testo 177

Instruction manual en

Copyright

All rights reserved.

No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without the prior permission of Testo AG.

We reserve the right to modify the technical data contained in the

descriptions, data and graphics in this documentation.

Testo AG

Postfach 11 40

79849 Lenzkirch

Germany

Microsoft®, Windows®, Excel® and Internet Explorer® are

registered trademarks of the Microsoft Corporation.

2

Introduction / General information

Introduction

Dear Customer

Thank you for purchasing a Testo product. We hope you will enjoy the benefits of this product for a

long time to come and that it will help you with your work.

Please take the time to read the instruction manual carefully and make sure you become familiar with

how the instrument operates before using it.

If there are any problems, which you cannot solve yourself, please contact our Customer Service

Department or your nearest distributor. We will do our best to help you quickly and competently to

reduce downtimes.

General information

Warnings and particularly important information, which has to be observed when working with this

product, are highlighted in this instruction manual as follows

Warnings

Warnings are marked by a warning symbol. The appropriate Warning title indicates the danger level:

Warning! means death or serious physical injury may occur if the specified safety

measures are not carried out.

Caution! means minor physical injury or damage to property may occur if the specifed

Warning

titie!

Important information

Particularly important information is highlighted in this instruction manual by an exclamation mark.

safety measures are not carried out.

Read all the warnings carefully and carry out the specified safety measures to avoid

danger.

Standards

The conformity certificate confirms that this product fulfills the guidelines in accordance with

89/336/EWG.

3

Contents

Copyright ..........................................................2

Introduction / General information ....................3

Contents............................................................4

1. Basic safety instructions ..................................6

2. Intended use ....................................................7

3. Initial operation..................................................8

4. Display and control elements ..........................9

4.1 Display ........................................................................9

4.2 LED functions ............................................................10

4.3 Display sequence ......................................................11

4.4 Button functions ........................................................11

5. Mounting ........................................................12

5.1 Mounting the wall holder ..........................................12

5.2 Securing the data logger with a lock ........................12

5.3 Transportable unit ......................................................12

6. Connecting probes/switch ..............................13

7. Programming ..................................................14

7.1 Installing software ......................................................14

7.2 Connecting data logger to PC ..................................14

7.3 Setting up the connection ........................................15

7.4 Opening the connection ............................................16

7.5 Programming the data logger ....................................17

7.6 Closing the connection ..............................................24

8. Reading out data ............................................25

9. Changing the battery ......................................26

10. Error messages ..............................................27

4

Contents

11. Technical data ................................................28

11.1 testo 177-T1 ..............................................................28

11.2 testo 177-T2 ..............................................................29

11.3 testo 177-T3 ..............................................................30

11.4 testo 177-T4 ..............................................................31

11.5 testo 177-H1 ..............................................................32

11.6 Battery life ................................................................33

12. Accessories/Spare parts ................................34

5

1. Basic safety instructions

Please read through the following safety instructions carefully:

Avoiding electricity:

Never use the instrument and external probes to measure on or near live parts if the instrument is

not expressly approved for current and voltage measurement!

Product safety:

Prior to each measurement, check if the connections are connected properly via the blind plug and

if the right probe is correctly inserted. Otherwise the protection class specified in the Technical data

cannot be guaranteed.

The logger should only be operated within the parameters specified in the Technical data.

Please handle the logger with care.

The instrument should only be opened if expressly described in the instruction manual for

maintenance purposes.

Force should never be applied!

Only for testo 177-4

The probe sockets in testo 177-4 are not isolated from one another. Please take note of this when

using surface probes with a non-insulate thermocouple.

Disposal:

Please dispose of spent batteries responsibly.

You can return your logger directly to us at the end of its service life. We will dispose of it

responsibly.

6

2. Intended use

The testo 177 data loggers are used to save and read out separate readings and measurement

sequences. The readings are measured, saved and transmitted to a PC, to the testo 575 fast printer

or to the testo 580 data collector per infrared using testo ComSoft software.

Applications

testo 177-T1

Fast and affordable temperature monitoring

in refrigeration and deep freeze sector:

during transport, in refrigerated rooms,

in display cabinets, in containers

Fulfills guidelines in accordance with

EN 12830 standards *

testo 177-T2

Temperature monitoring with display:

during transport, in glass cabinets,

in refrigerated rooms, in containers,

in domestic housing

Fulfills guidelines in accordance with

EN 12830 standards *

testo 177-T3

Temperature logger with display and switch

(door contact) for monitoring transport:

transport monitoring, refrigerated room

monitoring, in containers, in warehouses

Fulfills guidelines in accordance with

EN 12830 standards *

* In accordance with EN 12830, please ensure that a regular check and calibration in accordance with

EN 13486 (recommendation: once a year) is carried out on this instrument. Please contact us for

more detailed information.

testo 177-T4

Fast measurement of high temperatures:

during production processes, in laboratories

in heating installation sector, in containers

in domestic housing

testo 177-H1

Monitoring of humidity and temperature

values with external temperature and dew

point measurement

in domestic housing, in the pharmaceutical

sector, in museums, in warehouses,

in industry

Only for testo 177 - T3

The following components of the product are designed for continuous contact with

foodstuffs in accordance with the regulation

(EG) 1935/2004:

The measurement probe up to 1 cm before the probe handle or the plastic housing. If

provided, the information about penetration depths in the instruction manual or the mark(s)

on the measurement probes should be noted.

