Page 1

testo 320 · Flue gas analyzer

testo 320 LX · Flue gas analyzer

Instruction manual

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 2

1 Contents

1 Contents

1 Contents ................................................................................................... 3

2 Safety and the environment .................................................................... 6

2.1. About this document ........................................................................ 6

2.2. Ensure safety................................................................................... 7

2.3. Protecting the environment .............................................................. 8

3 Specifications .......................................................................................... 9

3.1. Use .................................................................................................. 9

3.2. Technical data ................................................................................. 9

3.2.1. Examinations ....................................................................................................... 9

3.2.2. Bluetooth® module (option) ...............................................................................10

3.2.3. Licenses ............................................................................................................10

3.2.4. Declaration of Conformity .................................................................................13

3.2.5. Measurement ranges and resolution ................................................................14

3.2.6. Accuracy and response time ............................................................................14

3.2.7. Other instrument data .......................................................................................16

4 Product description ............................................................................... 17

4.1. Case 0516 3300 (accessory) ......................................................... 17

4.1.1. Bottom level view ..............................................................................................17

4.1.2. Top level view ...................................................................................................18

4.2. Case 0516 3301 (accessory) ......................................................... 19

4.2.1. Bottom level view ..............................................................................................19

4.2.2. Middle level view ...............................................................................................20

4.2.3. Top level view ...................................................................................................21

4.3. Measuring instrument .................................................................... 22

4.3.1. Front view ..........................................................................................................22

4.3.2. Keypad ..............................................................................................................22

4.3.3. Display...............................................................................................................23

4.3.4. Instrument connections .....................................................................................24

4.3.5. Condensate outlet and interfaces .....................................................................24

4.3.6. Rear view ..........................................................................................................25

4.3.7. Components ......................................................................................................26

4.4. Compact flue gas probe ................................................................ 27

4.5. Modular flue gas probe .................................................................. 27

5 First steps .............................................................................................. 28

5.1. Commissioning .............................................................................. 28

5.2. Getting to know the product ........................................................... 28

5.2.1. Mains operation.................................................................................................28

5.2.2. Connecting probes ............................................................................................28

5.2.3. Switching on ......................................................................................................29

5.2.4. Calling up the function ......................................................................................29

5.2.5. Entering values .................................................................................................30

5.2.6. Printing/saving data ..........................................................................................31

3

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 3

1 Contents

5.2.7. Saving data to the clipboard (temporary memory) ........................................... 31

5.2.8. Confirming an error message ........................................................................... 31

5.2.9. Switching off ..................................................................................................... 32

5.3. Address/Location .......................................................................... 32

5.4. Measurement records ................................................................... 34

5.5. Instrument diagnosis ..................................................................... 35

6 Using the product ................................................................................. 36

6.1. Performing settings ....................................................................... 36

6.1.1. Assigning the right function key ........................................................................ 36

6.1.2. Instrument settings ........................................................................................... 36

6.1.2.1. Measurement view ............................................................................. 36

6.1.2.2. Alarm limits ......................................................................................... 38

6.1.2.3. Units ................................................................................................... 38

6.1.2.4. Date / time .......................................................................................... 39

6.1.2.5. Energy management.......................................................................... 39

6.1.2.6. Display brightness .............................................................................. 39

6.1.2.1. Choose measurement type ................................................................ 39

6.1.2.2. Printer ................................................................................................. 40

6.1.2.3. Bluetooth® .......................................................................................... 40

6.1.2.4. Language ........................................................................................... 41

6.1.2.5. Country version .................................................................................. 41

6.1.2.6. Password protection .......................................................................... 42

6.1.3. Sensor settings ................................................................................................. 42

6.1.3.1. O2 reference ....................................................................................... 42

6.1.3.2. Sensor protection ............................................................................... 43

6.1.3.3. Recalibration/adjustment ................................................................... 43

6.1.4. Fuels ................................................................................................................. 44

6.2. Measuring ..................................................................................... 45

6.2.1. Preparing for measurement .............................................................................. 45

6.2.1.1. Testing for leaks ................................................................................. 45

6.2.1.2. Zeroing phases .................................................................................. 45

6.2.1.3. Using flue gas probe .......................................................................... 46

6.2.1.4. Measurement view ............................................................................. 46

6.2.1.5. Setting the location and fuel .............................................................. 47

6.2.2. Flue gas ............................................................................................................ 47

6.2.3. Draught measurement ...................................................................................... 48

6.2.4. External micro pressure probe ......................................................................... 49

6.2.5. Average ............................................................................................................. 49

6.2.6. BImSchV ........................................................................................................... 50

6.2.7. CO undiluted ..................................................................................................... 51

6.2.8. Smoke number/HCT ......................................................................................... 52

6.2.9. Pressure ............................................................................................................ 52

6.2.10. Differential temperature .................................................................................... 53

6.2.11. O2 air ................................................................................................................ 54

6.2.12. Gas flow rate ..................................................................................................... 54

6.2.13. Oil flow .............................................................................................................. 55

6.2.14. Ambient CO ...................................................................................................... 55

6.2.15. CO2 ambient ..................................................................................................... 56

6.2.16. Leak detection .................................................................................................. 57

6.3. Transferring data ........................................................................... 58

6.3.1. Report printer .................................................................................................... 58

4

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 4

1 Contents

6.3.2. PC / Pocket PC .................................................................................................58

7 Maintaining the product ........................................................................ 59

7.1. Cleaning the measuring instrument ............................................... 59

7.2. Replacing the rechargeable battery ............................................... 59

7.3. Charging the battery ...................................................................... 61

7.4. Replacing sensors ......................................................................... 61

7.5. Recalibrating/adjusting sensors ..................................................... 62

7.6. Modular flue gas probe .................................................................. 62

7.6.1. Cleaning the flue gas ducts ..............................................................................62

7.6.2. Replacing the probe module .............................................................................62

7.6.3. Replacing the thermocouple .............................................................................63

7.6.4. Checking the particle filter.................................................................................63

7.6.5. Replacing the particle filter: ..............................................................................64

7.7. Compact flue gas probe ................................................................ 64

7.7.1. Cleaning the probe shaft ...................................................................................64

7.7.2. Replacing the thermocouple .............................................................................65

7.7.3. Checking the particle filter.................................................................................67

7.7.4. Replacing the particle filter................................................................................67

7.8. Condensate container ................................................................... 68

8 Tips and assistance............................................................................... 69

8.1. Questions and answers ................................................................. 69

8.2. Accessories and spare parts ......................................................... 69

8.3. Updating the instrument software .................................................. 73

5

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 5

2 Safety and the environment

Representation

Explanation

2 Safety and the environment

2.1. About this document

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

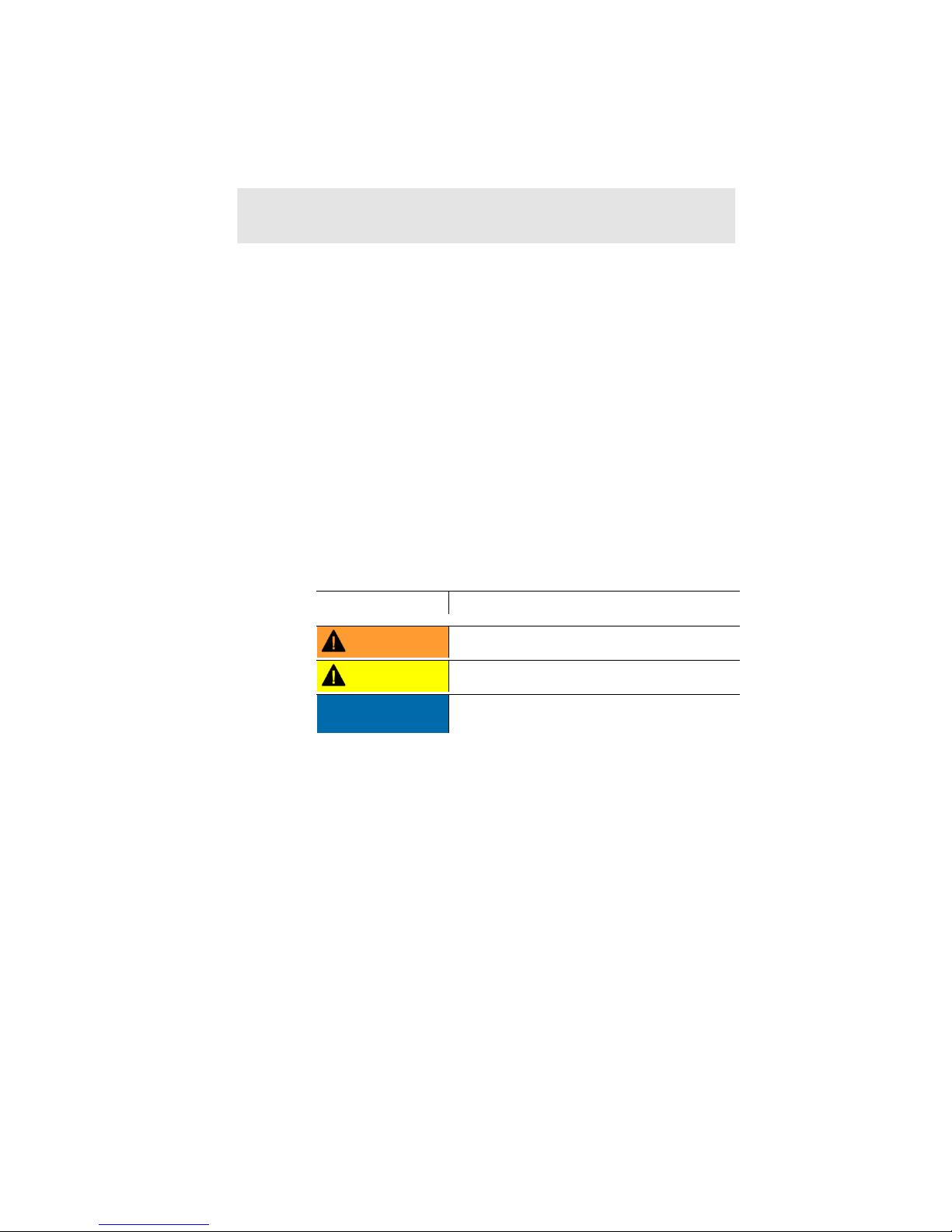

Warnings

Always pay attention to information that is marked by the following

warnings with warning pictograms. Implement the specified

precautionary measures.

