TERUMO STC-523 User manual

TERUFUSION®

SYRINGE

Model

Service

STC-523

Manual

PUMP

D

1

S

5

(DTERUMO

Box

Making

312

North

:

(02)9878

:

(02)9878

TERUMO®

Ryde

5122/1800

5085/1800

PO

Phone

Fax

life

NSW

easier

1670

036

185

334

190

Quality

Company

seem

A

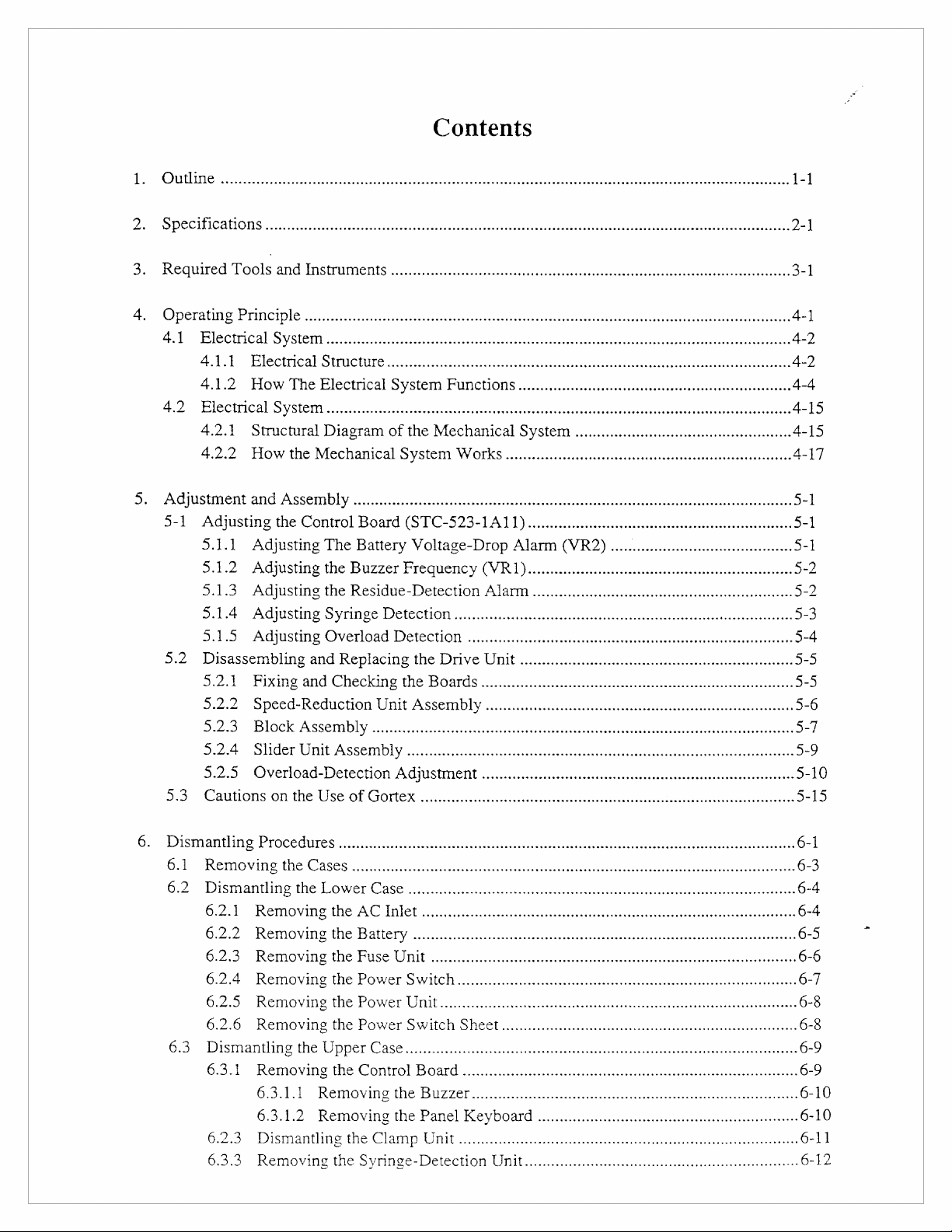

1.

OUTLINE

This

In

response

service

manual

to

user

has

been

claims,

written

repairs

for

should,

field

maintenance

in

principle,

be

carried

of

the

out

STC-523

using

syringe

the

following

pump.

procedure:

Before

(1)

Instruction

Check

(2)

If

(3)

(4)

(5)

(6)

J)

Cautions

(1)

(2)

(3)

(4)

the

instructions

Double-check

understood

If

the

ing

If

you

have

required

If

possible,

come

without

package.

Do

turned

Before

connectors

strange

On

correct

the

When

*

Ground

insulated

*

When

conductive

styrofoam

*

Do

If

replacing

(5)

again.

possibility.

setting

Manual

that

the

failure

on

the

equipment

procedures

are

not able

to

be

repaired

and

sterilize

into

contact

being

not

attempt

ON.

starting,

and

smells

completion

positions,

repairs

you

handling

your

transporting

not

subject

a

If

not,

out

for

and

conditions

is a

result

the

correct

the

claim

nature

described

forward

sterilized,

to

faulty

(burning

soldering

sheeting

pads.)

PCB

it

of

fails

to

to

repair

at

the

any

with

patients’

disconnect

visually

or

of

the

clean

have

made.

semiconductors

body

irons,

ICs

ICs

and

cures

is

likely

the

user’s

Service

this

of

use

of

incorrect

use

of

before

perform

the

exchange

they

damaged

resistors,

inspection

the

and

(aluminum

that

starting repairs,

problem.

the

in

this

the

equipment

factory.

equipment

body

must

or

connect

check

eguipment

(specially

soldering

but

and

PCBs,

PCBs

a

fault,

the

premises

Manual.

are

as

indicated

usage,

the

equipment.

correctly

Service

Clearly

the

to

parts

that

fluids,

be

hermetically

connectors

the

eguipment

parts,

listen

etc.).

and

repairs,

and

irons,

you

must

place

foil,

to

shock

replace

contacts

the

to

carry

correct

and

even

when

Manual.

using

the

indicate

factory.

are

being

etc.

If

for

make

its

surroundings,

MOS

ICs),

etc.,

check

them

etc.).

(Avoid

or

excessive

original

were

faulty,

out

in

the

the

cause

only

used

procedures

the

returned

this

is

sealed

or

PCBs

for

disconnected

abnormal

sure

take

via

a

the

insulation).

in

conductive

the

pressure.

PCB

and

Tepairs,

Instruction

of

the

start

the

properly,

contained

nature

IMO

not

and

sounds,

that

then

care

use

to

you

of

to

possible

a

warning

with

the

all

notify

to

prevent

resistor

of

check

should

carefully

Manual.

failure,

repairs

carry

in

the

problem

the

factory

and

the

included

eguipment's

wires,

and

make

the

switches

the

person

damage

(this

containers

plastics

that

the

thoroughly

re-read

then

give

after

you

out

the

troubleshoot-

this

manual,

and

or

those

parts

in

power

shorting,

sure

are

responsible

by

does

or

wrap

such

as

original

investigate

both

the

have

the

that

are

returned

the

returned

unplugged

there

set

to

static,

not

apply

them

vinyl

fault

the

user

fully

it

will

repairs

have

supply

are

no

their

of

etc.

to

in

and

occurs

this

2.

SPECIFICATIONS

Name:

Model:

Product

Syringes

Filling

Precision:

Cover

Fast

Alarms:

Operating

Idle

Range:

detection

feed:

conditions:

Code:

Used:

conditions:

pressure:

Terufusion

STC-523

ME-STC523

Terumo

0.1-150.0ml/h

within

Greater

Approx

Approx

Approx

Residual

(visual

Ambient

Relative

Air

Ambient

Relative

Air

20mi,

11%

than

400ml/h

500ml/h

800ml/h

amount,

and

temperature:

humidity:

pressure:

temperature:

humidity:

pressure:

Syringe

30ml,

(0.1ml/h

(13%

0.7kg/cm2

(20ml]

(30ml

(50m]

audial

Pump

and

50ml

steps)

including

syringe,

syringe,

syringe,

overload,

alarms,

10-40°C

30-85%

700-1060

-20-45°C

10-95%

500-1060

syringes

syringe)

battery

and

buzzer

(no

(according

normal

normal

normal

power

power

power

switch

condensation)

millibars

millibars

supply)

supply)

supply)

provided)

to

packaging)

Storage

Power

Maximum

Shock

External

Weight:

Accessories:

conditions:

supply:

prevention:

dimensions:

*

Specifications

consumption:

and

Ambient

Relative

Air

90

About 2 hours

15УА

Internal

(after

Class

300mm

2kg

Pole

AC

Instruction

appearance

temperature:

humidity:

pressure:

to

132/180

battery

15-hour

II

(w) x 128mm

clamp

power

to

on

charge)

CF

source

Manual

subject

-20-45°C

10-95%

500-1060

264VAC+10%

internal

gives 2 hours

type

cable

to

battery

(h) x 139mm

change

(x1)

(xl)

(xl)

without

(no

condensation)

millibars

(after

of

continuous

(d)

notice.

15-hour

use

charge)

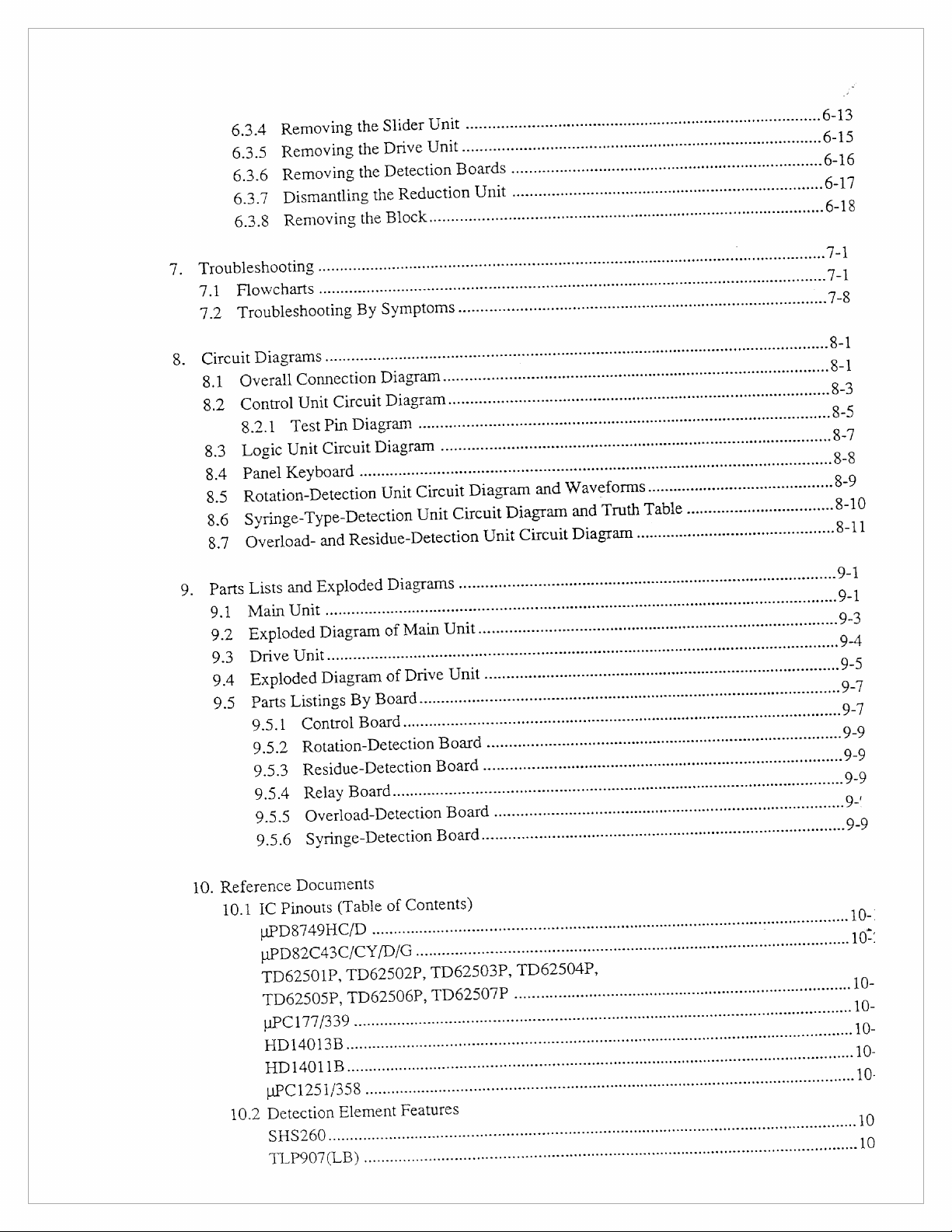

3.

REQUIRED

(1)

Digital

(2)

Synchroscope

(3)

Adjustable

(4)

Frequency

:

(5)

Pressure

(6)

New

Terumo

(7)

Standard

voltmeter

power

counter

meter

tool

TOOLS

supply

syringes

kit

AND

Voltage

Frequency

Voltage

Frequency

Pressure

2071,

30101

range

range

0-15V

range

range

3200

INSTRUMENTS

10V,

resistance

500KHz

10KHz

0-3.0kg/cm?

