Terex TL80, TL100 Operating Instructions Manual

OPERATING INSTRUCTIONS

Language version: EN

Edition: 2010-07

Order number: 5780211303

From vehicle ID No.:

Translation of the original operating instructions

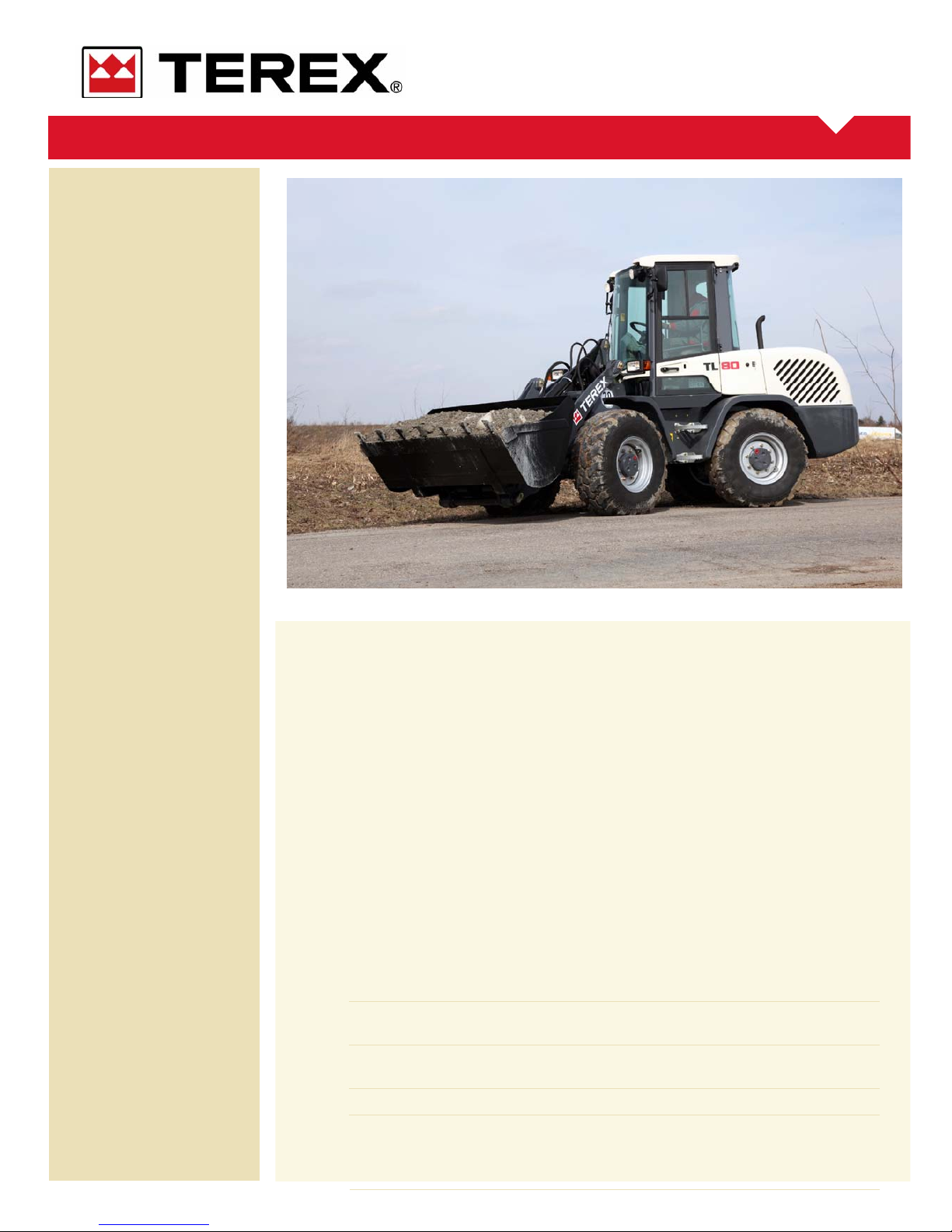

tl80

Wheel Loader

tl80

Wheel Loader

Terex GmbH

Geschäftsbereich Terex

|Schaeff

Schaeffstr. 8

74595 Langenburg

Germany

Phone +49(0)7905/58-0

Fax +49(0)7905/58-114

www.terex.com

E-mail: info@terex.com

Please complete before commissioning the wheel loader:

Vehicle model: ..........................................................................

Vehicle ID No.: ..........................................................................

Year of construction: ...............................................................

Commissioned on: ...................................................................

Dealer:

This operating manual is protected by limited copyright. It may be reproduced for and used by the drive /

plant operator.

Table of Contents

TL80

1 Introduction...................................................................................................................................1

1.1 Warranty and Maintenance.......................................................................................................................2

1.2 Copyright...................................................................................................................................................2

1.3 Notes on using the Operating Instructions................................................................................................2

1.4 Environmental standards..........................................................................................................................3

1.5 Pictograms................................................................................................................................................3

1.6 Location of safety signs ............................................................................................................................5

2 Safety and Accident Prevention..................................................................................................7

2.1 Introductory remarks.................................................................................................................................7

2.2 Intended use .............................................................................................................................................8

2.3 General safety notes.................................................................................................................................9

2.4 Operation ..................................................................................................................................................9

2.5 Danger zone............................................................................................................................................10

2.6 Transport of persons...............................................................................................................................10

2.7 Stability....................................................................................................................................................10

2.8 Travel operation......................................................................................................................................11

2.9 Working Operation..................................................................................................................................11

2.10 Guides...................................................................................................................................................12

2.11 Danger of falling objects .......................................................................................................................12

2.12 Working in the vicinity of underground power lines ..............................................................................12

2.13 Working in the vicinity of overhead power lines....................................................................................13

2.14 Operation in closed rooms....................................................................................................................13

2.15 Work stoppages....................................................................................................................................13

2.16 Change of work attachments, maintenance, repair..............................................................................14

2.17 Recovery, loading, transportation.........................................................................................................15

2.18 Monitoring and inspections...................................................................................................................15

2.19 Fire prevention......................................................................................................................................16

2.20 Emergency exit .....................................................................................................................................16

2.21 Other dangers.......................................................................................................................................16

3 Technical data.............................................................................................................................17

3.1 Views.......................................................................................................................................................17

3.2 Diesel engine ..........................................................................................................................................25

3.3 Electrical system.....................................................................................................................................25

3.4 Transmission...........................................................................................................................................25

3.5 Brakes.....................................................................................................................................................26

3.6 Hydraulic system.....................................................................................................................................26

3.7 Axles .......................................................................................................................................................27

3.8 Tires ........................................................................................................................................................27

3.9 Consumables..........................................................................................................................................28

3.9.1 Filling quantities................................................................................................................................28

3.9.2 Consumable specifications...............................................................................................................29

3.10 Permissible loads in compliance with German Road Traffic Regulations (StVZO)..............................31

3.11 Sound level values, vibration................................................................................................................31

3.11.1 Equivalent vibration values................................................................................................................31

3.12 Dimensions and weights.......................................................................................................................32

3.13 Front loader installation.........................................................................................................................33

3.14 Bucket...................................................................................................................................................33

3.15 Fork lift attachment................................................................................................................................34

3.16 Optional accessories (options)..............................................................................................................35

4 Operation.....................................................................................................................................37

4.1 First Instruction........................................................................................................................................37

4.2 Display elements and operating controls................................................................................................38

4.3 Engine.....................................................................................................................................................42

4.3.1 Starting the engine...........................................................................................................................42

4.3.2 Monitoring during operation..............................................................................................................43

4.3.3 Switching off the engine...................................................................................................................43

4.4 Driver's seat / Steering wheel tilt adjustment..........................................................................................44

4.5 Heating / ventilation.................................................................................................................................45

4.6 Lighting in compliance with German Road Traffic Regulations (StVZO)................................................46

4.7 Hydroinflation of tires ..............................................................................................................................46

Table of Contents

TL80

4.8 Driving, steering and braking..................................................................................................................47

4.8.1 Driving ..............................................................................................................................................47

4.8.2 Steering............................................................................................................................................49

4.8.3 Brakes ..............................................................................................................................................49

4.8.4 Driving on roads ...............................................................................................................................50

4.8.5 Switching off the machine (parking).................................................................................................51

5 Working Operation of the machine ...........................................................................................53

5.1 General notes..........................................................................................................................................53

5.1.1 Lever controls.......................................................................................................................................53

5.2 Operation - Loader..................................................................................................................................54

5.3 Changing work attachments ...................................................................................................................56

5.3.1 General notes...................................................................................................................................56

5.3.2 Assembly of work attachments.........................................................................................................57

5.4 Notes on how to work with the machine .................................................................................................59

5.4.1 Loading.............................................................................................................................................59

5.4.2 Scraping and grading .......................................................................................................................59

5.4.3 Excavating........................................................................................................................................59

6 Recovery and transport of the machine ...................................................................................61

6.1 Recovery of the machine........................................................................................................................61

6.2 Loading the machine using a crane........................................................................................................62

6.3 Transporting the machine.......................................................................................................................62

7 Maintenance and Care................................................................................................................63

7.1 General notes..........................................................................................................................................63

7.2 Intervals...................................................................................................................................................63

7.3 Regular oil analysis.................................................................................................................................64

7.4 Warranty..................................................................................................................................................64

7.5 Inspection parts and aids........................................................................................................................65

7.6 Care and cleaning...................................................................................................................................66

7.7 Notes for winter operation.......................................................................................................................66

7.8 Checking, maintenance and inspection plans ........................................................................................68

7.8.1 Initial inspection (hand-over inspection)...........................................................................................68

7.8.2 Daily and weekly tasks.....................................................................................................................70

7.8.3 Overview of lubricating points ..........................................................................................................72

7.8.4 Inspection plan .................................................................................................................................74

7.9 Inspection and maintenance work ..........................................................................................................76

7.9.1 Engine oil..........................................................................................................................................76

7.9.2 Engine oil filter..................................................................................................................................77

7.9.3 Cooling system - combined hydraulic oil-water cooler.....................................................................78

7.9.4 Fuel system......................................................................................................................................80

7.9.5 Air filter, air intake.............................................................................................................................82

7.9.6 V-belt................................................................................................................................................85

7.9.7 Checking Valve Lash........................................................................................................................85

7.9.8 Brakes ..............................................................................................................................................86

7.9.9 Hydraulic oil tank..............................................................................................................................87

7.9.10 Hydraulic oil cooler.........................................................................................................................88