WARNING

CAUTION

NOTICE

Indicates potential serious injuries

indicates potential minor injuries

indicates circumstances that may lead to

damage to the products

6

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 6

2 Safety and the environment

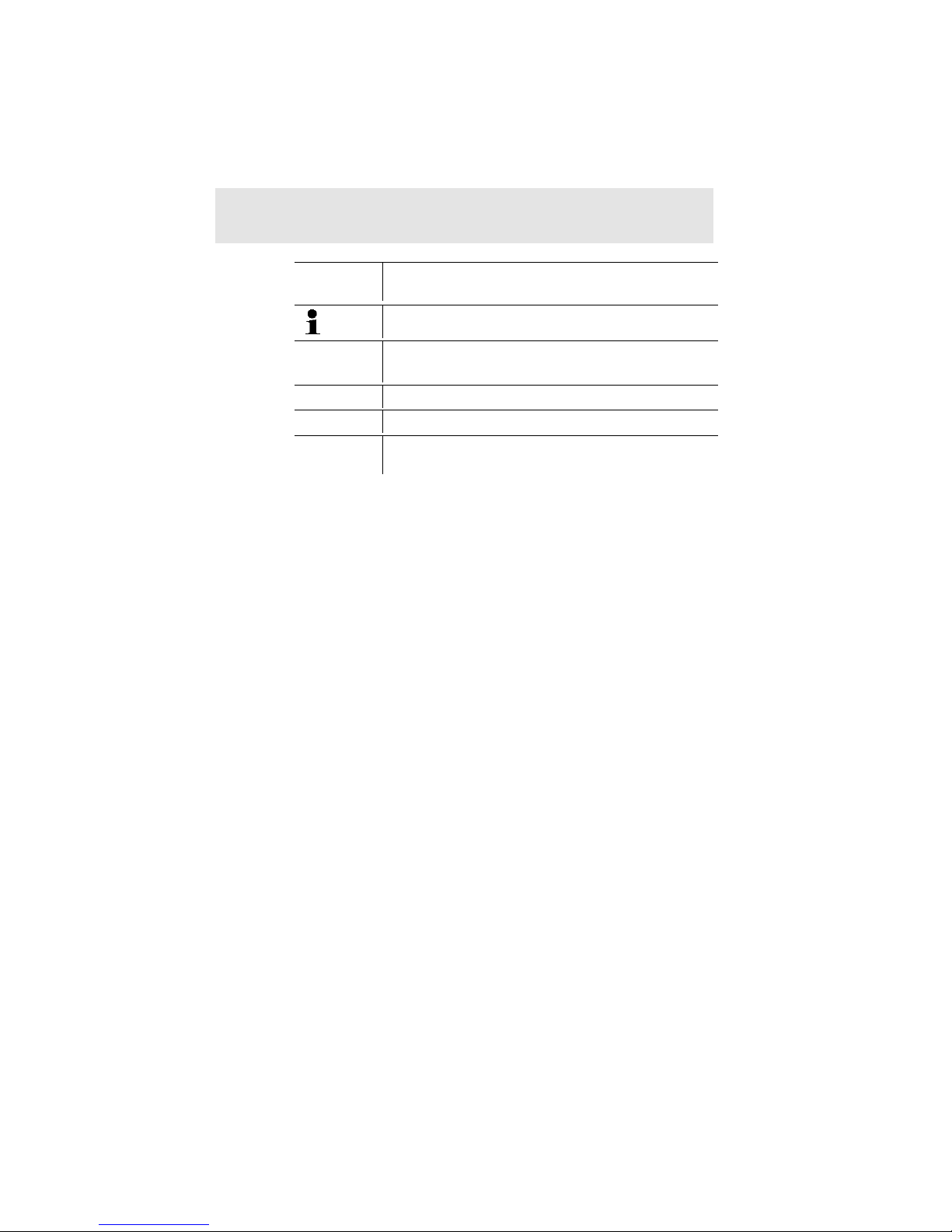

tation

Symbols and writing standards

Represen-

Explanation

Note: Basic or further information.

1. ...

2. ...

> ... Action: a step or an optional step.

- ... Result of an action.

Action: more steps, the sequence must be followed.

[OK] Control keys of the instrument or buttons of the

2.2. Ensure safety

program interface.

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

use any force.

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> Do not perform contact measurements on non-insulated, live

parts.

> The flue gas analyzer is not suitable for long-term

measurements and should not be used as a safety (alarm)

instrument.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts

from Testo.

> Any further or additional work must only be carried out by

authorised personnel. Testo will otherwise refuse to accept

responsibility for the proper functioning of the measuring

instrument after repair and for the validity of certifications.

> Only use the device in closed, dry rooms and protect it from rain

and moisture.

> Temperatures given on probes/sensors relate only to the

measuring range of the sensors. Do not expose handles and

feed lines to any temperatures in excess of 70 °C unless they

are expressly permitted for higher temperatures.

7

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 7

2 Safety and the environment

> The flue gas analyzer must be checked before

commissioning for any visible damage. Do not commission

the flue gas analyzer if there are signs of damage on the

housing, mains unit or supply lines. Electrical risk.

> Dangers may also arise from the systems being measured or

the measuring environment: Note the safety regulations valid in

your area when performing the measurements.

Use distilled water, or alternatively mild solvents such as

isopropanol to clean the flue gas analyzer. If using

isopropanol, please refer to the instruction leaflet for the

product. Isopropanol fumes have a slight narcotic effect,

and typically cause irritation of the eyes and sensitive

mucous membranes. When using it, please ensure that

there is adequate ventilation.

Do not store any objects that have come into contact with

solvents and/or degreasers (e.g. isopropanol) in the case.

Evaporating or leaking solvents and/or degreasers may

cause damage to the instrument and to the sensors.

The use of strong or harsh alcohol or brake cleaner can

result in damage to the instrument.

For products with Bluetooth® (optional)

Changes or modifications that have been made without the explicit

consent of the responsible approval authority, may cause the

retraction of the type approval.

Data transfer may be disturbed by equipment that uses the same

ISM-band, e.g. WLAN, microwave ovens, ZigBee.

The use of radio communication links is not permitted, among

others, in aeroplanes and hospitals. For this reason the following

points must be ensured before entering:

> Switch off the device:

> Isolate the device from any external power sources (mains

cable, external rechargeable batteries, ...).

2.3. Protecting the environment

> Dispose of faulty rechargeable batteries/spent batteries in

> At the end of its useful life, send the product to the separate

8

accordance with the valid legal specifications.

collection for electric and electronic devices (observe local

regulations) or return the product to Testo for disposal.

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 8

3 Specifications

3.1. Use

The flue gas analyzer is a handheld measuring device for the

professional flue gas analysis of combustion plants:

• Small combustion plants (burning oil, gas, wood, coal)

The solid fuel measurement adapter (0600 9765) is

required for measurements on solid fuel systems. The

adapter protects the measuring instrument from harmful

substances (dust, organic compounds, etc.).

• Low-temperature and condensing boilers

• Gas water heaters

These systems can be adjusted using the flue gas analyzer and

checked for compliance with the applicable limit values.

The following tasks can also be carried out with the flue gas

analyzer:

• Regulating the O2, CO and CO2 values in combustion plants

for the purpose of ensuring optimal operation.

• Draught measurement.

• Measuring and regulating the gas flow pressure in gas water

heaters.

• Measuring and optimising the flow and return temperatures of

heating systems.

• Ambient CO measurement (only possible with additional

ambient CO probe 0632 3331).

• Ambient CO measurement (only possible with additional

ambient CO probe 0632 1240).

• Detection of CH4 (methane) and C3H8 (propane) (only possible

with additional gas leak probe 0632 3370).

The Bluetooth

is type approved.

®

option may only be operated in countries in which it

3 Specifications

3.2. Technical data

3.2.1. Examinations

As declared in the certificate of conformity, this product complies

with Directive 2014/30/EC.

This product is TÜV-tested in compliance with 1. BImSchV. The

sensors 0393 0105 (CO, H2-compensated), 0393 0003 (O2),

9

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 9

3 Specifications

The use of the wireless module is subject to the regulations and

stipulations of the respective country of use, and the module may only be

used in countries for which a country certification has been granted. The

has the obligation to adhere to these regulations

sale, export,

import etc. in particular in countries without wireless permits, is his

responsibility.

Testo 320

0632 3220

23.02.2018

Country

Comments

Canada

contains IC 5123A-WT11U

IC Warnings

Europa + EFTA

The EU Declaration of Conformity

(IE), Italy (IT), Latvia (LV), Lithuania (LT), Luxembourg (LU),

temperature and pressure are TÜV-tested in accordance with EN

50379 part 2.

