Page 1

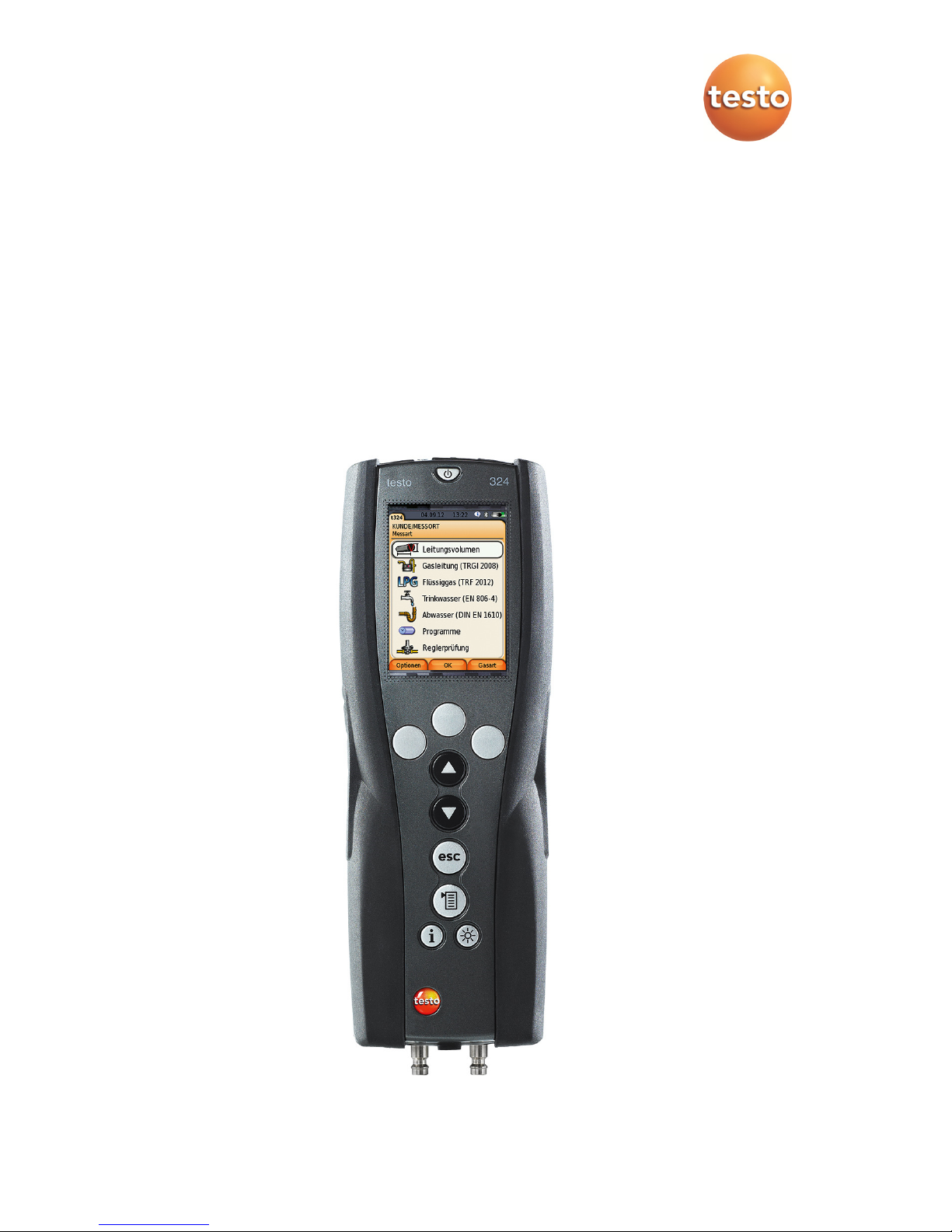

testo 324 - Leakage rates measuring instrument

Instruction manual

Page 2

2

Page 3

1 Contents

3

1 Contents

1 Contents ................................................................................................... 3

2 Safety and the environment .................................................................... 6

2.1. About this document ........................................................................ 6

2.2. Ensure safety ................................................................................... 8

2.3. Protecting the environment .............................................................. 9

3 Specifications ........................................................................................ 10

3.1. Use ................................................................................................ 10

3.1. Physical principles ......................................................................... 11

3.1.1. Physical influence of temperature on the

pressure to be measured ............................................................................... 11

3.1.2. The standardised measurement result of the testo 324

relating to temperature influences .................................................................. 11

3.2. Technical data ............................................................................... 12

3.2.1. Examinations and licenses ............................................................................ 12

3.2.2. Bluetooth® module (option) ............................................................................ 12

3.2.3. Declaration of conformity ............................................................................... 13

3.2.4. Measuring ranges and accuracies ................................................................. 13

3.2.5. Other instrument data .................................................................................... 14

4 Product description ............................................................................... 16

4.1. Measuring instrument .................................................................... 16

4.1.1. Overview ........................................................................................................ 16

4.1.2. Keypad .......................................................................................................... 17

4.1.3. Display ........................................................................................................... 18

4.1.4. Instrument connections .................................................................................. 19

4.1.5. Interfaces ....................................................................................................... 19

4.2. testo 324 in the case system with feeding unit .............................. 20

5 First steps .............................................................................................. 22

5.1. Commissioning .............................................................................. 22

5.2. Getting to know the product ........................................................... 22

5.2.1. Mains unit, rechargeable batteries ................................................................. 22

5.2.1.1. Charging the battery ........................................................................ 22

5.2.1.2. Rechargeable battery care .............................................................. 23

5.2.1.3. Mains operation ............................................................................... 23

5.2.2. Connecting hoses/probes .............................................................................. 23

5.2.3. Switching on .................................................................................................. 23

5.2.4. Calling up the function ................................................................................... 24

5.2.5. Entering values .............................................................................................. 24

5.2.6. Printing/saving data ....................................................................................... 26

5.2.7. Confirming an error message ......................................................................... 26

5.2.8. Switching off .................................................................................................. 27

5.3. Address/location ............................................................................ 27

Page 4

1 Contents

4

5.4.

Measurement records ................................................................... 29

5.5. Instrument diagnosis ..................................................................... 30

6 Using the product ................................................................................. 31

6.1. Performing settings ....................................................................... 31

6.1.1. Assigning the right function key ..................................................................... 31

6.1.2. Instrument settings ........................................................................................ 31

6.1.2.1. Units ................................................................................................ 31

6.1.2.2. Date/Time ........................................................................................ 32

6.1.2.3. Energy management ....................................................................... 32

6.1.2.4. Display brightness ........................................................................... 32

6.1.2.5. Printer ............................................................................................. 32

6.1.2.6. Bluetooth® ....................................................................................... 33

6.1.2.7. Automatic measuring rate ................................................................ 33

6.1.2.8. Inspector ......................................................................................... 34

6.1.2.9. Language ........................................................................................ 34

6.1.2.10. Country version ............................................................................... 35

6.1.2.11. Password protection ........................................................................ 35

6.1.3. Gas type ........................................................................................................ 36

6.2. Measuring ..................................................................................... 37

6.2.1. Preparing for measurement ........................................................................... 37

6.2.2. Options menu ................................................................................................ 38

6.2.3. Pipe volume ................................................................................................... 39

6.2.4. Gas pipe (TRGI 2008) ................................................................................... 40

6.2.4.1. Pretest ............................................................................................. 41

6.2.4.2. Main test .......................................................................................... 43

6.2.4.3. Leakage test (leakage measurement) ............................................. 44

6.2.4.4. Combined pretest/main test ............................................................. 47

6.2.4.5. Caravan Check ................................................................................ 48

6.2.5. Liquid gas (DVGW TRF 2012) ....................................................................... 50

6.2.5.1. Pressure test ................................................................................... 51

6.2.5.2. Main test .......................................................................................... 52

6.2.5.3. Repeated testing (PS>0.5 bar / PS<=0.5 bar) ................................. 53

6.2.5.4. Carrying out repeated testing PS <0.5 bar ....................................... 55

6.2.6. Drinking water (ZVSHK sheet as per DIN EN 806-4) ..................................... 56

6.2.6.1. Testing with air – main test .............................................................. 57

6.2.6.2. Testing with air – pretest ................................................................. 58

6.2.6.3. Test with water ................................................................................ 60

6.2.7. Waste water (DIN EN 1610) with air .............................................................. 62

6.2.8. Programs ....................................................................................................... 63

6.2.8.1. Spot measurement .......................................................................... 63

6.2.8.2. Programs 2-5 .................................................................................. 65

6.2.9. Controller test ................................................................................................ 68

6.2.9.1. Static pressure ................................................................................ 69

6.2.9.2. Flow pressure .................................................................................. 70

6.2.9.3. SAV_triggering pressure ................................................................. 71

6.2.9.4. SRV triggering pressure .................................................................. 72

6.3. Transferring data ........................................................................... 73

6.3.1. Record printer ................................................................................................ 73

6.3.2. PC/pocket PC ................................................................................................ 73

6.3.3. Data transfer to IrDA record printer ................................................................ 73

Page 5

1 Contents

5

7 Maintaining the product ........................................................................ 74

7.1. Cleaning the measuring instrument ............................................... 74

7.2. Regular calibration ......................................................................... 74

7.3. Replacing the gas bladder ............................................................. 74

8 Tips and assistance ............................................................................... 75

8.1. Questions and answers ................................................................. 75

8.2. Accessories and spare parts ......................................................... 75

8.3. Updating the instrument software .................................................. 77

Page 6

2 Safety and the environment

6

2 Safety and the environment

2.1. About this document

This document describes the product testo 324 with the instrument

setting Country version | Germany.

