Page 1

Instruction manual en

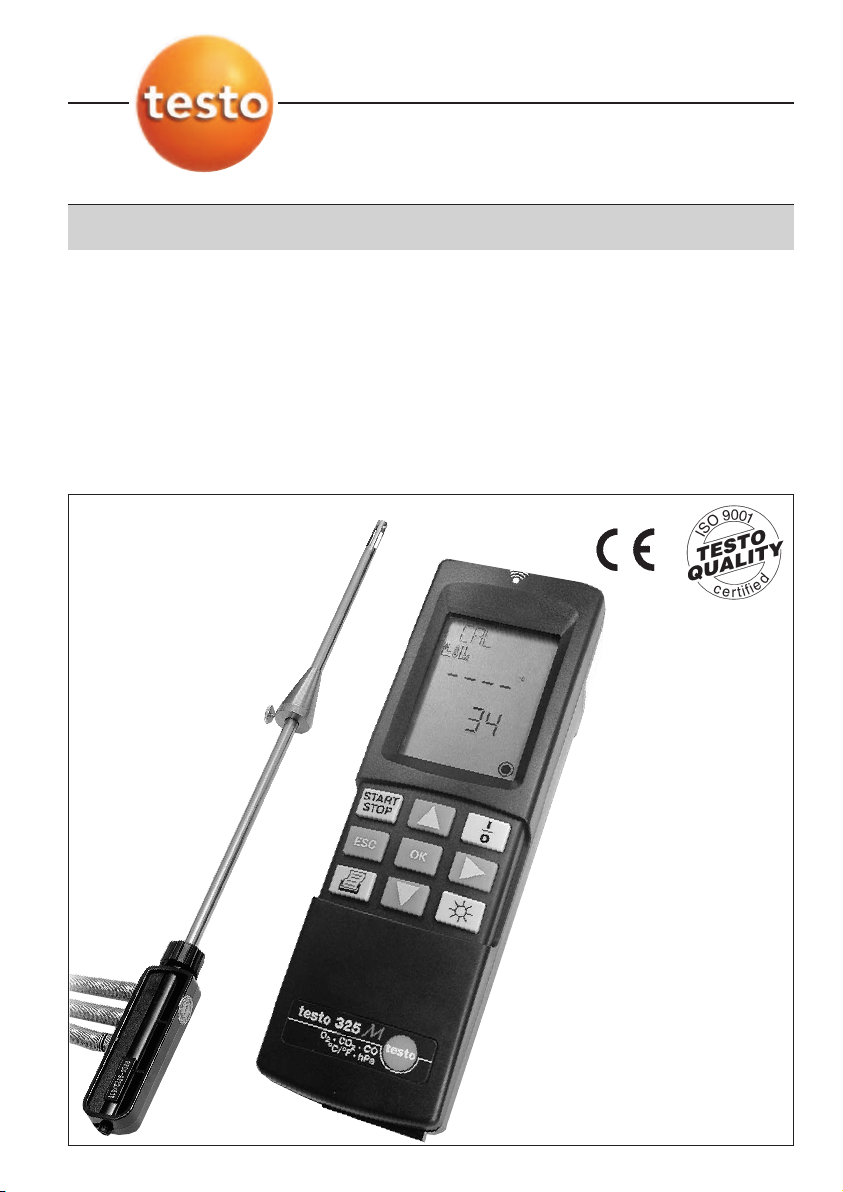

testo 325 M/XL

Flue gas analyser

Page 2

Preface / Copyright

Preface

Dear Customer

Thank you for purchasing a Testo product. We hope you will

enjoy the benefits of this product for a long time to come and

that it will aid you with your work.

Please read this instruction manual carefully and familiarise

yourself with the operation of the instrument before putting it to

use.

If problems should occur which you cannot rectify yourself,

please consult our Customer Service Department or your

nearest distributor. We will do our best to help you quickly and

competently to reduce downtimes.

Copyright

This documentation is subject to the copyright of Testo AG.

Reproduction and use contrary to the legitimate interests of

Testo AG are prohibited without the prior, written consent of the

company.

We reserve the right to modify technical details from the

descriptions, specifications and illustrations contained in this

documentation.

Testo AG

Postfach 11 40

D-79849 Lenzkirch

2

Page 3

General Information

Symbols

Incorrect operation of this instrument could lead to danger. Particularly important information, which

has to be observed when working with this product, is highlighted in this instruction manual as

follows:

Warnings are highlighted by a warning triangle. The Warning title indicates the danger level:

Warning! means death or serious physical injury may occur if the specified safety

measures are not carried out.

Caution! means minor physical injury or damage to property may occur if the specified

Warning title

Notes on special cases and peculiarities in the handling of your unit are indicated by an

exclamation mark.

Standards/tests

This product is TÜV approved.

Test Code Number: testo 325 M: TÜV By RgG 218

safety measures are not carried out.

Read all the warnings carefully and carry out all the specified safety measures to avoid

danger.

The conformity certificate confirms that this product fulfills the guidelines in accordance with

89 / 336/EEC.

testo 325 XL: TÜV By RgG 222

3

Page 4

Contents

Preface /Copyright............................................2

General information ..........................................3

Contents............................................................4

1. Basic safety instructions ..................................6

2. Intended use ....................................................7

3. Product description ..........................................8

3.1 Power supply................................................................8

3.2 Dispaly and control elements ......................................8

3.3 Menu overview ..........................................................10

3.4 Gas path ....................................................................10

4. Initial operation................................................11

4.1 Putting in rechargeable batteries / batteries ..............11

4.2 Connecting the mains unit..........................................11

4.3 Connecting sensors / probes ....................................11

5. Basic instructions............................................12

5.1 Switching on ..............................................................12

5.2 Selecting menu items ................................................12

5.3 Measuring ambient air temperature ..........................12

5.4 Measuring flue gas temperature ................................13

5.5 Regular maintenance ................................................13

5.6 Switching off ..............................................................14

6. Settings ..........................................................15

6.1 Selecting fuel..............................................................15

6.2 Setting display sequence ..........................................15

6.3 Selecting units............................................................16

6.4 Setting date/time ........................................................16

7. Measuring ......................................................18

7.1 Measuring flue gases ................................................17

7.2 Measuring pressure....................................................17

7.3 Measuring differential temperature ............................18

7.4 Measuring undiluted CO ............................................19

7.5 Measuring ambient CO ..............................................19

7.6 Printing readings taken ..............................................20

7.7 Saving/reading/deleting readings ..............................21

7.8 Printing saved readings..............................................22

4

Page 5

Contents

8. Maintenance ..................................................23

8.1 Changing rechargeable batteries/batteries ................23

8.2 Emptying the condensate trap ..................................23

8.3 Changing the filter ......................................................24

8.4 Cleaning the analyser ................................................24

8.5 Cleaning the flue gas probe ......................................24

8.6 Changing the thermocouple ......................................25

8.7 Cleaning the flue gas pump ......................................25

8.8 Changing the measuring cells....................................26

9. Troubleshooting ..............................................29

10. Technical data ................................................31

10.1 Measuring ranges and accuracies ............................31

10.2 Other instrument data ................................................32

10.3 Calculation fundamentals ..........................................32

10.4 Calculation formulae ..................................................33

11. Accessories / Spare parts................................34

Short instructions ............................................35

5

Page 6

1. Basic safety instructions

Avoid electrical hazards:

Never make measurements with the unit and its external probes on or near live components

unless the unit is expressly approved for current and voltage mesurements.

Use only the supplied power supply unit when using the instrument under mains power.

Allow only authorised persons to replace damaged mains cables.

Protect the unit/measuring cells:

Never store the unit together with solvents (e.g. acetone).

The condensate trap should be emptied once the maximum line has been reached. Switch off the

pump to empty.

Measure correctly:

Prior to every measurement, check the complete measurement system (probe, condensate trap,

hoses and connections) for leaks in order to avoid incorrect measurements caused by the intake

of air.

