Tennant B10 User Manual

B10

Rider Burnisher

English EN

Operator Manual

QA ControlsSupervisor Settings

TennantTrue

To view, print or download

the latest manual, visit:

www.tennantco.com/manuals

Parts

North America / International

www.tennantco.com

9010734

Rev. 00 (01-2013)

INTRODUCTION

y

INTENDED USE

This manual is furnished with each new model.

It provides necessary operation and maintenance

instructions.

Read this manual completel

and

understand the machine before

operating or servicing it.

A complete illustrated Parts Manual is also furnished

with each new model. Use the Parts Manual to order

replacement parts. To ensure prompt delivery, follow

the “HOW TO ORDER PARTS” instructions printed in

the Parts Manual.

This machine will provide excellent service. However,

the best results will be obtained at minimum costs if:

S The machine is operated with reasonable care.

S The machine is maintained regularly - per the

maintenance instructions provided.

S The machine is maintained with manufacturer

supplied or equivalent parts.

To view, print or download manuals online visit

www.tennantco.com/manuals

PROTECT THE ENVIRONMENT

Please dispose of packaging materials

and used machine components such

as batteries in a safe environmentally

way according to your local waste

disposal regulations.

The B10 Rider Burnisher machine is intended for

commercial use, for example in hotels, schools,

hospitals, factories, shops, offices and rental

businesses. It is designed to burnish dry hard floor

surfaces in an indoor environment and is not

constructed for any other use. Use only recommended

burnishing pads intended for machine application. Do

not use this machine other than described in this

Operator Manual.

MACHINE DATA

IMPORTANT: To ensure full warranty protection, fill out

the attached MACHINE INSTALLATION / WARRANTY

REPORT REPL Y CARD and return to Tennant within

30 days of purchase.

Please fill out at time of installation

for future reference.

Model No. --

Serial No. --

Installation Date --

Always remember to recycle.

Tennant Company

PO Box 1452

Minneapolis, MN 55440

Phone: (800) 553--8033 or (763) 513--2850

www.tennantco.com

QA Contols and 1--STEP are US registered and unregistered trademarks of

Tennant Company.

Trojan and HydroLINK are registered trademarks of Trojan Battery Company.

Specifications and parts are subject to change without notice.

Original Instructions. Copyright E2012 Tennant Company.

All rights reserved. Printed in U.S.A.

2

Tennant B10 (01--2013)

TABLE OF CONTENTS

INTRODUCTION 2............................

INTENDED USE 2............................

MACHINE DATA 2............................

OPERATION

IMPORTANT SAFETY INSTRUCTIONS 4.......

SAFETY LABELS 6...........................

MACHINE COMPONENTS 7...................

CONTROL PANEL COMPONENTS 8...........

MACHINE INSTALLATION 9...................

UNCRATING MACHINE 9..................

BATTERY INSTALLATION 9................

HOW THE MACHINE WORKS 10...............

MACHINE SETUP 11..........................

INSTALLING BURNISHING PAD 1 1..........

INSTALLING DUST COLLECTION BAG 1 1....

MACHINE OPERATION 12.....................

PRE--OPERATION 12.......................

OPERATING THE MACHINE 12.............

EMERGENCY SHUT--OFF BUTTON 14.......

WHILE OPERATING THE MACHINE 14.......

QA CONTROLS SUPERVISOR SETTINGS 14

BATTERY CHARGE LEVEL INDICATOR 15...

HOUR METER 15..........................

CIRCUIT BREAKERS / FUSE 15.............

FAULT INDICATOR LIGHT AND FAULT

BEEP CODES 16..........................

CHARGING BATTERIES 17....................

BATTERY CHARGER 17....................

CHARGING BATTERIES 17.................

BATTERY CHARGER SETTINGS 19.........

BATTERY CHARGER ERROR CODES 20....

BATTERY CHARGER FUSE 20..............

MAINTENANCE

MAINTENANCE CHART 21.....................

MACHINE MAINTENANCE 22..................

AFTER EVERY USE 22.....................

AFTER WEEKLY USE 23...................

AFTER EVERY 50 HOURS OF USE 23.......

