbulence to

be calculated for the flow value in accordance with DIN EN 13779.

The turbulence probe 0628 0143 has an internal absolute pressure

sensor used to carry out automatic compensation. There is no need

to enter an absolute pressure value here.

✓ Turbulence probe 0628 0143 is connected.

1. Press [].

- Explorer structure is displayed.

2. Select the desired measuring point.

3. [] → New turbulence measurement.

- Turbulence calculation window is opened.

4. Start measurement: [].

- Turbulence determination is started. It takes 180 sec., but can

also be ended early.

- When measurement is completed: turbulence is displayed in %,

calculated according the formula:

38

Page 39

and draught rating as per EN ISO 7730 is displayed.

5. [] → Save and close.

- Measurement protocol is saved under the selected measuring

point.

6.6.6. Pitot tube measurement

To measure flow with a Pitot tube, the following parameters must

be entered in the measuring point (manual entry or measured

values).

• Temperature

• Relative humidity

• Absolute pressure

6 Using the product

These three paramet

These three parameters are taken into account in the calculation of

the flow.

The Pitot factor for Pitot tubes is generally the same and must be

entered:

• Pitot tubes from Testo 1.00

• Straight Pitot tubes, Pitot factor: 0.67

For Pitot tubes from other manufacturers, the Pitot factor can be

found in the instruction manual or you should ask your supplier.

For carrying out the measurement, see Measuring program, page

31 or see Grid measurement, page 34.

39

Page 40

6 Using the product

6.6.7. Measurement with the funnel

A flow rate funnel is required to determine the flow rate at

ventilation systems. The funnel set (art. no. 0563 4170) comprises

a funnel for measuring at poppet valves (200 x 200 mm) and a

funnel for measuring at fans (330 x 330 mm). The opening of the

funnel should cover the grille completely and tightly.

1. Secure the 100 mm wheel measuring head in the funnel

handle.

2. Connect 100 mm wheel measuring head to the instrument.

3. Switch the instrument on.

The following parameters must be entered for the funnel

measurement in the measuring point, as they influence the

measurement result:

• Flow rate correction factor: value 1.00

• Channel geometry (dimensions of the funnel used)

The input variables for the testovent 410/415 can be found

in the funnel instruction manual or on the funnel label.

For the testovent 417 funnel set, use the following

information (deviates from the information on the funnel):

Ø 8,5cm.

For carrying out the measurement, see Measuring program, page

31.

6.6.8. Pressure measurement

The testo 480 has an internal absolute and differential pressure

sensor. The pressure measurement values are therefore displayed

on the Int tab.

1. Connect pressure tubes for differential pressure measurement

(2) to + and -.

40

Caution! Danger of injury caused by the pressure tube

jumping away from the connection socket!

> Ensure correct connection.

2. Switch the instrument on with [].

Page 41

6 Using the product

3. Position the instrument ready for measurement and stabilise.

The parameter display depends on the position of the

pressure sensor.

4. Zero parameter display: []→ Zero.

- Current pressure measurement value appears on the Int tab in

the set unit.

> Change pressure unit in the parameter display: []→

Display→ Parameter display→ []→ Select measurement

parameter from list → []→[]→ Save and close.

If the measurement values fluctuate widely, it is advisable to damp

the measurement values. Damping is activated in the probe menu

see Probe menu, page 26.

6.6.9. CO2 measurement

• The CO2 probe measures the absolute pressure. The displayed

CO

value is compensated automatically in line with the

2

absolute pressure.

• Due to the sensor, the probe has a relatively high power

consumption. For continuous measurements, use a mains unit

for the power supply.

• To avoid the effects of the CO

probe as far away from your body as possible.

• If sudden changes occur in the concentration, the probe will

require approx. 30 - 60 sec. to adapt to the environment. Gently

waving the probe reduces the adjustment period.

content of respired air, hold the

2

6.6.10. WBGT measurement

Measurement program available as of firmware version

1.05.

