Page 1

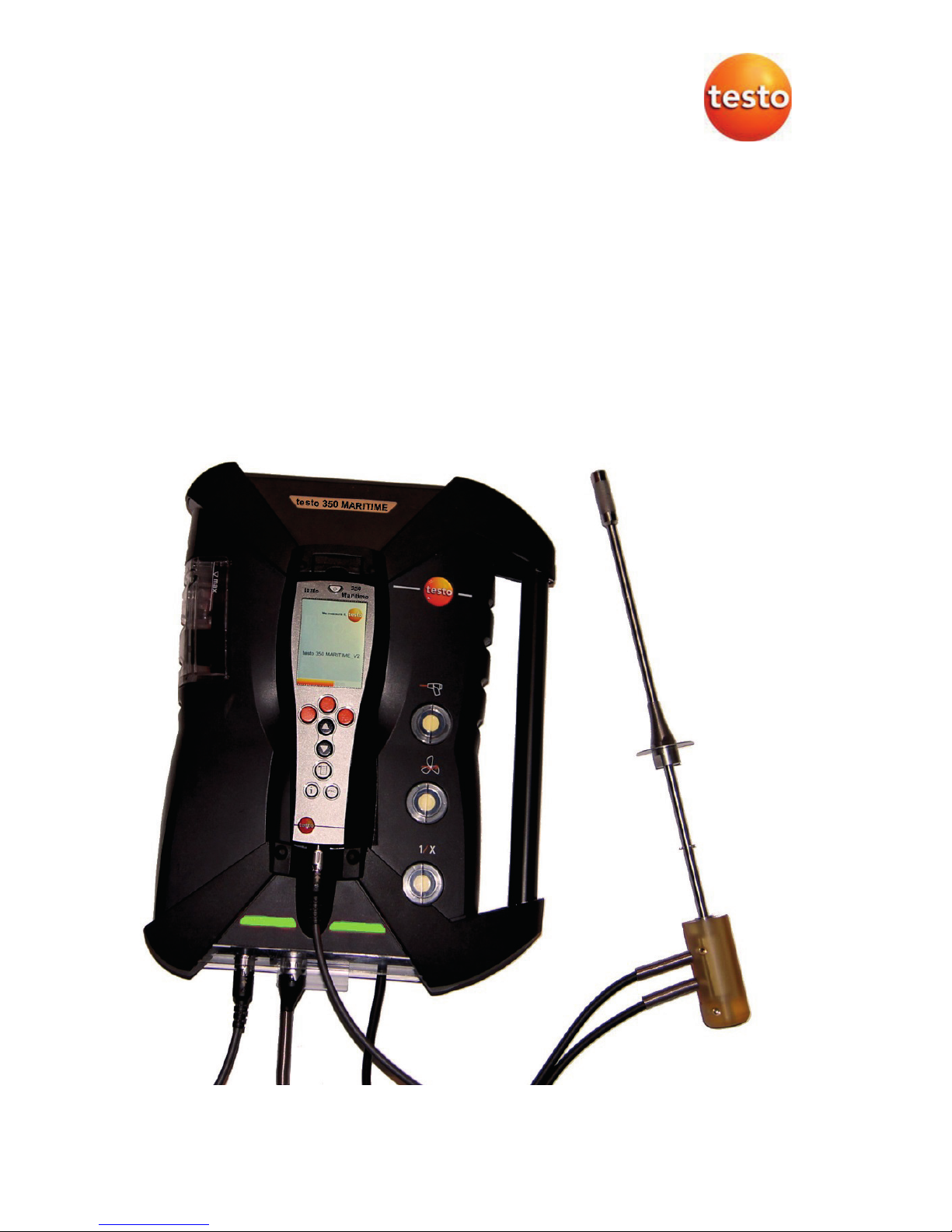

testo 350 MARITIME V2 · Flue gas analyzer

Instruction manual

Page 2

2

Page 3

1 Contents

3

1 Contents

1 Contents ...................................................................................................3

2 Safety and the environment....................................................................6

2.1. About this document........................................................................6

2.2. Ensure safety...................................................................................7

2.3. Hazard warnings..............................................................................8

2.4. Protecting the environment............................................................11

3 Specifications ........................................................................................12

3.1. Use ................................................................................................12

3.2. Technical data ...............................................................................14

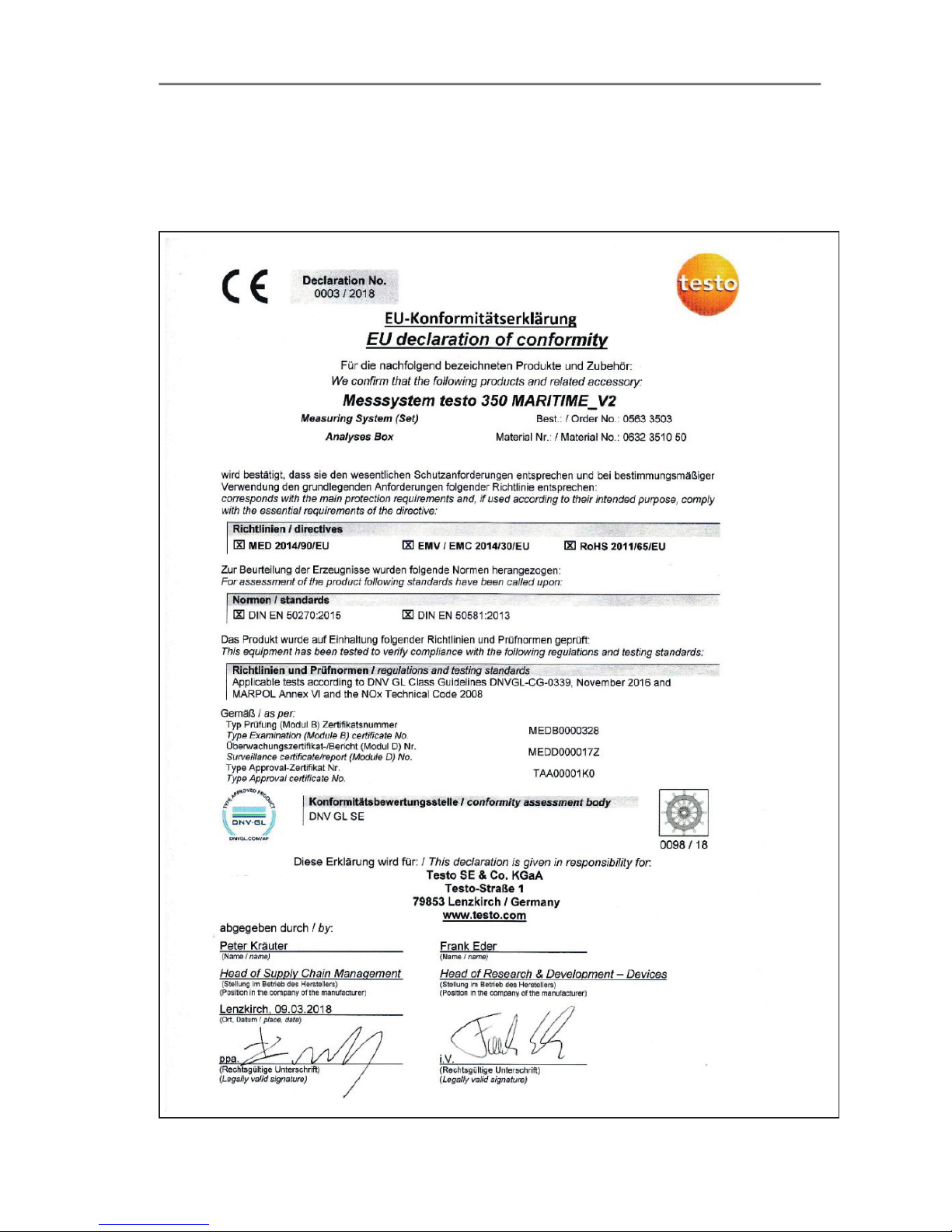

3.2.1. Declaration of Conformity ..............................................................................14

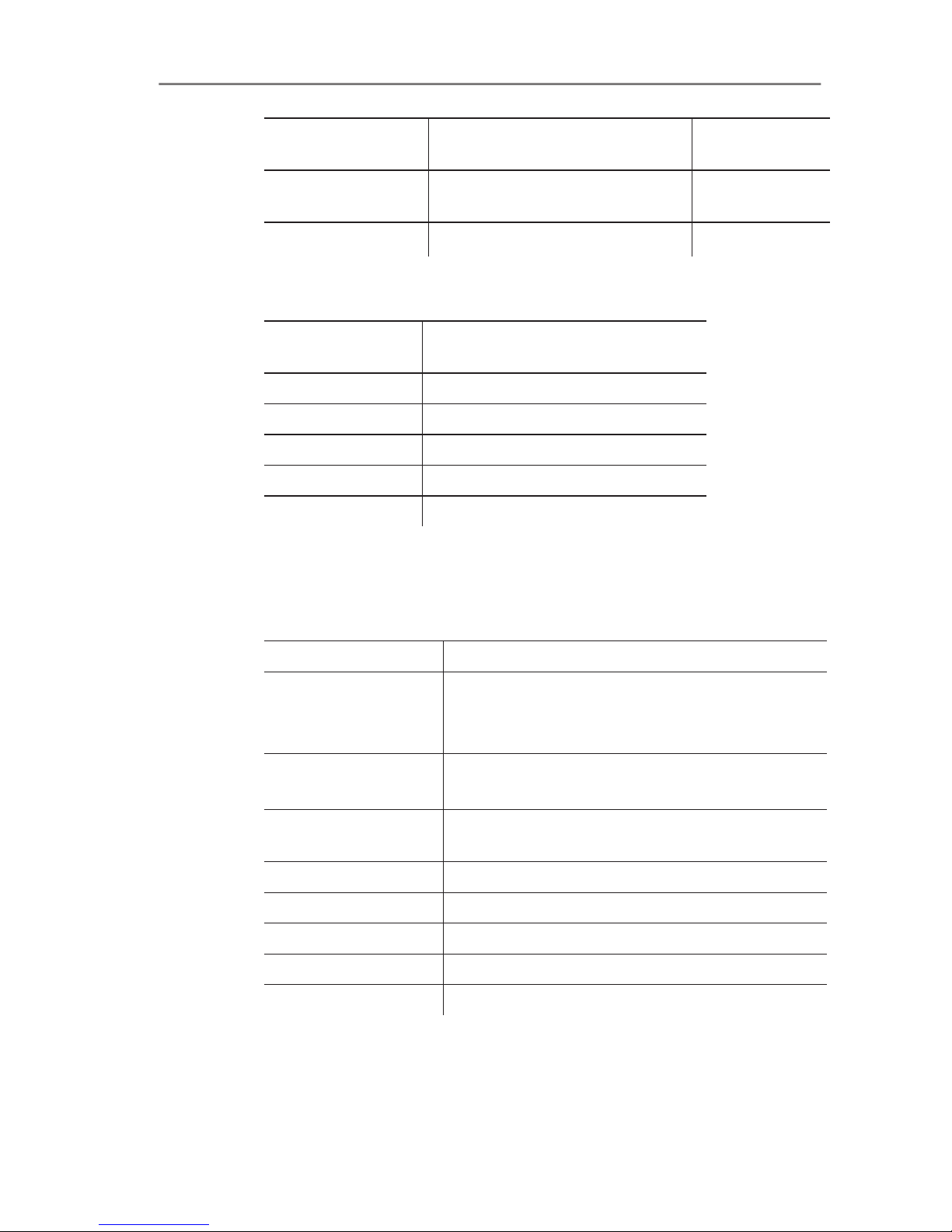

3.2.2. Measuring ranges and accuracies .................................................................15

3.2.3. Recommended test gas concentrations ......................................................... 16

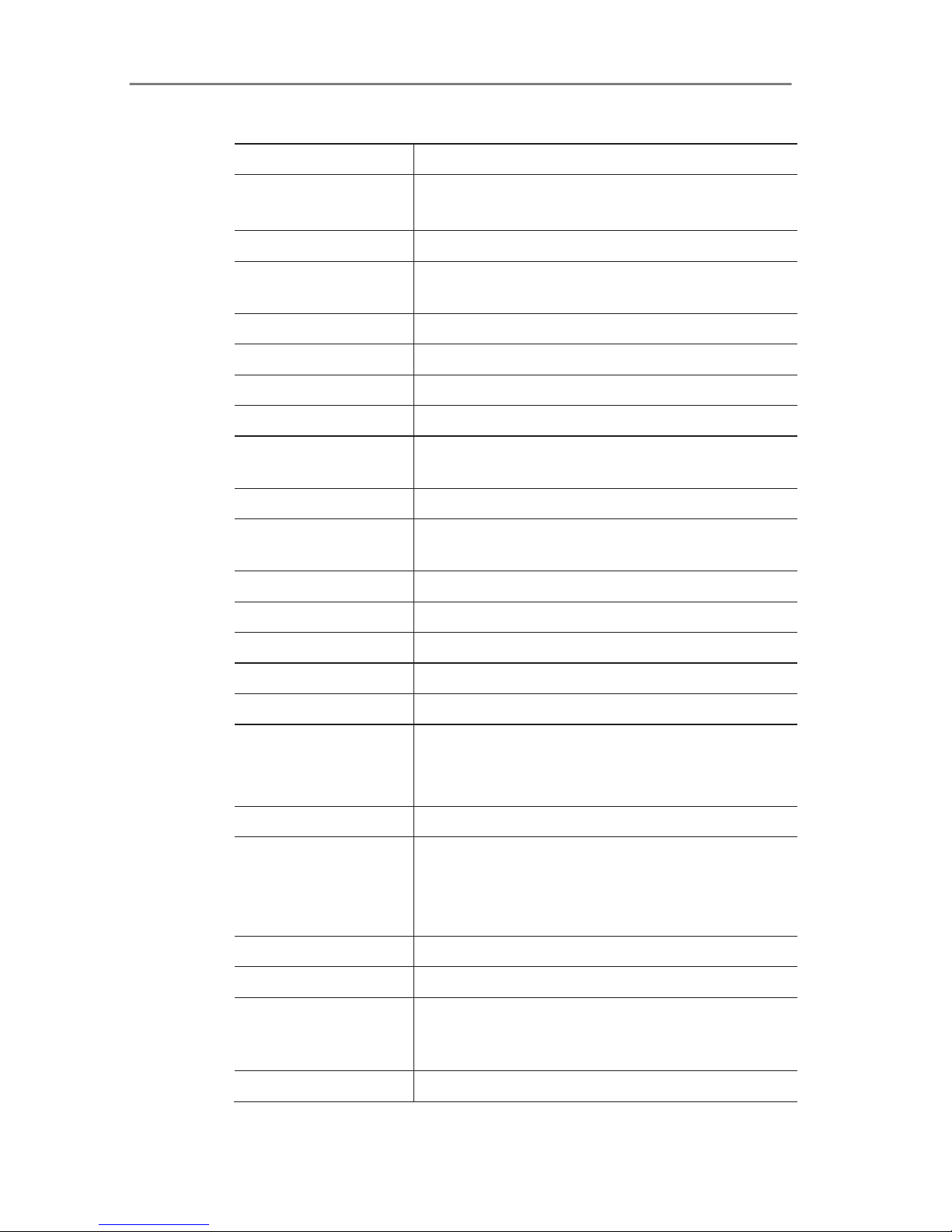

3.2.4. Other instrument data.................................................................................... 16

4 Product description...............................................................................18

4.1. Scope of delivery ...........................................................................18

4.2. Control unit ....................................................................................19

4.2.1. Overview........................................................................................................19

