Page 1

Flue gas analyser, country-specific version GB

Instruction manual en

testo 327

Page 2

Contents2

Contents

Contents ................................................................................................2

Safety and the environment ....................................................................3

EC declaration of conformity ..................................................................7

Product description ................................................................................8

First steps ..............................................................................................9

Using the product ..................................................................................12

Preparing for measurement ....................................................................12

Performing the measurement ..................................................................14

Checking the instrument ........................................................................18

Maintaining the product ........................................................................19

Tips and assistance ..............................................................................25

Accessories and spare parts ................................................................26

Appendix ..............................................................................................27

Page 3

Safety and the environment 3

Safety and the environment

About this document

Please read this documentation through carefully and familiarise yourself with

the product before putting it to use. Keep this documentation to hand so

that you can refer to it when necessary. Hand this documentation on to any

subsequent users of the product.

Pay particular attention to information emphasised by the following symbols:

· With the signal word Warning!:

Warns against hazards which could result in serious physical injury if the

precautionary measures indicated are not taken.

· With the signal word Caution!:

Warns against hazards which could result in minor physical injury or damage

to equipment if the precautionary measures indicated are not taken.

· Additional information.

Avoiding personal injury/damage to equipment

Do not make measurements with the measuring instrument and its sensors

on or near live components unless the instrument is expressly approved for

current/voltage measurements!

Never store the measuring instrument together with solvents and do not use

any desiccants.

Only operate the measuring instrument properly, for its intended purpose

and within the parameters specified in the technical data. Do not use force.

Only carry out the maintenance and repair work that is described in the

documentation. Follow the prescribed steps exactly. Only use original spare

parts from Testo.

Any additional work must only be carried out by authorised personnel.

Testo will otherwise refuse to accept responsibility for the proper functioning

of the measuring instrument after repair and for the validity of certifications.

Temperatures given on probes/sensors relate only to the measuring range of

the sensors. Do not expose handles and feed lines to any temperatures in

excess of 70 °C unless they are expressly permitted for higher temperatures.

deenfresitptsvnl????

Page 4

Specifications4

Products with BluetoothÒ (Option)

Changes or modifications, which are not expressly approved by the responsible

official body, can lead to a withdrawal of operating permission.

Interference with data transfer can be caused by instruments which transmit on

the same ISM band, e.g. microwave ovens, DECT telephony, non-secure

software in cellphones when telephoning, transmitting/receiving text messages

etc.

The use of radio connections is not allowed in e.g. aeroplanes and hospitals.

For this reason, the following point must be checked before entering:

Deactivate Bluetooth function

Main menue - Settings - Buetooth - deactivate Bluetooth (Off)

Protecting the environment

Take faulty rechargeable batteries/spent batteries to the collection points

provided for them.

Send the product back to Testo at the end of its useful life. We will ensure

that it is disposed of in an environmentally friendly manner.

Specifications

Functions and use

The testo 327 is a hand-held measuring instrument for the professional flue gas

analysis of domestic and light commercial gas and oil boilers and appliances.

This includes condensing boilers and gas heaters. The unit is designed to carry

out tests shown in BS 7967, and has a timed tightness test, let by test and a

timed CO function.

These systems can be adjusted using the testo 327 and checked for

compliance with the applicable limit values.

The testo 327 is available in four versions; the scope of function varies

according to the version:

· testo 327 O

· testo 327 CO: Infrared interface

· testo 327-1 (O2, CO): Infrared interface

· testo 327-2 (O2, CO): Infrared / IRDA interface, memory, automatic sensor

: Infrared interface

2

diagnosis, option: Bluetooth (data interface)

Page 5

Specifications 5

Warning The testo 327 must not be used in areas at risk of explosion,

for long-term measurements or as a safety (alarm) device!

The testo 327 with the Bluetooth option may only be operated in countries in

which it is type approved (see Technical Data).

Technical data

Display variables [units] Measuring range/resolution Accuracy/response time

Oxygen, via internal electro-chemical sensor (not 327 CO):

O2content [%],

O2air supply [%],

Reference value O2ref [%] 0...21% / 0.1% ±0.2% / t90 <40s

Carbon monoxide, 327-1:

CO content [ppm, mg/m³] 0...4,000ppm / 1ppm ±20ppm (0...400ppm), ±5% of reading (401...1,000ppm),

(H2share <10%) ±10% of reading (1,001...4,000ppm) / t90 <60s

Carbon monoxide, via internal electro-chemical sensor (only 327-2 with option COH2):

CO content [ppm, mg/m³] 0...8,000ppm / 1ppm ±20ppm (0...200ppm), ±5% v. Mw. (201...2,000ppm),

±10% of reading (2001...8,000ppm) / t90 <40s

Ambient Carbon monoxide, via internal electro-chemical sensor:

Ambient CO content

amCO [ppm] 0...2,000ppm / 1ppm ±10ppm (0...100ppm), ±10% of reading (>100ppm) /

t90 <40s

Temperature, via type K thermocouple of flue gas probe (NiCr-Ni):

Flue gas temperature FT,

Flue gas dew point ATP,

Ambient air AT -40...+600°C / 0.1°C, ±0.5°C (-40...100°C), ±0.5% of reading (>100°C),

