Terex Genie AL5HT Service Manual

Service Manual

AL5HT

Part No. 1265482

Rev A

May 2015

Service Manual May 2015

Introduction

Introducti on Introducti on

Important

Read, understand and obey the safety rules and

operating instructions in the appropriate Operator's

Manual on your machine before attempting any

maintenance procedure.

This manual provides detailed scheduled

maintenance information for the machine owner

and user. It also provides troubleshooting and

repair procedures for qualified service

professionals.

Basic mechanical, hydraulic and electrical skills are

required to perform most procedures. However,

several procedures require specialized skills, tools,

lifting equipment and a suitable workshop. In these

instances, we strongly recommend that

maintenance and repair be performed at an

authorized Terex dealer service center.

Technical Publications

Terex has endeavored to deliver the highest

degree of accuracy possible. However, continuous

improvement of our products is a Terex policy.

Therefore, product specifications are subject to

change without notice.

Readers are encouraged to notify Terex of errors

and send in suggestions for improvement. All

communications will be carefully considered for

future printings of this and all other manuals.

Contact Us:

Internet: www.genielift.com

E-mail: awp.techpub@tere x .c om

Compliance

Machine Classification

Group A/Type 1 as defined by ISO 16368

Machine Design Life

Unrestricted with proper operatio n, inspec t ion and

scheduled maintenance.

Copyright © 2014 by Terex Corporation

1255863 Rev A, May 2015

First Edition, First Printing

'Terex' and 'AWP' are registered trademarks of Terex USA, LLC

in the U.S.A. and many other countries.

ii AL5HT Part No. 1265482

May 2015 Service Manual

Safety Rules

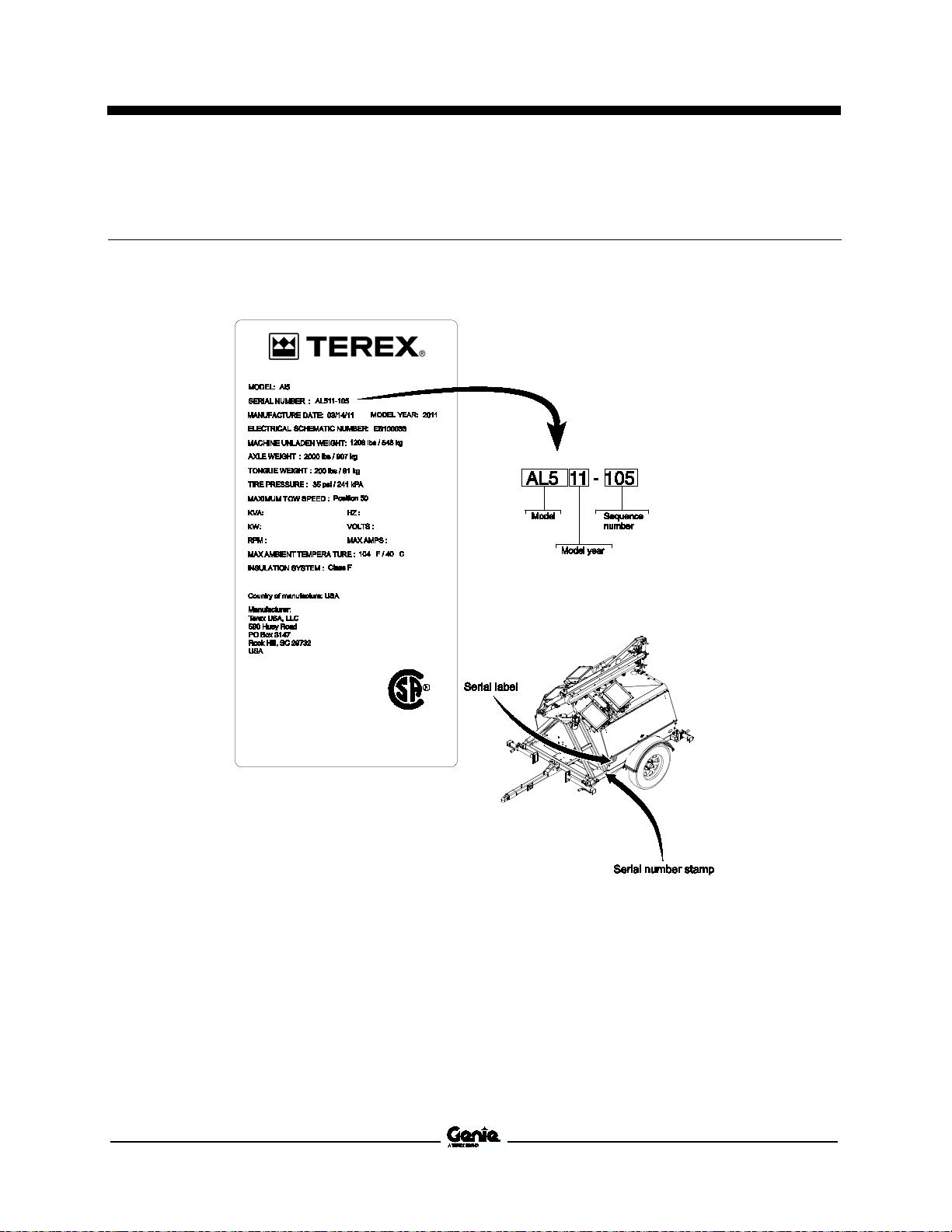

Serial Number Legend

Serial Number Legend

1 Model

2 Model year

3 Sequence number

4 Serial label (located on cabinet)

Part No. 1265482 AL5HT 3

5 Serial number (stamped on chassis)

Service Manual May 2015

Safety Rules

Section 1 Safety Rules

Danger

Failure to obey the instructions and safety rules in

this manual and the appropriate Operator's Manual

on your machine will result in death or serious

injury.

Many of the hazards identified in the operator's

manual are also safety hazards when maintenance

and repair procedures are performe d.

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

• manufacturer's instructions and safety rules

• employer's safety rules and worksite

regulations

• applicable governmental regulations

You hav e the appr o priat e tools , lift ing

equipment and a suitable workshop.

iv AL5HT Part No. 1265482

May 2015 Service Manual

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that

to avoid possible injury or death.

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death o

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Be sure to wear protective

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when lifting or

placing loads. Always wear approved

steel

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible materials like battery gases

and engine fuels. Always have an

approved fire extinguisher within easy

reach.