4.2.2. Keyboard .......................................................................................................20

4.2.3. Display........................................................................................................... 21

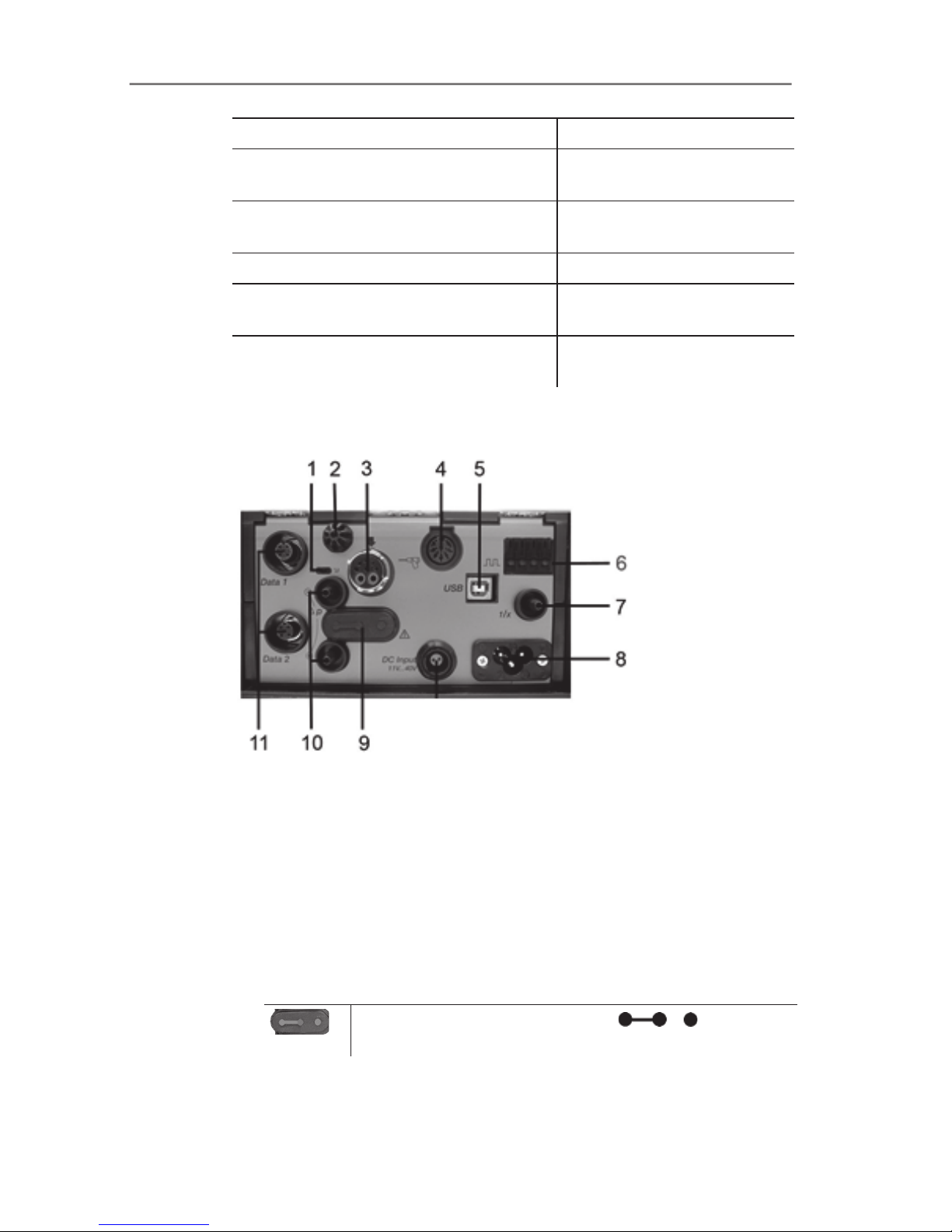

4.2.4. Connections / interfaces ................................................................................22

4.2.5. Menu guide for control unit ............................................................................22

4.3. Measuring box...............................................................................23

4.3.1. Overview........................................................................................................23

4.3.2. Status display ................................................................................................24

4.3.3. Connections / interfaces ................................................................................ 25

4.3.4. Functions / instrument options .......................................................................26

4.3.5. Menu guide for measuring box.......................................................................26

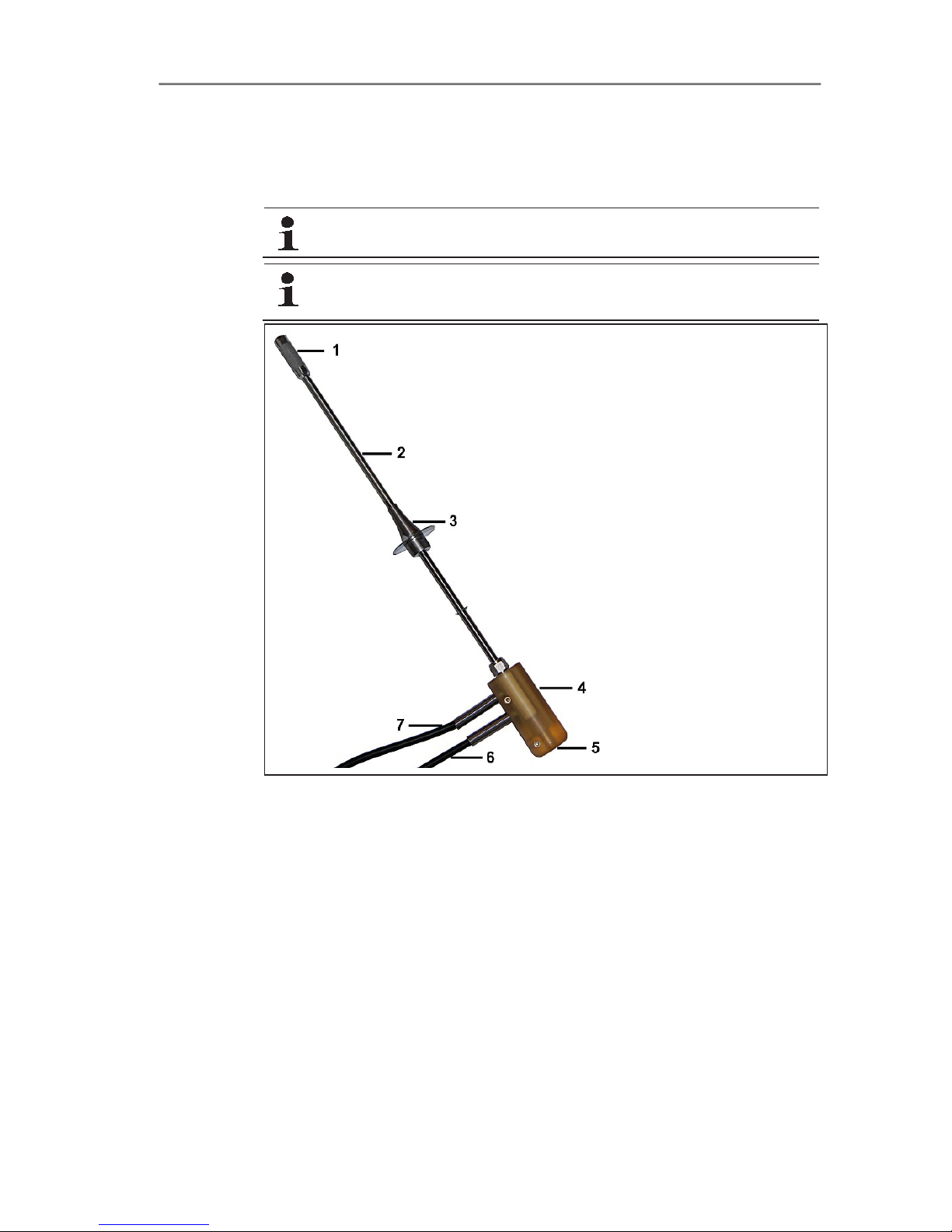

4.4. Flue gas probe...............................................................................28

4.4.1. Overview........................................................................................................28

5 First steps ..............................................................................................29

5.1. Commissioning ..............................................................................29

5.2. Getting to know the product...........................................................29

5.2.1. Mains unit, batteries/rechargeable batteries...................................................29

5.2.1.1. Recharging the rechargeable battery for the control unit .................30

5.2.1.2. Charging the rechargeable battery for the measuring box ...............30

5.2.1.3. Battery care.....................................................................................31

5.2.1.4. Mains operation............................................................................... 31

5.2.2. Connecting probes / sensors .........................................................................32

5.2.3. Occupying the trigger input............................................................................32

5.2.4. Connecting system components .................................................................... 33

5.2.4.1. Connection via contact strip.............................................................33

5.2.4.2. Connection to a bus system via data bus cable (accessory)............ 33

Page 4

1 Contents

4

5.2.5. Switching on .................................................................................................. 35

5.2.6. Calling up the function ................................................................................... 36

5.2.7. Entering values.............................................................................................. 36

5.2.8. Printing / saving data ..................................................................................... 38

5.2.9. Search for boxes ...........................................................................................38

5.2.10. Confirming an error message ........................................................................38

5.2.11. Switching off .................................................................................................. 38

5.3. Folder............................................................................................ 39

5.4. Measurement records................................................................... 41

5.5. Instrument diagnosis..................................................................... 42

5.5.1. Error diagnosis ..............................................................................................42

5.5.2. Gas path check.............................................................................................. 42

5.5.3. Sensor diagnosis........................................................................................... 43

5.5.4. Device information......................................................................................... 43

6 Using the product ................................................................................. 43

6.1. Performing settings....................................................................... 43

6.1.1. Assigning the right hand function key ............................................................ 43

6.1.2. Instrument settings ........................................................................................ 43

6.1.2.1. Measurement view .......................................................................... 43

6.1.2.2. Units................................................................................................ 45

6.1.2.3. Date / time....................................................................................... 46

6.1.2.4. Power options..................................................................................46

6.1.2.5. Display brightness ........................................................................... 46

6.1.2.6. Printer .............................................................................................47

6.1.2.7. Language ........................................................................................ 47

6.1.2.8. Password protection........................................................................ 47

6.1.2.9. Analog input .................................................................................... 48

6.1.2.10. Data bus.......................................................................................... 49

6.1.3. Fuels.............................................................................................................. 49

6.1.4. Sensor settings.............................................................................................. 50

6.1.4.1. Sensor protection ............................................................................ 50

6.1.4.2. Calibration / adjustment................................................................... 51

6.1.4.3. Calibration data ............................................................................... 53

6.1.4.4. Negative values............................................................................... 54

6.1.5. Programs....................................................................................................... 54

6.2. Measuring ..................................................................................... 56

6.2.1. Preparing for measurement ........................................................................... 56

6.2.2. Position flue gas probe .................................................................................. 58

6.2.2.1. Flue gas flow with hot spot characteristics....................................... 58

6.2.2.2. Flue gas flow without hot spot characteristics.................................. 58

6.2.3. Attachment options for the flue gas probe...................................................... 59

6.2.3.1. Using the probe stop ....................................................................... 59

6.2.3.2. Using the welded pipe..................................................................... 60

6.2.4. Vibrations ......................................................................................................60

6.2.5. Flue gas measurement.................................................................................. 61

6.2.6. Differential pressure measurement (determining the pressure in the flue gas

duct) ..............................................................................................................63

6.2.7. EMDS measurement ..................................................................................... 64

6.3. Analog outputs.............................................................................. 65

Page 5

1 Contents

5

7

Maintaining the product........................................................................67

7.1. Changing the rechargeable battery ...............................................67

7.2. Cleaning the flue gas analyser ......................................................67

7.3. Changing / retrofitting sensors.......................................................68

7.4. Recalibrating sensors....................................................................70

7.5. Cleaning the flue gas probe...........................................................70

7.6. Changing the thermocouple...........................................................71

7.7. Condensate container ...................................................................72

7.8. Checking / replacing the dirt filter ..................................................73

7.9. Cleaning / replacing the pump .......................................................75

7.9.1. Cleaning the main gas pump .........................................................................75

7.9.2. Changing the main gas pump ........................................................................76

7.9.3. Changing the condensate pump .................................................................... 77

7.9.4. Replacing the motor of the condensate pump................................................ 78

7.10. Replacing the filtration non-woven in the gas cooler .....................80

7.11. Recommended maintenance cycles..............................................81

8 Tips and assistance...............................................................................82

8.1. Questions and answers.................................................................82

8.2. Accessories and spare parts .........................................................84

8.3. Updating the instrument software..................................................86

9 Appendix ................................................................................................88

9.1. Cross-sensitivities..........................................................................88

9.2. Recommendation for emissions measurements over an extended

period of time.................................................................................89

9.3. Fuel parameters ............................................................................90

9.4. Certificates/Type Approvals...........................................................91

Page 6

2 Safety and the environment

6

2 Safety and the environment

2.1. About this document

This document describes the testo 350 MARITIME.