Ensure that the gas output in the instrument is always free of obstacles so that the sample gas

can escape unhindered.

Preserve product safety/warranty entitlement:

Operate the instrument only within the parameters specified in the technical data.

Please handle the instrument with care.

Force should never be applied.

The temperature data for the probes only refer to the sensor measuring range. Never subject

handles or pipes to temperatures greater than 70°C unless they are expressly approved for higher

temperatures.

The instrument should only be opened for maintenance and repair work if expressly described in

the Instruction manual.

Only carry out the maintenance and repair work described in the Instruction manual. Please follow

instructions. For safety reasons, only original spare parts from Testo should be used.

Any other work should only be carried out by authorised trained personnel. Otherwise

responsibility for the perfect functioning of the instrument following repairs and for the validity of

approvals will be denied by Testo.

Ensure correct disposal:

The measuring cells contain low concentrations of alkaline solutions and acids. Please dispose of

carefully.

Dispose of defective rechargeable batteries and spent batteries responsibly.

You can return your instrument directly to us at the end of its service life. We will dispose of it

responsibly.

6

Page 7

2. Intended use

Employ the analyser for the following applications only:

testo 325 M / XL is a hand-held instrument for the professional

analysis of flue gas in burners:

- Small-scale burners (oil, gas, wood)

- Low temperature and condensing boilers

- Gas heaters

These systems can be adjusted using testo 325 M / XL and

checked for their adherence to valid limit valids.

testo 325 M / XL can be used to carry out the following tasks:

- Adjustment of O2, CO and CO2values in burners in order to

guarantee smooth operation

- Measurement and adjustment of gas flow pressure in gas

heaters

- Measurement and adjustment of flow and return temperatures

in heating systems

7

Page 8

3. Product description

3.1 Power supply

testo 325 M / XL can be powered as follows:

- 4 batteries (1.5V round cell alkaline IEC LR6 Type AA)

- 4 rechargeable batteries (1.5V IEC KR 15/51 corresp. Type AA)

- Mains connection via mains unit (Part no. 0554 1084)

- Rechargeable battery pack (testo 325 XL only)

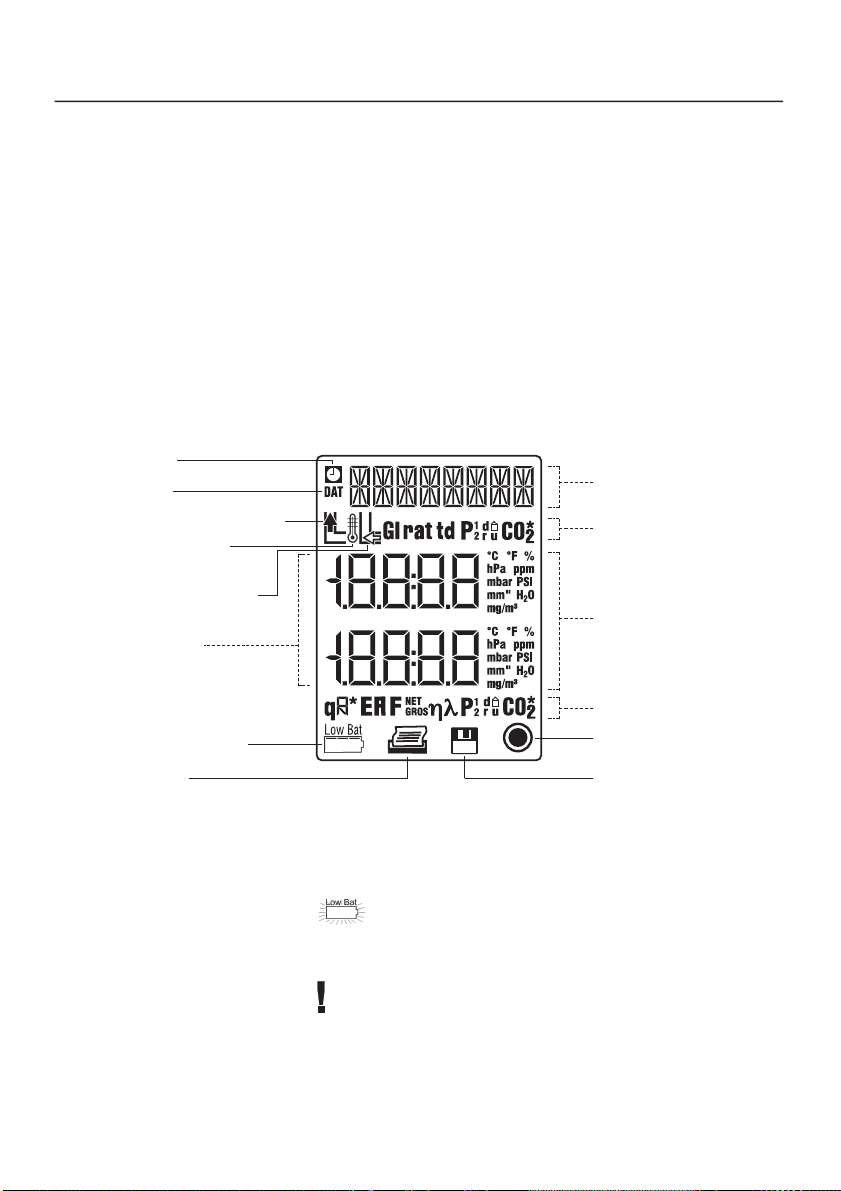

3.2 Display and control elements

Display

Time

Date

Flue gas temperature

Temperature

measurement

Ambient air

temperature

Readings

Battery capacity

Print

Fuel name/

menu item

Parameters

Measuring units

Parameters

Pump on

Save

Battery capacity

A warning flashes in the display if the battery is running low

during rechargeable batttery/battery operation:

Remaining capacity is then approx. 1 hour for batteries, approx.

1 hour for rechargeable batteries

The instrument switches itself off automatically when the

rechargeable battery/battery capacity is too low, in order to

protect from total discharge.