AFTER EVERY 200 HOURS OF USE 23......

BA TTER Y MAINTENANCE 24...................

SEALED AGM BATTERIES 24...............

WET/LEAD-- ACI D BATTERIES 24............

HYDROLINK

SYSTEM (OPTION) 24.....................

MACHINE JACKING 25........................

PUSHING, TOWING, AND

TRANSPORTING MACHINE 26.................

PUSHING OR TOWING THE MACHINE 26....

TRANSPORTING THE MACHINE 26.........

STORING MACHINE 26........................

TROUBLESHOOTING 27.......................

BATTERY WATERING

SPECIFICATIONS

GENERAL MACHINE

DIMENSIONS/CAPACITIES/PERFORMANCE 28..

MACHINE DIMENSIONS 29....................

Tennant B10 (01--2013)

3

OPERATION

IMPORTANT SAFETY INSTRUCTIONS -- SAVE THESE INSTRUCTIONS

The following warning precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

The following information signals potentially

dangerous conditions to the operator. Know when

these conditions can exist. Locate all safety devices on

the machine. Report machine damage or faulty

operation immediately.

WARNING: To Reduce the Risk of Fire,

Explosion, Electric Shock or Injury:

-- Read manual before opera ting machine.

-- Do not use or pick up flammable materials.

-- Do not use near flammable liquids, vapors or

combustible dusts.

This machine is not equipped with an

explosion proof motor. The electric motor will

spark upon start up and during operation

which could cause a flash fire or explosion if

machine is used in an area where flammable

vapors/liquids or combustible dusts are

present.

-- Batteries emit hydrogen gas. Explosion or fire

can result. Keep sparks and open flame away

when charging. Open battery compartment for

ventilation.

-- Disconnect battery cables and charger cord

before cleaning and servicing machine.

-- Do not charge batteries with damaged cord. Do

not modify plug.

If the charger supply cord is damaged or

broken, it must be replaced by the

manufacturer or its service agent or a similarly

qualified person in order to avoid a hazard.

The use of unapproved battery chargers may

damage the battery and potentially cause a fire

hazard.

-- Do not use outdoors or on wet surfaces. Store

indoors. This machine is for dry use only.

-- This machine is not suitable for picking up

hazardous dust.

FOR SAFETY:

1. Do not operate machine:

-- Unless trained and authorized.

-- Unless operator manual is read and

understood.

-- Unless mentally and physically capable of

following machine instructions.

-- Under the influence of alcohol or drugs.

-- While using a cell phone or other types of

electronic devices.

-- If not in proper operating condition.

-- In outdoor areas. This machine is for

indoor use only.

-- With pads or accessories not supplied or

approved by Tennant. The use of other

pads may impair safety .

-- In areas with possible falling objects.

-- In areas that are too dark to safely see the

controls or operate machine.

-- With brake disabled.

-- Without dust bag and/or filters in place.

2. Before operating machine:

-- Make sure all safety devices are in place

and operate properly.

-- Check brakes and steering for proper

operation.

-- Inspect charger cord regularly for signs of

damage or aging.

3. When operating machine:

-- Use only as described in this manual.

-- Report machine damage or faulty operation

immediately .

-- Reduce speed when turning.

-- Drive slowly on inclines and slippery

surfaces.

-- Do not operate on inclines that exceed a

7% grade level.

-- Keep all parts of body inside operator

station while machine is moving.

-- Do not carry passengers on machine.

-- Keep hands away from spinning pad.

-- Use care when reversing machine.

-- Never allow children to play on or around

machine.

-- Keep children and unauthorized persons

away from machine.

-- Do not allow to be used as a toy.

4

Tennant B10 (01--2013)

OPERATION

4. Before leaving machine:

-- Stop on level surface.

-- T urn off machine and remove key.

5. When servicing machine:

-- Disconnect battery cables and charger plug

before working on machine.

-- All work must be done with sufficient

visibility and lighting.

-- All repairs must be performed by a trained

service mechanic.

-- Use manufacturer supplied or approved

replacement parts.

-- Do not modify the machine from its original

design.

-- Avoid moving parts. Do not wear loose

clothing or jewelry. Secure long hair when

working around machinery.

