Terex Genie Z-34/22 IC Service And Repair Manual

Service and Repair Manual

Serial Number Range

Z-34/22 IC

from Z3406-4800

This manual includes:

Repair procedures

Fault

Electrical and

Hydraulic Schematics

For detailed maintenance

procedures, refer to the

appropriate Maintenance

Manual for your machine.

Part No. 1268527

Rev A

September 2015

Codes

Service and Repair Manual September 2015

Introduction

Introducti on Introducti on

Important

Read, understand and obey the safety rules and

operating instructions in the appropriate Operator's

Manual on your machine before attempting any

procedure.

This manual provides troubleshooting and repair

procedures for qualified service professionals.

Basic mechanical, hydraulic and electrical skills

are required to perform most procedures. However,

several procedures require specialized skills, tools,

lifting equipment and a suitable workshop. In these

instances, we strongly recommend that

maintenance and repair be performed at an

authorized Genie dealer service center.

Technical Publications

Genie has endeavored to deliver the highest

degree of accuracy possible. However, continuous

improvement of our products is a Genie policy.

Therefore, product specifications are subject to

change without notice.

Readers are encouraged to notify Genie of errors

and send in suggestions for improvement. All

communications will be carefully considered for

future printings of this and all other manuals.

Contact Us:

Internet: www.genielift.com

E-mail: awp.techpub@terex.com

Compliance

Machine Classification

Group B/Type 3 as defined by ISO 16368

Machine Design Life

Unrestricted with proper operation, inspection and

scheduled maintenance.

Find a Manual for this Model

Go to http://www.genielift.com

Use the links to locate Operator's, Parts,

Maintenance, and Service and Repair manuals.

Copyright © 2015 by Terex Corporation

1268527 Rev A, September 2015

First Edition, First Printing

Genie is a registered trademark of Terex South Dakota, Inc. in

the U.S.A. and many other countries.

“Z” is a trademark of Terex South Dakota, Inc.

ii Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Revision

Date

Section

Procedure / Page / Description

Introduction

Revision History

A 9/2015

Release

Reference Examples:

Section – Repair Procedure, 4-2

Section – Fault Codes, All charts

Section – Schematics, Legends and schematics

Part No. 1268527 Z-34/22 IC iii

Click on any content or procedure in the Table of Contents to view

Electronic Version

the update.