The measuring cell 0393 0053 (CO, not H2-compensated) is TÜVtested as per EN 50379 part 3.

This product is EMC-tested as per DIN EN 61326-1.

For official measurements in accordance with 1. BImSchV

(chimney sweeps), the measuring instrument must be checked

every six months by a technical testing body of the Guild of Master

Chimney Sweeps or another testing body recognised by the

authorities.

3.2.2. Bluetooth® module (option)

user and every owner

and prerequisites for use, and acknowledges that the re-

3.2.3. Licenses

Product

Mat.-No.

Date

(Länderliste einfügen)

10

can be found on the testo

EU countries:

Belgium (BE), Bulgaria (BG), Denmark (DK), Germany (DE),

Estonia (EE), Finland (FI), France (FR), Greece (GR), Ireland

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 10

3 Specifications

Malta (MT), Netherlands (NL), Austria (AT), Poland (PL),

Iceland, Liechtenstein, Norway, Switzerland

Japan

Japan Information

Turkey

Authorized

USA

FCC Warnings

Radio module

Feature

Values

Bluetooth Range

<10 m (free

field)

Bluetooth type

Bluegiga

Module

Qualified Design ID

22298

Declaration ID

B016141

Bluetooth radio

class

Class 1

Bluetooth company

Silicon

Inc.

RF Band

2402 - 2480

MHz

Nominal output

power

17 dBm

Portugal (PT), Romania (RO), Sweden (SE), Slovakia (SK),

Slovenia (SI), Spain (ES), Czech Republic (CZ), Hungary (HU),

United Kingdom (GB), Republic of Cyprus (CY).

EFTA countries:

contains FCC ID: QOQWT11U

IC Warnings

RSS-Gen & RSS-247 statement:

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause interference, and

11

WTT11u

Bluetooth

Laboratories

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 11

3 Specifications

(2) this device must accept any interference, including interference that may cause undesired

operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes :

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

Caution: Radio Frequency Radiation Exposure

This equipment complies with IC radiation exposure limits set forth for an uncontrolled

environment and meets the IC radio frequency (RF) Exposure Guidelines. This equipment should

be installed and operated keeping the radiator at least 20 cm or more away from person´s body in

normal use position.

Co-Location:

This transmitter must not be co-located or operated in conjunction with any other antenna or

transmitter.

Attention : exposition au rayonnement de radiofréquences

Cet équipement est conforme aux limites d'exposition aux radiofréquences IC fixées pour un

environnement non contrôlé et aux Lignes directrices relatives à l'exposition aux radiofréquences

(RF). Cet équipement devrait être installé et utilisé à une distance d'au moins 20 cm d'un radiateur

ou à une distance plus grande du corps humain en position normale d'utilisation.

Co-location

Ce transmetteur ne peut pas être installé en colocation ou être utilisé avec une autre antenne ou

transmetteur, quel qu'en soit le type.

FCC Warnings

Information from the FCC (Federal Communications Commission)

For your own safety

Shielded cables should be used for a composite interface. This is to ensure continued protection

against radio frequency interference.

FCC warning statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

12

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 12

3 Specifications

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

Caution

Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment. Shielded interface cable must be used in

order to comply with the emission limits.

Warning

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation

Caution: Radio Frequency Radiation Exposure

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment and meets the FCC radio frequency (RF) Exposure Guidelines. This equipment should

be installed and operated keeping the radiator at least 20 cm or more away from person´s body in

normal use position.

.

Japan Information

当該機器には電波法に基づく、技術基準適合証明等を受けた特定

無線設備を装着している。

3.2.4. Declaration of Conformity

You can find the EU declaration of conformity on th

13

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 13

3 Specifications

Flue gas loss

0 to 99.9 %

0.1 %

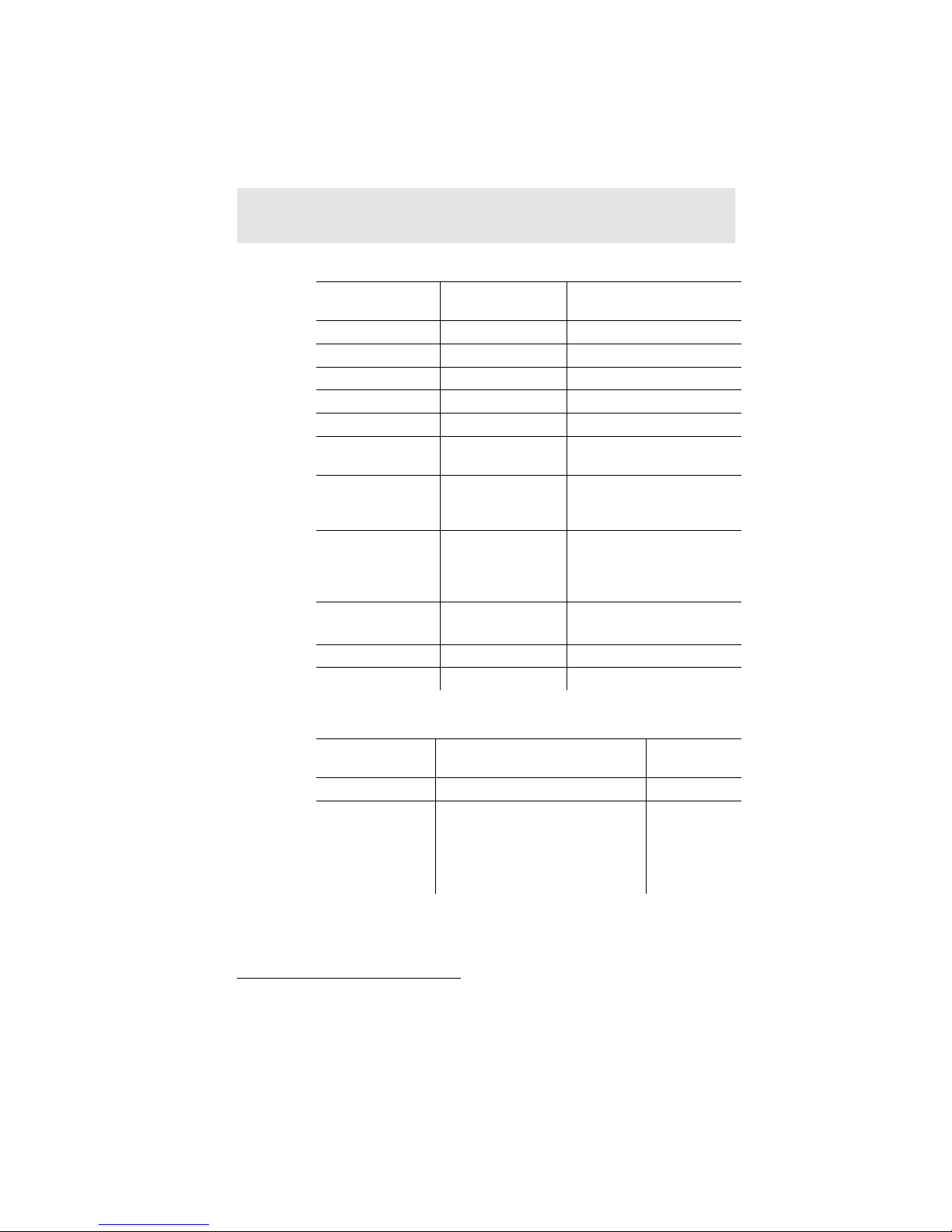

3.2.5. Measurement ranges and resolution

Measurement

parameter

O2 0 to 21 Vol.% 0.1 vol.%

CO 0...4000 ppm 1 ppm

CO, H2-comp.

COlow, H2-comp. 0 to 500 ppm 0.1 ppm

Draught1 -9.99 to 40.00 hPa 0.01 hPa

Fine draught1 -9.999 hPa to

ΔP (only with gas

pressure set 0554

1203)

Fine pressure1

(only with gas

pressure set 0554

1203)

temperature -40 to 1200°C 0.1°C (-40.0 to 999.9°C)

Efficiency 0 to 120 % 0.1 %

Measuring range Resolution

0 to 8000 ppm 1 ppm

+40.000 hPa

0 to 300 hPa 0.1 hPa

0 to 300 hPa 0.01 hPa

0.001 hPa

1°C (from 1000°C)

3.2.6. Accuracy and response time

Measurement

parameter

O2 ±0.2 vol.% < 20 s

CO

1

Depending on the country version

14

Accuracy Response

±20 ppm (0 to 400 ppm)

±5% of meas. val. (401 to 2000

ppm)

±10% of meas. val. (2001 to

4000 ppm)

time (t

< 60 s

)

