Page 1

testo

testo 454

Data logger

Instruction Manual

testo

454

Logger

testo

0

1

2

3

4

5

6

7

8

9

•

Aus

Off

Ein

On

Enter /

10...14V DC

TESTO

QUALITY

I

S

O

9

0

0

1

c

e

r

t

i

f

i

e

d

Page 2

testo

Contents

1 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Description of instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Keyboard layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Hot keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

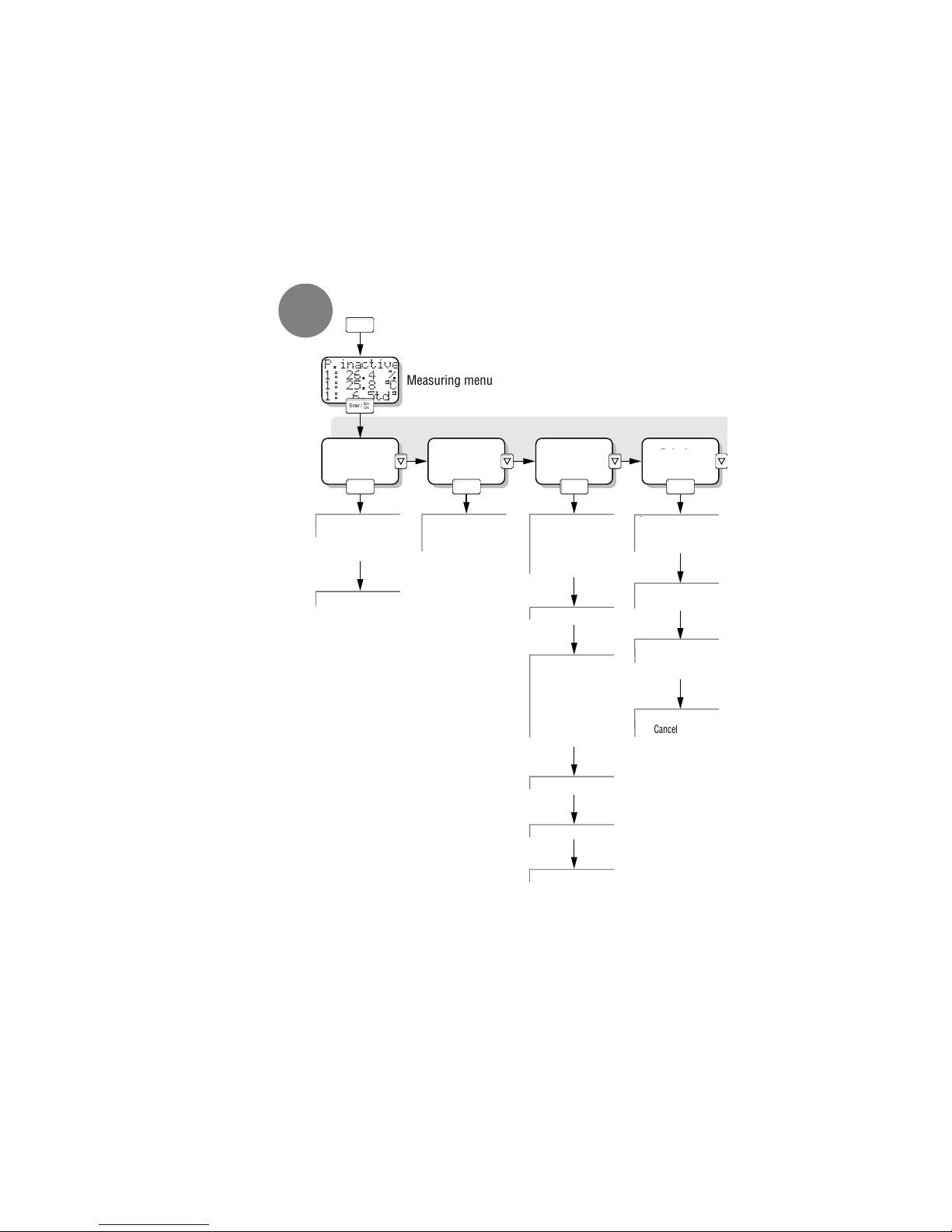

5 Menu overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

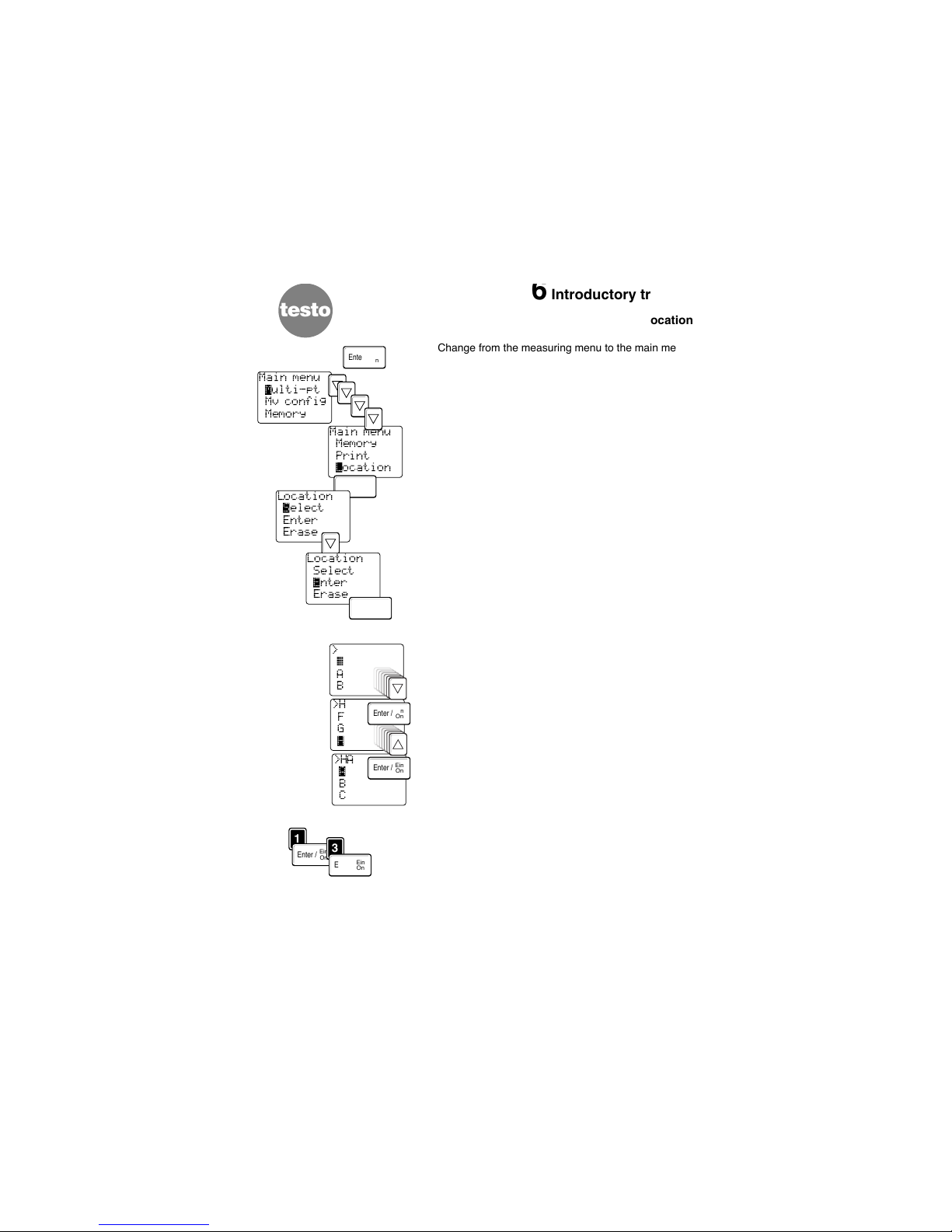

6 Introductory training

6.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

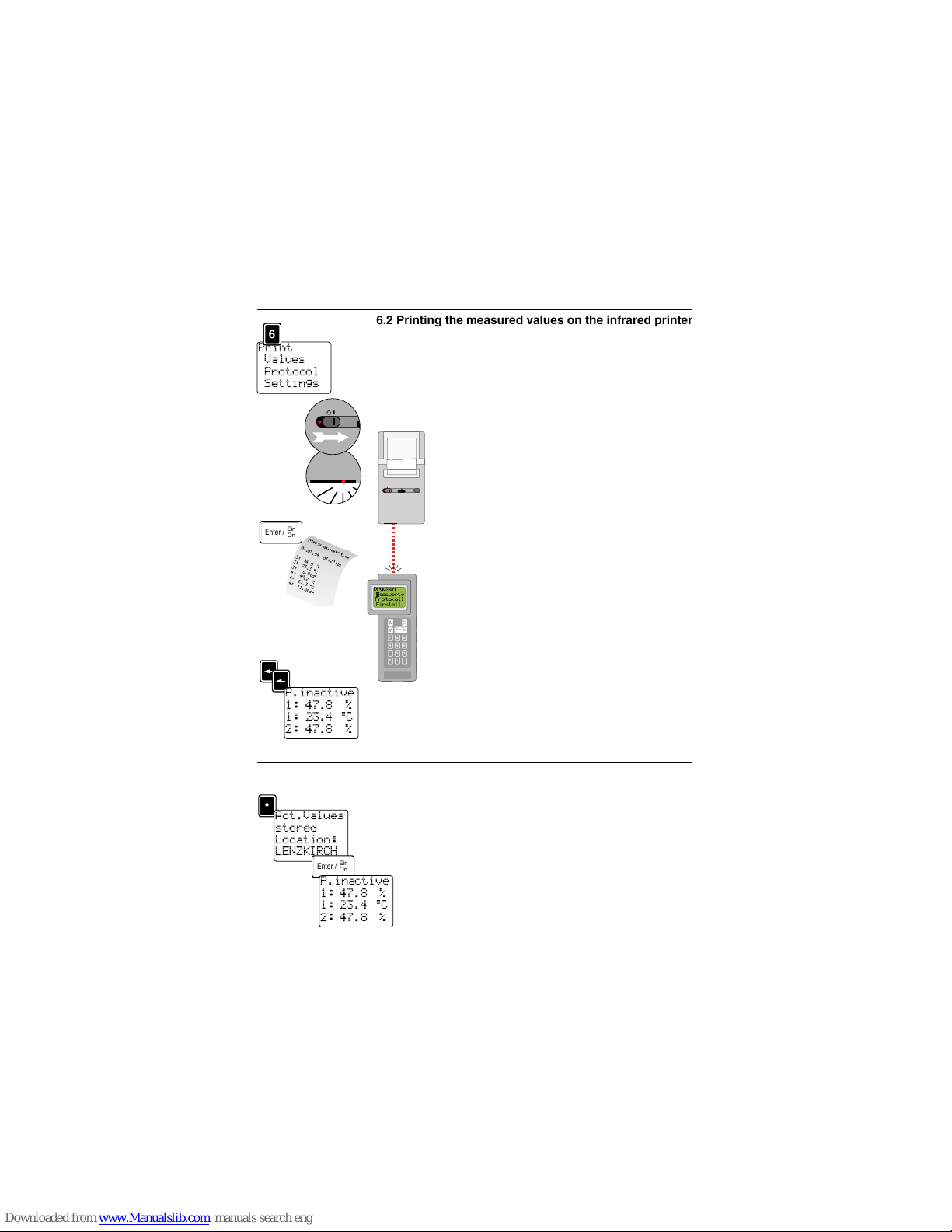

6.2 Printing the measured values on the infrared printer . . . . . 11

6.3 Saving measured values . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.4 Setting up a location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Operating instructions

7.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Main menu

8.1 Averaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.2 Mean value configuration. . . . . . . . . . . . . . . . . . . . . . . 15

8.3 Memory

8.3.1 View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.3.2 State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.3.3 Programs 1 - 3

8.3.3.1 Starting criterium . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3.3.2 Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.3.3.3 Activating duration and program. . . . . . . . . . . . . . . 21

8.3.3.4 Overview of the programming system . . . . . . . . . . 22

8.3.4 Minimimum rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.3.5 Keylock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3.6 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.4 Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.5 Location

8.5.1 Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.5.2 Enter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.5.3 Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.6 Device

8.6.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.6.2 Date/Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.6.3 Rechargeable battery. . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.6.3.1 Notes on battery operation. . . . . . . . . . . . . . . . . . . . . . 25

8.6.3.2 Examples for rechargeable battery lifetime . . . . . . . . . 25

8.6.4 Auto-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.6.5 Intermediate rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.6.6 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.6.7 Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.7 Probes

8.7.1 Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.7.2 Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.7.3 Calibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.7.4 Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.7.5 Discard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.8 Specials

8.8.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.8.2 Flow volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.8.3 Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.8.4 Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2

Page 3

testo 454 -The handy measuring instrument

Nearly all of the probes from the Testo range can be connected to the universal hand-held

instrument. The automatic probe recognition function facilitates quick control measurements. In air conditioning technology several parameters can be quickly measured on

location e.g. temperature, humidity, velocity and pressure. The probe designs are fully

adapted to the respective applications.

testo 454 - The powerful data logger

All of the boundary conditions for an independent long-term measurement are programmable: start of measurement, end of measurement, location name and alarm outputs are

determined by selectable starting criteria. The six freely assignable channels and three

measuring programs make the data logger very versatile. There are various additional special functions available for air conditioning and ventilation technology: averaging, volume

flow display, Pitot tube calculation etc.

testo 454 - Independent application

The rechargeable, environment friendly rechargeable battery makes the user independent

of the power supply. Power can also be supplied from a car battery.

testo 454 - User-friendly operation

The housing is ergonomic and ideal for practical operation and is made of robust ABS.

