Page 1

testo 300 XXL

Instruction manual

en

Page 2

Page 3

3

Contents

Page

Contents..........................................................................................................................3

Preface ............................................................................................................................7

Principal safety information ..............................................................................................8

System description 9

Control unit ..............................................................................................................9

Device operation ....................................................................................................10

Touchscreen (option) ..............................................................................................11

Overview of the measuring system..........................................................................12

Menu overview 14

Control unit with analyser box..........................................................................14

Control unit......................................................................................................15

Commissioning ..............................................................................................................16

Function menu and function bar..............................................................................16

Status display of the LED (analyser box)..................................................................17

Power supply ..........................................................................................................18

Power supply, analyser box/control unit ..........................................................18

Mains operation ......................................................................................18

Rechargeable battery operation ..............................................................18

Power supply, control unit................................................................................18

Mains operation ......................................................................................18

Rechargeable battery operation with battery pack ..................................18

Battery operation ....................................................................................18

Rechargeable battery operation with standard batteries..........................18

Charging batteries ..................................................................................................19

Charging batteries, analyser box/control unit ..................................................19

Charging battery pack, control unit..................................................................19

Example measurement ..................................................................................................20

Correct use of the flue gas probe............................................................................20

Preparing for measurements with the control unit and analyser box........................21

Core current search with the control unit and analyser box ....................................22

Flue gas measurement at burners with control unit and analyser box ....................23

Conducting a CO measurement in gas burners

with the control unit and the analyser box ..............................................................24

Draught measurement with the control unit and analyser box ................................25

In compliance with the conformity certificate, the units fulfil the guidelines of

DIN EN 61010-1 safety regulations for electrical devices, control, regulating

and laboratory equipment of guideline 73/23/EEC.

In compliance with the conformity certificate, the unit fulfils the guidelines of

2004/108/EEC.

Page 4

Page

Differential pressure measurement with the control unit ..........................................26

Differential pressure measurement with the control unit ..........................................27

CO measurement with the control unit ....................................................................28

Gas leak probe with control unit..............................................................................29

Humidity measurement with the control unit............................................................30

Velocity measurement with the control unit..............................................................31

Volume measurement in a duct ......................................................................32

Mean value ......................................................................................................33

Volume flow measurement ..............................................................................34

Velocity measurement with the pitot tube ........................................................35

CO

2

measurement with the control unit ..................................................................36

Current/voltage measurement with the control unit ................................................37

Printing ..........................................................................................................................38

Printing the measurement results ............................................................................38

Main menu Memory (analyser box and control unit) ......................................................39

Overview ................................................................................................................39

Saving without selecting a location..........................................................................40

Creating a new location ..........................................................................................41

Selecting saved location..........................................................................................42

Using an existing location as format for a new location ..........................................43

Changing existing location ......................................................................................44

Deleting existing location ........................................................................................45

Barcode pen overview ............................................................................................46

Reading a location with the barcode pen ................................................................47

Reading a location from the measurement menu ....................................................47

Reading several locations with barcode pen from the measurement menu ............47

Displaying saved readings ......................................................................................48

Mean calculation ....................................................................................................49

Printing mean calculation result ..............................................................................50

Deleting entire memory............................................................................................51

Printing saved readings of a location ......................................................................52

Free memory? ........................................................................................................53

Main menu Probe for control unit ..................................................................................54

Scaling ....................................................................................................................54

Resetting ................................................................................................................55

Info..........................................................................................................................55

Main menu Input for control unit ....................................................................................56

Parameters..............................................................................................................56

Temperature ....................................................................................................56

Humidity ........................................................................................................57

Pressure ..........................................................................................................58

Density ............................................................................................................59

Contents

4

Page 5

5

Contents

Page

Pitot tube factor ..............................................................................................60

Cross section ..................................................................................................61

Offset factor ....................................................................................................62

Info ..................................................................................................................62

Alarm limits..............................................................................................................63

Timer ......................................................................................................................63

Main menu Device for control unit ................................................................................64

Changing date/time ................................................................................................64

Setting the date ..............................................................................................64

Setting the time ..............................................................................................66

Auto off ..................................................................................................................66

Printer ....................................................................................................................67

Setting the contrast ........................................................................................67

Entering print text............................................................................................67

Light........................................................................................................................68

Diagnostic ..............................................................................................................68

Units ......................................................................................................................69

Main menu Service for control unit ................................................................................70

Operating values ....................................................................................................70

Resetting factory settings ........................................................................................70

Address ..................................................................................................................70

Device data ............................................................................................................70

Language ................................................................................................................71

Main menu Periphery (with touchscreen only) ................................................................71

Solid fuel measurement option for analyser box ............................................................72

CO measuring ranges in different dilution stages ....................................................73

Main menu Sensors for analyser box and control unit ..................................................73

Recalibration ..........................................................................................................74

NO

2

addition ..........................................................................................................75

Print cal. data..........................................................................................................75

Main menu Input for analyser box and control unit ........................................................76

Spot number index / WTT / oil derivatives ..............................................................76

Fuel ........................................................................................................................77

O

2

rel/CO2max/coefficient ........................................................................................77

Parameters..............................................................................................................79

Pressure ..........................................................................................................79

Pitot tube factor ..............................................................................................80

Cross section ..................................................................................................81

Offset factor ....................................................................................................82

Info ..................................................................................................................83

Dew point AT ..........................................................................................................84

Main menu Device for analyser box and control unit......................................................85

View (display sequence) ..........................................................................................85

Diagnostic ..............................................................................................................86

Page 6

6

Contents

Page

Main menu Service for analyser box and control unit ....................................................87

Operating values ....................................................................................................87

Switching off CO/NO ..............................................................................................88

Device data ............................................................................................................89

Bus address............................................................................................................89

Maintenance ..................................................................................................................90

Inserting new paper roll in printer ............................................................................90

Changing the battery pack ......................................................................................91

Control unit......................................................................................................91

Analyser box....................................................................................................91

Filter change ..........................................................................................................92

Condensation trap ..................................................................................................92

Flue gas probe ........................................................................................................93

Cleaning the flue gas probe ............................................................................93

Cleaning the flue gas probe with gas path closed............................................93

Changing a defective thermocouple ................................................................93

Changing O

2

, CO and NO measuring cells..............................................................94

Installation of CO/NO2 measuring cell ....................................................................94

Installation of NO measuring cell ............................................................................94

Maintenance of the gas pumps ..............................................................................95

Opening the analyser box ................................................................................95

Cleaning the main gas pump and the purging pump ......................................95

Cleaning the main gas pump with optional gas preparation ............................96

Changing the pump cassette of the condensation pump

with optional gas preparation ..................................................................................97

Upgrades ................................................................................................................98

Calculation information ..................................................................................................99

Error messages ..........................................................................................................100

Technical data..............................................................................................................101

Ordering data ..............................................................................................................106

Notes

Page 7

7

Preface

Dear Testo customer,

Your decision to buy the testo 300 XXL was an excellent choice.

The testo 300 XXL is designed for flue gas analysis and all measurements in

heating systems.

Thousands of customers buy our high-quality products every year. There are at

least 7 good reasons for this:

1) Our price/performance ratio is good. Reliable quality at a fair price.

2) Substantially extended warranty periods up to 2 years – depending on the model.

3) We provide an optimum solution to your measuring tasks with over 40 years of

professional experience.

4) Our high quality standards are confirmed by the ISO 9001 certificate.

5) Of course, our devices also bear the CE label required by the EU.

6) Calibration certificates for all relevant measurements. Seminars, consulting and

calibration on site.

7) We don’t leave you on your own after your purchase.

Page 8

Use the device only in the operating and

measuring ranges specified in “Technical data”.

Use the device only under the conditions and for

the purpose for which it was designed. For this,

particularly observe the safety information and the

technical data.

To prevent damage to the instrumentation and

items under test, suitably trained persons should

only use the equipment.

Observe all local Health and Safety regulations

before operating the test equipment.

Do not make measurements on live components.

Observe the warnings on the control unit and

analyser box!

Magnets of the control unit

The magnets of the control unit can damage EC

cards, telephone cards etc.

Operation with mains adapter

Use only the original mains adapter to operate the

device. Replace damaged mains cable only with

an original mains cable of the manufacturer or

agent (i.e. by authorised service).

Check for leaks

The entire measuring system (probe, condensation

trap, filter, hoses and connections) must be

checked for leaks before each measurement, e.g.

by pushing on a collapsed rubber bladder.

Measuring errors can be caused if external air

infiltrates.

Expose the gas outlet

When measuring, ensure that the gas outlets are

exposed to allow the gas to escape unobstructed.

If this is not the case, the measurement results

can be falsified.

Empty the condensation trap

The condensation trap must only be emptied when

the pump is switched off (the measuring cells are

otherwise in danger of damage)!

Disposing of batteries

The end user is legally required to dispose of all

used batteries in accordance with their country’s

regulations.

Disposing of measuring cells

Storing the analyser in rooms containing solvents,

vapours or gases will damage the measurement

cells e.g. cleaning fluids, polishes, paints, cooking

operations. Protect the device from direct sunlight

and store at temperatures <45°C.

Storing the device

Storing the analyser in rooms containing solvents,

vapours or gases will damage the measurement

cells e.g. cleaning fluids, polishes, paints, cooking

operations. Protect the device from direct sunlight

and store at temperatures <45°C.

Charge the battery before use

Before making the first measurement or after

several days of disuse, fully charge the internal

battery (see menu Service

Operating values). Charge the battery at least

every 4 weeks during longer periods of disuse to

prevent damagingly low discharging.

Changing the configuration

Switch off the device to change the configuration

(e.g. probe change), as the device reads the

probe-specific values when it is switched on.

PC cable connected

When the PC cable is connected, it is impossible

to issue a print command.

Using probes with plug head

Ensure the good contact of probes with plug

heads. Fully tighten the union nut on the probe

handle.

Opening the device

If the device is opened, misused or subjected to

force, the warranty will be voided.

Because the pressure sensor heats up, it is

recommended to wait on the “Warm up” for 15

minutes to achieve the best possible accuracy.