7

3. Initial operation

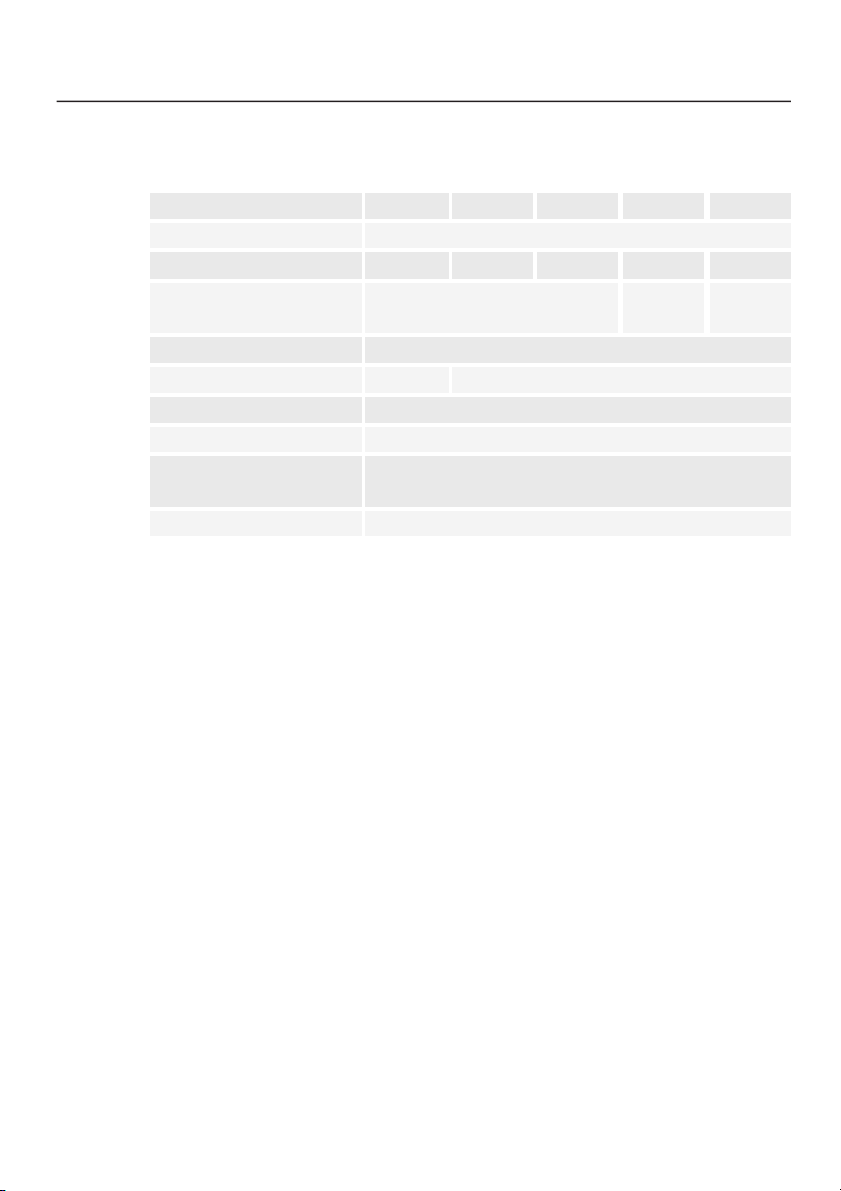

Type 177-T1 177-T2 177-T3 177-T4 177-H1

Start criterion Key start

Measuring rate 5 Min. 5 Min. 5/1 Min.* 3 Sek. 1 Min.

Stop criterion Wraparound Until memory Wraparound

Alarm values Respective measuring range full-scale values (See Technical data)

Display -On

LEDs Status led (green): Off / Alarm led (red): On

Measurement channels All channels switched on **

Fast printer- / Stop: Switched on

data collector function New programming: Switched on

Protocol name testo177-{Type}_{Serial number}

* Depending on event: switch (e.g. door contact) open or not connected/switch closed

** testo 177-T4: T/C -Type “K” programmed

The data loggers have the defaults below:

memory is full memory

The data logger with the above factory defaults can be used

immediately.

If you wish to use other measurement criteria, you will have to

program your data logger in accordance with your requirements

using testo ComSoft software (See 7. Programming, P. 14).

External probes can be attached to many of the data loggers (See

6. Connecting probes, S. 13).

8

Readings

Top alarm value

4. Display and control elements

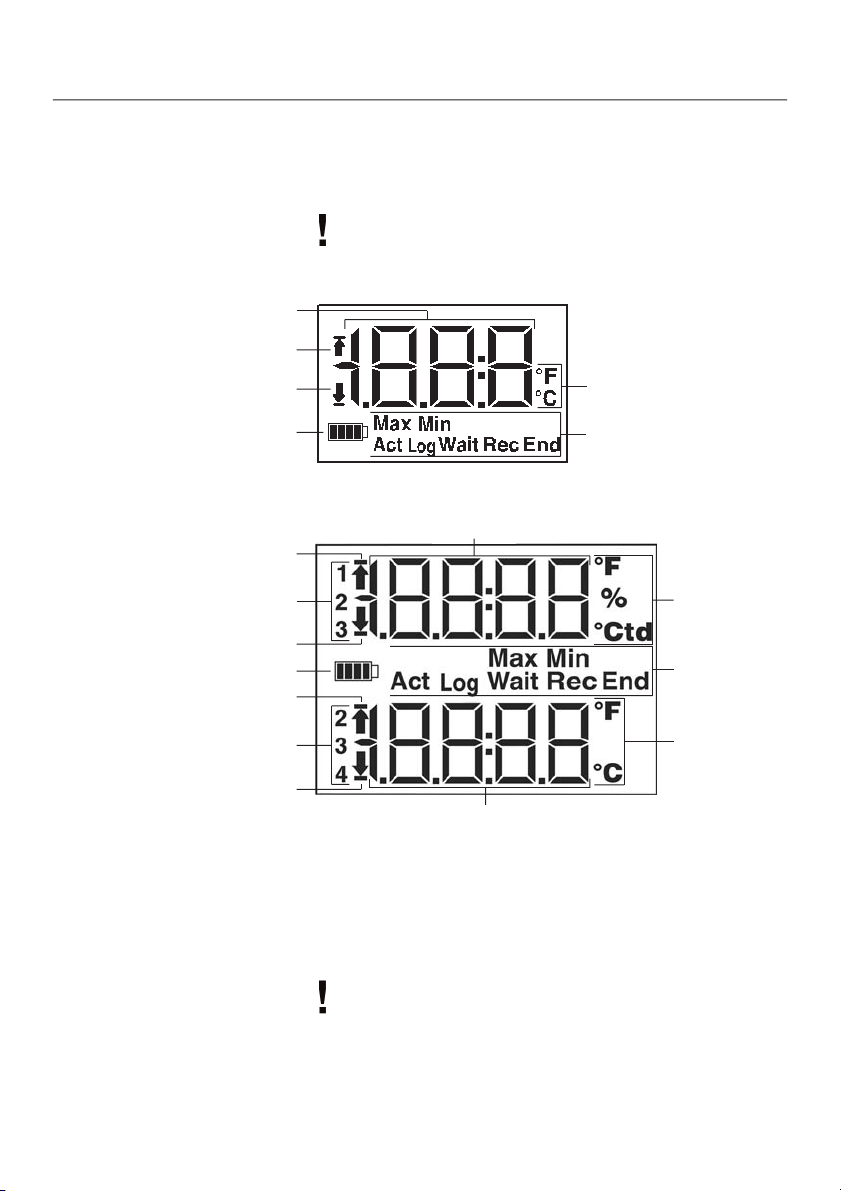

4.1 Display

The display function can be activated/deactivated via the testo

ComSoft

a display.

testo 177-T2:

software. The testo 177-T1 data logger do not have

Bottom alarm value

Battery capacity

testo 177-T3, testo 177-T4, testo 177-H1:

Readings

Top alarm value

Channels

Bottom alarm value

Battery capacity

Top alarm value

Channels

Bottom alarm value

Readings

* Reading information:

Max = highest reading, Min = lowest reading, Act = Intermediate reading (is shown in display but is

not saved), Log = saved reading

Status information:

Wait

= Waiting for program to start,

program is finished

Rec

= Measuring program is running,

Units

Reading and status

information *

Units

Reading and

status

information *

Units

End

= Measuring

Due to technical reasons, the display speed of the liquid

crystals slows down at temperatures below 0 °C

(approx. 2 s at -10 °C, approx. 6 s at -20 °C). However, this

does not have any influence on the accuracy of the

measurement.