The large, illuminated display can be easily read and can display three different parameters. The menu-driven user operation via the sealed keyboard makes the instrument easy

to use.

testo 454 - Configuring and data processing on the PC

If a PC and the Comfort software are connected you can take full advantage of the benefits

offered by the data logger. All of the settings in the data logger are prepared first in the PC

and are then loaded into the data logger. Only the measurement is started on the measuring location. The processing of saved measured in the PC is just as uncomplicated as configuring.

Contents

9 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10 Technical data

10.1 Measuring instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2 Infrared printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.3 Comfort software - 454 module . . . . . . . . . . . . . . . . . . . . . 35

10.4 Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.4.1 Connection cables for probes . . . . . . . . . . . . . . . . . . . . . . 40

11 Ordering data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12 Warranty conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Probe description - Measuring technology. . . . . . . . . . . . . Appendix

1Applications

3

Page 4

testo

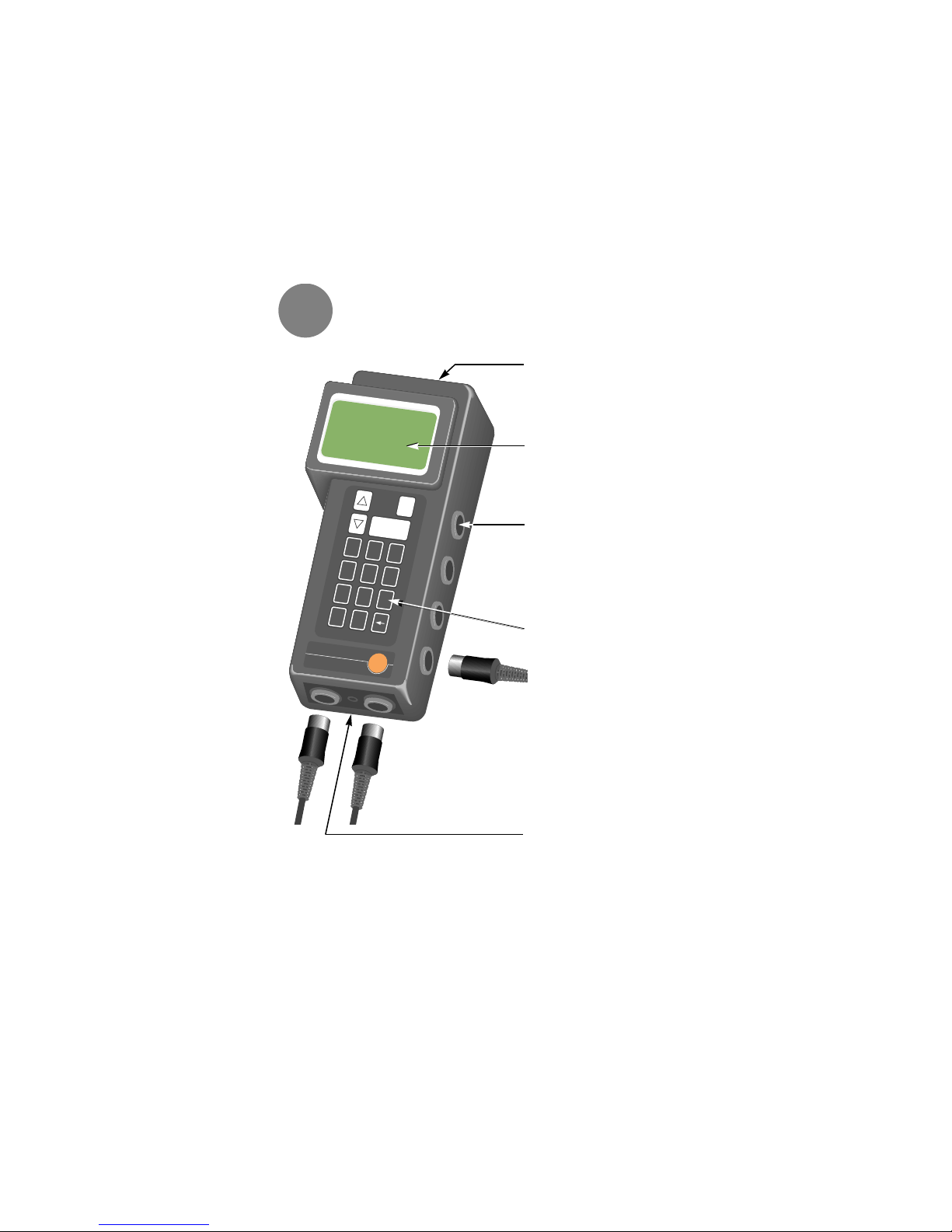

2Description of instrument

4

testo

454

Logger

testo

0

1

2

3

4

5

6

7

8

9

•

Aus

Off

Ein

On

Enter /

10...14V DC

Top of housing

with protective cover for PC interface and alarm/trigger interface.

Display with 4 lines.

6 probe inputs

Assignment is freely selectable,

the instrument recognises the

probes connected by way of a

special code. See label on the

back for socket assignment.

Keyboard

The keyboard commands are

described in the Chapter “Keyboard layout”.

Mains connection

Measuring instrument conforms with

EN 50 082-1 / EN 55 011 Group 1 Class A

Page 5

RS/232 Trigger/Alarm

2Description of instrument

5

Trigger/alarm connection for

alarm/ trigger connection cable

0554.0012

Infrared diode for transferring

data to the infrared printer. The

cover does not need to be

removed before printing.

RS/232 interface for connection

to the PC.

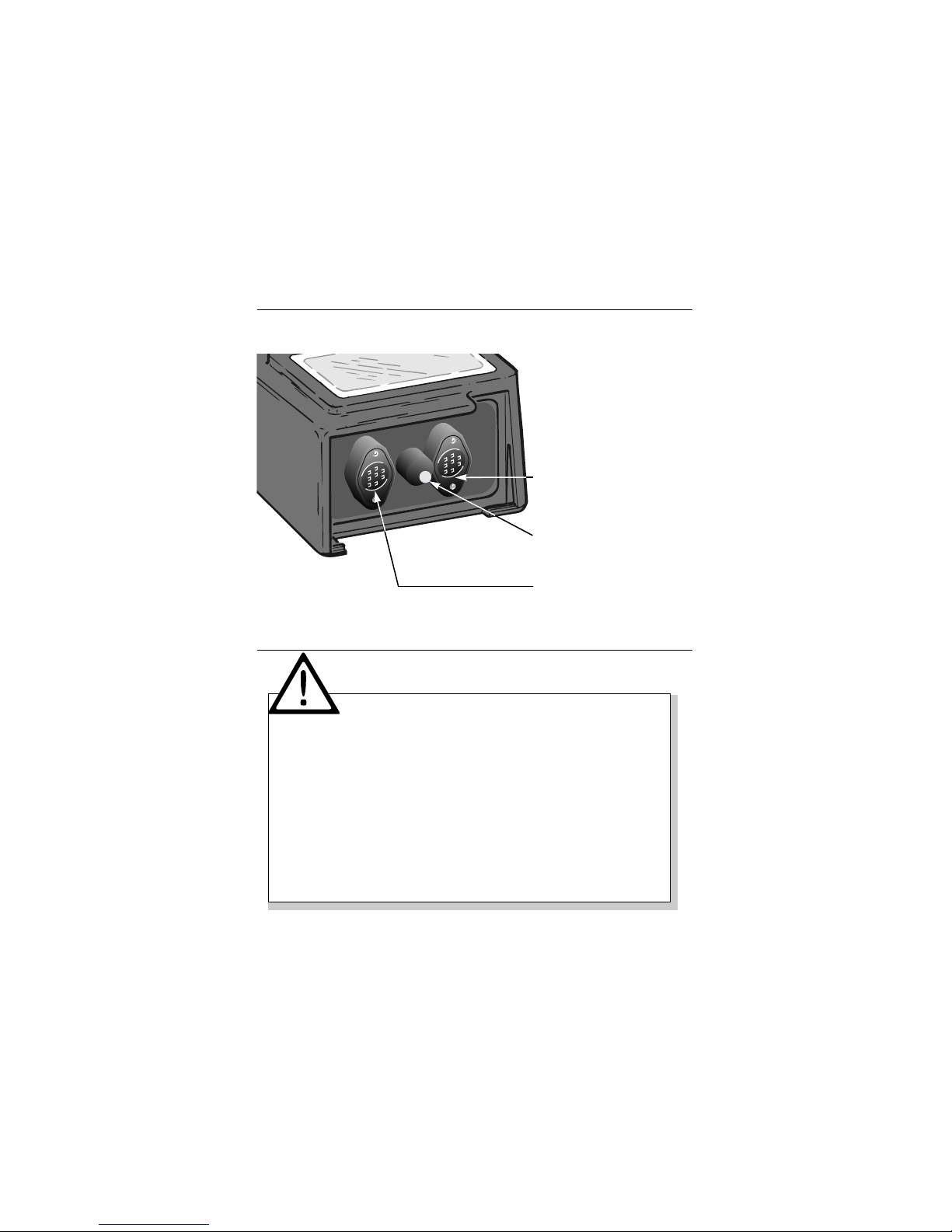

3

Warning

Please read before using instrument

Do not measure on live parts.

Observe permissible storage and transport temperatures and the permissible oper-

ating temperature (e.g. protect measuring instrument from direct sunlight)!

Switch off the instrument when changing the configuration (e.g. probe change, plug-

ging in the V24 cable) because the values specific to the probes can only be read

after the instrument is switched on.

If the instrument is opened, improperly handled or force is used the warranty rights

are cancelled.

In the case of temperature probes which come into contact with metal, there may

be an electric discharge caused by the different potential between metal and the

surface probe. Please apply adhesive tape to the point of measurement during

this type of application. In this way a discharge which could limit the functioning

of the instrument is preventde.

