Page 1

testo 191 data logger

Instruction manual

Page 2

Page 3

Contents

Contents

1 Safety and disposal.............................................................................. 5

1.1 About this document .............................................................................. 5

1.2 Security .................................................................................................. 5

1.3 Warning notices ..................................................................................... 7

1.4 Symbols ................................................................................................. 8

1.5 Transport ................................................................................................ 8

1.6 Disposal ................................................................................................. 8

2 Description of the instrument ............................................................... 9

2.1 Use ......................................................................................................... 9

2.2 testo 191 data logger variants .............................................................. 10

2.3 testo 191 data logger overview ............................................................ 10

2.4 Power supply ....................................................................................... 11

2.5 Programming and readout unit ............................................................ 11

2.6 testo 191 Professional software ........................................................... 12

3 Commissioning .................................................................................. 13

3.1 Installing the battery ............................................................................. 13

3.2 Positioning the distance adapter in the programming and readout unit

.......................................................................................................... 14

3.3 Positioning the data logger in the programming and readout unit ....... 15

3.4 Connecting the programming and readout unit to the PC via USB ..... 16

4 Operation ........................................................................................... 17

4.1 Bending flexible probe shafts ............................................................... 17

4.2 Changing the battery ............................................................................ 18

4.3 Installing the freeze-drying probe holder.............................................. 18

4.4 Aligning the can stand .......................................................................... 19

4.5 Installing the can and bottle attachment .............................................. 20

4.6 Mounting the retaining clamp .............................................................. 22

5 Maintenance ...................................................................................... 24

5.1 Cleaning the instrument ....................................................................... 24

5.2 Calibration ............................................................................................ 24

6 Technical data ................................................................................... 25

6.1 testo 191 T1 ......................................................................................... 25

6.2 testo 191 T2 ......................................................................................... 26

6.3 testo 191 T3 ......................................................................................... 26

Page 4

Contents

6.4 testo 191 T4 ......................................................................................... 27

6.5 testo 191 P1 ........................................................................................ 28

6.6 Large battery ....................................................................................... 29

6.7 Small battery........................................................................................ 29

6.8 Accessories and spare parts ............................................................... 30

Page 5

1 Safety and disposal

5

1 Safety and disposal

1.1 About this document

• The instruction manual is an integral part of the instrument.

• Keep this documentation to hand so that you can refer to it when

necessary.

• Always use the complete original instruction manual.

• Please read this instruction manual through carefully and familiarize yourself

with the product before putting it to use.

• Hand this instruction manual on to any subsequent users of the product.

• Pay particular attention to the safety instructions and warning advice in

order to prevent injury and damage to the product.

1.2 Security

General safety instructions

• Only operate the product properly, for its intended purpose, and within the

parameters specified in the technical data.

• Do not apply any force.

• Do not operate the instrument if there are signs of damage to the housing or

connected cables.

• Dangers may also arise from objects to be measured or the measuring

environment. Always comply with the locally valid safety regulations when

carrying out measurements.

• Do not store the product together with solvents.

• Do not use any desiccants.

• Only perform maintenance and repair work on this instrument that is

described in this documentation. Follow the prescribed steps exactly when

doing the work.

• The instrument is not explosion-proof and must not be used in potentially

explosive atmospheres.

• Maintenance work that is not described in this documentation must only be

carried out by trained service engineers.

Page 6

1 Safety and disposal

6

• Use only original spare parts from Testo.

Batteries

• Improper use of batteries may cause destruction of the batteries, injuries

due to current surges, fire or the escape of chemicals.

• Only use the battery supplied in accordance with the instructions in the

instruction manual.

• Do not charge batteries. Attempting to charge a non-rechargeable battery

may cause gas to be produced or heat to be generated. That may lead to

the escape of gases, an explosion and/or possibly to fire.

• Do not short batteries. If the positive (+) and negative (-) terminals of a

battery are directly connected to one another, the battery will be shorted.

For example, batteries can be shorted when you have them loose in your

pocket along with keys or coins. This may lead to the escape of gases and

the leakage of battery acid.

• Do not deform batteries. Batteries must not be squashed, drilled,

dismantled, pierced, modified or damaged in any other way. This may lead

to the leakage of battery acid, to the escape of gases and/or to an

explosion.

• Do not heat batteries above the permitted temperature or burn them. If a

battery is heated, this may lead to the leakage of battery acid and/or to an

explosion. Lithium batteries can, for instance, react very strongly in

combination with fire. This may involve battery components being emitted

with considerable power.

