Terex TA35, TA40 User Manual

TA35/TA40

Operation - Safety - Maintenance

WHEN RE-ORDERING THIS HANDBOOK,

SPECIFY - PART NUMBER 15275590

TECHNICAL PUBLICATIONS DEPARTMENT

TEREX EQUIPMENT LIMITED

MOTHERWELL, SCOTLAND ML1 5RY

Ref No. OHE 836/820 June 2005

ONLY TRAINED PERSONNEL SHOULD BE

ALLOWED TO OPERA TE THIS VEHICLE

The operator is responsible and must be

familiar with the contents of the Operator's

Handbook and any local regulations prior to

operating this vehicle .

CALIFORNIA

Proposition 65 Warnings

WARNING: Diesel engine exhaust and

some of its constituents are known to the

State of California to cause cancer, birth

defects, and other reproductive harm.

WARNING: Battery posts, terminals

and related accessories contain lead

and lead compounds, chemicals

known to the State of California to cause

cancer and reproductive harm.

Wash hands after handling.

SPARE PARTS STATEMENT

When carrying out repairs, alterations or fitting attachments, it is important that only genuine spare parts are

used to ensure the operating safety of the machine is not impaired.

It is only by using genuine parts that the technical requirements stipulated by the manufacturer can be

maintained.

If a General Operating Approval is issued for this machine, it may be considered null and void if non-genuine

parts are used.

