Terex AL8000HT Service Manual

Service Manual

TM

AL8000HT

First Edition

Rev A

Part No. 116478

September 2008

Introduction

Important

Read, understand and obey the safety rules and

operating instructions in the appropriate Operator's

Manual on your machine before attempting any

maintenance procedure.

Basic mechanical, hydraulic and electrical

skills are required to perform most procedures.

However, several procedures require specialized

skills, tools, lifting equipment and a suitable

workshop. In these instances, we strongly

recommend that maintenance and repair be

performed at an authorized Terex dealer

service center.

September 2008

Technical Publications

Terex has endeavored to deliver the highest degree

of accuracy possible. However, continuous

improvement of our products is a Terex policy.

Therefore, product specifications are subject to

change without notice.

Readers are encouraged to notify Terex of errors

and send in suggestions for improvement. All

communications will be carefully considered for

future printings of this and all other manuals.

Contact Us:

Internet: www.genielift.com

e-mail: techpub@genieind.com

Copyright © 2008 by Terex

Terex Rock Hill

590 Huey Road

Rock Hill, SC. 29730

116478 Rev A September 2008

First Edition, First Printing

" Printed on recycled paper

Printed in U.S.A.

ii

AL8000HT Light Tower Part No. 116478

September 2008

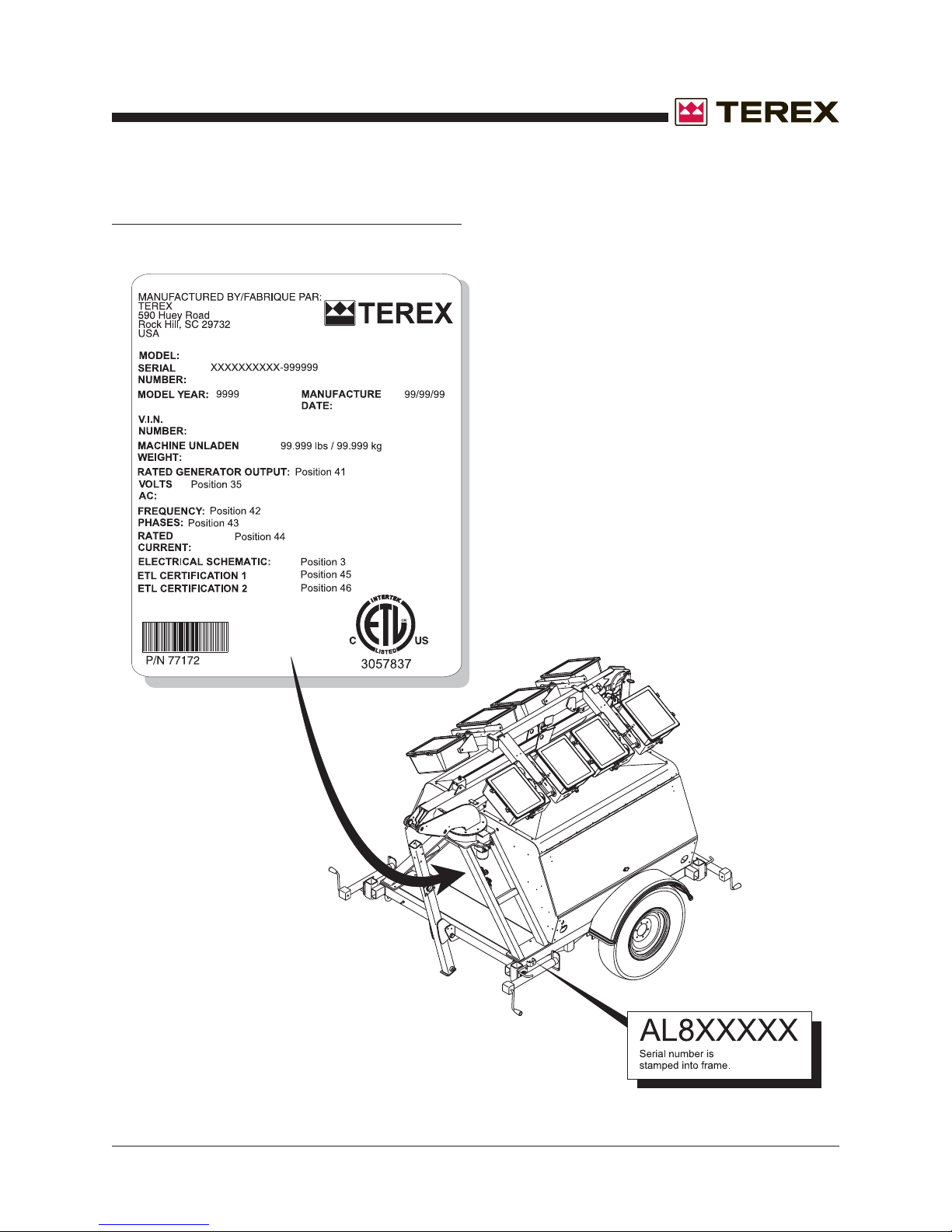

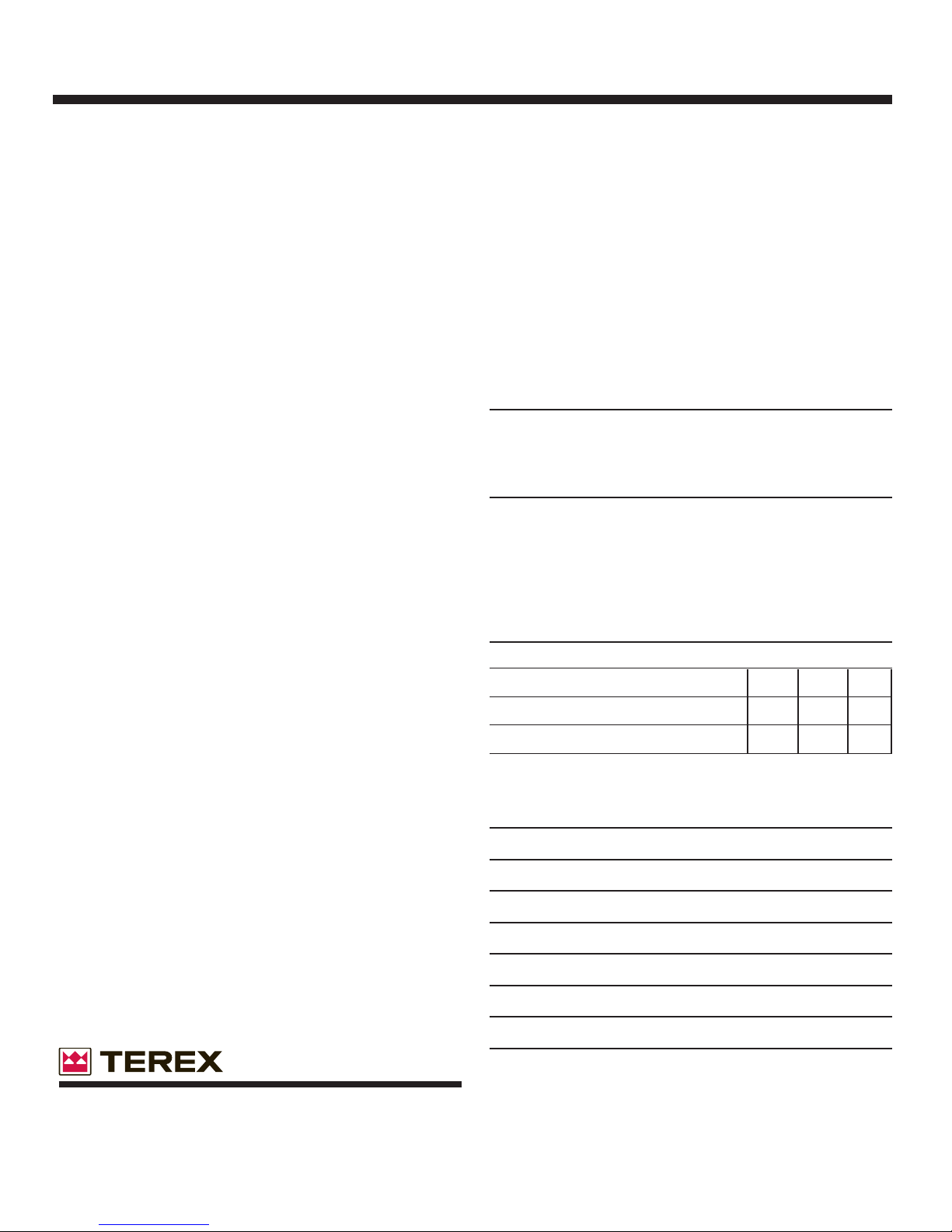

How to Read Your Serial Number

Serial Number Legend

Part No. 116478 AL8000HT Light Tower

iii

Section 1 • Safety Rules September 2008

Safety Rules

Danger

Failure to obey the instructions and safety rules

in this manual and the

Manual

serious injury.

Many of the hazards identified in the operator’s

manual are also safety hazards when maintenance

and repair procedures are performed.