• Do not consume battery, risk of burns due to hazardous substances. Keep

new and used batteries away from children.

• In principle, contact with escaping battery components may present a risk

to health and to the environment. Adequate body and breathing protection

is therefore required when in contact with batteries that have peculiar

aspects (escaping contents, deformations, discolourations, dents or the

like).

• Do not leave batteries lying around loose once they have been unpacked. If

batteries that have been unpacked are left lying around loose, they can

easily short one another, particularly button cells. In some cases, this is very

dangerous because the batteries may heat up. This may lead to an

explosion.

• Always store batteries in a cool, dry place.

• Batteries must be disposed of in accordance with the local and country-

specific regulations. In order to prevent short circuits and the associated

heating, lithium batteries must never be stored unprotected in bulk.

Page 7

1 Safety and disposal

7

Appropriate measures against short circuits are for instance inserting the

batteries into the original packaging or a plastic bag, masking the poles or

embedding them in dry sand.

• Lithium batteries must be transported and shipped in accordance with the

local and country-specific regulations.

• Do not expose the batteries to heavy impacts, water or fire.

• Only use the batteries in environments with a maximum temperature of

+140 °C.

• Do not store unused batteries in the proximity of metal objects.

• Do not use any damaged batteries.

First-aid measures

• If there is any contact with the skin or eyes, the areas must be rinsed with

water for at least 15 minutes. If there is any contact with the eyes, a doctor

must be contacted in addition to the rinsing.

• If burns are caused, these must be treated appropriately. You are also

strongly advised to contact a doctor.

• Airways: Leave the room immediately when smoke development or gas

release is acute. Consult a doctor when amounts are larger and airways are

irritated.

• Swallowing: Rinse out mouth and surrounding area with water. Get medical

assistance immediately.

• In the event of contact with battery acid: rinse the affected areas thoroughly

with water and if necessary consult a doctor.

1.3 Warning notices

Always pay attention to any information denoted by the following warnings.

Implement the precautionary measures specified!

DANGER

Risk of death!

WARNING

Indicates possible serious injury.

Page 8

1 Safety and disposal

8

CAUTION

Indicates possible minor injury.

CAUTION

Indicates possible damage to equipment.

1.4 Symbols

Representa

tion

Explanation

Note: basic or further information

1

2

…

Action: several steps, the sequence must be followed

>

Action: one step or optional step

Result of an action

Requirement

Menu

Elements of the program interface

[OK]

Buttons of the program interface

1.5 Transport

• Always transport and store the data loggers and accessories in the Testo

cases.

1.6 Disposal

• Dispose of faulty and/or spent batteries in accordance with the valid legal

specifications.

• At the end of its useful life, deliver the product to the separate collection

point for electric and electronic devices (observe local regulations) or return

the product to Testo for disposal.

• WEEE Reg. No. DE 75334352

Page 9

2 Description of the instrument

9

2 Description of the instrument

2.1 Use

Testo guarantees the functionality of its products when used in

accordance with their intended purpose. This guarantee does not

apply to features of Testo products in combination with unauthorized

third-party products. Competitor products are not authorized by Testo.

As is common practice, Testo generally excludes support, warranty or

guarantee claims relating to functionality that has not been guaranteed

by Testo as part of the product offered. Claims of this kind shall also

be excluded in the event of improper use or handling of the products,

e.g. in combination with unauthorized third-party products.

The testo 191 data loggers are used to measure individual temperature and

pressure readings and measurement series.

The testo 191 data loggers measure and store temperature and pressure

readings which, with the aid of the configuration and readout unit and a USB

cable, are transmitted to the PC, where they can be read out and evaluated

using the testo 191 Professional software. The software also enables the data

loggers to be individually programmed and the readings analyzed and printed

out via a report and subsequently archived.

Application examples

The testo 191 T1, testo 191 T2, testo 191 T3, testo 191 T4 and testo 191 P1

data loggers are ideal for measuring temperature and pressure in order to

validate pasteurization and sterilization processes in autoclaves, containers and

freeze-drying systems.

In conjunction with the freeze-drying probe holder, the testo 191 T3 and

testo 191 T4 data loggers are also ideal for measuring the plate surface

temperature distribution in freeze-drying systems.

All testo 191 data loggers can also be used for various control measurements

of temperature and pressure within the defined temperature range.

