Page 1

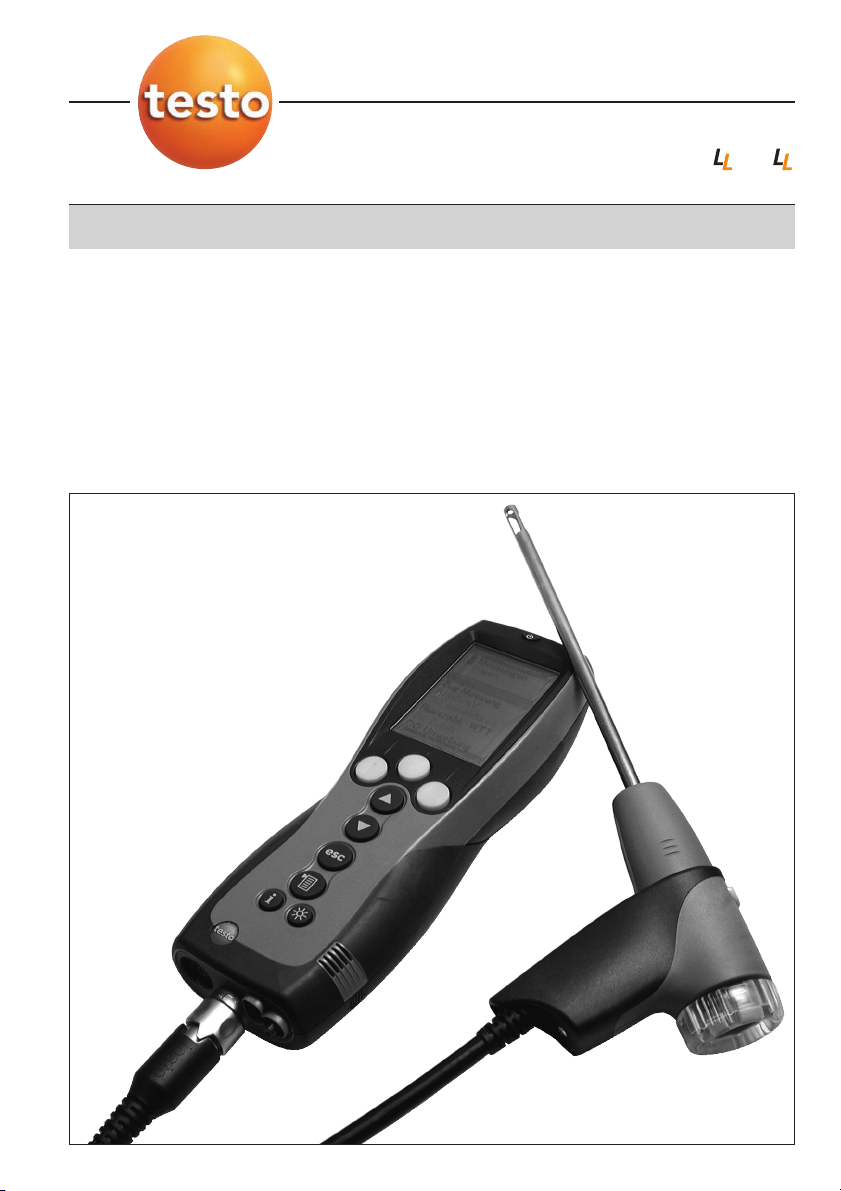

testo 330-1, -2, -3 / testo 330-1 , -2

Flue gas analyser

Instruction manual en

Page 2

2

General notes

General notes

Please read this documentation through carefully and familiarise yourself with the

operation of the product before putting it to use. Keep this document to hand so that

you can refer to it when necessary.

The document describes the country-specific version Dof the testo 330-1, -2, -3 and

testo 330-1LL, -2LL products.

Identification

Symbol Meaning Comments

Warning advice: Warning! Read the warning advice carefully and take

Serious physical injury could be caused if the the specified precautionary measures!

specified precautionary measures are not taken.

Warning advice: Caution! Read the warning advice carefully and take

Slight physical injury or damage to equipment the specified precautionary measures!

could occur if the specified precautionary

measures are not taken.

Important. Please pay particular attention.

(testo 330-1) The description applies only for the -

Tex t Text appears on the instrument’s display -

OK

instrument indicated: testo 330-1, -2, -3 /

testo 330-1LL,-2LL.

Key Press the key.

Function key with the function “OK”. Press function key.

xyz Short form for operating steps. See

short form

,p.3.

Page 3

General notes

Short form

This document uses a short form for describing operating steps (e.g. calling up a

function).

Example: Calling up the

Short form:

Flue gas function

Measurements Flue gas

OKOK

(1) (2) (3) (4) (5)

Steps required:

1

Open main menu: .

2

Select

Measurements menu: , .

3

Confirm selection: .

4

Select

Flue gas menu: , .

5

Confirm selection: .

OK

OK

3

Page 4

4

Contents

Contents

See also

Functional overview

, p. 60.

General notes ........................................................................................2

Contents ................................................................................................4

A. Safety advice ........................................................................................7

B. Intended purpose ..................................................................................9

C. Product description ............................................................................10

C.1 Measuring instrument ..................................................................10

C.1.1 Overview ..................................................................................10

C.1.2 Keypad ....................................................................................11

C.1.3 Display ....................................................................................11

C.1.4 Device connections ..................................................................12

C.1.5 Interfaces ................................................................................13

C.1.6 Components ............................................................................13

C.1.7 Carrying strap /barcode pen holder ..........................................14

C.2 Modular flue gas probe ................................................................15

D. Commissioning ....................................................................................16

E. Operation ............................................................................................17

E.1 Mains unit / rechargeable battery ..................................................17

E.1.1 Changing the battery ..............................................................17

E.1.2 Charging batteries ....................................................................18

E.1.3 Operation with the mains unit ..................................................18

E.2 Probes /Sensors ..........................................................................19

E.2.1 Connecting probes/sensors ....................................................19

E.2.2 Replacing the probe module ....................................................20

E.3 Regular care ................................................................................20

E.3.1 Condensate trap ......................................................................20

E.3.2 Checking/replacing the particle filter ........................................21

Page 5

Contents

E.4 Basic operating steps ..................................................................21

E.4.1 Switching the measuring instrument on ....................................21

E.4.2 Calling up a function ................................................................22

E.4.3 Entering values ........................................................................22

E.4.4 Printing data ............................................................................23

E.4.5 Saving data ..............................................................................23

E.4.6 Confirming an error message ..................................................23

E.4.7 Scanning locations with the barcode pen ................................24

E.4.8 Switching the measuring instrument off ....................................24

E.5 Memory / Location ........................................................................24

E.6 Instrument diagnosis ..................................................................26

F. Configuration ......................................................................................28

F.1 Instrument settings ......................................................................28

F.1.1 Display edit ..............................................................................28

F.1.2 Printer ......................................................................................29

F.1.3 Alarm limits ..............................................................................30

F.1.4 Start Keys edit ........................................................................30

F.1.5 Communication ........................................................................31

F.1.6 Date /Time ..............................................................................31

F.1.7 Language ................................................................................31

F.2 Sensor settings ............................................................................32

F.3 Fuels ..........................................................................................33

G. Measuring ............................................................................................34

G.1 Preparing measurements ............................................................34

G.1.1 Zeroing phases ........................................................................34

G.1.2 Using the modular flue gas probe ............................................35

G.1.3 Configuring the reading display ................................................35

G.1.4 Set memory/location ................................................................35

5

Page 6

6

Contents

G.2 Measurements ............................................................................36

G.2.1 Flue gas ..................................................................................36

G.2.2 Draught ....................................................................................37

G.2.3 Fine pressure probe (accessory) ..............................................37

G.2.4 BImSchV (testo 330-3 / testo 330-2LL) ..................................38

G.2.5 CO undiluted ............................................................................40

G.2.6 Smoke No./HCT ....................................................................40

G.2.7 Differential pressure ..................................................................41

G.2.8 Differential temperature ............................................................42

G.2.9 O2 air ......................................................................................42

G.2.10 Gas flow rate ..........................................................................43

G.2.11 Oil flow rate ..............................................................................43

G.2.12 Leak detection ........................................................................44

G.2.13 Ambient CO ............................................................................44

G.2.14 Ambient CO2 ..........................................................................45

G.2.15 Burner control ..........................................................................46

H.1 Protocol printer ............................................................................48

H.2 PC /Pocket PC ............................................................................48

I. Care and maintenance ........................................................................49

I.1 Cleaning the measuring instrument ..............................................49

I.2 Replacing measuring cells ..........................................................49

I.3 Recalibrating measuring cells ......................................................50

I.4 Replacing additional filter ............................................................50

I.5 Cleaning the modular flue gas probe ............................................51

I.6 Changing the thermocouple ........................................................51

J. Questions and Answers ......................................................................52

K. Technical data ....................................................................................52

K.1 Standards and inspections ..........................................................52

K.2 Measuring ranges and accuracies ..............................................53

K.3 Other device data ........................................................................54

K.5 Principles of calculation ..............................................................56

K.5.1 Fuel parameters ......................................................................56

K.5.2 Calculation formulae ................................................................56

L. Accessories/Spare parts ....................................................................58

Functional overview ....................................................................................60

Page 7

A. Safety advice

A. Safety advice

Avoid electrical hazards:

Never use the measuring instrument and probes to measure on or near live parts!

Protect the measuring instrument:

Never store the instrument/measuring cells together with solvents (e.g. acetone). Do

not use any dessicants.

Product with Bluetooth

Changes or modifications, which are not expressly approved by the responsible official

body, can lead to a withdrawal of operating permission.

Interference with data transfer can be caused by instruments which transmit on the

same ISM band, e.g. microwave ovens, ZigBee.

The use of radio connections is not allowed in e.g. aeroplanes and hospitals. For this

reason, the following point must be checked before entering:

Deactivate Bluetooth function:

Inst’ settings Communication IrDA .

®

(Option)

OKOKOK

7

Product safety/preserving warranty claims:

Operate the measuring instrument only within the parameters specified in the

technical data.

Handle the instrument properly and according to its intended purpose.

Never apply force!

Temperatures given on probes/ sensors relate only to the measuring range of the

sensors. Do not expose handles and feeders to any temperatures in excess of 70 °C

unless they are expressly permitted for higher temperatures.

Open the measuring instrument only when this is expressly described in the

Operating Instructions for maintenance purposes.

Carry out only the maintenance and repair work that is described in the Operating

Instructions. Follow the prescribed steps exactly. For safety reasons, use only original

spare parts from Testo.