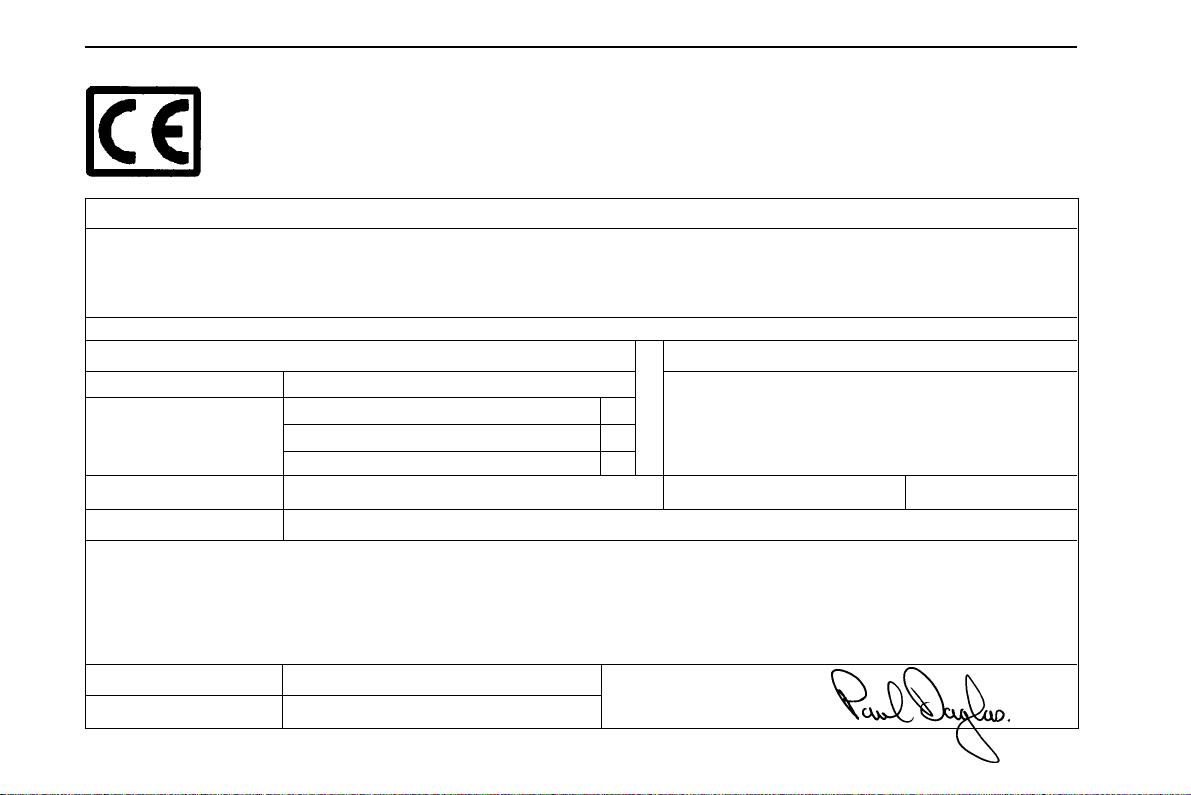

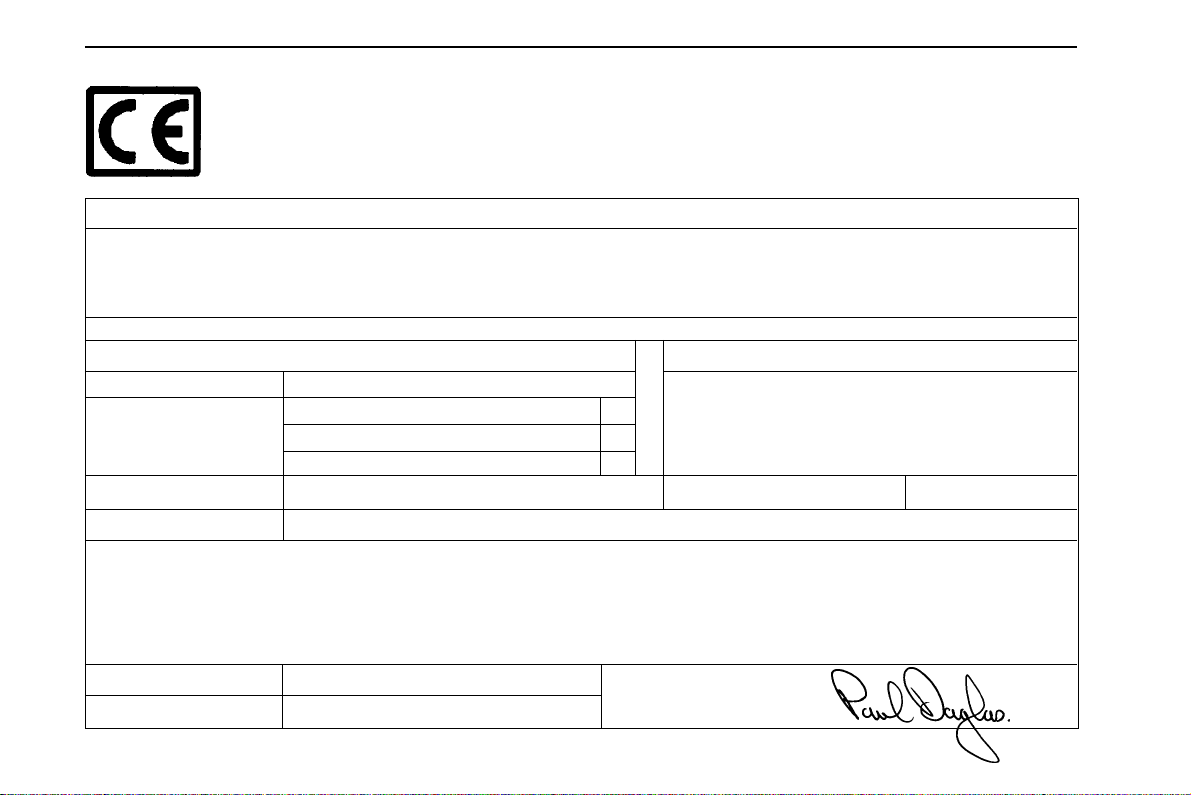

EC DECLARATION OF CONFORMITY

MANUFACTURERS NAME AND FULL ADDRESS

TEREX EQUIPMENT LIMITED,

MOTHERWELL,

SCOTLAND,

ML1 5RY

DESCRIPTION OF MACHINERY DIRECTIVES COMPLIED WITH

MAKE: TEREX 87/404/EEC 97/23/EC

MODEL: TA35 ARTICULATED TRUCK 89/336/EEC

TA40 ARTICULATED TRUCK 98/37/EEC

2000/14/EC

UNIT SERIAL NO. DATE OF MANUFACTURE:

INSPECTOR:

THE ABOVE MACHINERY, TAKING INTO ACCOUNT THE STATE OF THE ART,

COMPLIES WITH, OR IS DESIGNED AND CONSTRUCTED AS FAR AS POSSIBLE TO COMPLY WITH,

THE ESSENTIAL HEALTH AND SAFETY REQUIREMENTS OF THE MACHINERY DIRECTIVE.

FOR AND ON BEHALF OF THE MANUFACTURER:

NAME: PAUL DOUGLAS SIGNATURE:

POSITION: CHIEF ENGINEER

SPARE PARTS STATEMENT

When carrying out repairs, alterations or fitting attachments, it is important that only genuine spare parts are

used to ensure the operating safety of the machine is not impaired.

It is only by using genuine parts that the technical requirements stipulated by the manufacturer can be

maintained.

If a General Operating Approval is issued for this machine, it may be considered null and void if non-genuine

parts are used.

EC DECLARATION OF CONFORMITY

MANUFACTURERS NAME AND FULL ADDRESS

TEREX EQUIPMENT LIMITED,

MOTHERWELL,

SCOTLAND,

ML1 5RY

DESCRIPTION OF MACHINERY DIRECTIVES COMPLIED WITH

MAKE: TEREX 87/404/EEC 97/23/EC

MODEL: TA35 ARTICULATED TRUCK 89/336/EEC

TA40 ARTICULATED TRUCK 98/37/EEC

2000/14/EC

UNIT SERIAL NO. DATE OF MANUFACTURE:

INSPECTOR:

THE ABOVE MACHINERY, TAKING INTO ACCOUNT THE STATE OF THE ART,

COMPLIES WITH, OR IS DESIGNED AND CONSTRUCTED AS FAR AS POSSIBLE TO COMPLY WITH,

THE ESSENTIAL HEALTH AND SAFETY REQUIREMENTS OF THE MACHINERY DIRECTIVE.

FOR AND ON BEHALF OF THE MANUFACTURER:

NAME: PAUL DOUGLAS SIGNATURE:

POSITION: CHIEF ENGINEER

SPARE PARTS STATEMENT

When carrying out repairs, alterations or fitting attachments, it is important that only genuine spare parts are

used to ensure the operating safety of the machine is not impaired.

It is only by using genuine parts that the technical requirements stipulated by the manufacturer can be

maintained.

If a General Operating Approval is issued for this machine, it may be considered null and void if non-genuine

parts are used.

