TERRALUX DLSQ8 Install

MODEL TLK-DLSQ8-A242XXDO /-A34XXDO

LED RETROFIT KIT INSTALLATION INSTRUCTIONS

WARNING - RISK OF FIRE OR ELECTRIC SHOCK. LED RETROFIT KIT INSTALLATION

REQUIRES KNOWLEDGE OF ELECTRICAL SYSTEMS. IF NOT QUALIFIED, DO NOT

ATTEMPT INSTALLATION. CONTACT A QUALIFIED ELECTRICIAN.

WARNING - RISK OF FIRE OR ELECTRIC SHOCK. INSTALL THIS KIT ONLY IN

LUMINAIRES THAT HAVE CONSTRUCTION FEATURES AND DIMENSIONS SHOWN IN

THE DRAWINGS “MIN. LAMP COMPARTMENT VOLUME 488 IN3 (8000 CM3)”

WARNING – TO PREVENT WIRING DAMAGE OR ABRASION, DO NOT EXPOSE WIRING

TO EDGES OF SHEET METAL OR SHARP OBJECTS

DO NOT MAKE OR ALTER ANY OPEN HOLES IN AN ENCLOSURE OF WIRING OR

ELECTRICAL COMPONENTS DURING KIT INSTALLATION.

FOR CONNECTIONS USE WIRE RATED FOR AT LEAST 75°C.

SUITABLE FOR DRY AND DAMP LOCATIONS.

THIS RETROFIT KIT IS FOR INSTALLATION INTO INDOOR RECESSED NON-IC TYPE CEILING MOUNTED DOWN

LIGHT LUMINAIRES THAT ARE USED IN NON-FIRE-RATED INSTALLATIONS ONLY. CHECK FOR THIS MARKING

ON THE LUMINAIRE, OR WITH THE BUILDING CODE AUTHORITIES HAVING EXPERTISE IN THIS AREA PRIOR TO

INSTALLATION OF THIS RETROFIT KIT.

THE LED DRIVER MODULE HAS AN OUTPUT RATED AT 53V PEAK. THIS OUTPUT COMPLIES WITH THE

DEFINITION OF CLASS 2 PER CANADIAN ELECTRICAL CODE. THIS OUTPUT CANNOT BE ACCESSIBLE BASED ON

MAXIMUM VOLTAGE RESTRICTIONS FOR CLASS 2 CIRCUITS IN CANADIAN ELECTRICAL CODE. THIS KIT

INCLUDES AN ACCESSIBLE LED ARRAY. THE LED ARRAY SHOULD BE IN COMPLIANCE WITH THIS ACCESSIBILITY

REQUIREMENT, EITHER BASED ON DESIGN OR BASED ON MANUFACTURERS SPECIFICATIONS FOR ITS USE IN

RESTRICTED ACCESS AREAS ONLY.