Be sure that all tools and working areas

are properly maintained and ready for

use. Keep work surfaces clean and free of

debris

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing the

weight to be lifted. Use only chains or

straps that are in good condi

ample capacity.

Be sure that fasteners intended for one

time use (i.e., cotter pins and self

nuts) are not reused. These components

may fail if they are used a second time.

Be sure to properly dispose of old oil or

other fluids.

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

Safety Rules

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

follow this symbol

r serious

Workplace Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

that could get into machine

tion and of

-toed shoes.

eye wear and

-locking

Use an approved container.

Part No. 1265482 AL5HT v

May 2015

Table of Contents

Introduction Introduction .......................................................................................................... ii

Important Information .............................................................................................. ii

Serial Number Legend ......................................................................................... 3

Serial Number Legend ........................................................................................... 3

Section 1 Safety Rules ......................................................................................................... iv

General Safety Rules ............................................................................................. iv

Section 2 Specifications ....................................................................................................... 1

Machine Specifications .......................................................................................... 1

Performance Specificatio ns ................................................................................... 1

Generator Options ................................................................................................. 1

Kubota D1105-E Engine Specifications ................................................................. 2

Kubota D1505-E Engine Specifications ................................................................. 3

Isuzu 4LE1 Engine Specifications .......................................................................... 4

Isuzu 4LE2 Engine Specifications .......................................................................... 5

Isuzu 4LE2-T Engine Specifications ...................................................................... 6

Machine Torque Specifications .............................................................................. 7

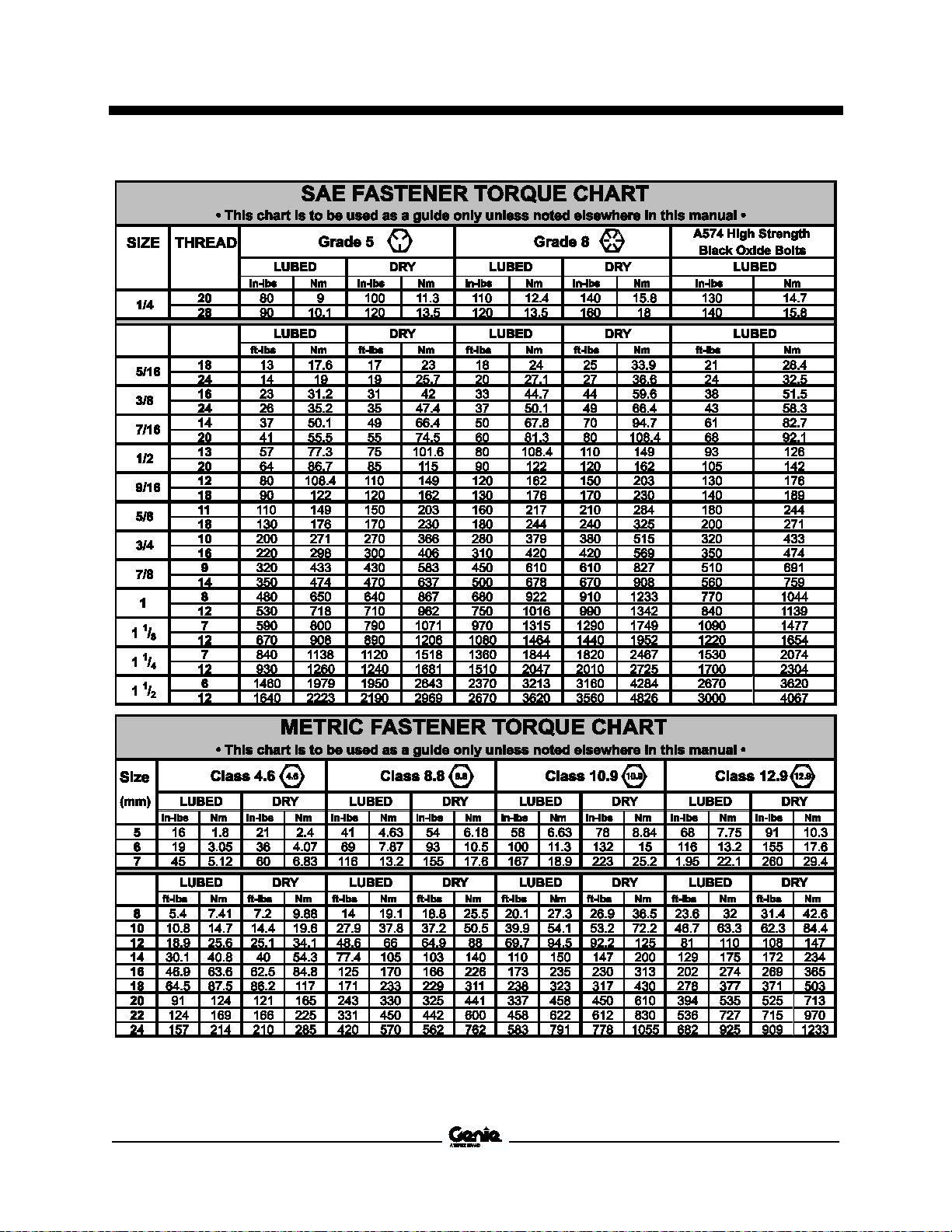

SAE and Metric Fasteners Torque Charts ............................................................. 8

vi AL5HT Part No. 1265482

May 2015

Table of Contents

Section 3 Scheduled Maintenance Procedures ................................................................. 9

Introduction ............................................................................................................. 9

Pre-Delivery Prepar at ion R eport .......................................................................... 12

Maintenance Inspection Report............................................................................ 13

Checklist A Procedures ..................................................................................... 15

A-1 Inspect the Manuals and Decals.................................................................... 15

A-2 Perform Pre-operat ion Ins pec ti on .................................................................. 16

A-3 Perform Function Tests ................................................................................. 16

A-4 Perform Engine Maintenance ........................................................................ 17

A-5 Perform Generator Maintenance ................................................................... 17

A-6 Perform Axle Maintenance ............................................................................ 18

A-7 Torque the Wheel Lug Nuts ........................................................................... 18

A-8 Perform Engine Maintenance ........................................................................ 19

A-9 Perform Coupler Maintenance ....................................................................... 19

A-10 Grease turntable bearing and rotate gear ................................................... 20

A-11 Perform Engine Maintenance ...................................................................... 20

A-12 Perform Engine Maintenance ...................................................................... 21

Checklist B Procedures ..................................................................................... 22

B-1 Inspect the Engine Start Battery .................................................................... 22

