Terex AL4, AL4000 Service Manual

Discount-Equipment.com

Discount-Equipment.com is your online resource for commercial and industrial

Discount-Equipment.com

quality parts and equipment sales.

Locations:

Florida (West Palm Beach): 561-964-4949

Outside Florida TOLL FREE: 877-690-3101

Need parts? Check out our website at www.discount-equipment.com

Can’t find what you need?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and fill out

the request form.

Please have the machine model and serial number available in order to help us get

you the correct parts. One of our experienced staff members will get back to you with

a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mayco, Toro/Stone,

Diamond Products, Magnum, Airman, Mustang, Power Blanket, Nifty Lift, Atlas Copco,

Chicago Pneumatic,

Tsurumi, Husquvarna/Target, Whiteman-Concrete/Mortar, Stow-Concrete/Mortar, Baldor,

Wacker, Sakai, Snorkel, Upright, Mi-T-M, Sullair, Neal, Basic, Dynapac, MBW, Weber,

Bartell, Bennar Newman, Haulotte, Ditch Runner, Blaw-Knox, Himoinsa, Best, Buddy,

Crown, Edco, Wyco, Bomag, Laymor, Terremite, Barreto, EZ Trench, Takeuchi, Basic, Bil-

Jax, Curtis, Gehl, Heli, Honda, ICS/PowerGrit, Puckett,

Clipper, MMD, Koshin, Rice, Gorman Rupp, CH&E, Cat Pumps, Comet, General Pump,

Giant,AMida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, Small Line, Wanco, Yanmar

Allmand Brothers, Essick, Miller Spreader, Skyjack, Lull, Skytrak,

Waldon, ASV, IHI, Partner, Imer,

Introduction

Discount-Equipment.com

Introduction

Important

Read, understand and obey the safety rules and

operating instructions in the appropriate operator's

manual on your machine before attempting any

maintenance or repair procedure.

This manual provides detailed scheduled

maintenance information for the machine owner

and user. It also provides troubleshooting fault

codes and repair procedures for qualifi ed service

professionals.

Basic mechanical, hydraulic and electrical skills

are required to perform most procedures. However,

several procedures require specialized skills,

tools, lifting equipment and a suitable workshop.

In these instances, we strongly recommend that

maintenance and repair be performed at an

authorized Terex dealer service center.

August 2016

www.discount-equipment.com

Technical Publications

Terex has endeavored to deliver the highest

degree of accuracy possible. However, continuous

improvement of our products is a Terex policy.

Therefore, product specifi cations are subject to

change without notice.

Readers are encouraged to notify Terex of errors

and send in suggestions for improvement. All

communications will be carefully considered for

future printings of this and all other manuals.

Copyright © 2012 by Terex Corporation

218567 Rev B August 2016

First Edition, Second Printing

Terex is a registered trademarks of

Terex USA, LLC in the USA and many other

countries.

Printed on recycled paper

Printed in U.S.A.

AL4 • AL4000 Part No. 218567

ii

ii

August 2016

Discount-Equipment.com

Revision History

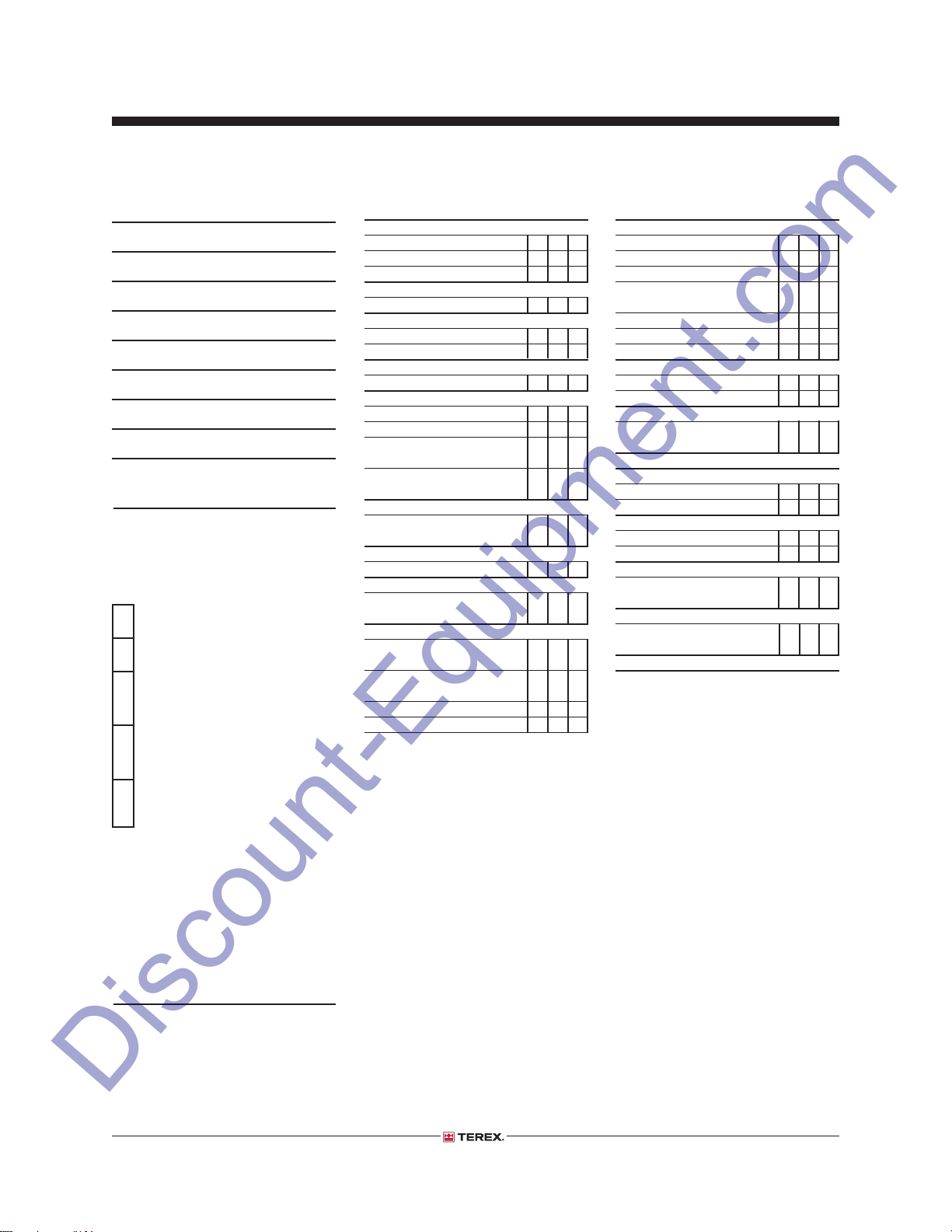

Revision Date Section Procedure / Schematic Page / Description

A 8/2012 New release

B 8/2016 Section 1 Updated revision history and serial number legend

REFERENCE EXAMPLES:

Kubota Engine_Section 2_Specifi cations.