CONTENTS

1.INTRODUCTION

Introduction ........................................ 1-2

Safety Precautions ............................ 1-2

Machine Identification ........................ 1-4

Theft Deterrent Practices .................. 1-5

2. SAFETY PRECAUTIONS

General .............................................. 2-2

Articulation and Oscillation Locks ..... 2-3

Vehicle Lifting Precautions ................ 2-4

Vehicle Tie Down Precautions .......... 2-4

Preventing Fire Hazards....................2-5

Mounting and Dismounting................ 2-7

Pre-Starting........................................ 2-8

Starting............................................... 2-8

Operating ........................................... 2-9

Roading............................................ 2-11

Lubrication and Servicing ................ 2-12

Wheels and Tyres............................ 2-14

Avoid Tyre Explosion Hazard .......... 2-15

Decals and Instruction Plates.......... 2-16

3. CONTROLS AND OPERATING

Controls and Instruments .................. 3-3

Basic Data ......................................... 3-4

Warning Lights ............................... 3-4

Instruments .................................... 3-6

Switches.........................................3-8

Controls........................................ 3-11

Heater .......................................... 3-12

Air Conditioning............................ 3-12

3. CONTROLS AND OPERATING (Cont)

Operator's Seat -

Air Suspension (Grammer) ...... 3-13

Operator's Seat - Operation ........ 3-14

Seat Belt ...................................... 3-15

Machine Controls............................. 3-16

Braking ......................................... 3-16

Retarder ....................................... 3-17

Engine .......................................... 3-18

Electronic Foot Pedal............... 3-18

DDEC III & IV ........................... 3-20

Description ............................... 3-20

Operation ................................. 3-21

Steering........................................ 3-30

EST-37 Powershift

Transmission............................ 3-31

Differential Lock ........................... 3-40

Body Control ................................ 3-41

4. OPERATING THE TRUCK

Pre-Starting Inspection ...................... 4-2

Component Checks ........................... 4-3

Engine Operation............................... 4-6

Starting the Engine ............................ 4-7

Starting the Engine

with Jumper Cables ....................... 4-9

Pre-Operating Checks ..................... 4-10

Brake Function Checks ................... 4-11

Driving and Stopping ....................... 4-13

Stopping the Engine ........................ 4-15

Parking............................................. 4-16

5. WORKING THE TRUCK

Working the Truck ............................5-2

Loading ......................................... 5-2

Hauling .......................................... 5-5

Dumping........................................5-6

Empty Return ................................5-8

6. ROADING

Roading.............................................6-2

General ......................................... 6-2

Preparation Prior to Roading ........ 6-2

In Case Of Trouble ....................... 6-4

7. MOVING DISABLED TRUCK

Moving Disabled Truck .....................7-2

8. LUBRICATION AND SERVICING

Safety Precautions ........................... 8-2

Lubrication and Servicing ................. 8-3

Lubrication and Service Chart .......... 8-5

Miscellaneous Servicing

Information .................................... 8-8

Recommended Lubricants .............. 8-13

9. TECHNICAL DATA

Technical Data - TA35 ......................9-3

Technical Data - TA40 ......................9-8

10. SYMBOL IDENTIFICATION

1-1

INTRODUCTION

This Handbook is provided as a guide to familiarize the operator and serviceman

with the controls, recommended inspections, start-up, operating, shutdown and

parking procedures for TA35 and TA40 Articulated Trucks.

Look for this symbol to point out important safety precautions. It means:

ATTENTION! BECOME ALERT! YOUR SAFETY AND THE SAFETY OF

OTHERS IS INVOLVED!

Safety Precautions

The vehicle should be properly operated and maintained to keep it in safe,

efficient operating condition. Be sure that all controls are free of mud, grease, or

other matter that might cause slips hazardous to the operator, serviceman, or

other personnel or equipment. Report all malfunctions to those responsible for

maintenance, and, do not operate the equipment until corrected. Normal service

or maintenance performed as required can prevent unexpected and unnecessary

downtime.

This Handbook describes general inspections, servicing and operation with the

normal safety precautions required for normal servicing and operating conditions.

It is not a guide however, for other than normal conditions or situations, and

therefore, servicemen and operators must be safety conscious and alert to

recognize potential servicing or operating safety hazards at all times, and take,

necessary precautions to assure safe servicing and operation of the vehicle.

READ the CIMA Safety Manual supplied with this vehicle.

1-2

WARNING

These vehicles are equipped with cylinders containing compressed

nitrogen gas. Transportation of these vehicles by any method may

require a special permit from the appropriate authority of the country

involved. Consult your dealer for details.

All information, illustrations and specifications contained in this publication are

based on the latest product information available at the time of publication. The

right is reserved to make changes at any time without notice.

Continuing improvement and advancement of the design may cause changes to

your vehicle which may not be included in this publication. Each publication is

reviewed and revised, as required, to update and include these changes in later

editions.

This Handbook contains lubrication and routine servicing instructions, most of

which can be performed in the field. Service manuals containing repair/rebuild

procedures can be obtained from your dealer.

1-3

Machine Identification

While reading this handbook you will

notice references to controls and

equipment which may not be found on

all vehicles. It is important that you

know your vehicle and its equipment

and how to operate it properly.

Information regarding the vehicle

model, code and chassis serial

number is found on the unit serial

number plate on the rear right of the

front frame. The vehicle model and

serial number should always be

referenced in any correspondence

with your dealer or factory.

1-4

There is a dealer serving every part of

the world. Your dealer is ready to

provide you with any additional

information needed and should be

consulted for additional publications

for this vehicle.

1454

Theft Deterrent Practices

General

The owner/operator should take the following precautions to discourage theft, to

aid in the recovery in the event that the vehicle is stolen, or to reduce vandalism.

Actions to Discourage Theft and Vandalism

Remove all keys any time the vehicle is left unattended.