Service and Repair Manual September 2015

Introduction

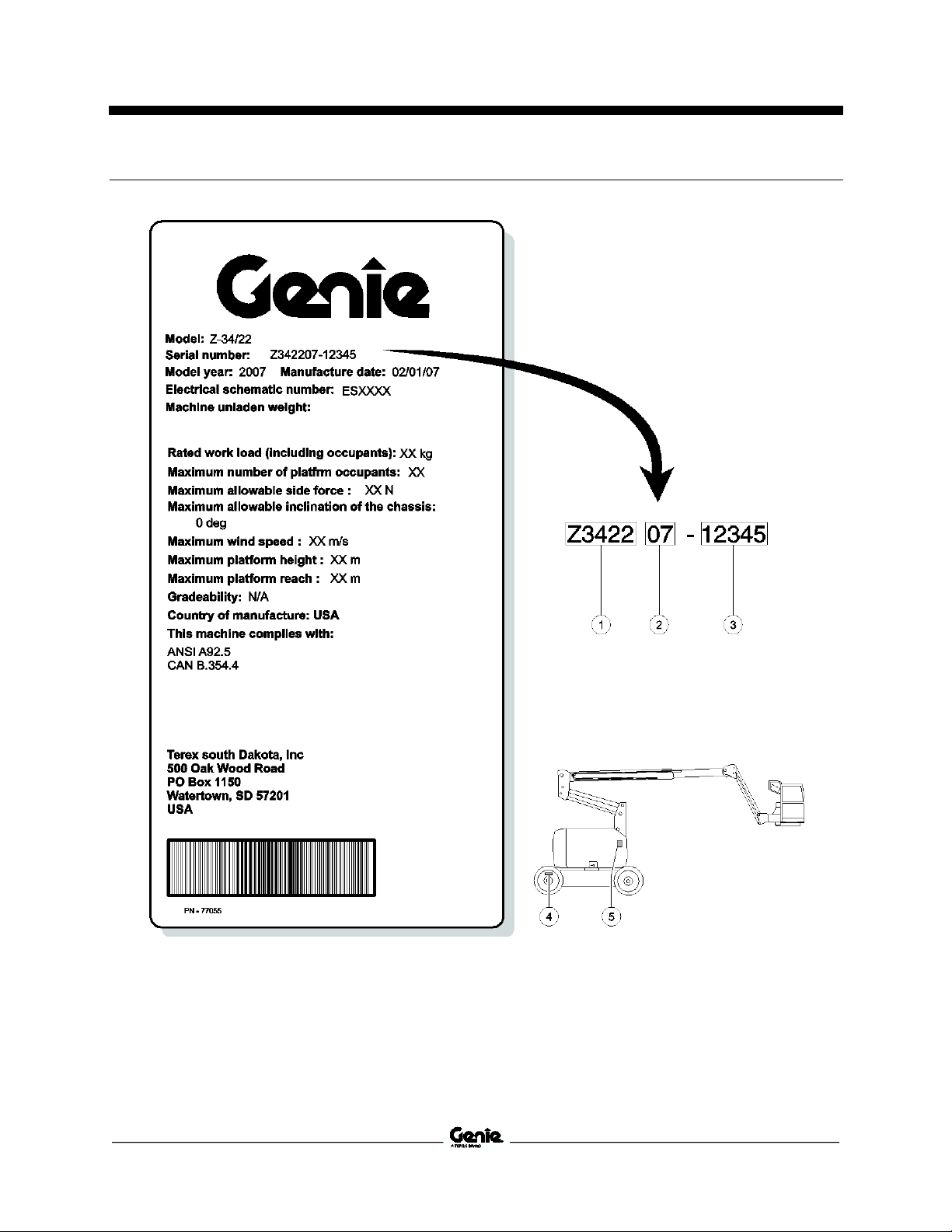

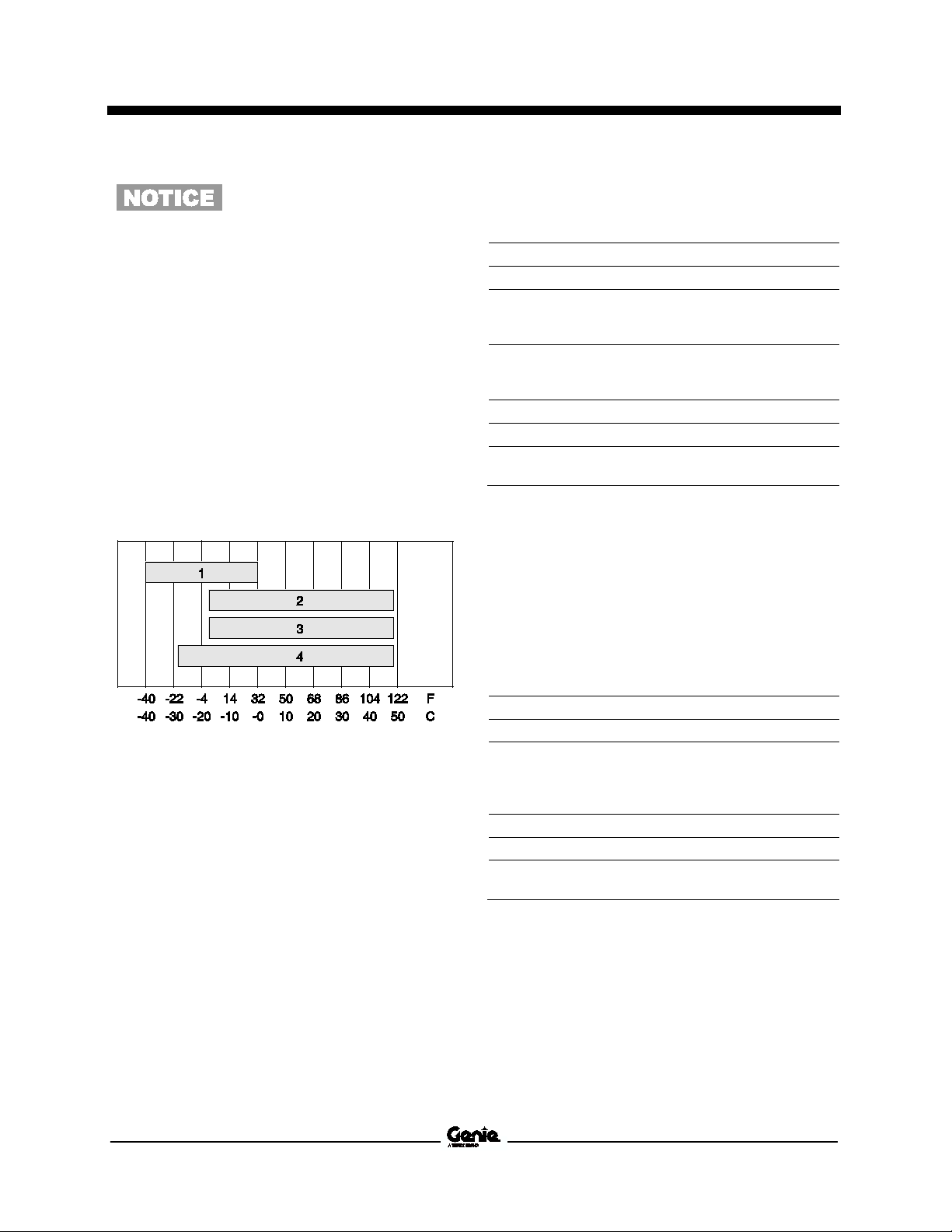

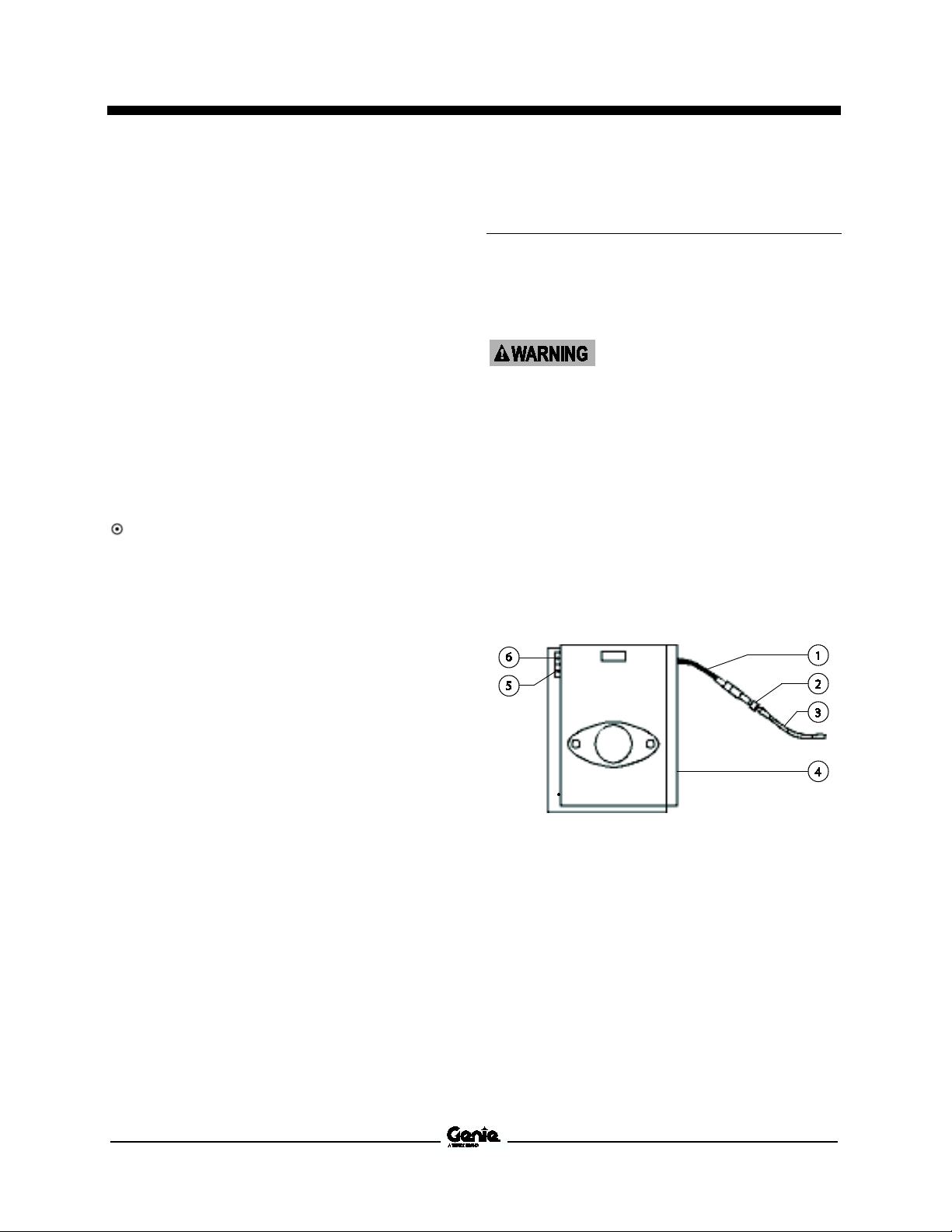

Serial Number Legend

1 Model

2 Model year

3 Sequence number

4 Serial number (stamped on chassis)

iv Z-34/22 IC Part No. 1268527

5 Serial label

September 2015 Service and Repair Manual

Safety Rules

Section 1 Safety Rules

Danger

Failure to obey the instructions and safety rules in

this manual and the appropriate Operator's Manual

on your machine will result in death or serious

injury.

Many of the hazards identified in the operator's

manual are also safety hazards when maintenance

and repair procedures are performed.

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

• manufacturer's instructions and safety rules

• employer's safety rules and worksite

regulations

• applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

Part No. 1268527 Z-34/22 IC v

Service and Repair Manual September 2015

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol

alert

personal injury hazards. Obey all

safety messages that follow this

symbol to avoid possible injury or

death.

Indicates a imminently hazardous

situation which, if not avoided,

will result in death or serious

injury.

Indicates a

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which,

may result in property damage.

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when lif

placing loads. Always wear approved

steel

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible materials like battery gases

and engine fuels. Always have an

approved fire extinguisher within easy

reach.

Be sure that all tools and working areas

are properly

use. Keep work surfaces clean and free

of debris that could get into machine

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing

weight to be lifted. Use only chains or

straps that are in good condition and of

ample capacity.

Be sure that fasteners intended for one

time use (i.e., cotter pins and self

nuts) are not reused. These components

may fail if they are used a

Be sure to properly dispose of old oil or

other fluids. Use an approved container.

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

Safety Rules

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

—used to

personnel to potential

potentially hazardous

Workplace Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

maintained and ready for

the

-toed shoes.

vi Z-34/22 IC Part No. 1268527

if not avoided,

ting or

-locking

second time.

September 2015

Table of Contents

Introduction Introduction ........................................................................................................... ii

Important Information ............................................................................................. ii

Find a Manual for this Model .................................................................................. ii

Revision History..................................................................................................... iii

Serial Number Legend .......................................................................................... iv

Section 1 Safety Rules .......................................................................................................... v

General Safety Rules ............................................................................................. v

Section 2 Specifications ....................................................................................................... 1

Machine Specifications ........................................................................................... 1

Performance Specifications .................................................................................... 2

Hydraulic Specification ........................................................................................... 2

Hydraulic Component Specifications...................................................................... 4

Machine Torque Specifications .............................................................................. 6

Kubota D-905 Engine Specifications ...................................................................... 7

Kubota DF-752 Engine Specifications ................................................................... 8

Perkins 403C-11 Engine Specifications ................................................................. 9

Hydraulic Hose and Fitting Torque Specifications ............................................... 10

Torque Procedure ................................................................................................ 11

SAE and Metric Fasteners Torque Charts ........................................................... 12

Part No. 1268527 Z-34/22 IC vii

September 2015

Table of Contents

Section 3 Repair Procedures ............................................................................................. 13

Introduction .......................................................................................................... 13

Platform Controls ............................................................................................... 15

1-1 Drive Joystick ................................................................................................. 15

How to Adjust the Drive Joystick .................................................................... 15

1-2 Boom Function Speed Controller Adjustments .............................................. 17

Boom Function Speed Controller Adjustments ............................................... 17

Platform Components ....................................................................................... 19

2-1 Platform Leveling Slave Cylinder ................................................................... 19

How to Remove the Platform Leveling Slave Cylinder ................................... 19

How to Bleed the Leveling Slave Cylinder ...................................................... 19