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

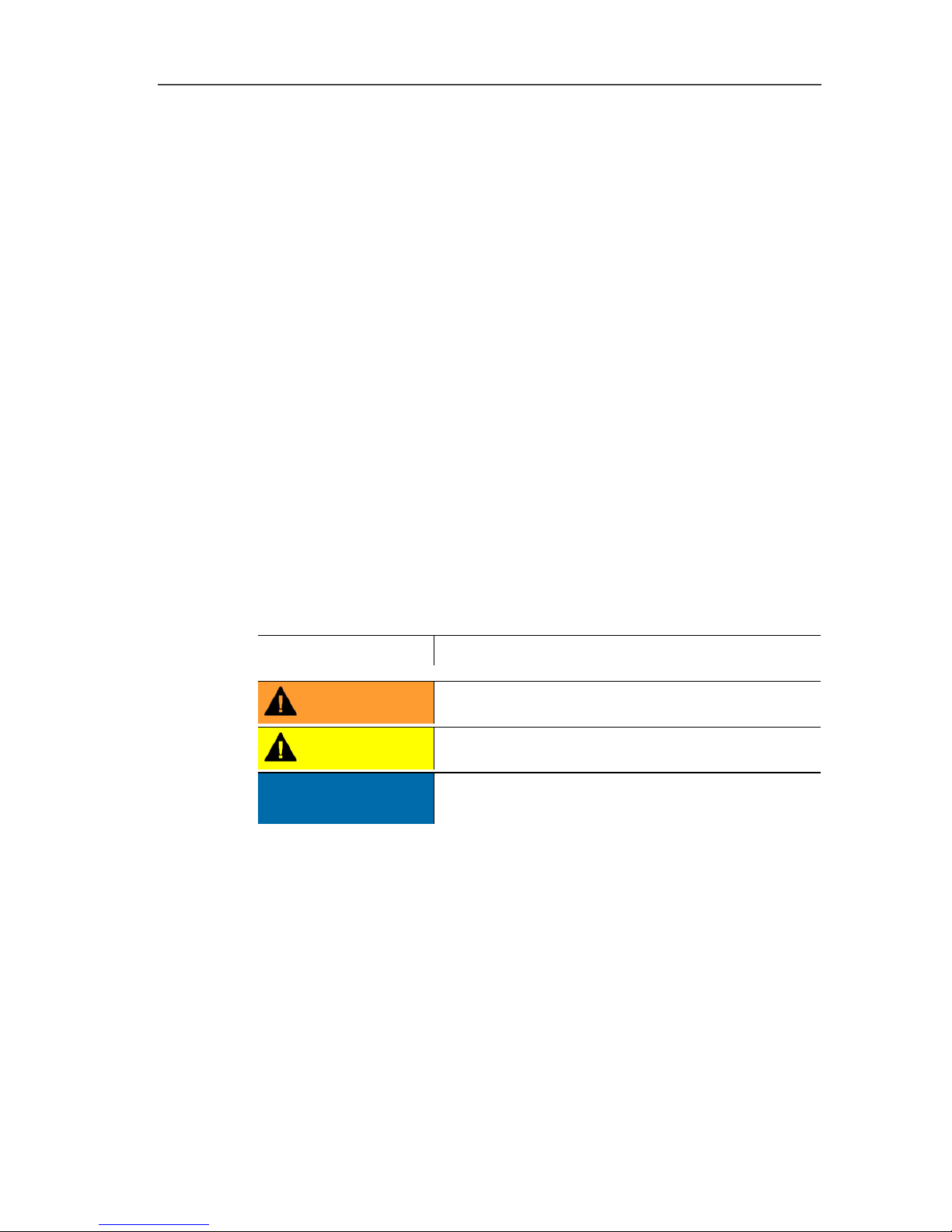

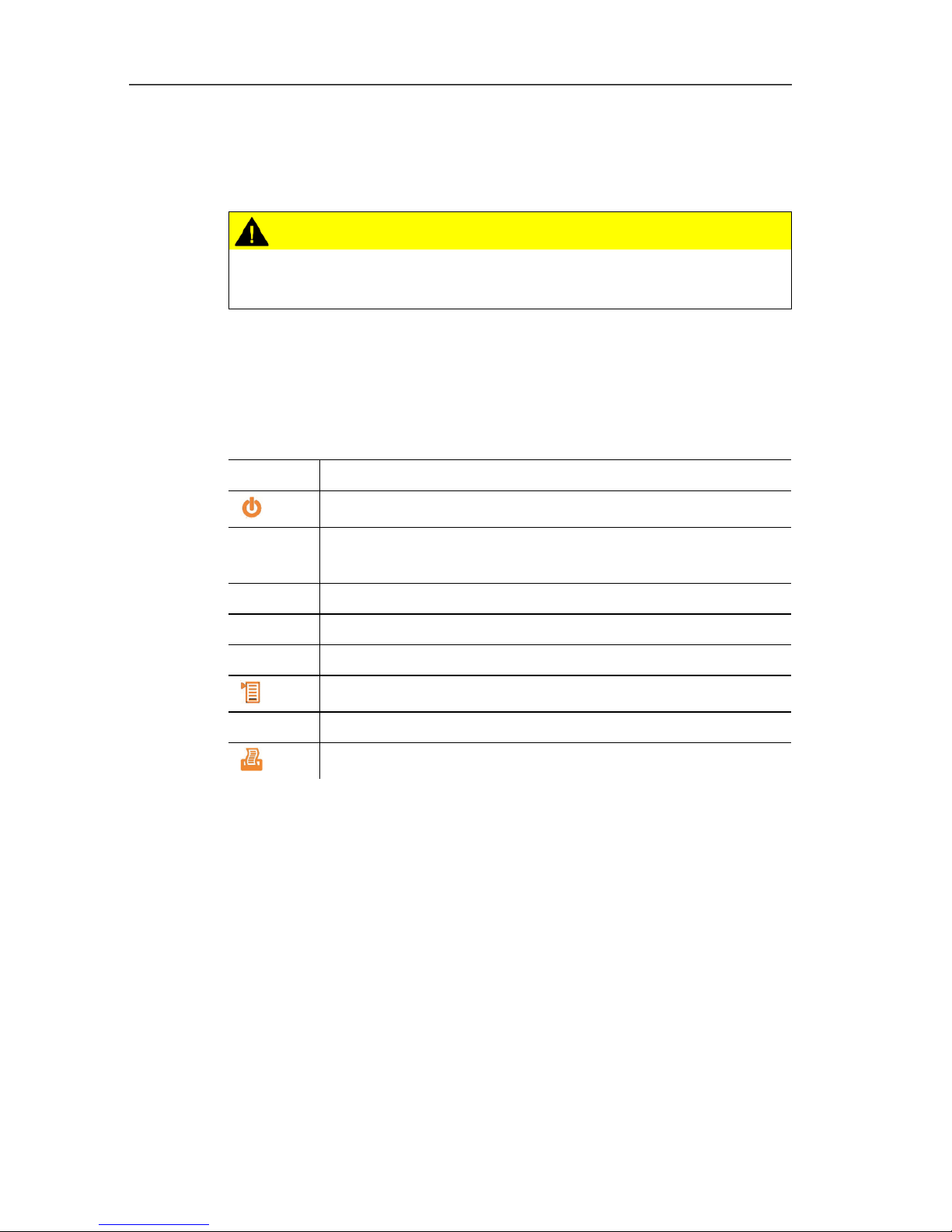

Warnings

Always pay attention to information that is marked by the following

warnings with warning pictograms. Implement the specified

precautionary measures.

Representation Explanation

WARNING

Indicates potential serious injuries

CAUTION

indicates potential minor injuries

NOTICE

indicates circumstances that may lead to

damage to the products

Page 7

2 Safety and the environment

7

Symbols and writing standards

Representation

Explanation

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Symbols and writing standards

Display Explanation

Warning advice, risk level according to the

signal word:

Warning! Serious physical injury may occur.

Caution! Minor physical injury or damage to the

equipment may occur.

> Take the specified precautionary measures.

Note: Basic or further information.

1. …

2. …

Handling: several steps, the sequence must be

followed.

> … Handling: one step or optional step.

- … Result of an action.

Menu Elements of the instrument, the instrument

display or the program interface.

[OK] Control keys of the instrument or buttons of the

program interface.

… | … Functions/paths within a menu.

“…” Example entries

Page 8

2 Safety and the environment

8

2.2. Ensure safety

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

use any force.

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> Do not perform contact measurements on non-insulated, live

parts.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts

from Testo.

> Any further or additional work must only be carried out by

authorised personnel. Testo will otherwise refuse to accept

responsibility for the proper functioning of the measuring

instrument after repair and for the validity of certifications.

> Only use the device in closed, dry rooms and protect it from rain

and moisture.

> Temperatures given on probes/sensors relate only to the

measuring range of the sensors. Do not expose handles and

feed lines to any temperatures in excess of 70 °C unless they

are expressly permitted for higher temperatures.

> The gas feeding unit should only be emptied in an open

environment.

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> Dangers may also arise from the systems being measured or

the measuring environment: Note the safety regulations valid in

your area when performing the measurements.

Page 9

2 Safety and the environment

9

For products with Bluetooth

®

(optional)

Changes or modifications that have been made without the explicit

consent of the responsible approval authority, may cause the

retraction of the type approval.

Data transfer may be disturbed by equipment that uses the same

ISM-band, e.g. WLAN, microwave ovens, ZigBee.

The use of radio communication links is not permitted, among

others, in aeroplanes and hospitals. For this reason the following

points must be ensured before entering:

> Switch off the device:

> Isolate the device from any external power sources (mains

cable, external rechargeable batteries, ...).

2.3. Protecting the environment

> Dispose of faulty rechargeable batteries/spent batteries in

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to Testo for disposal.

Page 10

3 Specifications

10

3 Specifications

3.1. Use

testo 324

The testo 324 is a leakage measuring instrument for the

professional performance of the following measuring tasks:

• Pretest and main test on gas pipes

• Determining the usability of gas pipes

• Measuring low pressure against atmospheric pressure

• Pressure test on waste water pipes

• Pressure tests on liquid gas pipes

• Controller test

• Temperature measurement

WARNING

Escaping gas can produce an explosive mixture of gases!

Potential risk of explosion!

> The testo 324 leakage measuring instrument may only be used

by authorised personnel who have been trained in the

maintenance and inspection of gas systems.

> Observe local accident prevention and test regulations.

Testo guarantees the functionality of its products when

used in accordance with their intended purpose. This

guarantee does not apply to features of Testo products in

combination with unauthorised third-party products.

Competitor products are not authorised by Testo.

As is common practice, Testo generally excludes support,

warranty or guarantee claims relating to functionality that

has not been guaranteed by Testo as part of the product

offered. Claims shall also be excluded in the event of

improper use or handling of the products, e.g. in

combination with unauthorised third-party products.

Further warranty terms: see website

www.testo.com/warranty.

testo 324 with Option Bluetooth

®

:

The use of the wireless module is subject to the regulations

and stipulations of the respective country of use, and the

module may only be used in countries for which a country

certification has been granted. The user and every owner

has the obligation to adhere to these regulations and

Page 11

3 Specifications

11

prerequisites for use, and acknowledges that the re-sale,

export, import etc. in particular in countries without wireless

permits, is his responsibility.

Feeding unit

When used in conjunction with the testo 324 leakage measuring

instrument, the feeding unit (gas bladder) enables leakage

measurement to be carried out independently of the gas supply.

3.1. Physical principles

3.1.1. Physical influence of temperature on the pressure to

be measured

Temperature fluctuations and positional changes have an effect on

the measuring accuracy of pressure measurements. The following

should therefore be observed:

✓ The entire measurement system must be adapted to the

ambient temperature and to the temperature of the line system

to be tested.

✓ The temperature of the measurement system and the line

system must remain stable during measurement.

Example of temperature influence:

with a test pressure of 100 hPa and an air pressure of 1000 hPa,

the ambient temperature changes from +22 °C to +23 °C. The air in

the test system expands and the test pressure increases by

3.73 hPa. The temperature influence on the pressure change is

unaffected by the test volume.

3.1.2. The standardised measurement result of the testo

324 relating to temperature influences

The testo 324 leak rate measuring instrument certified to

DVGW G 5952 enables measuring values to be reproduced.

Comparable results based on the standardised reference operating

pressure of 23 mbar are always achieved. The volume measured

during the test is based on a reference temperature of 20 °C and

the current air pressure.

A change in the ambient temperature therefore has no influence on

the measuring values!

The ambient temperature and the relevant test gas or medium for

each test section must nevertheless show a constant temperature

Page 12

3 Specifications

12

within the range of 15 °C to 25 °C with a maximum deviation of ±

2 °C. Only then can a measurement be carried out. During the

stability time at the start of each measurement, this check is carried

out automatically and a warning is issued if the temperature and

therefore the pressure fluctuates too greatly.

3.2. Technical data

3.2.1. Examinations and licenses

Tested in accordance with DVGW1 G5952 by DVGW Karlsruhe.

As declared in the Certificate of Conformity, this product complies

with Directive 2014/30/EU.

3.2.2. Bluetooth® module (option)

• Bluetooth® type: BlueGiga WT 11 / WT 11i-A (from

October 2013)

• Bluetooth

®

product note: WT11

• Bluetooth

®

identification: B017401 (WT 11) /

B017633 (WT11i-A)

• Bluetooth

®

company: 10274

Belgium (BE), Bulgaria (BG), Denmark (DK), Germany (DE),

Estonia (EE), Finland (FI), France (FR), Greece (GR), Ireland (IE),

Italy (IT), Latvia (LV), Lithuania (LT), Luxembourg (LU), Malta (MT),

Netherlands (NL), Austria (AT), Poland (PL), Portugal (PT),

Romania (RO), Sweden (SE), Slovakia (SK), Slovene (SI), Spain

(ES), Czech Republic (CZ), Hungary (HU), United Kingdom (GB),

Republic of Cyprus (CY).

EFTA countries

Iceland, Liechtenstein, Norway and Switzerland.

