Terex TS14G, TS14F Maintenance Manual

TS14G

Overhung Scraper

Maintenance Manual

SM 1882 Rev 1 3-01

TECHNICAL PUBLICATIONS DEPARTMENT

TEREX EQUIPMENT LIMITED,

MOTHERWELL, SCOTLAND, ML1 5RY

REF. NO. 790

THIS PAGE IS INTENTIONALLY LEFT BLANK

Service

The information contained within this

Alert must not be made available to

third parties not authorised to receive it.

Information

Alert

DATE: April 1994 B168

MODEL: General

SUBJECT: VITON 'O' RINGS AND SEALS (FLUORO-ELASTOMERS) - SAFETY HAZARDS

PURPOSE:

To advise potentially hazardous condition.

DETAIL:

It has been brought to our attention that 'Viton' material used in manufacture of oil seals and 'O' rings, produces a

highly corrosive acid (Hydrofluoric) when subjected to temperatures above 315° C.

The resulting contamination can have extreme consequences on human tissue since it is almost impossible to

remove after contact.

We therefore recommend the following procedure when it is necessary to inspect any equipment that has been

subjected to a high temperature i.e. fire.

a. Visually inspect for any gaskets or seals which have suffered from heat; they will appear black and sticky.

b. If this is affirmed - Do Not Touch

c. Make enquiries to ascertain the material composition. Any Fluoro-elastomer (Viton, Fluorel or Tecmoflon)

should be considered dangerous but natural rubber and nitrile are non-hazardous.

d. If Fluoro-elastomer seals have been used, then the affected area MUST be decontaminated before

undertaking further work.

e. Disposable Heavy Duty Gloves (Neoprene) MUST be worn and the affected area decontaminated by washing

thoroughly with Limewater (Calcium Hydroxide solution).

f. Any cloths, residue and gloves used MUST be safely discarded after use.

Note: Burning of the discarded items is NOT RECOMMENDED, except in an approved incineration process

where the gaseous products are treated by alkaline scrubbing.

TEREX SERVICE DEPARTMENT

TEREX Equipment Limited, Motherwell, Scotland ML1 5RY Tel. (0698) 732121 Tlx. 77141 Fax. (0698) 734046

TEREX Division, Tulsa, Oklahoma, 74107 USA Tel. (918) 446-5581 Fax. (918) 446-9752

THIS PAGE IS INTENTIONALLY LEFT BLANK

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all motor vehicles. The service

procedures recommended and described in this publication, are effective methods for performing service

operations. Some of these service operations require the use of tools specially designed for the purpose.

The special tools should be used when, and as recommended.

It is important to note that this publication contains various WARNINGS and NOTES which should be

carefully read in order to minimize the risk of personal injury to personnel, or the possibility that improper

service methods will be followed which may damage the vehicle or render it unsafe. It is also important to

understand these WARNINGS and NOTES are not exhaustive. It is not possible to know, evaluate and

advise the service trade of ALL conceivable ways in which service might be carried out, or, of the

possible hazardous consequences of each way. Consequently, no such broad evaluation has been

undertaken. Accordingly, anyone who uses a service procedure, or tool, which is not recommended, must

first satisfy themselves thoroughly that neither their safety, nor vehicle safety, will be jeopardized by the

service method he/she selects.

Two types of heading are used in this manual to attract your attention.

1. WARNING - This symbol is used when an operating procedure, practice, etc., which, if not correctly

followed could result in personal injury or loss of life. Look for this symbol to point out important safety

precautions. It means - ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

2. Note - This is used when an operating procedure, practice, etc., which, if not strictly observed, could result in

damage to or destruction of equipment.

WARNING

Never use parts which are altered, modified, or weakened in operation. This can seriously

jeopardize the integrity of the machine and could result in property damage or serious personal

injury.