8

Principal safety information

Page 9

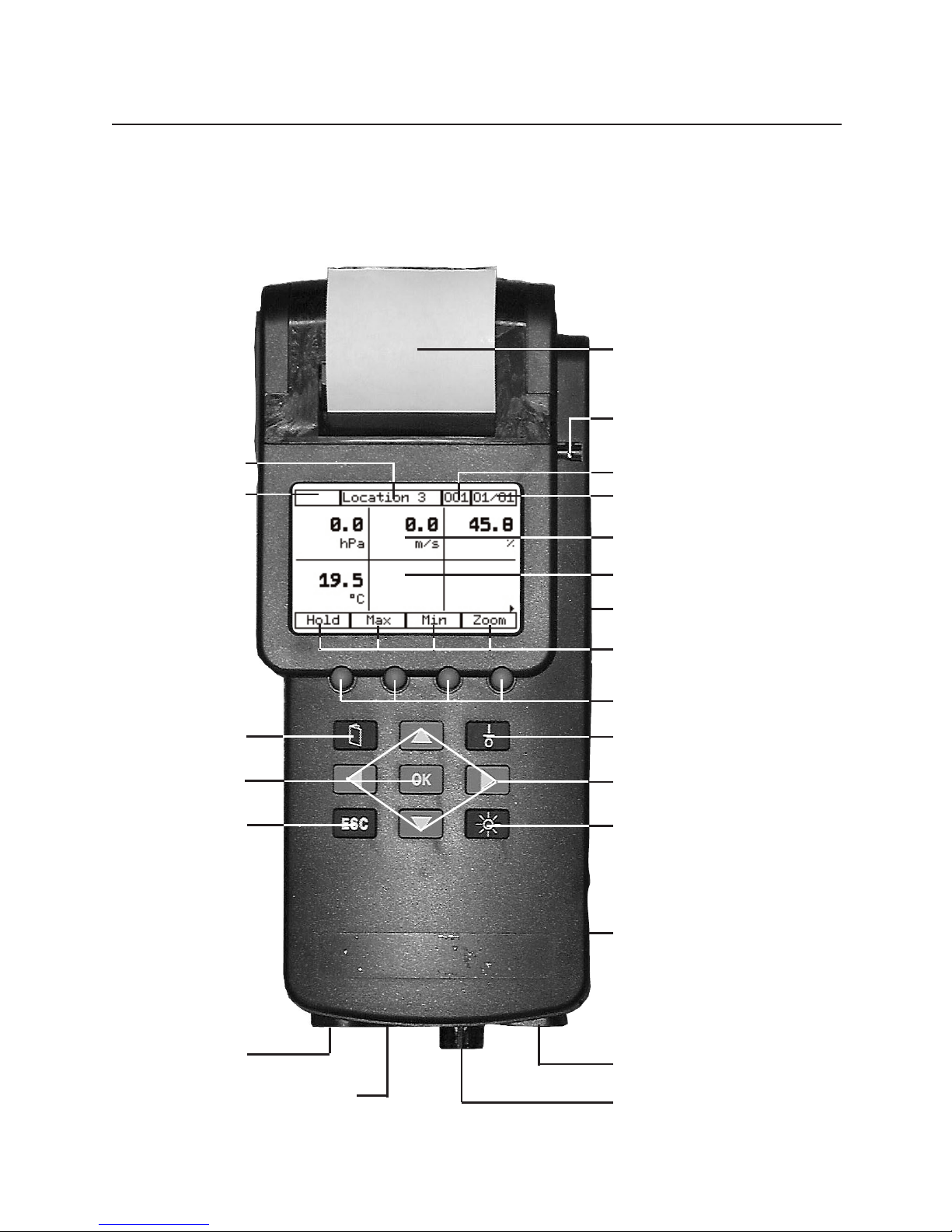

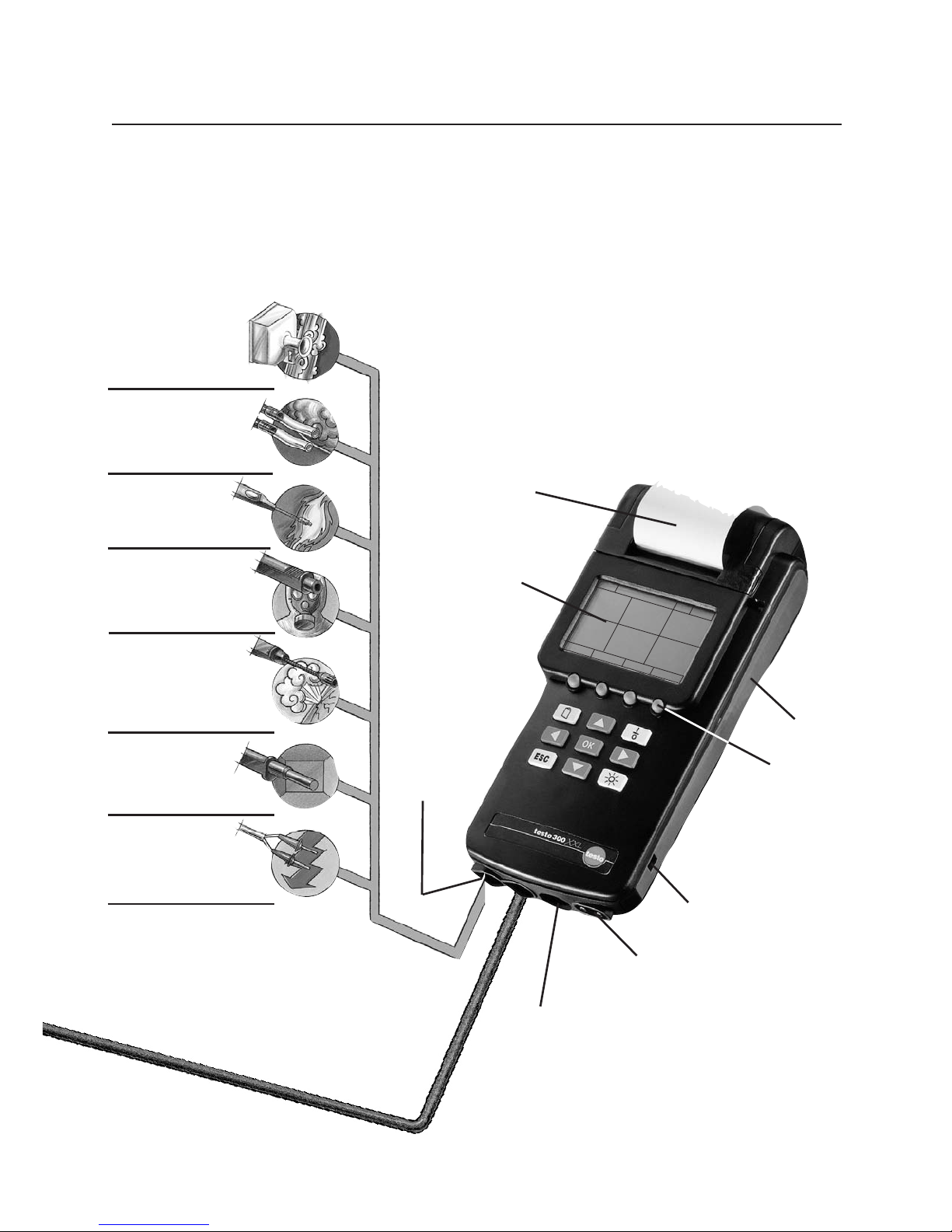

System description

Control unit

9

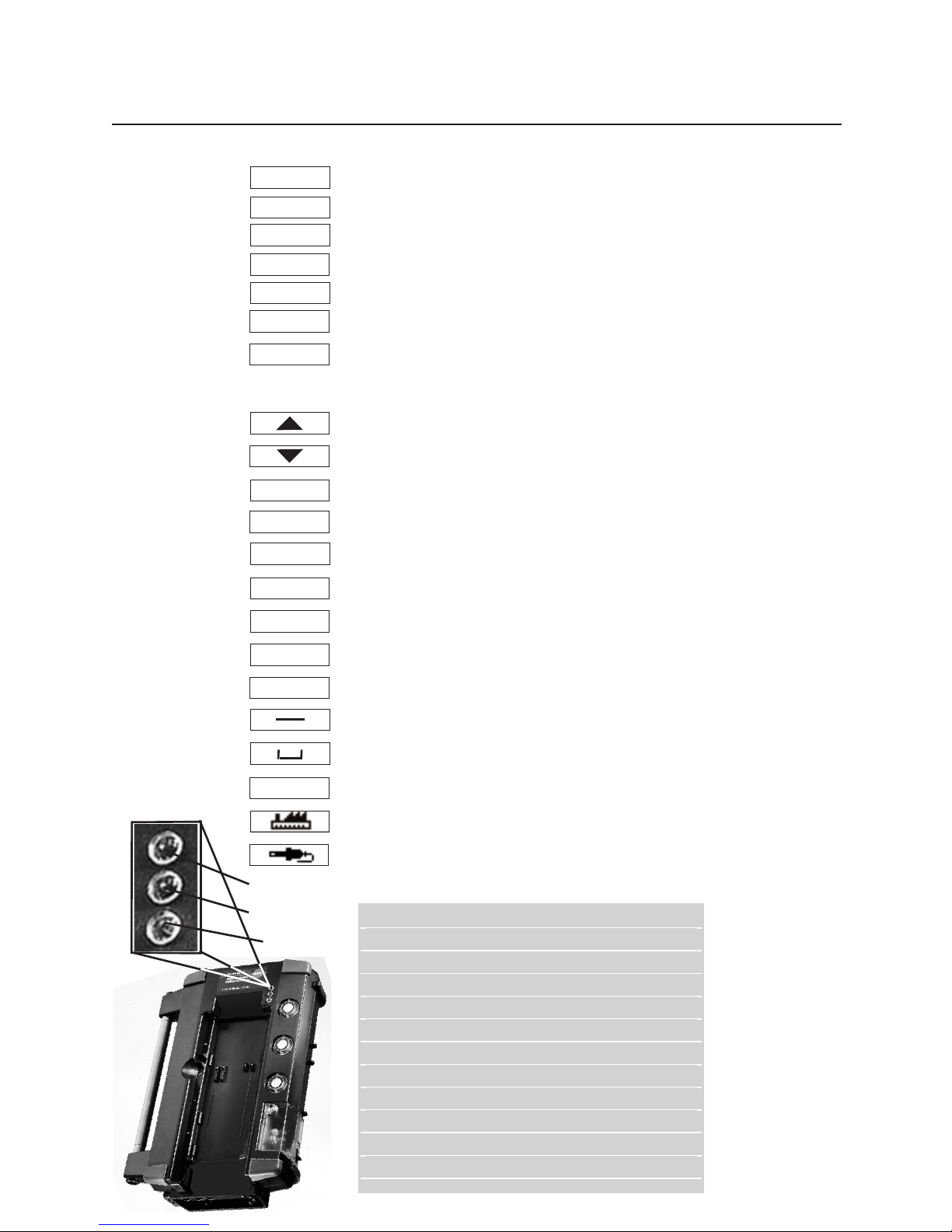

On/off button

Function keys

Function bar

Touchscreen (option)

on the rear:

Contacts to analyser box

Reading display

Device active display

Touchscreen pen

holder

Printer

Reading window

Display lighting

Mains adapter connection

Pressure connection

Probe connection

Cancel/back

PC connection

Main menu display

Status display

Location

Acknowledgement

Cursor keys

Connection of the spiral BUS

cable to the analyser box

Page 10

10

System description

Device operation

The analyser measurement box is controlled, read

and programmed using the control unit.

The operation of the testo 300 XXL is designed so

that the key functions are visible at all times on

the display.

The keypad

The function keys allow rapid changes of the

functions of the device and the overall control of

the measurement. The significance of the function

keys is indicated in the function bar. Not all

function keys are used in every menu. Arrows in

the function bar indicate further accessible

functions in the menu. When the right or

left cursor key is pressed, these additional

functions are displayed and can be activated with

the function key.

With the up /down cursor keys, you

can browse between the reading windows (in the

measurement menu) or select a menu item in a

list. When you have reached the last

window/menu item, the device automatically loops

back to the first window or the first menu item.

With the Browse key, you can branch from

the measurement menu to the main menu or from

a submenu to the measurement menu.

The I/O button switches the device on and off.

With the Cancel key, you can terminate

selected procedures or a chosen selection and exit

submenus. When you exit a submenu, you will

always move one menu window backwards until

you reach the main menu.

With the Acknowledge key, the selection or

the execution of the selected function is accepted.

If the key is pressed in the measurement

menu, the menu “Device selection list” appears.

The menu provides information on which device is

in use. 001=Control unit active, 002=Analyser box

active etc. If an analyser box is connected, this is

indicated automatically in the window when the

device is started.

With the Lighting key , the display lighting

can be switched on and off or the automatic timer

can be started.

The display

The display constantly shows all important

information.

In the Reading/Menu display area, 6 readings

per window are indicated in the measurement

menu. Only three readings are indicated in larger

lettering when the zoom function is used (by

function key).

The function bar indicates the significance of the

individual function keys . Their effects can

change according to the menu. The description of

the function keys changes accordingly on the

display.

The function bar can be assigned as desired to

all functions of the function menu. When the key

is pressed together with a function key, the

function menu opens. The entries in the function

menu change according to the connected

components of the measuring system.

The Operation display provides a graphic de-

scription of the current mode of the device, e.g.

whether the pump of the device is running and if

the device is running in mains operation.

The Location box constantly shows whether and

which location hasn’t been selected and is active.

If no location has been selected, “NONAME”

appears on the display.

In the measurement menu, the Reading window

on the right indicates the measured value window

in which you are currently working, e.g. 2/5

indicates that you are working in the second of 5

possible pages.

Errors are indicated on the display as soon as they

occur. The “!” symbol in the status display often

indicates the occurrence of errors.

The touchscreen function (option) allows

direct access to the functions indicated on the

display using a special pen. A brief

touch is sufficient to activate the function.

Page 11

11

System description

Touchscreen (option)

Touch a position on the display with the special

pen. The main menu appears. Each menu item

can be accessed and activated with the special

pen. The example shows the individual steps to

set the lighting status of the control unit.

Measurement menu

Measurement menu

Main menu

Change “Device” settings

Change “Device” settings

or

Adjustment menu

Adjust “Light”

Adjust “Light”

Set “On/Off”