Other countries

USA, Canada, Turkey, Colombia, El Salvador, Venezuela,

Ecuador, New Zealand, Bolivia, Dominican Republic,

Peru, Chile, Cuba, Costa Rica, Nicaragua

1

German Technical and Scientific Association for Gas and Water

Page 13

3 Specifications

13

USA

FCC ID: QOQWT11l

This instrument complies with Part 15C of the FCC Rules and

Industry Canada RSS-210 (revision 8). Commissioning is subject to

the following two conditions: (1) This instrument must not cause

any harmful interference and (2) this instrument must be able to

cope with interference, even if this has undesirable effects on

operation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to

operate the equipment."

Canada

IC ID: 5123A-BGTWT11l

This instrument complies with Part 15C of the FCC Rules and

Industry Canada RSS-210 (revision 8). Commissioning is subject to

the following two conditions: (1) This instrument must not cause

any harmful interference and (2) this instrument must be able to

cope with interference, even if this has undesirable effects on

operation.

Cet appareil satisfait à la partie 15C des directives FCC et au

standard Industrie Canada RSS-210 (révision 8). Sa mise en

service est soumise aux deux conditions suivantes : (1) cet appareil

ne doit causer aucune interférence dangereuse et (2) cet appareil

doit supporter toute interférence, y compris des interférences qui

provoquerait des opérations indésirables.

Turkey

Authorized

3.2.3. Declaration of conformity

You can find the EU declaration of conformity on the Testo

homepage www.testo.com under the product-specific downloads.

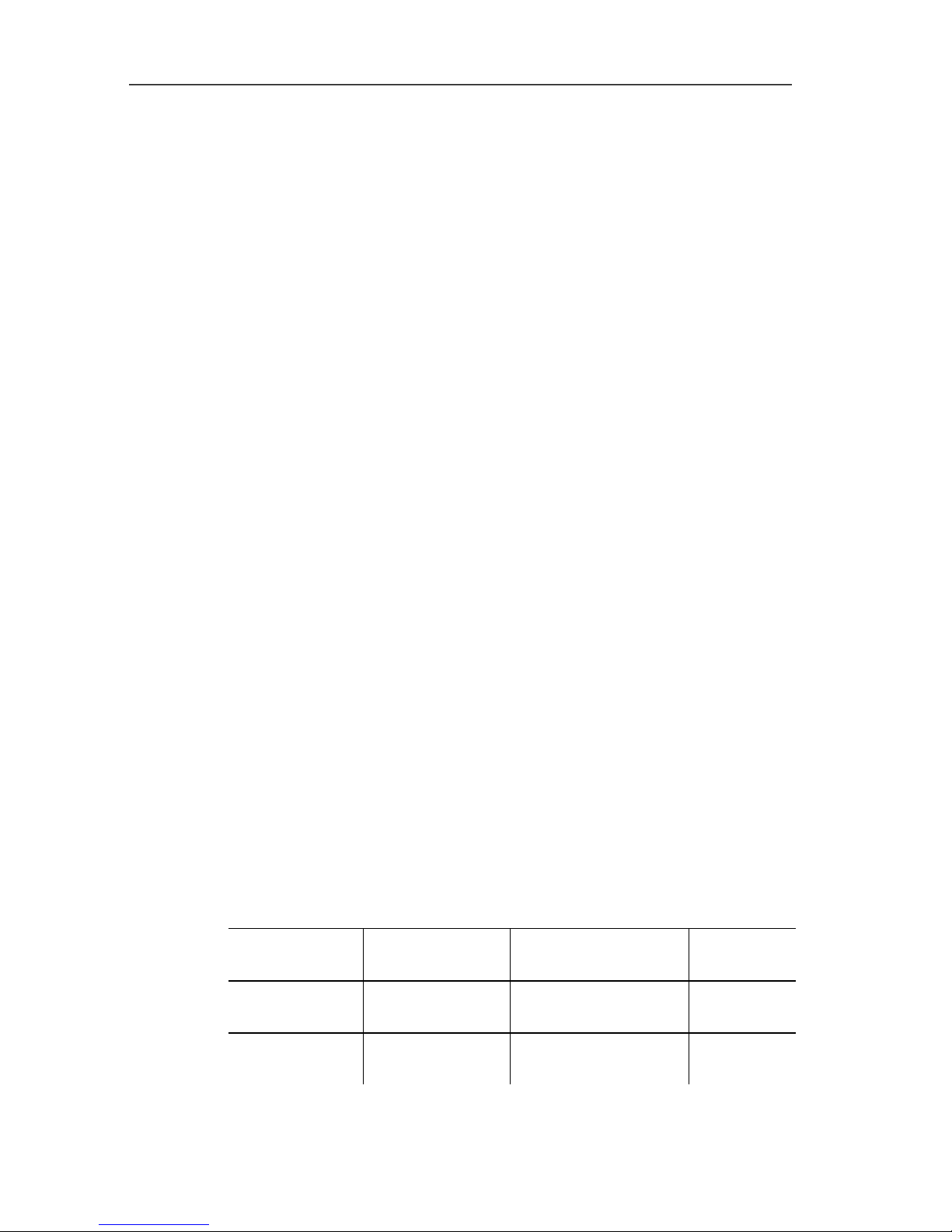

3.2.4. Measuring ranges and accuracies

Measurement

type

Measuring

range

Accuracy Resolution

Flow (Leakage

measurement)

0 to 10 l/h

±0.2 l/h or ±5% of

meas. val.

0.1 l/h

Pressure 0…1000 hPa

±0.5 hPa or ±3% of

meas. val.

0.1 mbar

Page 14

3 Specifications

14

Measurement

type

Measuring

range

Accuracy Resolution

Pressure

measurement

with a high

pressure probe

(optional)

0…25 bar

0…10 bar:

± 0.6 % of fullscale

>10…25 bar:

± 0.6 % of fullscale

10 hPa

Temperature

measurement

TC type K

(only instrument)2

-40…600 °C

± 0,5°C

(0,0...100,0 °C)

± 0,5% of meas. val.

(rest of range)

0,1°C

Instrument

overload

Max. 1200 hPa

Pipe volume

calculation

Max. 1200 l.

3

+/-0,2l or 5% of

meas. val. (1-200l)

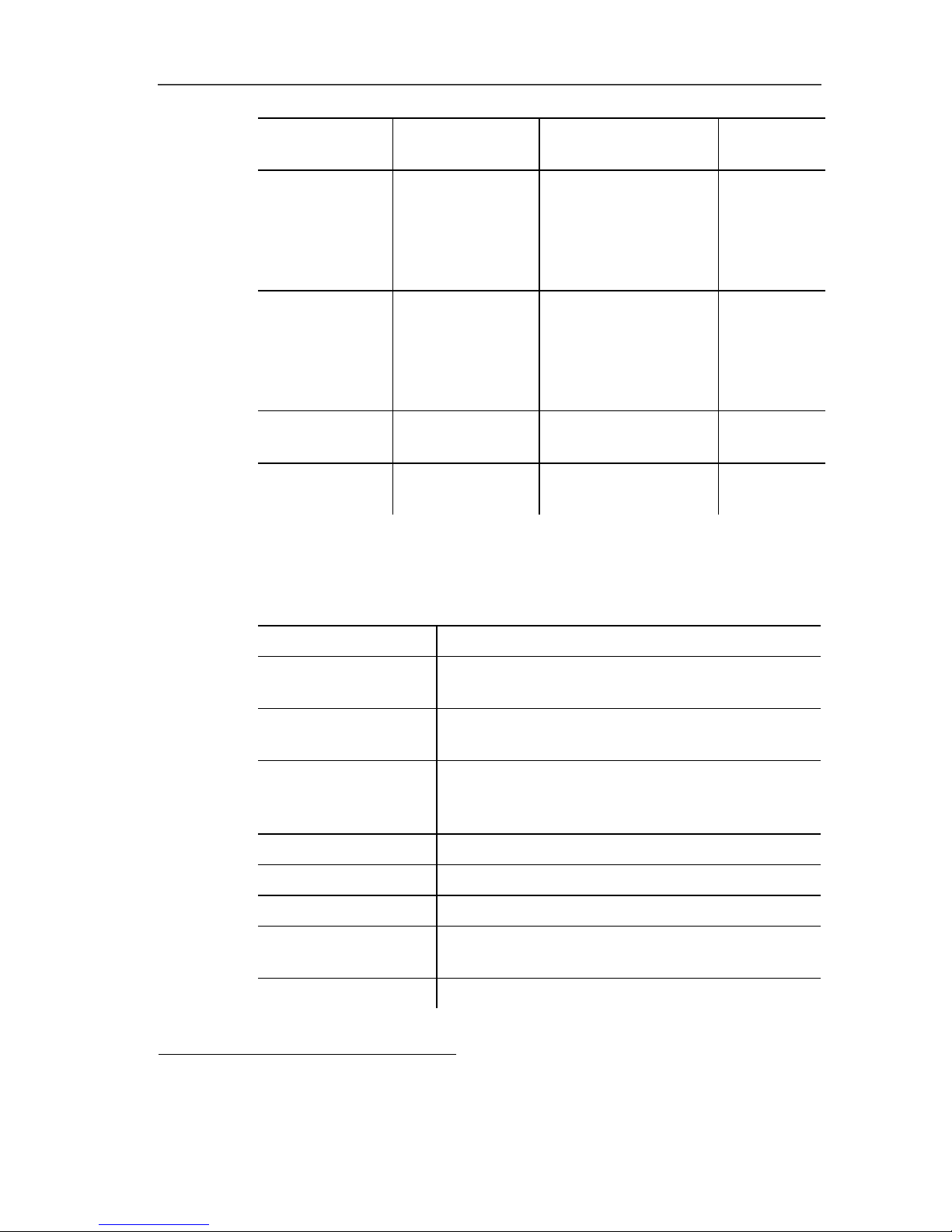

3.2.5. Other instrument data

Flue gas analyser

Feature Values

Storage/transportati

on conditions

Temperature: -20 to 50°C

Operating

conditions

5 to 40°C

Power supply

Rech. batt.: Lithium-ion battery 11.0 V /

2400 mAh

Mains unit: 115-230 V – 50/60 Hz

Protection class IP40 acc. to EN 60529

Weight 1070 g (incl. battery)

Dimensions 270 x 90 x 75 mm

Additional probe

sockets

2 Hirschmann sockets for connecting

pressure probes and temperature probes

Gas connections 2 pressure connections DN 5

2

The accuracy of a connected temperature probe must also be taken into

account.

3

per 200 l: Test time 12 min

Page 15

3 Specifications

15

Feature Values

Interference

immunity and

interference

emission

According to DIN EN 61326-1

Memory 500,000 measuring values

Integrated pressure

pump

For test pressure build-up up to 300 mbar

and for filling the feeding unit

Display Graphic colour display, 240 x 320 pixels

Data transfer to PC USB or Bluetooth (option)

Battery charge time Approx. 5-6 h

Rech. batt. life > 5 h (pump on, 20°C ambient temperature)

Supported

testo printer

0554 0549, 0554 0547, 0554 0544 or

0554 0553, 0554 0620 (with Bluetooth

option)

Bluetooth® (option) Range < 10 m

Warranty Measuring instrument: 24 months

Thermocouple: 12 months

Rech. batt.: 12 months

Terms of warranty

Terms of warranty: see website

www.testo.com/warranty

Page 16

4 Product description

16

4 Product description

4.1. Measuring instrument

4.1.1. Overview

Page 17

4 Product description

17

1 Switch on/off

2 Attachment eye for carrying strap

3 Interfaces (USB, infrared) and reset button

CAUTION

Risk of injury from infrared beam!

> Do not direct infrared beam at human eyes!