2-2 Platform Rotator ............................................................................................. 20

How to Remove the Platform Rotator ............................................................. 20

How to Bleed the Platform Rotator ................................................................. 21

2-3 Platform Overload System ............................................................................. 22

How to Calibrate the Platform Overload System (if equipped) ....................... 22

Jib Boom Components ...................................................................................... 24

3-1 Jib Boom ........................................................................................................ 24

How to Remove the Jib Boom ........................................................................ 24

3-2 Jib Boom Bell Crank ...................................................................................... 25

How to Remove the Jib Boom Bell Crank ...................................................... 25

3-3 Jib Boom Lift Cylinder .................................................................................... 25

How to Remove the Jib Boom Lift Cylinder .................................................... 25

viii Z-34/22 IC Part No. 1268527

September 2015

Table of Contents

Primary Boom Components .............................................................................. 27

4-1 Cable Track .................................................................................................... 27

How to Repair the Primary Boom Cable Track ............................................... 27

4-2 Primary Boom................................................................................................. 27

How to Shim the Primary Boom ...................................................................... 27

How to Remove the Primary Boom ................................................................. 28

How to Disassemble the Primary Boom ......................................................... 30

4-3 Primary Boom Lift Cylinder ............................................................................ 31

How to Remove the Primary Boom Lift Cylinder ............................................. 31

4-4 Primary Boom Extension Cylinder ................................................................. 32

How to Remove the Primary Boom Extension Cylinder.................................. 32

4-5 Platform Leveling Master Cylinder ................................................................. 34

How to Remove the Platform Leveling Master Cylinder ................................. 34

Secondary Boom Components ......................................................................... 36

5-1 Secondary Boom ............................................................................................ 37

How to Disassemble the Secondary Boom ..................................................... 37

5-2 Secondary Boom Lift Cylinders ...................................................................... 40

How to Remove the Secondary Boom Lift Cylinders ...................................... 40

Engines ................................................................................................................ 42

6-1 Kubota Diesel Models .................................................................................... 42

Timing Adjustment .......................................................................................... 42

How to Check the Glow Plugs ......................................................................... 42

RPM Adjustment ............................................................................................. 42

How to Remove the Flex Plate........................................................................ 43

How to Install the Flex Plate ............................................................................ 43

Coolant Temperature and Oil Pressure Switches ........................................... 43

Part No. 1268527 Z-34/22 IC ix

September 2015

Table of Contents

6-2 Kubota Gasoline / LPG Models ..................................................................... 44

Choke Adjustment .......................................................................................... 44

Timing Adjustment .......................................................................................... 44

Carburetor Adjustment .................................................................................... 44

RPM Adjustment ............................................................................................. 44

How to Remove the Flex Plate ....................................................................... 45

How to Install the Flex Plate ........................................................................... 45

Coolant Temperature and Oil Pressure Switches .......................................... 45

6-3 Perkins Diesel Models ................................................................................... 46

Timing Adjustment .......................................................................................... 46

RPM Adjustment ............................................................................................. 46

How to Remove the Flex Plate ....................................................................... 47

How to Install the Flex Plate ........................................................................... 47

Coolant Temperature and Oil Pressure Switches .......................................... 47

Hydraulic Pumps ................................................................................................ 49

7-1 Auxiliary Pump ............................................................................................... 49

How to Test the Auxiliary Pump ...................................................................... 49

How to Remove the Auxiliary Pump ............................................................... 49

7-2 Function Pump ............................................................................................... 50

How to Test the Function Pump ..................................................................... 50

How to Removet the Function Pump .............................................................. 50

7-3 Drive Pump .................................................................................................... 51

How to Remove the Drive Pump .................................................................... 51

How to Prime the Drive Pump ........................................................................ 51

x Z-34/22 IC Part No. 1268527

September 2015

Table of Contents

Manifolds ............................................................................................................. 52

8-1 Function Manifold Components ..................................................................... 52

8-2 Valve Adjustments - Function Manifold .......................................................... 56

How to Adjust the Primary Boom Down Relief Valve...................................... 56

How to Adjust the Secondary Boom Down Relief Valve ................................. 56

8-3 Jib Boom and Platform / Jib Boom Rotate Manifold Components ................. 57

8-4 Brake/Two-Speed Manifold Components ...................................................... 58

8-5 Traction Manifold Components, 2WD ............................................................ 59

8-6 Traction Manifold Components, 4WD ............................................................ 60

8-7 Valve Adjustments, 4WD Traction Manifold ................................................... 62

8-8 Valve Coils ..................................................................................................... 63

How to Test a Coil ........................................................................................... 63

Valve Coil Resistance Specification ................................................................ 63

How to Test a Coil Diode ................................................................................ 64

Fuel and Hydraulic Tanks .................................................................................. 65

9-1 Fuel Tank ....................................................................................................... 65

How to Remove the Fuel Tank ........................................................................ 65

9-2 Hydraulic Tank ............................................................................................... 66

How to Remove the Hydraulic Tank................................................................ 66

Turntable Rotation Components ...................................................................... 67

10-1 Turntable Rotation Hydraulic Motor ............................................................. 67

How to Remove the Turntable Rotation Motor ................................................ 67

Axle Components ............................................................................................... 68

11-1 Hub and Bearings, 2WD Models .................................................................. 68

How to Remove the Hub and Bearings ........................................................... 68

How to Install the Hub and Bearings ............................................................... 68

Part No. 1268527 Z-34/22 IC xi

September 2015

Table of Contents

Section 4 Schematics ......................................................................................................... 69

Introduction .......................................................................................................... 69

Electrical Symbol Legend .................................................................................... 70

Hydraulic Symbols Legend .................................................................................. 71

Electrical Component and Wire Color Legends ................................................... 72

Electrical Schematics - Gasoline/LPG Models ................................................ 75

Electrical Schematic - Gasoline/LPG Models ...................................................... 76

Ground Control Box Switch Panel Wiring Diagram - Gasoline/LPG Models ....... 80

Ground Control Box Terminal Strip Wiring Diagram - Gasoline/LPG Models ..... 81

Platform Control Box Wiring Diagram - Gasoline/LPG Models ........................... 84

Electrical Schematics - Diesel Models ............................................................. 85

Electrical Schematic - Diesel Models ................................................................... 86

Ground Control Box Switch Panel Wiring Diagram - Diesel Models ................... 90

Ground Control Box Terminal Strip Wiring Diagram - Diesel Models .................. 91

Platform Control Box Wiring Diagram - Diesel Models ........................................ 94

Electrical Schematics - Options ....................................................................... 95

Platform Control Box Wiring Diagram - Options .................................................. 96

Manifold and Limit Switch Wiring Diagram .......................................................... 97

Hydraulic Schematics ........................................................................................ 99

Hydraulic Schematic, 2WD Models.................................................................... 100

Hydraulic Schematic, 4WD Models.................................................................... 104

xii Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Tires and wheels

rough

terrain

industrial

Tire size

16.5 NHS 9-14.5 LT

Tire ply rating

8 Ply

Tread 6

Sidewall 6

Tire and wheel weight,

foam filled (minimum)

bs

g

bs

g

Overall tire diameter

n

m

n

m

Wheel diameter

n

m

n

m

Wheel width

n

m

n

m

Wheel lugs, 4WD

18

Wheel lugs, 2WD

Front

Rear

18

18

18

18

Lug nut torque, dry

lbs

170 Nm

lbs

170 Nm

Lug nut torque,

lubricated

lbs

129 Nm

lbs

129 Nm

si

ar

si

ar

Tires and wheels

Hi-flotation (option)