Set automatic

PPeerriipphheerryy

PPeerriipphheerryy

Page 12

12

System description

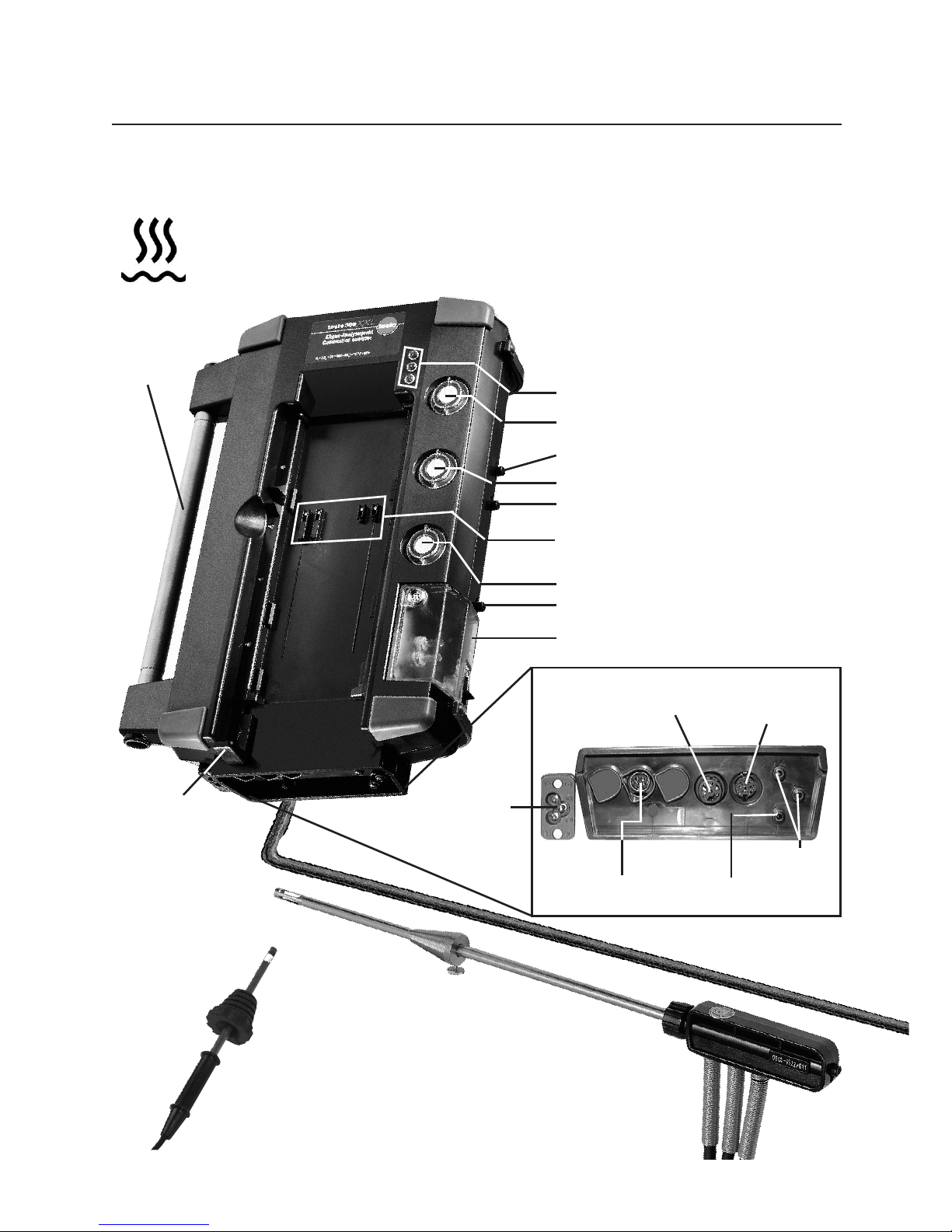

Overview of the measuring system

Measuring cell heater

protects against

destruction by

condensation

Gas

connection

DP

measurement

Spiral BUS cable

connection

Flue gas probe

connection

Probe

connection

110/230 V

50/60 Hz

Carrying

handle

Control unit

catch

Contact strips to the

control unit

LED status display

Gas path filter

Gas outlet 2

Fresh air inlet filter

Fresh air inlet

Diluting air filter

Gas outlet 1

Condensation tank

Page 13

13

System description

Overview of the measuring system

0

12.1

1.27

92.4

180.1

22.2

BrSt

l

AT °C

VT °C

h %

002

04/06

Noname

Hold

Max

Min

Zoom

Volume flow

rate

measurement

with funnel

Pressure

measurement

Temperature

measuremen

t

CO safety

measurement

Gas leak

measurement

CO

2/humidity

measurement

Current

measurement

Voltage

measurement

Cable connection control

unit/spiral analyser box cable

Control unit

4 user-defined

function keys

Mains connection/

fast battery charge

Integrated differential

pressure measurement

Integrated printer

Multi-probe

input

RS 232

interface

Display

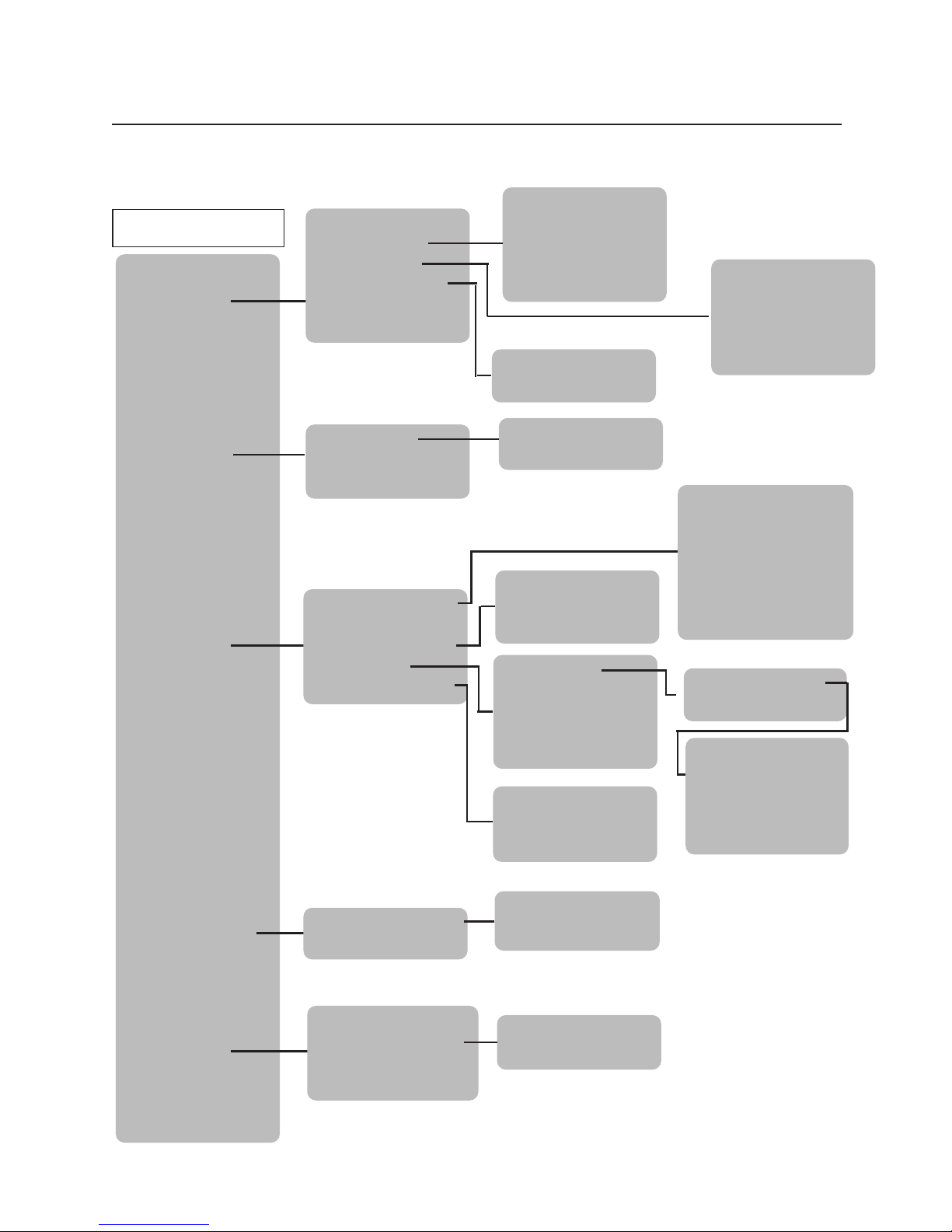

Page 14

14

MEMORY

SENSORS

INPUT

DEVICE

SERVICE

MMaaiinn mmeennuu

Op. values

Switch-off

Device data

Bus address

Display sequence

Units

View

Diagnostic

Spot number/HCT

Fuel

O2rel/CO2max

Parameter

Dewpoint/ambient

Smoke number 1

Smoke number 2

Smoke number 3

Heat carrier temp.

Oil derivative

Info

O2 rel.

CO2max.

coeff.

Temperature VL

Humidity VL Dew

point VL

Pres.

Pitot tube factor

Cross-section

Offset factor

Info

Recal.

NO2 addition

Print cal. data

CO

NO

CO

NO

Read out

Mean value

Fuel meas.

Delete memory

Free memory?

System description

Menu overview

Control unit with analyser box

from height

Absolute

Pres.

Metres above

m.s.l.

Diff. pressure

Duration

No. values

Info

Save

Delete

Duration

Dilution

Info

Save

Delete

Yes

No

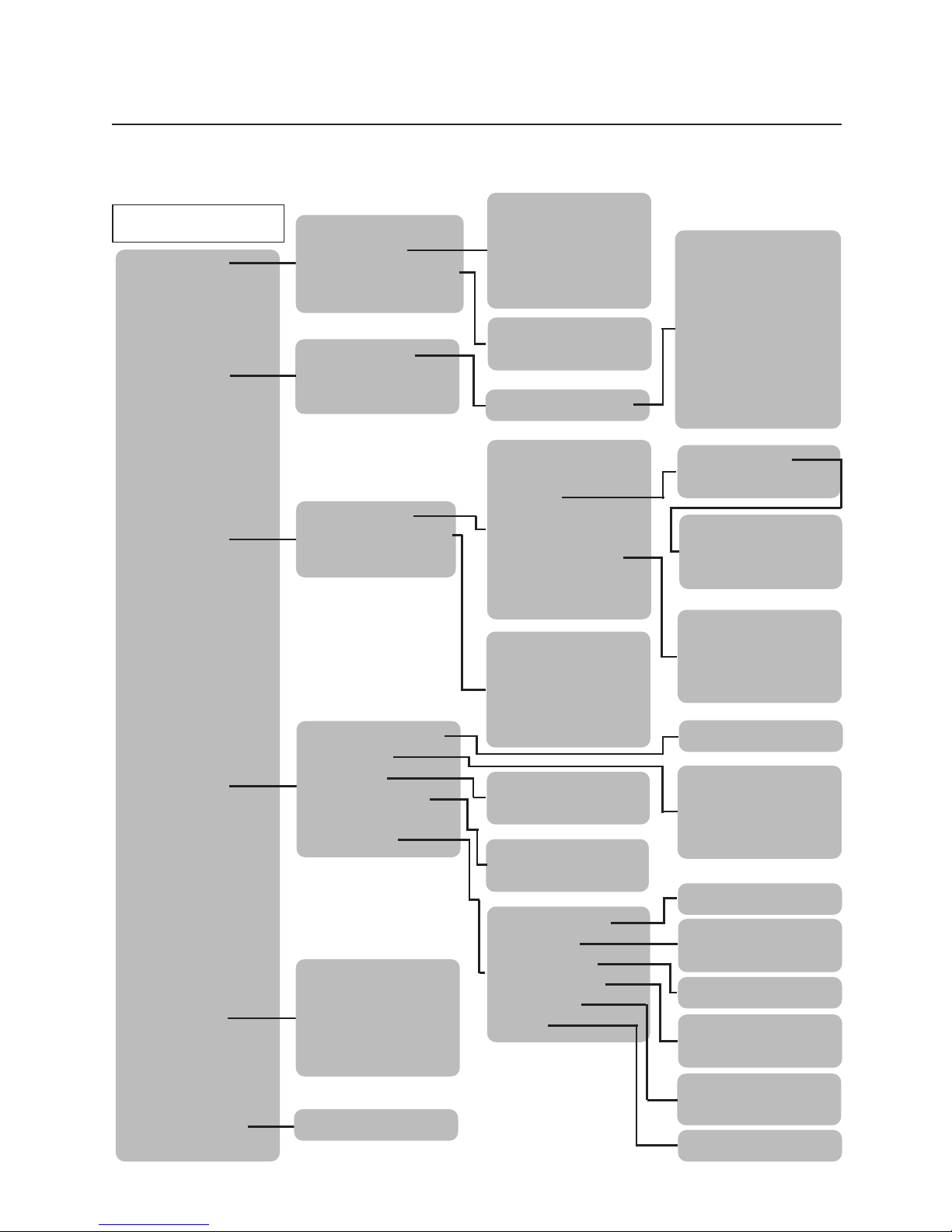

Page 15

15

MEMORY

SENSORS

INPUT

DEVICE

SERVICE

PERIPHERY*

MMaaiinn mmeennuu

Op. values

Reset factory

Address

Device data

Lang.

Change date

Auto Off

Printer

Light

Diagnostic

Units

Touchscreen cal.

Set date

°C, °F

m/s, fpm

ppm, %

Off, td°C, g/m3,

g/kg, J/g

m3/h, cfm, m3/m,

m

3

/s, l/s, M3/h

hPa, inW, mbar,

Pa, bar, psi

Parameter

Alarm limits

Timer

Temp.

Humid.

Pres.

Density

Pitot tube factor

Cross-section

Offset factor

Info

CO limit

CO2 limit

dP limit 1

dP limit 2

Acoustic alarm

Duration

No./values

Info

Save

Delete

Circle

Square

Rectangle

Area

from height

absolute

Pressure

Metres above m.s.l.

Diff. pressure

contrast

Print text

On/off

Automatic

Temp.

Humid.

Velocity

Vol.-Flow

Pressure

Gas

yes

no

Probe socket 1

min input

max input

min output

max output

Unit

Decimal place

Info

Save

Delete

Scaling

Reset

Info

Read out

Mean

Delete memory

Free memory?

System description

Menu overview

Control unit

Off

5 Min.

10 Min.

....

*with touchscreen option only

Page 16

Function menu and function bar

Commissioning

16

The function bar can be assigned as desired to all functions

of the function menu. Pressing the key with a function

key opens the function menu. The entries in the function

menu change according to the connected components of

the measuring system.

F

UNCTION MENU ANALYSER BOX/CONTROL UNIT

Pump starts. Flue gas measurement runs.

Doubles the character size.

Saves readings.

Differential temperature measurement with 2 probe inputs of

the analyser box.

Graphic display of the temperature during core current

search.

Fine draught with 0.001 hPa resolution.

Starts solid fuel measurement.

Prints readings.

Printer paper line feed.

Re-zeros the measuring cell.

Fresh air purging of the measuring cells.

Starts CO undiluted measurement.

F

UNCTION MENU, CONTROL UNIT

Doubles the character size.

Freezes the current readings.

Shows the highest value during a measurement.

Shows the lowest value during a measurement.

Calculates mean value.

Additional display for volume flow rate measurement.

Displays in metres per second.

Zeros external pressure probe.

Zeros CO probe.

Starts solid fuel measurement.

Analyser box is detected without restarting the

device.

PPSSttaarrtt

uuCCOO oonn

SSttaarrtt

MMeemm..

DDeellttaa TT

CCoorrccuurr

DDrraagghhtt

PPrriinntt

ZZeerroo

GGaass

ZZoooomm

ZZoooomm

HHoolldd

MMiinn

MMaaxx

VVooll

MMeeaann

mm//ss

hhPPaa==00

ppppmm==00

SSeeaarrcchh

SSttaarrtt

LLFF PPrr

Page 17

17

Commissioning

Function menu and function bar

LED 1

LED 2

LED 3

DDeellttaa TT

MMeemm..

ddPP 11

ddPP 22

PPrriinntt

LLFF PPrr

DDiiaagg..

EESSCC

OOKK

TTeesstt

CChhaannggee

EEnndd

IInnffoo

aa AA

<<

Status display of the LED

Saves readings.

T1 + T2, displays differential temperature.

Differential pressure 0 - 80 mbar

Differential pressure 0 - 1000 mbar

Prints readings.

Printer paper line feed

Direct display of all error messages

F

UNCTION BAR

Cursor up (optional with touchscreen)

Cursor down (optional with touchscreen)

Menu exit (optional with touchscreen)

Confirms input (optional with touchscreen).

Set values come into effect

Change

Prints test page.

Accepts settings and closes window.

Upper/lower case switch

Back + deletes 1 character.

Space

Overview of settings

Sets standard values.

Current value comes into effect

CCuurrrr..