B-2 Inspect the Electrical Wiring .......................................................................... 23

B-3 Torque the Wheel Lug Nuts ........................................................................... 24

B-4 Perform Hydraulic Oil Analysis ...................................................................... 24

B-5 Perform Engine Maintenance ........................................................................ 25

B-6 Perform Engine Maintenance ........................................................................ 25

B-7 Perform Generator Maintenance ................................................................... 26

B-8 Perform Coupler Maintenance ....................................................................... 26

B-9 Perform Engine Maintenance ........................................................................ 27

B-10 Perform Axle Maintenance .......................................................................... 27

Part No. 1265482 AL5HT vii

May 2015

Table of Contents

Checklist C Procedures ..................................................................................... 28

C-1 Inspect the Tower Extend/Retract Cables and Pulleys ................................ 28

C-2 Perform Engine Maintenance........................................................................ 29

C-3 Perform Axle Maintenance ............................................................................ 29

C-4 Perform Engine Maintenance........................................................................ 30

C-5 Perform Engine Maintenance........................................................................ 30

Checklist D Procedures ..................................................................................... 31

D-1 Perform Engine Maintenance........................................................................ 31

D-2 Check the Tower Rotation Bearing Bolts ..................................................... 31

D-3 Replace the Hydraulic Return Filter .............................................................. 32

D-4 Perform Engine Maintenance........................................................................ 33

D-5 Perform Engine Maintenance........................................................................ 33

D-6 Perform Engine Maintenance........................................................................ 34

D-7 Perform Generator Maintenance .................................................................. 34

D-8 Perform Tongue Jack and Outrigger Jack Maintenance .............................. 35

D-9 Perform Axle Maintenance ............................................................................ 35

Checklist E Procedures ..................................................................................... 36

E-1 Perform Hydraulic Oil Analysis ...................................................................... 36

E-2 Perform Engine Maintenance ........................................................................ 37

E-3 Perform Engine Maintenance ........................................................................ 38

E-4 Perform Generator Maintenance ................................................................... 38

E-5 Perform Generator Maintenance ................................................................... 39

viii AL5HT Part No. 1265482

May 2015

Table of Contents

Section 4 Repair Procedures ............................................................................................. 40

Introduction ........................................................................................................... 40

Lighting ............................................................................................................... 42

1-1 How to Remove a Lamp ................................................................................. 42

1-2 How to Check Line Voltage ............................................................................ 42

1-3 How to Check the Open Circuit Voltage [Terex SM] ...................................... 43

Mast ..................................................................................................................... 44

2-1 How to Remove the Light Bar Assembly ....................................................... 44

2-2 How to Remove the Light Bar Lift Cylinder .................................................... 44

Tower Components ............................................................................................ 46

3-1 Tower Component ......................................................................................... 46

3-2 How to Remove the Cable Track .................................................................. 47

3-3 How to Remove the Tower Assembly ........................................................... 47

3-4 How to Disassemble the Tower .................................................................... 48

3-5 How to Remove the Tower Lift Cylinder ....................................................... 50

3-6 How to Remove the Tower Extension Cylinder ............................................ 51

3-7 How to Remove the Tower Rotation Motor ................................................... 52

3-8 How to Adjust the Tower Rotation Gear Backlash ........................................ 52

Kubota D1105-E / V1505-E Engine .................................................................... 53

4-1 Timing Adjustment-Kubota Engines ............................................................... 53

4-2 Glow Plugs-Kubota En gines .......................................................................... 53

4-3 Coolant Temperature and Oil Pressure Switches-Kubota Engines ............... 53

Isuzu 4LE1 Engine .............................................................................................. 54

5-1 Timing Adjustment-Isuzu 4LE1 ...................................................................... 54

5-2 Glow Plugs-Isuzu 4LE1 .................................................................................. 54

5-3 Coolant Temperature and Oil Pressure Switches-Isuzu 4LE1 ...................... 54

Isuzu 4LE2 Engine .............................................................................................. 55

6-1 Timing Adjustment-Isuzu 4LE2 ...................................................................... 55

6-2 Glow Plugs-Isuzu 4LE2 .................................................................................. 55

6-3 Coolant Temperature and Oil Pressure Switches-Isuzu 4LE2 ...................... 55

Part No. 1265482 AL5HT ix

May 2015

Table of Contents

Isuzu 4LE2-T Engine .......................................................................................... 56

7-1 Timing Adjustment-Isuzu 4LE2-T .................................................................. 56

7-2 Glow Plugs-Isuzu 4LE2-T .............................................................................. 56

7-3 Coolant Temperature and Oil Pressure Switches-Isuzu 4LE2-T ................... 56

Generator ............................................................................................................ 57

8-1 Generator ....................................................................................................... 57

8-2 How to Check a Generator Capacitor ............................................................ 58

8-3 How to Check a Generator Diode .................................................................. 59

Light Ballast ........................................................................................................ 60

9-1 Ground Controls ............................................................................................ 60

9-2 Light Ballast ................................................................................................... 61

Fuel Tank ............................................................................................................ 62

10-1 Fuel Tank ..................................................................................................... 62

Section 5 Diagnostics ......................................................................................................... 64

Introduction .......................................................................................................... 64

Diagnostic Charts .............................................................................................. 65

Section 6 Schematics ......................................................................................................... 69

Introduction .......................................................................................................... 69

Wire Color Legend ............................................................................................... 70

Electrical Wiring Schematic ANSI / CSA ............................................................. 72

Electrical Wiring Schematic AUS ......................................................................... 73

Control Box and Engine Wiring - Kubota Models ................................................ 76

Control Box and Engine Wiring - AUS Models .................................................... 77

Trailer Wiring Diagram - ANSI / CSA Models ...................................................... 80

Trailer Wiring Diagram - AUS Models .................................................................. 81

x AL5HT Part No. 1265482

May 2015 Service Manual

Total lighting wattage

4

8

atts

atts

Axle load capacity, maximum

bs

g

Fluid capacities

Hydraulic tank capacity

allons

iters

Hydraulic system capacity

(including tank)

allons

iters

Fuel capacities

Single tank

allons

iters

Large tank (option)

allons

iters

Tires and wheels (U.S. models)