Tire size

15

Tire ply

8

Overall tire diameter

n

m

Wheel diameter

n

m

Wheel width

n

m

Wheel lugs

18

Lug nut torque, dry

lbs

170 Nm

Lug nut torque,

lubricated

lbs

129 Nm

Tire pressure,

si

ar

Fuel

LPG tank

ounds

g

Fuel tank

allons

iters

Hydraulic tank

allons

iters

Hydraulic system

(including tank)

allons

iters

Drive hubs

l oz

c

Drive hub oil type: SAE 9

API service classification GL5

Specifications

Section 2 Specificati ons

Machine Specifications

10-

175 l

30.5 i

16.5 i

10 i

9 @ 5/8 -

125 ft-

Tire pressure,

rough terrain

79 k

77.5 c

42 c

25.4 c

8 @ 5/8 9 @ 5/8 -

95 ft-

45 p

3.1 b

175 l

79 k

28 i

37 c

14.5 i

36.8 c

18 c

8 @ 5/8 9 @ 5/8 -

125 ft-

95 ft-

100 p

6.9 b

7 i

capacities

33.5 p

9.3 g

18 g

0 multipurpose hypoid gear oil

15.2 k

35.2 l

68.1 l

22 g

83.3 l

17 f

503 c

31-15.5-

rating

Part No. 1268527 Z-34/22 IC 1

31 i

78.7 c

15 i

38.1 c

13 i

33 c

9 @ 5/8 -

125 ft-

95 ft-

44 p

3 b

Service and Repair Manual September 2015

Drive speed, maximum

Stowed position

ph

m/h

ec

ec

Raised or extended

ph

m/h

ec

ec

Gradeability

See Operator's Manual

Braking distance, maximum

High range on paved surface

t

m

Joystick function speeds, maximum from platform

controls

Primary boom up

econds

Primary boom down

econds

Primary

econds

Primary boom retract

econds

Secondary boom up

econds

Secondary boom down

econds

Jib boom up

econds

Jib boom down

econds

Turntable rotate, 355°

econds

Platform rotate

econds

Hydraulic Fluid Specifications

Genie specifications require hydraulic oils which are

designed to give maximum protection to hydraulic

systems, have the ability to perform over a wide

temperature range, and the viscosity index

exceed 140. They should provide excellent antiwear,

oxidation prevention, corrosion inhibition, seal

conditioning, and foam and aeration suppression

properties.

Cleanliness level,

minimum

ISO 15/13

Water content,

maximum

pm

Recommended Hydraulic Fluid

Hydraulic oil type

Chevron Rando HD Premium

Viscosity grade

32

Viscosity index

200

Optional Hydraulic Fluids

Mineral based Shell Tellus S2 V 32

Shell Tellus S2 V 46

Shell Tellus S4 VX 32 Shell

Shell Donax TG (Dexron III)

Chevron 5606A

Biodegradable

46

Fire resistant

5046

Optional fluids may not have

the same hydraulic lifespan and

may result in component

damage.

Specifications

Performance Specifications

3.0 m

5.1 k

40 ft / 6.1 s

12.2 m / 6.1 s

0.6 m

0.98 k

40 ft / 45 s

12.2 m / 45 s

3 to 4 f

0.9 to 1.2

15 to 21 s

13 to 19 s

boom extend 14 to 20 s

14 to 20 s

15 to 21 s

11 to 17 s

24 - 30 s

15 to 21 s

62 to 72 s

4 - 7 s

For operational specifications, refer to the

Operator's Manual.

Hydraulic Oil Specifications

should

250 p

Petro Canada Environ MV

UCON Hydrolube HP-

Note: Genie specifications require additional

equipment and special installation instructions for

the approved optional fluids. Consult Genie

Product Support before use.

Continuous improvement of our products is a

Genie policy. Product specifications are

subject to change without notice or obligation.

2 Z-34/22 IC Part No. 1268527

Note: Extended machine operation can cause the

hydraulic fluid temperature to increase beyond it's

maximum allowable range. If the hydraulic fluid

temperature consistently exceeds 200°F / 90°C an

optional oil cooler may be required.

September 2015 Service and Repair Manual

Do not top off with incompatible

hydraulic fluids. Hydraulic fluids

may be incompatible due to the

differences in base additive

chemistry. When incompatible

fluids are mixed,

materials may form and deposit

in the hydraulic system,

plugging hydraulic lines, filters,

control valves and may result in

component damage.

ISO Grade

32

Viscosity index 200

Kinematic Viscosity

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

7.5

33.5

Brookfield Viscosity

cP @

cP @

1040

3310

Flash point 375°F / 190°C

Pour point

50°C

Maximum continuous operating

temperature

171°F / 77°C

ISO Grade

15

Viscosity index 300

Kinematic Viscosity

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

cSt @

5.5

15.0

510

Flash point 180°F / 82°C

Pour point

63°C

Maximum continuous operating

temperature

124°F / 51°C

Specifications

insoluble

Note: Do not operate the machine when the

ambient air temperature is consistently above

120°F / 49°C.

Hydraulic Fluid Temperature

Range

Chevron Rando HD Premium Oil

MV Fluid Properties

-4°F / -20°C

-22°F / -30°C

-58°F / -

Note: An hydraulic oil heating system is

recommended when the ambient temperature is

consistently below 0°F / -18°C.

Note: Do not operate the machine when the

ambient temperature is below -20°F / -29°C with

Rando HD Premium MV.

1 Chevron hydraulic oil 5606A

2 Petro-Canada Environ MV 46

3 UCON Hydrolube HP-5046D

4 Chevron Rando HD premium oil MV

Part No. 1268527 Z-34/22 IC 3

Ambient air temperature

Chevron 5606A Hydraulic Oil

Fluid Properties

Note: Use of Chevron 5606A hydraulic fluid, or

equivalent, is required when ambient temperatures

are consistently below 0°F / -17°C unless an oil

heating system is used.

-40°F / -40°C

-81°F / -

Service and Repair Manual September 2015

Continued use of Chevron

5606A hydraulic fluid, or

equivalent, when ambient

temperatures

above 32°F / 0°C may result in

component damage

ISO Grade

46

Viscosity index 154

Kinematic Viscosity

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

8.0

44.4

Flash point 482°F / 250°C

Pour point

45°C

Maximum continuous operating

temperature

180°F / 82°C

ISO Grade

46

Viscosity index 192

Kinematic Viscosity

cSt @ 149°F / 65°C

cSt @ 104°F / 40°C

cSt @ 0°F /

22

46

1300

Flash point None

Pour

63°C

Maximum continuous operating

temperature

189°F / 87°C

Drive Pump

Type: bi

c

pm

84 L/min

Function pump

(standard)

Displacement per revolution

c

Flow rate @ 300

pm

11.4 L/min

Function pump

(230V generator

Specifications

are consistently

Petro-Canada Environ MV 46

Fluid Properties

Hydraulic Component Specifications

-directional variable displacement piston pump

Displacement per revolution 1.71 cu in

28 c

Flow rate @ 3000 rpm 22 g

-49°F / -

UCON Hydrolube HP-5046 Fluid

Properties

-18°C

point -81°F / -

Type: fixed displacement gear pump

0.24 cu in

4 c

0 rpm 3 g

option)

Type: fixed displacement gear pump

Displacement per revolution 0.37 cu in

6 cc

Flow rate @ 3000 rpm 4.4 gpm

16.7 L/min

4 Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Auxiliary Pump

Displacement per revolution

pm

1.9 L/min

Auxiliary pump relief pressure

si

ar

Function manifold

System relief valve pressure,

maximum

si

ar

Primary boom down relief valve

pressure

si

ar

Secondary boom down relief

valve pressure

si

ar

Steer flow regulator

pm

3.8 L/min

platform rotate flow

pm

1.1 L/min

Traction Manifold

si

ar

si

ar

Steer end drive motors (4WD models)

u in

c

Non

u in

c

Hydraulic Filters

Medium pressure filter

Beta 3 ˆ 200

Medium pressure filter bypass

pressure

si

ar

Hydraulic tank return filter

icron with

ar

bypass

Specifications

Type: fixed displacement gear pump

0.5 g

3400 p

1.0 g

regulator 0.3 g

Hot oil relief pressure

2WD

4WD

234.5 b

3200 p

220.6 b

1600 p

110 b

1600 p

110 b

170 p

11.7 b

150 p

10.3 b

-steer end drive motors

Displacement per revolution 1.53 c

10 m

25 psi / 1.7 b

25 c

50 p

3.4 b

Displacement per revolution 1.53 c

25 c

Part No. 1268527 Z-34/22 IC 5

Service and Repair Manual September 2015

Platform Rotator

3/4

3/4

lbs

515 Nm

lbs

379 Nm

3/8

3/8

lbs

60 Nm

lbs

45 Nm

Turntable rotate assembly

Rotate bearing mounting bolts, lubricated

lbs

244 Nm

Rotate bearing motor mounting bolts,

lubricated

lbs

126 Nm

Drive motors and hubs

Drive hub mounting bolts, lubricated

lbs

244 Nm

Drive motor mounting bolts, lubricated

3/8

7/16

lbs

31 Nm

lbs

50 Nm

Specifications

Machine Torque Specifications

-10 center bolt, GR 8, dry

-10 center bolt, GR 8, lubricated

-16 outer bolts, GR 8, dry

-16 outer bolts, GR 8, lubricated

-16, GR5

-14, GR5

380 ft-

280 ft-

44 ft-

33 ft-

180 ft-

93 ft-

180 ft-

23 ft-

37 ft-

6 Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Displacement

u in

Number of cylinders

3

Bore and Stroke

nches

m

Horsepower, gross

intermittent

pm

pm

Firing order

3

Low idle

pm

260 Hz

High idle

pm

600 Hz

Compression ratio

23:1

Compression pressure

si

ar

Governor

centrifugal mechanical

Valve Clearance, cold

n

m

Lubrication system

Oil pressure

si

ar

Oil capacity

(including filter)

uarts

Oil viscosity requirements

-

30 (synthetic)

-

40

Above 23° F /

50

Unit ships with 15W

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine Operator

Manual for your engine.