9

4. Display and control elements

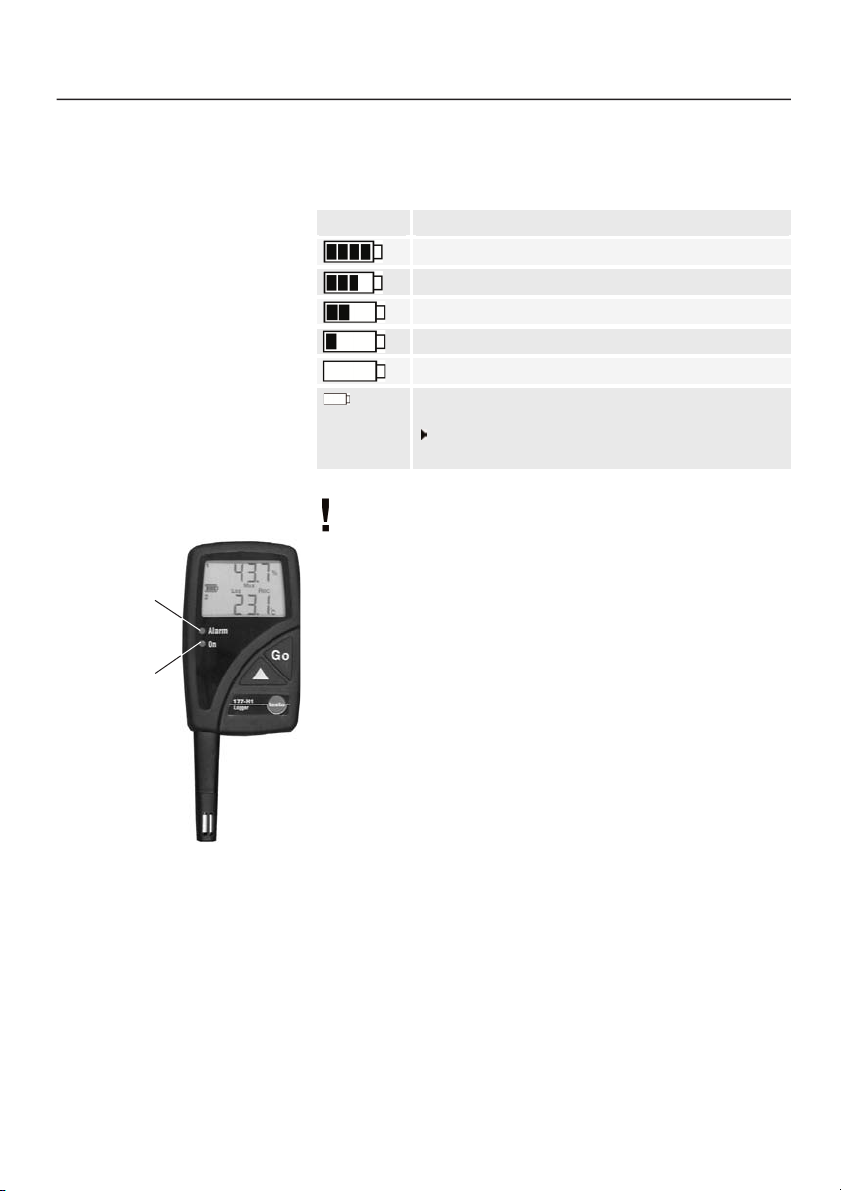

4.2 LED functions

2

Reference values (See 11.6 Battery

life, P. 33)

3

The battery symbol is updated

when:

- the wraparound memory is full

- measurement program is

started/ended

Record

- In

Once a day

- the

if last measurement was more than

24 hours ago

mode:

GO

button is pressed:

Alarm led

(red LED)

Status led

(green LED)

Symbol

3

Capacity

75-100%

50-75%

25-50%

10-25%

<10%

OFF

Battery empty (measuring program was stopped)

Reading out data and changing battery (See

9. Changing battery, P. 26)

The LED functions can be switched on/off via

testo ComSoft software.

In all modes:

The Alarm led flashes three times every 15 seconds if the

remaining battery capacity is less than10% (even if Alarm led is

deactivated).

Wait

mode and

Key start

start criterion programmed:

The status led flashes five times if the GObutton is kept pressed

for approx. 3 s (even if the Status led is deactivated).

It is confirmation that the measuring program was started and

that the data logger is now in the

Record

mode:

Record

mode.

The Alarm led flashes once every 15 s if alarm values have been

exceeded (only if Alarm led is activated).

The Status led flashes once every 15 s (only if the Status led is

activated).

It is confirmation that the measuring program is running.

The Status led flashes five times if the GObutton is kept pressed

for approx. 3 s (even if Status led is deactivated).

It is confirmation that a time mark has been set.

10

4. Display and control elements

4.3 Display sequence

Depending on the mode, different information can be displayed in

the data loggers with display. You will find a detailed description of

the information which can be called up in the short version of the

instruction manual enclosed with every data logger.