Tire size ST205/75D15

Load range

C

Lug nut torque, dry

lbs

122 Nm

Lug nut torque, lubricated

lbs

91.5 Nm

Tires and

Tire size

7.5R16 C 112/110L

Lug nut torque, dry

lbs

108 Nm

Lug nut torque, lubricated

si

ar

Tongue weight, maximum

With fuel (single tank)

bs

g

With fuel (large tank)

bs

g

Run time

Single tank

ours

Large tank

ours

Marathon

Generator rpm @ full load

pm

Temperature, ambient maxi mum

104° F

40° C

Power

W

Marathon

Generator rpm @ full load

pm

Temperature, ambient maxi mum

104° F

40° C

Power

W

Marathon 12 kW 281CSL1513

Generator rpm @ full load

pm

Temperature, ambient maxi mum

104° F

40° C

Power

W

Marathon 2

Generator rpm @ full load

pm

Temperature, ambient maxi mum

104° F

40° C

Power

W

Specifications

Section 2 Specificati ons

Machine Specifications

lights

lights

1.4 g

30 g

60 g

90 ft-

67.5 ft-

4000 w

8000 w

4200 l

1905 k

5.3 l

2 g

7.6 l

114 l

227 l

Performance Specifications

150 l

68 k

130 l

59 k

50 h

100 h

Generator Options

8 kW 201CSA5412

60Hz, 1800 r

8 k

8 kW 201CSA5420

60 Hz, 1800 r

8 k

wheels (Australia models)

80 ft-

75 p

5.2 b

60 Hz, 1800 r

12 k

0 kW 334CSA3028

60 Hz, 1800 r

20 k

For operational specifications, refer to the

Operator's Manual.

Continuous improvement of our produ cts is a

Genie policy. Product specifications are

subject to change without notice or obligation.

Part No. 1265482 AL5HT 1

Service Manual May 2015

Displacement

u in

iters

Number of cylinders

3

Bore and Stroke

nches

m

Horsepower

@ 1800

W

Firing order

3

Compression ratio

23:1

Compression pressure

si

ar

Engine speed

pm

Governor

centrifugal

mechanical

Valve Clearance, cold

n

m

Engine coolant

Capacity

uarts

iters

Lubrication system

Oil pressure

si

ar

Oil capacity (including filter)

uarts

iters

Oil pressure switch (engine

shutoff pressure)

si

Oil viscosity requirements

Unit ships with

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine Operator

Manual for your engine.

Injection system

Injection pump

Bosch MD mini

Injection timing 19° BTDC

Injection pump

maximum

si

ar

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your engine.

Battery

Type

12V DC

Group

27TM

Quantity

1

Cold cranking ampere 500

Reserve capacity @ 75A rate

inutes

Alternator

Alternator output

40A, 12V DC

Fan belt deflection

m

Specifications

Kubota D1105-E4BG Engine

0.0057 to 0.0072 i

0.145 to 0.185 m

3.27 q

28 to 64 p

5.4 q

10W-30. Extreme operating

68.53 c

3.07 x 3.09 i

78 x 78.4 m

13.6

412 to 469 p

28.4 to 32.3 b

1.93 to 4.41 b

1.12 l

10.1 k

1 - 2 -

1800 r

3.1 l

5.1 l

7 p

pressure,

1991 p

137 b

105 m

1/4 to 3/8 inch

7 to 9 m

2 AL5HT Part No. 1265482

May 2015 Service Manual

Displacement

u in

iters

Number of cylinders

4

Bore and Stroke

nches

m

Horsepower

17.9 @ 1800

W

Firing order

2

Compression ratio

22:1

Compression pressure

si

ar

Engine speed

pm

Governor

centrifugal

mechanical

Valve Clearance, cold

n

m

Engine coolant

Capacity

uarts

iters

Lubrication system

Oil pressure

si

ar

Oil capacity (including filter)

uarts

iters

Oil pressure switch (engine

shutoff pressure)

si

Oil viscosity requirements

Unit

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine Operator

Manual for your engine.

Injection system

Injection pump

Bosch MD mini

Injection timing 19° BTDC

Injection pump pressure,

maximum

si

ar

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your engine.

Battery

Type

12V DC

Group

27TM

Quantity

1

Cold cranking ampere 630

Reserve capacity @ 75A rate

inutes

Alternator

Alternator output

30A, 12V DC

Fan belt deflection

nch

m

Specifications

Kubota D1505-E Engine

4.23 q

28 to 64 p

7.08 q

ships with 10W-30. Extreme operating

3.07 x 3.09 i

0.0057 to 0.0072 i

0.145 to 0.185 m

91.41 c

1.5 l

78 x 78.4 m

13.4 k

1 - 3 - 4 -

412 to 469 p

28.4 to 32.3 b

1800 r

4 l

1.93 to 4.41 b

6.7 l

7 p

1991 p

137 b

105 m

1/4 to 3/8 i

7 to 9 m

Part No. 1265482 AL5HT 3

Service Manual May 2015

Displacement

u in

iters

Number of cylinders

4

Bore and Stroke

nches

m

Horsepower

31.4 @ 1800

W

Firing order

2

Compression ratio

21.5:1

Compression pressure

si

ar

Engine speed

pm

Governor

variable speed,

mechanical

Valve Clearance, cold

Intake

n

m

Exhaust

n

m

Engine coolant

Capacity

uarts

iters

Coolant temperature switch

(engine shut

221°± 7°F

105° ± 4°C

Lubrication system

Oil pressure (hot @ 180

si

ar

Oil capacity (including filter)

uarts

iters

Oil pressure switch (engine

shutoff pressure)

si

ar

Oil viscosity requirements

Unit ships with 10W

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine

Manual for your engine.

Injection system

Injection pump

Bosch, PFR type

Injection timing 16° BTDC

Injection pump pressure,

maximum

si

ar

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your

Battery

Type

12V DC

Group

27TM

Quantity

1

Cold cranking ampere 630

Reserve capacity @ 75A rate

inutes

Alternator

Alternator output

35A, 12V DC

Fan belt deflection

m

Specifications

Isuzu 4LE1 Engine

0.0157 i

0.0157 i

4 q

-off temperature)

0 rpm) 64 p

7.08 q

-30. Extreme operating

3.35 x 3.78 i

28.4 to 32.3 b

133 c

2.179 l

85 x 96 m

23.4 k

1 - 3 - 4 -

412 to 469 p

1800 r

0.4 m

0.4 m

3.8 l

4.4 b

6.7 l

14 p

0.96 b

1920 p

132.8 b

engine.