-40...1,112°F / 0.1°F ±0.9°F (-40...212°F), ±0.5% of reading (>212°F) /

t98 <50s (TE 0.5mm);<100s (TE 1mm)

Temperature, via differential temperature set 0554 1208:

Flue gas socket T1 [°C, °F],

Sensor socket T2 [°C, °F] -40...+600°C / 0.1°C, ±0.5°C (-40...100°C), ±0.5% of reading (>100°C),

-40...1,112°F / 0.1°F ±0.9°F (-40...212°F), ±0.5% of reading (>212°F) /

t98 <50s (TE 0.5mm);<100s (TE 1mm)

Pressure, via internal differential pressure sensor:

Flue draught Drght [mbar,

hPa, inW, in Hg] -40...40hPa / 0.01hPa ±0.02hPa (-0.50...0.60hPa), ±0.03hPa (0.61...3hPa),

±1.5% of reading (>3hPa) /-

Flue draught Drght, with option

of precision draught [Pa] -100...100Pa / 0.1Pa ±3Pa / -

Pressure and tightness test via internal differential pressure sensor, with differential pressure set 0554 1203:

Differential pressureΔp [hPa] -200...200hPa / 0.1hPa ±0.5hPa (0.0...50.0hPa)

(with option precision ±1% of reading (50.1...100.0hPa)

difference pressure: 0.01hPa) ±1.5% of reading (100.1...200.0hPa)

Efficiency, calculated:

Efficiency

2

η

[%],

Efficiency η+3)[%] 0...120% / 0.1% ±0.2% / -

1)

deenfresitptsvnl????

Page 6

Specifications 6

Display variables [units] Measuring range/resolution Accuracy/response time

Flue gas loss, calculated

1)

Flue gas loss qA2)[%], 0...99.9% / 0.1% - / Flue gas loss qA+3)[%], -20.0...99.9 / 0.1% - / -

Air ratio (not 327 CO)

Air ratio λ[-] 1...20 / 0.01 - / -

Carbon dioxide

CO2content [%] 0...CO

1) Recommended minimum duration of measurement to guarantee correct readings: 3min, 2) Calorific value range not taken into account,

3) Calorific value range taken into account

Calculation formulae for calculated display variables

· See Appendix

Fuels

· Quantity: 5

· Designation/fuel parameters: See Appendix

Ambient conditions

· Operating temperature: -5...45°C/23...113°F

· Storage temperature for measuring instrument:

-20...50°C/-4...122°F,

Li-ion rechargeable battery: 0...35°C/32...95°F

Housing

· Material: ABS/PA/TPU

/ 0.01% - / -

2max

Warranty

· Measuring instrument, flue gas probe: 24 months

· Measuring cells: 24 months

· Thermocouple: 12 months

· Rech. batt.: 12 months

Option Bluetooth (testo 327-2 only)

· Type-designation: BlueNiceCom IV

· Bluetooth Qualified Product Notice:

BNC4_HW2x_SW2xx

· Bluetooth listing identifier: B013784

· Bluetooth listing company: 10274

Range <10m

· Dimensions: 240 x 90 x 58mm

· Weight: Approx. 620g

· Protection class: IP40

Voltage supply

· Current source: Li-ion rechargeable battery

3.7 V/1.4 Ah (0515 0114) / 3.7 V/2.4 Ah (0515 0100),

mains unit 6.3V/1.2A

· Battery life (measuring gas pump on, display light off):

Approx. 4 h (0515 0114) / approx. 10h (0515 0100)

· Battery charge time: Approx. 5-6 h

Display

· Type: Illuminated LCD

· Updating of readings: 1/s

Directives, standards and tests

Option Bluetooth® Certification

EU countries

Belgium (BE), Bulgaria (BG), Denmark (DK),

Germany (DE), Estonia (EE), Finland (FI),France (FR),

Greece (GR), Ireland (IE), Italy (IT), Latvia (LV),

Lithuania (LT), Luxembourg (LU), Malta (MT),

Netherlands (NL), Austria (AT), Poland (PL),

Portugal (PT), Romania (RO), Sweden (SE),

Slovakia (SK), Slovenia (SI), Spain (ES), Czech

Republic (CZ), Hungary (HU), United Kingdom (GB) and

Republic of Cyprus (CY).

Other EFTA Countries

Iceland, Liechtentein, Norway and Switzerland

Non-european countries

Japan, Columbia, Turkey

· EC Directive: 2004/108/EEC

· Tests: EN 50379, Part 2 (O2, °C, hPa),

Part 3 (CO), testo 327-2 with option

COH2 additionally: EN 50379, Part 2

(CO)

CO accuracy: independantly tested to

BS7967

Page 7

EC conformity declaration 7

EC declaration of conformity

deenfresitptsvnl????