50121

range

1Q

(8)

Special

tool

kit

*

*

for

for

removing

removing

M16

seal

tube nuts

nuts

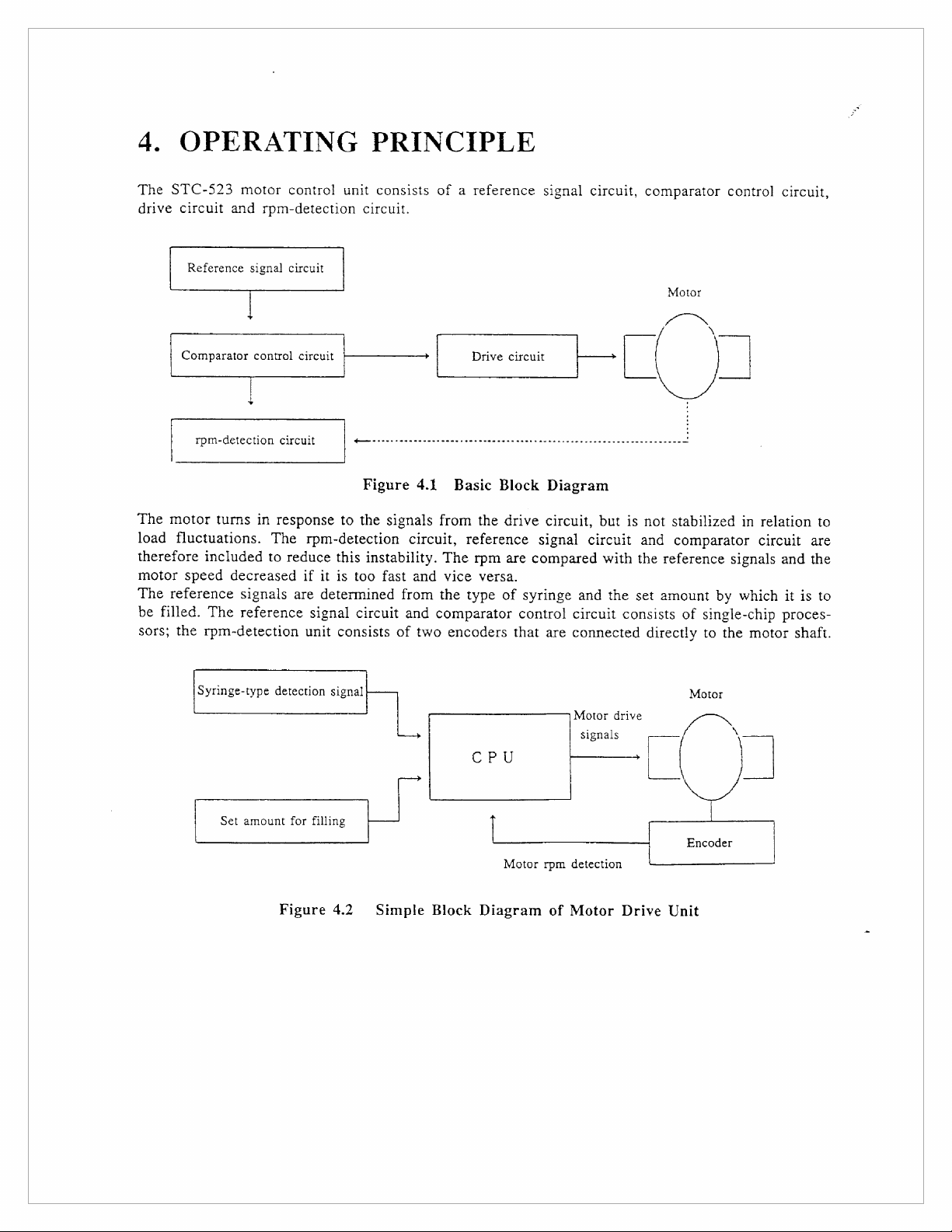

4.

OPERATING

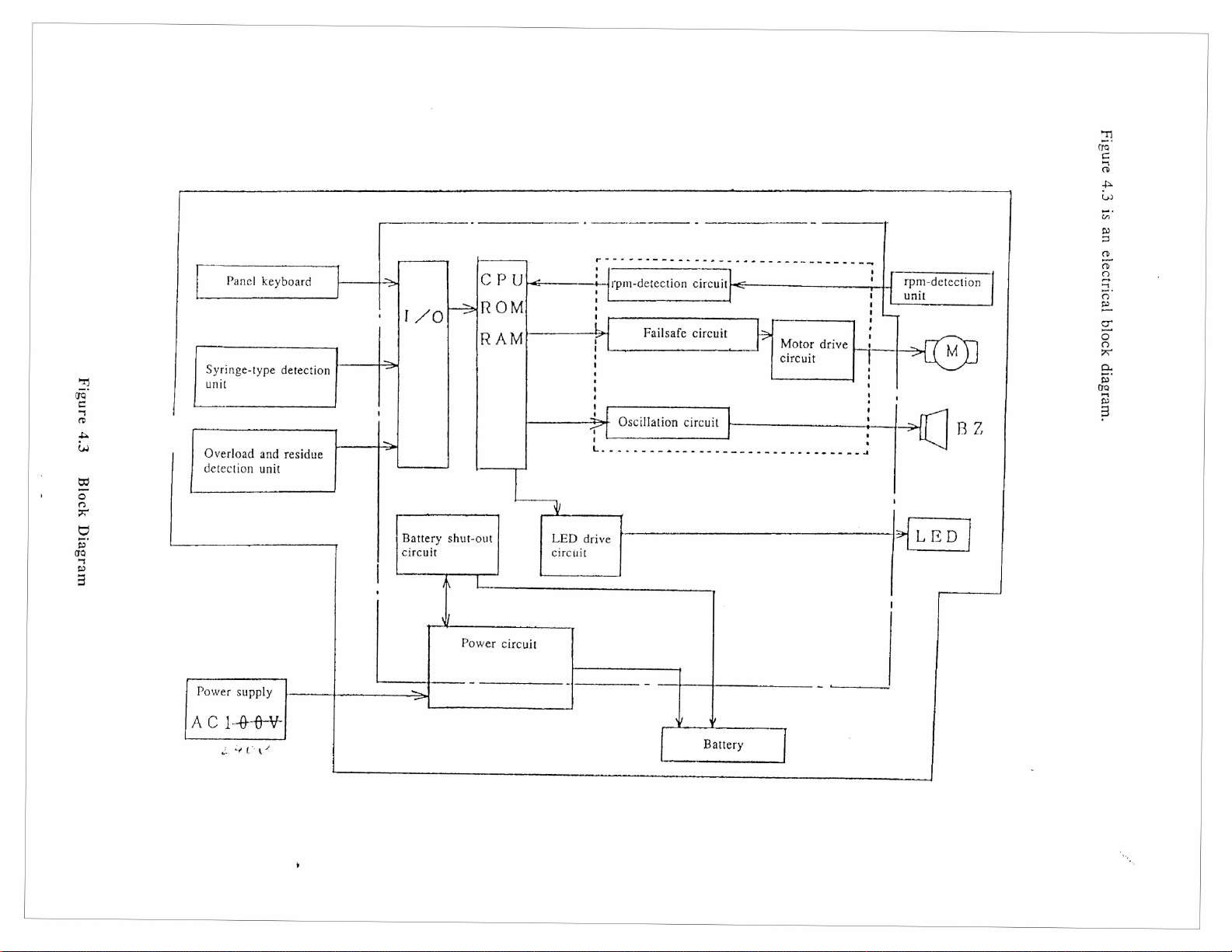

The

STC-523

drive

circuit

|

Reference

motor

and

rpm-detection

signal

|

control

circuit

PRINCIPLE

unit

consists

circuit.

of a reference

signal

circuit,

comparator

Motor

control

circuit,

Comparator

|

The

motor

load

fluctuations.

therefore

motor

The

be

sors;

speed

reference

filled.

the

control

rpm-detection

turns

in

included

The

rpm-detection

Syringe-type

Set

to

decreased

signals

reference

amount

circuit

circuit

response

The

rpm-detection

reduce

if

it

are

determined

signal

unit

detection

for

filling

一

m

Figure

to

the

this

instability.

is

too

circuit

consists

signal

一

4.1

signals

circuit,

fast

and

from

and

of

two

Drive

Basic

from

the

reference

The

rpm

vice

versa.

the

type

comparator

encoders

CPU

circuit

Block

drive

are

compared

of

syringe

control

that

Motor

—

áno

Diagram

circuit,

signal

and

circuit

are

connected

Motor

signals

一 一 一 一

rpm

detection

but

is

circuit

with

the

the

set

consists

drive

一

X

一

cena

tees

一

not

stabilized

and

comparator

reference

amount

directly

ーーーーーーーーーーーーーーー

by

of

single-chip

to

Motor

v

Encoder

一

in

signals

which

the

motor

\

relation

circuit

are

and

the

it

is

proces-

shaft.

to

to

Figure

4.2

Simple

Block

Diagram

of

Motor

Drive

Unit

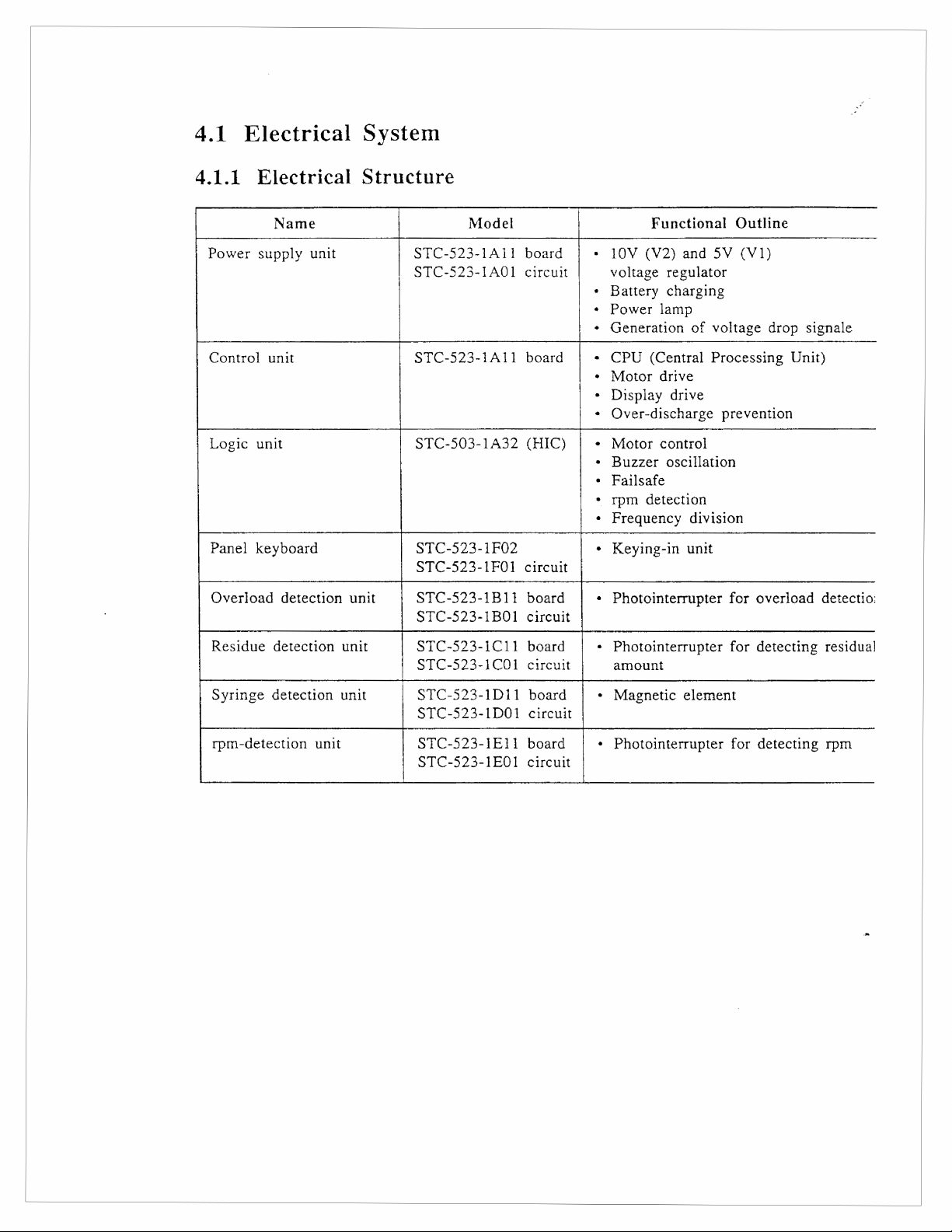

4.1

4.1.1

Electrical

Electrical

Power

Control

Logic

Panel

Overload

Residue

Syringe

rpm-detection

supply

unit

unit

keyboard

Name

unit

detection

detection

detection

unit

System

Structure

unit

unit

unit

Model

STC-523-1A11

STC-523-1A01

STC-523-1A11

STC-503-1A32

STC-523-1F02

STC-523-1F01

STC-523-1B11

STC-523-1B01

STC-523-1C11

STC-523-1C01

STC-523-1D11

STC-523-1D01

STC-523-1E11

STC-523-1E01

board

circuit

board

(HIC)

circuit

board

circuit

board

circuit

board

circuit

board

circuit

Functional

10V

(V2)

and

voltage

Battery

Power

Generation

CPU

Motor

Display

Over-discharge

Motor

Buzzer

Failsafe

rpm

Freguency

Keying-in

Photointerrupter

Photointerrupter

amount

Magnetic

Photointerrupter

regulator

charging

lamp

of

(Central

drive

drive

control

oscillation

detection

division

unit

element

Processing

Outline

5V

(V1)

voltage

prevention

for

overload

for

detecting

for

detecting

drop

Unit)

signale

detectio:

residual

rpm

91314

y

ainsi

Ep

420jg

шее

Overload

detection

Panel

keyboard

Syringe-type

unit

and

unit

detection

residue

y

Battery

circuit

CPUle

=>

ROM

RAM

shut-out

ーー

'

'

+4rpm-detection

+

t

'

b

i

!

‘

a

1

‘

4

‘

1

1

し

LED

drive

Failsafe

ㆍ

Oscillation

ㆍ

ㆍ

.

circuit

.