Page 10

2 Description of the instrument

10

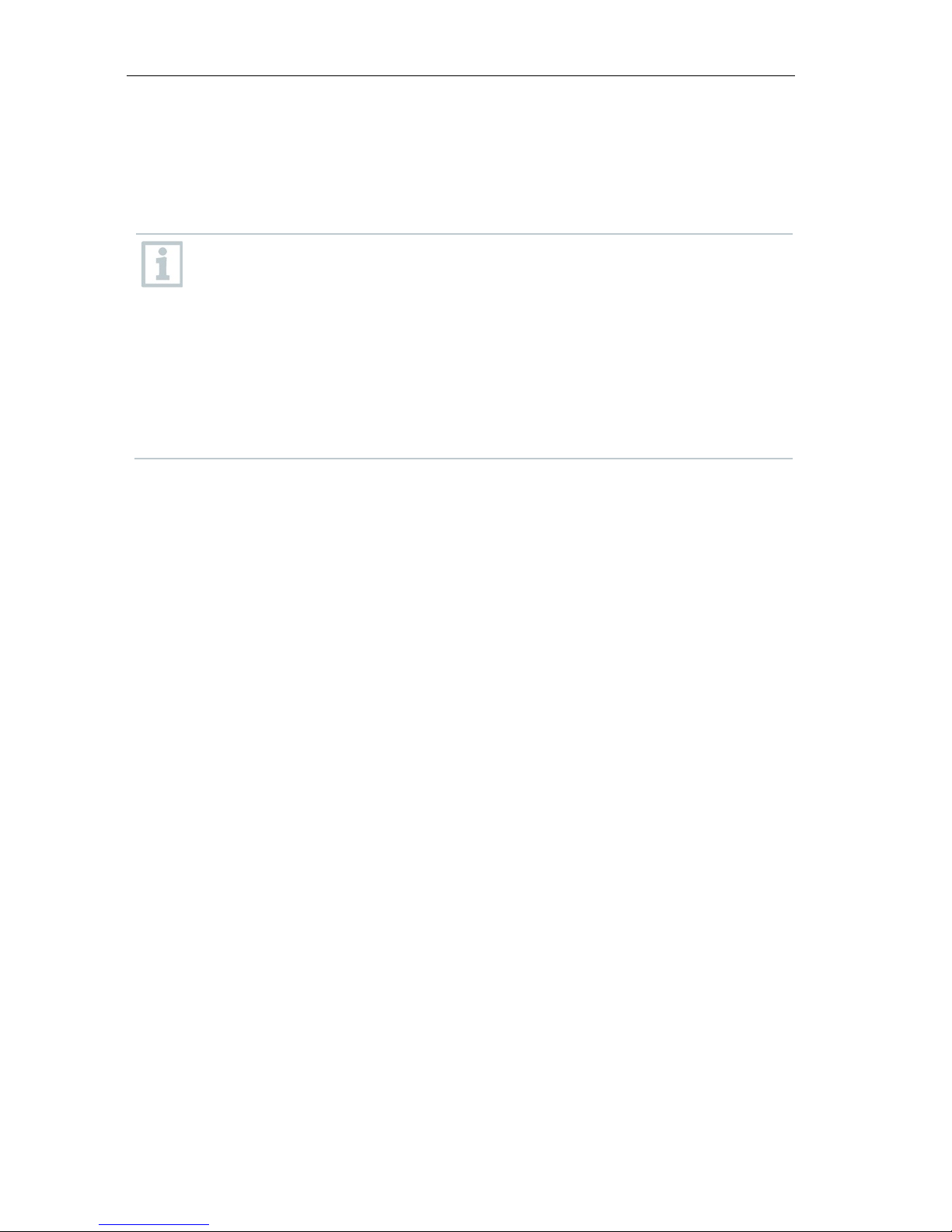

2.2 testo 191 data logger variants

1

testo 191 T1

2

testo 191 T2

3

testo 191 T3

4

testo 191 T4

5

testo 191 P1

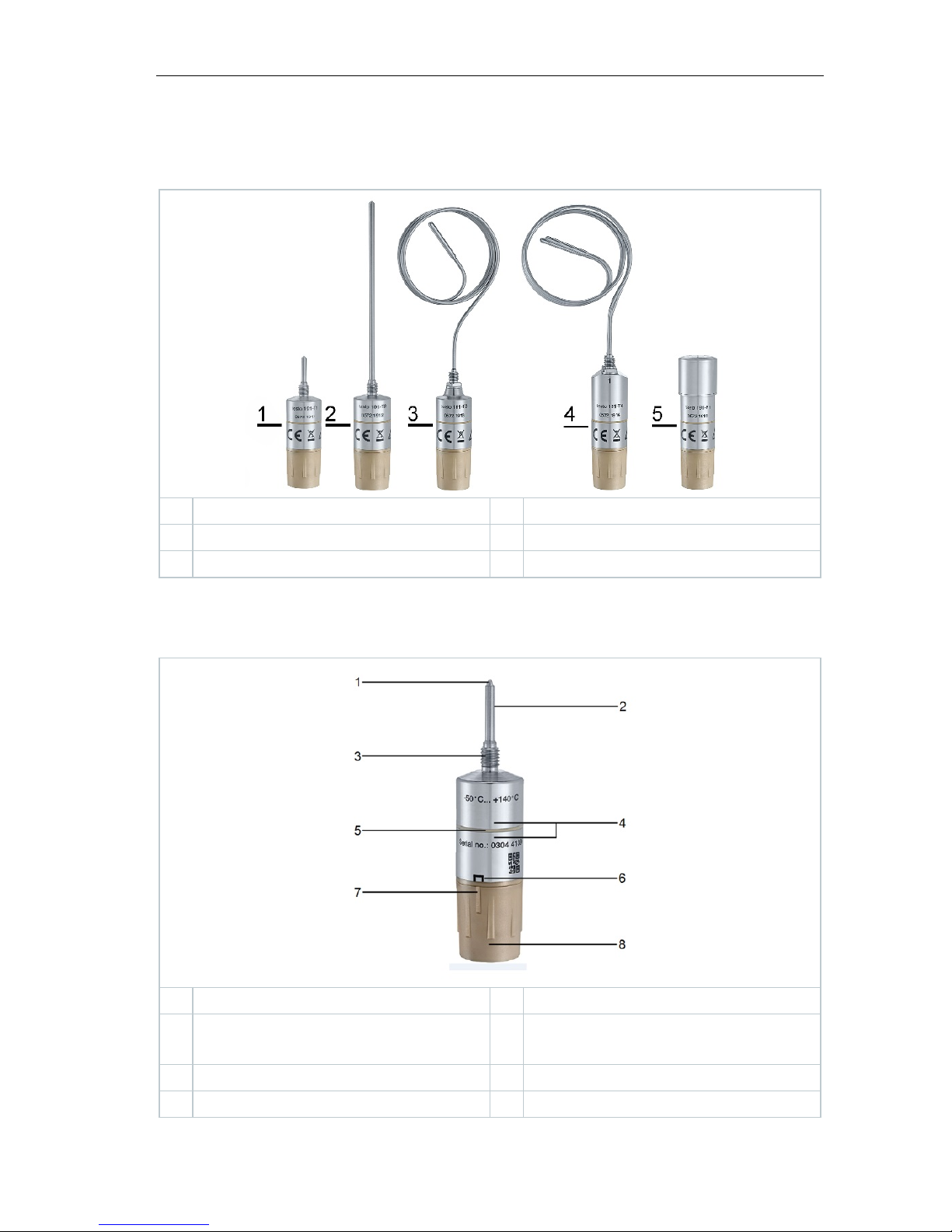

2.3 testo 191 data logger overview

1

Probe shaft tip

2

Probe shaft

3

Thread

4

Programming and readout

contacts

5

Isolator ring

6

Position marking

7

Rib

8

Battery

Page 11

2 Description of the instrument

11

The testo 191 T4 and testo 191 P1 data loggers have no thread. For

the probe shaft dimensions of the testo 191 data loggers, please refer

to the technical data in Section 6,

Technical data

.

2.4 Power supply

Large and small battery types are available for all testo 191 data loggers. For

information on installing and changing the batteries, please refer to Section 3.1

Installing the battery and 4.2 Changing the battery. Section 6 contains the

Technical data for the batteries.

1

Large battery (1/2 AA)

2

Small battery (2 x button cell)

2.5 Programming and readout unit

Communication between the testo 191 data loggers and the testo 191

Professional software occurs exclusively via the programming and

readout unit. See Section 3.3,

Positioning the data logger in the

programming and readout unit

.

Page 12

2 Description of the instrument

12

Element Element

1

Micro USB port

2

Sliding bracket

3

Distance adapter

4

Communication contacts

The programming and readout unit is installed in the case. The data

loggers can also be transported in this.