Page 8

Product description8

Product description

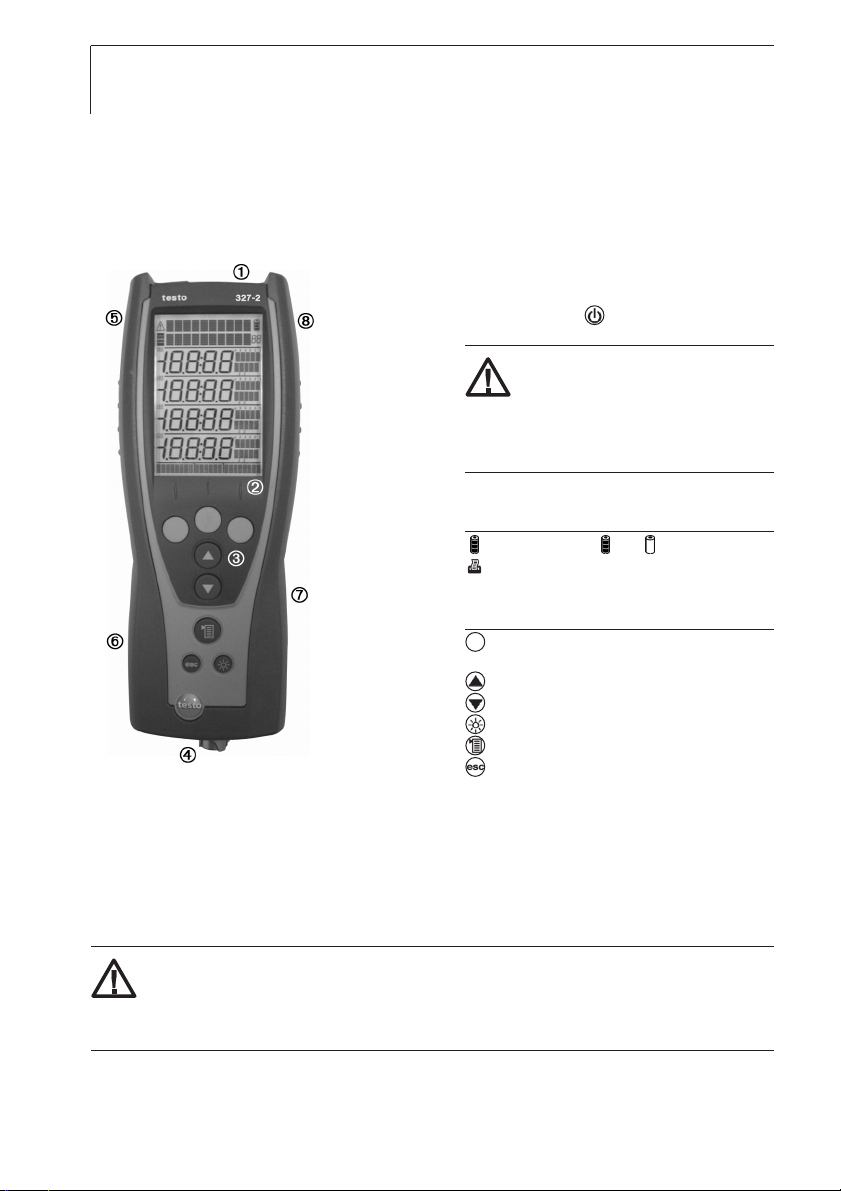

At a glance: Measuring instrument

Head: IR interface (327-2: IRDA) for

connection to Testo protocol printers,

ON/OFF switch ( ),

condensate outlet.

Caution! Risk of injury from

infrared beam!

Do not point infrared beam at people's

eyes!

Display.

Display symbols

: Battery capacity( : full, : empty)

: Print function: sends data

Control keys

Key functions

: Function keys (3x): shows relevant function on

the display.

: Up/down keys: changes display view.

: Light key: switches display light on/off.

: Menu key.

: Cancel key.

Sensor socket for TC temperature probe, flue gas socket for flue gas probe,

gas outlet, mains socket

Sides: window of condensate trap with fill level display

Rear: service compartment (battery, measuring cells)

Rear: magnets for fixing measuring instrument to metallic surfaces.

Warning! Strong magnets can cause damage!

Keep well away from products which could be damaged through the effects of

magnetism (e.g. pacemakers, monitors, computers, credit cards).

Rear: eyelet for attaching a carrying strap (accessory).

Page 9

First steps 9

At a glance: Flue gas probe

Removable filter chamber with window

and particle filter

Probe handle

Connecting cable

Connector for measuring instrument

First steps

Charging rechargeable battery

Charge the rechargeable battery fully before using the measuring instrument.

The rechargeable battery can only be charged at an ambient temperature of

0...+35 °C. If the rechargeable battery pack has discharged completely, the

charging time at room temperature is approx. 5-6 hrs.

Charging tthe rrechargeable bbattery iin tthe mmeasuring iinstrument:

The measuring instrument must be switched off.

1 Connect the plug of the mains unit to the mains unit socket on the

measuring instrument.

2 Connect the mains plug of the mains unit to a mains socket.

- The charging process will start. The charge status will be shown on the

display. The charging process will stop automatically when the

rechargeable battery is fully charged.

deenfresitptsvnl????

Charging tthe rrechargeable bbattery iin ccharger 00554 11087 ((accessory):

Refer to the documentation that comes with the charger.

Page 10

First steps10

Operation with the mains unit

If the mains unit is connected, the measuring instrument is automatically

powered from the mains unit. It is not possible to charge the rechargeable

battery in the measuring instrument during operation.