At night lock all doors and attach, secure or lock all anti-vandalism and

anti-theft devices on the vehicle.

Immobilize the vehicle by removing a critical electrical or starting system device.

Upon receipt of a vehicle, record the vehicle serial number and the serial

numbers of all major components and attachments. Keep this list up to date and

filed in a safe location for fast retrieval.

Place a decal or notice on the vehicle that all serial numbers are recorded.

Discourage the thief! Inspect the gates and fences of the machinery storage yard

or construction site. Keep vehicles in well-lit areas and ask the local law

enforcement authorities to make frequent checks around the storage yard or

work site.

Establish liaison with neighbours and ask them to watch equipment left at job

sites and to report any suspicious activities to the local law enforcement

authorities.

Make frequent inventories of vehicles to promptly detect losses or vandalism.

1-5

Actions to Aid in Recovery of Stolen Vehicles

In the event of theft, immediately notify the law enforcement authorities having

jurisdiction. Provide the investigating officer with name, type of equipment,

chassis and serial numbers of major attachments and components. It is helpful to

show the investigating officer an Operator’s Handbook, photographs, and

advertising, to familiarize him with the appearance of the vehicle.

Report the theft to the insurance company. Provide the model and all serial

numbers.

Report the model and serial numbers of the stolen vehicle to a dealer handling

the respective line of equipment. Request that the dealer forward this same

information to the equipment manufacturer.

1-6

2 - Safety Precautions

2-1

SAFETY PRECAUTIONS

General

* Read this Operator’s Handbook and learn the operating characteristics and

limitations of the vehicle. Know what operating clearances the vehicle

requires.

* Read the CIMA Safety Manual and follow the recommended safety

precautions.

* Know clearances of all side and overhead obstructions such as wires,

bridges, etc., for operating safely.

* Always know all traffic rules, signs, flags and hand signals used on the job

and know who has the responsibility for signalling.

* Be aware of operating hazards that weather changes can create on the job.

Know proper procedures to follow when a severe rain or electrical storm

strikes.

* Never attempt to operate or work on a machine when not feeling physically fit.

* Know what safety equipment is required and use it. Such equipment may be:

Hard hat, safety glasses, reflector type vests, respirators, ear plugs etc..

* Never wear loose clothing, rings, watches etc., that might catch levers and

controls and cause loss of control.

* Keep hands and controls free from water, grease and mud to assure nonslip

control.

2-2

* Handle fuels and lubricants carefully and clean up spills to avoid fire and

slipping hazards.

* Clean any mud, grease or oil from controls, handrails, ladders and decks.

Lash necessary tools securely and remove all loose items before operating

the vehicle. Never rush. Walk, do not run.

* Never carry more than one passenger and only in the passenger seat.

WARNING

The protection offered by the roll over and falling object

protective structure may be impaired if it has been subjected to

any modification or damage. Unauthorized modification will void

certification.

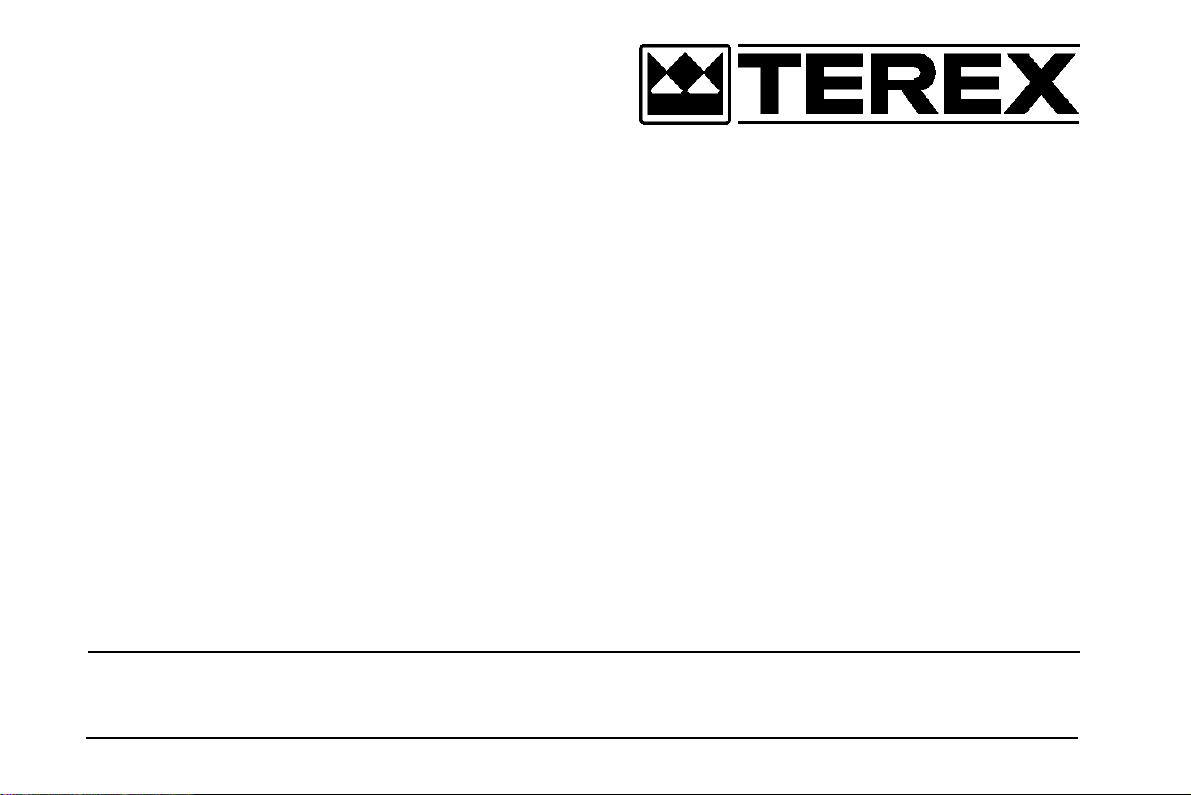

327

Steering Lock Bar Locked Position

Steering Lock Bar Stowed Position

328

Articulation and Oscillation Locks

* Always connect the steering lock bar and oscillation lock pin before working

in the articulation area, before lifting the vehicle and during transporting of

this vehicle by trailer/vessel.