Make sure that the specific instrument and cable

temperatures are not exceeded. Extension cables should

be used for high radiation temperatures in particular.

With the WBGT set, the WBGT (Wet Bulb Globe Temperature)

climate index is determined as per DIN 33403 or ISO 7243. The

WBGT index is used to determine the maximum permissible

exposure time at workplaces exposed to heat (e.g. steel industry,

foundries, glass industry or blast furnaces).

41

Page 42

6 Using the product

To calculate the WBGT, 3 different temperatures must be

measured:

• Radiation temperature T

• Ambient temperature T

• Wet bulb temperature T

The calculation is carried out with the following formulas:

WBGT = 0.7 x T

WBGTS = 0.7 x T

Preparing for measurement

✓ Globe thermometer, wet bulb temperature and air temperature

1. Switch the instrument on.

Selecting a suitable measuring point

Performing a measurement

✓ All points under "Preparing for measurement" have been carried

(globe thermometer)

g

a

(temperature of a naturally ventilated

nw

psychrometer)

+ 0.3 x Tg

nw

+ 0.2 x Tg + 0.1 x Ta

nw

probes are connected and mounted on a tripod.

The settings in the measuring point have no effects on the

measurement result.

out.

42

1. Press [].

- Explorer structure is displayed.

2. Select the desired measuring point.

3. [] → New WBGT measurement.

- WBGT measurement is opened.

4. Select ID numbers of the individual probes.

5. Select measuring type and measuring rate.

6. Set criteria for start and end of the measurement.

7. [] → Save and start measurement

During the measurement, the values are calculated from

the current measuring values.

After the measurement, a calculation is carried out based

on mean values.

8. [] → Save and close

- Measurement protocol is saved under the selected measuring

point.

Page 43

6.6.11. PMV/PPD measurement

Measurement program available as of firmware version

1.05.

The PMV/PPD measurement determines the comfort level (PMV =

Predicted Mean Vote) and the relative discomfort (PPD = Predicted

Percentage Dissatisfied) e.g. at workstations and is described in

the ISO 7730.

The mean radiation temperature required for determining

PMV/PPD is calculated in the testo 480 from the measurement

parameters of globe temperature, ambient temperature and air

speed. The formula is based on forced convection and applies to

standard bulbs with 150 mm diameter.

Necessary measuring values

• Mean radiation temperature in °C = t

• Globe temperature in °C = t

• Ambient temperature in °C = t

• Air speed in

m

/s = va

tr = [(tg+273)4+2.5*108*va0.6*(tg-ta)]1/4-273

Factors to be entered

• Clothing

Clothing reduces body heat losses and is therefore classified

based on its insulating value.

The insulating effect of clothing is given in the unit clo or m²

°K/W (1 clo = 0.155 m² °K/W).

The clo value can be calculated by adding together the values

of the individual items of clothing.

Insulating values for individual items of clothing can be found in

ISO 7730.

Alternatively, a clo range can be selected.

6 Using the product

2

r

g

a

2

Only with positive pressures

43

Page 44

6 Using the product

• Activity

Input parameters for clothing

Parameter

in clo

0 – 0.02 No clothing

0.03 – 0.29 0.005 – 0.045 Underwear

0.30 – 0.49 0.046 – 0.077 Shorts and T-shirt

0.50 – 0.79 0.078 – 0.122 Trousers and T-shirt

0.80 – 1.29 0.123 – 0.200 Light business wear

1.30 – 1.79 0.201 – 0.277 Warm business wear

1.80 – 2.29 0.278 – 0.355 Jacket or coat

2.30 – 2.79 0.356 – 0.432 Warm winter clothing

2.80 – 3.00 0.433 – 0.465 Extremely warm winter clothing

The metabolic rate gives the energy released by oxidation

processes in the human body, and depends on muscle activity.