Page 8

8

A. Safety advice

Any further or additional work must only be carried out by authorised personnel.

Testo will otherwise refuse to accept responsibility for the proper functioning of the

measuring instrument after repair and for the validity of certifications.

Ensure correct disposal:

Dispose of defective rechargeable batteries and spent batteries at the provided

collection points.

Send the measuring instrument directly to us at the end of its life cycle. We will

ensure that it is disposed of in an environmentally friendly manner.

Page 9

B. Intended purpose

B. Intended purpose

This chapter describes the areas of application for which the measuring instrument is

intended.

The testo 330 is a handheld measuring device for the professional flue gas analysis of

furnace systems:

· Small furnaces (burning oil, gas, wood, coal)

· Low-temperature and condensing boilers

· Gas heaters

These systems can be adjusted using the testo 330 and checked for compliance with

the applicable limit values.

The measuring instrument is approved for measurements under the German regulations

on immissions protection (1. BImSchV).

The following tasks can also be carried out with the testo 330:

· Regulating the O

ensuring optimal operation.

· Draught measurement.

· Measuring and regulating the gas flow pressure in gas heaters.

· Measuring and optimising the flow and return temperatures of heating systems.

· CO- and CO

· Detection of CH

testo 330 should not be used:

· for continuous measurements

· as a safety (alarm) instrument

-, CO- and CO2-, NO-, NOxvalues in furnaces for the purpose of

2

environment measurement.

2

(methane) and C3H8(propane).

4

9

The testo 330 with the Bluetooth option may only be operated in countries in which it

is type approved (see Technical Data).

Page 10

C. Product description

10

C.1 Measuring instrument

C. Product description

This chapter provides an overview of the individual components of the product.

C.1 Measuring instrument

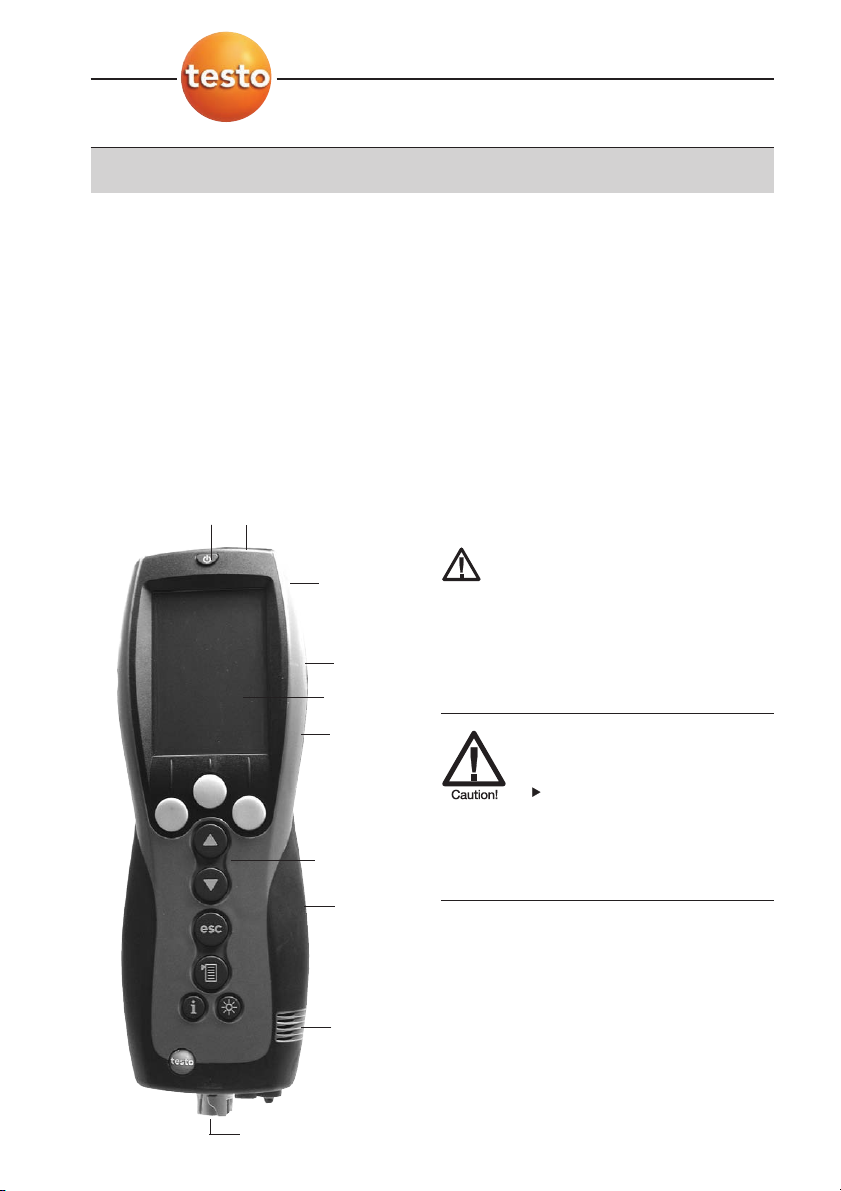

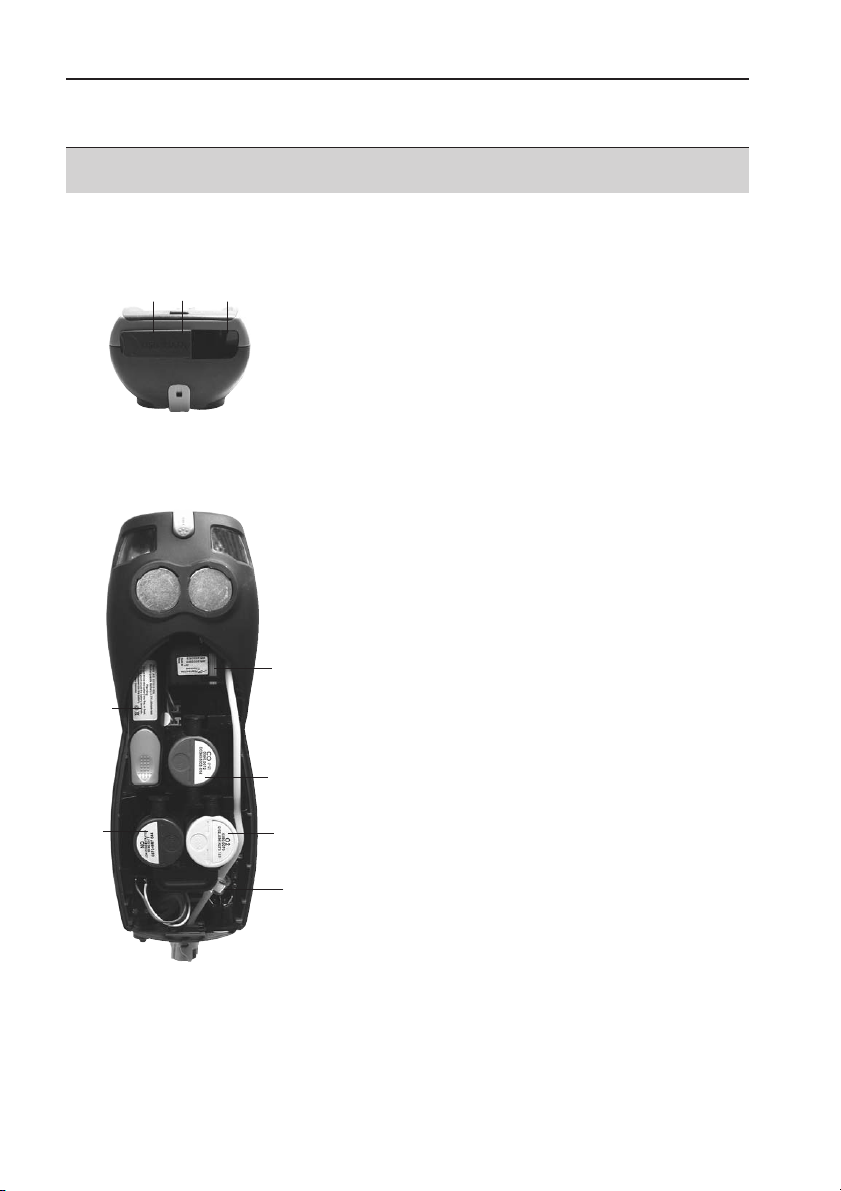

C.1.1 Overview

Placeholder:

Uebersicht.tif

Switch on /off

Interfaces: USB, PS2, infrared

Do not direct infrared beam at

human eyes.

Condensate trap (on rear)

Fixing eyelets for carrying strap (left and

right)

Display

Magnetic holders (on rear)

Strong magnets

Damage tto oother mmagnets

Keep safe distance from

products which could be

damaged by magnets (e.g.

monitors, computers,

pacemakers, credit cards).

Keypad

Service cover (on rear)

Gas outlet

Unit connections: flue gas probe,

probe, pressure probe, mains unit

Page 11

C. Product description

C.1 Measuring instrument

C.1.2 Keypad

Key Functions

Switch measuring instrument on/off

Function key (orange, 3x), relevant function is shown on the display

Scroll up, increase value

Scroll down, reduce value

Back, cancel function

Open Main menu: press briefly (changed settigs are stored, measurement values are carried over into the menu

Flue gas); open Measurements menu: press and hold down for 2s (changed settigs are stored, measurement

values are carried over into the menu Flue gas)

Open Inst’ diagnosis menu

Switch over display light: display light is permanently on or display light goes on for 10 seconds everytime a key

is activated.

C.1.3 Display

Depending on the menu that is active, the display shows a variety of elements.

Header (active in all views)

Warning symbol (only if there is a device error; the

device error is displayed in the

menu).

Active location.