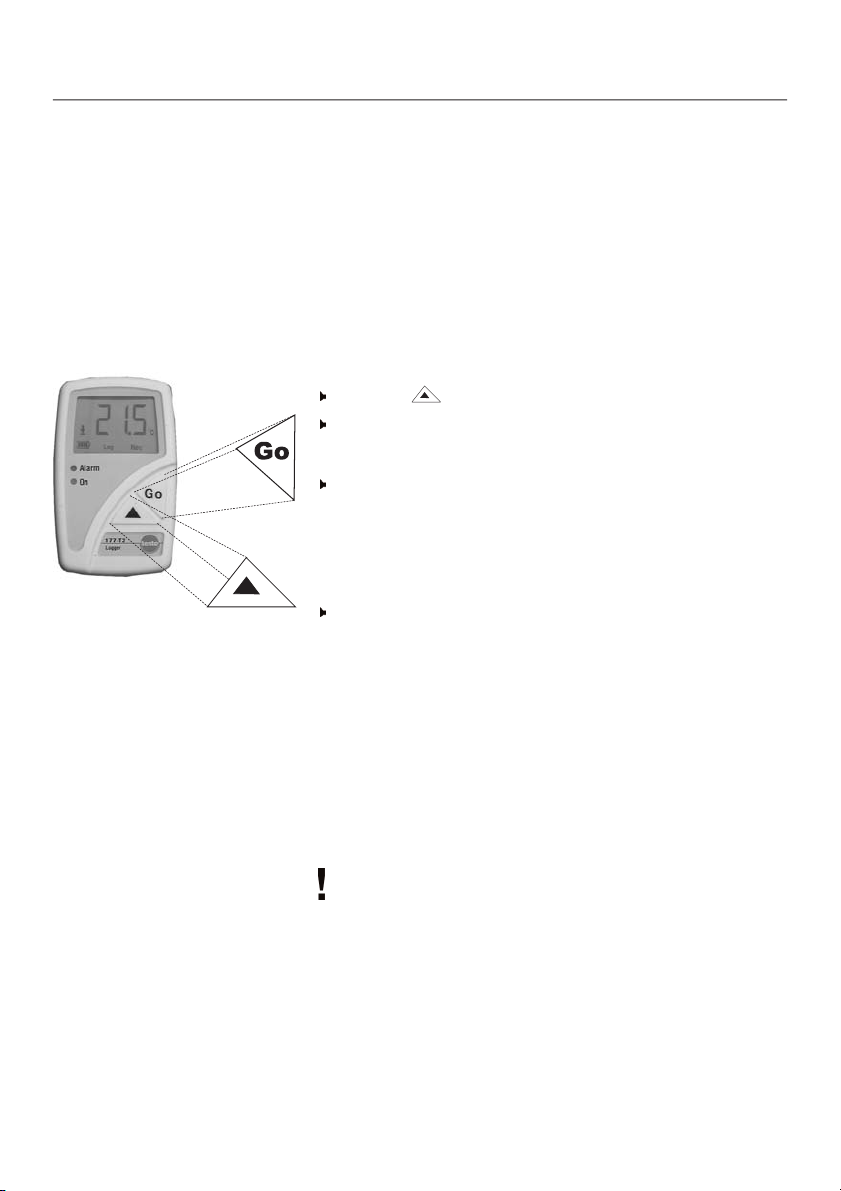

4.4 Button functions

In all modes in data loggers with display:

Press the button to switch between the displays.

Press the GObutton to activate an intermediate measurement.

Wait

mode and

Press the GObutton for approx. 3 s to start the measuring

program.

- The measuring program starts,

(if available) and the Status led flashes five times.

Record

Press the GObutton for approx. 3 s to set a time mark.

- The Status led flashes five times.

Time mark: This function enables you to monitor and read

out/print out the memory content from a specified point in time

(

time mark

readings from

The readings from

read out on the testo 575 fast printer or the testo ComSoft

software.

The readings from

testo 580 data collector.

Only one time mark can be set. If the GObutton is pressed for

approx. 3 seconds in the

is deleted and a new time mark is set up.

- The readings (max./min. values, exceeding of alarm values)

are shown in the display (if available) from the set time mark.

Key start

mode:

) without having to reprogram the data logger. The

Start(All readings

start criterion programmed:

Record

) are also saved.

Start(All readings

Start(All readings

Record

) or

) can be read out on the

mode, the existing time mark

appears in the display

From time mark

can be

11

5. Mounting

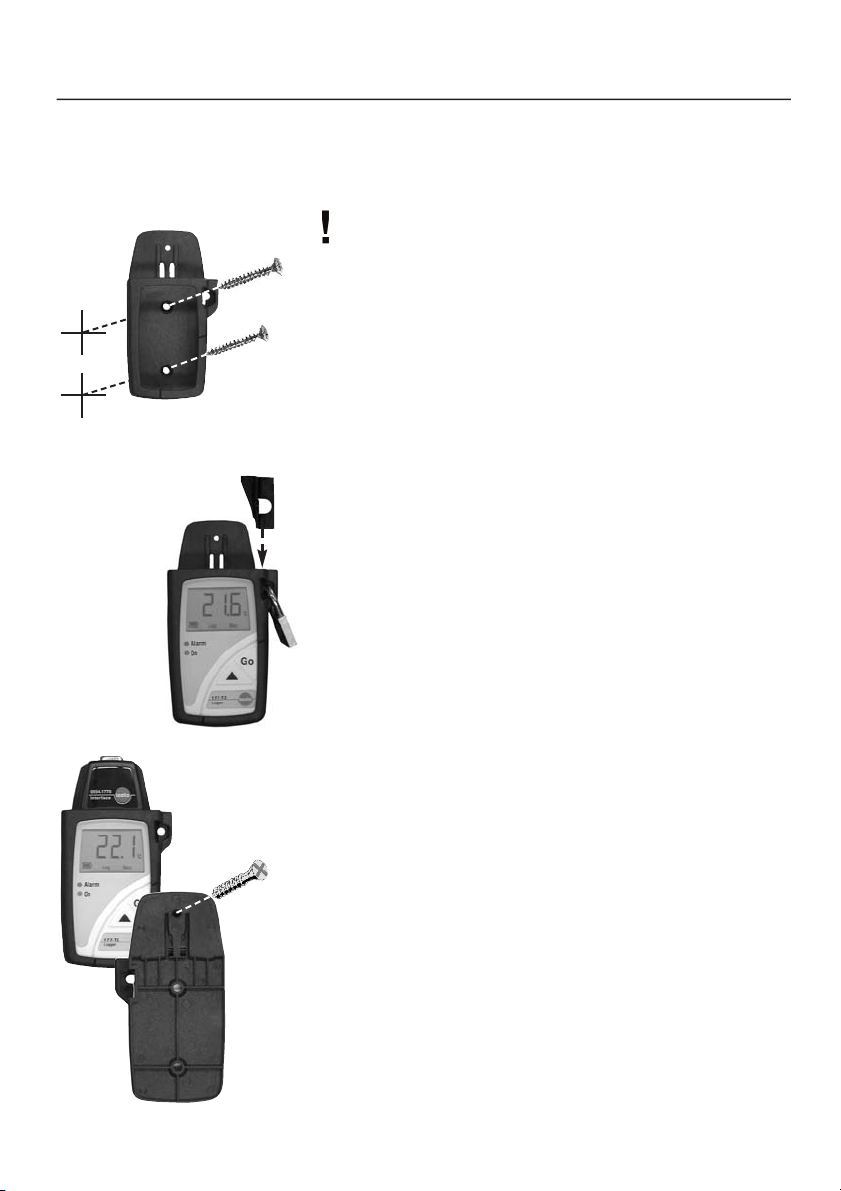

5.1 Mounting the wall holder

Mounting materials (e.g. screws, dowels) are not included.

1 Position the wall holder at the required location.

2 Using a pencil or similar, mark where the fixing screw is to go.

3 Prepare the area for mounting (e.g. drill a hole, put in dowel).

4 Mount the wall holder using a screw which fits.

5.2 Securing the data logger with a lock

1 Insert the data logger into the wall holder.

2 Place the retainer key in the wall holder.

3 Attach the lock to the wall holder (Accessory: Part no.

0554 1755).

12

5.3 Transportable unit

A unit can be made out of the wall holder, logger and the

interface to make transport or dispatch easier.

1 Push the data logger into the wall holder.

2 Push the interface onto the wall holder.

3 Secure the unit by connecting the wall holder and the interface

using the screw supplied.

Warning!

6. Connecting probes/switch

Observe the following points when connecting the probes to the

data logger and to the measurement points:

Observe poles of plug.

Insert the plugs firmly into the connections to guarantee that

they are properly in place. Force should not be used.