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

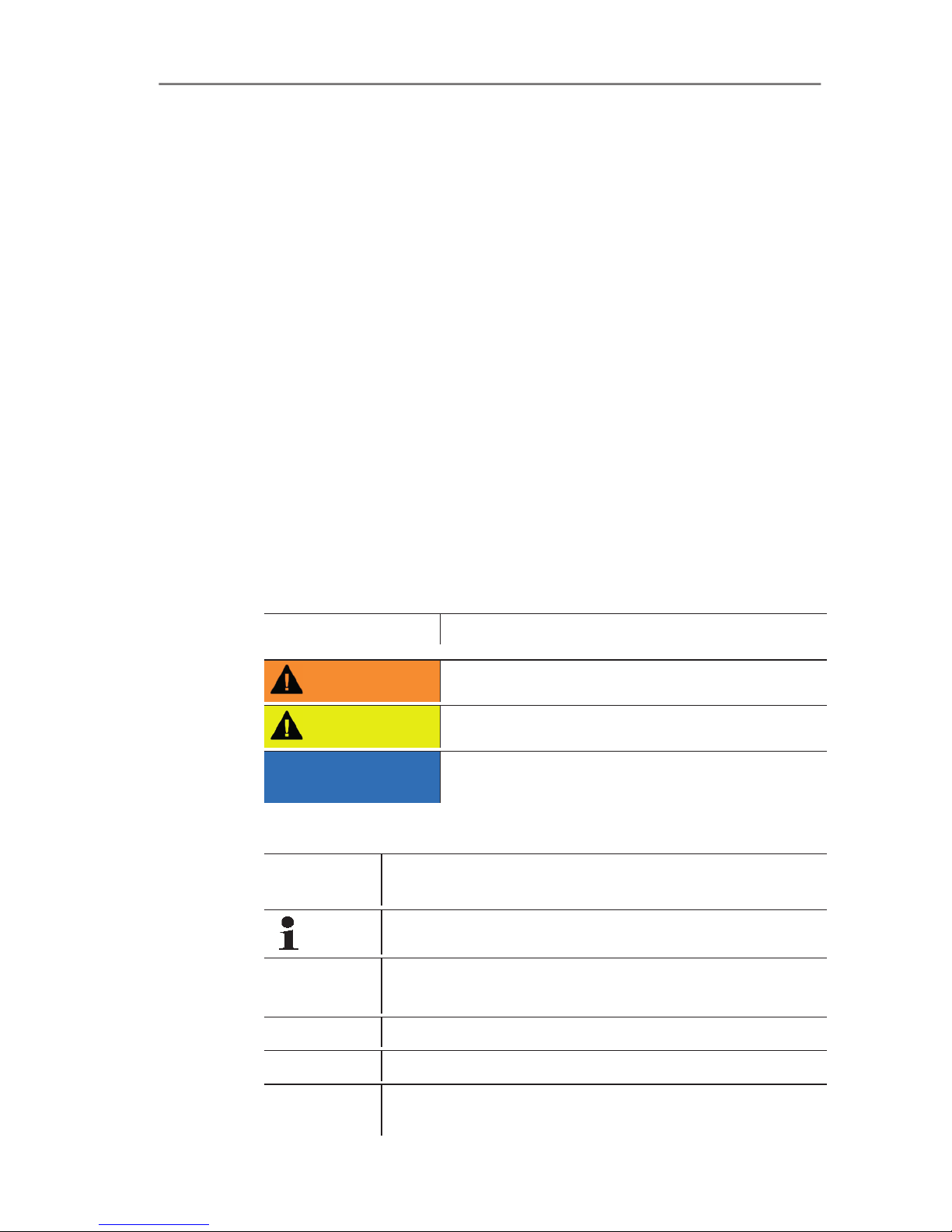

Warnings

Always pay attention to information that is marked by the following

warnings with warning pictograms. Implement the specified

precautionary measures.

Representation Explanation

WARNING Indicates potential serious injuries

CAUTION

indicates potential minor injuries

NOTICE

indicates circumstances that may lead to

damage to the products

Symbols and writing standards

Representation

Explanation

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu

Elements of the instrument, the instrument displays

or the program interface.

Page 7

2 Safety and the environment

7

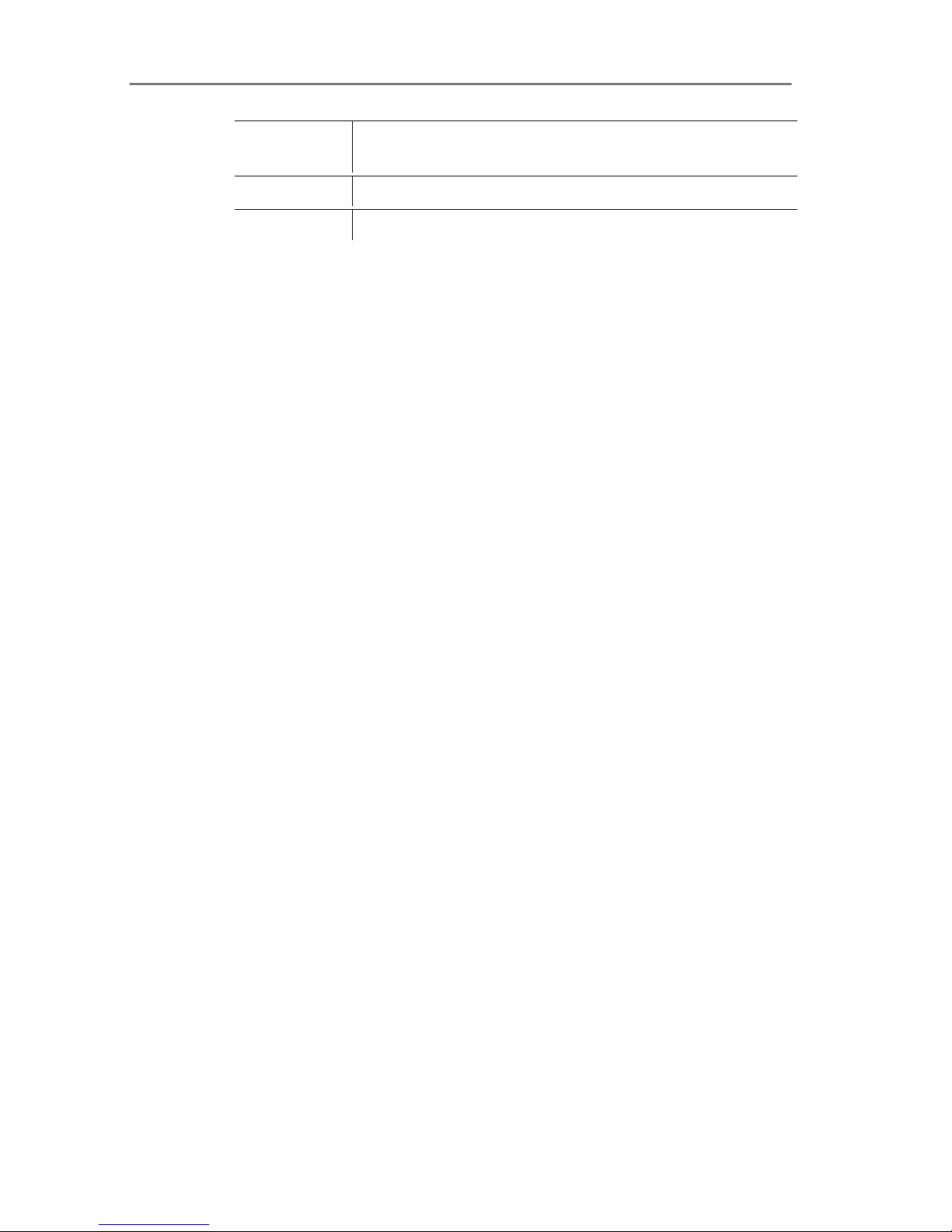

[OK]

Control keys of the instrument or buttons of the

program interface.

... | ... Functions/paths within a menu.

“...” Example entries

2.2. Ensure safety

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

use any force.

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> Do not perform contact measurements on non-insulated, live

parts.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts

from Testo.

> Any further or additional work must only be carried out by

authorised personnel. Testo will otherwise refuse to accept

responsibility for the proper functioning of the measuring

instrument after repair and for the validity of certifications.

> The measuring instrument should not be installed in locations

with extremely high vibrations.

> Before use: Pay strict attention to the installation information for

the flue gas probe.

> To prevent damage to the instrument, engine system or

persons due to powerful vibration of the flue gas duct, the gas

sampling probe must be attached in such a way that it is

impossible for it to come loose. The probe must be positioned

so that any parts that come loose cannot get into the machine

system's moving components.

> Once measurement has been completed, remove the gas

sampling probe from the flue gas duct and close the sampling

point.

> Temperatures given on probes/sensors relate only to the

measuring range of the sensors. Do not expose handles and

feed lines to any temperatures in excess of 70 °C unless they

are expressly permitted for higher temperatures.

> Do not operate the measuring instrument in the transport case.

Page 8

2 Safety and the environment

8

2.3. Hazard warnings

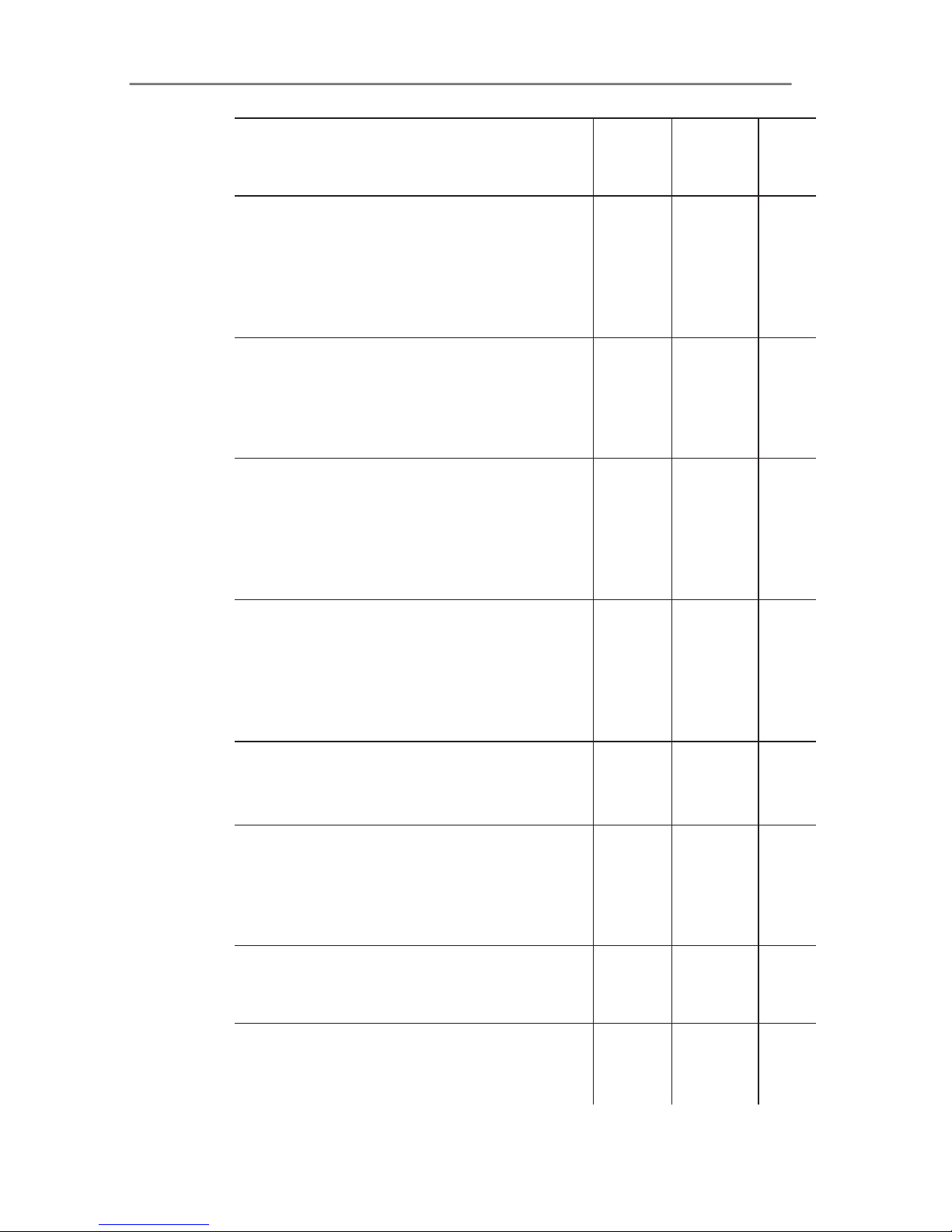

Description Man

Hazard

to

system

Instru

ment

Power supply

Disconnecting the protective conductor by

any means inside or outside the device is

prohibited! Using the identification plate,

check that the type, line voltage and

power correspond to the actual data.

XX

Disposing of sensors

The sensors contain small quantities of

concentrated acids. Dispose of as

hazardous waste!

Hazardous when

handled inappropriately!

X

Storing the measuring instrument

Never store the measuring instrument in

rooms together with solvents. Danger of

destruction of the sensors! Ensure that the

permissible storage, transport end

operating temperatures are observed.

X

Rechargeable battery

Fully charge the rechargeable battery

before the first measurement and after

several days of disuse. Recharge the

rechargeable battery every 4 weeks

during long periods of disuse. The testo

battery block for the control unit must be

inserted so that the marking is visible on

the upper side. Otherwise, there is the risk

of short circuit and reverse polarity if the

insulating foil is damaged

X

Operating the flue gas probe

Be careful when removing the probe from

the flue gas duct, because the probe will

be hot!