90

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

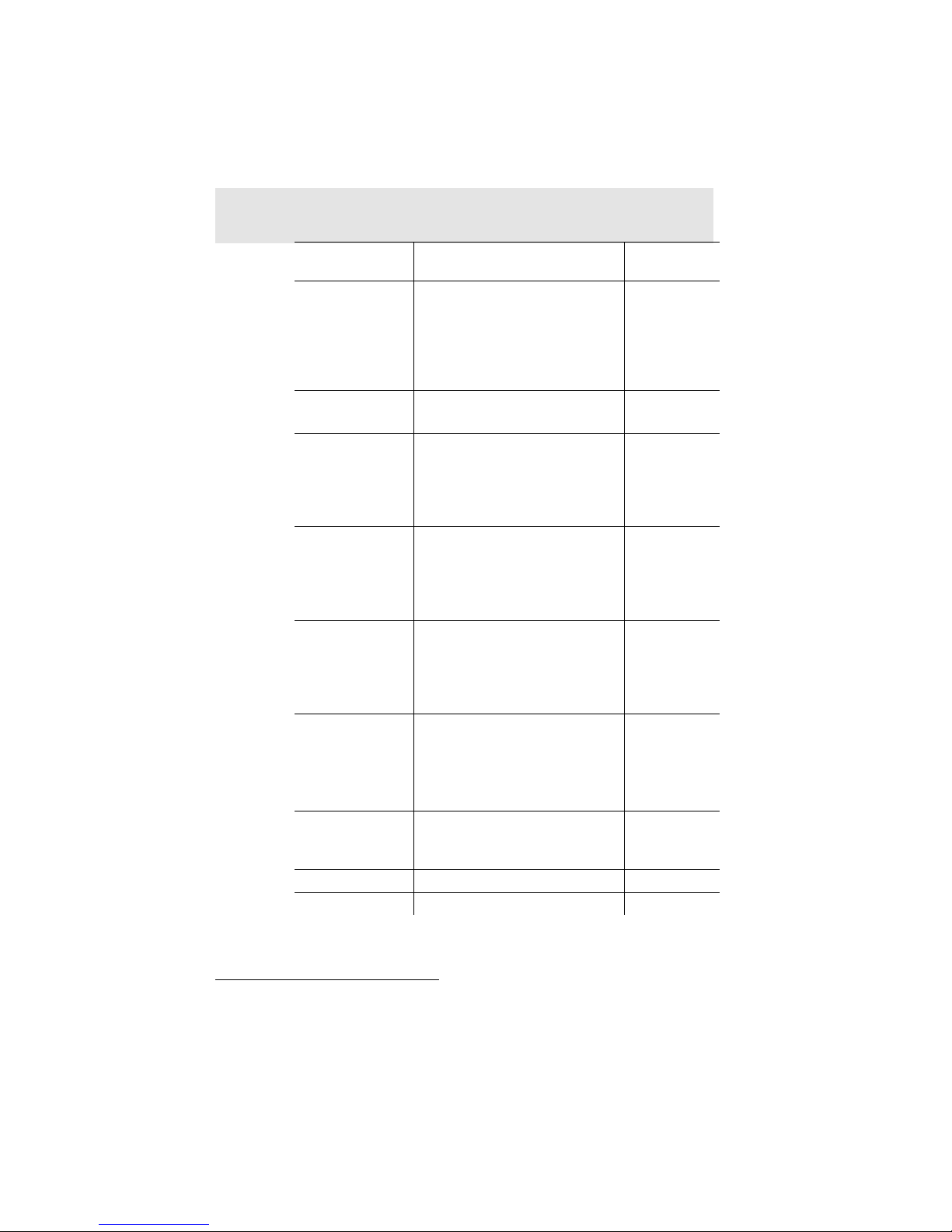

Page 14

3 Specifications

parameter

time (t90)

pressure set 0554

pressure set 0554

Measurement

Accuracy Response

CO, H2-comp. ±10 ppm or ±10% of meas. val.2

(0 to 200 ppm)

2

±20 ppm or ±5% of meas. val.

(201 to 2000 ppm)

±10% of meas. val. (2001 to

8000 ppm)

COlow, H2-comp. ±2 ppm (0 to 39.9 ppm)

±5% of meas. val.

Draught1 ±0.02 ppm or ±5% of meas. val.

(rest of range)

2

(-0.50 to 0.60 hPa)

± 0.03 hPa (0.61 to 3.00 hPa)

±1.5% of meas. val. (3.01 to

40.00 hPa)

Fine draught1 ±0.02 ppm or ±5% of meas. val.

2

(-0.50 to 0.60 hPa)

± 0.03 hPa (0.61 to 3.00 hPa)

±1.5% of meas. val. (3.01 to

40.00 hPa)

ΔP (only with gas

± 0.5 hPa (0.0 to 50.0 hPa)

±1% of meas. val.

1203)

(50.1 to 100.0 hPa)

±1.5% of meas. val. (rest of

range)

Fine pressure1

(only with gas

1203)

± 0.5 hPa (0.0 to 50.0 hPa)

±1% of meas. val.

(50.1 to 100.0 hPa)

±1.5% of meas. val. (rest of

range)

temperature ± 0.5°C (0.0 to 100.0°C)

±0.5% of meas. val. (rest of

range)

Efficiency - Flue gas loss - -

< 40 s

< 40 s

-

-

depending on

the probe

2

higher value is valid

15

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 15

3 Specifications

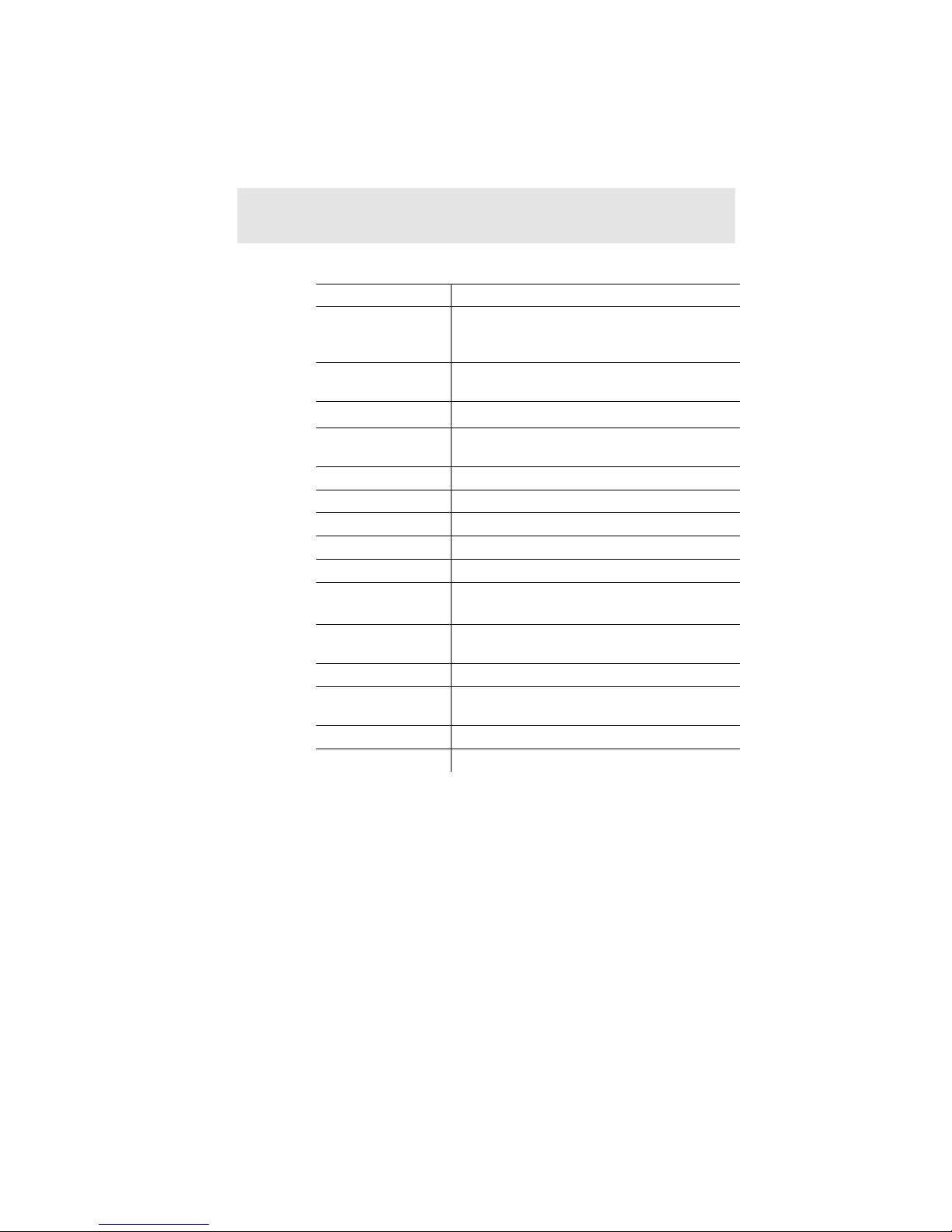

3.2.7. Other instrument data

Feature Values

Storage and

-20 to 50°C

transport

temperature

Operating

-5 to 45°C

temperature

Ambient humidity

0…90 % rH, not condensing

Power supply Rech. batt.: 3.7 V / 2.4 Ah

Mains unit: 5.0 V/1000 mA

Protection class IP40

Weight 573 g

Dimensions 240 x 85 x 65 mm

Memory 500 measured values

Display Graphic colour display, 240 x 320 pixels

Gas leak testing

probe

Optimum rech. batt.

storage conditions

visual indication (LED)

audible indication by buzzer

Charge level: capacity at 50-80% ambient

temperature: 10-20°C

Battery charge time Approx. 5-6 h with mains unit supplied

Rechargeable

battery life

Approx. 6 h (pump on, 20°C ambient

temperature)

Data transfer IrDA, USB, Bluetooth® (option)

Bluetooth® (option) Range < 10 m

16

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 16

4 Product description

4.1. Case 0516 3300 (accessory)

Recommended for stowing away the measuring instrument and

accessories (example)

4.1.1. Bottom level view

4 Product description

1 Sealing clip

2 Flue gas analyser testo 320

3 Repository for printer accessories

• Spare batteries for IRDA printer

• 1 roll of spare thermal paper (0554 0568)

4 Repository for printer

• IRDA printer (0554 0549)

