19-5650; Rev 1.0; 1/11

A Maxim Integrated Products Brand

73S8014BN

Demo Board User Manual

January 2011

Rev. 1.0

UM_8014BN_069

73S8014BN Demo Board User Manual UM_8014BN_069

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit

patent licenses are implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

2011 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products.

UM_8014BN_069 73S8014BN Demo Board User Manual

Table of Contents

1

Introduction .......................................................................................................................................... 4

1.1 General .......................................................................................................................................... 4

1.2 Safety and ESD Notes .................................................................................................................. 4

1.3 Recommended Operating Conditions and Absolute Maximum Ratings ....................................... 5

1.3.1Recommended Operating Conditions ...................................................................................... 5

1.3.2Absolute Maximum Ratings ...................................................................................................... 5

1.4 Getting Started .............................................................................................................................. 6

2 Design Considerations ....................................................................................................................... 7

2.1 General Layout Rules ................................................................................................................... 7

2.2 Optimization for Compliance with NDS ......................................................................................... 7

3 Demo Board Hardware Description .................................................................................................. 8

3.1 Jumpers, Switches, and Test Points ............................................................................................. 8

3.2 73S8014BN Pin Description ........................................................................................................10

3.3 73S8014BN Pinout (Top View) ...................................................................................................12

3.4 Schematic ....................................................................................................................................13

3.5 Bill of Materials ............................................................................................................................14

3.6 PCB Layouts ...............................................................................................................................15

4 Demo Board Errata ............................................................................................................................ 18

5 Ordering Information ........................................................................................................................ 18

6 Contact Information .......................................................................................................................... 18

Revision History ........................................................................................................................................ 19