1 Connect the plug of the mains unit to the mains unit socket on the

measuring instrument.

2 Connect the mains plug of the mains unit to a mains socket.

- The measuring instrument is powered via the mains unit.

- If the instrument is switched off and a rechargeable battery is inserted,

the charging process will start automatically. Switching the measuring

instrument on has the effect of stopping rechargeable battery charging

and the measuring instrument is then powered via the mains unit.

Switching on/off

Switching tthe iinstrument oon:

Press .

- Initialisation phase:

· All display segments are lit (length of time: 3 s).

· Serial number, firmware version, instrument designation, date, time and country-

specific version of instrument are displayed (length of time: 5 s).

- The Measure flue gas option is displayed.

Switching tthe iinstrument ooff:

Press .

- sometimes: The pump starts and the measuring cells are rinsed until the

switch-off thresholds (O

>20 %, other parameters 50 ppm) are reached.

2

Rinsing lasts no more than 2 minutes.

Performing instrument settings

Performing ssettings:

1 Press .

2 Select Settings using / and confirm entry with the OK function key.

Page 11

First steps 11

3 Select the required function using / and confirm entry with the OK

function key.

Functions

1. Displ. seq: selects parameters and units of measurement and assigns a position number for the

display/protocol printouts.

2. Date/Time: sets the date and time

3. Language: sets the language.

4. Printer: sets the printer to be used.

- The selected function is opened and the position number

(Displ. seq function only) or parameter which can be set flashes.

5. Bluetooth (327-2 with option Bluetooth only): activate / deactivate interface.

4 Set the position number (Displ. seq function only)/parameter:

For Displ. seq function only: Select the position number to be changed

using / and confirm with the Change function key.

Alternatively: Delete the position number with Del. and insert a new

position number using Ins..

Displ. seq function: Only parameters and units of measurement which are

assigned to a position number appear in the display and on printouts.

A maximum of 20 position numbers can be activated.

Key functions

· : Change parameters.

· For Date/Time function: changes between hours, minutes, day, month and year.

· For Displ. seq function: changes between parameter and unit of measurement (only available if

there are several units of measurement for the selected parameter).

· OK for Displ. seq function and a flashing position number: confirms setting and moves to next display

position.

· OK for Displ. seq and Finish flashing: confirms settings and leaves the function.

· OK for Date/Time, Language, and Printer: functions: confirms setting and leaves the function.

· esc: leaves the parameter or function without applying the changes.

Example: "Change display position"

The position number to be changed has been selected.

1 Press / several times until the required parameter flashes.

2 Press the or function key to go to the menu for selecting the unit of measurement.

3 Press / several times until the required unit of measurement flashes.

4 Press the OK function key to confirm the setting and move to the next display position.

5 At the end of performing the settings: Press / several times until Finish flashes

(appears after the last position number) and confirm entry with OK.

deenfresitptsvnl????

Page 12

Using the product12

Using the product

Preparing for measurement

Connecting probes/sensors

The instrument needs to detect which probes or sensors are connected, before

switch on. If you fail to do this simply turn off instrument connect probe and

re-start unit.

Connecting tthe pprobes:

Insert the connector into the flue gas

socket and lock by turning it clockwise

gently (bayonet lock).

There must be no more than one extension

lead (0554 1201) between the measuring

instrument and the flue gas probe.

Connecting tthe ssensor:

If no ambient air temperature sensor is connected, the temperature

measured by the thermocouple of the flue gas probe during the zeroing

phase is used as the ambient air temperature. All dependent parameters

are calculated using this value. This method of measuring ambient air

temperature is sufficient for systems dependent on ambient air. However,

ensure that the flue gas probe is near the intake duct of the burner during

the zeroing phase.

If an ambient air temperature sensor is connected, the ambient air

temperature is measured continuously by this sensor.

Insert the connector of the sensor into the sensor socket.

Using the flue gas probe

Checking tthe tthermocouple:

The thermocouple of the flue gas probe must not lie against the probe cage.

Check before use. Bend the thermocouple

back if necessary.

Page 13

Using the product 13

RGS

Aligning tthe fflue ggas pprobe:

The flue gas must be able to flow freely past the thermocouple.

Align the probe by turning it as required.

The tip of the probe must be in the centre of the flue gas flow.

Align the flue gas probe in the flue gas duct

so that the tip is in the centre of the flow

(area of the highest flue gas temperature).

Activating the required functions

Switching tthe iinstrument oon:

Press .

Activating ffuel:

1 Press .

2 Select Fuel using / and confirm entry with the OK function key.

3 Select the fuel to be measured using / and confirm entry with the

OK function key.

deenfresitptsvnl????

Page 14

Using the product14

Activating mmeasuring ffunction:

1 Press .

2 Select Measure using / and confirm entry with the OK function key.

3 Select the required measuring function using / and confirm entry with

the OK function key.

Functions

1. Flue gas: flue gas measurement with flue gas probe and central measurement menu for

displaying/printing out all readings obtained from the various measuring functions.

2. Let by: timed measurement of differential pressure with differential pressure set (accessory).

3. tightness: timed measurement of differential pressure with differential pressure set (accessory).

4. Draught: flue draught measurement with flue gas probe and differential pressure measurement with

gas pressure set (accessory).