4 Display

5 Keypad

6 Instrument connections

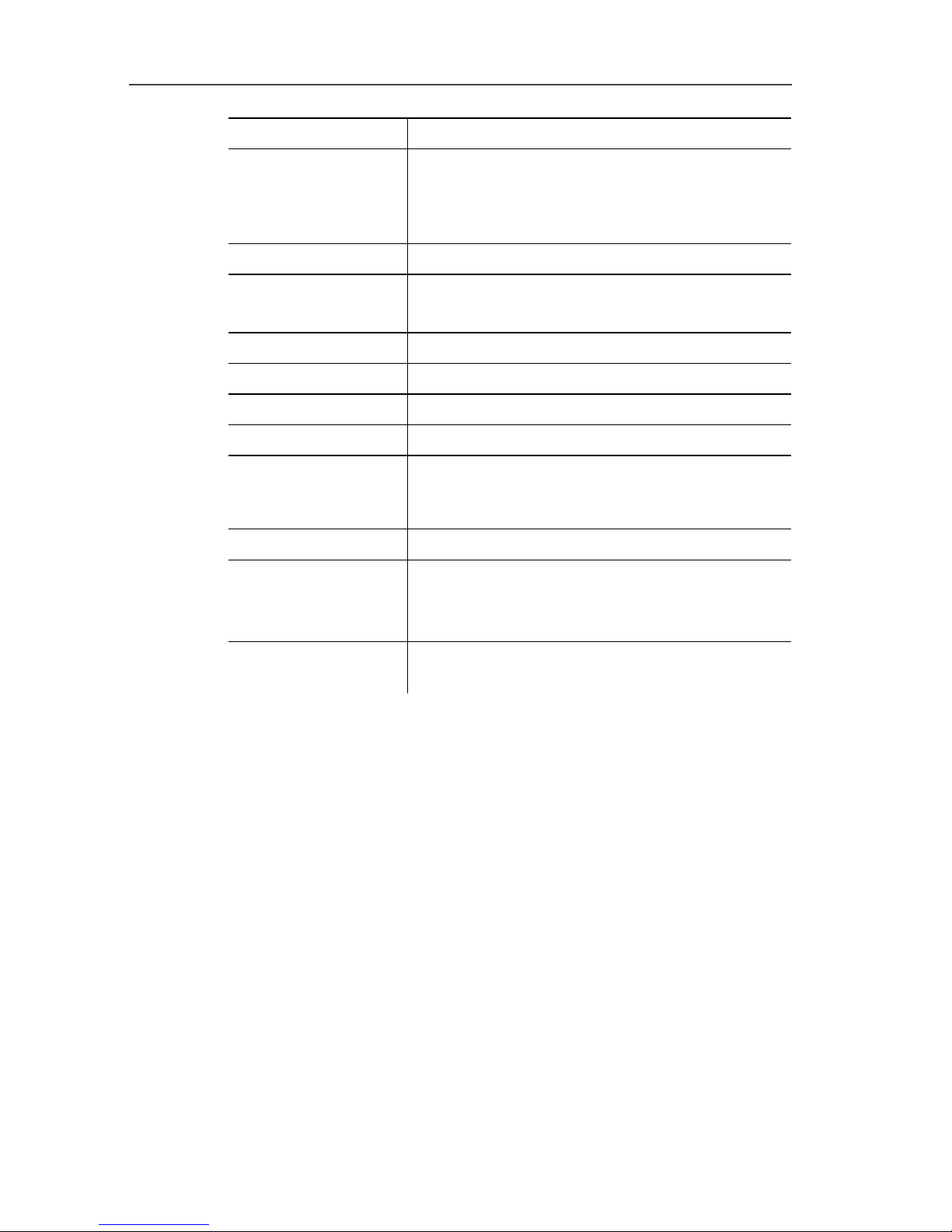

4.1.2. Keypad

Button Functions

[]

Switch measuring instrument on/off

[OK]

Example

Function key (grey, 3x), relevant function is shown on

the display

[▲]

Scroll up, increase value

[▼]

Scroll down, reduce value

[esc]

Back, cancel function

[]

Open main menu

[ i ]

Help texts, e.g. for individual measurements

[]

Transmit data to the record printer.

Page 18

4 Product description

18

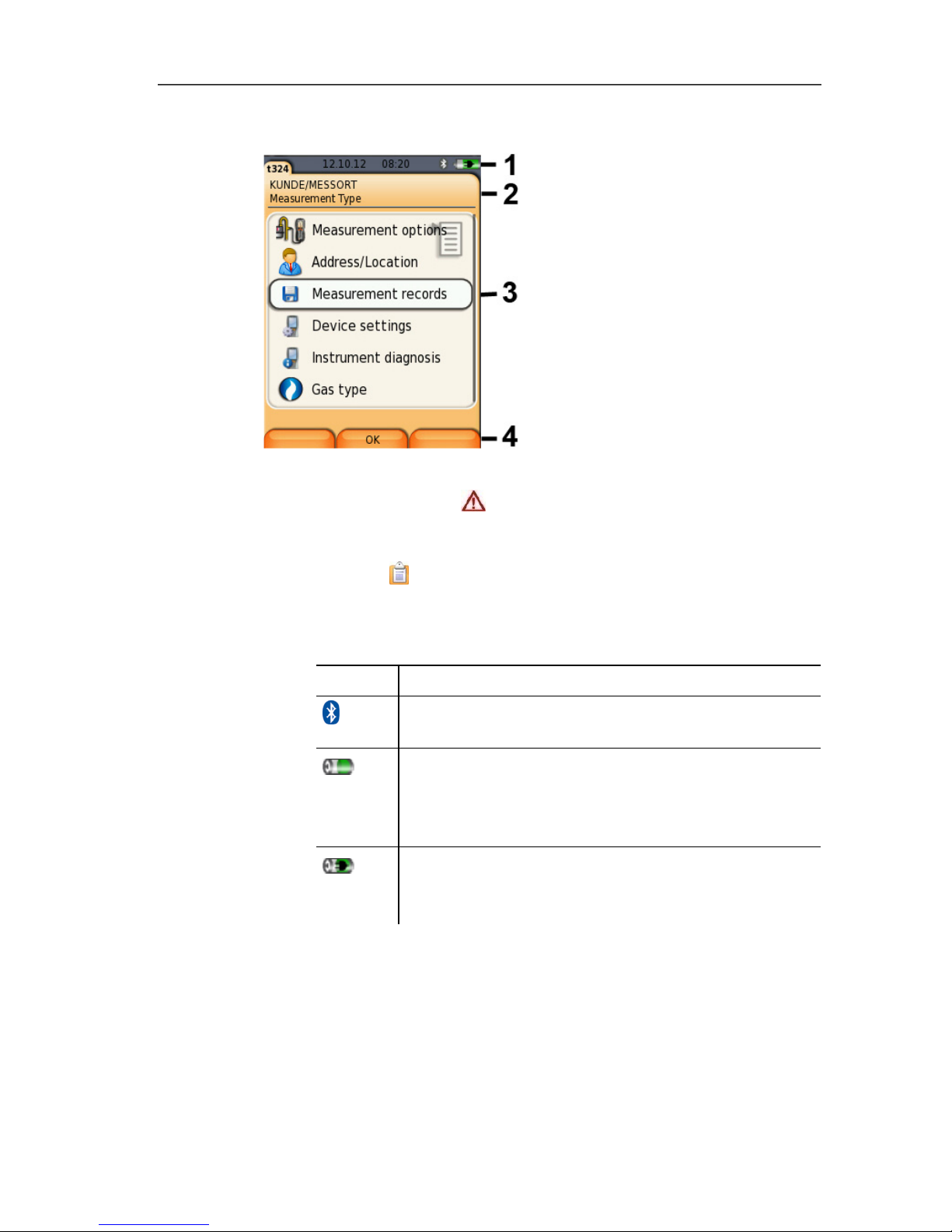

4.1.3. Display

1 Status bar (dark grey background):

• Warning symbol (only if there is an instrument error,

display of error in instrument diagnosis menu), otherwise:

Instrument designation.

• Symbol

• Display of date and time.

• Indication of Bluetooth

®

status, power supply and remaining

rechargeable battery capacity:

Symbol Feature

Blue symbol = Bluetooth

®

on,

Grey symbol = Bluetooth

®

off

Battery operation

Display of remaining rechargeable battery

capacity by colour and fill level of the battery icon

(green = 5 - 100%, red = < 5%)

Mains operation

Display of remaining rechargeable battery

capacity: see above

2 Info field of register tabs: Display of selected address/location,

selected measurement type.

3 Selection field for functions (selected menu item appears

against a white background, unavailable functions are identified

by grey font) or display of measuring values.