The metabolic rate is given in met or W/m2 (1 met = 58.2 W/m²

body surface area). The average adult has a body surface area

of 1.7 m². In a state of thermal comfort, a person with a

metabolic rate of 1 met has heat loss of approx. 100 W.

When calculating the metabolic rate, a mean value of the

activity of the relevant person affected within the past hour must

be used. Met values for various activities can also be found in

ISO 7730.

Parameter in

m2K/W

Explanation

44

Input parameters for activity

Parameter

in met

0.1 – 0.7 6 – 45 Lying down, relaxed

0.8 – 0.9 46 – 57 Sitting down, relaxed

1.0 – 1.1 58 – 59 Seated activity

1.2 – 1.5 70 – 92 Standing up

1.6 – 1.7 93 – 104 Standing up, light activity

1.8 – 1.9 105 – 115 Standing up, moderate activity

Parameter in

W/m2

Explanation

Page 45

6 Using the product

Parameter

in met

Parameter in

W/m2

Explanation

2.0 – 2.3 116 – 139 Slow walking

2.4 – 2.9 140 – 174 Quick walking

3.0 – 3.4 175 – 203 Strenuous activity

3.5 – 4.0 204 - 233 Extremely strenuous activity

The factors to be entered refer to the ISO 7730 Appendix B

and C.

We recommend using the following probes:

• Globe thermometer (0602 0743)

• Humidity probe (0636 9743)

• Comfort probe (0628 0143)

• Tripod (0554 0743)

Preparing for measurement

✓ Globe thermometer, wet bulb temperature and air temperature

probes are connected and mounted on a tripod.

1. Switch the instrument on.

Performing a measurement

✓ All points under "Preparing for measurement" have been carried

out.

1. Press [].

- Explorer structure is displayed.

2. Select the desired measuring point.

3. [] → New PPMV/PPD measurement.

- PMV/PPD measurement is opened.

4. Select ID numbers of the individual probes.

5. Specify parameters and unit for clothing and activity.

6. Select measuring type and measuring rate.

45

Page 46

6 Using the product

7. Set criteria for start and end of the measurement.

8. [] → Save and start measurement

9. [] → Save and close

- Measurement protocol is saved under the selected measuring

10. The measurement protocol is displayed.

11. [] → Graphic

Graphical representation

1 PPD axis, scale from 0% to 100%

2 PMV axis, scale from -3 to +3

3 Green area of curve from -0.5 to 0.5 PMV

4 Calculated point from PPD and PMV.

5 Critical area of curve

During the measurement, the values are calculated from the

current measuring values.

After the measurement, a calculation is carried out based

on mean values.

point.

46

Formula for display

PPD = 100-95*exp(-0.03353*PMV

4

– 0.2179*PMV2)

Page 47

6.6.12. Saving measurement values

All measurement protocols displayed in Explorer are saved in the

internal instrument memory.

Saving measurement values on an SD card

6 Using the product

1. Insert SD card.

Only SD cards with max. 2 GB space can be used.

2. Select root folder in the Explorer view.

3. [] → Export.

- An export message is displayed.

47

Page 48

6 Using the product

Importing measurement values from an SD card

When importing data from an SD card, all data in the

internal instrument memory is overwritten.

48

1. Insert SD card.

Only SD cards with max. 2 GB space can be used.

2. Select root folder in the Explorer view.

3. [] → Import.

- A list of importable data is displayed.

4. Select the required entry.

- An import message is displayed.

Page 49

6.6.13. Printing measurement values

Selection of the additional information that should be

included on a measurement value printout, see Performing

settings, page 22.

From measuring mode

✓ testo printer (0554 0549) has been switched on.

✓ Required tab has been selected.

1. Align IR interfaces testo 480 and testo printer.

2. Select [] → Print.

- The set measuring view and are displayed.

- Printout of the currently displayed measurement values is

produced.

From the instrument memory

✓ testo printer (0554 0549) has been switched on.