7.9.11 Hydraulic oil filter............................................................................................................................89

7.9.12 Breather..........................................................................................................................................90

7.9.13 Axles...............................................................................................................................................91

7.9.14 Wheels............................................................................................................................................93

7.9.15 Injection valves...............................................................................................................................94

7.9.16 Control cog belt for drive motor......................................................................................................94

7.9.17 Electrical equipment.......................................................................................................................94

7.9.18 Cab ventilation dust filter................................................................................................................95

7.9.19 Windshield washer system.............................................................................................................95

7.10 Taking out of service.............................................................................................................................96

7.10.1 Preservation for temporary taking out of service............................................................................96

7.10.2 During immobilization.....................................................................................................................96

7.10.3 After the machine had been taken out of service...........................................................................96

7.10.4 Disposing of the wheeled loader....................................................................................................96

Table of Contents

TL80

8 Troubleshooting..........................................................................................................................97

8.1 General notes..........................................................................................................................................97

8.2 Engine.....................................................................................................................................................97

8.3 No steering movement............................................................................................................................97

8.4 Insufficient performance of service brake...............................................................................................97

8.5 Insufficient performance of parking brake...............................................................................................97

8.6 Hydrostatic travel drive without neutral position .....................................................................................97

8.7 Hydraulic oil exceeds max. admissible temperature...............................................................................98

8.8 Sluggish acceleration and deceleration, too little propulsive power.......................................................98

8.9 Transmission works in one direction only...............................................................................................99

8.10 Transmission works in neither direction................................................................................................99

8.11 Loader installation is not working..........................................................................................................99

8.12 Decrease in machine's performance (loader installation)...................................................................100

8.13 Working cylinders not operating satisfactorily.....................................................................................100

8.14 Faults in the electrical system.............................................................................................................100

9 Appendix....................................................................................................................................101

9.1 Electrical system...................................................................................................................................101

9.2 Equipment options ................................................................................................................................102

9.3 Immobilizer............................................................................................................................................103

9.3.1 Activating the immobilizer...............................................................................................................103

9.3.2 Deactivating the immobilizer ..........................................................................................................103

9.3.3 Learning a new key........................................................................................................................103

9.3.4 Learning multiple new keys............................................................................................................104

9.3.5 Clearing learned keys.....................................................................................................................104

9.3.6 Security functions...........................................................................................................................104

9.3.7 Fault causes...................................................................................................................................105

Table of Contents

TL80

Introduction 1

TL80 1

1 Introduction

You decided to buy a Terex TL80 Wheel Loader.

The confidence placed in this model will be

rewarded by the efficient and economical

performance of the machine.

This operating manual contains all the information

and instructions that are required to handle the

machine correctly. Please read them carefully

before putting the machine into operation and

make sure that they are kept at hand at all times.

Should you need further explanations or should

anything be unclear, please contact your dealer

immediately.

Special equipment and attachments are not

included in these Operating Instructions.

We reserve the right to make improvements on the

machine within the scope of impending technical

developments, without incurring any obligation to

change these Operating Instructions.

Any modifications of Terex products and

their equipment using extras and work

attachments which are not included in

our product range require our written

approval. If our approval is not sought,

our warranty expires, as does our

product liability.

Please state the vehicle type and vehicle

identification number when making inquiries or

orders, and in all written correspondence.

The vehicle identification number of

the machine is stamped onto the type

label (1/1).

Fig. 1 Type label

1 Introduction

2 TL80

1.1 Warranty and Maintenance

The warranty period covers 12 months, beginning

with the day the machine is handed over or put into

operation.

Safe working conditions and good working order of

the machine are prerequisites for efficient work.

Your Terex wheel loader fulfils these requirements

when correctly handled and when serviced and

maintained as specified.

Careful observation of the machine whilst in

function and the use of the specified fuels,

lubricants, and coolants will prevent malfunction.

Trained specialist personnel are responsible for

any servicing of the machine which requires expert

knowledge. Inspections and repairs must therefore

be carried out by your dealer’s customer service.

In respect of possible claims for damages during

the warranty period, all work specified in the

maintenance and inspection plan must be carried

out at the specified intervals.

After the warranty period, too, regular maintenance

must be performed in order to ensure that the

machine is constantly in good working order and

enjoys a reasonable service life.

Insist that only original Terex spare parts are

used in the event of any repair work. In this way,

you will have a product of lasting high quality,

thereby ensuring that your machine maintains its

original condition.

1.2 Copyright

This instruction book is intended for use by

personnel responsible for operation, maintenance,

repair and supervision of the machine.

This operating manual is copyrighted. It contains

technical specifications and documentation which

shall not, either in whole or in part, be reproduced,

transmitted or used for the purpose of competition

without our express permission.

1.3 Notes on using the Operating Instructions

References to pictures and items

The references to pictures and items contained in

the text, such as (Fig. 12/4) or (12/4) mean figure

12, item 4.

The figures shown in this manual partly contain

additional equipment.

Symbol "Danger "

This symbol indicates a high risk of

injuries. Strictly observe the safety

instructions.

Symbol "Warning "

Not abiding by the information indicated

by this symbol might cause substantial

property or equipment damage. Strictly

observe the safety instructions.

Symbol "Note "

This symbol is employed for information

containing important notes about the

correct use and/or how to proceed. Noncompliance may lead to malfunction.

Introduction 1

TL80 3

1.4 Environmental standards

When operating or working on the machine the

environmental standards currently valid must be

observed at all times.

During installation, repair and maintenance tasks,

particular care must be taken that substances that

would damage the environment such as

• lubricating oil and grease

• hydraulic oil

• fuel

• coolant

• cleaning fluids containing solvents

do not seep into the ground or the sewerage

system.

These substances must be kept, transported,

collected and disposed of in suitable containers.

If above-mentioned liquids seep into the ground,

their escape must be stopped immediately and the

liquid be bound with suitable binding agents. If

necessary, the soil involved must be removed.

Absorbent materials and removed soil must be

disposed of properly. The environmental standards

currently valid must be observed.

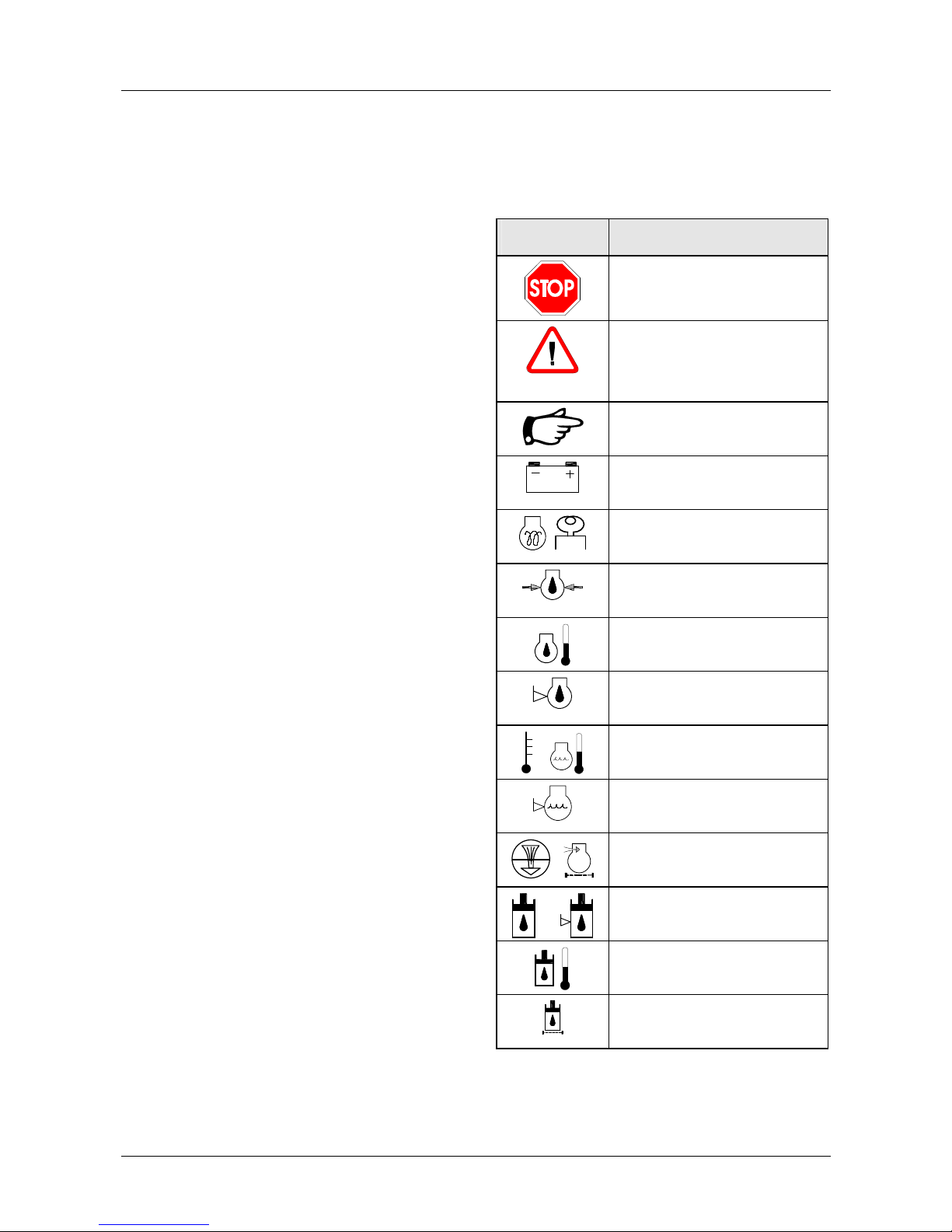

1.5 Pictograms

The following Table explains the meaning of the

pictograms which may be attached to your

machine.

