Tennant Centurion User Manual

CENTURIONr

Home

Find...

Go To..

Operator Manual

(002001-- )

331020

Rev. 02

*331020*

This manual is furnished with each new TENNANT Model Centurionr. It provides necessary operating

Home

Find...

Go To..

and preventive maintenance instructions. Read this manual completely and understand the machine

before operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum

costs if:

D The machine is operated with reasonable care.

D The machine is maintained regularly -- per the maintenance instructions provided.

D The machine is maintained with TENNANT supplied or equivalent parts.

Manual Number -- 331020

Revision: 02

Published: 9--05

CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust from this product contains

chemicals known to the State of California to cause cancer, birth defects, or other

reproductive harm.

Thermo Sentryr is a United States trademark of Tennant Company.

Streetsmartr is a United States trademark of Tennant Company.

Copyright E 2003, 2004, 2005 TENNANT, Printed in U.S.A.

CONTENTS

Home

Find...

Go To..

CONTENTS

Page

SAFETY PRECAUTIONS 4...................

OPERATION 8..............................

OPERATOR RESPONSIBILITY 8...........

MACHINE COMPONENTS 9...............

CONTROL PANEL SYMBOLS 10...........

CONTROLS AND INSTRUMENTS 1 1.......

RIGHT HAND STEERING

INSTRUMENT CONSOLE 11.........

UPPER CONTROL PANEL

SWITCHES (002001--002999) 12......

UPPER CONTROL PANEL

SWITCHES (003000-- ) 13.......

CENTER CONTROL PANEL

SWITCHES (002001--002999) 14......

CENTER CONTROL PANEL

SWITCHES (003000-- ) 15.......

TOUCH PANEL 16.....................

OPERATION OF CONTROLS 17..............

IGNITION SWITCH 17.....................

PARKING BRAKE KNOB 17................

OPERATOR CONTROL SWITCH 17........

REAR AXLE SHIFT CONTROL

SWITCH 18...........................

HEATED MIRROR SWITCH (OPTION) 18...

PUSHBUTTON RANGE SELECTOR 18.....

CRUISE CONTROL/THROTTLE LOCK 19...

PTO KILL SWITCH 19.....................

REAR WORK LIGHT SWITCH

(OPTION) 20..........................

HOPPER WORK LIGHT SWITCH

(OPTION) 20..........................

RIGHT SIDE INSTRUMENT

CONSOLE 20..........................

TACHOMETER 21........................

HOURMETER 21.........................

SPEEDOMETER 21.......................

ENGINE OIL PRESSURE GAUGE 22.......

ENGINE COOLANT TEMPERATURE

GAUGE 22............................

VOLTMETER 22..........................

FUEL LEVEL GAUGE 23..................

AIR BRAKE PRESSURE GAUGE 23........

BRIGHT HEADLIGHTS LIGHT 23...........

PREHEAT LIGHT 24......................

SIGNAL LIGHT 24........................

TOUCH PANEL 24........................

CONTRAST ADJUSTMENT KNOB 24.......

START UP SCREEN 25....................

DISPLAY CLOCK 25......................

PTO HOURMETER 25.....................

BRUSH HOURMETER 26..................

MORE SWITCH 26........................

PTO SWITCH 27..........................

FAST IDLE 27...........................

Page

SWEEP SWITCH 28......................

SWEEP MODE SWITCH 29................

SUPER SWEEP SWITCH 29...............

MAIN BROOM WEAR INDICATOR 29.......

WATER FLOW SWITCH 30................

WATER TANK LEVEL GAUGE 30...........

FILTER SHAKER SWITCH 31..............

VACUUM FAN SWITCH 32.................

LEFT SIDE GUTTER BROOM SWITCH

(OPTION) 32..........................

RIGHT SIDE GUTTER BROOM

SWITCH 32...........................

HOPPER UP SWITCH 33..................

HOPPER DOWN SWITCH 33..............

HOPPER DUMP SWITCH 34...............

HOPPER HOME SWITCH 34...............

CONVEYOR IN SWITCH 35................

CONVEYOR FORWARD SWITCH 35.......

CONVEYOR REVERSE SWITCH 35........

CONVEYOR OUT SWIT CH 36.............

CONVEYOR WATER SPRAY SWITCH 36...

FRONT WATER SPRAY SWITCH 37........

LEFT SIDE WATER SPRAY SWITCH 37.....

RIGHT SIDE WATER SPRAY SWITCH 37...

FUSES 38...............................

LEFT SIDE GUTTER BROOM TILT

SWITCH (OPTION) 39..................

RIGHT SIDE GUTTER BROOM TILT

SWITCH (OPTION) 39..................

GUTTER BROOM SPEED/PRESSURE

ADJUSTMENT (OPTION) 39............

REVOLVING LIGHT SWITCH

(OPTION) 40..........................

GUTTER BROOM LIGHT SWITCH

(OPTION) 40..........................

LATCHES 40.............................

HOPPER TILT SUPPORT BAR 41..........

HOPPER LIFT SUPPORT BARS 41.........

ALARMS 42.................................

HOPPER UP ERROR ALARM 42...........

CONVEYOR NOT BACK ALARM 42........

CONVEYOR STALL ALARM 42.............

HOPPER FIRE ALARM 43.................

TANK LOW, PUMP OFF ALARM 43.........

REDUCE ENGINE RPM ALARM 43.........

CHECK HYDRAULIC FILTER ALARM 44....

ACTIVATE PARK BRAKE ALARM 44........

ERROR--BROOMS DOWN ALARM 44.......

SHAKE FILTER ALARM 45.................

OVERSPEED ENGINE ALARM 45..........

RELEASE E--STOP ALARM 45.............

MACHINE NOT LEVEL ALARM 46..........

HYDRAULIC FLUID LOW ALARM

(OPTION) 46..........................

Centurion 331020 (9-- 05)

1

CONTENTS

Home

Find...

Go To..

Page

HOW THE MACHINE WORKS 47..............

PRE AND POST OPERATION

CHECKLIST 48...........................

STARTING THE MACHINE 49.................

SWEEPING AND BRUSH INFORMATION 51...

SWEEP MODES 52.......................

SETTING THE CUSTOM MODE 54.........

FILLING THE WATER TANK 55.............

SWEEPING 57...........................

STOP SWEEPING 59.....................

EMPTYING THE HOPPER 60..............

STOPPING THE MACHINE 62.............

OPERATION ON INCLINES 63.............

ENGAGING HOPPER TILT SUPPORT

BAR 64...............................

DISENGAGING HOPPER TI LT

SUPPORT BAR 66.....................

ENGAGING HOPPER LIFT SUPPORT

BARS 68..............................

DISENGAGING HOPPER LIFT

SUPPORT BARS 70....................

MACHINE TROUBLESHOOTING 72........

MACHINE TROUBLESHOOTING 73........

MAINTENANCE 74..........................

MAINTENANCE CHART 75................

LUBRICATION 77.........................

HOPPER LIFT/TILT 77..................

ENGINE 77...........................

GUTTER BROOM SUPPORT

RODS 78...........................

GUTTER BROOM SUPPORT

ARMS 78...........................

GUTTER BROOM PIVOT 78............

DUST CONTROL SKIRT CYLINDER

(OPTION) 79.......................

DUST CONTROL SKIRT PIVOTS

(OPTION) 79.......................

DUST CONTROL BUMPER PIVOTS

(OPTION) 79.......................

MAIN BRUSH SUPPORT ARMS 80......

MAIN BRUSH IDLER BEARING 80.......

DRAG SHOE PIVOT 80.................

MAIN BRUSH LIFT CYLINDER 81.......

DRAG SHOE LIFT CYLINDER 81........

MAIN BRUSH AND DRAG SHOE

CYLINDERS 81.....................

CONVEYOR BEARINGS 82.............

CONVEYOR LIFT PIVOTS 82...........

CONVEYOR LIFT CYLINDERS 82.......

CONVEYOR TILT CYLINDER 83.........

DRY DUST CONTROL SKIRT WING

PIVOTS (OPTION) 83...............

PROPULSION SHAFT SLIP JOINT 83....

AUTO LUBE (OPTION) 84..............

Page

HYDRAULICS 85.........................

HYDRAULIC FLUID RESERVOIR 85.....

HYDRAULIC FLUID 86.................

HYDRAULIC PUMP LOAD SENSE

FILTERS 87........................

CHECKING THE LOAD SENSE

FILTERS 87........................

HYDRAULIC FLUID FILTER 88..........

HYDRAULIC COOLING SYSTEM 88.....

HYDRAULIC HOSES 88................

ENGINE 89..............................

ENGINE 89...........................

AIR FILTER RESTRICTI ON

INDICATOR 89......................

RADIATOR 89.........................

TRANSMISSION 90.......................

TRANSMISSION ACCESS 90...........

REMOVING DRY DUST

CONTROL ASSEMBLY 90.........

WET DUST CONTROL SYSTEM 94.........

WATER TANK 94.......................

WATER PUMP 94......................

WATER FILTER 95.....................

WATER HOSES 95.....................

SPRAY NOZZLES 95...................

DEBRIS HOPPER 96......................

THERMO SENTRY 96..................

HOPPER DUST FILTER 96..............

RINSING THE HOPPER DUST

FILTER 97..........................

TO REMOVE OR REPLACE

HOPPER DUST FILTER 98...........

CONVEYOR 100.........................

ADJUSTING THE CONVEYOR

HEIGHT 101.......................

FLUSHING THE CONVEYOR

BELT 102..........................

ADJUSTING THE CONVEYOR BELT

TRACKING 103....................

TO REPLACE THE CONVEYOR

BELT 105.........................

BRUSHES 108...........................

MAIN BRUSH 108.....................

TO REPLACE THE MAIN BRUSH 108...

TO CHECK AND ADJUST MAIN

BRUSH PATTERN 112...............

GUTTER BROOM(S) 113...............

TO REPLACE THE GUTTER

BROOM(S) 113.....................

TO CHECK AND ADJUST THE

GUTTER BROOM PATTERN 114.....

MAIN BRUSH AND DRAG SHOE CABLE

AND ARM STOPS 116..................

TO CHECK MAIN BRUSH ARM

STOPS 116......................

2

Centurion 331020 (9-- 05)

TO ADJUST MAIN BRUSH ARM

Home

Find...

Go To..

STOPS 117......................

TO CHECK AND ADJUST DRAG

SHOE CABLES 118..............

TO CHECK AND ADJUST DRAG

SHOE ARM STOPS 119...........

SKIRTS AND SEALS 120.................

BRUSH COMPARTMENT SIDE

SKIRT 120.........................