1. Press [].

2. Navigate to the saved measuring protocol.

3. Select [] → Open measurement protocol.

- Measurement data view is opened.

4. Align IR interfaces testo 480 and testo printer.

5. Select [] → Print.

- The printout is generated.

The saved measurement protocols can also be displayed

via the testo EasyClimate software.

6 Using the product

6.6.14. Display measuring values graphically

Measuring values of max. four measurement parameters can be

displayed as a colour graphic over a period of 110 seconds. In the

case of longer time frames, the oldest values are deleted and

replaced by the new ones. The graphic mode is purely a display

mode, i.e. the measuring values cannot be stored.

Selection of the displayed measurement parameters is based on

the display sequence in measuring mode.

• First measurement parameter displayed: red

• Second measurement parameter displayed: green

49

Page 50

6 Using the product

• Third measurement parameter displayed: blue

• Fourth measurement parameter displayed: violet

1. Select the required tab.

> If necessary change the order of the measurement parameters,

2. [] → Graphic mode.

- Graphic mode is activated .

> Exit graphic mode: [] → Graphic mode or [ESC].

as only the first four measurement parameters are displayed.

The values are deleted when switching tabs, however

graphic mode is not terminated. On returning to the tab, the

measurement starts again in graphic mode.

If the values are to be retained after switching tabs, [] →

select Hold .

50

1 Displayed measuring values

2 Graphically displayed measuring value

3 Average, minimum and maximum values since graphic mode

selection

4 Vertical scaling marking (5 seconds)

5 Specific x-axis of the respective measurement parameter in the

same colour as the graphically displayed measuring value

Page 51

6.6.15. Transferring measurement values

To view and evaluate the measurement results on the PC,

you need the testo EasyClimate software.

1. Switch on the testo 480.

2. Connect the instrument to the PC with a mini USB cable.

- Instrument is identified by the PC as a USB mass storage

device. The operating system automatically assigns the

instrument memory a drive letter. This is displayed in Windows

Explorer.

When the instrument is connected to the PC, the

instrument control keys are locked. As soon as the

instrument is disconnected from the PC, it can be operated

again via the control keys.

3. For carrying out an instrument readout via testo EasyClimate

software and processing data, see separate testo EasyClimate

software instrument manual.

6 Using the product

51

Page 52

7 Maintaining the product

7 Maintaining the product

Cleaning the instrument

> If the housing of the instrument is dirty, clean it with a damp

cloth.

Do not use any aggressive cleaning agents or solvents! Weak

household cleaning agents and soap suds may be used.

7.1.1. Battery care

> Charge new rechargeable battery fully before commissioning.

> If possible, always discharge the rechargeable battery and

recharge it fully.

> At low ambient temperatures, the rechargeable battery running

time decreases. This reduces the available useful life.

> Do not store the rechargeable battery for long periods when

discharged. (The best storage conditions are at 50-80 % charge

level and 10-20 °C ambient temperature; charge fully before

using again).

> The rechargeable battery life depends on the storage, operating

and ambient conditions. The available useful life of the

rechargeable battery reduces more and more with frequent use.

If the useful life is significantly shortened, the rechargeable

battery should be replaced.

7.1.2. Carrying out humidity adjustment

In humidity calibration, the measurement parameter of the

connected probe is adjusted to the reference value at the two

standard adjustment points 11.3 % RH and 75.3 % RH and the

deviations between the measuring value and the nominal value are

minimised across the entire measuring range.

The Testo adjustment set provides a reference value to calculate

the offset for a humidity adjustment.

Humidity adjustment is possible with the following probes:

• Humidity probe

• IAQ probe

52

• Thermal air flow measuring head and humidity probe

When a thermal air flow measuring head and humidity

probe is used, the probe must be deactivated before the

adjustment ([] → Switch off flow probe). The probe can

only then be exposed to the reference conditions.