A-6,B-3,C-7_Section 3_Maintenance Procedure.

3-2, 6-4, 9-1_Section 4_Repair Procedure.

Fault Codes_Section 5.

6-35, 6-56, 6-104_Section 6_Schematic Page #.

Part No. 218567 AL4 • AL4000

Click on any procedure or page number

highlighted in blue to view the update.

Electronic Version

iii

August 2016

Discount-Equipment.com

REVISION HISTORY

Revision Date Section Procedure / Schematic Page / Description

REFERENCE EXAMPLES:

Kubota Engine_Section 2_Specifi cations.

A-6,B-3,C-7_Section 3_Maintenance Procedure.

3-2, 6-4, 9-1_Section 4_Repair Procedure.

Fault Codes_Section 5.

6-35, 6-56, 6-104_Section 6_Schematic Page #.

AL4 • AL4000 Part No. 218567

iv

Click on any procedure or page number

highlighted in blue to view the update.

Electronic Version

August 2016

Discount-Equipment.com

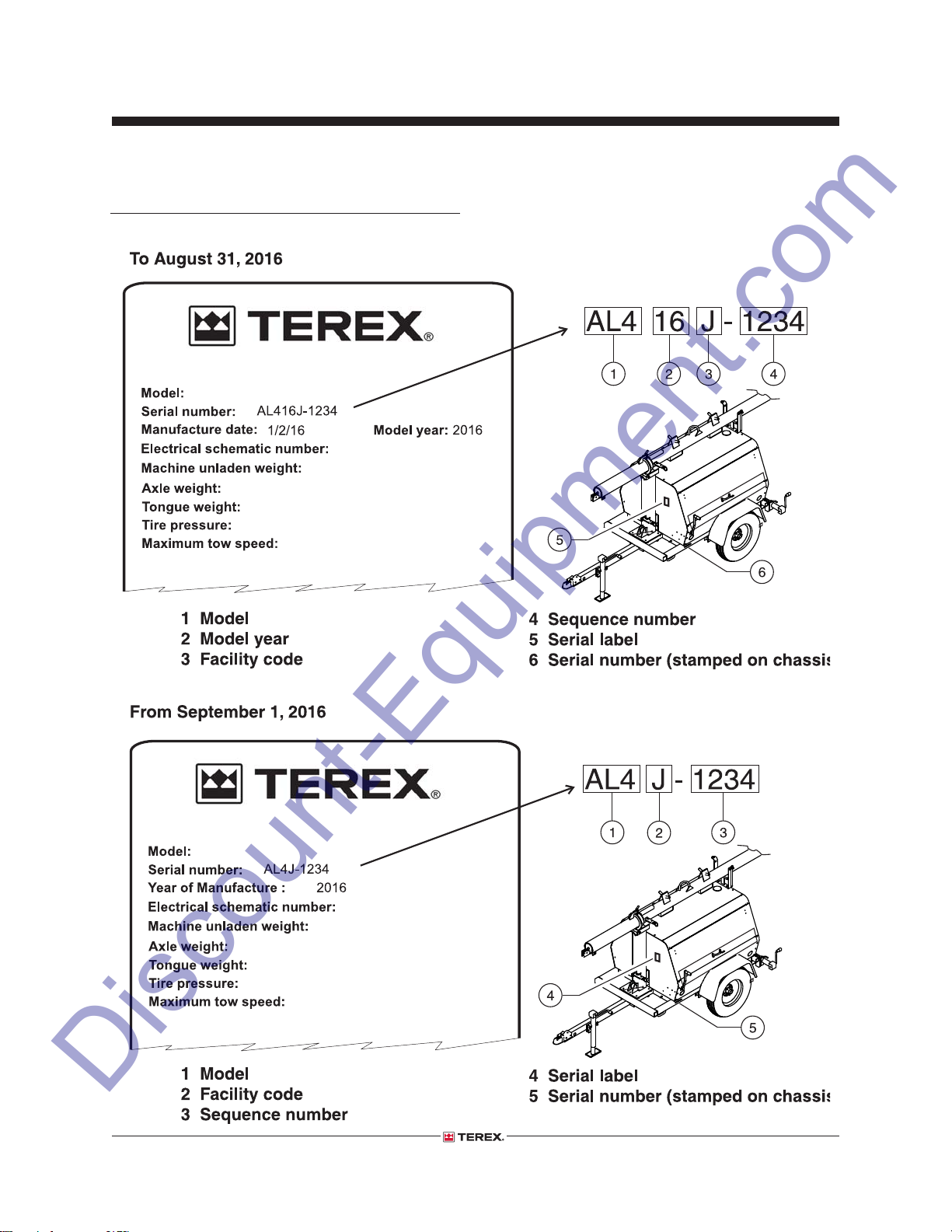

Serial Number Legend

INTRODUCTION

Part No. 218567 AL4 • AL4000

v

Section 1 • Safety Rules

Discount-Equipment.com

Safety Rules

Danger

Failure to obey the instructions and safety rules

in this manual, and the appropriate operator's

manual on your machine will result in death or

serious injury.

Many of the hazards identifi ed in the operator's

manual are also safety hazards when maintenance

and repair procedures are performed.

Do Not Perform Maintenance

Unless:

You are trained and qualifi ed to perform

maintenance on this machine.

You read, understand and obey:

- manufacturer’s instructions and safety rules

- employer’s safety rules and worksite

regulations

- applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

August 2016

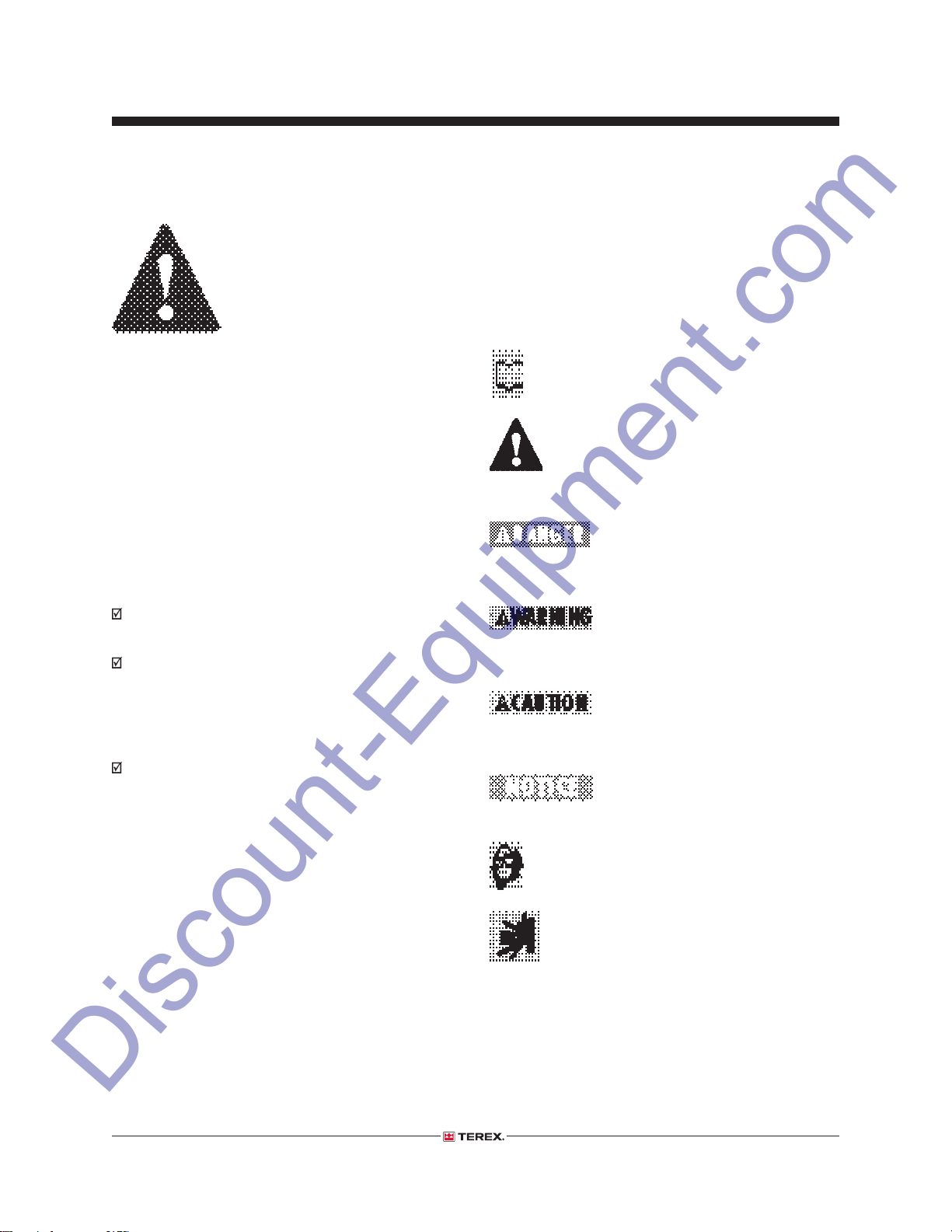

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol—used

to alert personnel to potential

personal injury hazards. Obey all

safety messages that follow this

symbol to avoid possible injury or

death.

Indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when lifting or

placing loads. Always wear approved steel-toed

shoes.

AL4 • AL4000 Part No. 218567

vi

August 2016

Discount-Equipment.com

Workplace Safety

Be sure to keep sparks, fl ames and

lighted tobacco away from fl ammable

and combustible materials like battery

gases and engine fuels. Always have an

approved fi re extinguisher within easy reach.

Be sure that all tools and working areas

are properly maintained and ready for

use. Keep work surfaces clean and free

of debris that could get into machine

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing

the weight to be lifted. Use only chains

or straps that are in good condition and of ample

capacity.

Section 1 • Safety Rules

SAFETY RULES

Be sure that fasteners intended for one

time use (i.e., cotter pins and self-locking

nuts) are not reused. These components

may fail if they are used a second time.

Be sure to properly dispose of old oil or

other fl uids. Use an approved container.

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

Part No. 218567 AL4 • AL4000

vii

August 2016

Discount-Equipment.com

Table of Contents

Introduction

Important Information ................................................................................................... ii

Revision History .......................................................................................................... iii

Serial Number Legend ................................................................................................. v

Section 1 Safety Rules

General Safety Rules .................................................................................................. vi

Section 2 Specifi cations

Machine Specifi cations ...........................................................................................2 - 1

Performance Specifi cations .....................................................................................2 - 1

Generator Options ...................................................................................................2 - 2

Perkins 403D-11 Engine .........................................................................................2 - 2

Kubota D1105-D3BG Engine Specifi cations ...........................................................2 - 4