BRUSH COMPARTMENT REAR

SKIRT 120.........................

TOP CONVEYOR SKIRTS 120.........

BOTTOM CONVEYOR SKIRTS 121.....

HOPPER CHUTE DOOR SKIRT 121....

HOPPER CHUTE DOOR SEALS 121....

HOPPER ACCESS DOOR SEAL 122....

HOPPER FILTER COVER SEAL 122....

VACUUM DUCT SEALS

(OPTION) 122.....................

ACCESS PANEL DUST SKIRTS

(OPTION) 123.....................

FRONT DRY DUST CONTROL

SKIRTS (OPTION) 123..............

CENTER DRY DUST CONTROL

SKIRT (OPTION) 123...............

REAR DRY DUST CONTROL

SKIRTS (OPTION) 124..............

DRY DUST CONTROL WING

SKIRTS (OPTION) 124..............

DRY DUST CONTROL GUTTER

BROOM SKIRT(S) (OPTION) 124....

MAIN BRUSH DRAG SHOES 125.......

MACHINE JACKING 126...............

STORING MACHINE 126..............

FREEZE PROTECTION FOR WET

DUST CONTROL SYSTEM 126...

TRANSPORTING THE MACHINE 128...

SPECIFICATIONS 129......................

GENERAL MACHINE DIMENSIONS/

CAPACITIES 129......................

GENERAL MACHINE

PERFORMANCE 130..................

POWER TYPE 130.......................

TRANSMISSION FLUID 130...............

STEERING 130..........................

HYDRAULIC SYSTEM 131................

BRAKING SYSTEM 131..................

MACHINE DIMENSIONS 131..............

INDEX 133.................................

CONTENTS

Page

Centurion 331020 (9-- 05)

3

SAFETY PRECAUTIONS

Home

Find...

Go To..

SAFETY PRECAUTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices which could result in

severe personal injury or death.

FOR SAFETY: To identify actions which

must be followed for safe operation of

equipment.

The machine is suited to sweep disposable

debris. Do not use the machine other than

described in this Operator Manual.

The following information signals potentially

dangerous conditions to the operator or

equipment:

WARNING: Burn Hazard. Hot Surface.

Do Not Touch.

WARNING: Raised hopper may fall.

Engage hopper support bar.

WARNING: Tilted hopper may fall.

Engage hopper support bar.

WARNING: Brush linkage pinch points.

Stay clear when linkage is moving.

WARNING: Side brush can move. Do

not step on side brush.

WARNING: High dump vertical

clearance. Stay clear of overhead

obstructions and power lines.

WARNING: Conveyor throws debris.

Conveyor pinch point. Stay clear when

in operation.

WARNING: Flammable materials can

cause explosion or fire. Do not use

flammable materials in tank. Only use

water.

WARNING: Lift arm pinch point. Stay

clear of hopper lift arms.

WARNING: Engine emits toxic gases.

Severe respiratory damage or

asphyxiation can result. Provide

adequate ventilation. Consult with your

regulatory agency for exposure limits.

Keep engine properly tuned.

WARNING: Rotating PTO Shaft.

Never Get Under Machine If Engine

Is Running.

FOR SAFETY:

1. Do not operate machine:

-- Unless trained and authorized. This

machine requires an updated

Commercial Drivers License for

operation.

-- Unless all TENNANT and truck

manuals are read and understood.

-- In flammable or explosive areas.

2. Before starting machine:

-- Check for fuel leaks.

-- Keep sparks and open flame away

from refueling area.

-- Make sure all safety devices are in

place and operate properly.

-- Check brakes and steering for proper

operation.

3. When using machine:

-- Use brakes to stop machine.

-- Go slow on inclines and slippery

surfaces.

-- Use care when reversing machine.

-- Do not move machine when hopper is

raised.

-- Only dump the hopper on a level

surface.

-- Make sure adequate clearance is

available before raising hopper.

-- Do not carry riders on machine.

-- Always follow safety and traffic rules.

-- Report machine damage or faulty

operation immediately.

4. Before leaving or servicing machine:

-- Stop on level surface.

-- Set parking brake.

-- Turn off machine and remove key.

WARNING: Loss Of Steering Control

Can Result. Stop Machine And Place In

Neutral Before Switching Operator

Control.

4

Centurion 331020 (11--03)

5. When servicing TENNANT sweeping

Home

Find...

Go To..

components:

-- Avoid moving parts. do not wear loose

jackets, shirts, or sleeves.

-- Block machine tires before jacking

machine up.

-- Jack machine up at designated

locations only. Block machine up with

jack stands.

-- Use hoist or jack that will support the

weight of the machine.

-- Wear eye and ear protection when

using pressurized air or water.

-- Disconnect battery connections before

working on machine.

-- A void contact with battery acid.

-- Keep flames and sparks away from

fuel system service area. Keep area

well ventilated.

-- Use cardboard to locate leaking

hydraulic fluid under pressure.

-- Use Tennant supplied or approved

replacement parts.

SAFETY PRECAUTIONS

6. When loading/unloading machine

onto/off truck or trailer:

-- Turn off machine.

-- Use truck or trailer that will support

the weight of the machine.

-- Set parking brake after machine is

loaded.

-- Block machine tires.

-- Tie machine down to truck or trailer.

Centurion 331020 (11--03)

5

SAFETY PRECAUTIONS

Home

Find...

Go To..