Power supply symbol:

Symbol Characteristic Symbol Characteristic

Mains operation Rech. battery operation, capacity: 26-50%

Rech. battery operation, capacity: 76-100% Rech. battery operation, capacity: 6-25%

Rech. battery operation, capacity: 51-75% Rech. battery operation, capacity: 0-5%

Inst’ diagnosis

11

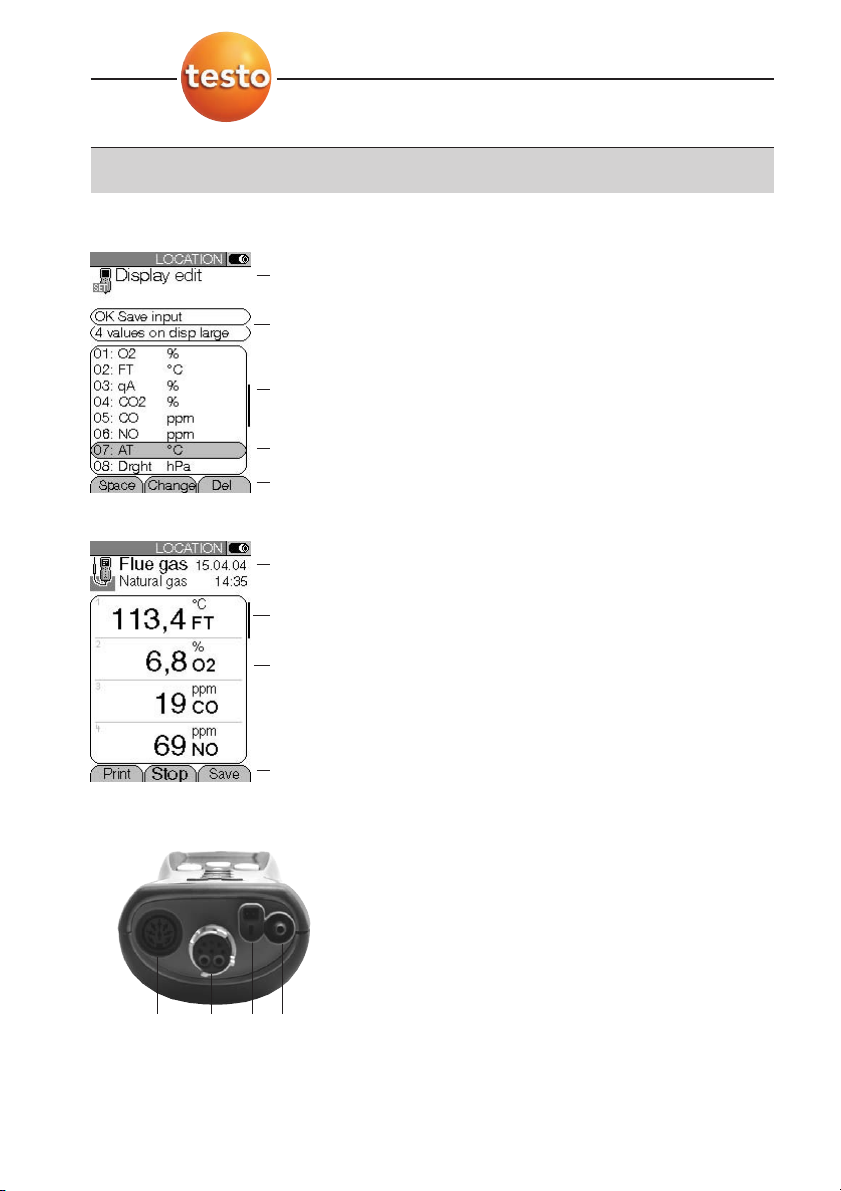

Function select view

Active menu, activated fuel

Selection field for functions:

The chosen function is shown with a grey

background.

Unavailable functions are written in grey type.

Scroll bar

Function keys for entering commands

Page 12

C. Product description

12

C.1 Measuring instrument

Settings view

Measuring view

Active menu

Function fields for entering commands

Scroll bar

Selection field for adjustable values:

The chosen value is shown with a grey

background. Unavailable values are written in grey

type.

Function keys for entering commands

Active menu, depending on the chosen function:

Additional information (e.g. activated fuel,

date and time)

Scroll bar

Display field for readings, parameters

Function keys for entering commands

C.1.4 Device connections

Probe socket

Flue gas socket

Mains unit socket

Pressure socket

Page 13

C.1.5 Interfaces

C.1.6 Components

C. Product description

C.1 Measuring instrument

USB interface:

connection to PC

PS2 interface:

connection to barcode pen, adapter for automatic

furnaces

Infrared interface (IrDA):

connection to Testo-printers/Pocket PC

Rechargeable battery

Measuring gas pump

Slot for CO measuring cell

Slot for O

measuring cell

2

Slot for NO-, NO low measuring cell

Additional filter

13

Page 14

C. Product description

14

C.1 Measuring instrument

C.1.7 Carrying strap /barcode pen holder

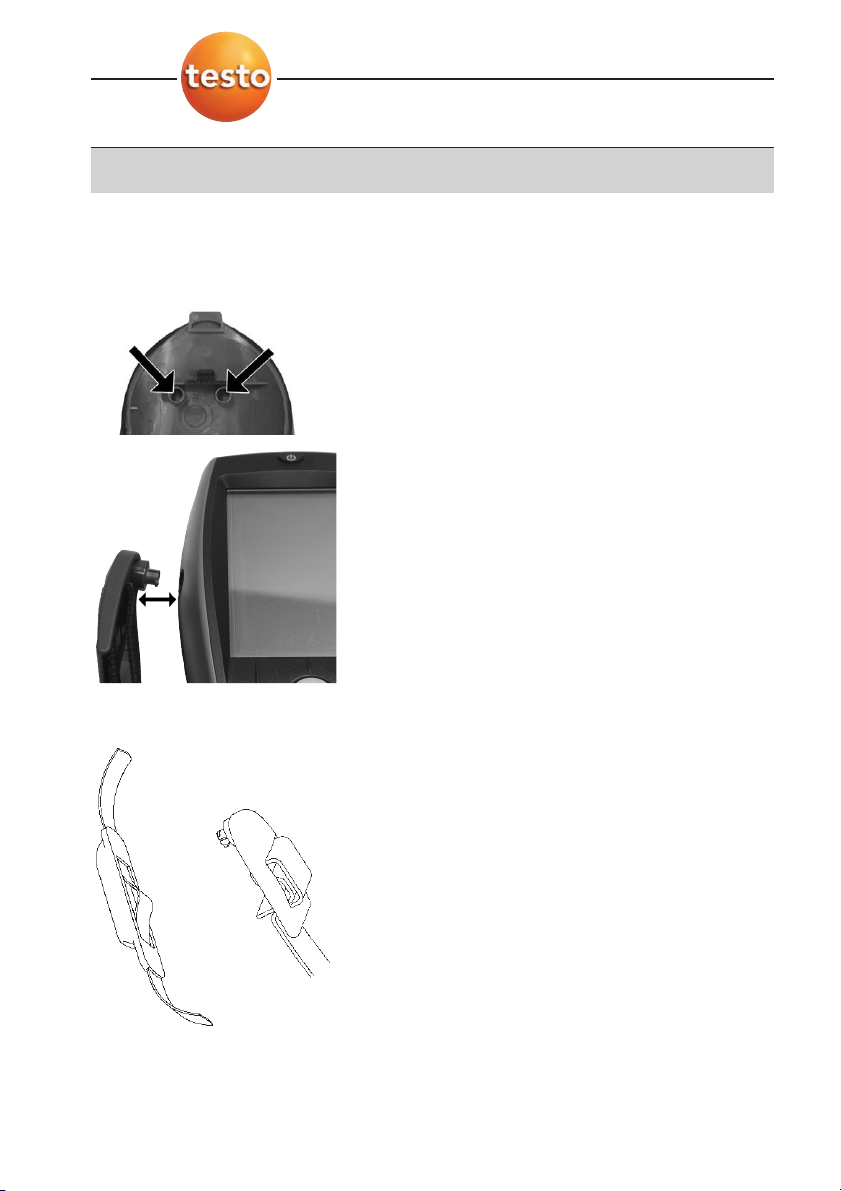

To secure the carrying strap:

1

To secure the barcode pen holder to the carrying strap:

Remove sealing caps from the sides of the

housing.

Fix ssealing ccaps oon tthe iinside oof tthe sservice ccover:

1 Place the measuring instrument on its front.

2 Pick the service cover up at the markings

(arrows) using your index finger and thumb and

press gently to release the lock.

3 Fold the service cover up and remove it.

4 Secure the sealing caps in the two holders on

the inside of the service cover (

5 Attach the service cover and engage it in place.

2

Engage the carrying strap clip in the fixing eyelets

on the side of the device. Note the guide groove.

The strap must point “down” (

1

Loosen the carrying strap at the buckle and

remove.

2

Lead carrying strap through the strap guide of the

barcode pen holder (

3

Lead carrying strap through the buckle (

tighten.

).

).

).

) and

Page 15

C.2 Modular flue gas probe

C. Product description

C.2 Modular flue gas probe

15

Removable filter chamber with window and particle

filter

Probe handle

Connecting cable

Connecting plug for measuring instrument

Probe module lock release

Probe module

Page 16

16

D. Commissioning

D. Commissioning

This chapter describes the steps required to commission the product.

Remove the protective film from the display.

The measuring instrument is supplied with a rechargeable battery already fitted.

Charge the battery up fully before using the instrument (see

p. 18).

Charging batteries

,

Page 17

E. Operation

E.1 Mains unit/rechargeable battery

E. Operation

This chapter describes the steps that have to be executed frequently when using the

product.

Please read this chapter carefully. The following chapters of this document will

assume you are already familiar with the content of this chapter.

E.1 Mains unit / rechargeable battery

If the mains unit is connected, the measuring instrument is automatically powered from

the unit. It is not possible to charge the battery in the instrument during operation.

E.1.1 Changing the battery

The measuring instrument must not be connected to a mains socket via the mains

unit. The instrument must be switched off. Change the rechargeable battery within

60 minutes so that device settings (e.g. date/time) are not lost.

1

Place the measuring instrument on its front.

2

Remove the service cover: Take hold of it at the

markings (arrows) using the index finger and

thumb, press slightly, fold up and remove.

3

Open the battery lock: Press the orange key and

push in the direction of the arrow.

4

Remove the battery and insert a new rechargeable

battery. Only use the Testo rechargeable battery

0515 0100.

5

Close battery lock: Press the orange key and push

against the direction of the arrow until the battery

engages.

6

Attach the service cover and engage it in place.

17

Page 18

E. Operation

18

E.1 Mains unit/rechargeable battery

E.1.2 Charging batteries

The rechargeable battery can only be charged at an ambient temperature of ±0 to +35°C.

If the battery has discharged completely, the charging time at room temperature is

approximately 5-6h.

Charging in the measuring instrument

The instrument must be switched off.

1

Connect the plug of the mains unit to the mains unit socket on the measuring

instrument.

2

Connect the mains plug of the mains unit to a mains socket.

- The charging process will start. The charge condition will be shown on the display.

The charging process will stop automatically when the battery is fully charged.

Recharging in the charging station (0554 1087)

Refer to the documentation enclosed with the charging station.

Battery care

If possible, always discharge the battery and recharge it fully.

