Terex Z-33 Operator's Manual

1.

Operator's Manual

Serial number range

Z ®-33

DC Power

from Z3318M-2801

ANSI/CSA

North America

South America

Asia

with

Maintenance

Information

Second Edition

First Printing

Part No. 1287493GT

Operator's Manual

Second Edition • First Printing

Contents

Introduction .......................................................... 1

Symbol and Hazard Pictorials Definitions............ 5

General Safety..................................................... 7

Personal Safety ................................................. 13

Work Area Safety .............................................. 14

Legend............................................................... 21

Controls ............................................................. 22

Inspections ........................................................ 27

Operating Instructions ....................................... 40

Transport and Lifting Instuctions ....................... 47

Maintenance ...................................................... 50

Specifications .................................................... 52

TEREX Global GmbH

Bleicheplatz 2

8200 Schaffhausen

Switzerland

Technical Assistance Service

Telephone: +39 075 9418129

+39 075 9418175

e-mail: UMB.Service@terex.com

II Z®-33 Part No. 1287493GT

Copyright © 2018 by Terex Corporation

Second Edition: First Printing, October 2019

Genie and "Z" are registered trademarks of Terex South

Dakota, Inc. in the U.S.A. and many other countries.

These machines comply with

ANSI/SAIA A 92.20

CAN/CSA B354.6

Second Edition • First Printing

Operator's Manual

Introduction

About this manual

Genie appreciates your choice of our machine for

your application. Our number one priority is user

safety, which is best achieved by our joint efforts.

This book is an operation and daily maintenance

manual for the user or operator of a Genie

machine.

This manual should be considered a permanent

part of your machine and should remain with the

machine at all times. If you have any questions,

contact Genie.

Product Identication

The machine serial number is located on the serial

label.

Serial label

(located under cover)

Sequence number

stamped on chassis

Intended Use and Familiarization

Guide

The intended use of this machine is to lift

personnel, including tools, and materials to an

aerial work site. Before operating the machine, it’s

the operator’s responsibility to read and

understand this familiarization guide.

Each person must be trained to operate a

MEWP.

Familiarization with the MEWP must be given

to each person who is authorized, competent

and trained.

Only trained and authorized personnel should

be permitted to operate the machine.

The operator is responsible to read,

understand, and obey the manufacturer’s

instructions and safety rules provided in the

Operator’s Manual.

The Operator’s Manual is located in the manual

storage container, at the platform.

For specific product applications, see

Contacting The Manufacturer.

Part No. 1287493GT Z®-33 1

Operator's Manual

Introduction

Second Edition • First Printing

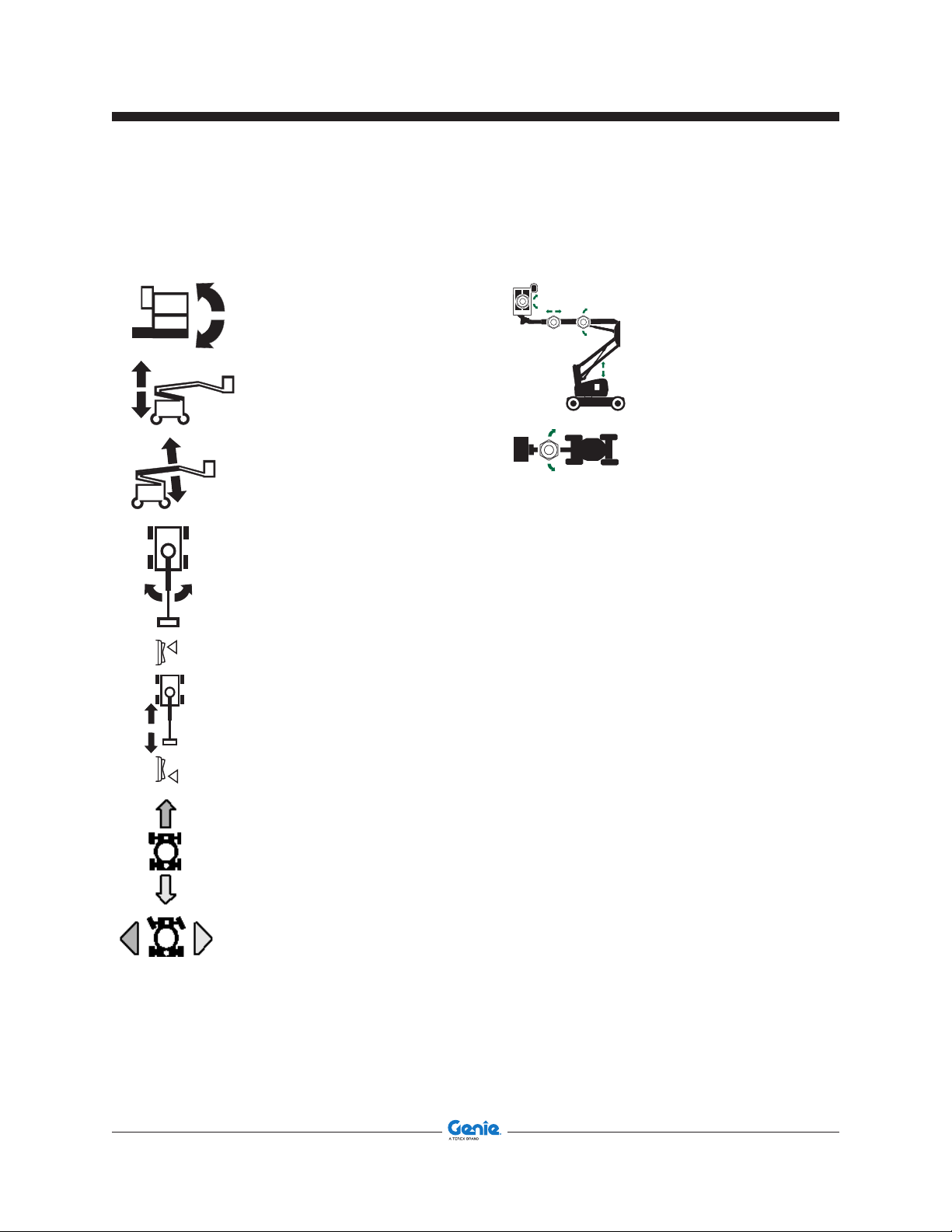

Platform controls symbology and

related machine movement:

Platform level

Secondary boom up/

down

Primary boom up/

down

Turntable rotate

Boom extend/

retract

Ground controls symbology and

related machine movement:

Platform level,

primary boom

extend/retract,

primary boom up/

down, secondary

boom up/down

Turntable rotate

Sequential functions and movement:

• Drive and steer.

Interlocked functions:

• Elevated drive speed.

• Elevated drive in an off-level condition.

• Drive enable when the boom is rotated past the

non-steer wheels.

Limitation of use:

• The intended use of this machine is to lift

personnel, including tools, and materials to an

aerial work site.

• Do not elevate the platform unless the machine

Drive forward/

reverse

Steer right/left

2 Z®-33 Part No. 1287493GT

is on a firm level ground.