5. Smoke/Oild: enter smoke number/oil derivative (only available if a liquid fuel has been activated).

6. HCT: enter the heat carrier temperature.

7. Diff-press: measurement of differential pressure with differential pressure set (accessory).

8. Diff-temp: measurement of differential temperature with differential temperature set (accessory).

9. Ambient CO: timed measurement of ambient CO with flue gas probe.

Flue gas function: When the measuring cells are first called up after the

measuring instrument is switched on, they are zeroed (length of time: 30 s).

Exception: the Ambient CO function has already been started.

During the zeroing phase, the fuel can be selected. Any connected probe

must be in the open air during the zeroing phase!

Performing the measurement

Measuring:

The steps described in the chapter Preparing for measurement have

been completed.

Let by and tightness function: The Diff Press Kit (0554 1203) must be

connected.

Warning! Risk of explosion due to dangerous mixture of gases!

Make sure there are no leaks between the sampling point and the

measuring instrument.

Do not smoke or use naked flames during measurement.

Draught function: The pressure sensors are zeroed when the Draught

function is started (length of time: 5 s). The measuring instrument must

not be pressurised during zeroing!

To help position the flue gas probe in the centre of the flow (area of the

Page 15

Using the product 15

highest flue gas temperature), the flue gas temperature measured is

shown graphically.

Do not measure for longer than 5 minutes, as the readings may fall

outside of the tolerances due to a possible drift of the pressure sensor.

Smoke/Oild function: Only available if a liquid fuel has been activated.

Diff-temp. function: The differential temperature set (0554 1208)

must be connected. The ambient air sensor must be unplugged (located

bottom left of unit) before connecting the T1 sensor. Be aware that the

connector is a firm fit, when disconnecting.

The differential temperature is calculated from T1 - T2.

Diff-press function: The gas pressure set (0554 1203) must be connected.

The pressure sensors are zeroed when the Diff.-press function is started

(length of time: 5 s). The measuring instrument must not be pressurised

during zeroing!

Do not measure for longer than 5 min, as a drift of the pressure sensor

may result in readings outside the tolerance limits.

Ambient CO: When the measuring cells are first started after the measuring

instrument is switched on, they are zeroed (length of time: 30 s).

Exception: The Flue gas function has already been called up.

Any connected probe must be in the open air during the zeroing phase!

The measurement values from the functions Draught, Diff.-temp., Diff.-press

and Smoke/Oild are transferred to the the central measurement menu Flue

gas and must therefore be carried out before the flue gas measurement.

deenfresitptsvnl????

Flue gas function:

1 Start the measurement with the Start function key.

- The current readings are displayed.

Ensure flue is at normal operating temperature and the readings are steady,

before accepting flue gas measurements.

2 Stop the measurement with the Stop function key.

Let by and tightness function:

- The time value is blinking.

1 Set measuring time (from 1 to 15 minutes) using / and confirm with

the Start function key.

- The message

- After zeroing, the message

Zeroing wwithout ooperating ppressure

Attach tto tthe ssystem aand sstart

is displayed.

is displayed.

Page 16

Using the product16

Start the measurement with the Start function key only when the required

2

gas pressure of 10mbar (Let by) or 20mbar (tightness) is displayed.

p1

-

displays the start pressure in mbar, p2displays the actual value in

mbar.

3 After measuring time, the pressure difference is displayed (

p2- p1

on let

by test, p2- p1on tightness test).

Option:

Stop the measurement with the Stop function key.

Draught, Diff.-temp., and Diff.-press functions:

1 Start the measurement with the Start function key.

- The current readings are displayed.

2 Stop the measurement with the Stop function key.

3 Transfer the readings to the central Flue gas measurement menu using the

OK function key.

Smoke/Oild and HCT functions:

Recording values with the smoke pump and manual input:

1 Select the value to be changed using / and confirm with the change

function key.

2 Set the value using / and confirm entry with the OK function key.

3 Once all values have been input, select Finish using / .

4 Transfer the readings to the central Flue gas measurement menu using the

OK function key.

The values entered are not shown in the central Flue gas measurement

menu. However, they can be printed out together with the readings from

other functions.

Recording values with the smoke tester testo 308 and wireless transfer:

- The testo 308 must be in data transfer mode ( lights up).

1 Press function key t308 .

- The values recorded by the smoke tester are transferred.

2 Once all values have been input, select Finish using / .

3 Transfer the readings to the central Flue gas measurement menu using the

OK function key.

The values entered are not shown in the central Flue gas measurement

menu. However, they can be printed out together with the readings from

other functions.

Page 17

Using the product 17

Ambient CO function:

- The time value is blinking.

1

Set measuring time (from 1 to 30 minutes) using / .

2

Start the measurement with the Start function key.

- The following values are displayed:

AmbCO: current ambient CO value in ppm.

aver.:average ambient CO value in ppm. Every minute the average

value is calculated. If the measured value is lower than the min value,

the min value will be set to the current value. If the measured value is

higher than the max value, the max value will be set to the current

value.

min: minimum ambient CO value in ppm.

max: maximum ambient CO value in ppm.

- Alarmlevels:

Current value > 10 ppm: The value blinks (1 sec on / 1 sec off).