4 Function display for function keys.

Page 19

4 Product description

19

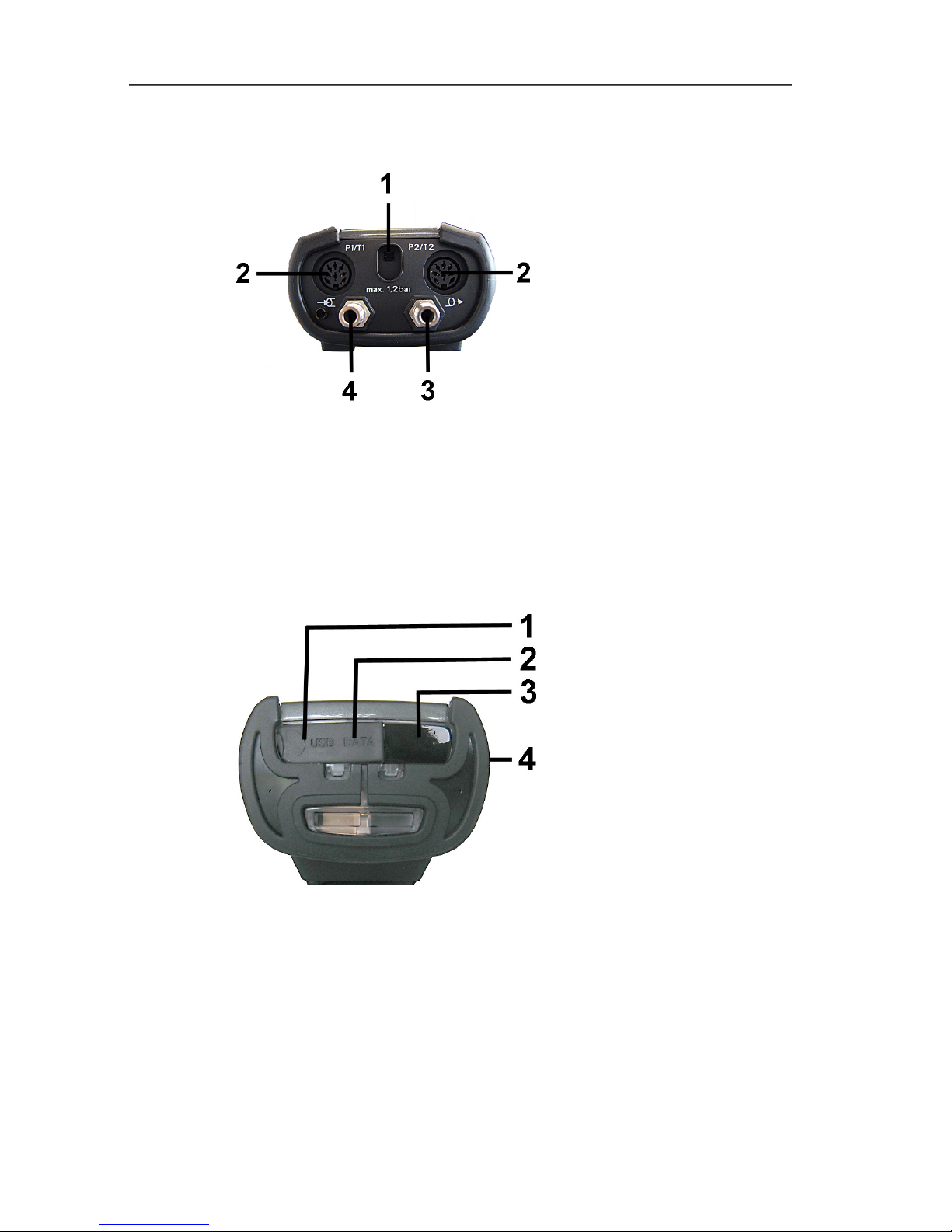

4.1.4. Instrument connections

1 Mains unit socket

2 Probe sockets for connecting the temperature probe or the high

pressure probes

3 Pressure connection 1.2 bar for connecting a pressure hose

4 Pressure connection for connecting a feeding unit or a pressure

hose

4.1.5. Interfaces

1 USB interface (under cover)

2 Reset button (under cover)

3 Infrared interface (IrDA)

4 Bluetooth interface (option)

Page 20

4 Product description

20

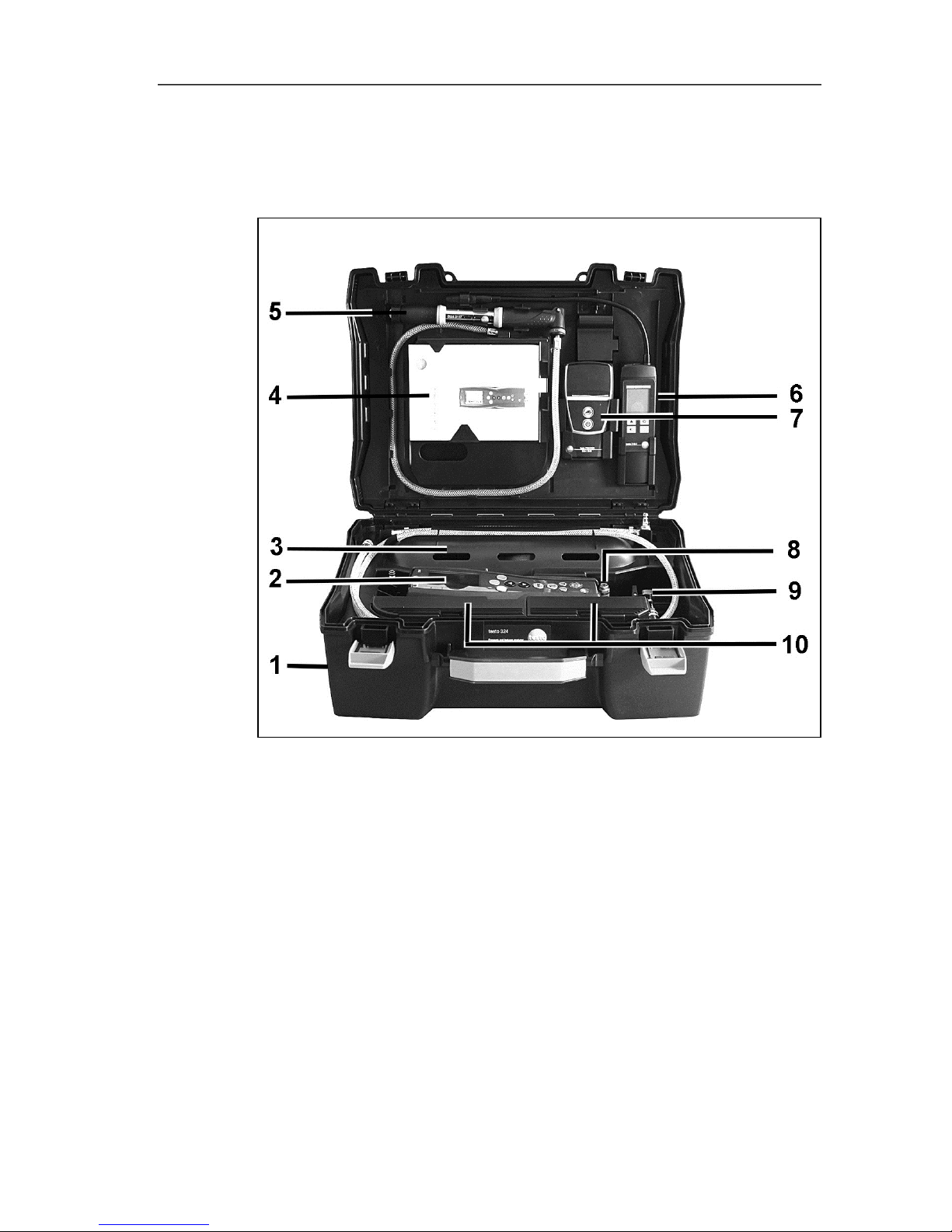

4.2. testo 324 in the case system with feeding unit

Overview

1 Transport case

2 testo 324

3 Feeding unit (gas bladder)

4 Storage compartment for instruction manual

5 Hand pump

6 Holder for gas leak detection instrument testo 316-2 or

testo 316-EX

7 Holder for IRDA or Bluetooth printer (option)

8 Connection for an external hand pump or a compressor

Page 21

4 Product description

21

9 Connection block with shut-off valve for pump, instrument and

hose connection

10 Storage compartments for accessories

Page 22

5 First steps

22

5 First steps

5.1. Commissioning

testo 324

The testo 324 has a permanently installed rechargeable battery.

> Charge the rechargeable battery fully before using the

measuring instrument.

> Remove the protective film from the display.

Feeding unit

Flushing is required when starting up the unit for the first time, after

replacing the gas bladder and when changing the medium.

> Fill and empty the feeding unit once, see Options menu, page

38

5.2. Getting to know the product

5.2.1. Mains unit, rechargeable batteries

In case of an extended interruption in the power supply to

the testo 324 (e.g. rechargeable battery pack empty), the

date/time settings will be lost.

5.2.1.1. Charging the battery

The rechargeable battery can only be charged at an ambient

temperature of 5 to +35 °C. If the rechargeable battery pack has

discharged completely, the charging time at room temperature is

approx. 5 - 6 h (charging with mains adapter).

Charging via a mains unit

✓ The testo 324 is off.

1. Connect the mains unit instrument plug to the mains unit

socket.

2. Connect the mains plug of the mains unit to a mains socket.

- The charging process starts. The charge status is shown on the

display.

- Once the rechargeable battery has been charged, the

instrument switches over automatically to trickle charge.

Page 23

5 First steps

23

5.2.1.2. Rechargeable battery care

> Do not fully exhaust rechargeable batteries.

> For extended periods of disuse, you should discharge and

recharge the batteries every 3 - 4 months. Trickle charging

should not exceed 2 days.

5.2.1.3. Mains operation

In case of danger, the instrument must be disconnected

from the power supply by simply pulling out the mains

cable.

> Always position the instrument so that the power supply plug

can be easily reached.

1. Connect the mains unit instrument plug to the mains unit

socket.

2. Connect the mains plug of the mains unit to a mains socket.

- The power supply is provided by the mains unit.

- If the testo 324 is switched off, the rechargeable battery

charging process starts automatically. Switching on the testo

324 stops the battery charging and the instrument is then

powered via the mains unit.

5.2.2. Connecting hoses/probes

> Connect the required hoses/probes at the corresponding

connections.

5.2.3. Switching on

> Press [].

When the instrument is switched on, the valves of the

testo 324 are activated. Four short acoustic signals are

output.

If fewer than 4 acoustic signals are sounded, the testo 324

must be switched on and off several times before use until

4 signals are sounded.

The testo 324 then starts up as usual.

- The start screen is displayed (duration: approx 15 s).

- If the voltage supply was interrupted for an extended period:

The Date/Time menu is opened.

- The pressure sensors are zeroed.

- If there is an instrument error, the Error diagnosis menu is

displayed.

- The Measurement options menu is displayed.

Page 24

5 First steps

24

5.2.4. Calling up the function

1. Select function: [▲], [▼].

- A box appears around the selected function.

2. Confirm selection: [OK].

- The selected function is opened.

5.2.5. Entering values

Some functions require values (numbers, units, characters) to be

entered. Depending on the selected function, the values are

entered either via a list field or an input editor.

List field

1. Select the value to be changed (numerical value, unit): [▲],

[▼], [◄], [►] (depending on the selected function).

2. Press [Edit] .

3. Set value: [▲], [▼], [◄], [►] (depending on the selected

function).

4. Confirm the entry: [OK].

5. Repeat steps 1 and 4 as required.

6. Save the entry: [Finished].

Page 25

5 First steps

25

Input editor

1. Select the value (characters) to be changed: [▲], [▼], [◄],

[►].

2. Adopt the value: [OK].

Options:

> Toggle between upper/lower case:

select Ι

← ABC→&$/ →Ι : [▲], [▼] → [ABC→&$/].

> Position the cursor in the text:

select Ι

← ABC→&$/ →Ι : [▲], [▼] → [Ι←] or [→Ι].

> Delete character before or after the cursor:

select Del Finished

←: [▲], [▼] → [←] or [Del].

3. Repeat steps 1 and 2 as required.

4. Save the entry: select Del Finished

← : [▲], [▼] →

[Finished].

Page 26

5 First steps

26

5.2.6. Printing/saving data

Data is printed out via the key [].

To be able to transfer data to a record printer via infrared or

Bluetooth interface, the printer used must be enabled, see Printer,

page 32

Data is saved via the Options menu. The Options menu is

accessed via the left function key and is available in many different

menus.

Once a measurement has been carried out, the measurement

result can be saved via the right function key Save. Assignment of

the right function key with the function Save or Print, see

Assigning the right function key page 31.

With other functions, saving is carried out automatically via the

function key Finished, e.g. when creating Address/Location or

entering Date/Time.

5.2.7. Confirming an error message

If an error occurs, an error message is shown on the display.

> Confirm error message: [OK].

Errors that have occurred but have not yet been rectified are

indicated by a warning symbol ( ) in the header.

Error messages not yet resolved can be displayed in the menu

Error diagnosis, see Instrument diagnosis, page 30.

Page 27

5 First steps

27

5.2.8. Switching off

Unsaved measuring values are lost if the testo 324 is

switched off.

> Press [].

- The measuring instrument switches off.

5.3. Address/location

All measuring values can be saved under the currently active

location. Measuring values that have not been saved are lost when

the measuring instrument is switched off!

Addresses and locations can be created, edited, copied and

enabled. Addresses and locations (incl. records) can be deleted.

Call up function:

> [] → Address/Location → [OK] .

There are various options for opening folders.

1. Edit search setting (Search / Filter / Show all): [Edit]

2. Select search setting: [▲], [▼] → [OK].

Possible settings:

• Show all: all addresses/locations are displayed

• Search: A search text only brings up addresses/locations

that contain characteristics of the search text.

• Filter: Individual letters or numbers can be selected. All data

beginning with the relevant letter/number is displayed.

The initial letter is the determining factor for the filter

function, and this can only be selected individually. The

search function can also be used to find a series of several

letters within the folder name!

3. Carry out search according to search setting: [Search]

Show all

1. Select address: [▲], [▼].

2. Show details: [Details].

3. Enable location: select location → [OK].

- The location is enabled.

> Open measurements menu: press [OK] again.

Page 28

5 First steps

28

Search

1. Edit search criterion: [►] → [Edit].

2. Select search criteria: [▲], [▼] → [OK].

Possible options:

• Contact person

• Folder name

• Town/city

• Postcode

• Street

- The selected criterion is displayed.

3. Call up entry field for search text: [►] or [▼]

> Enter search text → [Finished]

Filter

1. Edit search criteria: [Edit].

2. Select search criteria: [▲], [▼] → [OK].

Possible options:

• Contact person

• Folder name

• Town/city

• Postcode

• Street

- The selected criterion is displayed.

3. Enable tab: [▼]

4. Select the required tab: [▲], [▼] and sometimes [◄], [►] →

[Filter].

- The search result for the relevant letter or number is displayed.

Creating a new location:

A measuring location is always created under an address.

1. Select the address under which the location should be created.

2. [Options] → New location → [OK].