* Always disconnect the steering lock bar and oscillation lock pin and secure in

the 'Stowed' position before operating the vehicle. The vehicle would not be

free to steer otherwise.

2-3

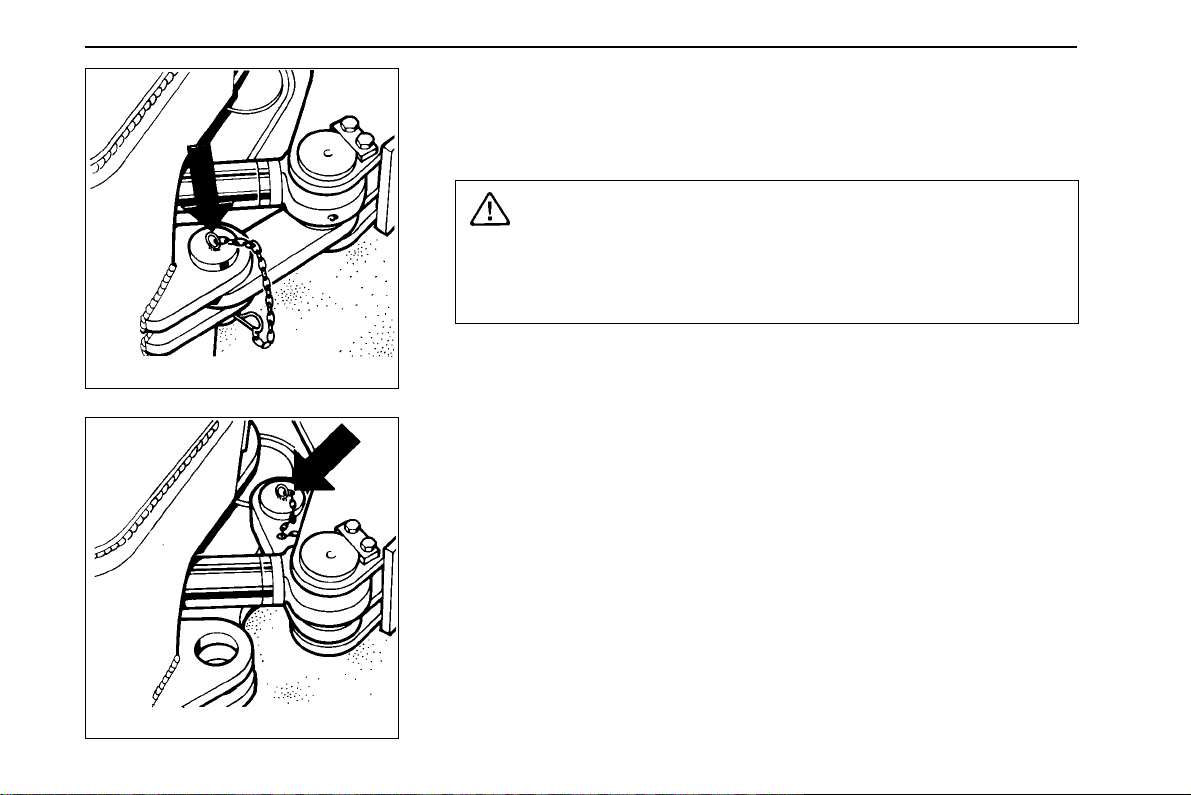

Vehicle Lifting Precautions

* Prior to lifting, the vehicle should be parked on a level surface, wheels

blocked, steering lock bar connected, oscillation lock pin inserted and the

parking brake disengaged.

* The vehicle should be lifted using a spreader bar if possible. Lift using FOUR

slings from the lifting points provided at the bumper end of the front chassis

and at the rear of the body.

Note: Be aware that this vehicle is free to oscillate if not lifted correctly. If in

any doubt contact your dealer for further information.

2-4

Vehicle Tie Down Precautions

* The vehicle should be secured at the tie down points located at the bumper

end of the front chassis, the front face of the trailer chassis and the tow pin at

the rear of the trailer chassis.

919

1010

Vehicle Lifting Instructions

FRONT REAR

CENTRE

Vehicle Tie Down Instructions

Preventing Fire Hazards

General Fire Precautions

* Make sure the vehicle has a fire extinguisher and that it is accessible and

fully charged. (Not furnished with machine).

* Never use an open flame as a light anywhere on, or around, the vehicle.

* Clean all dirt, oil, grease and other fluids from systems and components to

minimize fire hazards and aid in spotting loose or leaking lines, fittings etc..

* Check the engine compartment for rubbish, oily rags or other debris that

could cause fires before starting the engine.

* Don’t let greasy, oily rags or similar hazards accumulate in the cab.