SM 222 Rev 1 9-93

THIS PAGE IS INTENTIONALLY LEFT BLANK

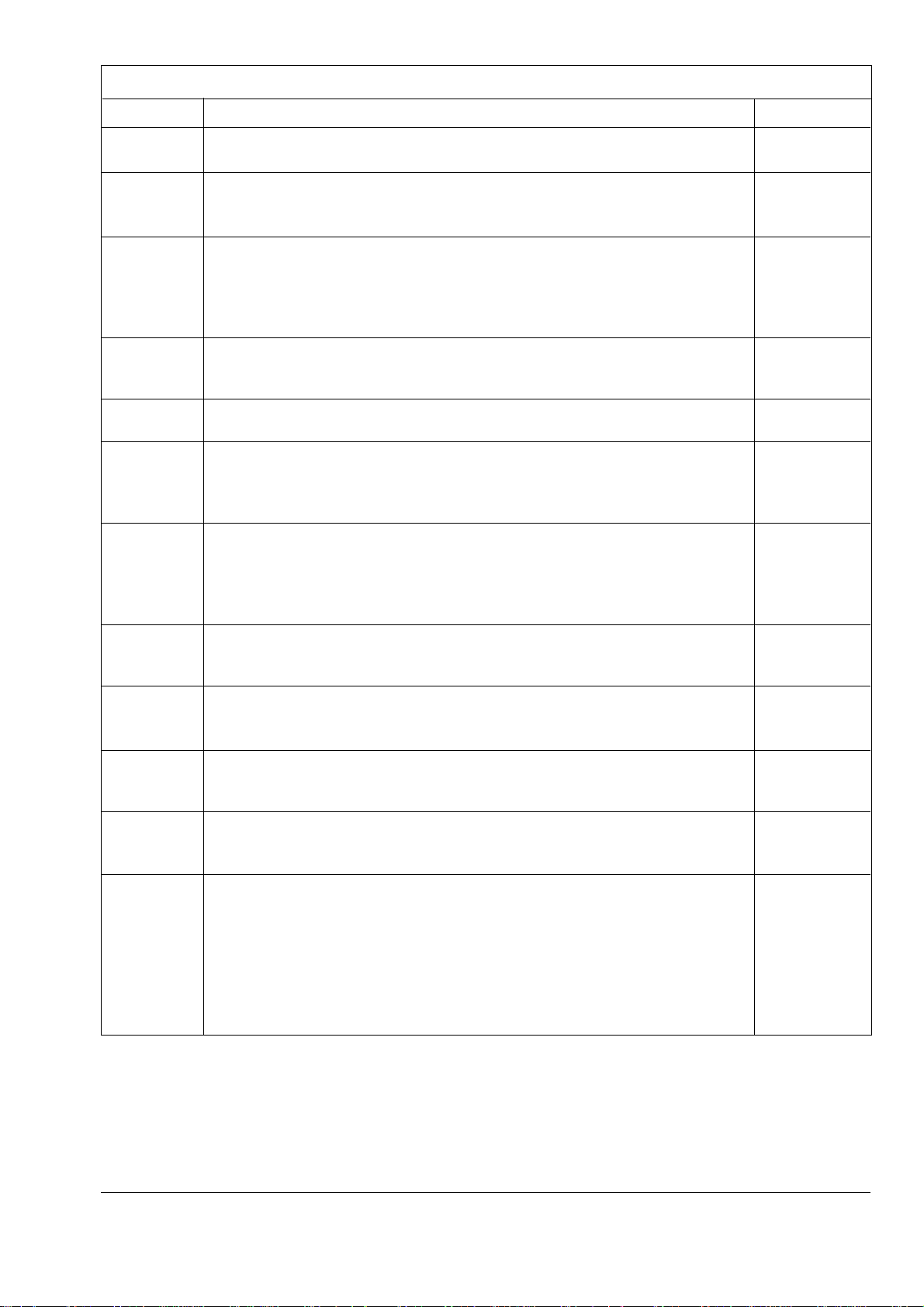

TABLE OF CONTENTS

Section No. Description SM No.

000 GENERAL INFORMATION

0000 TS14G Technical Data 1884

100 CHASSIS

0010 Chassis, Hood and Fenders - Tractor 1885

0130 Steering Trunnion - Tractor 1695

110 ENGINE

0030 Engine and Mounting 1691 Rev 2

0050 Air Cleaner 1692

0130 Power Takeoff - Tractor 1693

0130 Flywheel Cover Group - Scraper 1694

120 TRANSMISSION

0010 Transmission Mounting 1783

0070 Transmission Electronic Controls 1735

13 0 DRIVELINE

0010 Drivelines - Front and Rear 1796

14 0 FRONT AXLE GROUP

0030 Planetary Gearing (Refer to Section 160-0040) 0040 Wheel, Rim and Tyre (Refer to Section 160-0050) 0060 Differential 1778