on your machine will result in death or

Terex AL8000HT Operator's

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

- manufacturer’s instructions and safety rules

- employer’s safety rules and worksite

regulations

- applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

iv

AL8000HT Light Tower Part No. 116478

Section 1 • Safety RulesSeptember 2008

SAFETY RULES

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

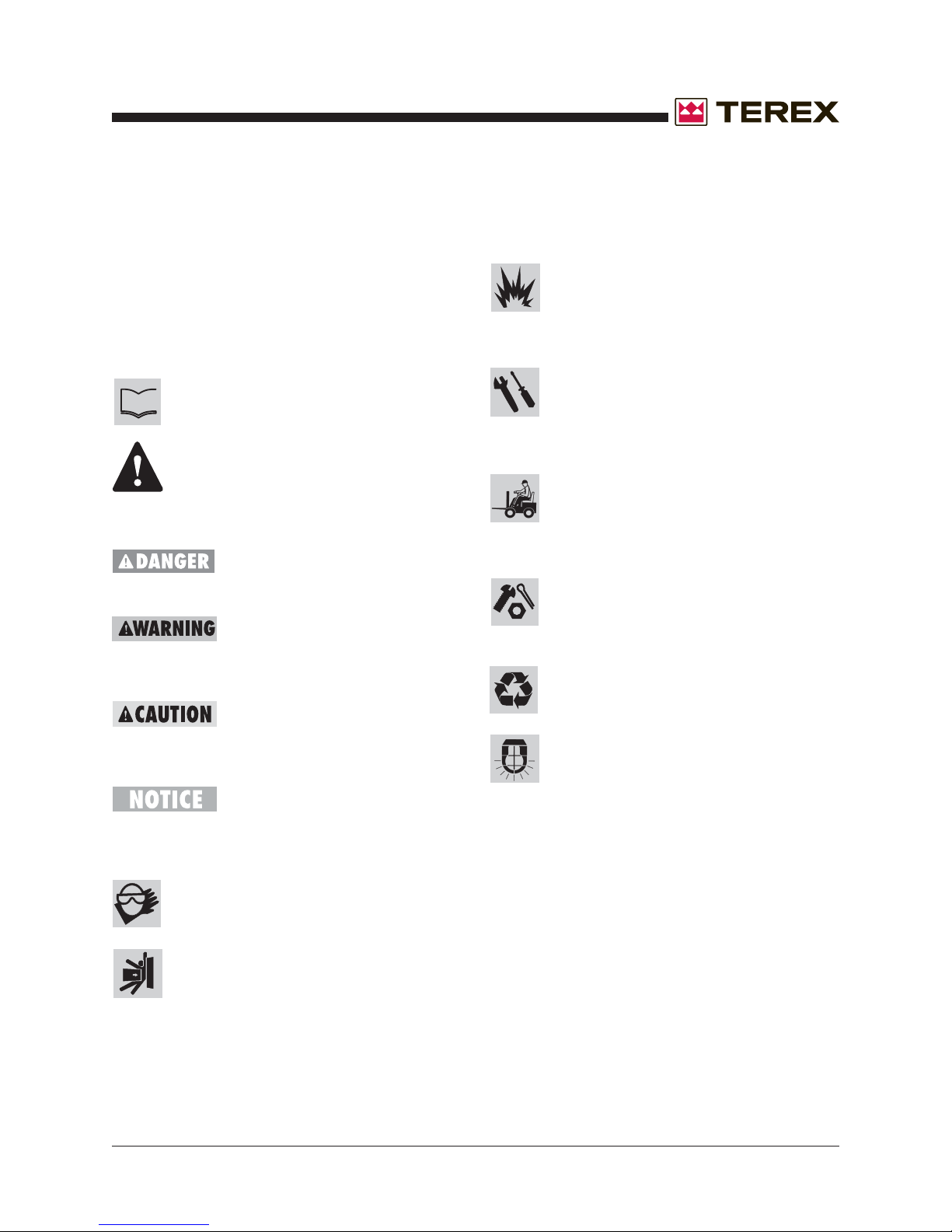

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Workplace Safety

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible materials like battery gases

and engine fuels. Always have an approved fire

extinguisher within easy reach.

Be sure that all tools and working areas

are properly maintained and ready for use.

Keep work surfaces clean and free of

debris that could get into machine components and

cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing the

weight to be lifted. Use only chains or straps that

are in good condition and of ample capacity.

Be sure that fasteners intended for one

time use (i.e., cotter pins and self-locking

nuts) are not reused. These components

may fail if they are used a second time.

Be sure to properly dispose of old oil or

other fluids. Use an approved container.

Please be environmentally safe .

Be sure that your workshop or work area is

properly ventilated and well lit.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when lifting or

placing loads. Always wear approved steel-toed

shoes.

Part No. 116478 AL8000HT Light Tower

v

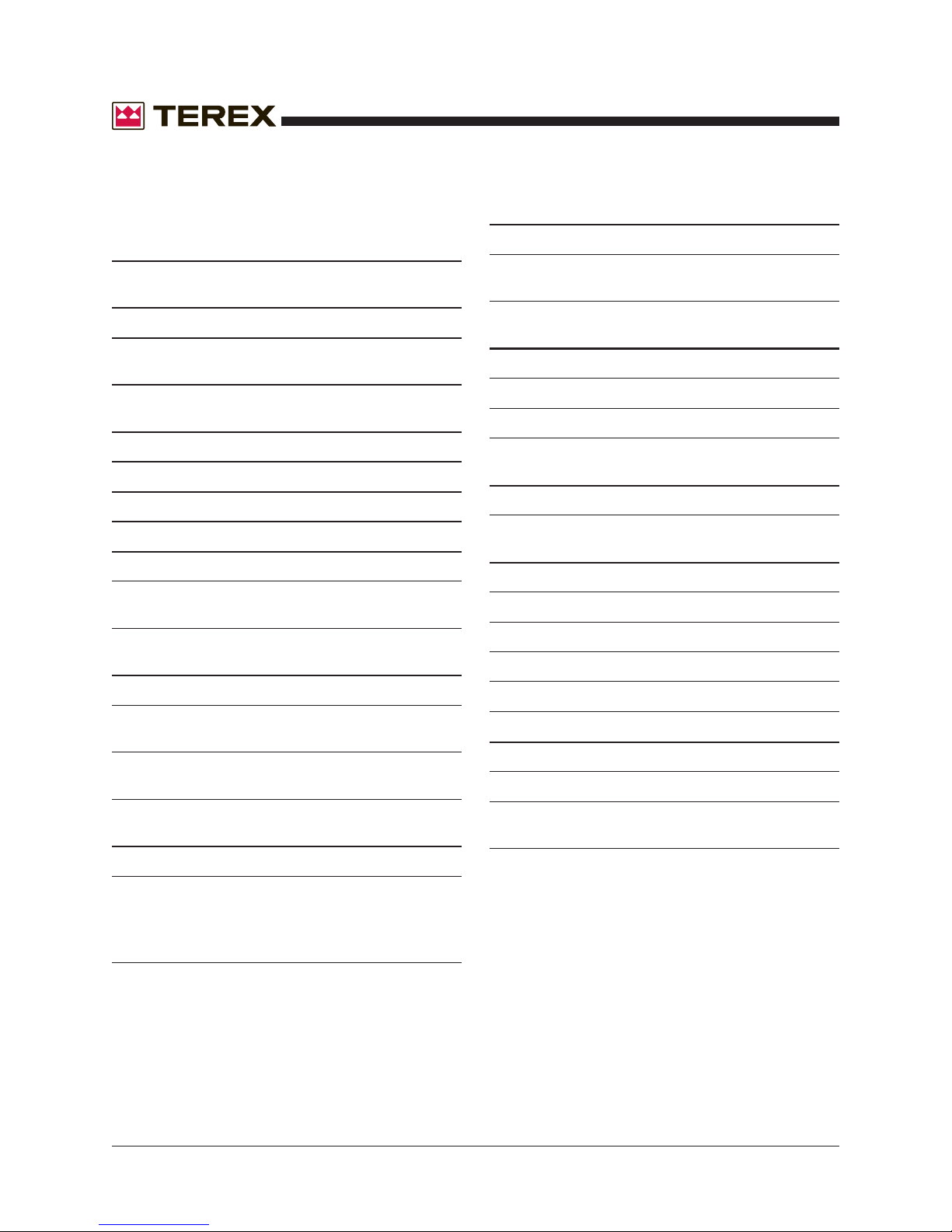

Table of Contents

Introduction

September 2008

Important Information ...........................................................................................................

How to Read Your Serial Number ........................................................................................

Parts Stocking List .............................................................................................................

How to Order Parts .............................................................................................................

Service Parts Fax Order Form ...........................................................................................

Section 1 Safety Rules

General Safety Rules ..................................................................................................

Section 2 Rev Specifications

A Machine Specifications .......................................................................................... 2 - 1

Performance Specifications ................................................................................... 2 - 1

Hydraulic Oil Specifications ................................................................................... 2 - 2

Hydraulic Component Specifications ...................................................................... 2 - 2

Manifold Component Specifications ....................................................................... 2 - 3

Kubota D1105-E Engine ......................................................................................... 2 - 4

Kubota V1505-E Engine ........................................................................................ 2 - 5

ii

iii

x

xi

xii

iv

Isuzu 4LE1 Engine................................................................................................. 2 - 6

Generator Specifications ........................................................................................ 2 - 7

Hydraulic Hose and Fitting Torque Specifications .................................................. 2 - 8

SAE and Metric Fasteners Torque Charts .............................................................. 2 - 9

Genset Torque Specifications .............................................................................. 2 - 10

Section 3 Rev Scheduled Maintenance Procedures

Introduction ............................................................................................................ 3 - 1

Pre-delivery Preparation Report .............................................................................. 3 - 3

Maintenance Inspection Report .............................................................................. 3 - 5

A Checklist A Procedures

A-1 Inspect the Manuals and Decals .................................................................. 3 - 7

A-2 Perform Pre-operation Inspection ................................................................. 3 - 8

A-3 Perform Function Tests ................................................................................ 3 - 8

vi

AL8000HT Light Tower Part No. 116478

September 2008

A-4 Perform Engine Maintenance - Isuzu Models ............................................... 3 - 9

Section 3 Rev Scheduled Maintenance Procedures, continued

A-5 Perform Generator Maintenance ................................................................... 3 - 9

A-6 Perform Axle Maintenance ......................................................................... 3 - 10

A-7 Perform 30 Day Service ............................................................................. 3 - 10

A-8 Perform Engine Maintenance ..................................................................... 3 - 11

A-9 Perform Hitch Maintenance ........................................................................ 3 - 11

A-10 Grease the Turntable RotationBearing and Rotate Gear ............................. 3 - 12

A-11 Perform Engine Maintenance - Kubota Models ........................................... 3 - 13

A-12 Perform Engine Maintenance - Kubota Models ........................................... 3 - 13

A Checklist B Procedures

TABLE OF CONTENTS

B-1 Inspect the Battery ..................................................................................... 3 - 14

B-2 Inspect the Electrical Wiring ....................................................................... 3 - 14

B-3 Inspect the Tires and Wheels (including lug nut torque) .............................. 3 - 15

B-4 Perform Hydraulic Oil Analysis ................................................................... 3 - 15

B-5 Perform Engine Maintenance - Isuzu Models ............................................. 3 - 16

B-6 Perform Generator Maintenance ................................................................. 3 - 16

B-7 Perform Hitch Maintenance ........................................................................ 3 - 17

B-8 Perform Engine Maintenance - Kubota Models ........................................... 3 - 17

B-9 Perform Axle Maintenance ......................................................................... 3 - 17

A Checklist C Procedures

C-1 Inspect the Tower Extend/Retract Cables and Pulleys ............................... 3 - 19

C-2 Perform Engine Maintenance ..................................................................... 3 - 19

C-3 Perform Axle Maintenance ......................................................................... 3 - 20

C-4 Perform Engine Maintenance - Isuzu Models ............................................. 3 - 20

C-5 Perform Engine Maintenance - Kubota Models ........................................... 3 - 21

A Checklist D Procedures

D-1 Perform Engine Maintenance - Kubota Models ........................................... 3 - 22

D-2 Check the Tower Rotation Bearing Bolts .................................................... 3 - 22

D-3 Replace the Hydraulic Return Filter ............................................................ 3 - 23

D-4 Perform Engine Maintenance - Isuzu Models ............................................. 3 - 24