Page 6

testo

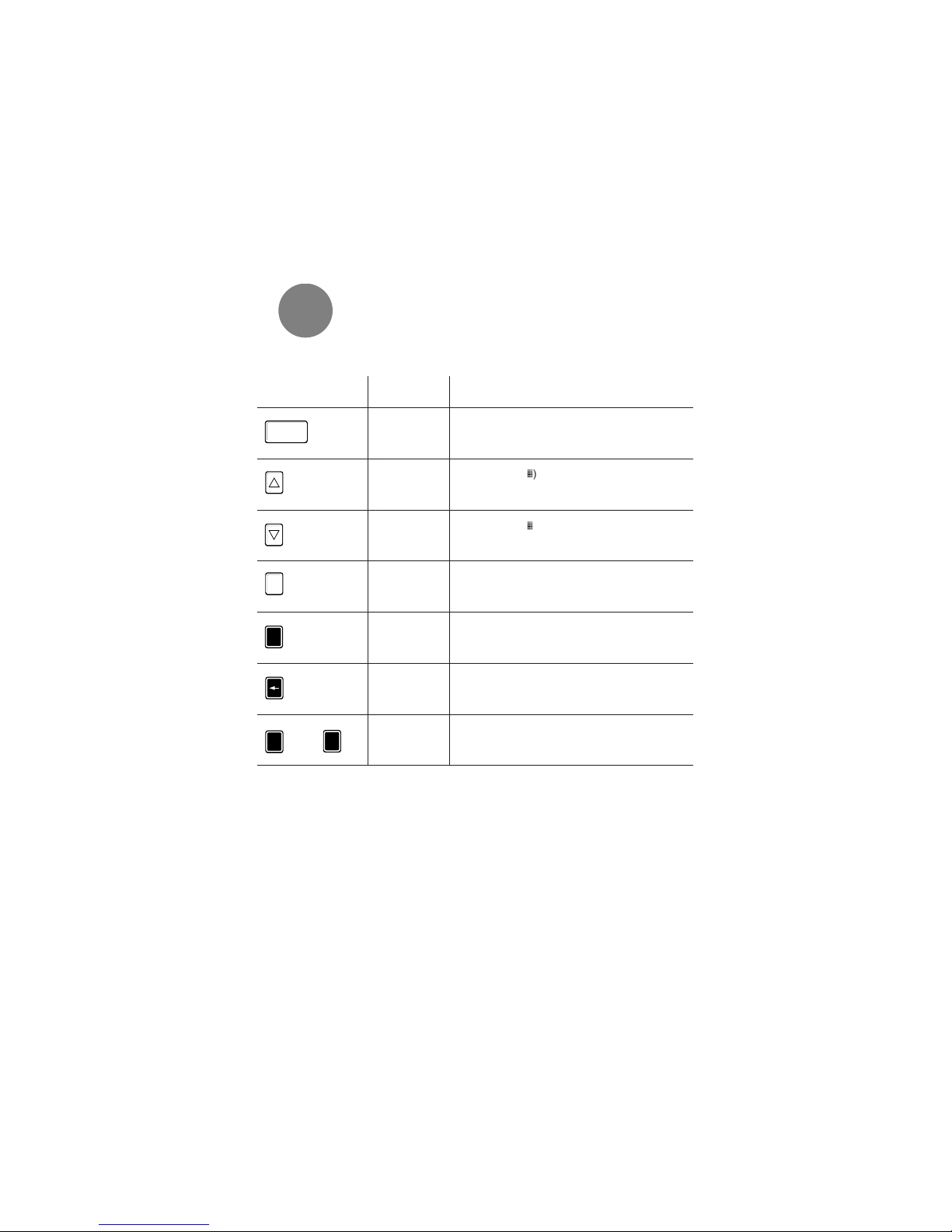

4Keyboard layout

6

Text Function

<Enter> Switches on instrument

Opens selected menu

Confirm entry

<Up> Moves cursor (˛) upward in the display

Scrolls display

Selects letters

<Down> Moves cursor (˛) downward in the display

Scrolls display

Selects letters

<Off> Switches off instrument

<Point> Decimal point

Hot key function

<Arrow> ESC key

Returns to a higher level

Inquiry on the hot key function (in the meas. menu)

<0>…<9> Enters numbers

Hot key function

Ein

On

Enter /

Aus

Off

•

0

9

…

Key

Page 7

Key Text Text in display

Function when key is pressed

4Keyboard layout

7

Backl. (Backlight)

Background light on/off

P1 I/O

Start/stop programming 1

P2 I/O

Start/stop programming 2

P3 I/O

Start/stop programming 3

Location

Selects from list

View

Activates protocol overview

Print

Activates print menu

P1 set

Defines programming 1

P2 Set

Defines programming 2

P3 Set

Defines programming 3

Pkt.Msg (Point measurement)

Files single measuring blocks in the memory.

0

1

2

3

4

5

6

7

8

9

•

<Point>

<0>

<1>

<2>

<3>

<4>

<5>

<6>

<7>

<8>

<9>

Displays version number

•

<Point>+<Enter>

“Zeroizes” pressure probe

Ein

On

Enter /

Ein

On

Enter /

<Up>+<Enter>

Hot key functions are short commands which make it possible to activate submenus directly without having to select them by scrolling through the menu tree. The hot key functions,

marked with black bars ( ), are only active parallel to the measuring menu.

+

+

4.1 Hot keys

Page 8

Multi-pt Mv

config.

Memory Printing

Collecting values and

multi-pt

Select parameter

Set time window

0-> point mv

View

Scroll through

protocol headings

Call up meas. val.

in the memory

Current mv

Display is printed

Mode

Protocol

Protocol selection

Set program

I, II, III

Starting criterion

Rate

Duration

Activate

programs

Settings

Measuring

programs

Minimum rate

Keylock

Reset

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

P.inactive

1: 26.4 %

1: 25.8 °C

1: 6.5td°

Ein

On

Enter /

Measuring menu

Ein

On

Enter /

•

Quit

Main menu

Cancel

Cancel printout

testo

8

8.1 8.3 8.48.2

State

Print

Values

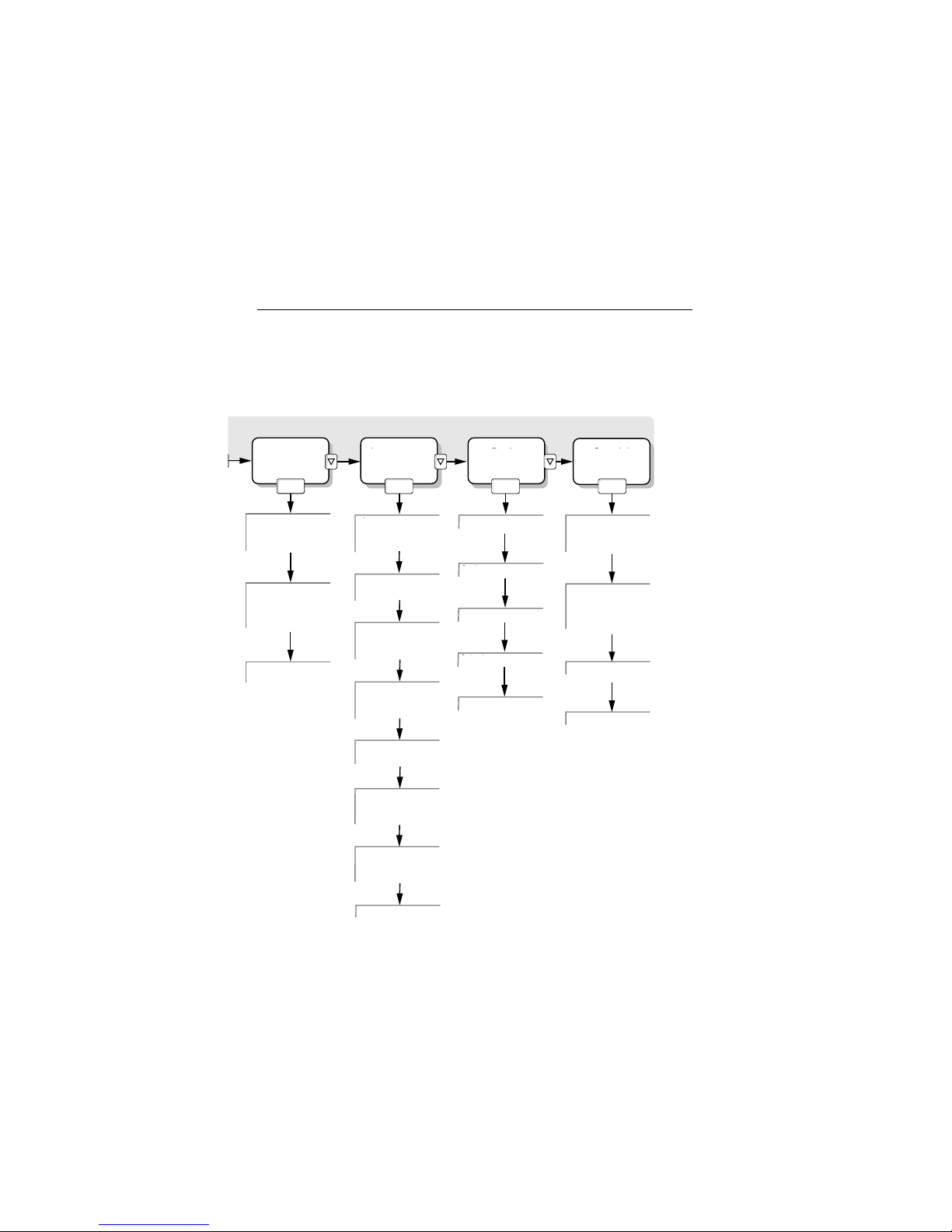

Page 9

Location

Selection

List of locations

Select location

Enter

Enter

number or

capital letters

Erase

Location

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Display

Configure:

select parameters

Unit

Speical function display

Automatic display

of derived values

Volume flow

Rd. cross-section

Sq. cross-

section

Density, manual

Absolute, manual

Date/Time

Displays/Correction

Rechargeable battery

Shows voltage

and capacity

Auto-Off

Activate

Deactivate

Intermediate rate

Enter rate

Alarm I

Configure

Activate

Instrument

Probe

Special

function

Alarm Il

Configure

Activate

Scale

Calibration

Selection

Erase

5Menu overview

9

8.5 8.6 8.7 8.8

Select

Device Probes

Scaling

Calibrate

Adjust

Discard

Specials

Flow volume

Pressure

Page 10

testo

454

Logger

testo

0

1

2

3

4

5

6

9

•

10...14V DC

Ein

On

Enter /

˛˛˛˛˛˛˛˛˛˛

˛˛˛˛˛˛˛˛˛˛

˛˛˛˛˛˛˛˛˛˛

˛˛˛˛˛˛˛˛˛3

P.inactive

1: 47.8 %

1: 23.4 °C

2: 47.8 %

testo

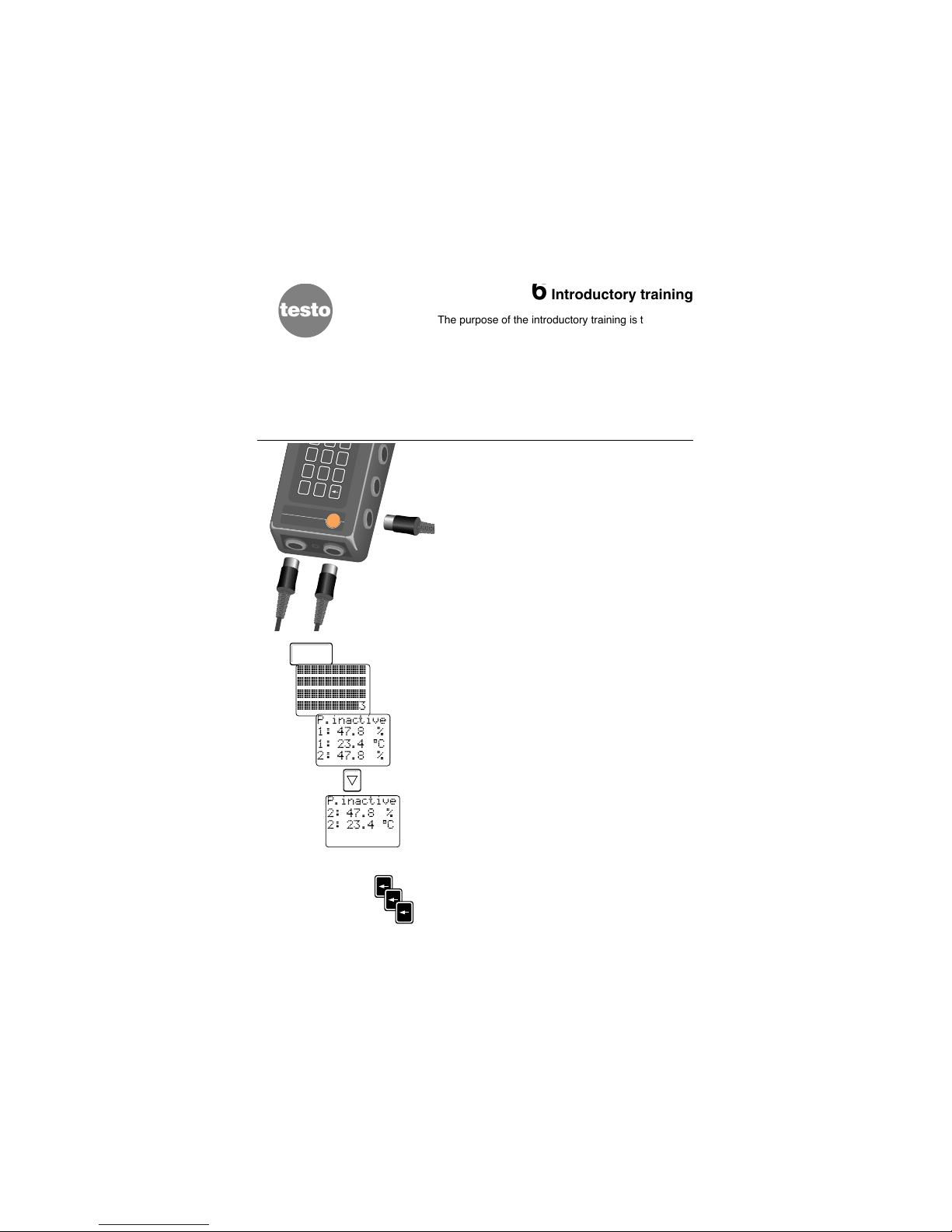

6Introductory training

The purpose of the introductory training is to make

the operation of the instrument easier for you.

Measuring, printing and saving is explained in short,

easy steps.

The functions of the testo 454 are described in

detail in Chapter 8.

Before using the instrument please check if the delivery is complete and undamaged.

6.1 Measuring

Connect one or more probes to the measuring instrument.

Irrespective of which sockets are assigned the measuring instrument recognises which sockets are

assigned and which probes are connected.

It is important that the probes are connected

before the instrument is switched on so that the

instrument can query the probe codes when switched

on.

Now switch on the measuring instrument.

A short function test is conducted. After several seconds the instrument is in the measuring menu and

the first set of information appears in the display.

The code of the respective measuring program is displayed in the top line. “P inactive” means that a

measuring program was not activated (refer to Chapter 8.3.3)

The measured values are shown in the lines below:

• the socket assignment is shown in the left

column

• the measured value is in the middle column

• the unit is in the right column

If you happen to go to the wrong menu when going

through the steps or if you simply do not know how to

proceed press the <Arrow> key several times and

you will return to the next highest menu and back to

the measuring menu.

10

P.inactive

2: 47.8 %

2: 23.4 °C

Page 11

6Introductory training

From the measuring menu go to the submenu “Print”

by pressing the key <6>, selection is on “MEASURED

VALUES”.

Switch on the printer.

Position the printer and the measuring instrument

such that the red control lamp is pointing in the direction of the infrared diode in the testo 454 measuring instrument.

Confirm the menu point selected “PRINT - M

EASURED

VALUES

” with <Enter>.

The printer immediately prints the current measured

values.

Ensure that the infrared connection from the

measuring instrument to the printer is not interrupted during the printing otherwise you may have

an incomplete printout.

Go back to the measuring menu after printing by

pressing <Arrow> twice.

6.3 Saving measured values

Save the current measured values out of the measuring menu via the <point> key.

“Act.Values stored Location: LENZKIRCH” appears

in the display. The location “LENZKIRCH” is set in

the factory. It is possible to change the measuring

location or to set up a selection of different locations

(see next page).

Return to the measuring menu by pressing <Enter>.

11

Print

Values

Protocol

Settings

6

P.inactive

1: 47.8 %

1: 23.4 °C

2: 47.8 %

•

Act.Values

stored

Location:

LENZKIRCH

Messwerte

01.01.94 03:27:18

3: 34.5 %

3: 23.3 °C

3: 6.8td°

4: 48.2 %

4: 23.3 °C

4: 11.8td°

Ein

On

Enter /

Ein

On

Enter /

P.inactive

1: 47.8 %

1: 23.4 °C

2: 47.8 %

0

1

2 3

4

5 6

7

8 9

•

Aus

Off

Ein

On

Enter /

Drucken

µesswerte

Protokoll

Einstell.

6.2 Printing the measured values on the infrared printer

Page 12

Main menu

Memory

Print

¬ocation

>HA

å

B

C

Ein

On

Enter /

>H

F

G

ª

testo

6Introductory training

12

Main menu

µulti-pt

Mv config

Memory

Ein

On

Enter /

Ein

On

Enter /

Location

‚elect

Enter

Erase

Location

Select

™nter

Erase

>

˛

A

B

Ein

On

Enter /

Ein

On

Enter /

1

Ein

On

Enter /

3

Ein

On

Enter /

6.4 Setting up a location

Change from the measuring menu to the main menu

by pressing <Enter>.

Move the cursor to “LOCATION” by pressing <down>

4 times and confirm by pressing <Enter>.

Select the submenu “ENTER” via the <down> key

and activate it by pressing the <Enter> key.

Now enter a location in this submenu with up to 9

characters.

Select letters via <up><down>; the letters confirmed

with <Enter> are written in the top line.

Numbers can be entered directly via the <0…9>

keys.

In order to save the location in the selection the top

line has to be filled right up to the 9th digit (e.g. with

blanks “_” ).

Page 13

6Introductory training

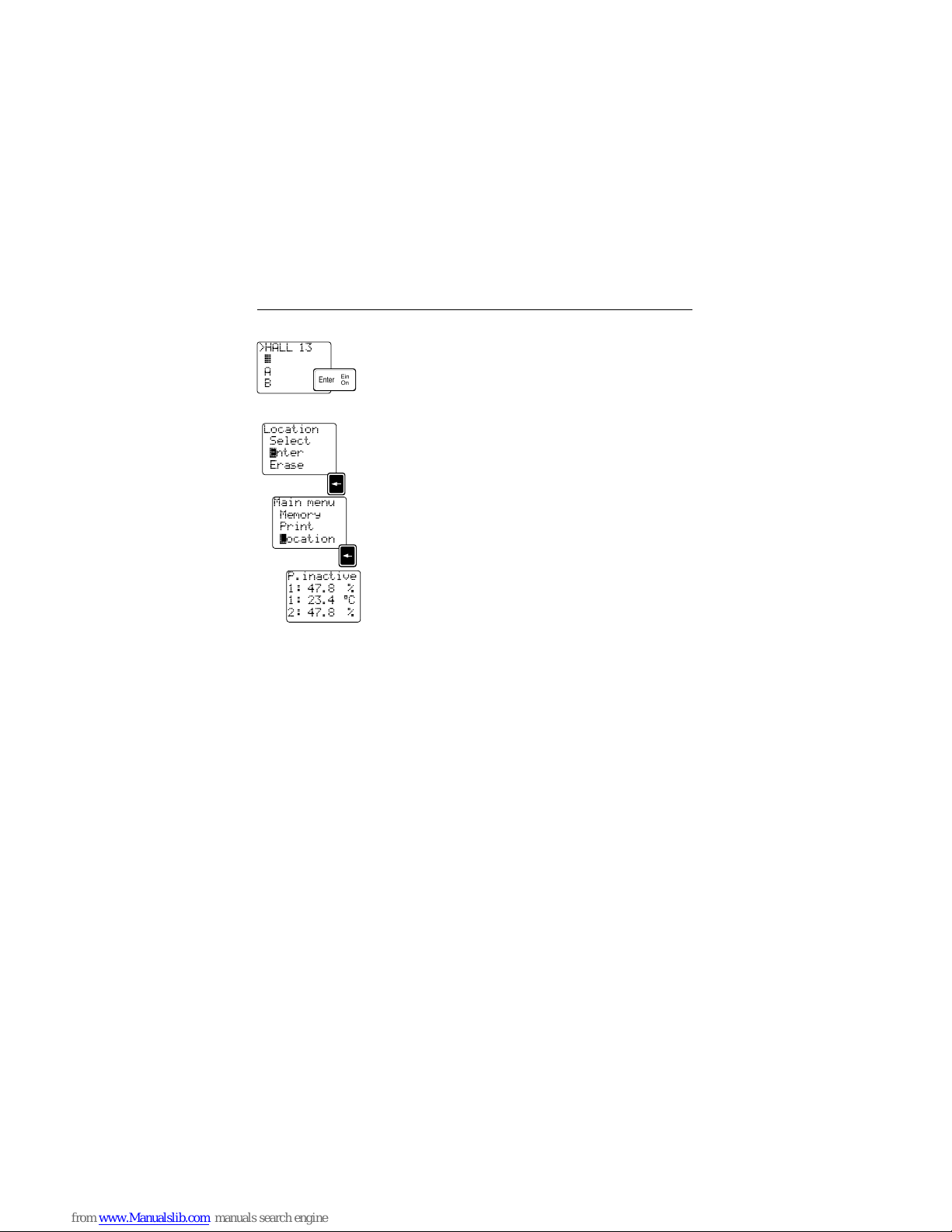

6.4 Setting up a location

Confirm the input location with <Enter>.

You are again in the “Location” menu.

By pressing the <Arrow> key twice you go back to

the measuring menu via the main menu.

13

>HALL 13

˛

A

B

Ein

On

Enter /

Location

Select

™nter

Erase

Main menu

Memory

Print

¬ocation

P.inactive

1: 47.8 %

1: 23.4 °C

2: 47.8 %

Page 14

7Operating instructions

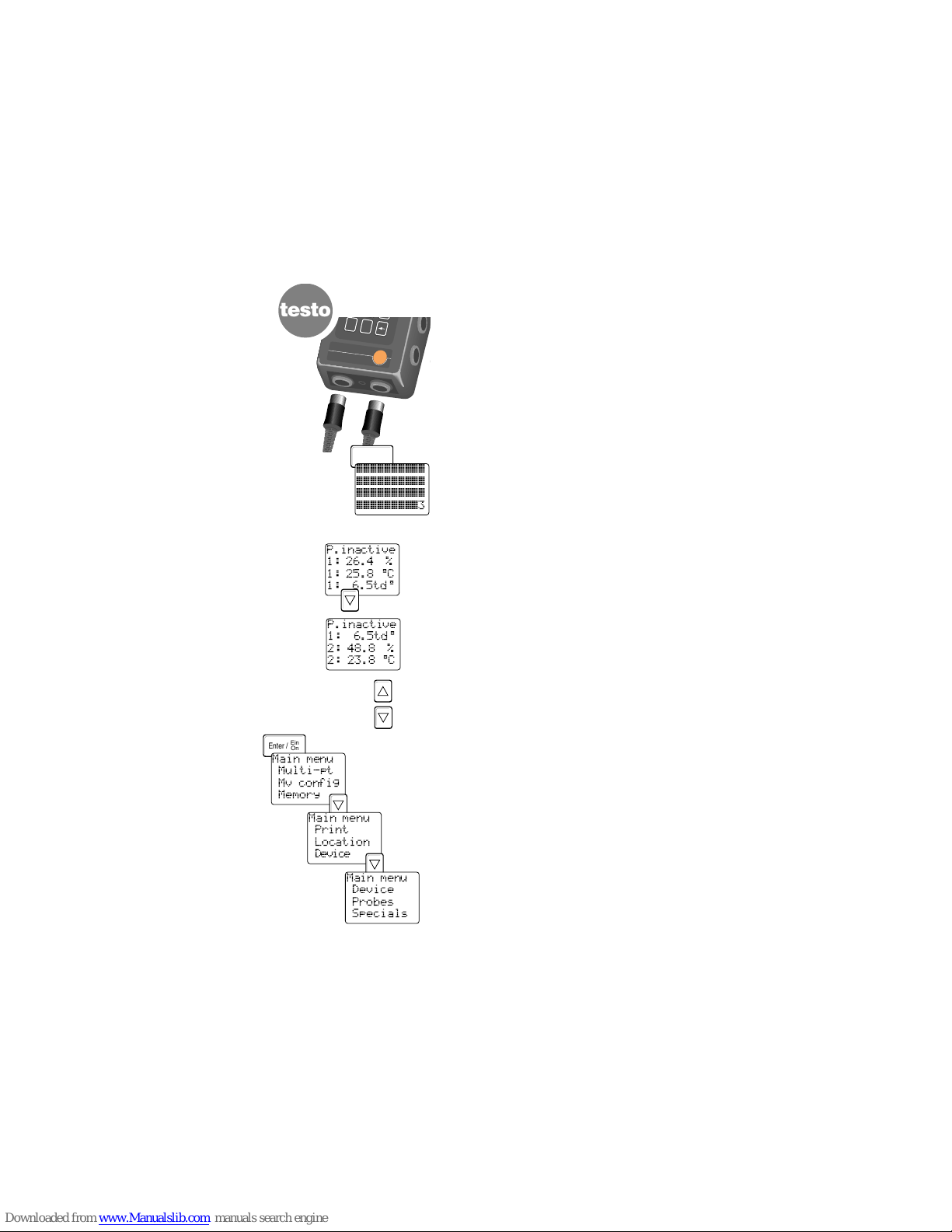

7.1 Measuring

When measuring the probes must be connected

before the instrument is switched on.

