Page 1

testo 312 - 2/3

Instruction manual

www. .com

information@itm.com1.800.561.8187

Page 2

Introduction2

Initial operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Diagram of instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measurement example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Switching on instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Differential pressure measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fine pressure/Draught measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connection options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-test / Main test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service ability test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setting alarm limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting date/time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting timer for printout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting number of printouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Changing the units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Changing rechargeable battery or battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ordering data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pressure transducer (Accessories). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dear Customer

You have made the right decision by purchasing testo 312.

testo 312 is designed to adjust and maintain gas heating systems.

Thousands of customers buy our high standard products every year. There are at least 7 good

reasons for doing so.

1) Cost-performance ratio. Reliable quality at a fair price.

2) Extended warranty times of up to 3 years - depending on instrument!

3) We have the ideal solutions for your measuring tasks based on our expert experience gained

over 40 years.

4) Our high quality standard is confirmed by the ISO 9001 certificate.

5) Of course, our instruments carry the CE symbol required by the EU.

6) Calibration certificates for all relevant parameters. Seminars, advice and calibration on location.

7) Our after-sales service. Contact us for more information.

Contents

Introduction

2

Instrument conforms with 2004/108/EEC

www. .com

information@itm.com1.800.561.8187

Page 3

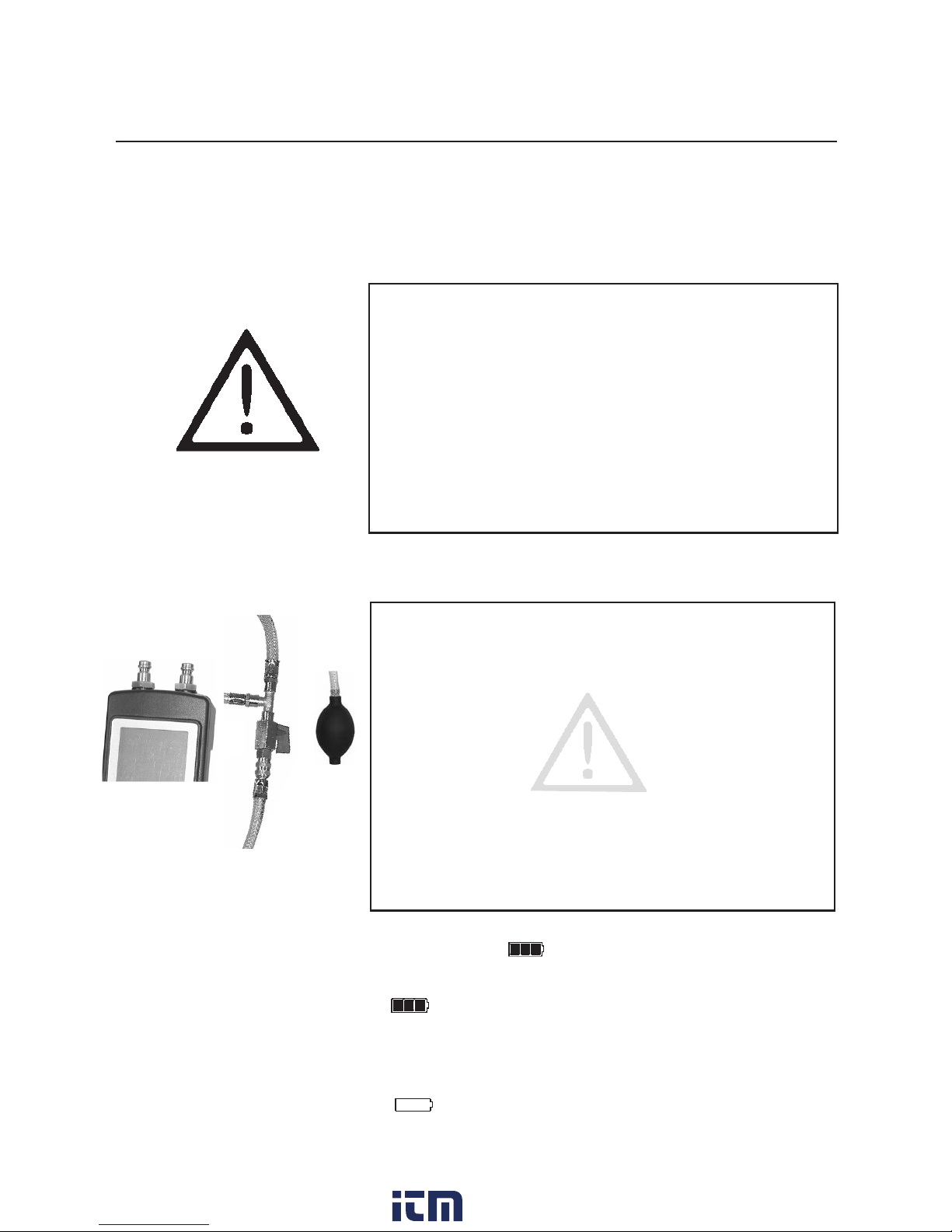

No reading in display?