Second Edition • First Printing

Operator's Manual

Introduction

Bulletin Distribution and

Compliance

Safety of product users is of paramount

importance to Genie. Various bulletins are used

by Genie to communicate important safety and

product information to dealers and machine

owners.

The information contained in the bulletins is tied to

specific machines using the machine model and

serial number.

Distribution of bulletins is based on the most

current owner on record along with their

associated dealer, so it is important to register

your machine and keep your contact information

up to date.

To ensure safety of personnel and the reliable

continued operation of your machine, be sure to

comply with the action indicated in a respective

bulletin.

To view any open bulletins for your machine, visit

us on the web at www.genielift.com.

Contacting the Manufacturer

At times it may be necessary to contact Genie.

When you do, be ready to supply the model

number and serial number of your machine,

along with your name and contact information. At

minimum, Genie should be contacted for:

Accident reporting

Questions regarding product applications and

safety

Standards and regulatory compliance information

Current owner updates, such as changes in

machine ownership or changes in your contact

information. See Transfer of Ownership, below.

Transfer of Machine Ownership

Taking a few minutes to update owner information

will ensure that you receive important safety,

maintenance and operating information that

applies to your machine.

Please register your machine by visiting us on the

web at www.genielift.com or by calling us toll free

at 1-800-536-1800.

Part No. 1287493GT Z®-33 3

Operator's Manual

DANGER

WARNING

CAUTION

NOTICE

Introduction

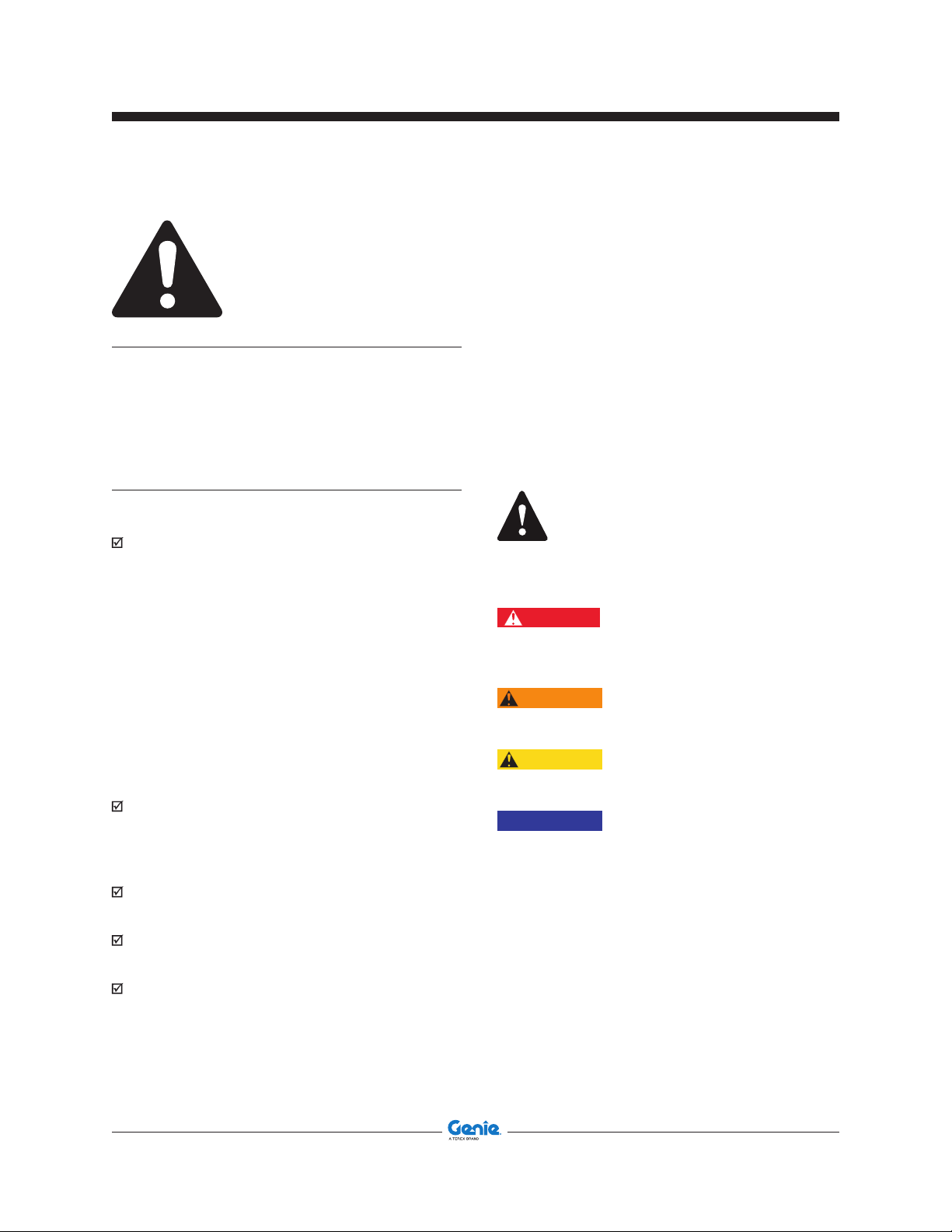

Danger

Second Edition • First Printing

Safety Sign Maintenance

Replace any missing or damaged safety signs.

Keep operator safety in mind at all times. Use

mild soap and water to clean safety signs. Do not

use solvent-based cleaners because they may

damage the safety sign material.

Failure to obey the instructions and

safety rules in this manual will result

in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

Know and understand the safety rules before

going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer’s instructions and safety

rules–safety and operator’s manuals and

machine decals.

Hazard Classication

Decals on this machine use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to

alert personnel to potential

personal injury hazards. Obey

all safety messages that follow

this symbol to avoid possible

injury or death.

Indicates an imminently

hazardous situation which, if

not avoided, will result in death

or serious injury.

Indicates a hazardous situation

which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation

which, if not avoided, may

cause minor or moderate injury.

Indicates a property damage

message.

You read, understand and obey employer’s

safety rules and work site regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.