Do not store the battery for long periods when discharged. (The best storage

conditions are at 50-80% charge level and 10-20 °C ambient temperature; charge

fully before further use).

E.1.3 Operation with the mains unit

1

Connect the plug of the mains unit to the mains unit socket on the measuring

instrument.

2

Connect the mains plug of the mains unit to a mains socket.

- The measuring instrument is powered via the mains unit.

- If the instrument is switched off and a rechargeable battery is inserted, the charging

process will start automatically. Switching the instrument on has the effect of

stopping battery charging and the instrument is then powered via the mains unit.

Page 19

E. Operation

E.2 Probes/Sensors

E.2 Probes /Sensors

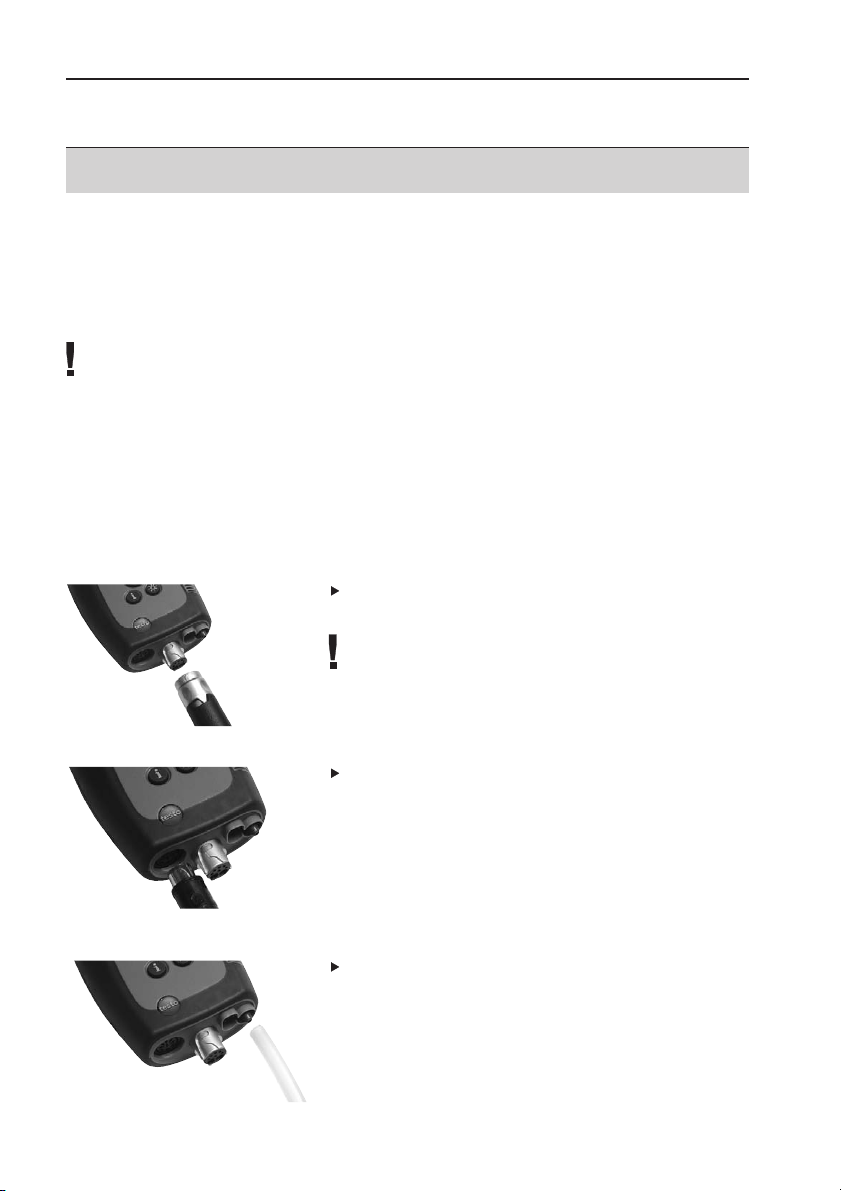

E.2.1 Connecting probes / sensors

Probe ssocket:

Probe detection is carried out at the socket during the initial switch on activation

process: Probes that are required must always be connected before the measuring

instrument is switched on, or the instrument must be switched off and then on again

after a change of probe, so that the correct data can be read into the instrument.

Flue ggas ssocket:

Probe/sensor detection at the flue gas socket is carried out continuously. It is

possible to change the probe/sensor even while the measuring instrument is

switched on.

Connect flue gas probes/gas pressure adapters /temperature adapters

Insert the connector into the flue gas socket and

lock by turning it clockwise gently (bayonet lock).

Only one hose extension (0554 1201) should be

connected between the measuring instrument and

the flue gas probe.

19

Connecting other probes

Connecting the pressure hose

Insert the connector of the probe into the probe

socket.

Fit the pressure hose on the connecting nipple of

the pressure socket.

Page 20

E. Operation

20

E.3 Regular care

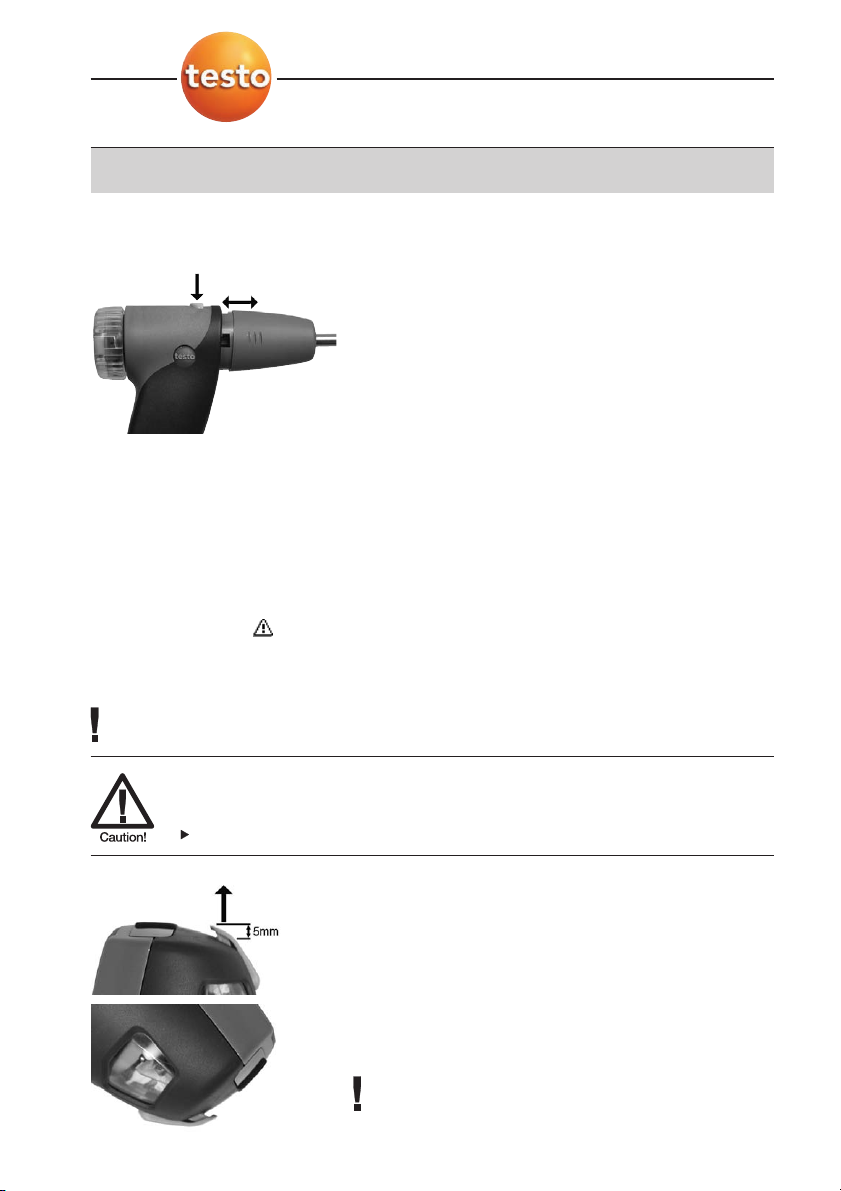

E.2.2 Replacing the probe module

1

Press the key on the top of the probe handle and

remove the probe module.

2

Fit a new probe module and engage it in place.

E.3 Regular care

E.3.1 Condensate trap

The fill level of the condensate trap can be read from the markings on the trap.

A warning message ( red flashing light) is displayed if the level in the condensate trap

reaches 90%.

Emptying the condensate trap

The condensate consists of a weak mix of acids. Avoid contact with the skin. Make

sure that the condensate does not run over the housing.

Condensate in gas path.

Damage tto mmeasuring ccells aand fflue ggas ppump.

Do not empty condensate trap while pump is operating.

Placeholder:

Kondensatfalle_oeffnen.tif

Kondensatfalle_leeren.tif

1

Hold the measuring instrument so that the

condensate outlet points up.

2

Open condensate outlet in condensate trap: Pull

out approx. 5mm or until it will not go any further

(

).

3

Let the condensate run out into a sink (

4

Dab off drops at condensate outlet using a cloth.

5

Close the condensate outlet.

The condensate outlet must be fully closed

(marking) otherwise incorrect measurements due to

inleaking air may result.

).

Page 21

E.4 Basic operating steps

E.3.2 Checking / replacing the particle filter

Checking the particle filter:

Particle filters of the modular flue gas probe must

be checked regularly for contamination:

Check visually by looking through the window of

the filter chamber.

Replace the filter if there are signs of

contamination.

Replacing the particle filter:

Filter chamber may contain condensate.

1

Open the filter chamber: Turn gently

anticlockwise.

2

Remove the filter plate and replace it with a

new one (0554 3385).

3

Fit the filter chamber and lock it: Turn gently

clockwise.

E.4 Basic operating steps

E. Operation

21

E.4.1 Switching the measuring instrument on

.

- The start screen is displayed (for about 5 s).

- Display illumination is switched on for 10 s.

Option:

To go directly to a measurement while the start screen is being displayed, press

the function key for the desired measurement. See also

p. 30.

- The

Measurements menu is opened.

-oor-

-

If another probe/sensor is connected rather than a flue gas probe: the measuring

menu for that probe/sensor is opened.

Start key configuration

,

Page 22

E. Operation

22

E.4 Basic operating steps

-or-

- If the power supply was interrupted for a longer period: the

opened.

-oor-

- There is an instrument error:

Error diagnosis is displayed.

Date/Time menu is

E.4.2 Calling up a function

Functions which cannot be selected, because the required probe/sensor is not

connected, are shown in grey type.

