Page 1

testo 270 · Deep-frying Oil Tester

Instruction manual

Page 2

2

Page 3

1 Contents

Pos: 1 /TD/Produktbeschreibung/Grundlegende Eigen schaften/testo 27 5/Inbetriebnahmehin weise Kalibrier ung testo 275 @ 15\mod_1407 391938938_79.docx @ 1940 97 @ @ 1

Practical tips before commissioning your new testo 270

Dear Customer,

Congratulations on purchasing your new testo 270 cooking oil tester.

All our measuring instruments are factory tested by us before delivery and

adjusted to their own specific level of accuracy. To ensure a consistently high

level of accuracy, we recommend the instrument is regularly checked.

You have the following options with the testo 270 cooking oil tester:

1 Testo factory calibration according to ISO (accuracy +/- 2% TPM

You can order an ISO calibration from Testo's calibration subsidiary, Testo

Industrial Services in Kirchzarten, using order number 0520 0028. This

means your testo 270 will be calibrated at two points (at approx. 3% and at

approx. 24% TPM) under precise laboratory conditions.

Furthermore, you have the following options for checking your testo 270 yourself

at any time:

2 with Testo reference oil (accuracy +/- 2.5% TPM

With the Testo reference oil (order no. 0554 2650), you can check the

measuring instrument precisely and, if necessary, readjust it (please pay

attention to the description in the instruction manual for this).

3 with the simple function test in cooking oil (accuracy +/- 3% TPM

For a simple function test without adjustment, we recommend you carry out

a measurement during the commissioning of your new instrument in unused

cooking oil at 150 to 180 °C.

You should ideally carry out this measurement several times in succession

and note the respective readings. The mean value of these readings

represents your specific reference value for subsequent instrument

checking. To use the determined reference value as a comparative value for

a check, always carry out the measurement for instrument checking in

unused cooking oil at 150 to 180 °C.

Please make sure that the reference value is recalculated if the type of oil or

oil supplier changes.

Your specific reference value:

___________________________

1

):

1

):

1

):

1

typically, based on Testo in-house reference, at an ambient temperature of

25 °C.

3

Page 4

1 Contents

Pos: 2 /TD/Überschriften/1. Inhalt @ 0\mod_117758781707 0_79.docx @ 1243 @ 1 @ 1

1 Contents

1 Contents .................................................................................................. 4

2 Safety and the environment ................................................................... 5

2.1. About this document ....................................................................... 5

2.2. Ensure safety .................................................................................. 6

2.3. Protecting the environment ............................................................. 7

3 Specifications .......................................................................................... 8

3.1. Use ................................................................................................. 8

3.2. Technical data ................................................................................. 8

4 Product description .............................................................................. 10

4.1. Overview ....................................................................................... 10

4.2. Basic properties ............................................................................ 12

5 First steps .............................................................................................. 13

5.1. Commissioning ............................................................................. 13

5.2. Getting to know the product .......................................................... 15

5.2.1. Switching the instrument on/off ...................................................................... 15

5.2.2. Description of important functions and displays ............................................. 16

5.2.2.1. Alarm indicator ................................................................................ 16

5.2.2.2. Setting the TPM limit values ............................................................ 16

5.2.2.3. Hold function ................................................................................... 17

5.2.2.4. Auto-Hold function ........................................................................... 17

5.2.2.5. Auto-off function .............................................................................. 17

5.2.2.6. Battery capacity ............................................................................... 18

5.2.3. Configuring the instrument ............................................................................. 18

5.2.4. Locking / unlocking configurations ................................................................. 20

6 Using the product ................................................................................. 22

6.1. General measurement information ................................................ 22

6.2. Carrying out measurements .......................................................... 23

6.3. Function test ................................................................................. 25

7 Maintaining the product ....................................................................... 26

7.1. Changing batteries ........................................................................ 26

7.2. Cleaning the sensor ...................................................................... 26

7.3. Cleaning the housing .................................................................... 27

7.4. Cleaning the plastic case .............................................................. 27

7.5. Calibrating/adjusting the instrument .............................................. 28

8 Tips and assistance .............................................................................. 32

8.1. Questions and answers ................................................................ 32

8.2. Accessories and spare parts ......................................................... 33

Pos: 3 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.docx @ 283 @ @ 1

4

Page 5

2 Safety and the environment

Pos: 4 /TD/Überschriften/2. Sicherheit und Umwelt @ 0\mod_1 173774719351_79.d ocx @ 292 @ 1 @ 1

2 Safety and the environment

Pos: 5 /TD/Überschriften/2.1 Zu diesem Dokument @ 0\mod_1173775252351_79.docx @ 346 @ 2 @ 1

2.1. About this document

Pos: 6 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Ver wendung/Verwendun g (Standard) @ 0\mod_117377 5068554_79.doc x @ 337 @ 5 @ 1

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

Pos: 7 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Tabellenko pf Warnhinweise @ 2\mod_120 7645198296_79.doc x @ 14334 @ 5 @ 1

product.

Warnings

Always pay attention to information that is marked by the following

warnings with warning pictograms. Implement the specified

precautionary measures.

Representation Explanation

Pos: 8 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Warnhinweis W ARNUNG @ 2\mod_1207646 966234_79.docx @ 14398 @ @ 1

Pos: 9 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Warnhinweis AC HTUNG (Produktschaden) @ 2\mod_1207651536812_7 9.docx @ 14434 @ @ 1

WARNING

NOTICE

Pos: 10 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Tabellenk opf Symbole und Schrei bkonv. @ 2\mod_1207652481703_7 9.docx @ 14452 @ 5 @ 1

Indicates potential serious injuries

indicates circumstances that may lead to

damage to the products

5

Page 6

2 Safety and the environment

Pos: 11 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Symbole und Schr eibkonv. [Standar d_klein] @ 2\mod_120765263214 0_79.docx @ 14470 @ @ 1

Symbols and writing standards

Represen-

Explanation

tation

Note: Basic or further information.

1. ...

Pos: 12 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Schrei bkonv. Menü @ 2\mod_1207655303 453_79.docx @ 14488 @ @ 1

2. ...

> ... Action: a step or an optional step.

- ... Result of an action.

Action: more steps, the sequence must be followed.

Menu Elements of the instrument, the instrument displays

Pos: 13 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Schrei bkonv. [OK] @ 2\mod_12076554892 18_79.docx @ 14506 @ @ 1

or the program interface.

[OK] Control keys of the instrument or buttons of the

Pos: 14 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Schrei bkonv. Funktionen/Pf ade (...|...) @ 2\mod_12 07655781390_79.doc x @ 14524 @ @ 1

Pos: 15 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/Schrei bkonv. Beispielangaben (" ...") @ 2\mod_1207656 016281_79.docx @ 14542 @ @ 1

Pos: 16 /TD/Überschriften/2.2 Sicherheit gewährl eisten @ 0\mod_11737807839 60_79.docx @ 366 @ 2 @ 1

2.2. Ensure safety

Pos: 17 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Produkt bes timmungsgemäß verwenden @ 0\mod_1173781261848_79. docx @ 386 @ @ 1

... | ... Functions/paths within a menu.