2.6 testo 191 Professional software

The testo 191 Professional software can be used to program the testo 191 data

loggers via the programming and readout unit (e.g. measuring cycle,

measurement start, measurement stop, etc.) and read them. It also offers

calculation and analysis options for the measurement data acquired. The

separate testo 191 Professional software instruction manual (order no. 0970

1911) is available for this.

Page 13

3 Commissioning

13

3 Commissioning

3.1 Installing the battery

The testo 191 data loggers are supplied with a large battery as standard. The

data logger can therefore be used in the temperature range from -50 °C to

+140 °C.

The small battery, which can be used in the temperature range from 20 °C to +140 °C, can be purchased as an accessory.

WARNING

Danger of explosion!

Ambient temperature too hot!

- Do not place the batteries in an environment hotter than 140 °C.

- Do not expose the batteries to any microwave radiation.

An undamaged seal ring must be inserted in the groove provided and

another seal ring must be fitted below the thread.

1

Place battery on data logger and

press lightly.

2

Tighten battery by turning clockwise.

Avoid the use of force! Handtighten the battery.

Page 14

3 Commissioning

14

The rib on the battery is in the position marking.

ATTENTION

Inserting the battery incorrectly will cause damage!

Ingress of moisture!

- The rib must be positioned inside the position marking on the data

logger.

The service life of the batteries depends very much on the conditions

in the area of use. Under typical autoclave and freeze-drying

conditions (measuring cycle 10 s and service life 2 h/d), we

recommend replacing battery 0515 1900 after one year at the latest

and battery 0515 1901 after 50 days. Increased measuring cycles or

reduced measuring rates may result in a shorter service life.

Therefore, please pay attention to the battery level indicator in the PC

software.

3.2 Positioning the distance adapter in the

programming and readout unit

The data loggers are supplied with the appropriate distance adapters.

The testo 191 P1 data logger does not have a distance adapter and

can be placed in the programming and readout unit without using one.

1

Insert the distance adapter into the

socket first.

2

Push forward until the side brackets engage easily.

Page 15

3 Commissioning

15

3.3 Positioning the data logger in the

programming and readout unit

The testo 191 data loggers are supplied with the appropriate distance

adapter for the programming and readout unit. A battery must be

connected to the data logger for positioning in the station

Battery is connected

1

Insert appropriate distance adapter into the socket.

2

Insert data logger onto sliding

bracket.

3

Push the data logger in the direction

of the arrow and click it into place in

the distance adapter.

The data logger is properly inserted if

the isolator ring is between the two

communication contacts.

ATTENTION

The sliding bracket may break off if the pressure is too great!

- Use light pressure to insert the data logger in the socket.

Page 16

3 Commissioning

16

ATTENTION

Strong lateral pressure may cause the communication contacts on the

bottom of the socket to break off!

- First place the data logger on the sliding bracket and deposit it gently

onto the contacts.

3.4 Connecting the programming and

readout unit to the PC via USB

Please ensure that the case is securely positioned so that the case lid

cannot fall onto the cable.

The computer is started up and the testo 191 Professional software

is enabled.

The battery is connected to the data logger and is functional.

Data logger is placed on a socket of the programming and readout

unit.

1

Insert the micro USB plug into the programming and readout unit and

connect to the computer.

The software establishes a connection to the programming and

readout unit.

Successful connection to the

programming and readout unit is

indicated in green.

If the connection is shown in black, check that the programming and

readout unit is properly connected to your PC. In addition, please

check whether the isolator ring of the data logger is between the

contact pins, see

Positioning the data logger in the programming

and readout unit.

The data loggers can be programmed for the measurements using the

testo 191 Professional software.

Page 17

4 Operation

17

4 Operation

4.1 Bending flexible probe shafts

The testo 191 T3 and testo 191 T4 data loggers have flexible probe

shafts. The testo 191 T1 and testo 191 T2 data loggers are equipped

with rigid probe shafts, which must not be bent.

ATTENTION

Incorrect bending of the probe shafts!

Material fatigue and probe breakage!

- Begin bending the probe shafts only from a distance of 30 mm from the

housing material and 50 mm from the probe tip. Otherwise, the

mechanical stress caused by the housing and probe tip edge would be

too great.

- Do not use a clamp or any other tools to bend the probe shafts.

- The probe shaft of the data logger must not fall below the bending

radius of 50 mm. Small bending radii or rapid bending back and forth

result in material fatigue and premature probe breakage.