Rev. 1.0 3

73S8014BN Demo Board User Manual UM_8014BN_069

1 Introduction

1.1 General

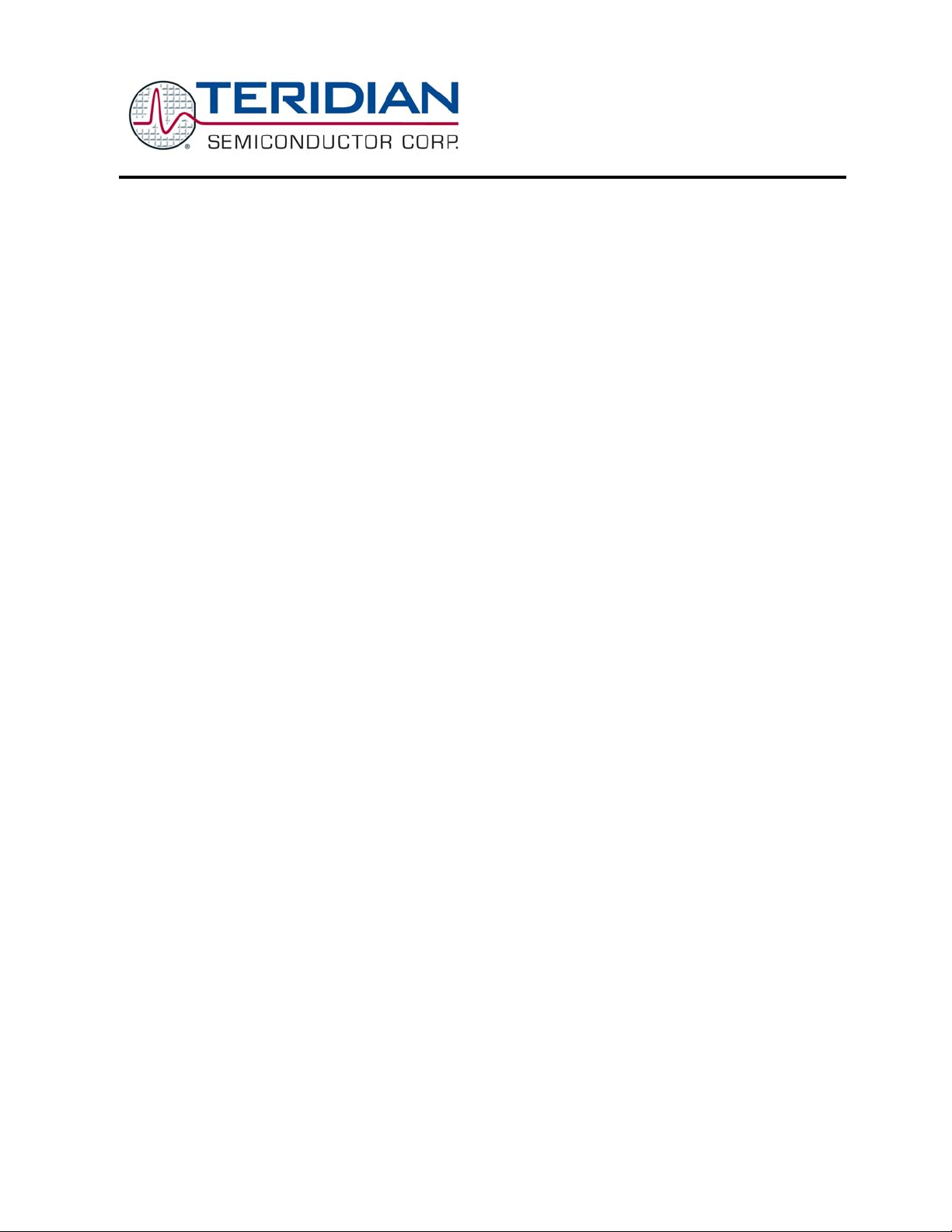

The Teridian Semiconductor Corporation (TSC) 73S8014BN demo board is a platform for evaluating the

Teridian 73S8014BN smart card interface IC. It incorporates the 73S8014BN integrated circuit, and it has

been designed to operate either as a stand-alone platform (to be used in conjunction with an external

microcontroller) or as a daughter card to be used in conjunction with the 73S12xxF evaluation platform.

The 73S8014BN uses the CMDVCC and 5V/3V control signals to generate VCC (smart card supply

voltage) at 1.8V, 3V, or 5V. The 73S8014BN uses a single multilevel clock-divider signal, CLKDIV, to

select between a divide by 1, 2, 4, and 8 for the smart card CLK output. The demo board uses a resistor

divider on two pins to generate the multilevel signal for the clock divider. Refer to the 73S8014BN IC data

sheet for details.

The board has been designed to comply with the NDS specification.

Figure 1: 73S8014BN Demo Board

Note: This board does not contain the required 20k pulldown resistor on V

Section 4 for details.

for 1.8V operation. See

CC

1.2 Safety and ESD Notes

Connecting live voltages to the demo board system results in potentially hazardous voltages on the

boards.

Extreme caution should be taken when handling the demo boards after

connection to live voltages!

The demo boards are ESD sensitive! ESD precautions should be taken when

handling these boards!

4 Rev. 1.0

UM_8014BN_069 73S8014BN Demo Board User Manual

1.3 Recommended Operating Conditions and Absolute Maximum Ratings

1.3.1 Recommended Operating Conditions

PARAMETER RATING

Supply Voltage Range, VDD 2.7V to 3.6V DC

4.75V to 5.5V DC (ISO 7816 and EMV

Supply Voltage Range, VPC

Ambient Operating Temperature Range -40°C to +85°C

Input Voltage Range for Digital Inputs 0V to (VDD + 0.3V)

applications)

4.85V to 5.5V DC (NDS applications)

1.3.2 Absolute Maximum Ratings

Operation outside these rating limits may cause permanent damage to the device.

PARAMETER RATING

Supply Voltage Range, VDD -0.5V to +4.0V DC

Supply Voltage Range, VPC -0.5V to +6.0V DC

Input Voltage Range for Digital Inputs -0.3V to (VDD + 0.5V) DC

Storage Temperature Range

Pin Voltage Range -0.3 to (VDD + 0.5V) DC

Pin Current

ESD Tolerance—Card Interface Pins

ESD Tolerance—Other Pins

Note: ESD testing on card pins is Human Body Model (HBM) condition, three pulses, each polarity

referenced to ground.

-60C to +150C

100mA

6kV

2kV

Rev. 1.0 5

73S8014BN Demo Board User Manual UM_8014BN_069

1.4 Getting Started

Figure 2 shows the basic connections of the demo board.