:

circuit

+

.

circuit

|

ㆍ

'

-

1

i

E

Motor

Circuit

.

drive

ーー

|

r

1

|

+

4

+

|

4

*

4

4

6

;

:

A

i

rpm-detection

unit

MO

>

|

|

LED

SN

€'p

SI

ие

[2212312

90]

“UIBISBIP

Power

ACI

име

supply

サ Y

Power

circuit

Battery

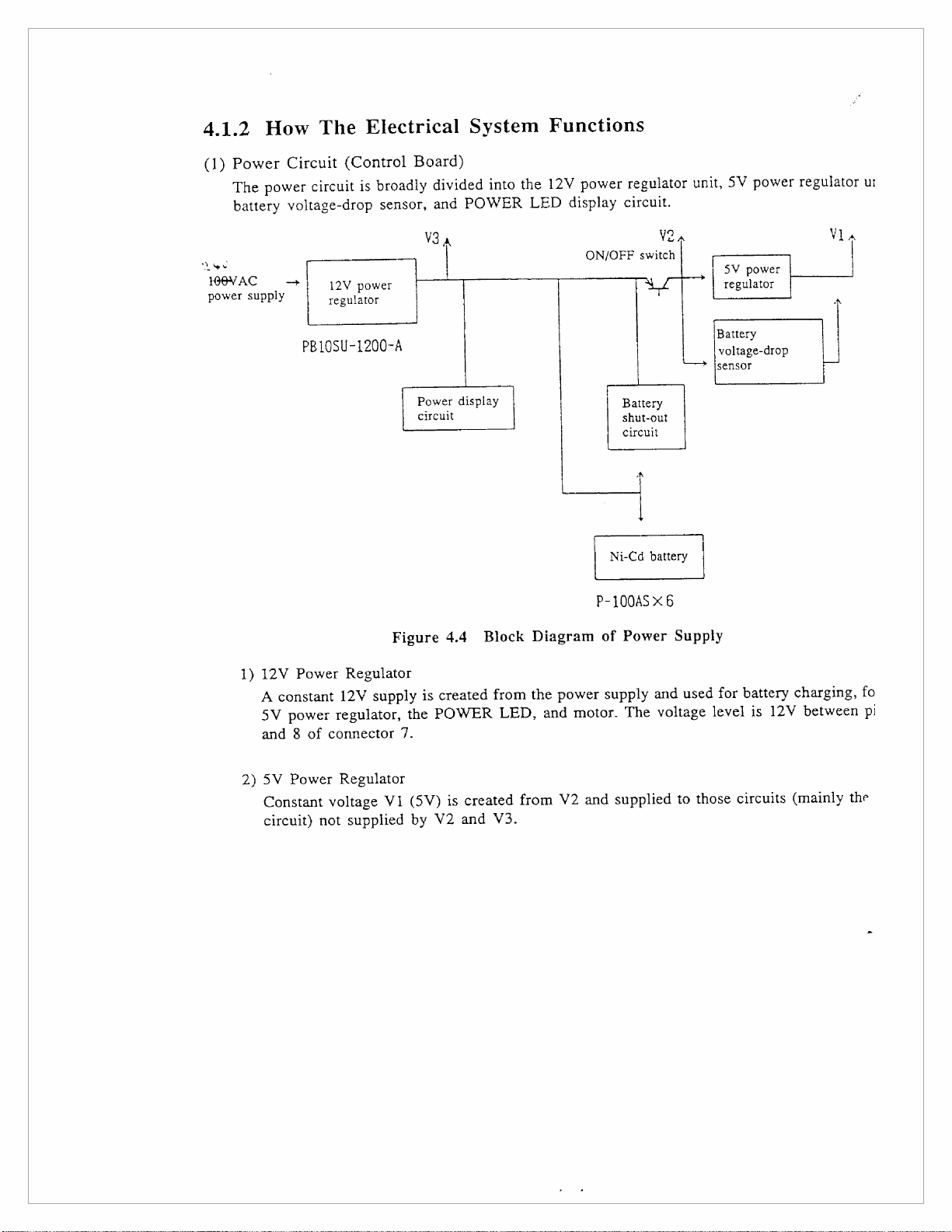

4.1.2

(1)

Power

The

battery

Me

EV

AC

power

How

Circuit

power

voltage-drop

—

supply

The

circuit

PB10SU-1200-A

Electrical

(Control

broadly

is

sensor,

12V

power

regulator

Board)

divided

and

a

VS

Power

Owe:

circuit

System

into

POWER

display

Functions

12V

the

display

LED

power

ON/OFF

|

Ni-Cd

regulator

circuit.

У.

switch

NL

|

Battery

shut-out

circuit

battery

unit,

r

——

|

power

SV

一 一 一

SY

regulator

Battery

voltage-drop

sensor

一

power

regulator

VIA

ul

1)

12V

A

SV

and

2)

5V

Constant

circuit)

Power

constant

8

of

Power

not

regulator,

connector

voltage

power

Figure

Regulator

supply

12V

Regulator

V1

supplied

the

7.

(5V)

by

4.4

created

is

POWER

is

V2

Block

from

LED,

created

V3.

and

Diagram

the

and

from

power

motor.

and

V2

P-100AS

of

Power

supply

The

supplied

X6

Supply

used

and

voltage

to

for

level

those

battery

12V

is

circuits

charging,

between

(mainly

the

fo

pi

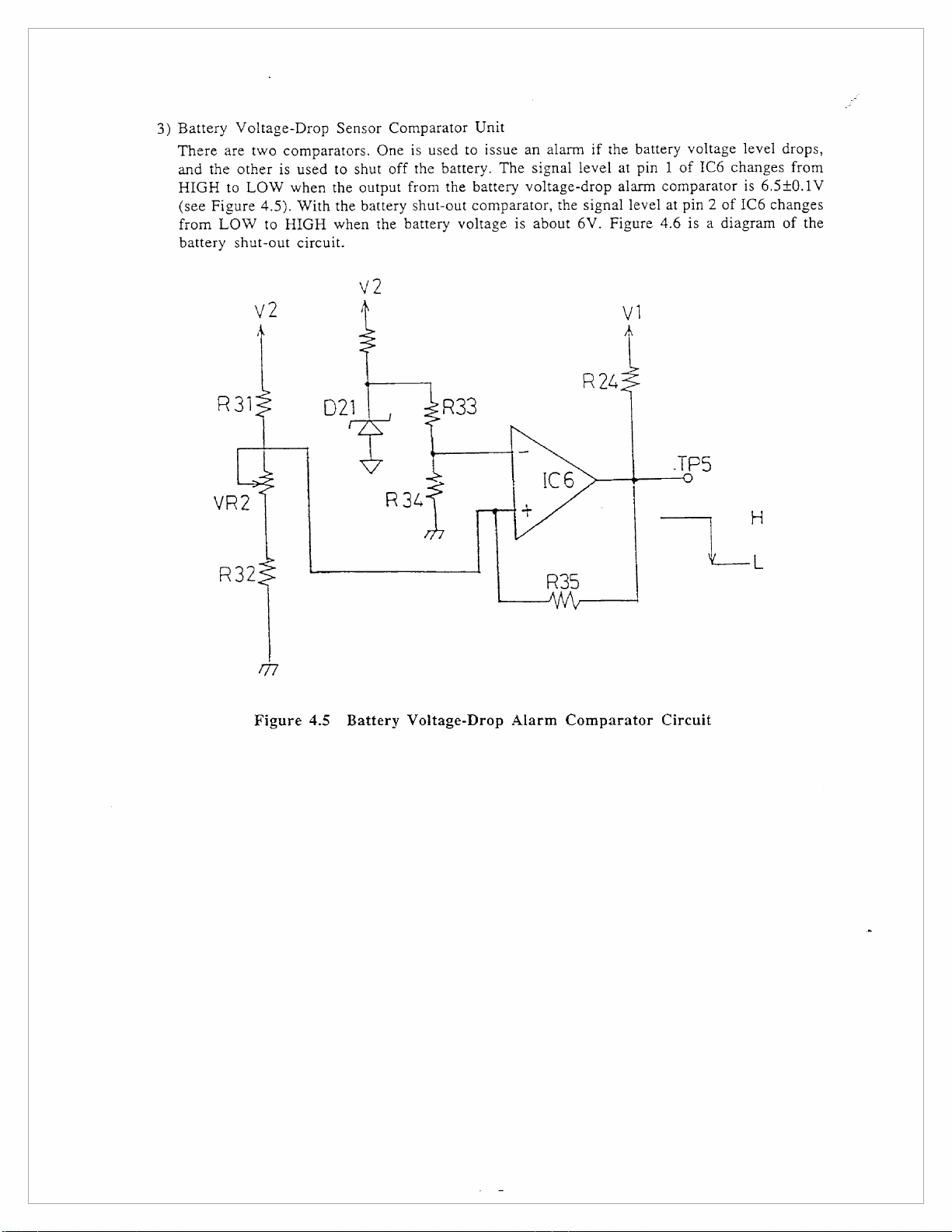

3)

Battery

There

and

HIGH

(see

from

battery

Voltage-Drop

are

two

the

other

to

LOW

Figure

VR2

LOW

shut-out

R

31

4.5).

VŽ

comparators.

is

used

when

With

to

HIGH

circuit.

Sensor

to

the

the

when

D21

Comparator

One

shut

off the

output

battery

the

V2

is

used

battery.

from

the

shut-out

battery

Unit

to

issue

The

battery

comparator,

voltage

is

an

alarm

if

signal

voltage-drop

the

about

level

signal

6V.

the

battery

at

pin 1 of

alarm

level

Figure

voltage

IC6

comparator

at

pin 2 of

4.6

is a diagram

TPS

O

level

changes

is

6.5+0.1V

IC6

changes

drops,

from

of

the

R32

777

Figure

4.5

Battery

Voltage-Drop

Alarm

Comparator

0

Circuit

R46

952.

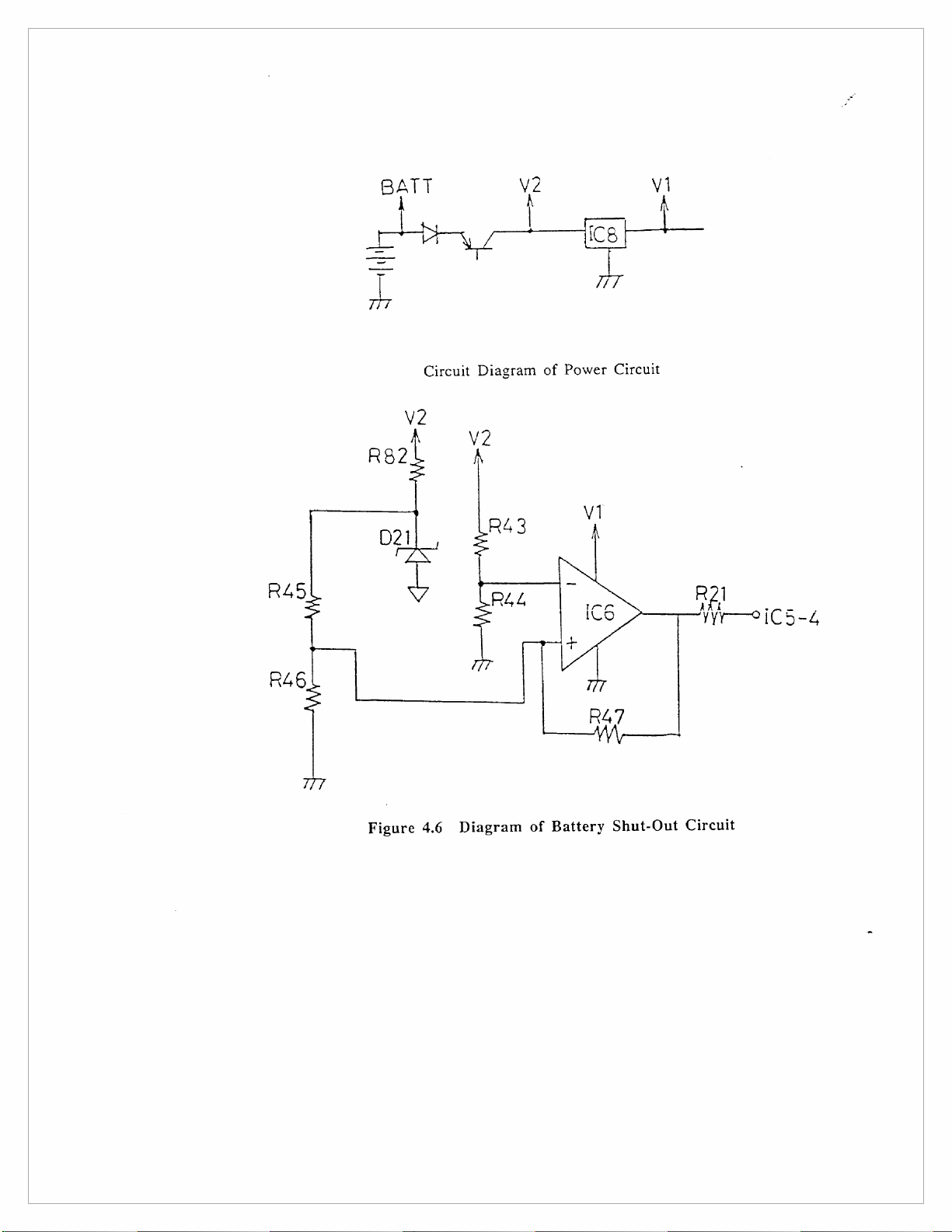

BATT

F

V2

Circuit

Diagram

V2

Å

V2

of

Power

R47

Circuit

L

|

TVN

YO

CAL,

Figure

4.6

Diagram

Battery

of

Shut-Out

Circuit

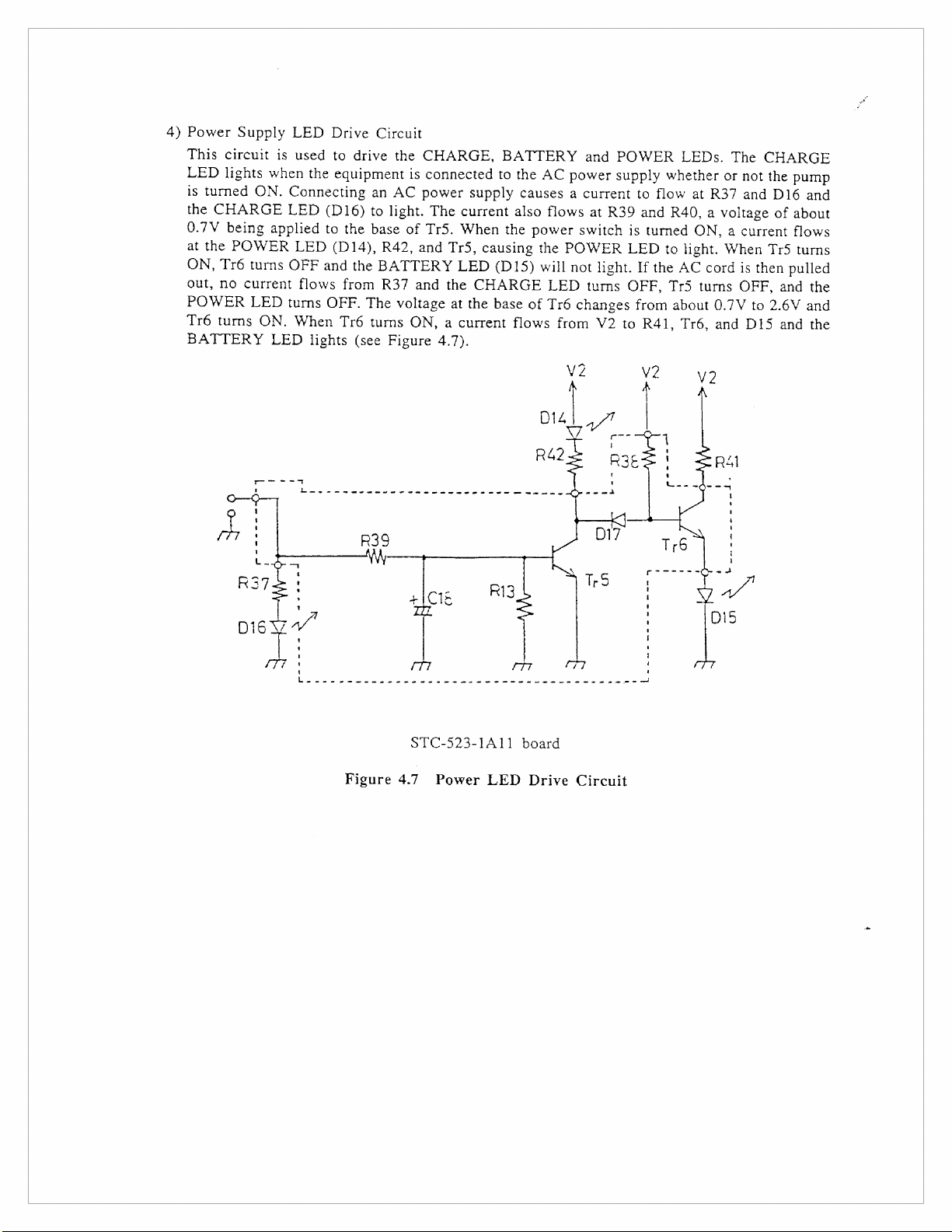

4)