1

Select the function: , .

- The chosen function is shown with a grey background.

2

Confirm selection: .

- The chosen function is opened.

OK

E.4.3 Entering values

Some functions require values (numbers, units, characters) to be entered. Depending on

the function that is chosen, the values are entered via either a list field or an input editor.

List field

1

Select the value to be changed (number, unit):

, .

2

Set the value: , .

3

Repeat steps 1and 2as required.

4

Confirm the input: .

5

Save the input:

OK

OK Save input .

OK

Page 23

E. Operation

E.4 Basic operating steps

Input editor

1

Select the value (character): , , , .

2

Accept the value: .

Options:

To switch between upper-case/ lower-case

letters:

A <=> a (not always available).

To delete characters:

To position the cursor in the text: Select the text

input field: , and position the cursor:

,.

To delete characters in front of the cursor:

Del.

3

Repeat steps 1and 2as required.

4

Save the input:

OK

<=.

.

OK Save input .

OK

E.4.4 Printing data

Printer

Print

, p. 29.

Data are printed out via the function key . The function is only available if a

printout is possible.

If data are to be transferred to a protocol printer via the infrared interface, the printer that

is to be used must be activated, see

23

E.4.5 Saving data

Data are saved either via the function key or the function field OK Save input. The

functions are only available if saving is possible.

See also

Memory/Location

, p. 24.

Save

E.4.6 Confirming an error message

If an error occurs, an error message is shown in the display.

To confirm an error message: .

Errors which have occurred and have not yet been rectified are shown by a warning

symbol ( ) in the header.

Error messages which have not yet been removed can be viewed in the

menu, see

Instrument diagnosis

OK

Inst’ diagnosis

, p. 26.

Page 24

E. Operation

24

E.4 Basic operating steps

E.4.7 Scanning locations with the barcode pen

Locations marked with barcode labels can be scanned using the barcode pen

(0554 0461).

1

Connect the connector of the barcode pen to the PS2 interface of the measuring

instrument.

2

Memory / Location .

3

Scan the barcode: Hold the barcode pen over the white surface and then move

swiftly over the barcode label.

- If the scanned barcode is already created as a location in the measuring instrument,

this location is activated automatically.

If the scanned barcode is not yet created as a location in the instrument, a new

location is created.

See also

Memory/Location

OK

, on this page.

E.4.8 Switching the measuring instrument off

Unsaved readings are lost when the measuring instrument is switched off.

.

- Possibly: The pump starts and the measuring cells are rinsed until the shut-off

thresholds (O

more than 3 minutes.

- The measuring instrument switches off.

>20%, other parameters <50 ppm) are reached. Rinsing lasts no

2

Page 25

E. Operation

E.5 Memory/Location

E.5 Memory / Location

All readings are allocated to the location that is activated at the time and can be saved in

the

Flue gas menu. Unsaved readings are lost if the measuring instrument is switched off!

Locations can be created, edited and activated. (Measuring) protocols can be printed.

The special function

protocols can be printed or deleted. The entire memory (locations and protocols) can

also be cleared.

Calling up the function:

Memory / Location .

Creating a new location:

Locations are identified by a unique location name. Each location name can only be

allocated once.

1

New location .

2

Select

Location name .

3

Enter values

4

Execute steps 2and 3for the other criteria accordingly (only testo 330-2, -3 /

testo 330-2LL).

5

OK Go to measurement or OK TO memory /location .

Ordering a list (testo 330-2, -3):

1

Locations list .

2

Select the order criterion: , (only testo 330-2, -3 / testo 330-2 LL) or

Addr’

(only testo 330-2, -3 / testo 330-2LL).

Restoring a list (testo 330-2, -3):

1

Order the list in the sequence in which the locations were created:

Restore list .

Activating a location:

Select the location .

-

The location is activated and the

Printing/displaying protocols:

If automatic furnace data are stored with a measurement protocol the following symbol

is displayed next to the protocol name: . The data are printed with the protocol

printout.

Extras memory can be used to display the available memory. All

OK

OK

change

OK Save input .

OK

OK

OK

OK

OK

NameLocat

Measurements menu is opened.

25

Page 26

E. Operation

26

E.5 Memory/Location

1

Select the location .

Protoc.

Options:

To print all data of the chosen location:

To delete all data of the chosen location:

2

To print a single data: Select the protocol .

Print all .

Delete all .

OK

OK

Print

-oor-

2

To display saved readings of a measurement: Select the protocol .

Options:

To print the protocol: .

To delete the protocol: .

Print

Del

Editing the location:

1

Select the location .

Edit

Options:

To delete the location: .

To change the location: .

Del

Change

Special function Extras memory

Calling uup aa ffunction:

Memory/Location .

Extra

- The available memory is displayed.

Options:

Print all data .

Delete all data .

Delete memory .

OK

OK

OK

Value

Page 27

F. Configuration

E.6 Instrument diagnosis

E.6 Instrument diagnosis

Important operating values and device data are displayed. A gas path check

(testo 330-2, -3 / testo 330-2LL) can be carried out. The status of the measuring cells

and device errors which have not yet been rectified can be viewed.

Calling up the function:

Inst’ diagnosis .

-oor-

.

Carrying out a gas path check (testo 330-2, -3 / testo 330-2LL)

1

Gas path check .

2

Place the black sealing cap on the tip of the flue gas probe.

- The pump flow is displayed. If the flow rate is ≤ 0,02l/min, the gas paths are not

leaking.

3

End the check: .

Viewing device errors:

Error diagnosis .

- Unrectified errors are displayed.

View next/previous error: , .

Viewing sensor diagnosis:

1

Sensor check .

- Possibly: Gas zeroing (30 s).

2

Select measuring cell: , .

- The status of the measuring cell is displayed.

OK

OK

OK

OK

OK

27

Page 28

F. Configuration

28

F.1 Instrument settings

F. Configuration

This chapter describes the possible steps for adapting the product to the particular

measurement task or the requirements of the user.

Familiarity with the contents of the chapter

Operation

(see p. 17)

is assumed.

F.1 Instrument settings

F.1.1 Display edit

The parameters/units and the display representation (number of readings displayed per

display page) can be set.

Available parameters and units:

Display Parameter Units

FT Flue gas temperature °C, °F

CO2 Carbon dioxide %

qA Flue gas loss %

λλ

O2 Oxygen %

CO Carbon monoxide ppm, %,

uCO Carbon monoxide undiluted ppm

ηη

NO Nitrogen monoxide ppm, %,

NOx Nitrogen oxide ppm, %,

AT Ambient temperature °C, °F

O2 air Oxygen addition %

Drght Flue draught mbar, hPa,

Air ratio -

Efficiency %

mgm

g/GJ,

mgKW

mgm

g/GJ,

mgKW

mgm3,

g/GJ,

mgKW

mmWS,

inW

3

3

Display Parameter Units

T1 Temperature 1 (flue gas socket) °C, °F

T2 Temperature 2 (probe socket) °C, °F

ΔΔ

T Differential temperature T1- T2 °C, °F

Itemp Instrument temperature °C, °F

DP Flue gas dew point temperature °C, °F

ΔΔ

,

,

P Differential pressure mbar, hPa,

Gasfl Gas flow rate m3/h, l/h

GasP Gas burner output kW

OilFl Oil flow rate kg/h

Oil p Oil pressure bar

OilP Oil burner output kW

CO2 Carbon dioxide %

amCO2 Ambient carbon dioxide ppm

amCO Ambient carbon monoxide ppm

Pabs Absolute pressure hPa, mbar

Pump Pump output l/m

mmW, inW

Page 29

F. Configuration

F.1 Instrument settings

Calling up the function:

Inst’ settings Display edit .

OKOK

Setting the display representation:

Select

4 values on disp large or 8 values on disp small .

OK

Changing parameters and units:

1

Select the display position.

Options:

To insert a line: .

To delete a parameter: .

2

Select parameter Select unit .

Space

Del

OKOKChange

Saving settings:

OK Save input .

OK

F.1.2 Printer

The headers (lines 1-3) and the footer for the printout can be set. The printer that is used

can be activated.

Calling up the function:

Inst’ settings Printer .

Setting the printed text:

1

Print text .

2

Select

3

Enter values

4

Execute steps 2and 3for the other lines in the same way.

5

OK Save input .

OK

Line 1, Line 2, Line 3 or Footnote .

OK Save input .

OK

Printer selection:

Select Printer Select printer .

OKOK

change

OK

OKOK

29

Page 30

F. Configuration

30

F.1 Instrument settings

F.1.3 Alarm limits

A limit value can be set for ambient CO probes, leak detection probes and CO2probes.

A visual and optical alarm is triggered if a limit value is exceeded.

Calling up the function:

Inst’ settings Alarm limits .

OKOK

Setting the alarm thresholds/alarm signal :

Optional:

To reset all values to default values:

1

Select the parameter.

Default values .

OK

Optional:

To reset the alarm threshold of the chosen parameter to the default value:

Deflt

.

2

3

Repeat steps 1and 2for the other parameters/the alarm signal as required.

Set the values .

OKChange

Saving settings:

OK Save input .

OK

F.1.4 Start Keys edit

How the function keys are configured depends on the chosen function. Only the

function keys in the start screen (shown when the measuring instrument is switched on)

can be assigned any function from the

Measurements menu.

The function keys are only active if the required probes are connected.

Calling up the function:

Inst’ settings Start Keys edit .

OKOK

Assigning a function to the start keys:

1

Select function Press the function key that is to be assigned the chosen function.

2

Repeat step 1for the other function keys as required.

Saving settings:

OK Save input .

OK

Page 31

F.1.5 Communication

Select interface IrDa/Bluetooth.

Calling up the function:

Inst’ settings Communication

Set IrDa/Bluetooth:

Select

IrDA oder Bluetooth .

OK

F.1.6 Date/ Time

The date and the time can be set.

Calling up the function:

Inst’ settings Date/Time

Setting the date/time:

Select

Time or Date Set the values .

Saving settings:

OK Save input .

OK

F.1.7 Language

F. Configuration

F.1 Instrument settings

OKOK

OKOK

OKChange

31

The menu language can be set.

Calling up the function:

Inst’ settings Language .

-oor-

Geräteeinst. Sprache .

Setting the language:

Select

Deutsch or Englisch .

-oor-

Select

German or English .

OKOK

OKOK

OK

OK

Page 32

F. Configuration

32

F2. Sensor settings

F.2 Sensor settings

NO2addition and shut-off thresholds for protecting the measuring cells can be set.