105 m

1/4 to 3/8 inch

7 to 9 m

4 AL5HT Part No. 1265482

Operator

May 2015 Service Manual

Displacement

u in

iters

Number of cylinders

4

Bore and Stroke

nches

m

Horsepower

31.4 @ 1800

W

Firing order

2

Compression ratio

21.5:1

Compression pressure

si

ar

Engine speed

pm

Governor

variable speed,

mechanical

Valve Clearance, cold

Intake

n

m

Exhaust

n

m

Engine coolant

Capacity

uarts

iters

Coolant temperature switch

(engine shut

221°± 7°F

105° ± 4°C

Lubrication system

Oil pressure (hot @ 180

si

ar

Oil capacity (including filter)

uarts

iters

Oil pressure switch (engine

shutoff pressure)

si

ar

Oil viscosity requirements

Unit ships with 10W

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine Operator

Manual for your engine.

Injection system

Injection pump

Bosch, PFR type

Injection timing 16° BTDC

Injection pump

maximum

si

ar

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your engine.

Battery

Type

12V DC

Group

27TM

Quantity

1

Cold cranking ampere 630

Reserve capacity @ 75A rate

inutes

Alternator

Alternator output

35A, 12V DC

Fan belt deflection

nch

m

Specifications

Isuzu 4LE2 Engine

0.0157 i

0.0157 i

4 q

-off temperature)

0 rpm) 64 p

7.08 q

-30. Extreme operating

3.35 x 3.78 i

28.4 to 32.3 b

133 c

2.179 l

85 x 96 m

23.4 k

1 - 3 - 4 -

412 to 469 p

1800 r

0.4 m

0.4 m

3.8 l

4.4 b

6.7 l

14 p

0.96 b

pressure,

1920 p

132.8 b

105 m

1/4 to 3/8 i

7 to 9 m

Part No. 1265482 AL5HT 5

Service Manual May 2015

Displacement

u in

iters

Number of cylinders

4

Bore and Stroke

nches

m

Horsepower

31.4 @ 1800

W

Firing order

2

Compression ratio

21.5:1

Compression pressure

si

ar

Engine speed

pm

Governor

variable speed,

mechanical

Valve Clearance, cold

Intake

n

m

Exhaust

n

m

Engine coolant

Capacity

uarts

iters

Coolant temperature switch

(engine shut

221°± 7°F

105° ± 4°C

Lubrication system

Oil pressure (hot @ 180

si

ar

Oil capacity (including filter)

uarts

iters

Oil pressure switch (engine

shutoff pressure)

si

ar

Oil viscosity requirements

Unit ships with 10W

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine

Manual for your engine.

Injection system

Injection pump

Bosch, PFR type

Injection timing 16° BTDC

Injection pump pressure,

maximum

si

ar

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your

Battery

Type

12V DC

Group

27TM

Quantity

1

Cold cranking ampere 630

Reserve capacity @ 75A rate

inutes

Alternator

Alternator output

35A, 12V DC

Fan belt deflection

m

Specifications

Isuzu 4LE2-T Engine

0.0157 i

0.0157 i

4 q

-off temperature)

0 rpm) 64 p

7.08 q

-30. Extreme operating

3.35 x 3.78 i

28.4 to 32.3 b

133 c

2.179 l

85 x 96 m

23.4 k

1 - 3 - 4 -

412 to 469 p

1800 r

0.4 m

0.4 m

3.8 l

4.4 b

6.7 l

14 p

0.96 b

1920 p

132.8 b

engine.

105 m

1/4 to 3/8 inch

7 to 9 m

6 AL5HT Part No. 1265482

Operator

May 2015 Service Manual

Generator

Flex plate to flywheel

lbs

20 Nm

Generator case to bell housing

lbs

41 Nm

Generator isolators

lbs

102 Nm

Wheel lugs

Lug nut torque, lubricated

lbs

91.5 Nm

Lug nut torque, dry

lbs

122 Nm

Engine vibration isolators

Mounting bolts, dry

lbs

81 Nm

Mounting bolts, lubricated

lbs

61 Nm

Specifications

Machine Torque Specif ications

15 ft-

67.5 ft-

90 ft-

60 ft-

45 ft-

30 ft-

75 ft-

Continuous improvement of our produ cts is a

Genie policy. Product specifications are

subject to change without notice or obligation.

Part No. 1265482 AL5HT 7

Service Manual May 2015

Specifications

8 AL5HT Part No. 1265482

May 2015 Service Manual

Failure to perform each

procedure as presented and

scheduled may cause death,

serious injury or sub

damage.

Scheduled Maint enance Procedures

Section 3 Scheduled M aintenanc e Procedur es

Observe and Obey:

Maintenance inspections shall be completed

by a person trained and qualified on the

maintenance of this machine.

Scheduled maintenance inspections shall be

completed daily, quarterly, s emi-annually,

annually and every 2 years as specified of the

Maintenance inspection Report. The frequency

and extent of periodic examinations and tests

may also depend on national regulations.

stantial

Machine Configuration:

Unless otherwise specified, perform each

procedure with the machine in the following

configuration:

• Machine parked on a firm, level surface

• Mast in the stowed position

• Key switch in the off position with the key

removed

• The red Emergency Stop button in the off

position on the electrical control box

• Wheels chocked

• Light switches in the off position

• All external AC power supply disconnected

from the machine

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Use only Terex approved replacement parts.

Machines that have been out of service for a

period longer than 3 months must complete the

quarterly inspection.

Part No. 1265482 AL5HT 9

Service Manual May 2015

Safety alert symbol—used to alert

personnel to potenti

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not

may result in property damage.

Scheduled Maint enance Procedures

About This Section

This section contains detailed procedures for each

scheduled maintenance inspection.

Each procedure includes a descr iption, safety

warnings and step-by-s tep i ns truc tions .

Symbols Legend

al personal

hazardous

avoided,

Indicates that a specific result is expected

after performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

10 AL5HT Part No. 1265482

May 2015 Service Manual

Indicates that tools will be required to

perform

Indicates that new parts will be required to

perform this procedure.

Indicates that dealer service will be

required to perform this procedure.

Indicates that a cold engine will be

required to perform this procedure.

Indicates that a warm engine will be

required to perform this procedure.

Inspection Checklist

Daily or every

A

Quarterly or every 25

A + B

Semi

A + B + C

Annually or every 100

A + B + C + D

Two

A + B + C + D + E

Scheduled Maint enance Procedures

Maintenance Symbols Legend

Pre-delivery Preparation Report

Note: The following symbols have been used in this

manual to help communicate the intent of the

instructions. When one or more of the symbols

appear at the beginning of a maintenance

procedure, it conveys the meaning below.

this procedure.