Power

This

LED

is

the

0.7V

at

ON,

out,

POWER

Tr6

BATTERY

Supply

circuit

lights

turned

CHARGE

being

the

POWER

Tr6

no

turns

is

when

ON.

applied

turns

current

LED

ON.

LED

LED

Drive

used

to

the

equipment

Connecting

LED

(D16)

to

the

LED

(D14),

OFF

and

flows

from

turns

OFF.

When

Tr6

lights

Circuit

drive

an

to

base

R42,

the

BATTERY

R37

The

turns

(see

the

CHARGE,

is

connected

AC

power

light.

of

Tr5.

and

and

voltage

ON,

Figure

The

Tr5,

the

at

a

4.7).

to

supply

current

When

causing

LED

(D15)

CHARGE

the

base

current

BATTERY

the

AC

causes

also

the

power

the

will

of

flows

power

a

flows

POWER

not

LED

Tr6

changes

from

and

POWER

supply

current

at

R39

switch

light.

tums

V2

is

LED

OFF,

from

to

to

flow

and

turned

If

the

R41,

LEDs.

whether

at

R40,

a

ON,

to

light.

AC

cord

Tr5

turns

about

Tr6,

The

or

not

R37

and

voltage

a

current

When

is

OFF,

0.7V

and

then

to

D15

CHARGE

the

pump

D16

of

about

flows

Tr5

turns

pulled

and

2.6V

and

and

the

and

the

=...

+

[CIE

R13

—

we

ος

Figure

STC-523-1A11

4.7

Power

LED

board

Drive

Circuit

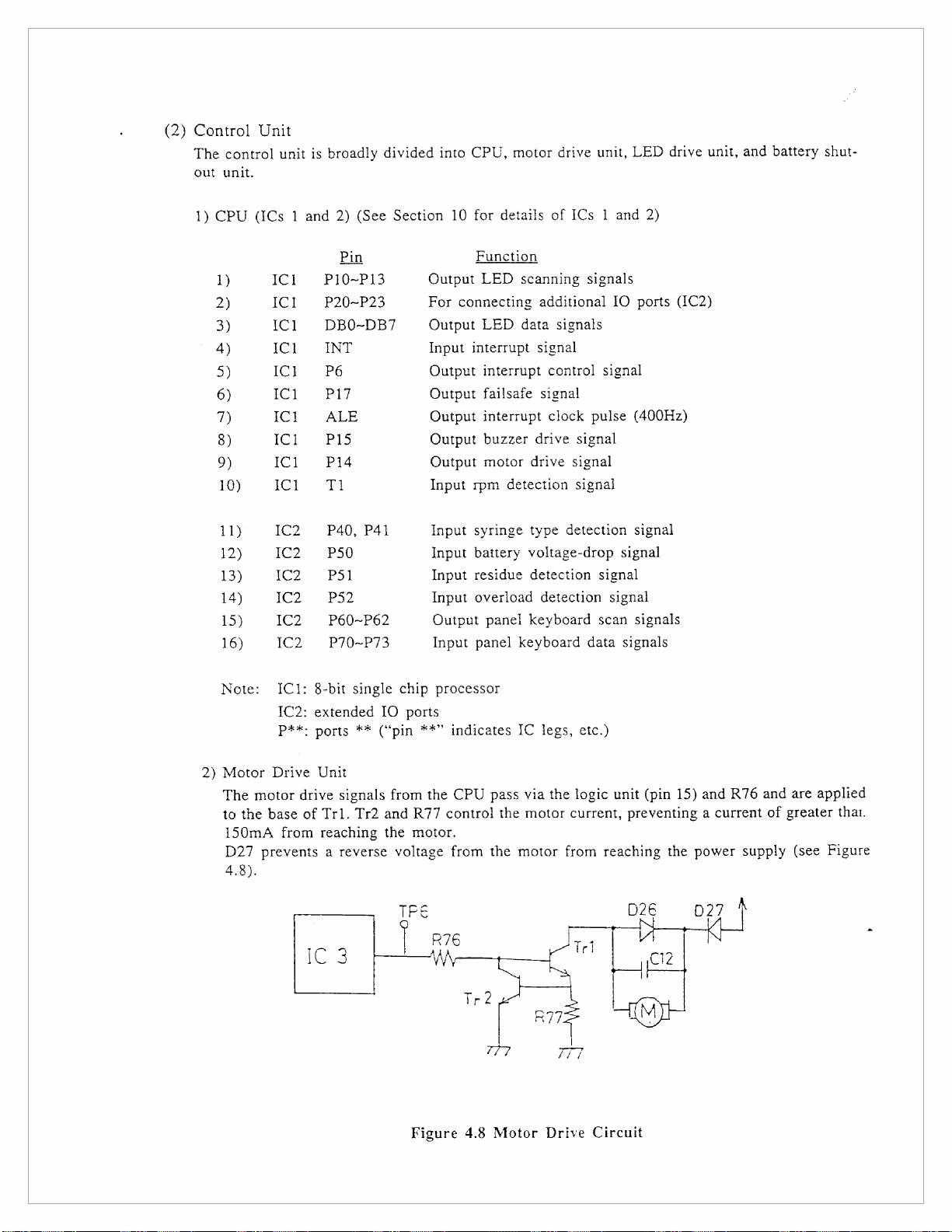

(2)

Control

control

The

out

unit.

1)

CPU

Unit

is

unit

(Cs 1 and

broadly

2)

(See

divided

Section

into

10

CPU,

for

motor

details

drive

of

ICs 1 and

unit,

LED

2)

drive

unit,

and

battery

shut-

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

15)

16)

Note:

ICI

ICI

ICI

ICI

ICI

ICI

ICI

ICI

ICI

ICI

IC2

IC2 = P50

IC? PSI

IC2

IC2

IC2

ICI:

IC2:

P**:

P10~P13

P20~P23

DB0-DB7

INT

P6

P17

ALE

P15

P14

TI

P40,

P52

P60~P62

P70-P73

8-bit

extended

ports

Pin

P41

single

**

chip

IO

ports

(“pin

Output

For

connecting

Output

Input

Output

Output

Output

Output

Output

Input

Input

Input

Input

Input

Output

Input

processor

**”

indicates

Function

LED

scanning

LED

data

interrupt

interrupt

failsafe

interrupt

buzzer

motor

drive

rpm

detection

syringe

battery

residue

overload

panel

panel

keyboard

IC

type

voltage-drop

detection

keyboard

signals

additional

signals

signal

control

signal

clock

drive

signal

signal

signal

detection

detection

data

legs,

etc.)

IO

signal

pulse

signal

signal

signal

scan

signals

ports

(400Hz)

signal

signals

(IC2)

2)

Motor

The

to

150mA

D27

4.8).

Drive

motor

drive

the

base

of

from

prevents a reverse

Unit

signals

Trl.

Tr2

reaching

from

and

R77

the

motor.

voltage

Figure

the

control

from

CPU

4.8

pass

the

the

Motor

via

the

motor

motor

Drive

logic

current,

from

reaching

Circuit

unit

(pin

15)

and

preventing a current

the

power

026

027

|

[8

1

É

R76

supply

and

of

are

applied

greater

(see

Figure

thar.

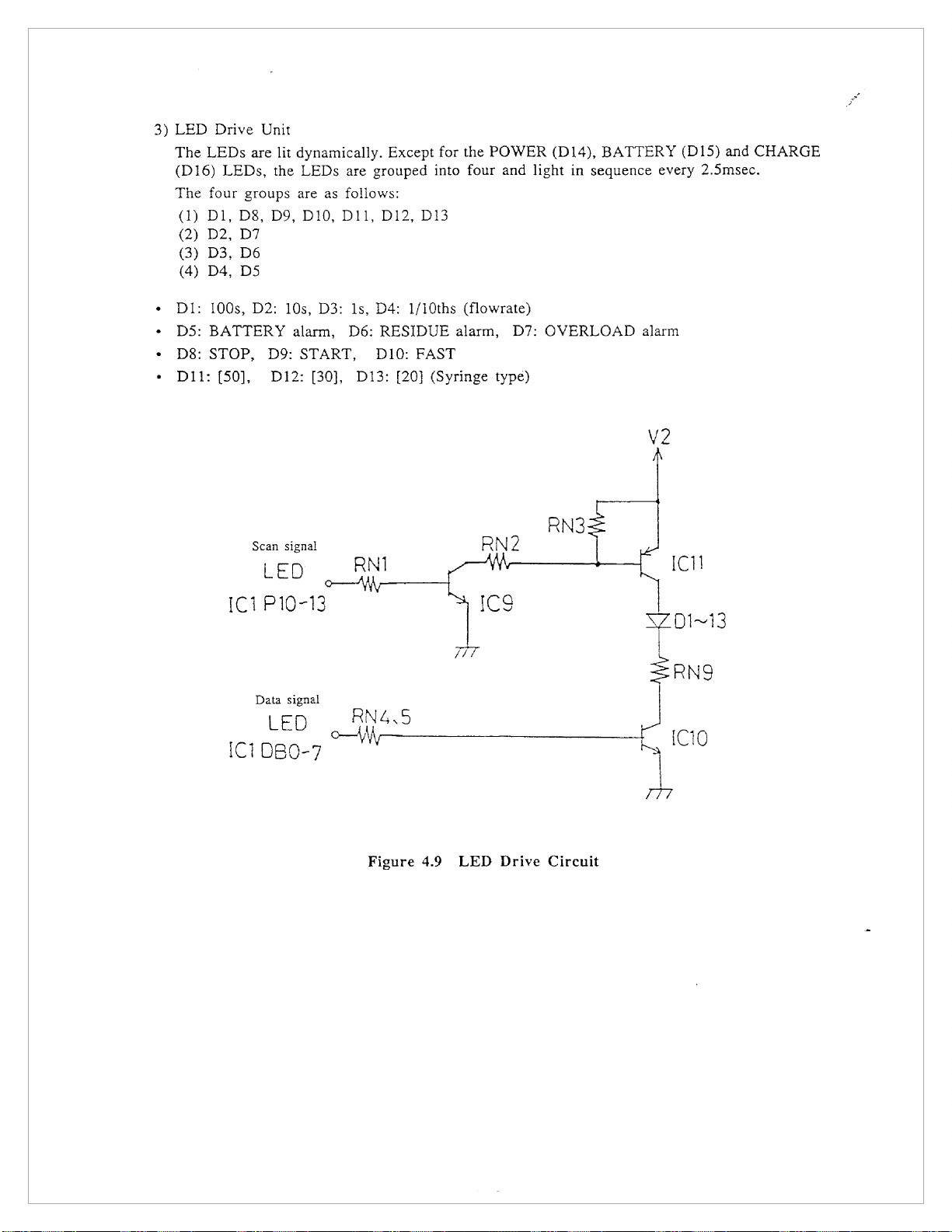

3)

LED

Drive

Unit

The

LEDs

are

lit

»

ㆍ

«

ㆍ

(D16)

The

(1)

(2)

(3)

(4)

DI:

D5:

D8:

DIL:

LEDs,

four

groups

Di,

D8,

D2,

D7

D3,

D6

D4,

D5

1005,

BATTERY

STOP,

[50],

dynamically.

the

D9,

D2:

105,

alarm,

D9:

012:

LEDs

are

as

D10,

D3:

START,

[30],

Except

are

grouped

follows:

DI1,

D12,

15s,

D4:

D6:

RESIDUE

DIO:

D13:

D13

1/10ths

FAST

[20]

for

the

into

four

(flowrate)

alarm,

(Syringe

POWER

and

D7:

type)

(D14),

light

in

OVERLOAD

BATTERY

sequence

every

alarm

V2

A

(D15)

2.5msec.