• • Bluetooth

5. Instruction manual

6 Lock testo 320

7 Probes

17

®

/IRDA printer (0554 0620)

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 17

4 Product description

• Flue gas probe (e.g. 0600 9741)

• Pitot tube for heating check (0635 2050)

8 Large storage compartment

• Mains unit fortesto 320 (0554 1105)

• Differential temperature set (0554 1208)

• Spare dirt filter (0554 0040)

9 Round storage compartment

• Hose connection set with pressure adapter (0554 1203)

4.1.2. Top level view

1 Soot pump set (0554 0307)

2 Storage compartment

3 Storage compartment

18

• Fine pressure probe (0638 0330)

• Capillary hose set for fine pressure probe (0554 1215)

• Connecting cable for surface probe (0430 0143)

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 18

4 Combustion air temperature probe (0600 9787)

5. Surface temperature probe Type K (0604 0994)

4.2. Case 0516 3301 (accessory)

Recommended for stowing away the measuring instrument and

accessories (example)

4.2.1. Bottom level view

4 Product description

1 Fine pressure probe (0638 0330)

2 testo 308 smoke tester (0632 0308)

19

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 19

4 Product description

4.2.2. Middle level view

20

1 Sealing clip

2 testo 330-1 /-2 LL flue gas analyzer

3 Repository for printer accessories

• Spare batteries for IRDA printer

• 1 roll of spare thermal paper (0554 0568)

4 Repository for printer

• IRDA printer (0554 0549)

• Bluetooth

5. Instruction manual

6 Lock

7 Probes

• Flue gas probe (e.g. 0600 9741)

• Pitot tube for heating check (0635 2050)

8 Large storage compartment

®

/IRDA printer (0554 0620)

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 20

• Mains unit for testo 330-1 /-2 LL (0554 1096)

• Differential temperature set (0554 1208)

• Spare dirt filter (0554 0040)

9 Round storage compartment

• Hose connection set with pressure adapter (0554 1203)

4.2.3. Top level view

4 Product description

1 Soot pump set (0554 0307)

2 Storage compartment

• Fine pressure probe (0638 0330)

3 Storage compartment

• Capillary hose set for fine pressure probe (0554 1215)

• Connecting cable for surface probe (0430 1215)

4 Combustion air temperature probe (0600 9787)

5. Surface temperature probe Type K (0604 0994)

21

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 21

4 Product description

[ ]

4.3. Measuring instrument

4.3.1. Front view

1 Display

2 Function keys

3 Keypad

4.3.2. Keypad

22

Button Functions

Switch measuring instrument on / off

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 22

Button Functions

Function key (orange, 3x), relevant function is shown on

[esc]

Back, cancel function

[ ]

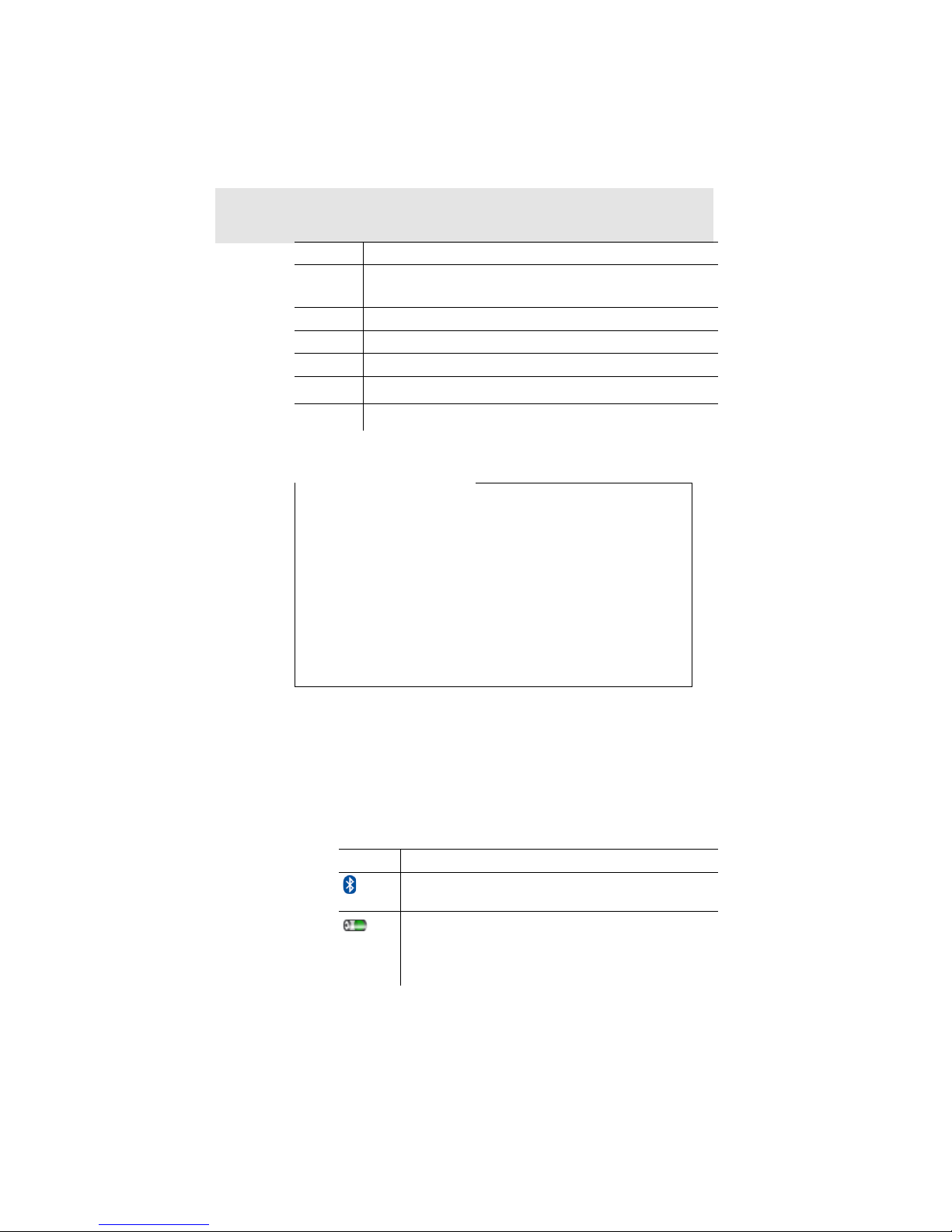

Icon

Feature

[OK]

Example

[▲] Scroll up, increase value, navigate

[▼] Scroll down, reduce value, navigate

[ ]

4.3.3. Display

4 Product description

the display

Open main menu

Transmit data to the Testo protocol printer.

1 Status bar (dark grey background):

• Warning symbol (only if there is an instrument error,

display of error in instrument diagnosis menu), otherwise:

Instrument designation.

• Symbol (only if data is stored in the temporary memory).

• Display of date and time.

• Indication of Bluetooth

®

status, power supply and remaining

rechargeable battery capacity:

blue symbol = Bluetooth® on,

grey symbol = Bluetooth

Battery operation

®

off

Display of remaining rechargeable battery

capacity by colour and fill level of the battery icon

(green = 5-100%, red = < 5%)

23

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 23

4 Product description

Icon Feature

Mains operation

Display of remaining rechargeable battery

capacity: see above

2 Info field of register tabs: Indication of selected

address/location, chosen fuel, chosen measurement type.

3 Selection field for functions (selected function appears against a

white background, unavailable functions are identified by grey

font) or display of measured values.

4.3.4. Instrument connections

4 Function display for function keys.

1 Probe socket

2 Gas outlet

3 Probe socket

4 Micro USB socket (battery charging, data transfer)

4.3.5. Condensate outlet and interfaces

24

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 24

1 Infrared interface (IrDA)

2 Bluetooth interface (option)

3 Condensate outlet

4.3.6. Rear view

4 Product description

1 Attachment for carrying strap

2 Condensate trap

3 Magnetic holder

25

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 25

4 Product description

WARNING

Magnetic field

May be harmful to those with pacemakers.

> Keep a minimum distance of 15 cm between pacemaker and

instrument.

ATTENTION

Magnetic field

Damage to other devices!

> Keep a safe distance away from products which could be

damaged by the effects of magnetism (e.g. monitors,

computers or credit cards).

4 Service lid

4.3.7. Components

26

1 Rechargeable battery

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 26

2 Measured gas pump

3 Slot for O2 sensor

4 Slot for CO sensor, COlow sensor or CO, H2-compensated

sensor

4.4. Compact flue gas probe

1 Removable filter chamber with window and particle filter

2 Probe handle

3 Connector plug for measuring instrument

4 Connecting cable

4 Product description

4.5. Modular flue gas probe

1 Removable filter chamber with window and particle filter

2 Lock release

3 Probe module

4 Connector plug for measuring instrument

5 Probe handle

6 Connecting cable

27

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 27

5 First steps

5 First steps

5.1. Commissioning

The measuring instrument is supplied with a rechargeable battery

already fitted.

> Charge the rechargeable battery fully before using the

5.2. Getting to know the product

measuring instrument, see Charging the battery, page 61.

5.2.1. Mains operation

If the mains unit is connected, the measuring instrument is

automatically powered from the unit.

1. Connect the mains unit instrument plug to the instrument's

micro USB socket.

2. Connect the mains plug of the mains unit to a mains socket.

During mains operation the battery is charged

automatically.

5.2.2. Connecting probes

Probe detection at the flue gas socket is carried out

continuously. New probes are recognised automatically.

Connect a probe to the probe socket before switching on

the measuring instrument or start sensor detection

manually after changing the probe: [Options] → Sensor

detection.