Send instrument for service.

Function test

for both pressure nipples

Warnings

Safety instructions

Initial operation

3

Capacity display

Voltage >7.2 V

Life of rechargeable battery: approx. 5 h

Life of battery: approx. 15 h

(at an ambient temperature of 20°C)

Flashing symbol, voltage: <7.2 V

Life of rechargeable battery: approx. 15 min.

Life of battery: approx. 45 min.

If the rechargeable battery voltage drops below

6.7 V automatic switch-off follows as protection

against total discharge.

Low Bat

++

Function check/Leak check

Prior the commencing any testing the complete

measuring system (intrument, probe and hoses) should

be checked for leaks

Temperature influence on the leak test

During any leak tests the ambient temperature must

remain constant to obtain valid data.

Instrument should only be used by trained personnel.

Always adhere to any system safety instructions and

never use the equipment in an explosive environment.

Under normal operating conditions gas will not escape

from the instrument when connected to the gas pipe /

system under test.

The instrument is not designed to operate while wet, or

in an environment of condensing humidity

The instrument should only be used in the conditions

and for the purposes for which it was constructed.

Please take particular note of the safety instructions

and the technical data.

The instrument should only be used in the operation and

measurement ranges specified in the technical data.

www. .com

information@itm.com1.800.561.8187

Page 4

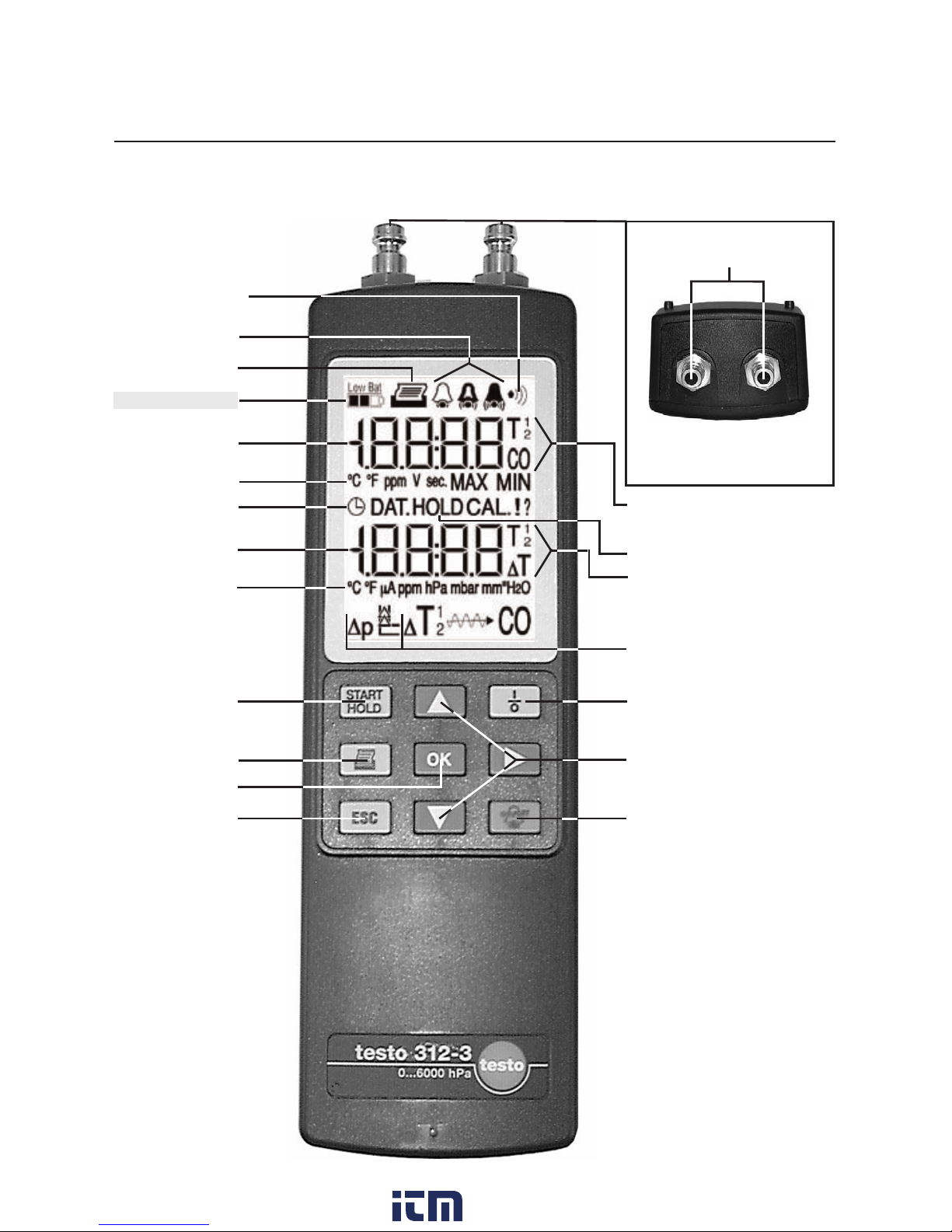

Initial operation

4

Symbol for alarm

On/Off

Print

Battery capacity

Start

measurement/

Freeze readings

Print button

Cancel/Restore

Audible alarm

On/Off button

Alarm levels

Parameters

Parameters

Measuring units

Measuring units

Date/Time

On/Off button

OK button

Scroll buttons

Time

Pressure

connection

Freeze readings

Parameters

Readings

Diagram of instrument

www. .com

information@itm.com1.800.561.8187

Page 5

Initial operation

5

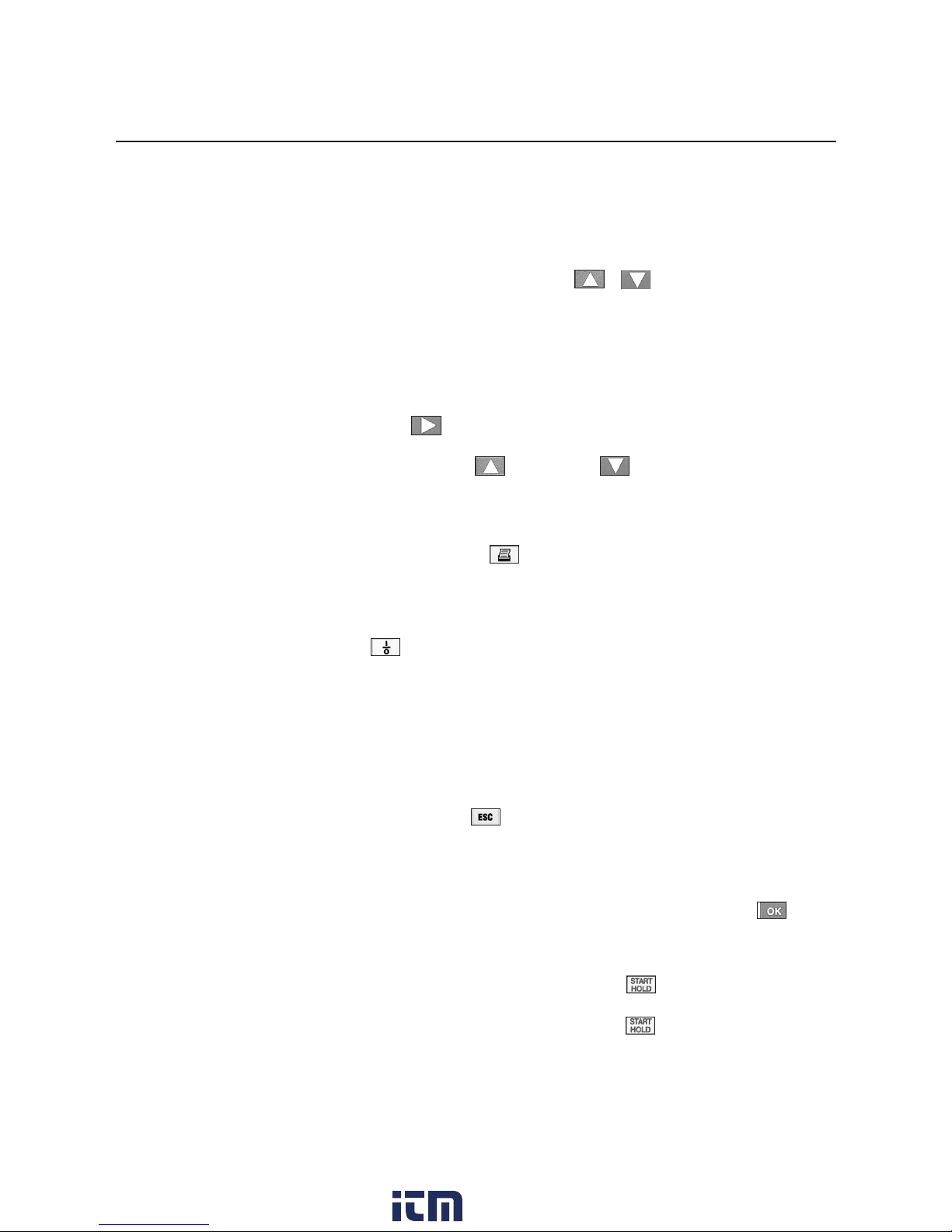

Operating the instrument

Keypad

- Scrolling buttons

Using the arrow buttons / you can scroll

between the parameters, digits in date/time and the alarm

limits can be set.