LED1 (Power):

Mains operation Green/Permanent

Battery operation (batt. full) Green/Flashing

Battery operation (batt. empty) Red/Flashing

Battery recharging, Off mode Off

LED2 (Status):

Measuring Green/Permanent

Fresh air/Zeroing Green/Flashing

Defect Red/Flashing

LED3 (Battery recharging):

Battery recharging (fast charge) Green, flashing

Batt. full, compensation charge Green, permanent

Page 18

18

Commissioning

Power supply

115/230 V

Mains

adapter

0554.1084

or

or

Plug mains cable into analyser box. The power supply for

the control unit is ensured when

- control unit is connected to the analyser box by the

contact strips

or

- control unit is connected to the analyser box by the spiral

BUS cable

The power supply for the control unit in rechargeable

battery operation is ensured when:

- control unit is connected to the analyser box by the

contact strips

or

- control unit is connected to the analyser box by the spiral

BUS cable

Observe battery capacity.

Ensure correct polarity.

There should always be rechargeable batteries/batteries in

the control unit.

Power supply, analyser box/control unit

Control unit power supply

MAINS OPERATION

Connect mains adapter to the control unit.

MAINS OPERATION

RECHARGEABLE BATTERY OPERATION

RECHARGEABLE BATTERY OPERATION with battery pack

(art. no. 0554.0097)

RECHARGEABLE BATTERY OPERATION WITH STANDARD

BATTERIES

BATTERY OPERATION

Page 19

19

Battery charging

Commissioning

Charging batteries, analyser box/control unit

Charging battery pack, control unit

The battery packs must be installed in the analyser box and

the control unit for charging.

Plug mains cable into analyser box.

Note

The units must be switched off. Charging is impossible

during operation.

The charging of the battery pack for the control unit is

ensured when:

- control unit is connected to the analyser box by the

contact strips

or

- control unit is connected to the analyser box by the

spiral BUS cable.

Charge level displays:

- Analysis box:

Recharging is in progress: Recharging battery LED

flashes green,

Recharging is complete: Recharging battery LED lights

up green

- Control unit: Shows charge level in display.

The battery pack must be installed in the control unit for

charging.

Standard batteries cannot be charged.

Plug mains adapter into the control unit.

Note

The control unit must be switched off. Charging is

impossible during operation.

Charge level display:

- Charge level is shown in display.

115/230 V

Mains

adapter

0554.1084

The end user is legally required to dispose of all used batteries in

in accordance with their country’s regulations.

CChhaarrggiinngg CCoonnttrrooll UUnniitt

CChhaarrggiinngg CCoonnttrrooll UUnniitt

Page 20

20

Example measurement

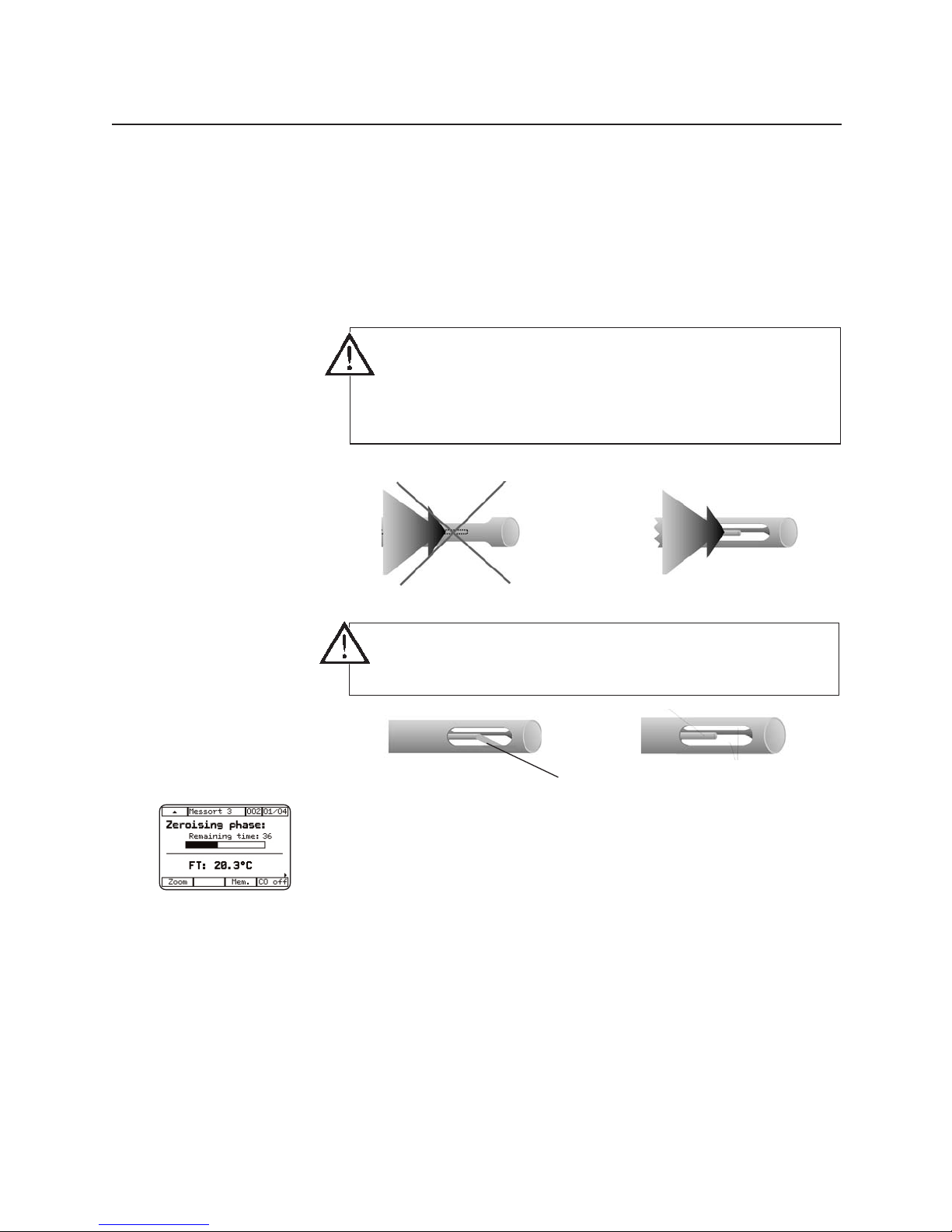

Correct use of the flue gas probe

The measurement of the flue gas temperature is made by

the thermocouple at the tip of the flue gas probe. The probe

tube protects the thermocouple, but has openings in to

allow the stream of flue gas to envelop the thermocouple.

The

temperature

measurement is made during the zeroing phase. The flue

gas probe can be adjusted in the flue at this time (Note: the

AT probe must be connected). This makes it possible to

conduct a core current search during the zeroing phase. The

temperature measured by the flue gas probe is interpreted

by the testo 300 XXL as the combustion air temperature

unless a AT probe is connected (Note: the probe must be

removed from the flue). When the zeroing phase has been

completed, this value is saved as the combustion air

temperature value.

All dependent parameters are calculated by this value.

incorrect

Flue gas

stream

Thermocouple

incorrect

correct

correct

The thermocouple must always be exposed to the stream

of flue gas to allow an exact measurement of the flue

gas temperature and thereby a precise determination of

the flue gas losses. It must not be screened by a web of

the probe pipe.

The tip of the thermocouple must not touch the guard. If

necessary, bend the tip of the thermocouple accordingly.