Engine coolant

Capacity

uarts

Fuel injection system

Injection pump make

Bosch MD

Injection pump pressure,

maximum

si

ar

Injection timing

13° to 25° BTDC

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for

Starter motor

Cranking speed

300 RPM

Current draw, normal load

155A

Battery

Type

12V DC

Group

34/78

Quantity

1

Ampere hour 75AH

Cold cranking ampere

900A

Reserve capacity @ 25A rate

inutes

Alternator output

30A @ 12V DC

Fan belt deflection

nch

m

Specifications

Kubota D-905 Engine

36 to 64 p

54.86 c

0.90 liters

2.83 x 2.9 i

72 x 73.6 m

26 @ 2600 r

19.3 kW @ 2600 r

1 - 2 -

1300 r

3000 r

412 to 469 p

28.4 to 32.3 b

0.0057 to 0.0072 i

0.145 to 0.185 m

2.48 to 4.41 b

5.4 q

5.1 liters

1991 p

137 b

your engine.

200 -

125 m

1/4 to 3/8 i

7 to 9 m

22° F to 86° F/ -30° C to 30° C 5W-

4° F to 90° F / -20° C to 32° C 10W-

-5° C 20W-

-40. Extreme operating

3.3 q

Part No. 1268527 Z-34/22 IC 7

3.1 liters

Service and Repair Manual September 2015

Displacement

u in

iters

Number of cylinders

3

Bore and Stroke

nches

m

Horsepower

pm

pm

Firing order

3

Low idle

pm

320 Hz

High idle

pm

600 Hz

Compression ratio

9.2:1

Compression pressure

si

ar

Governor

centrifugal mechanical

Valve Clearance, cold

n

m

Lubrication system

Oil pressure

si

ar

Oil capacity

(including filter)

uarts

iters

Oil viscosity requirements

Below 86°F / 30°C

20

-

30

Above 14°F /

40

Unit ships with

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine Operator

Manual for your engine.

Fuel Pump

Fuel pressure, static

si

ar

Fuel flow rate

pm

0.47 L/min

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your engine.

Alternator output

30A @ 12V DC

Fan belt deflection

n

m

Starter motor

Brush length, new

n

m

Brush length, minimum

n

m

Brush spring tension

unces

o 25.5 Newtons

Battery

Type

12V DC

Group

34/78

Quantity

1

Ampere hour 75AH

Cold cranking ampere 900A

Reserve capacity @ 25A rate

inutes

Engine coolant

Capacity

Ignition system

Ignition spark advance

18° BTDC

Ignition coil primary resistance

Ω

@ 75°F / 24°C

Ignition coil secondary

resistance

Ω

@ 75°F / 24°C

#1 Spark plug wire resistance

Ω

#2 Spark plug wire resistance

Ω

#3 Spark plug wire resistance

Ω

Spark plug type

11

Spark plug gap

n

m

Specifications

Kubota DF-752 Engine

2.68 x 2.68 i

24.8 @ 3600 r

18.5 kW @ 3600 r

0.0057 to 0.0072 i

0.145 to 0.183 m

28 to 64 p

5W-

4°F to 104°F / -20°C to 40°C 10W-

-10°C 15W-

15W-40. Extreme operating

2.84 p

0.125 g

45 c

0.74 l

68 x 68 m

1 - 2 -

1600 r

3000 r

128 to 185 p

8.8 to 12.7 b

1.9 to 4.4 b

3.4 q

3.25 l

0.19 b

1/4 to 3/8 i

7 to 9 m

0.669 i

17 m

0.453 i

11.5 m

50 to 91 o

13.7 t

125 m

3.1 quarts

2.9 liters

1.3 to 1.6

10.7 to 14.5 k

2.81 to 4.79 k

3.4 to 5.8 k

3.57 to 6.09 k

NGK BKR4E-

0.039 to 0.043 i

1 to 1.1 m

8 Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Displacement

u in

iters

Number of cylinders

3

Bore and Stroke

nches

m

Horsepower

pm

pm

Firing order

3

Low idle

pm

300 Hz

High idle

pm

600 Hz

Compression ratio

23:1

Compression pressure

si

ar

Pressure (psi) of

3.4

Governor

mechanical, all speed

Valve Clearance, cold

n

m

Lubrication system

Oil pressure

si

ar

Oil capacity

(including filter)

uarts

iters

Oil viscosity requirements

Below 86°F / 30°C

20

-

30

Above 14°F /

40

Unit ships with 15W

temperatures may require the use of alternative engine

oils. For oil requirements,

Manual for your engine.

Fuel injection system

Injection pump make

Bosch

Injection timing

23° BTDC @

pm

Injection pressure

si

ar

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your engine.