-- Do not disconnect the off--board charger’s

DC cord from the machine’s receptacle

when the charger is operating. Arcing may

result. If the charger must be interrupted

during charging, disconnect the AC power

supply cord first.

-- Keep work area well ventilated.

-- Avoid contact with battery acid.

-- Do not power spray or hose off machine.

-- Do not push or tow the machine on inclines

with the brake disabled.

-- Jack machine up at designated locations

only. Block machine up with jack stands.

-- Block machine tires before jacking machine

up.

-- Use jack or hoist that will support machine

weight.

-- Wear appropriate personal protection

equipment as needed and where

recommended in this manual.

6. When loading/unloading machine onto/off

truck or trailer:

-- Use a ramp that can support the machine

weight and operator.

-- Do not operate the machine on a ramp

incline that exceeds a 19.5% grade level.

-- Use a winch if ramp incline exceeds a

19.5% grade level.

-- Do not push or tow the machine on inclines

with the brake disabled.

-- Lower the pad driver after loading.

-- T urn machine off.

-- Block machine wheels.

-- Use tie--down straps to secure machine.

For Safety: wear protective gloves.

For Safety: wear eye protection.

For Safety: wear protective dust mask.

Tennant B10 (01--2013)

5

OPERATION

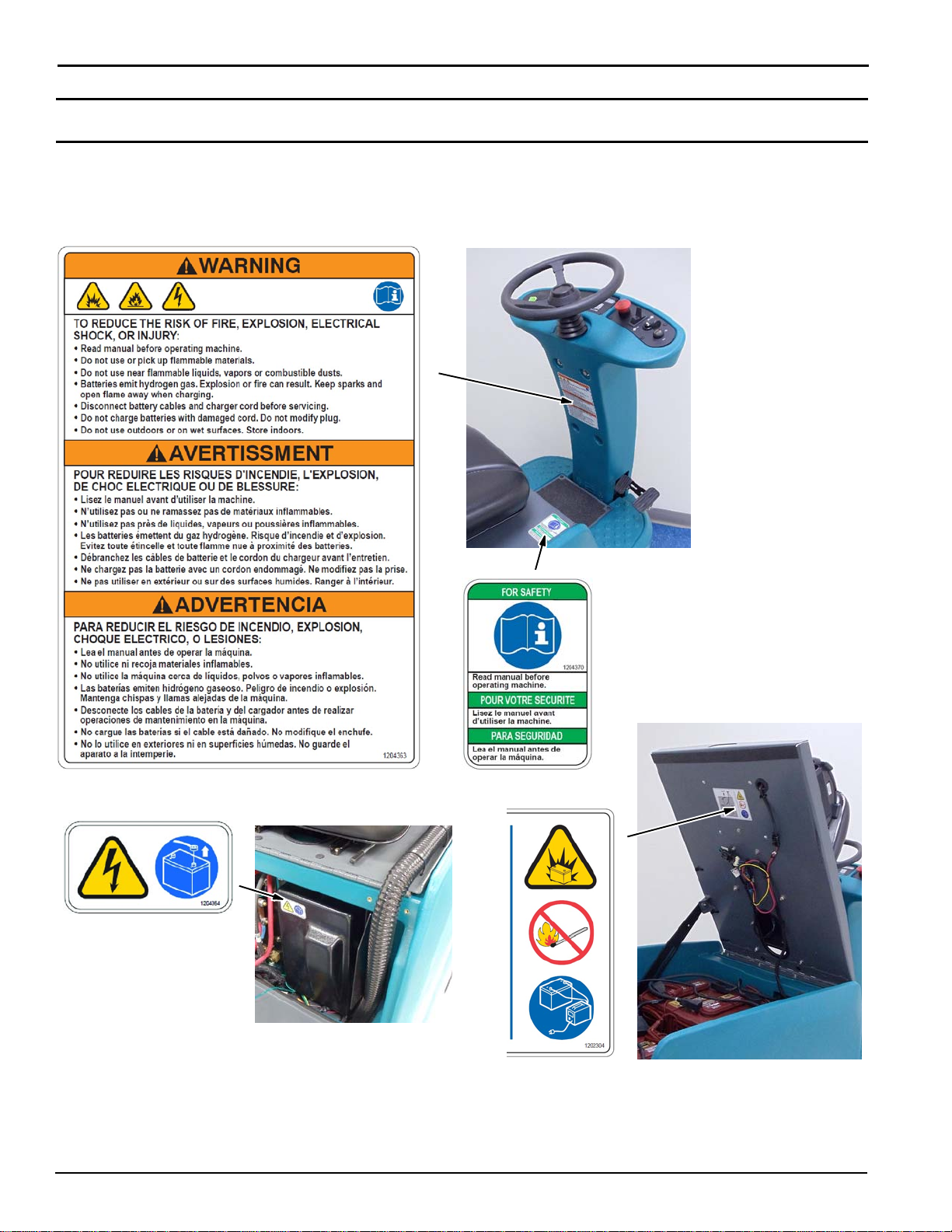

SAFETY LABELS

The safety labels appear on the machine in the locations indicated. Replace labels if they are missing or become

damaged or illegible.

WARNING LABEL -- Located on steering column.

WARNING LABEL -Disconnect battery

cables before servicing

machine.

-- Located behind kick

panel on control board

cover.

FOR SAFETY LABEL -Read manual before

operating machine.

-- Located on seat panel

WARNING LABEL -Batteries emit hydrogen gas. Explosion or fire

can result. Keep sparks and open flame away

when charging.

-- Located on backside of seat panel.

6

Tennant B10 (01--2013)

MACHINE COMPONENTS

OPERATION

10

2

11

1

12 15

13

14

17

9

16

18

19

20

3

4

5

6

7

8

1. Control Panel