X

Page 9

2 Safety and the environment

9

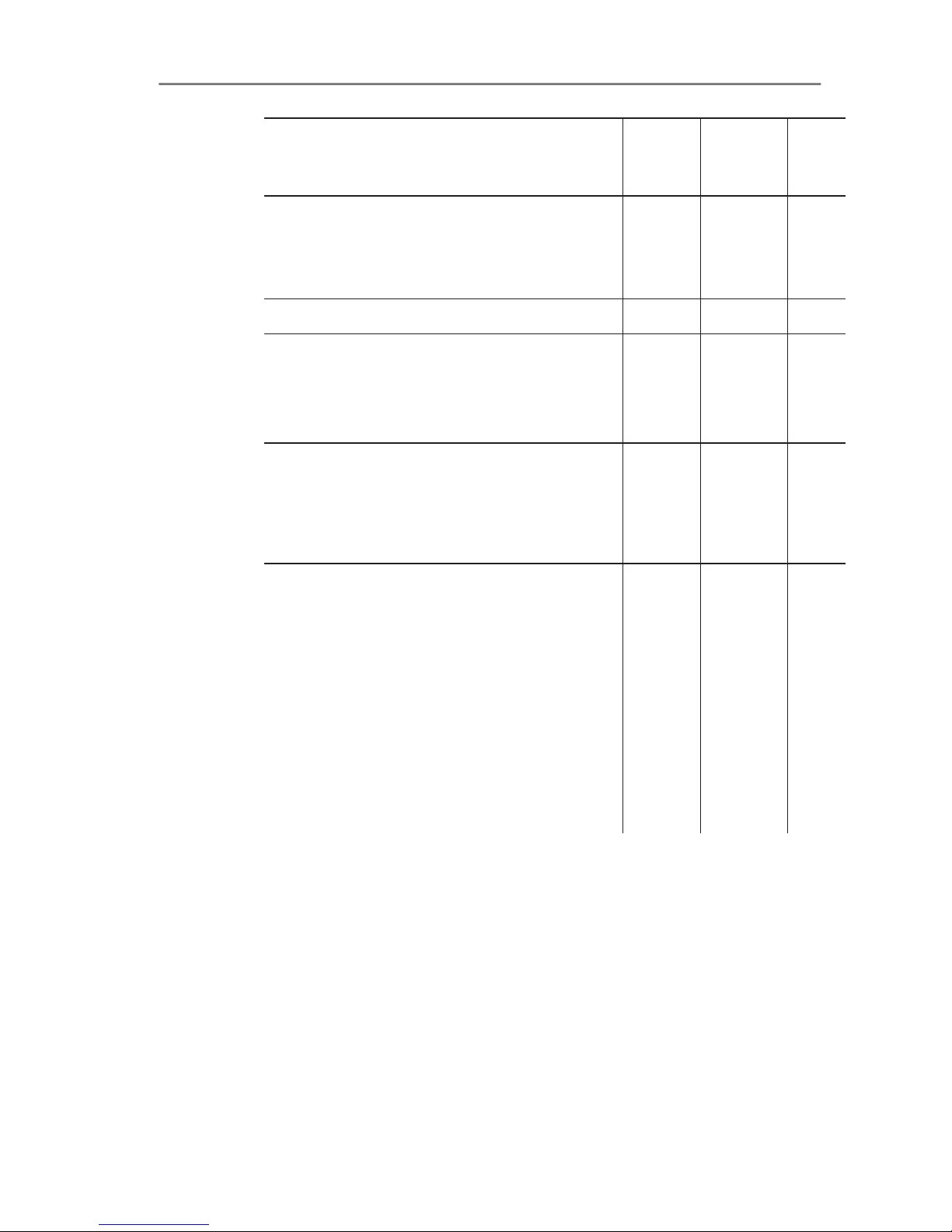

Description Man

Hazard

to

system

Instru

ment

Condensate outlet

Aggressive condensate (acid) escapes

from the condensate outlet. If there is no

appropriate drainage facility (e.g. hose),

this constitutes a hazard to materials and

user!

XX

Service and maintenance

The mains plug must always be pulled out

before opening the housing. Danger of

electric shock! Only authorised persons

may carry out work inside the instrument!

XXX

Non-permissible measurements

This instrument must NOT be used to

measure explosive or flammable gas

mixtures and gases that form flammable

mixtures when exposed to atmospheric

air!

X

Test gas pressure

A maximum of 50 mbar is permissible.

Higher pressures run the risk of

destroying the gas sensors! In addition,

test gas must only be used in well

ventilated rooms!

XX

Cleaning the instruments

Prevent the penetration of water into the

instrument at all costs!

X

Differential pressure sensor

When taking measurements, observe the

permissible measuring ranges. Exceeding

the measuring range will result in

destruction of the sensor!

X

Condensation

Avoid exposing the instrument and the

instrument electronics to condensation.

X

Measuring in closed rooms

Ensure that there is adequate ventilation.

Danger of poisoning!

X

Page 10

2 Safety and the environment

10

Description Man

Hazard

to

system

Instru

ment

Entire system

Do not connect any part of the system to

live parts for measurement. Danger of

electric shock!

X

Protect system against overvoltage. X

CO measurement

Ensure that there is adequate ventilation

when measuring toxic gases

(CO). Danger of poisoning!

X

Power supply to the entire system

Always ensure that the entire system is

supplied with sufficient power (new or

charged batteries, mains unit). Danger of

the entire system becoming unstable.

X

EMC

Increased electromagnetic interference

can result in readings deviating from the

standard specifications. Danger if the

analog/switching outputs are connected.

The mains plug must have a protective

earth conductor connected. The

temperature display with control unit and

separate probe can jump by up to 2°C in

the case of a thermocouple with earth

contact in connection with a switchedmode power supply.

XX

Page 11

2 Safety and the environment

11

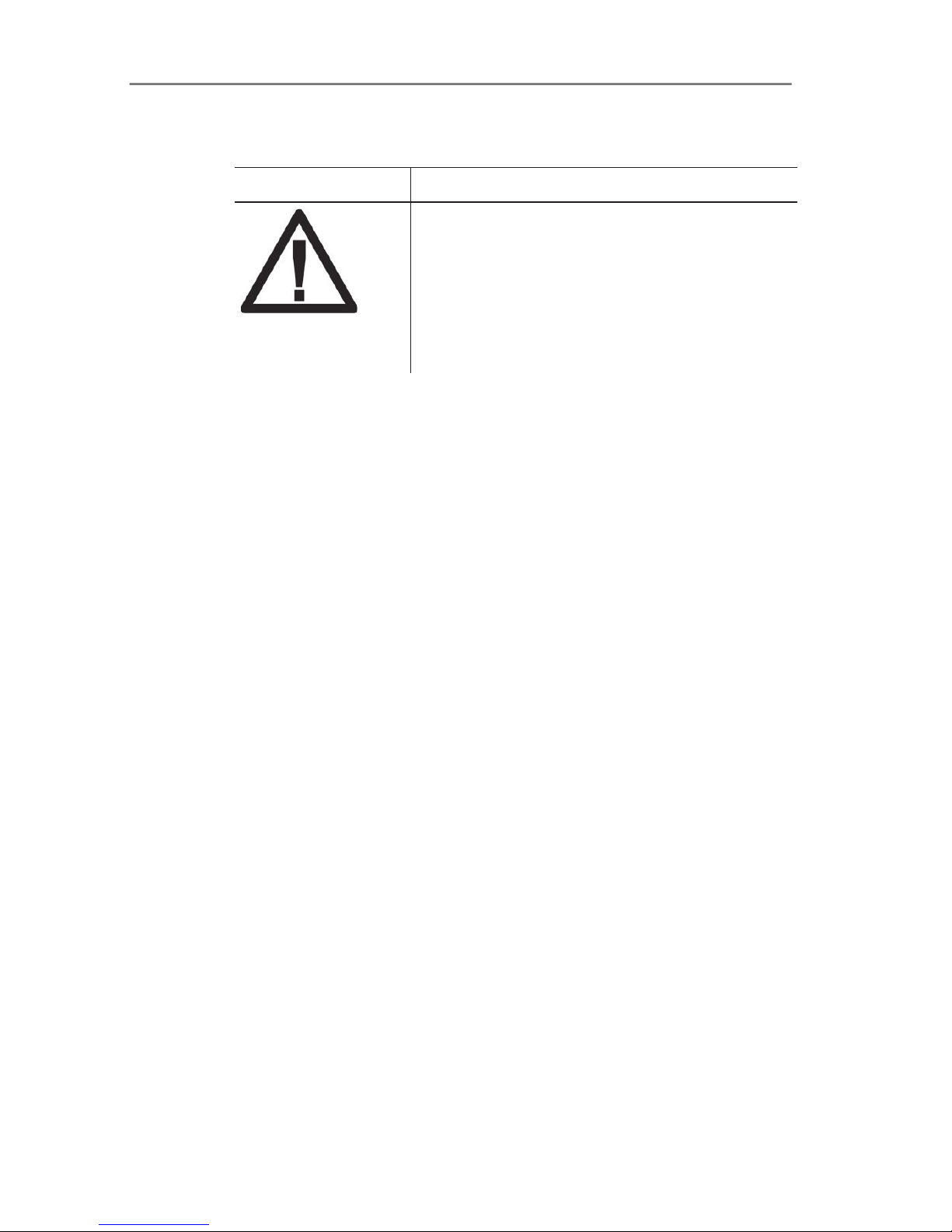

Safety related symbols on the instrument

Representation Explanation

If the product is not used in strict compliance

with this documentation, the intended

protection may be impaired.

> Operate the product only as described in

this documentation.

> Please consult your dealer or the

manufacturer if in doubt.

2.4. Protecting the environment

> Dispose of faulty rechargeable batteries/spent batteries in

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to Testo for disposal.

Page 12

3 Specifications

12

3 Specifications

3.1. Use

Do not use the testo 350 MARITIME for continuous flue gas

measurements, i.e. the sensors must be regularly rinsed with fresh

air. Recommended measurement periods and rinse phases, see

Recommendation for emissions measurements over an extended

period of time, page 89.The testo 350 MARITIME is a portable

flue gas analyser, which can be used as a system component

within a complete monitoring system to measure flue gas

emissions from marine diesel engines in accordance with

MARPOL 73/78 Annex VI and NOx Technical Code 2008

(MEPC.177(58)). In order to fully comply with the on-board

detection procedure of the “Direct Measurement and

Monitoring Method” MARPOL 73/78 Annex VI and NOx

Technical Code 2008 (MEPC.177(58)), additional parameters

must be recorded.

The testo 350 MARITIME has been designed for the following

applications:

• The testo 350 MARITIME can be used as a system component

to measure the gaseous flue gas concentrations of O

2

, CO,

CO

2

, NOx and SO2for the following procedures:

• for periodical examinations and for intermediary

examinations for direct measurement and monitoring on

board

• as a component for a simplified test and measuring method

(HC must be measured separately

• testing the NOx limits specified in MARPOL Annex VI for official

NOx monitoring measurements on board.

• NOx measurement as proof in regional special zones, e.g. as

proof of NOx reduction for NOx tax in Norway

The flue gas analyser testo 350 MARITIME is certified by

DNV GL for measuring gaseous flue gas components as a

system component (e.g. for the “direct measurement and

monitoring” on board procedure, and for simplified

measurement procedures).

Other system components required in accordance with

NOx Technical Code for the “direct measurement and

monitoring” on board procedure are not included in this

certification!

Page 13

3 Specifications

13

Prior authorisation from the respective flag state is

required in order to use a monitoring system and its

measurement results.

The testo 350 MARITIME V2 is not suitable for measuring

SO2 exhaust gas concentrations that correspond to sulfur

concentrations below 0.5%.

Page 14

3 Specifications

14

3.2. Technical data

3.2.1. Declaration of Conformity

Page 15

3 Specifications

15

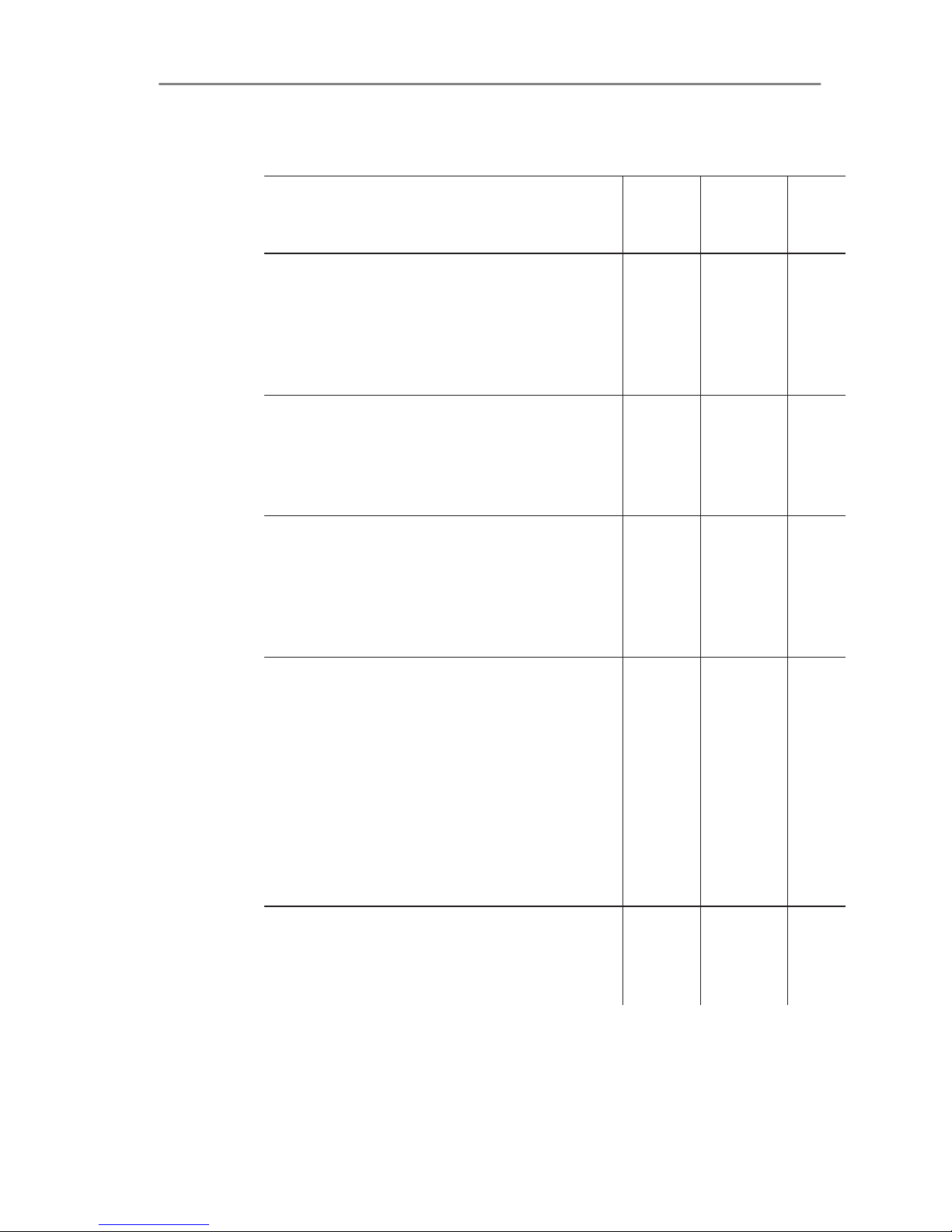

3.2.2. Measuring ranges and accuracies

Measuring box

Measurement

parameter

Measurement

range

Tolerance

°C, flue gas -40 to +1000 °C max. ± 5 K

O

2

0 to 25vol.% according to Marpol,

CO 0 to 3000 ppm Annex VI or NOx

NO 0 to 3000 ppm Technical Code 2008

NO

2

0 to 500 ppm

SO

2

100 to 3000 ppm

CO2(IR) 0 to 40Vol.%

P

abs

600 to 1150 hPa ± 5 hPa at 22 °C

± 10 hPa at -5 to +45 °C

Measurement

parameter

Measurement

range

Resolution

Differential

pressure

-200 to 200 hPa 0.1 hPa

NTC (permanently

installed)