Page 18

4 Operation

18

4.2 Changing the battery

Before use, check that the battery is suitable for the operating temperature

range. For the operating temperature range of the battery types, please read

Section 6 Technical data.

1

Unscrew the battery from the data

logger by briefly turning to the left.

2

Remove battery from the data logger.

After removal of the battery, the data logger loses the information on

battery capacity.

Stored data is retained when the battery is replaced or if the battery

fails.

3

Connect new battery, see Section 3.1, Installing the battery.

The battery replacement must be confirmed in the testo 191

Professional software

. This can be done under the menu item

Programming of loggers.

4.3 Installing the freeze-drying probe holder

The freeze-drying probe holder can only be used in conjunction with the

testo 191 T3 and testo 191 T4 data loggers.

Page 19

4 Operation

19

ATTENTION

Damage to the instrument due to improper use!

- The freeze-drying probe holder can only be used in a freeze-drying

system.

1

Insert the probe shaft tip of the data

logger into the slot.

2

Place the puck with the probe tip at

the point to be measured on the

temperature plate.

3

Bend the probe shaft so that the freeze-drying probe holder is in full

contact with the support surface.

The data logger must be positioned in such a way that the freezedrying probe holder cannot slip.

4.4 Aligning the can stand

The can stand enables the testo 191 T1 data logger to be positioned in cans in

a way that is stable and safe. Depending on the size of the can, the can stand

can be bent into the correct position.

Page 20

4 Operation

20

1

Attach the retaining clamp to the wire

stand. The thread opening must point

upwards.

2

If necessary, bend the wire stand into the correct position.

3

Rotate the testo 191 T1 data logger clockwise onto the retaining

clamp.

4

Position the can stand with the

testo 191 T1 data logger in the can.

The can stand can also be used as a device to make the position of

the testo 191 T1 data logger more stable.

4.5 Installing the can and bottle attachment

Used in conjunction with the testo 191 T2 data logger, the can and bottle

attachment enables the core temperature of food in cans and bottles to be

measured during a pasteurisation process.

Page 21

4 Operation

21

No additional tools are required to install the can and bottle

attachment on cans or bottles.

1

Lightly press the can and bottle attachment onto the insertion

position on the can or bottle.

2

The retaining thread penetrates through the top of the can or bottle

via a light tap on the can and bottle attachment head.

3

The can and bottle attachment can now be rotated in a clockwise

direction into the can or bottle.

Before inserting the probe shaft through the opening, make sure that

the fastening screw on the head is not fully screwed in, but is slightly

undone.

4

Slightly unscrew the fastening screw

on the head by turning it in a

counterclockwise direction.

Page 22

4 Operation

22

5

The probe shaft can be guided

through the opening of the can and

bottle attachment into the can or

bottle.

6

The fastening screw on the head of

the can and bottle attachment can be

tightened by turning it in a clockwise

direction.

4.6 Mounting the retaining clamp

The testo 191 T1, testo 191 T2 and testo 191 T3 data loggers have a thread on

the probe shaft, which is intended for attaching the retaining clamp. The data

logger can therefore be attached in systems or loading baskets without the use

of adhesive tape. The retaining clamp can be used multiple times.

Page 23

4 Operation

23

1

With the thread in front, push the retaining clamp over the probe

shaft.

2

Screw the retaining clamp clockwise

onto the thread on the data logger.

3

A fixing material (cable tie, wire, etc.)

can be fed through the opening of the

retaining clamp.

4

Secure the data logger to an object (e.g. metal grid).

No additional tools are required to attach the retaining clamp. Materials

such as cable ties or wires are not included in the delivery.

Page 24

5 Maintenance

24

5 Maintenance

5.1 Cleaning the instrument

• If the housing of the instrument is dirty, clean it with a damp cloth or a

brush.

• Do not use any aggressive cleaning agents or solvents! Mild household

cleaning agents and soap suds may be used.

5.2 Calibration

The testo 191 data loggers feature a high level of accuracy. In order to maintain

this accuracy of the measurement results, Testo recommends calibrating the

instrument once a year. This service can be carried out by Testo Industrial

Services GmbH.

If you have any questions about other services related to calibration,

validation and qualification, please contact Testo Industrial Services

GmbH. Give Testo Industrial Services GmbH a call on +49 7661

90901-0 or go to the website www.testotis.com.