“...” Example entries

program interface.

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

Pos: 18 /TD/Sicherheit und Umwelt/Sicherheit gewährlei sten/Gerät bei Besc hädigungen nicht in Betr ieb nehmen @ 0\mod_118698594 5375_79.docx @ 2252 @ @ 1

use any force.

> Do not operate the instrument if there are signs of damage at

Pos: 19 /TD/Sicherheit und Umwelt/Sicherheit gewährlei sten/vor Ort gülti ge Sicherheitsbesti mmungen beachten @ 0\mod_1186 997107328_79.doc x @ 2298 @ @ 1

the housing, mains unit or feed lines.

> The objects to be measured or the measurement environment

may also pose risks: Note the safety regulations valid in your

Pos: 20 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Tempera turangaben auf Sonden/Füh lern @ 0\mod_117569329307 0_79.docx @ 610 @ @ 1

area when performing the measurements.

> Temperatures given on probes/sensors relate only to the

measuring range of the sensors. Do not expose handles and

feed lines to any temperatures in excess of 70 °C unless they

Pos: 21 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Keine Messung an sp annungsführenden Teilen @ 0\mod_11756925 64164_79.docx @ 592 @ @ 1

are expressly permitted for higher temperatures.

> Do not perform contact measurements on non-insulated, live

Pos: 22 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/testo 270/ Transport und Lagerung @ 2\ mod_1206696880578_79. docx @ 13401 @ @ 1

parts.

6

Page 7

> Transport and store the instrument exclusively in the aluminium

Pos: 23 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Nicht mit Lö sungsmitteln lagern @ 0\ mod_1175692375179_7 9.docx @ 583 @ @ 1

case provided in order to avoid damage to the sensor.

> Do not store the product together with solvents. Do not use any

Pos: 24 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Nur beschr iebene Wartungsarbeit en durchführen @ 0\mod_1175 692705195_79.doc x @ 601 @ @ 1

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Pos: 25 /TD/Überschriften/2.3 Umwelt schützen @ 0\mod_11 73780843645_79.doc x @ 375 @ 2 @ 1

2.3. Protecting the environment

Pos: 26.1 /TD/Sicherheit und Umwelt/Umwelt schützen/ Akkus/Batterien en tsorgen @ 0\mod_1175693637 007_79.docx @ 619 @ @ 1

Testo.

> Dispose of faulty rechargeable batteries/spent batteries in

Pos: 26.2 /TD/Sicherheit und Umwelt/Umwelt schützen/ Produkt entsorgen @ 0\ mod_1173780307072_79. docx @ 357 @ @ 1

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

Pos: 27 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.docx @ 283 @ @ 1

regulations) or return the product to Testo for disposal.

2 Safety and the environment

7

Page 8

3 Specifications

Pos: 28 /TD/Überschriften/3. Leistungsbeschrei bung @ 0\mod_117377479155 4_79.docx @ 301 @ 1 @ 1

3 Specifications

Pos: 29 /TD/Überschriften/3.1 Verwendung @ 0\mod_1176211 016437_79.doc x @ 695 @ 2 @ 1

3.1. Use

Pos: 30 /TD/Leistungsbeschreibung/Verwendung/ testo 2xx/Verwendung ( testo275) @ 15\mod_140 7394154990_79.doc x @ 194132 @ @ 1

The testo 270 is a handy measuring instrument for fast testing of

cooking oils.

The TPM value (total polar materials) enables a statement on the

ageing of cooking oils due to the effects of heat.

The following measuring tasks can be performed with the testo

270:

• Displaying the temperature of the cooking oil:

Indicator for correct setting of the deep fat fryer, checking of

integrated temperature displays.

• Displaying the TPM value:

Indicator for the ageing of the cooking oil.

The sensor works on a capacitive basis and determines as the

reading the total polar materials as a %.

The free fatty acids, which are determined above all for the

evaluation of unloaded oils (rancidity), cannot be detected with the

testo 270.

The temperature of the cooking oil to be measured must be

at least 40 °C. The maximum operating temperature is

200 °C.

The sensor and the probe tube are designed to come into

contact with oil used in deep fat fryers for the typical

duration of a spot check measurement. The materials used

in these components meet the relevant requirements in the

Pos: 31 /TD/Überschriften/3.2 Technische Daten @ 0\mod_ 1176211088437_79.doc x @ 704 @ 2 @ 1

Regulation (EC)1935/2004.