Part No. 116478 AL8000HT Light Tower

vii

TABLE OF CONTENTS

D-5 Perform Engine Maintenance - Isuzu Models ............................................. 3 - 24

D-6 Perform Engine Maintenance ..................................................................... 3 - 25

Section 3 Rev Scheduled Maintenance Procedures, continued

D-7 Perform Generator Maintenance ................................................................. 3 - 25

D-8 Perform Tongue Jack and Outrigger Jack Maintenance ............................. 3 - 26

D-9 Perform Axle Maintenance ......................................................................... 3 - 26

E-1 Test or Replace the Hydraulic Oil ............................................................... 3 - 27

E-2 Perform Engine Maintenance - Kubota Models ........................................... 3 - 28

E-3 Perform Engine Maintenance - Kubota Models ........................................... 3 - 29

E-4 Perform Generator Maintenance ................................................................. 3 - 29

E-5 Perform Generator Maintenance ................................................................. 3 - 30

September 2008

Section 4 Rev Repair Procedures

Introduction ............................................................................................................ 4 - 1

A Lighting

1-1 Lighting ........................................................................................................ 4 - 2

A Light Bar Components

2-1 Light Bar ...................................................................................................... 4 - 4

2-2 Light Bar Lift Cylinder ................................................................................... 4 - 5

A Tower Components

3-1 Plastic Cable Track ...................................................................................... 4 - 7

3-2 Tower Assembly .......................................................................................... 4 - 7

3-3 Tower Lift Cylinder ..................................................................................... 4 - 10

3-4 Tower Extension Cylinder ........................................................................... 4 - 11

3-5 Tower Rotation Motor ................................................................................. 4 - 12

A Kubota D1105-E/V1505-E Engine

4-1 Timing Adjustment ..................................................................................... 4 - 13

4-2 Glow Plugs ................................................................................................. 4 - 13

4-3 Coolant Temperature and Oil Pressure Switches ........................................ 4 - 13

A Isuzu 4LE1 Engine

5-1 Timing Adjustment ..................................................................................... 4 - 14

viii

AL8000HT Light Tower Part No. 116478

September 2008

TABLE OF CONTENTS

5-2 Glow Plugs ................................................................................................. 4 - 14

5-3 Coolant Temperature and Oil Pressure Switches ........................................ 4 - 14

Section 4 Rev Repair Procedures, continued

A Generator

6-1 Generator ................................................................................................... 4 - 15

A Chassis Components

7-1 Ground Controls ......................................................................................... 4 - 19

7-2 Light Ballast ............................................................................................... 4 - 20

7-3 Fuel Tank ................................................................................................... 4 - 21

8-1 Function Manifold Components .................................................................. 4 - 23

8-2 Valve Adjustments - Function Manifold ...................................................... 4 - 24

Section 5 Rev Troubleshooting

Introduction ............................................................................................................ 5 - 1

A Troubleshooting Guide ........................................................................................... 5 - 2

A Light Fixture Troubleshooting ................................................................................. 5 - 5

Section 6 Rev Schematics

A Introduction ............................................................................................................ 6 - 1

A Electrical Symbols Legend .................................................................................... 6 - 2

A Hydraulic Symbols Legend .................................................................................... 6 - 3

A Electrical Schematic - Machine Functions ............................................................. 6 - 4

A DC Electrical Schematic - Control Box and Engine - Isuzu Models ....................... 6 - 5

A DC Electrical Schematic - Control Box and Engine - Kubota Models .................... 6 - 6

A DC Electrical Schematic - Control Box and Engine - with Autostart Option ........... 6 - 7

A AC Electrical Schematic - Standard Models with 4 Lights ...................................... 6 - 8

A AC Electrical Schematic - Standard Models with 6 Lights ...................................... 6 - 9

A AC Electrical Schematic - Standard Models with 8 Lights .................................... 6 - 10

A AC Electrical Schematic - Autostart Models with 4 Lights .................................... 6 - 11

A AC Electrical Schematic - Autostart Models with 6 Lights .................................... 6 - 12

A AC Electrical Schematic - Autostart Models with 8 Lights .................................... 6 - 13

A Receptacle Wiring Diagrams ................................................................................ 6 - 14

A Hydraulic Schematic ............................................................................................ 6 - 15

Part No. 116478 AL8000HT Light Tower

ix

Parts Stocking List

Required Parts

The following parts are required to perform

maintenance procedures as outlined in the

TEREX AL8000HT Parts and Service Manual.

Description Part No.

Kubota Models

Oil Filter .............................................................. 866050

Air Filter .............................................................. 866127

Fuel Filter ........................................................... 839200

V-belt ................................................................. 839209

Isuzu Models

Oil Filter .............................................................. 868075

Air Filter .............................................................. 834460

Fuel Filter ........................................................... 868137

V-belt ................................................................. 868067

September 2008

Manuals

TEREX Corporation offers the following manuals for

these models:

Title Part No.

TEREX AL8000HT Operator's Manual, .............. 114426

First Edition

TEREX AL8000HT Part's Manual, ..................... 116447

First Edition

TEREX AL8000HT Service Manual, ..................116478

First Edition

Newage Generator Manual ................................ 830001

Leroy Somer Manual .......................................... 116118

Isuzu Engine Manual ......................................... 116133

Kubota Engine Manual ....................................... 893020

Axis Manual ........................................................ 116117

Marathon Manual ............................................... 116188

x

AL8000HT Light Tower Part No. 116478

September 2008

How To Order Parts

Please be prepared with the following information

when ordering replacement parts for your TEREX

product:

Machine model number

Machine serial number

Terex part number

Part description and quantity

Purchase order number

"Ship to" address

Desired method of shipment

Name and telephone number of the

authorized TEREX Distributor in your area

Use the Service Parts Fax Order Form on the

next page and fax your order to our Parts

Department.

If you don't know the name of your authorized

distributor, or if your area is not currently serviced

by an authorized distributor, please call TEREX

Corporation.

Machine Information

Genie Industries

18340 NE 76th Street

P.O. Box 97030

Redmond, WA 98073-9730

Telephone (877) 367-5606

Fax (888) 274-6192

genieindustries.com

Model

Serial Number

Date of Purchase

Authorized TEREX Distributor

Phone Number

Part No. 116478 AL8000HT Light Tower

xi

September 2008

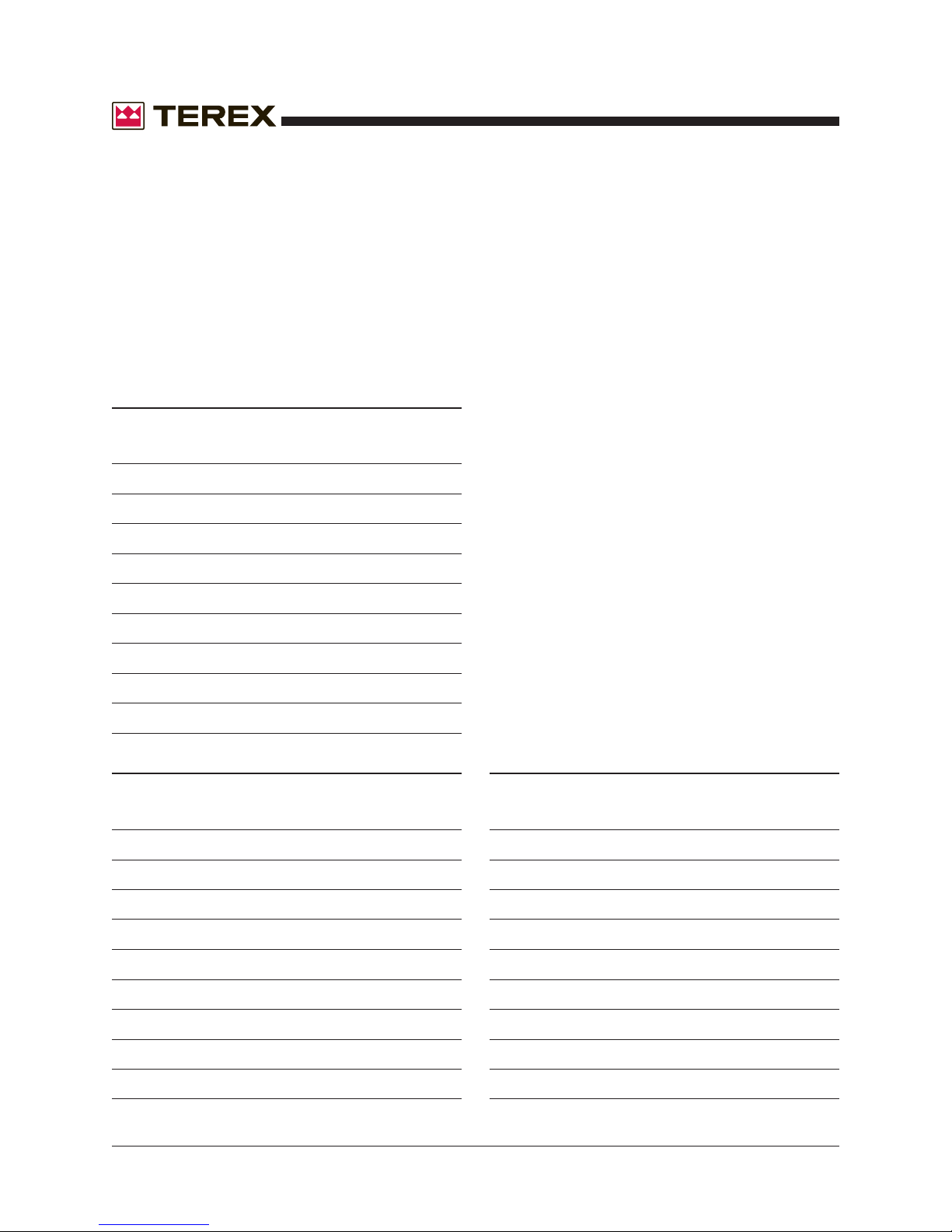

Service Parts fax Order Form

Please fill out completely

Date _________________________________ Account Number _______________________________

Your Name ______________________________ Your Fax Number _____________________________

_________________________________ Your Phone Number ___________________________

Bill To _________________________________ Ship To ___________________________________

_________________________________ ___________________________________

_________________________________ ___________________________________

_________________________________ ___________________________________

Purchase Order Number ____________________ Ship Via ___________________________________

Model(s) ______________________________________________________ Serial No.(s) _________________

FAX TO: (888) 274-6192 OR TOLL FREE: 877-367-5606

Optional Equipment ___________________________________________________________________________

Part Number Description Quantity Price

remove this page and make copies

All backordered parts will be shipped when available via the same ship method as the original order unless

noted below:

o Ship complete order only - no backorders

o Ship all available parts and contact customer on disposition of backordered parts

o Other (please specify)