Insert one or more probe plugs into the data logger

socket(s). It does not matter which socket you

choose as the data logger recognises the assignment of the input channels and the probes connected.

Switch on the instrument.

A short function test is carried out.

The instrument then goes to the measuring menu.

A 4 line display appears.

The first line shows the program status, in this case

“P. inactive” for program inactive which means that a

measurement is not activated (activated programs

wait on the respective programmed starting criterion,

see Chapter 8.3.3).

The current measured values are shown in the following lines. The input channel (socket no.) is shown

in the left column while the current measured value is

shown in the right column.

Using <up>/<down> the measured values can be

scrolled up and down in the display (if more than 3

are active).

Leave the measuring menu by pressing <Enter> and

change to the main menu.

The main menu includes the following submenus:

Averaging Chapter 8.1

Mean value configuration Chapter 8.2

Memory Chapter 8.3

Print Chapter 8.4

Location Chapter 8.5

Device Chapter 8.6

Probes Chapter 8.7

Specials Chapter 8.8

14

testo

454

Logger

testo

0

•

10...14V DC

Ein

On

Enter /

˛˛˛˛˛˛˛˛˛˛

˛˛˛˛˛˛˛˛˛˛

˛˛˛˛˛˛˛˛˛˛

˛˛˛˛˛˛˛˛˛3

P.inactive

1: 26.4 %

1: 25.8 °C

1: 6.5td°

P.inactive

1: 6.5td°

2: 48.8 %

2: 23.8 °C

Ein

On

Enter /

testo

Main menu

Multi-pt

Mv config

Memory

Main menu

Print

Location

Device

Main menu

Device

Probes

Specials

Page 15

8Main menu

8.1 Averaging

The parameters, taken as a basis when averaging,

are defined by you in the menu point “MV

CONFIG

”.

A measuring rate of 1 second is the basis for averaging. The time is defined in the menu “MV

CONFIG”.

Select “M

ULTI-PT” from the main menu.

Measurement is started via the <Point> key.

The mask gives information on the

- remaining averaging time in seconds,

- number of averagings,

- parameter to be averaged (unit),

- current measured value,

- averaged measured value.

An averaging calculation which has been started can

be cancelled with the <Arrow> key and the measured

values are not saved. When leaving the menu by

pressing <Enter> the individual mean values and the

total mean values are automatically saved as a

protocol with the current location. Saved mean values can be called up in the menu “V

IEW MEMORY”.

8.2 Mean value configuration

Open the “MV CONFIG” menu.

Select a channel (=Parameter) via <up>/<down>.

Confirm with <Enter>, the cursor jumps to the next

line.

Enter the duration of the averaging in seconds (three

digit value e.g.

030

). Confirm with <Enter> and you

return to the main menu.

If you wish to check the entry or take an average

directly move the cursor via <up> to “M

ULTI-PT” and

confirm with <Enter>.

Proceed in the “M

ULTI-PT” menu as described above.

15

Main menu

Multi-pt

Mv config

Memory

Channel

∆1: %

Duration

10 s

Channel

∆2: °C

Duration

10 s

Ein

On

Enter /

Ein

On

Enter /

Channel

K1: %

Duration

˛10 s

Main menu

Multi-pt

µv config

Memory

Channel

K1: %

Duration

125 s

1

2

5

Ein

On

Enter /

Time 5 s

No 2 %

Act 27.7

Mv 26.9˛

Time s

No 0 %

Act 27.7˛

Mv

Ein

On

Enter /

•

.....

Page 16

testo

8.3 Memory

8.3.1 View

All of the completed measuring programs and averages are saved in numerical order.

Via the menu point “M

EMORY: VIEW”

an information mask appears which shows you the

number of protocols (“

PROTOCOLS

”) already available.

In the following masks you will see the protocol headings of the saved protocols:

1st line: - Protocol number and measuring location

2nd line: - Number of measuring channels (Kor

MW

in average protocols

- Number of measured values (W)

3rd line: - Date

4th line: - Time (start of protocol)

Select a heading via the <up><down> keys and call it

up via <Enter>.

The 1st line of the protocol contains information on

the channel and the parameter of the listed measured values. The other channels are reached via

<Enter>.

You can scroll through the measuring protocol to the

last measuring value via <up><down> keys.

You can return to the “M

EMORY: VIEW” menu by

pressing the <arrow> key.

8.3.2 State

Select the “S

TATE ” menu point from the “MEMORY”.

The following display includes:

2nd line: - used kByte

3rd line: - free kByte

4th line: - free memory in %

Your testo 454 has a memory capacity of

224 kByte which corresponds to 110,000 measured

values. Return to the “MEMORY” menu by pressing the

<arrow> key and go to the measuring menu via

<Enter>.

8Main menu

16

Protocol

13

Main menu

Multi-pt

Mv config

µemory

Memory

√iew

State

Prog. I

Memory

√iew

State

Prog. I

1 Testo

12K, 120W

16.03.94

12:01:46

1°C

1 19.2

2 19.2

3 19.2

1°C

2 19.2

3 19.2

4 19.4

2%

1 31.6

2 31.9

3 32.1

2 Testo

MW % 3W

16.03.94

13:25:57

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Memory

View

‚tate

Prog.I

Memory

Used: 9kB

Rem:215kB

Free:93%

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Page 17

8Main menu

8.3 Memory

8.3.3 Programs 1-3

Measurements can be controlled via 3 freely definable measuring/saving programs. The

channel, starting criteria, measuring rate, measurement duration or number of values are

defined in the programs 1-3. The programs are started once the “starting criterion” is fulfilled. The starting criterion is checked at the measuring rate: if a slow rate has been set it

is advisable to set a an intermediate rate when checking the starting criterion (see Chapter

8.6.5). All 3 programs can be started independently of each other, they save all of the connected probe values at the set measuring rate. “Programming 1” can be taken as an example for all 3 programmings.

17

Example 1: Measurement with activated “Program 1”, Starting criterion: “Overrun”

Example 2: Measurement with two activated programs (Prog. 1 and Prog. 2),

Starting criteria: “Exceeding”

Display, channel 1

Display, channel 1

Time

Time

Limit value of

starting criterion

”Exceeding”

Limit of starting

criterion

“Exceeding”

Prog. 2

Limit of

starting criterion

“Exceeding”

Prog. 1

Prog.1

active

Prog. 2

active

Start of program 1 when

the programmed starting

criterion is entered

xxxxx =

Checking the

starting criterion

at a quicker rate

(“Device” menu,

“Intermediate

rate” submenu)

End of program 1, the starting

criterion is lifted

The program can be ended prematurely via “Measuring rate” or

“Number of values

Progression of parameter at channel 1

Progression of parameter at channel 1

x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

Prog.1

active

Changing measuring rate e.g. high

resolution in critical areas

Data acquisition corresponding to the

“Measuring rate”

Page 18

testo

8 Main menu

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Memory

View

State

πrog.I

Prog.Start

Ext.Signa

Prog.Start

Time

02.06.93

12:23:47

Prog.Start

Overrun

K1: %

+ 50.00

Prog.Start

Underrun

K1: %

+ 50.00

Prog.Start

Gradient

K1: %

5.00

8.3 Memory

8.3.3.1 Program starting criterion

Select a starting criterion:

External signal

The starting command is triggered when an external

voltage signal is input. Please use the lead

0554.0012 (See Ordering data) when inputting an

external voltage signal. In the case of a trigger circuit

the limit values of the trigger input must be adhered

to (Refer to Technical data). The trigger input in

testo 454 is electrically isolated from the other

circuit.

Time

The program start is made dependent on the date

and time. If the instrument is switched off the start is

delayed by approximately 5 seconds until the instrument has completed the function test and probe recognition.

Overrun

Saving begins when the measured value of a parameter, defined by you, overruns on a channel specified

by you. An intermediate rate is recommended to

check the starting criterion frequently (see Chap.

8.6.5).

Underrun

Saving begins when the measured value of a parameter, defined by you, underruns on a channel specified by you. An intermediate rate is recommended to

check the starting criterion frequently (see Chap.

8.6.5).

Gradient

The program is started once the measured value of a

specified parameter in the defined channel changes

quicker than that of the limit value defined by you.

The specified value refers to:

∆ t = 1 s

The display opposite means that

the program is started when the measured value

changes by more than 5 %RH in 1 second.

Difference

When the differential value (of a parameter) in two of

the channels specified by you is overrun measurement is started. If, for example, the temperature of

K1 is 50 °C below that of K2 the program is started.

∆ <w>

∆ t

Programm

Rate

˛1s

Prog.Start

Difference

K2: °C -K1

25.00

Ein

On

Enter /

18

Page 19

8 Main menu

8.3 Memory

Note on the differential trigger programming in

combined probes:

If combined probes are used for the starting criterion

“Difference” there is not enough space in line 3 of the

display to show clearly the channel and the parameter.

In the 3rd line of the display opposite only “K2”

appears at the end of the line. The parameter is allocated correctly by numbering the key confirmations

of <up> <down>.

The confirmation of a starting criterion via <Enter>

triggers a jump to the"PROGRAM RATE" parameter.

Prog.Start

Difference

K2: °C -K2

10.00

19

Note:

The program end criterion is delayed in relation

to the programmed start limit value (hysteresis):

the program continues saving for a short time

even though the programmed limit value is no

longer overrun.

Page 20

testo

8.3 Memory

8.3.3.2 Rate

Specify the rate at which the measuring instrument

should save the probe data during this measurement.

Entries from 0.1 seconds to 24 hours are possible.

Seconds can be given in fractions. Minutes and hourly rates are usually whole numbers. All values are

saved according to the probes connected.

8Main menu

20

Program

Rate

˛1s

Ein

On

Enter /

Please note that some measuring time must be

allowed for each connected probe since the sockets

must be serially checked.

The probe with the longest measuring time

defines the minimum measuring rate.

The following is the time required for each probe:

Hum. probe °C/%RH w. dew-point .0.3 seconds

Vanes . . . . . . . . . . . . . . . . . . . . . . . .0.7 seconds

Shell anemometer . . . . . . . . . . . . . .2.2 seconds

Frequency sources . . . . . . . . . . . . .0.7 seconds

Pt100 probes . . . . . . . . . . . . . . . . .0.1 seconds

Other . . . . . . . . . . . . . . . . . . . . . . . .0.2 seconds

In the menu MIN.RATE (See Chap. 8.3.4) the shortest measuring rate depending on the probes connected can be checked.

0

Page 21

8.3 Memory

8.3.3.3 Activating duration and program

By confirming the input "PROGRAM RATE

"with <Enter>

you will go to the input mask "P

ROGRAM DURATION

".

You have 3 ways of defining the program duration:

1) as a time range (=“Duration”)

2) as a “# of values”

3) as an “Open End” measurement i.e. the measure-

ment runs until the memory is full or crashes.