Symbol Description

Danger

In Operating Instructions:

Warning

On machine:

Caution

Note

Battery charge indicator

Preheating

Engine oil pressure

Engine oil temperature

Engine oil level

Coolant temperature

Coolant level

Air filter

Hydraulic oil

Hydraulic oil level

Hydraulic oil temperature

Hydraulic oil filter clogging

indicator

1 Introduction

4 TL80

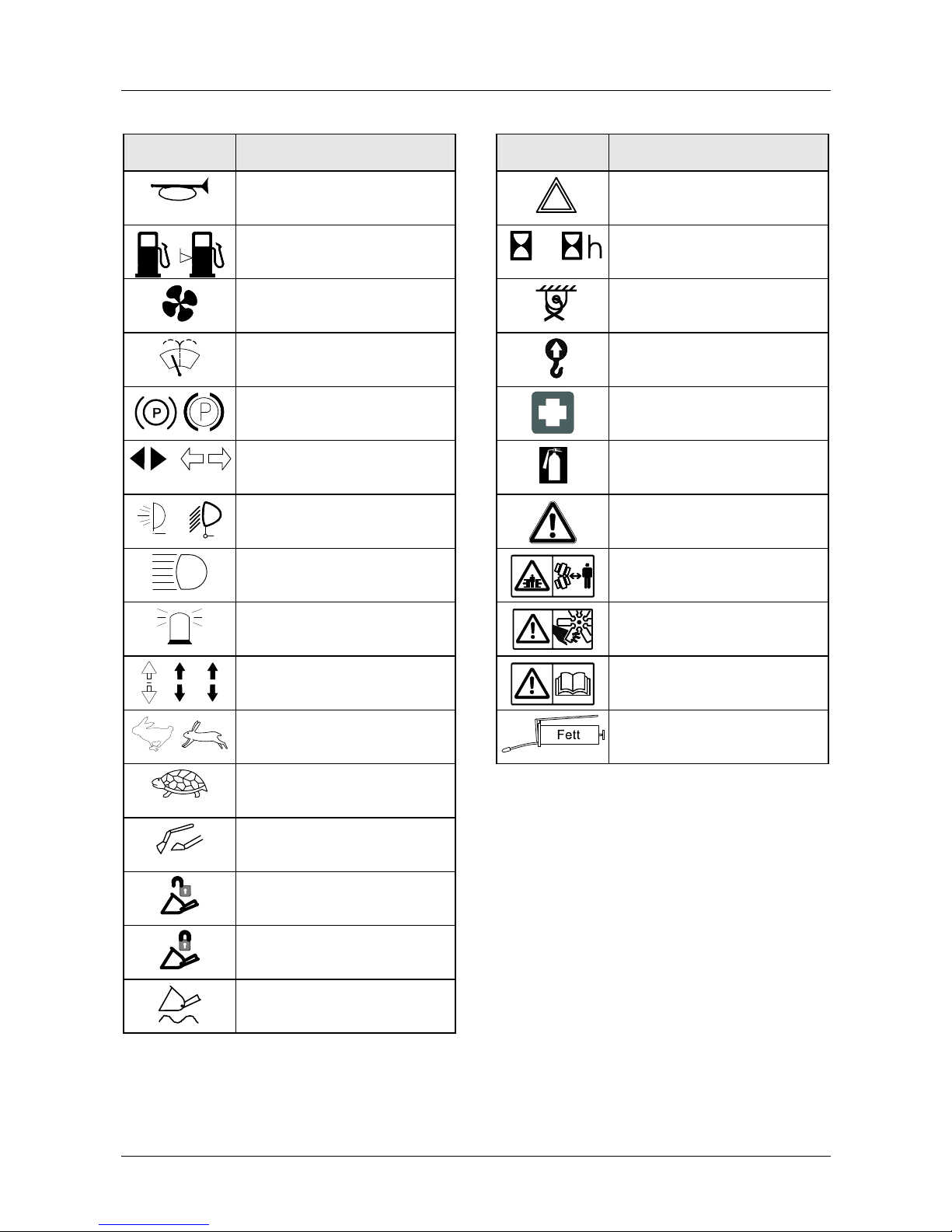

Symbol Description

Horn

Fuel

Fuel level

Blower

Heating/ventilation

Windshield washer and wiper

system

Parking brake

Direction indicator LT/RT

Working floodlights

High-beam indicator

Rotating beacon

V

R

Travel direction

FWD/REV

Travel speed

FAST

Travel speed

SLOW

Working hydraulics shut-off

Unlocked

Locked

Float position

Symbol Description

Hazard warning system

Operating mode indicator

Operating hours

Lashing points

Suspension points for loading

by crane

First-aid kit

Fire extinguisher

On machine:

Safety distance

Danger of crushing

Danger of injury

The relevant notes in the

operating instructions should

be observed

Grease gun

Lubricating point

Introduction 1

TL80 5

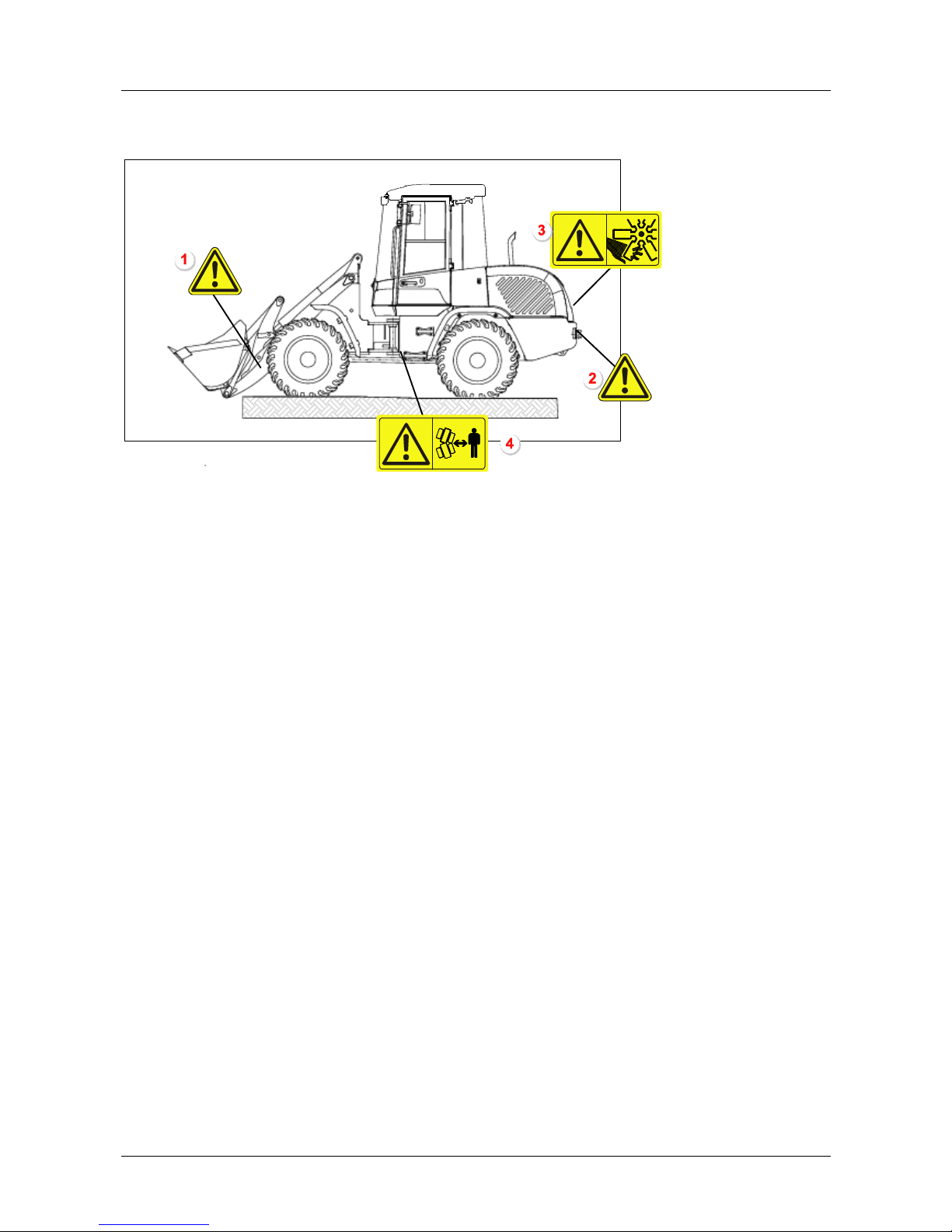

1.6 Location of safety signs

The safety signs are located in the following positions on the machine:

Locations of safety signs

1 Safety distance (left and right sides of lifting frame)

2 Safety distance

3 Danger of injury

4 Danger of crushing

Servicing and replacing safety signs

- The safety of the operator always has to come first.

- Safety signs must always be kept in good condition and legible.

- Replace any safety sign which has been damaged or disappeared.

- Use mild detergents and water to clean the safety signs.

- Do not use any detergents containing solvents.

- Always specify machine serial number and language when ordering safety signs.