Connecting flue gas probes/gas pressure

adapters/temperature adapters

28

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 28

5 First steps

1201) between measuring instrument and flue gas probe.

> Insert the connector plug into the flue gas socket and lock by

slightly turning it clockwise (bayonet lock).

There must be no more than one extension lead (0554

Connecting other sensors

5.2.3. Switching on

> Press [ ].

- The start screen is displayed (duration: approx 15 s).

- During commissioning, when the instrument is switched on, the

Country version menu is displayed.

Set the country version:

1. Select the country version: [▲], [▼] → [OK].

2. Confirm confirmation request: Yes → [OK]

- The flue gas analyzer switches off.

3. Restart instrument: Press [ ].

- If the voltage supply was interrupted for a longer period: The

Date/time menu opens.

- The gas sensors are zeroed.

- There is an instrument error: The Error diagnosis is displayed.

- The Measurement options menu is displayed.

5.2.4. Calling up the function

1. Select function: [▲], [▼].

- The selected function appears in a frame.

2. Confirm selection: [OK].

- The selected function is opened.

> Insert the connector plug of the probe into the probe socket.

29

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 29

5 First steps

5.2.5. Entering values

Some functions require values (numbers, units, characters) to be

entered. Depending on the selected function, the values are

entered either via a list field or an input editor.

List field

1. Select the value to be changed (numerical value, unit): [▲],

[▼], [◄], [►] (depending on the selected function).

2. Press [Edit].

3. Set value: [▲], [▼], [◄], [►] (depending on the selected

function).

4. Confirm the entry: [OK].

5. Repeat steps 1 and 4 as required.

6. Save the entry: [Finished].

30

Input editor

1. Select the value (character) to be changed: [▲], [▼], [◄], [►].

2. Apply value: [OK].

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 30

Options:

> Toggle between upper/lower case:

select Ι← ABC→&$/ →Ι: [▲], [▼] → [ABC→&$/].

> Position the cursor in the text:

select Ι← ABC→&$/ →Ι: [▲], [▼] → [Ι←] or [→Ι].

> Delete character before or after the cursor:

select ← next → [▲], [▼] → [←] or [→].

3. Repeat steps 1 and 2 as required.

4. Save the entry: Select ← next → [▲], [▼]

5.2.6. Printing/saving data

Data is printed out via the key [ ]. Data is saved via the Options

menu. The Options menu is accessed via the left function key and

is available in many different menus.

To assign the right function key with the Save function or see

Assigning the right function key, page 36,

Only readings assigned a display field in the measurement view will

be saved / printed out.

The measurement data can be printed out parallel to the

saving process, while a measurement program is running.

To be able to transfer data to a record printer via infrared or

Bluetooth interface, the printer used must be enabled, see Printer,

page 40.

Graph charts can be printed out using the Bluetooth® /

IRDA printer 0554 0620.

5 First steps

→ [Next].

5.2.7. Saving data to the clipboard (temporary memory)

Using the clipboard, measurement results from various

measurement types can be combined to produce a common

record, which can then be printed out (see above). Data is saved to

the clipboard via the Options menu and the Clipboard command.

If there is data in the clipboard, the status bar shows the symbol .

If there is data in the clipboard and the Print command is triggered,

all data in the clipboard will be printed out.

> [Options] → Delete clipboard: Any data saved to the

clipboard is deleted.

5.2.8. Confirming an error message

If an error occurs, an error message is shown on the display.

> Confirming an error message: [OK].

31

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 31

5 First steps

Errors that have occurred but have not yet been rectified are

indicated by a warning symbol ( ) in the header.

Error messages that have not yet been cancelled can be displayed

in the Error diagnosis menu, see Instrument diagnosis, page 35.

5.2.9. Switching off

Unsaved measured values are lost if the flue gas analyser

is switched off.

> Press [ ].

- Depending on the instrument status, the pump starts and the

sensors are rinsed until the switch-off thresholds (O

other measurement parameters < 50 ppm) are reached. Rinsing

lasts no more than 3 minutes.

- The measuring instrument switches off.

5.3. Address/Location

All measuring values can be saved under the currently active

location. Measuring values that have not been saved are lost when

the measuring instrument is switched off!

Addresses and locations can be created, edited, copied and

enabled. Addresses and locations (incl. protocols) can be deleted.

Call up function:

> [ ] → Address/Location → [OK].

> 20 %,

2

There are various options for opening address.

1. Edit search setting: [Edit].

2. Select search setting: [▲], [▼] → [OK].

Possible settings:

• Show all: All address/location are displayed.

• Search: A search text only brings up address/location that

contain characteristics of the search text.

• Filter: Individual letters or numbers can be selected. All data

beginning with the relevant letter/number is displayed.

The initial letter is the determining factor for the filter

function, and this can only be selected individually. The

search function can also be used to find a series of

several letters within the address!

3. Carry out search according to search setting: [Search]

32

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 32

5 First steps

Show all

1. Select address: [▲], [▼].

2. Show details: [Details].

3. Enable a location: select the location → [OK].

- The location is activated.

> Open measurements menu: press [OK] again.

Search

1. Edit search criteria: [►] → [Edit].

2. Select search criteria: [▲], [▼] → [OK].

Possible options:

• Contact person

• Address

• Town/city

• Postcode

• Street

- The selected criterion is displayed.

3. Call up entry field for search text: [►] or [▼]

> Enter search text → [Finished]

Do not use the special character * as a placeholder.

Filter

1. Edit search criteria: [Edit].

2. Select search criteria: [▲], [▼] → [OK].

Possible options:

• Contact person

• Address

• Town/city

• Postcode

• Street

- The selected criterion is displayed.

3. Enable tab: [▼]

4. Select the required tab: [▲], [▼] and sometimes [◄], [►]→

[Filter].

- The search result for the relevant letter or number is displayed.

Create a new measuring location:

A location is always created under an address.

1. Select the address in which the location is to be created.

33

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 33

5 First steps

2. [Options] → New/Location → [OK].

3. Enter values or make settings.

4. Finalise the entry: [Finished].

Other location options:

> [Options] → Edit location: make changes to an existing

location.

> [Options] → Copy location: make a copy of an existing

location in the same address.

> [Options] → Delete location: delete an existing location.

Create new address:

1. [Options] → New address → [OK].

2. Enter values or make settings.

3. Finalise the entry: [Finished].

Other address options:

• Edit address: make changes to an existing folder.

• Copy address: make a copy of an existing folder.

• Delete address: delete an existing folder, including the

locations created therein.

• Delete All addresses: delete all existing folders, including the

locations created in them.

5.4. Measurement records

Call up function:

> [ ] → Measurement records → [OK].

There are various options for opening records. see

Address/Location, page 32.

Displaying a record:

1. Choose the required record from the detailed view.

2. Print [Data].

Printing all records for a location:

1. Select measuring location: [▲], [▼]

2. Start printout: [ ].

- All records for the location are printed out.

Options:

> [Options] → Delete Record: delete the selected record.

34

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 34

> [Options] → Delete all Records: delete all saved records for a

location.

5.5. Instrument diagnosis

Important operating values and instrument data are displayed. The

status of the sensors and any instrument errors not yet rectified can

be displayed.

Call up function:

> [ ] → Instrument diagnosis → [OK].

Displaying instrument errors:

> Error diagnosis→ [OK].

- Unrectified errors are displayed.

> Display next/previous error: [▲], [▼].

Displaying sensor diagnosis:

1. Sensor diagnosis → [OK].

2. Select sensor. [▲], [▼].

- The status of the sensor is indicated by a traffic light.

A sensor is able to recover. The sensor status indication

may therefore change from yellow to green or from red to

yellow.

5 First steps

Displaying instrument information

> Device information → [OK].

- Information is displayed.

35

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 35

6 Using the product

First steps

6 Using the product

6.1. Performing settings

6.1.1. Assigning the right function key

The right function key can have a function from the Options menu

assigned to it. The menu Options is accessed via the left function

key and is available in many different menus. This assignment is

only valid for the currently opened menu / the opened function.

✓ A menu / function is opened in which the Options menu is

6.1.2. Instrument settings

displayed on the left function key.

1. Press [Options] .

2. Select option: [▲], [▼].

Depending on the menu / function from which the Options menu

was opened, the following functions are available.

3. Assign the selected function to the right function key: Press

[Config. Key].

It is assumed that the contents of the chapter First steps

(see

, page 28) are known.

Calling up a function:

> [ ] → Device Settings.

see First steps, page 28

6.1.2.1. Measurement view

The parameters/units and the display (number of measured values

shown per display page) can be set.

The settings are only valid for the currently chosen measurement

type, which is indicated by the symbol in the info field.

Total overview of selectable measurement parameters and units

(available selection depends on the set country version and

selected measurement type):

Display Measurement parameter

FT Flue gas temperature

AT Combustion air temperature

GT Instrument temperature

36

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 36

6 Using the product

Display Measurement parameter

O2 Oxygen

CO2 Carbon dioxide

qA+ Flue gas loss with due consideration of the

calorific value range

η+ Efficiency with due consideration of the calorific

value range

CO Carbon monoxide

COunv Carbon monoxide undiluted

λ Air ratio

COumg Ambient carbon monoxide

CO2um Ambient carbon dioxide

O2ref Oxygen reference

Draught Draught measurement

ΔP Differential pressure measurement

E draught External draught (external micro pressure

probe)

E-ΔP External differential pressure (external micro

pressure probe)

cCO Carbon dioxide reduction

ExAir Air surplus

qA Flue gas loss without due consideration of the

calorific value range

η Efficiency without consideration of the heat

value range

Dew Pt Flue gas dew point temperature

Nett Differential temperature

GI Toxin index

ET qA+ - qA

37

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 37

6 Using the product

Parameter

Unit

Altitude

m, ft

Calling up the function:

> [ ] → Device settings → [OK] → Measurement view →

[OK]

Changing the parameter/unit in a line:

1. Select the line: [▲], [▼] → [Edit]

2. Select the parameter: [▲], [▼] → [OK]

3. Select the unit: [▲], [▼] → [OK]

4. Save changes: [OK]

Options:

> [Options] → Number of lines: change the number of

measured values per display page.