8

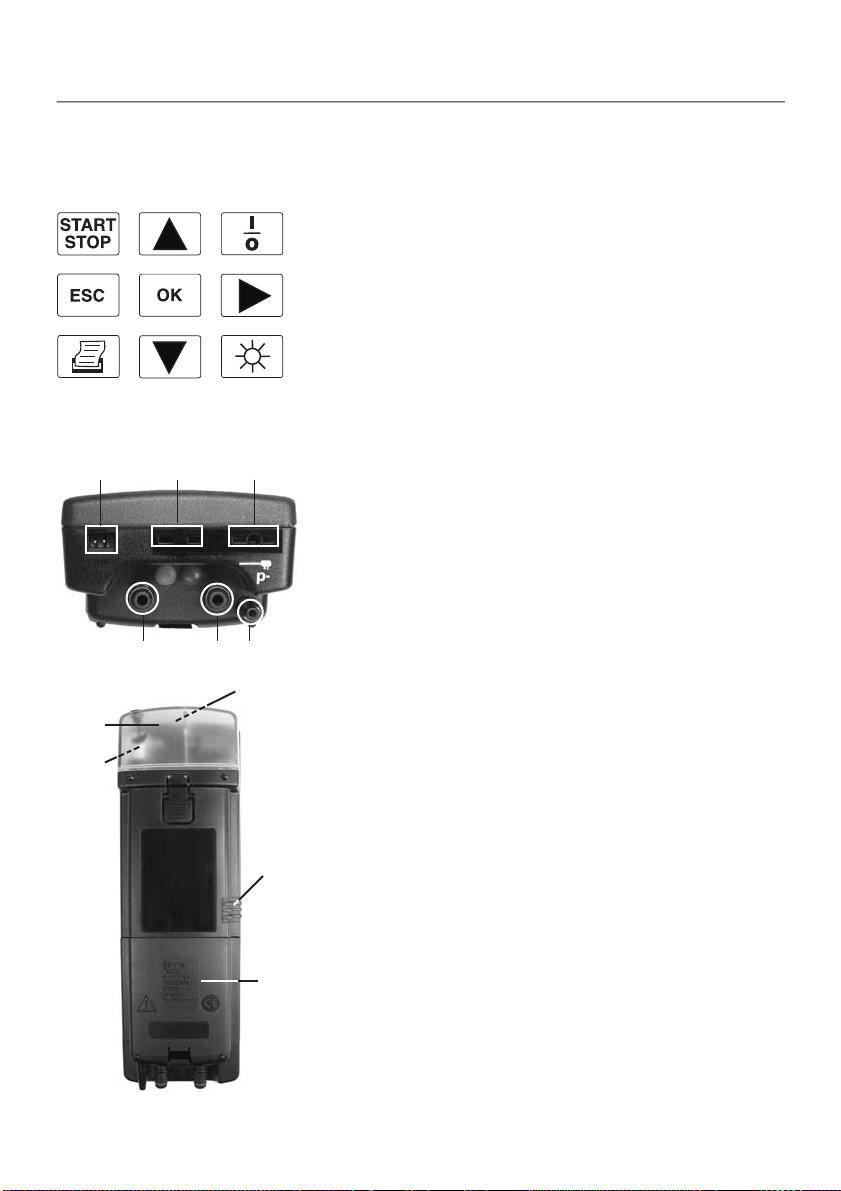

Page 9

➀

➃

➆

➁

➂

➅➄

➁➇

➁

➂

3. Product description

Keyboard

➀ Start/stop flue gas pump

➁ Select display, select menu items

➂ Switch analyser on/off

➃ Interrupt operation, return to superior menu level

➄ Open main menu / sub-menu / menu item, confirm selection

➅ Select parameters

➆ Print current readings

➇ Switch display light on/off

Connections

➀ Mains unit

➁ Probes: ambient air temperature (AT) /temperature T2

➂ Probes: flue gas temperature (FT) / temperature T1

➃ Flue gas (red)

➄ Pressure+ (blue)

➅ Pressure - (p-)

➃

➄

➃

➄➀➅

➀

Other

➀ Infrared interface (on front side)

➁ Gas outlet

➂ Battery compartment

➃ Condensate trap

➄ Filter (behind the condensate trap)

➁

➂

9

Page 10

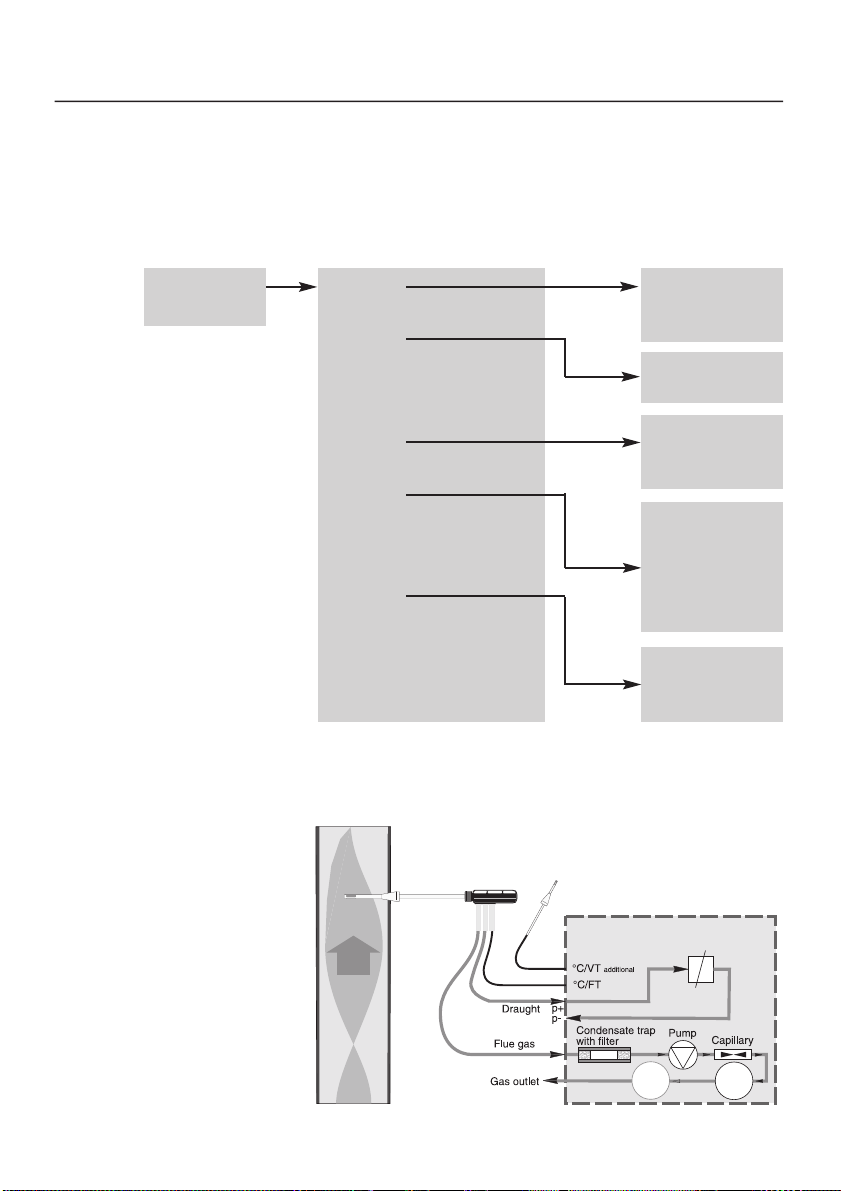

3. Product description

3.3 Menu overview

Measurement

menu Sub-menus

Measurement

view

Main menu

Memory

delta p

delta t

1

memory1

·

·

·

memory20

delta p1

delta p2

View

Fuel

Dat/Clk

Unit

co amb

co undil

1

(testo 325XL only)