6 TL80

Safety and Accident Prevention 2

TL80 7

2 Safety and Accident Prevention

2.1 Introductory remarks

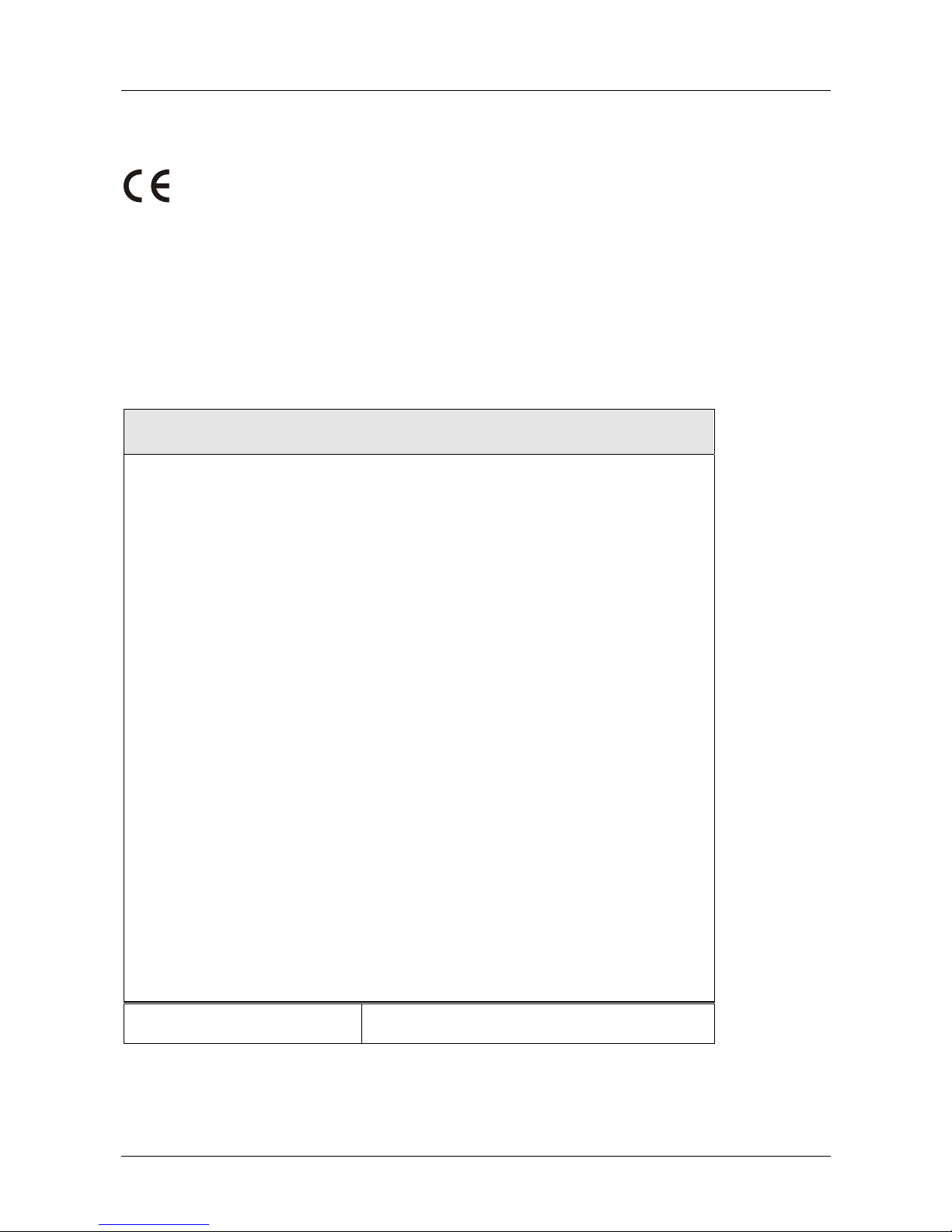

Declaration of Conformity

The machine complies with the

fundamental requirements stipulated in

the applicable European guidelines.

Conformity has been proven. The

respective documents and the original of

the Certificate of Conformity are kept by

the manufacturer.

A copy of the Certificate of Conformity is

attached to the sales documents.

EC declaration of conformity

according to the machinery directive 2006/42/EC

1. We hereby declare that the earth-moving machine of type TL 80:

Wheel Loader: TL80

Vehicle ID No.:TL0802

Actual productivity: 44 KW

2. complies with the following applicable regulations:

2006/42/EC, 2004/108/EC (EMC), RL 2000/14/EC Appendix VIII (noise emission)

3. Representative sound power level:

100,0 dB (A)

4. Guaranteed sound power level:

101 dB (A)

5. Applied harmonized standards:

EN ISO 12100-2

6. Applied European standards:

EN 474-1

EN 474-3

7. Document editor, who is authorized to compile technical documentation:

Maik Schulze, D 74564 Crailsheim, Kraftwerkstraße 4, Germany

8. Voluntary type examination performed as well as certification in accordance with RL 2000/14/EC

Appendix VIII at:

Fachausschüsse Bau (BAU) und Tiefbau (TB)

Prüf- und Zertifizierungsstelle im BG-PRÜFZERT

80687 Munich, Germany

The EC declaration of conformity only applies if the earth-moving machine is used in accordance with the

operating instructions. It includes the use of original Terex work attachments and other work attachments,

which are mentioned in the operating instructions or in other Terex documentation for application at this earthmoving machine.

Replaceable equipment manufactured by Terex or third party manufacturers may only be installed and used if

the installation at the affected earth-moving machine is performed by Terex. In all other cases, special written

approval is required from Terex.

Date of the declaration of conformity 29.12.2009

Langenburg

Terex GmbH

Geschäftsbereich Terex Schaeff

Schaeffstraße 8

74595 Langenburg, Germany

2 Safety and Accident Prevention

8 TL80

Read the operating instructions thoroughly and

follow the notes on safe operation before putting

the earth-moving machine into operation.

National safety regulations - e.g. the Accident

Prevention Regulations, "Earth-Moving Machinery"

(BGR 500 Chapter 2.12) and "Vehicles" (BGV

D29) in the Federal Republic of Germany - must

also be complied with when operating the earthmoving machine.

In addition to the Operating Instructions, legal

regulations governing road traffic and road safety

measures must also be observed. Such duties

could also apply in respect of e.g. handling

hazardous goods or the wearing of personal safety

gear.

Furthermore, safety laws governing work in

particular locations (tunnels, adits, quarries,

pontoons, contaminated areas, etc.) must likewise

be observed.

2.2 Intended use

The earth-moving machine with standard bucket

equipment is intended solely for work which is

suitable for the function of the machine and its

work implements.

Such work involves loosening, taking up,

transporting and dumping soil, rock or other

materials as well as loading these materials on

trucks, conveyor belts or other means of transport,

when the transport of the material is normally done

by positioning the earth-moving machine.

The assembly of special work attachments such as

multi-purpose bucket, side-dump bucket, broom,

fork lift attachment etc. allows the machine to

perform the corresponding applications.

Any usage above and beyond that specified here,

e.g. the transport of persons or the usage of the lift

equipment as work platform is regarded as

improper use. The supplier cannot be held

responsible for any damage resulting from

improper use. This risk is borne solely by the user.

Strict compliance with the operating and

maintenance instructions and the performance of

maintenance work, as well as adherence to the

maintenance intervals is also part of intended use.

Safety and Accident Prevention 2

TL80 9

2.3 General safety notes

• It is important to refrain from any working

methods which impair safety.

• The earth-moving machine is only to be used if

it is in a safe, operational condition.

• The manufacturer’s instructions must be

complied with for operation, maintenance,

repair, assembly, and transportation.

• The plant operator must provide additional

special safety instructions, wherever necessary,

for specific local conditions.

• The operating instructions and any information

pertaining to safety must be carefully kept in the

driver's cab.

• The operating instructions and safety notes

must be complete and fully readable.

• Safety equipment on earth-moving machines

must not be deactivated or removed.

• Protective clothing must be worn during

operation. Rings, scarves and unbuttoned

jackets are to be avoided. Protective goggles,

protective boots, helmets, gloves, reflecting

jackets, ear-muffs, etc. may be required.

• Before commencing work, information must be

obtained on first aid and possible means of

rescue (emergency ambulance, fire brigade,

helicopters).

• A check must be carried out to ensure that the

first aid box is at hand and that its contents

comply with regulations.

• Personnel must be aware of the location and

method of operation of the fire extinguishers on

the earth-moving machine as well as on-site

fire-warning and fire-fighting equipment.

• Loose parts such as tools or other accessories

must be secured to the earth-moving machine.

• Open doors, windows, covers, flaps, etc. must

be closed or secured so that they cannot slam

shut.

2.4 Operation

Earth-moving machines shall only be

independently operated and serviced by persons

who

• are physically and mentally suitable

• have been instructed in the operation or

maintenance of earth-moving machines and

have demonstrated this ability to the plant

operator

• can be expected to perform their allocated

duties reliably.

All such persons must be of the legal minimum

age.

They must be designated by the plant operator to

operate or service the earth-moving machine.

Operating equipment and controls are only to be

operated from the driver’s seat.

The earth-moving machine is only to be ascended

and entered using the entrances and surfaces

intended for this purpose.

It is the driver’s responsibility to ensure that the

operator’s stand, entrances and other surfaces of

the earth-moving machine which have to be

stepped on are free of dirt, grease, oil, ice and

snow.

2 Safety and Accident Prevention

10 TL80

2.5 Danger zone

• Nobody must be allowed to remain in the

danger zone of an earth-moving machine.

The danger zone encompasses the

area around the earth-moving machine

in which persons may be injured by

movements of the earth-moving

machine during operation, its work

implements and attachments, or by

swinging out or falling loads.

• The machine operator is only to work the earthmoving machine if nobody is in the danger

zone.

• The machine operator must give a warning

signal to persons who may be in danger.

• The machine operator must stop work with the

earth-moving machine if someone remains in

the danger zone despite the warning.

• To ensure no danger of crushing, a sufficient

safety distance (min. 0.5 m) must be kept from

solid objects, e.g. buildings, excavation slopes,

scaffolding, other machines, etc.

• If the above safety distance cannot be

maintained, the area between solid objects and

the working zone of the earth-moving machine

must be blocked off.

• If conditions are such that the machine

operator’s view of the driving and working zone

is restricted, he must be guided or the driving

and working zone must be marked by a solid

barricade.

2.6 Transport of persons

The transport of persons on the machine is

forbidden.

2.7 Stability

• The earth-moving machine must be used,

driven and operated in such a manner that its

stability against overturning is ensured at all

times.

• The machine operator must drive at speeds

which are suitable for local conditions.

• The permitted payload of the earth-moving

machine must not be exceeded.

• The earth-moving machine must remain at a

sufficient distance from the edges of quarries,

pits, mounds and slopes to ensure there is no

risk of falling.

• Earth-moving machines must be secured so

that they cannot roll or slip when in the vicinity

of excavations, shafts, ditches, pits and slopes.

Safety and Accident Prevention 2

TL80 11

2.8 Travel operation

Before putting the earth-moving machine into

operation, the driver’s seat, mirrors and operator

controls must be adjusted so as to ensure safe

working.

A safety belt (seat belt), if installed, must always be

fastened.

The windows must be clean and free of ice.

Driving tracks must be designed so as to ensure

smooth, safe operation, i.e. they must be

sufficiently wide, on ground which has as few

slopes as possible and sufficient carrying capacity.

Downhill tracks must be set out in such a way that

earth-moving machines can be safely braked.

Before driving downhill, the appropriate gear for

the terrain must be selected and the gear lever not

be moved during downhill travel (road or off-road

gear).

On steep drops and uphill gradients, the load must

be carried on the uphill side, if possible, in order to

increase stability.

Before driving downhill, the appropriate gear for

the terrain must be selected and the gear lever

shall not be moved during downhill travel (on-road

or off-road gear).

The internal dimensions of constructions must be

noted before entering underground passages,

tunnels, etc.

It is the plant operator's responsibility to ensure

that equipment such as first-aid box, warning

triangle, hazard lights are kept with the earthmoving machine according to the traffic regulations

valid in the user’s country and that the driver has

the appropriate license as required by the national

traffic laws of the country in question.

Outside areas covered by general traffic

regulations, e.g. on factory premises, traffic

regulations should be applied in the proper

manner. This should also apply with regard to

drivers’ licenses.

2.9 Working Operation

Daily before start of operation and after every

attachment change, the machine operator must

check the correct fastening of the work

attachments as well as the correct locking of the

quick-mount hitch. Work attachments are to be

carefully moved at low height. During this check

nobody must be allowed to remain in the danger

zone of the earth-moving machine.