Ensure that the plugs are firmly attached to the data logger or

that the connections are in place with a blind plug.

Ensure that the probe is positioned properly to avoid disturbing

influences on the measurement.

testo 177-T3:

Use the enclosed twin-wire cable to connect the switch (door

contact). Connect a potential-free button or switch to it.

False connection!

Electric shock! Damage to data logger!

Do not apply electrical signal to cable and avoid contact with live parts.

Only one potential-free contact should be connected.

Measuring rate

both cables are not connected with one another.

Measuring rate Door

cables are connected with one another (See page 24).

The data logger requires slightly more energy if the contact is

electrically closed. It is recommended to select the contact so

that it is electrically open most of the time.

testo 177-T4:

Ensure that each respective configured probe is connected to

the socket (via testo ComSoft software).The numbers of the

connections are printed on the housing!

is activated if the contact is open electrically i.e. if

if the contact is closed electrically i.e. if both

13

7. Programming

7.1 Installing software

In order to program your data logger in accordance with your

individual needs, you will need a PC on which the testo ComSoft

software is installed.

You will find instructions on the installation and operation of the

software in the testo ComSoft instruction manual.

Continue with 7.2 Connecting data logger to PC, P. 14 once

the software is successfully installed.

7.2 Connecting data logger to PC

You will need a free serial interface (RS232) or a USB interface

to connect the data logger interface to your PC.

Proceed with Step 1 if using a serial interface.

The USB driver must already be installed in the PC when

using a USB interface. The driver and installation instructions

are enclosed with the USB interface. Proceed with Step 1

once successfully installed.

1 Connect the serial connection cable or USB connection cable

of the interface to your PC.

2 Connect the interface to the connection cable.

3 Insert the interface in the desk-top holder.

4 Place the logger in the desk-top holder.

The interface can be placed directly in the wall holder. In this

way, the data can be read out directly on location.

Ensure that the interface is completely plugged on and

snapped into place. Otherwise the connection is not

guaranteed.

5 Start the testo ComSoft software.

14

7. Programming

7.3 Setting up the connection

1 Start testo ComSoft software.

2 Select

-

- The connection to the data logger found is set up

-or-

2 Select

- The

Instrument > Autodetect...

Autodetect

automatically and the name of the connection appears in the

Data

opens.

window.

Instrument> New device

New device setup wizard

.

.

opens.

3 Select

4 Select the interface in

5 Enter a name for the connection and click on

testo175-177

connected your data logger to your PC and click on

in Device selection and click on

Connection

, with which you have

Finish

Next

Next

.

.

.

15

7. Programming

Confirmation of battery change

- If the data logger is used for the first time or the data logger

battery has been changed, the

Enter the date when the battery was changed.

Enter the temperature range in which you will use the data

logger and confirm with OK.

- The connection to the data logger is set up. The name of the

connection appears in the

New battery

Data

window.

window opens.

7.4 Opening the connection

Click twice on the connection, which you want to open, in the

Data

window.

- If a protocol is saved in the data logger, the protocol symbol

and the title appear under the opened connection.

16

The readings saved in the data logger are not transmitted to

the PC when the connection is opened. Carry out the following

to transmit the readings:

Click twice on the title of the protocol (See testo ComSoft

software instruction manual).

Use one connection for several data loggers

You can connect different data loggers once a connection has

been set up. The connection must be closed when changing

the data logger and then opened again for the new data

logger. Otherwise, it cannot be identified by the software (See

7.6 Closing the connection, P.24).

7. Programming

7.5 Programming the data logger

Any readings in the data logger are deleted if the data logger

is programmed.

Read out any data from the data logger which may exist

before programming

(See testo ComSoft software instruction manual).

Select

Instrument> Device control

This function is only activated if the name of the connection is

highlighted. If this is not the case:

First click on the name of the connection so that it is

highlighted and then select

- The window for programming the data logger opens.

.

Instrument> Device control

.

Window selection

You will find a bar on on the left side in which the available

windows are shown. Click to select.

Programming recommendation

It is recommended to carry out programming first in the

and

Settings

windows and then in the

Program window

Probes

.

17

7. Programming

Instrument

You can read general information on the data logger in the

Instrument

Protocol

window.

This window is a pure information window. Programming is not

possible.

18

You can read information from the protocol currently stored in the

data logger in the

values

and

This window is an information window. Programming is not

possible.

Protocol

Since time mark

window.You can choose to display

.

All

7. Programming

Probes

Probes:

Activate the probes available or deactivate them.

Unit:

Displays the set unit for the respective channel.

You cannot change the unit in this window, but in the

window.

Settings

LL:

The lower alarm limit for the channels is entered here.

UL:

The upper alarm limit for the channels is entered here.

Name:

Enter a name for the channel here.

19

7. Programming

Settings

Date and time:

The set date and the time in the data logger are shown.

Select

Synchronize

data logger with the clock in your PC.

Date/Time can only be synchronized when the data logger is

in the

Wait

or

to synchronize the date and the time in the

End

mode.

20

Temperature:

Select the required temperature unit for the temperature

channels (°Cor °F).

testo 575/ testo 580

Select whether the data logger is to be newly programmed

(

New programming

printer and the testo 580 data collector.

- Function:

) and stopped (

Stop

) via the testo 575 fast

7. Programming

Humidity calibration (

Select between

If

Custom

- The

Display functions:

is selected, the

Click on

Carry out humidity calibration using the control and adjustment

set (Part no. 0554.0660). Follow the instructions in the

Instruction Manual for the Control and Adjustment Set.

Select whether the LEDs, the

on are to be activated in the data logger.

Only the data display is deactivated when the display is

switched off. Status information on mode and battery capacity

are always shown.

Custom ...

Humidity calibration

testo 177-H1

Factory defaults

Custom ...

.

window opens.

only):

or

Custom

button is activated.

Alert led

, Status led and

.

Display

Enable limit signal output

From ComSoft Version 3.4 on, the external alarm signal output

testo 581 can be activated if connected to a data logger.

21

7. Programming

Program

Start criterion:

Select the required criterion for the start of the program.

You have the choice between

PC Start

If

can enter/select the required date/time.

.

Date/Time

is chosen, an additonal field appears in which you

Date/Time, Key start

and

22

Measuring rate:

Select the time cycle in which the measurements are to be

carried out.

You can choose between sec (seconds),

and d(days).

The smallest/largest measuring rate differs depending on the

instrument type (Refer to 11. Technical data, P. 28).

Measuring rate Door (

Select the time rate in which the measurements are to take

place, if the contact is closed electrically.

Stop criterion:

Select the required criterion to stop the measuring program.

You can choose between

Wraparound memory

testo 177-T3

Until memory is full, No. of logs

and

Date / Time.

only):

min

(minutes), h(hours)

,

7. Programming

It is only possible to select

selected as

additional field will appear in which the number of

measurements required can be entered.

testo 177-T3:

door contact is activated.