16 0 REAR AXLE GROUP

0020 Differential 1780

0040 Planetary Gearing 1779

0050 Wheel, Rim and Tyre 1721

0080 NoSpin Element 1781

165 BRAKE PARTS

0031 Brake Parts - Scraper 1777

0060 Slack Adjuster 1751

19 0 ELECTRICAL SYSTEM

0000 Circuit Diagrams 1789

0270 Switches and Sensors 1792

200 FUEL SYSTEM

0040 Fuel Tanks, Lines and Mounting 1886

0051 Electronic Foot Pedal 1719

21 0 COOLING SYSTEM

0040 Radiator and Mounting 1723 Rev 1

0060 Transmission Oil Cooler 1798

22 0 STEERING SYSTEM - TRACTOR

0000 Steering System Schematic 1760

0010 Steering Lines and Fittings 1768 Rev 1

0090 Steering Valve 1765

0120 Steering Cylinder 1897

0130 Double Relief Valve 1747

0160 Flow Reversing Valve 1764

0190 Steering Linkage 1766

SM 1883 Rev 1 3-01

1

TABLE OF CONTENTS

Section No. Description SM No.

23 5 BOWL HYDRAULIC SYSTEM

0000 Hydraulic System Schematic 1893

0010 Hydraulic Lines and Fittings 1894

0020 Bowl Cylinder 1769

0030 Ejector Cylinder 1895

0035 Apron Cylinder 1896

0040 Hydraulic Tank - Tractor 1722

0050 Triple Pump 1739

0060 Bowl Control Valve 1887

0070 Accumulator 1791

0120 Relief Valve 1776

0160 Servo Control Valve 1775

25 0 BRAKING SYSTEM

0000 Air Braking System Schematic 1784 Rev 1

0070 Treadle Valve 1755

0170 Air Tanks and Mounting 1788

0180 Quick Release Valve 1793

0190 Park/Emergency Brake Control Valve 1795

0200 Air Drier 1753

0260 Brake Chamber 1782

0280 Relay Emergency Valve 1800

0280 Relay Valve 1794

0290 Pressure Protection Valve 1752

25 5 AIR SYSTEM

0020 Air Horn 1797

260 OPERATOR'S COMPARTMENT

0010 Cab and Mounting 1728 Rev 1

0090 Driver Seat and Mounting (Air Suspension) 1742 Rev 1

0130 Air Conditioning 1787

28 0 BOWL - SCRAPER

0010 Bowl and Tail 1799 Rev 1

0020 Pull Yoke 1888

0030 Apron and Ejector 1890

0040 Ejector Lever 1892

0040 Bowl Linkage 1891

0050 Cutting Edges and Side Blades 1726