The machine operator shall only swing the work

equipment over occupied driver’s seats, operator

consoles and workplaces of other machines when

these are protected by overhead guards (FOPS).

If a cabin does not have the required protection,

the driver of this vehicle must leave the operator’s

stand while the work equipment is being swung

overhead.

The vehicles must be loaded in such a manner as

to ensure that there is no overloading and no

material can be lost as long as the machine is

moving. The vehicle must be loaded from the

lowest possible height.

At dumping points, earth-moving machines may

only be operated if suitable measures have been

taken to prevent rolling or falling.

2 Safety and Accident Prevention

12 TL80

2.10 Guides

Guides must be easily recognizable, e.g. by means

of reflective clothing. They must remain within the

machine operator’s field of vision.

While guiding the machine, guides shall not be

given other jobs which may distract them from their

task.

2.11 Danger of falling objects

Earth-moving machines are only to be used where

there is a danger of falling objects if the operator's

stand has a canopy (FOPS). A front guard must

be employed if there is a risk of materials breaking

through into the cabin.

In front of walls e.g. of stacked materials, earthmoving machines must be positioned and operated

in such a way that the driver's seat and entry to the

driver's seat are not situated on the side facing the

wall.

Demolition work is only to be performed by earthmoving machines where there is no danger to

persons and if the machine is equipped with

canopy, cabin-mounted front guard and the

appropriate work implement.

See regulations book "Demolition work" (ZH 1/614)

published by the German TiefbauBerufsgenossenschaft (Civil Engineering

Employer’s Liability Insurance Association).

2.12 Working in the vicinity of underground

power lines

Before commencing excavating work using earthmoving machines, it must be determined whether

any underground power lines are present in the

intended working zone which may present a

danger to persons.

If underground power lines are present, their exact

position and course must be determined in

consultation with the proprietor or operator of the

lines, and the necessary safety precautions

decided and implemented.

The course of power lines in the work area must be

clearly marked, under supervision, before

commencing any excavation work. If the position of

lines cannot be determined, search ditches must

be dug - manually, if need be.

If underground power lines are encountered

unexpectedly or they or their protective covers are

damaged, the machine operator must discontinue

work immediately and notify the supervisor.

Safety and Accident Prevention 2

TL80 13

2.13 Working in the vicinity of overhead power

lines

If the earth-moving machine is being used in the

vicinity of overhead power lines and trolley wires, a

safety distance which varies depending on the

nominal voltage of the overhead line must be

maintained between the lines and the earthmoving machine and its work equipment, to

prevent current overspill. This also applies to the

distance between these lines and attached

implements or loads.

The safety distances specified below must be

complied with:

Nominal voltage in Volt Safety distance in

meters

- 1,000 V 1.0 m

more than 1 kV - 110 kV 3.0 m

more than 110 kV - 220

kV

4.0 m

more than 220 kV - 380

kV

5.0 m

nominal voltage unknown 5.0 m

In the observation of safety distances, all working

movements of earth-moving machines, e.g.

positions of the work equipment and the

dimensions of attached loads must be taken into

consideration. Uneven ground which would cause

the earth-moving machine to be inclined and thus

nearer to overhead lines must also be taken into

account.

During work in windy conditions, both overhead

lines and work equipment may swing out, thus

reducing the safety distance.

If it is impossible to maintain sufficient distance

from overhead power lines and trolley wires, the

plant operator must consult with the proprietor or

operator of the overhead lines to find other safety

precautions to prevent current overspill. Such

measures could be, e.g.

• Switching off the current

• Re-routing the overhead line

• Cabling, or

• Limiting the work zone of earth-moving

machines.

2.14 Operation in closed rooms

If earth-moving machines are to be used in closed

spaces, these areas must be sufficiently ventilated

and special regulations observed.

2.15 Work stoppages

Before rest periods and at the end of the working

day, the driver of the earth-moving machine must

park the machine on ground which has sufficient

carrying capacity and is as level as possible, and

must secure it against unintended movement.

Before rest periods and at the end of the working

day, the driver must lower the work equipment onto

the ground or secure it so that it cannot move.

The driver is not to leave the earth-moving

machine if the work equipment has not been

lowered to the ground or secured.

Earth-moving machines shall only be parked in

places where they do not present an obstacle, e.g.

on the construction site or to plant traffic. Warning

devices, e.g. triangles, warning cordons, flashing

or hazard lights are to be used if necessary.

Before leaving the operator stand, the driver must

bring all operating equipment and controls into

home position, switch off the working hydraulics

and apply the brakes.

If the driver is leaving the earth-moving machine

unattended, he must first turn off the drive motors

and ensure that they cannot be started up by

unauthorized persons (e.g. removing ignition keys).

2 Safety and Accident Prevention

14 TL80

2.16 Change of work attachments,

maintenance, repair

Earth-moving machines shall only be converted,

maintained or serviced under the guidance of a

suitable person designated by the plant operator

and following the manufacturer’s Operating

Instructions.

After every change of work attachments, the driver

must convince himself that the quick-attach system

is correctly fastened and locked.

Work on e.g.

• brake systems,

• steering systems,

• hydraulic and

• electric systems

of the machine is only to be carried out by expert

personnel specially trained in these areas.

Stability must be ensured during all type of work on

the machine at all times.

The work equipment must be secured against

movement by lowering it to the ground or

equivalent measures, e.g. cylinder supports,

trestles. With the engine running, the unprotected

articulation range of articulated loaders shall not be

entered.

When jacking up earth-moving machines, jacking

devices must be positioned so that they cannot

slip. Jacks must be positioned and applied

absolutely straight, without tilting.

Raised earth-moving machines must be supported

by suitable structures such as crosswise stacks of

planks, square timbers or steel trusses.

Stabilize the earth-moving machine that has been

lifted with the work attachment, immediately after

lifting with a supporting structure. Work under

raised machines which are only supported by their

hydraulics is forbidden.

The engine/motor(s) must be turned off prior to all

maintenance and repair work. These requirements

may only be ignored in the case of maintenance or

repair work which cannot be performed without the

engine/motor(s) running.

When performing maintenance and repair work on

the hydraulic system, the hydraulic system must be

relieved of pressure. With the engine turned off,

lower the work equipment to the ground and

actuate all hydraulic control levers until there is no

pressure in the hydraulic system.

Before working on the electrics or when performing

arc-welding on the machine, the connection to the

battery must be disconnected.

When disconnecting the battery, first the negative

pole then the positive pole must be disconnected.

The battery must be re-connected in reverse order.

During repair work around the battery, it must be

covered with insulating material. Tools should

never be placed on or near the battery.

Protective devices of moving machine parts are

only to be opened or removed after the drive has

been switched off and cannot be switched on

again by unauthorized persons. Protective devices

are e.g. engine/motor covers, doors, protective

grating, trim.

Upon completion of assembly, maintenance or

repair work, all protective devices must once more

be attached in the proper manner.

Load-bearing parts of earth-moving machines are

only to be welded following consultation with the

manufacturer and in accordance with recognized

welding principles.

Protective structures (ROPS; FOPS) are not to be

welded or drilled in any way.

Safety and Accident Prevention 2

TL80 15

Before commencing work on the hydraulic system,

the operating pressure, pilot pressure, back

pressure and pressure inside the tank must be let

off.

Alterations, such as welding of the hydraulic

system, are only to be undertaken with the

manufacturer’s permission.

Swallowing lubricants as well as long and repeated

skin contact can be hazardous to health and

should therefore be avoided. When used properly,

there is no particular danger to health. The safety

specification sheets from the mineral companies

must be observed.

Only the hoses specified by the manufacturer shall

be used.

Hydraulic hoses must be routed and assembled by

expert personnel.

In the vicinity of fuel or batteries, smoking and

naked flames are prohibited.

2.17 Recovery, loading, transportation

Earth-moving machines are only to be loaded onto

recovery vehicles if adequate towing vehicles are

used.

The tow fixing points specified by the manufacturer

must be employed.

For loading and transportation, earth-moving

machines and all necessary auxiliary equipment

must be secured against unwanted movement.

The traveling gear and crawler unit of earth-moving

machines must be sufficiently cleaned of mud,

snow and ice to ensure that ramps can be driven

up without risk of slipping.

When transporting the earth-moving machine on

trucks, flatbed trailers, or by rail, it must be

sufficiently secured with chocks and by attachment

to the lashing points.

Before setting off, the route to be taken must be

examined to determine whether the roads are wide

enough, entrances and passages under bridges

are large enough and that roads and bridges have

sufficient carrying capacity.

2.18 Monitoring and inspections

The machine must be submitted to a general

inspection according to the existing UVVregulations (Accident Prevention Regulations).

This inspection must be carried out by an expert

(e.g. machine engineer or machine foreman):

• before the machine is put into operation for the

first time and before the machine is again put

into operation after essential modifications have

been made

• at least once a year

• in the meantime, according to operating

conditions and local environments.

The results of this inspection have to be recorded

in writing and this record kept until the next

inspection takes place.

Prior to every work shift, the machine operator

must check the earth-moving machine according to

the inspection and maintenance plan.

Hydraulic hoses must be replaced as soon as the

following damage is recognized:

• Damage to the outer layer which reaches the

intermediate layer,

• Embrittled patches on the outer layer,

• Deformations when under pressure or without

pressure which differ from the original shape of

the installed hose,

• Leaks,

• Damage to hose fittings or to the connection

between the fitting and the hose.

The coolant level may only be checked after the

engine has cooled down; the cap must be turned

carefully in order to let off excess pressure.

Prior to operations, the machine operator must

check the function of the safety devices.

The machine operator must advise the supervisor

immediately - and his replacement, if there is a

change of operator - with regard to any

shortcomings.

In the event of shortcomings which jeopardize the

operating safety of the earth-moving machine, it is

not to be used until these have been eliminated.

2 Safety and Accident Prevention

16 TL80

2.19 Fire prevention

• Switch off the engine when filling the fuel tank

and take special care as long as the engine is

hot.

• Never smoke or handle open flames whilst

refueling the tank of the machine.

MTK115002

The fire extinguisher must be kept in

the cabin (operator’s stand). The fire

extinguisher symbol must be

attached.

2.20 Emergency exit

The right-hand cab door acts as an emergency

exit.