Power Supplies: Apply 3.3V to pin 10 of J4 and 5V to pin 10 of J2.

Control signals to the device can be connected through J2 and J4 (see Figure 2 and the electrical

schematic Figure 4).

Setting the clock frequency with an external clock source:

o Set JP1 to the SCLK setting.

o Apply clock source to pin 1 of J2.

o Apply 3.3V (1) or GND (0) to CLKDIV1 and CLKDIV2 pins allows the following:

- CLKDIV1 = CLKDIV2 = 0 clock frequency = SCLK/4

- CLKDIV1 = 0, CLKDIV2 =1 clock frequency = SCLK

- CLKDIV1 = 1, CLKDIV2 =0 clock frequency = SCLK/8

- CLKDIV1 = CLKDIV2 = 1 (or leaving both open) clock frequency = SCLK/2

Setting the clock frequency using crystal Y1:

o Crystal included in the demo board is 12MHz (NDS applications can use up to 27MHz).

o Set JP1 to XTAL position.

o Apply 3.3V (1) or GND (0) to CLKDIV1 and CLKDIV2 pins allows the following:

- CLKDIV1 = CLKDIV2 = 0 clock frequency = 3MHz

- CLKDIV1 = 0, CLKDIV2 =1 clock frequency = 12MHz

- CLKDIV1 = 1, CLKDIV2 = 0 clock frequency = 1.5MHz

- CLKDIV1 = CLKDIV2 = 1 (or leaving both open) clock frequency = 6MHz

External clock source. JP1

must be in position SCLK

when use of an external

clock. Otherwise, pin

SCLK can be left open.

IOUC

OFF

GND

V

PC

Supply:

+4.5V to +5.5V

(5V Typ.)

/200mA

2

VPC

Power

SCLK

Figure 2: 73S8014BN Demo Board: Basic Connections

VDD Power Supply:

+2.7V to +3.6V

1

(3.3V Typ.) / 50mA

VDD

RSTIN

CMDVCC

5V/#V

CKDIV2

CKDIV1

GND

6 Rev. 1.0

UM_8014BN_069 73S8014BN Demo Board User Manual

2 Design Considerations

2.1 General Layout Rules

Keep the CLK signal as short as possible and with few bends in the trace. Keep route of the CLK trace to

one layer (avoid vias to other plane). Keep CLK trace away from other traces, especially RST and VCC.

Filtering of the CLK trace is allowed for noise purposes. Up to 30pF to ground is allowed at the CLK pin of

the smart card connector. Also, the 0 series resistor, R7, can be replaced for additional filtering (no

more than 100).

Keep the VCC trace as short as possible. Make trace a minimum of 0.5mm thick. Also, keep VCC away

from other traces especially RST and CLK.

Keep RST trace away from VCC and CLK traces. Up to 30pF to ground is allowed for filtering.

Keep 0.1F close to the V

Keep 0.1F and 10F close to the V

Keep 1.0F close to the V

2.2 Optimization for Compliance with NDS

Default configuration of the demo board contains a 27pF capacitor (C12) from the CLK pin of the smart

connector to ground and a 27pF capacitor (C13) from the RST pin of the smart connector to ground.

These capacitors serve as filters for the CLK and RST signals in the case of long traces or test equipment

perturbations. The capacitor on CLK reduces ringing on the trace, reduces coupling to other traces and

slows down the edge of the CLK signal. The capacitor on RST helps the perturbation specification in a

noisy environment. The filter capacitors can be useful in the EMV test environment and have no effect on

NDS testing.

C12 and C13 are represented on both the schematic and BOM. These capacitors are optional filter

capacitors on the smart card lines CLK and RST, respectively, for each card interface. These capacitors

can be adjusted (value, not to exceed 30pF) or removed to optimize performance in each specific

application (PCB, card clock frequency, compliance with applicable standards, etc.).

pin of the device and directly take other end to ground.

DD

pin of the device and directly take other end to ground.