-20 to 50°C 0.1°C

Absolute pressure 600 to 1150 hPa 1 hPa

Type K (NiCr-Ni) -200 to 1370°C 0.1°C

Type S (Pt10RhPt)

0 to 1760°C 1°C

Measurement

parameter

Accuracy Response

time

Differential

pressure

± 0.5 hPa (-49.9 to 49.9 hPa)

±1.5% of reading (rest of

range)

-

Absolute pressure ±10 hPa -

Type K (NiCr-Ni)

±0.4°C (-100 to 200°C)

±1°C (rest of range)

-

Page 16

3 Specifications

16

Measurement

parameter

Accuracy Response

time

Type S (Pt10RhPt)

±1°C (0 to 1760°C)

-

3.2.3. Recommended test gas concentrations

Measurement

parameter

Measurement range

CO 500 ppm (in N2)

CO

2

15% (in N2)

NO 1800 ppm (in N2)

NO2 100 ppm (in synthetic air)

SO2 1000 ppm (in N2)

3.2.4. Other instrument data

Control unit

Feature Values

Power supply • via Li-ion rechargeable battery

• via measuring box

• via mains adapter

Battery charge time 7h (via mains adapter)

14h (via CAN interface)

Rechargeable

battery life

approx. 5 hrs (display switched on)

Memory 250,000 readings

Housing material ABS_UL_94V0_black

Weight 440g

Display Graphic colour display, 240 x 320 pixels

Dimensions 88 x 38 x 220mm

Page 17

3 Specifications

17

Measuring box

Feature Values

Power supply • via Li-ion rechargeable battery

• 100...240V/0.8...0.4A

Battery charge time <6h

Rechargeable

battery life

2.5 hrs (with gas cooler and IR module)

Dimensions 330 x 128 x 438mm

Housing ABS URL 94V0

Weight 4800g (completely assembled)

Memory 250,000 readings

Flue gas

overpressure

max 50 hPa

Underpressure max. 300 hPa

Pump volumetric

flow rate

1 l/min (controlled), standard litre ±0.1 l/min

Hose length max. 5m

Diluting gas Fresh air or nitrogen

Flue gas dust load max. 20g/m

3

Humidity load max. 70°Ctd at measuring input

USB interface USB 2.0

Trigger input Voltage: 5 to 12 V (falling or rising flank)

Pulse width: >1 s

Load: 5V/max. 5 mA, 12 V/max. 40mA

Feature Values

Ambient

temperature

-5°C to 45°C

short-term (max. 5min.): up to 80°C by

radiated heat (e.g. heat radiation from a hot

flue gas duct)

Ambient pressure 600 to 1100mbar (abs.)

Ambient humidity 5 to 95%RH

Storage and

transport

temperature

-20 to 50°C

Protection class IP40

Page 18

4 Product description

18

4 Product description

4.1. Scope of delivery

• testo 350 MARITIME control unit

• testo 350 MARITIME flue gas analyser, equipped with:

ƕ O

2

, CO, CO2(IR), NO, NO2and SO2sensor incl. differential

pressure sensor

ƕ Temperature probe input Type K NiCr-Ni and Type S

Pt10Rh-Pt

ƕ Testo data bus connection

ƕ Rechargeable battery

ƕ Integrated combustion air probe (NTC)

ƕ Trigger input

ƕ Measurement data memory

ƕ USB interface

ƕ Gas processing

ƕ Measurement range extension for single slot (only for SO

2

)

ƕ Fresh air valve

• Connecting cable (5m) between flue gas analyser and control

unit

• Flue gas probe for industrial engines with probe shaft prefilter

ƕ 335mm immersion depth incl. probe stop and heat

protection plate,

ƕ Tmax 1000°C,

ƕ Special hose for NO2/SO2 measurements, length 4m, incl.

thermocouple for flue gas temperature measurement (NiCrNi, length 400mm, Tmax. +1000°C) with 4m connection

cable and additional temperature protection

• Printer

• Mains cable

• Humidity measuring instrument testo 610

• CO2 calibration kit including service adapter for applying

calibration gas

• Silicone hose, ø 4mm, length: 5m

• Hose connector

• Spare filter (optional)

• Thermal paper for printer

• Instruction manual

• Calibration report

Page 19

4 Product description

19

• EC declaration of conformity

• Robust protective case with trolley function

4.2. Control unit

4.2.1. Overview

1 IrDA interface

2 Switch on / off

Page 20

4 Product description

20

3 Magnetic holder (on rear)

WARNING

Magnetic field

May be harmful to those with pacemakers.

> Keep a minimum distance of 15 cm between pacemaker and

instrument.

ATTENTION

Magnetic field

Damage to other devices!

> Keep a safe distance away from products which could be

damaged by the effects of magnetism (e.g. monitors,

computers or credit cards).

4 Display

5 Keyboard

6 Contact strip for connection to the measuring box (on rear)

7 Interfaces: USB 2.0, charger, Testo data bus

4.2.2. Keyboard

Button Functions

[]

Switch measuring instrument on / off

[OK]

Example

Function key (orange, 3x), relevant function is shown on

the display

>Ÿ@ Scroll up, increase value

>ź@ Scroll down, reduce value

[esc] Back, cancel function

[]

Open main menu

[ i ] Open menu Instrument diagnosis

Page 21

4 Product description

21

4.2.3. Display

1 Status bar (dark grey background):

• Display of date and time (valid for control unit and

measuring box).

• Display of status, power supply and remaining rechargeable

battery capacity (valid for control unit):

Icon Feature

Battery operation

Indication of remaining capacity of the

rechargeable battery by colour and fill level of the

battery icon (green = 20-100%, red = < 20%)

Mains operation

Indication of remaining capacity of rechargeable

battery: see above

2 Tabs and tab info field:

• Tabs: Display of measuring system components (CU =

control unit, 2, 3, etc. = measuring boxes, analog output

box) connected to the control unit.

The tabs provide access to the individual components.

Warning symbol:

- Red frame, red symbol / white background:

Display of instrument errors in the instrument diagnosis

menu, otherwise: Instrument designation.

- Black frame, black symbol / yellow background:

Information message (symbol is displayed alternately with

the instrument designation).

Page 22

4 Product description

22

- Yellow frame, yellow symbol / red background:

Warning (symbol is displayed alternately with the

instrument designation).

• Information field on tab (only in the tabs of measuring

boxes): Indication of selected folder/location, selected fuel,

selected application, status of power supply and remaining

rechargeable battery capacity (valid for measuring box,

symbols such as display for control unit, see above).

3 Selection field for functions (selected function appears against a

white background, unavailable functions are identified by grey

characters) or display of readings.

4 Function display for function keys.

4.2.4. Connections / interfaces

1 USB 2.0

2 Testo data bus

3 Connecting socket for mains unit 0554 1094

4 Guide groove for locking with the measuring box

4.2.5. Menu guide for control unit

Main menu Menu Description

Measurement records - Display of saved

measurement records

Device settings Date/Time Set date, time, time

format:

Power Options Automatic instrument

shut-down on / off

Display backlight in

battery operation on / off

Display brightness Set display brightness

Printer Select printer, enter print

text

Language Set instrument language

Page 23

4 Product description

23

Main menu Menu Description

Password protection Change password

Data bus Display of bus address,

enter bus rate

Instrument diagnosis Error diagnosis Display of errors present

Device information Display of device

information

Search for boxes - Set up connection to

measuring boxes

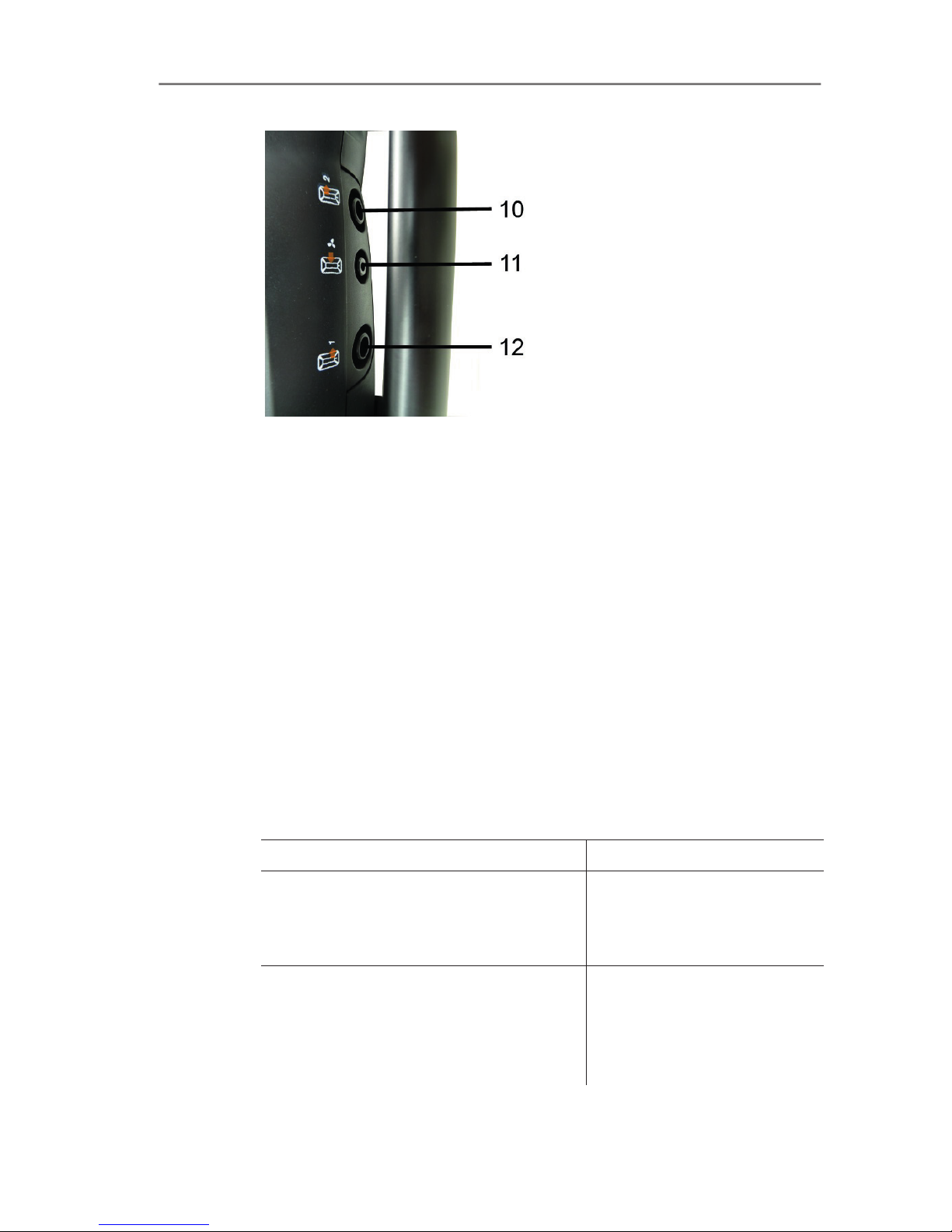

4.3. Measuring box

4.3.1. Overview

Page 24

4 Product description

24

1 Condensate container

2 Locking/unlocking button for control unit

3 Measuring gas particle filter

4 Fresh air inlet filter

5 Contact bar for connection to control unit

6 Guide pins for locking with control unit

7 Dilution air filter

8 Status display

9 Full-visibility tab for labelling/marking

10 Gas outlet 1

11 Fresh air inlet

12 Gas outlet 2

4.3.2. Status display

The status display shows the operating status of the measuring

box:

Display Status

green / permanent (measuring box

switched on)

Mains operation or

rechargeable battery

operation / rechargeable

battery fully charged

red / flashing (measuring box switched

on)

• Rechargeable battery

operation / residual

rechargeable battery

capacity < 20%

• Other system failure

Page 25

4 Product description

25

Display Status

green / flashing (measuring box

switched off)

Rechargeable battery or

trickle charging

green / permanent (measuring box

switched off)

Rechargeable battery fully

charged,

green, red / alternately flashing Update mode active

green / yellow alternately flashing

(green is on longer)

Instrument is in the switchon phase

yellow / green alternately flashing

(yellow is on longer)