- Selection button

In the date/time and alarm limits menu, access to the

variable parameters is via the arrow button pointing to the

right .

The units can also be changed. The parameters are set

using the up and down buttons.

- Printing

All of the saved readings can be printed on the printer by

pressing Print .

- I/O button

The instrument is switched on or off via the I/O button

. The display switches off automatically after 5

seconds once the instrument is switched off. This can be

prevented by pressing any button. The instrument then

goes to the Δp measurement menu.

The readings in the display are usually lost when the

instrument is switched off.

- Cancel button

The Cancel button is used to cancel a selected

process or to leave a sub-menu.

- OK button

The changed parameters are saved by pressing .

- START/HOLD button

Start measurement by pressing . The displayed

readings are frozen by pressing again

.

- Alarm on/off button

Switches audible signal on or off.

www. .com

information@itm.com1.800.561.8187

Page 6

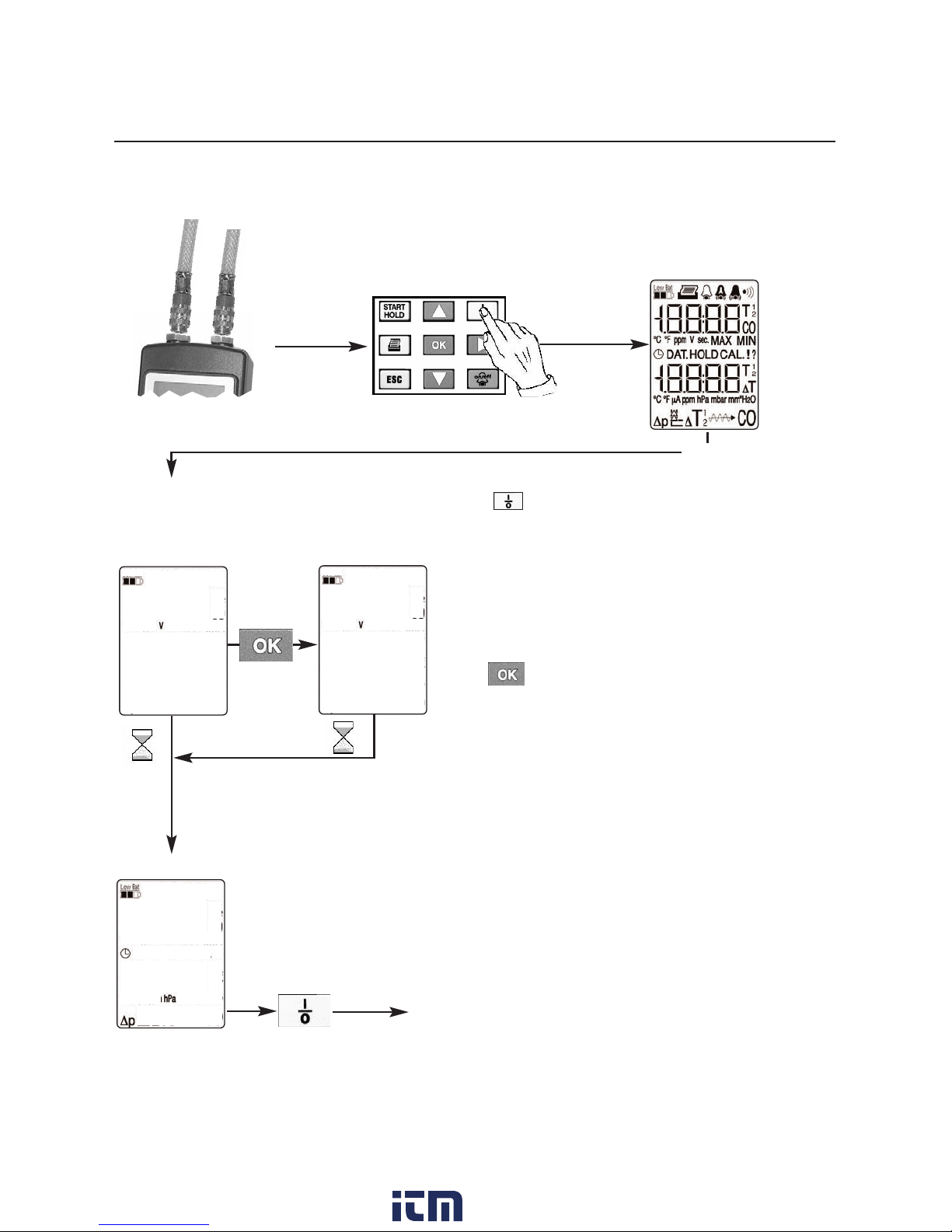

Self-test

Press button. Displays all segments for

approx. 3 seconds.

Battery capacity / Instrument version (2 digit)

Displays battery/rechargeable battery voltage

and instrument version for approx. 3 seconds.