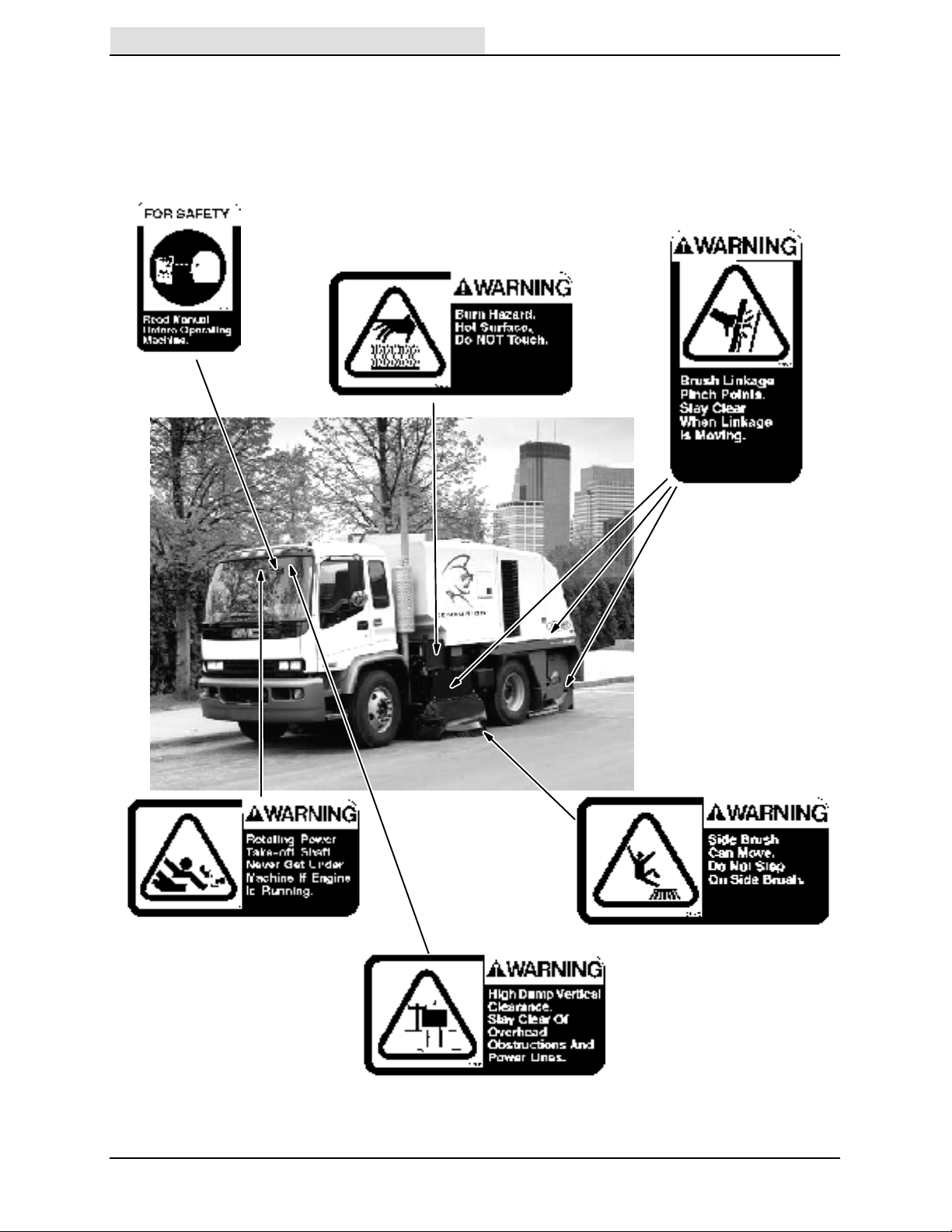

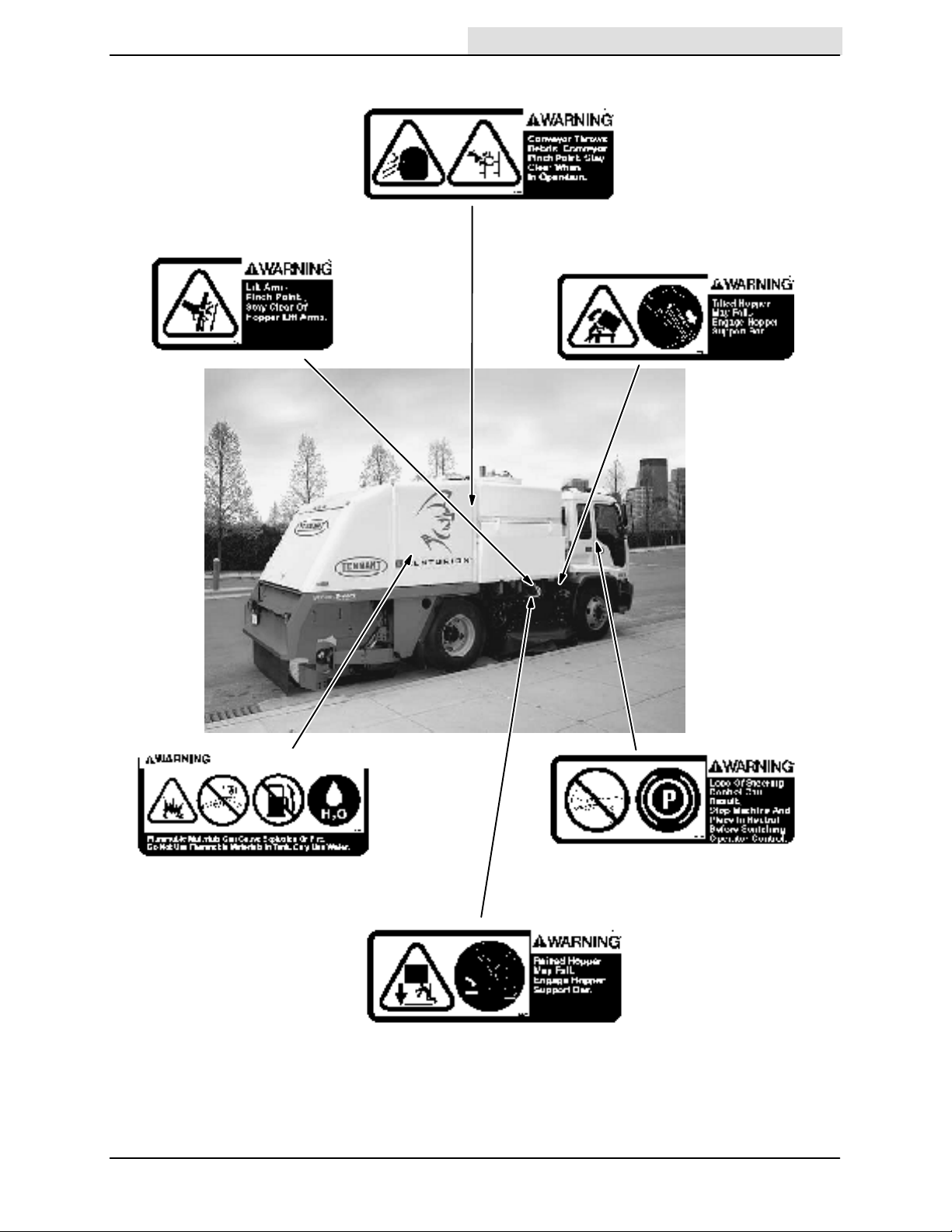

The following safety labels are mounted on the

machine in the locations indicated. If these or any

label becomes damaged or illegible, install a new

label in its place.

FOR SAFETY LABEL -Located on the upper console.

HOT SURFACE LABEL -Located on the side of

the hydraulic tank.

BRUSH LINKAGE LABEL -Located on each main brush lift

arm, gutter broom and next to

main brush lift cylinders.

ROTATING PTO SHAFT LABEL -Located on the upper console

and on the side of the machine.

6

SIDE BRUSH LABEL -Located on top of the side

brush(es).

HIGH DUMP LABEL -- Located on the

upper console and on the side of the machine.

Centurion 331020 (11--03)

SAFETY PRECAUTIONS

VEY

Home

Find...

Go To..

CON

Located on each side of the conveyor.

LIFT ARMS LABEL (High Dump) -Located on the side of the hopper lift.

OR LABEL --

HOPPER SUPPORT BAR LABEL

(Low Dump) -- Located on both sides

of the scissor lift in the lower rail.

FLAMMABLE MATERIALS LABEL -Located on the right side of the machine

behind the water hose shields.

HOPPER SUPPORT BAR LABEL

(High Dump) -- Located on both sides

of the scissor lift in the lower rail.

Centurion 331020 (11--03)

OPERATOR CONTROL SWITCH LABEL -Located on the control panel between the

operator seats.

7

OPERATION

Home

Find...

Go To..

OPERATOR RESPONSIBILITY

- The operator is responsible for conducting

daily maintenance and checkups and

keeping the machine in good working

condition. The operator must inform the

service mechanic or supervisor when the

required maintenance intervals occur as

stated in the MAINTENANCE section of this

manual.

- This machine requires a Commercial Drivers

License for operation. Keep updated with all

licenses and machine operation training.

- Read this manual carefully before operating

this machine. Review all of the training

materials supplied with the machine.

FOR SAFETY: Do not operate machine,

unless operation manual is read and

understood.

OPERAT ION

- Check the machine for shipping damage.

Check to make sure machine is complete

per shipping instructions.

- Keep the machine regularly maintained by

following the maintenance information in this

manual and all other truck manuals supplied

with the machine. We recommend taking

advantage of a regularly scheduled service

contract from your TENNANT

representative.

- Order parts and supplies directly from an

authorized TENNANT representative. Use

the parts manual provided when ordering

parts.

- The model CENTURIONt has a GVWR of

14,850 kg (33,000 lb), 4536 kg (12,000 lb)

front axle and 9450 kg (21,000 lb) rear axle.

Operate only on surfaces capable of

supporting this weight.

07324

8

Centurion 331020 (11--03)

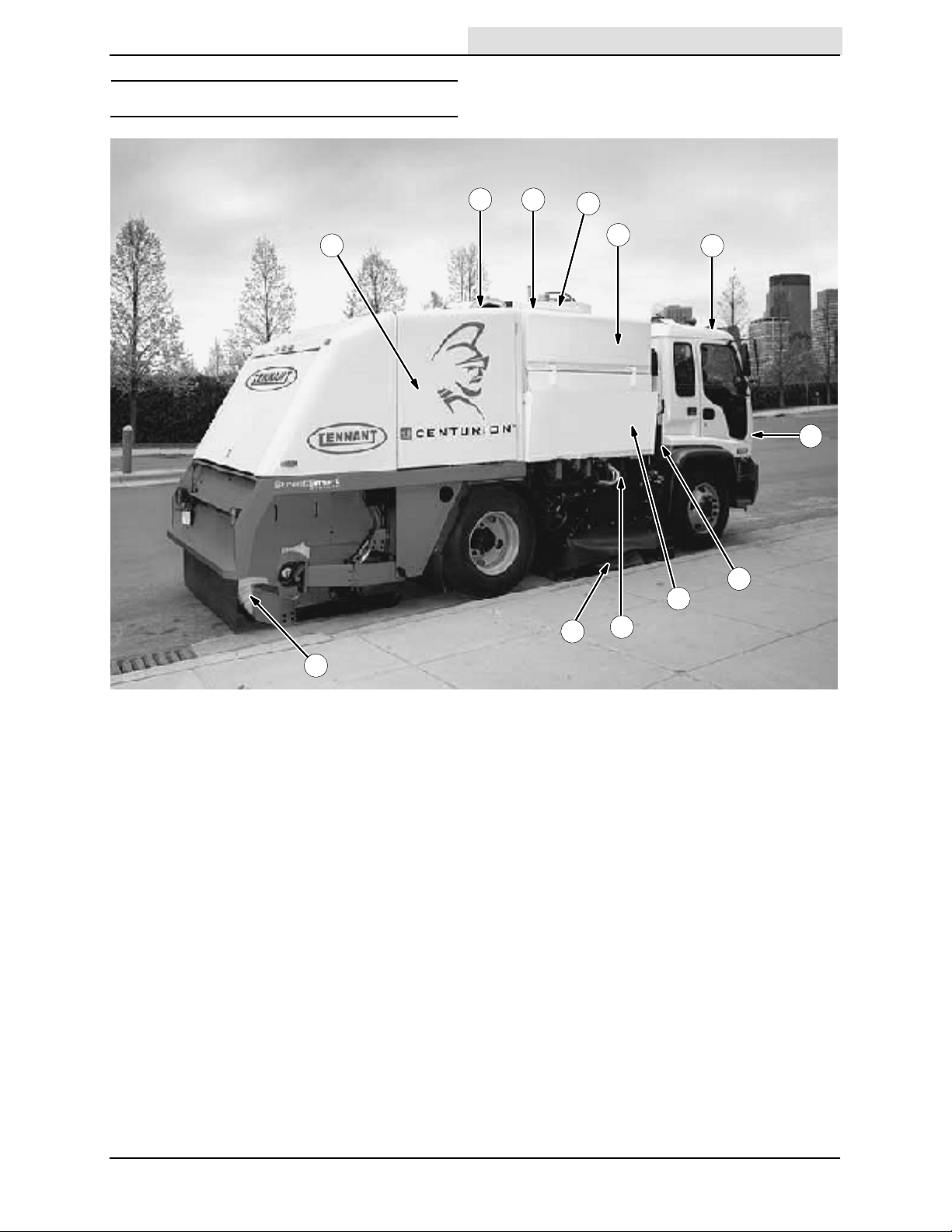

MACHINE COMPONENTS

Home

Find...

Go To..

OPERATION

A B

L

C

D

J

I

E

F

G

H

K

A. Conveyor

B. Dust Filters

C. Vacuum Fan

D. Hopper

E. Cab

F. Diesel Engine

G. Fuel Tank

H. Hopper Door

I. Hopper Lift

J. Gutter Brooms

K. Main Brush

L. Water Tank

Centurion 331020 (11--03)

9

OPERATION

Home

Find...

Go To..

CONTROL PANEL SYMBOLS

These symbols identify controls and displays on

the machine:

Right Side Gutter Broom Light Bright Headlights

Left Side Gutter Broom Light Signal Lights

Revolving Light Air Inlet Heater (Preheat)

Fuel

10

Centurion 331020 (11--03)

CONTROLS AND INSTRUMENTS

Home

Find...

Go To..

OPERATION

A

H

F

G

I

E

RIGHT HAND STEERING INSTRUMENT CONSOLE

B

C

D

A. Oil Pressure Gauge

B. Fuel Gauge

C. Air Brake Pressure Gauge

D. Speedometer

E. Signal Light Display

F. Tachometer

G. Voltmeter

H. Coolant Temperature Gauge

I. Hourmeter

Centurion 331020 (11--03)

11

OPERATION

Home

Find...

Go To..

D

C

A

B

I

H

G

F

E

UPPER CONTROL PANEL SWITCHES (002001 --002999)

A. Open

B. Rear Work Light

C. Hopper Work Light

D. PTO (Power Take Off) Kill Switch

E. Left Side Gutter Broom Tilt Switch (Option)

F. Op en

G. Revolving Light Switch (Option)

H. Gutter Broom Work Lights

I. Right Side Gutter Broom Tilt Switch (Option)

12

Centurion 331020 (9-- 05)

OPERATION

Home

Find...

Go To..