Current value > 30 ppm: The value blinks (0.5 sec on / 0.5 sec off).

- After measuring time the average ambient CO value is displayed.

Option:

Stop the measurement with the Stop function key.

Printing rreadings:

To print out the readings recorded in the instrument, you need Testo

protocol printer 0554 0545 or 0554 0547. You must also follow the

operating instructions for the printer!

deenfresitptsvnl????

The Print function key is only available if a printout is possible in the

instrument's current status.

Start the printout with the Print function key.

- Printing out from Flue gas function: All readings taken since the

instrument was last switched on and transferred to the central Flue

gas measurement menu are printed out.

Printing out from other functions: Only those readings taken using the

respective measuring function are printed.

Saving rreadings ((327-22 oonly):

The Save function key is only available if saving is possible in the

instrument's current status.

Start saving with the Save function key.

Page 18

Using the product18

Printing/deleting/displaying mmeasurement ddata ((327-22 oonly):

There are 20 memory locations (Position 1 to Position 20) to which one

measurement data record can be saved per location. Memory locations

that have already been assigned are indicated by the display of the

date/time of saving.

1 Press .

2 Select Memory using / .

- The memory capacity and available memory locations are displayed.

To print the memory: press the Print function key.

To delete the whole memory: press the Del function key and confirm entry

with the Yes function key.

3 Press OK.

4 Select memory location using / .

To display the measurement data record: press the Value function key.

To print the measurement data record: press the Print function key.

To delete the measurement data record: press the Del function.

Transfer ddata tto aa PPocket PPC ((327-22 oonly):

Data can be transferred to a Pocket PC via infrared or Bluetooth.

You must also refer to the documentation that comes with the software.

Checking the instrument

Performing aan iinstrument ddiagnosis:

1 Press .

2 Select Diagnosis using / and confirm entry with the OK function key.

3 Select the required function using / and confirm entry with the OK

function key.

Functions

1. Info: displays instrument information: serial number, instrument temperature, operating hours, qA

version, last service

2. Error: displays list of errors.

3. Rech. batt: displays the battery capacity.

4. Sens. Diag (327-2 only): performs sensor diagnosis.

Key functions for Sens. Diag function (327-2 only)

· : select sensor.

· Read: performs sensor diagnosis and displays results of diagnosis.

Page 19

Maintaining the product 19

Maintaining the product

Condensate trap

The fill level of the condensate trap can be read from the markings on the

condensate trap.

Emptying tthe ccondensate ttrap

Flue Gas condensate consists of a weak mix of acids. Avoid contact with the

skin. Make sure that the condensate does not run over the housing.

Caution! Failure to empty the condensate trap when the fill level is

reached results in condensate entering the sensors and pump. This

voids the warranty and results in costly repairs and replacements.

Do not empty the condensate trap while the flue gas pump is in operation!

1 Keep measuring instrument in an upright

position (condensate outlet pointing upwards).

2 Open the condensate outlet on the

condensate trap: pull out approx. 7 mm to

the stop.

3 Let the condensate run out into a sink.

4 Mop up any remaining drops on the

condensate outlet using a cloth.

5 Close the condensate outlet.

The condensate outlet must be completely

closed, otherwise measuring errors could occur if external air gets in. It is

advisable to empty water trap at regular intervals, (preferably daily).

deenfresitptsvnl????

Page 20

Maintaining the product20

Particle filter

Checking tthe pparticle ffilter:

Replacing tthe pparticle ffilter:

Check the particle filter of the flue gas

probe for contamination at regular intervals:

check visually by looking through the

window of the filter chamber. Replace the

filter if there are signs of contamination.

The filter chamber may contain condensate.

1 Open the filter chamber by turning it gently

anticlockwise.

2 Remove spent filter and fit new filter

(0554 0040).

3 Fit the filter chamber and lock it by turning

it gently clockwise.

Housing

Cleaning tthe hhousing:

Clean the housing with a damp cloth (soap suds) if it is dirty. Do not use

aggressive cleaning agents or solvents!

Rech. batt.

Rechargeable bbattery ccare:

If possible, always discharge the rechargeable battery fully before

recharging it.

Do not store the rechargeable battery for long periods when discharged.

The best storage conditions are at 50 - 80 % charge level and 10 - 20 °C

ambient temperature; charge fully before further use.

Page 21

Maintaining the product 21

Changing tthe rrechargeable bbattery:

The measuring instrument must not be connected to a mains socket via

the mains unit. The measuring instrument must be switched off.

1 Place the measuring instrument on its front.

2 Undo the screws with a cross-head

screwdriver and remove service lid.

3 Open the battery lock by pressing the button

and pushing in the direction of the arrow.

4 Remove the rechargeable battery and insert

new rechargeable battery.

5 Close the battery lock by pressing the

button and pushing against the direction of

the arrow until the battery engages.

6 Replace service lid and fasten with screws.

Measuring cells

Used measuring cells must be disposed of as special waste!

Changing tthe mmeasuring ccells ((327 CCO, 3327 OO2, 3327-11):

A slot bridge (0192 1552) must be inserted in slots which do not have a

measuring cell. Used measuring cells must be disposed of as special waste!

deenfresitptsvnl????