Recalibration can be carried out (a calibration adapter is required: 0554 1205).

Calling up the function:

Sensor settings .

Setting the NO

NO2 addition Set the value .

O

reference:

2

The O

reference value is set to 21.00%. It cannot be changed.

2

addition:

2

Setting sensor protection:

Protection limits can be set to protect the measuring cells against overload. The sensor

protection is activated if the threshold is exceeded:

· testo 330-1 / testo 330-1 LL: Switch-off

· testo 330-2, -3 / testo 330-2 LL: Dilution, if exceeded again: Switch-off

If the threshold is set to 0ppm, the sensor protection is deactivated.

1

Sensor protection .

2

Select the parameter.

3

4

Repeat steps 2and 3for the other parameters in the same way.

Saving settings:

Set the values .

OK Save input .

Recalibration:

CO and NO measuring cells can be recalibrated. A calibration adapter (0554 1205) must

be connected.

If obviously unrealistic readings are displayed, the measuring cells should be checked

and recalibrated as required.

Have the check/recalibration carried out by a Testo qualified service centre.

OK

OKChange

OK

OKChange

OK

Dangerous gases

Danger oof ppoisoning!

Observe safety regulations/accident prevention regulations when

handling test gases.

Use test gases in well ventilated rooms only.

Page 33

F. Configuration

F.3 Fuels

Recalibration with low gas concentrations can lead to fluctuations in accuracy in the

upper measuring ranges.

1

Connect the calibration adapter to the flue gas socket.

2

Recalibration .

OK

- Gas zeroing (30 s).

3

Select the parameter Enter the test gas concentration (required value).

4

Attach the connecting cable of the test gas bottle to the calibration adapter.

5

Charge the measuring cell with test gas.

6

Start calibration: .

7

Accept the actual value as soon as the required value is stable: .

Change

Start

OK

F.3 Fuels

The fuel can be chosen. The fuel-specific coefficients can be set.

Calling up the function:

Fuels .

Activating fuel:

Select the fuel .

Setting coefficients:

Coeff

1

Optional:

To reset all coefficients to default values:

2

Select the coefficients.

Optional:

To reset the chosen coefficients to default values: .

3

4 OK Save input Ý .

OK

OK

.

Set the values .

OK

OKChange

Default values .

OK

Deflt

33

Page 34

G. Measuring

34

G.1 Preparing measurements

G. Measuring

This chapter describes the measuring tasks that can be carried out with the product.

Familiarity with the contents of the chapter

Operation

(see p. 17) is assumed.

G.1 Preparing measurements

G.1.1 Zeroing phases

Measuring the combustion air temperature

If no combustion air temperature probe is connected, the temperature measured by the

thermocouple of the flue gas probe during the zeroing phase is used as the combustion

air temperature. All dependent parameters are calculated by this value. This method of

measuring combustion air temperature is sufficient for systems dependent on ambient

air. However, the flue gas probe must be near the intake duct of the burner during the

zeroing phase.

If a combustion air temperature probe is connected, the combustion air temperature is

measured continuously via this probe.

Gas zeroing

The first time a gas measuring function is called up after the instrument has been

switched on, the measuring cells are zeroed.

testo 330-1, -3 / testo 330-1LL: The flue gas probe must be in the open air during

the zeroing phase!

The “Gas zeroing, probe in flue (0440 3331)” option is available as an option for the

testo 330-3.

testo 330-2 / testo 330-2LL: The flue gas probe can be in the flue pipe even during

the zeroing phase, if a separate AT probe is attached.

Draught/pressure zeroing

The pressure sensors are zeroed when a pressure measuring function is called up.

testo 330-1, -2 / testo 330-1LL: The flue gas probe must be in the open air during

the zeroing phase/the instrument must not be pressurised during zeroing! The

“Draught zeroing, probe in flue (0440 3330)” option is available as an option for the

testo 330-2.

testo 330-3 / testo 330-2LL: The flue gas probe can be in the flue pipe even during

the zeroing phase, if a separate AT probe is attached.

Page 35

RGS

G.1 Preparing measurements

G.1.2 Using the modular flue gas probe

Checking the thermocouple

The thermocouple of the flue gas probe must not lie

against the probe cage.

Check before use. Bend the thermocouple back if

necessary.

Aligning the flue gas probe

The flue gas must be able to flow freely past the

thermocouple.

Align the probe by turning it as required.

The tip of the probe must be in the centre of the flue

gas flow.

Align the flue gas probe so that the tip is in the

centre of the flow (area of the highest flue gas

temperature).

G. Measuring

35

G.1.3 Configuring the reading display

Only those parameters and units which are activated in the reading display appear in the

reading display, the saved measurement protocols and the protocol printouts.

Before beginning measurements, configure the reading display so that the required

parameters and units are activated, see

Display edit

, p. 28.

G.1.4 Set memory/location

Before carrying out measurements, the measurement location and the fuel must be

correctly selected siehe

Memory/Location, p. 24

and

Fuels, p.33.

Page 36

G. Measuring

36

G.2 Measurements

G.2 Measurements

G.2.1 Flue gas

The Flue gas menu is the main measuring menu in which - in addition to the readings

measured with this function - the readings of all measurements carried out are displayed

(if selected in the

this menu.

The

Flue gas menu can always be selected, regardless of which probes are connected.

The measurement values from the functions

Differencial press and Smoke No./HCT are transferred to the the central measurement

menu Flue gas and must therefore be carried out before the flue gas measurement.

Calling up the function:

Measurements Flue gas .

- Possibly: Gas zeroing (30 s).

If nno ffuel hhas yyet bbeen sselected:

Select the fuel .

Measuring:

1

Start measuring: .

Reading CCO uundiluted:

If a separate measurement of CO undiluted has not yet been carried out, this value is

calculated using the readings of the flue gas probe and is updated continuously.

If CO undiluted has already been measured separately, the value obtained is

adopted.

- The readings are displayed.

2

Stop measuring: .

Options:

To print readings: .

To save readings: .

- The readings from the flue gas measurement, as well as any readings taken over

into the menu

printed in a measurement protocol (automatic furnace data are not printed).

Display edit menu). All readings can also be saved or printed out from

Draught, O2 air, Differencial temp.,

OKOK

OK

Start

Stop

Print

Save

Flue Gas from other measurement functions are stored and/or

Page 37

G. Measuring

G.2 Measurements

G.2.2 Draught

A flue gas probe must be connected.

The pressure socket of the instrument must be free (i.e. unpressurised, not closed).

Do not measure for longer than 5 min, as the drift of the pressure sensor means that

the readings could be outside the tolerance limits.

Calling up the function:

Measurements Draught .

Measuring:

1

Start measuring: .

Start

- Draught zeroing (5 s).

2

Position the flue gas probe in the hot spot (area of the highest flue gas temperature).

The display showing the maximum measured flue gas temperature (FT) helps when

positioning the probe.

- The reading is displayed.

3

Stop measuring .

Stop

- The reading is recorded.

Optional:

To print the reading: .

4

Copy the reading to the

- The

Measurements menu is opened.

Print

Flue gas menu: .

OKOK

OK

37

G.2.3 Fine pressure probe (accessory)

The following measurements can be carried out using the fine pressure probe:

· E-draught

· E-Delta-P

· See also instruction manual

Fine pressure probe.

Page 38

G. Measuring

38

G.2 Measurements

G.2.4 BImSchV (testo 330-3 / testo 330-2LL)

Two different prescribed measurement sequences can be performed in the BImSchV

menu: They are the BImSchV measurement sequence and the qA mean value

measurement sequence.

CO measurement can then be switched off.

In the qA mean value sequence, 3 successive flue gas loss measurements are taken

and the mean value is calculated from them.

In the BImSchV sequence, a draught measurement is performed first, then a flue gas

measurement. Regardless of the device settings, 8 readings are shown per display page

in a fixed order.

The readings are recorded in the

A flue gas probe and a combustion air temperature probe must be connected.

Calling up the function:

Measurements BImSchV .

- Possibly: Gas zeroing (30 s).

If nno ffuel hhas yyet bbeen sselected:

Select the fuel .

Activating/deactivating the CO measurement and Hot spot search:

1

Select

CO measurement ON or CO measurement OFF.

2

Position the flue gas probe in the hot spot (area of the highest flue gas temperature).

The display showing the current and maximum measured flue gas temperature (FT)

helps when positioning the probe.

Optional:

To reset the temperature value

qA mean value measurement sequence:

3

Start the measurement sequence: .

- The

qA menu is opened.

4

Start qA value measuring: .

- The three qA values are measured one after the other (25s respectively).

- The mean value of the three qA measurements is shown.

5

Copy the readings to the

- The

BImSchV menu is opened.

BImSchV menu and are not copied to the Flue gas menu!

OKOK

OK

max FT: .

Start

BimSchV menu: .

Reset

qA

OK

Page 39

G.2 Measurements

Options:

To print readings: .

To save readings: .

Print

Save

Start flue gas measurement (BImSchV measurement sequence): continue with the

BImSchV sequence, Step

4

, on this page.

BImSchV measurement sequence:

3

Start the measurement sequence: .

- The

BImSchV menu is opened.

4

Start flue gas measurement: .

BImS.

Start

- The readings are displayed.

5

Stop flue gas measurement: .

- The

Draught menu is opened.

6

Start draught measurement: .

Stop

Start

- Draught zeroing (5 s).

- The reading is displayed.

7

Stop measurement .

Stop

- The reading is recorded.

8

Copy the reading to the

BImSchV menu: .

- The reading is copied to the

- The

BImSchV menu is opened.

BImSchV menu.

OK

Options:

To print readings: .

To save readings: .

Print

Save

G. Measuring

39

Page 40

G. Measuring

40

G.2 Measurements

G.2.5 CO undiluted

A multi-hole probe (0554 5762) must be connected.

Calling up the function:

Measurements CO undiluted .

OKOK

Measuring:

1

Start measurement: .

Start

- Possibly: Gas zeroing (30 s).

- The reading is displayed.

2

Stop measurement: .

Stop

- The reading is recorded.

Options:

To print the reading: .

3

Copy the reading to the

- The

Measurements menu is opened.

Print

Flue gas menu: .

OK

G.2.6 Smoke No./ HCT

Calling up the function:

Measurements Smoke No./HCT .

Recording smoke tester no./smoke numbers / oil derivative with the smoke pump

and manual input:

The function is only available if the chosen fuel is an oil.

1

Sm. tester no. Enter pump number .

2

Smoke# 1 Enter the value .

3

Repeat step 2for the other smoke numbers and oil derivative as required.