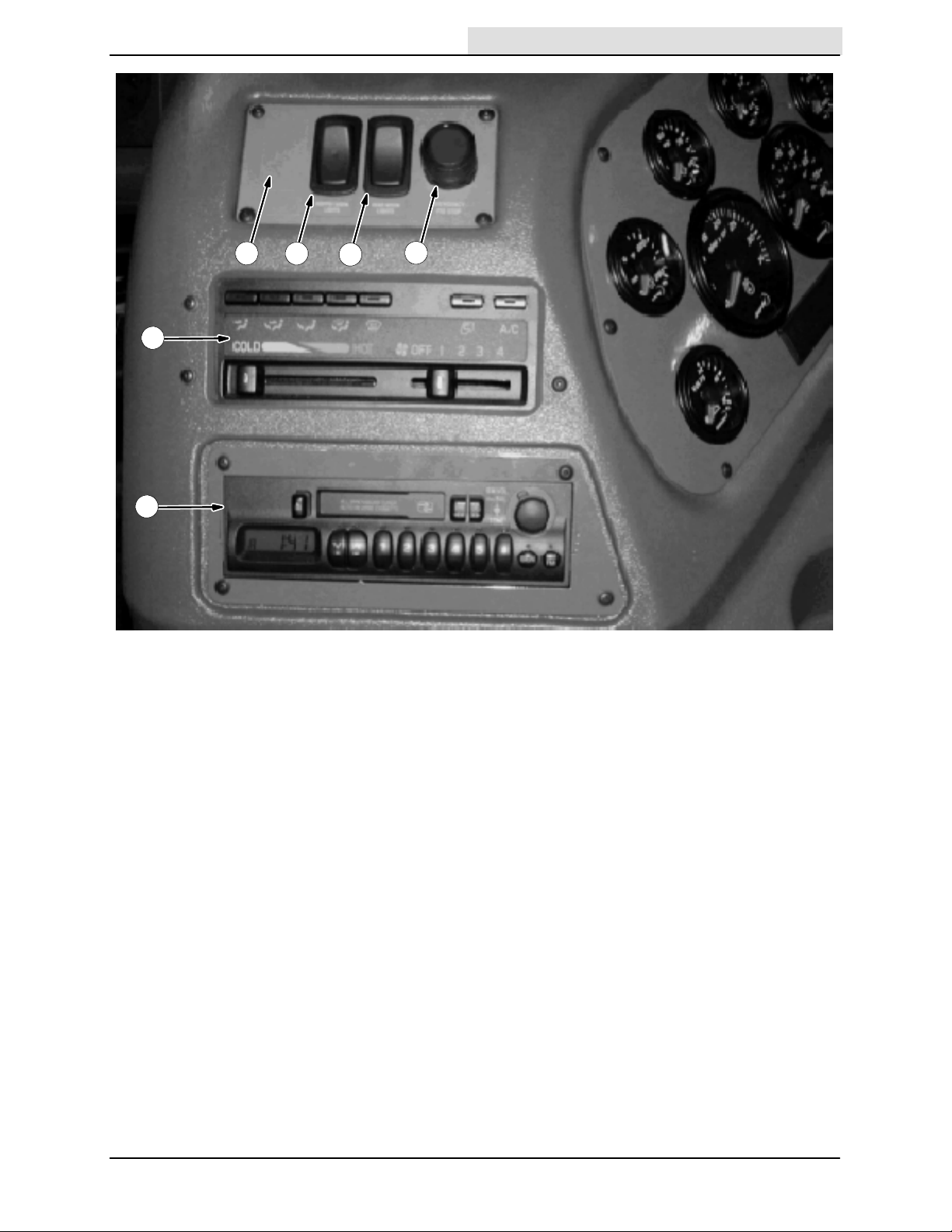

A

E

F

A. Open

B. Hopper Work Light

C. Rear Work Light

D. PTO (Power Take Off) Kill Switch

E. HVAC Controller

F. Ra d io

B

UPPER CONTROL PANEL SWITCHES (003000 -- )

C

D

Centurion 331020 (9-- 05)

13

OPERATION

Home

Find...

Go To..

A B

C

D

E

F

G

CENTER CONTROL PANEL SWITCHES (002001--002999)

A. Rear Axle Shift Control Switch

B. Heated Mirror Switch (option)

C. Pushbutton Range Selector Digital Display

D. Pushbutton Range Selector

E. Ignition Switch

F. Operator Control Switch

G. Parking Brake Knob

14

Centurion 331020 (9-- 05)

OPERATION

Home

Find...

Go To..

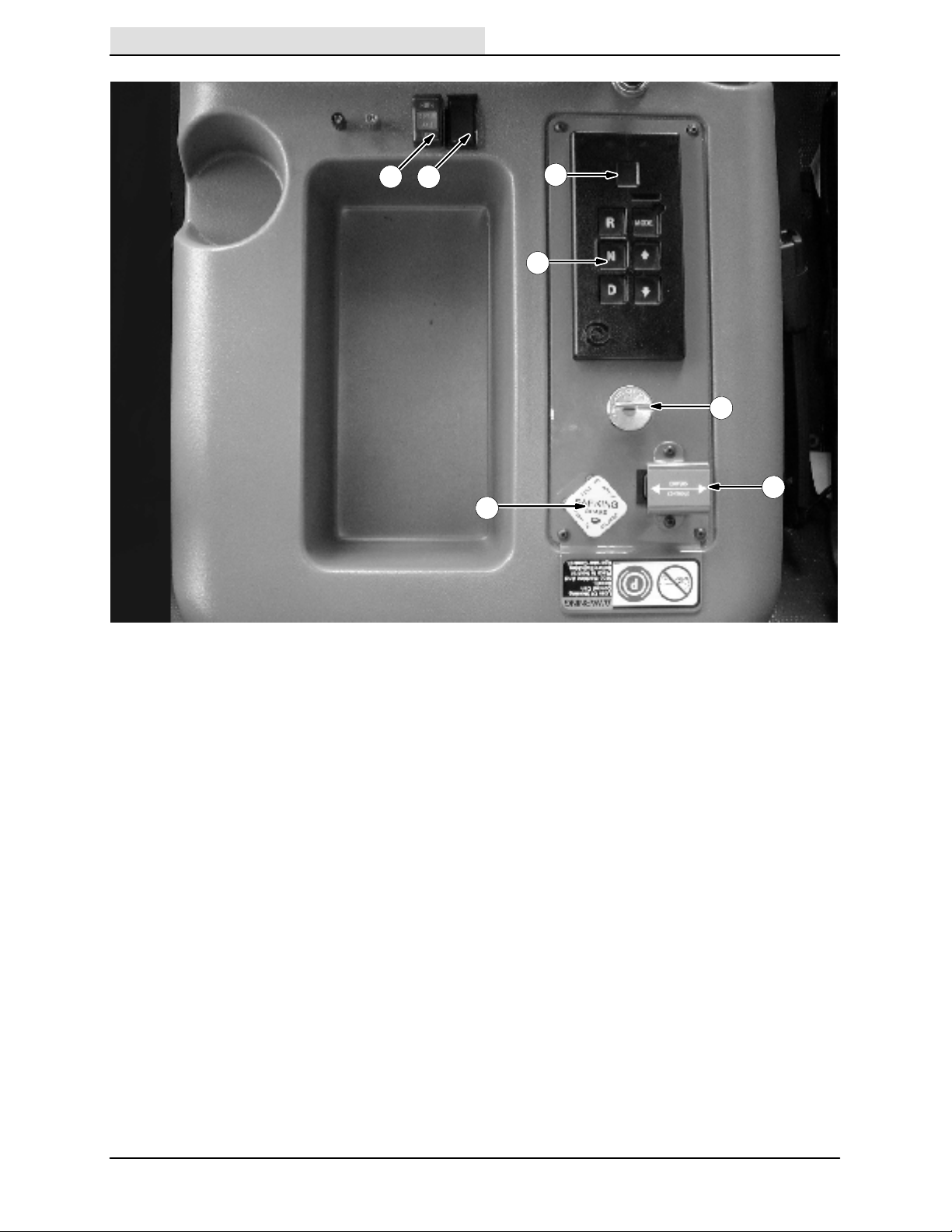

M

G

F

H

N

I J K

O

P

L

A

Q

R

B

C

D

E

CENTER CONTROL PANEL SWITCHES (003000-- )

A. Pushbutton Range Selector Digital Display

B. Pushbutton Range Selector

C. Ignition Switch

D. Operator Control Switch

E. Parking Brake Knob

F. Left Gutter Broom Tilt Switch (Option)

G. Extended LH Gutter Broom Switch (Option)

H. Rotating Lights Switch (Option)

I. Front Work Lights Switch (Option)

J. Gutter Broom Work Lights Switch

K. Extended RH Gutter Broom Switch (Option)

L. Right Gutter Broom Tilt Switch (Option)

M. Rear Axle Shift Control Switch

N. Engine Brake Switch (Option)

O. Front Strobes Switch (Option)

P. Rear Strobes Switch (Option)

Q. Heated Mirrors Switch (Option)

R. Power Mirrors Toggle Switch (Option)

Centurion 331020 (9-- 05)

15

OPERATION

Home

Find...

Go To..

A

B

B

B

J

H

I

TOUCH PANEL

A. Display Screen

B. Multi--Function Switches (6)

C. Front Spray Nozzle Switch

D. Right Side Gutter Broom Spray Nozzle Switch

E. Conveyor Spray Nozzle Switch

F. Left Side Gutter Broom Spray Nozzle Switch (Option)

G. Right Side Gutter Broom Switch

H. Left Side Gutter Broom Switch (Option)

I. PTO (Power Take Off) Switch

J. Sweep Switch

K. Contrast Adjustment Knob

E

G

B

B

B

F

C

D

K

16

Centurion 331020 (7-- 04)

OPERATION OF CONTROLS

Home

Find...

Go To..

IGNITION SWITCH

The ignition switch starts and stops the truck

engine with a key. Refer to the truck manuals for

proper operation.

FOR SAFETY: Do not operate machine

unless all TENNANT and truck manuals

are read and understood.