3.4 Gas path

RGS

Line 1

·

·

·

Line 12

Nat gas

L oil

H oil

LPG

1

Butane

1

Coal

Pressure

Temperat

Gas

testoter

m

testo 325

p

10

P

CO O

2

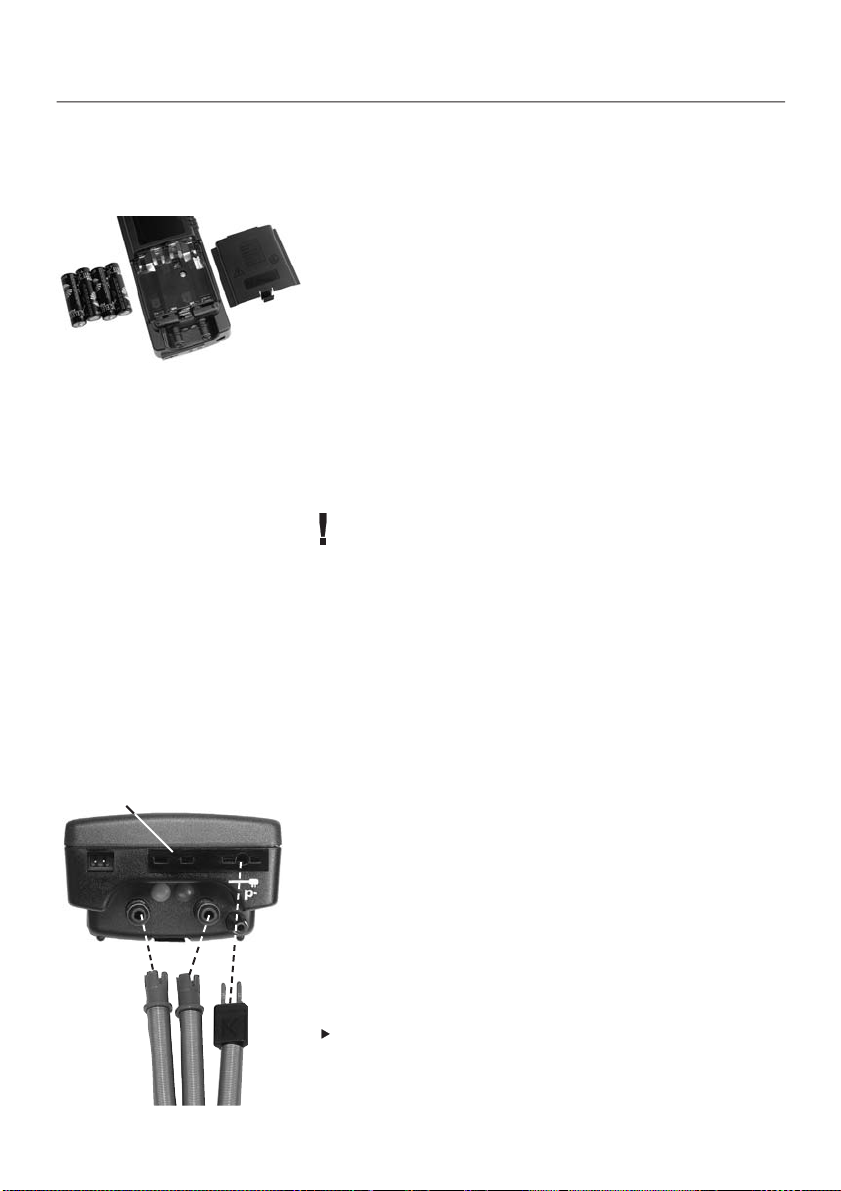

Page 11

➀

4. Initial operation

4.1 Putting in rechargeable batteries/

batteries

testo 325XL: Insert and connect rechargeable battery pack. No

other steps are necessary.

testo 325M: 4 batteries are included, please insert prior to

initial operation:

1 Remove battery cover at rear of instrument.

2 Insert batteries correctly (+/-).

3 Close cover on battery compartment.

Refer to Chapter 6, Setting up on page 15 for information on

how to set date/time, fuel and measurement units.

4.2 Connecting the mains unit

Operation via mains unit (0554 1084) is also possible if the

rechargeable batteries/batteries are spent. It is normal for the

mains unit to heat up. If the temperature becomes too high

(e.g. due to a defect in the analyser), the mains unit is

protected from overheating by a thermal safety switch.

The rechargeable battery block in testo 325 XL is recharged

in the analyser when it is switched off and is connected to the

mains (battery symbol flashes during recharging, recharging

stops and battery symbol disappears when rechargeable

battery is full). Conventional rechargeable batteries cannot be

recharged in the analyser.

1 Connect plug to analyser.

2 Connect mains plug to mains.

4.3 Connecting sensors/probes

Flue gas probe (accessory)

1 Connect hose for gas (red) to the socket marked by red.

2 Connect hose for pressure (blue) to the pressure+ socket

(blue).

3 Connect flue gas temperature probe pipe to the FT socket.

Ambient air probe (accessory)

Connect ambient air probe pipe to the AT socket ➀.

11

Page 12

5. Basic instructions

➁➀

➂➃

➄

5.1 Switching on

1 Press to switch on analyser.

➀ Display test: All segments in the display light up for approx.

5s.

➁ The software version number and the power is displayed for

3s (rechargeable batteries / batteries: ,

mains unit: ---- ).

➂ Zeroing phase: CAL lights up, pump runs for approximately

60s (remaining time is shown in display).

The flue gas probe must be located in fresh air during

zeroing!

In the case of error messages, refer to “Troubleshooting” on

page 28.

➃ The set fuel flashes in the display

2 Use or to select the required fuel and confirm

with .

➄ Selected fuel now applies.The analyser changes to the

measurement menu and is ready to operate.

12

5.2 Selecting menu items

The pump stops automatically when the main menu is

opened.

1 Open main menu using .

2 Select required menu item via or and confirm via .

If sub-menu is available:

3 Select required menu item via or and confirm via .

Press to go back one menu level.

Page 13

5. Basic instructions

5.3 Measuring ambient air temperature

There are 2 ways to measure the ambient air temperature:

1. Measurement using flue gas probe

If a separate ambient air probe is not connected, the

temperature measured by the flue gas probe thermocouple

during the zeroing phase is used as the ambient air temperature.

All dependent variables are calculated with this value.This type

of ambient air temperature measurement is sufficient for systems

dependent on ambient air.

Ensure that the flue gas probe is located near the intake duct

of the burner during the zeroing phase.

2. Measurement using separate probe

If a separate ambient air probe is connected, the ambient air

temperature is measured continuously by this probe.

5.4 Measuring flue gas temperature

The flue gas temperature is measured via the flue gas probe

thermocouple. The probe pipe has openings at the side so that

the thermocouple is protected and can simultaneously come into

contact with the flue gas.

Ensure that the thermocouple is positioned in the flue gas

flow.

The thermocouple should not be covered by the probe stem

frame. This is the only way to make it possible to measure the

flue gas temperature accurately and consequently to determine

the exact flue gas loss.

The tip of the thermocouple should not touch the protective

casing!

If possible, bend back the tip of the thermocouple.

Inserting probe pipe in flue gas duct

Insert flue gas probe pipe, horizontally if possible, in the

flue gas duct.

Condensation drops running down the probe pipe could lead to a

dramatic drop in the temperature measured.

13

Page 14

5. Basic instructions

5.5 Regular maintenance

Check the level in the condensate trap

Condensate trap overflowing

Damage to pump and measuring cells

Check the level in the condensate trap prior to every

Caution

Check the state of the filter

Caution

Rinse measuring cells

The measuring cells should be rinsed with fresh air after each

measurement :

1 Remove flue gas probe from flue gas duct.

2 Start pump using .

3 Wait until the O2level is above 20.0% and the CO level is

below 50ppm.

4 Press to stop pump.

measurement: Hold the instrument horizontally or

vertically. The condensate trap should be emptied once

the MAX level has been reached (See 8.2 Emptying the

condensate trap, P. 23)!

Filter dirty

Damage to pump!

The state of the filter should be checked on a regular

basis: change the filter when clogged (See 8.3

Changing the filter, P.24).

14

You will find more information about servicing and maintaining

your analyser in Chapter 8. Maintenance, P.23!

5.6 Switching off

The readings stored in the instrument are lost when the

analyser is switched off.

➁➀

In the case of error messages, refer to “Troubleshooting” on

page 29.

Switch off analyser using .

- The analyser automatically rinses the measuring cells if the

O2level drops below 20% or the CO level exceeds 50ppm ➀.

- OFF is displayed for 5s ➁ (press to discontinue switchoff), the analyser then switches off.

Page 15

6. Settings

6.1 Selecting fuel

1 Select Fuel in main menu ➀ and confirm selection

➁➀

using .

- The set fuel flashes in the display ➁.

2 Select required fuel via or and confirm selection using

.

- Selected fuel is accepted and the analyser changes to the

measurement menu.

6.2 Setting display sequence

Selectable parameters:

O

2

Oxygen level

Flue gas temperature (FT)

Ambient air

temperature (AT)

Differential temperature

(FT - AT)

NET

EFF

EFF

Efficiency referred to H

Efficiency referred to H

GROS

rat Ratio

AA

E

CO

2

Excess Air (EXA)

Carbon dioxide

CO Carbon monoxide

uCO Carbon monoxide

undiluted

Air ratio

1

P

P

td Dew point

CO

Pressure (0 to 40hPa)

Pressure (0 to 200hPa)

2

*

CO maximum

1

CO CO ambient

1

(testo 325XL only)

The sequence in which the parameters are shown in the display

can be selected as required. In this way, frequently used

parameters can be combined and then called up quickly

1 Select View in the main menu and confirm selection

with .