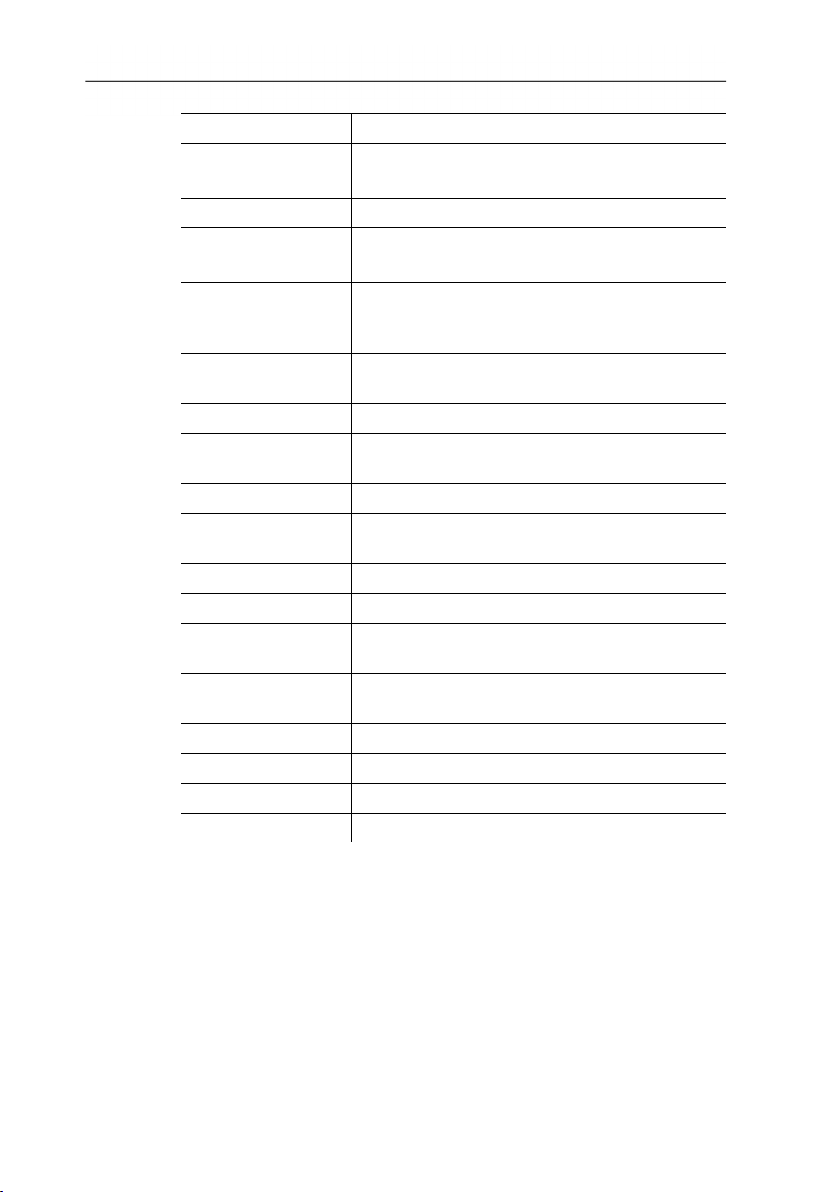

3.2. Technical data

Pos: 32 /TD/Leistungsbeschreibung/Technische Dat en/Technische Daten ( testo275) @ 15\mod_140739 4378201_79.doc x @ 194167 @ @ 1

Feature Values

Measuring range

Temperature: 40.0 to 200.0 °C /

104.0 to 392.0°F

TPM: 0 to 40%

Accuracy Temperature: ± 1.5 °C

2

TPM

: ±2% (40.0 to 190.0 °C / 104 to 374 °F)

2

typically, based on Testo in-house reference, at an ambient temperature of

25 °C.

8

Page 9

3 Specifications

Feature Values

Resolution Temperature: 0.1 °C / 0.1 °F

TPM: 0.5%

Power supply Batteries: 2x micro (type AAA)

Battery (micro AAA) Designation according to IEC: LR03

Chem. composition: Zn-MnO2 (alkaline)

Battery life at 20 °C

Approx. 25 hrs continuous operation

(corresponds to 500 measurements) without

display illumination

Temperature

PTC

sensor

TPM sensor Capacitive sensor (Testo)

Operating

0 to 50 °C / 32 to 122 °F

temperature

Ambient humidity 0 to 90%RH

Storage/transport

-20 to 70 °C / -4 to 158 °F

temperature

Display LCD, 2-line, display illumination

Weight 255 g

Housing material

Top part: ABS

Lower part: ABS-PC glass fibre 10%

Dimensions

Approx. 50 mm x 170 mm x 300 mm

(WxHxD)

TPM response time Approx. 30 secs

Protection class IP65

Warranty 24 months

EC Directive 2014/30/EC

Pos: 33 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.docx @ 283 @ @ 1

9

Page 10

4 Product description

Pos: 34 /TD/Überschriften/4. Produktbeschreibung @ 0\ mod_1173774846679_79. docx @ 310 @ 1 @ 1

4 Product description

Pos: 35 /TD/Überschriften/4.1 Übersicht @ 0\mod_11763799 46003_79.docx @ 733 @ 2 @ 1

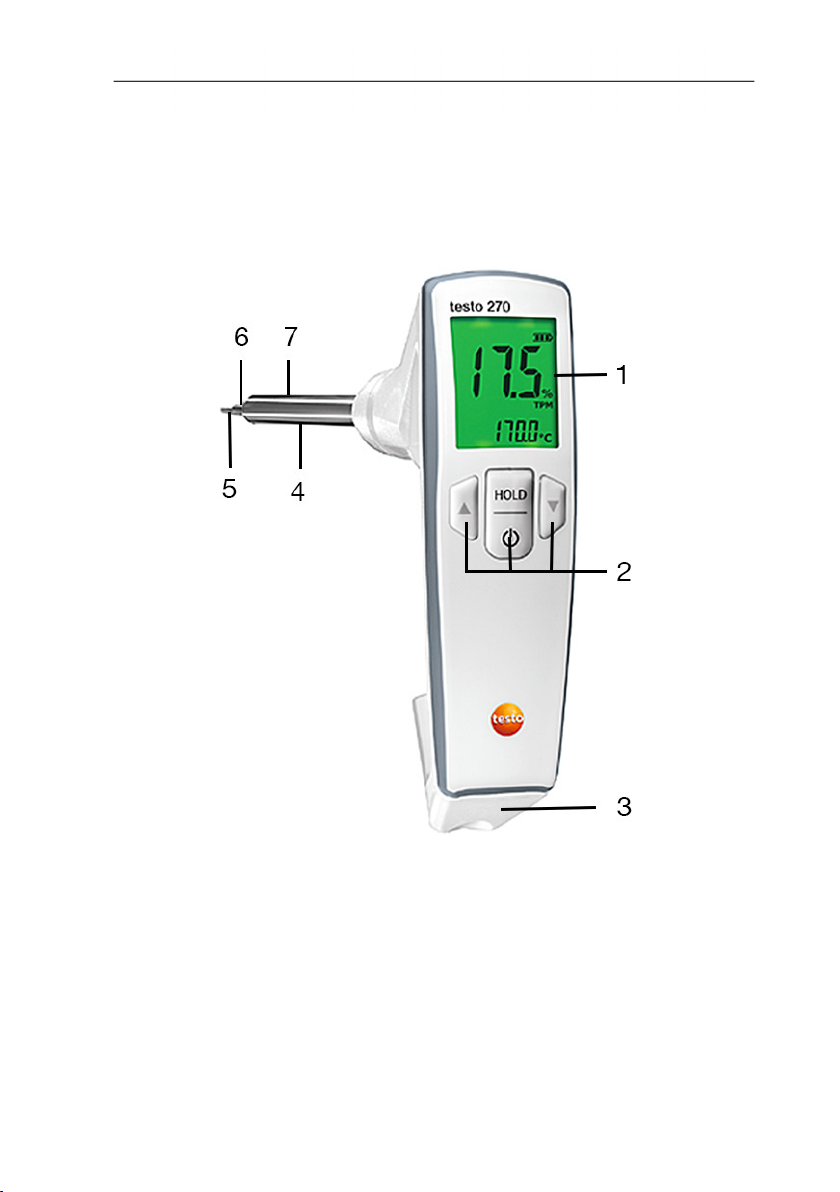

4.1. Overview

Pos: 36 /TD/Produktbeschreibung/Übersicht/tes to 275/Übersicht ( testo275) @ 15\mod_140739681 8539_79.docx @ 194203 @ @ 1

10

1 Display

2 Control keys

3 Battery compartment

4 Probe shaft

5 Oil quality (%TPM) and temperature sensor

6 Min. immersion depth

7 Max. immersion depth

Page 11

Pos: 37 /TD/Produktbeschreibung/Übersicht/tes to 275/Display (tes to 275) @ 15\mod_1407397717503 _79.docx @ 194238 @ 5 @ 1