Alternator output

40A @ 12V DC

Fan belt deflection

n

m

Starter motor

Current draw, normal load

150A

Battery

Type 12V DC, Group 34/78

Quantity

1

Ampere hour 75AH

Cold cranking ampere

900A

Reserve capacity

inutes

Engine coolant

Capacity

uarts

iters

Specifications

Perkins 403C-11 Engine

3.03 x 3.19 i

19.5 kW @ 3000 r

lowest cylinder must be within 50 psi /

5 bar of highest cylinder

40 to 60 p

5W-

4°F to 104°F / -20°C to 40°C 10W-

-10°C 15W-

69 c

1.13 l

77 x 81 m

26 @ 3000 r

1 - 2 -

1500 r

3000 r

425 p

29.3 b

0.008 i

0.2 m

2.76 to 4.1 b

4.3 q

4.07 l

-40. Extreme operating

refer to the Engine Operator

3000 r

2133 p

147 b

3/8 i

10 m

100 -

@ 25A rate 125 m

3.28 q

3.1 l

Part No. 1268527 Z-34/22 IC 9

Service and Repair Manual September 2015

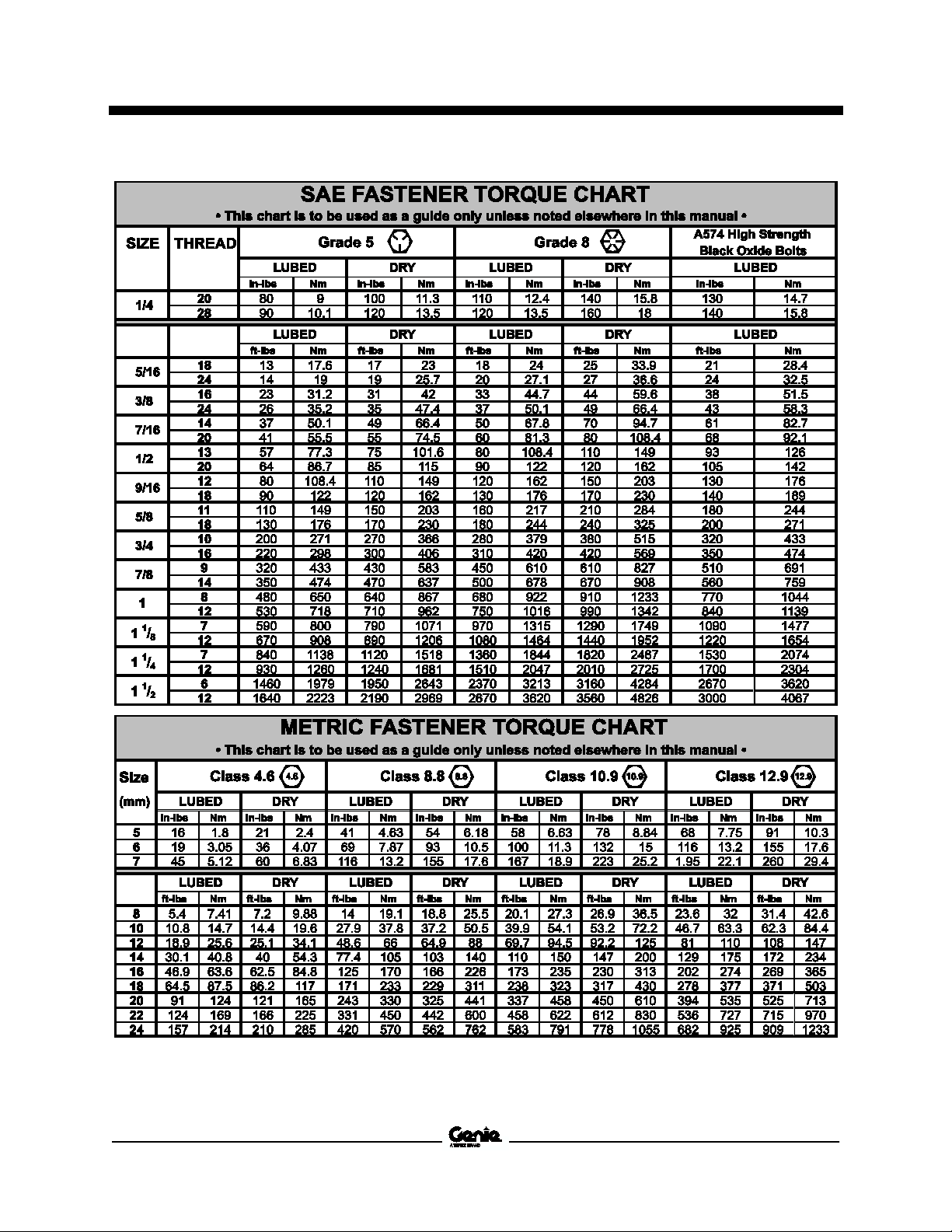

SAE Dash Size

Torque

Specifications

Hydraulic Hose and Fitting Torque Specifications

Your machine is equipped with Parker Seal-Lok™

ORFS or 37° JIC fittings and hose ends. Genie

specifications require that fittings and hose ends

be torqued to specification when they are removed

and installed or when new hoses or fittings are

installed.

Seal-Lok™ Fittings

(hose end - ORFS)

-4 10 ft-lbs / 13.6 Nm

-6 30 ft-lbs / 40.7 Nm

-8 40 ft-lbs / 54.2 Nm

-10 60 ft-lbs / 81.3 Nm

-12 85 ft-lbs / 115 Nm

-16 110 ft-lbs / 150 Nm

-20 140 ft-lbs / 190 Nm

-24 180 ft-lbs / 245 Nm

JIC 37° Fittings

(swivel nut or hose connection)

SAE Dash Size Thread Size Flats

-4 7/16-20 2

-6 9/16-18 1 ¼

-8 3/4-16 1

-10 7/8-14 1

-12 1 1/16-12 1

-16 1 5/16-12 1

-20 1 5/8-12 1

-24 1 7/8-12 1

SAE O-ring Boss Port

(tube fitting - installed into Aluminum)

(all types)

SAE Dash Size Torque

-4 14 ft-lbs / 19 Nm

-6 23 ft-lbs / 31.2 Nm

-8 36 ft-lbs / 54.2 Nm

-10 62 ft-lbs / 84 Nm

-12 84 ft-lbs / 114 Nm

-16 125 ft-lbs / 169.5 Nm

-20 151 ft-lbs / 204.7 Nm

-24 184 ft-lbs / 249.5 Nm

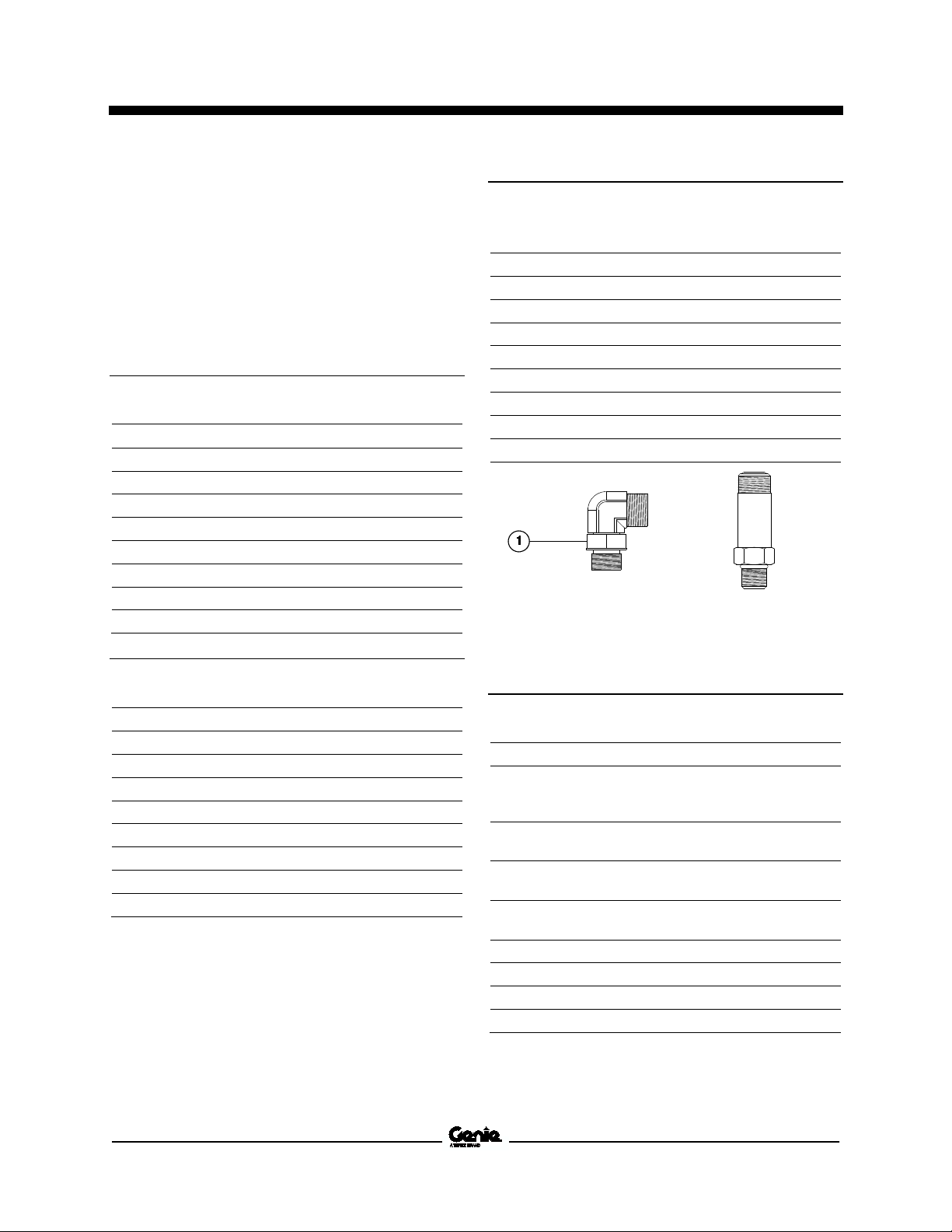

Adjustable Fitting Non-adjustable fitting

1 jam nut

SAE O-ring Boss Port

(tube fitting - installed into Steel)

SAE Dash Size Torque

-4 ORFS / 37° (Adj)

ORFS (Non-adj)

37° (Non-adj)

-6 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-8 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-10 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-12 (All types) 135 ft-lbs / 183 Nm

-16 (All types) 200 ft-lbs / 271.2 Nm

-20 (All types) 250 ft-lbs / 339 Nm

-24 (All types) 305 ft-lbs / 413.5 Nm

15 ft-lbs / 20.3 Nm

26 ft-lbs / 35.3 Nm

22 ft-lbs / 30 Nm

35 ft-lbs / 47.5 Nm

29 ft-lbs / 39.3 Nm

60 ft-lbs / 81.3 Nm

52 ft-lbs / 70.5 Nm

100 ft-lbs / 135.6 Nm

85 ft-lbs / 115.3 Nm

10 Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Specifications

Torque Procedure

Seal-Lok™ fittings

1 Replace the O-ring. The O-ring must be

replaced anytime the seal has been broken.

The O-ring cannot be re-used if the fitting or

hose end has been tightened beyond finger

tight.