- Line1 flashes in the display and the set parameters and units

for line 1 and 2 are shown.

2 Use to select required parameter for line 1.

3 Use to change to Line 2 and select required parameter

u

o

for line 2 with .

4 Set up additional parameters for lines 3 to 12. Repeat

procedure as described in step 3.

5 Confirm settings with .

- Selected settings are accepted and the analyser changes to

the measurement menu.

15

Page 16

6. Settings

➀

➂

6.3 Selecting units

1 Select Unit in the main menu ➀ and confirm

➁

with .

- Pressure flashes and the set unit for pressure is shown in

the display ➁.

2 Select required pressure unit using .

3 Change to Temperat using and select required

temperature unit using .

4 Change to GAS using and select required gas unit using

.

5 Confirm settings using .

- Selected units are accepted and the analyser changes to the

measurement menu.

6.4 Setting date/time

1 Select Dat/Clk in the main menu ➀ and confirm selection

➁➀

selection via .

- The set date is shown and “Day” flashes ➁.

2 Set “Day” using or .

3 Change to “Month” and “Year” using and set using or

respectively.

4 Change to time setting via .

- The set time is shown and “Hour” flashes ➂.

5 Set “Hour” via or .

6 Use to change to “Minutes” and set via or

“Minutes”.

7 Confirm selection via .

- Selected date and time are accepted and the analyser

changes to the measurement menu.

16

Page 17

➀

7. Measuring

Measurements are carried out with the flue gas probe unless

otherwise indicated.

7.1 Measuring flue gases

Select fuel (See: 6.1 Selecting fuel, P. 15).

1 Insert flue gas probe pipe in the flue gas duct.

2 Begin measurement by pressing .

- The pump starts, flashes and the current readings are

displayed ➀.

Use or to change between the different views.

3 End measurement with .

- The pump stops and the last readings are retained in the

analyser until the next flue gas measurement.

7.2 Measuring pressure

With this function, you can measure the draught in a flue gas

channel or the flow pressure in gas heaters.

Draught is measured using the flue gas probe.

You will need the pressure set (Part no. 0554 0315) to

measure the gas flow pressure.

Please observe the following when measuring pressure:

It is only possible to measure pressure if the pump is

switched off.

When the pump is switched off, there is still a dynamic

pressure in the hose which first has to be reduced.

Wait approximately 30 s before starting to measure

pressure.

Remove any condensate in the flue gas probe prior to

measuring pressure (shake probe with tip pointing towards

the ground).

Hold flue gas probe in fresh air during the zeroing phase.

Do not change the position of the analyser while measuring

pressure.

Do not change between rechargeable battery/battery

operation and mains operation when measuring pressure;

fluctuations in the current could influence the measured

result.

Reading display: negative symbol stands for negative

pressure, positive sign stands for positive pressure.

17

Page 18

7. Measuring

➀

➂➃

Measuring draught

1 Select Delta P in the main menu ➀ and confirm selection

➁

via .

2 Select required pressure range:

Delta P1 ( 0 to 40hPa) or Delta P2 (0 to 200hPa) ➁.

3 Confirm selection via .

- The analyser starts zeroing (duration: 5s), CAL lights up in the

display ➂.

4 Once the zeroing phase is complete, insert the flue gas probe

pipe in the flue gas duct.

- The selected pressure range and the current reading are

displayed ➃.

5 End measurement via .

- The last reading is retained in the analyser until the next

draught measurement.

Measuring gas flow pressure

Gas flow pressure is measured in the same way as draught is

measured. Please note the following:

The silicone hoses from the pressure set should only be

connected to the gas heater after the zeroing phase.

18

➀

7.3 Measuring differential temperature

Use this function to measure the flow and return temperature in

heating systems.

You will need 2 pipe clamp probes (Part no. 0628 0020)

for the measurement.

1 Connect probes to analyser.

2 Select Delta t in the main menu ➀ and confirm selection

via .

➁ The temperature at the FT socket (T1) is shown in the top

➁

➂

reading line.

➂ The temperature at the AT socket (T2) is shown in the bottom

reading line.

3 End measurement with .

- The last reading is retained in the analyser until the next

differential temperature measurement.

Page 19

CO undil CO undil

CO amb CO amb

7. Measuring

7.4 Measuring undiluted CO

Always carry out a COundiluted measurement prior to a

flue gas measurement because the values for O2, CO and

in the instrument are overwritten during a COundiluted

➁➀

➁➀

measurement.

1 Select CO undil in the main menu ➀ and confirm via .

- The pump starts automatically and the measured value for

undiluted CO (uCO) is shown ➁.

2 End measurement via .

- The last reading is retained in the instrument until the next

COundiluted measurement.

7.5 Measuring ambient CO

Always carry out an ambient CO measurement before a

flue gas measurement since a value for CO, retained in

the analyser, will be written over when ambient CO is

measured.

Carry out zeroing in fresh air (preferably outdoors) prior to

measuring ambient CO.

1 Select CO amb in the main menu ➀ and confirm selection

with .

- The pump starts automatically and the measured value for

ambient CO ( ) is displayed.

2 End measurement via .

- The last reading is retained in the analyser until the next

ambient CO measurement.

19

Page 20

7. Measuring

-----------------------

➀

➁

NAT GAS

➂

➃

HCT: ______

➄

SmoN: ______

t325XL

-----------------------

30.06.2002 10:05:38

FT 130.6 °C

O2 4,5 %

AT 26.6 °C

AmCO 150 ppm

dP 1 -0.50 hPa

CO2 12.1 %

1.27

CO 101 ppm

7.6 Printing readings taken

You will need the Testo printer 0554 0545 to print the

readings in the analyser. Follow the instructions in the printer

manual.

You will have to be in the measurement menu before you can

start printing and the pump must be switched off.

Start printing procedure by pressing .

- lights up and the following data is printed:

➀ Header: Device name

➁ Date / Time

➂ Selected fuel

➃ Parameters with corresponding reading and unit: the

printout is completed according to the display sequence

set in the instrument (See: 6.2 Setting display sequence,

P. 15), parameters which occur twice are only printed

once.

AmCO = ambient CO, COmx= CO*

➄ HCT: / SmoN: Heat carrier temperature or smoke number

can be entered by hand

➅ Serial number of instrument

-----------------------

# 00000000

➅

-----------------------

20

Page 21

7. Measuring

7.7 Saving/reading/deleting readings

Readings can only be saved with testo 325XL.

20 memory blocks are available (Memory 1 to Memory20) in

which 1 set of readings can be saved.

Blocks which are already occupied are identified by and

the date and time when saved are displayed. Saving on a

memory block which is already occupied means that the

readings that are already saved are overwritten.

➀

➂

1 Select Memory in the main memory ➀ and confirm your

➁

selection with .

2 Select required memory block with or ➁ and confirm

with .

3 Using or choose from Write (save readings) ➂, Read

(read readings) or Delete (delete readings) and confirm

selection with .

If you select Write:

➃

- Clearance query (Really) appears if data is already stored

on the memory block.

Answer clearance query (Really) with .

- The selected memory block name flashes and and

date/time when saved light up ➃. The readings are saved.

-or-

If you select Read:

- The readings contained in the selected memory block are

displayed and flashes.

-or-

If you select delete:

Answer clearance query (Really) with .

- The readings stored in the selected memory block are

deleted.

Press to return to memory selection or measurement

menu.

21

Page 22

7. Measuring

7.8 Print saved readings

You will need the Testo printer 0554 0545 to print the

readings saved in the instrument. Please also follow the

instructions in the printer manual.

1 Select Memory in main memory and confirm selection with

.

2 Select required memory block using or and start

printout via .

-or-

Start printout via while the saved readings are displayed

( is shown).

- is shown and the data is printed.

22

Page 23

➁

➀

8. Maintenance

8.1 Changing rechargeable batteries /

batteries

Switch off the analyser before opening it!