PC

pin of the smart card connector and directly take other end to ground

CC

Rev. 1.0 7

73S8014BN Demo Board User Manual UM_8014BN_069

3 Demo Board Hardware Description

3.1 Jumpers, Switches, and Test Points

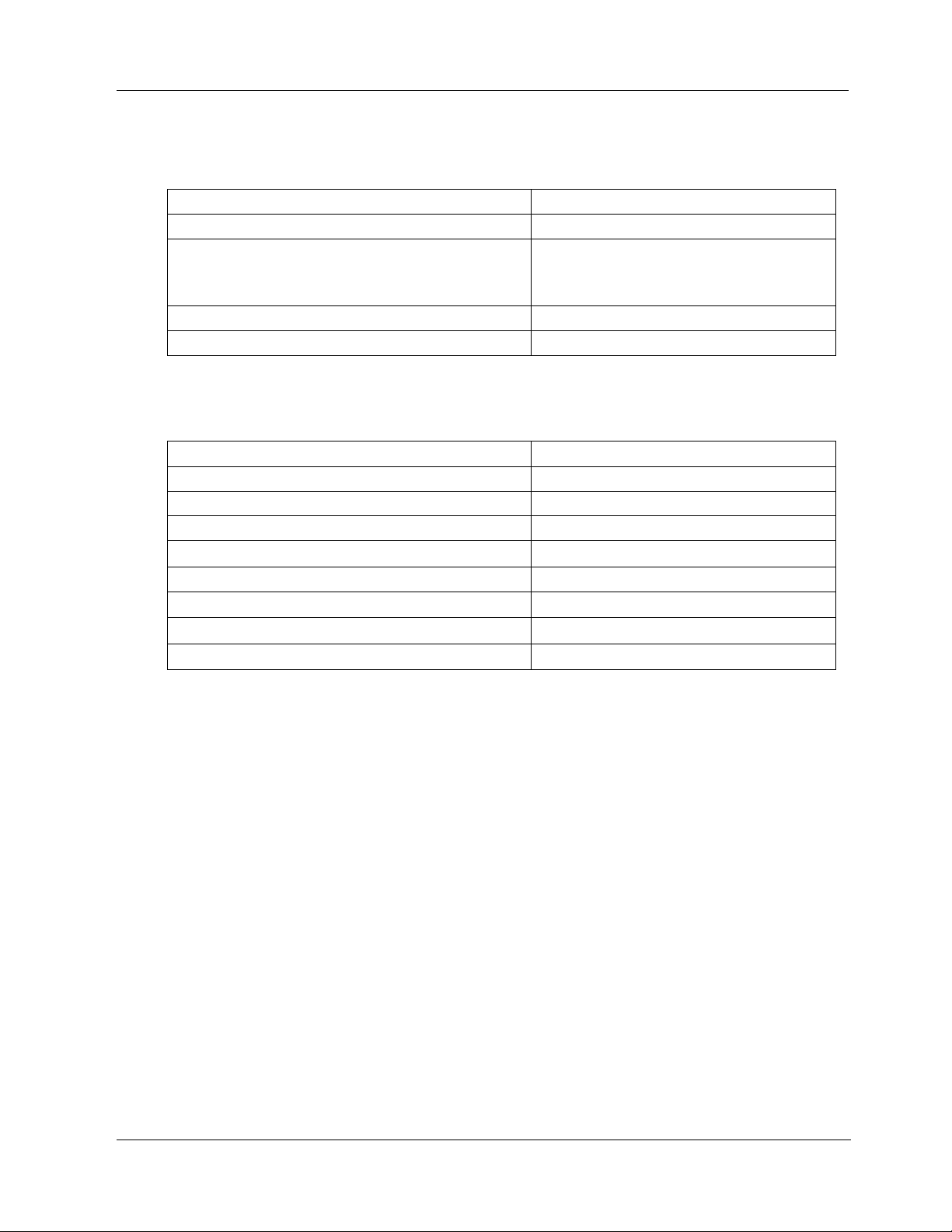

The items described in the following tables refer to the flags in Figure 3.