2.21 Other dangers

Failure of hydraulic system

If the hydraulic system fails because the diesel

engine is not running, the hydraulic pump is

damaged or hydraulic oil has been lost, only the

following emergency functions can still be

performed:

• manual steering (without servo assistance) and

• lower work equipment (only if ignition is

switched on).

Technical data 3

TL80 17

3 Technical data

3.1 Views

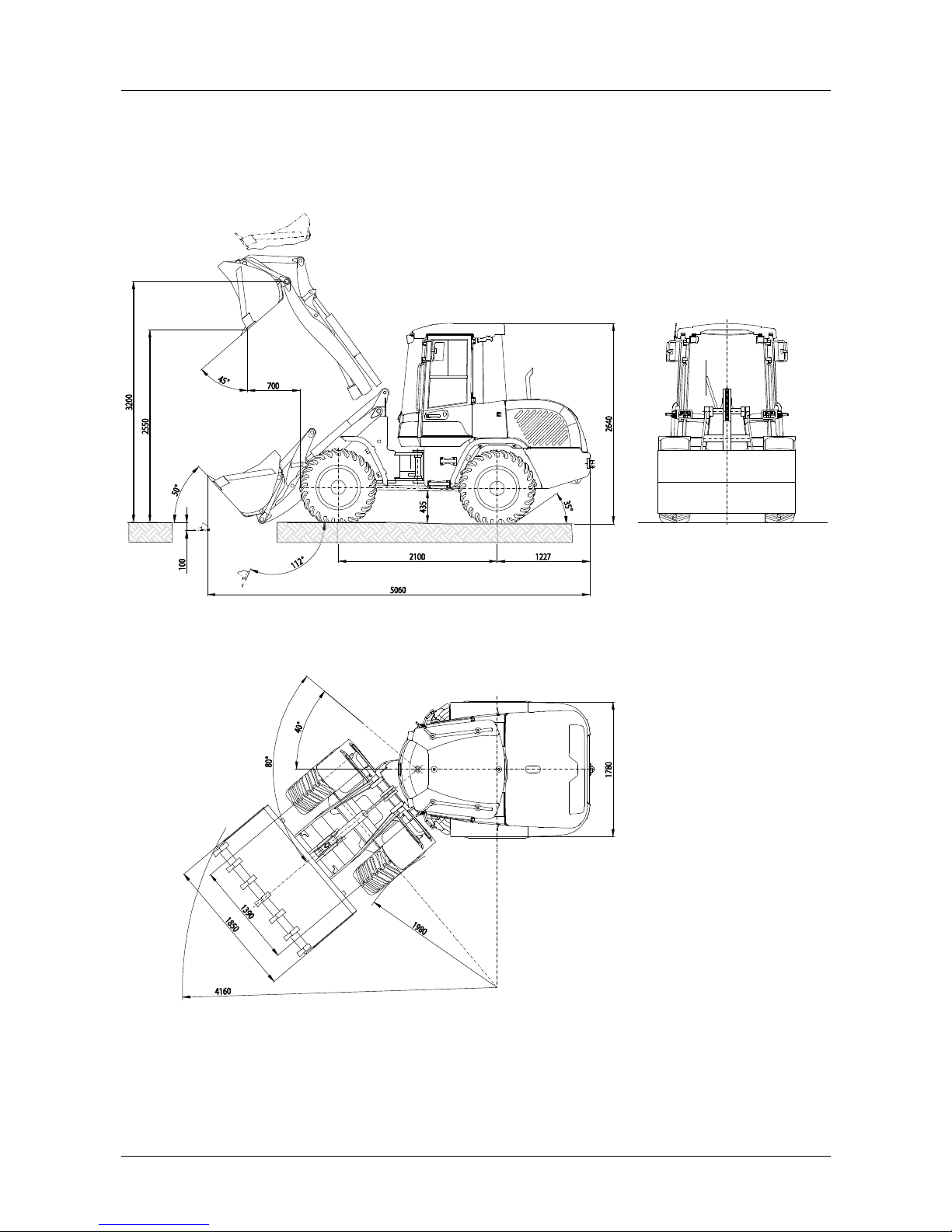

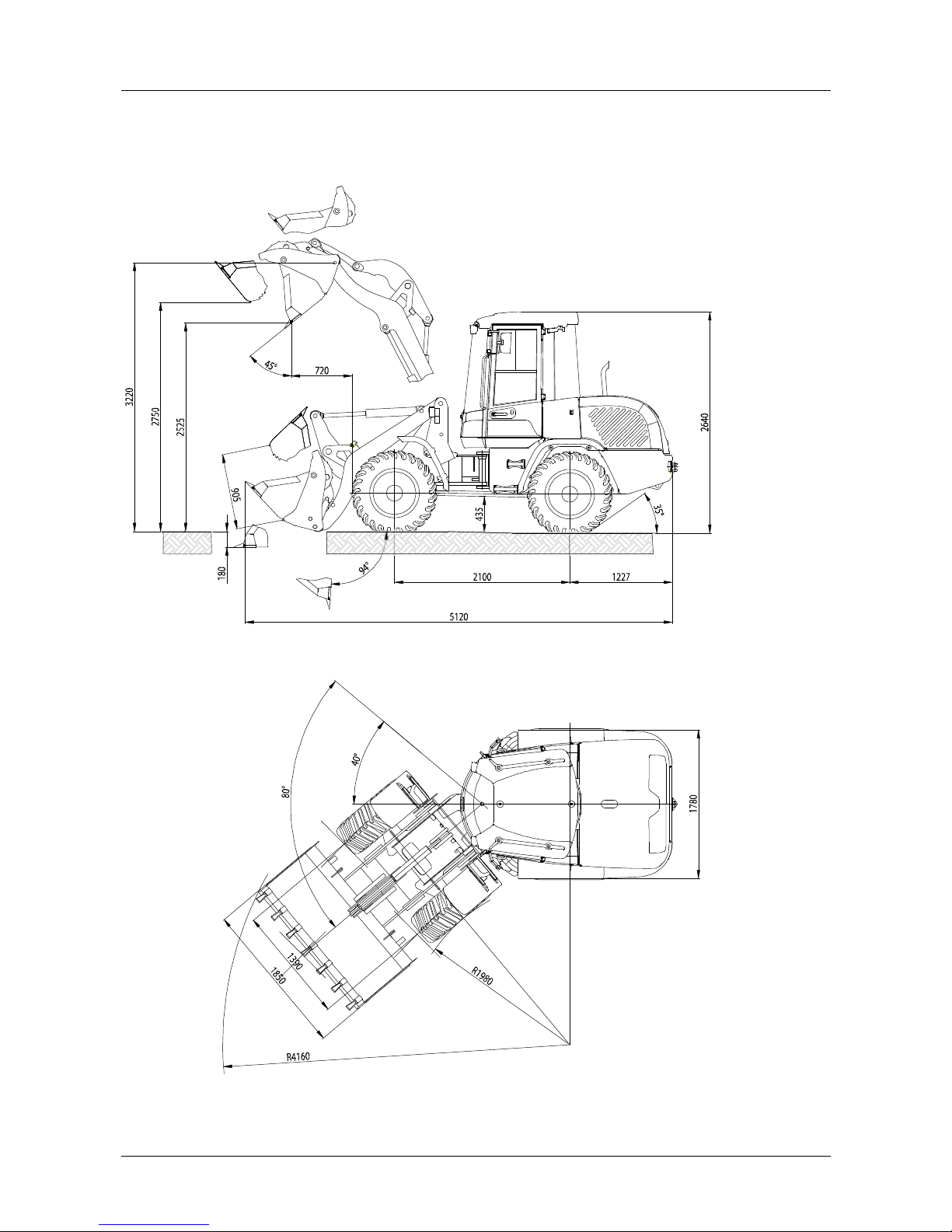

• General-purpose bucket and paralell kinematics

Fig. 3 Dimensioned drawing - standard bucket and parallel kinematics

Tires 405/70 R18

3 Technical data

18 TL80