If the trigger function refers to measured values, the

number of saved values can be lower than the number

of values programmed to be measured. Cause: the program running was prematurely interrupted because of

the following:

- a second activated program has been

started or

- the starting criterion for the current

program has not been fulfilled.

Confirm your entries with <Enter>.

To activate the program, switch the display

“activ.off” to “activ.on” via <up> <down>.

The program can be activated at any time.

When confirmed with <Enter> the measuring instrument takes over programming and goes back to the

"MEMORY" submenu.

8Main menu

21

Program

∂uration

0 sec

activ.off

Program

# of val.

activ.off

Program

øpen End

activ.off

Program

Open End

Å

activ.off

Program

Open End

active.øn

Memory

View

State

πrog.I

A.P:1e

1: 24.4 %

1: 22.5 °C

1: 1.3td°

Ein

On

Enter /

Ein

On

Enter /

•

Page 22

testo

8.3 Memory

The active programmings are indicated in the measuring menu. The first line in the example opposite

displays the following code:

A

= active,

P:1

= Program 1, e= start crit. extern. signal

A

= Active

P:1 - P:3

= Active program 1 - 3

e

= External trigger / external signal

t

= Time trigger / time plan

w

= Value trigger / Overrun/Underrun etc.

w

= Difference

w

= Gradient

P.2:321:

= Program 2 is running, 321 values are

currently saved (in this protocol)

You can start the following from the measuring menu:

- program 1 with <1> key

- program 2 with <2> key

- program 3 with <3> key.

8.3.4 Minimum rate

The “M

IN. RATE ” menu shows the specified minimum

rate of the probes connected. This value cannot be

underrun when programming the instrument.

Select “M

IN.RATE ” from the memory menu list and

confirm with <Enter>.

8Main menu

Memory

øn.rate

Keylock

Reset

Min.rate

0.4 s

Ein

On

Enter /

Ein

On

Enter /

8.3.3.4 Overview of the programming system

22

A.P:1e

1: 24.4 %

1: 22.5 °C

1: 1.3td°

Function required Here´s how....

Start program with instrument - Select program

switched on - Switch off Auto Off function (See

Chapter 8.6.4)

- Check charge in rechargeable batteries or

connect mains unit

Start program with instrument

switched off

Starting criterion: Time plan or trigger - Carry out settings

- Switch off instrument

Starting criterion: Overrun/underrun - Set limit values and parameter

or gradient or difference - Set and activate intermediate rate

- Switch off instrument

Note: Activated measuring programs (P1 – P3), which take measured values as the basis

for starting criterion, are executed with the instrument switched off only if the intermediate

rate and the measuring rate are set at more than 1 minute. For rates of less than 60 seconds the instrument must be switched on to start the measuring program. The Auto-Off

function then has to be deactivated.

Page 23

8.4 Printing

Via the print menu you can control whether you wish

to print the following:

- current measured values

- a particular protocol

- activated settings with reference to

Programming I, Programming II,

Programming III, Alarm 1 or Alarm 2

Before operating the printer please read the

enclosed Instruction Manual.

If “CANCEL” is selected the instrument completes the

current (processed internally) block and printing is

stopped after max. 10 lines.

8Main menu

23

Print

Values

Protocol

Settings

Values

01.01.94 03:27:18

3: 34.5 % 3:

23.3 °C 3:

6.8td°

4: 48.2 % 4: 23.3

°C 4: 11.Std°

Print

Values

∏rotocol

Settings

Protocol

11 Shaft 7

3K, 15 W

13.12.93 10:00:00

13.12.93 10:00:00

%RH °C td°

1 33.6 20.4 3.9

2 33.6 20.4 3.9

Print

‚ettings

Cancel

Settings

Prog.Start 1

Ext.Signal

Rate:0.50 s

# values:100

Prog.Start 2

Ext.Signal

Rate:1.00 sec

# values:150

Memory

Min.rate

Keylock

®eset

Memory

Min.rate

∆eylock

Reset

Keylock

off

Keylock

on

Memory

Min.rate

Keylock

®eset

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Reset

Erases

everyth.

OK

Ein

On

Enter /

8.3 Memory

8.3.5 Keylock

In this submenu the hot key function for the keys

<1>,<2> and <3> can be switched on or off which

means that when the keylock function is switched on

it is not possible to activate a program from the

measuring menu via the keys <1>,<2> and <3>.

8.3.6 Reset

Beware. Overrun

Using this command you can erase the complete

data memory. It is not possible to delete selected

protocols. Configuration, measuring programs etc.

remain.

Select the submenu “R

ESET” from the menu “MEMO-

RY

” and press <Enter>. The whole memory is

erased.

You then return to the “M

EMORY

” menu.

During the inquiry “

RESET, ERASES EVERYTH., OK” it is

possible to cancel the process with the <Point> key.

Page 24

Device ...

∂isplay

Date,Time

Rech.bat

Display

˛1:K1: %

2:K1: °C

3:K2: %

˛1 :K1: %

Min off

Max off

AVG

1 :K1: %

Min øff

Max off

AVG

1 :K1: %

Min øn

Max off

AVG

1 :K1: %

Min on

Max øff

AVG

Display

1:K1: %

˛2:K1: °C

3:K2: %

testo

8Main menu

8.5 Measuring location

8.5.1 Selection

Via the <up>/<down> key select the location relevant

to the measurement from the locations saved here

and confirm via <Enter>.

The selected designation is saved with the measured

values. The latter appears on printouts from the infrared printer and in the protocol head (Refer to the

Chapter 8.3.1 “Memory: View”).

8.5.2 Enter

Select “L

OCATION-ENTER”.

Select a letter via the <up><down> keys and confirm

via <Enter>. The numbers can also be entered (e.g.

“

HALL 3

”). The line must be filled right to the end

(e.g. B. with blank). This is the only way to complete

the entry before returning to the “L

OCATION

” menu.

The location entered is now available via

“S

ELECT

”.

8.5.3 Erase

In order to maintain an overview it is possible to

erase entries. Select the location which you want to

erase via the <up>/<down> key and press <Enter> to

confirm.

8.6 Device

8.6.1 Display

The display contains the current measured values of

the connected probes. In addition to the measured

values the minimum, maximum and mean values can

be displayed.

Once you have selected the submenu “D

ISPLAY” from

the “D

EVICE” menu you can look for the respective

channel and the required parameter via the

<up><down> keys. Confirm the selection via

<Enter>.

With <Enter> you also select “M

IN”, “MAX” and/or

“AVG”, switch the display “on” or “off” with

<up><down>.

This setting depends on the constellation and is lost

when the instrument is switched off.

Go from the “Display” menu back to the “Device”

menu by pressing <Arrow>.

24

Location

‚elect

Enter

Erase

Location

Select

™nter

Erase

Location

Selection

Enter

™rase

>

_

A

B

Locations

Testo I

Testo II

Locations

Testo I

Testo II

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

...

...

Ein

On

Enter /

Page 25

8.6.3.1 Notes on battery operation

- In order to protect the instrument from total discharge when not operating connect it for one

day a month to the mains unit.

- If “Emergency” is displayed, a one-minute refresh cylce takes place which regenerates the

run down rechargeable battery. The red LED lights up in the battery charger. If the cycle has been

successfully completed “Charge quickly” appears in the display. If the refresher impulse was

insufficient the procedure can be repeated by switching the mains unit on and off with the instrument switched off. If the instrument does not go into the fast recharging mode the rechargeable

battery is defect. In order that the complete battery capacity is available the recharging cycle

should be repeated 2 - 3 times following total discharge.

- A recharging cycle takes approx. three hours and is displayed by the instrument by going from

“Quick” to “Conserve”. The compensation charge fills the rechargeable battery completely.

- The charge is active if testo 454 if switched off and the mains unit is connected or if the mains

unit is connected when the instrument is switched off.

- If the mains unit is plugged out during rapid recharging the instrument deactivates itself within one

second. Deactivation can take two minutes in the conservation mode.

- Long-term measurements should be started with a newly charged battery.

- The capacity of the rechargeable battery is correctly displayed in the instrument menu 4 hours

after charging.

- The operating limits of the rechargeable battery are shown with ”LowBat” or ”TempOut”.

8.6.3.2 Examples of the service life of testo 454

The service life depends on the probe assignment and the measuring rate. The following is a list of

typical examples which influence the service life of the rechargeable battery.

8Main menu

8.6 Device

8.6.2 Date/Time

Enter the date in the format DD:MM:YY, the time in

the format hh:mm:ss.

Confirm the entry of the numbers with <Enter>.

8.6.3 Rechargeable battery

The battery charge is shown by the voltage available,

instrument temperature and the capacity of the

rechargeable batteries (

ччччч

= Battery charged).

25

Device...

Display

∂ate, Time

Rech.bat

Ein

On

Enter /

Device....

Display

Date,Time

®ech.bat

Accu

Volt:8.5V

Tem: 26°

Cap:ччччч

Ein

On

Enter /

Date/Time

“¡.03.94

11:18:06

2

2

Ein

On

Enter /

Date/Time

22.≠¶.94

11:18:06

2

2

Ein

On

Enter /

Connection Warm up time Meas. rate Service life

approx.

1 x thermal anemometer (70 mA) 20 s 30 min 5.0 days

6 x thermocouple None 30 min 15 days

1 x thermal anemometer (70 mA) 20 s 10 min 2.7 days

1 x digital humidity (10 mA) 2 s 10 min 9.0 days

Page 26

testo

8Main menu

8.6 Device

8.6.4 Auto-Off

The instrument automatically switches off after 10

minutes when not used if the Auto-off function is on.

This helps to save the batteries and hence the

environment. Key confirmations, serial communication, measuring programs with a measuring rate of

less than one minute which have been already started keep the instrument “awake” and it is not switched

off automatically.

Note: Activated measuring programs (P1 – P3) which

take the measured values as a basis for the starting

criteria are only executed if the intermediate rate and

the measuring rate are set at longer than 1 minute.

For rates less than 60 seconds the instrument should

stay switched on in order to start the measuring program. The Auto-Off should then be deactivated.

Make sure to switch off the instrument when you

are not using it and the auto-off function is off.

8.6.5 Intermediate rate

Indicate the time intervals within which the measuring

instrument has to check the conditions for a measurement (program start at overrun or underrun of

measured value or gradient). If you do not activate

this input the instrument only checks the conditions if

switched on or if the running program is at the set

measuring rate. This input is valid for all programs

and alarms.

Note: Intermediate rates in the seconds range are

not possible if the measuring rate is > 50 min i.e. the

minimum intermediate rate is 1 min.

26

Ein

On

Enter /

Device...

Date,Time

Rech.bat

åuto-Off

Power off

10 min

later

øff

Power off

10 min

later

øn

Ein

On

Enter /

Device...

Rech.bat

Auto-Off

⁄m. rate

Device

Rech.bat

Auto-Off

⁄m. rate

Interm.

rate

˛ 1 sec

activ.off

Interm.

rate

002 ˛

activ.off

Interm.

rate

002 ˛in

activ.off

Interm.

rate

002 min

activ.˛ff

Interm.

rate

002 min

activ.on

0

6

6

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Page 27

8Main menu

8.6 Device

Select an alarm criterion:

Overrun

The alarm is triggered when the parameter measured

value, defined by you, overruns on a specified channel. An intermediate rate is recommended to check

the alarm criterion frequently (see Chapter 8.6.5).

Underrun

The alarm is triggered when the parameter measured

value, defined by you, underruns on a specified

channel. An intermediate rate is recommended to

check the alarm criterion frequently (see Chapter

8.6.5)

Gradient

The alarm is triggered once the measured value of a

specified parameter in the defined channel changes

quicker than that of the limit value defined by you.

The specified value refers to::

∆ t = 1 s

Difference

When a differential value (of a parameter) in two of

the channels specified by you has been overrun the

alarm is triggered.

Confirm your selected alarm criterion with <Enter>.