4 Z®-33 Part No. 1287493GT

Second Edition • First Printing

12.5 m/sec

12.5 m/sec

c

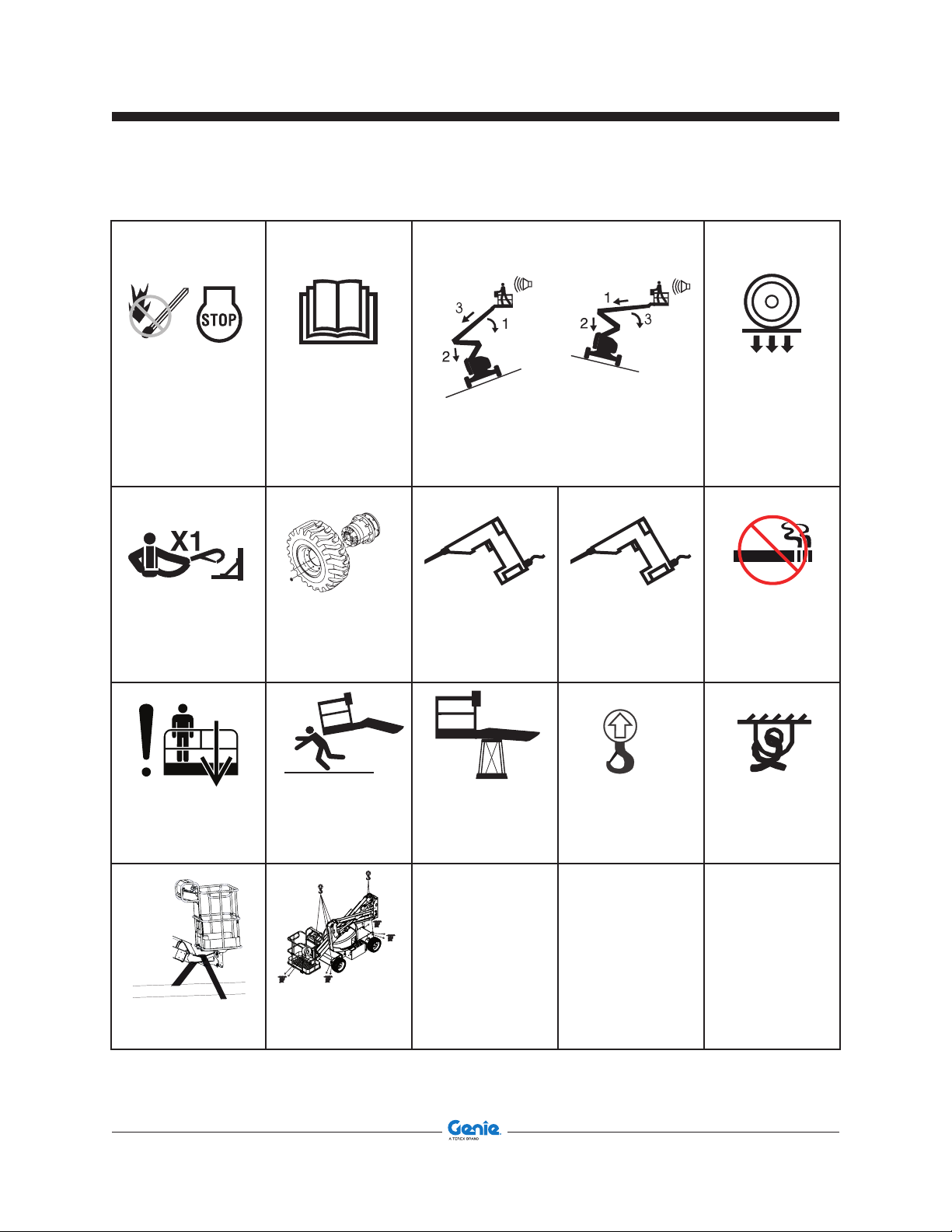

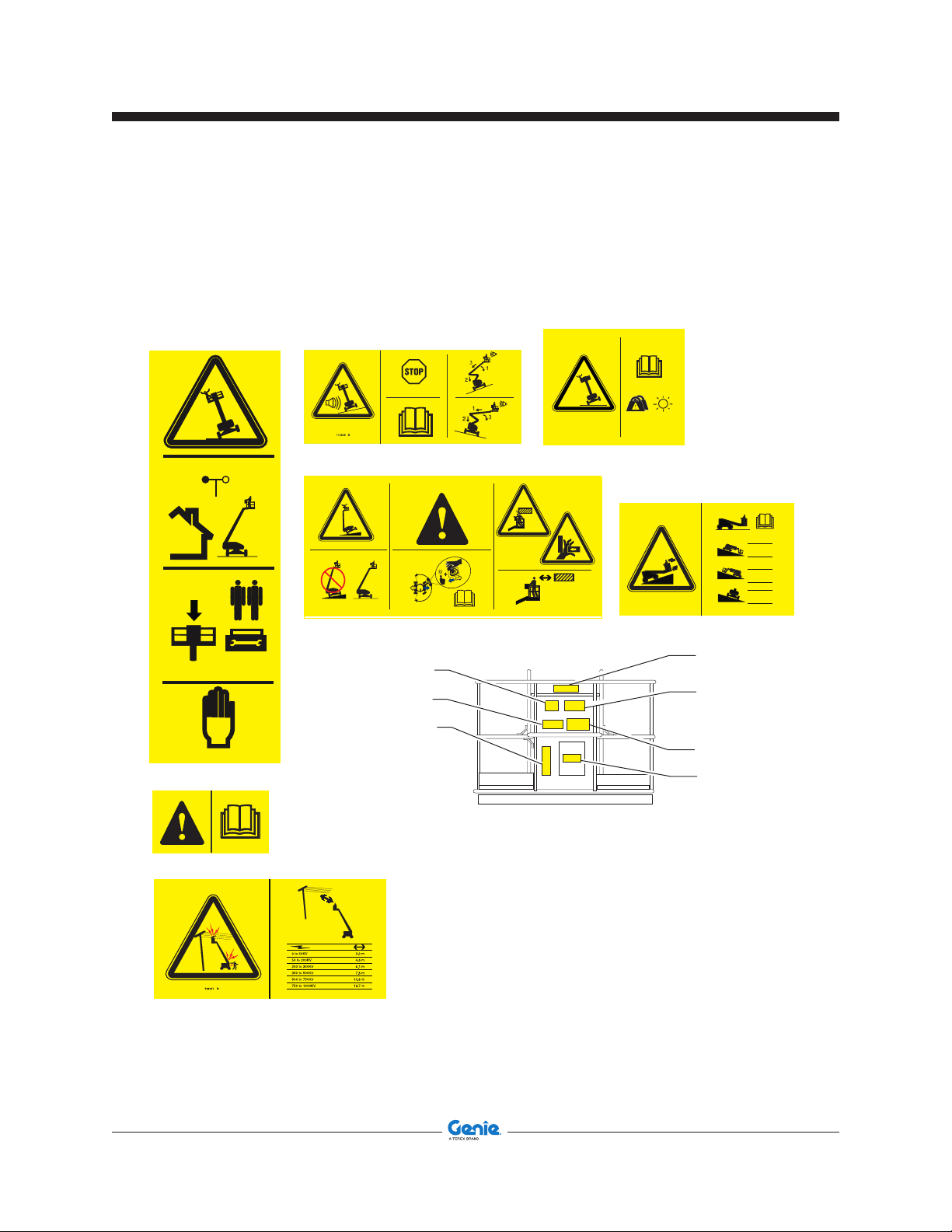

Symbol and Hazard Pictorials Denitions

Operator's Manual

Crush hazard Explosion hazard Collision hazard Collision hazard Runaway Hazard

Tip-over hazard Tip-over hazard Raise platform on

firm, level surface

12.5 m/se

Electrocution

hazard

Maintain required

clearance

Color Coded

Direction Arrows

Maximum capacity Wind speed Manual force

Access by trained

and authorized

personnel only

Electrocution

hazard

Part No. 1287493GT Z®-33 5

Grounded AC

3-wire outlet only

Replace damaged