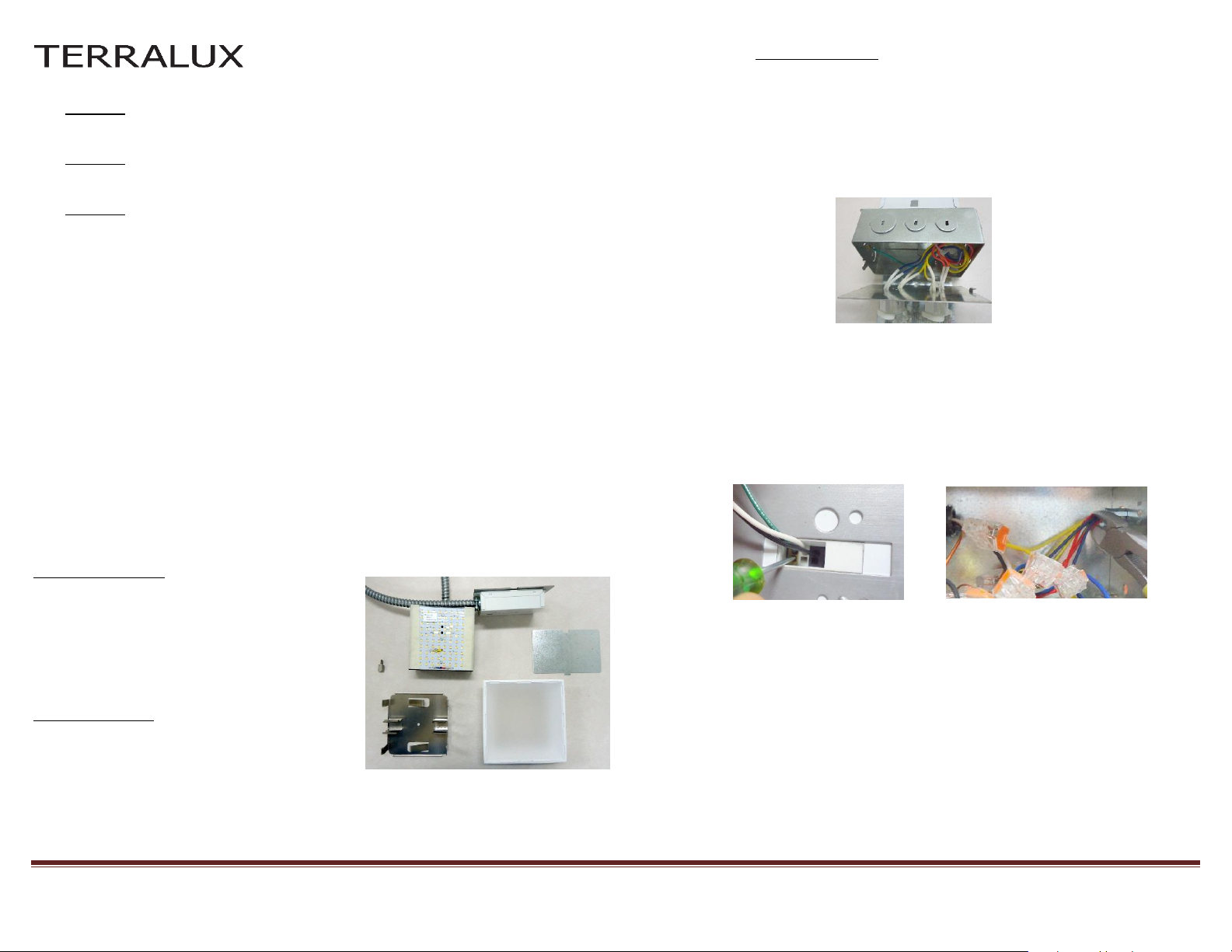

INCLUDED COMPONENTS (KITS MAY BE BULK PACKAGED)

(1) LED RETROFIT KIT, MODEL TLK-DLSQ8-

A242XXDO (a)

(1) BLANK FIXTURE J-BOX COVER (b)

(1) LED HEATSINK MOUNTING BRACKET (c)

(1) DIFFUSER ASSEMBLY (d)

(1) 3/8” THREADED METAL STAND-OFF (e)

USER REQUIRED TOOLS

SLOTTED SCREWDRIVER WITH 2.5 MM (0.100”)

BLADE

INSTALLATION STEPS

1. SHUT OFF POWER TO LIGHT FIXTURE AT THE BREAKER PANEL

2. REMOVE CFL BULBS

3. UNSCREW TRIM HOUSING WING NUT AND REMOVE TRIM FROM FIXTURE.

4. UNLATCH THE JUNCTION BOX COVER THAT THE CFL BULB BASES ARE ATTACHED TO. NOTE - SOME

FIXTURES DO NOT HAVE CFL BULB BASES INSTALLED ON THE JUNCTION-BOX COVER. IF YOU HAVE

ONE OF THESE FIXTURES, REMOVE THE BLANK JUNCTION BOX COVER PLATE THAT FACES THE TRIM

HOUSING OPENING.

5. UNLATCH THE OPPOSITE JUNCTION BOX COVER (WITH CFL BALLAST ATTACHED), AND PULL AWAY

FROM JUCTION BOX TO EXPOSE MAINS WIRING.