Page 25

6 Technical data

25

6 Technical data

6.1 testo 191 T1

Feature Value

Order no.

0572 1911

Measurement parameter

Temperature (°C / °F / K)

Probe type

PT1000

Measuring range

-50 °C to +140 °C

Accuracy 0.1 °C (-40 °C to +140 °C)

0.2 °C (-50 °C to -40 °C)

Resolution

0.01 °C

Operating temperature 0 °C to +140 °C

Storage temperature -20 °C to +50 °C

Battery type

See Large battery / Small battery

Battery life

See Large battery / Small battery

Dimensions without probe

shaft (D x H)

(with large battery)

Ø 20 mm x 59 mm

Dimensions without probe

shaft (D x H)

(with small battery)

Ø 20 mm x 40 mm

Probe shaft dimensions

(D x H)

Ø 3 mm x 25 mm

Weight

47 g

Housing material

Stainless steel 316L/WNR. 1.4404/SUS 316L

Measuring cycle

1 s to 24 h

Measurement data memory

60,000 readings

Guideline 2014/30/EU (EMC)

2011/65/EU (RoHS)

EU declaration of conformity You can find the EU declaration of conformity

on the Testo website www.testo.com under

the product-specific downloads.

Page 26

6 Technical data

26

6.2 testo 191 T2

Feature Value

Order no.

0572 1912

Measurement parameter

Temperature (°C / °F / K)

Probe type

PT1000

Measuring range -50 °C to +140 °C

Accuracy 0.1 °C (-40 °C to +140 °C)

0.2 °C (-50 °C to -40 °C)

Resolution 0.01 °C

Operating temperature -50 °C to +140 °C

Storage temperature

-20 °C to +50 °C

Battery type

See Large battery / Small battery

Battery life

See Large battery / Small battery

Dimensions without probe

shaft (D x H)

(with large battery)

Ø 20 mm x 59 mm

Dimensions without probe

shaft (D x H)

(with small battery)

Ø 20 mm x 40 mm

Probe shaft dimensions (D x

H)

Ø 3 mm x 115 mm

Weight

48 g

Housing material

Stainless steel 316L/WNR. 1.4404/SUS 316L

Measuring cycle

1 s to 24 h

Measurement data memory

60,000 readings

Guideline 2014/30/EU (EMC)

2011/65/EU (RoHS)

EU declaration of

conformity

You can find the EU declaration of conformity

on the Testo website www.testo.com under the

product-specific downloads.

6.3 testo 191 T3

Feature Value

Order no.

0572 1913

Measurement parameter

Temperature (°C / °F / K)

Probe type

PT1000

Page 27

6 Technical data

27

Feature Value

Measuring range

-50 °C to +140 °C

Accuracy 0.1 °C (-40 °C to +140 °C)

0.2 °C (-50 °C to -40 °C)

Resolution

0.01 °C

Operating temperature

-50 °C to +140 °C

Storage temperature

-20 °C to +50 °C

Battery type

See Large battery / Small battery

Battery life See Large battery / Small battery

Dimensions without probe

shaft (D x H)

(with large battery)

Ø 20 mm x 63 mm

Dimensions without probe

shaft (D x H)

(with small battery)

Ø 20 mm x 45 mm

Probe shaft dimensions

(D x H)

Ø 1.5 mm x 775 mm

Probe shaft tip dimensions

(D x H)

Ø 3 mm x 25 mm

Weight

61 g

Housing material

Stainless steel 316L/WNR. 1.4404/SUS 316L

Measuring cycle 1 s to 24 h

Measurement data memory 60,000 readings

Guideline 2014/30/EU (EMC)

2011/65/EU (RoHS)

EU declaration of conformity You can find the EU declaration of conformity

on the Testo website www.testo.com under

the product-specific downloads.

6.4 testo 191 T4

Feature Value

Order no.

0572 1914

Measurement parameter

Temperature (°C / °F / K)

Probe type

2 x PT1000

Measuring range -50 °C to +140 °C

Accuracy 0.1 °C (-40 °C to +140 °C)

0.2 °C (-50 °C to -40 °C)

Resolution 0.01 °C

Page 28

6 Technical data

28

Feature Value

Operating temperature

-50 °C to +140 °C

Storage temperature

-20 °C to +50 °C

Battery type

See Large battery / Small battery

Battery life

See Large battery / Small battery

Dimensions without probe

shaft (D x H)

(with large battery)

Ø 20 mm x 72 mm

Dimensions without probe

shaft (D x H)

(with small battery)

Ø 20 mm x 53 mm

Probe shaft dimensions

(D x H)

Ø 1.5 mm x 775 mm

Probe shaft tip dimensions

(D x H)

Ø 3 mm x 25 mm

Weight

92 g

Housing material

Stainless steel 316L/WNR. 1.4404/SUS 316L

Measuring cycle

1 s to 24 h

Measurement data memory 30,000 readings per channel

Guideline 2014/30/EU (EMC)

2011/65/EU (RoHS)

EU declaration of conformity You can find the EU declaration of conformity

on the Testo website www.testo.com under

the product-specific downloads.