Table 1: Demo Board Description

SCHEMATIC

ITEM

(FIGURE 3)

1 J2

2

3

4

5

9

10

AND PCB

SILKSCREEN

REFERENCE

TP8

TP7

TP5

TP3

TP4

TP6

NAME USE

Connector that gathers the 5V supply of the board,

Board 5V

supply and host

digital interface

Test Points:

C4

CLK

RST

VCC

I/O

C8

the 73S8014BN data interface (I/OUC, C4UC, and

C8UC), external clock (SCLK), and interrupt (OFF)

pins. Note that the external clock (SCLK) can be left

open when JP1 is in position XTAL.

2-pin test points for each respective smart card

signal. The pin label name is the respective signal

(i.e., VCC, CLK) and the other pin is GND.

Board 3.3V

6 J4

7 Y2

8 J6

11 JP1 Clock Selection

12 J5

Supply and

Digital Control

Signals

Resonator

(Optional)

Smart Card

Connector

Smart Card

Connector

Connector that gathers the 3.3V supply of the

board, the 73S8014BN host control signal pins

RSTIN, CMDVCC, 5V/3V, CLKDIV2, and CLKDIV1.

A footprint is available to accommodate an optional

ceramic resonator in place of the crystal oscillator.

SIM/SAM smart card format connector. Note that J6

is wired is parallel to the smart card connector J5

(underneath the PCB). No SIM/SAM should be

inserted when using the credit card size connector

J5.

Jumper to select between a crystal and external

clock as the frequency reference to the device. The

default setting is for a crystal.

Smart card connector. When inserting a card (credit

card size format), contacts must face up.

8 Rev. 1.0

UM_8014BN_069 73S8014BN Demo Board User Manual

4

2

3

5

1

6

7

11

910

8

12

Figure 3: Teridian 73S8014BN Demo Board: Board Description

Rev. 1.0 9

73S8014BN Demo Board User Manual UM_8014BN_069

3.2 73S8014BN Pin Description

Table 2: 73S8014BN Pin Description: Card Interface

NAME PIN DESCRIPTION

I/O 13 Card I/O: Data Signal to/from Card. Includes a pullup resistor to V

C4 12 Card C4: Data Signal to/from Card. Includes a pullup resistor to VCC

C8 14 Card C8: Data Signal to/from Card. Includes a pullup resistor to VCC

RST 15 Card Reset. Provides reset (RST) signal to card.

Card Clock. Provides clock signal (CLK) to card. The rate of this clock is

CLK 17

determined by crystal oscillator frequency or external clock input and CLKDIV

selections.

Card Presence Switch. Active high indicates card is present. Includes a high-

PRES 19

impedance pulldown current source. The PRES input includes a 5ms

debounce for card insertion.

VCC 18

Card Power Supply. Logically controlled by sequencer, output of LDO

regulator. Requires an external filter capacitor to the card GND.

GND 16 Device Ground

Table 3: 73S8014BN Pin Description: Miscellaneous and Outputs

CC.

NAME PIN DESCRIPTION

XTALIN 10

XTALOUT 11

Crystal Oscillator Input. Can either be connected to the crystal or driven as a

source for the card clock.

Crystal Oscillator Output. Connected to the crystal. Left open if XTALIN is

being used as external clock input.

Table 4: 73S8014BN Pin Description: Power Supply and Ground

NAME PIN DESCRIPTION

VDD 7 System Interface Supply Voltage and Supply Voltage for Internal Circuitry

VPC 4 LDO Regulator Power Supply Source

10 Rev. 1.0

UM_8014BN_069 73S8014BN Demo Board User Manual

Table 5: 73S8014BN Pin Description: Microcontroller Interface

NAME PIN DESCRIPTION

(Negative Assertion): Logic-low on this pin causes the LDO

CC

supply to the card and initiates a card activation

CC

CMDVCC 8

Command V

regulator to ramp the V

sequence, if a card is present.

5V/3V/1.8V Card Selection. Logic-high selects 5V for V

and card interface.

CC

Logic-low selects 3V operation. Logic going from high to low within 400ns of

CMDVCC falling selects 1.8V. When the device is used with a single card

5V/3V

voltage (3V or 5V only), this pin should be connected to either GND or V

9

DD

.

However, it includes a high-impedance pullup resistor to default this pin high

(selection of 5V card) when not connected. This pin has no effect after

CMDVCC is low.