4 Product description

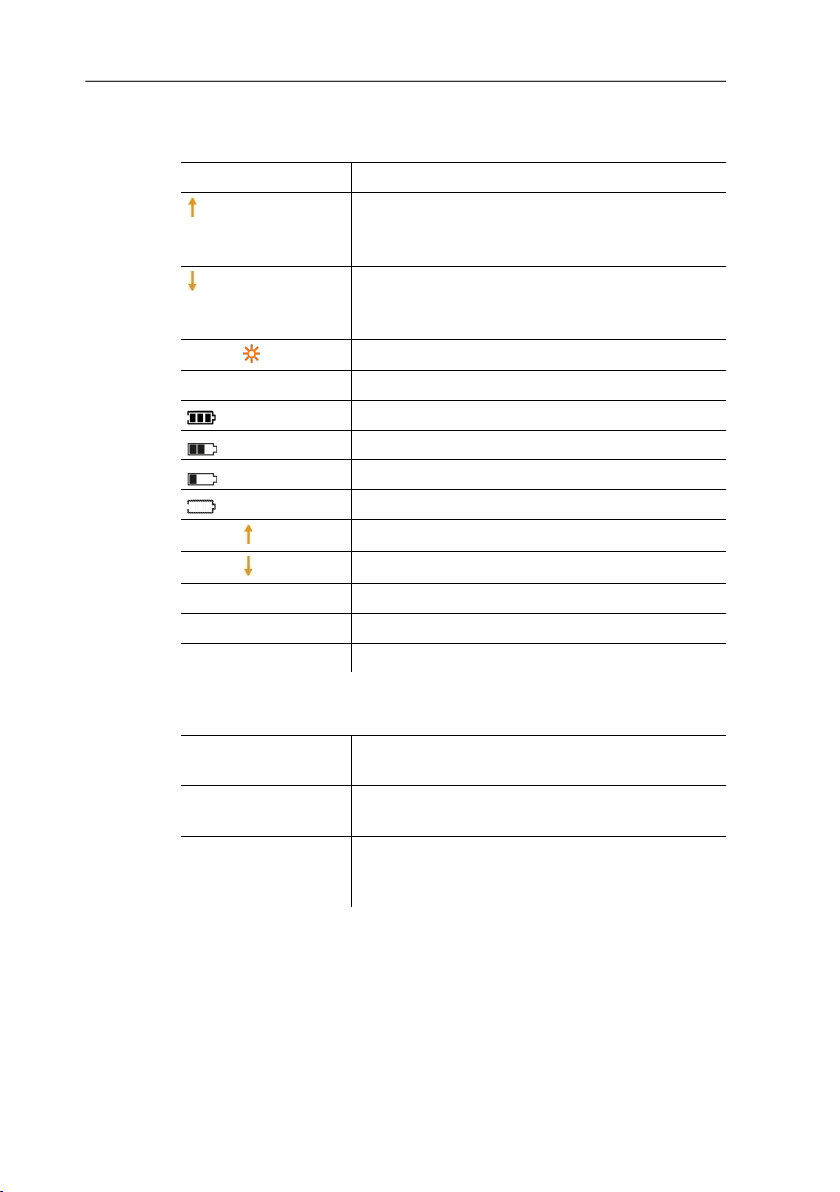

Items shown on the display:

Items shown Function/property

200 (flashing

temperature value

> 200 °C)

40 (flashing

temperature value

< 40 °C)

Alarm

PIN

Alarm

Alarm

Hold

Auto-Hold

°C / °F

Pos: 38 /TD/Produktbeschreibung/Übersicht/tes to 275/wichtige Disp laymeldungen (testo 27 5) @ 15\mod_140740113542 9_79.docx @ 194273 @ 5 @ 1

Important display messages

Item shown on the

display

000 lights up Instrument is ready to measure, sensor is not

Reading >190

flashes

Pos: 39 /TD/Produktbeschreibung/Übersicht/tes to 275/Bedientasten ( testo 275) @ 15\mod_1407401 539747_79.doc x @ 194308 @ 5 @ 1

Temperature measuring range exceeded

Temperature measuring range undershot

Alarm indicator activated

Configuration mode locked

Battery capacity 100 %

Battery capacity 66 %

Battery capacity 33 %

Battery capacity < 10 %

Upper TPM limit value exceeded

Lower TPM limit value exceeded

Readings held (manually)

Readings held (automatically)

Temperature in °C or °F

Explanation

in oil.

Measured temperature is above 190 °C

(374 °F). The reading flashes in the range

from 190.1 °C (374 °F) to 200 °C (392 °F).

11

Page 12

4 Product description

Control keys

Buttons Function/property

[ ]

[Hold]

[ ] • on/off; yes/no - Configure instrument

[ ] • on/off; yes/no - Configure instrument

Pos: 40 /TD/Produktbeschreibung/Übersicht/tes to 275/Batterief ach (testo 275) @ 15\mod_1407 401830742_79.docx @ 194 343 @ 5 @ 1

Battery compartment

• Switch instrument on/off

• Configure instrument

• Hold measuring values manually

• Switch to the measuring mode

• Configure instrument

Pos: 41 /TD/Überschriften/4.2 Grundlegende Eigensc haften @ 0\mod_117638039 9692_79.docx @ 742 @ 2 @ 1

4.2. Basic properties

Pos: 42 /TD/Produktbeschreibung/Grundlegende Eige nschaften/testo 2 70/Stromversorgung @ 2\ mod_1206701354953_79. docx @ 13477 @ 5 @ 1

Power supply

The power is supplied to the instrument via two micro batteries

Pos: 43 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.docx @ 283 @ @ 1

(type AAA). The batteries are included in the delivery.

12

Page 13

Pos: 44 /TD/Überschriften/5. Erste Schritte @ 0\mod_117 3774895039_79.doc x @ 319 @ 1 @ 1

5 First steps

Pos: 45 /TD/Überschriften/5.1 Inbetriebnahme @ 0\mod_11 85342823812_79.doc x @ 1885 @ 2 @ 1

5.1. Commissioning

Pos: 46 /TD/Erste Schritte/testo 275/Batterien ein legen (testo 275) @ 15\ mod_1407402146449_79.d ocx @ 194379 @ 5 @ 1

Inserting batteries

CAUTION

Incorrectly inserted batteries can damage the instrument!

> Adhere to the polarity when inserting the batteries.

1. Undo the screw on the battery compartment.

5 First steps

2. Remove the battery holder.

13

Page 14

5 First steps

3. Insert batteries. Adhere to the polarity.

4. Insert the battery holder into the battery compartment.

5. Secure battery compartment with screw.

6. Switch instrument on: Press [ ].

- Display test is carried out: all segments light up.

- The instrument switches to the measuring mode.

- 000 lights up on the display, the instrument is ready for use.

7. If necessary, switch instrument off.

Pos: 47 /TD/Erste Schritte/testo 275/Aufbewahrung @ 15\ mod_1407407083273 _79.docx @ 194414 @ 5 @ 1

14

Page 15

Pos: 48 /TD/Überschriften/5.3 Produkt kennenlernen @ 0\mod_1185342901015_79. docx @ 1894 @ 2 @ 1

5 First steps

For storage of the instrument

Suspension attachment

> The integrated suspension attachment can be used to hang the

instrument on a hook.