and

CHARGE

Scan

LED

[C1

P10-13

Data

LED

ICI

080-7

signal

signal

R

©

RNI

N45

Figure

ICH

XZ

D1~13

77

ZRNY

一

CD

4.9

LED

Drive

Circuit

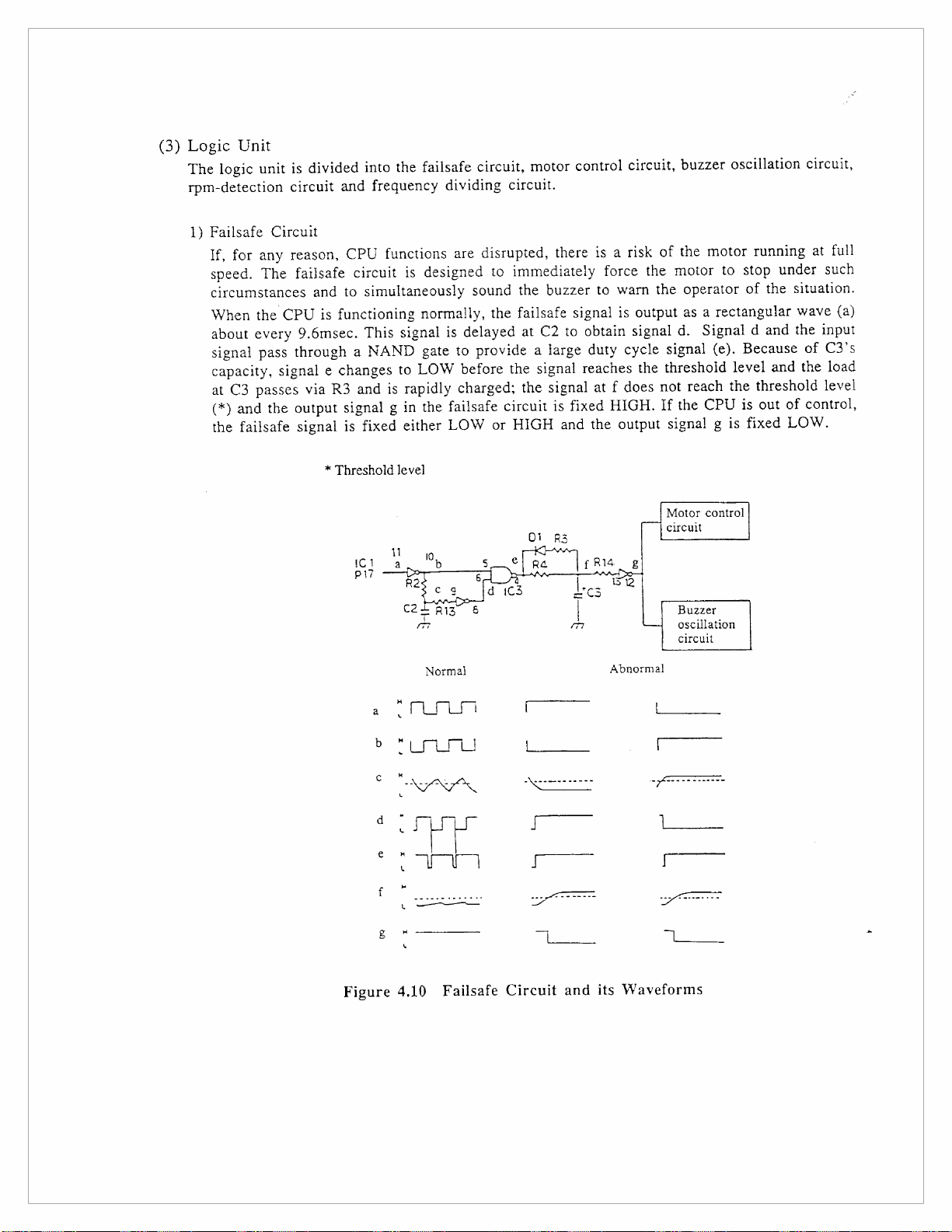

(3)

Logic

The

rpm-detection

1)

Failsafe

If,

speed.

circumstances

When

about

signal

capacity,

at

(*)

the

Unit

logic

for

C3

and

failsafe

is

unit

circuit

Circuit

reason,

any

failsafe

The

CPU

the

every

through

pass

signal

passes

output

the

divided

and

CPU

to

and

functioning

is

9.6msec.

changes

e

R3

via

signal

is

signal

*

Threshold

failsafe

the

into

frequency

functions

circuit

simultaneously

This

NAND

a

to

is

and

g

fixed

level

dividing

designed

is

normally,

signal

gate

LOW

rapidly

the

in

either

is

circuit,

disrupted,

are

to

sound

the

delayed

provide

to

before

charged;

failsafe

or

LOW

motor

circuit.

there

immediately

buzzer

the

failsafe

C2

at

large

a

signal

the

signal

the

HIGH

is

and

circuit

control

is

force

to

signal

obtain

to

duty

reaches

at

fixed

the

circuit,

risk

a

the

warn

output

is

signal

cycle

the

does

f

HIGH.

output

buzzer

the

of

motor

operator

the

a

as

Signal

d.

signal

threshold

reach

not

CPU

the

If

signal

oscillation

running

motor

under

stop

to

the

of

rectangular

and

d

Because

(e).

and

level

threshold

the

out

is

fixed

is

g

circuit,

full

at

such

situation.

(a)

wave

input

the

C3’s

of

load

the

level

control,

of

LOW.

IC

1

P17

a

b

cr

9

e

f

so

Normal

、LLTLTI

“LTrLTU

.

λος

HE

M

x

ba

EE

[

Lo

ペーーー

「

P

cs

E

Abnormal

に

[

Lo

lo

Motor

circuit

ーー

T

P.

control

Buzzer

oscillation

circuit

グ

人

T

~

Figure

4.10

Failsafe

Circuit

and

its

Waveforms

5.

ADJUSTMENT

The

following

semble

See

example,

and

the

exploded

replace

see

procedure

the

diagrams

#3

in

exploded

should

drive

in

unit,

diagram

AND

be

used

to

replace

syringe-detection

9.3

and

9.6

for

9.3

for

ASSEMBLY

the

control

unit,

clamp

parts

with

numbers

the

control

board

board

(STC-523-1A11)

or

overload-detection

(9. - )

(9.3

after

8).

the

or

unit.

part

to

disas-

name.

For

5.1

Measuring

+

+

*

5.1.1

able

variable

Connect

4

Adjusting

Digital

Adjustable

Frequency

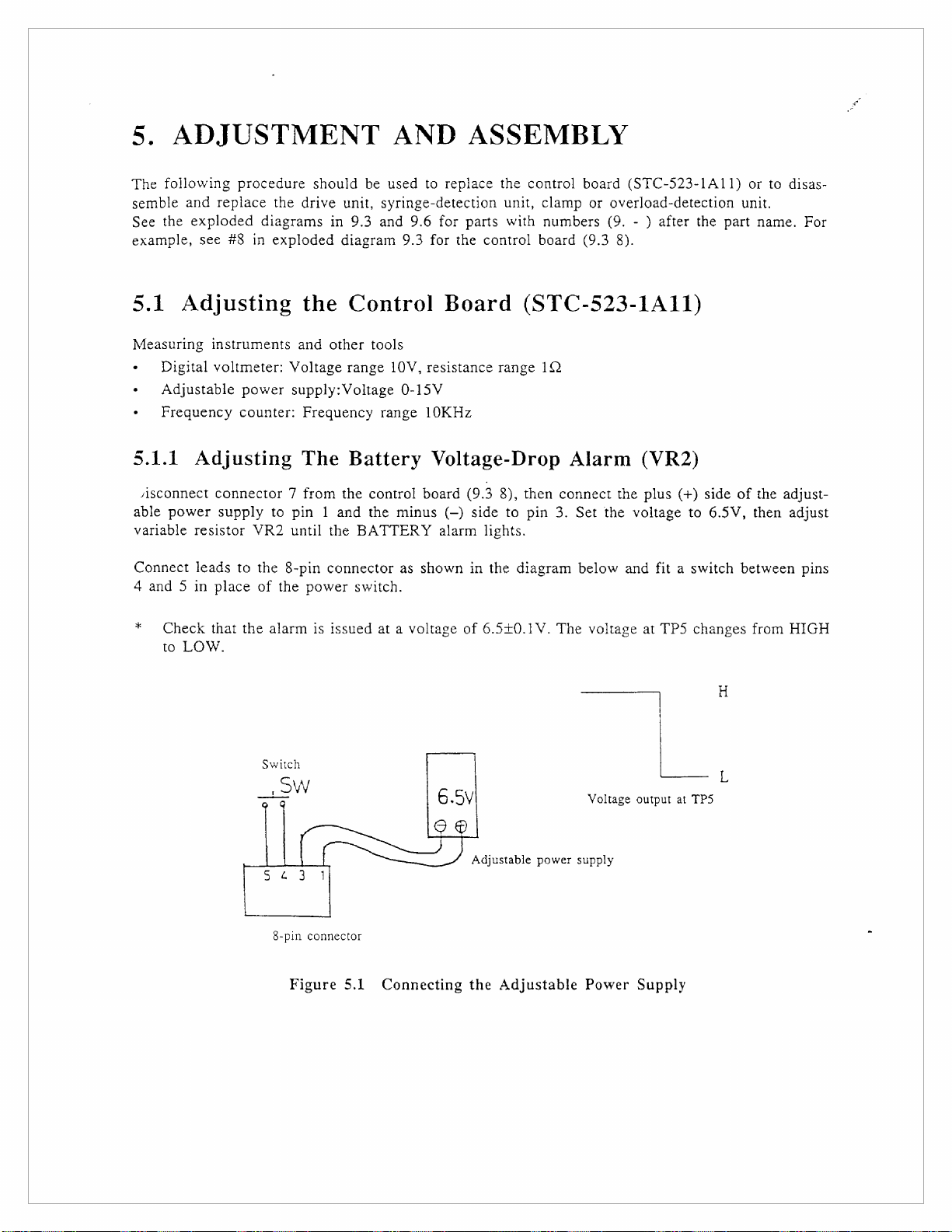

„isconnect

power

and 5 in

*

Check

to

LOW.

instruments

voltmeter:

power

counter:

Adjusting

connector 7 from

supply

resistor

leads

place

that

to

the

VR2

the

of

to

the

alarm

the

and

other

Voltage

supply:

pin 1 and

until

8-pin

Voltage

Frequency

The

the

connector

power

is

issued

Control

tools

range

10V,

0-15V

range

Battery

the

control

the

minus

BATTERY

as

switch.

at a voltage

Board

resistance

10KHz

Voltage-Drop

board

(9.3

(-)

side

alarm

shown

in

of

(STC-523-1A11)

range

8),

then

to

pin

lights.

the

diagram

6.510.1V.

1Q

connect

3.

The

Alarm

Set the

below

voltage

(VR2)

the

plus

voltage

and

at

(+)

side

to

6.5V,

fit a switch

TPS

changes

of

the

then

between

from

adjust-

adjust

pins

HIGH

Switch

_

SW

8-pin

connector

Figure

5.1

6.5V

Connecting

Adjustable

the

Adjustable

power

Voltage

supply

Power

output

Supply

at

TPS

-

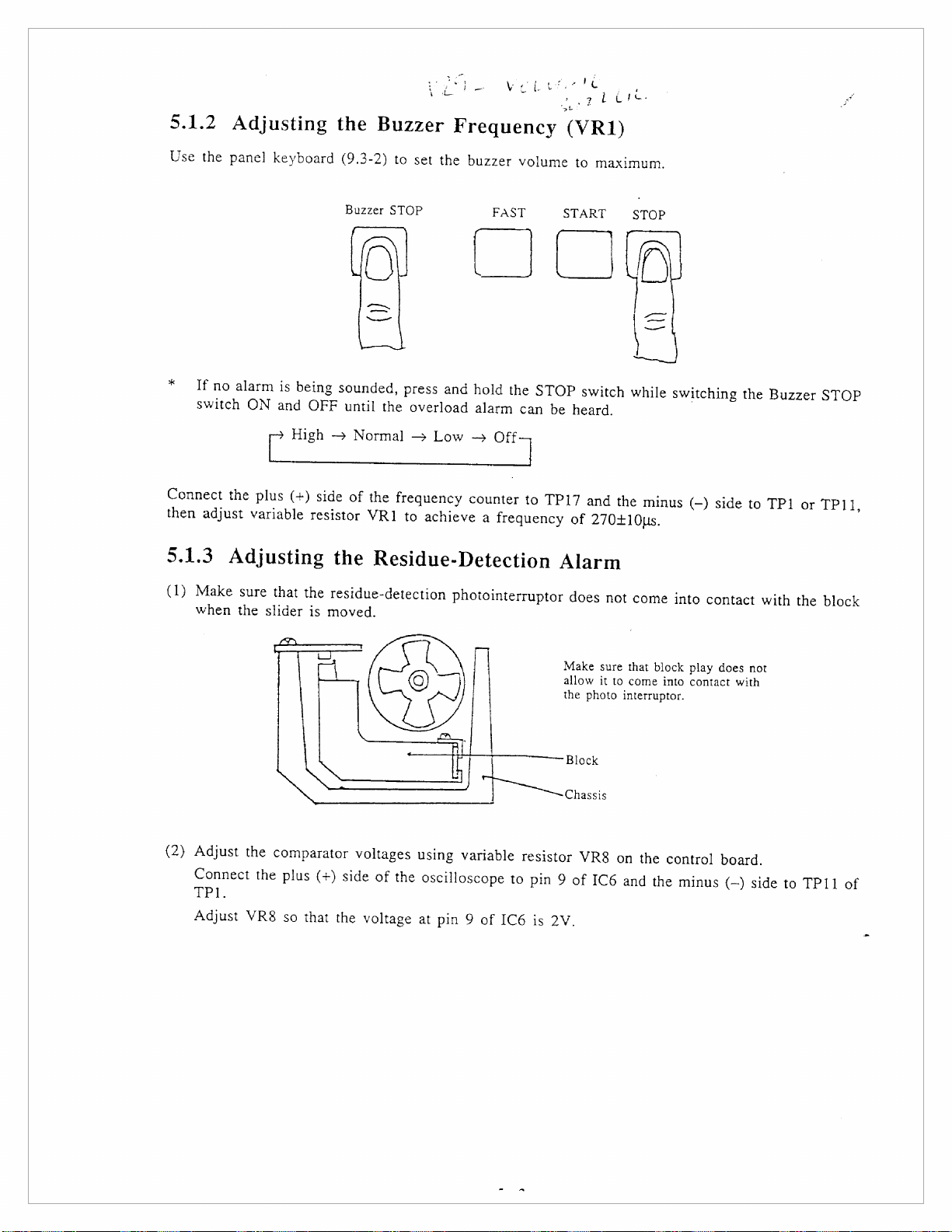

5.1.2

Use

the

*

If

switch

Connect

then

adjust

Adjusting

panel

keyboard

no

alarm

ON

jé

the

plus

variable

is

and

(+)

being

the

(9.3-2)

Buzzer

sounded,

OFF

until

>

Normal

side

of

resistor

Buzzer

to

STOP

press

the

overload

the

frequency

VR1

to

Mİ

iv

set

the

>

Low

achieve

li

and

„==.