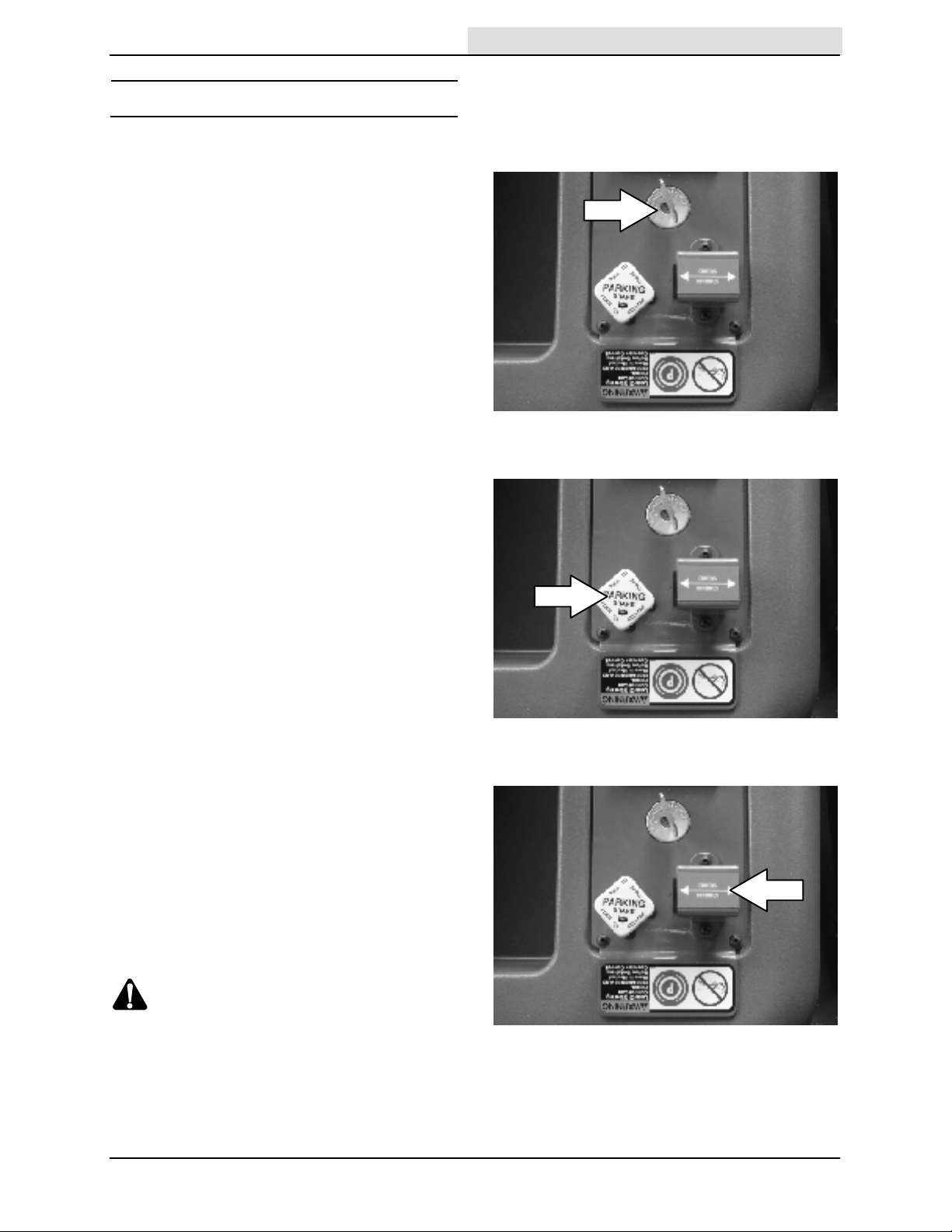

PARKING BRAKE KNOB

The parking brake knob sets and releases the

machine parking brake. Refer to the truck

manuals for proper operation.

OPERATION

FOR SAFETY: Do not operate machine

unless all TENNANT and truck manuals

are read and understood.

OPERATOR CONTROL SWITCH

The operator control switch transfers the throttle

and power steering controls from one side of the

operator’s compartment to the other. It also turns

on the side instrument console.

Activate Right Side Controls: Press the right side

of the switch.

Activate Left Side Controls: Press the left side of

the switch.

WARNING: Loss Of Steering Control

Can Result. Stop Machine And Place In

Neutral Before Switching Operator Control.

Centurion 331020 (7-- 04)

17

OPERATION

Home

Find...

Go To..

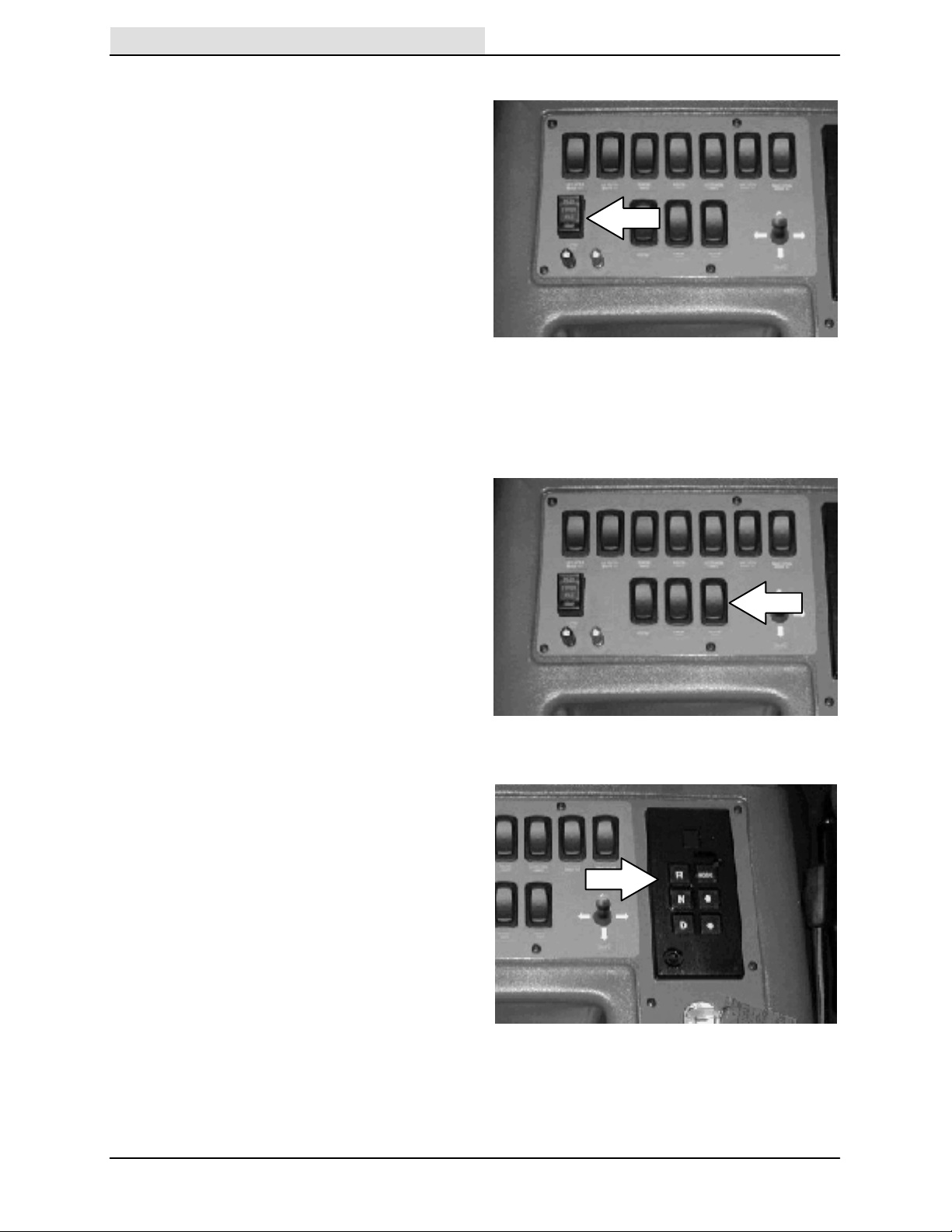

REAR AXLE SHIFT CONTROL SWITCH

The rear axle shift control switch controls the rear

axle operating range. Refer to the truck manuals

for proper operation.

FOR SAFETY: Do not operate machine

unless all TENNANT and truck operation

manuals are read and understood.

NOTE: For best slow speed sweeping results,

drive the machine in D1 (first gear) with the rear

axle in low range.

NOTE: To engage the low range on t he rear

axle, park the machine on level gr ound, and

select low range.

HEATED MIRROR SWITCH (OPTION)

The heated mirror switch controls the heated

mirror option. Refer to the truck manuals for

proper operation.

FOR SAFETY: Do not operate machine

unless all TENNANT and truck operation

manuals are read and understood.

PUSHBUTTON RANGE SELECTOR

The pushbutton range selector is used to select

the different operating gears and D (Drive)

ranges. The digital display shows what gear or

operating range the truck is in. Refer to the truck

manuals for proper operation.

FOR SAFETY: Do not operate machine

unless all TENNANT and truck operation

manuals are read and understood.

NOTE: For best slow speed sweeping results,

drive the machine in D1 (first gear) with the rear

axle in low range.

NOTE: To engage the low range on the rear axle,

park the machine on level ground, and select low

range.

18

Centurion 331020 (9-- 05)