3. Enter values or make settings.

4. Finalise the entry: [Finished].

Other location options:

> [Options] → Edit location: make changes to an existing

location.

> [Options] → Copy location: make a copy of an existing

location in the same folder.

> [Options] → Delete location: delete an existing location.

Page 29

5 First steps

29

Creating new addresses:

1. [Options] → New address → [OK].

2. Enter values or make settings.

3. Finalise the entry: [Finished].

Additional address options:

• Edit address: make changes to an existing folder.

• Copy address: make a copy of an existing address.

• Delete address: delete an existing address, including the

locations created there.

• Delete all addresses: delete all existing addresses, including

the locations created there.

5.4. Measurement records

Call up function:

> [] → Measurement records → [OK].

There are various options for opening records, see

Address/location, page 27.

Displaying a record:

1. Select the required record from the detailed view.

2. [Data].

Options:

> [Options] → Show Graphic: display saved record data as

graphic.

> [Options] → Delete Record: delete the selected record.

> [Options] → Number of lines: change the number of

measuring values per display page.

> [Options] → Delete all records: delete all saved records for a

location.

Page 30

5 First steps

30

5.5. Instrument diagnosis

Important operating values and instrument data are displayed. A

main test can be carried out. Instrument errors that have not yet

been rectified can be displayed.

Call up function:

> [] → Instrument diagnosis → [OK].

Error diagnosis

> Error diagnosis → [OK].

- Unresolved errors, warnings and notes are displayed.

> View next/previous error: [▲], [▼].

Instrument information

> Device Information → [OK].

- Information is displayed.

Tightness test

1. Main test → Tightness test → [OK]

2. Short both gas connections through the connection hose.

3. Start the check: [OK].

- Zeroing of pressure sensor

- Pressure is built up and measurement is carried out

- The result of the measurement is indicated by a traffic light.

Gas feeding unit test

1. Gas feeding unit test → [OK].

2. Connect the measuring instrument to the gas feeding unit.

3. Start the test: [OK].

- If the gas feeding unit is full, it is emptied.

4. Gas feeding unit is filled.

• Settling period expires (15 min)

• Measuring time expires (5 min)

- The measurement result is indicated by a traffic light.

5. Gas feeding unit is emptied.

6. Exit testing: [Back]

Page 31

6 Using the product

31

6 Using the product

6.1. Performing settings

6.1.1. Assigning the right function key

The right function key can have a function from the Options menu

assigned to it. The menu Options is accessed via the left function

key and is available in many different menus. This assignment is

only valid for the currently opened menu / the opened function.

✓ A menu / function is opened in which the Options menu is

displayed on the left function key.

1. Press [Options] .

2. Select option: [▲], [▼].

Depending on the menu / function from which the Options menu

was opened, the following functions are available.

3. Assign the selected function to the right function key: Press

[Config. Key].

6.1.2. Instrument settings

It is assumed that the contents of the chapter First steps

(see First steps, page 22) are known.

Calling up a function:

> [] → Device Settings.

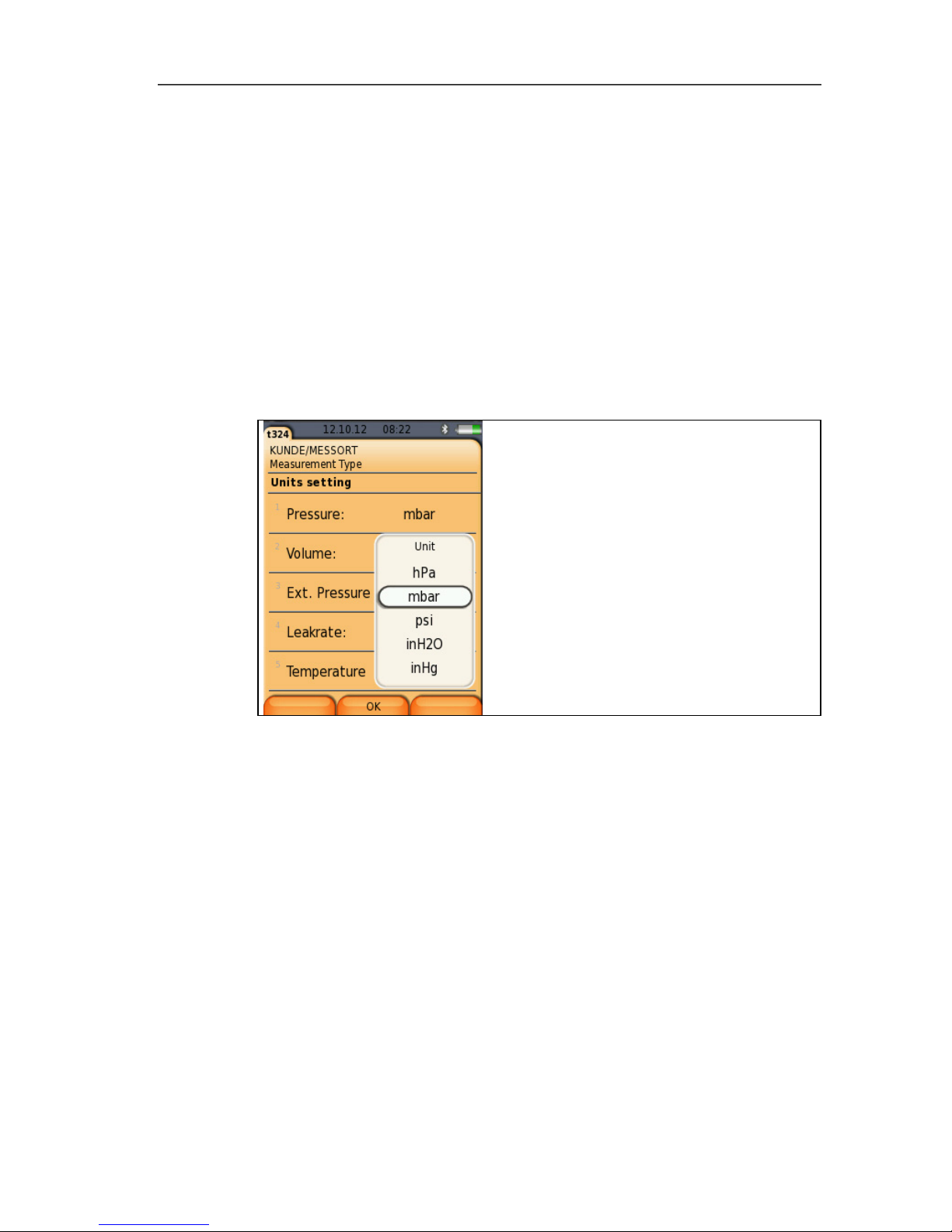

6.1.2.1. Units

The units used for parameters in configuration menus can be set.

Call up function:

> [] → Instrument settings → [OK] → Units → [OK].

Adjustable units

Parameter Unit

Pressure

hPa, mbar, psi, inW,

inHg

Volume m3, l, ft3

Ext. Pressure bar, psi, kPa

Leakrate l/h, fl.oz, ml/min

Page 32

6 Using the product

32

1. Select the line: [▲], [▼] → [Edit].

2. Select the unit to be changed: [▲], [▼] → [OK].

3. Confirm the entry: [Finished].

6.1.2.2. Date/Time

Date, time mode and time can be set.

Calling up the function:

> [] → Instrument settings → [OK] → Date/Time → [OK].

Set date/time:

1. Select parameter: [◄], [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and sometimes [◄], [►] → [OK].

3. Save settings: [Finished].

6.1.2.3. Energy management

Automatic instrument shutdown (Auto-Off) and switching off of the

display light in battery operation can be set.

Calling up the function:

> [] → Instrument Settings → [OK] → Energy Management

→ [OK]

Making settings:

1. Select function or parameter: [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and partly [◄], [►] → [OK].

3. Save changes: [Finished].

6.1.2.4. Display brightness

The intensity of the display illumination can be set.

Calling up the function:

> [] → Instrument Settings → [OK] → Display Brightness →

[OK]

Performing settings

> Set parameter: [◄], [►] → [OK].

6.1.2.5. Printer

The headers (lines 1-3) and the footer for the printout can be set.

The printer that is used can be enabled.

Call up function:

> [] → Instrument settings → [OK] → Printer → [OK].

Page 33

6 Using the product

33

Enabling the printer:

The 0554 0553 and 0554 0620 printers can only be

selected if the Bluetooth® interface is enabled, see

Bluetooth®, page 33.

When using the testo IrDA record printer 0554 0547, the

testo IrDA fast printer 0554 0549 must be selected.

Graphics can be printed out using the following Testo

printers:

0554 0547 IrDA report printer

0554 0549 IrDA report printer

0554 0553 Bluetooth® printer

0554 0620 Bluetooth® printer

1. Select printer → [OK].

2. Select the printer: [▲], [▼] → [OK].

- The printer is enabled and the Printer menu is opened.

Setting the print text:

1. Print text → [OK].

2. Select function: [▲], [▼] → [Edit].

3. Enter values → [OK].

4. End input: [Finished].

5. Save the entry: [Finished].

6.1.2.6. Bluetooth®

This menu is only available if the instrument is equipped with

Bluetooth. The Bluetooth module can be switched on / off.The relay

can now be tested.

Calling up the function:

> [] → Instrument Settings → [OK] → Bluetooth → [Edit].

Making settings:

> Set parameter → [OK].

6.1.2.7. Automatic measuring rate

The automatic measuring rate can be switched on or off.

If the automatic measuring rate is on, the following measuring rate

is saved for the individual measurement programs (except

Programs menu):

Page 34

6 Using the product

34

Messzeit Measuring rate

< 15 min 1 s

> 15 min 1 min

If the automatic measuring rate is switched off, a measuring rate of

1 second is used, irrespective of the measuring time.

Call up a function:

> [] → Instrument settings → [OK] → Autom. meas. rate →

[OK].

Making settings:

1. [Edit]

2. Set parameter: [▲], [▼] → [OK].

6.1.2.8. Inspector

In this menu, an inspector can be selected and/or a new one can

be created.

Calling up the function:

> [] → Instrument settings → [OK] → Inspector → [OK].

Making settings:

1. Edit/create inspector: [▼] → [Edit] → [Finished].

2. Set parameter: [▲], [▼] and sometimes [◄], [►] → [OK].

3. Save changes: [Finished].

4. [Finished].

Selecting an inspector

> Select inspector: [▲], [▼] → [Enable] → [Finished].

6.1.2.9. Language

The menu language can be set. The number of available

languages depends on the activated country version, see Country

version, page 35.

Calling up the function:

> [] → Instrument Settings → [OK] → Language → [OK]

Activating the language:

> Select the language → [OK].

Page 35

6 Using the product

35

6.1.2.10. Country version

The country version with national defaults (measurement types,

standard values) can be set. The selection of the country version

influences the menu languages that can be enabled.

Call up function:

> [] → Instrument settings → [OK] → Country version →

[OK].

This setting can be password protected. A password is

specified in the menu Password Protection, see

Password protection, page 35.

Possibly:

> Enter password: [Enter] → Enter password → [Finished] →

[OK].

Setting the country version:

1. Select the country version: [▲], [▼] → [OK].

2. Confirm confirmation request: Yes → [OK]

- The system is restarted.

6.1.2.11. Password protection

The password protection is only valid for functions identified by the

following symbol: or .

Password protection can be enabled/disabled, the password can

be changed.

To disable password protection, change the password to 0000

(factory setting).

Call up function:

> [] → Instrument settings → [OK] → password protection

→ [OK].

Possibly:

> Enter the current password:

[Enter] → Enter password → [Finished] → [OK].

Changing the password:

1. [Edit].

2. Enter a new password → [Finished].

3. [Edit].

4. Enter the new password again to confirm → [Finished].

5. Save changes: [Finished].

Page 36

6 Using the product

36

6.1.3. Gas type

The gas type can be selected. The gas-specific coefficients and

threshold values can be set.