Note: The O-ring in Parker Seal Lok™ fittings and

hose end are custom-size O-rings. They are not

standard size O-rings. They are available in the

O-ring field service kit (Genie part number 49612).

2 Lubricate the O-ring before installation.

3 Be sure the O-ring face seal is seated and

retained properly.

4 Position the tube and nut squarely on the face

seal end of the fitting, and tighten the nut

finger tight.

5 Tighten the nut or fitting to the appropriate

torque. Refer to the appropriate torque chart

in this section.

6 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

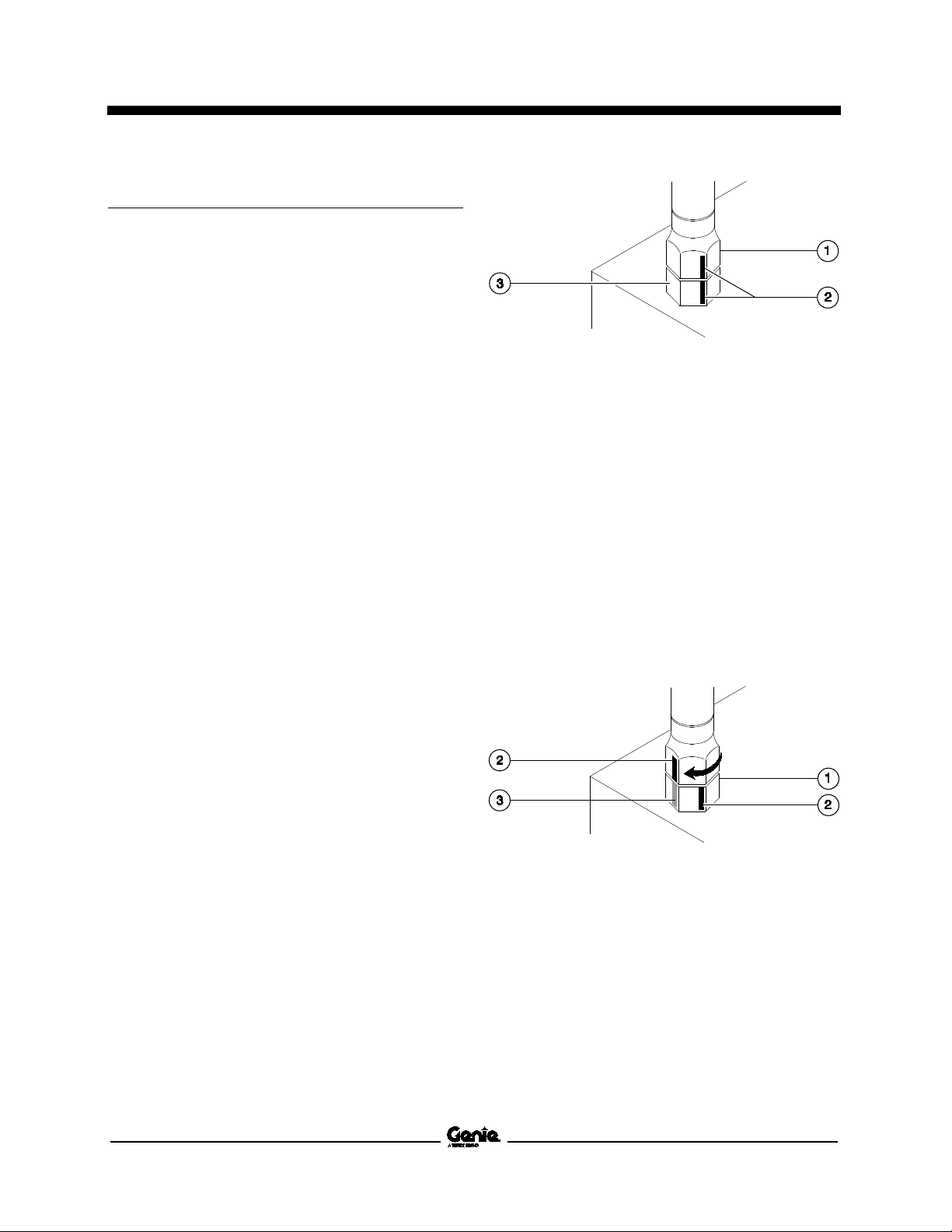

1 hex nut

2 reference mark

3 body hex fitting

3 Working clockwise on the body hex fitting,

make a second mark with a permanent ink

marker to indicate the proper tightening

position. Refer to Illustration 2.

Note: Use the JIC 37° Fitting table in this section to

determine the correct number of flats, for the

proper tightening position.

Note: The marks indicate the correct tightening

positions have been determined. Use the second

mark on the body hex fitting to properly tighten the

joint after it has been loosened.

Illustration 1

JIC 37° fittings

1 Align the tube flare (hex nut) against the nose

of the fitting body (body hex fitting) and tighten

the hex nut to the body hex fitting to hand

tight, approximately 30 in-lbs / 3.4 Nm.

2 Using a permanent ink marker, make a

reference mark on one the flats of the hex nut

and continue the mark onto the body of the

hex fitting. Refer to Illustration 1.

1 body hex fitting

2 reference mark

3 second mark

4 Tighten the hex nut until the mark on the hex

nut is aligned with the second mark on the

body hex fitting.

5 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

Part No. 1268527 Z-34/22 IC 11

Illustration 2

Service and Repair Manual September 2015

Specifications

12 Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Repair Procedures

Section 3 Repair Proc edur es

Observe and Obey:

Repair procedures shall be completed by a

person trained and qualified on the repair of

this machine.

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Before Repairs Start:

Read, understand and obey the safety rules

and operating instructions in the appropriate

operator's manual on your machine.

Machine Configuration:

Unless otherwise specified, perform each

repair procedure with the machine in the

following configuration:

• Machine parked on a firm, level surface

• Key switch in the off position with the key

removed

• The red Emergency Stop button in the off

position at both ground and platform

controls

• Wheels chocked

• All external AC power supply disconnected

from the machine

• Boom in the stowed position

• Turntable secured with the turntable rotation

lock

Be sure that all necessary tools and parts are

available and ready for use.

Use only Genie approved replacement parts.

Read each procedure completely and adhere

to the instructions. Attempting shortcuts may

produce hazardous conditions.

Part No. 1268527 Z-34/22 IC 13

Service and Repair Manual September 2015

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could res

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Repair Procedures

About This Section

Most of the procedures in this section should only

be performed by trained service professional in a

suitably equipped workshop. Select the

appropriate repair procedure after troubleshooting

the problem.

Perform disassembly procedures to the point

where repairs can be completed. Then to

re-assemble, perform the disassembly steps in

reverse order.

Symbols Legend

ult in death or serious

Indicates that a specific result is expected

after performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

14 Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

watches and other jewelry.