* If the vehicle has been operated with an under inflated tyre. Make sure that

the tyre has cooled sufficiently before parking and leaving the vehicle

unattended.

Flammable Fluid Precautions

* Don’t use diesel fuel or other flammable fluids for cleaning purposes. Use

approved, nonflammable solvents.

* Make sure all fluid system caps, drain cocks, valves, fittings, lines etc., are

secure and leak free.

* Never use an open flame (match, lighter etc.) when checking fuel, lubricant,

coolant and battery fluid levels or when checking for fluid leaks. Use a

flashlight or other safe lighting only.

2-5

* Shut off engine and use extra caution if engine is hot when refuelling. Ground

the hose spout to prevent sparks when spout is touched to fuel tank filler tube.

* Never smoke while checking or adding fuel or other fluids or handling fluid

containers and lines.

* Use care and do not stand downwind when adding fuel or other flammable fluids

to tanks and reservoirs to avoid fluids being blown or splashed onto clothing.

* Close fuel tank shut-off valves, if used, before servicing fuel system.

* When preparing machines or components for storage, seal and tape all

openings and close containers tightly to seal in all volatile inhibitor fluids and

compounds used.

* Follow manufacturer’s recommendations when handling and using engine-

starting fluids and disposing of spent containers. Do not puncture or burn

empty containers. These fluids are explosive and highly flammable.

Electrical Hazard Precautions

* Never smoke or allow open flames or sparks near batteries.

* Leave battery box open when charging batteries in machine for adequate

ventilation of explosive gas (hydrogen) produced.

* Always disconnect batteries before repairing electrical system to avoid

danger of fire-causing sparks. Disconnect battery ground cable first and

reconnect last.

2-6

* Always disconnect batteries, alternator leads, engine ECU, transmission ECU

and body hydraulic joystick before carrying out any welding on the machine.

* Never check battery charge by placing metal objects across battery posts to

avoid sparks at battery posts.

* Use jumper cables only as recommended. Improper use can result in battery

explosion or unexpected vehicle motion.

* Never operate engine starter for more than 30 seconds and allow two

minutes between cranking periods for cooling. An overheated starter could

cause a fire.

* If electric coolant or lubricant heaters are used, be sure to follow heater

manufacturer’s recommendations for use to avoid electrical and/or fire

hazards.

Mounting and Dismounting

* Only use steps and hand holds provided to mount or dismount the vehicle.

Do not grasp steering wheel.

* Always face the access system and maintain at least three points of support

to mount or dismount the vehicle.

* Always use care when mounting the vehicle with oil covered, frosted, or iced

fenders, decks, hand holds or steps.

* Never mount or dismount a moving vehicle. Never jump off the vehicle.

2-7

Pre-Starting

* If engine is to be started and run indoors, ensure proper ventilation to

remove deadly exhaust gases.

* Always perform 'Pre-Starting Inspection' instructions described on page 4-2

to ensure the vehicle is ready for operation.

* Always walk around the vehicle to make sure no-one is working on,

underneath or close to the vehicle before starting the engine or operating the

vehicle.

* Adjust, secure and latch the seat and fasten the seat belt before starting the

vehicle.

* Sound horn before starting the engine or beginning to move the vehicle; two

blasts for forward and three blasts for reverse.

Starting

* Do not start the engine or operate any control if there is a 'DO NOT

OPERATE' or similar warning sign attached to any control.

* Use jumper cables only as recommended. Improper use can result in battery

explosion or unexpected vehicle motion.

* Always obey 'Starting the Engine' instructions described on page 4-6.

* Do not bypass the vehicle’s neutral-start system. The neutral-start system

must be repaired if it malfunctions.

2-8

* Start and operate the vehicle only from the operator’s station.

Operating

* Ensure all cab glass, mirrors and light lenses are clean during vehicle

operation for maximum visibility.

* Always keep cab floor clear of anything that could restrict full operation of

pedals.

* Always make sure all gauges, warning/indicator lights and controls are

working properly before operating vehicle.

* Always perform 'Pre-Operating Checks' described on page 4-9 to ensure the

vehicle is ready for operating.

* Always wear seat belts when operating the vehicle.

* In the event of a loss of steering system supply pressure, a red warning light

on the instrument panel will illuminate. If this light illuminates, indicating a loss

of steering power, the vehicle must be stopped immediately and no further

operation attempted until the fault is corrected.

* Do not operate if exposed personnel enter the immediate work area.

* Sound horn before starting engine or beginning to move vehicle; two blasts

for forward and three blasts for reverse.

* Watch for ground crew and other personnel on foot. Sound horn as a warning

before setting vehicle in motion and when approaching ground crew.

* Be sure the body is fully down before moving the vehicle.

* Always try to face or look in the direction the vehicle is travelling.

2-9

* Use extreme caution and turn on lights at night or when fog, dust or similar

hazards limit visibility. Do not overdrive your headlights.

* Observe instruments frequently. Report any defects or unusual noises in

vehicle during operation.

* Stay in gear when driving downhill. Do not coast with transmission in neutral.

Select the proper gear and maintain safe speed with the service brakes and/

or retarder. Always maintain safe speeds for haul road operating conditions

for maximum control. Reduce speed before turning.

* In the event of a loss of electric power to the gear shift control, the

transmission will automatically shift to NEUTRAL. If this occurs, stop the

vehicle using the service brakes, apply the parking brake and do not operate

until the fault is corrected.

* Always operate straight up or down slopes whenever possible, side-hill

operation can cause sideslip and possible roll-over.

* Slow down when moving in congested areas. Do not race with other vehicles.