In order to maintain the measuring accuracy of the

instrument, the correct gas must be selected or configured.

Correct representation of measuring results is only assured

if the threshold values for the ideal range of the

corresponding measurement task have been set correctly.

Preset threshold values are typical values for the selected

gas type.

Gas Standard

designation

Gas

composition

Measuring

range

Natural gas

(G20)

Complies with

G20

Methane 100% 0 to 10 l/h

Natural gas

(G25)

Complies with

G25

Methane 86%

Nitrogen 14%

0 to 10 l/h

Propane G31

G31 burner

test gas

Propane 100% 0 to 5 l/h

Propen G32

G32 burner

test gas

Propen 100% 0 to 5.7 l/h

G21

G21 burner

test gas

EN 437,

DIN 3362

Methane 87%

Propane 13%

0 to 10 l/h

G30

G30 burner

test gas

n-butane 50%

Iso-butane 50%

0 to 3.2 l/h

Air -

Nitrogen 78%

Oxygen 21%

0 to 10 l/h

CO2 -- CO2 100% 0 to 9 l/h

Call up function:

> [] → Gas type → [OK].

Enabling gas type:

> Select the gas type → [OK].

- The gas type is enabled and the main menu is opened.

Page 37

6 Using the product

37

Setting coefficients:

1. Select gas type → [Coeff.].

2. Select the coefficients: [Edit].

Possibly:

> Enter password: [Enter] → Enter password → [Finished] →

[OK].

3. Set values → [OK].

4. Save changes: [Finished].

6.2. Measuring

6.2.1. Preparing for measurement

The feeding unit (gas bladder) must be tested for leaks at

regular intervals, see Instrument diagnosis, page 30, gas

feeding unit test.

Caution

Avoid damage to the instrument due to high pressure!

> For tests with a test pressure of > 1 bar or using a liquid test

medium e.g. water, a high pressure probe (art. no. 0638 1748)

must be used.

The First steps chapter (see First steps, page 22) must

have been read.

General information on the tightness tests on gas and

water pipes according to DVGW

• Before starting work on pipes carrying gas, the relevant

shut-off device must be closed and secured against

opening by unauthorised persons (e.g. when the key or

the hand wheel is removed). Where gas escapes or

could escape, it is necessary to ensure that the gas is

disposed of safely through ventilation or routing it

outdoors via a hose. The shut-off device should only be

opened again when all openings of the pipes through

which gas could escape have been tightly sealed. The

above does not apply when dealing with external

maintenance measures on pipes.

• If a leak is detected in accessible pipes carrying gas

using a gas detector in accordance with DVGW advice

G465-4 or with foaming agents in accordance with DIN

EN 14291, the point must be sealed by means of

suitable measures. Illumination with flames is not

Page 38

6 Using the product

38

permitted. Temporary sealing is only permissible in the

short term to avoid immediate risks.

• Pipes with operating pressures up to 100 mbar are

subject to a pretest and a main test, as well as a

serviceability test (for system in operation). The tests

should be carried out before the pipe is plastered over

or covered and its connections are coated or encased.

The tests can also be carried out in step-by-step.

• All tests must be documented.

To protect the testo 324, it is necessary to ensure that the

gases flowing into the pipes are free of oil, dust and

moisture.

Setting the location and gas type

Before carrying out measurements, the location and gas type must

be correctly selected, see Address/location, page 27 and see Gas

type, page 36.

6.2.2. Options menu

In the Measurement Type menu, for the various measurement

types, under [Options], the following selection is available:

> [Options] → Address/Location: The Address/Location folder

is opened.

> [Options] → Gas type: The Gas type folder is opened.

> [Options] → Main test: A main test can be carried out.

> [Options] → Please empty gas feeding unit: If a gas feeding

unit is available, this is emptied automatically.

This option is only available in conjunction with a feeding

unit.

> [Options] → Release air: Air is released from the pipe into the

environment.

> [Options] → Release gas: Gas is released from the pipe into

the gas feeding unit.

This option is only available in conjunction with a feeding

unit.

There are other options depending on the measurement type used.

Page 39

6 Using the product

39

6.2.3. Pipe volume

Based on the pipe volume calculation, unknown pipe volumes can

be determined and allocated to the relevant measuring location.

Particularly for the tightness test, where the stability time and

measurement time depends on the pipe volume, the advantage is

even more accurate and more reliable measurement.

Calling up the function:

> [] → Measurements → [OK] → Pipe volume → [OK].

Setting parameters

Parameter Selection Explanation

Gas feeding unit Yes/No Enable/disable gas feeding

unit

Test gas Air, CO2,

G30, G21,

propane,

natural gas,

Select test gas

1. Select parameter → [Edit].

2. Select or enter values: [▲], [▼] and sometimes [◄], [►] →

[OK].

Carrying out the measurement:

3. Start measurement: [].

> When Gas feeding unit Yes is selected: carry out steps in

accordance with the information on the display and confirm with

[OK].

- Zeroing starts (5 s)

- Volume calculation is carried out (bar shows progress of the

calculation)

-

Volume is displayed.

4. Adopt measurement result: [Apply].

Page 40

6 Using the product

40

6.2.4. Gas pipe (TRGI 2008)

WARNING

Risk of explosion due to hazardous gas/air mixtures

> Do not feed air into pipes carrying gas.

> Observe the information for the instrument if there is a risk that

air is being routed into pipes carrying gas.

CAUTION

Avoid damage to the instrument due to high pressure!

> The test pressure of 1.2 bar must not be exceeded.

There are 5 different test types to choose from:

Test type Explanation

Pretest The pretest (using air) is used for the load

test (stability test) of newly laid gas pipes.

The test is performed on the pipe without

gas meter and fittings.

Main test

The main test (using air or inert gas, e. g.

CO

2

or N2) is used for the tightness test

(acceptance test) on newly laid or

renovated pipes. The test is performed at

the pipe, including the fittings, without gas

installations and corresponding control

and safety equipment.

Leakage test

This measurement is carried out to test

the serviceability of an existing gas pipe

system and is used to check the actual

condition of the pipes. The pipe system

may be in operation or disused. After

handover of a gas system, the operator is

responsible for proper operation, which is

why it is recommended that the

serviceability test is carried out every 12

years.

Page 41

6 Using the product

41

Test type Explanation

Combined

pretest/main test

This measurement is carried out for newly

laid pipe systems with operating

pressures of 100 mbar to 1 bar.

The test includes pipe systems including

fittings, but without gas pressure

controllers, gas appliances, gas meters

and relevant regulating and safety

devices.

Caravan check

Tightness test on gas pipes in

accordance with the EN 1949 standard

and DVGW G 607. Since1 April 2006, a

valid G 607 test is a requirement for the

HU (general inspection) with the TÜV

(German Technical Inspection Agency).

Caravan and motorhome owners are

obliged to have their liquid gas systems

checked every 2 years.

6.2.4.1. Pretest

This test is used as a load test for newly laid gas pipes and is

carried out before the main test. The test is performed on the pipe

without a gas meter and fittings. The pipe is subjected to many

times the subsequent operating pressure, so the material is

exposed to a significantly greater load than is expected during

normal operation.

Calling up the function:

> [] → Measurements → [OK] → Gas pipe (TRGI 2008 →

Pretest → [OK].

Setting parameters

Parameter Explanation

Stability time Set stability time

Measurement period Adopt or set measurement period

According to DVGW TRGI 2008,

the measurement period is 10

min.

Page 42

6 Using the product

42

Parameter Explanation

Test pressure (target) Adopt or set test pressure

According to DVGW TRGI 2008,

the test pressure (target) is

1000 mbar

Pressure Set pressure

1. Edit values: [Edit].

2. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

Carrying out a pretest

1. Build up test pressure (target) manually with the test pump or a

compressor at the connection provided.

2. Close the shut-off valve.

The valve must always be closed during measurements.

Only open to apply pressure. Close it again

3. Start measurement: [].

- Zeroing starts (5 s)

Option

> End stability time early: [Next]

> End measurement period early: [Next]

- Pretest is ended.

4. Evaluate measurement result: [▲], [▼] → [OK].

- The measurement result is displayed

5. Save measurement result: [Save].

Options

> [Options] → Show Graphic: a section of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼]).

> [Options] → Manometer: the measuring values are displayed

in the same way.

> [Options] → Factory setting: the values are reset to the

default settings.

> [Options] → Overall graphic curve: the measuring values

across the overall measuring time are displayed in a line graph.

Page 43

6 Using the product

43

6.2.4.2. Main test

The main test (using air or inert gas such as CO2 or N2) is a

tightness test for pipes including fittings, but without gas appliances

and the relevant regulating and safety devices. The main test is

carried out after a successfully completed pretest on newly laid gas

pipes or after renovation of existing gas pipes and is used for the

acceptance of these pipes. It shows up even the smallest leaks in

gas pipes.

Calling up the function:

> [] → Measurements → [OK] → Gas pipe (TRGI 2008 →

Main test → [OK].

Setting parameters

According to DVGW TRGI 2008, the stability time and

measurement period depend on the pipe volume.

• Pipe volume < 100 l: Adjustment time 10 min,

measurement period 10 min.

• Pipe volume > 100 l - < 200 l: Adjustment time 30 min,

measurement period 20 min.

• Pipe volume > 200 l: Adjustment time 60 min,

measurement period 30 min.

Parameter Explanation

Volume Set volume

The pipe volume can also be

measured directly, see [Options]

→ Volume

Stability time Set stability time

Measurement period Set measurement period

Test pressure (target) Set test pressure

According to DVGW TRGI 2008,

the test pressure (target) is

150 mbar.

1. Edit values: [Edit].

2. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

Page 44

6 Using the product

44

Carrying out a main test

1. Start measurement: [].

- Zeroing starts (5 s)

- Test pressure (target) is built up automatically by the instrument

Option

> End stability time early: [Next]

> End measurement period early: [Next]

- Main test is ended.

2. Evaluate measurement result: [▲], [▼] → [OK].

- The measurement result is displayed

3. Save measurement result: [Save].

Options

> [Options] → Show Graphic: a section of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼]).

> [Options] → Volume: The pipe volume is determined directly

(the option is no longer available after the measurement).

> [Options] → Manometer: The measuring values are displayed

in the same way.

> [Options] → Factory setting: the values are reset to the

default settings.

> [Options] → Overall graphic curve: the measuring values

across the overall measuring time are displayed in a line graph.

6.2.4.3. Leakage test (leakage measurement)

This measurement is carried out to test the serviceability of an

existing gas pipe system (in contrast to the pretest and main test)

and is used to check the actual condition of the pipes. The pipe

system may be in operation or disused

For the serviceability test, the testo 324 can be operated together

with the feeding unit. The feeding unit supplies the test medium

(gas or air).

The advantages of a measurement with the feeding unit:

• Pressure fluctuations that may occur in gas pipes and affect the

measurement are compensated (test independent of the gas

supply).

• No need to dismantle the gas meter/the instrument can be used

at any point on the system.

• Safe measurements thanks to the feed-in of gas, as there is no

risk caused by air in a pipe carrying gas.

Page 45

6 Using the product

45

Test pressure:

• Operating pressure <30 mbar = reference pressure (23 mbar)

• Operating pressure >30 mbar = operating pressure

According to DVGW TRGI 2008, the stability time and

measurement period depend on the pipe volume.

• Pipe volume < 100 l: Adjustment time 10 min,

measurement period 5 min.

• Pipe volume < 200 l: Adjustment time 30 min,

measurement period 10 min.

• Pipe volume < 300 l: Adjustment time 60 min,

measurement period 15 min.

• Pipe volume < 400 l: Adjustment time 120 min,

measurement period 20 min.

• Pipe volume < 500 l: Adjustment time 240 min,

measurement period 25 min.