Frequency

buzzer

FAST

-

VM

~

volume

+

hold

the

alarm

can

一

oF

counter

to

a

frequency

っ

STOP

be

TP17

)

了

t

o,

7

i

(VR1)

to

maximum.

START

switch

heard.

and

of

270+10us.

Lit.

the

,

STOP

while

minus

switching

()

side

the

to

Buzzer

TP1

or

STOP

TP11,

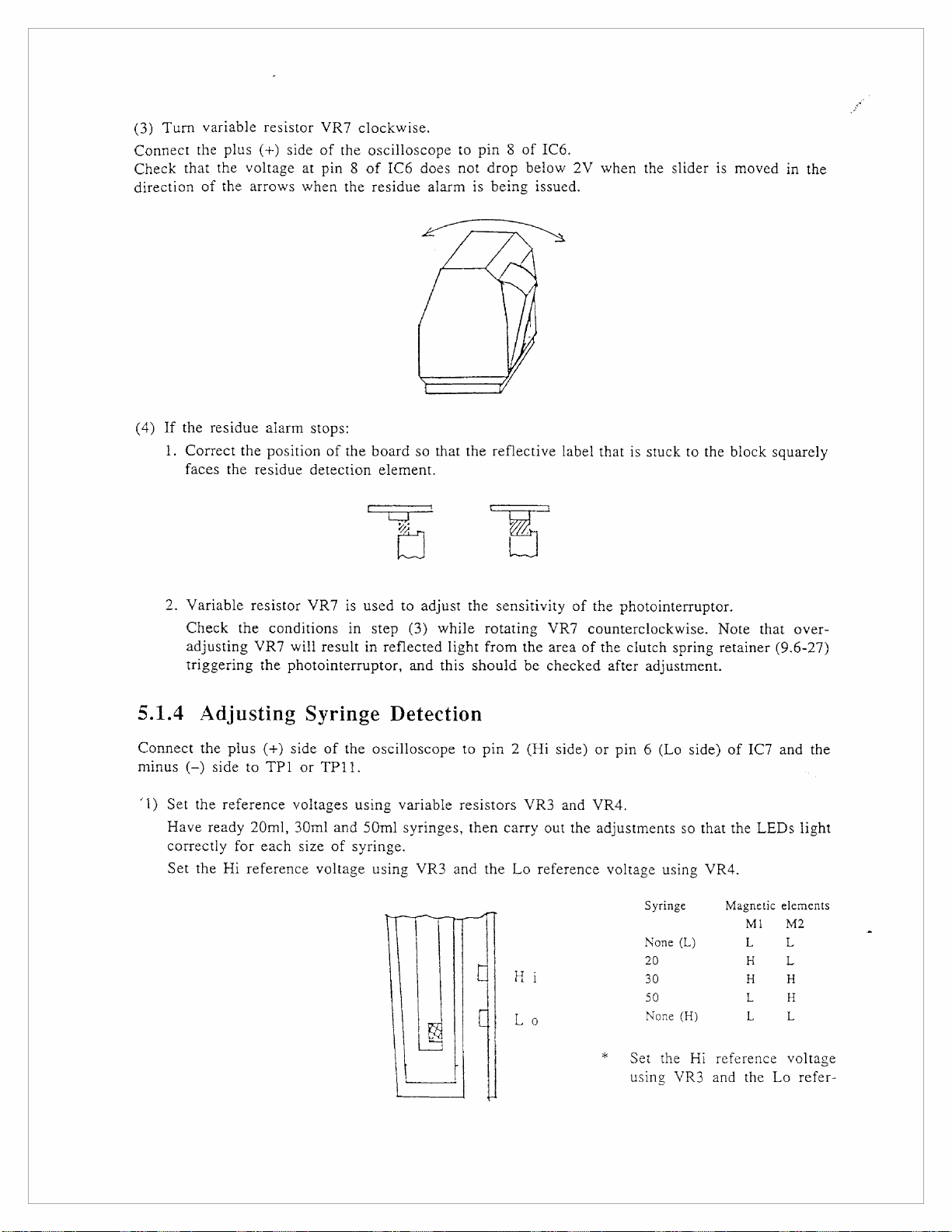

5.1.3

(1)

Make

when

(2)

Adjust

Connect

TPl.

Adjust

Adjusting

sure

that

the

the

slider

is

the

comparator

the

plus

(+)

VR8

so

that

the

Residue-Detection

residue-detection

moved.

@)

voltages

side

the

voltage

of

using

the

oscilloscope

at

pin

photointerruptor

variable

9

of

resistor

to

pin

IC6

is

9

2V.

Alarm

does

not

Make

sure

allow

it

the

photo

Block

Chassis

VR8

of

IC6

come

that

block

to

come

into

interruptor.

on

the

control

and

the

into

play

contact

minus

contact

does

not

with

board.

(—)

with

side

to

the

TP11

block

of

(3)

Turn

Connect

Check

direction

(4)

that

If

the

1.

Correct

faces

variable

the

the

of

residue

plus

the

the

the

resistor

(+)

side

voltage

arrows

alarm

position

residue

VR7

of

the

at

pin 8 of

when

the

stops:

of

the

detection

clockwise.

oscilloscope

IC6

does

residue

board

element.

alarm

ETL

so

that

to

pin 8 of

not

drop

is

being

the

IC6.

below

issued.

reflective

2V

label

when

that

is

the

stuck

slider

to

the

is

block

moved

in

the

squarely

2.

Variable

Check

adjusting

triggering

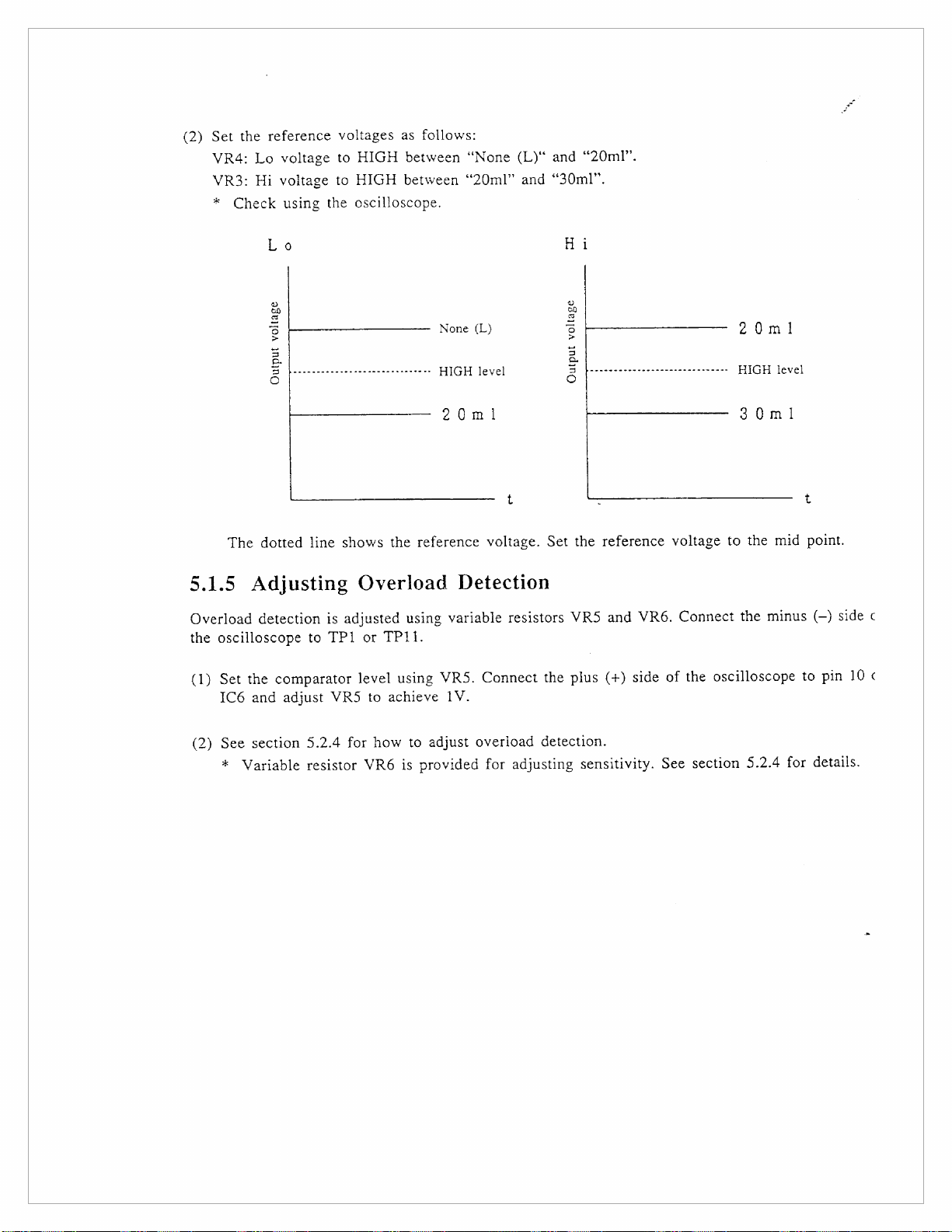

5.1.4

Connect

minus

1)

Set

Have

correctly

Set

(-)

resistor

the

conditions

VR7

the

Adjusting

the

plus

(+)

side

to

TP1

the

reference

ready

20ml,

for

each

the

Hi

reference

EE

VR7

is

used

in

step

will

result

in

reflected

photointerruptor,

Syringe

side

of

or

TP11.

voltages

30ml

and

size

of

voltage

Detection

the

oscilloscope

using

50ml

syringe.

using

variable

to

adjust

(3)

while

light

and

this

syringes,

VR3

and

T

the

sensitivity

rotating

from

should

to

pin 2 (Hi

resistors

then

carry

the

Lo

-

Пн;

|

Lo

VR7

the

area

be

checked

side)

VR3

and

out

reference

of

the

photointerruptor.

counterclockwise.

of

the

clutch

after

adjustment.

or

pin 6 (Lo

VR4.

the

adjustments

voltage

Syringe

None

20

30

50

None

spring

side)

so

using

(L)

(H)

Note

retainer

of

that

VR4.

Magnetic

IC7

the

LEDs

Mi

L

H

H

L

L L

that

over-

(9.6-27)

and

elements

M2

L

L

H

H

the

light

o

*

Set

using

the

VR3

Hi

reference

and

the

voltage

Lo

refer-

(2)

Set

the

VR4:

VR3:

*

Check

reference

Lo

voltage

Hi

voltage

using

L

o

voltages

to

HIGH

to

HIGH

the

oscilloscope.

as

follows:

between

between

“None

“20ml”

(L)*

and

and

“20ml”.

“30ml“.

Hi

The

5.1.5

Overload

oscilloscope

the

the

Set

(1)

IC6

(2)

See

Variable

*

ad

op

=

8

5

a e

ο”

È

dotted

Adjusting

detection

and

section

line

is

TP1

to

comparator

VRS

adjust

5.2.4

resistor

shows

the

Overload

adjusted

ΤΡ11.

or

level

achieve

to

for

how

VR6

None

HIGH

20ml

reference

using

VR5.

using

to

adjust

provided

is

(L)

level

t

voltage.

Detection

variable

IV.

resistors

Connect

overload

adjusting

for

v

Da

5

S

5

pe

è

the

Set

VR5

plus

the

detection.

sensitivity.

reference

VR6.

and

of

side

(+)

See

esse

voltage

Connect

oscilloscope

the

section

20πι

HIGH

30ml

to

the

mid

the

minus

5.2.4

|

level

t

point.

to

for

side

(=)

10

pin

details.

c

«

5,2

5.2.1

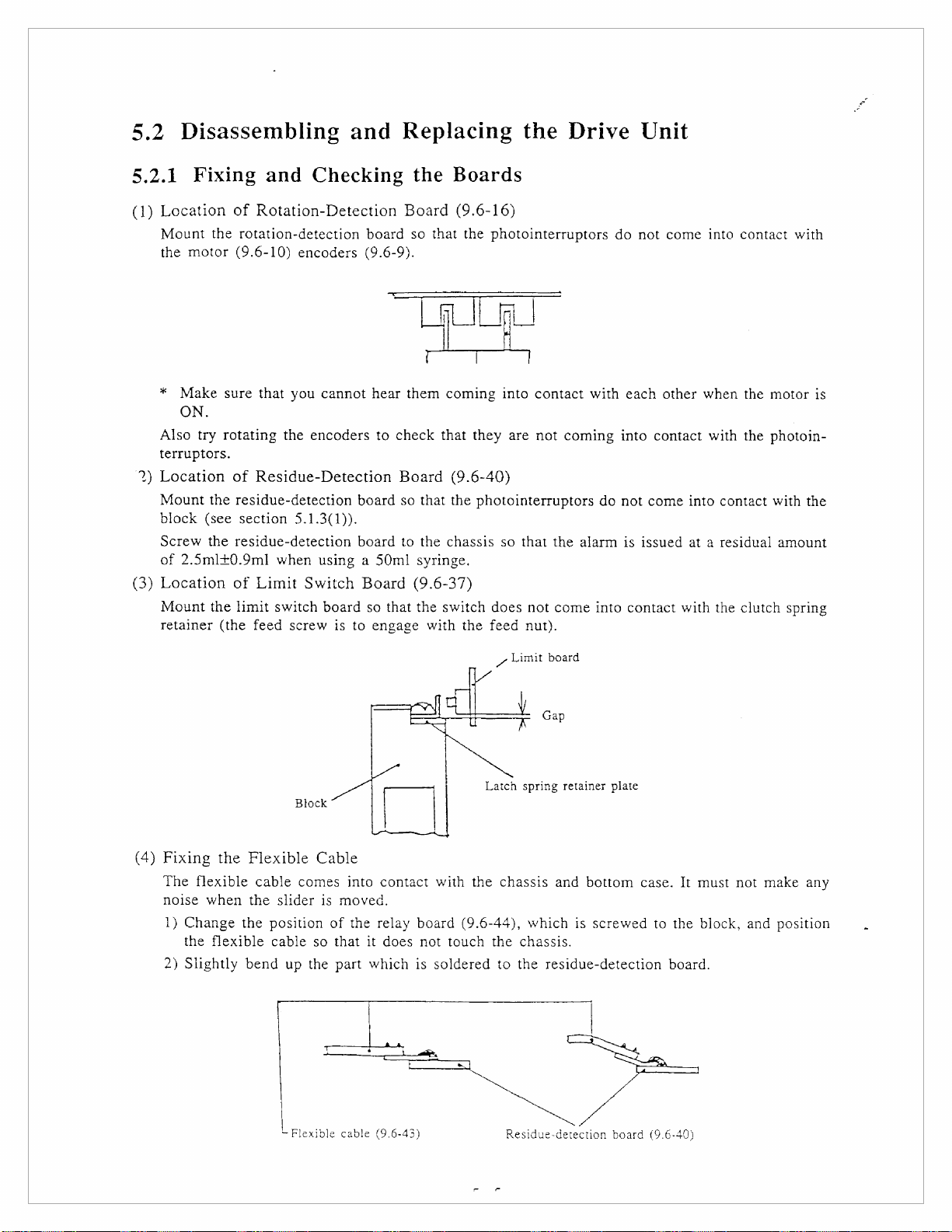

(1)

(3)

Disassembling

Location

Mount

the

*

Make

ON.