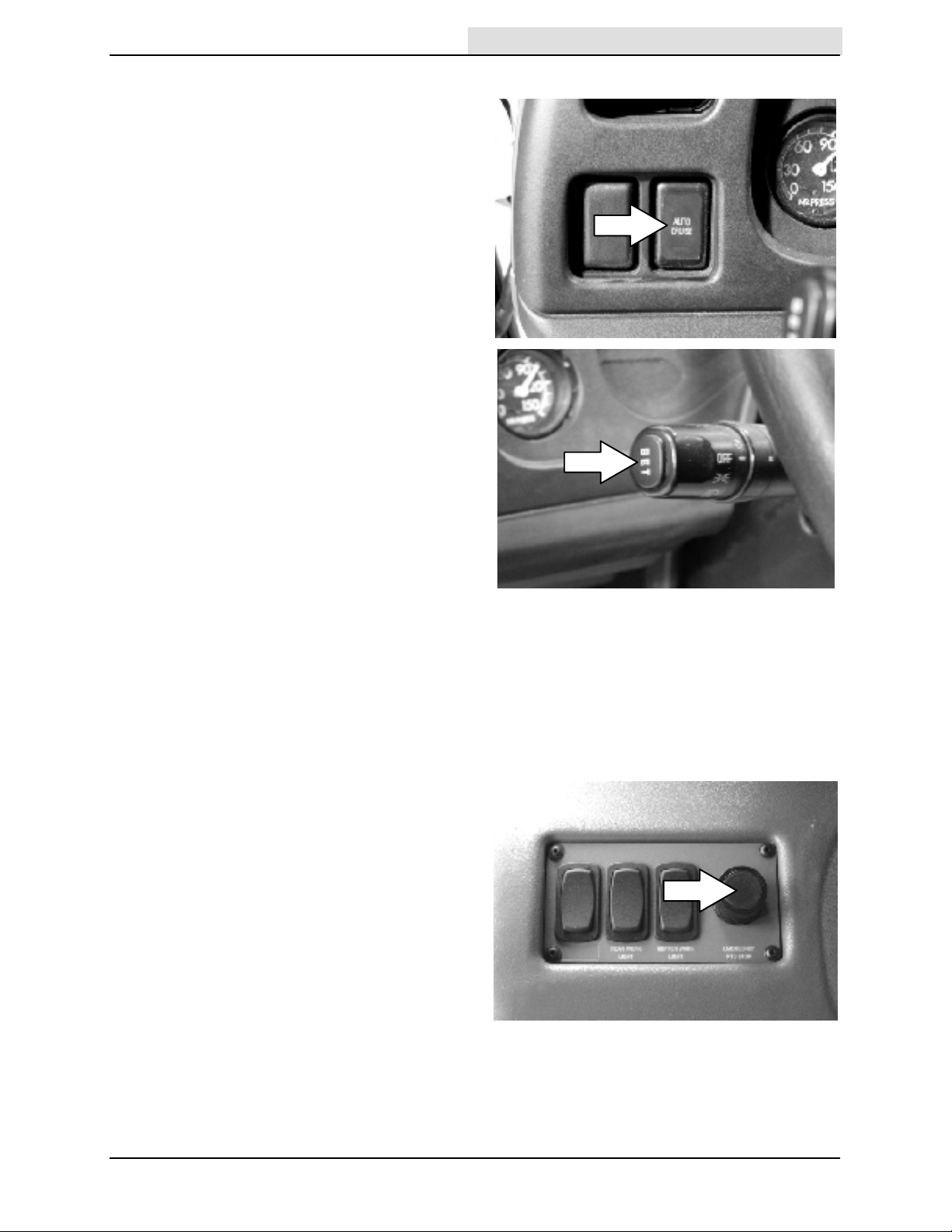

CRUISE CONTROL/THROTTLE LOCK

Home

Find...

Go To..

The cruise control/throttle lock functions as a

normal cruise control when the PTO is not

engaged and functions as a throttle lock when the

PTO is engaged.

The cruise control function locks the machine to

a desired speed and does not work at speeds

below 25 MPH (40 km/h). Refer to the truck

operation manual to operate the cruise control

function.

The throttle lock locks the engine to a desired

RPM. To operate the throttle lock, press the

sweep switch to engage the PTO. Then the

throttle lock operates the same as the cruise

control function with the exception of it locking the

engine RPM instead of the machine speed. Refer

to the Cruise Control section of the truck

operation manual for more details.

OPERATION

NOTE: When the THROTTLE LOCK is operating

at a higher RPM (approx 1800--2200) the

transmission can shift and increase the vehicle

speed.

FOR SAFETY: Do not operate machine

unless all TENNANT and truck operation

manuals are read and understood.

PTO KILL SWITCH

The PTO kill switch halts all power to the power

take off shafts, sweeping functions and hopper lift

functions.

Halt PTO shafts: Push the center of the PTO kill

switch in until the switch ’clicks’ and remains down

in the engaged position. The touch panel will

display the release E--Stop alarm, and the switch

will illuminate while engaged.

Restart PTO shafts: Push the center of the PTO

kill switch in until the switch ’clicks’, and release

the switch in the disengaged position. The light

will turn off and the touch panel will return to the

idle startup screen when the switch is disengaged.

Press the sweep switch or PTO switch to restart

the PTO shafts.

Centurion 331020 (11--03)

19

OPERATION

Home

Find...

Go To..

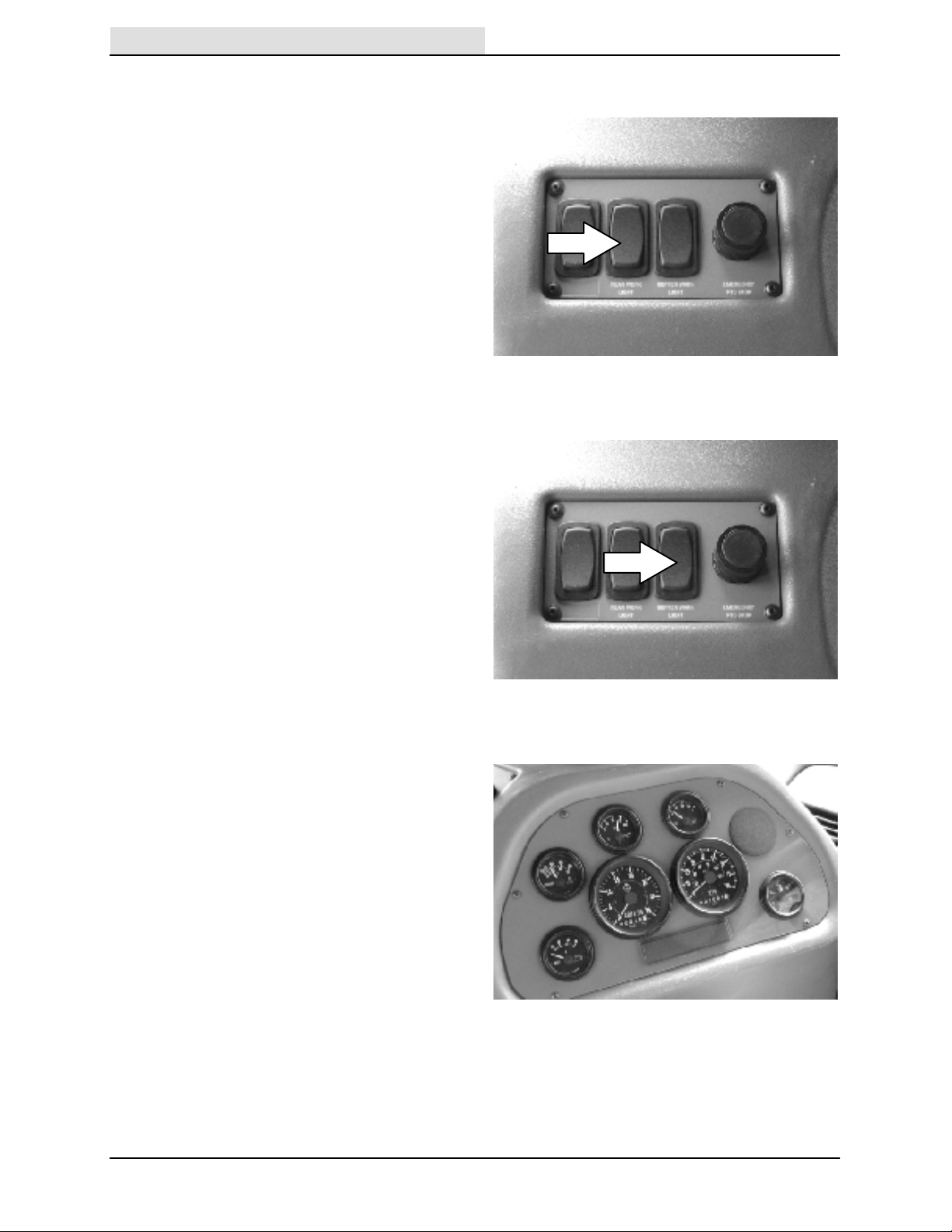

REAR WORK LIGHT SWITCH (OPTION)

The rear work light switch powers on and off the

rear work light.

On: Press the top of the rear work light switch.

The rear work light will come on.

Off: Press the bottom of the rear work light

switch. The rear work light will turn off.

HOPPER WORK LIGHT SWITCH (OPTION)

The hopper work light switch powers on and off

the hopper work light.

On: Press the top of the hopper work light switch.

The hopper work light will come on.

Off: Press the bottom of the hopper work light

switch. The hopper work light will turn off.

RIGHT SIDE INSTRUMENT CONSOLE

The right side instrument console is activated by

the operator control switch, and displays the

gauges for the machine operator sitting in the

right side operator’s compartment.

20

Centurion 331020 (11--03)

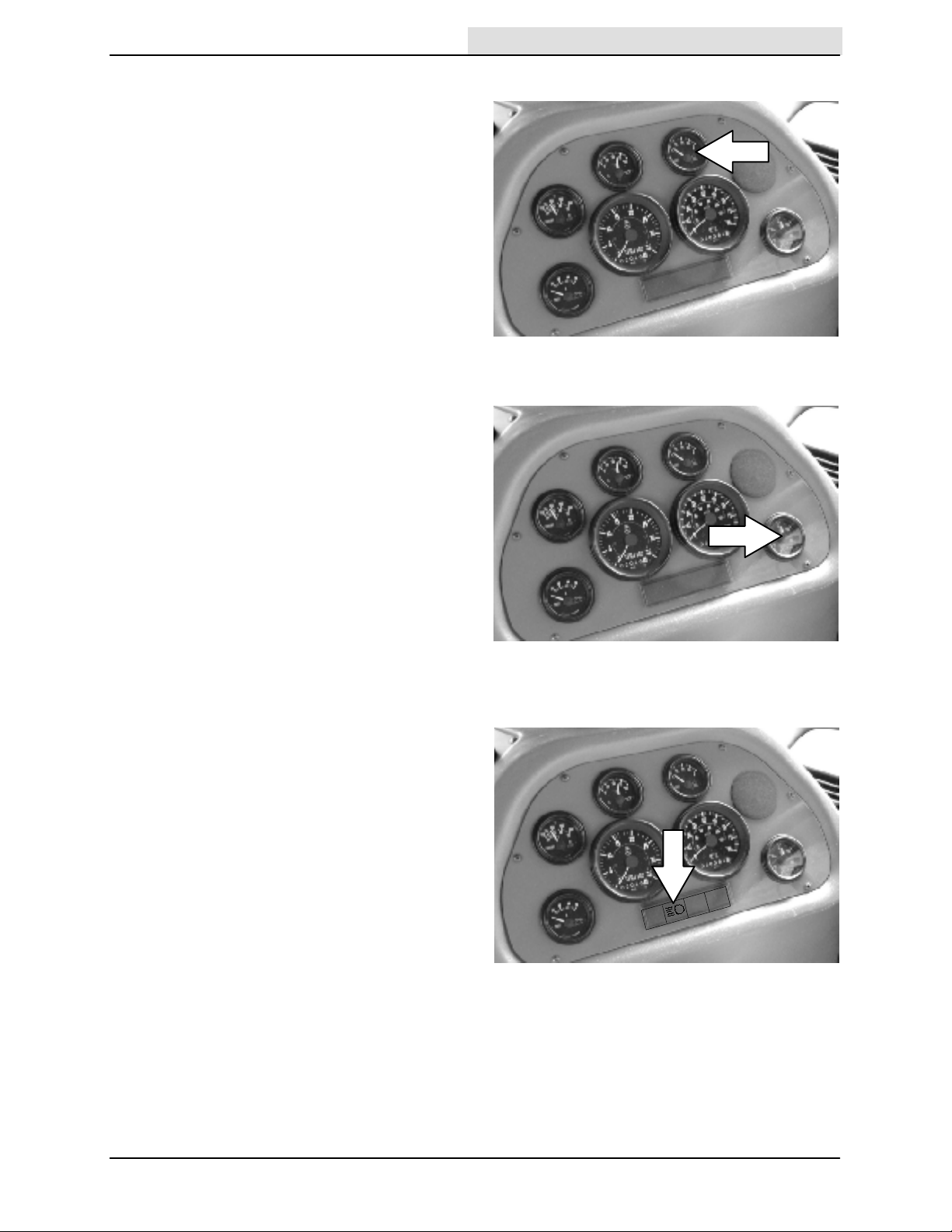

TACHOMETER

Home

Find...