FOR TEREX USE O NLY

Order Number ______________ Origin Code ________________ Comments _________________________

Date Scheduled ____________ Ship Condition _____________ __________________________________

Order Total ________________ Terms Code _______________ __________________________________

remove this page and make copies

AL8000HT Light Tower Part No. 116478

September 2008

Section 2 • Specifications

REV A

Machine Specifications

Lights

Type: BT-37 Metal Halide, 1000 watt

Total lighting wattage

4 lights 4000 watts

8 lights 8000 watts

Axle

Axle load capacity, maximum 4200 lbs

1905 kg

Fluid capacities

Hydraulic tank capacity 1.4 gallons

5.3 liters

Hydraulic system capacity 2 gallons

(including tank) 7.6 liters

Single fuel tank 30 gallons

114 liters

Dual fuel tanks 60 gallons

227 liters

Tires and wheels (U.S. models)

Tire size ST205/75R15

Load range C

Lug nut torque, dry 80 ft-lbs

108 Nm

Tire pressure, maximum (cold) 50 psi

3.4 bar

Tires and wheels (Australia models)

Tire size 7.5R16 C 112/110L

Lug nut torque, dry 80 ft-lbs

108 Nm

Specifications

Performance Specifications

Tongue weight, maximum 350 lbs

159 kg

Run time, full load

Kubota D1105 (8kW) @ .82 Gallons per hour

Single full fuel tank 36.5 hours

Dual full fuel tanks 73 hours

Run time, full load

Kubota V1505 (12kW) @ 1.1 Gallons per hour

Single full fuel tank 27.25 hours

Dual full fuel tanks 54.5 hours

Run time, full load

Isuzu 4LE1 (20kW) @ 1.8 Gallons per hour

Single full fuel tank 16.5 hours

Dual full fuel tanks 33 hours

Towing speed, maximum 62 mph

100 km/h

Function speeds

Boom up 12 to 24 seconds

Boom down 12 to 21 seconds

Boom extend 17 to 37 seconds

Boom retract 13 to 27 seconds

Light bar up 18 to 30 seconds

Light bar down 14 to 24 seconds

Tower rotate, 359° 31 to 68 seconds

Tire pressure, maximum (cold) 75 psi

For operational specifications, refer to the

Operator's Manual.

Part No. 116478 AL8000HT Light Tower 2 - 1

5.2 bar

Continuous improvement of our products is a

Terex policy. Product specifications are subject

to change without notice.

Section 2 • Specifications

September 2008

SPECIFICATIONS

Hydraulic Oil Specifications

Hydraulic Oil Specifications

Hydraulic oil type Chevron Rando HD Premium MV

Viscosity grade Multi-viscosity

Viscosity index 200

Cleanliness level, minimum 15/13

Water content, maximum 200 ppm

Chevron Rykon MV oil is fully compatible and

mixable with Shell Donax TG (Dexron III) oils.

Genie specifications require hydraulic oils which are

designed to give maximum protection to hydraulic

systems, have the ability to perform over a wide

temperature range, and the viscosity index should

exceed 140. They should provide excellent antiwear,

oxidation, corrosion inhibition, seal conditioning, and

foam and aeration suppression properties.

Optional fluids

Biodegradable Petro Canada Environ MV46

Statoil Hydra Way Bio Pa 32

BP Biohyd SE-S

Fire resistant UCON Hydrolube HP-5046

Quintolubric 822

REV A

Hydraulic Component

Specifications

Function pump

Type: Fixed displacement gear pump

Displacement 0.056 cu in

per revolution 0.92 cc

Flow rate @ 3200 psi 0.6 gpm

2.27 L/min

System relief pressure 3200 psi

220.6 bar

Function manifold

Light bar up/down 0.2 gpm

flow regulator 0.76 L/min

Tower rotate relief 1200 psi

valve pressure 82.7 bar

Hydraulic filter

Hydraulic tank Beta 10 ≥ 200

return filter with 25 psi / 1.7 bar bypass

Mineral based Shell Tellus T32

Shell Tellus T46

Chevron Aviation A

Continued use of Chevron Aviation

A hydraulic fluid when ambient

temperatures are consistently

above 32°F / 0°C may result in

component damage.

Note: Use Chevron Aviation A hydraulic fluid when

ambient temperatures are consistently below

0°F / -18°C.

Note: Use Shell Tellus T46 hydraulic oil when oil

temperatures consistently exceed 205°F / 96°C.

Note: Terex specifications require additional

equipment and special installation instructions for

the approved optional fluids. Consult the Terex

Service Department before use.

Continuous improvement of our products is a

Terex policy. Product specifications are subject

to change without notice.

2 - 2 AL8000HT Light Tower Part No. 116478

September 2008

Section 2 • Specifications

REV A

Manifold Component

Specifications

Plug torque

SAE No. 2 36 in-lbs / 4 Nm

SAE No. 4 10 ft-lbs / 13 Nm

SAE No. 6 14 ft-lbs / 19 Nm

SAE No. 8 38 ft-lbs / 51 Nm

SAE No. 10 41 ft-lbs / 55 Nm

SAE No. 12 56 ft-lbs / 76 Nm

Valve Coil Resistance

Note: The following coil resistance specifications are at

an ambient temperature of 68°F / 20°C. As valve coil

resistance is sensitive to changes in air temperature,

the coil resistance will typically increase or decrease by

4% for each 18°F / 20°C that your air temperature

increases or decreases from 68°F / 20°C.

Valve coil specifications

SPECIFICATIONS

Machine Torque Specifications

Tower rotation assembly

Rotate bearing mounting bolts, lubricated

1

/2 -13 SHC bolts 95 ft-lbs

5

/8 -11 SHC bolts 195 ft-lbs

Rotation motor mounting bolts, dry 75 ft-lbs

1

/2 -13, GR 5 102 Nm

Rotation motor mounting bolts, lubricated 57 ft-lbs

1

/2 -13, GR 5 77 Nm

Generator

Generator case to engine 25 ft-lbs

bell housing fasteners 34 Nm

Generator vibration 75 ft-lbs

isolator fasteners 102 Nm

Flex plate to flywheel 25 ft-lbs

129 Nm

264 Nm

34 Nm

3 position 4 way solenoid valve, 10V DC 6Ω

(schematic items B, C, E and G)

Continuous improvement of our products is a

Terex policy. Product specifications are subject

to change without notice.

Part No. 116478 AL8000HT Light Tower 2 - 3

Section 2 • Specifications

September 2008

SPECIFICATIONS

Kubota D1105-E Engine

Displacement 68.53 cu in

1.12 liters

Number of cylinders 3

Bore and stroke 3.07 x 3.09 inches

78 x 78.4 mm

Horsepower, continuous 13.6 @ 1800 rpm

10.1 kW

Firing order 1 - 2 - 3

Compression ratio 23:1

Compression pressure 412 to 469 psi

28.4 to 32.3 bar

Engine speed 1800 rpm

Governor centrifugal mechanical

Valve clearance, cold 0.0057 to 0.0072 in

0.145 to 0.185 mm

REV A

Injection system

Injection pump make Bocsh MD mini

Injection timing 19° BTDC

Injection pump pressure 1991 psi

137 bar

Fuel requirement

For fuel requirements, refer to the engine Operator's

Manual on your machine.

Battery

Type 12V DC

Group 27TM

Quantity 1

Cold cranking ampere 500

Reserve capacity @ 25A rate 105 minutes

Alternator

Engine coolant

Capacity 3.27 quarts

3.1 liters

Lubrication system

Oil pressure 28 to 64 psi

1.93 to 4.41 bar

Oil capacity 5.4 quarts

(including filter) 5.1 liters

Oil pressure switch 7 psi

(engine shutoff pressure)

Oil viscosity requirements

Units ship with 10W-30.

Extreme operating temperatures may require the use of

alternative engine oils. For oil requirements, refer to the

Engine Operator Handbook on your machine.

Output 40A, 12V DC

Fan belt deflection

1

/4 to 3/8 inch

7 to 9 mm

Continuous improvement of our products is a

Terex policy. Product specifications are subject

to change without notice.

2 - 4 AL8000HT Light Tower Part No. 116478

September 2008

Section 2 • Specifications

REV A

Kubota V1505-E Engine

Displacement 91.41 cu in

1.5 liters

Number of cylinders 4

Bore and stroke 3.07 x 3.09 inches

78 x 78.4 mm

Horsepower, continuous 17.9 @ 1800 rpm

13.4 kW

Firing order 1 - 3 - 4 - 2

Compression ratio 22:1

Compression pressure 412 to 469 psi

28.4 to 32.3 bar

Engine speed 1800 rpm

Governor centrifugal mechanical

Valve clearance, cold 0.0057 to 0.0072 in

0.145 to 0.185 mm

SPECIFICATIONS

Injection system

Injection pump make Bocsh MD mini

Injection timing 19° BTDC

Injection pump pressure 1991 psi

137 bar

Fuel requirement

For fuel requirements, refer to the engine Operator's

Manual on your machine.

Battery

Type 12V DC

Group 27TM

Quantity 1

Cold cranking ampere 630

Reserve capacity @ 25A rate 105 minutes

Alternator

Engine coolant

Capacity 4.23 quarts

4 liters

Lubrication system

Oil pressure 28 to 64 psi

1.93 to 4.41 bar

Oil capacity 7.08 quarts

(including filter) 6.7 liters

Oil pressure switch 7 psi

(engine shutoff pressure)

Oil viscosity requirements

Units ship with 10W-30.

Extreme operating temperatures may require the use of

alternative engine oils. For oil requirements, refer to the

Engine Operator Handbook on your machine.

Output 30A, 12V DC

Fan belt deflection

1

/4 to 3/8 inch

7 to 9 mm

Part No. 116478 AL8000HT Light Tower 2 - 5

Section 2 • Specifications

September 2008

SPECIFICATIONS

Isuzu 4LE1 Engine

Displacement 133 cu in

2.179 liters

Number of cylinders 4

Bore and stroke 3.35 x 3.78 inches

85 x 96 mm

Horsepower, continuous 31.4 @ 1800 rpm

23.4kW

Firing order 1 - 3 - 4 - 2

Compression ratio 21.5:1

Engine speed 1800 rpm

Governor variable speed, mechanical

Valve clearance, cold

Intake 0.0157 in

0.4 mm

Exhaust 0.0157 in

0.4 mm

Lubrication system

Oil pressure (hot @ 1800 rpm) 64 psi

4.4 bar

Oil capacity 7.08 quarts

(including filter) 6.7 liters

Oil pressure switch 14 psi

(engine shut-off pressure) 0.96 bar

REV A

Engine coolant

Capacity 4 quarts

3.8 liters

Coolant temperature switch 221° ±7°F

(engine shut-off temperature) 105° ±4°C

Injection system

Injection pump make Bosch, PFR ype

Injection timing 16° BTDC

Injection pump pressure 1920 psi

132.8 bar

Fuel requirement

For fuel requirements, refer to the engine Operator's

Manual on your machine.