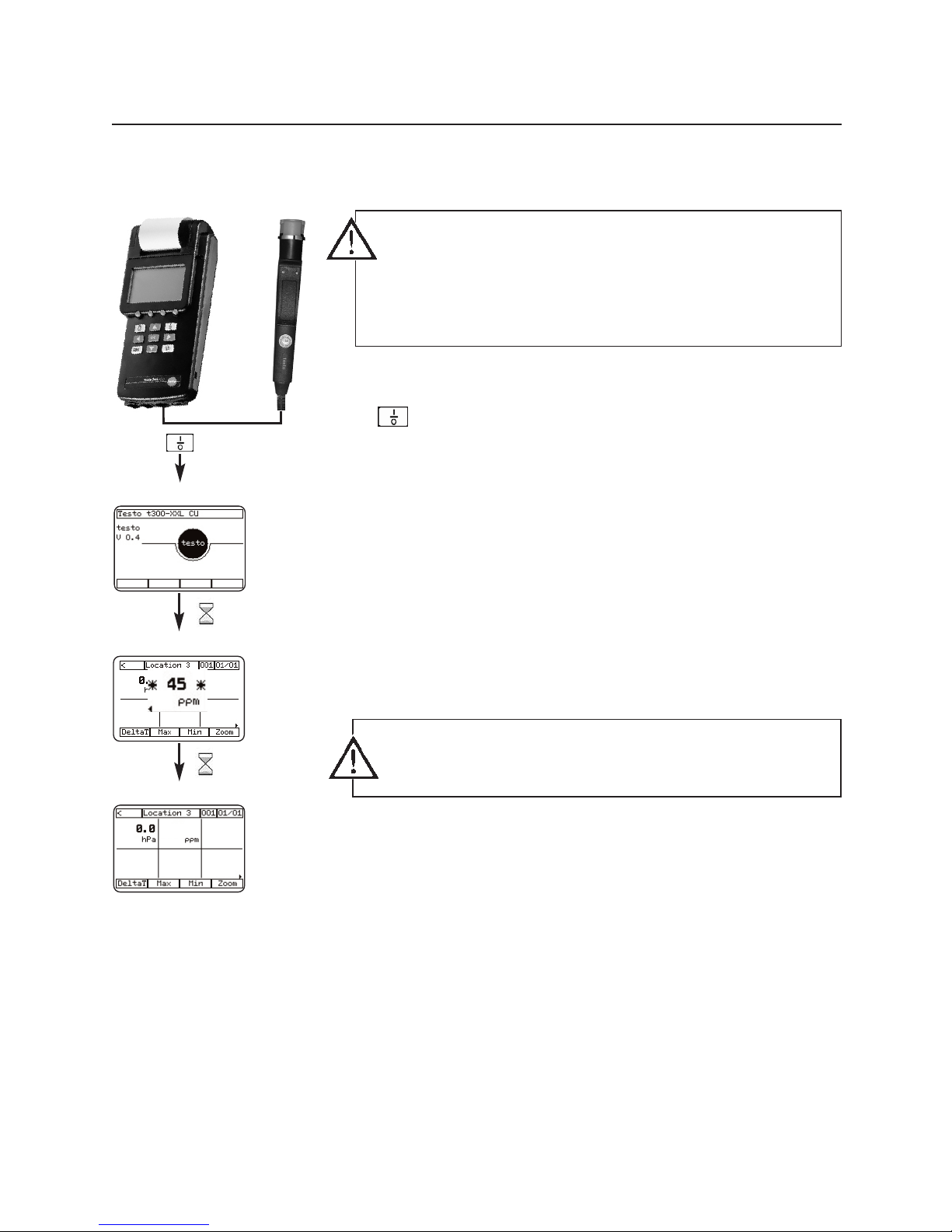

Page 21

Example measurement

21

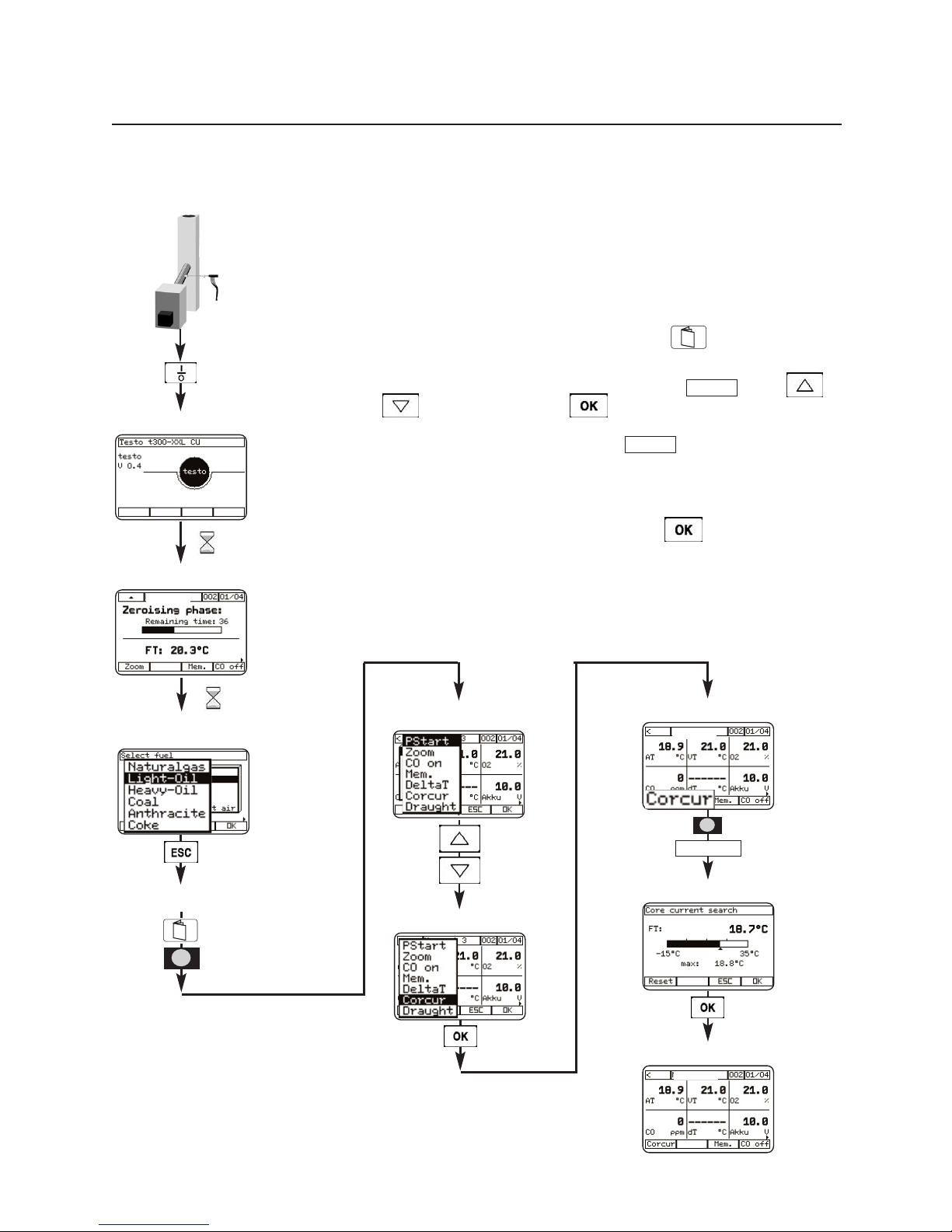

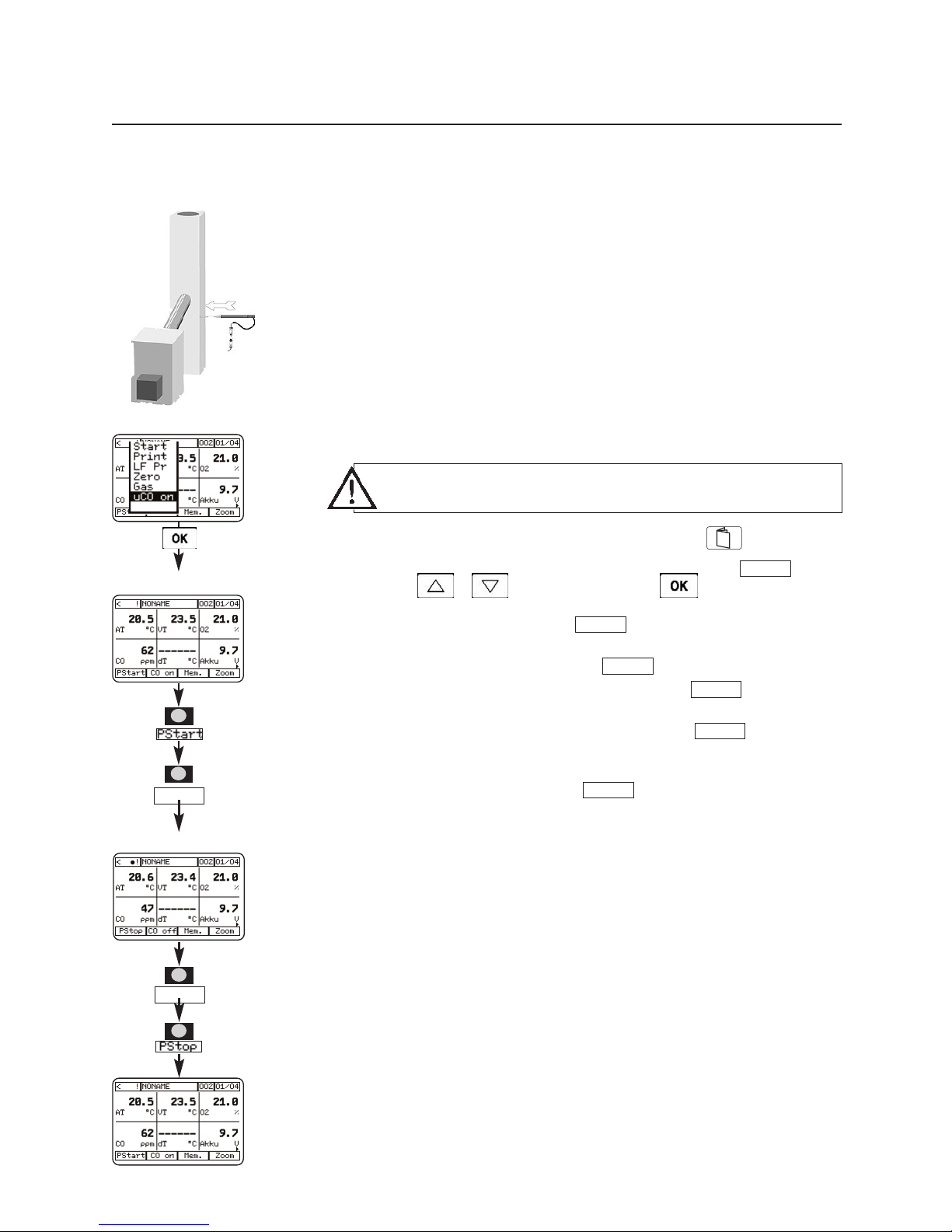

Preparing for measurement

with the control unit and analyser box

Control unit + analyser box + flue gas probe

1 Connect flue gas probe to analyser box.

2 Switch on .

3 Zeroing phase

Any connected CO probe and the gas measuring cells of

the analyser box are zeroed during the zeroing phase.

4 Fuel selection

The menu “Fuel selection” appears during the zeroing

phase.

Select the desired fuel with the keys or and

confirm with .

5. Back to the zeroing phase.

Note

After zeroing phase back to the measurement menu with

the key.

10 sec

Flue gas probe

Analyser box

Initialisation

Zeroing phase

Select the

fuel

Connect the flue gas probe before switching on the control

unit and the analyser box.

Note

The analyser box does not need to be activated in the

device selection menu. It is detected automatically when

the measuring unit starts.

LLooccaattiioonn 33

Page 22

22

Example measurement

Starting core current search:

1 Connect flue gas probe to analyser box.

2 Place flue gas probe in flue pipe.

3 Activate the function menu with the key and one of

the function keys. Select function key with

and confirm with .

4 Start core current search with .

5 Determine core current temperature.

6 Terminate core current search with .

Note

A core current search is also possible during the zeroing

phase.

Corcur

Corcur

Core current search

with the control unit and analyser box

Measurement menu

Measurement menu

Core current menu

Select core current

10 sec

Initialisation

Device zeroing

Automatic fuel display

Zeroing phase

3 x

1 sec

Function menu

CC oo rr ccuu rr

LLooccaattiioonn 33

LLooccaattiioonn 33

Page 23

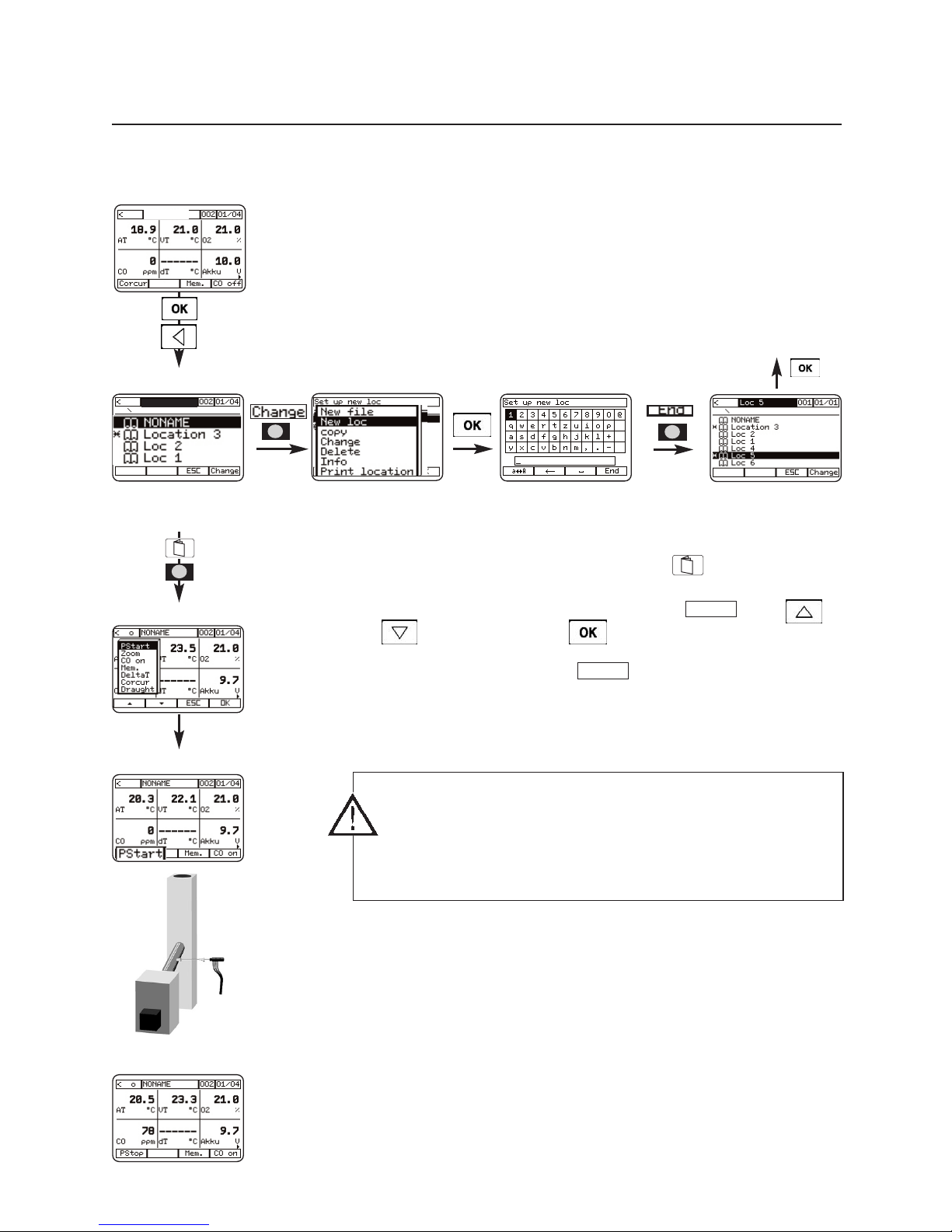

Preparing for measurement

1 Specify new location and select (see page 41):

2 The four function keys of the control unit are freely

configurable with the functions of the function menu.

3 Activate the function menu with the key and one of

the function keys. Select function key with

and confirm with .

4 Start measurement with .

5 Position the flue gas probe in the core current:

Seek flue gas temperature AT max, then fasten the probe

with the cone in this position.

6 When the readings no longer change, stop the pump.

Place flue gas probe in fresh air.

The readings are retained until the pump is next started.

PStart

PStart

Example measurement

Flue gas measurement at burners

with the control unit and the analyser box

23

Back to the measurement menu

If the flue gas probe is positioned vertically or at an angle

of up to 45°, falling drops of condensation can cause a

sudden drop in the temperature.

Remedy: Readjust flue gas probe.

Measurement menu

Location

Measurement menu

Function menu

Measurement menu

Measurement menu

1 sec

Page 24

Conducting a CO measurement in gas burners (flue gas path test)

with the control unit and analyser box

1 Activate the function menu with with the key and

one of the function keys. Select function key

with and confirm with .

2 Start measurement with .

3 Measure undiluted CO with .

Display of the function key changes to .

4 Finish undiluted CO measurement with .

Undiluted CO is saved.

5 Finish measurement with .

PStop

uCO off

uCO off

uCO on

PStart

uCO on

uCO off

uCO on

24

Example measurement

Measurement menu

Function menu

Measurement menu

CO limit for the rejection of a system (in relation to

undiluted flue gas): > 1000 ppm uCO

Page 25

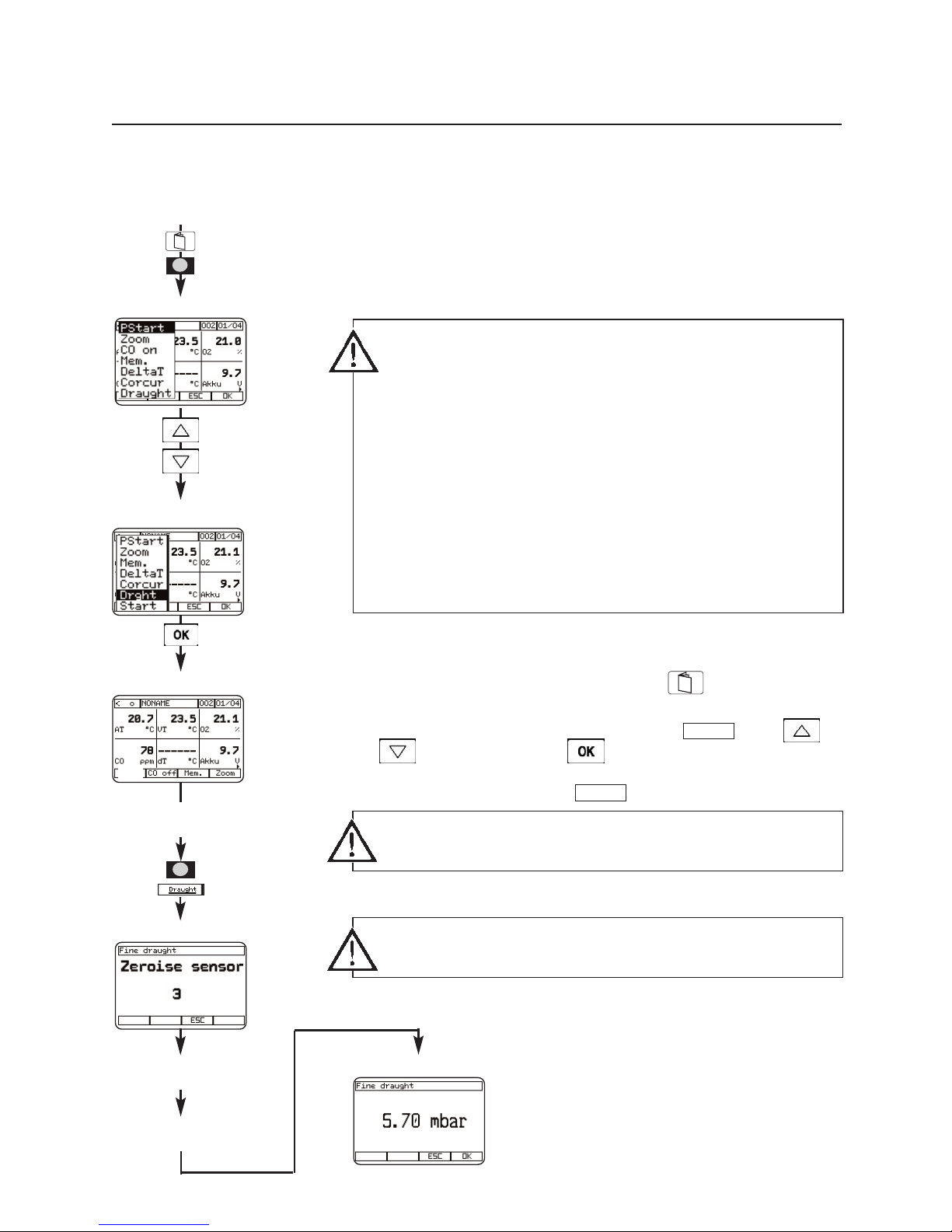

Draught measurement

with the control unit and the analyser box

25

Preparing for measurement

Use the flue gas probe for the draught measurement. The

draught measurement can be conducted before or after a

flue gas measurement.