Sets the divide ratio from the XTAL oscillator (or external clock input) to the

card clock. This is a multilevel input that uses a ratio of the V

voltage to

DD

select the clock divider as shown below.

Note: This input has no internal pullup or pulldown so it must not be allowed

to be left unconnected.

CLKDIV 6

CLKDIV CLOCK RATE

GND XTALIN/4

VDD/3 XTALIN

VDD x 2/3 XTALIN/8

VDD XTALIN/2

Active-Low Interrupt Signal to the Processor. Multifunction indicating fault

conditions or card presence. Open-drain output configuration. This pin

OFF

20

includes an internal 22k pullup to V

DD.

RSTIN 1 Reset Input. This signal is the reset command to the card.

I/OUC 3 System Controller Data I/O to/from the Card. Includes a pullup resistor to V

C4UC 5 System Controller Data C4 to/from the Card. Includes a pullup resistor to V

C8UC 2 System Controller Data C8 to/from the Card. Includes a pullup resistor to V

DD.

DD.

DD.

Rev. 1.0 11

73S8014BN Demo Board User Manual UM_8014BN_069

3.3 73S8014BN Pinout (Top View)

Figure 4: 73S8014BN Pinout

12 Rev. 1.0

UM_8014BN_069 73S8014BN Demo Board User Manual

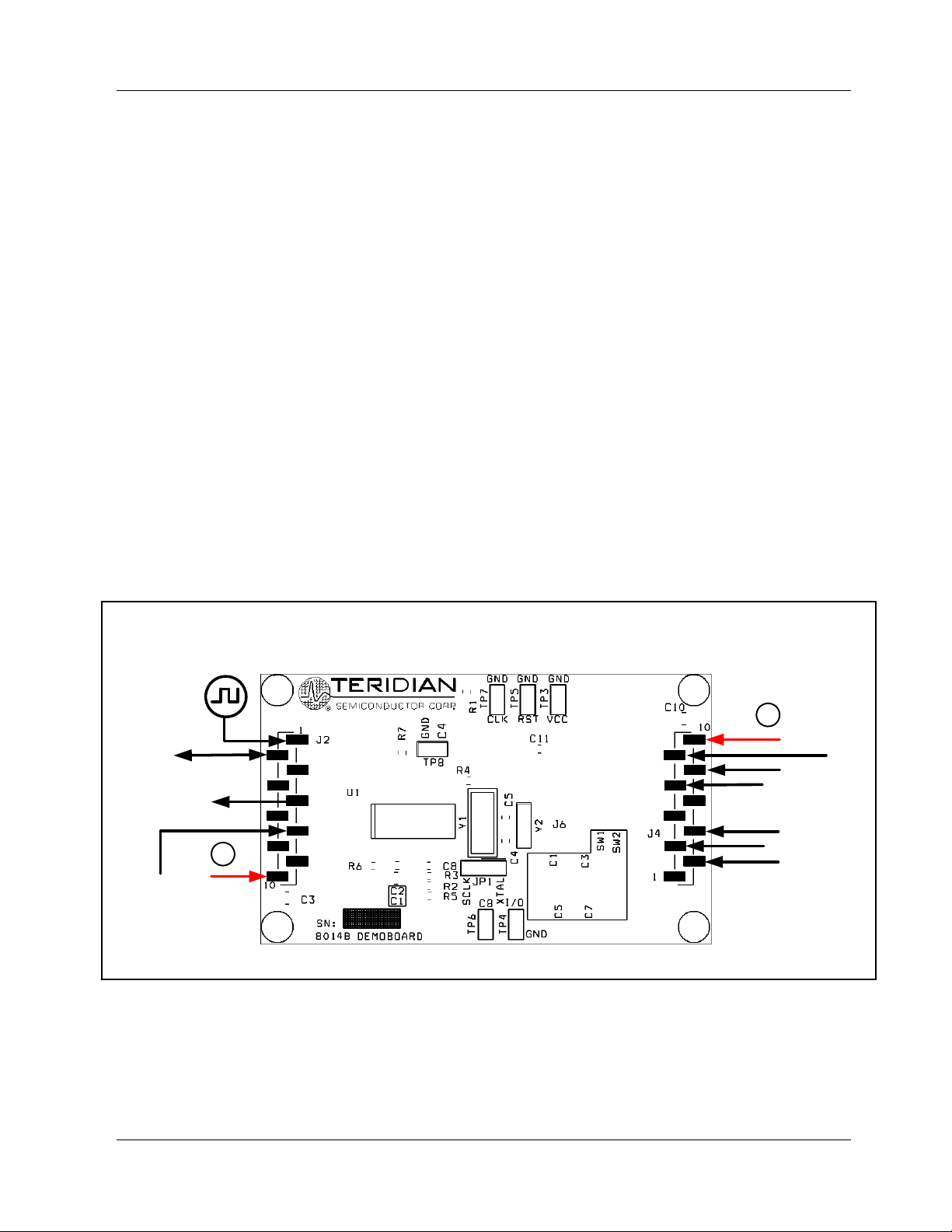

3.4 Schematic

J1

SCLK

OFFB

SSM_110_L_SV

TSM_110_01_L_SV

CLKDIV1

CLKDIV2

5V3VB

CMDVCCB

RSTIN

GND

+3.3V

SSM_110_L_SV

TSM_110_01_L_SV