6. INSERT A 2.5MM FLATBLADE SCREWDRIVER INTO THE RECTANGULAR SLOT, ADJACENT TO EACH

WIRE OF TERMINAL BLOCK WHILE PULLING WIRE FROM TERMINAL REPEAT UNTIL ALL MAINS

WIRES AND CFL BULB WIRES HAVE BEEN DISCONNECTED FROM THE BALLAST. NOTE: IF THE

FIXTURE JUNCTION BOX CONTAINS BALLAST WIRING THAT EXITS THE JUNCTION BOX THROUGH

CONDUIT, CUT ALL BALLAST WIRES AT POINT WHERE THEN WIRES EXIT THE JUNCTION BOX.

7. REMOVE AND DISCARD THE JUNCTION BOX COVER WITH CFL BULB BASES/SOCKETS ATTACHED (IF

APPLICABLE), AND ALL BULB WIRING.

8. POSITION THE LED DRIVER/COVER PLATE NEAR THE JUNCTION BOX. USING A 2.5MM

SCREWDRIVER, DEPRESS THE RECTANGULAR SLOT ADJACENT TO EACH TERMINAL WHILE

INSERTING THE BALLAST MAINS WIRES REMOVED IN STEP 6. REPEAT FOR EACH WIRE UNTIL ALL

WIRES HAVE BEEN INSTALLED:

LINE TO BLACK TERMINAL

NEUTRAL TO WHITE TERMINAL.

GROUND TO GREEN TERMINAL

GENTLY PULL ON EACH WIRE TO ENSURE THAT THEY ARE LOCKED INTO TERMINAL BLOCK.

TerraLUX Inc. Document P/N 025000110

1-866-498-1564

www.terralux.com

9. REINSTALL BALLAST WITH COVER PLATE AND INSTALL LED DRIVER WITH COVER PLATE OVER THE

FIXTURE’S J-BOX OPENINGS. ENSURE THAT BOTH COVERS ARE PROPWERLY POSITIONED AND

FULLY LATCHED IN PLACE.

10. ROUTE LED HEAD ASSEMBLY AROUND OUTSIDE OF FIXTURE SUPPORT POSTS, AND OUT THROUGH

TRIM HOUSING OPENING.

11. GUIDE LED HEAD ASSEMBLY THROUGH OPENING IN TRIM HOUSING BEING CAREFUL NOT TO

SCRAPE AGAINST THE LED SURFACE.

12. INSERT TRIM HOUSING BACK INTO FIXTURE, AND POSITION THE LED MOUNTING BRACKET INTO

BOTTOM OF TRIM HOUSING SUCH THAT THE ROUNDED CLIPS ALIGN WITH THE TRIM HOUSING

OPENING. SECURE BOTH TRIM RING HOUSING AND LED MOUNTING BRACKET TO THE FIXTURE

USING WING NUT REMOVED IN STEP 3.

NOTE – BASED ON THE BOTTO M DIMENSIONS OF SOME TRIM HOUSINGS, THE MOUNTING SCREW

MAY NOT BE LONG ENOUGH TO INSTALL THE LED MOUNTING BRACKET. IF THIS HAPPENS, THREAD

THE PROVIDED 3/8” THREADED METAL STANDOFF ONTO THE TRIM HOUSING MOUNTING SCREW

BEFORE INSTALLING LED MOUNTING BRACKET.

13. REMOVE THE PLASTIC PROTECTIVE COVER FROM OVER THE LED’S AND DISCARD.

14. INSTALL DIFFUSOR BRACKET OVER LED’S AS SHOWN. DIFUSSER BRACKET SHOULD FULLY SEAT IN

PLACE

15. PRESSING DOWN ON THE CORNERS OF THE DIFFUSER BRACKET, FIRMLY SEAT THE LED HEAD

ASSEMBLY INTO THE LED MOUNTING BRACKET. NOTE: THE LED MOUNTING BRACKET IS SELF-

ALIGNING AND WILL GUIDE THE LED/DIFFUSER ASSEMBLY INTO PLACE.

16. TURN POWER BACK ON AT THE BREAKER PANEL AND VERIFY OPERATION

TerraLUX Inc. Document P/N 025000110

1-866-498-1564

www.terralux.com

Loading...

Loading...