Instrument is in the switchoff phase

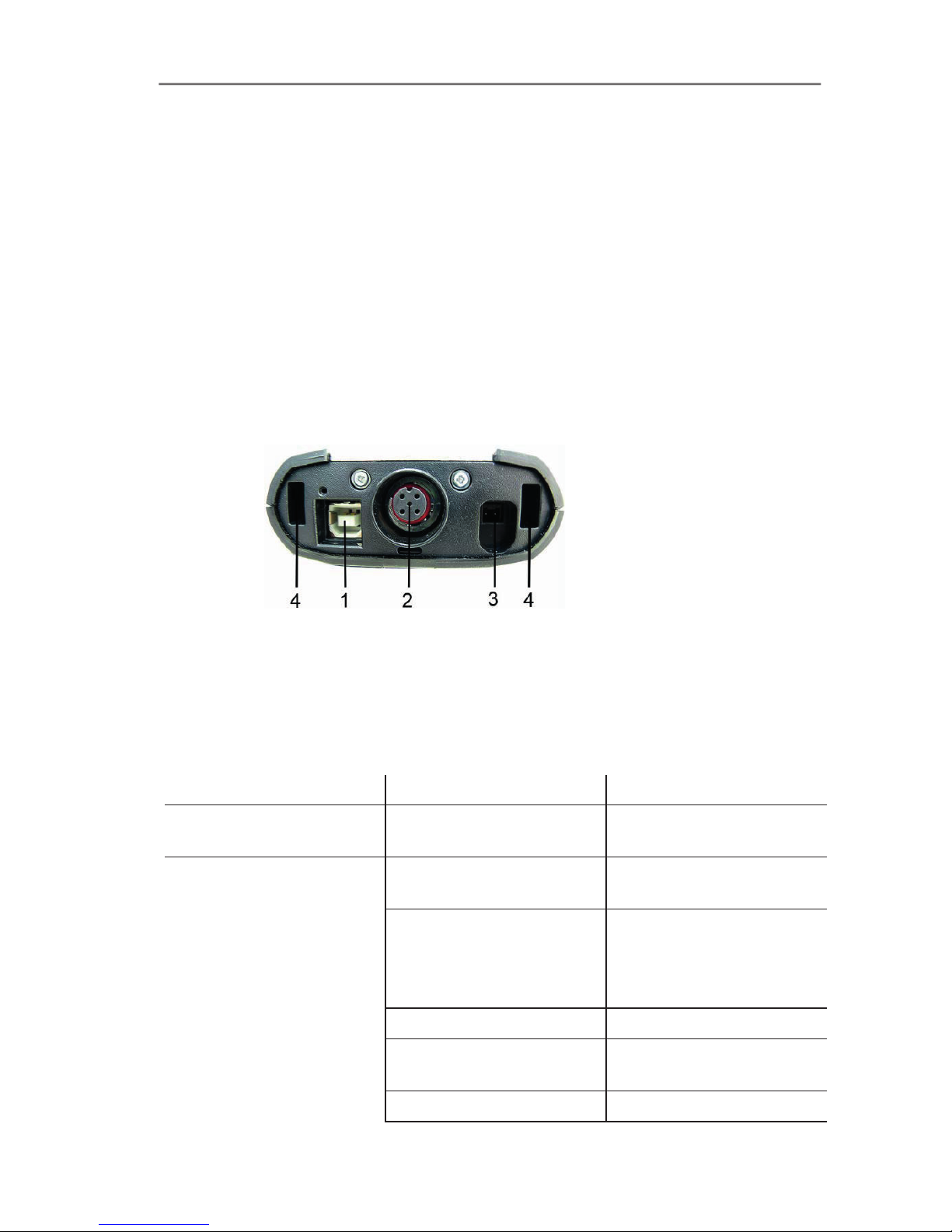

4.3.3. Connections / interfaces

1 Data bus termination slide switch

2 Sensor for combustion air temperature (VT)

3 Flue gas probe

4 Sensor input

5 USB 2.0

6 Trigger input

7 Dilution air inlet for measurement range extension

8 Mains connection 100 to 240V AC, 50-60Hz

9 Gas channel access cover cap (only for servicing purposes)

Plugged in cover cap: Position ( ) must not

be changed!

10 Pressure ports p+ and p11 Testo data bus

Page 26

4 Product description

26

4.3.4. Functions / instrument options

Some functions are available as optional extras. The functions your

measuring box is equipped with (condition as delivered) can be

read on the identification plate on the bottom of the measuring box.

Imprint Description

CO, NO, NO2, SO2,

O

2

, CO2(IR)

The sensor of the specified type is plugged in

SG Special main gas pump for long-term

measurement

1/x Measurement range extension (SO2 sensor)

GP Gas preparation, by means of reduced and

constant measuring gas dew point

temperature for higher measuring accuracy

4.3.5. Menu guide for measuring box

Main menu Menu Description

Measurementoptions - Select measurement type

• Flue gas

• Differential pressure

• EMDS

• Prog. 1

• Prog. 2

Folder - Create and manage folders

and locations

Fuels - Select and configure fuel

Measurement records - Display and manage

measurement records

Device settings Measurement view Configure display, set

measurement parameters

and units

Units Set units for display

variables

Date/Time Set date, time, time format:

Power Options

Set automatic instrument

shut-down and switch off

display backlight during

rechargeable battery

operation

Page 27

4 Product description

27

Main menu Menu Description

Display brightness Set display brightness

Printer Select printer, enter print

text

Language Set instrument language

Password protection Change password

Analog input Configure analog input

Data bus Display of bus address,

enter bus rate

Sensor settings Sensor protection Set safety cut-out

Recalibration Carry out calibration /

adjustment:

ppm counter Consumption display for the

sensors

Calibration data Calibration data display

Negative values Select negative values

display

Programs - Configure and activate

measuring programs

Instrument diagnosis Error diagnosis Display of errors present

Gas path check Carry out tightness test

Sensor diagnosis Carry out sensor diagnosis

Device information Display of device information

Page 28

4 Product description

28

4.4. Flue gas probe

4.4.1. Overview

Follow the safety instructions,

Before use: Pay strict attention to the installation

information for the flue gas probe,

1 Prefilter

2 Probe shaft

3 Probe shaft stop

4 Probe handle with connections for probe shaft and gas tubes /

thermocouple

5 Thermocouple

6 Gas tube

7 Overpressure outlet with locking clip

Page 29

5 First steps

29

5 First steps

5.1. Commissioning

Control unit

The control unit has a permanently installed rechargeable battery.

> Remove the protective film from the display.

> Charge the rechargeable battery fully before using the control

unit.

Measuring box

The measuring box is supplied with a rechargeable battery already

fitted.

> Charge the rechargeable battery fully before using the

measuring box.

For longer measurements, we recommend using via the

integrated mains unit.

In order to guarantee the security of the data connection, it

is recommended to connect the control unit and the flue

gas analyser using the connecting cable (item no.

0449 0042 included in the kit).

5.2. Getting to know the product

5.2.1. Mains unit, batteries/rechargeable batteries

In case of longer interruption of the power supply to the

control unit (e.g. rechargeable battery empty) the settings

for date / time will be lost.

If the power supply to the flue gas analyser is interrupted

for a long time (empty rechargeable battery pack), it takes

approx. 2 hours before an accurate NOx measurement

can be carried out.

Page 30

5 First steps

30

5.2.1.1. Recharging the rechargeable battery for the control unit

The rechargeable battery can only be charged at an ambient

temperature of ±0 to +35°C. If the rechargeable battery has been

completely discharged, the charging time at room temperature will

take about 7h (charging with mains adapter) or approx. 14h

(charging via Testo data bus).

Charging via mains unit (item no. 0554 1094)

㾐 The control unit is switched off.

1. Connect the plug of the mains unit to the mains unit socket on

the control unit.

2. Connect the mains plug of the mains unit to a mains socket.

- The charging process starts. The charge status will be shown

on the display.

- Once the rechargeable battery has been charged, the

instrument will automatically change to trickle charge.

Charging via measuring box

㾐 Control unit is locked to measuring box or is connected via the

Testo data bus cable.

㾐 The measuring box is supplied via the mains unit.

During operation with low charge power or in switched off state.

5.2.1.2. Charging the rechargeable battery for the measuring box

The rechargeable battery pack can only be charged at an ambient

temperature of ±0 to +35°C. If the rechargeable battery has been

discharged completely, the charging time at room temperature is

approx. 6h.

㾐 The measuring box is switched off.

> Connect mains cable to measuring box and mains socket.

- Charging will start, the fan may come on automatically. The

status LEDs lights green while the rechargeable battery is being

charged.

- Once the rechargeable battery has been charged, the

instrument will automatically change to trickle charge. The

charging status of the measuring box is shown on the control

unit display.

Page 31

5 First steps

31

5.2.1.3. Battery care

> Do not fully exhaust rechargeable batteries.

> Store rechargeable batteries only in charged condition and at

low temperatures, but not below 0°C.

> For longer breaks, you should discharge and recharge the

batteries every 3-4 months. Trickle charging should not exceed

2 days.

5.2.1.4. Mains operation

In case of danger, the instrument must be disconnected from the

electric power supply by simply pulling out the mains cable.

> Always position the instrument so that the power supply plug

can be easily reached.

Control unit

1. Connect the plug of the mains unit to the mains unit socket on

the control unit.

2. Connect the mains plug of the mains unit to a mains socket.

- The control unit is powered by the mains unit.

- If the control unit is switched off, the rechargeable battery

charging process will start automatically. Switching the control

unit on has the effect of stopping battery charging and the

control unit being powered via the mains unit.

Measuring box via internal mains unit

> Connect the mains cable to the measuring box and a mains

socket.

- The measuring box is powered via the internal mains unit.

- If the measuring box is switched off, the rechargeable battery

charging process will start automatically. Battery charging stops

when the flue gas analyser is switched on via the control unit.

Page 32

5 First steps

32

5.2.2. Connecting probes / sensors

Sensor detection takes place during the activation

process: Sensors that are required must always be

connected before the flue gas analyser is switched on,

or the flue gas analyser must be switched off and then

on again after a sensor change, so that the correct

sensor data can be read.

> Connect the supplied flue gas probe for industrial engines to the

corresponding connection.

- Measurement of the flue gas temperature is carried out via the

thermocouple at the tip of the flue gas probe inside the probe

filter.

5.2.3. Occupying the trigger input

The trigger input can be used as a criterion to either start or stop

(ascending or descending flank) measuring programs.

> Occupying the trigger input, with external voltage supply

(5...12 V):

> Occupying the trigger input, with supply via instrument voltage

(12 V):

In case of supply via instrument voltage the flue gas

analyser can only be started via the trigger input from

switched off state when the mains plug is plugged in.

Page 33

5 First steps

33

5.2.4. Connecting system components

5.2.4.1. Connection via contact strip

The control unit can be plugged onto the measuring box.

1. Insert the guide groove on the bottom of the control unit into the

guide pins of the measuring box.

2. Press the control unit against the measuring box until the

locking/unlocking button noticeably clicks into place twice.

To protect the display (e.g. during transport) the control unit

can also be inserted with the back facing up, however, in

this case there is no connection to the measuring box.

5.2.4.2. Connection to a bus system via data bus cable (accessory)

The individual components (e.g. control unit to measuring box or

measuring box to measuring box) can be connected to a bus

system using the Testo data bus cable.

Prior to commissioning a bus system, the bus address and

the data rate of the connected components must be

changed.

Before the components are joined up to a bus system, each

component must be configured separately via the control unit.

Page 34

5 First steps

34

Call up function:

[]ĺDevice settings ĺ[OK] ĺData bus ĺ[OK].

Bus address

The bus address of each component connected to the Testo data

bus must be unique. The bus address of the connected component

can be changed, if this should be necessary.

1. Bus Address ĺ [Edit].

2. Setting a new bus address: [], [], [Ż], [Ź].

3. Confirm the entry: [OK].

Data rate

Select the appropriate data rate, depending on the number of

connected components in a system,

• Control unit with a measuring box: 500 kbit/s

• All other systems: 50 kbit/s

>SelectData rate 500 kbit/s or 50 kbit/s : [], [], ĺ [Edit]

ĺ []or [ESC].

If several measuring boxes are connected to the control

unit, only the measurement data from one measuring box

can be displayed at a time, or only one measuring box can

be activated respectively. This is accomplished by selecting

the measuring box, see Search for boxes, page 38.

> Connect the data bus cable to the data bus interfaces.

Please observe the following points when setting up a connection

via data bus cable:

• Use only Testo data bus cables.

• Do not route data bus cables anywhere near electric power

cables.

• Ensure sufficient power supply by supplying each measuring

box with line voltage.

• The cables should ideally be plugged in before the system is

switched on. Connecting during operation (hot plugging) is

possible, however, depending on the combination the system

may need to be switched off and on again.

• The connection cannot be disconnected under load.

•

Page 35

5 First steps

35

Data bus subscribers: max. 3 measuring boxes in one data bus

system.

• Cable length: max. 100 m between control unit and measuring

box, max. 800 m between all measuring boxes in the data bus

system.

• The bus system must have a defined electrical termination, see

below.

Electrical termination of the bus system

The data bus system is linear in structure. The control unit or the

Testo data bus controller with USB connection represents the

beginning of the line.

The end is represented by the last components connected in the

system (measuring box or analog output box). This component

must have a defined electrical termination.

An analog output box is the furthest subscriber.

> Plug the data bus termination plug into the data bus socket on

the analog output box.

A measuring box is the furthest subscriber.

> Set the data bus terminating slide switch on the measuring box

( see Connections / interfaces, page 25, point 1) to switch

position right ( ).

5.2.5. Switching on

Before switching on

> Connect all system components.

> Connect all required probes / sensors.

> Connect all system components to the electric power supply.

When switching on, the control unit

- should be plugged to the contact strip of the measuring box

or

- connected to a data bus cable

Switching on

> Press [].

- The welcome screen is displayed (approx. 5s)

- The control unit display screen appears.

- The control unit searches for connected measuring boxes and

shows these as independent tabs on the display.

Page 36

5 First steps

36

Control unit and measuring box are not connected:

If the control unit has already been switched on, you must

press []once again briefly to set up a connection to the

measuring box.

5.2.6. Calling up the function

1. Select function: >Ÿ@, >ź@.

- The selected function appears in a frame.

2. Confirm selection: [OK].

- The selected function is opened.

5.2.7. Entering values

Some functions require values (numbers, units, characters) to be

entered. Depending on the function that is selected, the values are

entered either via a list field or an input editor.

List field

1. Select the value to be changed (numerical value, unit): >Ÿ@,

>ź@, [Ż], [Ź] (depending on the selected function).

2. Press [Edit].

3. Set value: >Ÿ@, >ź@, [Ż], [Ź] (depending on the selected

function).

4. Confirm the entry: [OK].

5. Repeat steps 1 and 4 as required.

6. Save the entry: [Finished].

Page 37

5 First steps

37

Input editor

1. Select the value (character) to be changed: >Ÿ@, >ź@, [Ż], [Ź].

2. Accept value: [OK].

Options:

> Toggle between letters and special characters:

Select ǿ

ĸ ABCĺ&$/ ĺǿ : >Ÿ@, >ź@ĺ [ABCĺ&$/].