Start criterion

Date/Time

Date/Time

. If you choose

is not possible as

if

Date/Time

No. of logs

is also

an

Stop criterion

if

Duration:

Indicates running time of program calculated on the basis of the

values for

If the

until the memory is full is calculated.

Start criterion, Measuring rate

Wraparound

stop criterion is selected, the length of time

and

Stop criterion

.

Estimated battery life:

Indicates estimated battery life.

Title:

Enter a Title for the measuring program.

Maximum 24 characters can be entered.

The title of the measuring program is accepted into the testo

ComSoft

appear at the top of the printout when the protocol is printed on

the testo 575 printer.

software when the data logger is read out. The title will

Comments:

Additional information on the measuring program can be

entered here.

The entered text is printed on the testo 575 printer printout. Up

to 96 characters can be entered. The fast printer automatically

enters return after every 24 characters.

Send to:

Activate the function by clicking on the selection window and

enter an e-mail address in the text box.

Once the measurement protocol has been opened in the testo

ComSoft

The entered email address and the log are automatically saved in

your e-mail.

software, you can send it by e-mail via

System requirement for this function:

Microsoft Windows 95 or newer and

Microsoft Internet Explorer 5.0 or newer.

File > Send

...

23

7. Programming

Start and Stop:

Click on

This function can only be selected if

has been selected as

Click on

This function can only be selected if a measurement is

running.

Programming ended

Click on

A measuring program can only apply in the data logger if it is

in the

If a measurement is running (

- The

programming.

Start

to start a measuring program..

PC start

Start criterion

Stop

to end a measuring program.

Apply

to transmit the programming to the data logger.

Wait

or

End

mode.

Finish the measurement by clicking on

Programming data

window opens to confirm the following

Record

.

mode):

Stop.

24

7.6 Closing the connection

1 Click on the connection you wish to close with your right

mouse button in the

2 Select

- The connection to the data logger is closed.

Close

Data

window.

.

8. Reading out data

You have three options to read out data from the data logger:

1. Via testo ComSoft software. Data is transmitted directly to a

PC.

Please read the Instruction manual on the testo ComSoft

software.

testo ComSoft software is available in 2 versions with the

following range of functions:

testo ComSoft 3 Basic (0554.1758)

- Programming and reading out the testo 174,

testo 175 and testo 177 data loggers

- Display and printout as table or diagram

- Data export (e.g. in Microsoft Excel)

- Automatic search for instrument driver when started

(Auto Detect)

testo ComSoft 3 Professional (0554.0830)

like testo ComSoft 3 Basic, but with the following additional

features:

- Programming and reading out other Testo instruments such

as testo 400, testo 650, etc.

- Display and printout as number box, histogram, form, analog

instrument, parametric graph

- Data management function

- Analysis functions (compensation curve, mean function)

- Selection of different printing heads for table and graph

printouts

- Adaptation of menus and range of functions

- Developer ToolBox with functions to incorporate the instrument

driver in non-Testo software

2. Via the testo 580 data collector.

Data can then be read out via testo Comsoft software.

For more information, refer to the testo 580 Instruction

manual.

3. Printout via testo 575 fast printer

For more information, refer to the testo 575 Instruction

manual.

25

9. Changing the battery

1 Please read out the saved data before changing the battery.

See testo ComSoft software Instruction manual

If it is not possible to read out the saved data due to low

battery capacity, please carry out the following:

2 Remove the screw at the back of the data logger using a small

crosstip screwdriver.

3 Using a screwdriver, lift the back wall at the bottom of the data

logger and then remove from data logger 1.

4 Attach the jumper (included with spare battery) to the plug

connector beside the connection for the battery 2.

The inserted jumper prevents the memory from being deleted

or written over.

5 Take the battery out of the battery compartment and pull out

the plug-in connection to the data logger 3.

6 Connect the new battery to the data logger`s plug-in

connection and place in battery compartment.

Only original Testo spare batteries should be used

(see 12. Accessories/Spare parts, P. 34 for Part nos).

7 Remove the jumper from the plug connector.

8 Hold the back wall at a 45° angle to the top of the instrument

and then flip down.

Ensure that both O rings are positioned on the screw so as to

guarantee that it is sealed completely.

9 Press the back wall onto the logger with your thumbs. Make

sure that it is closed properly 4 and then secure using screw.

10 Place the data logger in the desk-top holder and attach to

interface.

11 Start the testo ComSoft software and set up a connection to

the data logger by clicking twice on the required connection

with the left mouse button.

- The

- The data logger is now ready for use.

4

3

1

2

First change the battery and then read out the saved data

(no data will be lost).

New battery

Enter the date of battery change.

Enter the temperature range in which you will be using the

data logger and confirm with OK.

window is opened 5.

26

10. Error messages

If problems occur which are not described here, please contact Testo or your local distributor.You will

find contact details in the Warranty booklet or in Internet at

www.testo.com

.

Error message

OFF

and

END

are lit,

flashes

OFF

is lit

OFF, END

are lit

PC

date

Red and green LEDs

flash alternately five

times

and

is lit

is lit

Possible causes

Battery power too low

Battery empty

Measuring program was

cancelled by Reset

An attempt was made to

start the data logger via

GO

: data logger indicates

that

Start criterion PC

Start

is programmed.

An attempt was made to

start the data logger via

GO

: data logger indicates

that

Start criterion

Date/Time Start

programmed.

The GObutton was

pressed for more than 3

seconds in the

is

END

mode

Remedy / Comments

Read out data and change battery

(See 9. Changing battery, P. 26)

Communication with PC is possible. Communication with testo 575 fast printer/ testo 580

data collector is not possible.

Change battery (See 9. Changing

battery, P. 26)

No communication with PC / testo 575 fast

printer/ testo 580 data collector possible.

Reactivate data logger via testo ComSoft

software

Start the data logger via PC

or change the

Key start

Change

Key start

No function is allocated.

Start criterion

.

Start criterion

.

to

to

27

11. Technical data

11.1 testo 177-T1

Parameter ......................................................Temperature (°C/°F)

Sensor ....................................................................................NTC

Number of measuring channels ................................1 x internal

Measuring range ......................................................-40 to +70 °C

Accuracy..............................................±0.4 °C (-25 °C to +70 °C)

..........................................................±0.8 °C (-40 °C to -25,1 °C)

............................................................................................±1 digit

Resolution............................................................................0.1 °C

Measuring rate ................................2 s to 24 h (freely selectable)

Adaptation time t90(internal) ......Approx. 30 min. at wind speed 1m/s

Storage temperature................................................-40 to +85 °C

Operating temperature ............................................-40 to +70 °C

Memory capacity ................................................48,000 readings

Protection class ....................................................................IP 68

Housing ..........................................................................ABS/TPE

Dimensions in mm (lxwxh) ....................................103 x 64 x 33

Weight ....................................................................................111g

Battery ....................................................................Lithium (1 AA)

Battery life............................................................Typical: 5 years*