J1 and J3 are placed on the bottom. J2 and J4

are placed on the top side.

J1 and J3 must be aligned with J8 and J9 on the

1121 evaluation board (E1121T8), respectively, in

order for this board to be stacked on it.

J1 must be aligned with J2 and J3 must be

aligned with J4 in order for this daughter

board to be stacked on another.

SIO

SC4

SC8

GND

GND

GND

+5V

+5V

1

2

3

4

5

6

7

8

9

10

J2

SCLK

1

SIO

2

S_C4

3

S_C8

4

INT2

5

6

7

8

5.0V

9

10

J3

1

2

3

4

5

6

7

8

9

10

J4

1

2

3

4

5

6

7

8

9

10

USR0

USR1

USR2

USR3

USR4

USR5

USR6

USR7

3.3V

C3

C10

10uF

+

10uF

+

(VDD)

3.3V

R5

100K

R2 1K

R3 2K

0.1uF

3.3V

C8

R6

1M

SCLK

When using external clock

source set JP1 for SCLK

and remove JP2. When

using crystal, set JP1

for XTAL.

JP1

XTALIN

SELECT

5.0V

XTAL

123

C1 10uF

+

C2 0.1uF

U1

1

RSTIN

2

C8UC

3

I/OUC

4

VPC

5

C4UC

6

CLKDIV

7

VDD

8

CMDVCC

9

5V/3V

10

XTALI N

73S8014BN

C4

22pF

C1, C2 and C8 must be placed

within 5mm of the U1 pins and

connected by thick track (wider

than 0.5mm)

OFF

PRES

VCC

CLK

GND

RST

C8

I/O

C4

XTALOUT

Y1 12.000MHz

12

Y2

1 2

3

Y2 is an optional

footprint for a

ceramic resonator

20

19

18

17

16

15

14

13

12

11

C5

22pF

I/O

C8

(VDD)