27

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Device

Auto-Off

Im.rate

ålarm I

Alarm off

øverrun

K1: °C

+123.4

Alarm off

©radient

K1: °C

15.00

Alarm off

∂ifference

K1: °C-K1

38.00

Alarm off

¨nderrun

K1: °C

+123.4

∆ <w>

∆ t

8.6.6 Alarm

testo 454 offers two alarm outputs whose trigger criteria, separated from each other, can

be defined in the menu “D

EVICE”, submenu “ALARM”. The alarm is controlled when the

measuring program is running or not running. The alarm outputs are electrically isolated

from the usual wiring parts in the testo 454 but are connected to one another.

Please use the cable 0554.0012 available as an accessory. The alarm output is switched

through and remains active as long as one of the following alarm criteria applies. The gradient is the exception which remains active if once activated and can only be switched off

manually (“Alarm off”).

Page 28

Alarm off

Overrun

˛2:m/s

+35.00

Alarm off

Overrun

K2:m/s

+˛5.0

Alarm off

Overrun

K2: m/s

˛32.0

Alarm øff

Overrun

K2: m/s

+32.00

Alarm øn

Overrun

K2: m/s

+32.00

testo

8Main menu

8.6 Device

After having confirmed your alarm criterion select the

channel required and the respective measuring units

using the <up>< down> keys. Confirm your input by

pressing <Enter>.

Enter the limit required in the bottom line and confirm

by pressing <Enter>.

Set the top line to “Alarm on” via <up><down> and

confirm with <Enter>. You then return to the

“DEVICE” menu.

The example opposite is representative for all alarm

criteria.

The alarm remains active for as long as the measured value fulfills the alarm criteria selected.

The settings in the “Alarm 1” and “Alarm 2” settings

remain even after the instrument has been switched

off.

8.6.7 Units

Converting the units:

°C

{ °F

hPa { inW (inch Water column)

m/s { fpm

With <Enter> you can choose the parameters in the

menu “U

NITS”. Change the unit with <up><down>

(see above).

Quit this menu by pressing <Enter>.

These settings apply to all channels and remain set

after switching off the instrument.

28

Device

Alarm I

Alarm II

¨¨nits

Ein

On

Enter /

Units

˛C

hPa

m/s

Ein

On

Enter /

Units

°C

ÓPa

m/s

Units

°C

ÛnW

m/s

Alarm off

Overrun

˛1: °C

+123.4

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Device

Auto-Off

Int. rate

ålarm I

(Select “+” or “–”)

Ein

On

Enter /

Page 29

8Main menu

8.7.1 Unit

The probe prepared with the current/voltage cable is

connected to the measuring instrument. The measuring range has to be set in the current/voltage cable

before the instrument is switched on. Please observe

the permissible measuring ranges.

Select the unit of your probe in the “P

ROBES” menu.

Go back to the “PROBES”menu.

8.7.2 Scaling

In the menu “Scaling” you can change or enter the

upgrade and the offset of a probe manufactured by

another company or of a measuring transducer. The

entry of A1 and AO is based on the formula

f(x) = A1 *x + AO

A1 is the upgrade and A0 is the offset from the zero

point. The + or - signs can be changed via

<up><down> and confirmed with <Enter>. Then

enter the respective numerical value and confirm

your entry with <Enter>.

Return to the “P

ROBE” menu via <Arrow>.

8.7.3 Calibration

Calibration is possible in this menu point if CO

2

probes are available. Please note the probe description.

29

Probes

¨¨nit

Scaling

Calibrate

Probes

Unit

‚caling

Calibrate

Probes

Unit

Scaling

çalibrate

Unit

K1: %

Units

°C

°F

%

8.7 Probes

Probes other than Testo probes which have a voltage output of 0 to 1 V or a current output

of 0/4 to 20 mA can be connected to the testo 454. The current/voltage cable no.

0554.0007 is offered for this. This cable is equipped with an automatic recognition of the

respective input signal, so that you can assign a unit and a scaling to this signal (as

described below in the “UNIT

” menu).

There is also the possibility to measure voltages, frequencies and resistances with the

adapter cable no. 0554.0013. These parameters are not automatically recognised and

have to be preprogrammed in the menu “S

ELECT”.

Ein

On

Enter /

Ein

On

Enter /

Scaling

K1: %

K1: %

A1 +6.24

A0 -24.60

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Page 30

testo

8Main menu

8.7 Probes

8.7.4 Adjust

When using the adapter cable no. 0554.0013 the

instrument has to be told what parameter is to be

measured. You can choose between voltage, frequency and resistance. Select an input channel from

the non-assigned socket and confirm with <Enter>.

After this you can assign the required parameter to

the channel selected.

Now the corresponding unit can be determined in the

“UNIT” menu and the upgrade in the “SCALING” menu.

8.7.4 Discard

Probes which were defined under “ADJUST” must be

discared before a new configuration. Otherwise the

set unit is displayed on the channel selected. (even

if the probes are not connected). If a probe is connected which is different to that defined the display“Invalid configuration” appears after the instrument is

switched on and all of the settings are erased.

Confirm the channel input whose definition you wish

to erase in the “DISCARD” menu. The instrument

restarts and you then find yourself in the measuring

menu.

30

Selection

K2:______

K3:______

K4:______

Sensortype

1V

kHz

Ohm

Probes

Scaling

Calibrate

ådjust

Probes

Calibrate

Adjust

∂iscard

Discard

K2: mV

K3: kHz

Restart

to

activate

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Page 31

Flow vol.

round

10.0 mm

Flow vol.

round

˛0.0 mm

Flow vol.

round

12.5 ˛m

8.8 Specials

8.8.1 Special functions display

Special functions, calculated from the measured values of the connected probes, are displayed in the

measuring menu if they are activated in the

“S

PECIALS.” menu.

td = Dew point (Combination probes %RH - °C)

m

3

/h = Volume flow (Velocity probe)

The accuracy of the volume flow display

follows from the accuracy of the velocity

measurement. Multiply the maximum and

minimum possible velocity value in the

accuracy data by the cross-section to get the

permissible deviation of the volume flow

measurement.

m/s = Air velocity (pressure probe)

The Pitot tube differential pressure is

converted to air velocity. Here the air density

is entered as a parameter (see Appendix

“Probe description”).

Switching on or off is carried out via <up><down>

and your entry is confirmed via <Enter>.

The special functions selected are activated by a

restart. The settings remain even after the measuring

instrument is switched off.

8.8.2 Flow volume

Enter the dimensions of the air channel (round,

square, cross-section area). The measuring instrument calculates the flow volume set in

“SF

DISPLAY”(see above).

8.8.3 Density

The density is required for the conversion of the

dynamic pressure into velocity. Please find the corresponding value in the enclosure Measuring engi-

neering.

8.8.4 Pressure

The air pressure is required for the compensation of

the CO

2

probe and the pressure probe (Pitot tube).

Refer to the more detailed description in the enclosure Measuring engineering.

Specials

‚F-no.

Flow vol.

Density

Specials

td øn

m3/h on

m/s on

Specials

td øff

m3/h on

m/s on

Specials

td on

m3/h øn

m/s on

Specials

td on

m3/h on

m/s øn

Restart

to

activate

Specials

SF display

ƒlow vol.

Density

Flow vol.

square

10.0 mm

10.0 mm

Flow vol.

Area

10.0 mm2

10.0 %

Ein

On

Enter /

Ein

On

Enter /

Specials

SF display

Flow vol.

∂ensity

Density

1123 g/m3

Ein

On

Enter /

Ein

On

Enter /

Abs. pressure

1013 hPa

Specials

Flow vol.

Density

πressure

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

8Main menu

31

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

Ein

On

Enter /

(Select from

“mm”, “cm”, “m”)

.....

.....

Page 32

testo

9Error messages

Cause: The measuring rate selected with the pro-

gram cannot be reached with the given

probe constellation.

Remedy: - Check min. rate

- Remove any unnecessary probes

- Slow down measuring rate

- Restart

Cause: The measured value memory is either full

or blocked because a measuring protocol

is being displayed or printed.

Remedy: - Quit the running program

- Quit “M

EMORY

-VIEW”

- Wait for printing or quit “P

RINT”

Cause: The program running cannot be changed.

Remedy: Quit program and restart.

Cause: The entered program start criterion can-

not be fulfilled:

- Starting time in the past

- Competing trigger criteria on the same

measuring channel.

Remedy: Correct entries for correctness and

change if necessary e.g.

- incorrect (past) time marks

- Difference trigger when only one probe

is assigned.

Cause: No recognisable probes connected

Remedy: Connect probe to program measured

value trigger.

Rate does

not match

the sensor

connected

Program

cannot

be

executed

Program

running

Program-

ming

error

No

sensors

connected

32

Page 33

33

9Error messages

Cause: Only CO2can be calibrated by customers.

For pressure probes an offset correction

(zero reset) is triggered with the key combination <up>+<Enter>. This applies to all

connected differential/pressure probes.

All other probes produce this display.

Remedy: Return by pressing <Enter>.

Cause: You have just assigned a new location.

Remedy: Return by pressing <Enter>.

Cannot

be

calibrated

New

Location

Page 34

testo

34

10Technical data

10.1 Measuring instrument

Temperature measurement

Pt100 sensor

Measuring range -200 to +800 °C

Resolution 0.1 °C

Accuracy ±0.1 °C (-49.9 to +99.9 °C)

±0.4 °C (-99.9 to -50 °C and +100 to +199.9 °C)

±1.0 °C (-200 to -100 °C and +200 to +800 °C)

NiCr-Ni sensor

Measuring range -200 to +1370 °C

Resolution 0.1 °C

Accuracy ±0.4 °C (-100 to +200 °C)

±1.0 °C (remaining range)

NTC sensor

Measuring range -20 to 80 °C

Resolution 0.1 °C

Accuracy ± 0.2 °C (-10 to 50 °C)

± 0.4 °C (remaining range)

PtRh-Pt sensor

Measuring range 0 to +1760 °C

Resolution 1 °C

Accuracy ±1.0 °C

FeCu-Ni sensor

Measuring range -200 to +1000 °C

Resolution 0.1 °C

Accuracy ±0.4 °C (-150 to +150 °C)

±1.0 °C (remaining range)

Humidity measurement

Measuring range 0 to 100 %RH

Resolution 0.1 %RH

Accuracy See probe data

Velocity measurement

Vane

Measuring range 0 to 60 m/s

Resolution 0.1 m/s

Accuracy See data on probes

Therm. anemometer

Measuring range 0 to 20 m/s

Resolution 0.01 m/s (0 to 4 m/s)

0.1 m/s (remaining range)

Accuracy ±0.01 m/s (0 to 1.99 m/s)

±0.02 m/s (2 to 4.9 m/s)

±0.04 m/s (5 to10 m/s)

Frequency measurement

Measuring range 30 Hz to 300 kHz

Resolution 0.01 kHz

Accuracy ±0.01 kHz

Current measurement

Measuring range Resolution Accuracy

0 to 20 mA 0.01 mA ±0.04 mA

Voltage measurement

Measuring range Resolution Accuracy

0 to ±1 V 1 mV ±1 mV

0 to ±10 V* 0.01 V ±0.01 V

* only with current/voltage cable 0554.0007!

Resistance measurement

Measuring instrument Resolution Accuracy

100 Ω to 300 kΩ 0.01 kΩ ±1 % of mv

CO2 measurement

Measuring range Accuracy

0 to 10,000 ppm ±5 % of m.v. or 50 ppm

0 to 1 Vol% ±5 % of m.v. or 50 ppm

Accuracies ±1 digit

Memory space 256 kB (corresponds to

approx. 110,000 measured values)

Alarm output Electrically isolated

open-collector outputs

max. load current 50 mA (internal limit)

max. permissible power 240 mW

max. permissible voltage 30 V

(6V with polarity reversal)

Trigger

max. permissible voltage 10 V

Actuating shaft 4 to 10 V

Input load 20 mA (at 10 V)

Programmable • Unit

channel settings • Scaling

• Calibration

Probe assignment • Max. 6 probes simultaneously

• Max. 4 probes simultaneously

when ball velocity probes

are connected

Power supply • 6 cell rechargeable batter

y,

built-in

• or via 12 V mains unit

Battery life

Continuous oper. with 6 thermocouple probes 8 h

10 minute measuring rate 11 days

Language versions G and E

Operating temperature 0 to +50 °C

short-term 0 to +60 °C

Storage and

transport temperature -25 to +60 °C

Connection Standard flange socket

Weight 650 g (incl. rechargeable battery)

Other • Automatic recognition

of all connected probes

• Housing material ABS

Pressure measurement

Meas. range Resolution Accuracy

±100 hPa 0.1 hPa ±0.1 hPa

±10 hPa 0.01 hPa ±0.01 hPa

2000 hPa 1 hPa ±2 hPa

10 bar 0.01bar ±0.2 % of f.v.