Also

terruptors.

2)

Location

Mount

block

Screw

of

2.5ml+0.9ml

Location

Mount

retainer

Fixing

of

the

motor

sure

try

rotating

of

the

residue-detection

(see

the

residue-detection

of

the

(the

and

and

Rotation-Detection

rotation-detection

(9.6-10)

that

Residue-Detection

section

Limit

limit

feed

Checking

encoders

you

the

encoders

5.1.3(1)).

when

using a 50m!

Switch

switch

screw

cannot

board

is

to

Replacing

Board

board

(9.6-9).

hear

them

to

check

Board

board

so

board

to

Board

so

that

engage

the

the

Boards

(9.6-16)

so

that

the

photointerruptors

DE

coming

that

(9.6-40)

that

the

the

chassis

syringe.

(9.6-37)

the

switch

with

into

contact

they

are

not

photointerruptors

so

that

does

not

the

feed

nut).

Drive

coming

the

alarm

come

with

do

into

Unit

do

not

each

into

not

is

issued

contact

come

other

contact

come

with

into

contact

when

the

with

the

into

contact

at a residual

the

clutch

with

motor

is

photoin-

with

the

amount

spring

(4)

Fixing

The

flexible

noise

1)

Change

the

2)

Slightly

the

Flexible

when

the

the

flexible

bend

cable

slider

position

cable

up

Block

Cable

comes

is

so

the

into

moved.

of

the

that

part

contact

relay

it

does

which

min

board

not

is

soldered

s

Ч

X

with

the

(9.6-44),

touch

一

Latch

ン

ILimit

А

spring

chassis

the

chassis.

to

the

board

Сар

retainer

and

which

residue-detection

bottom

is

screwed

plate

case.

to

board.

It

the

must

block,

not

and

make

position

any

=

Flexible

a

cable

(9.6-43)

Residue-detection

board

(9.6-40)

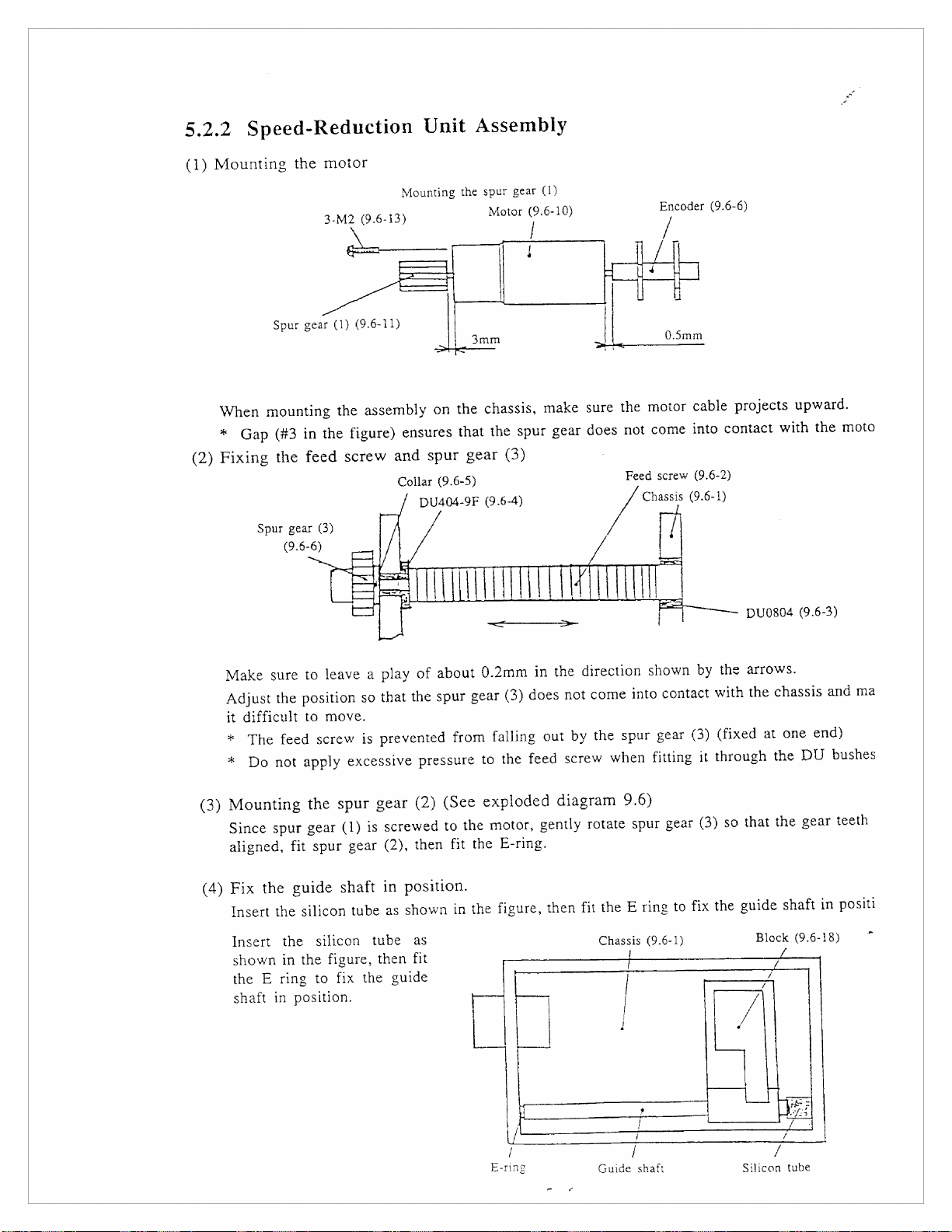

5.2.2

(1)

Mounting

When

*

Fixing

(2)

Speed-Reduction

the

motor

(9.6-13)

3-M2

Spur

gear

(1)

(9.6-11)

assembly

the

in

feed

the

figure)

screw

mounting

Gap

(#3

the

(9.6-6)

and

|

Unit

Mounting

on

ensures

spur

Collar

DU404-9F

the

the

that

gear

(9.6-5)

Assembly

spur

gear

(1)

(9.6-10)

Motor

|

|

chassis,

the

(9.6-4)

make

spur

(3)

m

gear

sure

does

[oi

ai

the

not

Feed

Encoder

motor

come

screw

(9.6-6)

cable

contact

into

(9.6-2)

(9.6-1)

projects

with

upward.

moto

the

Make

Adjust

it

*

*

Mounting

(3)

Since

(4)

sure

the

difficult

feed

The

not

Do

spur

aligned,

the

Fix

the

Insert

E

the

in

ring

in

Insert

shown

the

shaft

leave

to

position

to

move.

screw

excessive

apply

spur

the

(1)

gear

gear

spur

fit

guide

position.

shaft

silicon

silicon

figure,

the

fix

to

tube

FA

of

play

a

the

that

so

prevented

is

pressure

(2)

gear

screwed

is

then

(2),

position.

in

shown

as

as

tube

fit

then

guide

the

about

spur

from

(See

the

to

fit

in

0.2mm

(3)

gear

falling

the

to

exploded

motor,

E-ring.

the

figure,

the

|

|

mM

direction

the

in

come

not

does

the

by

out

screw

feed

diagram

then

rotate

the

fit

Chassis

gently

о

into

spur

when

9.6)

spur

E

|

|

shown

contact

gear

fitting

gear

to

ring

(9.6-1)

by

(3)

it

(3)

fix

DU0804

arrows.

the

the

with

(fixed

through

that

so

guide

the

Block

chassis

one

at

the

the

shaft

A

7

|

(9.6-3)

and

end)

bushes

DU

teeth

gear

positi

in

(9.6-18)

ma

7

/

1

E-ring

Guide

2

:

1/

shaft

/

Silicon

=)

tube

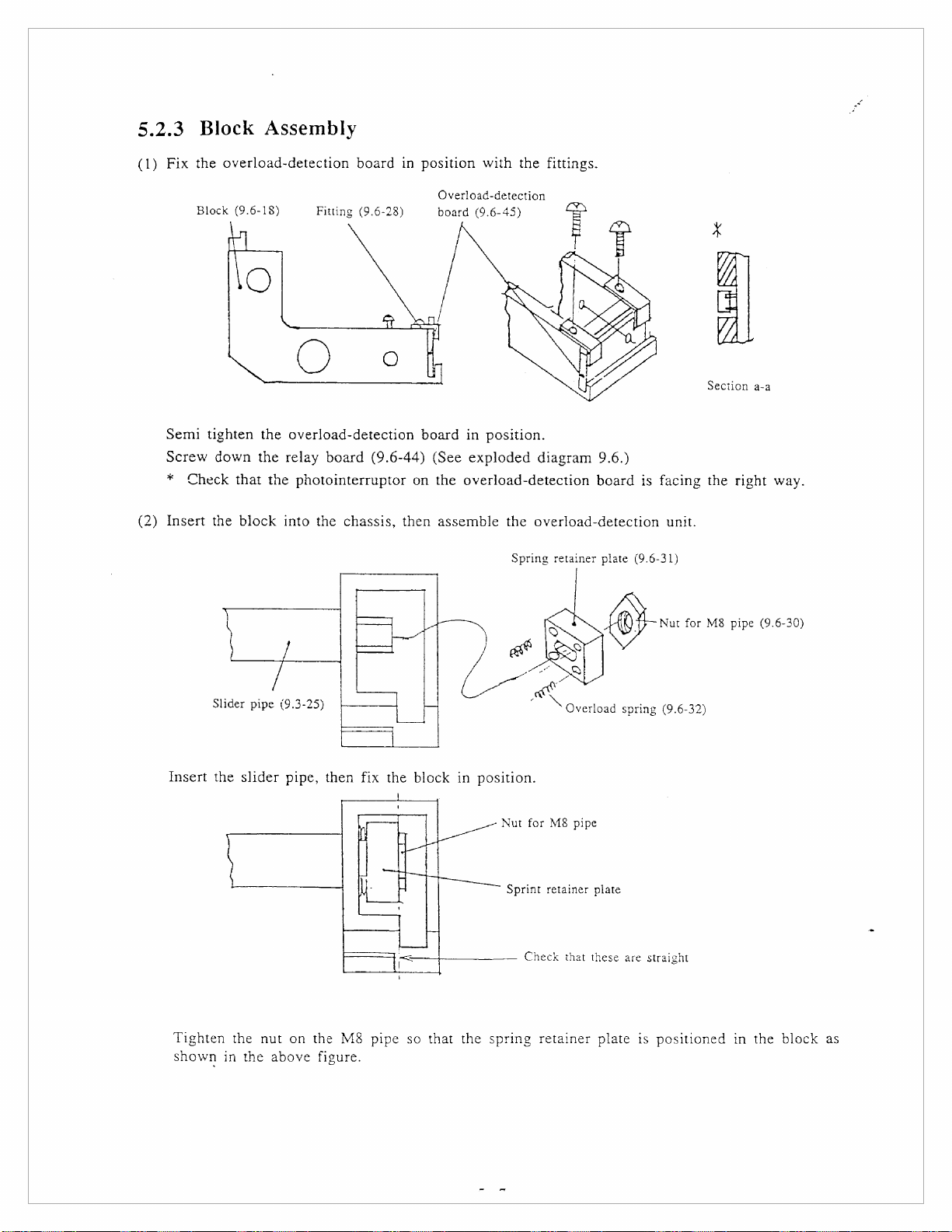

5.2.3

(1)

Fix

Semi

Screw

*

(2)

Insert

Block

the

Block

tighten

down

Check

the

Assembly

overload-detection

(9.6-18)

er.

the

overload-detection

the

relay

that

the

photointerruptor

block

into

Fitting

board

the

chassis,

board

(9.6-28)

(9.6-44)

in

position

Overload-detection

board

board

(See

on

the

then

assemble

with

the

fittings.

(9.6-45)

in

position.

exploded

overload-detection

diagram

the

overload-detection

Spring

retainer

9.6.)

board

plate

is

facing

unit.

(9.6-31)

the

right

way.

İnsert

Tighten

shown

Slider

the

slider

the

in

the

pipe

nut

(9.3-25)

pipe,

on

above

then

i

the

M8

figure.

fix

_

|

pipe

the

block

|

so

that

in

position.