Battery

Type 12V DC

Group 27TM

Quantity 1

Cold cranking ampere 630

Reserve capacity @ 25A rate 105 minutes

Alternator

Output 35A, 12V DC

Fan belt deflection

1

/4 to 3/8 inch

7 to 9 mm

Oil viscosity requirements

Units ship with 10W-30.

Extreme operating temperatures may require the use of

alternative engine oils. For oil requirements, refer to the

Engine Operating Instructions on your machine.

2 - 6 AL8000HT Light Tower Part No. 116478

Continuous improvement of our products is a

Terex policy. Product specifications are subject

to change without notice.

September 2008

Section 2 • Specifications

REV A

Leroy Somer LSA37M7

Generator

Generator speed @ full load 60 Hz 1800 rpm

Temperature, ambient maximum 104°F

40°C

Power 8 kW

Capacitor (disconnected) 100 µF @ 240V

Marathon 201CSA5412

Generator

Generator rpm @ full load 60 Hz 1800 rpm

Temperature, ambient maximum 104°F

40°C

Power 8 kW

SPECIFICATIONS

Newage BCI164D1J195A

Generator

Generator rpm @ full load 60 Hz 1800 rpm

Temperature, ambient maximum 104°F

40°C

Power 12 kW

Newage BCI184E1J203A

Generator

Generator rpm @ full load 60 Hz 1800 rpm

Temperature, ambient maximum 104°F

40°C

Power 20 kW

Continuous improvement of our products is a

Terex policy. Product specifications are subject

to change without notice.

Part No. 116478 AL8000HT Light Tower 2 - 7

Section 2 • Specifications

September 2008

SPECIFICATIONS

Hydraulic Hose and Fitting

Torque Specifications

Your machine is equipped with Parker Seal-Lok®

fittings and hose ends. Genie specifications require

that fittings and hose ends be torqued to

specification when they are removed and installed

or when new hoses or fittings are installed.

SAE O-ring Boss Port

(tube fitting - installed into Aluminum)

SAE Dash size Torque

-4 11 ft-lbs / 14.9 Nm

-6 23 ft-lbs / 31.2 Nm

-8 40 ft-lbs / 54.2 Nm

-10 69 ft-lbs / 93.6 Nm

-12 93 ft-lbs / 126.1 Nm

-16 139 ft-lbs / 188.5 Nm

-20 172 ft-lbs / 233.2 Nm

REV A

Seal-Lok® fittings

1 Replace the O-ring. The O-ring must be replaced

anytime the seal has been broken. The O-ring

cannot be re-used if the fitting or hose end has

been tightened beyond finger tight.

Note: The O-rings used in the Parker Seal Lok®

fittings and hose ends are custom-size O-rings.

They are not standard SAE size O-rings. They are

available in the O-ring field service kit (Genie part

number 49612).

2 Lubricate the O-ring before installation.

3 Be sure that the face seal O-ring is seated and

retained properly.

4 Position the tube and nut squarely on the face

seal end of the fitting and tighten the nut finger

tight.

5 Tighten the nut or fitting to the appropriate

torque per given size as shown in the table.

6 Operate all machine functions and inspect the

hoses and fittings and related components to

confirm that there are no leaks.

-24 208 ft-lbs / 282 Nm

SAE O-ring Boss Port

(tube fitting - installed into Steel)

SAE Dash size Torque

-4 16 ft-lbs / 21.7 Nm

-6 35 ft-lbs / 47.5 Nm

-8 60 ft-lbs / 81.3 Nm

-10 105 ft-lbs / 142.4 Nm

-12 140 ft-lbs / 190 Nm

-16 210 ft-lbs / 284.7 Nm

-20 260 ft-lbs / 352.5 Nm

-24 315 ft-lbs / 427.1 Nm

SAE Dash size Torque

Seal-Lok® Fittings

(hose end)

-4 18 ft-lbs / 25 Nm

-6 30 ft-lbs / 40 Nm

-8 40 ft-lbs / 55 Nm

-10 60 ft-lbs / 80 Nm

-12 85 ft-lbs / 115 Nm

-16 110 ft-lbs / 150 Nm

-20 140 ft-lbs / 190 Nm

-24 180 ft-lbs / 245 Nm

2 - 8 AL8000HT Light Tower Part No. 116478

September 2008

Section 2 • Specifications

REV A

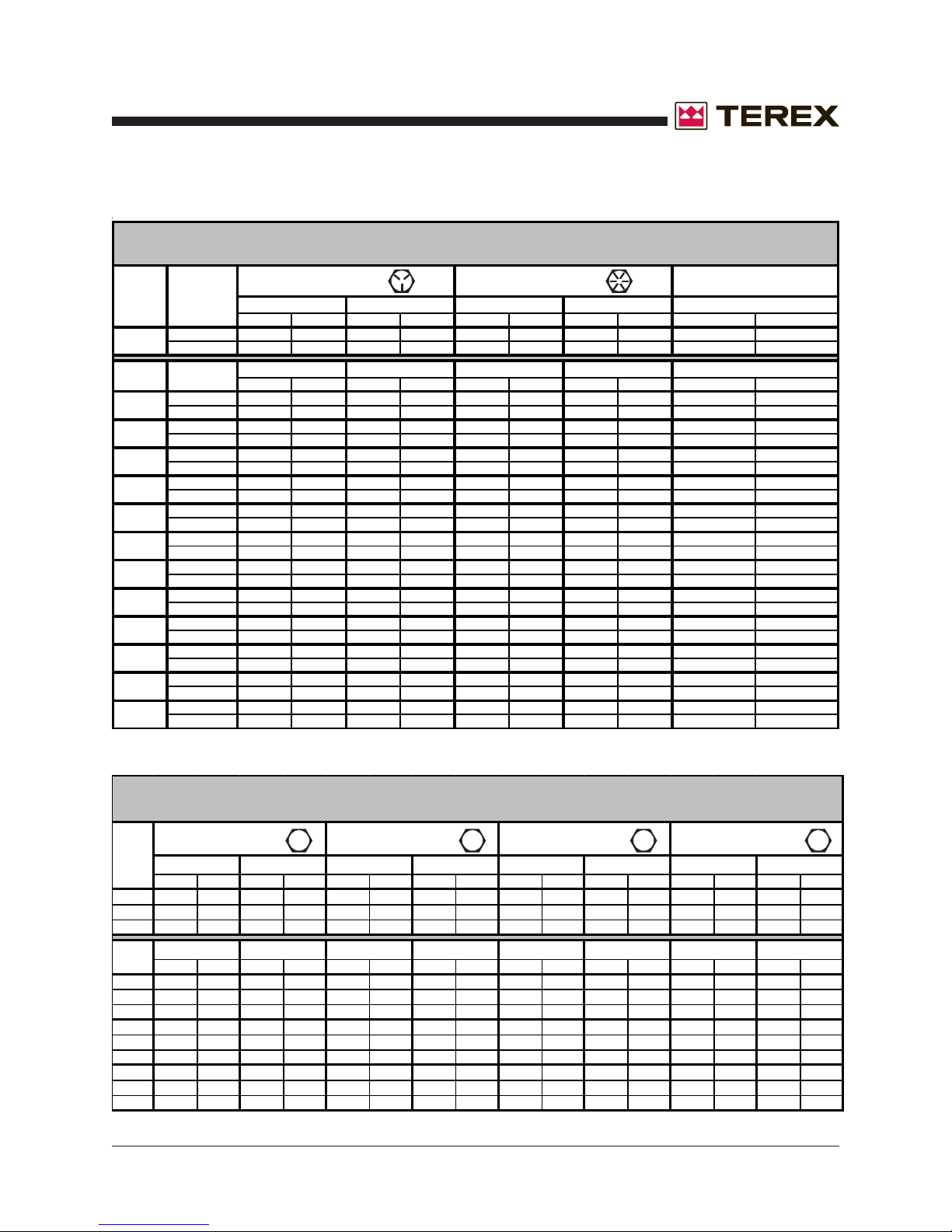

SIZE THREAD

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1 1/

1 1/

1

1

/

8

4

2

20

28 90 10.1 120 13.5

18

24 14 19 19 25.7

16

24

14 37 50.1 49 66.4

20

13

20 64 86.7 85 115

12

18

11

18

10 200 271 270 366

16

14 350 474 470 637

12

12

12

12

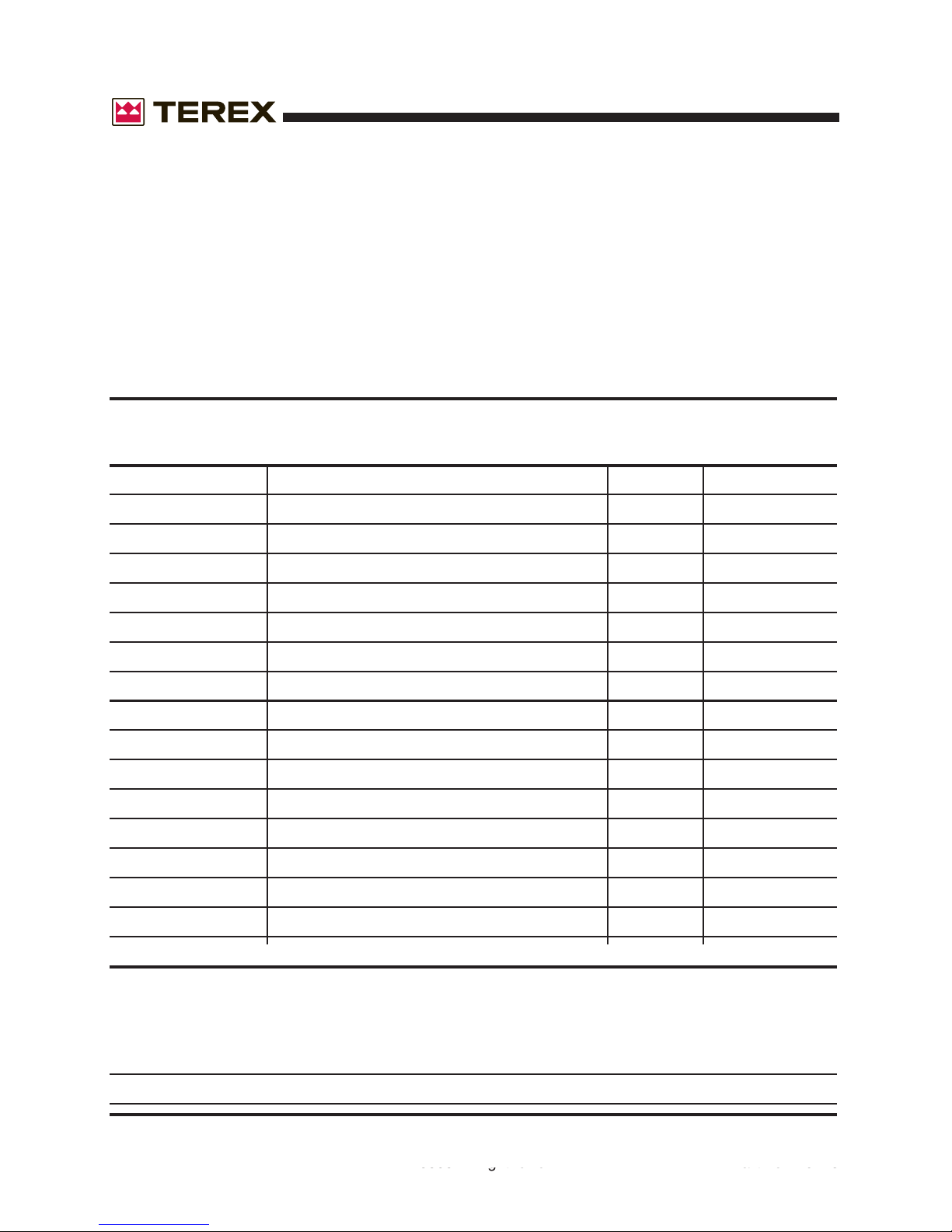

SAE FASTENER TORQUE CHART

• This chart is to be used as a guide only unless noted elsewhere in this manual •