wires and cords

Batteries used as

Burn hazard

counterweight

12.5 m/sec

12.5 m/sec

12.5 m/sec

12.5 m/sec

12.5 m/sec

Operator's Manual

Symbol and Hazard Pictorials Denitions

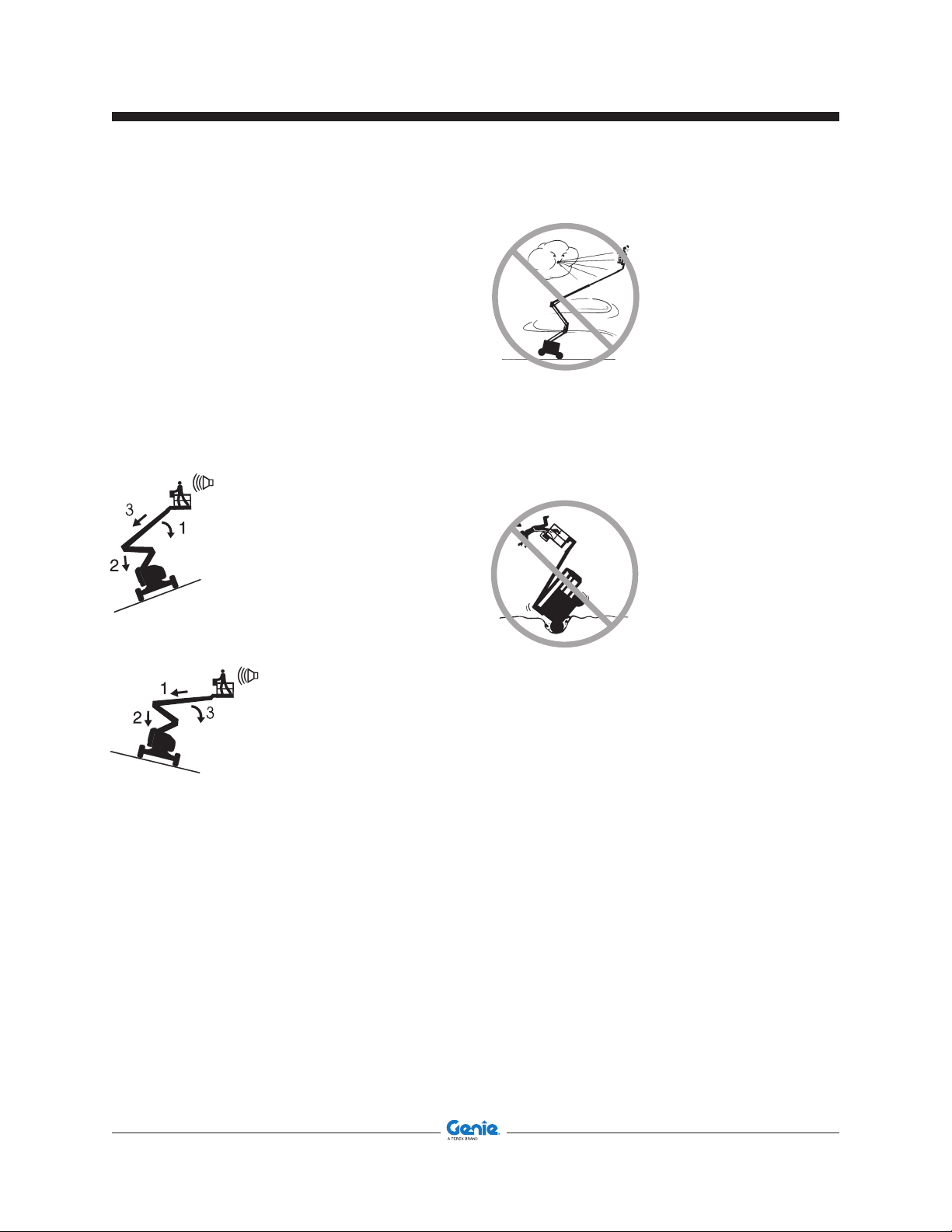

Recovery procedure if tilt alarm sounds

while elevated.

No smoking

No flame

Stop engine

Read the

operator’s

manual

Platform uphill:

1 Lower primary

2 Lower secondary

3 Retract primary

Platform downhill:

1 Retract primary

2 Lower secondary

3 Lower primary

Second Edition • First Printing

Wheel load

Lanyard anchorage

point

Emergency lowering Crush hazard Support the platform

Replace tires with

tires of same

specification.