> Position the cursor in the text:

Select ǿ

ĸ ABCĺ&$/ ĺǿ : >Ÿ@, >ź@ĺ [ǿĸ] or

[

ĺǿ].

> Delete character after the cursor:

Select ǿ

ĸ ABCĺ&$/ ĺǿ : [ĸ] or [ĺ]ĺ>ź@ĺ

[Del].

> Delete character in front of the cursor:

Select ǿ

ĸ ABCĺ&$/ ĺǿ : [ĸ] or [ĺ]ĺ>ź@ĺ

[

ĸ].

3. Repeat steps 1 and 2 as required.

4. Save the entry: Select

ĸ Finished ĺ : >Ÿ@, >ź@ ĺ

[Finished].

Page 38

5 First steps

38

5.2.8. Printing / saving data

Printing and saving is accomplished via the menu Options, which

is accessed via the left function key and is available in many

different menus.

To assign the right function key with the function Save or Print, see

Assigning the right hand function key, page 43.

Only readings which have a display field in the

measurement view assigned will be saved / printed out.

The measurement data can be printed out parallel to the

saving process, while a measurement program is running.

Readings from diluted sensors (with active measurement

range extension enabled) are underlined on the printout.

5.2.9. Search for boxes

(only available via the Control Unit tab)

> []ĺSearch for boxes ĺ[OK].

- Measuring boxes connected via Testo data bus: are displayed

(tabs)

5.2.10. Confirming an error message

If an error occurs, an error message is shown on the display.

> Confirming an error message: [OK].

Errors which have occurred and have not yet been resolved are

indicated by a warning symbol in the status bar.

Error messages not yet resolved can be displayed in the menu

Error diagnosis, See also Sensor diagnosis, page 43..

5.2.11. Switching off

Unsaved readings will be lost when the flue gas analyser is

switched off.

Rinsing phase

When switched off, the measuring box checks whether flue gases

are still in the sensors. The sensors are rinsed with fresh air, if this

should be necessary. The duration of the rinsing phase depends on

the gas concentration in the sensors.

> Press [].

- The rinsing phase starts.

Page 39

5 First steps

39

- The flue gas analyser switches off. It is normal for the fan of the

measuring box to run on for a while.

5.3. Folder

(only available via the Meas. Box tab)

All readings can be saved under the currently active location.

Readings that have not been saved are lost when the measuring

instrument is switched off!

Folders and locations can be created, edited, copied and activated.

Folders and locations (incl. records) can be deleted.

Call up function:

> []ĺFolders ĺ[OK] .

There are various options for opening folders.

1. Edit search setting: [Edit]

2. Select search setting: >Ÿ@, >ź@ĺ[OK].

Possible settings:

• Show all: All folders are displayed

• Search: A search text only brings up folders/locations that

contain characteristics of the search text.

• Filter: Individual letters or numbers can be selected. All data

beginning with the relevant letter/number is displayed.

The initial letter is the determining factor when using the

filter, and this can only be selected individually. The search

function can also be used to find a series of several letters

within the folder name!

3. Carry out search according to search setting: [Search]

Show all

1. Select folder: >Ÿ@, >ź@.

2. Show details: [Details].

3. $FWLYDWHDORFDWLRQ6HOHFWWKHORFDWLRQĺ[OK].

- The location is activated.

> Open Measurement options menu: Press [OK] again.

Search

1. Edit search criteria: [Ź]ĺ[Edit].

2. Select search criteria: >Ÿ@, >ź@ĺ[OK].

- The selected criteria is displayed.

3. Call up entry field for search text: [Ź@RU>ź@

> (QWHUVHDUFKWH[Wĺ[Finished]

Page 40

5 First steps

40

Filter

1. Edit search criteria: [Edit].

2. Select search criteria: >Ÿ@, >ź@ĺ[OK].

- The selected criteria is displayed.

3. Activate tab: >ź@

4. Select the required tab.: >Ÿ@, >ź@and sometimes [Ż], [Ź]ĺ

[Filter].

- The search result for the relevant letter or number is displayed.

Creating a new location:

A location is always created in a folder.

1. Select the folder in which the location is to be created.

2. [Options] ĺNew locationĺ[OK].

3. Enter values or make settings.

The following inputs/settings are possible:

Parameter Description

Location Enter name

Fuel Select fuel

4. Finalise the entry: [Finished].

Other location options:

> [Options] ĺEdit location: make changes to an existing

location.

> [Options] ĺCopy location: Make a copy of an existing

location in the same folder.

> [Options] ĺDelete location: Delete an existing location.

Create a new folder:

1. [Options] ĺNew Folderĺ[OK].

2. Enter values or make settings.

3. Finalise the entry: [Finished].

Other folder options:

• Edit Folder: Make changes to an existing folder.

• Copy Folder: Make a copy of an existing folder.

• Delete Folder: Delete an existing folder, including the locations

created in it.

• Delete All Folders: Delete all existing folders, including the

locations created in them.

Page 41

5 First steps

41

5.4. Measurement records

Measuring box

Measurement data is always saved in a measurement record in the

measuring box with which the measurement data were measured.

An overview with all created folders and locations is displayed. The

measurement records saved for the corresponding locations are

displayed. Measurement records can be displayed, printed, deleted

and copied to the control unit.

Control unit

Locations cannot be saved in the control unit. However,

measurement records saved in the measuring box can be copied to

the control unit.

For easy assignment the measurement records are saved under

the serial number of the measuring box. The data (folders,

locations, readings) contained in these records are displayed like in

the measuring box.

Call up function:

> []ĺMeasurement records ĺ[OK].

> only with Control Unit tab: Select the serial number of the

PHDVXULQJER[ĺ[OK].

There are various options for opening records. see Folder

, page

39.

Display record:

1. Select the required record from the detailed view.

2. [Data].

Options

> [Options] ĺ [Copy All Records]: The readings of all locations

will be copied.

Measuring box options

> [Options] ĺPrint Data: Transmit data of the selected record

to a record printer.

> [Options] ĺ Copy Record: Copy record into the record log of

the control unit.

> [Options] ĺDelete Record: Delete the selected record.

> [Options] ĺShow Graphic: Display saved record data as

graphic.

Page 42

5 First steps

42

> [Options] ĺNumber of lines: Change the number of readings

shown per display page.

> [Options] ĺDelete All Records: Delete all saved records for

a location.

> [Options] ĺ Copy All Records: Copy all records of a location

into the record log of the control unit.

Options for the control unit

> [Options] ĺDelete All Records: Delete all saved records for

a location.

5.5. Instrument diagnosis

Important operating values and instrument data are displayed. A

gas path check can be carried out. The status of the sensors and

any system failures not yet rectified are displayed.

Call up function:

> []ĺInstrument diagnosis ĺ[OK].

or

> [i].

5.5.1. Error diagnosis

> Error diagnosis ĺ[OK].

- Unresolved errors, warnings and notes are displayed.

> View next / previous error: >Ÿ@, >ź@.

5.5.2. Gas path check

(only available via the Meas. Box tab)

Check the flue gas analyser regularly for leaks, to ensure accurate

measurements.

The gas sampling probe should not be connected to the flue gas

analyser to carry out the leak-tightness test.

1. Gas path check ĺ[OK]

2. Close the measurement input. The leak-tightness of the test gas

path in the flue gas analyser testo 350 MARITIME can be

tested.

- The pump flow is displayed.

- Volumetric flow rate less than or equal to 0.04 l/min: The gas

paths are leak-tight (traffic light on the display lights up green).

- Volumetric flow rate higher than 0.04 l/min: The gas paths are

leaky (traffic light on the display lights up red). Measuring box

must be checked for leaks

Page 43

6 Using the product

43

5.5.3. Sensor diagnosis

(only available via the Meas. Box tab)

1. >Sensor diagnosis ĺ[OK].

2. Select sensor. >Ÿ@, >ź@.

- The status of the sensor is indicated by a traffic light.

A sensor is able to recover. It is therefore possible that the

sensor status indication will change from yellow to green or

from red to yellow.

5.5.4. Device information

> Device information ĺ[OK].

- Information is displayed.

6 Using the product

6.1. Performing settings

6.1.1. Assigning the right hand function key

The right function key can have a function from the Options menu

assigned to it. The menu Options is accessed via the left function

key and is available in many different menus. This assignment is

only valid for the currently opened menu / the opened function.

㾐 A menu / function is opened in which the Options menu is

displayed on the left function key.

1.Press [Options].

2. Select option: [], [].

Depending on the menu / function from which the Options menu

was opened, various functions are available.

3. Assign the selected function to the right function key: Press the

[Config. Key].

6.1.2. Instrument settings

6.1.2.1. Measurement view

(only available via the Meas. Box tab)

The parameters / units and the display representation (number of

readings displayed per display page) are preset and can be

changed if required. Editing of the reading display is protected by a

password, see Password protection, page 47.

Page 44

6 Using the product

44

Only those parameters and units that are activated in the

reading display appear in the reading display, in the saved

measurement records and on the record printouts.

Readings not listed in the reading display are not recorded

or stored either. Before carrying out measurements, set up

the reading display in such a way that the required

parameters and units are activated,

If the reading display is reconfigured in the graphical

representation [Show Graphic] while a measurement is

ongoing, readings previously displayed are no longer

shown. The reading display should be configured before

the Show Graphic menu is activated.

Complete overview of the selectable measurement parameters and

units:

Display Measurement parameter

NOxw

NOx displayed value corrected for CLD

(chemiluminescence). This displayed value

refers to ppm% wet flue gas.

NOxd NOx displayed value corrected for CLD

(chemiluminescence). This displayed value

refers to ppm% dry flue gas.

SO2w Sulphur dioxide wet

SO2d Sulphur dioxide dry

NOd Nitrogen monoxide dry

NO2d Nitrogen dioxide dry

H2Oc Flue gas humidity

O2d Oxygen dry

COd Carbon monoxide dry

H2d Hydrogen dry (this is only an indicator value

and is used to compensate the crosssensitivity)

CO2d Carbon dioxide IR dry active

pAin Absolute pressure

hAin Ambient humidity

°tAin Intake air temperature

Pump Pump flow

tEx Flue gas temperature

Page 45

6 Using the product

45

Display Measurement parameter

tInstr Instrument temperature

S-Fuel

Sulphur content of the fuel:

The displayed sulphur content of the fuel

(tolerance ±10%), based on complete

combustion as per MEPC 184(59), is

determined by the SO2/CO2-ratio and is

intended as a guide. Values between 0 and

0.5% sulphur are displayed as “<0.5%”.

Call up function:

> []ĺDevice settings ĺ[OK] ĺMeasurement view ĺ

[OK]

Change parameter / unit in a line:

1. Select the line: >Ÿ@, >ź@ĺ[Edit]

2. Select the parameter: >Ÿ@, >ź@ĺ[OK]

3. Select the unit: >Ÿ@, >ź@ĺ[OK]

4. Save changes: [OK]

Options:

> [Options] ĺNumber of lines: Change the number of readings

shown per display page.

> [Options] ĺBlank line: Insert the blank line in front of the

selected line.

> [Options] ĺDelete line: Delete the selected line.

> [Options] ĺFactory setting: Reset the readings display to the

factory setting.

6.1.2.2. Units

(only available via the Meas. Box tab)

Units for display variables used in configuration menus can be set.

Call up function:

> []ĺDevice settings ĺ[OK] ĺUnits ĺ[OK]

Adjustable units

Parameter Unit

Altitude m, ft

Length cm, inch, mm, ft

Area cm2, in2, mm2, ft

2

Page 46

6 Using the product

46

Setting the unit

1. Select the line: >Ÿ@, >ź@ĺ[Edit]

2. Select the unit: >Ÿ@, >ź@ ĺ[OK]

3. Confirm the entry: [Finished]

6.1.2.3. Date / time

This function is available in both the meas. box and the Control

Unit. Changes are accepted for the Control unit and for the meas.

box.

Date, time mode and time can be set.

Calling up the function:

> []ĺInstrument Settings ĺ[OK] ĺDate/Time ĺ[OK]

Set date/time

1. Select parameter: [Ż], >Ÿ@, >ź@ĺ[Edit].

2. Set parameter: >Ÿ@, >ź@and partly [Ż], [Ź]ĺ[OK].

3. Save changes: [Save].

6.1.2.4. Power options

This function is available in both the meas. box and the Control

Unit. Changes are accepted by the Control Unit and the meas. box.

Automatic instrument shut-down (Auto-Off) and switching off of the

display light in battery operation can be set.

Calling up the function:

> []ĺDevice settings ĺ[OK] ĺPower Options ĺ[OK]

Making settings:

1. Select function or parameter: >Ÿ@, >ź@ĺ[Change]

2. Set parameter: >Ÿ@, >ź@and partly [Ż], [Ź] ĺ[OK].

3. Save changes: [Finished]

6.1.2.5. Display brightness

This function is available in both the meas. box and the Control

Unit. Changes are accepted for the Control unit and for the meas.

box.

The intensity of the display illumination can be set.

Calling up the function:

> []ĺInstrument Settings ĺ[OK] ĺDisplay Brightness ĺ

[OK]

Page 47

6 Using the product

47

Performing settings

> Set parameter: [Ż], [Ź]ĺ[OK].

6.1.2.6. Printer

This function is available in both the measuring box and the control

unit. Changes are accepted for the control unit and the measuring

box.

The headers (lines 1-3) and the footer for the printout can be set.

The printer that is used can be activated.

Call up function:

> []ĺDevice settings ĺ[OK] ĺPrinter ĺ[OK].

1. Select printer ĺ[OK].

2. Select the printer: >Ÿ@, >ź@ ĺ[OK].

- The printer is activated and the menu Printer is opened.

Configuring the print text:

1. Print text ĺ[OK].

2. Select function: >Ÿ@, [ź] ĺ[Edit].

3. (QWHUYDOXHVĺ[Next].

4. Save the entry: [Finished].

6.1.2.7. Language

This function is available in both the measuring box and the control

unit. Changes are accepted for the control unit and for the

measuring box.

The menu language can be set.

> []ĺDevice settings ĺ[OK] ĺLanguage ĺ[OK].

Activate the language:

> 6HOHFWWKHODQJXDJHĺ[OK].

6.1.2.8. Password protection

This function is available in both the meas. box and the Control

Unit. Changes are accepted for the Control unit and for the meas.

box.