• Multi-purpose bucket and paralell kinematics

Fig. 4 Dimensioned drawing - multi-purpose bucket and parallel kinematics

Tires 405/70 R 18

Technical data 3

TL80 19

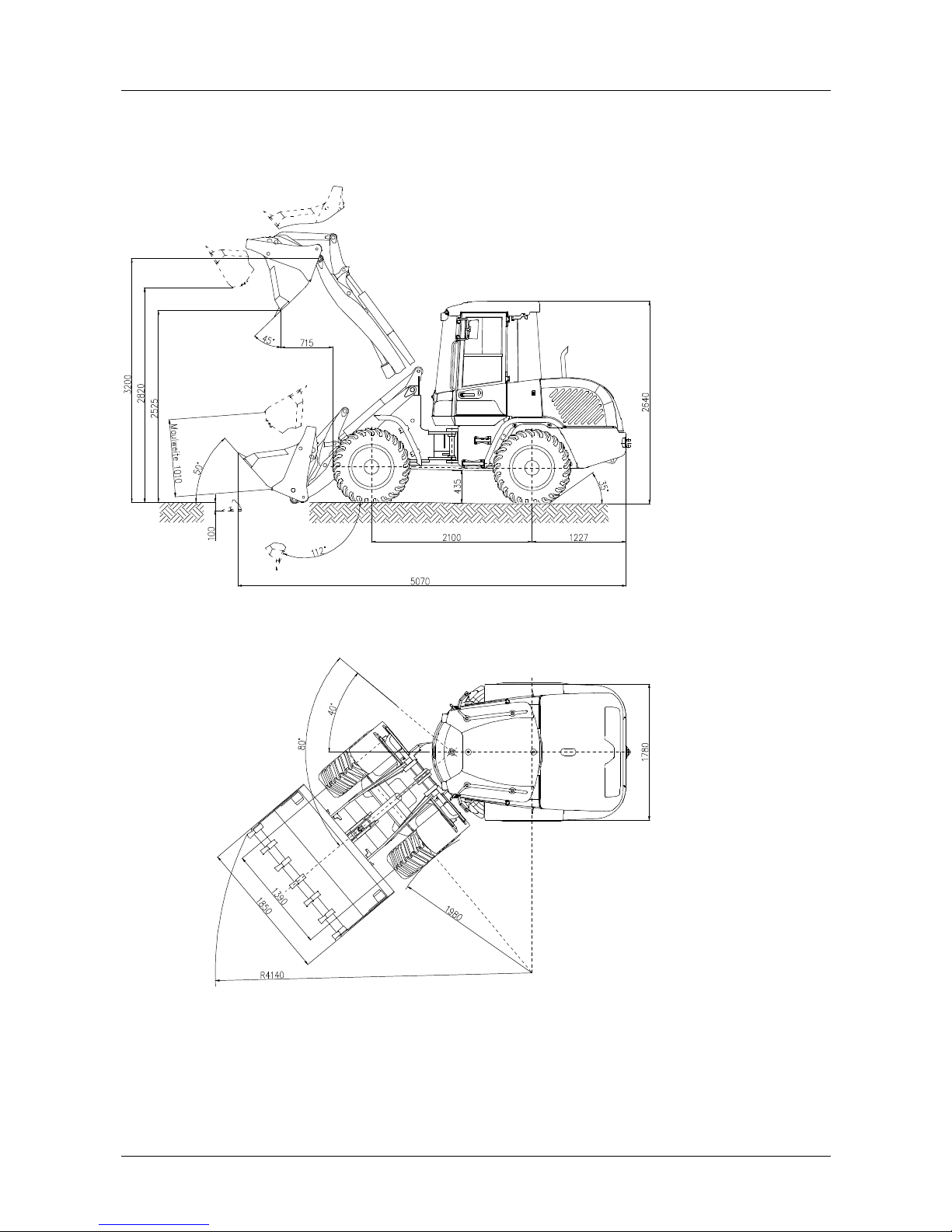

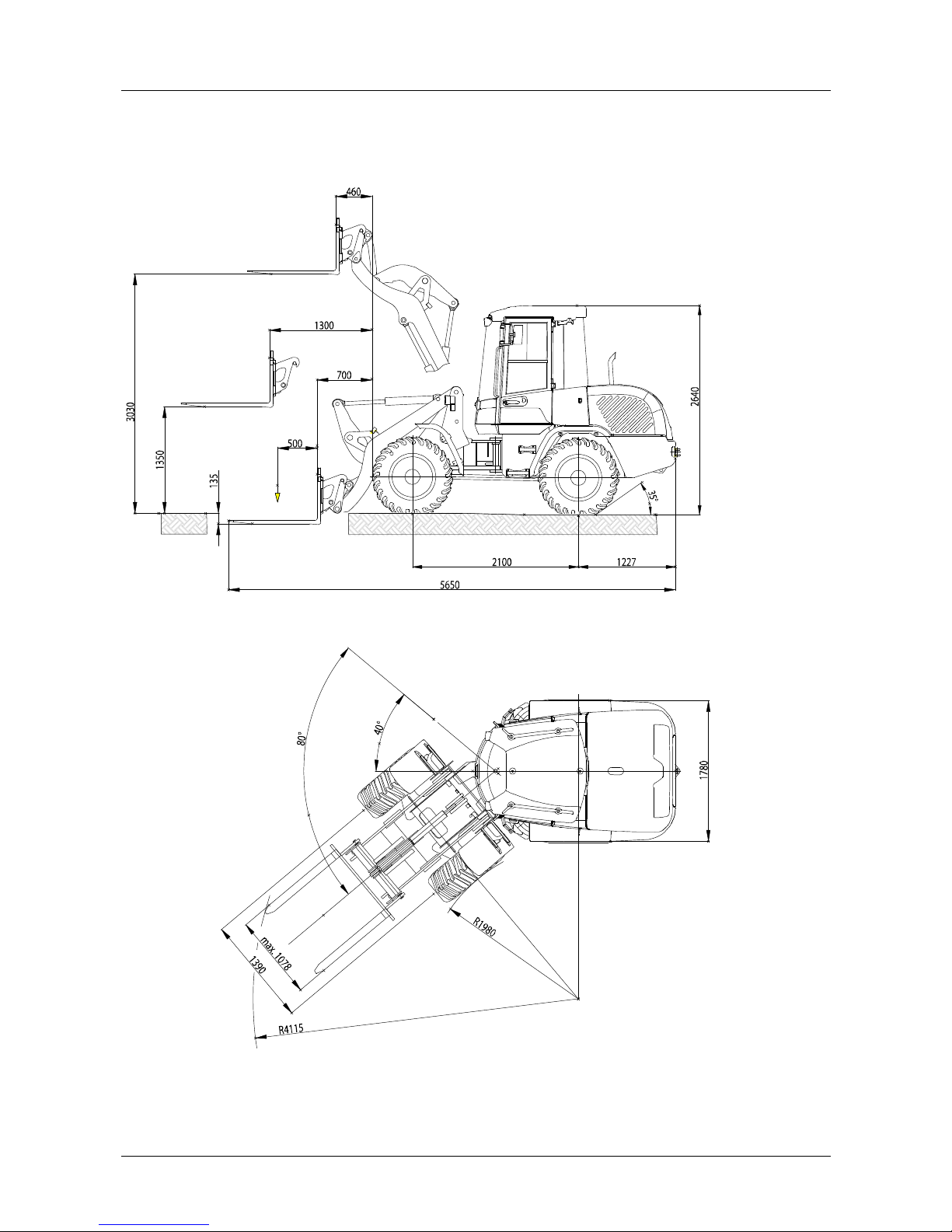

• Fork lift attachment and paralell kinematics

Fig. 5 Dimensioned drawing - fork lift attachment and parallel kinematics

Tires 405/70 R 18

3 Technical data

20 TL80

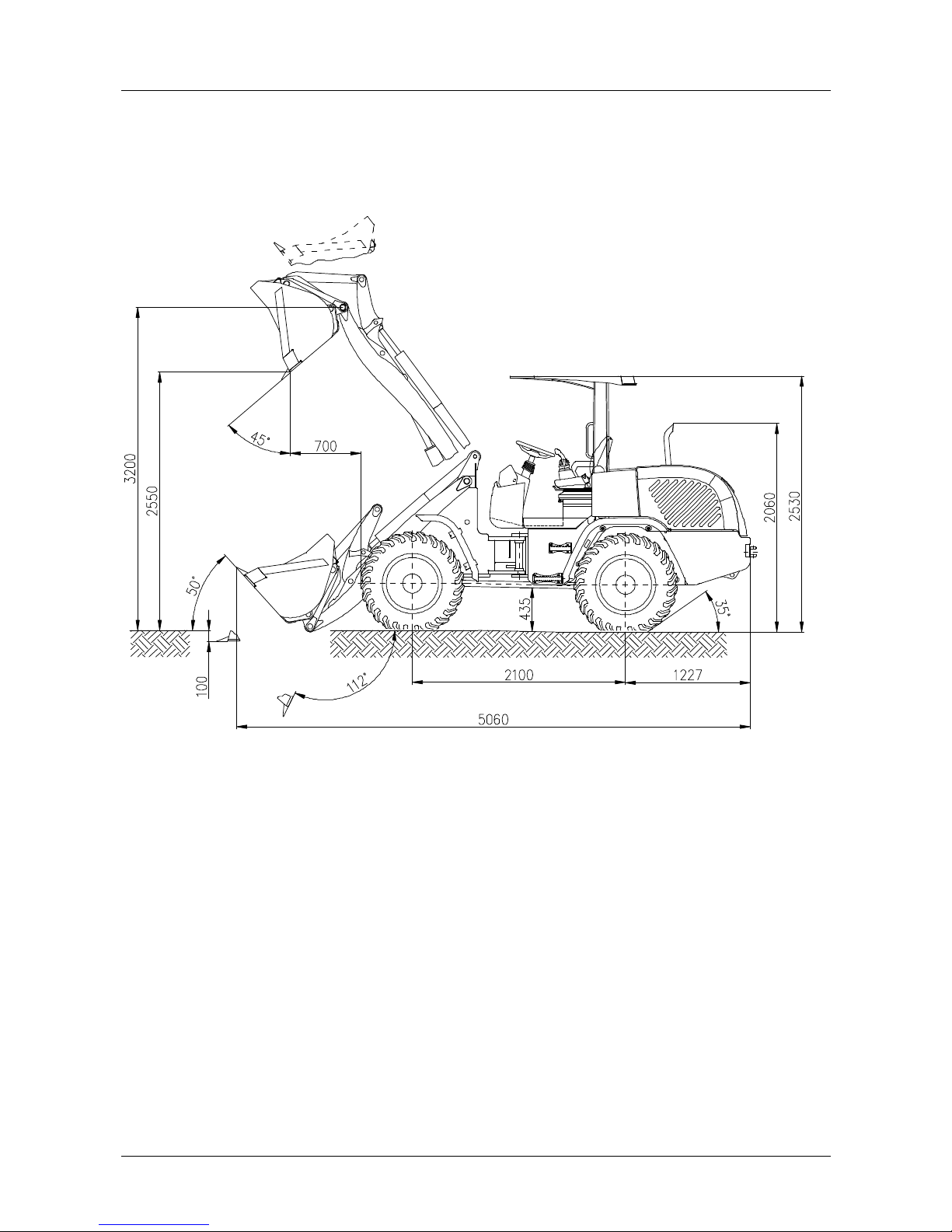

• General-purpose bucket and Z kinematics

Fig. 6 Dimensioned drawing - standard bucket and Z kinematics

Tires 405/70 R18

Technical data 3

TL80 21

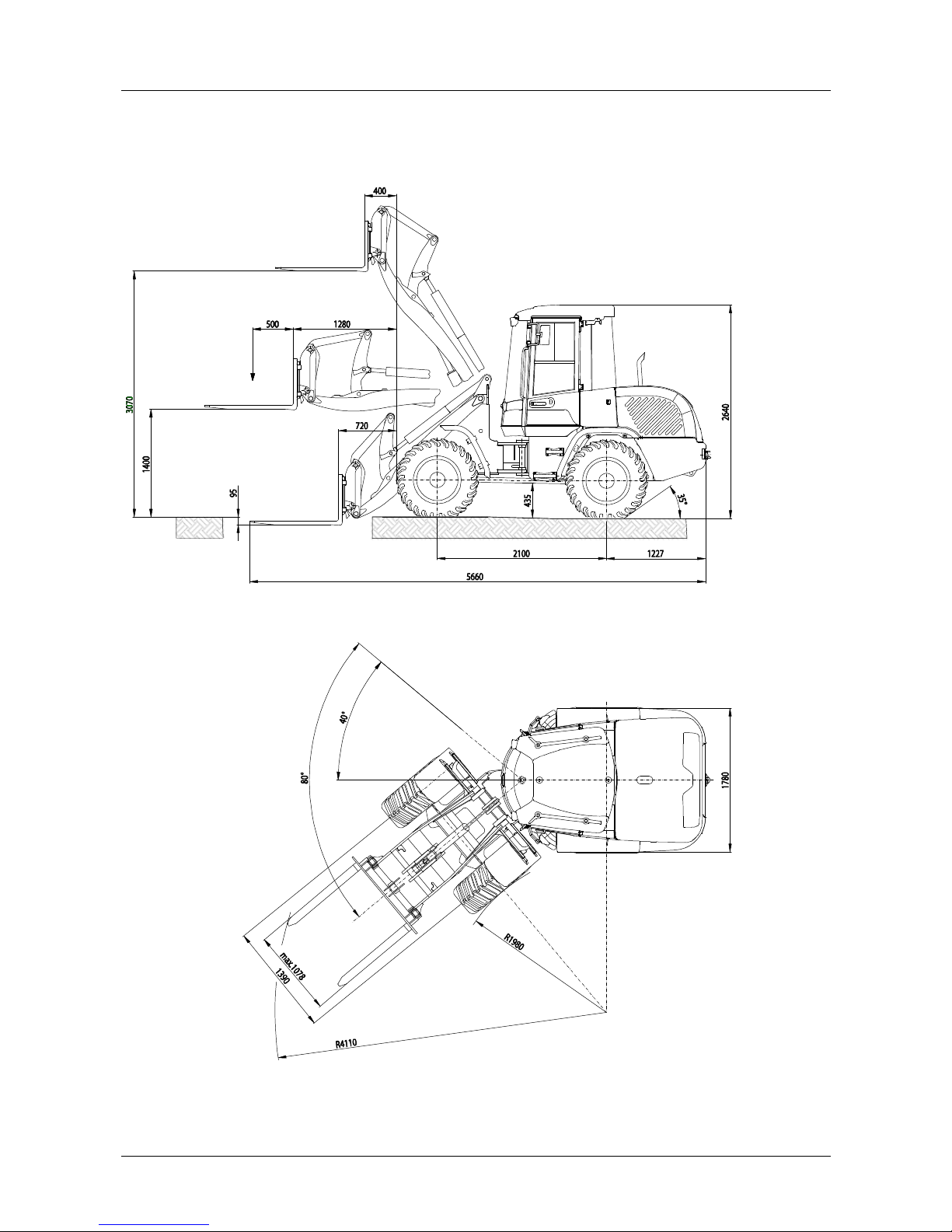

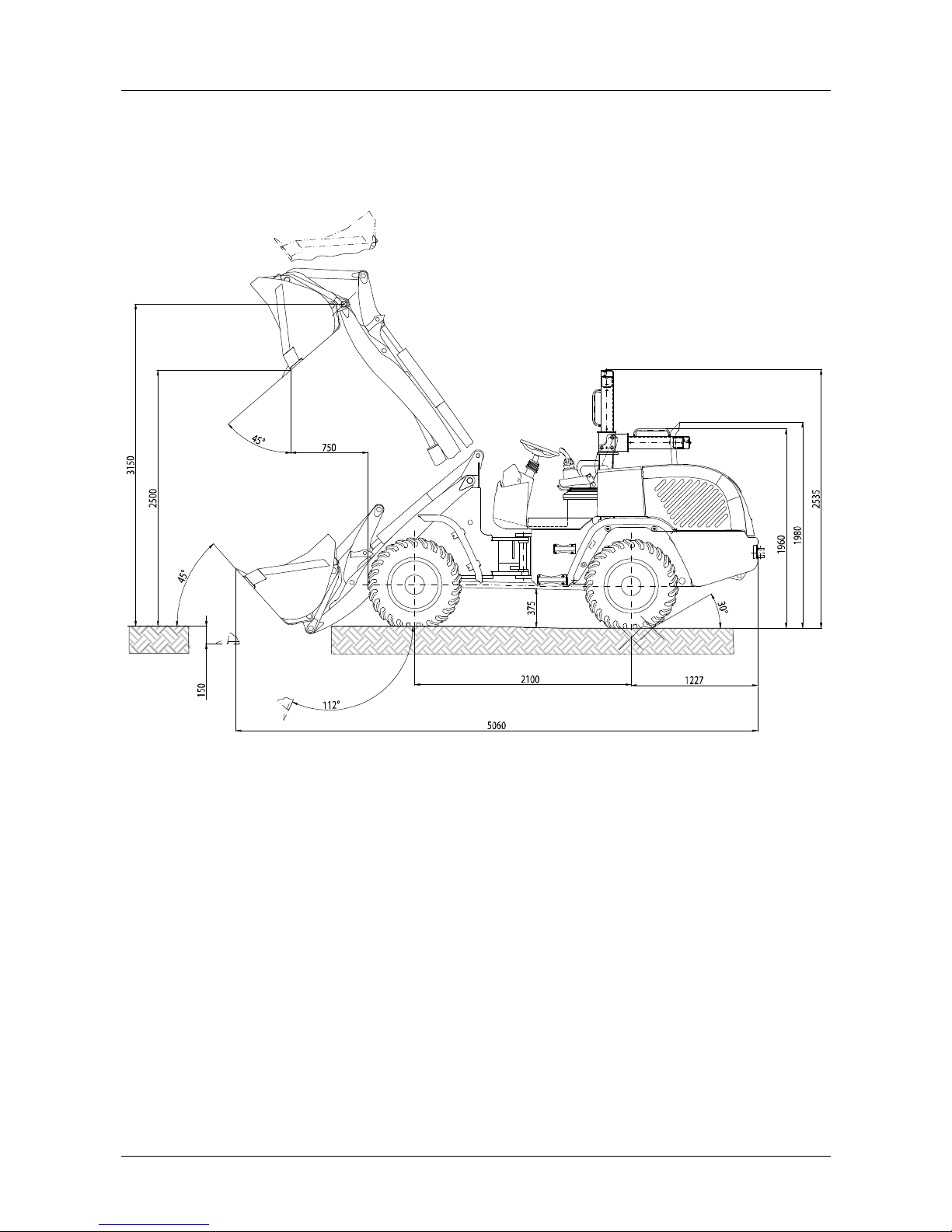