Recording smoke tester no./smoke numbers / oil derivative with the smoke tester

testo 308 and wireless transfer:

- testo 308 must be in data transfer mode ( lights up).

1 Press function key .

t308

- The values recorded by the smoke tester are transferred.

2 Once all values have been transferred, select function key .

Entering the heat carrier temperature:

Heat carrier Enter the value .

OKOK

OKChange

OKChange

OK

OKChange

Page 41

G. Measuring

G.2 Measurements

Copy the values to the Flue gas menu:

The smoke number/HCT-values are not displayed in the menu

Flue gas. They can,

however, be printed or stored in a measurement protocol, together with the

measurement values of a flue gas measurement. In the menu

Memory / Location, the

smoke count/WTT values can be displayed in the measurement program, printed or

transferred to a Pocket PC/PC.

OK Copy readings .

Measurements menu is opened.

- The

OK

G.2.7 Differential pressure

The gas pressure set (0554 1203) must be connected.

Dangerous mixture of gases

Danger oof eexplosion!

Make sure there are no leaks between the sampling point and the

measuring instrument.

Do not smoke or use naked flames during measurement.

Do not measure for longer than 5 min, as the drift of the pressure sensor means that

the readings could be outside the tolerance limits.

Calling up the function:

Measurements Differential press. .

Measuring:

1

Start measurement: .

Start

- Pressure zeroing (3 s).

Pressurise the connecting lines.

- The reading is displayed.

2

Stop measurement: .

Stop

- The reading is recorded.

Options:

To print the reading: .

3

Copy the reading to the

- The

Measurements menu is opened.

Print

Flue gas menu: .

OK

OKOK

41

Page 42

G. Measuring

42

G.2 Measurements

G.2.8 Differential temperature

The difference temperature set (0554 1204) must be connected.

Calling up the function:

Measurements Differential temp. .

OKOK

Measuring:

1

Start measurement: .

Start

- The readings and the calculated temperature difference (T1 - T2) are displayed.

2

Stop measurement: .

Stop

- The readings are recorded.

Options:

To print readings: .

3

Copy the readings to the

- The

Measurements menu is opened.

Print

Flue gas menu: .

OK

G.2.9 O2 air

An O2dual wall clearance probe (0632 1260) must be connected.

Calling up the function:

Measurements O2 air .

Measuring:

1

Start measurement: .

Start

- Possibly: Gas zeroing (30 s).

- The reading is displayed.

2

Stop measurement: .

Stop

- The reading is recorded.

Optional:

To print the reading: .

3

Copy the reading to the

- The

Measurements menu is opened.

Print

Flue gas menu: .

OKOK

OK

Page 43

G. Measuring

G.2 Measurements

G.2.10 Gas flow rate

The Gas flow rate function is only available if the activated fuel is a gas.

Calling up the function:

Measurements Gas flow rate .

OKOK

Measuring:

1

Enter the duration of measurement:

180

2

Start measuring: . Observe the counter reading of the gas meter.

OK

s) .

Start

Sample time Enter the value (18, 36 or

Change

- The remaining measurement period is displayed.

- When the measurement period has lapsed, a long beep is emitted. The last 5s are

indicated by a short beep.

3

Enter the flow rate:

Flow rate Enter the value .

OK

- The calculated gas burner output is displayed.

4

Copy the values to the

- The

Measurements menu is opened.

Flue gas menu: OK Copy readings .

OK

G.2.11 Oil flow rate

The Oil flow rate function is only available if the activated fuel is an oil.

Calling up the function:

Measurements Oil flow rate .

Measuring:

1

Enter the flow rate:

2

Enter the oil pressure:

Flow rate Enter the value .

Oil pressure Enter the value .

- The calculated oil burner output is displayed.

3

Copy the values to the

- The

Measurements menu is opened.

Flue gas menu: OK Copy readings .

OKOK

OKChange

OKChange

OK

43

Page 44

G. Measuring

44

G.2 Measurements

G.2.12 Leak detection

Gas is detected during leak detection; the gases are not measured.

A gas leak probe (0632 3330) must be connected.

Please refer to the documentation enclosed with the gas leak probe.

Calling up the function:

Measurements Leak detection .

Measuring:

Carry out the setting for the gas to be detected according to the instructions found in

the documentation for the gas leak probe.

- The gas concentration is shown in a graph (trend display).

- An alarm message is given if the alarm threshold is exceeded.

Set alarm threshold: see

Alarm limits

, p. 30.

OKOK

G.2.13 Ambient CO

An ambient CO probe (recommended) or a flue gas probe must be connected.

Cigarette smoke influences the measurement by more than 50 ppm. The breath of a

smoker influences the measurement by about 5 ppm.

When using an ambient CO probe, note that:

The direction of flow of the gas has an effect on the accuracy of measurement.

Frontal flow onto the probe leads to higher readings. The best measurement results

are achieved when the probe is moved gently backwards and forwards.

When using the ambient CO probe 0632 1247, note that:

The sealing cap must remain closed during the zeroing phase.

Only open the sealing cap for the period of measurement.

When using ambient CO probe 0632 3331 or a flue gas probe, note that:

The probe must be located in fresh air (CO free) during the zeroing phase.

Calling up the function:

Measurements Ambient CO .

Measuring:

1

Start measurement: .

- If measuring using a flue gas probe or the ambient CO probe 0632 1247 possibly:

gas zeroing (30 s).

- Measuring starts and the reading is displayed as a number and graphically.

Start

OKOK

Page 45

G. Measuring

G.2 Measurements

- An alarm message is given if the alarm threshold is exceeded.

Set alarm threshold: see

2

Stop measurement: .

Stop

Alarm limits

, p. 30.

- The reading is recorded.

Options:

To print the reading: .

3

Copy the reading to the

- The

Measurements menu is opened.

Print

Flue gas menu: .

OK

G.2.14 Ambient CO2

An ambient CO2probe (0632 1240) must be connected.

In order to obtain correct readings, it is imperative to enter the prevailing absolute

pressure.

Calling up the function:

Measurements Ambient CO2 .

Enter aabsolute ppressure ddirectly:

Absolute Set the value .

OKOK

-oor-

Enter aabsolute ppressure vvia bbarometric ppressure aand hheight:

1

From height Barometric Set the value .

2

Altitude Set the value .

3

OK Save input .

OK

Measuring:

1

Start measuring: .

Start

- Possibly: warming-up phase (up to 30 s).

- The reading is displayed.

- An alarm message is given if the alarm threshold is exceeded.

Set alarm threshold: see

2

Stop measuring: .

Stop

Alarm limits

- The reading is recorded.

Optional:

To print the reading: .

Print

OKOK

OKChangeOK

OKChange

, p. 30.

45

Page 46

G. Measuring

46

G.2 Measurements

3

Copy the reading to the Flue gas menu: .

- The

Measurements menu is opened.

OK

G.2.15 Burner control

With the help of the readout adapter for automatic furnaces (0554 1206), status data

and malfunction reports can be read out from compatible automatic furnaces, see also

documentation for readout adapter. The range of data which can be read out is

dependent on the automatic furnace type.

Calling up the function:

1

Connect readout adapter to the instrument (PS2 interface) and the automatic furnace

(use adapter ring if necessary).

2

Measurements Burner Control.

Option:

Display type and version of the adapter: .

OK

3

.

- The data are read from the automatic furnace. An update of the data takes place

every 30s at the latest, this is dependent on the automatic furnace.

Reading out current status data:

The current data are displayed when a connection to the automatic furnace exists. The

following data are displayed with the help of symbols:

Component Status ON Status OFF Component Status ON Status OFF

Air controller Flame Symbol

Motor Ignition

OK

Adapt.

not displayed

Valve1 Oil prewarmer

Valve 2

Printing data:

Print

.

Display identification data:

Info .

OK

Display failure statistic:

Failure statistic .

OK

Page 47

G. Measuring

G.2 Measurements

Reading out failure store:

Automatic furnaces are equipped with circular buffer memories, i.e. failure reports are

overwritten when the failure store is full.. The last failure occurring is at position 1 in the

failure list.

Failure

.

Option:

Scroll through failure list: , .

Taking readings over into the menu Flue Gas:

The readings are not presented in the display, in the menu

Flue Gas they can be stored

with the readings from a flue gas measurement, stored in a measurement protocol or

transferred to a pocket PC/PC.

For taking data over into the menu

Flue Gas the function fields Info and Failure statistic

must not be active (grey background).

OK

.

- The Menu Measurements is opened.

47

Page 48

H. Transferring data

48

H.1 Protocol printerI. Care and maintenance

H. Transferring data

H.1 Protocol printer

If data are to be transferred to a Testo protocol printer via the infrared interface, the

printer that is to be used must be activated, see

Data are printed out via the function key . The function is only available if a

printout is possible.

H.2 PC/ Pocket PC

Print

Printer

, p. 29.

Data can be transferred to a PC via USB, IrDA oder Bluetooth®.

Data can be transferred to a Pocket PC via infrared or Bluetooth

You must also refer to the documentation that comes with the software.

®

.

Page 49

I. Care and maintenance

I.1 Cleaning the measuring instrument

I. Care and maintenance

This chapter describes the steps and action required in order to keep the product

functioning properly.

49

See also

Regular care

, p. 20.

I.1 Cleaning the measuring instrument

If the housing of the instrument is dirty, clean it with a damp cloth. Do not use any

aggressive cleaning agents or solvents! Weak household cleaning agents and soap

water may be used.

I.2 Replacing measuring cells

A slot bridge (0192 1552) must be inserted in slots which do not have a measuring cell.

Used measuring cells must be disposed of as special waste!

The instrument must be switched off.

1

Place the measuring instrument on its front.

2

Remove the service cover: Take hold of it at the markings (arrows) using the index

finger and thumb, press slightly, fold up and remove.

3

Pull hose connections from the fault measuring cell/bridge.

4

Remove the faulty measuring cell/bridge from the slot.

Placeholder:

Zellenwechsel.tif

Remove short-circuit brackets/additional boards

from the new measuring cells just prior to insertion.

Do not leave measuring cells for longer than 15

minutes without short-circuit brackets/additional

boards.

CO measuring cell for testo 330-1 / testo 330-1LL:

Remove the shorting jumper

CO measuring cell for testo 330-2, -3 / testo 330-2LL:

Remove the shorting jumper

NO/NO

Remove the auxiliary circuit board

measuring cell:

low

.

.

.

Page 50

I. Care and maintenance

50

I.3 Recalibrating measuring cells

5

Insert a new measuring cell/bridge in the slot.