Instrument version (3 digit)

If the button is pressed within 3 seconds

the version number is shown in 3 digits. You then

go to the measurement menu.

Instrument switches off

6

9.0

08:38

--------

1.0

Self-test

Measurement menu

Display for

battery

capacity /

instrument version

9.0

1.00

Instrument

version

Connect hose.

3 s

3 s

5 s

3 s

Measurement example: testo 312-2/-3

Switching on instrument

www. .com

information@itm.com1.800.561.8187

Page 7

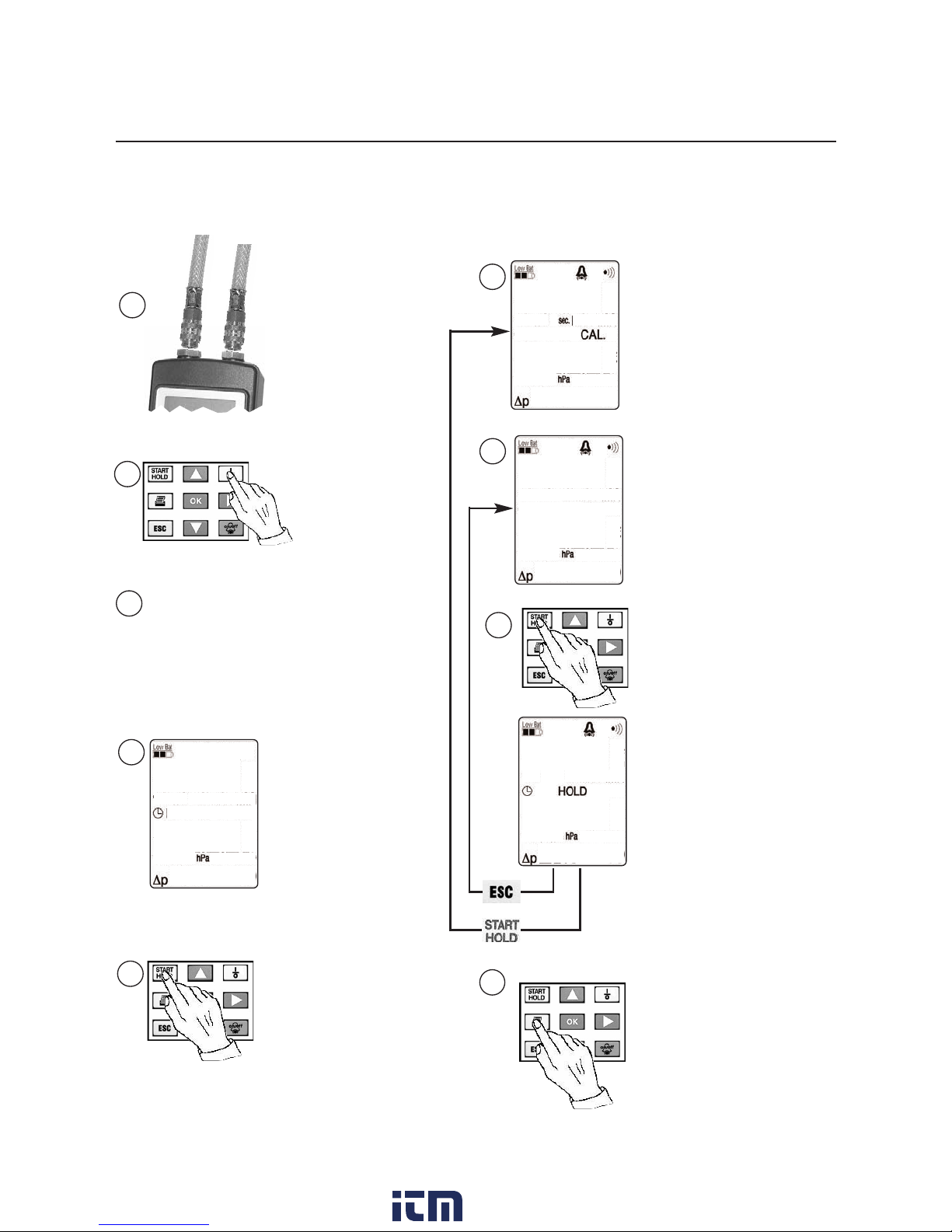

7

08:38

2

09:15

13.0

08:38

-----

Measurement

menu

Switch on

instrument

Wait on calibration

phase (5 s)

Save reading.

HOLD appears in

display.

The saved readings can

be printed.

Position pressure

measurement hose. The

reading appears in the

display.

Start measurement

- Segment test (3 s)

- Voltage display (3 s)

(see page 6)

8

7

09:15

13.0

6

5

3

2

4

9

Measurement example: testo 312-2/-3

Differential pressure measurement

Connect

pressure

measuring

hose

testo 312-2: Range: 0 to 200 hPa. Resolution: 0.1 hPa

testo 312-3: Range: 0 to 6000 hPa. Resolution: 1 hPa

1

www. .com

information@itm.com1.800.561.8187

Page 8

8

5

152

--

08:38

-----

Measurement

menu

08:38

-----

Measurement

menu

Measurement

menu selection

with arrow

button.