300 MISCELLANEOUS

0020 Lubrication System 1889

0070 Service Tools 1802 Rev 1

0080 Standard Bolt and Nut Torque Specs 1238

0090 Unit Storage 1239

2

* * * *

SM 1883 Rev 1 3-01

GENERAL INFORMA TION - TS14G T echnical Data

Section 000-0000

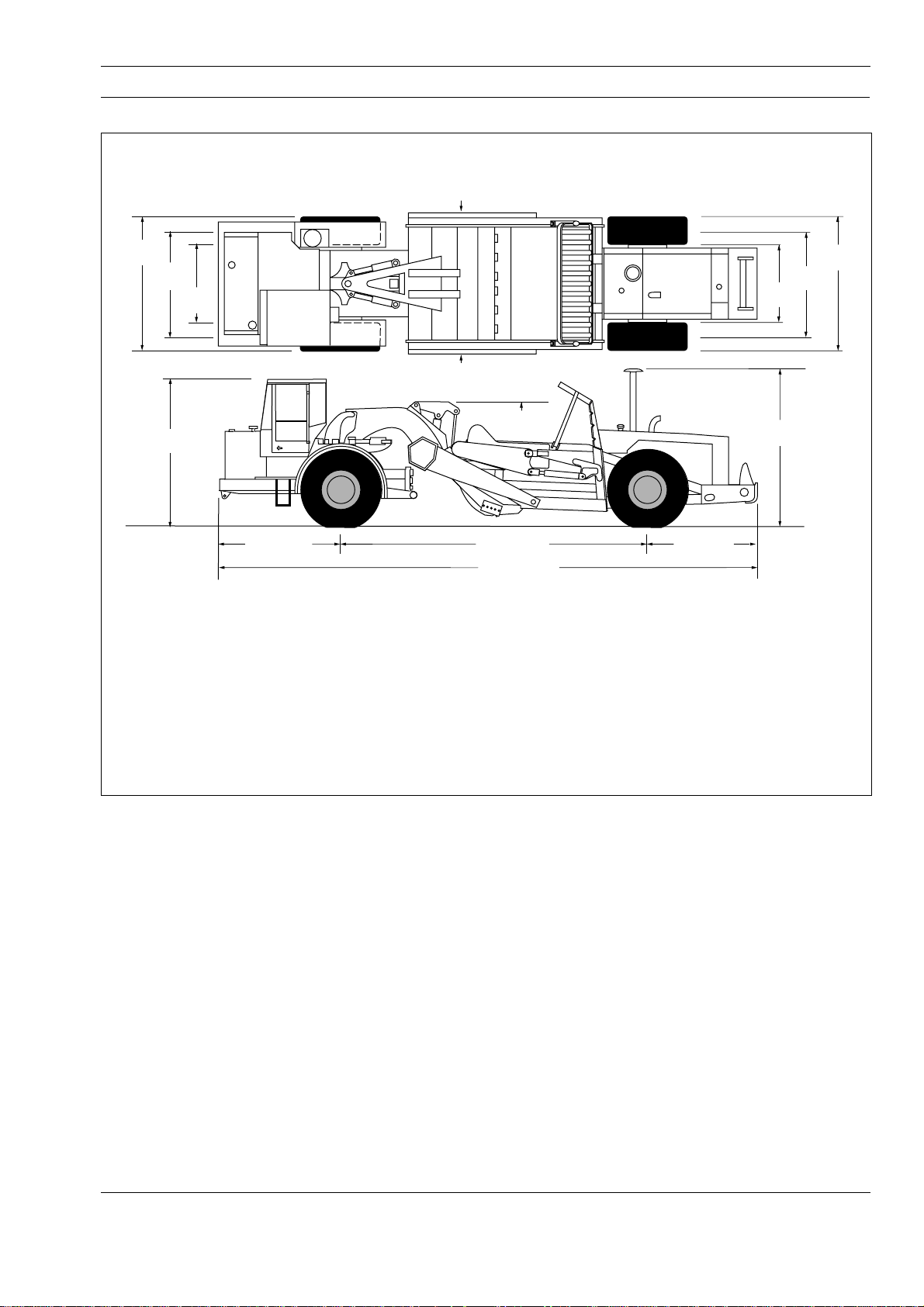

SM - 2376

3 440 (11-3.5) Max. Width

3 060

(10-0.5)

2 260

(7-5)

1 460

(4-9.5)

3 250

(10-8)

2 770 (9-1) 2 590 (8-6)

All vertical dimensions with bowl at 300 mm (12 in) carry position. Unit empty.

Apron opening .................................. 2 100 mm (6 ft 11 in)

Width of Bowl and Cutting Edge ......... 2 910 mm (9 ft 7 in)

Width of cut .......................................3 000 mm (9 ft 10 in)

Depth of cut - maximum......................... 305 mm (1 ft 0 in)

Depth of spread - maximum .................. 685 mm (2 ft 3 in)

Clearance under drive axle.................. 585 mm (1 ft 11 in)

Clearance under bowl - maximum .......585 mm (1 ft 11 in)

2 260

(7-5)

1 460

(4-9.5)

3 150 (10-4)

to ground

7 040 (23-1)

12 400 (40-8)

Dimensions in mm (ft-in)

3 810

(12-6)

Dimensions in mm (ft-in)

Overall length with optional Twin Hitch

Bail Raised...................................... 13 900 mm (45 ft 7 in)

Bail Lowered ................................... 14 340 mm (47 ft 8 in)

Note: All vertical measurements are with bowl at 300 mm

(12 in) carry position. Unit empty.

3 060

(10-0.5)

Fig. 1 - Machine Dimensions

ENGINE

Tractor

Engine Series .......................Detroit Diesel Series 40E

Type ............................ 4 Cycle Diesel, Turbocharged,

Electronic Management

Gross power at 2 200 rev/min............ 136 kW (185 hp)

Net power at 2 200 rev/min................ 123 kW (167 hp)

Note: Gross power rated to SAE J1995 June 90.

Engine emission meets USA EPA/CARB MOH 40

CFR 89 and EU NRMM (non-road mobile

machinery) directive.