Platform Controls

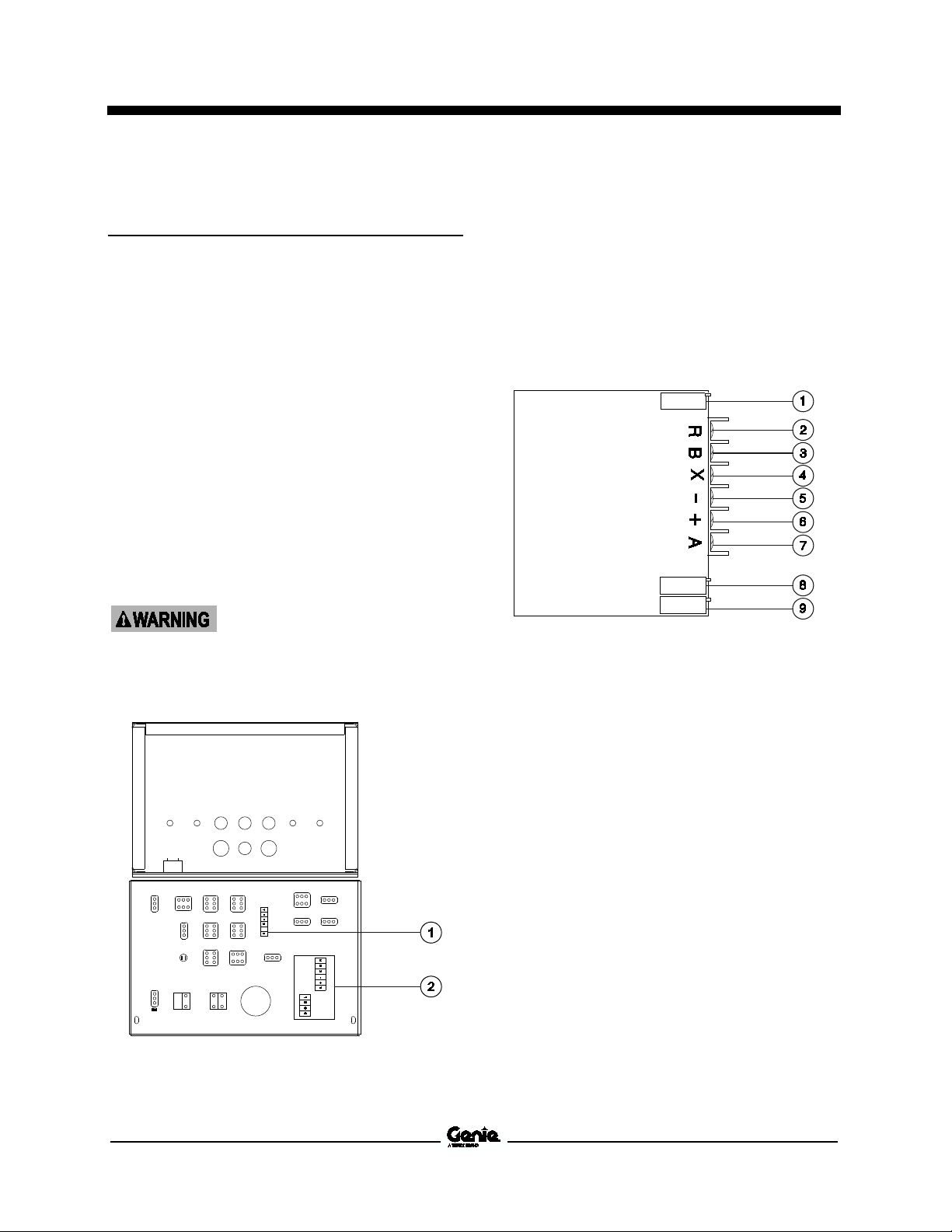

1-1 Drive Joystick

The drive joystick is connected to the drive motor

controller, located under the drive chassis cover at

the non-steer end of the machine. Maintaining the

boom function speed controller at the proper

settings is essential to safe machine operation.

The boom function speed controller should operate

smoothly and provide proportional speed control

through its entire range of motion. For further

information or assistance, contact the Genie

Product Support.

How to Adjus t t he D riv e Joy sti ck

How to Adjust the Drive Joystick

Note: Perform this procedure with the engine off.

1 Remove the fasteners from the platform

control box lid.

3 Locate and disconnect the wire connected to

terminal "A" on the drive joystick circuit board.

4 Set a multimeter to read DC current.

Note: The multimeter, when set to read DC current,

should be capable of reading up to 1200 mA.

5 Connect the black(-) lead from the multimeter

to the wire that was just disconnected.

Connect the red(+) lead of the multimeter to

terminal "A" on the joystick.

2 Open the control box lid and locate the drive

joystick.

1 low range potentiometer

2 terminal "R", activates low range

3 terminal "B", drive reverse

4 terminal "X", brake release

5 terminal "-", ground

6 terminal "+", positive

7 terminal "A", drive forward

8 threshold potentiometer

9 high range potentiometer

6 Turn the keyswitch to platform controls and

pull out the red Emergency Stop button out to

the on position at both the ground and

platform controls. Do not start the engine.

1 boom function speed controller

2 drive joystick

Part No. 1268527 Z-34/22 IC 15

Service and Repair Manual September 2015

Platform Controls

Set the threshold:

Set the stowed drive speed:

Note: The drive joystick adjustments are not final

adjustments. Final adjustments will need to be

made to meet drive speed specifications. Refer to

Section 2, Specifications.

7 Press down the foot switch. Move the drive

joystick off center in either direction just until a

current reading appears on the mulitmeter

display.

8 Hold the drive joystick in position and adjust

the threshold potentiometer until the

multimeter displays approximately 600 mA.

Set the high range:

9 Press down the foot switch. Move and hold

the drive joystick full stroke in either direction.

10 Hold the drive joystick in position and adjust

the hi range potentiometer until the multimeter

displays slightly higher than 1100 mA.

Set the low range:

11 Start the engine from the platform controls

and raise the primary boom approximately

3 feet / 1 m. Turn the engine off.

12 Press down the foot switch. Move and hold

the drive joystick full stroke in either direction.

13 Hold the drive joystick in position and adjust

the lo range potentiometer until the multimeter

displays approximately 700 mA.

14 Push in the red Emergency Stop button to the

off position at the platform controls.

Note: Select a test area that is firm, level and free

of obstructions.

17 Pull out the red Emergency Stop button out to

the on position at both the ground and

platform controls.

18 Create start and finish lines by marking two

lines on the ground 40 feet / 12.2 m apart.

19 Start the engine from the platform controls

and move the engine idle select switch to foot

switch activated high idle (rabbit and foot

switch symbol).

20 Choose a point on the machine; i.e., contact

patch of a tire, as a visual reference for use

when crossing the start and finish lines.

21 Bring the machine to top drive speed before

reaching the start line. Begin timing when your

reference point on the machine crosses the

start line.

22 Continue at full speed and note the time when

the machine reference point passes over the

finish line. Refer to Section 2, Specifications.

Result: The stowed drive speed does not

meet specification. Adjust the hi range

potentiometer on the drive joystick clockwise

to increase the speed or counterclockwise to

decrease the stowed drive speed. Continue to

perform steps 20 through 22 until the stowed

drive speed meets specification.

15 Disconnect the multimeter.

16 Connect the wire that was disconnected in

step 3 to terminal "A" of the drive joystick.

16 Z-34/22 IC Part No. 1268527

September 2015 Service and Repair Manual

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

watches and other jewelry.

Platform Controls

Set the raised drive speed:

Note: Select a test area that is firm, level and free

of obstructions.

23 Press down the foot switch and raise the

primary boom approximately 3 feet / 1 m.

24 Choose a point on the machine; i.e., contact

patch of a tire, as a visual reference for use

when crossing the start and finish lines.

25 Bring the machine to top drive speed before

reaching the start line. Begin timing when your

reference point on the machine crosses the

start line.

26 Continue at full speed and note the time when

the machine reference point passes over the

finish line. Refer to Section 2, Specifications.

Result: The raised drive speed does not meet

specification. Adjust the lo range

potentiometer on the drive joystick clockwise

to increase the speed or counterclockwise to

decrease the raised drive speed. Continue to

perform steps 24 through 26 until the raised

drive speed meets specification.

1-2

Boom Function Speed Controller

Boom Functi on Spe ed C ontr oll er Adjus tm ents

Boom Function Speed Controller Adjustments

Note: Do not adjust the boom function speed

controller unless the static battery supply voltage is

above 24V DC.

1 Turn the key switch to platform controls and

pull out the red Emergency Stop button to the

on position at both the ground and platform

controls.

2 Open the platform control box lid and locate

the boom function speed controller.

27 Lower the primary boom to the stowed

position. Turn the engine off.

28 Close the platform control box lid and install

the fasteners.

1 black wire

2 diode

3 white/red wire

4 boom function speed controller

5 threshold trimpot

6 max out trimpot

Part No. 1268527 Z-34/22 IC 17

Service and Repair Manual September 2015

Boom function speed controller specifications

Threshold

o 6V DC

Max out

o 9V DC

Platform Controls

3 Locate the diode between the black wire from

the boom function speed controller and the

white/red wire.

4 Connect the red (+) lead from a volt meter to

the wire connector of the white/red wire next

to the diode. Connect the black (-) lead to

ground.

5 Turn the boom function speed controller to the

creep position.

6 Set the threshold: Press down the foot switch.

Move the primary boom toggle switch in the

up direction until the voltage reading appears.

Adjust the voltage to 5.5 to 6V DC. Turn the

threshold trimpot adjustment screw clockwise

to increase the voltage or counterclockwise to

decrease the voltage.

7 Turn the boom function speed controller to the

9 position.

8 Set the max-out: Press down the foot switch.

Move the primary boom toggle switch in the

up direction. Adjust the voltage to 8.5 to 9V

DC. Turn the max-out trimpot adjustment

screw clockwise to increase the voltage or

counterclockwise to decrease the voltage.

5 t

8.5 t

18 Z-34/22 IC Part No. 1268527

Loading...

Loading...