Voltage rating for

power to platform

or boom during

maintenance

Pressure rating for

air line to platform

Lifting point

No smoking

Tie-down point

Platform tie-down

instructions

Lifting & tie-down

instructions

6 Z®-33 Part No. 1287493GT

Second Edition • First Printing

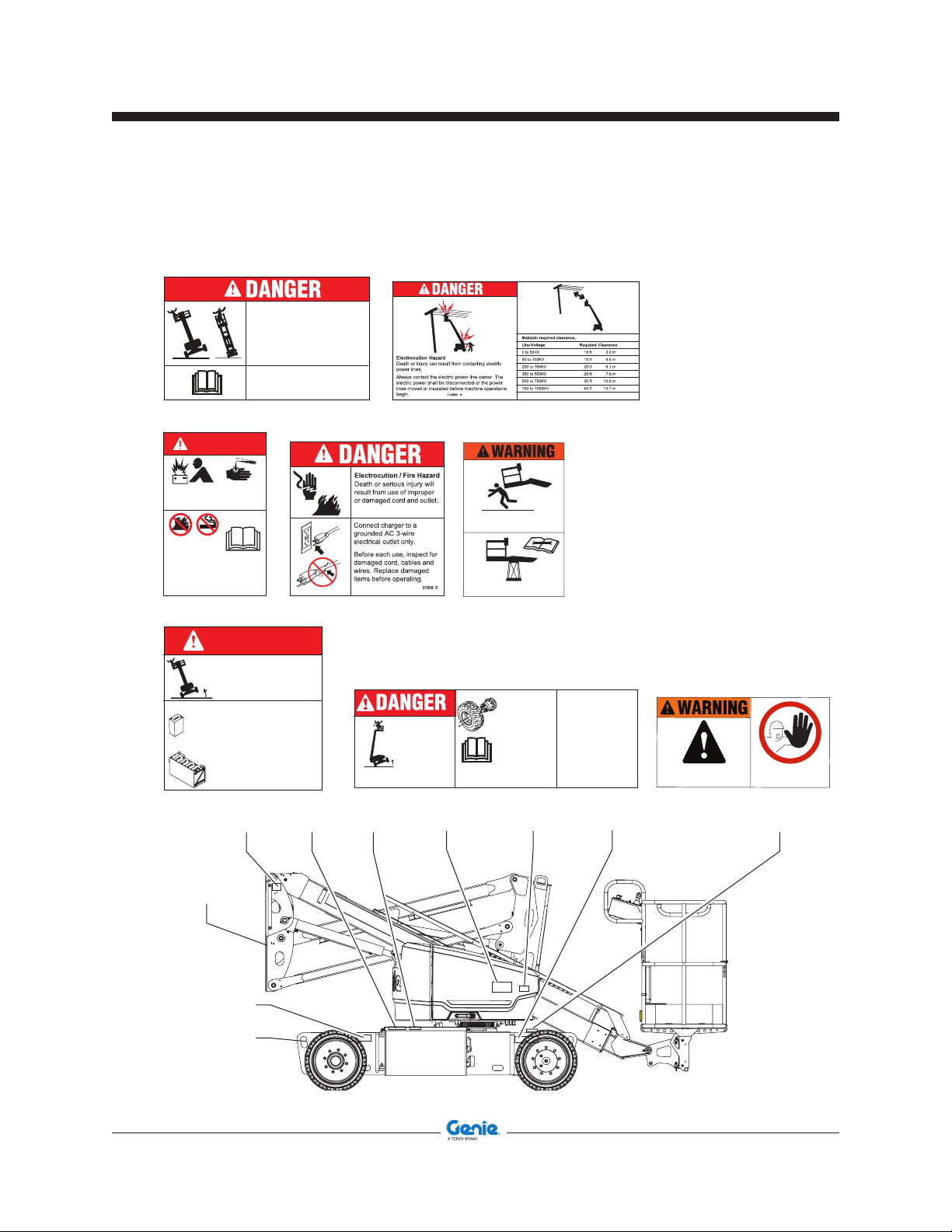

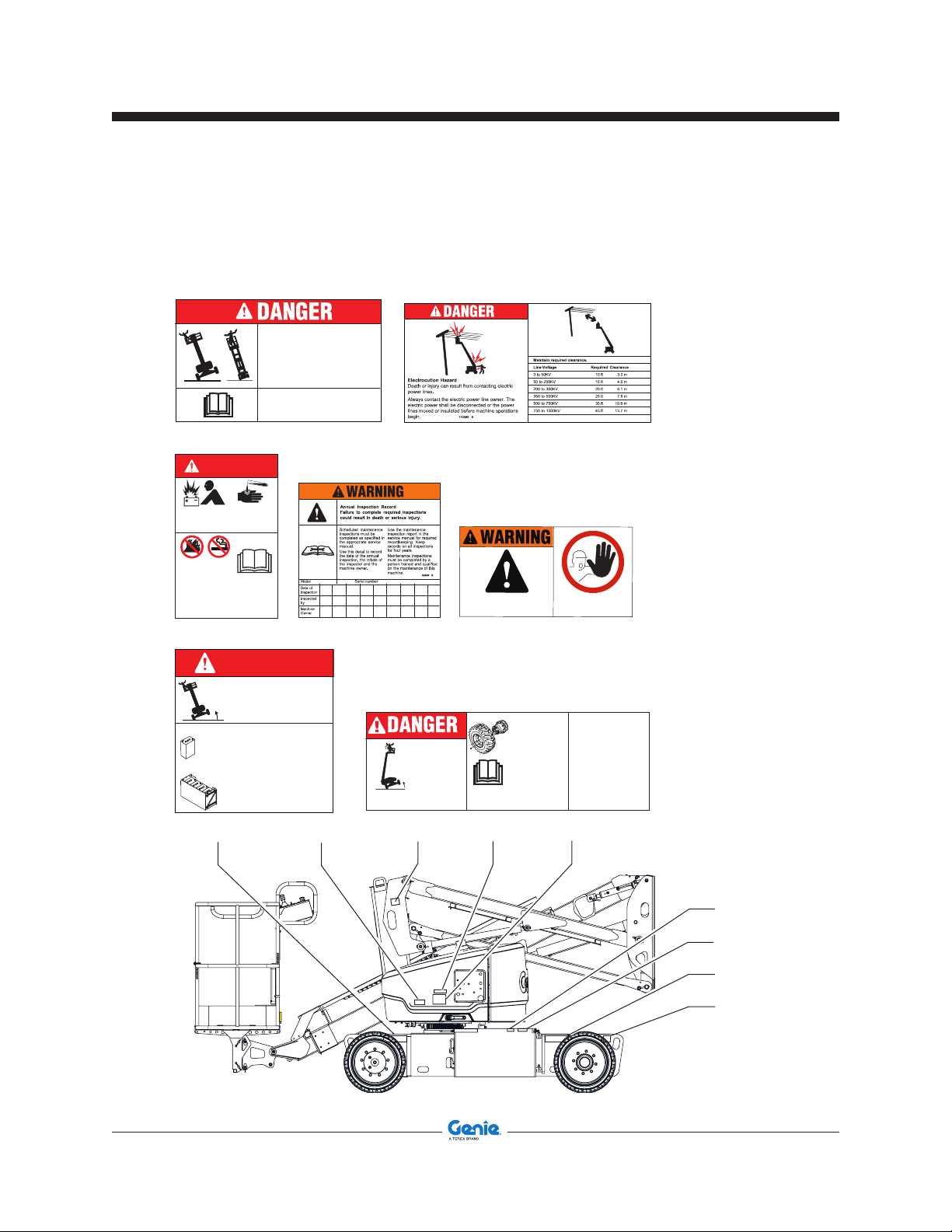

Safety Signs and Locations

Operator's Manual

General Safety

31060

31788

DANGER

Explosion/Burn Hazard

Battery explosion and/or contact with

corrosive acid will result in death or serious

injury.

Keep all open flames

and sparks away.

Wear appropriate personal protective

equipment, including gloves, face shield

and long sleeve shirt.

Read manuals. If you do not understand

the information in the manuals, consult your

supervisor, the owner or the manufacturer.

31788 D

31787

DANGER

Tip-over Hazard

Tipping over this machine

will result in death or

serious injury.

Minimum battery weight:

≥ 105 lbs / 47.6 kg

Minimum battery box weight:

≥ 530 lbs / 240.4 kg

Tip-over Hazard

Altering or disabling limit

switches can result in machine

tip-over. Machine tip-over will

result in death or serious injury.

Do not alter or disable limit

switch(s).

31060 C

31508

1261933

31787 G

114390

Tip-over Hazard

Tipping over this

machine will

result in death or

serious injury.

1267121

Crush Hazard

Contact with moving work platform or

boom can result in death or serious injury.

Securely brace work platform or boom

during maintenance.

Do not replace

factory installed

tires with tires of

a different

specification or

ply rating

1267121 A

Solid Rubber NM Tires

Tire size: 22x9x17

Tire Contact Pressure

70 psi / 483 kPa

Wheel Lug Torque

Dry: 125 ft-lbs / 169 Nm

Lubricated: 94 ft-lbs /

127 Nm

1261933 B

1263543

Improper operation or maintenance o f

this equipment can result in death or

serious injury.

Access by trained and

authorized personnel only.

1263543 A

31060

3178731788

114390

1263543

1261933

31060

1267121

1261933

31508

Part No. 1287493GT Z®-33 7

Operator's Manual

General Safety

Safety Signs and Locations

Second Edition • First Printing

31060

31788

DANGER

Explosion/Burn Hazard

Battery explosion and/or contact with

corrosive acid will result in death or serious

injury.

Keep all open flames

and sparks away.

Wear appropriate personal protective

equipment, including gloves, face shield

and long sleeve shirt.

Read manuals. If you do not understand

the information in the manuals, consult your

supervisor, the owner or the manufacturer.