The password protection is only valid for functions identified by the

following symbol: or .

Password protection can be activated / deactivated, the password

can be changed.

To deactivate the password protection change the password to

0000 (factory setting).

Page 48

6 Using the product

48

Calling up the function:

> []ĺInstrument Settings ĺ[OK] ĺPassword Protection

ĺ[OK]

Possibly:

> Enter the currently valid password:

[Enter] ĺ(QWHUSDVVZRUGĺ[Next] ĺ[OK].

Changing the password:

1. [Edit].

2. (QWHUWKHQHZSDVVZRUGĺ[Next].

3. [Edit].

4. (QWHUWKHQHZSDVVZRUGDJDLQWRFRQILUPĺ[Next].

5. Save changes: [Finished].

6.1.2.9. Analog input

(Only available via Meas. Box tab)

Power cable 0554 0007 (accessory) is required.

An analog signal is read in by an external instrument. The signal is

scaled and assigned to a physical parameter. The calculated value

is displayed.

Before the flue gas analyser is started, insert power

cable 0554 0007 at the measuring box probe input port.

1. Select analog signal (±1 V, ±10 V, 0…20 mA) at power cable

0554 0007.

Calling up the function:

> []ĺDevice settings ĺ[OK] ĺAnalog input ĺ[OK].

Configuring the analog input:

1. Measurement parameter ĺ[Edit].

2. Enter or set values: >Ÿ@, >ź@, [Ż], [Ź] ĺ[OK].

3. Save the entry: [Finished].

4. Entry of min. and max. measure value limit (Min0V or Min0mA)

ĺ[Edit].

5. Enter or set values: >Ÿ@, >ź@, [Ż], [Ź] ĺ[OK].

6. [Finished].

Page 49

6 Using the product

49

6.1.2.10. Data bus

Bus address

See Connection to a bus system via data bus cable (accessory),

page 33.

Data rate

See also Connection to a bus system via data bus cable

(accessory), page 33.

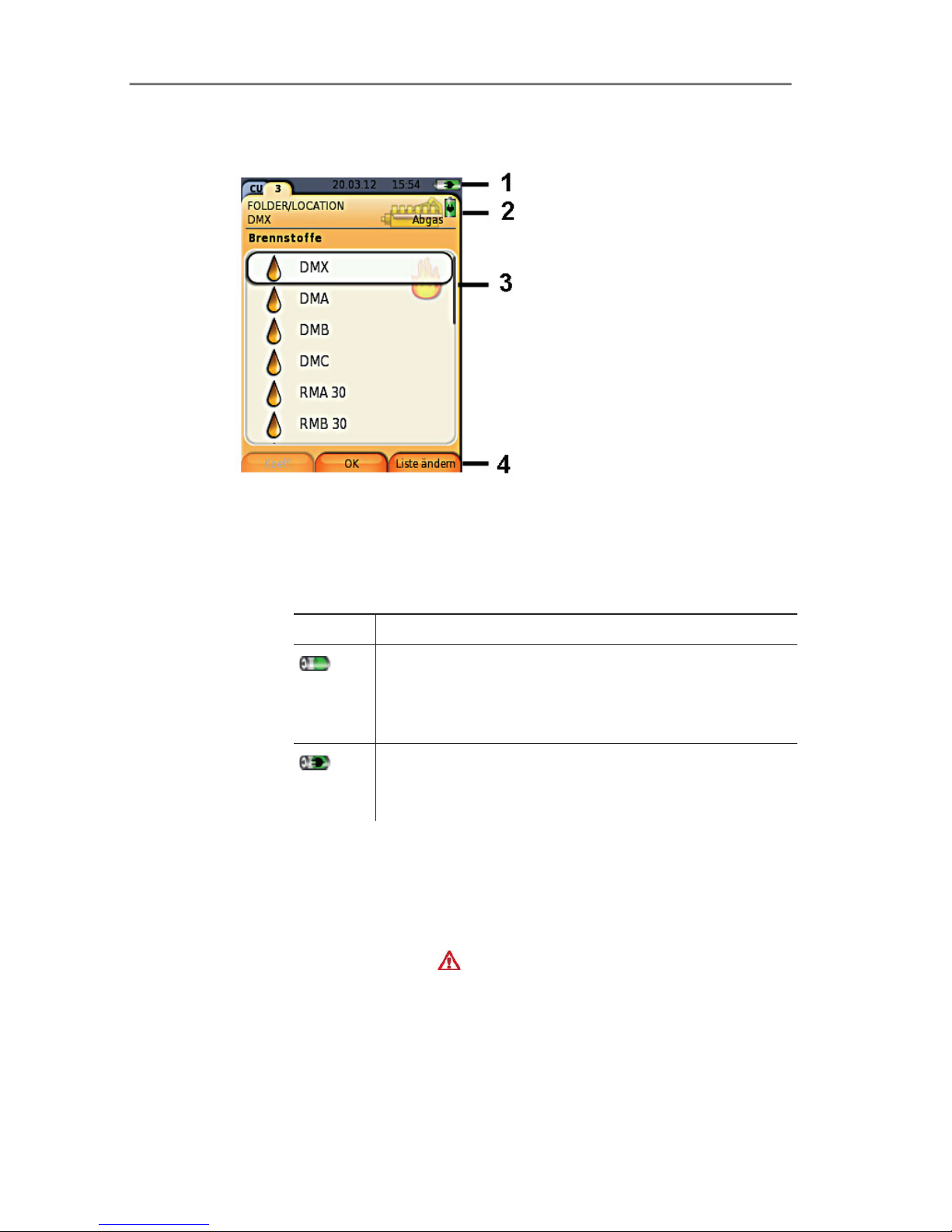

6.1.3. Fuels

The following fuels can be selected:

Fuel Designation

Distillate Fuel Oil (DM) DMX

DMA

DMB

DMC

Residual Fuel Oil (RM, RFO) RMA 30

RMB 30

RMD 80

RME 180

RMF 180

RMG 380

RMH 380

RMK 380

RMH 700

RMK 700

Rapeseed Oil Methylester (RME) RME (FAME)

Low-sulphur diesel (0.1% sulphur) MDO 0.1 % S

Test gas Test gas

Customised 1 to 5 Fuel 1 to 5

Page 50

6 Using the product

50

Call up function:

> []ĺFuels ĺ[OK].

View coefficients of configured fuels

> Select fuel: >Ÿ@, >ź@ĺ [Coeff.].

- Coefficient information window opens and the factory setting for

hydrogen, carbon and sulphur content of the selected fuel is

displayed.

Set coefficients for customised fuels

In addition to the pre-configured fuels, 5 customer-specific fuels

can be created.

> Select customer-specific fuel: >Ÿ@, >ź@ĺ [Coeff.].

Possibly:

> Enter the password: [Enter] ĺ[Next] ĺ[OK].

Configure fuel name / coefficients:

1. Edit fuel name: [Edit] ĺ>Ÿ@, >ź@, [Ż], [Ź] ĺ[OK].

2. Save change: [Finished].

3. Select coefficient for hydrogen, carbon or sulphur content: >Ÿ@,

>ź@ĺ[Edit].

4. Set values: >Ÿ@, >ź@and [Ż], [Ź] ĺ[OK].

• H-content setting range: 0.1 to 99.9%

• C-content setting range: 0.1 to 99.9%

• S-content setting range: 0.0 to 5.0%

The sum of the H, C and S-content should not be >100%.

5. Repeat steps 3 and 4 as required.

6. Save the entry: [Finished].

6.1.4. Sensor settings

6.1.4.1. Sensor protection

Protection limits can be set to protect the sensors against overload.

The sensor protection switch-off is available for the following

sensors: NO, NO

2

, CO, SO2.

The sensor protection is activated if the threshold is exceeded, the

measuring gas is diluted. If the threshold is exceeded again, the

system will be shut down.

To deactivate sensor protection, the thresholds must be set to 0

ppm.

Page 51

6 Using the product

51

Call up function:

> []ĺSensor settings ĺ[OK] ĺ Sensor protection ĺ

[OK]

Setting sensor protection thresholds:

1. Select parameter: [Edit]

2. Set parameter ĺ [OK]

3. Save changes: [Finished]

6.1.4.2. Calibration / adjustment

CO, SO2, NO2, NO and O2 sensors can be tested (calibrated) and

readjusted; the CO2 (IR) sensor can be readjusted. A readjustment

of O2 only lasts until another zeroing is carried out or the testo 350

MARITIME is switched off. Calibration data is stored in the sensor,

not in the instrument! The relevant calibration instructions of the

standards/guidelines to be applied must be followed (e.g.

calibration or adjustment of the gas sensors before and after a flue

gas measurement).

If obviously unrealistic readings are displayed, the

measuring cells should be checked and readjusted as

required. To ensure that specific accuracies are retained,

Testo recommends testing every 3 months and readjusting

when required.

Adjustments made with low gas concentrations can lead to

accuracy deviations in the upper measuring ranges.

The sensor protection (shut-down function) is not

deactivated. The test gas concentration should therefore be

lower than the thresholds set for the sensor protection.

The following boundary conditions must be met when calibrating /

adjusting:

• Use absorption-free hose material.

• Select Test gas fuel.

• Switch on the flue gas analyser at least 20 minutes before

calibration / adjustment (to warm up)

• Use clean air for gas zeroing

• Maximum overpressure of the test gas 30 hPa (recommended:

pressureless via bypass)

• Apply the test gas for at least 3 minutes

Recommended test gas concentrations and compositions can be

found in the Testo Test Gas Manual (order no. 0980 2313 version

D) or in the Download Centre.

Page 52

6 Using the product

52

Call up function:

Make sure that the ambient air us free of interfering gases

(e.g. CO, NO, etc.) during zeroing!

> []ĺ Sensor settings ĺ [OK] ĺ Calibration ĺ [OK]

Possibly:

> Enter password: [Enter] ĺ(QWHUSDVVZRUGĺ [Next] ĺ [OK]

- Gas zeroing (30s).

Carry out calibration / adjustment of CO, SO

2

, NO2, NO, O

2ref

sensors:

WARNING

Dangerous gases

Danger of poisoning!

> Observe safety regulations / accident prevention regulations

when handling test gas.

> Use test gases in well ventilated rooms only.

Application of test gas via service adapter (0440 3352) is

recommended, or apply test gas directly to the probe tip to

avoid possible absorptions in the gas path.

1.Select the parameter: >Ÿ@, >ź@ĺ[OK]

2.[Edit] ĺ(QWHUWKHWHVWJDVFRQFHQWUDWLRQQRPLQDOYDOXH

3. Apply test gas to the sensor.

4.Start calibration: [Start]

5. Accept the nominal value once the actual value is stable

(adjustment): [Adjust]

-orCancel (no adjustment): [esc]

6. Save changes: [Finished]

Carry out calibration / adjustment of the CO

2

(IR) sensor

Check the CO

2

(IR) sensor with the aid of the absorption filter to

obtain accurate readings. The CO

2

value displayed should be

<0.03% CO

2

. If the value is higher, carry out calibration and

gradient adjustment.

Page 53

6 Using the product

53

WARNING

Dangerous gases

Danger of poisoning!

> Observe safety regulations / accident prevention regulations

when handling test gas.

> Use test gases in well ventilated rooms only.

Application of test gas via service adapter (0554 3352) is

recommended, or apply test gas directly to the probe tip to

avoid possible absorptions in the gas path.

1.Select CO2IR sensor: >Ÿ@, >ź@ĺ[OK]

2. Connect absorption filter or apply test gas with 0% CO2.

3. [Ż], [Ź], [Yes] ĺ[OK]

- Stabilisation phase (120s)

4. Start measured value admission manually: [Start]

or

wait for stabilisation phase: Measured value admission is

automatically started.

- Measured value admission ends automatically.

5. [Next]

6. Enter the nominal gradient value: [Edit] ĺ>Ÿ@, >ź@, [Ż], [Ź]

ĺ[OK].

7. Start stabilisation phase: [Start]

- Stabilisation phase (120s)

8. Start measured value admission manually: [Start]

or

wait for stabilisation phase: Measured value admission is

automatically started.

- Measured value admission ends automatically.

9. Carry out adjustment: [Finished]

-orCancel (no adjustment): [esc]

6.1.4.3. Calibration data

Use this function to display the current calibration data and the

sensor status of the individual sensors.

The condition of the sensor is checked with each sensor calibration

/ adjustment. The graphic representation shows the last 25

calibrations.

Call up function:

> []ĺSensor settings ĺ[OK] ĺCalibration data ĺ [OK]

Page 54

6 Using the product

54

Options

> [Options] ĺ[Print]: The current calibration data of all sensors

is printed out.

> [Options] ĺ[Graphic]: The status of the selected sensor is

displayed graphically.

Threshold Explanation

100% Full capacity

70% Reduced sensor sensitivity

Recommendation: Acquire a replacement

sensor

50% Replace sensor

6.1.4.4. Negative values

The display for negative values can be activated / deactivated.

Call up function:

> []ĺSensor settings ĺ[OK] ĺNegative values

Switching negative values on/off

1. [Edit]

2. Select setting: >Ÿ@, >ź@

3. Confirm the entry: [OK]

6.1.5. Programs

Two flue gas measuring programs can be configured, saved and

carried out.

The Trigger function (trigger signal as start/stop criterion) is only

available for devices with the trigger input option.

Device settings cannot be changed if a program is active or

running.

Call up function:

>[]ĺPrograms ĺ[OK].

Activating / deactivating a program:

> Select the program: >Ÿ@, >ź@ĺ[Enable] or [Disable].

- When activating a program: The program is activated and the

measurement type matching the program is opened.

Page 55

6 Using the product

55

Editing the measuring program:

Adjustable parameters:

Parameter Function

Measurement

program

Edit program name

Measurement

type

• Flue gas

Readings per

mean value

With mean value Yes only mean values will be

saved.

Start Determine the start criterion

•

The measuring program is started at any

time (the function key automatically changes

to the stop function).

• External signal

Trigger signal to control the start of

measuring programs.

Stop Determining the stop criterion

•

The measuring program is stopped at any

time (the function key automatically changes

to the start function)

•Time

The recoding of readings stops at a desired

time.

• External signal

Trigger signal to control the stop of

measuring programs.

• Duration

Setting cycles to save readings.

•Memory full

Saving readings ends when the memory is

full.

Gas phase Selection of gas phase cycle