Plastic case

- The instrument is securely stored in a plastic case for protection

against contamination and for transport.

5.2. Getting to know the product

Pos: 49 /TD/Erste Schritte/testo 275/Gerät ein-/ aussc halten (testo 275) @ 16\mod_1408009443923_79.d ocx @ 196896 @ 355 @ 1

5.2.1. Switching the instrument on/off

To switch on

> Press [ ] until the indicator elements appear in the display.

- Display test is carried out: all segments light up.

- The instrument switches to the measuring mode and is ready

for operation.

To switch off

> Press and hold [ ] for approx. 2 secs.

Pos: 50 /TD/Erste Schritte/testo 275/Überschri ft Beschreibung wichtiger Funktionen @ 16\mod_14080 02615627_79.doc x @ 196757 @ 3 @ 1

15

- Display goes off, instrument switches off.

Page 16

5 First steps

5.2.2. Description of important functions and displays

Pos: 51 /TD/Erste Schritte/testo 275/Alarm Backlig ht @ 15\mod_1407407343094_7 9.docx @ 194449 @ 3 @ 1

5.2.2.1. Alarm indicator

The alarm indicator uses the following display colours to show what

range the measured TPM value is in:

Green TPM value < lower limit value

Orange TPM value is between the lower and the upper limit value

Red TPM value > upper limit value

The alarm indicator is switched on when the instrument is

delivered. The TPM limit values are set as follows (only for the

standard set, order no. 0563 2750):

Lower limit value 20%

Upper limit value 24%

To activate/deactivate the alarm indicator, see Configuring the

instrument, page 18.

To set the TPM limit values, see Setting the TPM limit values, page

Pos: 52 /TD/Erste Schritte/testo 275/TPM-Grenzwerte ei nstellen (testo 275) @ 15\mod_1407409482149_ 79.docx @ 194519 @ 355 @ 1

16.

5.2.2.2. Setting the TPM limit values

The TPM limit values can be between 0 and 40%. The

upper limit value (Alarm ) must be at least 1% higher than

the lower limit value (Alarm ).

In order to apply the settings of the lower and upper TPM

limit value, you must make sure you confirm the input of the

upper TPM limit value with [Hold].

16

Setting the lower TPM limit value

Requirement: Instrument is in configuration mode, See also

Carrying out the configuration, page 19.

1. Alarm and the set lower limit value appear on the display.

- When alarm indicator is activated: the display lights up orange.

2. Set the lower limit value with [ ] or [ ].

3. Confirm with [Hold].

- New lower limit value is applied.

- The instrument switches to the upper TPM limit value (Alarm ).

Page 17

Setting the upper TPM limit value

Requirement: Instrument is in configuration mode,

lower TPM limit value has been set and confirmed with [Hold] .

1. Alarm and the set upper limit value appear on the display.

- When alarm indicator is activated: the display lights up red.

2. Set the upper limit value with [ ] or [ ].

3. Confirm with [Hold].

- New upper limit value is applied.

> Carry out further settings in the configuration menu or quit the

Pos: 53 /TD/Erste Schritte/testo 275/Hold-Funktion ( testo 275) @ 15\mod_1407409 349521_79.doc x @ 194484 @ 4 @ 1

configuration menu with [ ].

5.2.2.3. Hold function

Measured values can be held manually.

Requirement: Sensor is in the oil.

1. Briefly press [Hold] (< 1 sec).

- Hold appears in the display.

- Readings are held.

2. To switch to the measuring mode: Briefly press [Hold] (<

1 sec).

- Hold function is deactivated.

Pos: 54 /TD/Erste Schritte/testo 275/Auto-Hold Funk tion (testo 275) @ 16\mod_140 8003188527_79.doc x @ 196826 @ 4 @ 1

- Current readings are displayed.

5 First steps

5.2.2.4. Auto-Hold function

When the Auto-Hold function is activated, the measured values

are automatically held by the instrument after the equalization

period.

To activate/deactivate the Auto-Hold function, see Carrying out the

Pos: 55 /TD/Erste Schritte/testo 275/Auto off Funktion ( testo 275) @ 16\mod_140800 3278359_79.doc x @ 196861 @ 4 @ 1

configuration, page 19

5.2.2.5. Auto-off function

When the Auto-off function is activated, the instrument

automatically switches off after a certain time

• If the instrument is in measuring mode: automatic switch-off

after 2 mins.

• If the instrument is in hold or configuration mode: automatic

switch-off after 10 mins.

To activate/deactivate the Auto-off function, see Configuring the

instrument, page 18

17

Page 18

5 First steps

Pos: 56 /TD/Erste Schritte/testo 275/Batteriekapazi tät (testo 275) @ 16\mo d_1408002874610_79.doc x @ 196791 @ 4 @ 1

5.2.2.6. Battery capacity

With decreasing battery capacity, a symbol lights up in the display (

). If the empty battery symbol ( ) flashes in the display, the

remaining capacity is only approx. 30 min.

If the battery voltage is too low, the instrument automatically

switches off.

Pos: 57 /TD/Erste Schritte/testo 275/Gerät konfi gurieren (testo 275) @ 15\ mod_1407410840205_79. docx @ 194589 @ 35 @ 1

> Change batteries, see Changing batteries, page 26

5.2.3. Configuring the instrument

Setting options in the configuration mode

Configurations Setting options

Setting the TPM limit values

Alarm , Alarm

Carry out calibration

CAL

Automatically hold readings

Auto-Hold

Lower TPM limit value Alarm

Upper TPM limit value Alarm

no: Do not carry out calibration.

yes: Carry out calibration.

on: Readings are automatically

held by the instrument.

off: Readings are not

automatically held.

Automatically switch off the

instrument Auto-off

on: Instrument switches off

automatically after 2 or 10 mins.

off: No automatic switch-off.

Set alarm indicator

Alarm

Set temperature unit

on: Alarm indicator activated

off: Alarm indicator deactivated

°C or °F

°C, °F

Lock configuration, including

TPM limit values

no: Do not lock configuration.

yes: Lock configuration

PIN

Carry out reset

rst

no: Do not reset the adjustment

value to the factory setting.

yes: Reset the adjustment value

to the factory settings.

Firmware version

Firmware versions of the product

components are shown.

18

Page 19

Pos: 58 /TD/Erste Schritte/testo 275/Konfiguratio n durchführen (test o 275) @ 15\mod_1407413778 547_79.docx @ 194694 @ 5 @ 1

5 First steps

Carrying out the configuration

Requirement: The instrument is switched off.

1. Switch the instrument on.

> Switch the instrument on, press [Hold] during the display

test and hold down for approx. 2 secs.

- When the configuration menu is locked, PIN lights up.