31788 D

31787

DANGER

Tip-over Hazard

Tipping over this machine

will result in death or

serious injury.

Minimum battery weight:

≥ 105 lbs / 47.6 kg

Minimum battery box weight:

≥ 530 lbs / 240.4 kg

Tip-over Hazard

Altering or disabling limit

switches can result in machine

tip-over. Machine tip-over will

result in death or serious injury.

Do not alter or disable limit

switch(s).

31060 C

52865

1261933

31787 G

114390

Tip-over Hazard

Tipping over this

machine will

result in death or

serious injury.

1263543

Improper operation or maintenance o f

this equipment can result in death or

serious injury.

Do not replace

factory installed

tires with tires of

a different

specification or

ply rating

Access by trained and

authorized personnel only.

1263543 A

Solid Rubber NM Tires

Tire size: 22x9x17

Tire Contact Pressure

70 psi / 483 kPa

Wheel Lug Torque

Dry: 125 ft-lbs / 169 Nm

Lubricated: 94 ft-lbs /

127 Nm

1261933 B

1261933

1263543

31060

1143901280819

31787

31788

1261933

52865

8 Z®-33 Part No. 1287493GT

Second Edition • First Printing

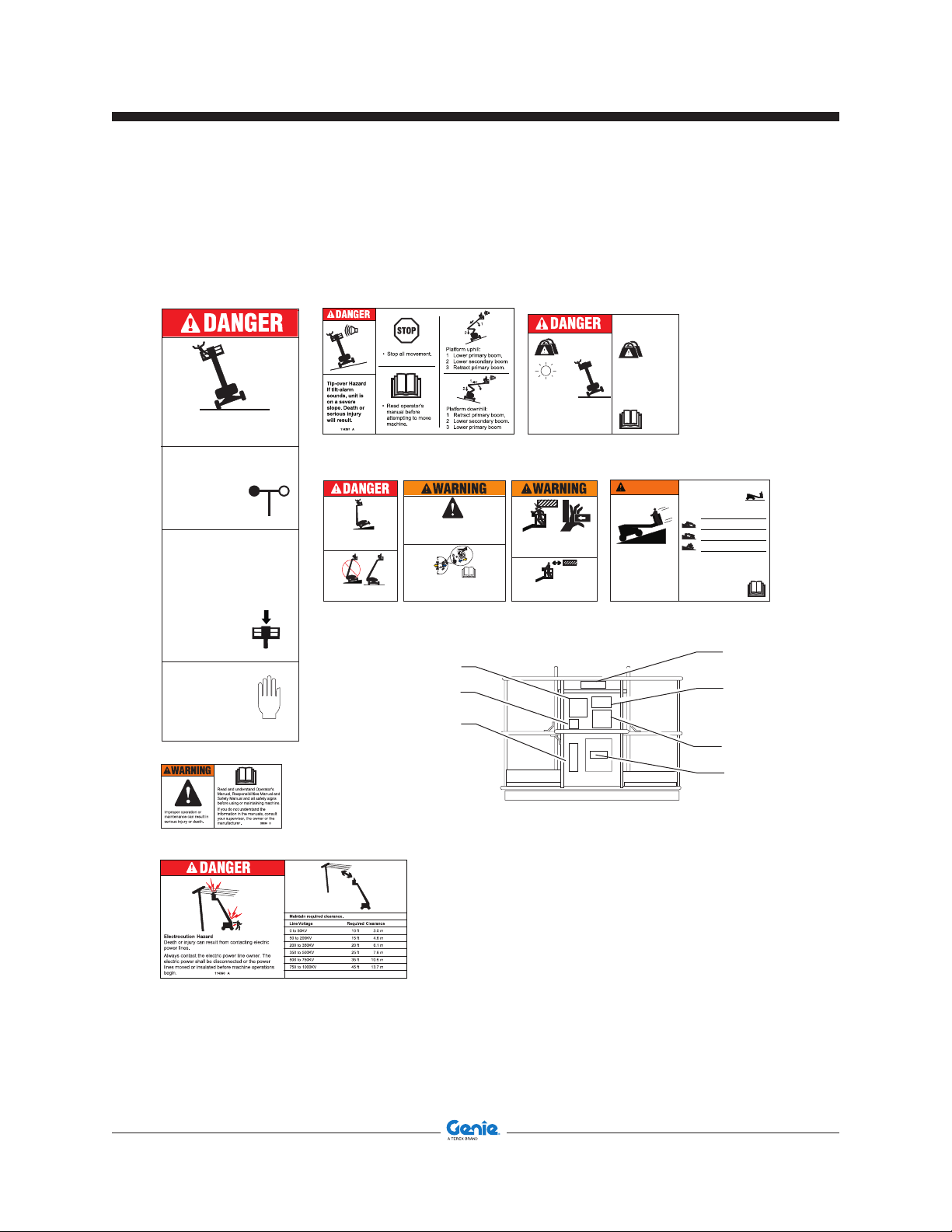

Safety Signs and Locations

Operator's Manual

General Safety

1261934

Tip-over Hazard

Tipping over the machine will result

in death or serious injury.

Maximum

allowable wind

speed:

28 mph /

12.5 m/sec

Maximum Capacity:

441 lbs / 200 kg

Occupants and

equipment must not

exceed

441 lbs / 200 kg

Maximum

Occupants: 2

Maximum

Allowable

Manual Force:

150 ft lbs / 667 N

28236

1261934 A

114397

218559

Tip-over Hazard

Tipping over this machine will

result in death or serious injury.

Only raise the platform when the

machine is on a firm, level

Drive Direction Hazard

Machine can move in opposite direction of

joystick movement. Movement in an unplanned

direction can result in death or serious injury.

Always match the color-coded direction arrows

on platform controls and drive chassis to

determine direction of machine travel. Read

surface.

and understand operator's manual.

1262132

219487

1261934

219487

3

Crush Hazard

Contact with overhead obstructions

could result in death or serious injury.

Keep away from overhead obstructions

or other possible hazards.

2198

Tip-over Hazard

Do not overload platform.

Platform overload will result in

death or serious injury.

218559 A

Platform Overload

Indicator Light

Light flashing

indicates

the platform

is overloaded.

The engine

will stop and no functions will

operate.

Remove weight from the

platform until the light goes off

and then restart the engine.

219487 A

1262132

WARNING

Runaway Hazard

Machine movement can occur

when machine is operated on

a slope that exceeds rated

uphill, downhill or side slope

rating. A runaway machine

could result in death or

serious injury.

Driving on a Slope

Do not drive machine on a slope

that exceeds maximum uphill,

downhill or side slope rating.

Determine slope and side slope ratings for

and determine slope grade.

Maximum slope rating, platform

(gradeability)

downhill

Maximum slope rating,

platform uphill 20% (11°)

Maximum side slope rating

Note: Slope rating is subject to ground

conditions and adequate traction. Gradeability

applies to platform downhill configuration only.

Be sure boom is below horizontal

and platform is between non-steer

wheels.

Move drive speed select switch to

machine on incline symbol.