The measuring instrument must be switched off.

1 Place the measuring instrument on its front, facia.

2 Loosen the screws with a cross-head screwdriver and remove service lid.

3 Pull hose connections from the faulty measuring cell.

4 Remove the faulty measuring cell/bridge from the slot.

CO measuring cell only: Remove the shorting

jumper

.

Do not remove shorting jumpers of the new

measuring cells until immediately before installation.

Do not leave the measuring cells without a shorting

jumper for longer than 15 minutes.

5 Insert a new measuring cell in the slot.

6 Attach hose connections to the measuring cell.

7 Replace service lid and fasten with screws.

8 Continue with

calibration of O2 measuring cell

and/or

input of cell

coefficients for CO measuring cell.

Page 22

Maintaining the product22

Calibrating tthe OO2measuring ccell ((327 OO2, 3327-11):

After replacing an O

measuring cell, wait for an stabilisation period of 60

2

minutes to elapse before starting the calibration.

During the calibration, any flue gas probes that are connected must be in the

open air.

1 Press .

2 Select Sensors using / and confirm entry with the OK function key.

3 Select 0

-Sensor using / and confirm entry with + (press

2

simultaneously).

- Instrument performs calibration (30s) and is then ready for use again.

Inputting ccell ccoefficients ffor CCO mmeasuring ccell ((327 CCO, 3327-11):

If you do not enter the correct cell coefficients, you will get incorrect

readings! You will find the cell coefficients on the leaflet enclosed with the

spare measuring cell. If you enter incorrect coefficients:

Abort the process using and enter cell coefficients again.

1 Press .

2 Select Sensors using / and confirm entry with the OK function key.

3 Select CO Sensor using / and confirm entry with + (press

simultaneously).

- The first number of the first cell coefficient flashes.

4 Press Change function key and set number using / .

5 Change to further digits by pressing the function keys one after the

other and confirm entry with OK function key.

- Instrument automatically changes to the second cell coefficient

6 Repeat steps 4 and 5. Confirm the input with the OK function key.

7 Complete the entry with the OK function key.

Replacing mmeasuring ccells, ttesto 3327-22:

The measuring instrument must be switched off.

1 Place the measuring instrument on its front facia.

2 Loosen the screws with a cross-head screwdriver and remove service lid.

3 Pull hose connections from the faulty measuring cell.

4 Remove the faulty measuring cell from the slot.

Page 23

Maintaining the product 23

CO measuring cell only: Remove shorting jumper

(0390 0095, 0390 0109).

Do not remove shorting jumpers of the new

measuring cells until immediately before

installation. Do not leave the measuring cells

without a shorting jumper for longer than

15 minutes.

5 Insert a new measuring cell/bridge in the slot.

6 Attach hose connections to the measuring cell/bridge.

7 Replace service lid and fasten with screws.

After replacing an O2 measuring cell, wait for an stabilisation period of 60

minutes to elapse before starting a new measurement.

Thermocouple

Replacing tthe tthermocouple oof tthe fflue ggas pprobe

1

Loosen and remove halfshell handles ().

2

Turn sealing cap clockwise as far as it will go

and remove (

).

deenfresitptsvnl????

Page 24

Maintaining the product24

3

Unlock halfshell elements and remove ().

4 Remove adaptor and hose (

couple out of its holder (

from thermocouple (

5

Connect lines to the new thermocouple

(

, white -, green +) and push thermocouple

into holder again.

6

Connect adaptor and hose to thermocouple (

Adjust lines and hoses (

7 Attach sealing cap and turn anticlockwise

(as far as possible, note markings).

8 Attach halfshell handles and close screws.

), Push thermo-

) and disconnect cable

).

) and attach halfshells.

).

Page 25

Tips and assistance 25

Tips and assistance

Questions and answers

Measuring instrument switches itself off or will not switch on?

· Rechargeable battery is low: charge battery or connect mains unit.

· On 327-2 models condensate trap is full, red lights indicate.

Battery capacity seems to be faulty?

· Rechargeable battery was repeatedly not fully discharged/charged: discharge rechargeable battery (until

measuring instrument switches itself off) and then charge fully.

---- appears instead of a reading?

· Sensor/probe is not plugged in: connect the sensor/probe

· Sensor/probe or measuring cell faulty: check sensor/probe or measuring cell.

Message: Pump flow rate too high?

· Gas outlet is blocked: make sure that the gas outlet is clear.

Message: ERROR + two-digit no. and service?

Device error: switch off the instrument and contact your dealer or Testo Customer Service.

If the above information does not solve the problem, please contact your dealer

or Testo Customer Service. For contact data, see back of this document or

web page www.testo.com/service-contact

deenfresitptsvnl????

Page 26

Accessories and spare parts26

Accessories and spare parts

Designation Article no.