Start measurement

1 Activate the function menu with the key and one of

the function keys. Select function key with

and confirm with .

2 Start measurement with .

3 Place probe in flue.

4 Display of the current reading.

Draught

Draught

Example measurement

A draught measurement is only possible with the pump

switched off. The + pressure inlet of the device must be

open!

Do not change between battery and mains operation

during the draught measurement (voltage fluctuations

influence the result of the measurement)!

If you conduct the draught measurement after a flue gas

measurement, a head of pressure exists in the hose after

the pump has stopped, which must be dispelled. This

occurs within approx. 30 seconds.

Remove any traces of condensation in the flue gas probe

(shake out the probe with the tip towards the floor).

Sensor zeros automatically, probe must be outside

the flue.

Negative sign indicates vacuum,

positive sign indicates pressure in the flue.

Select “Draught”

Measurement menu

Flue gas probe

outside flue

Place probe in flue

Stable reading?

Autom. zeroing

Result

Measurement menu

Function menu

1 sec

DDrrgghhtt

Page 26

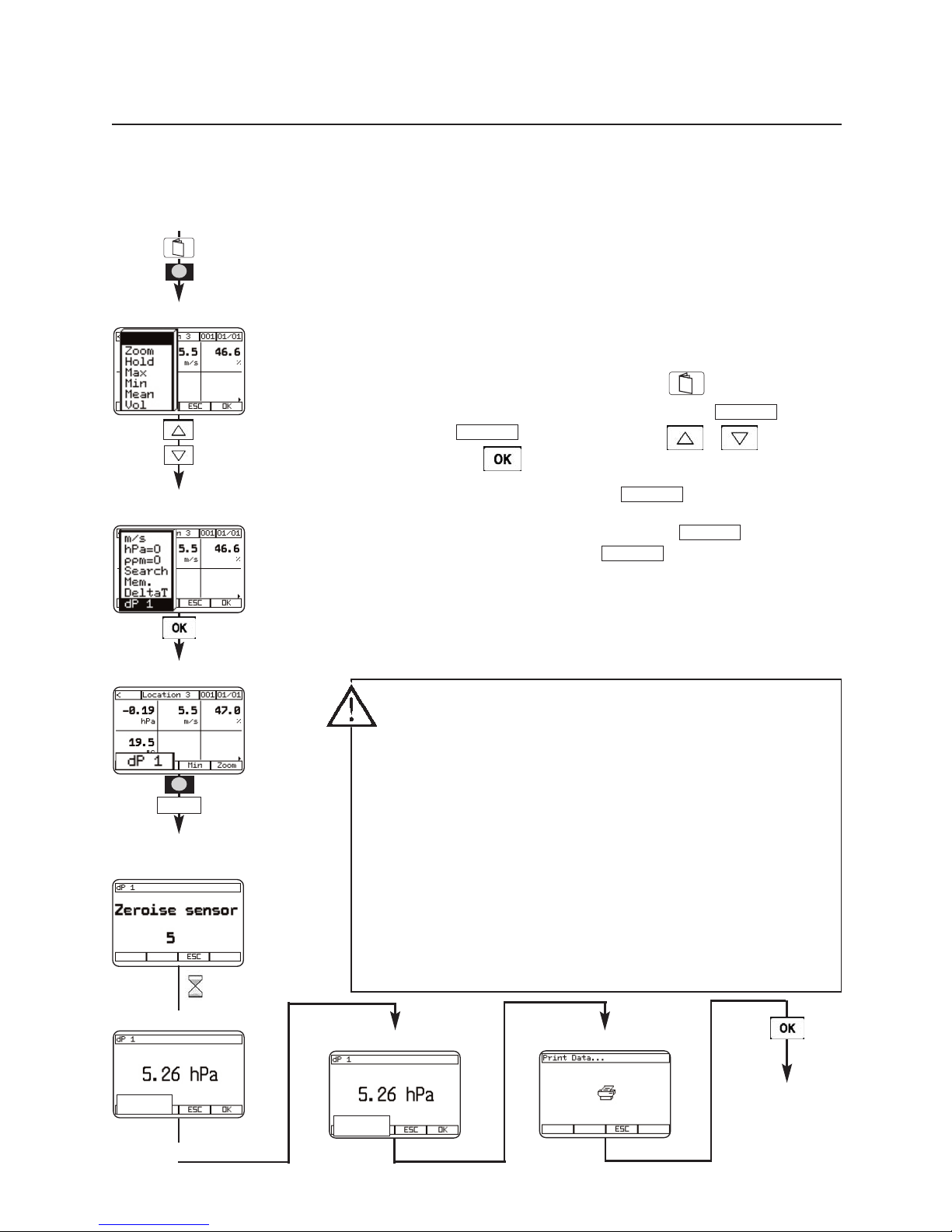

Preparing for measurement

Selection of a suitable measuring range.

Two measuring ranges P1 (-80 to +80 hPa) and P2 (-1000

to +1000 hPa) are available in the function menu:

Start measurement

1 Device selection: control unit

2 Activate the function menu with the key and one of

the function keys. Select the function key (low

range) or (high range) with and

confirm with .

3 Zero sensor with function key .

4 Start measurement with function key , stop

measurement with function key or the measurement is terminated automatically when the time has

expired (Input menu - Timer).

5 Display and printing of the current reading.

TStop

TStart

dP1

dP2

dP1

26

Differential pressure measurement

with the control unit

Example measurement

Do not use in the main duct!

Ensure that there are no leaks between the sampling

point and the device (escaping gas and atmospheric

oxygen can create an explosive mixture)!

Do not smoke or use naked flames during the

measurement!

Observe the rated pressure of the connections!

Do not exceed the measuring range!

No gas enters the device because an air cushion forms

between the sensor and the gas inlet. The measuring unit

is therefore not protected against explosions.

Measurement menu

Measurement menu

Measurement menu

Function menu

Select “dP1” and/or

“dP2”

Automatic sensor

zeroing

Start measurement

Stop measurement

Print

1 sec

10 sec

dP1

TT SStt aarrtt

TT SStt oopp

01:00 min

00:27 min

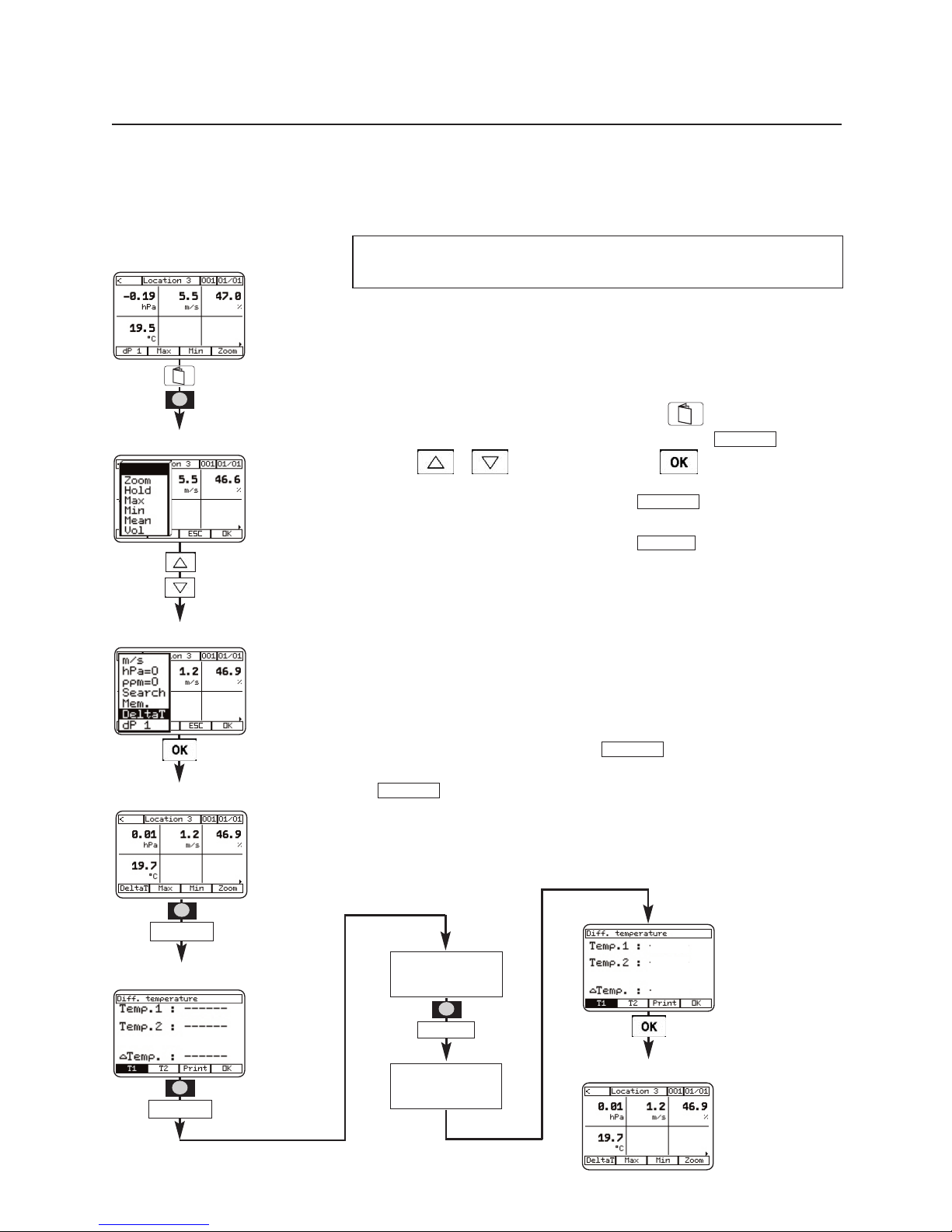

Page 27

27

Measurement with control unit + temperature probe

For pure temperature measurement, e.g. supply / return

temperature

The testo 300 XXL control unit has a multi-probe input.

1 Activate the function menu with the key and one of

the function keys. Select the function key

with and confirm with .

2 Measure T1: Press function key .

3 Measure T2: Press function key .

4 Display of the measured differential temperature value

Measurement with control unit + analyser box + 2

temperature probes

Device selection: flue gas measuring box

1 Configure function key with (see above)

2 display of the current value of Temp.1 (probe

connection), Temp.2 (flue gas probe connection) and the

differential temperature.

DeltaT

DeltaT

T2

T1

DeltaT

Differential temperature measurement

with the control unit

Display

Temp. 1

Display

Temp. 2

Before switching on the testo 300 XXL, connect the

temperature probe!

Example measurement

T1 T2

Measurement menu

Differential temperature

Measurement menu

Measurement menu

Function menu

Select “Delta T”

1 sec

DDeellttaa TT

TT 11

TT 22

4499..88

1155..44

3344..44

Page 28

Measurement with: control unit + CO probe

1 - Initialisation - Zeroing of the CO probe (60 sec)

After zeroing, the CO probe is ready for measuring.

2 Open cap.

Note

The direction of flow of the gas to the probe influences

the measuring accuracy! Optimum measurement results

are achieved when the probe is moved gently backwards

and forwards. Frontal flow onto the probe leads to

excessive readings!

3 Close cap after the measurement.

28

CO measurement

with the control unit

Example measurement

Connect probe before switching on the control unit!

Cap must be closed during zeroing (measuring error

otherwise possible).

Open the cap only during the measurement, then replace.

Warning message when adjusted CO value is exceeded

(change limit in Main menu “Input - Alarm limits Æ- CO

limit”).