Maximum Torque

at 1 600 rev/min............................. 720 Nm (531 lbf ft)

Number of cylinders/configuration ...................6, Inline

Bore x Stroke................ 109 x 136 mm (4.30 x 5.35 in)

Total Displacement...........................7.6 litres (466 in³)

SM 1884 1-00

Air cleaner .............................................Dry, Aspirated

Starting .............................................................Electric

Maximum Speed (No load) .....................2 450 rev/min

Maximum Speed (Full load).................... 2 200 rev/min

Idle Speed .................................................700 rev/min

Safe Operating Angle ..........................30°/57% Grade

Scraper

Engine Series .......................Detroit Diesel Series 40E

Type ............................ 4 Cycle Diesel, Turbocharged,

Electronic Management

Gross power at 2 200 rev/min............ 123 kW (167 hp)

Net power at 2 200 rev/min................ 113 kW (153 hp)

Note: Gross power rated to SAE J1995 June 90.

Engine emission meets USA EPA/CARB MOH 40

CFR 89 and EU NRMM (non-road mobile

machinery) directive.

1

General Information - TS14G Technical Data

Section 000-0000

Maximum Torque

at 1 600 rev/min............................. 644 Nm (475 lbf ft)

Number of cylinders/configuration ...................6, Inline

Bore x Stroke................ 109 x 136 mm (4.30 x 5.35 in)

Total Displacement...........................7.6 litres (466 in³)

Air cleaner .............................................Dry, Aspirated

Starting .............................................................Electric

Maximum Speed (No load) .....................2 450 rev/min

Maximum Speed (Full load).................... 2 200 rev/min

Idle Speed ................................................. 700 rev/min

Safe Operating Angle ..........................30°/57% Grade

TRANSMISSION

Make/Model........................... Funk DF158 Powershift,

counter-shaft type transmission with integral torque

converter. Seven speeds forward and one reverse.

Automatic lockup in the top six forward gears.

Manual, electric shifting and downshift inhibitor. Rear

transmission is equipped with an alarm to warn the

operator in the event of transmission malfunction.