> To unlock, set the last two figures of the serial number with [

] or [ ].

If an incorrect PIN is entered, the instrument switches into

measuring mode.

- When the configuration menu is not locked, you can gain

access by setting the limit values.

2. Set the alarm limit values.

- Alarm lights up in the display.

> Set lower limit value (Alarm ): [ ] or [ ] and confirm with

[Hold].

- Alarm lights up in the display.

> Set upper limit value (Alarm ): [ ] or [ ] and confirm with

[Hold].

3. Carry out / do not carry out calibration.

- CAL and no or yes light up in the display.

> Activate / deactivate calibration / adjustment function (no is

the standard setting): [ ] or [ ] and confirm with [Hold].

- Selection of yes: The instrument can be calibrated /

adjusted, see Calibrating/adjusting the instrument, page 28

- Selection of no: No calibration / adjustment possible

4. Automatically hold readings.

- Auto-Hold and on or off light up in the display.

> Switch Auto-Hold on or off: [ ] or [ ] and confirm with

[Hold].

5. Automatically switch the instrument off.

- Auto-off and on or off light up in the display.

> Switch Auto-off on or off: [ ] or [ ] and confirm with

[Hold].

19

Page 20

5 First steps

6. Set alarm indicator

7. Set the temperature unit.

8. Enable / disable PIN.

9. Carry out reset.

Pos: 59 /TD/Erste Schritte/testo 275/Konfiguratio n verlassen / speic hern @ 15\mod_1407412864655 _79.docx @ 194659 @ 5 @ 1

Quitting configuration mode early and saving

You can quit the configuration mode early.

> Quit configuration mode early: Press and hold [ ] for approx.

- Configuration mode is stopped.

- The values which have so far been set and confirmed with

Pos: 60 /TD/Erste Schritte/testo 275/Konfiguratio nsmodus sperren/ entsperren (testo 275) @ 15\ mod_1407488193105_79. docx @ 194737 @ 3 @ 1

- The instrument switches to the measuring mode.

- Alarm and on or off light up in the display.

> Switch alarm indicator on or off: [ ] or [ ] and confirm with

[Hold].

- °C or °F lights up in the display.

> Set the temperature unit (°C/°F): [ ] or [ ] and confirm

with [Hold].

- PIN and yes or no light up in the display.

> Activate PIN (yes) or deactivate it (no is the standard

setting).

- rst and yes or no light up.

> Activate or deactivate rst: [ ] or [ ].

- Selection of yes: Delete adjustment value, is reset to the

factory setting.)

- Selection of no: no reset, adjustment value is retained).

The configuration mode cannot be stopped in the

adjustment / calibration process.

1 sec.

[Hold] are applied.

5.2.4. Locking / unlocking configurations

You can lock/unlock the set values, including TPM limit values,

from the configuration mode. The instrument is delivered with the

configuration mode unlocked (PIN is deactivated, no).

Requirements: Instrument is in configuration mode.

> Go through the configuration mode with [Hold], until PIN

and yes or no light up in the display.

Lock configuration mode

> Activate PIN: Select yes with [ ] or [ ].

- PIN is activated and the configuration mode is locked.

20

Page 21

The last two figures of the instrument's serial number are

automatically set as the PIN (see sticker on the instrument).

Unlock configuration mode

Requirement: PIN is activated and the instrument is in configuration

mode.

Enter PIN:

> Select first figure: [ ] or [ ] and confirm with [Hold].

> Select second figure: [ ] or [ ] and confirm with [Hold].

If an incorrect PIN is entered, the instrument switches into

measuring mode.

- The configuration mode is enabled for the duration of the

settings being carried out.

Deactivate PIN:

> Go through the configuration mode with [Hold], until PIN

and yes or no light up in the display.

> Deactivate PIN: Select no with [ ] or [ ].

Pos: 61 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.docx @ 283 @ @ 1

- Settings can be carried out without entering the PIN.

5 First steps

21

Page 22

6 Using the product

Pos: 62 /TD/Überschriften/6. Produkt verwenden @ 0\mod_ 1173774928554_79.doc x @ 328 @ 1 @ 1

6 Using the product

Pos: 63 /TD/Produkt verwenden/testo 275/Allgemein e Messhinweise (testo 27 5) @ 15\mod_140749103230 1_79.docx @ 194774 @ 25555 @ 1

6.1. General measurement information

The testo 270 enables several measurements to be carried out one

immediately after the other without any waiting times.

Which oils/cooking fats can be measured?

In principle, all oils and fats intended for deep fat frying can be

measured.

This includes, for example, rapeseed, soya bean, sesame, palm,

olive, cotton seed or groundnut oil. Fats from animal sources can

also be measured. There may be a variation of several percentage

points in the % TPM value for fresh cooking oils, depending on the

type.

The maximum service life for the cooking oil cannot be derived

from this.

Example: Fresh palm oil has a higher % TPM value than other

cooking oils, but ages considerably more slowly.

Use of additives

The testo 270 is designed for the use of pure fats/oils. If additives

are used, deviations may occur.

22

Comparison of laboratory methods / testo 270

Cooking oil is a mixture of substances with a wide variety of

polarities. During ageing, the proportion of more highly polar

components increases. The laboratory method of column

chromatography separates the fat into a polar and a non-polar

group. The proportion of the polar group compared to the total

amount of cooking oil being investigated is described as the

% TPM value (total polar materials).

The % TPM value established by column chromatography may

vary slightly depending on the setting of the separation limit

between the polar and the non-polar group.

Depending on the type of fat, slight variations of the polarity in both

groups (polar/non-polar) may occur which are not however

identified by the chromatography.

On the other hand, the testo 270 records the entire polarity of the

cooking oil and thus the actual polarity of both groups (polar/nonpolar). This means the reading of the testo 270 may be higher or

lower than that of the column chromatography in individual cases.

Page 23

An example of this is coconut oil, for which the testo 270 shows

WARNING

higher TPM values than column chromatography. However, this fat

is unsuitable for deep fat frying and is therefore primarily used for

roasting.

Free fatty acids

The testo 270 measures the total amount of polar materials in the

cooking fat (% TPM) which makes it very possible to evaluate the

load of the oil as a result of deep fat frying. On the other hand, free

fatty acids (FFAs) are used for the evaluation of the age of the fat

during storage. FFAs are not suitable for identifying the thermal

loads of the oil. FFAs cannot be measured with the testo 270.

Polymeric triglycerides (PTGs)

Polymeric triglycerides are also being used for the evaluation of

cooking oils with increasing frequency. The results of this method

are in most cases comparable with the % TPM value.

Pos: 64 /TD/Produkt verwenden/testo 275/Messungen durc hführen (testo 275) @ 15\mod_1407494268340_79. docx @ 194919 @ 255 @ 1

6.2. Carrying out measurements

PTG ≈ % TPM/2

Risk of burns due to hot instrument parts (sensor and probe

shaft)!