6

Attach hose connections to the measuring cell/bridge.

7

Attach the service cover and engage it in place.

After replacing an O

again.

The corresponding parameter and unit have to be activated when measuring cells are

upgraded. See

measuring cell, wait 60 minutes before using the instrument

2

Display edit

, p.28.

I.3 Recalibrating measuring cells

See

Sensor settings

, p. 32.

I.4 Replacing additional filter

The additional filter provides added protection should problems occur with the particle

filter in the flue gas probe. The additional filter is very rarely contaminated if the

measuring instrument is used normally.

Check the additional filter (visually) for contamination from time to time and replace it

if necessary.

1

Place the measuring instrument on its front.

2

Remove the service cover: Take hold of it at the

markings (arrows) using the index finger and

thumb, press slightly, fold up and remove.

3

Release the additional filter from the hose

connections.

4

Fit a new filter (0133 0010) on the hose

connections.

5

Attach the service cover and engage it in place.

Page 51

I. Care and maintenance

I.5 Recalibrating measuring cells

I.5 Cleaning the modular flue gas probe

Disconnect the flue gas probe from the measuring

instrument prior to cleaning.

1

Release the probe catch by pressing the key on

the probe handle and remove the probe module.

2

Blow compressed air through the flue ducts of the

probe module and probe handle (see illustration).

Do not use a brush!

3

Fit a new probe module on the handle and engage

it in place.

I.6 Changing the thermocouple

1

Release the probe catch by pressing the key on

the probe handle and remove the probe module.

2

Remove the thermocouple plug-in head from the

socket using a screwdriver and pull the

thermocouple out of the probe shaft.

3

Keep inserting new thermocouple in the probe

shaft until the connection head clicks into place.

4

Fit a new probe module on the handle and engage

it in place.

51

Page 52

52

J. Questions and Answers

J. Questions and Answers

This chapter gives answers to frequently asked questions.

Question Possible causes Remedy

Measuring instrument keeps Battery spent Charge the battery or connect the

switching off by itself or mains unit (see

Measuring instrument will

not switch on.

Display of the battery capacity Battery was often not fully discharged / Discharge battery fully (until instrument

appears faulty charged. switches off by itself) and then charge

Failure report: Gas output closed. Ensure that gas output is free

Pump flow rate to high

If we were unable to answer your question. please contact your distributor or Testo

Customer Service. For contact data, see back of this document or web page

www.testo.com/service-contact

fully.

Operation

K. Technical data

, p. 17).

K.1 Standards and inspections

· As declared in the certificate of conformity, this product fulfils the guidelines of

2004/108/EEC.

· This product is TÜV approved to 1. BImSchV.

· This product is TÜV tested in accordance with EN50379 part 2, exception: The

parameter CO in the instrument versions testo 330-1/testo 330-1 LL are TÜV tested in

accordance with EN50379 part 3.

Page 53

K. Technical data

K.2 Measuring ranges and accuracies

K.2 Measuring ranges and accuracies

53

Parameter Measuring range Accuracy Resolution t90

1

O2 0...21 Vol.% ±0.2 Vol.% 0.1 Vol.% <20s

CO 0...4,000 ppm ±20 ppm at 0...400 ppm 1 ppm <40s

(testo 330-1 / (H2 level < 10%) ±5 % of reading at 400.1...1,000 ppm

testo 330-1LL) ±10 % of reading at 1,000.1...4,000 ppm

CO, H2-comp. 0...8,000 ppm ±10 ppm or 1 ppm < 40s

(testo 330-2, -3 / ±10 % of reading

testo 330-2LL)

2

±20 ppm or

±5 % of reading

±10 % of reading at 2,001...8,000 ppm

3

at 0...200 ppm

3

at 201...2,000 ppm

amCO, via 0...2,000 ppm ±10 ppm at 0...100 ppm 1 ppm < 35s

flue gas probe ±10 % of reading at 101...2,000 ppm

amCO, via 0...500ppm ±5ppm at 0...100ppm

0632 3331 ±5% of reading at 101...500ppm

4

1ppm -

4

NO (NOlow 0...300 ppm ±2 ppm at 0.0...40.0 ppm 0.1 ppm <30s

meas. cell) ±5 % of reading at 40.1...300.0 ppm

NO (NO meas. 0...3,000 ppm ± 5ppm at 0...100ppm 1ppm <30s

cell) ±5% of reading at 101...2,000ppm

±10% of reading at 2001...3,000ppm

5

Draught

-9.99...40 hPa ± 0.02 hPa or 0.01 hPa ±5% of reading

±0.03 hPa at 0.61...3.00 hPa

±1.5 % of reading at 3.01...40.00 hPa

3

at -0.50...0.60 hPa

ΔP 0...200 hPa ±0.5 hPa at 0.0...50.0 hPa 0.1 hPa -

±1 % of reading at 50.1...100.0 hPa

±1.5 % of reading at 100.1...200.0 hPa

1

Response time 90%; recommended minimum measurement time to ensure correct measurement values: 3 min;

2

above sensor protection limit: Resolution 500ppm (up to max. 30000ppm);3 the larger value applies;

4

at 10...30°C, outside this range additionally ±0.2% of reading/°C ; 5with fine draught measurement option:

Measuring range 0...100.0Pa, Resolution 0.1Pa

Parameter Measuring range Accuracy Resolution t90

1

Temperature -40...1,200 °C ±0.5 °C at 0.0...100.0 °C 0.1 °C at -40...999.9 °C Depending

±0.5 % of reading in rem. range 1 °C at 1,000°C...1,600 °C on probe

Efficiency 0...120 % - 0.1 % Flue gas loss -20.0...99.9 % - 0.1 % amCO2, via 0...10,000ppm ±50ppm+2% of reading at 0...5,000ppm 1ppm -

0632 1240 ±100ppm+3% of reading at 5001...10,000ppm

1

Response time 90%; recommended minimum measurement time to ensure correct measurement values: 3 min

Page 54

K. Technical data

54

K.3 Other device data

K.3 Other device data

Characteristic Values

Operating temperature range -5...45 °C

Storage/ transport temperature -20...50 °C

Power supply Battery block: 3.7 V/2.4Ah

Dimensions (L x W x H) 270 x 90 x 65 mm

Weight 600g (excluding battery)

Memory testo 330-1, -2 / testo 330-1 LL: 200 locations

Display Monochrome, 4 grey levels, 160 x 240 pixels

Battery storage temperature: ±0...35°C

Battery life >6h (pump on, display lighting off, 20 °C ambient temperature)

Battery charge time approx. 5-6 h

Warranty testo 330-1, -2, -3: testo 330-1LL, -2LL:

Option Bluetooth

Option Bluetooth

Option Bluetooth

Certification Belgium (BE), Bulgaria (BG), Denmark (DK), Germany (DE), Estonia (EE), Finland (FI), France (FR),

®

®

®

Mains unit: 6.3 V/1.2 A

testo 330-3 / testo 330-2LL: 400 locations

Measuring instrument: 24 months Measuring instrument: 48 Monate

Measuring cells: 24 months LL-Measuring cells 0

Flue gas probe: 24 months Flue gas probe: 48 Monate

Thermocouple: 12 months Thermocouple: 12 Monate

Battery: 12 months Battery: 12 Monate

Typ-designation: BlueNiceCom IV

Bluetooth Qualified Product Notice: BNC4_HW2x_SW2xx

Bluetooth listing identifier: B013784

Bluetooth listing company: 10274

Range <10m

EU countries

Greece (GR), Ireland (IE), Italy (IT), Latvia (LV), Lithuania (LT), Luxembourg (LU), Malta (MT),

Netherlands (NL), Austria (AT), Poland (PL), Portugal (PT), Romania (RO), Sweden (SE),

Slovakia (SK), Slovenia (SI), Spain (ES), Czech Republic (CZ), Hungary (HU), United Kingdom (GB)

and Republic of Cyprus (CY).

Other EFTA Countries

Iceland, Liechtenstein, Norway and Switzerland

Non-European countries

Colombia, Turkey

Information from FCC (Federal Communcations Commision)

Contains FCC ID: PI403B

- Paragraph 15.19 Labeling requirements

- This instrument fulfils 15 of the FCC guideline

- Commissioning is subject to the following two conditions:

1. This instrument may not cause any dangerous interference

2. This instrument must accept any interference received, including interference which may

cause undesired operation.

Changes

The FCC requires that the user is informed that all changes and modifications to the

instrument which are not expressly approved by Testo AG, can void the right of the user to

operate the instrument.

Other Measuring cells: 24 Monate

, CO: 48 Monate,

2

Page 55

K. Technical data

K.4 EC conformity declaration

.K.4 EC declaration of conformity

55

Page 56

K. Technical data

56

K.5 Principles of calculation

K.5 Principles of calculation

K.5.1 Fuel parameters

Fuel A2

Natural gas 0,660 0,009 11,8 Vol.% 3 Vol.%

Light oil 0,680 0,007 15,4 Vol.% 3 Vol.%

LPG 0,630 0,008 13,7 Vol.% 3 Vol.%

Wood 0,765 0,000 20,3 Vol.% 13 Vol.%

Pellets 0,765 0,000 20,3 Vol.% 13 Vol.%

Briquette 0,833 0,000 18,9 Vol.% 8 Vol.%

Lignite 0,955 0,000 19,8 Vol.% 8 Vol.%

Anthracite 0,758 0,000 20,5 Vol.% 8 Vol.%

Coke oven 0,600 0,011 10,3 Vol.% 3 Vol.%

gas

Town gas 0,630 0,011 13,6 Vol.% 3 Vol.%

Test gas 0,0000 0,000 0,00 Vol.% 0 Vol.%

1

Fuel-specific factor

2

Default setting

1

K.5.2 Calculation formulae

1

B

CO2max O2reference

CCaarrbboonn ddiiooxxiiddee::

FFlluuee ggaass lloossss::

EEffffiicciieennccyy:: ηη

CO

x (21% - O2)

CO2 = C02max: Maximum carbon dioxide

qA =

2max

21%

(FT-AT) x ( + B )

(

= 100 - qA

A2

21% - O2

21%: Oxygen level of air

O2: Measured oxygen level in %

- Kk FT: Flue gas temperature

)

AT: Ambient temperature

A2/B: Fuel-specific parameters

21%: Oxygen level of air

O2: Measured oxygen level in %

Kk: Calculated value

qA

specific to fuel

allowing for

regained condensate heat

if dewpoint level is not

reached

(for condensing furnaces).

: Calculated flue gas loss

Page 57

K. Technical data

K.5 Principles of calculation

57