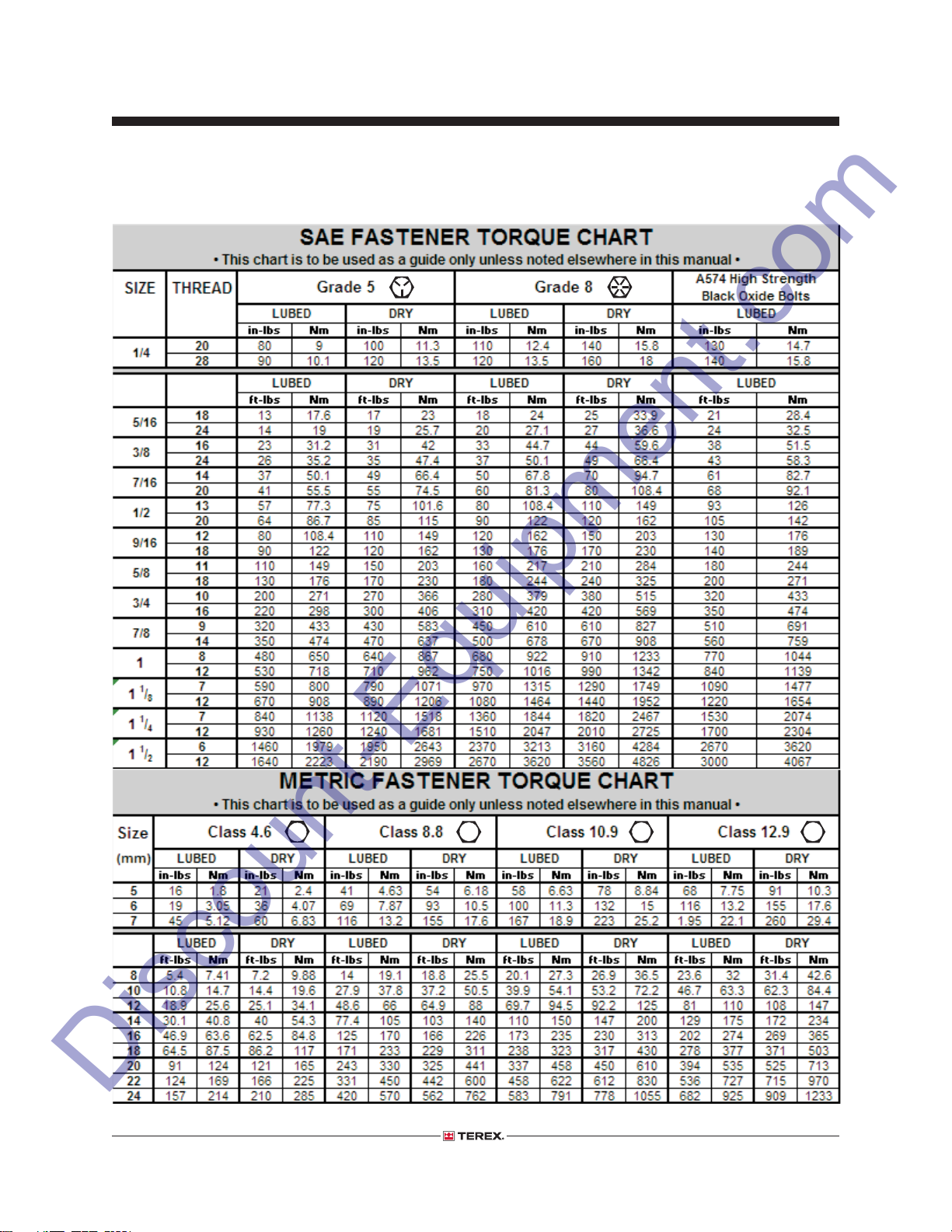

SAE and Metric Fasteners Torque Charts ...............................................................2 - 5

Section 3 Scheduled Maintenance Procedures

Introduction .............................................................................................................3 - 1

Maintenance Inspection Report ..............................................................................3 - 3

Checklist A Procedures

A-1 Inspect the Manuals and Decals ...................................................................3 - 5

A-2 Perform Pre-operation Inspection ..................................................................3 - 6

A-3 Perform Function Tests ..................................................................................3 - 6

Section 3 Scheduled Maintenance Procedures, continued

A-4 Perform Engine Maintenance ........................................................................3 - 7

A-5 Perform Coupler Maintenance .......................................................................3 - 7

AL4 • AL4000 Part No. 218567

viii

August 2016

Discount-Equipment.com

TABLE OF CONTENTS

A-6 Test the Brakes (if equipped) .........................................................................3 - 8

A-7 Torque the Wheel Lug Nuts ...........................................................................3 - 8

A-8 Check the Tires and Wheels ..........................................................................3 - 9

A-9 Inspect the Engine Air Filter ..........................................................................3 - 9

A-10 Perform Generator Maintenance - Leroy Somer Models .............................3 - 10

A-11 Perform Engine Maintenance - Kubota Models ...........................................3 - 10

A-12 Perform Engine Maintenance - Kubota Models ...........................................3 - 11

A-13 Inspect the Cable and Cable Pulleys ...........................................................3 - 11

A-14 Perform Engine Maintenance - Kubota Models ...........................................3 - 12

A-15 Perform Engine Maintenance - Kubota Models ...........................................3 - 13

A-16 Perform Generator Maintenance - Marathon Models ..................................3 - 13

A-17 Drain the Fuel Filter/Water Separator - Kubota Models ...............................3 - 14

A-18 Adjust the Brakes (if equipped) ...................................................................3 - 15

Checklist B Procedures

B-1 Inspect the Engine Start Battery or Lighting Battery Pack ..........................3 - 17

B-2 Inspect the Electrical Wiring ........................................................................3 - 18

B-3 Torque the Wheel Lug Nuts .........................................................................3 - 19

B-4 Perform Engine Maintenance - Perkins Models ..........................................3 - 19

B-5 Perform Jack Maintenance ..........................................................................3 - 20

B-6 Inspect and Lubricate the Winch .................................................................3 - 20

B-7 Lubricate the T-bolt ......................................................................................3 - 21

B-8 Inspect and Adjust the Brakes (if equipped) ................................................3 - 21

B-9 Inspect the Suspension ...............................................................................3 - 23

B-10 Perform Engine Maintenance - Kubota Models ...........................................3 - 24

Section 3 Scheduled Maintenance Procedures, continued

Checklist C Procedures

C-1 Perform Engine Maintenance ......................................................................3 - 25

C-2 Clean the Light Assemblies .........................................................................3 - 25

Part No. 218567 AL4 • AL4000

ix

August 2016

Discount-Equipment.com

TABLE OF CONTENTS

C-3 Grease the Wheel Bearings ........................................................................3 - 26

C-4 Inspect the Electric Brake Magnets (if equipped) ........................................3 - 27

C-5 Perform Engine Maintenance - Kubota Models ...........................................3 - 28

C-6 Perform Generator Maintenance - Leroy Somer Models .............................3 - 29

Checklist D Procedures

D-1 Perform Engine Maintenance - Kubota Models ...........................................3 - 30

D-2 Perform Generator Maintence - Leroy Somer Models .................................3 - 30

D-3 Perform Coupler Maintenance .....................................................................3 - 31

Checklist E Procedures

E-1 Replace the Mast Lift Cable ........................................................................3 - 32

E-2 Perform Engine Maintenance ......................................................................3 - 32

E-3 Perform Engine Maintenance ......................................................................3 - 33

E-4 Perform Generator Maintenance - Marathon Models ..................................3 - 33

E-5 Perform Generator Maintenance - Leroy Somer Models .............................3 - 34

E-6 Perform Generator Maintenance - Leroy Somer Models .............................3 - 34

Section 4 Repair Procedures

Introduction .............................................................................................................4 - 1

Mast

1-1 Mast ...............................................................................................................4 - 2

Winch

AL4 • AL4000 Part No. 218567

x

August 2016

Discount-Equipment.com

TABLE OF CONTENTS

2-1 Winch ............................................................................................................4 - 5

Generator

3-1 Generator ......................................................................................................4 - 8

Engine

4-1 Engine RPM ................................................................................................4 - 12

Section 5 Troubleshooting

Introduction .............................................................................................................5 - 1

Troubleshooting .......................................................................................................5 - 2

Section 6 Schematics

Introduction .............................................................................................................6 - 1

Wire Color Legend ..................................................................................................6 - 2

Trailer Lighting Wiring Diagram ...............................................................................6 - 3

Electrical Schematic, (ANSI / CSA) .........................................................................6 - 4

Electrical Schematic, (AUS) ....................................................................................6 - 5

Control Box and Engine Wiring, (Kubota Models) ...................................................6 - 8

Control Box and Engine Wiring, (Perkins Models) ..................................................6 - 9

Control Box and Engine Wiring, (AUS) ..................................................................6 - 12

Trailer Wiring Diagram, (ANSI / CSA) ....................................................................6 - 13

Trailer Wiring Diagram, (AUS) ...............................................................................6 - 15

Part No. 218567 AL4 • AL4000

xi

August 2016

Discount-Equipment.com

This page intentionally left blank.