> [Options] → Blank line: insert a blank line in front of the

selected line.

> [Options] → Delete line: delete the selected line.

> [Options] → Factory setting: reset the measured value

display to the factory settings.

6.1.2.2. Alarm limits

Alarm limits can be set for several display parameters. An audible

alarm signal is triggered when the alarm limit is reached.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Alarm Limits → [OK]

Switching alarm signals on / off, changing alarm limits:

1. Select function or parameter: [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and partly [◄], [►] → [OK].

3. Save changes: [Finished].

> Reset the enabled value to the factory setting: [Standard].

6.1.2.3. Units

The units used for parameters in configuration menus can be set.

Call up function:

> [ ] → Device settings → [OK] → Units → [OK].

38

Adjustable units

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 38

Parameter Unit

Pressure mbar, hPa

1. Select the line: [▲], [▼]→ [Edit].

2. Select the unit to be changed: [▲], [▼] → [OK].

3. Confirm the entry: [Finished].

6.1.2.4. Date / time

Date, time mode and time can be set.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Date/Time → [OK]

Setting date/time:

1. Select parameter: [◄], [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and partly [◄], [►] → [OK].

3. Save changes: [Save].

6.1.2.5. Energy management

Automatic instrument shutdown (Auto-Off) and switching off of the

display light in battery operation can be set.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Energy Management

→ [OK]

6 Using the product

Making settings:

1. Select function or parameter: [▲], [▼] → [Edit].

2. Set parameter: [▲], [▼] and partly [◄], [►] → [OK].

3. Save changes: [Finished].

6.1.2.6. Display brightness

The intensity of the display illumination can be set.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Display Brightness →

[OK]

Performing settings

> Set parameter: [◄], [►] → [OK].

6.1.2.1. Choose measurement type

Individual measurement types can be shown or hidden. These are

displayed or hidden accordingly under Measurement options.

Call up function:

39

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 39

6 Using the product

> [ ] → Device settings → [OK] → Choose measurement

type → [OK].

Show or hide measurement types:

1. Select measurement type: [▲], [▼]

2. Enable / disable measurement type: [ ] (enabled), [ ]

(disabled)

3. Save selection: [Finished].

6.1.2.2. Printer

The headers (lines 1-3) and the footers for the printout can be set.

The printer that is used can be activated.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Printer → [OK]

Activating the printer:

1. Select Printer → [OK].

2. Select the printer: [▲], [▼] → [OK].

- The printer is activated and the menu Printer is opened.

The printer 0554 0543 can only be selected after the

Bluetooth

Bluetooth

®

-interface has been activated, see

®

, page 40.

Configuring the print text:

1. Print text → [OK].

2. Select function: [▲], [▼] → [Edit].

> Enter values for Line 1, Line 2, Line 3 and the Footnote

> Print out system data and/or customer data: [ ]

3. Save the entry: select [Finished].

see Bluetooth

6.1.2.3. Bluetooth®

This menu is only available if the instrument is equipped with

Bluetooth. The Bluetooth module can be switched on / off.The relay

40

can now be tested.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Bluetooth → [Edit].

Making settings:

> Set parameter → [OK].

®

, page 40

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 40

6.1.2.4. Language

The menu language can be set. The number of available

languages depends on the activated country version, see Country

version, page 41.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Language → [OK]

Activating the language:

> Select the language → [OK].

see Country version, page 41

6.1.2.5. Country version

Changing the country version may alter the basis for calculation

and therefore also the displayed measurement parameters, fuels,

fuel parameters and calculation formulas.

The selection of the country version influences the menu languages

that can be enabled.

Calling up the function:

> [ ] → Instrument Settings → [OK] → Country Version →

[OK]

This action can be password protected. A password is

specified in the menu Password Protection, see

Password protection, page 42.

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

6 Using the product

Setting the country version:

1. Select the country version: [▲], [▼] → [OK].

2. Confirm the confirmation request: Yes → [OK]

- The system is restarted.

see Password protection, page 42

41

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 41

6 Using the product

6.1.2.6. Password protection

The password protection is only valid for functions identified by the

following symbol: or .

Password protection can be activated / deactivated, the password

can be changed.

To deactivate the password protection change the password to

0000 (factory setting).

Calling up the function:

> [ ] → Instrument Settings → [OK] → Password Protection

→ [OK]

Possibly:

> Enter the currently valid password:

[Enter] → Enter password → [Next] → [OK].

Changing the password:

1. [Edit].

2. Enter the new password → [Next].

3. [Edit].

4. Enter the new password again to confirm → [Next].

5. Save changes: [Finished].

6.1.3. Sensor settings

6.1.3.1. O2 reference

The O2 reference value can be set.

The O2 reference value setting may be password protected, see

Password protection, page 42.

Call up function:

> [ ] → Sensor settings → O2 reference → [Edit].

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

Setting the O

> Set value → [OK].

42

reference:

2

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 42

6.1.3.2. Sensor protection

WARNING

Protection limits can be set to protect the sensors against overload.

Sensor protection switch-off is available for the CO sensor.

Sensor protection is activated if the threshold is exceeded.

To disable sensor protection, the threshold values must be set to 0

ppm.

Call up function:

> [ ] → Sensor settings → Sensor protection → [OK].

Setting sensor protection thresholds:

1. Select parameter: [Edit].

2. Set value → [OK].

3. Save changes: [Finished].

6.1.3.3. Recalibration/adjustment

The CO sensor can be recalibrated and adjusted.

For recalibration/adjustment, Testo recommends using calibration

adapter 0554 1205 or sending the instrument off to Testo Customer

Service.

If obviously unrealistic measured values are displayed, the

sensors should be checked (calibrated) and, if required,

adjusted.

Adjustments made with low gas concentrations can lead to

accuracy deviations in the upper measuring ranges.

Call up function:

> [ ] → Sensor settings → Recalibration → [OK].

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

- Gas zeroing (30 s).

6 Using the product

Performing recalibration/adjustment:

Dangerous gases

Danger of poisoning!

> Observe safety regulations/accident prevention regulations

> Use test gases in well ventilated rooms only.

1. Connect the calibration adapter to the flue gas socket.

43

when handling test gas.

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 43

6 Using the product

2. Enable CO measurement parameter: [OK].

3. [Edit] → Enter the test gas concentration (nominal value).

4. Attach the connecting line of the test gas bottle to the

calibration adapter.

5. Apply test gas to the sensor.

6. Start recalibration: [Start].

7. Apply the target value once the actual value is stable

(adjustment): [OK].

-or-

Cancel (no adjustment): [esc].

8. Save changes: [Finished].

6.1.4. Fuels

The fuel can be selected. The fuel-specific coefficients and limits

can be set.

Call up function:

> [ ] → Fuels → [OK].

In order to maintain the measuring accuracy of the

instrument, the correct fuel must be selected or configured.

Correct representation of measuring results is only

assured if the threshold values for the ideal range of the

corresponding measurement task have been set correctly.

The pre-set threshold values are typical values for the

selected system type and the chosen type of fuel.

44

Activating fuels:

> Select the fuel → [OK].

- The fuel is activated and the main menu is opened.

Setting coefficients:

1. Select the fuel → [Coeff.].

2. Select the coefficients: [Edit].

Possibly:

> Enter the password: [Enter] → Enter password → [Next] →

[OK].

3. Set values → [OK].

4. Save changes: [Finished].

Setting limits:

1. Select limit → [Edit].

2. Set values → [OK].

3. Save changes: [Finished].

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 44

6.2. Measuring

6.2.1. Preparing for measurement

The First steps chapter (see First steps, page 28) must

have been read.

6.2.1.1. Testing for leaks

The entire measurement system (probe, condensate trap, hoses

and connections) must be tested for leaks before each

measurement to avoid incorrect measurements due to the

infiltration of external air. Testing is carried out while the pump is

running and may be performed by attaching a compressed balloon

pump. The measurement system is leak-tight if the balloon pump is

not filled with air.

6.2.1.2. Zeroing phases

Measuring the combustion air temperature

If no combustion air temperature probe is connected, during the

zeroing phase, the measured temperature of the flue gas probe is

taken as the combustion air temperature.

The flue gas probe should not be in the flue gas duct

during the zeroing phase.

All dependent parameters are calculated using this value. This

method of measuring combustion air temperature is sufficient for

systems dependent on ambient air.

If a temperature probe is connected, the combustion air

temperature is measured continuously via this probe.

6 Using the product

Gas zeroing

When the instrument is switched on, the measurement menu is

opened and the gas sensors are zeroed.

Draught/pressure zeroing

The pressure sensors are zeroed when a pressure measuring

45

function is called up.

The flue gas probe must be in fresh air during the zeroing

phase!

The flue gas probe must be in the fresh air during the

zeroing phase / the instrument must not be pressurised

during zeroing.