Switch on

instrument.

- Segment test (3 s)

- Voltage display (3 s)

(See page 6)

- Function check

(See page 7)

3

2

1

4

09:25

2

09:25

- 0.24

Wait on calibration

phase (5 s)

Save reading.

HOLD appears in the

display

The saved readings

can be printed.

Position probe in flue

gas duct. The reading

appears in the display.

Start measurement.

9

8

7

6

10

Measurement example: testo 312-2

Fine pressure / Draught measurement

Connect

probe.

09:25

13.0

testo 312-2: ΔP range 0 to 40 hPa. Resolution: 0.01 hPa

testo 312-3: ΔP range 0 to 300 hPa. Resolution: 0.1 hPa

www. .com

information@itm.com1.800.561.8187

Page 9

9

Testing

pump

Balloon

pump

Compressor Inert gas

Connection hose

High pressure

stepped plugs

Conical

test plugs

Single-pipe

counter cap

JunctionMini valve

Connect pressure transducer

directly to instrument. Do not

use extensions. Apply

pressure.

Remove pressure from pipe

before detaching pressure

transducer from instrument.

Connection options

Measurement example: testo 312-2/-3

Suitable for:

- Pre-test

- Main test

- Testing service ability

- Checking pressure in

water pipelines

Observe maximum pressure

range.

Positive pressure destroys the

instrument.

Pressure

drop set

Pressure transducer (for liquid

substances); Refer to instructions

on page 22.

www. .com

information@itm.com1.800.561.8187

Page 10

3

2

1

4

5

Insert singlepipe counter

cap and

tighten.

Example

Manual printout

triggers an

automatic

printout after 10

minutes.

6

Pre-test / Main test

Measurement example: testo 312-2/-3

10

Switch on

instrument.

Start measurement

with START/HOLD

button.

Ensure

connection is

correct.

Connect

pressure drop

set and

testo 312.

Compare

printouts

OK/not OK

Build up test

pressure

Carry out function test! Gas should not

get into the instrument when carrying

out measurements on gas pipes.

Pressure drop

The complete measuring system

(instrument, probe, hoses and connec-

tions) should be checked for a drop in

pressure e.g. using pressure drop test

set by attaching the single-valve stop.

Preliminary test

Pipes are checked, without fittings, with a

test pressure of 1 bar. This pressure should

not fall during the 10-minute duration of

the test.

Main test

Pipes are checked, with fittings, with a

test pressure of 110 mbar. This pressure

should not fall during the 10-minute

duration of the test. The measuring

instrument should be able to recognise

a drop in pressure of 0.1 mbar.

www. .com

information@itm.com1.800.561.8187

Page 11

11

Start

measurement

with

START/HOLD

button.

3

2

1

4

5

Insert singlepipe counter

cap and

tighten.

Printout of initial

pressure

6

10

7

Switch on

instrument.

Ensure

connection is

correct.

Connect

pressure drop

set and

testo 312.

Freeze reading

with START/HOLD

Audible signal

after 1 min

8

9

Prints reading

Determines Δp

Build up test

pressure.

Use slide rule

to determine

what measure

to take

Measurement example: testo 312-2/-3

Service ability test

45

Carry out function test! Gas should not

get into the instrument when carrying

out measurements on gas pipes.

Pressure drop

The complete measuring system

(instrument, probe, hoses and

connections) should be checked for a

drop in pressure e.g. using pressure

drop test set by attaching the single-

valve stop.

Checking if fit for use

The pipe is pumped with air up to the

respective test pressure and the drop in

pressure in one minute is measured.

www. .com

information@itm.com1.800.561.8187

Page 12

12

08:54

-----

Measurement

menu

Switch on

instrument.

- Segment test (3 s)

- Voltage display (3 s)

(See page 6)

3

2

1

4

5

-----

--

Measurement

menu

selection via

arrow button.

08:54

-----

08:51

100.0

Increase or decrease

alarm limits via arrow

buttons.

Go automatically to

measurement menu.

Differential pressure

Draught

08:54

- 0.04

6

8

7

Note:

If the alarm limit has a value of 0.00 or 0.0,

the alarm of the corresponding alarm limit is

switched off. The dP or draught alarm is

inactivated following initialisation. Alarm

symbols do not appear on the display.

The alarm is deactivated by the manufacturer

i.e. the alarm limit is set at 0.00 or 0.0.

Press the alarm button once the alarm limit is

changed. The symbol is visible.

After the measurement, the flashing is a sign

that an alarm limit is set and was reached.