> Do not touch hot instrument parts with your hands.

> In the event of burns, immediately cool the relevant spot with

cold water and see a doctor if necessary.

Please take note of the following information in order to

obtain correct measurement results:

• Take the product being deep fried out of the oil and wait

5 mins until there are no more bubbles rising before

measuring.

• If you suspect a measurement error due to water being

contained: Repeat the measurement after 5 mins (do

not deep fry during this time, keep oil/fat at a high

temperature). If the new reading is lower, measure

again after 5 mins until the reading stabilises if

necessary.

• Keep the sensor away from metallic parts (e.g. deepfrying basket, pan walls), as these may affect the

measurement result. Minimum distance from metal

parts: 1 cm on each side.

6 Using the product

23

Page 24

6 Using the product

With activated Auto Hold function

1. Immerse the sensor in cooking oil. Adhere to the immersion

- If the temperature is within the permissible measuring range (40

2. Wait until Auto Hold is shown in the display.

- Readings are automatically held by the instrument, with the

3. Read the measurement values.

4. To switch to the measuring mode: Briefly press [Hold] (<

With deactivated Auto Hold function

1. Immerse the sensor in cooking oil. Adhere to the immersion

2. If the temperature is within the permissible measuring range (40

- Readings are displayed.

- Measurement is finished when the temperature display no

3. To hold readings: Briefly press [Hold] (< 1 sec).

- Hold appears in the display.

- Readings are held.

4. Read the measurement values.

5. To switch to the measuring mode: Briefly press [Hold]

• Measurement in hot oil min. 40 °C, max. 200 °C.

• Adhere to min. and max. marking when immersing in

oil.

• "Temperature striations" in the oil may cause

measurement errors. Move instrument in the deep fat

fryer.

• Cleaning of the sensor is recommended before every

measurement or when changing from one deep fat fryer

pan to the next, see Cleaning the sensor, page 26.

• Switch off induction deep fat fryers during the

measurement or take a cooking oil sample, as the

electromagnetic field can lead to incorrect readings.

• Change cooking oil as from approx. 24% TPM. A

different limit value applies in some countries. If the

measured values are above the country-specific limit

value, the cooking oil should be changed!

depth!

to 200 °C): Auto flashes, along with the reading and the alarm

indicator (display colour).

alarm indicator activated, the display colour lights up.

1 sec).

depth!

to 200 °C): Wait for the end of the equalization period (approx.

30 secs).

longer changes.

(< 1 sec).

24

Page 25

Pos: 65 /TD/Produkt verwenden/testo 270/Funktions test @ 4\mod_1248176181060 _79.docx @ 46233 @ 2 @ 1

6.3. Function test

For a simple function test without adjustment (accuracy

+/- 3 % TPM

commissioning of your new instrument in unused deep-frying oil at

150 to 180 °C.

We recommend performing the function test every time after

refilling the deep fryer with fresh oil.

1. Perform measurement in unused deep-frying oil at 150 to

180 °C, see Carrying out measurements, page 23.

2. Note reading.

3. Repeat steps 1 and 2 several times.

- The average of the readings is your specific reference value for

subsequent instrument testing.

Your specific reference value:

Pos: 66 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.docx @ 283 @ @ 1

___________________________

3

), we recommend a measurement during the

When changing the type of oil or the oil supplier, the

reference value must be determined anew.

With implausible readings, we recommend the calibration or

adjustment in the testo reference oil, see

Calibrating/adjusting the instrument, page 28.

6 Using the product

3

typical, referred to testo internal reference, at an ambient temperature of 25 °C

25

Page 26

7 Maintaining the product

WARNING

Pos: 67 /TD/Überschriften/7. Produkt instand halte n @ 0\mod_1173789831362_79. docx @ 397 @ 1 @ 1

7 Maintaining the product

Pos: 68 /TD/Produkt instand halten/testo 275/Batter ien wechseln (testo 275) @ 15\mod_1407494908084_7 9.docx @ 194985 @ 2 @ 1

7.1. Changing batteries

CAUTION

Incorrectly inserted batteries can damage the instrument!

> Adhere to the polarity when inserting the batteries.

Requirement: The instrument is switched off.

1. Undo the screw on the battery compartment cover and open the

battery compartment.

2. Remove the empty batteries from the holder and insert new

batteries (type AAA).

Pos: 69 /TD/Produkt instand halten/testo 270/Sensor reinigen @ 2\mod_1206628000 890_79.docx @ 13273 @ 25 @ 1

7.2. Cleaning the sensor

3. Close battery compartment and secure with screw.

Risk of burns due to hot instrument parts (sensor and probe

shaft)!

> Do not touch hot instrument parts with your hands.

> Allow instrument to cool sufficiently before cleaning.

> In the event of burns, immediately cool corresponding spot with

cold water and see a doctor if necessary.

26

CAUTION

Possible damage to the sensor!

> Do not remove cold oil residues from the sensor.

> Do not use any sharp-edged objects.

> Do not use aggressive cleaning agents and solvents.

> Use weak household cleaning agents, standard household

rinsing agents, water or soap suds.

> Gently clean sensor with a soft paper towel, or rinse under

running water.

> Carefully dry sensor with a soft paper towel.

Page 27

With cold oil residues on the sensor

1. Immerse sensor in hot oil.

2. Allow sensor and probe shaft to cool until there is no longer a

risk of burns.

Pos: 70 /TD/Produkt instand halten/testo 275/Gehäuse r einigen (testo 275) @ 16\mod_1408017834842_7 9.docx @ 196931 @ 2 @ 1

3. Clean sensor before the oil residues cool down.

7.3. Cleaning the housing

Pos: 71 /TD/Produkt instand halten/testo 275/Koff er reinigen (testo 275) @ 16\ mod_1413438648965_79. docx @ 202997 @ 2 @ 1

Requirement: The instrument is switched off.

CAUTION

Possible damage to housing!

> Do not use sharp-edged objects.

> Do not use any aggressive cleaning agents or solvents.

> Use mild household cleaning agents, standard household

washing-up liquids, water or soap suds.

> Clean housing with a damp cloth.

> Dry housing.

7 Maintaining the product

7.4. Cleaning the plastic case

CAUTION

Possible damage on and in the plastic case!

> Do not use sharp-edged objects.

> Do not use any aggressive cleaning agents or solvents.

> Use mild household cleaning agents, standard household

washing-up liquids, water or soap suds.

> Clean plastic case with a damp cloth.

Pos: 72 /TD/Produkt instand halten/testo 275/Insta ndhaltung Gerät kalibr ieren/justieren ( testo275) @ 15\mod_140749 5334611_79.doc x @ 195020 @ 255 @ 1

27

> Wipe plastic case with a dry cloth.

Page 28

7 Maintaining the product

7.5. Calibrating/adjusting the instrument

You can check the accuracy of your instrument by carrying out a

comparative measurement with the Testo reference oil (calibrating).