Probes/sensors

Compact flue gas probe, 180 mm, Ø 6 mm, TC 1 mm, incl. cone, up to 500 °C / 932 °F 0600 9740

Compact flue gas probe, 300 mm, Ø 6 mm, TC 1 mm, incl. cone, up to 500 °C / 932 °F 0600 9741

Thermocouple for compact flue gas probe, 180 mm, 0430 0383

Thermocouple for compact flue gas probe, 300 mm, 0430 0382

O2annular gap probe 0632 1260

Ambient air temperature (AT) probe, 300 mm 0600 9791

Ambient air temperature (AT) probe, 190 mm 0600 9787

Ambient air temperature (AT) probe, 60 mm 0600 9797

Pipe wrap probes 0600 4593

Surface probes 0600 0194

Differential temp kit (adaptor, 2 x pipe wrap probes) 0554 1208

Differential pressure set 054 1203

Pipe wrap probe 0600 0020

Thermocouple adaptor 0440 1261

B1 gas cooker grill probe (BS7967) 300002 7967

B2 angled probe for open flue applications (BS7967) 300001 7967

Spare measuring cells

02measuring cell for testo 327-1 0390 0047

CO measuring cell for testo 327-1 0390 0046

02measuring cell for testo 327-2 0390 0092

CO measuring cell for testo 327-2 0390 0095

CO/H2 measuring cell for testo 327-2 0390 0109

Miscellaneous

Rechargeable battery for testo 327-O2, 327-CO, 327-1 0515 0114

Rechargeable battery for testo 327-2 0515 0100

Protocol printer, IrDA 0554 0547

Spare thermal paper for protocol printer, long-term legibility for up to 10 years 0554 0568

Charger with spare rechargeable battery 0554 1087

Smoke tester for measuring soot in flue gas 0554 0307

Spare particle filter, 10 pcs. 0554 0040

For a complete list of all accessories and spare parts, please refer to the

product catalogues and brochures or look up our website at: www.testo.co.uk

Page 27

Appendix 27

Appendix

Fuel parameters

Fuel CO

MAX (%) [%] [1/K] [1/K] [-] [% by weight][% by weight] [MJ/kg] [MJ/kg]

Natural Gas 11.9 3 0.35 0.39 40 24.4 0.0 53.42 48.16

Light Oil 15.5 3 0.48 0.51 53 13.0 0.0 45.60 42.80

Heavy Oil 15.8 3 0.51 0.54 54 11.5 0.2 42.90 40.50

Propane 13.8 3 0.42 0.45 48 18.2 0.0 50.00 46.30

Butane 14.1 3 0.43 0.46 48 17.2 0.0 49.30 45.80

Kerosene 15.4 3 0.47 0.51 52.36 13.6 0.0 46.56 43.12

Calculation formulae

CCaarrbboonn ddiiooxxiiddee::

CCaarrbboonn mmoonnooxxiiddee::

O2ref Kgr Knet K1 H MH2O Qgr Qnet

2

CO

x (21% - O2)

2max

CO2= C02max: Fuel-specific carbon

CO [mg/m

21%

21%: Oxygen content of the air

O

21% - O2ref

3

] = x CO [ppm] x 1.25 21%: Oxygen content of the air

21% - O

2

O

O

dioxide value

: Measured oxygen

2

content as %

: Measured oxygen

2

content as %

ref: Fuel-specific oxygen

2

reference number as %

deenfresitptsvnl????

RRaattiioo::

CO

CO

x 10O00

2

: carbon dioxide

CO

2

ratio = C0: carbon monoxide

Page 28

Appendix28

Efficiency referred to Gross Efficiency:

Effg = 100 -

Efficiency referred to Nett Efficiency:

Effn= 100 -

EExxcceessss AAiirr ((EExxAAiirr))::

AAiirr rraattiioo:: λλ

CCaarrbboonn mmoonnooxxiiddee

uunnddiilluutteedd::

Kgrx (FT - AT)

()+ ()+ ()

(

CO

2

K

x (FT - AT)

net

()+ ()+ ()

(

CO

2

21%

( -1 )x 100 21%: Oxygen level of air

=

21% - O

CO2max

= C0

CO

uCO = CO x

(MH2O + 9 x H) x (2488 + 2.1 x FT - 4.2 x AT)

(MH2O + 9 x H) x (210 + 2.1 x FT - 4.2 x AT)

2

2

λλ

Q

x 1000

gr

Q

x 1000

net

K1 x CO

CO

+ CO

2

K1 x Qgrx CO

Q

x (CO2+ CO)

net

Kgr/Knet/Qgr/Qnet/K1/MH2O/H:

FT: Flue gas temperature

AT: Ambient temperature

CO: Measured carbon monoxide

CO

O

CO

CO

λ: Calculated air ratio

Fuel-specific factors

value in %

: Calculated carbon dioxide

2

value in %

: Measured oxygen level in %

2

max: Fuel-specific carbon

2

dioxide value

: Calculated carbon dioxide

2

value

: Measured carbon

monoxide value

)

)

FFlluuee ggaass ddeeww ppooiinntt

tteemmppeerraattuurree::

FH20 x PAbs

ln (

ln (

610.78

FH20 x PAbs

610.78

FTP = FH20: Flue gas specific water

)x 234.175

)- 17.08085

PAbs: Absolute pressure in

vapour level in Vol.%

mbar/hPa

Page 29

Notes 29

deenfresitptsvnl????

Page 30

Notes30

Page 31

Notes 31

deenfresitptsvnl????

Page 32

0970 3270 05 en V01.09 en_GB

Loading...

Loading...