The pre-delivery preparation report contains

checklists for each type of scheduled inspection.

Make copies for each inspection. Store completed

forms as required.

Maintenance Schedule

The Scheduled Maintenance Procedures section

and the Maintenance Inspection Report hav e bee n

divided into subsections. Use the following chart to

determine which group(s) of procedures are

required to perform a scheduled inspection.

8 hours

0 hours

-annually or every 500 hours

0 hours

-year or every 2000 hours

Maintenance Inspection Report

The maintenance inspection report contains

checklists for each type of scheduled inspection.

Make copies of the Maintenance Inspection Report

to use for each inspection. Maintain completed

forms for a minimum of 4 years or in compliance

with your employer, jobsite and governmental

regulations and requirements.

Part No. 1265482 AL5HT 11

Service Manual May 2015

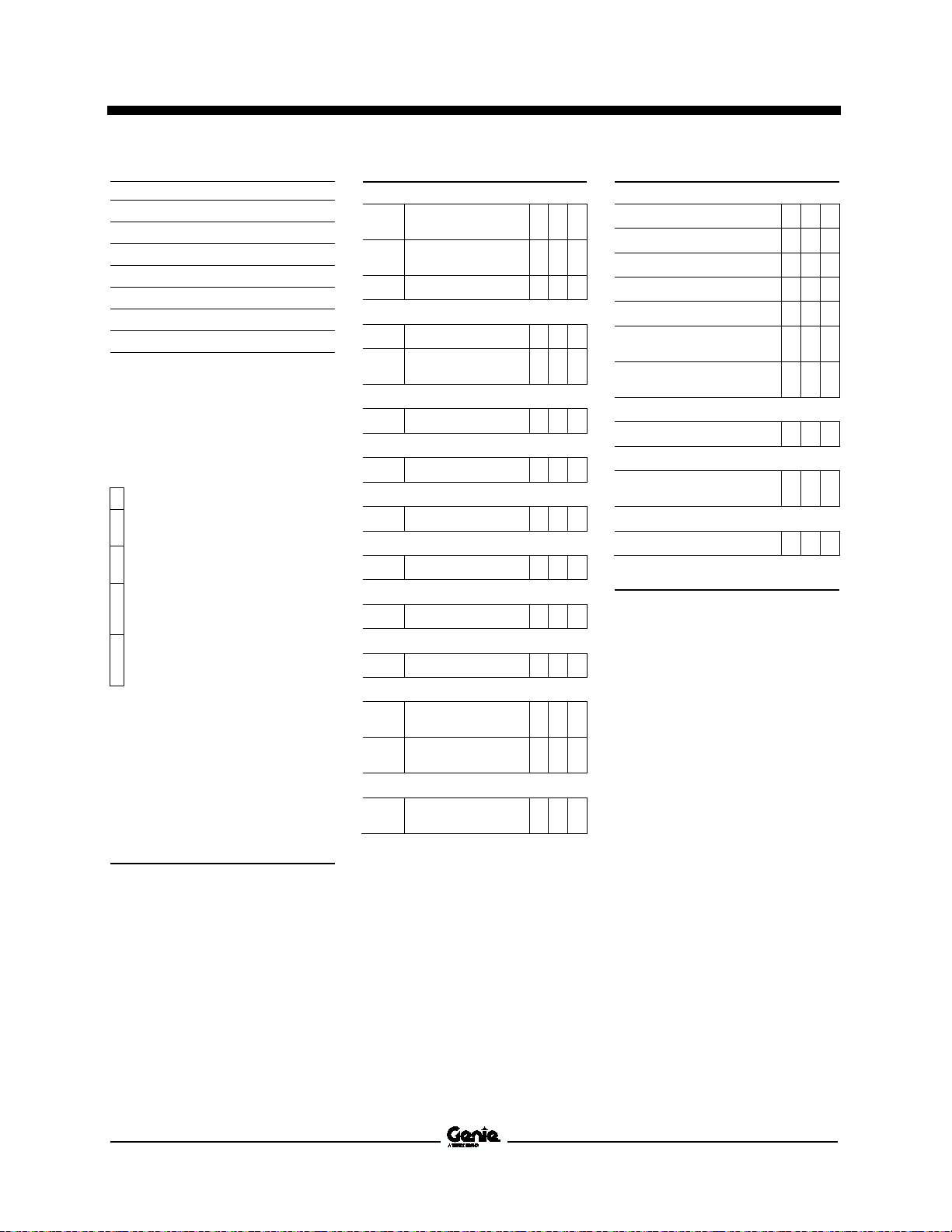

Legend

Comments

Pre

Pre

Maintenance items completed

Function tests completed

Model

Serial number

Date

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Pre-Delivery Preparation Report

Fundamentals

It is the responsibility of the owner or dealer to

perform the Pre-deliver y Pr eparation.

The Pre-delivery Preparation is performed prior to

each delivery. The inspection is designed to

discover if anything is apparently wrong with a

machine before it is put into service.

A damaged or modified machine must never be

used. If damage or any variation from factory

delivered condition is discovered, the machine

must be tagged and removed from service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer's specifications.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications and

the requirements listed in the responsibilities

manual.

Instructions

Use the operator’s manual on your machine.

The Pre-delivery Preparation consists of

completing the Pre-operation Inspection, the

Maintenance items and the Function Tests.

Use this form to record the results. Place a check in

the appropriate box after each part is completed.

Follow the instructions in the operator’s manual.

If any inspection receives an N, remove the

machine from service, repair and re-inspect it. After

repair, place a check in the R box.

Y = yes, acceptable

N = no, remove from service

R = repaired

-delivery Preparation

-operation inspection c om plete d

Y N R

May 2015 Service Manual

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Daily or every

Quarterly or every

25

Semi

every 50

Annually or

every

100

Two

every

200

Legend

Comments

Maintenance Inspection Report

Instructions

• Make copies of this report to use for

each inspection.

• Select the appropriate checklist(s) for

the type of inspection(s) to perform.

0 hours

-annually or

0 hours

-year or

0 hours

• Place a check in the appropriate box

after each inspection procedure is

completed.

• Us e t he step-by-step procedures in

this section to learn how to perform

these inspections.

• I f any inspect i on receives an "N," tag

and remove the machine from service,

repair and re-inspect it. After repair,

place a check in the "R" box.