Grade 5

DRYLUBED

in-lbs Nm in-lbs Nm in-lbs Nm in-lbs Nm in-lbs Nm

80 9 100 11.3

LUBED DRY LUBED DRY

ft-lbs Nm ft-lbs Nm ft-lbs Nm ft-lbs Nm ft-lbs Nm

13 17.6 17 23 18 24 25 33.9 21 28.4

23 31.2 31 42

26 35.2 35 47.4

41 55.5 55 74.5

57 77.3 75 101.6

80 108.4 110 149

90 122 120 162

110 149 150 203

130 176 170 230

9

8

7 590 800 790 1071

7

6

220 298 300 406

320 433 430 583

480 650 640 867

530 718 710 962

670 908 890 1206 1080 1464 1440 1952 1220 1654

840 1138 1120 1518 1360 1844 1820 2467 1530 2074

930 1260 1240 1681

1460 1979 1950 2643

1640 2223 2190 2969 2670 3620 3560 4826 3000 4067

110 12.4 140 15.8

120

20 27.1 27 36.6

33 44.7 44 59.6

37 50.1 49 66.4

50 67.8 70 94.7

60 81.3 80 108.4

80 108.4 110 149

90 122 120 162

120 162 150 203

130 176 170 230

160 217 210 284

180 244 240 325

280 379 380 515

310 420 420 569

450 610 610 827

500 678 670 908

680 922 910 1233

750 1016 990 1342

970 1315 1290 1749

1510 2047 2010 2725

2370 3213 3160 4284

Grade 8

13.5

160 18

SPECIFICATIONS

A574 High Strength

Black Oxide Bolts

LUBEDDRYLUBED

130 14.7

140 15.8

LUBED

24 32.5

38 51.5

43 58.3

61 82.7

68 92.1

93 126

105 142

130 176

140 189

180 244

200 271

320 433

350 474

510 691

560 759

770 1044

840 1139

1090 1477

1700 2304

2670 3620

METRIC FASTENER TORQUE CHART

• T his chart i s t o be used as a gu i de onl y unless noted elsewhere in this manual •

Size

(mm)

in-lbs Nm in-lbs N m in-lbs Nm in-lbs N m in-lbs N m in-lbs Nm in-lbs N m in-lbs N m

16 1.8 21 2.4 41 4.63 54 6.18 58 6.63 78 8.84 68 7.75 91 10.3

5

19 3.05 36 4.07 69 7.87 93 10.5 100 11.3 132 15 116 13.2 155 17.6

6

45 5.12 60 6.83 116 13.2 155 17.6 167 18.9 223 25.2 1.95 22.1 260 29.4

7

ft-lbs Nm ft-lbs Nm ft-lbs N m ft-lbs Nm ft-lbs Nm ft-lbs Nm ft-lbs Nm ft-lbs N m

5.4 7.41 7.2 9.88 14 19.1 18.8 25.5 20.1 27.3 26.9 36.5 23.6 32 31.4 42.6

8

10.8 14.7 14.4 19.6 27.9 37.8 37.2 50.5 39.9 54.1 53.2 72.2 46.7 63.3 62.3 84.4

10

18.9 25.6 25.1 34.1 48.6 66 64.9 88 69.7 94.5 92.2 125 81 110 108 147

12

30.1 40.8 40 54.3 77.4 105 103 140 110 150 147 200 129 175 172 234

14

46.9 63.6 62.5 84.8 125 170 166 226 173 235 230 313 202 274 269 365

16

64.5 87.5 86.2 117 171 233 229 311 238 323 317 430 278 377 371 503

18

91 124 121 165 243 330 325 441 337 458 450 610 394 535 525 713

20

124 169 166 225 331 450 442 600 458 622 612 830 536 727 715 970

22

157 214 210 285 420 570 562 762 583 791 778 1055 682 925 909 1233

24

Part No. 116478 AL8000HT Light Tower 2 - 9

DRYLUBED

Class 10.9Class 8.8

LUBEDDRYLUBED

10.9 12.98.84.6

DRY

Class 12.9Class 4.6

LUBED DRY

LUBED DRY LUBED DRYLUBED DRY LUBED DRY

GENSET TORQUE SPECIFICATIONS

Generator FT*LB

Flex Plate to Flywheel 25

Generator Case to Bellhousing 25

Genset Isolators 75

September 2008

2 - 10 AL8000HT Light Tower Part No. 116478

September 2008

Scheduled Maintenance Procedures

Section 3 • Scheduled Maintenance Procedures

About This Section

This section contains detailed procedures for each

scheduled maintenance inspection.

Each procedure includes a description, safety

warnings and step-by-step instructions.

Observe and Obey:

Maintenance inspections shall be completed by

a person trained and qualified on the

maintenance of this machine.

Scheduled maintenance inspections shall be

completed daily, quarterly, semi-annually,

annually and every 2 years as specified on the

Maintenance Inspection Report.

Failure to perform each procedure

as presented and scheduled could

result in death, serious injury or

substantial damage.

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Use only Terex approved replacement parts.

Machines that have been out of service for a

period longer than 3 months must complete the

quarterly inspection.

Unless otherwise specified, perform each

maintenance procedure with the machine in the

following configuration:

· Machine parked on a firm, level surface

· Key switch in the off position

(manual start models)

· Toggle switch in the off position

(automatic start models)

· Mast in the stowed position

· Light switches in the off position

· Wheels chocked

Symbols Legend

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Indicates that a specific result is expected after

performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

Part No. 116478 AL8000HT Light Tower 3 - 1

Section 3 • Scheduled Maintenance Procedures

SCHEDULED MAINTENANCE PROCEDURES

September 2008

Maintenance Symbols Legend

The following symbols have been used in this

manual to help communicate the intent of the

instructions. When one or more of the symbols

appear at the beginning of a maintenance

procedure, it conveys the meaning below.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be required

to perform this procedure.

Indicates that a cold engine will be

required to perform this procedure.

Indicates that a warm engine will be

required to perform this procedure.

Pre-delivery Preparation Report

The pre-delivery preparation report contains

checklists for each type of scheduled inspection.

Make copies of the Pre-delivery Preparation report

to use for each inspection. Store completed forms

as required.

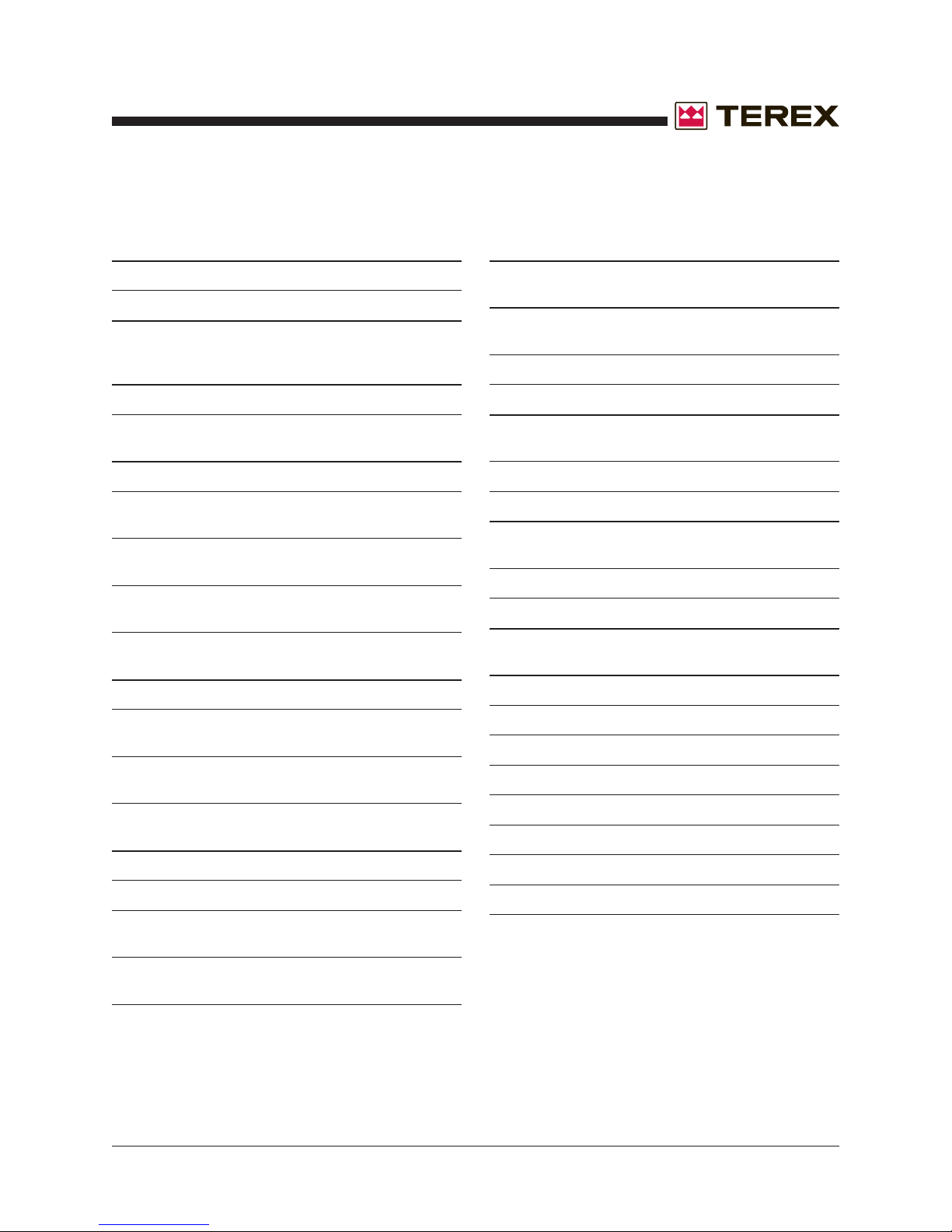

Maintenance Schedule

There are five types of maintenance inspections

that must be performed according to a schedule—

daily, quarterly, semi-annually, annual and

two year. The

Section

Scheduled Maintenance Procedures

and the

Maintenance Inspection Report

have been divided into five subsections—A, B, C,

D and E. Use the following chart to determine which

group(s) of procedures are required to perform a

scheduled inspection.