AL4 • AL4000 Part No. 218567

xii

Section 2 • Specifi cationsAugust 2016

Discount-Equipment.com

Specifi cations

Machine Specifi cations

Total lighting wattage 4 x 1000 watts

Fuel capacities

Single tank 30 gallons

114 liters

Dual tanks (option) 60 gallons

227 liters

Tires and wheels

Tire size ST205/75D15

Load range C

Lug nut torque, dry 90 ft-lbs

122 Nm

Lug nut torque, lubricated 67.5 ft-lbs

91.5 Nm

Tire pressure, maximum (cold) 50 psi

3.4 bar

Performance Specifi cations

Tongue weight, maximum

With fuel (single tank) 150 lbs

68 kg

(dual tank) 130 lbs

59 kg

Run time

Single tank 50 hours

Continuous improvement of our products

For operational specifi cations, refer to the

Operator's Manual.

Part No. 218567 AL4 • AL4000 2 - 1

is a Genie policy. Product specifi cations are

subject to change without notice.

Section 2 • Specifi cations

Discount-Equipment.com

SPECIFICATIONS

August 2016

Generator Options 6 kw and 8 kw

Generator speed @ full load 60 Hz 1800 rpm

Temperature, ambient maximum 104°F

40°C

Capacitor (disconnected) 25 µF

7 kw

Generator speed @ full load 50 Hz 1500 rpm

Temperature, ambient maximum 104°F

40°C

Capacitor (disconnected) 25 µF

Perkins 403D-11 Engine

Displacement 68.9 cu in

1.1 liters

Number of cylinders 3

Bore and stroke 3.03 x 3.19 inches

77 x 81 mm

Horsepower, net intermittent 25 @ 3000 rpm

18.6 kW

Firing order 1 - 2 - 3

Compression ratio 23:1

Compression pressure 425 psi

29 bar

Pressure of the lowest cylinder must be within

50 psi / 3.5 bar of the highest cylinder, though

at no time less than 360 psi / 25 bar

Idle speed @ no load 1500 rpm

(with 7kw generator)

Frequency 50 hz

Idle speed @ no load 1800 rpm

(with 6kw or 8kw generator)

Frequency 60 hz

Governor centrifugal mechanical

Valve clearance, cold 0.0078 in

0.2 mm

Engine coolant capacity 2.0 quarts

1.9 liters

Engine coolant should be clean soft water with 50% anti

freeze concentration ethylene glycol to BS 6580:1992 or

ASTMD 3306-89 or AS 2108-1977

Continuous improvement of our products

is a Genie policy. Product specifi cations are

subject to change without notice.

2 - 2 AL4 • AL4000 Part No. 218567

Section 2 • Specifi cationsAugust 2016

Discount-Equipment.com

SPECIFICATIONS

Lubrication system

Oil pressure 40 to 60 psi

(hot @ 2000 rpm) 3 to 4 bar

Oil capacity (including fi lter) 4.6 quarts

4.4 liters

Oil viscosity requirements

Units ship with 15W-40.

Extreme operating temperatures may require the use of

alternative engine oils. For oil requirements, refer to the

Engine Operator Handbook on your machine.

Injection system

Injection pump make Bosch

Injection timing 23° BTDC @ 3000 rpm

Injection pump pressure 2133 psi

150 bar

Fuel requirement diesel number 2-D

Standard battery

Type 12V DC

Group 24

Quantity 1

Ampere hour 75 A

Cold cranking ampere 500

Reserve capacity @ 25A rate 65 minutes

Heavy duty battery

Type 12V DC

Group 24

Quantity 1

Ampere hour 75 A

Cold cranking ampere 700

Reserve capacity @ 25A rate 125 minutes

Alternator

Output 40A, 12V DC

Fan belt defl ection

5 mm

3

/

16

inch

Continuous improvement of our products

is a Genie policy. Product specifi cations are

subject to change without notice.

Part No. 218567 AL4 • AL4000 2 - 3

Section 2 • Specifi cations

Discount-Equipment.com

SPECIFICATIONS

August 2016

Kubota D1105-D3BG Engine

Displacement 68.53 cu in

1.123 liters

Number of cylinders 3

Bore and stroke 3.07 x 3.09 inches

78 x 78.4 mm

Horsepower, gross intermittent 13.6 @ 1800 rpm

10.1 kW

Firing order 1 - 2 - 3

Compression ratio 24:1

Compression pressure 412 to 469 psi

28.4 to 32.3 bar

Idle speed @ no load 1500 rpm

(with 7kw generator)

Frequency 50 hz

Idle speed @ no load 1800 rpm

(with 6kw or 8kw generator)

Frequency 60 hz

Governor centrifugal mechanical

Valve clearance, cold 0.0057 to 0.0072 in

0.145 to 0.185 mm

Engine coolant capacity 3.3 quarts

3.1 liters

Lubrication system

Oil pressure 28 to 64 psi

1.93 to 4.41 bar

Oil capacity (including fi lter) 5.4 quarts

5.1 liters

Injection timing 18° BTDC

Injection pump pressure 1991 psi

137 bar

Fuel requirement

For fuel requirements, refer to the engine Operator's

Manual on your machine.

Standard battery

Type 12V DC

Group 24

Quantity 1

Ampere hour 75 A

Cold cranking ampere 500

Reserve capacity @ 25A rate 65 minutes

Heavy duty battery

Type 12V DC

Group 24

Quantity 1

Ampere hour 75 A

Cold cranking ampere 700

Reserve capacity @ 25A rate 125 minutes

Alternator

Output 40A, 14V DC

Fan belt defl ection

7 to 9 mm

0.28 to 0.35 inch

Oil viscosity requirements

Units ship with 10W-30.

Extreme operating temperatures may require the use of

alternative engine oils. For oil requirements, refer to the

Engine Operator Handbook on your machine.

Injection system

Injection pump make Bosch MD

Continuous improvement of our products

is a Genie policy. Product specifi cations are

subject to change without notice.

2 - 4 AL4 • AL4000 Part No. 218567

Section 2 • Specifi cationsAugust 2016

Discount-Equipment.com

SPECIFICATIONS

4.6

Part No. 218567 AL4 • AL4000 2 - 5

10.9 12.98.8

Section 2 • Specifi cations

Discount-Equipment.com

August 2016

This page intentionally left blank.