Y = yes, acceptable

N = no, remove from service

R = repaired

8 hours A

A + B

A + B + C

0 hours

A + B + C + D

A + B + C + D + E

Checklist A Y N R

A-1 Inspect the manuals

and decals

A-2 Pre-operation

inspection

A-3 Function tests

Perform after 8 hours:

A-4 Engine maintenance

A-5 Generator

maintenance

Perform after 10 miles:

A-6 Axle maintenance

Perform after 25 miles:

A-6 Axle maintenance

Perform after 50 miles:

A-6 Axle maintenance

Perform after 40 hours:

A-7 30-day service

Perform after 50 hours:

A-8 Engine maintenance

Perform weekly:

A-9 Coupler

Perform after 100 hours:

A-10 Grease turntable

bearing

A-11 Engine maintenance

- Kubota models

Perform after 200 hours:

A-12 Engine maintenance

- Kubota models

Checklist B Y N R

B-1 Batteries

B-2 Electrical wiring

B-3 Lug nuts

B-4 Hydraulic oil analysis

B-5 Engine maintenance

B-6 Engine maintenance

- Kubota models

B-7 Generator

maintenance

Perform quarterly:

B-8 Coupler

Perform every 400 hours:

B-9 Engine maintenance

- Kubota models

Perform every 3000 miles:

B-10 Axle maintenance

Part No. 1265482 AL5HT 13

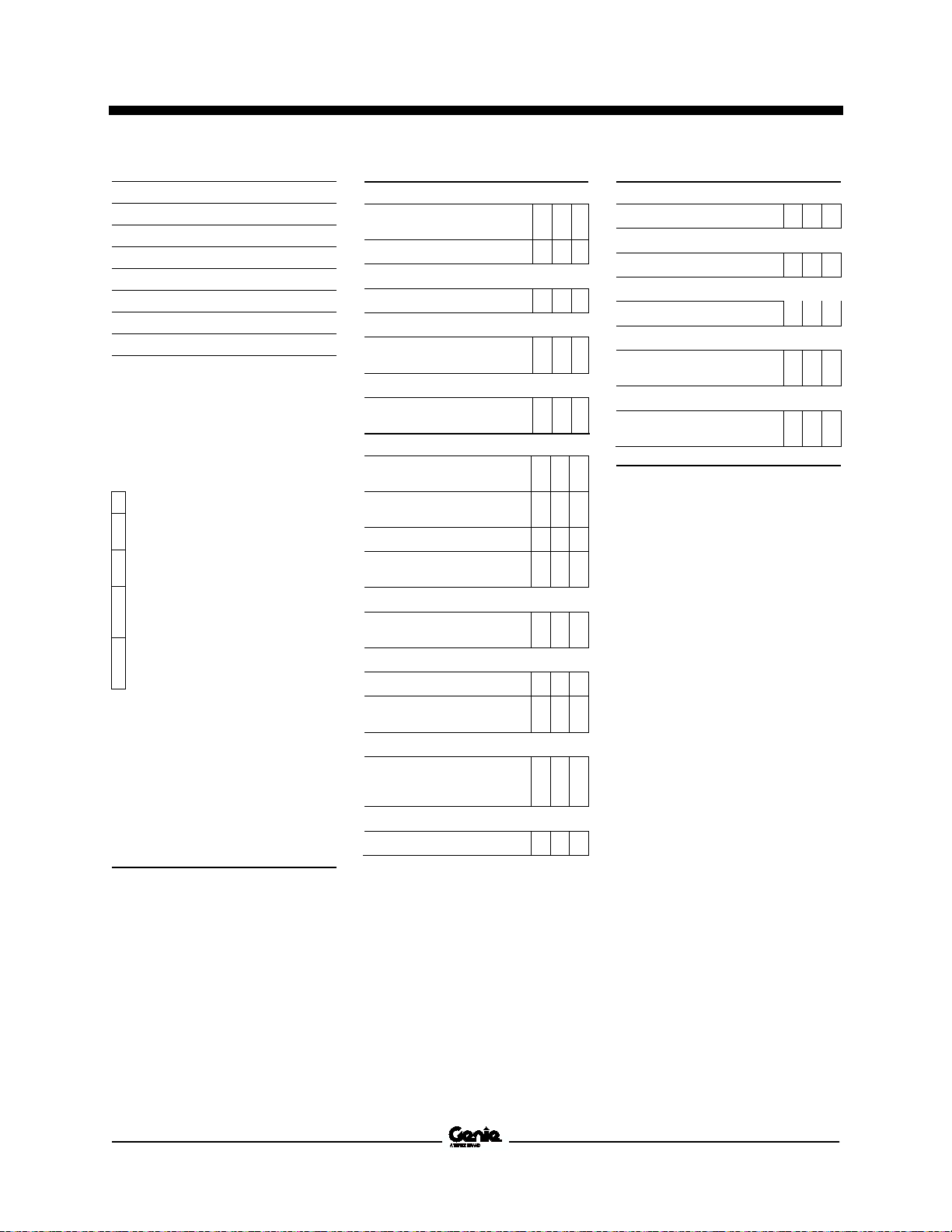

Service Manual May 2015

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Daily or every

Quarterly or every

25

Semi

every 50

Annually or

every

100

Two

every

200

Legend

Checklist D

Y N R

Checklist E

Comments

Maintenance Inspection Report

Instructions

• Make copies of this report to use for

each inspection.

• Select the appropriate checklist(s) for

the type of inspection(s) to perform.

0 hours

-annually or

0 hours

-year or

0 hours

• Place a check in the appropriate box

after each inspection procedure is

completed.

• Us e t he step-by-step procedures in

this section to learn how to perform

these inspections.

• I f any inspect i on receives an "N," tag

and remove the machine from service,

repair and re-inspect it. After repair,

place a check in the "R" box.