....(Measuring rate: 15 Min., Operating temperature: -10 to +50°C,

......................................Display: On, Status led (green LED): Off)

* See Chapter 11.6 Battery life, P. 33

28

11. Technical data

11.2 testo 177-T2

Parameter ......................................................Temperature (°C/°F)

Sensor ....................................................................................NTC

Number of measuring channels ................................1 x internal

Measuring range ......................................................-40 to +70 °C

Accuracy ..................................................± 0.4 °C (-25 to +70 °C)

................................................................± 0.8 °C (-40 to -25,1 °C)

............................................................................................±1 digit

Resolution............................................................................0.1 °C

Measuring rate ................................1 s to 24 h (freely selectable)

Adaptation time t90(internal) ......Approx. 30 min. at wind speed 1m/s

Storage temperature................................................-40 to +85 °C

Operating temperature ............................................-40 to +70 °C

Display ..........................................................................LCD, 1 line

Operating temperature/Display ..............................-30 to +65 °C

Memory capacity ................................................48,000 readings

Protection class ....................................................................IP 68

Housing ..........................................................................ABS/TPE

Dimensions in mm (lxwxh) ....................................103 x 64 x 33

Weight ....................................................................................122g

Battery ....................................................................Lithium (1 AA)

Battery life............................................................Typical: 5 years*

....(Measuring rate: 15 Min., Operating temperature: -10 to +50°C,

......................................Display: On, Status led (green LED): Off)

* See Chapter 11.6 Battery life, P. 33

29

11. Technical data

11.3 testo 177-T3

Parameter ......................................................Temperature (°C/°F)

Sensor ................................................NTC (internal and external)

Number of measuring channels ..........4 channel (2x ext./1x int./

............................................................1x event, e.g. door contact)

Measuring range ......................................-40 to +70 °C (internal)

................................................................-40 to +120 °C (external)

Accuracy, internal ..................................±0.8 °C (-40 to -25,1 °C)

(System) ....................................................±0.4 °C (-25 to +70 °C)

............................................................................................±1 digit

Accuracy, external..................................±0.4 °C (-40 to -25,1 °C)

(only Logger) ............................................±0.2 °C (-25 to +70 °C)

............................................................±0.4 °C (+70.1 to +120 °C)

............................................................................................±1 digit

Resolution............................................................................0.1 °C

Measuring rate..............2 s to 24 h (event channel switched off) /

........................................2 s to 9,1 h (event channel switched on)

................2 measuring rates (event-dependent, freely selectable)

Adaptation time t90(internal)Approx. 30 min at wind speed 1m/s

Storage temperature................................................-40 to +85 °C

Operating temperature ............................................-40 to +70 °C

Display ........................................................................LCD, 2 lines

Operating temperature/Display ..............................-30 to +65 °C

Memory capacity ................................................48,000 readings

Protection class ....................................................................IP 67

Housing ..........................................................................ABS/TPE

Dimensions in mm (lxwxh) ....................................103 x 64 x 33

Weight ....................................................................................127g

Battery ....................................................................Lithium (1 AA)

Battery life............................................................Typical: 5 years*

....(Measuring rate: 15 Min., Operating temperature: -10 to +50°C,

......................................Display: On, Status led (green LED): Off)

* See Chapter 11.6 Battery life, P. 33

30

11. Technical data

11.4 testo 177-T4

Parameter ......................................................Temperature (°C/°F)

Sensor ..........................................Type K, T and J thermocouples

Number of measuring channels................................4 x external

Measuring range Type K....................................-200 to +1000 °C

Measuring range Type T ......................................-200 to +400 °C

Measuring range Type J......................................-100 to +750 °C

Accuracy Logger ..................................±0.3 °C (-100 to +70 °C)

..............................................±0.5% of reading (+70 to +1000 °C)

..............................................±1.5% of reading (-200 to -100,1 °C)

............................................................................................±1 digit

Resolution............................................................................0.1 °C

Measuring rate....................1 or 2 channels activated: 2 s to 24 h

............................................3 or 4 channels activated: 3 s to 24 h

............................................................................(freely selectable)

Storage temperature................................................-40 to +70 °C

Operating temperature ..............................................0 to +70 °C

Display ........................................................................LCD, 2 lines

Operating temperature/Display..................................0 to +65 °C

Memory capacity ................................................48,000 readings

Housing ..........................................................................ABS/TPE

Protection class ....................................................................IP 43

Dimensions in mm (lxwxh) ....................................103 x 64 x 33

Weight ....................................................................................129g

Battery ....................................................................Lithium (1 AA)

Battery life............................................................Typical: 5 years*

....(Measuring rate: 15 Min., Operating temperature: -10 to +50°C,

......................................Display: On, Status led (green LED): Off)

* See Chapter 11.6 Battery life, P. 33

31

11. Technical data

11.5 testo 177-H1

Parameter........................Humidity (%RH) / Temperature (°C/°F) /

......................................................................Dew point (td°C/td°F)

Sensor ......................................Humidity sensor / NTC (internal) /

................................................................................NTC (external)

Number of measuring channels ......4 (3 x internal: %RH, °C/°F,

..........................................................td°C/td°F, 1 x external: °C/°F)

Measuring range ......................................................0 to 100%RH

....................................................................-20 to +70 °C (internal)

................................................................-40 to +120 °C (external)

................................................................................-40 to +70 td°C

Accuracy, internal ..............±2 %RH at rated temperature +25°C

(System) ....................................................±0.5 °C (-25 to +70 °C)

............................................................................................± 1 digit

Accuracy, external....................................±0.2 °C (-25 to +70 °C)

(only Logger) ................................±0.4 °C in the remaining range

............................................................................................± 1 digit

Resolution ............................................0.1%RH / 0.1°C / 0.1td°C

Measuring rate ................................2 s to 24 h (freely selectable)

Storage temperature................................................-40 to +85 °C

Operating temperature ............................................-20 to +70 °C

Display ........................................................................LCD, 2 lines

Operating temperature/Display ..............................-20 to +65 °C

Memory capacity ................................................48,000 readings

Housing ..........................................................................ABS/TPE

Protection class ....................................................................IP 54

Dimensions in mm (lxwxh) ..........103 x 64 x 33 (without probe)

..............................................................160 x 64 x 33 (with probe)

Weight ....................................................................................130g

Battery ....................................................................Lithium (1 AA)

Battery life............................................................Typical: 5 years*

....(Measuring rate: 15 Min., Operating temperature: -10 to +50°C,

......................................Display: On, Status led (green LED): Off)

* See Chapter 11.6 Battery life, P. 33

32

11. Technical data

11.6 Battery life

Typical approximate values for the expected battery life are

included in the programming windows of the software.These

values are calculated on the basis of the following factors:

- Measuring rate

- Number of probes connected

- Status led (green LED) activated/deactivated

The calculated data is only an approximation since the battery life

depends on many additional factors.