6.5 testo 191 P1

Feature Value

Order no.

0572 1916

Measurement parameter Pressure (mbar / bar / hPa / kPa / psi / kg/cm²

/ Torr)

Probe type

Piezoresistive sensor

Measuring range

1 mbar to 4 bar

Accuracy

± 20 mbar

Resolution 1 mbar

Operating temperature 0 °C to +140 °C

Storage temperature

-20 °C to +50 °C

Battery type

See Large battery / Small battery

Battery life

See Large battery / Small battery

Page 29

6 Technical data

29

Feature Value

Dimensions without probe

shaft (D x H)

(with large battery)

Ø 22 mm x 83 mm

Dimensions without probe

shaft (D x H)

(with small battery)

Ø 22 mm x 64 mm

Weight

91 g

Housing material

Stainless steel 316L/WNR. 1.4404/SUS 316L

Measuring cycle

1 s to 24 h

Measurement data memory

60,000 readings

Guideline 2014/30/EU (EMC)

2011/65/EU (RoHS)

EU declaration of conformity You can find the EU declaration of conformity

on the Testo website www.testo.com under

the product-specific downloads.

6.6 Large battery

Feature Value

Order no.

0515 1901

Housing material PEEK

Output 3.6 V (800 mAh)

Battery type

1/2 AA lithium battery

Field of application -50 °C to +140 °C,

1 mbar to 4 bar (abs.)

Storage temperature

-20 °C to +50 °C

Dimensions

Ø 20 mm; length 31.3 mm

Battery life (measuring cycle 10

seconds at 121 °C)

2,500 operating hours

6.7 Small battery

Feature Value

Order no.

0515 1900

Housing material

PEEK

Output 3.6 V (48 mAh)

Battery type 2 x button cell

Page 30

6 Technical data

30

Feature Value

Field of application -20 °C to +140 °C,

1 mbar to 4 bar (abs.)

Storage temperature

-20 °C to +50 °C

Dimensions

Ø 20 mm; length 12.6 mm

Battery life (measuring cycle 10

seconds at 121 °C

250 operating hours

6.8 Accessories and spare parts

Description Order no.

testo 191 T1, HACCP temperature data logger including

large battery, long distance adapter for programming

and readout unit and calibration protocol

0572 1911

testo 191 T2, HACCP temperature data logger including

large battery, long distance adapter for programming

and readout unit and calibration protocol

0572 1912

testo 191 T3, HACCP temperature data logger including

large battery, long distance adapter for programming

and readout unit and calibration protocol

0572 1913

testo 191 T4, HACCP temperature data logger including

large battery, short distance adapter for programming

and readout unit and calibration protocol

0572 1914

testo 191 P1, HACCP pressure data logger including

large battery and calibration protocol

0572 1916

Small battery 0515 1901

Large battery 0515 1900

Case small

0516 1901

Case large

0516 1902

Testo 191 Professional software

0554 1911

Retaining clamp (pack of 5)

0554 0297

Freeze-drying probe holder

0554 1907

Can tripod 0554 1906

Can and bottle attachment 0554 0458

Distance adapter short

0554 0298

Distance adapter long

0554 0299

ISO calibration certificate (temperature)

0520 0141

DAkkS calibration certificate (temperature)

0520 0281

Page 31

6 Technical data

31

Description Order no.

ISO calibration certificate (pressure)

0520 0025

DAkkS calibration certificate (pressure)

0520 0215

For further accessories and spare parts, please refer to the product catalogues

and brochures or look up at

www.testo.com.

Page 32

0970 1911 en 01

Testo SE & Co. KGaA

Testo-Strasse 1, D-79853 Lenzkirch,

Germany

Phone: +49 7653 681-0

Fax: +49 7653 681-100

E-mail: info@testo.de

Internet: www.testo.com

Loading...

Loading...