Inspection Checklist

Daily or every 8 hours A

Quarterly or every 250 hours A + B

Indicates that dealer service will be

required to perform this procedure.

Semi-annually or every 500 hours A + B + C

Annually or every 1000 hours A + B + C + D

Two years or every 2000 hours A + B + C + D + E

Maintenance Inspection Report

The maintenance inspection report contains

checklists for each type of scheduled inspection.

Make copies of the

Maintenance Inspection Report

to use for each inspection. Maintain completed

forms for a minimum of 4 years or in compliance

with employer, jobsite and governmental

regulations and requirements.

3 - 2 AL8000HT Light Tower Part No. 116478

Pre-DeliverPre-Deliver

Pre-Deliver

Pre-DeliverPre-Deliver

y Preparationy Preparation

y Preparation

y Preparationy Preparation

Fundamentals

It is the responsibility of the dealer to perform the

Pre-delivery Preparation.

The Pre-delivery Preparation is performed prior to each

delivery. The inspection is designed to discover if anything

is apparently wrong with a machine before it is put into

service.

A damaged or modified machine must never be used. If

damage or any variation from factory delivered condition is

discovered, the machine must be tagged and removed from

service.

Repairs to the machine may only be made by a qualified

service technician, according to the manufacturer's

specifications.

Scheduled maintenance inspections shall be performed by

qualified service technicians, according to the

manufacturer's specifications and the requirements listed in

the responsibilities manual.

Instructions

Use the operator’s manual on your machine.

The Pre-delivery Preparation consists of completing the

Pre-operation Inspection, the Maintenance items and the

Function Tests.

Use this form to record the results. Place a check in the

appropriate box after each part is completed. Follow the

instructions in the operator’s manual.

If any inspection receives an N, remove the machine from

service, repair and re-inspect it. After repair, place a check

in the R box.

Legend

Y = yes, completed

N = no, unable to complete

R = repaired

Comments

TEREX Rock Hill

P.O. BOX 3147

Rock Hill, SC 29732 USA

Toll Free (800) 433-3026 in U.S.A. and Canada

Copyright © 2006 by TEREX Corporation. TEREX® is a registered trademark of TEREX

Corporation.

Rev B

Pre-Delivery Preparation Y N R

Pre-operation inspection completed

Maintenance items completed

Function tests completed

Model

Serial number

Date

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Section 3 • Scheduled Maintenance Procedures

September 2008

This page intentionally left blank.

3 - 4 AL8000HT Light Tower Part No. 116478

September 2008

Section 3 • Scheduled Maintenance Procedures

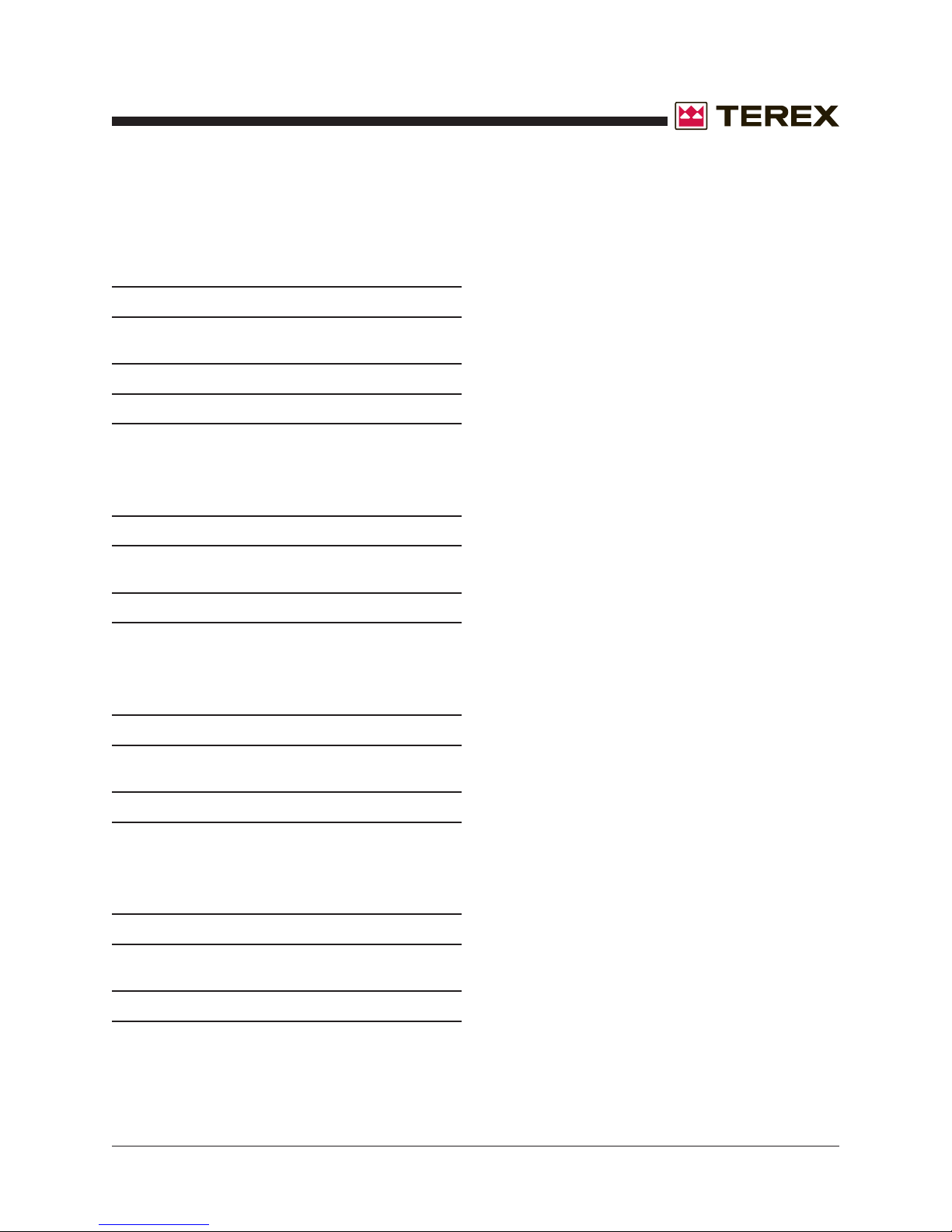

Maintenance Inspection Report

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

· Make copies of this report to use for

each inspection.

· Select the appropriate checklist(s)

for the type of inspection to be

performed.

Daily or 8 hours

Inspection: A

Quarterly or 250 hours

Inspection: A+B

Semi-annually or

500 hours

Inspection: A+B+C

Annually or

1000 hours

Inspection: A+B+C+D

Two year or

2000 hours

Inspection: A+B+C+D+E

· Place a check in the appropriate box

after each inspection procedure is

completed.

· Use the step-by-step procedures in

this section to learn how to perform

these inspections.

· If any inspection receives an “N”, tag

and remove the machine from

service, repair and re-inspect it. After

repair, place a check in the “R” box.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

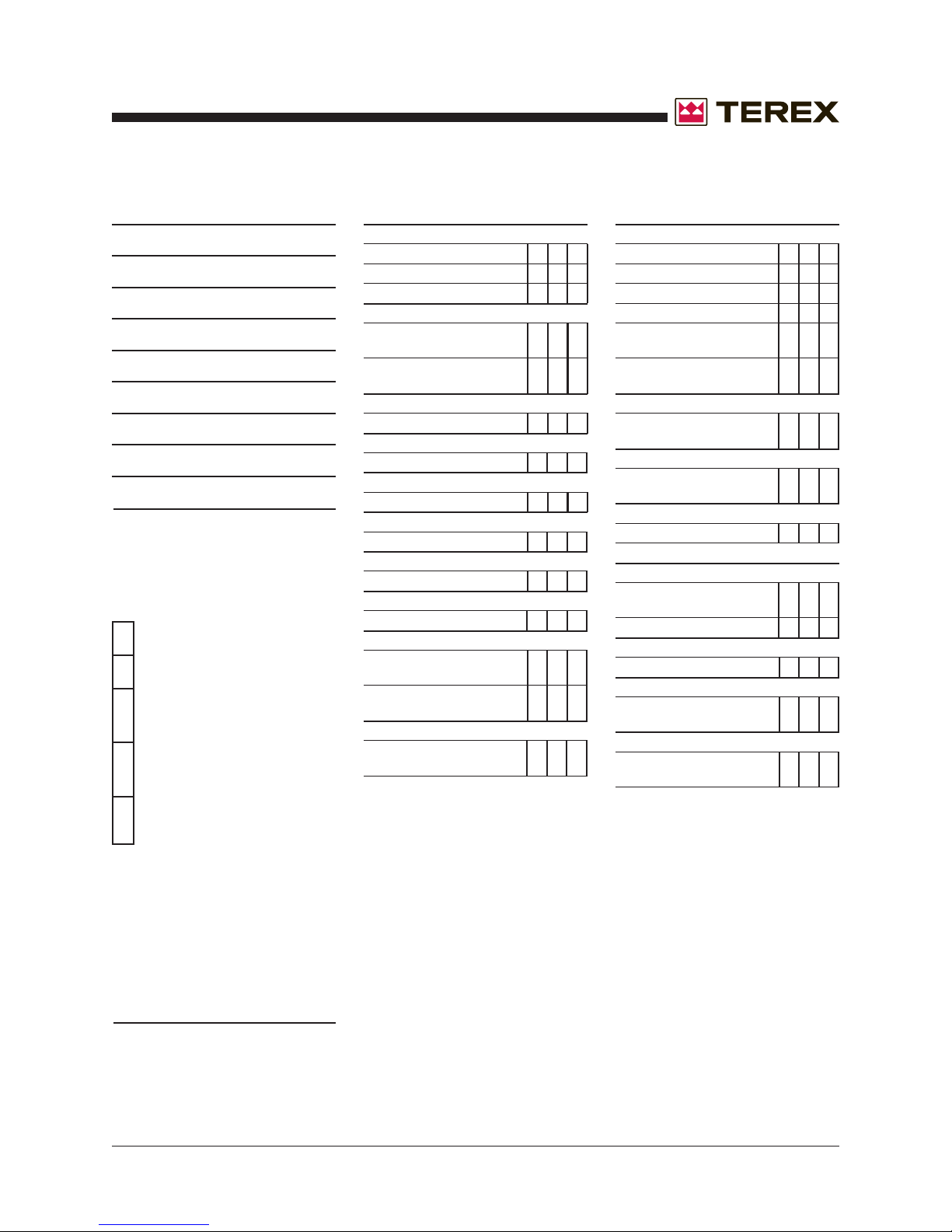

Checklist A - Rev A YNR

A-1 Manuals and decals

A-2 Pre-operation inspect

A-3 Function tests

Perform every 8 hours:

A-4 Engine maintenance -

Isuzu models

A-5 Generator

maintenance

Perform after 10 miles:

A-6 Axle maintenance

Perform after 25 miles:

A-6 Axle maintenance

Perform after 50 miles:

A-6 Axle maintenance

Perform after 40 hours:

A-7 30 day service

Perform every 50 hours:

A-8 Engine maintenance

Perform weekly:

A-9 Hitch maintenance

Perform every 100 hours:

A-10 Grease rotation

bearing

A-11 Engine maintenance -

Kubota models

Perform every 200 hours:

A-12 Engine maintenance -

Kubota models

Checklist B - Rev A YNR

B-1 Battery

B-2 Electrical wiring

B-3 Tires and wheels

B-4 Hydraulic oil analysis

B-5 Engine maintenance -

Isuzu models

B-6 Generator

maintenance

Perform quarterly:

B-7 Hitch coupler

maintenance

Perform every 400 hours:

B-8 Engine maintenance -

Kubota models

Perform every 3000 miles:

B-9 Axle maintenance

Checklist C - Rev A YNR

C-1 Extend/retract cables

and pulleys

C-2 Engine maintenance

Perform every 6000 miles:

C-3 Axle maintenance

Perform every 750 hours:

C-5 Engine maintenance -

Isuzu models

Perform every 800 hours:

C-6 Engine maintenance -

Kubota models

Part No. 116478 AL8000HT Light Tower 3 - 5

Section 3 • Scheduled Maintenance Procedures

MAINTENANCE INSPECTION REPORT

September 2008

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

· Make copies of this report to use for

each inspection.

· Select the appropriate checklist(s)

for the type of inspection to be

performed.

Daily or 8 hours

Inspection: A

Quarterly or 250 hours

Inspection: A+B

Semi-annually or

500 hours

Inspection: A+B+C

Annually or

1000 hours

Inspection: A+B+C+D

Two year or

2000 hours

Inspection: A+B+C+D+E

· Place a check in the appropriate box

after each inspection procedure is

completed.

· Use the step-by-step procedures in

this section to learn how to perform

these inspections.

· If any inspection receives an “N”, tag

and remove the machine from

service, repair and re-inspect it. After

repair, place a check in the “R” box.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

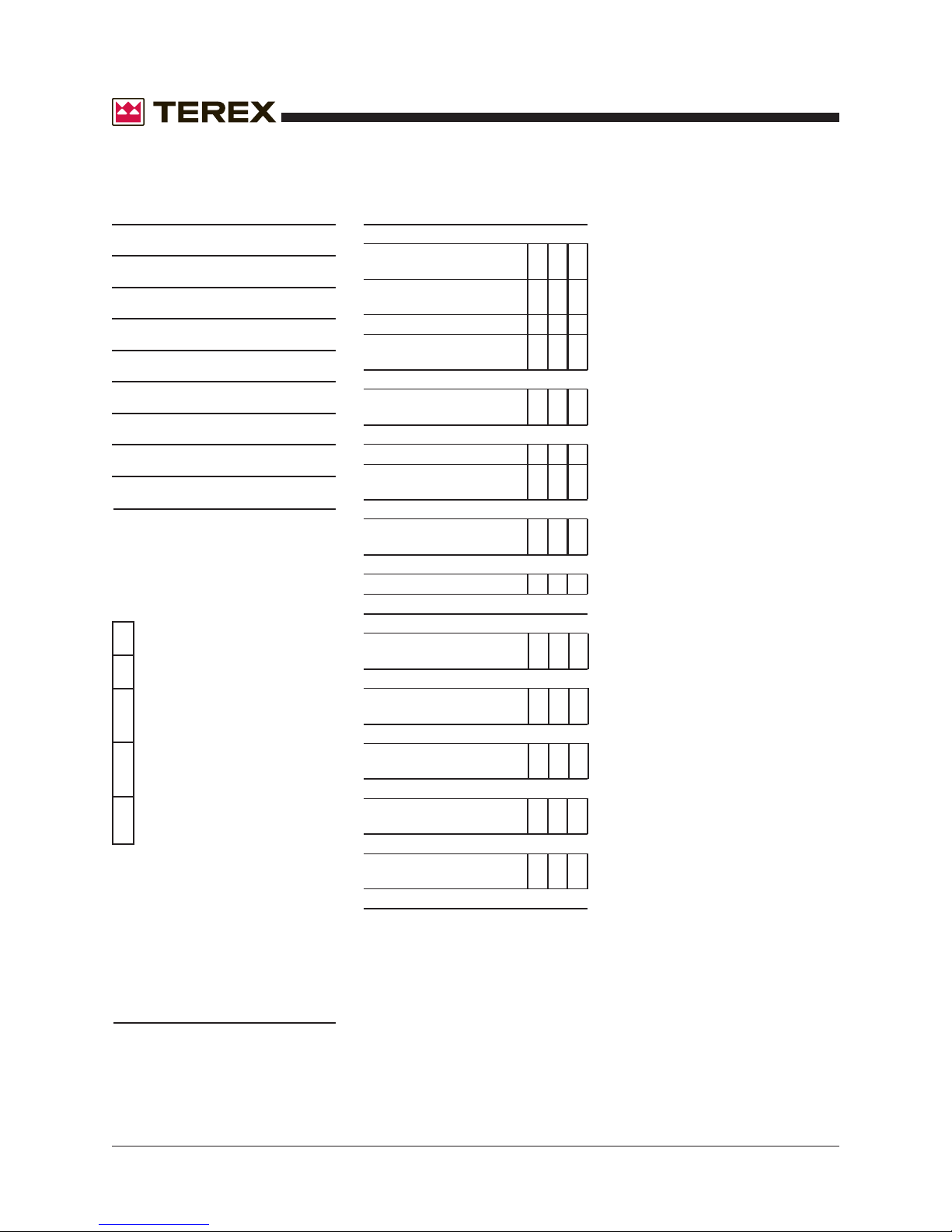

Checklist D - Rev A YNR

D-1 Engine maintenance -

Kubota models

D-2 Tower rotation bearing

bolts

D-3 Hydraulic filter

D-4 Engine maintenance -

Isuzu models

Perform every 1250 hours:

D-5 Engine maintenance -

Isuzu models

Perform every 1500 hours:

D-6 Engine maintenance

D-7 Generator

maintenance

Perform annually:

D-8 Tongue and outrigger

jack maintenance

Perform every 12,000 miles:

D-9 Axle maintenance

Checklist E - Rev A YNR

E-1 Test or replace

hydraulic oil

Perform every 3000 hours:

E-2 Engine maintenance -

Kubota models

Perform every 2 years:

E-3 Engine maintenance -

Kubota models

Perform every 4500 hours:

E-4 Generator

maintenance

Perform every 15,000 hours:

E-5 Generator

maintenance

Comments

3 - 6 AL8000HT Light Tower Part No. 116478

September 2008

Section 3 • Scheduled Maintenance Procedures

REV A

Checklist A Procedures

A-1

Inspect the Manuals and Decals

Note: Terex specifications require that this

procedure be performed daily or every 8 hours,

whichever comes first.

Maintaining the operator’s and safety manuals in

good condition is essential to safe machine

operation. Manuals are included with each machine

and should be stored in the container provided in

the cabinet. An illegible or missing manual will not

provide safety and operational information

necessary for a safe operating condition.

In addition, maintaining all of the safety and

instructional decals in good condition is mandatory

for safe machine operation. Decals alert operators

and personnel to the many possible hazards

associated with using this machine. They also

provide users with operation and maintenance

information. An illegible decal will fail to alert

personnel of a procedure or hazard and could result

in unsafe operating conditions.

3 Open the operator's manual to the decals

inspection section. Carefully and thoroughly

inspect all decals on the machine for legibility

and damage.

Result: The machine is equipped with all

required decals, and all decals are legible and in

good condition.

Result: The machine is not equipped with all

required decals, or one or more decals are

illegible or in poor condition. Remove the

machine from service until the decals are

replaced.

4 Always return the manuals to the storage

container after use.

Note: Contact your authorized Terex distributor if

replacement manuals or decals are needed.

1 Check to make sure that the operator's and

safety manuals are present and complete in the

storage container inside the cabinet.

2 Examine the pages of each manual to be sure

that they are legible and in good condition.

Result: The operator's manual is appropriate for

the machine and all manuals are legible and in

good condition.

Result: The operator's manual is not appropriate

for the machine or all manuals are not in good

condition or are illegible. Remove the machine

from service until the manual is replaced.

Part No. 116478 AL8000HT Light Tower 3 - 7

Section 3 • Scheduled Maintenance Procedures

September 2008

CHECKLIST A PROCEDURES

A-2

Perform Pre-operation

Inspection

Note: Terex specifications require that this

procedure be performed every 8 hours or daily,

whichever comes first.

Completing a pre-operation inspection is essential

to safe machine operation. The pre-operation

inspection is a visual inspection performed by the

operator prior to each work shift. The inspection is

designed to discover if anything is apparently wrong

with a machine before the operator performs the

function tests. The pre-operation inspection also

serves to determine if routine maintenance

procedures are required.

Complete information on how to perform this

procedure is available in the appropriate Operator's

Manual. Refer to the Operator's Manual on your

machine.

REV A

A-3

Perform Function Tests

Note: Terex specifications require that this

procedure be performed every 8 hours or daily,

whichever comes first.

Completing the function tests is essential to safe

machine operation. Function tests are designed to

discover any malfunctions before the machine is

put into service. A malfunctioning machine must

never be used. If malfunctions are discovered, the

machine must be tagged and removed from

service.

Complete information on how to perform this

procedure is available in the appropriate Operator's

Manual. Refer to the Operator's Manual on your

machine.

3 - 8 AL8000HT Light Tower Part No. 116478

Loading...

Loading...