Page 53

7 Maintaining the product

✓ Instrument is switched on and probe is connected.

✓ Probe is already exposed to reference conditions (e.g. salt pot)

for an adequate adjustment time.

• Adjustment time for humidity probe at least 30 min

• Adjustment time for IAQ probe at least 1 h

• Adjustment time for thermal air flow measuring head and

humidity probe at least 3 h

✓ Tab for the relevant probe is activated.

1. [] → Probe menu.

2. Select reference value used (11.3%RH/75.3%RH).

3. [] → Adjustment.

- A pop-up window with the remaining adjustment time is

displayed.

4. [] → End.

- Adjustment menu is closed.

5. Carry out adjustment for the second adjustment point.

53

Page 54

7 Maintaining the product

7.1.3. Carrying out a firmware update

Updated firmware can be installed on the instrument.

A firmware update can also be carried out with testo

EasyClimate.

✓ Instrument is switched on.

1. Download the current firmware file from

www.testo.com/download-center (registration required).

2. Unzip downloaded zip file.

3. Connect the instrument to the PC with a mini USB cable.

- Instrument is identified by the PC as a USB mass storage

device. The operating system automatically assigns the

instrument memory a drive letter. This is displayed in Windows

Explorer.

When the instrument is connected to the PC, the

instrument control buttons are locked. As soon as the

instrument is disconnected from the PC, it can be operated

again via the control buttons.

4. Copy unzipped firmware file and res folder to Update folder.

5. Log out instrument from Windows (safely remove hardware).

6. Unplug USB cable.

7. Switch the instrument off.

8. Switch the instrument on.

- Firmware has been updated.

54

Page 55

8 Tips and assistance

8.1. Questions and answers

Question Possible causes / solution

flashes Rechargeable battery is low.

> Switch to mains operation.

-+++- lights up instead of

the measurement

parameter display

The value is above the permissible

measuring range.

> Keep to the permissible measuring

range.

+---+ lights up instead of

the measurement

parameter display

The value is below the permissible

measuring range.

> Keep to the permissible measuring

range.

- - - - lights up instead of

the measurement

parameter display

Data cannot be copied to

the SD card or imported

from the SD card.

Instrument no longer

responds when a button is

pressed.

Instrument sensor is faulty.

> Contact your dealer or the Testo

Customer Service.

SD card is write-protected.

> Cancel write protection (small

slider control on the SD card).

Internal error has occurred.

1. Hold down [] for >10 sec.

- The instrument is switched off.

2. Switch instrument on with [].

If we could not answer your question, please contact your dealer or

Testo Customer Service. For contact data, see back of this

document or website www.testo.com/service-contact.

8 Tips and assistance

55

Page 56

8 Tips and assistance

8.2. Accessories and spare parts

Description Article no.

System case for comfort level measurement 0516 4801

System case for grid measurements 0516 4800

Tripod for workplace evaluation with holders

for hand instrument and probe; can also be

used as probe extension, e.g. for 100 mm

probe

Connection hose, silicone-free, 5 m, load to

max. 700 hPa

Connection hose, silicone, 5 m, load to max.

700 hPa

Funnel set comprising funnel for disc valves

(Ø 200 mm) and funnel for fans (330 x

330 mm) for supply and exhaust air

Testovent 410, flow rate funnel, Ø

340 mm/330 x 330 mm, incl. case

Testovent 415, flow rate funnel, Ø

210 mm/190 x 190 mm, incl. case

Testo high speed printer with wireless

infrared interface, 1 roll of thermal paper and

4 AA batteries

For a complete list of all accessories and spare parts, please refer

to the product catalogues and brochures or look up our website

www.testo.com

0554 0743

0554 0453

0554 0440

0563 4170

0554 0410

0554 0415

0554 0549

56

Page 57

8 Tips and assistance

57

Page 58

0970 4800 en 04 V01.05 en-GB

Loading...

Loading...