10 sec

Initialisation

CO probe zeroing

60 sec

Measurement menu

11 0000

Page 29

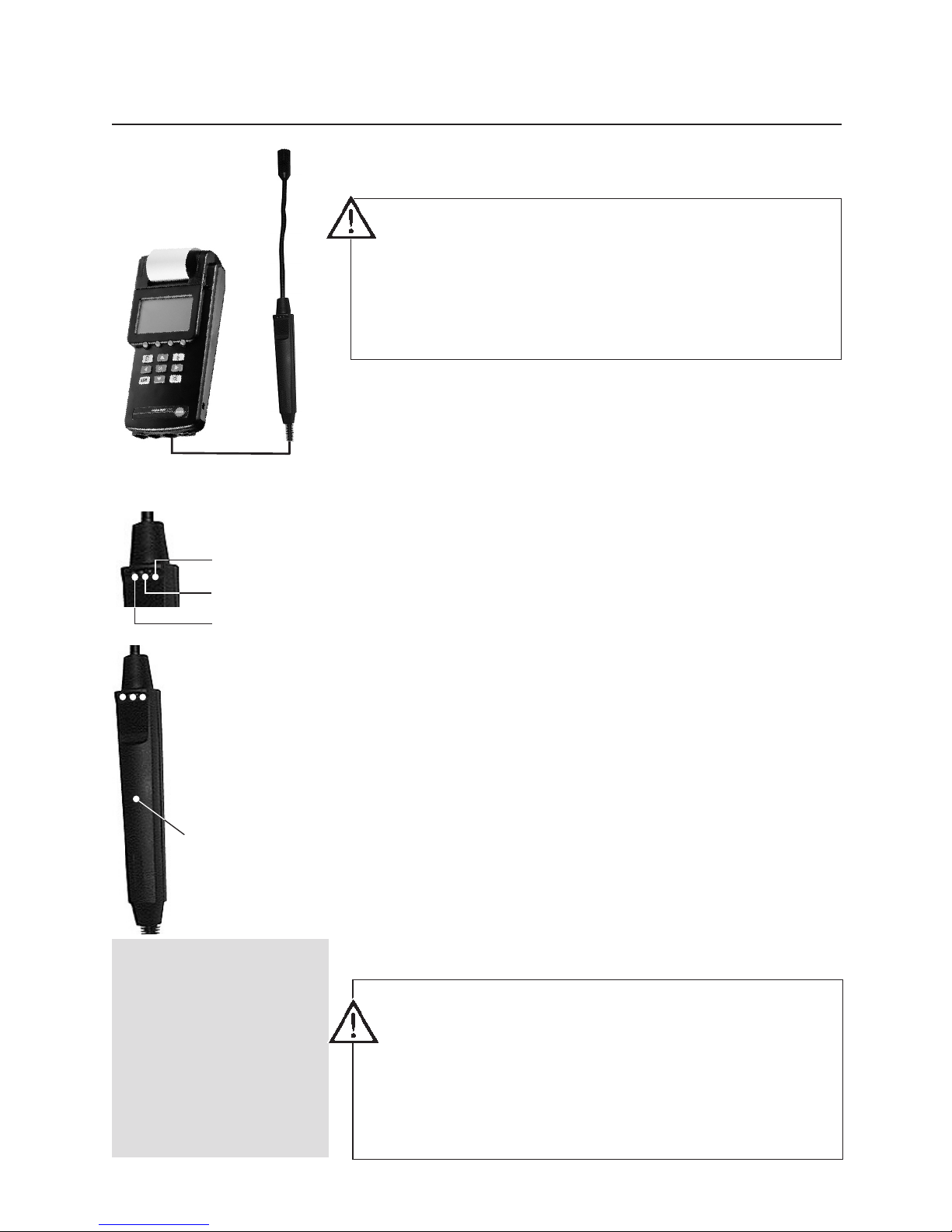

Explosive and flammable gases, particularly natural gas and

propane, are detected by the gas leak probe even in low

concentrations in the air. For example, suitable for finding

leaks in gas pipes, vessels and equipment.

1 Connect the probe before switching on the

testo 300 XXL.

2 After the device has been switched on, the warming up

phase of the leak detection probe is automatically started

(approx. 30 sec). Green, yellow and red LED, steady

tone.

3 Ready for use

Green LED flashes steadily, steady tone stops.

4 Conduct leak detection:

• When gas escapes, acoustic signal

(ticking) is audible, becoming faster with increasing

concentration.

• When the 1st switching limit (> 200 ppm) is exceeded,

yellow LED flashes.

• When the 2nd switching limit (> 1%) is exceeded, red

LED flashes, steady tone. No readings of the gas leak

probe are indicated in the display.

The power supply of the gas leak probe is provided by the

control unit.

29

Service tip:

The trigger limit is factory

adjusted to 200 ppm

CH4 gas.

The 1st alarm limit can

be finely adjusted in a

range from 0...1000 ppm

(perform in fresh air only).

Example measurement

Gas leak probe

with control unit

Do not use the gas leak probe and testo 300 XXL in

enclosed rooms or facilities in which gases have

accumulated into an explosive mixture.

The use of other electrical equipment is also prohibited.

It must be ensured that the gas concentration does not

exceed 20% LEL.

Duration of measurement with the gas leak probe with fully

charged battery, maximum 2 hours.

Remove the gas leak probe from the device

immediately after the measurement to prevent heavy

battery discharge.

Never leave the gas leak probe connected when charging

the batteries.

red LED

yellow LED

green LED

Trimmer potentiometer

for fine adjustment of

the 1st alarm limit.

Page 30

30

Example measurement

Humidity measurement

with the control unit

Measurement with: combination humidity probe, e.g.

Part no. 0636.9740

1 Connect combination humidity probe to the probe input

of the control unit.

2 Switch on the control unit.

3 Current readings of relative humidity, temperature and

dew point are displayed.

Changing units:

- Press key

- In Main menu - Device - Units – Change unit

A detailed description is contained in chapter Main menu,

Device for control unit - Units.

10 sec

Initialisation

Zeroing

Measurement menu

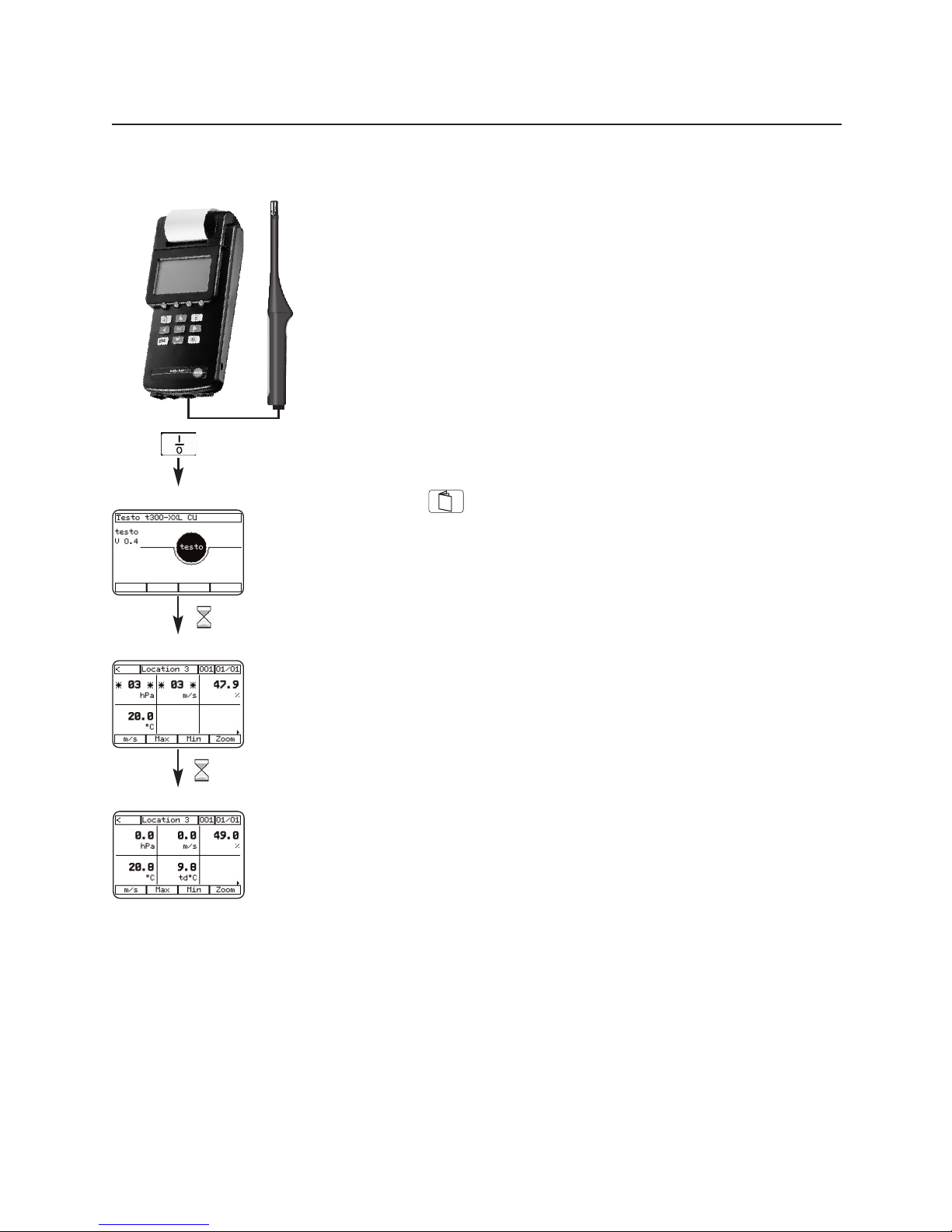

Page 31

31

Example measurement

Velocity measurement

with the control unit

Special notes on the thermal velocity probe with

direction probe 0635.1041

Fully push down the cap of the probe.

During the measurement, observe the markings of the

probe head and on the telescope. The markings must form

a line.

For velocity measurements with a known

direction of flow, the arrow mark on the probe

head must point in the direction of flow.

For velocity measurements with an unknown

direction of flow, turn the probe 360° around its

axis. Observe the reading. The maximum value

indicates the direction of flow.

Note

Measurement against the direction of the arrow falsifies the

readings by up to 40%.

Page 32

32

Example measurement

Velocity measurement (hot wire or vane)

with the control unit

Volume flow measurement in a duct with 500 mm

diameter with velocity probe.

1 Connect the velocity probe to the probe input of the

control unit.

2 Switch on control unit.

3 Activate the function menu with the key and one of

the function keys. Select the function key

with and confirm with .

4 Enter duct diameter:

- Press key.

- From Main menu – Input – Parameter – Cross section Circle – enter value

5 Accept the value with function key .

6 Return to the measurement menu with .

7 Start measurement with .

VOL

End

Zeroing

10 sec

Initialisation

Measurement menu

Measurement menu

Measurement menu

Measurement menu

VOL

1 sec

20 sec

Select “Vol”

Main menu

Select “Input”

Select “Parameter”

Function menu

Select “Cross section”

Select “Circle”

Value is automatically

saved

Enter value

End

Vol

Page 33

33

Example measurement

Velocity measurement (hot wire or vane)

with the control unit

Mean value

1 Connect the velocity probe to the probe input of the

control unit.

2 Switch on control unit.

3 Activate the function menu with the key and one of

the function keys. Select the function key with

and confirm with .

4 Enter averaging:

- Press function key .

- Select menu and enter value.

5 Accept value with function key and return to the

measurement menu.

6 Start averaging with .

7 End averaging with .

8. Return to the measurement menu with .

ESC

End

Start

End

Mean

Zeroing

10 sec

Initialisation

Measurement menu

Measurement menu

Measurement menu

1 sec

20 sec

Select “Mean”

Select “Timed/Multi-

point”

Start averaging

Calculating mean

value

Mean calculation

result

Function menu

Enter value

End

End

ESC

Start

22..2255

Mean

Page 34

34

Example measurement

Velocity measurement (volume velocity measurement with funnel)

with the control unit

Volume flow measurement at an inducing opening

A volume flow rate funnel is required for volume flow rate

measurement at an inducing opening (grid or cap with

annular gap).

The opening of the funnel must completely cover the grid

(max. 200 x 200 mm with 0554.0400 or max. 350 x

350 mm with 0554.0410).

1 Connect velocity probe, preferably 0635.1041, to the

probe input of the control unit.

2 Switch on control unit.

3 Activate the function menu with the key and one of

the function keys. Select function key with

and confirm with .

4 Enter duct diameter:

- Press key

- From Main menu - Input - Parameter - Cross section -

Circle - enter value 8.82 cm.

5 Accept the value with function key

6 Return to the measurement menu with .

7 Start measurement with .

VOL

End

VOL

Zeroing

10 sec

Initialisation

Measurement menu

Measurement menu

Measurement menu

Measurement menu

1 sec

20 sec

Select “Vol”

Main menu

Select “Input”

Select “Parameter”

Function menu

Select “Cross section”

Select “Circle”

Value is automatically

saved

Enter value

End

Vol

Page 35

35

Example measurement

Velocity measurement (pitot tube)

with the control unit

Velocity measurement with pitot tube

Method 1 (limited):

Connect the pitot tube directly to the pressure inlet of the

control unit. Limitation: Only the pressure value is shown

during the measurement. The values for velocity speed and

volume flow are shown when the measurement is complete.

Method 2:

Use the pitot tube preferably with the pressure probe order

no. 0638.1445 due to the optimum accuracy. Measuring

range up to approx. 40 m/s. An additional channel is also

displayed (hPa, m/s, m

3

/h).

The velocity is calculated automatically by the device from

the pressure difference at the pitot tube.

Note

The pitot tube factor of the standard Testo pitot tubes is

1.00 and need not be changed. Enter the factor 0.67 for

the straight testo pitot tubes. For other pitot tubes, ask the

supplier for the pitot tube factor and store.

1 Connect the pressure probe to the probe input or the

pitot tube to the pressure outlet of the control unit.

2 Switch on control unit.

3 Enter the pitot tube factor:

- Press key

- From Main menu – Input – Parameter – Pitot factor –

Set value

5 Accept the value with function key .

6 Return to the measurement menu with .

End

Select “Parameter”

Main menu

Select “Input”

Select “Pitot factor”

Measurement menu

Value is automatically

saved

Enter value

End

10 sec

5 sec

Initialisation

Zeroing

Measurement menu

Page 36

36

Example measurement

CO2measurement with the control unit

The probe 0632.1240 measures concentrations of 0...9999

ppm.

1 Connect probe, switch on control unit.

2 Warming up phase of the CO2 sensor

3 Display of a reading

4 Enter absolute pressure:

- Press key.

- From Main menu – Input – Parameter – Pressure –

Absolute pressure – Set value

5 Accept the value with function key .

6 Return to measurement menu with .

7 Display of the current reading.

End

The measured CO2 value depends on the absolute

atmospheric pressure. This effect is compensated by the

device internally. For this, enter the absolute pressure of

the location in the main menu. The displayed CO2 value

is automatically compensated to the entered absolute

pressure.

To avoid the effects of the CO2 content of respired air, hold

the probe as far away from your body as possible.

The measuring principle is based on infrared absorption.

This type of probe has a relatively high power

consumption. For long-term measurements, use the

mains adapter and rechargeable batteries.

If sudden changes occur in the concentration, the probe

will require 30 – 60 sec. to adapt to the environment.