Connect the analyser to the mains unit (accessories),

otherwise the analyser settings (e.g. date/time ...) and the

readings retained in the analyser are lost.

Saved Readings (testo 325XL only) do not get lost!

1 Place analyser on its front and open and remove battery

compartment cover at the back of the analyser.

2 Remove spent rechargeable batteries/batteries from the

battery compartment.

3 Place new rechargeable batteries/batteries in the battery

compartment. Insert correctly (+/-).

- The analyser switches off once the rechargeable batteries /

batteries are inserted!

4 Close cover on battery compartment.

Changing the rechargeable battery block

The rechargeable battery block ( testo 325XL only) is

changed in the same way as the rechargeable

batteries/batteries, however it must be connected to the white

socket in the battery compartment via the plug-in connection

➀ and held in position in the battery compartment via the

available adapter ➁.

8.2 Emptying the condensate trap

Switch off analyser before emptying the condensate trap!

1 Hold analyser with the condensate trap outlet in an upward

position and remove the plugs ➀ somewhat from the outlet

➀

opening.

The condensate is made up a weak acidic mixture. Avoid contact

with skin.

2 Empty condensate into container.

3 Close off outlet using plugs.

23

Page 24

8. Maintenance

➂

➁

➀

8.3 Changing the filter

Change the filter if clogging is visible

Switch off the analyser before changing the filter and empty

the condensate trap (See: 8.2 Emptying condensate trap,

P. 23)!

1 Release condensate trap holder at the back of the analyser

➀ and remove condensate trap ➁.

Only original Testo filters should be used

(Part no. 0554 0040)!

2 Remove clogged filter ➂ and attach new filter.

3 Attach condensate trap to analyser until it clicks into place.

8.4 Cleaning the analyser

The analyser housing should be cleaned with a damp cloth.

Please do not use corrosive cleaning substances or solutions.

Weak household cleaning agents or soap solutions can also

be used.

8.5 Cleaning the flue gas probe

24

➀

➀

➁

Deposits in the flue gas probe pipe can be removed as follows:

1 Release knurled nut in the handle of the flue gas probe by

turning it anti-clockwise ➀ and remove flue gas pipe ➁.

2 Rinse flue gas pipe with hot water and then purge with air or

clean with a brush (e.g. made of brass).

3 Push flue gas pipe over the thermocouple pipe of the flue gas

probe and screw knurled nut tightly by turning it clockwise.

8.6 Changing the thermocouple

1 Unscrew the back bending protection spring on the flue gas

probe handle and the bending protection spring in the

thermocouple plug from their holders by turning them in an

anti-clockwise direction.

2 Release thermocouple cable from the holders in the handle

part and pull the defective thermocouple out of the probe pipe

using a pincers ➀.

Page 25

➁

➀

➂

➁

8. Maintenance

3 Remove thermocouple cable from the slit hose sleeve ➁ and

pull out the defective thermocouple through the bending

protection springs.

4 Guide the new thermocouple through the bending protection

springs and through the handle into the probe pipe.

5 Position thermocouple cable in the holders in the handle.

6 Place thermocouple cable in the slit hose sleeve and press

bending protection springs in the handle and plug in

clockwise direction onto the holders.

8.7 Cleaning the flue gas pump

You will need the Pump Tool (Part no. 0192 0468) to clean the

flue gas pump.

When cleaning the flue gas pump, retained or saved readings

and the instrument settings (Date / Clock...) are lost.

Print out the readings you still need beforehand.

Open instrument

Switch off the instrument before opening and empty the

condensate trap (See: 8.2 Emptying the condensate trap

P. 23)!

Remove the connected sensors, probes and mains units from

the analyser.

Reduce the static charge in your body by touching a

conducting and grounded object. Avoid contact with

instrument electronics.

1 Place analyser on its front and open and remove the battery

compartment cover at the back of the analyser.

2 Remove rechargeable batteries/batteries from the battery

compartment.

3 Release the holder for the condensate trap at the back of the

analyser and remove the condensate trap.

4 Remove filter and release and remove the fixing plate using a

screwdriver ➀.

5 Remove top part of housing from bottom part of housing as

shown in the figure opposite ➁.

Remove flue gas pump and clean

6 Carefully remove flue gas pump from analyser

disconnect flue gas pump plug-in connection using a small

flat nose pincers.

7 Place Pump Tool in the holder in the pump head and then pull

it out.

➂ and

25

Page 26

8. Maintenance

Pump Tool

Pump head

Membrane

Membrane

sensor

Flue gas pump

Measuring cell type Part no.

O2 0390 0085

CO (testo 325M) 0390 0297

CO/H2(testo 325XL) 0390 0245

➀

➂

➀

8 Remove membrane sensor and membrane from pump head ➃.

➃

9 Clean removed parts and the pump plate with spirit or water.

10 Place membrane and membrane sensor in the pump head.

11 Attach pump head and remove Pump Tool.

12 Insert plug-in connection of flue gas pump and plug flue gas

pump into analyser (watch out cables don´t get caught!).

Reassemble analyser

1 Place bottom part of housing on top part of housing and put

back together again by sliding the two parts against each

other.

2 Attach fixing plate, filter and condensate trap.

3 Put in rechargeable batteries/batteries. Insert correctly (+/-)

4 Close cover on battery compartment.

8.8 Changing the measuring cells

Retained or saved (testo 325XL only) readings and

instrument settings (Date / Clock...) are lost when the

measuring cells are changed.

Print the readings which are still needed beforehand.

Only the original Testo measuring cells, listed opposite,

should be used.

Opening the instrument

Proceed as described in the paragraph “Open instrument” in

the Chapter 8.6 Cleaning the flue gas pump, P. 25 and

continue as follows:

6 Remove the 3 screws at the back of the mounting block and

remove the mounting block from the upper part of the

housing ➀.

7 Carefully remove board with display from mounting block ➀.

Changing CO measuring cell in testo 325M

The NO filter also has to be changed when the CO

measuring cell is changed!

➁

Before doing so, carefully remove the short-circuit spring from

the measuring cell contacts of the spare measuring cell.

8 Remove defective CO measuring cell and attach spare

measuring cell to board ➀.

9 Remove filter holder and NO filter

chamber

the measuring chamber (perforated side of filter should point

downward).

➂, clip new NO filter into filter holder and place in

➁ from the measuring

26

Page 27

8. Maintenance

➂

➀

➀ ➁

➁

➁

➁

➀

Changing O2measuring cell in testo 325M

8 Remove screw from O2measuring cell holder and remove

➀

holder ➀.

9 Remove defective O2measuring cell ➁ from measuring

chamber and disconnect plug-in connection.

10 Connect plug-in connection of the spare measuring cell and

place spare measuring cell in the measuring chamber.

11 Attach O2measuring cell holder (place cable through opening

of cell holder) and keep in position using screw.

Changing the CO/H2measuring cell in testo 325XL

8 Remove screw from CO/H2measuring cell holder and remove

holder ➀.

9 Remove defective CO/H2measuring cell ➁ from the

measuring chamber and replace by a spare measuring cell.

Please ensure the measuring cell is correctly aligned: The

lone standing PIN has to be positioned at the right outer

side of the measuring block!

10 Attach CO/H

using screw.

Changing the O2measuring cell in testo 325XL

8 Remove measuring cell holder and measuring cell ➀ from

the measuring chamber ➁ and disconnect the plug-in

connection from the defective O2measuring cell ➂.

9 Place spare measuring cell in the measuring chamber and

place measuring cell holder on the measuring cell (thread

cable through cell holder).

10 Connect plug-in connection of spare measuring cell and

position plug-in connection cable in the holder slot.

Ensure that the connections for measuring cell and pump

do not get mixed up.The measuring cell will be destroyed

if connected incorrectly.

Assembling the analyser

1 Carefully attach board with display to mounting block (ensure

cables are not trapped and ensure that the pressure sensor

connections are connected correctly).