30% (17°)

25% (14°)

1262132 A

3

218559

114390

114397

28236

114390

119

Part No. 1287493GT Z®-33 9

Operator's Manual

General Safety

Safety Signs and Locations

Second Edition • First Printing

114252

114334

114345

133067

82481

114249

82481 D

1286362

1286362A

126342

1263542

1263542 A

114252

11434582481

133067

1263542 114249

126342

11424

114252

1286362

114249

114334

10 Z®-33 Part No. 1287493GT

Second Edition • First Printing

82487

Safety Signs and Locations

Operator's Manual

General Safety

114252

114345

114249

82487 D

114252

82481

114249

1263542

82481

133067

133067

1263542

1263542 A

82487

114345

82481

114249

Part No. 1287493GT Z®-33 11

Operator's Manual

General Safety

Safety Signs and Locations

1258501

114248

Second Edition • First Printing

219956

219956 A

12.5 m/sec

200 kg

82487

133067

400 N

+

< =

200 kg

82487 D

1258501 A

219958

219956

114248

1258501

219958 A

1261869

30% (17°)

20% (11°)

25% (14°)

219958

1261869

133067

82487

1261869 A

12 Z®-33 Part No. 1287493GT

Second Edition • First Printing

Personal Fall Protection

Personal fall protection equipment (PFPE) is

required when operating this machine.

Occupants must wear a safety belt or harness in

accordance with governmental regulations. Attach

the lanyard to the anchor provided in the platform.

Operators must comply with employer, job site and

governmental rules regarding the use of personal

protective equipment.

All PFPE must comply with applicable

governmental regulations, and must be

inspected and used in accordance with the PFPE

manufacturer’s instructions.

Operator's Manual

Personal Safety

Part No. 1287493GT Z®-33 13

Operator's Manual

Work Area Safety

Second Edition • First Printing

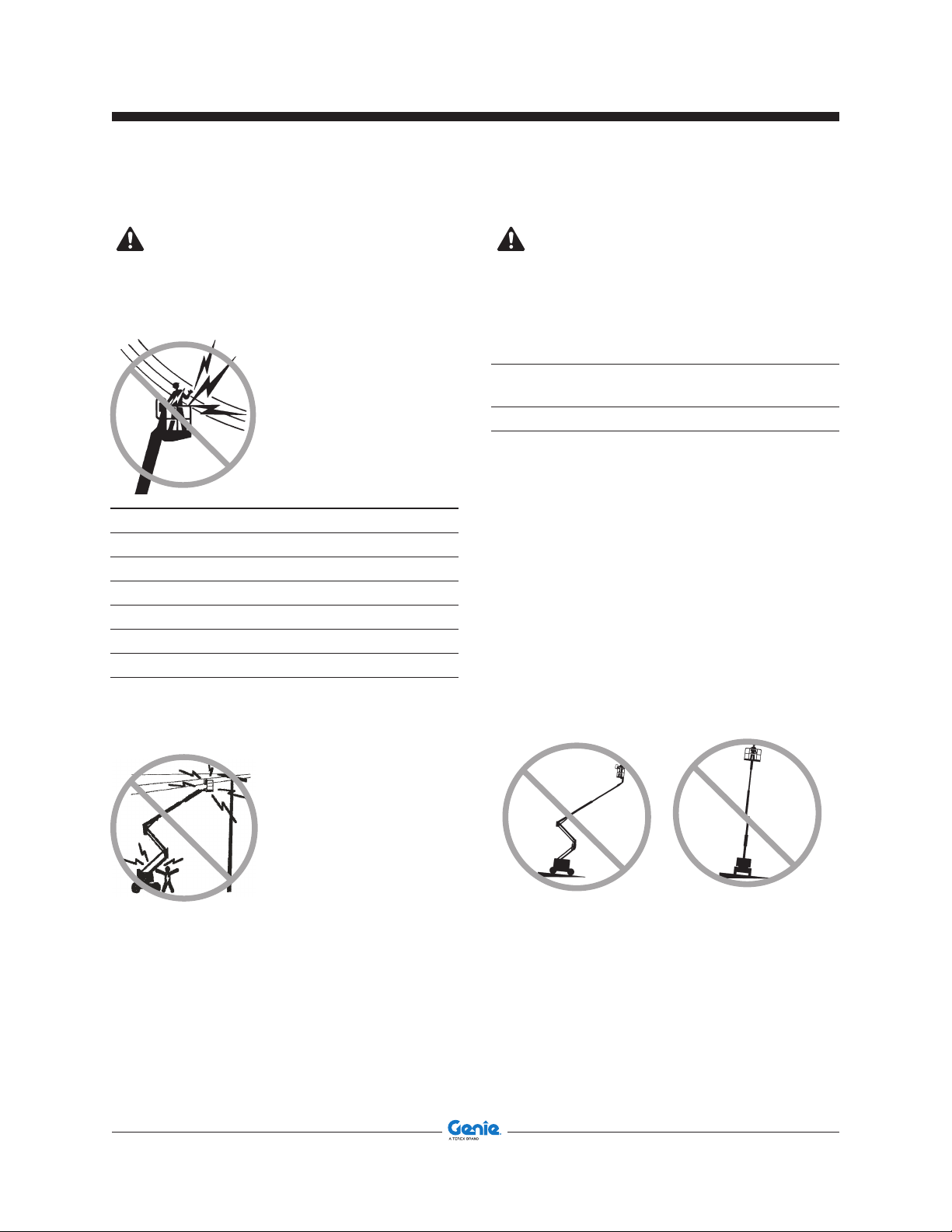

Electrocution Hazards

This machine is not electrically insulated and will not

provide protection from contact with or proximity to

electrical current.

ì Obey all local and

governmental regulations

regarding required

clearance from electrical

power lines. At a minimum,

the required clearance

contained in the chart

below must be followed.

Line Voltage Required Clearance

0 to 50KV 10 ft 3.05 m

50 to 200KV 15 ft 4.60 m

200 to 350KV 20 ft 6.10 m

350 to 500KV 25 ft 7.62 m

500 to 750KV 35 ft 10.67 m

750 to 1000KV 45 ft 13.72 m

Allow for platform movement, electrical line sway

or sag, and beware of strong or gusty winds.

Tip-over Hazards

Occupants, equipment and materials shall not

exceed the maximum platform capacity or the

maximum platform capacity of the platform

extension.

Maximum platform capacity

Maximum occupants 2

The weight of options and accessories, such

as pipe cradles, panel cradles and welders, will

reduce the rated platform capacity and must be

subtracted from the platform capacity. See the

decals with the options and accessories.

If using accessories, read, understand and obey

the decals, instructions and manuals with the

accessory.

Do not alter or disable the limit switches.

Do not raise or extend the boom unless the

machine is on a firm, level surface.

440 lbs /

200 kg

Keep away from the

machine if it contacts

energized power lines.

Personnel on the ground

or in the platform must not

touch or operate the

machine until energized

power lines are shut off.

Do not operate the machine during lightning or

storms.

Do not use the machine as a ground for welding.

14 Z®-33 Part No. 1287493GT

Do not depend on the tilt alarm as a level indicator.

The tilt alarm sounds in the platform only when the

machine is on a severe slope.