0 to 200 0 to 6000

0 to -40 0 to 300

testo 312-2

testo 312-3

Alarm setting range

Setting alarm limits

Differential pressure (testo 312-2/-3),

draught (testo 312-2)

Δ

P

www. .com

information@itm.com1.800.561.8187

Page 13

13

Setting date/time

08:34

-----

Measurement

menu

Switch on

instrument

- Segment test (3 s)

- Voltage display (3 s)

(See page 6)

3

2

1

5

4

6

Press and buttons

simultaneously.

Increase or

decrease digit

with arrow

buttons.

Return to

measurement

menu via OK

Increase or

decrease digit

with arrow

buttons. Press

OK button to

return to

measurement

menu

Increase or

decrease digit

with arrow

buttons. Press

OK button to

return to

measurement

menu

Setting the hour

08:35

-----

7

Press button.

Setting minutes

08:35

-----

Press button

Setting the day

02.06

-----

www. .com

information@itm.com1.800.561.8187

Page 14

14

Save selection with

OK button.

Return to

measurement menu

selection.

Note

You can leave the menu by pressing ESC

but the changes are not carried out.

8

Press button

Note:

The date display can be changed from

Day/Month (EUR) to Month/Day (US) by

pressing

.

Setting the month

02:06

-----

9

10

Press button.

Setting the year

1999

-----

Setting date/time

Increase or

decrease digit

with arrow

buttons. Press

OK button to

return to

measurement

menu.

Increase or

decrease digit

with arrow

buttons. Press

OK button to

return to

measurement

menu.

www. .com

information@itm.com1.800.561.8187

Page 15

15

08:34

-----

Measurement

menu

Switch on

instrument

- Segment test (3 sec.)

- Voltage display (3 sec.)

(See page 6)

3

2

1

5

4

Press button 2 sec.

Increase or

reduce value

using arrow

buttons.

7

Alarm limit

display

8

Press button.

9

Press button. Return to

measurement menu.

08:35

205

Timer

setting

6

08:35

00

Press button.

Increase or

reduce value

using arrow

buttons.

Timer

setting

08:35

05

Setting timer for printout

www. .com

information@itm.com1.800.561.8187

Page 16

16

7

Timer display

8

Press button

Alarm limit display

9

Press button

10

Press button. Return to

measurement menu.

Display timer

6

08:35

15

Press button

Increase or

reduce

number using

arrow buttons.

Set number of

printouts

08:35

2

Setting number of printouts

08:34

-----

Measurement

menu

Switch on

instrument

- Segment test (3 sec.)

- Voltage display (3 sec.)

(See page 6)

3

2

1

5

4

Press button 2 sec.

www. .com

information@itm.com1.800.561.8187

Page 17

17

Changing the units

1

2

3

4

Selection saved.

Return to measurement

menu.

You can leave the menu by pressing but

the changes are not made.

Press button

-

Measurement menu

Measurement

menu

selection with

arrow button.

Select units by pressing :

Differential pressure measurement

hPa, mbar, mmH

2

O, inchH2O

Draught measurement

hPa, mbar, mmH2O, inchH2O (testo 312-2 only)

08:57

- 20.4

www. .com

information@itm.com1.800.561.8187

Page 18

Phase Symbol Cause

General Low Bat is flashing Power to instrument is too low. If the

battery voltage drops below 6.7 volt, the

instrument switches off automatically.

T in top line is Non-permitted ambient temperature

flashing Adapt to ambient temperature.

The message Send instrument for service.

Exxx appears in the

bottom line

-- -- -- -- Pressure sensor is overloaded.

Error messages

18

Remove empty/defect rechargeable batteries or empty

batteries from the battery compartment and replace with

new ones.

Remove rechargeable batteries/batteries if the instrument

is not used for a longer period of time. If the battery cells

leak in the instrument, return instrument to factory to be

cleaned and checked.

Only the rechargeable batteries/batteries specified in the

technical data should be used.

Observe correct polarisation of rechargeable batteries or

batteries.

Instrument should only be used if the battery

compartment cover is closed.

Switch off instrument and disconnect from all

measuring circuits before changing the rechargeable

battery or battery.

Date and time are saved when the instrument is switched

off.

Maintenance

Changing the rechargeable battery or battery

1

2

3

4

old

new

If we were unable to answer your question, please contact your distributor or Testo

Customer Service. For contact data, see back of this document or web page

www.testo.com/service-contact

www. .com

information@itm.com1.800.561.8187

Page 19

19

testo 312

Technical data

testo 312-2

Measuring range* ±40 hPa ±200 hPa

Accuracy** <3.00 hPa ±0.03 hPa ±0.5 hPa (0 to 50 hPa)

>3.00 hPa ±1.5% of m.v.±1,5% of m.v. (>50 hPa)

Resolution ±0.01 hPa ±0.1 hPa

Alarm limit -0.01 to -40 hPa 0.1 to 200 hPa

Adjustment step 0.01 hPa 0.1 hPa

Alarm display Audible and optical

Max. overload 1 bar

Differential pressure measurement

Draught (testo 312-2 only)

testo 312-2

Measuring range* ±40 hPa

Accuracy** <3.00 hPa ±0.03 hPa

>3.00 hPa ±1.5% of m.v.