If there is too great a difference between the reading and the

reference value, future instrument readings can be adjusted to the

reference value (adjusting).

• The testo 270 should be checked with the Testo

reference oil on a regular basis and adjusted if

necessary (accuracy +/- 2.5% TPM)

4

). We recommend

a monthly check as part of quality assurance.

• We recommend you always use the Testo reference oil

for calibration/adjustment of the sensor (order no.

0554 2650, 1 piece).

• The sensor is exposed to large temperature jumps and

pollutants while in measuring mode. We therefore

recommend having an annual test carried out by Testo

Customer Service. For more information go to:

www.testo.com.

For measurements as part of a quality-assurance concept

(e.g. ISO 9001), we recommend the annual renewal of

a calibration certificate (accuracy +/- 2% TPM

more information go to: www.testo.com

Prepare calibration / adjustment

1. Clean sensor before the calibration/adjustment, see Cleaning

the sensor, page 26.

When heating the reference oil, make sure that no water

gets into the reference oil or onto the sensor.

The reference oil must be heated to approx. 50 °C for

calibration and adjustment.

4

). For

4

typically, based on Testo in-house reference, at an ambient temperature of

25 °C.

28

Page 29

7 Maintaining the product

2. Heat water in a container (e.g. a cup) to approx. 50 °C. Place

closed reference oil bottle in the water bath for approx. 10 min

(maximum water level to lower edge of sealing cap). Then

briefly shake the closed reference oil bottle, for better heat

distribution in the bottle.

Carry out calibration / adjustment

1. Switch the instrument on, press and hold down [Hold] during

the display test for approx. 2 secs.

- When the PIN is deactivated, Alarm lights up in the

display.

> when the PIN is activated: Enter PIN.

2. Go through the configuration mode with [Hold], until CAL and

yes or no light up in the display.

3. Switch on the calibration/adjustment function with [ ] or [ ]

(yes).

4. Confirm with [Hold].

- OIL and CAL light up in the display.

There is a negative effect on the accuracy of the

calibration/adjustment when the reference oil bottle is held

by hand.

29

Page 30

7 Maintaining the product

5. Immerse sensor in reference oil. Adhere to the immersion

depth!

- When alarm indicator is activated: the display lights up orange.

6. Start calibration/adjustment process with [Hold]. For faster

recording of readings: move sensor in oil.

- The display lights up red.

- Measured TPM value and temperature are displayed.

- With a stable reading: Control keys are enabled, display lights

up green.

7. Compare the value shown in the display with the target value

indicated on the label of the reference oil bottle.

> If there is a deviation of > 1%, adjustment should be carried

> If there is a deviation of </= 1%, no adjustment is required.

8. With [ ] or [ ] set the TPM value to the value that is indicated

on the label of the reference oil bottle.

9. Save with [Hold] and carry out further settings in the

configuration mode. Use [ ] to quit the configuration mode.

out. Continue with step 8.

Continue with step 9.

Adjustment with reference oil impairs the accuracy by

0.5% TPM compared to the factory calibration.

A maximum correction of +/-3% TPM is possible. If the

TPM value displayed deviates by more than 3% TPM from

the target value of the reference oil, a technical check of

the instrument by Testo Service is recommended.

30

Page 31

Carry out reset (delete adjustment and reset to factory setting)

1. Switch the instrument on, press and hold down [Hold] during

the display test for approx. 2 secs.

- When the PIN is deactivated, Alarm lights up in the

display.

2. Go through the configuration mode with [Hold], until rst and

yes or no light up in the display.

3. Select yes (=delete adjustment value and reset to factory

setting) or no (=no resetting of the adjustment value) with [ ]

or [ ].

Pos: 73 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.docx @ 283 @ @ 1

4. Confirm with [Hold].

7 Maintaining the product

31

Page 32

8 Tips and assistance

Pos: 74 /TD/Überschriften/8. Tipps und Hilfe @ 0\mod_117378 9887985_79.doc x @ 406 @ 1 @ 1

8 Tips and assistance

Pos: 75 /TD/Überschriften/8.1 Fragen und Antworten @ 0\mo d_1177402017078_79.doc x @ 1093 @ 2 @ 1

8.1. Questions and answers

Pos: 76 /TD/Tipps und Hilfe/Fragen und Antworten/Frage n und Antworten (testo2 75) @ 15\mod_1407496446 093_79.docx @ 195065 @ @ 1

Items shown on the

Possible causes / solution

display:

lights up and flashing

temperature value <40 °C

appears in the display

lights up and flashing

temperature value >

200 °C appears in the

Permissible measuring range

undershot

> Increase oil temperature.

Permissible measuring range

exceeded

> Reduce oil temperature.

display

Battery symbol lights

up

Battery charge level low (approx. 7 hrs

remaining life)

> Change batteries if necessary, see

Changing batteries, page 26

Battery symbol flashes

Batteries empty

(approx. 30 min remaining life)

> Change batteries, see Changing

batteries, page 26

000 lights up

Sensor not in oil

> Instrument is ready for

measurement. Immerse sensor in

oil.

PIN lights up

Configuration mode locked.

> Unlock configuration mode. see

Locking / unlocking configurations,

page 20

Err 1 lights up

TPM sensor faulty

> Contact Testo Customer Service

or your dealer.

Err 2 lights up

Temperature sensor faulty

> Contact Testo Customer Service

or your dealer.

Err 3 lights up TPM sensor and temperature sensor

faulty

> Contact Testo Customer Service

or your dealer.

32

Page 33

8 Tips and assistance

Items shown on the

Possible causes / solution

display:

Err 4 lights up

Other fault

> Contact Testo Customer Service

or your dealer.

ser lights up When entering the adjustment value, a

TPM value discrepancy of more than

10% TPM. occurs.

> We recommend a technical check

of the instrument by Testo

Customer Service.

If we have not been able to answer your question: please contact

your local dealer or the Testo Customer Service. For contact

details, see the back of this document or visit the website

Pos: 77 /TD/Überschriften/8.3 Zubehör und Ersatztei le @ 0\mod_1177402058734 _79.docx @ 1102 @ 2 @ 1

8.2. Accessories and spare parts

Pos: 78 /TD/Tipps und Hilfe/Zubehör und Ersatzteile/ Zubehör und Ersatztei le (testo275) @ 15\mod_140 7497041658_79.doc x @ 195100 @ @ 1

www.testo.com/service-contact.

Description Item no.

testo 270 In the plastic case, Testo

reference oil

Plastic case for testo 270 (spare part) 0516 7301

ISO calibration certificate for testo 270,

calibration points 3% and 24% TPM 0520 0028

Testo reference oil (1 x) 0554 2650

For further accessories and spare parts, please refer to the product

catalogues and brochures or look up on the Internet at

=== Ende der Liste für Textmarke Inhalt ===

www.testo.com

0563 2750

33

Page 34

0970 2750 en 02 V01.00

Loading...

Loading...