2 Place mounting block in the upper part of the housing and fix

into position using 3 screws (

Proceed as described in the paragraph “Reassemble the

analyser” in 8.7 Cleaning the flue gas pump, P. 25. Now adjust

the new O2 measuring cell and enter the cell coefficients for

the new CO or CO/H2 measuring cell (See page 28)!

measuring cell holder and keep in position

2

➀ long screw, ➁ short screws).

27

Page 28

8. Maintenance

➂

Calibrating the O2measuring cell

Your readings will be incorrect if full adjustment has not been

carried out. Adjustment takes 15 minutes.

If a flue gas probe is connected, it should be located in fresh

air during adjustment.

1 Switch on analyser by pressing and press and

simultaneously while version number and rechargeable

battery/battery capacity are being displayed (duration: 3s)

➁➀

- 02-Calib lights up ➀.

testo 325M:

2 Start calibraiton by pressing .

testo 325XL:

2 Start calibration by pressing twice.

- The pump starts, O2and CAL flash and the minutes until the end

of the calibration are displayed ➁.

- Once calibration is complete, zeroing is carried out and is

then ready for operation.

Entering cell coefficients for CO or CO/H2measuring cell

The readings will be incorrect if the correct cell coefficients

are not entered! You will find the cell coefficients on the sheet

enclosed with the spare measuring cell.

➁➀

If input is incorrect:

Cancel procedure with and enter cell coefficients once

again.

1 Switch on analyser by pressing and press and

simultaneously while version number and rechargeable

battery/battery capacity are being displayed (duration: 3s)

- 02 Calib lights up ➀.

2 Select CO Coeff via ➁ and confirm selection with .

- The first digit in the first cell coefficient flashes ➂.

3 Set digit using or .

4 Advance to the next positions and change to the next cell

coefficients using . Set digits using or .

6 Complete input by pressing .

- The set values are accepted. The analyser carries out zeroing

and is now ready for operation.

28

Page 29

9. Troubleshooting

If defects not described here should occur, please contact your distributor or Testo Customer

Service. You will find contact details in the Warranty booklet or in Internet at

Defects when switching on:

Defect Possible causes Remedy

Analyser cannot Spent rechargeable Change rechargeable batteries/batteries (See Chapter 8.1,

be switched on batteries/batteries P. 23) or connect mains unit (accessory)

flashes and Operating temperature Analyser should be brought into permissible operating

zeroing starts too high or too low temperature range

again

flashes and Flue gas temperature Connect flue gas temperature probe

zeroing probe not attached or or check connection

starts again incorrectly attached

-or-

Thermocouple of flue Change thermocouple

gas temperature probe (See Chapter 8.6 Changing thermocouple, P. 25)

defective

O2flashes and O2value too low because Expose probe to fresh air and run zeroing phase again.

zeroing starts flue gas probe pipe is

again in flue gas duct If not successful: O2measuring cell is defect and has

to be changed (See 8.8 Changing measuring cells, P.26)

CO flashes and Flue gas probe pipe Expose probe to fresh air and run through

zeroing starts in flue gas duct zeroing phase.

again -or- If not successful: C0 / CO/H2measuring cell is defect and

CO value not and has to be changed (See 8.8 Changing measuring cells,

stable P. 26)

Error and an Various Switch off analyser and contact Testo Customer

error number Service Department or contact your nearest dealer

are displayed

www.testo.com

.

29

Page 30

9. Troubleshooting

Defects when measuring

Defect Possible causes Remedy

flashes and Flue gas temperature Connect flue gas temperature probe

---- probe is not or is or check connection

appears incorrectly connected

-or-

Thermocouple in flue Change thermocouple

gas temperature probe (See 8.6 Changing thermocouple, P. 25)

defective

---- is shown Probe not/incorrectly Connect probe or check connection or change filter

in place of connected

reading or defective

02flashes and ---- O2measuring cell defect Change O2measuring cell

appears (See 8.8 Changing measuring cells, P. 26)

C0 flashes and ---- C0 / CO/H2measuring Change C0/ CO/H2measuring cell

appears cell defective (See 8.8 Changing measuring cells, P. 26)

Pump stops and CO value is above the Expose probe to fresh air and start pump via ,

CO flashes switch-off limit to purge the measuring cells.

Caution! Meas. cell can be destroyed if CO value is too high!

Analyser switches Rechargeable batteries/ Change rechargeable batteries/batteries (See Chapter 8.6,

itself off batteries spent P. 23) or connect mains unit (accessory)

Defects when switching off:

Defect Possible causes Remedy

CO and / or CO value too high and / Expose probe to fresh air and wait for rinse to end.

O2flash or O2value too low If not successful: O2or C0/ CO/H2measuring cell is

defective and has to be changed (See Chapter 8.8 Changing

measuring cells, P. 26)

30

Page 31

10. Technical data

10.1 Measuring ranges and accuracies

testo 325 M

Measurement type Meas. range Accuracy Resolution Adapt. time 90%

Temperature

Efficiency 0 to 120% - 0.1% -

Oxygen 0 to 21% ±0.2% 0.1% Approx. 30s

Carbon dioxide 0 to CO

Carbon monoxide20 to 4000ppm < 400ppm ± 20ppm 1ppm Typically 60s

Pressure (Delta P1)30 to 40hPa <3hPa ±0.03hPa 0.01hPa -

Pressure (Delta P2)30 to 200hPa <50hPa ±0.5hPa 0.1hPa -

testo 325 XL

Measurement type Meas. range Accuracy Resolution Adapt. time 90%

Temperature

Efficiency 0 to 120% - 0.1% -

1

-40 to + 600°C <100°C ± 0,5°C 0.1°C Depending on

>100°C ± 0.5% of reading probe used

2max

- 0.1% Approx. 40s

400 to 1000ppm ±5% of reading

>1000ppm ± 10% of reading

>3hPa ± 1.5% of reading

>50hPa ±1.5% of reading

1

-40 to + 1000°C < 100°C ±0.5°C 0.1°C Depending on

>100°C ± 0.5% of reading probe used

Oxygen 0 to 21% ±0.2% 0.1% Approx. 30s

Carbon dioxide 0 to CO

2max

- 0.1% Approx. 40s

Carbon monoxide 0 to 4000ppm < 400ppm ±20ppm 1ppm Typically 40s

400 to 2000ppm ± 5% of read.

>2000ppm ± 10% of reading

Pressure (dP1)

3

0 to 40hPa <3hPa ±0.03hPa 0.01hPa -

>3hPa ± 1.5% of reading

Pressure (dP2)

3

0 to 200hPa <50hPa ±0.5hPa 0.1hPa -

>50hPa ±1.5% of reading

1

Sensor: Thermocouple Type K (NiCr-Ni) to DIN IEC 584 Part 2, Class 1

2

Accuracy data apply to H2level <10%

3

Max. overload: 1000hPa

31

Page 32

10. Technical data

10.2 Additional instrument data

Power supply Batteries: 4x 1.5V round cell alkaline IEC LR6 Type AA

Rech. batt.: 4x 1.5V IEC KR 15/51 Type AA

Rech. batt. 4x 1.5V IEC KR 15/51 Type AA cascaded with plug

block: (testo 325XL only)

Mains unit: 8V/ 1A (Part no. 0554 1084)

Rechargeable battery life at 20°C Approx. 8h (pump on, light off)

Battery life at 20°C Approx. 8h (pump on, light off)

Storage/Transport temperature -20 to + 50°C

Operating temperature -5 to + 45°C

Weight incl. rechargeable battery 450g

Housing material ABS

Dimensions (h x w x l) 52 x68 x216mm

Switch-off threshold for CO 4500ppm

Memory (testo 325XL only) 20 memory blocks

Recharging time/rech. batt. pack 4h (when recharged in analyser)

(testo 325XL only)

Warranty Instrument: 2 years

CO, CO/H2 measuriong cells: 12 months

02 measuring cells: 18 months

Probes and sensors: 24 months

Thermocouples: 6 months

10.3 Calculation fundamentals

Fuels and their calculation formulae

Fuel K

1

K

net

K11Q

gr

1

gr

1

Q

MH2O1H

net

1

Natural gas 0.35 0.39 40 53.42 48.16 0.0 24.4 11.9 3

Light Oil 0.48 0.51 53 45.60 42.80 0.0 13.0 15.5 3

Heavy Oil 0.51 0.54 54 42.90 40.50 0.2 11.5 15.8 3

LPG 0.42 0.45 48 50.00 46.30 0.0 18.2 13.8 3

2

Butane

2

Coal

1

Fuel-specific factor

2

testo 325XL only

0.43 0.46 48 49.30 45.80 0.0 17.2 14.1 3

0.62 0.45 63 26.75 25.50 13.0 4.0 18.4 7

32

1

CO

2maxO2

ref.