Stop in authorized areas only, except in emergency.

* Brake firmly in one application. Do not FAN the pedal. Never operate the

vehicle if a warning light indicates a fault in the braking system.

* Always give loaded vehicles the right-of-way when your vehicle is empty.

* Always watch for holes, soft edges or other hazards when backing to dump

over a spoil bank.

2-10

* Always apply the brakes with the Parking-Emergency brake control when the

vehicle is being loaded or when dumping a load.

* Always stay in cab when being loaded.

* Always lower the body and shut down the vehicle according to the procedure

under 'Stopping The Engine' described on page 4-14 before leaving the

vehicle unattended. If on a grade wheels should be blocked.

Roading

* Match speed to road conditions.

* Yield the right of way when required. Obey the rules of the road.

* Stay as close to the side of the road as possible. Pass other equipment only

when the road is clear and enough room and reserve power are available.

* Stop at appropriate intervals to inspect the vehicle and allow the tyres to cool.

Tyre air pressure will rise during operation. Do not reduce tyre pressure.

Excess speed will cause tyres to heat up. Reduce your travel speed, not tyre

pressure.

* Use accessory lights and devices at night or in poor visibility. Carry a flare kit.

Do not overdrive your headlights.

2-11

Lubrication and Servicing

* Do not allow unauthorized personnel to service or maintain this vehicle.

Study the Operator’s Handbook and Maintenance Manual before starting,

operating or servicing this vehicle. Always follow procedures and safety

precautions detailed throughout the Maintenance Manual.

* Always attach a 'DO NOT OPERATE' or similar warning sign to ignition

switch or a prominent control before cleaning, lubricating or servicing the

vehicle.

* Never allow anyone to work on the vehicle while it is moving. Make sure no

one is on the vehicle before working on it.

* Do not work under or near unblocked or unsupported body. Always use the

body safety prop. The body safety prop must only be used when the body is

empty.

* Do not work under or near any unblocked or unsupported linkage, part or

machine.

* Always install the steering lock bar before making adjustments or servicing

the vehicle with the engine running. Refer to 'General' safety section.

* Always shut down vehicle according to the procedure under 'Stopping The

Engine', described on page 4-14, and turn off the master switch before

cleaning, lubricating or servicing the vehicle except as called for in this

Operators Handbook or the Maintenance Manual.

* Always relieve pressure before servicing any pressurized system. Follow the

procedures and safety precautions detailed in the relevant Maintenance Manual

section.