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 45

6 Using the product

6.2.1.3. Using flue gas probe

Checking the thermocouple

The thermocouple of the flue gas probe must not lie against the

probe cage.

> Check before use. Bend the thermocouple back if necessary.

Aligning the flue gas probe

The flue gas must be able to flow freely past the thermocouple.

> Align the probe by turning it as required.

The tip of the probe must be in the centre of the flue gas flow.

> Align the flue gas probe in the flue gas duct so that the tip is in

the core current (area of the highest flue gas temperature).

6.2.1.4. Measurement view

Only those measurement parameters and -units that are enabled in

the reading display appear in the reading display, in the saved

measurement records and on record printouts.

> Before carrying out measurements, set up the measured value

display in such a way that the required parameters and units

are enabled, see Measurement view, page 36.

46

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 46

6.2.1.5. Setting the location and fuel

measurement

Before carrying out measurements, the location and fuel must be

correctly selected, see Address/Location, page 32

6.2.2. Flue gas

and see Fuels, page 44.

To achieve usable measurement results, the

period of a flue gas measurement should be approx. 3 min

and the measuring instrument should display stable

measuring values.

Call up function:

1. [ ] → Measurement options → [OK] → Flue Gas → [OK].

2. Select the fuel → [OK].

Carrying out the measurement:

1. Start measurement: [ ].

If a separate measurement of CO undiluted has not yet

been carried out, this value is calculated using the

measured values of the flue gas probe and is updated

continuously.

If CO undiluted and/or a draught measurement has already

been carried out separately, the value obtained is applied.

- The measured values are displayed.

2. End measurement: [ ].

6 Using the product

Options

> [Options] → Clipboard: data is saved to the clipboard.

> [Options] → Delete clipboard: any data saved to the clipboard

is deleted.

> [Options] → Save: the measured values are saved in a record.

> [Options] → Fluegas matrix: the measured values are

displayed as a flue gas matrix, see below.

> [Options] → Number of lines: change the number of

measured values per display page.

> [Options] → Recalibrate: the gas sensors are set to zero.

> [Options] → Measurement view: (This function is not available

during a measurement): the measured value display menu is

opened.

47

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 47

6 Using the product

Showing the flue gas matrix

This function is only available if the measurement parameter CO

has been activated in the measured value display.

Call up function:

✓ The flue gas function is open.

> [Options] → Fluegas matrix.

Options

> [Options] → Clipboard: data is saved to the clipboard.

> [Options] → Delete clipboard: any data saved to the clipboard

> [Options] → Save: the measured values are saved in a record.

> [Options] → Show numeric value: data is displayed as

> [Options] → System type: (This function is not available

> [Options] → Reset graphic: the displayed graphical values are

> [Options] → Thresholds: (This function is not available during

> [Options] → CO + O2 or CO + CO2: choose which parameter

> [Options] → Measurement view: (This function is not available

3.

is deleted.

numerical values.

during a measurement) Set the system type to be able to

configure the ideal zone (green) of the flue gas matrix, using the

limits pre-configured for each system type.

deleted.

a measurement) Enter limits to be able to configure the ideal

zone (green) of the flue gas matrix.

should be assigned to the x-axis of the display matrix (O2 or

CO2).

during a measurement) Open the measured value display

menu.

6.2.3. Draught measurement

Call up function:

✓ A flue gas probe must be connected.

1. [ ] → Measurement options → [OK] → Draught → [OK].

Carrying out the measurement:

48

During the zeroing phase, the flue gas probe must be

outside the flue gas duct.

Do not measure for longer than 5 min, as a drift of the

pressure sensor means that the measured values may be

outside the tolerance limits.

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 48

1. Start measurement: [ ].

- Draught zeroing is carried out.

2. Position the flue gas probe in the hot spot (area of the highest

flue gas temperature).

The display showing the maximum measured flue gas

temperature (AT max) helps when positioning the probe.

- The measured value is displayed.

3. End measurement [ ].

Options:

> [Options] → Clipboard: Data is saved to the clipboard.

> [Options] → Delete clipboard: Any data saved to the clipboard

is deleted.

> [Options] → Save: The measured values are saved in a

record.

> [Options] → Measurement view: (This function is not available

during a measurement): The measured value display menu is

4.

6.2.4. External micro pressure probe

opened.

The following measurements can be performed using the external

micro pressure probe (0638 0330):

• Ext-Draught

• Ext-Delta-P Single meas.

• Ext-Delta Program

• Ext 4Pa-Measurement (only available if Germany country

version is selected)

• Heating Check (only available if Germany country version is

selected)

5.

See instruction manual for external micro pressure probe.

6 Using the product

6.2.5. Average

This function is only available when the Italy country version is

selected.

Call up function:

✓ A flue gas probe or a multi-hole probe (0554 5762) is

connected.

> [ ] → Measurement options → [OK] → Average → [OK].

49

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 49

6 Using the product

Options:

> [Options] → Recalibrate: the gas sensors are set to zero.

> [Options] → Addresse/Location: the Address/Location folder

> [Options] → Fuels: select fuel.

> [Options] → Sensor detection: once the probe has been

To calculate the average, a series of 3 measurements are carried

out.

Averaging:

1. Position the flue gas probe in the centre of flow (area of the

2. Start measurements

> First measurement: [ ].

> Second and third measurement: [OK]

- The set measurement parameters, measurement period and

- A signal is sounded after 2 min (recommended measurement

3. End measurements: [ ].

- Once the series of measurements has been carried out, the

> If necessary, scroll through the record: [◄], [►]

4. [Next]

5. Enter checks:

6. End check: [Close]

7.

- The record is saved.

is opened.

changed, start sensor detection manually.

highest flue gas temperature).

measured values are displayed.

period)

record for averaging is displayed.

> Select criterion: [▲], [▼].

> Change value: [Edit] → [▲], [▼] → [OK].

6.2.6. BImSchV

This function is only available when the Germany country version

is selected.

A qA average value measurement can be carried out. For this

purpose the average is determined continuously over a period of 30

s, the measuring cycle takes 1 s. The average values actually valid

at the corresponding time of recording are displayed.

Call up function:

✓ A flue gas probe and a combustion air temperature probe must

50

be connected.

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 50

4.

6 Using the product

> [ ] → Measurement options → [OK] → BImSchV → [OK].

> Select the fuel → [OK].

Carrying out the measurement:

1. Start the measurement series: [ ]

Wait for the balancing time, until O

20%.

shows a value below

2

2. [Next].

- The qA measured values (O

, AT, VT) are determined (30 s).

2

- The measurement stops automatically.

- The measured values are displayed and saved automatically in

a record.

3. End measurement: [Close]

or

End measurement and call up draught measurement function:

[Draught - Measuring].

Options:

> [Options] → Clipboard: data is saved to the clipboard.

> [Options] → Delete clipboard: any data saved to the clipboard

is deleted.

> [Options] → Save: the measured values are saved in a record.

> [Options] → Address/Location: the Address/Location folder is

opened.

6.2.7. CO undiluted

Call up function:

✓ A multi-hole probe (0554 5762) should be connected.

> [ ] → Measurement options → [OK] → CO undiluted →

[OK].

Carrying out the measurement:

1. Start measurement: [ ]

- The measured value is displayed.

2. End measurement: [ ]

Options:

> [Options] → Clipboard: data is saved to the clipboard.

> [Options] → Delete clipboard: any data saved to the clipboard

is deleted.

51

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 51

6 Using the product

> [Options] → Save: the measured values are saved in a record.

6.2.8. Smoke number/HCT

Calling up the function:

> [ ] → Measurement options → [OK] → Smoke

number/HCT→ [OK].

The parameters Smoke No. and Oil depos. are only

available for oil fuels.

Determine smoke tester no./smoke nos./oil depos. with the

smoke pump and enter manually:

1. Select parameter → [Edit].

2. Enter data or values → [OK].

Determine smoke tester no./smoke nos./oil depos. with the

smoke tester testo 308 and transmit wirelessly:

- The testo 308 must be in data transfer mode ( lights up).

> [Options] → t308.

- The values recorded by the smoke tester are transferred to the

testo 320.

Entering the heat carrier temperature:

> Heat carrier. → [Edit] → enter value → [OK].

Options:

> [Options] → Clipboard: data is saved to the clipboard.

> [Options] → Delete clipboard: any data saved to the clipboard

is deleted.

> [Options] → Save: the measured values are saved in a record.

> [Options] → Reset values: The entered values are deleted.

6.2.9. Pressure

✓ The gas pressure set (0554 1203) must be connected.

Call up function:

> [ ] → Measurement options → [OK] → Pressure → [OK].

52

www.Testo-Direct.com

1.888.610.7664 info@Testo-Direct.com

Page 52

6 Using the product

WARNING

Carrying out the measurement:

Dangerous mixture of gases

Danger of explosion!

> Make sure there are no leaks between the sampling point and

the measuring instrument.

> Do not smoke or use naked flames during measurement.

Do not measure for longer than 5 min, as the drift of the

pressure sensor could mean that the measured values are

outside the tolerance limits.

1. Connect the gas pressure set to the probe socket.

2. Start measurement: [ ].

- Pressure zeroing is carried out (system must be unpressurised).

3. Pressurise the system.

- The measured value is displayed

4. End measurement: [ ].

Options:

> [Options] → Clipboard: data is saved to the clipboard.

> [Options] → Delete clipboard: any data saved to the clipboard

is deleted.

> [Options] → Save: the measured values are saved in a record.

> [Options] → Measurement view: (This function is not available

during a measurement): the measured value display menu is

opened.

6.2.10. Differential temperature