• Multi-purpose bucket and Z kinematics

Fig. 7 Dimensioned drawing - multi-purpose bucket and Z kinematics

Tires 405/70 R18

3 Technical data

22 TL80

• Fork lift attachment and Z kinematics

Fig. 8 Dimensioned drawing - fork lift attachment and Z kinematics

Tires 405/70 R18

Technical data 3

TL80 23

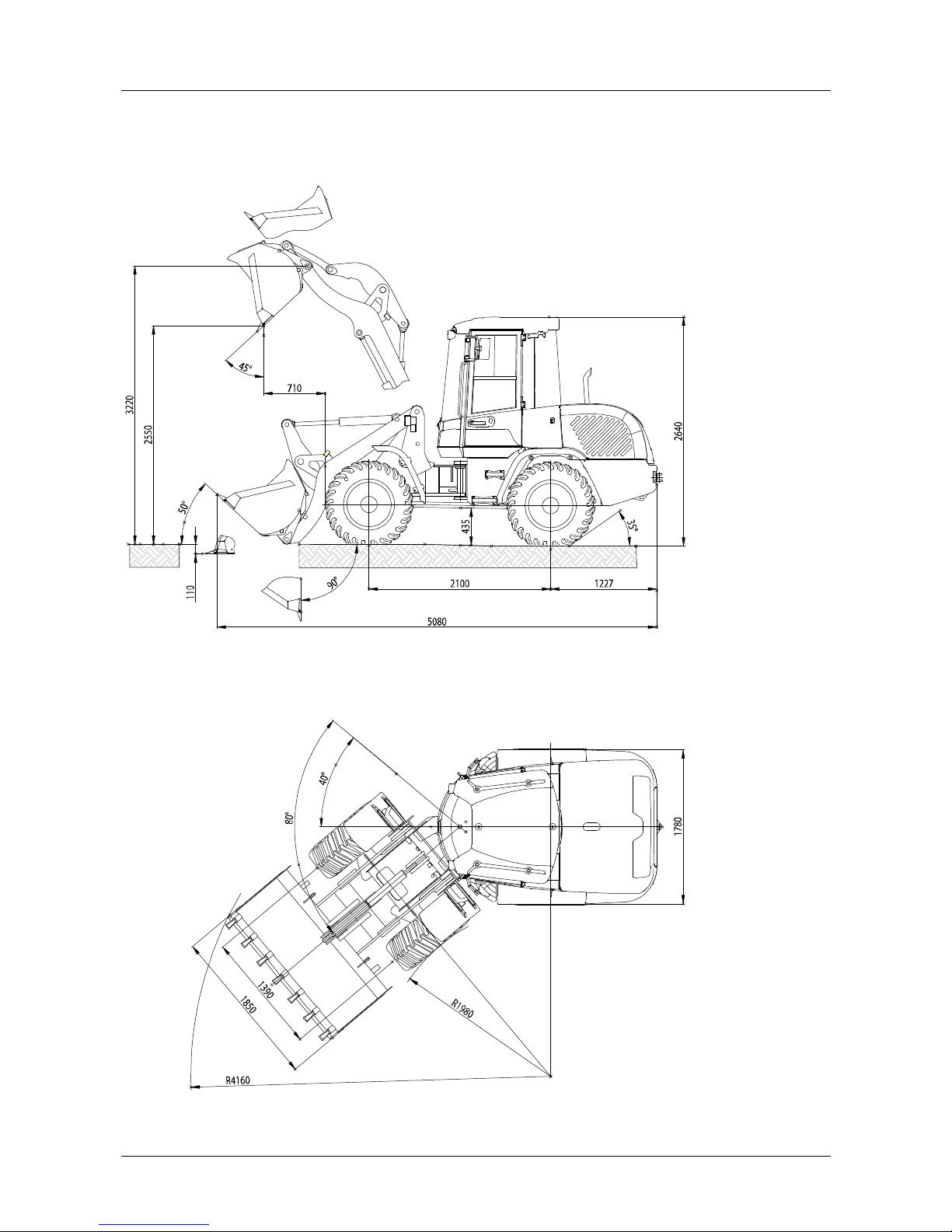

• Low profile canopy with general-purpose bucket 0.8 m³

Fig. 9 Dimensioned drawing - low profile canopy with standard bucket 0.8 m³

Tires 15.5/55 R18

3 Technical data

24 TL80

• Fold-down bar with general-purpose bucket 0.8 m³

Fig. 10 Dimensioned drawing - fold-down bar with standard bucket 0.8 m³

Tires 15.5/55 R18

Loading...

Loading...