Calling up the function:

1. [] → Measurements → [OK] → Gas pipe (TRGI 2008 →

Leakage test → [OK].

2. Select Feeding with gas (feeding unit required), Feeding with

air, as gas meter replacement: [▲], [▼] → [OK].

Setting parameters

Parameter Explanation

Volume Set volume

The pipe volume can also be

measured directly, see [Options]

→ Volume

Stability time Set stability time

Measurement period Set measurement period

Pipe type Set pipe type

1. Edit values: [Edit].

2. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

Carrying out a leakage test (leakage measurement)

1. Start measurement: [].

> When Feeding with gas, Feeding with air is selected: carry

out steps in accordance with the information on the display and

confirm with [OK].

Page 46

6 Using the product

46

- Zeroing starts (5 s)

- Regulation

Option

> End stability time early: [Next]

> End measurement period early: [Next]

- Measurement is cancelled.

- Leakage test (leakage measurement) is ended.

2. Evaluate measurement result: [▲], [▼] → [OK].

- The measurement result is displayed

3. Save measurement result: [Save].

- The measurement result is displayed

4. Evaluate measurement result:

Leakage test result Select result

Visual check Select result

System checked Enter system details

Gas meter number Enter gas meter number

Gas meter level Enter gas meter level

Inspector Enter name of inspector

5. Edit values: [Edit].

6. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

7. Save entries: [Save].

Option

> [Options] → Show Graphic: a section of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼]).

> [Options] → Settings: The type of test (reference

pressure/operating pressure) can be set and the reference

pressure of 23 mbar is displayed.

> [Options] → Volume: the pipe volume is determined directly

(the option is no longer available after the measurement).

> [Options] → Manometer: the measuring values are displayed

in the same way.

> [Options] → Factory setting: the values are reset to the

default settings.

> [Options] → Overall graphic curve: the measuring values

across the overall measuring time are displayed in a line graph.

Page 47

6 Using the product

47

6.2.4.4. Combined pretest/main test

The combined pretest/main test is carried out on newly laid pipe

systems with operating pressures of 100 mbar to 1 bar.

The test includes pipe systems including fittings, but without gas

pressure controllers, gas appliances, gas meters and relevant

regulating and safety devices.

A high pressure probe is required for this test.

Calling up the function:

> [] → Measurement → [OK] → Gas pipe (TRGI 2008 →

Combined Pre-/ Maintest → [OK].

Setting parameters

Parameter Explanation

Volume Set volume

The pipe volume can also be

measured directly, see [Options]

→ Volume

Stability time Set stability time

Measurement period Set measurement period

Test pressure (target) Set test pressure

1. Edit values: [Edit].

2. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

Carrying out a combined pretest/main test

1. Start measurement: [].

- Zeroing starts (5 s)

- Build up test pressure (target) manually with the test pump or a

compressor at the connection provided.

Option

> End stability time early: [Next]

> End measurement period early: [Next]

- Measurement is cancelled.

- Combined pretest/main test is ended.

Page 48

6 Using the product

48

2. Evaluate measurement result: [▲], [▼] → [OK].

- The measurement result is displayed

3. Save measurement result: [Save].

Options

> [Options] → Show Graphic: a section of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼]).

> [Options] → Manometer: The measuring values are displayed

in the same way.

> [Options] → Factory setting: the values are reset to the

default settings.

> [Options] → Overall graphic curve: the measuring values

across the overall measuring time are displayed in a line graph.

6.2.4.5. Caravan Check

The caravan check is a tightness test in accordance with DVGW

G 607 and relates to vehicles with a permanently installed gas

system. The whole gas installation is checked.

Call up function:

> [] → Measurements → [OK] → Gas pipe (TRGI 2008 →

Caravan Check → [OK].

Set parameters

Parameters Explanation

Stability time Set stability time

Measurement period

(nominal)

Set measurement period (nominal)

Diff. pressure ∆pmax

Set maximum permissible differential

pressure

Pressure build-up

Automatic

Pressure is built up automatically via the

integrated pressure pump (up to max.

200 mbar, up to max. line volume 5 l)

Test pressure (nom.) Set test pressure

Vehicle number Enter vehicle number

Inspector Enter inspector's name

Page 49

6 Using the product

49

1. Edit values: [Edit].

2. Enter values: [▲], [▼] and sometimes [◄], [►] → [OK].

Carry out caravan check

1. Start measurement: [].

- Zeroing starts (5 s).

- Test pressure (nom.) is built up automatically.

If the test pressure (nom.) is not reached after 2 min. 30

sec., the pressure build-up is terminated and an information

is displayed.

Reasons for aborting the pressure build-up can be too

much leakage in the gas line.

Option

> End stability time early: [Next].

> End measurement period early: [Next].

If the test pressure drops by more than 10 % within the

stabilization or measuring time, the measurement is

interrupted and an information is displayed.

- Measurement is cancelled.

- Caravan check ends.

2. Evaluate measurement result: [▲], [▼] → [OK].

- Measurement result is displayed.

3. Save measurement result: [Save].

Options

> [Options] → Show Graphic: An excerpt of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼]).

> [Options] → Manometer: The measuring values are shown in

an analogue display.

> [Options] → Overall graphic curve: The measuring values

across the overall measuring time are displayed in a line graph.

Page 50

6 Using the product

50

6.2.5. Liquid gas (DVGW TRF 2012)

CAUTION

Avoid damage to the instrument due to high pressure!

> The test pressure of 1.2 bar must not be exceeded.

Liquid gas pipes must be subjected to a pressure test and a

main test before corrosion protection is applied, before

plastering or any other covering work and before a liquid

gas vessel is commissioned (filled). It must be certified that

the pipelines have been properly constructed.

There are 3 different test types to choose from:

• Pressure test

During the pressure test, the liquid gas pipes are tested at a

higher pressure than the normal operating pressure. This

means that the material is exposed to a greater load. The

pressure test detects weaknesses and shows up any material

defects.

Installed pressure controllers and gas meters must be

dismantled before the pressure test. The pressure test is

carried out before commissioning.

Pressure testing of liquid gas pipelines must be carried out with

air or nitrogen, taking equipment accessories into account.

However, it can also be carried out using water as the test

medium. According to the TRF (Germany), the pressure during

the pressure test must be 1.1 times the permissible pressure

(determined by the SSV triggering pressure), but at least 1 bar.

A pressure drop is not permissible after expiry of the stability

time and measurement period.

• Main test

The main test (using air or inert gas, e.g. CO2 or N2) is carried

out immediately before commissioning. It is used as a tightness

test (acceptance test) on newly laid or renovated pipes. The

test includes all pipelines up to the closed instrument

connectors of the gas appliances.

Immediately prior to commissioning and following the pressure

test, all pipelines, going as far as the adjustment elements of

the instrument, must be tested for tightness using air at an

overpressure of 100 mbar (TRF, Germany).

Page 51

6 Using the product

51

• Repeated testing PS >0.5 bar

Pipelines with PS >0.5 bar must be subjected to a pressure test

every 10 years. Pipelines with DN > 25 must be subjected to a

main test under operating conditions every 2 years.

• Repeated testing PS <=0.5 bar

Pipelines with PS <=0.5 bar must be subjected to a main test

every 10 years.

6.2.5.1. Pressure test

Calling up the function:

> [] → Measurements → [OK] → Liquid gas (TRF) →

Pressure test → [OK].

Setting parameters

Parameter Explanation

Stability time Set stability time

TRF 2012 stipulates a stability

time of 10 min.

Measurement period Set measurement period

TRF 2012 stipulates a

measurement period of 10 min.

Test pressure (target) Set test pressure

TRF 2012 stipulates a test

pressure of 1000 mbar.

1. Edit values: [Edit].

2. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

Carrying out a pressure test

1. Build up test pressure (target) manually with the test pump or a

compressor at the connection provided.

2. Start measurement: [].

- Zeroing starts (5 s)

Option

> End stability time early: [Next]

> End measurement period early: [Next]

- Measurement is cancelled.

- Pressure test is ended.

Page 52

6 Using the product

52

3. Evaluate measurement result: [▲], [▼] → [OK].

- The measurement result is displayed

4. Save measurement result: [Save].

Options

> [Options] → Show Graphic: a section of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼]).

> [Options] → Manometer: The measuring values are displayed

in the same way.

> [Options] → Factory setting: the values are reset to the

default settings.

> [Options] → Overall graphic curve: the measuring values

across the overall measuring time are displayed in a line graph.

6.2.5.2. Main test

Immediately prior to commissioning and following the pressure test,

all pipelines, going as far as the closed instrument connectors of

the gas appliances, must be tested for tightness using air at an

overpressure of 150 mbar (TRF 2012). The pipelines are deemed

leak-proof if, following temperature equalisation, the test pressure

does not drop throughout the subsequent 10 minute duration of the

test.

Calling up the function:

> [] → Measurements → [OK] → Liquid gas (TRF) → Main

test → [OK].

Setting parameters

Parameter Explanation

Stability time Set stability time

Measurement period Set measurement period

TRF 2012 stipulates a

measurement period of 10 min.

Test pressure (target) Set test pressure

According to TRF 2012, the test

pressure is 150 mbar.

1. Edit values: [Edit].

2. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

Page 53

6 Using the product

53

Carrying out a main test

1. Start measurement: [].

- The test pressure (target) is built up automatically by the

instrument.

- Zeroing starts (5 s)

Option

> End stability time early: [Next]

> End measurement period early: [Next]

- Measurement is cancelled.

- Pressure test is ended.

2. Evaluate measurement result: [▲], [▼] → [OK].

- The measurement result is displayed

3. Save measurement result: [Save].

Options

> [Options] → Show Graphic: a section of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼])

> [Options] → Manometer: The measuring values are displayed

in the same way.

> [Options] → Factory setting: the values are reset to the

default settings.

> [Options] → Overall graphic curve: the measuring values

across the overall measuring time are displayed in a line graph.

6.2.5.3. Repeated testing (PS>0.5 bar / PS<=0.5 bar)

The aim of this testing is to establish, at the time of testing, whether

the pipe is in proper working condition for the intended application

and can satisfy the requirements until the next test.

Calling up the function:

> [] → Measurements → [OK] → Liquid gas (TRF) →

Repeated testing PS>0.5 bar or Repeated testing PS<=0.5

bar → [OK].

Page 54

6 Using the product

54

Setting parameters

Parameter Explanation

Stability time Set stability time

Measurement period Set measurement period

TRF 2012 stipulates a

measurement period of 10 min.

Test pressure (target) Set test pressure

According to TRF 2012, the test

pressure is 150 mbar.

1. Edit values: [Edit].

2. Enter values. [▲], [▼] and sometimes [◄], [►] → [OK].

Carrying out repeated testing PS>0.5 bar

1. Build up test pressure (target) manually with the test pump or a

compressor at the connection provided.

2. Start measurement: [].

- Zeroing starts (5 s)

Option

> End stability time early: [Next]

> End measurement period early: [Next]

- Measurement is cancelled.

- Pressure test is ended.

3. Evaluate measurement result: [▲], [▼] → [OK].

- The measurement result is displayed

4 Save the measurement result: [Save].

Options

> [Options] → Show Graphic: a section of past measuring

values is displayed in a line graph (zoom function available [▲],

[▼]).

> [Options] → Manometer: The measuring values are displayed

in the same way.

> [Options] → Factory setting: the values are reset to the

default settings.

> [Options] → Overall graphic curve: the measuring values

across the overall measuring time are displayed in a line graph.

Page 55

6 Using the product

55

6.2.5.4. Carrying out repeated testing PS <0.5 bar

The aim of this testing is to establish, at the time of testing, whether

the pipe is in proper working condition for the intended application

and can satisfy the requirements until the next test.

Call up a function:

> [] → Measurement options → [OK] → Liquid gas (TRF) →

Repeated testing PS < 0.5 bar.

Setting parameters

Parameter Explanation