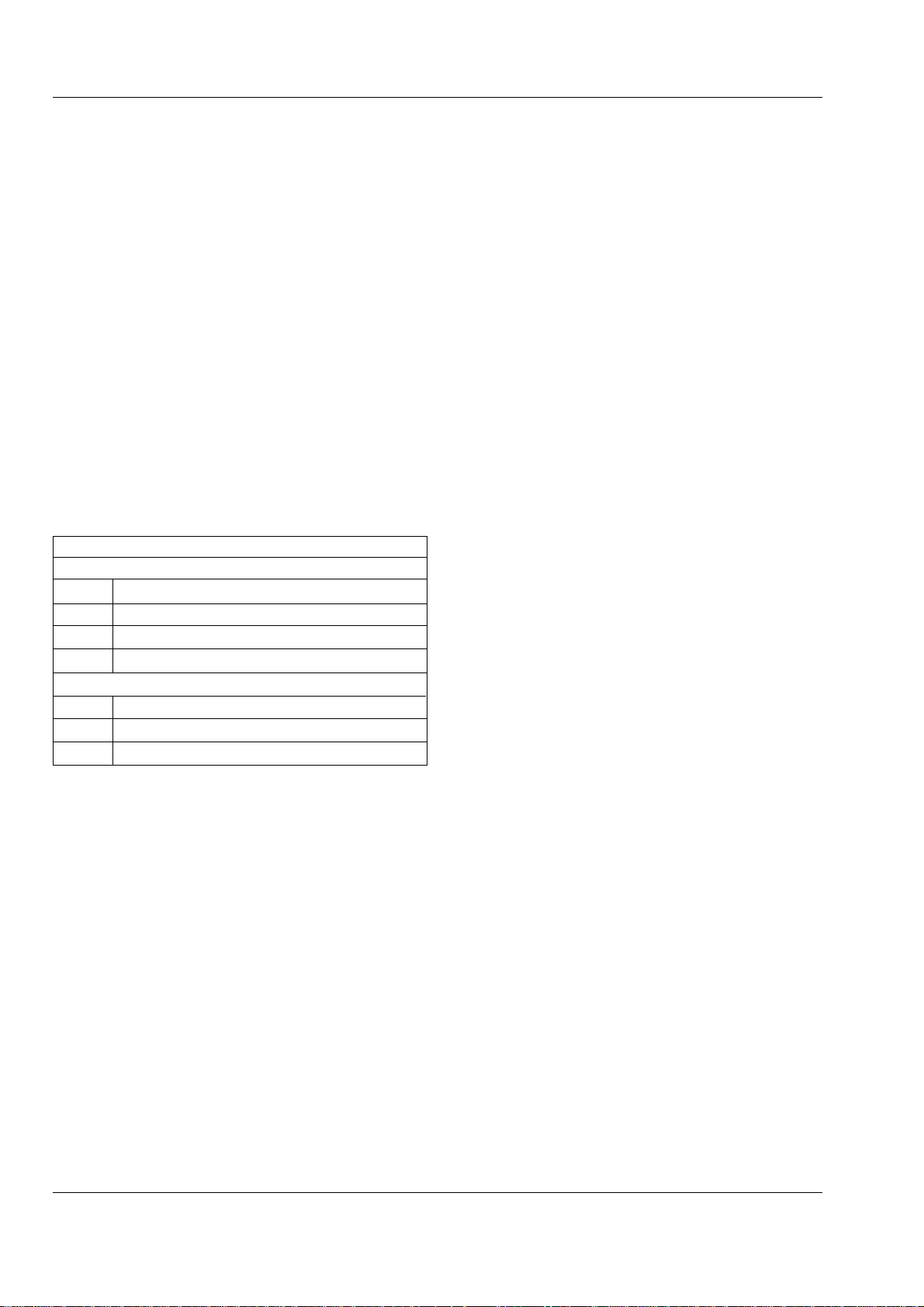

SPEEDS WITH STANDARD DIFFERENTIAL

Forward

Gear 1234567

Ratio 5.72 4.05 2.90 2.03 1.45 1.03 0.74

km/h 5.9 8.3 11.5 16.5 23.1 32.5 45.4

mile/h 3.6 5.1 7.2 10.2 14.3 20.2 28.2

Reverse

Ratio 4.05

km/h 8.3

mile/h 5.1

Stall Speed .............................................1 885 rev/min

Torque Converter Ratio (front and rear) .......... 2.408:1

AXLES

Heavy duty axles with fully-floating axle shafts, single

reduction bevel gear differential and planetary

reduction in each wheel. A NoSpin differential is

standard in the rear axle for improved traction in

difficult conditions. A pedal controlled power-locking

differential is optional in the front axle, operational in

first gear only.

BRAKES

Full air operated drum brakes with automatic

application on loss of air pressure. Secondary system

can also be manually applied. Spring-applied parking

brake actuators. Air drier standard.

Braking Lining:

Diameter.............................................. 508 mm (20 in)

Shoe Width............................................ 152 mm (6 in)

Lining Thickness................................. 19 mm (0.75 in)

Lining Area - Each Axle ................. 3 355 cm² (520 in²)

Air Compressor Capacity..... 374 litre/min (13.2 ft³/min)

WHEELS AND TYRES

Wheel Rim Width................................................. 25 in

Tyres:

Standard....................................... 29.5 R25** Radial

Optional .......................................29.5-25 (28PR) E3

Note: Consult tyre manufacturers for optimum tyre

selection and correct t-km/h (ton-mileh) capacity for

application.

STEERING SYSTEM

Full hydraulic type provided by two interchangeable

single stage, double acting steering cylinders. Steering

cylinders are mounted below the gooseneck to aid

stability.

System Pressure ....................... 135 bar (1 950 lbf/in²)

at 1 500 rev/min

Steering Cylinder:

Bore and Stroke .......... 140 x 445 mm (5.5 x 17.5 in)

Pump:

Type ................................................................. Gear

Drive......................... In tandem with hydraulic pump

Capacity at 2 200 rev/min...................... 147 litre/min

(38.7 US gal/min)

Steering Angle to either side...................................90°

Vehicle clearance circle (SAE) .................. 10 m (33 ft)

HYDRAULICS AND CONTROLS

Hydraulic system is filtered and has one reservoir

supplying a triple section gear pump for steering and

scraper hydraulics.

Ratios:

Differential ...................................................... 4.11:1

Planetary ........................................................ 5.33:1

Total Reduction ............................................ 21.91:1

2

Scraper Functions:

Capacity at 2 200 rev/min...................... 270 litre/min

(71.2 US gal/min)

System Pressure

at 1 500 rev/min................ 127.5 bar (1 850 lbf/in²)

SM 1884 1-00

Loading...

Loading...