Second Edition • First Printing

Operator's Manual

Work Area Safety

If the tilt alarm sounds while the boom is lowered:

do not extend, rotate or raise the boom above

horizontal. Move the machine to a firm, level

surface before raising the platform.

If the tilt alarm sounds when the platform is raised,

use extreme caution. The Machine Not Level

indicator light will come on and the drive function

in one or both directions will not operate. Identify

the condition of the boom on the slope as shown

below. Follow the steps to lower the boom before

moving to a firm, level surface. Do not rotate the

boom while lowering.

If the tilt alarm sounds with

the platform uphill:

1 Lower the primary

boom.

2 Lower the secondary

boom.

3 Retract the primary

boom.

If the tilt alarm sounds with

the platform downhill:

1 Retract the primary

boom.

2 Lower the secondary

boom.

3 Lower the primary

boom.

Do not raise the boom when

wind speeds may exceed

28 mph/12.5 m/s. If wind

speeds exceed 28 mph/12.5

m/s when the boom is

raised, lower the boom and

do not continue to operate

the machine.

Do not operate the machine in strong or gusty

winds. Do not increase the surface area of the

platform or the load. Increasing the area exposed

to the wind will decrease machine stability.

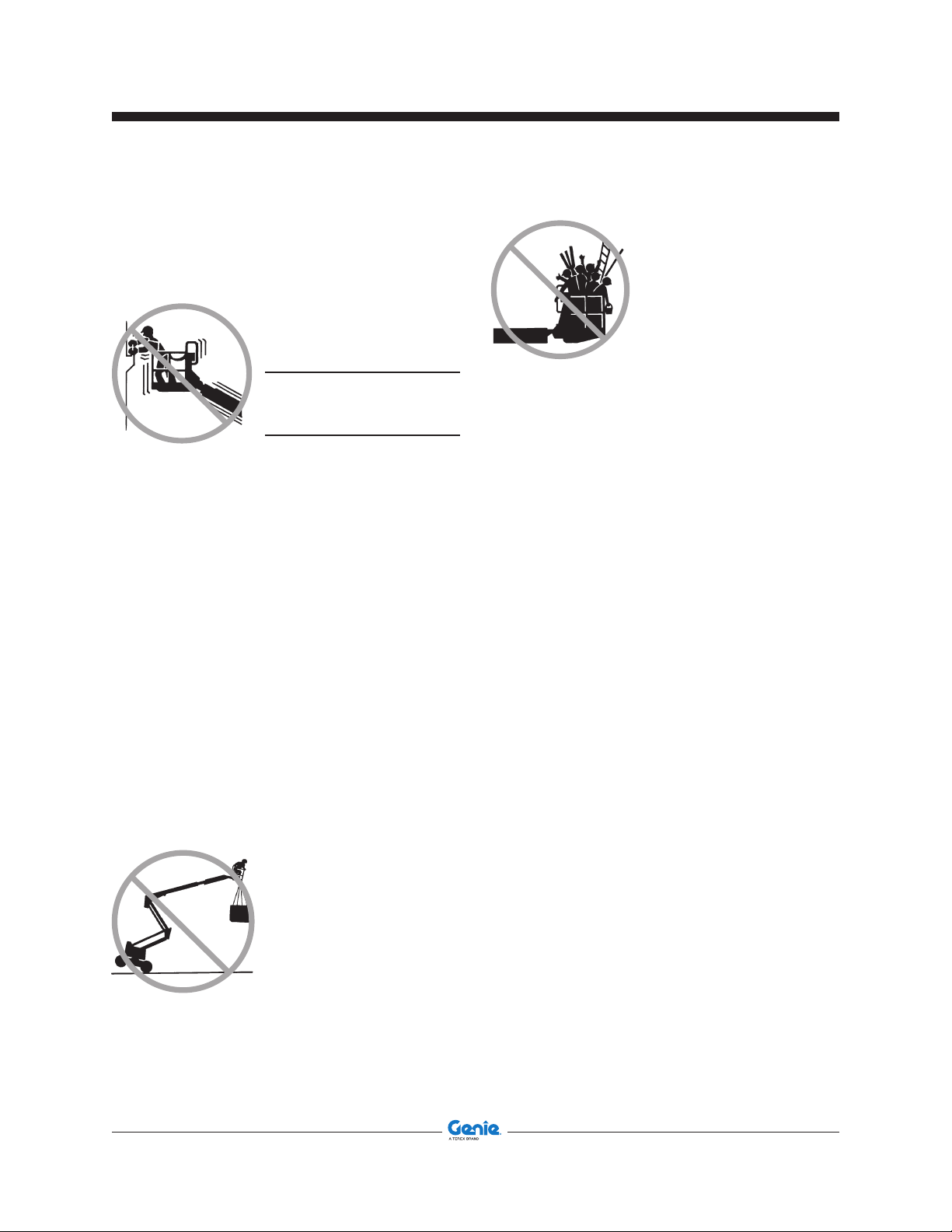

Use extreme care and

slow speeds while driving

the machine in the stowed

position across uneven

terrain, debris, unstable or

slippery surfaces and near

holes and drop-offs.

Do not drive the machine on or near uneven

terrain, unstable surfaces or other hazardous

conditions with the boom raised or extended.

Do not use the machine as a crane.

Do not push the machine or other objects with the

boom.

Do not contact adjacent structures with the boom.

-

Part No. 1287493GT Z®-33 15

Operator's Manual

Work Area Safety

Second Edition • First Printing

Do not tie the boom or platform to adjacent

structures.

Do not place loads outside the platform perimeter.

Do not push off or pull

toward any object outside of

the platform.

Maximum allowable

manual force

90 lbs / 400 N

Do not alter or disable machine components that

in any way affect safety and stability.

Do not replace items critical to machine stability

with items of different weight or specification.

Do not replace factory-installed tires with tires of

different specification or ply rating.

Do not use air-filled tires. These machines are

equipped with solid tires.

Wheel weight and proper counterweight

configuration are critical to stability.

Do not modify or alter an aerial work platform

without prior written permission from the

manufacturer. Mounting attachments for holding

tools or other materials onto the platform,

toeboards or guard rail system can increase the

weight in the platform and the surface area of the

platform or the load.

Do not place ladders or

scaffolds in the platform

or against any part of this

machine.

Do not transport tools and materials unless they

are evenly distributed and can be safely handled

by person(s) in the platform.

Do not use the machine on a moving or mobile

surface or vehicle.

Be sure all tires are in good condition and lug nuts

are properly tightened.

Do not use the platform controls to free a platform

that is caught, snagged or otherwise prevented

from normal motion by an adjacent structure. All

personnel must be removed from the platform

before attempting to free the platform using the

ground controls.

Do not use batteries that weigh less than the

original equipment. Batteries are used as

counterweight and are critical to machine stability.

Each battery must weigh a minimum of 105 lbs /

47.6 kg. Each battery box including batteries must

weigh a minimum of 530 lbs / 240.4 kg.

Do not place or attach

fixed or overhanging

loads to any part of this

machine.

16 Z®-33 Part No. 1287493GT

Loading...

Loading...