Go To..

The tachometer shows the engine RPM. Increase

or decrease the throttle until the tachometer

shows the desired engine RPM for transporting or

sweeping.

NOTE: The REDUCE ENGINE RPM ALARM will

sound and appear if the engine speed is greater

than 950 RPM when starting the sweeping

system.

NOTE: The OVERSPEED, ENGINE ALARM will

sound and appear if the engine speed becomes

greater than 2200 RPM while sweeping.

There are three engine speed displays; Idle

Speed, Low Speed and Full Power. The displays

are shown on the bottom of the display panel, and

are used to help maintain the proper engine

speeds while using the different sweeping modes.

IDLE SPEED -- < 950 RPM

LOW SPEED -- 950 to 1175 RPM

StreetSmart

10:45

00000

00000

system

IDLE SPEED

OPERATION

MORE

FULL POWER -- > 1175 RPM

Refer to the SWEEP MODES section of the

manual for the recommended engine speeds of

each sweeping mode.

HOURMETER

The hourmeter records the number of hours the

machine has been operated. Use this information

to determine machine maintenance intervals. The

hourmeter is located on the bottom of the

tachometer gauge.

SPEEDOMETER

The speedometer displays the machine’s travel

speed. Use this for determining the proper

operating speed for sweeping and transporting.

Centurion 331020 (11--03)

21

OPERATION

Home

Find...

Go To..

ENGINE OIL PRESSURE GAUGE

The engine oil pressure gauge displays the engine

oil pressure. If the oil pressure f alls too low, stop

the engine, locate the problem and have it

corrected. Refer to the ENGINE OIL section of

the truck manuals for proper operation.

ENGINE COOLANT TEMPERATURE GAUGE

The engine coolant temper. If the engine coolant

temperature is too hot, or if the engine coolant

temperature gauge warning light comes on, stop

the engine, locate the problem and have it

corrected. Refer to the COO LING SYSTEM

section of the truck manuals for proper operation.

VOLTMETER

The voltmeter displays the existing voltage of the

battery. Normal voltage ranges between 12--14.5

volts. If the voltage falls too low, stop operating

the machine, locate the problem and have it

corrected.

22

Centurion 331020 (11--03)

FUEL LEVEL GAUGE

Home

Find...

Go To..

The fuel level gauge indicates how much fuel is in

the fuel tank.

NOTE: Do not let the fuel tank empty completely.

Air can enter the fuel system and require

bleeding, before the next engine start.

AIR BRAKE PRESSURE GAUGE

The air brake pressure gauge displays the air

brake reservoir pressure. If the air brake pressure

drops too low, an alarm will sound and the parking

brake will apply. Stop the machine, locate the

problem, and have it corrected. Refer to the AIR

BRAKE section of the truck manuals for proper

operation.

OPERATION

NOTE: An audible alarm will sound when the

machine is started, until the brake reservoir

pressure reaches the minimum tank pressure

required to release the parking brake.

BRIGHT HEADLIGHTS LIGHT

The bright headlights light comes on when the

headlights are on the bright setting.

Centurion 331020 (7-- 04)

23

OPERATION

Home

Find...

Go To..

PREHEAT LIGHT

The preheat light comes on when the ignition

switch is turned to the ON position. The light will

go out when the engine is ready to start, usually 5

to 30 seconds depending on the weather

conditions.

SIGNAL LIGHT

The signal light arrows flash when the turn signals

are used or when the 4--way warning lights are

on.

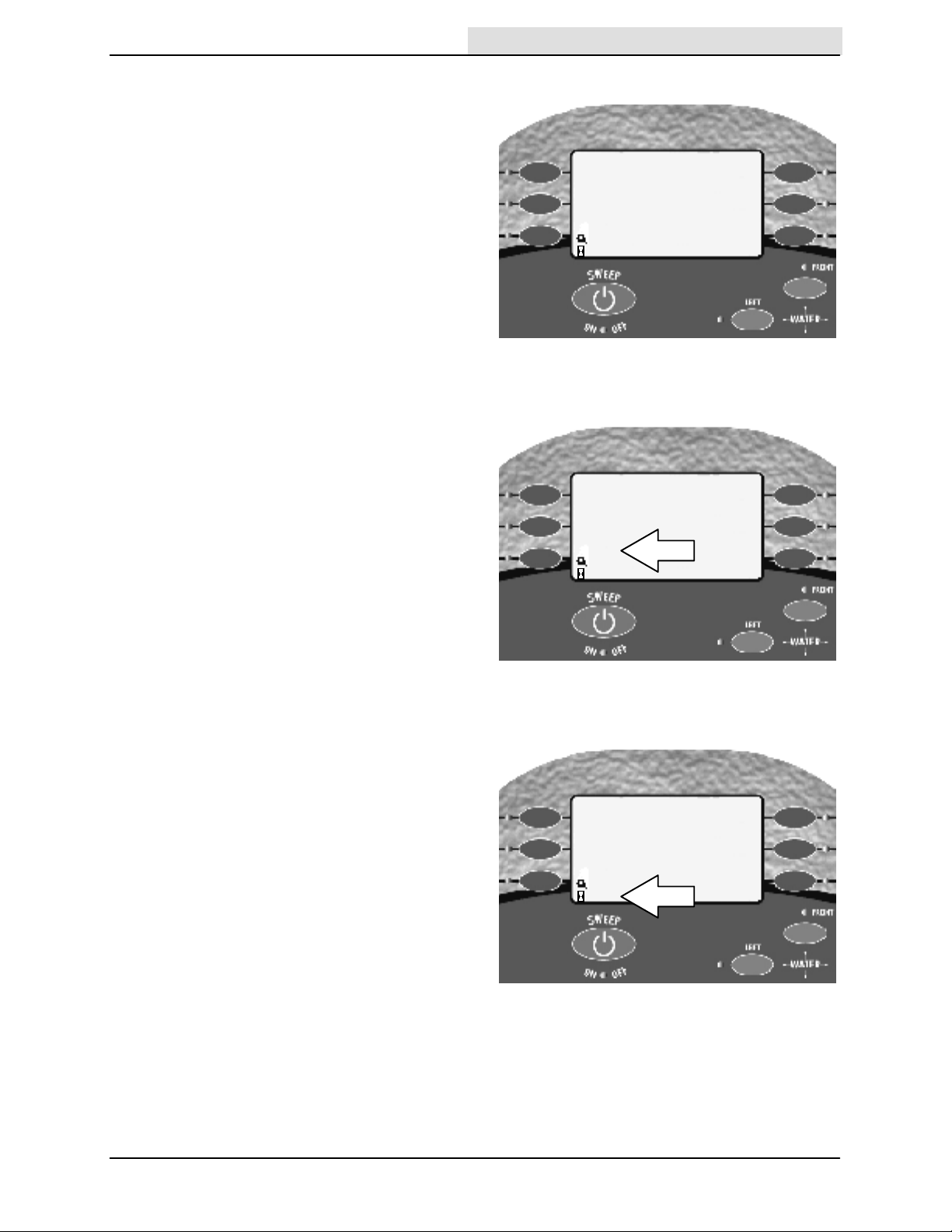

TOUCH PANEL

The touch panel contains the switches that control

the PTO, hopper and sweeping functions. It is

located on top of the console in the center of the

cab.

CONTRAST ADJUSTMENT KNOB

The contrast adjustment knob adjusts the contrast

on the display.

Adjust: Turn knob as necessary to adjust the

contrast on the display .

24

Centurion 331020 (7-- 04)