30bar 0.01 bar ±0.2 % of f.v.

Page 35

35

10Technical data

Printer type Infrared controlled

thermal printer,

adjustable contrast

Print capacity Approx. 300 printouts

per roll

Reception radius Max. 2 m

Operating temperature 0 to +50 °C

Storage and

transport temperature -40 to +60 °C

Dimensions 186 x 91 x 61 mm

Weight 0.43 kg (incl. batteries)

Power supply 4 round cell batteries

1.5 V or NC rechargeable batteries

10.2 Infrared printer

10.3 Comfort software – 454 module

Graphic measured data analysis under the modern

user environment WINDOWS®.

Multi-windows Different measurement

files are shown and

analysed in several windows

Functions • User-friendly

zoom functions

• Mathematical

smoothing function

• Statistical calculation

functions (average, variance…)

Printout of the measured data In table

or graphic form

Prerequisites • Computer

min. 386

• DOS from 3.1

• WINDOWS from 3.1

Other • Simplest operation

using a mouse

• Coloured fading-in of

freely selectable limit values

Page 36

testo

10Technical data

10.4 Probes

36

5) Magnetic probe for higher temp. a) Adhesion approx. 10 N

b) Adhesion approx. 20 N

testo

6) Pipe clamp probe for temperature measurements on pipes with

diameters of up to 2"

Spare measuring head for pipe clamp probe No.0602.0092

testoterm

1) Robust Pt100 sensor with widened measuring tip for

measurements on flat surfaces

Surface probes

testoterm

2) Robust NiCr-Ni sensor with widened measuring tip for

measurements on flat surfaces

testoterm

3) High temperature surface probe

with sprung thermocouple band

4) Velcro strip probe to attach to pipes etc., for long-term

measurements

Sensor

Pt100

(Class B)

NiCr-Ni

NiCr-Ni

(Class 2)

Pt100

NiCr-Ni

NiCr-Ni

(Class 2)

NiCr-Ni

(Class 2)

Infrared

sensor

t

99

(s)

40

25

3

40

–

–

5

2

Length of

probe pipe

150 mm

150 mm

200 mm

130 mm

Probe

length

180 mm

ø Meas.

tip

8 mm

4 mm

8 mm

25 mm

25 mm

65 mm

–

Measuring

range

-50 to +400 °C

-200 to +600 °C

-200 to +700 °C

-50 to +150 °C

-50 to +400 °C

-50 to +170 °C

-60 to +130 °C

-18 to +260 °C

Ø Meas. spot 5 7.5 14 21 33 mm

Meas. distance 16 25 50 76 130 mm

7) Infrared probes for non-contact temperature measurements on

live, inaccessible and rotating parts

Page 37

10Technical data

10.4 Probes

37

13) Adhesive thermocouples for surface measurements

Carrier material: aluminium foil

Thermocouples and adapters

14) Adapter to connect thermocouples and probes

to open ends of wires

Max.

temp.

+200 °C

Attachment to

meas. location

With common

glues or with

silicon heat paste

Order no.

0554.0004

Quantity

delivered

Packs of

two

Dimensions

Thickness

0.1 mm

ø Extension

2.0 x 0.2 mm

All of the data on Pt100 according to DIN IEC 751, Class A.

For thermocouples the technical data according to DIN IEC 584 Part 2, Class 1.

Temperature probe with PtRh-Pt or FeCu-Ni sensors on request.

12) Ball thermometer

for measuring radiation heat

10) Rapid-action probe for measurement

in liquids and gases

te

s

to

te

r

m

11) Highly accurate probe for air/gas and temp. measurements

te

s

to

te

rm

Air probes

Sensor

NiCr-Ni

NTC

Pt100

t

99

(s)

9

60

Length of

probe pipe

150 mm

150 mm

ø Ball

approx. 150 mm

ø Meas.

tip

0,5 mm

9 mm

Measuring

range

-200 to +600 °C

-40 to +130 °C

-25 to 80 ±0.2°C

-50 to +200 °C

9) Waterproof probe with sharpened meas. tip, boil-proof

Penetration probe

8) Probe for measurements in liquids and powder substances

a)

b)

te

s

to

te

rm

Immersion probe

Sensor

NiCr-Ni

Pt100

t

99

(s)

1

20

Length of

probe pipe

150 mm

150 mm

ø

probe pipe

1.5 mm

3 mm

Measuring

range

-200 to+600 °C

-200 to +600 °C

Sensor

Pt100

t

99

(s)

30

Length of

probe pipe

150 mm

ø Meas.

tip

3 mm

Measuring

range

-200 to +600 °C

Page 38

testo

10Technical data

10.4 Probes

38

20) Pitot tubes in various lengths, diameters and

materials, for velocity measurement (in connection with

diff. pressure probe)

testo

0638.1445

Pressure probes

Measuring

range

±100 hPa

±10 hPa

2 bar

Material

Brass

Brass

Stainless

steel

Accuracy

±0.1 hPa (0 to 20 hPa)

±0.5 % v. Mw. (20 to 100 hPa)

±0,03 hPa

±5 hPa

Length ø

500 mm 7 mm

350 mm 7 mm

300 mm 4 mm

Measuring

system

Differential

pressure

Diff. pressure

Abs. pressure

Temp.

max

350 °C

350 °C

500 °C

a)

b)

c)

a)

b)

c)

Absolute pressure probe c) for measuring abs. pressure

19) Differential pressure probes a) and b) for measuring

velocity (in connection with Pitot tube)

and differential pressure

Ø Pitot tube connection 5 mm

testoterm

16) High temperature humidity probe, for measurement

e.g. in channels or bulk material

testo

17) Flexible humidity probe for

measurement in

inaccessible places

18) Pressure-proof humidity probe for measurements

in compressed air plants, with standard plug

testo

term

15) Air probe for humidity and temperature measurements

Humidity probes

Measuring

range

0 to 100 %RH

(Probe tip)

-20 to +70 °C

0 to 100 %RH

-20 to +140 °C

0 to 100 %RH

-20 to +140 °C

0 to 100 %RH

Pressure dew

point tpd:

-50 to +40 °C

t

90

(s)

10

20

20

ø

21 mm

Probe

pipe

12 mm

Tip

12 mm

Length

Total

length

245 mm

Probe

pipe

300 mm

Probe

pipe

1500 mm

Total length 300 mm

Connection via

standard plug

Sensor

Capacitive

NTC

Capacitive

NTC

Capacitive

NTC

Capacitive

NTC

Spare sensors: % RH 0420.0019 / °C 0420.1243

Spare sensors: % RH 0420.0023 / °C 0420.1242

Spare sensors: %RH 0420.0023 / °C 0420.1242

Spare sensors: % RH 0420.0023 / °C 0420.1242

System accuracy for 15) - 18): ±2 %RH(2 to 98 %RH) ±0.4 °C (0 to 50 °C) ±0.5 °C (remaining range)

Page 39

10

Technical data

10.4 Probes

39

24) High temperature probe

for long-term measurements up to +350 °C,

Short-term meas. possible up to +500 °C

26) Vane Ø 60 mm for measurements in channel outlet,

with extendable telescope, application range -20 to+60 °C

25) Semi shell anemometer

27) Vane Ø 100 mm for measurement in grid outlets,

with handle (w/o fig.)

22) Combined vane/temperature probe

(plug-in)*, Ø 16 mm

rm

23) Low temperature anemometer probe with handle,

application range -20 to +60 °C

21) Combined vane/temperature probe

(plug-in)*, Ø 25 mm

Vane probes

(System accuracy with instrument)

Measuring

range

0.4 to 40.0 m/s

-30 to +140 °C

0.4 to 60.0 m/s

-30 to +140 °C

0.6 to 40.0 m/s

0.6 to 20.0 m/s

-40 to +350 °C

0.5 to 35 m/s

0.25 to 20.0 m/s

0.2 to 15 m/s

Sensor

Vane

NiCr-Ni

Vane

NiCr-Ni

Vane

Vane

NiCr-Ni

Vane

Vane

Vane

Accuracy

±1 %

of final val.

±0.4 m/s

(to 40 m/s)

±2 %

of final val.

±2.5 %

of final val.

±0.3 ms

±5 % of f.v.

±0.2 m/s

±2 % of f.v.

±0.3 m/s

Length

of probe

180

mm

180

mm

190

mm

560

mm

440

to

1100

mm

280 mm

ø

Tip

25

mm

16

mm

16

mm

25

mm

60

mm

100 mm

29) Robust probe with telescope for measurements

in the lower velocity range

testoterm

30) Rapid-action probe for measurements

in the lower velocity range,

with recognition of flow direction

t

e

s

to

t

e

r

m

28) Low-price, robust probe for measurements

in the lower velocity range

Thermal velocity probes

Meas.

range

0 to 10.00 m/s

-20 to +70 °C

0 to 10.00 m/s

-20 to +70 °C

0 to20.00 m/s

-20 to +70 °C

Sensor

Hot ball

NTC

Hot ball

NTC

Hot wire

NTC

Length

of probe

150 mm

190 to 850

mm

160 to 760

mm

ø

Tip

4 mm

4 mm

Accuracy of hot ball: ±0.03 m/s, +5 % of meas. value (0 to 10 m/s)

Accuracy of hot wire: ±0.03 m/s, +4% of meas. value (0 to 20 m/s)

* A handle or telescope is required for plug-in probes (See Ordering data)

Page 40

testo

10Technical data

10.4.1 Connection cables for probes

40

Parameter

NiCr-Ni

FeCu-Ni

PtRh-Pt

NTC

Pt100

% RH

10 hPa

100 hPa

2 bar

Vane 16, 25, 60, 100

Therm. anemometer

Ball probe

Therm. anemometer

Hot wire

Resistance

Frequency

Current

Voltage

Maximum

cable extensions

30 m

20 m

50 m

10 m

5 m

13 m

5 m

5 m

20 m

50 m

50 m

30 m

Errors due to specific resistance during

NTC temperature measurement

Temp. °C 5 m 10 m 20 m

- 20 0.00 0.00 0.00

20 0.00 0.00 0.04

50 0.04 0.10 0.17

70 0.10 0.20 0.40

The special cables marked “ * ” are only

available from the factory.

Additional extensions to the standard

probe using the extension cable

0409.0063 are not possible.

*

*

*

Page 41

11 Ordering data

Description Order no.

Measuring

instrument

Infrared printer

Probe

% RH

Probe

°C

41

testo 454 6 channel logger ............................................................................................................0560.4540

Comfort software V2 “Light”,

incl. 454 module, for graphic analysis of measured data under WINDOWS®,...............................0554.0279

ACCESSORIES

12 V mains unit, for mains operation and for charging rechargeable batteries .............................0554.0085

Carrying case (leather), with strap ...............................................................................................0516.0291

System case for testo 454, infrared printer, probes and accessories............................................0516.4540

Protective case for testo 454, lockable .........................................................................................On request

Adapter for Pt100 / Humidity ........................................................................................................0554.0454

Rech. battery connection cable, to connect rechargeable batteries made by other companies ....0409.0012

Interface cable RS 232, connection cable between PC and testo 454...........................................0409.0154

Alarm/trigger cable.......................................................................................................................0554.0012

Electrical isolation RS 232 ...........................................................................................................0554.0006

XT/AT adapter................................................................................................................................0554.0072

Infrared printer

, thermal printer for wireless printout of measured values,

incl. 4 round cell batteries and 1 roll of thermal paper...................................................................0554.0345

ACCESSORIES

Recharger,incl. 4 NC rechargeable batteries for an infrared printer ..............................................0554.0110