Page 33

10. Technical data

10.4 Calculation formulae

The formulae are specified for the instrument version .

CO

x (21% - O2)

CO

2max

CO

x 10000

2

21%

: Maximum carbon dioxide value

2max

specific to fuel

21%: Oxygen level of air

: Measured oxygen level in %

O

2

CO2: Calculated carbon dioxide value in %

Carbon dioxide: CO2= CO

Ratio: rat = CO: Measured carbon monoxide value in ppm

Efficiency

referred to Ho: EFF

Efficiency

referred to H

Excess Air (EXA): E

Air ratio: = CO: Measured carbon monoxide value in %

Carbon monoxide

undiluted: uCO = CO: Measured carbon monoxide value in %

Conversion of ppm in mg/m

CO (mg/m3) = x CO (ppm) x 1.25 21%: Oxygen level of air

Dew point

of flue gas: F

u

()

GROS

: EFF

21% - O

21% - O

= 100 - + +

NET

A

= -1 x 100 21%: Oxygen level of air

()

21% - O

CO

21% - O

2ref

2

ln x 234.175

()

td = factor in vol.%

ln - 17.08085

()

Kgrx (FT - AT)

= 100 - + +

()(

CO

2

K

x (FT - AT)

net

()(

CO

2

21%

2

2max

CO

2

21%

2

3

, referred to O2reference value:

F

x P

H20

Abs

610.78

F

x P

H20

Abs

610.78

(MH2O + 9 x H) x (2488 + 2.1 x FT - 4.2 x AT)

()

(MH2O + 9 x H) x (210 + 2.1 x FT - 4.2 x AT)

()

x 1000

Q

gr

x 1000

Q

net

K

gr/Knet/Qgr/Qnet

FT: Flue gas temperature

AT: Ambient temperature

CO: Measured carbon monoxide value in %

: Calculated carbon dioxide value in %

CO

2

: Measured oxygen level in %

O

2

CO2: Calculated carbon dioxide value in %

21%: Oxygen level of air

: Measured oxygen level in %

O

2

: Measured oxygen level in %

O

2

:O2 reference value in %

O

2ref

: Fuel-dependent water vapour

H20

: Absolute pressure in mbar/hPa

P

abs

/K1/MH2O/H: Fuel-specific factors

(fuel-specific)

K1 x CO

()

+ CO

CO

2

K1 x Qgrx CO

()

x (CO2+ CO)

Q

net

33

Page 34

11. Accessories/ Spare parts

Name Part no.

Flue gas probes and temperature probes

Standard flue gas probe, 180mm 0600 9544

Standard flue gas probe, 300mm 0600 9542

TÜV approved flue gas probe, 180mm 0600 9543

TÜV approved flue gas probe, 300mm 0600 9546

Flexible flue gas probe, 300mm 0600 9440

High temperature probe, 300mm, 1000°C 0600 8540

Dual wall clearance probe 0632 1244

Mini ambient air probe 0600 9798

Ambient air probe 0600 9788

Pipe clamp probe with velcro for pipe diameter to max. 120mm 0628.0020

Measuring cells

O2measuring cell for testo 325 M/ XL 0390 0085

CO measuring cell for testo 325 M incl. NO filter (0133 0069) 0390 0297

CO/ H2 measuring cell for testo 325 XL 0390 0245

Case

Aluminium case 0516 0325

Transport case (plastic) 0516 3250

System case (plastic) 0516 0326

Printer

Testo printer 0554 0545

Other

PE filter (10 off) 0554 0040

Printer paper (6 rolls) 0554 0569

Spare rechargeable battery for testo 325 XL 0515 0104

Pump membrane 0193 0072

Pump Tool (pump disassembly tool) 0192 0468

Thermocouple for probe 0600 9546 0430 0073

Thermocouple for probe 0600 8540 0430 0074

Thermocouple for probe 0600 9544 0430 0070

Thermocouple for probe 0600 9542 0430 0071

Thermocouple for probe 0600 9543 0430 0072

Hose connection set 0554 0315

Probe stop 0170 9051

SoftCase incl. magnetic plate 0516 2572

Mains unit (230V) 0554 1084

34

Page 35

Short instructions

Short instructions for testo 325 M / XL

Please also follow instructions in Instruction manual

Connections

➂

➁

➃

➄➀➅

Switching on instrument and selecting fuel

2 Set fuel using or and confirm selection by pressing .

- Instrument changes to measurement menu and is ready to operate.

Switching off analyser

1 Press to switch off analyser.

2 Wait on automatic rinse.

-

OFF is displayed for 5 s and then the analyser switches off.

Switching background light on/off

Switch background light on or off by pressing .

Selecting menu item

1 Open main menu by pressing .

2 Use / to select menu item and confirm selection via .

If sub-menu is available:

3 Select menu item via / and press to confirm.

Press to go back one menu level.

Setting date/time

1 Select Dat/Clk in main menu and press to confirm.

2 Set value via / , change to next value via .

3 Press to confirm settings.

➀ Mains unit

➁ Probes: Ambient air

temperature (AT) / temperature T2

➂ Probes: Flue gas temperature

(FT) / Temperature T1

➃ Flue gas inlet (red)

➄ Pressure + (blue)

➅ Pressure - (p-)

1 Switch on analyser via .

- The following appear:

display test, software version/

power, zeroing phase.

- Instrument changes to fuel

selection.

35

Page 36

Selecting uunits

11

Select

Unit in main menu and press to confirm.

22

Select parameter via / and confirm selection via .

33

Set unit via , change to next parameter via .

44

Press to confirm settings.

Measuring fflue ggases

11

Press to start measurement.

22

Press / to change between the options possible.

33

Press to end measurement.

Measuring ddraught

11

Select

Delta P in main menu and press to confirm.

22

Use / to select pressure range

Delta P1 (0 to 40hPa) or

Delta P2 (0 to 200hPa) and press to confirm.

- The analyser runs zeroing.

33

Insert probe pipe in flue gas duct.

- The current reading is displayed.

44

Press to end measurement.

Measuring ggas fflow ppressure

Pressure set (0554 0315) required. Procedure same as for draught

measurement.

Printing rreadings ttaken

Testo printer (0554 0545) required.

Start printing by activating in measurement menu.

Saving/reading/deleting rreadings ((

testo 325XL

only)

11

Select Memory in main menu and press to confirm.

22

Use / to select memory block and confirm via .

33

Select

Write, Read or Delete via / and press to

confirm.

Confirm clearance query with .

Printing ssaved rreadings ((

testo 325XL

only)

Testo printer (0554 0545) required.

11

Display readings (See: saving/reading readings).

22

Activate to start printing.

testo AG

Postfach 11 40, D-79849 Lenzkirch

Testo-Straße 1, D-79853 Lenzkirch

Tel. (0 76 53) 6 81 - 0

Fax (0 76 53) 6 81 - 1 00

E-Mail: info@testo.de

http://www.testo.de

0971.3257/01/T/dr/01.04.2004

Loading...

Loading...