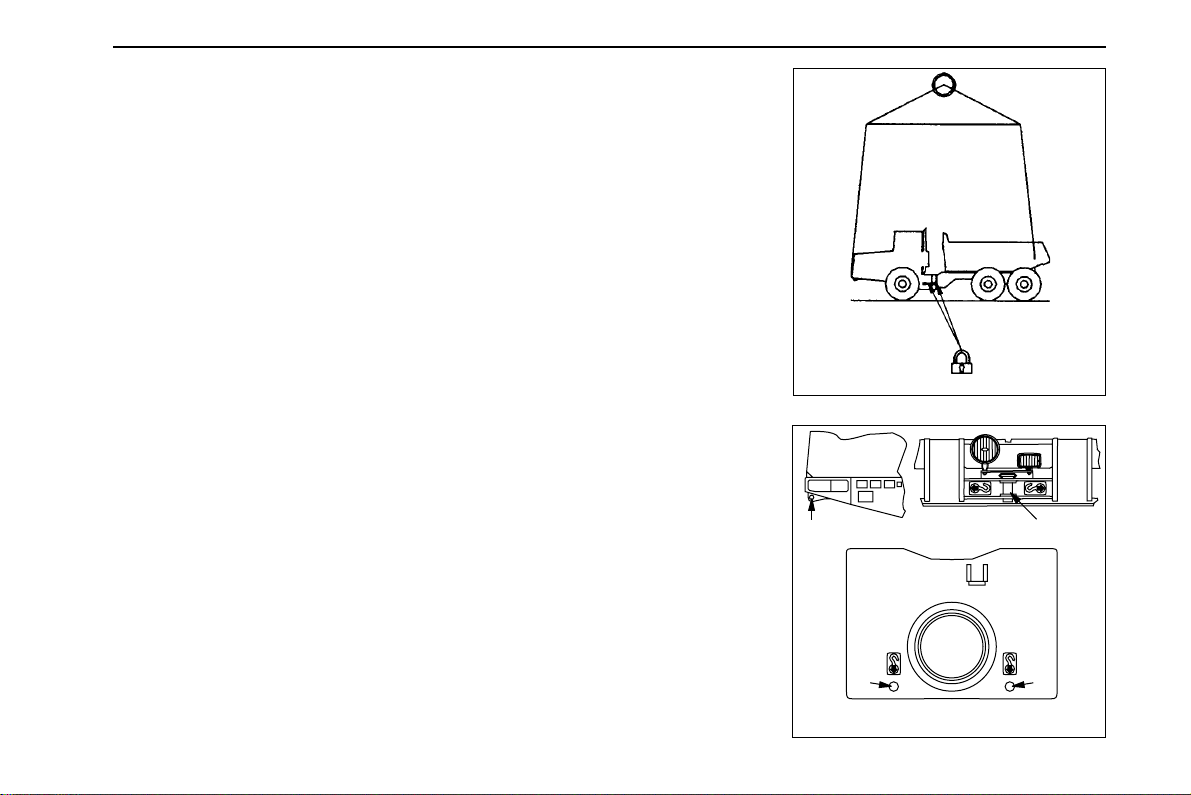

171

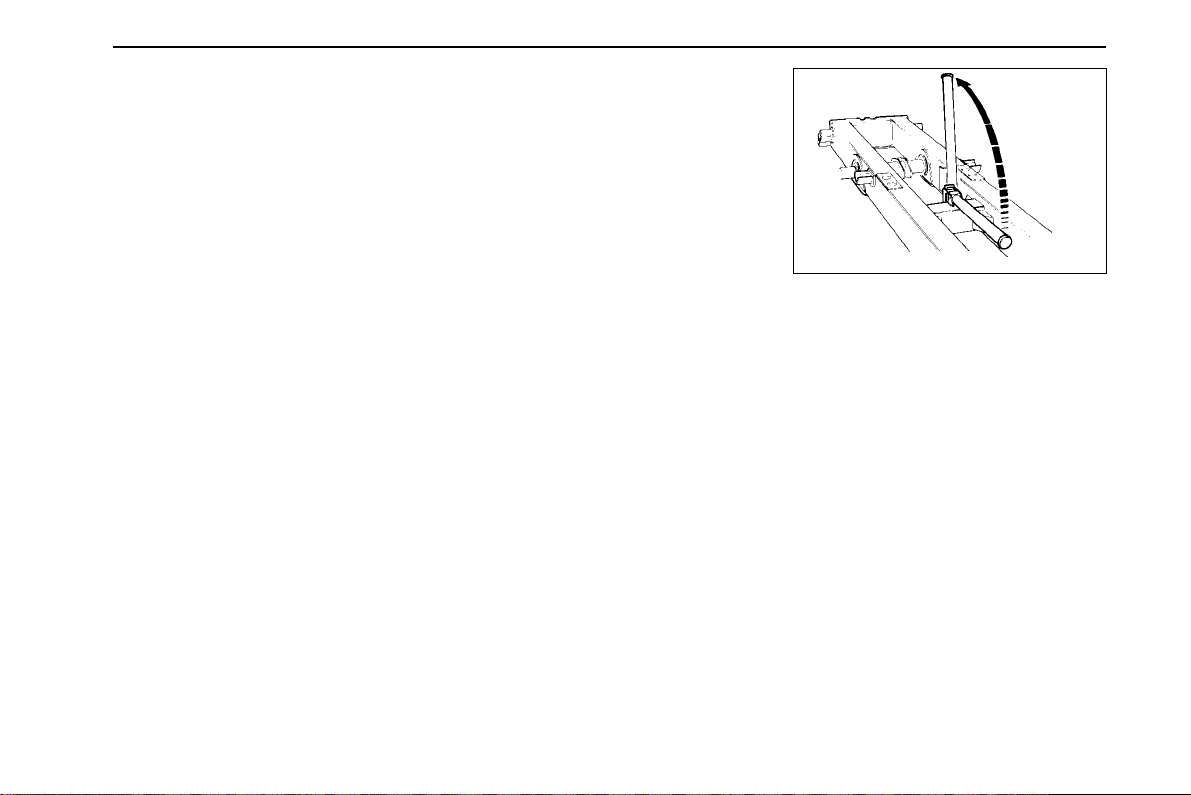

Body Prop

2-12

* When changing oil in the engine, transmission and hydraulic systems, or

removing hydraulic lines, remember that the oil may be hot and can cause

burns to unprotected skin.

* When working on or around exhaust components, remember that the

components may be hot and can cause burns to unprotected skin.

* Always deflate tyre before attempting to remove any embedded objects or

removing the tyre and rim assembly from the vehicle.

* Always use a self-attaching chuck with a long airline and stand to one side

while the tyre is inflating. Refer to Section 160-0050, WHEEL RIM AND TYRE

in the Maintenance Manual.

2-13

2-14

Wheels and Tyres

If tyres on the vehicle were inflated at the factory with dry nitrogen gas, the tyre

walls will be marked 'N' and the following factory installed decal will be found

mounted on the fenders.

NOTICE

TYRES ON THIS VEHICLE ARE FACTORY INFLATED WITH DRY

NITROGEN. IT IS RECOMMENDED THAT DRY NITROGEN BE USED

EXCLUSIVELY FOR ALL TYRE PRESSURE ADJUSTMENTS AS WELL AS

INFLATION OF REPLACEMENT TYRES.

Nitrogen gas improves tyre pressure retention, increases tyre life by reducing

carcass oxidation from within, minimizes rim rust, and has no known detrimental

effect on the tyre. It also reduces the potential of a tyre explosion because it is an

inert gas and will not support combustion inside the tyre. The same tyre inflation

pressure used for air inflation should be used for nitrogen inflation. Refer to

Section 160-0050, Nitrogen Inflation of Tyres of the vehicle Maintenance Manual for

recommended procedures for inflating and pressure adjusting tyres with dry

nitrogen gas. Only proper nitrogen charging equipment operated by personnel

trained in its use should be used.

WARNING

Never mix components of one manufacturer’s rims with those of

another. Using the rim base of one manufacturer with the lock ring of

another or vice versa is dangerous. The lock ring of one may not fully

engage with the lock ring groove of the other. Always consult the rim

manufacturers for proper matching, assembly and safety instructions.

Also, use and servicing of damaged, worn out or improperly assembled

rim assemblies is a very dangerous practice. Failure to comply with the

above warnings could result in an explosion from tyre pressure causing

serious property damage and serious personnel injury or death.

Loading...

Loading...