Resolution ±0.01 hPa

Alarm limit -0.01 to -40 hPa

Adjustment step 0.01 hPa

Alarm display Audible and optical

Max. overload 1 bar

testo 312-3

Measuring range* ±300 hPa ±6000 hPa

Accuracy** ±0.5 hPa <50 hPa ±4 hPa <400 hPa

±1.5% of m.v. ≥ 50 hPa ±2% of m.v. 400-2000 hPa

±4% of m.v. >2000 hPa

Resolution ±0.1 hPa ±1 hPa

Alarm limit 0.1 to 300 hPa 1 to 6000 hPa

Adjustment step 0.1 hPa 1 hPa

Alarm display Acoustic and optical

Max. overload 8 bar

Δ

P

General Technical data for testo 312-2 and testo 312-3

Storage temperature: -20 to +60 °C

Operation temperature: +5 to +45 °C

Dimensions: 215mm x 68mm x 47mm

Weight: Approx. 400 g

* Measuring instrument is temperature-compensated

** Accuracies do not apply in connection with pressure transducers

0554.3159 and 0554.3168

Warranty

Instrument: 2 years

Probes: 1 year

Accessories 6 months

Printer 1 year (excluding printing mechanism)

www. .com

information@itm.com1.800.561.8187

Page 20

20

testo 312

Ordering data

Description

Part no.

Instrument

testo 312-2 compact pressure gauge with

instruction manual and battery 0632.0313

testo 312-3 compact pressure gauge with

instruction manual and battery 0632.0314

Accessories

Testo printer, prints measurement data with location,

date and time 0554.0547

Spare rolls for printer 0554.0569

Rechargeable battery for printer (4 off) 0515.3120

Rechargeable battery 9V for instrument 0515.0025

Recharger for 9 V rechargeable battery 0554.0025

Recharger for printer 0554.0110

Pressure set with flue probe 0554.3150

TopSafe, indestructible protection case 0516.0443

Case 0516.0191

Service case 0516.3120

Pressure drop test set, 200 mbar 0554.3153

Test pump for pressure drop test set 0554.3157

Single-pipe counter cap 0554.3156

Two-valve junction 0554.3161

Single-valve stop 0554.3162

Connection hose LW6 0554.3158

Conical test plug 16-32mm 0554.3151

Conical test plug 24-44mm 0554.3155

Conical test plug 35-65mm 0554.3152

High pressure stepped plug 3/8” and 3/4” 0554.3163

High pressure stepped plug 1/2” and 1” 0554.3164

Complete high pressure set with case 0554.3160

Pressure transducer for liquid substances, 1 to 6000 mbar 0554.3159

Pressure transducer for liquid substances, 1 to 1000 mbar 0554.3168

System case 0554.3165

Leak detection spray 0554.3166

Slide rule 0554.3169

Test system set 0563.0314

www. .com

information@itm.com1.800.561.8187

Page 21

Normal use

The pressure transducer protects the testo 312

measuring instrument from moisture and high

temperatures: measures vapour and water pressure.

Measuring

Do not use an extension cable between the pressure

transducer and the instrument.

1 Connect connection A of the pressure transducer

directly to the instrument (+).

2 Switch on instrument.

3 Press “Start” and wait for calibration phase (5s).

4 Connect connection P of the pressure transducer

directly to the control pressure pipe.

Observe maximum pressure range of instrument and the

pressure transducer used!

5 Apply pressure to pipe.

6 Take readings.

7 Press “Hold”.

8 Remove pressure from pipe.

9 Disconnect pressure transducer from instrument.

Technical data

Connection size: ..........1/8” plug-in connection

Size

(Height/Diameter): ........33mm/64.8mm

Weight: ........................175g

Housing material:..........Aluminium

Pressure range: ............0-1bar (0554.3168)

....................................0-6bar (0554.3159)

Pressure loss: ..............0 to 6% of reading

Diaphragm: ..................Temperature resistant to 120°C,

....................................oil resisting

Overload:......................2bar (0554.3168)

....................................8bar (0554.3159)

Pressure transducer (Accessories)

Instructions

Connection

A

Connection P

21

www. .com

information@itm.com1.800.561.8187

Page 22

testo AG

Postfach 11 40, 79849 Lenzkirch

Testo-Straße 1, 79853 Lenzkirch

Telefon: (07653) 681-0

Fax: (07653) 681-100

E-Mail: info@testo.de

Internet: http://www.testo.com

0973 3124 en 02 V01.04 en_DE

www. .com

information@itm.com1.800.561.8187

Loading...

Loading...