Gently waving the probe reduces the adaptation time.

10 sec

30 sec

Initialisation

Measurement menu

Measurement menu

EE nn dd

Warming up phase

Main menu

Select “Parameter”

Select “Pres.”

Select “Absolute”

Enter value

Select “Input”

Measurement with control unit + CO2 probe

Page 37

37

Example measurement

Current/voltage measurement

with the control unit

Measurement with control unit + cable 0554.0007

Currents and voltages are measured with the probe

0554.0007.

These signals can be assigned to a different physical unit.

Example: 0...20 mA are to represent 0...100 %RH when

displayed later.

1 Connect current and voltage cable, switch on control

unit.

2 Enter the physical unit:

- Press key.

- From Main menu - Probe - Scaling- Probe socket 1 Menu min. input, max. input... Set values

- Min. input - - enter 0 -

- Max. input - - enter 20 -

- Min. output - - enter 0 -

- Max. output - - enter 100 -

- Enter unit

- %RH -

- Enter decimal places - .

3 Scaling info

4 Return to the measurement menu with .

5 Display of the current reading.

Main menu

Select “Probe”

Select “Scaling”

Select “min input”

Set value

Display info

Set further values

(see above)

Select “Probe”

socket 1

Measurement menu

10 sec

Initialisation

Measurement menu

EE nn dd

EE nn dd

OO KK

EE nn dd

EE nn dd

EE nn dd

EE nn dd

Page 38

38

Printing

Printing the measurement results

Printout of the currently displayed readings:

1 Activate the function menu with the key and

function key.

2 Configure function key with .

3 With key back to the measurement menu.

4 Press function key .

5 Print.

If no location is active, the printout is made with

“NONAME”.

Print

Print

testo 300 XXL

SN: 000321/D

Smith Ltd.

Manchester

Location: furnace 5

15:01:00 08:20:15

Fuel: Natural gas

10.9 % CO2

0.45 % O2

2348 ppm CO

320 ppm NO

15 ppm NO2

1050 °C Flue gas temp.

32.5 °C Comb. temp.

15.2 m/s Velocity

1.2 % Flue gas loss

Batch 25/2

Date/time

Memory identifier

Fuel

Readings

1 sec

Measurement menu

Function menu

Select print

Measurement menu

Print

Page 39

39

Main menu Memory

Overview

The memory organisation of the testo 300 XXL is designed

such that a so-called “Location” must exist to identify a

saved reading. This location can consist of up to 20

alphanumeric characters.

For example, a location may be:

- the name of the customer

- a customer number or

- the designation of a location.

Several measurements can be saved for each location. This

is possible by pressing the function key

“Mem.”

several

times.

It is also possible to place locations in directories

(see Measurement data processing).

The maximum possible number of measurements depends

on whether each individual measurement is saved with its

own location or all measurements are saved exclusively with

one location.

Page 40

40

Main menu Memory

Saving without selecting a location

Measurement menu

Function menu

Select “Mem.”

Measurement menu

Save under

“NONAME”

Depending on the selected devices, the readings are

saved in the activated component (control unit or

analyser box).

If no location has been chosen after the device was

switched on, data can still be saved. The location

“NONAME” is used for this. This location is the default

setting.

1 sec

Save currently displayed readings

1 Activate the function menu with the key and

function key.

2 Configure function key with .

3 With key to get back to the measurement menu.

4 Press function key .

5 Save.

If no location is active, the data is saved under “NONAME”.

MMeemm..

MMeemm..

MMeemmoorryy

Page 41

1. Change to menu “Location” with key and .

2. Press key

in window “Location”.

3. With keys , select “New loc”

and confirm with key .

4. Enter the location.

5. With function key , the location is accepted in the

“Location” menu.

End

Change

41

Main menu Memory

Creating a new location

Measurement menu

Location

“New loc” selected

Name location

Displays new

location

Measurement menu

Create new location

change

OK

Confirm selected character

with “OK” key.

End

Page 42

42

Main menu Memory

Selecting saved location

1. Change to menu “Location” with key and .

2. Select desired location with keys .

3. Accept with key . Returns to the measuring menu.

4. With the function key

“Mem.”

, the current readings are

saved under the selected location.

This menu item is accessible during the zeroing phase of the

testo 300 XXL.

Measurement menu

Measurement menu

Location

saved location

selected

Page 43

43

Main menu Memory

Using an existing location as format for a new location

Location selected

Select “copy”

Location

1. Change to menu “Location” with key and .

2. Select the location to serve as the source for the copy.

3. Press .

4. Activate the “copy” function. Press . The cursor is

behind the last character of the location.

5. Press function key “Å” to the desired character. The last

character is deleted each time.

6. With keys , , , , select the desired

character (text input) and accept with key .

7. When the location is complete, press function key

, returning to the location list. The newly created

location is displayed.

Branch to the measurement manu with key .

End

Change

Measurement menu

change

Å

“copy” is activated

Renaming a

location

Location renamed

Displays new

location

Measurement menu

End

Confirm

selected

character

with “OK”

key

Page 44

44

Main menu Memory

Changing existing location

Location selected

Select “Change”

Location

1. Change to menu “Location” with key and .

2. Select the location to be changed.

3. Press .

4. Activate the “Change” function. Press function key “OK”.

5. Press function key “Å” to the desired character. The last

character is deleted each time.

6. With keys , , , , select the desired

character (text input) and accept with key .

7. When the location is complete, press function key ,

returning to the location list. The renamed location is

displayed. The changed location is deleted.

Branch to the measurement menu with key .

End

Change

Measurement menu

change

Å

“Change” activated

Changes the

location name

Location renamed

Displays new

location

Measurement menu

End

Confirm

selected

letter with

“OK”

key

Page 45

45

Main menu Memory

Deleting existing location

1. Change to menu “Location” with key and .

2. Select the location to be deleted.

3. Press .

4. Activate “Delete” function. Press function key .

5. Location is deleted.

6. With function key or key back to the mea-

surement menu.

ESC

OK

change

Measurement menu

Select “Delete”

Entry deleted

“Delete” activated

Location selected

Location

Measurement menu

change

Note

s

OOKK

Page 46

46

Main menu Memory

Barcode pen overview

The barcode pen automates the allocation of measurement

data to a location.

If a barcode label is attached on site, this can be read with

the barcode pen.

The barcode pen is connected to the RS-232 socket on the

bottom of the device and can be connected and

disconnected whilst the device is switched on.

Activate the barcode pen by holding the tip of the pen briefly

against a white surface, e.g. the barcode label. Then move

the pen evenly and quickly in direct contact across the

barcode pattern. A correct reading is indicated by a signal

tone.

The location is automatically accepted in the location list of

the testo 300 XXL and is selectzed as the active location. It

is unnecessary to read or manually enter the customer

number of the customer where you are measuring

beforehand with a PC or by hand into the testo 300 XXL.

When you visit a customer whose customer number is not

saved in the device, you can read the number directly on

site by the barcode into the testo 300 XXL. If the location

read by the barcode pen already exists in the testo 300

XXL, this is activated.

Note

Barcodes can be created and decoded with the evaluation

software.

Page 47

47

Main menu Memory

Reading a location with the barcode pen (during the zeroing phase)

You can also enter the location after the expiry of the zeroing

phase.

Reading a location from the measurement menu

Reading several locations with the barcode pen from

measurement menu.

Procedure as described above (simply repeat the

procedure). The location last read is active.

10 sec

Initialisation

Device zeroing

Measurement menu

Measurement menu

Measurement menu

Page 48

48

Main menu Memory

Displaying saved readings

1.Change to menu “Location” with key and .

2.Select location and confirm with key .

3.Press key in the measurement menu.

4.Select “Memory” menu and confirm with key .

5.Activate “Read out” menu with key .

6.Display of the saved readings.

Main menu

Memory menu

Memory menu

Measurement menu

Displays saved

readings

Displays saved

readings

Measurement menu

Location selected

Location

2 x

Page 49

49

Main menu Memory

Mean calculation

Mean value menu

Mean value menu

Activated

Specify length of time

Main menu

Measurement menu

Start Mean

Calculation

1.Press in the measurement menu.

2.Select “Memory” menu and confirm via .

3.Select mean value menu and press .

4.Enter duration of mean calculation. Confirm reading by

clicking on .

5.Enter number of mean calculations. Confirm reading by

clicking on .

6.Information on input values. Mean calculation can be

started by clicking on .

Note:

Mean calculation stops automatically once the specified

length of time has elapsed.

EE nn dd

EE nn dd

EE nn dd

Enter number

EE nn dd

OO KK

OO KK

Information

Automatic Stop

Mean calculation

SS tt aa rrtt

Page 50

50

Main memory Memory

Printing mean calculation result

Main menu

Read out menu

Displaying and selecting

saved readings

1. Start mean calculation

2. To measurement menu after automatic stop.

3.Change to “Main menu” menu by clicking on .

4.Activate “Memory” menu.

3.Select “Read out” sub-menu.

4. Confirm by clicking on .

5.Displays saved readings. Select value which is to be

printed and start printing by clicking on

.

6.Return to measurement menu by clicking on .

Start

Mean calculation

Measurement menu

Automatic stop

Display of selected

values

Prints out data

Return to

measurement menu

PP rr ii nntt

PP rr ii nntt

Example of printout

Page 51

51

Main menu Memory

Deleting entire memory

Main menu

Measurement menu

Measurement menu

Memory menu

Select “Delete

memory”

Select yes

1. Change to menu “Main menu” with key .

2. Activate the “Memory” menu.

3. Select submenu “Delete memory”.

4. Delete memory “Yes/No”

5. Confirm with key .

6. Return to measurement menu via

Page 52

52

Main menu Memory

Printing saved readings of a location

Measurement menu

Measurement menu

Location selected

Select “Print location”

Print location

Location

cc hhaa nngg ee

Location

1. Change to menu “Location” with key and .

2. Select location and activate function key .

3. Select menu “Print location”.

4. Start printing with key .

5. Then return to the measurement menu with key .

CC hhaa nngg ee

Page 53

53

Main menu Memory

free memory?

Measurement menu

Measurement menu

Main menu

Select “Memory”

Select “free

memory?”

Displays free

memory

1. Change to the main menu with key .

2. Activate the “Memory” menu with .

3. Select “free memory?”

4. Display free memory with key .

5. Return to the measurement menu with key .

The menu provides information on the available memory

capacity to save readings.

Page 54

54

Scaling

Select “Probe”

Select “Scaling”

Select “min input”

Set value

Display info

Set further values

(see above)

Select “Probe

socket 1”

Measurement menu

Measurement menu

Currents and voltages are measured with the probe

0554.0007.

These signals can be assigned to a different physical unit.

Example: 0...20 mA are to represent 0...100 %RH when

displayed later.

1 Connect current and voltage cable, switch on control

unit.

2 Enter the physical unit:

- Press key.

- From Main menu - Probe - Scaling- Probe socket 1 Menu “min input.”, “max input”... “Set values”

- Min input - - enter 0 -

- Max input - - enter 20 -

- Min output - - enter 0 -

- Max output - - enter 100 -

- Enter unit

- %RH -

- Enter decimal places -

3 Scaling info

4 Return to the measurement menu with .

EE nn dd

EE nn dd

OO KK

EE nn dd

EE nn dd

EE nn dd

EE nn dd

Main menu Probe

for control unit

Page 55

55

Main menu Probe

for control unit

Info

Information on the entered values for calibration and

scaling.

Resetting

Entered scaling values are reset to the factory settings.

Select “Probe”

Select “Reset”

Probe socket 1

Reset

Measurement menu

Measurement menu

1. Change to the main menu with key .

2. Activate “Probe” menu with .

3. Select “Reset”.

4. Display the probe socket with key . .

5. Press key to reset.

5. Return to the measurement menu with key .

Page 56

56

Current reading

comes into effect

or

Menu: Set humidity value

Parameters

Note

The temperature, relative humidity and absolute pressure

influence the air density at the measuring point. When these

values have been entered, the density is calculated

automatically. The result is composed as follows:

Temperature

Humidity Density

Metres above sea level

Barometric pressure Absolute pressure

Differential pressure

TEMPERATURE

Enter the temperature as a parameter:

1 Connect probe, switch on control unit.

2 Change to the main menu with key .

3 From Main menu – Input – Parameter – select the

“Temp.” menu.

4 Accept the current reading with key or select

“Input temperature” with the cursor keys.

5 With function key , an automatic branch is made

to the menu “Input humidity” or with key back to the

measurement menu.

Main menu Input

for control unit

Measurement menu

Select “Input”

Select “Parameter”

Select “Temp.”

Enter temperature

EE nn dd

EE nn dd

Page 57

57

H

UMIDITY

Enter the humidity as a parameter:

1 Connect probe, switch on control unit.

2 Change to the main menu with key .

3 From Main menu – Input – Parameter – select Humidity

menu.

4 Accept the current reading with key or select

“Input humidity” with the cursor keys.

5 With function key , an automatic branch is made

to the menu “Input barometric pressure” or with key ,

back to the measurement menu.

Main menu Input

for control unit

Select “Humid.”

EE nn dd

Current reading

comes into effect

Menu: Set

pressure value

Enter humidity

EE nn dd

Measurement menu

Select “Input”

Activate “Parameter”

or

Page 58

58

P

RESSURE

Note

The absolute pressure is determined in the measuring

procedure depicted to the side. The absolute pressure

results from

• Altitude pressure (metres above sea level)

This has an annual average at sea level of 1013 mbar. The

higher the location is above sea level, the lower the

pressure.

• Barometric pressure

This has an annual average independent of the altitude

1013 mbar. This pressure can fluctuate from the annual

average by approx. ±20 mbar depending on the weather

(see local barometer display).

• Differential pressure

This is the higher or lower pressure in the duct.

The entry of the absolute pressure (in hPa only; it is

impossible to switch to other units) has an effect on the

pressure-dependent measurement values. These are