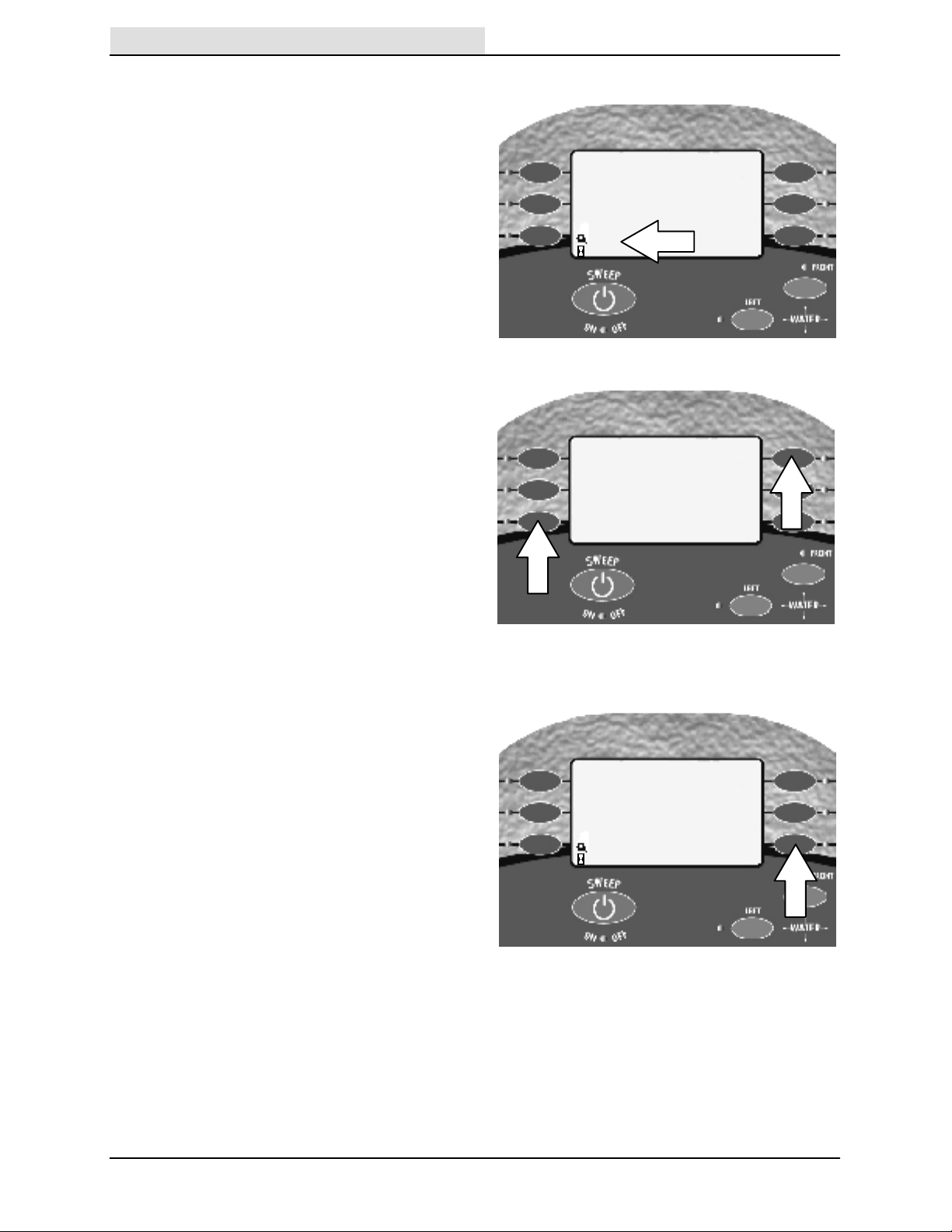

START UP SCREEN

Home

Find...

Go To..

The START UP screen appears on the display

screen when the machine is started. It displays

the display clock, hourmeter and the MORE

switch.

DISPLAY CLOCK

The display clock appears on the START UP

screen above the hourmeter, and shows the time

of day.

StreetSmart

10:45

00000

00000

OPERATION

system

MORE

PTO HOURMETER

The PTO hourmeter appears on the START UP

screen, and records the number of hours the

power take offs have been operating. Use this

information to determine machine maintenance

intervals.

StreetSmart

10:45

00000

00000

StreetSmart

10:45

00000

00000

system

MORE

system

MORE

Centurion 331020 (11--03)

25

OPERATION

Home

Find...

Go To..

BRUSH HOURMETER

The brush hourmeter appears on the START UP

screen, and records the number of hours the main

broom has been operating. Use this information to

determine machine maintenance intervals.

The display clock and brush hourmeter can

be set with the time adjust/brush hour reset

screen. Continue pressing the more switch to

cycle through the six operating screens until the

time adjust/brush hour reset screen appears.

Adjust the time using the buttons on either side of

the display panel.

StreetSmart

10:45

00000

00000

system

MORE

RESET BRUSH HR

MORE SWITCH

The MORE switch appears on the START UP

screen and the three operating screens. Press the

switch once to cycle to the next screen. The

switch will continue cycling through the five

screens each time it is pressed.

ADJUST TIME

StreetSmart

10:45

00000

00000

MORE

system

MORE

26

Centurion 331020 (11--03)

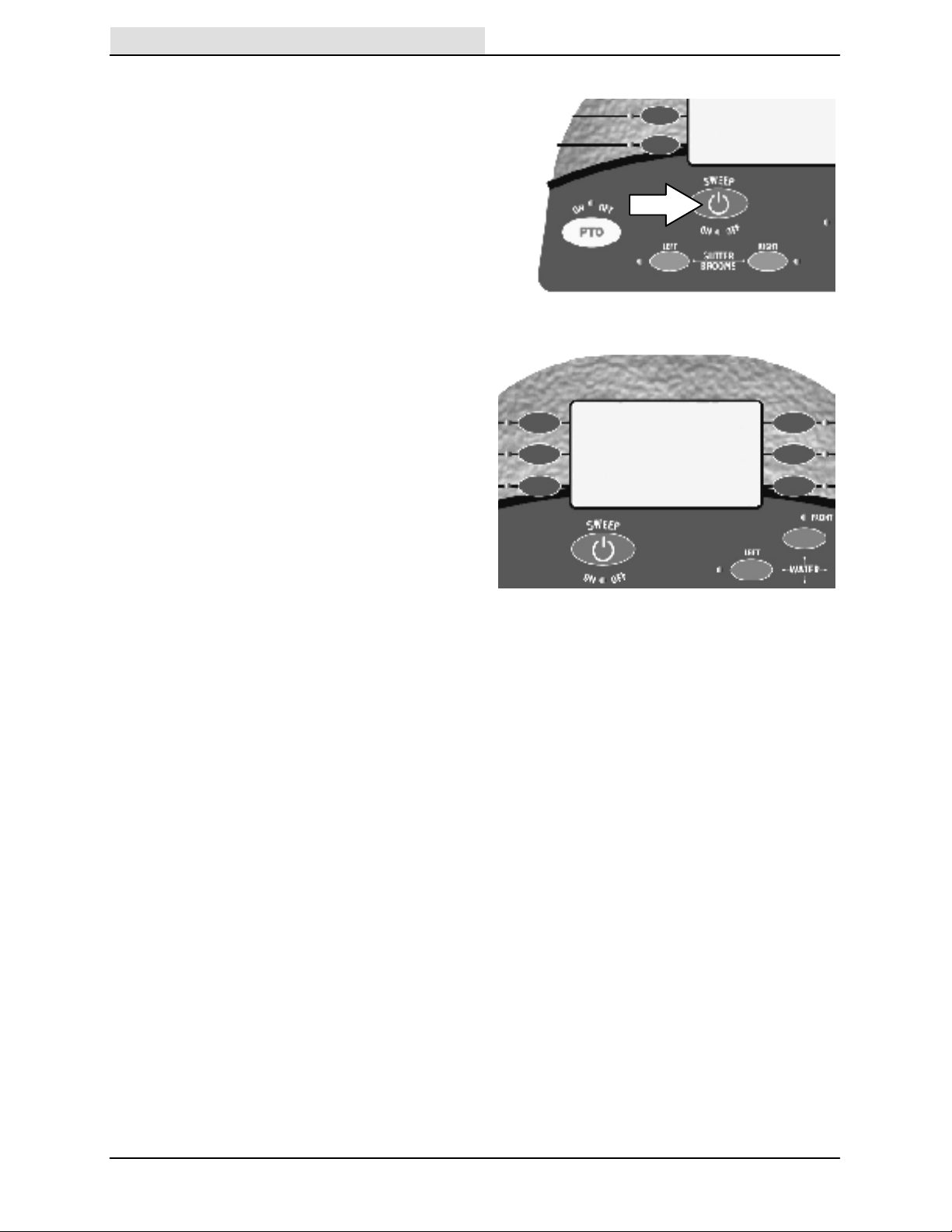

PTO SWITCH

Home

Find...

Go To..

The PTO switch controls the power take off. The

PTO drives the sweeping assembly and the

hopper lift. When the PTO is activated, the engine

idle speed will raise from 600 RPM to 850 RPM.

Keep the engine RPM below 950 RPM when

activating the PTO switch.

NOTE: The REDUCE ENGINE RPM ALARM will

sound and appear if the engine speed is greater

than 950 RPM when the PTO is engaged.

To start the PTO, press the PTO switch.The

touch panel will display the HOPPER MODE

screen and the light above the switch will come

on. The PTO will start and the idle speech will

increase

HOPPER UP

OPERATION

HOPPER DUMP

FAST IDLE

When the PTO or sweep switch is pressed while

the transmission is in neutral and the service

brake is depressed, the engine RPM will raise to

the fast idle setting of 1100 RPM.

The fast idle setting is useful for lifting the hopper

or starting the sweeping operations. The fast idle

is cancelled by pressing the service brake.

NOTE: The OVERSPEED, ENGINE ALARM will

sound and appear if the engine speed becomes

greater than 2200 RPM while the PTO is

engaged.

NOTE: The PTO shafts will automatically engage

when the sweep switch or the hopper up switch is

pressed.

The PTO will automatically shut off about two

minutes after the sweep switch is shut off.

To stop the PTO, check that the sweep switch is

off, and press the PTO switch again. The light

above the PTO switch will turn off.

HOPPER DOWN

F SHAKER

HOPPER HOME

MORE

NOTE: The ERROR--BROOMS DOWN ALARM

will sound and appear if you try to turn off the

PTO with the sweep switch on.

Centurion 331020 (7-- 04)

27

OPERATION

Home

Find...

Go To..

SWEEP SWITCH

The sweep switch starts and stops the sweeping

functions of the machine. These functions include

the vacuum fan, the main broom, the conveyor

and the gutter broom(s).

NOTE: The HOPPER UP ERROR ALARM will

sound and appear if the sweep switch or the

conveyor is activated with the hopper still in the

raised position. The sweep switch can NOT be

activated if any of the hopper control switches are

lit. The hopper must be closed and fully lowered

before sweeping.

To start the sweeping functions, press the sweep

switch. The touch panel will display a SWEEPER

TURNING ON message for a few seconds, and

then display the SWEEP MODE screen. The PTO

will automatically start and the engine idle will

increase.

The conveyor will lower and move in to the

sweeping position and the vacuum fan will turn

on. The lights next to these switches will come on.

The gutter broom(s), vacuum fan and water pump

will also automatically turn on with the sweep

switch IF they were in the on position when the

sweep switch was last turned off.

Sweep Mode

ECONOMY/LIGHT

SUPER SWEEP

WATER Main Broom

MEDIUM 100%

TANK = FULL

F SHAKER

VAC F AN

MORE

NOTE: The REDUCE ENGINE RPM ALARM will

sound and appear if the engine speed is greater

than 950 RPM when the PTO is engaged.

When the PTO or sweep switch is pressed while

the transmission is in neutral and the service

brake is not on, the engine RPM will raise to the

fast idle setting of 1100 RPM.

To stop and raise the sweeping functions, press

the sweep switch again. The lights next to these

sweeping function switches will turn off. The touch

panel will display a SWEEPER TURNING OFF

message for a few seconds, and then display the

SWEEP MODE screen.

NOTE: The sweep mode, water flow rate, gutter

broom(s), and vacuum fan will default to the last

setting used when the sweeping operations are

started again.

NOTE: For best slow speed sweeping results,

drive the machine in D1 (first gear) with the rear

axle in low range.

NOTE: The HOPPER FIRE ALARM will sound

and appear and the sweep functions will

automatically turn off when the Thermo Sentry

t

senses a possible fire in the hopper.

28

Centurion 331020 (7-- 04)

Loading...

Loading...