<

the

spring

Nut

S

for

+

print

Check

Overload

M8

pipe

,

retainer

that

retainer

plate

these

plate

spring

are

straight

is

Nut

for

M8

(9.6-32)

positioned

pipe

in

(9.6-30)

the

block

as

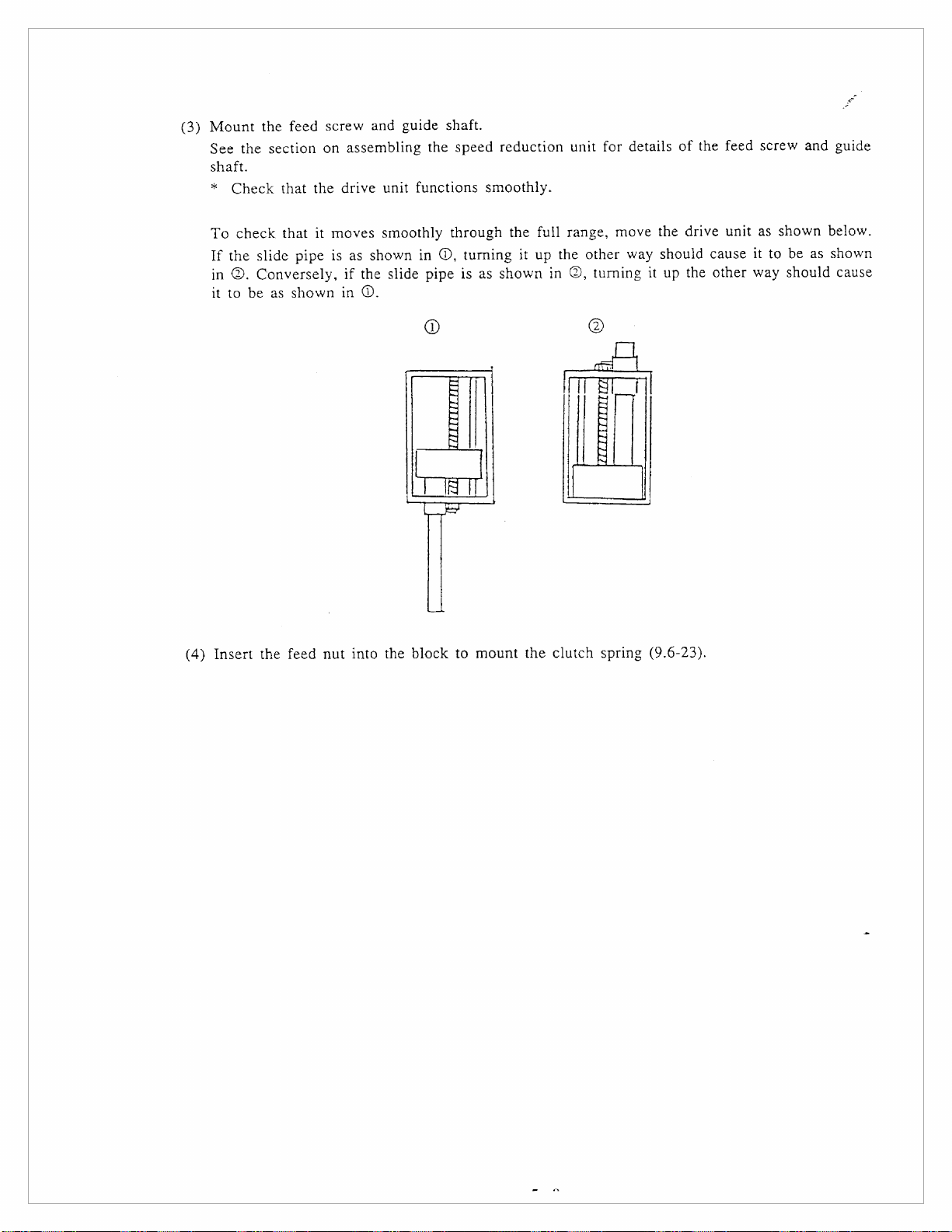

(3)

Mount

See

shaft.

*

To

If

in

it

the

the

section

Check

check

the

slide

@.

Conversely,

to

be

that

that

as

feed

the

it

pipe

shown

screw

on

assembling

drive

moves

is

as

if

the

in

©.

and

guide

unit

smoothly

shown

slide

shaft.

the

speed

reduction

functions

in

©,

pipe

© ©

smoothly.

through

turning

is

as

the

it

shown

full

up

in

unit

range,

the

@,

for

move

other

turning

details

the

way

should

it

up

of

the

drive

the

feed

unit

cause

other

screw

as

it

to

way

and

shown

be

should

below.

as

guide

shown

cause

(4)

Insert

the

feed

nut

into

the

block

to

ATT

ATTE

mount

the

clutch

ЕЕ

spring

(9.6-23).

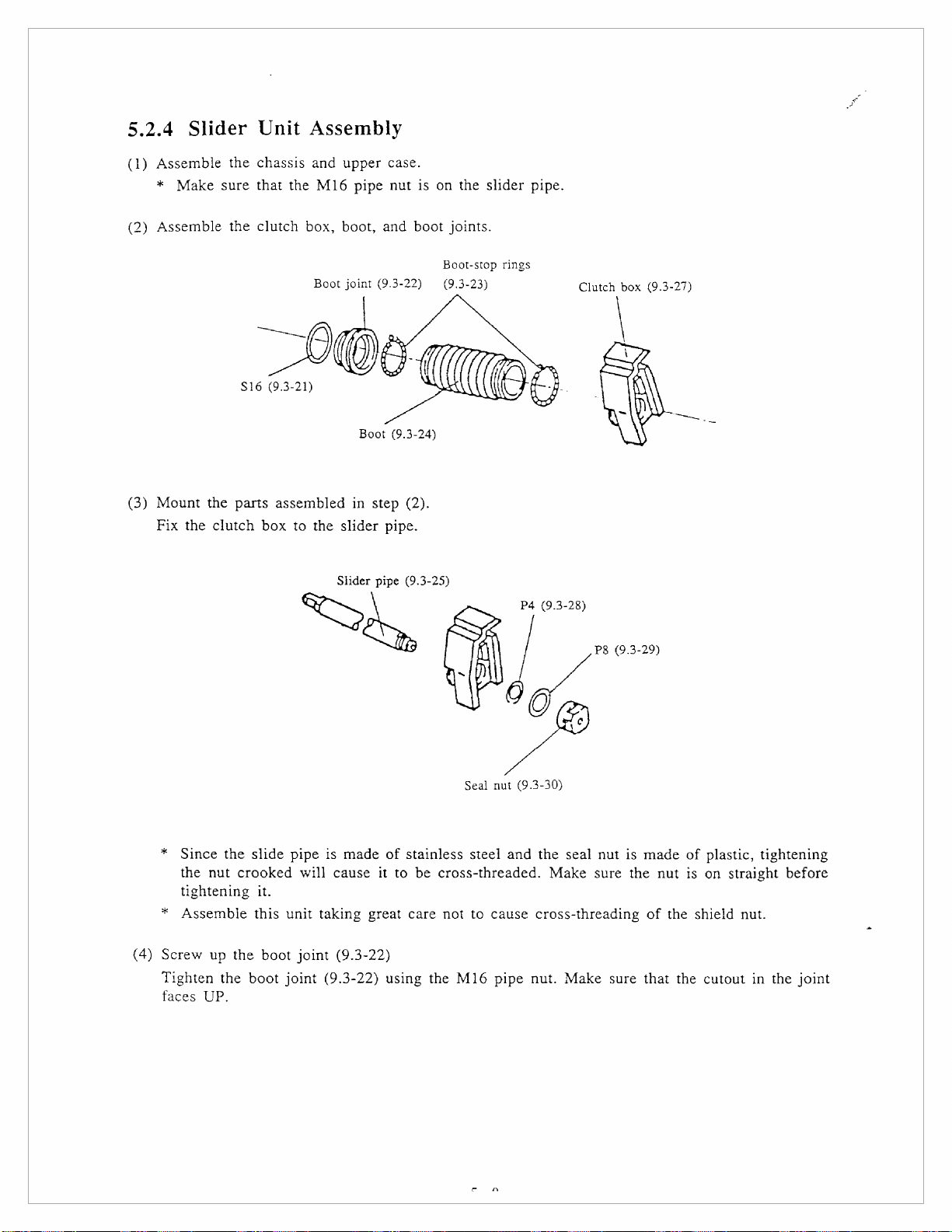

5.2.4

(1)

Assemble

*

(2)

Assemble

(3)

Mount

Fix

Slider

Make

the

the

clutch

the

sure

the

S16

parts

Unit

chassis

that

the

clutch

—..

(9.3-21)

assembled

box

to

“>

Assembly

and

upper

M16

pipe

box,

boot,

Boot

joint

(0

Boot

in

step

the

slider

Slider

|

case.

nut

and

boot

(93-22)

Da

|

(9.3-24)

(2).

pipe.

pipe

(9.3-25)

is

on

joints.

Boot-stop

(9.3-23)

the

slider

rings

P4

pipe.

Clutch

(9.3-28)

box

|

(9.3-27)

(4)

*

Since

the

tightening

*

Assemble

Screw

Tighten

faces

UP.

nut

up

the

the

slide

crooked

this

the

boot

it.

boot

pipe

will

unit

joint

joint

is

made

cause

taking

(9.3-22)

(9.3-22)

of

it

to

great

using

n

Seal

stainless

be

care

steel

cross-threaded.

not

to

the

M16

/

nut

(9.3-30)

and

the

cause

cross-threading

pipe

nut.

seal

Make

Make

P8

(9.3-29)

nut

is

sure

the

sure

made

nut

of

that

the

the

of

plastic,

is

on

shield

cutout

tightening

straight

nut.

in

the

before

joint

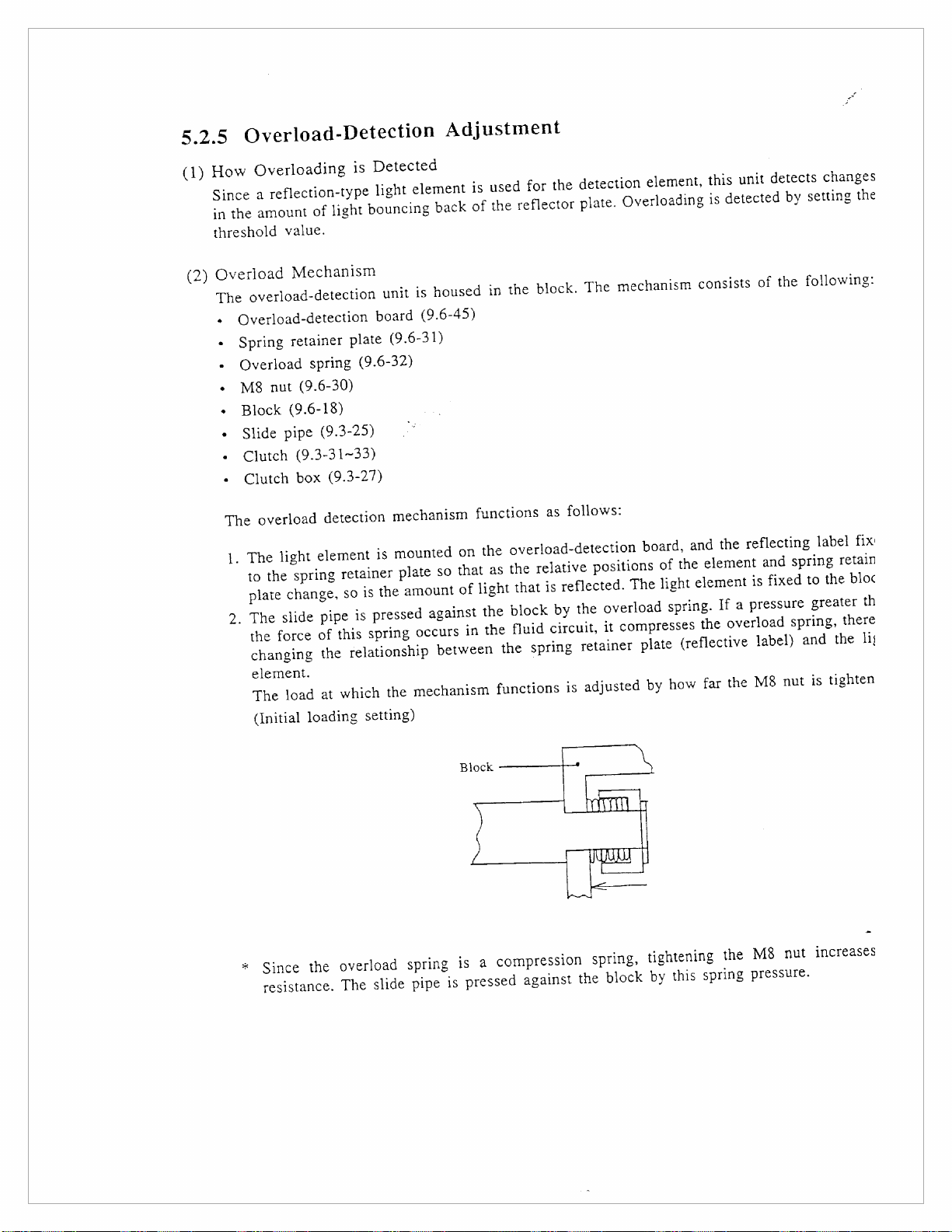

5.2.5

How

(1)

Since

in

threshold

Overload

(2)

The

>

The

Overload-Detection

Detected

light

of

plate

spring

(9.3-25)

(9.3-27)

detection

element

retainer

so

pipe

this

of

relationship

the

which

at

loading

is

light

bouncing

board

(9.6-32)

is

pressed

is

spring

setting)

Overloading

reflection-type

a

amount

the

value.

Mechanism

overload-detection

Overload-detection

nut

(9.6-18)

pipe

Clutch

overload

light

The

the

to

change,

plate

slide

The

force

the

changing

element.

load

The

(Initial

retainer

(9.6-30)

(9.3-31-33)

box

spring

Spring

Overload

M8

Block

Slide

Clutch

1.

.

element

unit

(9.6-31)

mechanism

mounted

is

plate

amount

the

mechanism

the

Adjustment

is

of

back

housed

is

(9.6-45)

functions

on

that

so

light

of

against

occurs

in

between

for the

d

use

flector

re

the

the

in

overload-detection

the

the

as

that

block

the

fluid

the

spring

the

functions

detection

plate.

block.

relative

The

follows:

as

reflected.

is

the

by

circuit,

retainer

adjusted

is

element,

Overloading

mechanism

board,

positions

The

overload

compresses

it

plate

by

this

is

consists

and

element

the

of

element

light

spring.

the

(reflective

far

how

unit

detected

of

reflecting

the

and

is

pressure

a

If

overload

label)

M8

the

detects

setting

by

following:

the

spring

to

fixed

greater

spring,

and

is

nut

changes

the

fix:

label

retain

bloc

the

there

the

tighten

th

li:

Since

*

resistance.

the

overload

slide

The

spring

is

pipe

Block

compression

a

is

pressed

against

spring,

block

the

tightening

spring

this

by

M8

the

pressure.

increases

nut

>

Loading...

Loading...