2 - 6 AL4 • AL4000 Part No. 218567

Section 3 • Scheduled Maintenance ProceduresAugust 2016

DANGER

WARNING

CAUTION

NOTICE

Discount-Equipment.com

Scheduled Maintenance Procedures

About This Section

This section contains detailed procedures for each

scheduled maintenance inspection.

Each procedure includes a description, safety

warnings and step-by-step instructions.

Observe and Obey:

Maintenance inspections shall be completed

by a person trained and qualifi ed on the

maintenance of this machine.

Scheduled maintenance inspections shall

be completed daily, quarterly, semi-annually,

annually and every 2 years as specifi ed on the

Maintenance Inspection Report.

WARNING

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Use only Terex approved replacement parts.

Machines that have been out of service for a

period longer than 3 months must complete the

quarterly inspection.

Unless otherwise specifi ed, perform each

maintenance procedure with the machine in the

following confi guration:

• Machine parked on a fi rm, level surface

• Mast in the stowed position

• Wheels chocked

• Light switches in the off position

• No external AC power devices connected to

the power outlets at the control box.

Failure to perform each procedure

as presented and scheduled could

result in death, serious injury or

substantial damage.

Symbols Legend

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Indicates that a specifi c result is expected after

performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

Part No. 218567 AL4 • AL4000 3 - 1

Section 3 • Scheduled Maintenance Procedures

Discount-Equipment.com

SCHEDULED MAINTENANCE PROCEDURES

August 2016

Maintenance Symbols Legend

Note: The following symbols have been used in

this manual to help communicate the intent of the

instructions. When one or more of the symbols

appears at the beginning of a maintenance

procedure, it conveys the meaning below.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be required

to perform this procedure.

Indicates that a cold motor or pump will

be required to perform this procedure.

Indicates that dealer service will be

required to perform this procedure.

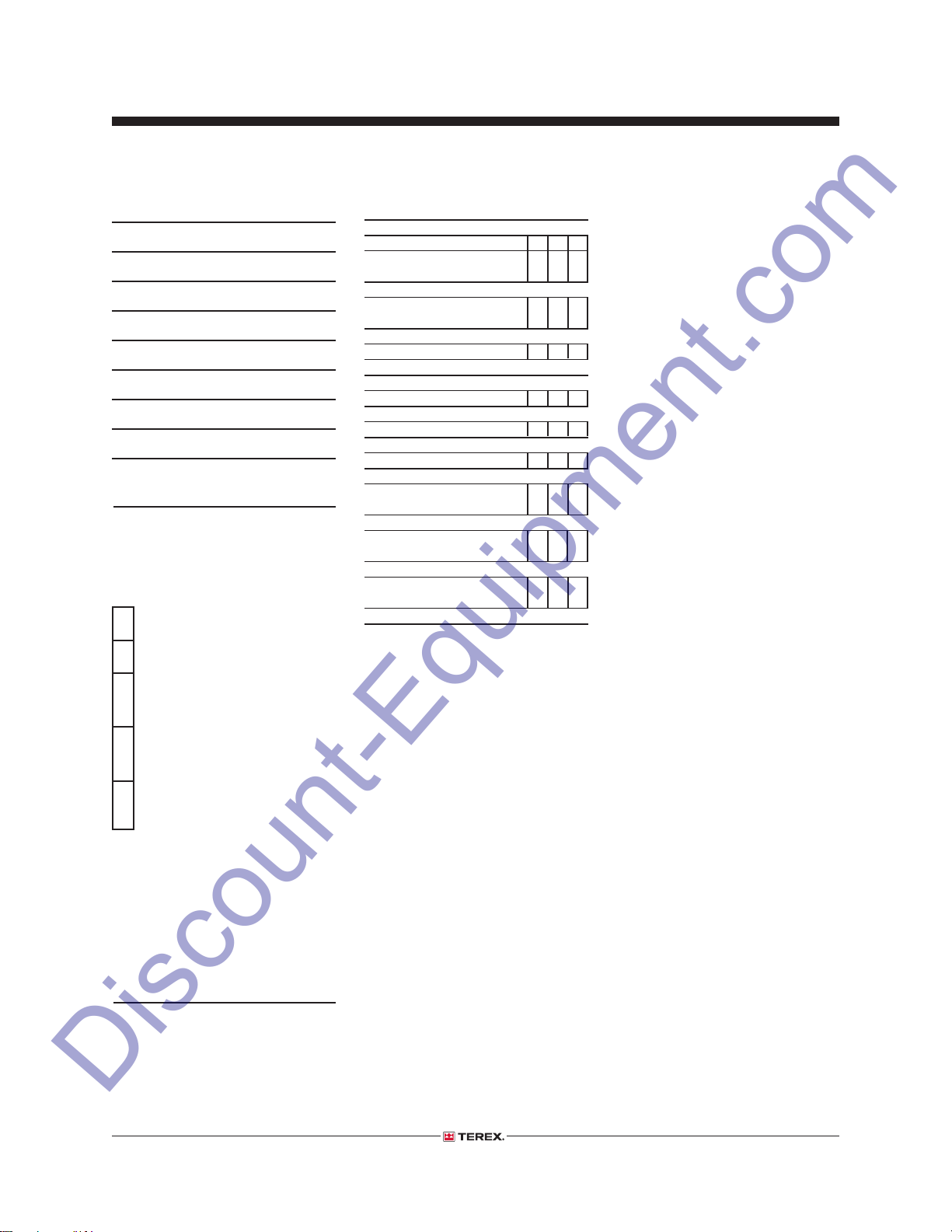

Maintenance Schedule

There are fi ve types of maintenance inspections

that must be performed according to a schedule—

daily, quarterly, semi-annually, annually, and

two year. The Scheduled Maintenance Procedures

Section and the Maintenance Inspection Report

have been divided into fi ve subsections—A, B,

C, D, and E. Use the following chart to determine

which group(s) of procedures are required to

perform a scheduled inspection.

Inspection Checklist

Daily or every 8 hours A

Quarterly or every 250 hours A + B

Semi-annually or every 500 hours A + B + C

Annually or every 1000 hours A + B + C + D

Two year or every 2000 hours A + B + C + D + E

Maintenance Inspection Report

The maintenance inspection report contains

checklists for each type of scheduled inspection.

Make copies of the Maintenance Inspection Report

to use for each inspection. Maintain completed

forms in compliance with employer, job site and

governmental regulations.

3 - 2 AL4 • AL4000 Part No. 218567

Section 3 • Scheduled Maintenance ProceduresAugust 2016

Discount-Equipment.com

Maintenance Inspection Report

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

• Make copies of this report to use for

each inspection.