The following factors have a negative influence on the battery life:

- Alarm LED flashing for longer periods of time

- Frequent reading out (several times a day)

- Strong fluctuations in operating temperature

The following factors have a positive influence on the battery life:

- Deactivated Status led (green LED) particularly in the case

of extended measuring rates

The battery capacity displayed is based on calculated values.

The data logger can be switched off if a critical power level

has been reached. The following could occur:

- The logger continues to take readings although the display

indicates that the battery capacity is “empty”.

- The measuring program is stopped even though the battery

capacity display indicated a short time previously that

battery capacity was available.

Saved readings are not lost if the battery is spent or

changed. Requirement:

The battery is changed by following the directions in the

Instruction manual.

33

12. Accessories/Spare parts

Description Part no.

testo 177-T1 (1 channel temp. internal, wall holder, calibration protocol) 0563 1771

testo 177-T2 (1 channel temp. internal, display, wall holder, calibration protocol) 0563 1772

testo 177-T3 (4 channel temp. internal/external, display, switch (e.g. for door contact), 0563 1773

wall holder, calibration protocol)

testo 177-T4 (4 channel temp. external (T/C), display, wall holder, calibration protocol) 0563 1774

testo 177-H1 (3 channel humidity/temp. internal/external, display, wall holder, 0563 1775

calibration protocol)

testo 580 data collector incl. desk-top holder for testo 175/177 data loggers 0554 1778

testo 575 fast printer, infrared controlled thermal line printer with 0554 1775

graph function, incl. 1 roll of thermal paper and batteries

Thermal paper for printer (6 rolls) 0554 0569

Thermal paper for printer (6 rolls) for long-term legible data documentation 0554 0568

up to 10 years

Self-adhesive label thermal paper for printer (6 rolls) 0554 0561

testo ComSoft 3 Basic Software Set for testo 175 incl. interface, desk-top holder and 0554 1774

PC connection cable

testo ComSoft 3 Professional Software (without interface) 0554 0830

Interface for testo 175/177 incl. desk-top holder and PC connection cable 0554 1757

Lock to secure testo 175/177 data logger in the wall holder 0554 1755

Retainer key to prevent testo 175/177 data logger from falling out of wall holder 0192 0638

Spare desk-top holder for testo 177 data logger 0554 1772

Spare wall holder for testo 177 data logger 0554 1771

Spare battery 1 AA (3.6V/1.9Ah) for testo 177 0515 0177

Transport case for up to 5 testo 177 data loggers and accessories 0516 1770

For testo 177-H1: metal protection cage for humidity probe, V4A stainless steel, 0554 0755

for velocities below 10m/s

For testo 177-H1: Cap with mesh wire filter 0554 0757

For testo 177-H1: Teflon sintered filter, for corrosive substances, high humidity range 0554 0756

(long-term measurements), high velocities

For testo 177-H1: Stainless steel sintered caps, to screw on humidity probe, 0554 0647

For high velocities or dirty air

For testo 177-H1: Control and adjustment set 11.3%RH/75.3%RH, incl. adapter 0554 0660

34

12. Accessories/Spare parts

Accurate NTC probes for testo 177-T3 and testo 177-H1 data loggers

Description

Stub probe *

Mounting probe with aluminium sleeve, IP65

Cable length: 2.40 m *

Accurate immersion/penetration probe,

cable length 6 m *

Screw-in probe for measurements in

difficult to access places, M6 thread, IP 54;

cable length: 2 m *

Probe for surface measurement;

cable length: 2 m *

Wall surface temperature probe,

e.g. for proof of damage to building

structure; cable length: 3 m

Pipe probe with Velcro, for pipe diameter

of max. 75 mm

Food probe (IP65) made of stainless steel,

PUR cable, can be used up to +80 °C,

plug-in connection IP54 *

Robust food penetration probe

with special handle, IP 65,

reinforced cable (PUR) and

reinforced bending protection *

Frozen food probe, no drilling required *

Robust, affordable air probe, for checking

storage temperature, for example *

Illustration Part no.

35 mm

Ø 3 mm

40 mm

Ø 6 mm

40 mm

Ø 3 mm

Ø 3 mm

Meas. range

-20... +70 °C

0628 7510

-20... +90 °C 0628 7503

-35... +80 °C 0610 1725

-50... +80 °C 0628 7514

40 mm

8 x 8 mm

-50... +80 °C 0628 7516

-50... +80 °C 0628 7507

-50... +70 °C 0613 4611

-50... +150 °C 0613 2211

-50... +150 °C 0613 2411

30 mm

Ø 3.5 mm

-50... +140 °C 0613 3211

-50... +150 °C 0613 1711

110 mm

Ø 8 mm

300 mm

115 mm

Ø 5 mm

125 mm

Ø 4 mm

110 mm

Ø 4 mm

30 mm

15 mm

Ø 3 mm

30 mm

Ø 4 mm

* Probe tested in accordance with EN 12830 for suitability in the areas of transport and storage.

35

12. Accessories/Spare parts

Accurate thermocouple probes for testo 177-T4 data loggers

Description

Mounting probe with stainless steel sleeve

and mini T/C plug, IP 54

Cable length: 1.90 m

Pipe wrap probe with Velcro, for

temperature measurement on pipes with

diameter up to 120 mm, Tmax +120 °C

Pipe wrap probe for pipe diameter

5 to 65 mm, with exchangeable meas. head

Measuring range short-term to +280 °C

Temperature probe Type 21,

fast action surface probe

Cable length: 2 m

Thermocouple, flexible, 1500 mm long,

fibre optic

Thermocouple, flexible, 1500 mm long,

Teflon

Immersion measurement tip, bendable

Magnet probe, adhesive force ap. 10 N, w.

adhesive magnets, for higher temperatures,

for measurements on metal surfaces

Water-tight immersion/penetration probe

Accurate and fast-action immersion probe,

water-tight

Robust, affordable air probe

Illustration Part no.

40 mm

Ø 6 mm

395 mm

20 mm

Meas. range

-100... +205 °C 0628 7533

-50... +120 °C 0628 0020

-60... +130 °C 0602 4592

-50... +180 °C 0628 7521

-100... +400 °C 0602 0645

-100... +250 °C 0602 0646

-100... +1000 °C 0602 5792

-50... +400 °C 0602 4892

-60... +400 °C 0602 1292

-60... +1000 °C 0602 0592

-60... +400 °C 0602 1792

75 mm

1500 mm

Ø 1.5 mm

1500 mm

Ø 1.5 mm

500 mm

Ø 1.5 mm

110 mm

Ø 4 mm

300 mm

Ø 1.5 mm

110 mm

Ø 4 mm

Ø 21 mm

30 mm

Ø 3.2 mm

36

notes

37

notes

38

notes

39

testo AG

Postfach 11 40, 79849 Lenzkirch

Testo-Straße 1, 79853 Lenzkirch

Telefon: (07653) 681-0

Fax: (07653) 681-100

E-Mail: info@testo.de

Internet: http://www.testo.com

0971.1770/04/T/dr/06.02.2007

Loading...

Loading...