3.3V

R7

R4

0

TP4

1

2

TP6

1

2

R1

100K

4

8

5

7

6

10

C4

C8

I/O

VPP

GND

SW-19SW-2

J5

Smart C ard C onnec t or

0

TP3

1

VCC

2

TP5

1

2

TP7

1

2

TP8

1

2

1

3

2

CLK

RST

VCC

C12

27pF

Capacitors C11, C12 and C13

should be placed very close

to the pads of J5

RST

CLK

C4

TP3 to TP8 should be

placed very close to

the pads of J5

C13

27pF

C11

1uF

8

6

SW17SW2

J6

SI M/SAM C onnec t or

Figure 5: Teridian 73S8014BN Demo Board: Electrical Schematic

C11C22C33C54C65C7

Rev. 1.1 13

73S8014BN Demo Board User Manual UM_8014BN_069

3.5 Bill of Materials

Table 6: Teridian 73S8014BN Demo Board: Bill of Materials

QTY REFERENCE PART PCB FOOTPRINT

3 C1, C3, C10

2 C2, C8

2 C4, C5 22pF, 50V SMD ceramic capacitors (0603) 603 PCC220ACVCT-ND ECJ-1VC1H220J Panasonic

1 C11

2 C12, C13 27pF, 50V SMD ceramic capacitors (0603) 603 PCC270ACVCT-ND ECJ-1VC1H270J Panasonic

2 J1, J3 10-pin SMD connectors SSM_110_L_SV N/A SSM_110_L_SV Samtec

2 J2, J4 10-pin SMD connectors TSM_110_01_L_SV N/A TSM_110_01_L_SV Samtec

1 J5

1 J6

1 JP1 3-pin header 3 pins, 2.54mm pitch S1011E-36-ND PZC36SAAN

2 R1, R5

1 R2

1 R3

2 R4, R7

1 R6

6 TP3–TP8 2-pin headers (test points) 2 pins, 2.54mm pitch S1011E-36-ND PZC36SAAN

1 Y1 12.000MHz, 20pF 49US crystal HC-49US X1116-ND ECS-120-20-4XDN ECS, Inc.

0 Y2 Not installed, crystal N/A N/A N/A N/A

1 U1 Smart card interface 20 SO N/A 73S8014BN-IL/F

10F, 6.3V X5R ceramic capacitors (0805)

0.1F, 16V X7R ceramic capacitors (0603)

1F, 6.3V X5R ceramic capacitor (0603)

8-pin smart card SMD connector with 2-pin

switch

6-pin SIM/SAM smart card SMD connector with

2-pin switch

100k 5%, 1/10W SMD resistors (0603)

1k 5%, 1/10W SMD resistor (0603)

2k 5%, 1/10W SMD resistor (0603)

0 5%, 1/10W SMD resistors (0603)

1M 5%, 1/10W SMD resistor (0603)

805 PCC2225CT-ND ECJ-2FB0J106M Panasonic

603 PCC1762CT-ND ECJ-1VB1C104K Panasonic

603 PCC1915CT-ND ECJ-1VB0J105K Panasonic

CCM02-2504 401-1715-ND CCM02-2504LFT C&K Components

ITT_CCM03-3013 401-1726-2-ND CCM03-3754 R102 C&K Components

603 P100KGCT-ND ERJ-3GEYJ104V Panasonic

603 P1.0KGCT-ND ERJ-3GEYJ102V Panasonic

603 P2.0KGCT-ND ERJ-3GEYJ202V Panasonic

603 P0.0GCT-ND ERJ-3GEY0R00V Panasonic

603 P1.0MGCT-ND ERJ-3GEYJ105V Panasonic

DIGI-KEY PART

NUMBER

PART NUMBER MANUFACTURER

Sullins Connector

Solutions

Sullins Connector

Solutions

Teridian

Semiconductor

14 Rev. 1.1

UM_8014BN_069 73S8014BN Demo Board User Manual

3.6 PCB Layouts

Figure 6: Teridian 73S8014BN Demo Board: Top View

Figure 7: Teridian 73S8014BN Demo Board: Bottom View

Rev. 1.0 15

73S8014BN Demo Board User Manual UM_8014BN_069

Figure 8: Teridian 73S8014BN Demo Board: Top Signal Layer

Figure 9: Teridian 73S8014BN Demo Board: Middle Layer 1, Ground Plane

16 Rev. 1.0

UM_8014BN_069 73S8014BN Demo Board User Manual

Figure 10: Teridian 73S8014BN Demo Board: Middle Layer 2, Supply Plane

Figure 11: Teridian 73S8014BN Demo Board: Bottom Signal Layer

Rev. 1.0 17

73S8014BN Demo Board User Manual UM_8014BN_069

4 Demo Board Errata

The VCC output supply when operating at 1.8V requires a minimum 20k load resistor to ground for

output voltage stability. The demo board does not contain a footprint for this resistor. If using V

this resistor must be added to provide proper output voltage stability.

= 1.8V

CC

5 Ordering Information

PART DESCRIPTION ORDERING NUMBER

73S8014BN Demo Board 73S8014BN-EVK

6 Contact Information

For more information about Maxim products or to check the availability of the 73S8014BN, contact

technical support at www.maxim-ic.com/support

.

18 Rev. 1.0

Loading...

Loading...