Y = yes, acceptable

N = no, remove from service

R = repaired

8 hours A

A + B

A + B + C

0 hours

A + B + C + D

A + B + C + D + E

Checklist C Y N R

C-1 Inspect tower

extend/retract cables

C-2 Engine maintenance

Perform every 6000 miles:

C-3 Axle maintenance

Perform after 750 hours:

C-4 Engine maintenance -

Isuzu models

Perform every 800 hours:

C-5 Engine maintenance -

Kubota models

D-1 Engine maintenance

- Kubota models

D-2 Generator

maintenance

D-3 Hydraulic filters

D-4 Engine maintenance

- Isuzu models

Perform every 1250 hours:

D-5 Engine maintenance

- Isuzu models

Perform every 1500 hours:

D-6 Engine maintenance

D-7 Generator

maintenance

Perform annually:

D-8 Tongue jack and

outrigger jack

maintenance

Perform every 12,000 hours:

D-9 Axle maintenance

Y N R

E-1 Hydraulic oil analysis

Perform every 3000 hours:

E-2 Engine maintenance

Perform every 2 years:

E-3 Engine maintenance

Perform every 4500 hours:

E-4 Generator

maintenance

Perform every 15,000 hours:

E-5 Generator

maintenance

14 AL5HT Part No. 1265482

May 2015 Service Manual

Checklist A Procedures

A-1 Inspect the Manuals and Decal s

Terex specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Maintaining the operator’s and safety manuals in

good condition is essential to safe machine

operation. Manuals are included with each

machine and should be stored in the container

provided in the platform. An illegible or missing

manual will not provide safety and operational

information necessary for a safe operating

condition.

In addition, maintaining all of the safety and

instructional decals in good condition is mandatory

for safe machine operation. Decals alert operators

and personnel to the many possible hazards

associated with using this machine. They also

provide users with operation and maintenance

information. An illegible decal will fail to alert

personnel of a procedure or hazard and could

result in unsafe operating conditions.

3 Open the operator's manual to the decals

inspection section. Carefully and thoroughly

inspect all decals on the machine for legibility

and damage.

Result: The machine is equipped with all

required decals, and all decals are legible and

in good condition.

Result: The machine is not equi ppe d with al l

required decals, or one or more decals are

illegible or in poor condition. Remove the

machine from service until the decals are

replaced.

4 Always return the manuals to the storage

container after use.

Note: Contact your authorized Terex distributor or

Terex if replacement manuals or decals are

needed.

1 Check to make sure that the operator's and

safety manuals are present and complete in

the storage container inside the cabinet.

2 Examine the pages of each manual to be sure

that they are legible and in good condition.

Result: The operator's manual is appropriate

for the machine and all manuals are legible

and in good condition.

Result: The operator's manual is not

appropriate for the machine or all manuals are

not in good condition or is illegible. Remove

the machine from service until the manual is

replaced.

Part No. 1265482 AL5HT 15

Service Manual May 2015

Checklist A Procedures

A-2 Perform Pre-operation Inspection

Terex specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Completing a Pre-operation Inspection is essential

to safe machine operation. The Pre-operation

Inspection is a visual inspection performed by the

operator prior to each work shift. The inspection is

designed to discover if anything is apparently

wrong with a machine before the operator performs

the function tests. The Pre-operation Inspection

also serves to determine if routine maintenance

procedures are required.

Complete information to perform this procedure is

available in the appropriate operator's manual.

Refer to the Operator's Manual on your machine.

A-3 Perform Function Tests

Terex specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Completing the function tests is essential to safe

machine operation. Function tests are designed to

discover any malfunctions before the machine is

put into service. A malfunctioning machine must

never be used. If malfunctions are discovered, the

machine must be tagged and removed from

service.

Complete information to perform this procedure is

available in the appropriate operator's manual.

Refer to the Operator's Manual on your machine.

16 AL5HT Part No. 1265482

May 2015 Service Manual

Isuzu 4LE1 Diesel Engine Owner's Manual

Genie part number 116133

Isuzu 4LE2 Diesel Engine Owner's Manual

Genie part number 1264609

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

Marathon Manual

Genie part number 116188

Checklist A Procedures

A-4 Perform Engine Maintenance

Engine specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

• Engine oil level – check

• Coolant level – check/add

• Fuel system filter/water separator – drain

• Engine tightness – check for leaks

• Exhaust system – check for leaks

• Loose or missing fasteners

Required maintenance procedures and additional

engine information is available in the Ku bota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number ) OR the Isuzu 4LE1

Diesel Engine Owner's Manual (Isuzu part number

IDE-6033) OR the Isuzu 4LE2 Diesel Engine

Owner's Manual (Isuzu part number IDE-6450).

A-5 Perform Generator Maintenance

Generator specifications require that this

procedure be performed every 40 hours or weekly,

whichever comes first.

• Clean and inspect the generator exterior

• Clean and replace the generator air filters -

(if equipped)

Part No. 1265482 AL5HT 17

Service Manual May 2015

Checklist A Procedures

A-6 Perform Axle Maintenance

Axle specifications require that this procedure be

performed initially and following a wheel change

after the first 10, 25 and 50 miles.

Proper axle maintenance, following the axle

manufacturer's maintenance schedule, is essential

to good axle performance and service life. Failure

to perform the maintenance procedures can lead to

poor axle performance and component damage.

Required maintenance procedures and additional

axle information is available in the Axis Axle

Operator Maintenance Manual included with your

machine.

A-7 Torque the Wheel Lug Nuts

Axle specifications require that this procedure be

performed initially at 10, 25 and 50 miles of use, or

after reinstallation of a tire.

Maintaining the wheel lug nuts at proper torque is

essential to safe operation and good service life of

the tires, wheel and axle.

1 Check each lug nut for proper torque. Refer to

Specifications, Machine Specifications.

18 AL5HT Part No. 1265482

May 2015 Service Manual

Isuzu 4LE1 Diesel Engine Owner's Manual

Genie part number 116133

Isuzu 4LE2 Diesel Engine Owner's Manual

Genie part number 1264609

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

Checklist A Procedures

A-8 Perform Engine Maintenance

Engine specifications require that this procedure be

performed every 50 hours or weekly, whichever

comes first.

Required maintenance procedures and additional

engine information is available in the Ku bota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number ) OR the Isuzu 4LE1

Diesel Engine Owner's Manual (Isuzu part number

IDE-6033) OR the Isuzu 4LE2 Diesel Engine

Owner's Manual (Isuzu part number IDE-6450).

A-9 Perform Coupler Maintenance

Coupler specifications require that this procedure

be performed weekly.

Maintaining the coupler in good condition is

essential to safe operation and good performance.

Coupler failure could result in a machine tip-over

during transport, and component damage may also

result if problems are not discovered and repaired

in a timely fashion.

1 Check coupler welds and mounting bolt

torque. Torque the fasteners to 35 ft-lbs / 48

Nm.

Result: 1.5 full threads of the locking bolt must

be exposed beyond the lock nut after the

adjustment.

2 Apply automotive grease to the coupler ball

pocket.

3 Oil coupler pivot points using SAE 30 motor

oil.

Part No. 1265482 AL5HT 19

Loading...

Loading...