• Select the appropriate checklist(s) for

the type of inspection to be performed.

Daily or 8 hours

Inspection: A

Quarterly or 250 hours

Inspection: A+B

Semi-annually or

500 hours

Inspection: A+B+C

Annually or

1000 hours

Inspection: A+B+C+D

Two year or

2000 hours

Inspection: A+B+C+D+E

• Place a check in the appropriate box

after each inspection procedure is

completed.

• Use the step-by-step procedures in

this section to learn how to perform

these inspections.

• If any inspection receives an “N”, tag

and remove the machine from service,

repair and re-inspect it. After repair,

place a check in the “R” box.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

Checklist A Y N R

A-1 Manuals and decals

A-2 Pre-operation inspect

A-3 Function tests

Perform every 8 hours:

A-4 Engine maintenance

Perform before towing:

A-5 Coupler

A-6 Brakes (if equipped)

Perform at 10 miles:

A-7 Lug nuts

Perform every week:

A-8 Tires and wheels

A-9 Engine air fi lter

A-10 Generator -

Leroy Somer Models

A-11 Engine maintenance -

Kubota models

Perform after 50 hours:

A-12 Engine maintenance -

Kubota models

Perform every month:

A-13 Cable and Pulleys

Perform every 100 hours:

A-14 Engine maintenance -

Kubota models

Perform every 200 hours:

A-15 Engine maintenance -

Kubota models

A-16 Generator

Marathon Models

A-17 Fuel/Water Separator

A-18 Brakes (if equipped)

Checklist B Y N R

B-1 Battery

B-2 Electrical wiring

B-3 Lug nuts

B-4 Engine maintenance -

Perkins models

B-5 Jack

B-6 Winch

B-7 T-bolt

Perform every 3000 miles:

B-8 Brakes (if equipped)

B-9 Suspension

Perform every 400 hours:

B-10 Engine maintenance -

Kubota models

Checklist C Y N R

C-1 Engine maintenance

C-2 Lights

Perform every 6000 miles:

C-3 Wheel bearings

C-4 Brakes (if equipped)

Perform every 800 hours:

C-5 Engine maintenance -

Kubota models

Perform every 2000 hours:

C-6 Generator -

Leroy Somer Models

Comments

Part No. 218567 AL4 • AL4000 3 - 3

Section 3 • Scheduled Maintenance Procedures

Discount-Equipment.com

MAINTENANCE INSPECTION REPORT

August 2016

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

• Make copies of this report to use for

each inspection.

• Select the appropriate checklist(s) for

the type of inspection to be performed.

Daily or 8 hours

Inspection: A

Quarterly or 250 hours

Inspection: A+B

Semi-annually or

500 hours

Inspection: A+B+C

Annually or

1000 hours

Inspection: A+B+C+D

Two year or

2000 hours

Inspection: A+B+C+D+E

• Place a check in the appropriate box

after each inspection procedure is

completed.

• Use the step-by-step procedures in

this section to learn how to perform

these inspections.

• If any inspection receives an “N”, tag

and remove the machine from service,

repair and re-inspect it. After repair,

place a check in the “R” box.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

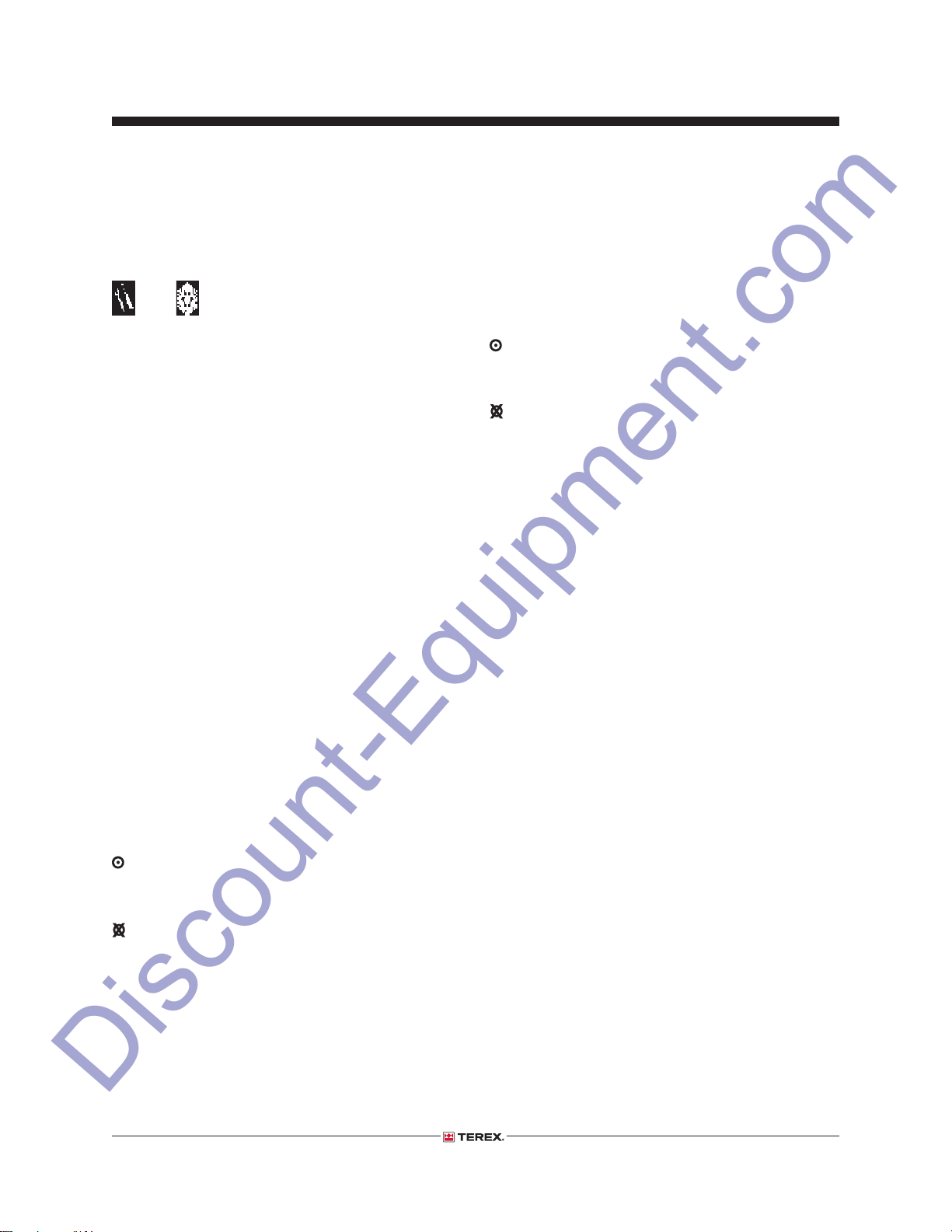

Checklist D Y N R

Perform every 1500 hours:

D-1 Engine maintenance -

Kubota models

Perform every 8000 hours:

D-2 Generator -

Leroy Somer Models

Perform annually:

D-3 Coupler

Checklist E Y N R

E-1 Cable

Perform every 2000 hours:

E-2 Engine maintenance

Perform every 3000 hours:

E-3 Engine maintenance

Perform every 10,000 hours:

E-4 Generator -

Marathon Models

Perform every 20,000 hours:

E-5 Generator -

Leroy Somer Models

Perform every 30,000 hours:

E-6 Generator -

Leroy Somer Models

Comments

3 - 4 AL4 • AL4000 Part No. 218567

Section 3 • Scheduled Maintenance ProceduresAugust 2016

Discount-Equipment.com

Checklist A Procedures

A-1

Inspect the Manuals and Decals

Terex specifi cations require that this procedure be

performed at the beginning of every work shift or

daily, whichever comes fi rst.

Maintaining the operator’s and safety manuals

in good condition is essential to safe machine

operation. Manuals are included with each

machine and should be stored in the container

provided in the cabinet. An illegible or missing

manual will not provide safety and operational

information necessary for a safe operating

condition.

In addition, maintaining all of the safety and

instructional decals in good condition is mandatory

for safe machine operation. Decals alert operators

and personnel to the many possible hazards

associated with using this machine. They also

provide users with operation and maintenance

information. An illegible decal will fail to alert

personnel of a procedure or hazard and could

result in unsafe operating conditions.

replaced.

3 Open the operator's manual to the decals

inspection section. Carefully and thoroughly

inspect all decals on the machine for legibility

and damage.

Result: The machine is equipped with all

required decals, and all decals are legible and

in good condition.

Result: The machine is not equipped with all

required decals, or one or more decals are

illegible or in poor condition. Remove the

machine from service until the decals are

replaced.

4 Always return the manuals to the storage

container after use.

Note: Contact your authorized Terex distributor

or Terex if replacement manuals or decals are

needed.

1 Check to make sure that the operator's and

safety manuals are present and complete in the

storage container in the cabinet.

2 Examine the pages of each manual to be sure

that they are legible and in good condition.

Result: The operator's manual is appropriate for

the machine and all manuals are legible and in

good condition.

Result: The operator's manual is not

appropriate for the machine or all manuals are

not in good condition or is illegible. Remove

the machine from service until the manual is

Part No. 218567 AL4 • AL4000 3 - 5

Section 3 • Scheduled Maintenance Procedures

Discount-Equipment.com

CHECKLIST A PROCEDURES

August 2016

A-2

Perform Pre-operation Inspection

Terex specifi cations require that this procedure be

performed at the beginning of every work shift or

daily, whichever comes fi rst.

Completing a Pre-operation Inspection is essential

to safe machine operation. The Pre-operation

Inspection is a visual inspection performed by the

operator prior to each work shift. The inspection

is designed to discover if anything is apparently

wrong with a machine before the operator

performs the function tests. The Pre-operation

Inspection also serves to determine if routine

maintenance procedures are required.

Complete information to perform this procedure

is available in the appropriate operator's manual.

Refer to the Operator's Manual on your machine.

A-3

Perform Function Tests

Terex specifi cations require that this procedure be

performed at the beginning of every work shift or

daily, whichever comes fi rst.

Completing the function tests is essential to safe

machine operation. Function tests are designed to

discover any malfunctions before the machine is

put into service. A malfunctioning machine must

never be used. If malfunctions are discovered,

the machine must be tagged and removed from

service.

Complete information to perform this procedure

is available in the appropriate operator's manual.

Refer to the Operator's Manual on your machine.

3 - 6 AL4 • AL4000 Part No. 218567

Section 3 • Scheduled Maintenance ProceduresAugust 2016

Discount-Equipment.com

CHECKLIST A PROCEDURES

A-4

Perform Engine Maintenance

Engine specifi cations require that this procedure

be performed every 8 hours or daily, whichever

comes fi rst.

• Check oil level

• Check radiator level

• Oil or coolant leaks

• Loose or missing fasteners

Required maintenance procedures and additional

engine information is available in the

Kubota D1105 Operator's Manual

(Kubota part number 16622-89166) OR the

Perkins 403D-11 User's Handbook

(Perkins part number SEBU8311-01)

Kubota D1105 Operator's Manual

Genie part number 131379

Perkins 403D-11 User's Handbook

Genie part number 131661

A-5

Perform Coupler Maintenance

Coupler specifi cations require that this procedure

be performed before towing.

Maintaining the coupler in good condition is

essential to safe operation and good performance.

Coupler failure could result in a machine tip-over

during transport, and component damage may

also result if problems are not discovered and

repaired in a timely fashion.

1 Check vehicle, mounting bracket, hitch ball and

coupler for signs of wear or damage and that

the coupler handle opens and closes freely.

Result: If coupler and/or mounting bracket

is deformed or damaged, replace complete

coupler and mounting bracket. Replace bent,

broken or worn parts before use.

2 Close coupler securely by ensuring that the

hitch ball is fully seated in the coupler ball

pocket and the pin is inserted behind the collar

or latch.

3 Check mounting bracket hardware for wear and

proper tightness.

Result: Replace bent, broken or worn hardware.

Part No. 218567 AL4 • AL4000 3 - 7

Section 3 • Scheduled Maintenance Procedures

Discount-Equipment.com

CHECKLIST A PROCEDURES

August 2016

A-6

Test the Brakes (if equipped)

Axle specifi cations require that this procedure be

performed before towing.

Maintaining the axle brakes in good condition is

essential to safe operation and good performance.

Brakes which are out of adjustment can result in

longer stopping distances and excessive brake

wear on the towing vehicle. Component damage

may also result if problems are not discovered and

repaired in a timely fashion.

1 Test the brakes for proper function. Repair or

replace any faulty components as needed.

A-7

Torque the Wheel Lug Nuts

Axle specifi cations require that this procedure be

performed initially at 10, 25 and 50 miles of use, or

after reinstallation of a tire.

Maintaining the wheel lug nuts at the proper torque

is essential to safe operation and good service life

of the tires, wheel and axle.

1 Check each lug nut for proper torque.

Specifi cation

Lug nut torque, dry 90 ft-lbs

122 Nm

Lug nut torque, lubricated 67.5 ft-lbs

91.5 Nm

3 - 8 AL4 • AL4000 Part No. 218567

Loading...

Loading...