2. Steering Wheel

3. Adjustable Operator Seat

4. Hour Meter

5. Circuit Breaker Panel

6. Burnishing Head

7. Dust Control Skirt

8. Propel Pedal

9. Brake Pedal

10. Stabilizer Arm

1 1. Propel Wheel

12. Off--board Battery Charger Receptacle

13. Flashing Safety Light (Option)

14. Active Dust Collection Vacuum

15. Operator Station Step

16. Vacuum Hose Connector

17. Battery Compartment

18. On--board Battery Charger

19. On--board Battery Charger Cord Storage Hooks

20. Anti--static Strap

n/s. Wall Roller (Option)

Tennant B10 (01--2013)

7

OPERATION

CONTROL PANEL COMPONENTS

1312 14

8910114261

573

1. 1--STEPt Burnishing Button

2. Pad Change Button

3. Vacuum Button

4. Pad Pressure Increase Button (+)

5. Pad Pressure Decrease Button (--)

6. Speed Increase Button (+)

7. Speed Decrease Button (--)

8. Emergency Stop Button

9. Forward/Reverse Directional Switch

10. Horn Button

1 1. Main Power On/Off Key Switch

12. QA Supervisor Controls Indicator (Lock--out)

13. Battery Discharge Level Indicator

14. Machine Fault Indicator

8

Tennant B10 (01--2013)

MACHINE INSTALLATION

UNCRA TING MACHINE

1. Carefully check machine for signs of damage.

Report damages at once to carrier.

2. Check the contents list. Contact distributor or

Tennant for missing items.

Contents:

D Burnishing Pad (pre--installed)

D Dust Collection Bag:

1 paper & 1 cloth bag pre--installed

D 6 Batteries (pre-installed Option)

D 5 Battery Cables

D 12 Battery Post Rubber Boots

D Battery Tray

D 6 Foam Battery Spacers

D 2 Battery Straps

D Battery Watering System (pre--installed Option)

D Off--Board Battery Charger (Optional)

D Operator Training DVD

D Parts Manual

D Use & Care Guide Wall Chart

3. To uncrate the machine, remove the shipping

hardware that secures the machine to the pallet.

Using the supplied ramp carefully back the

machine off the pallet. Make sure the burnishing

head is in the raised position. If machine shipped

without batteries installed see BATTERY

INSTALLATION below.

ATTENTION: Do not drive machine off pallet

without using the ramp, machine damage may

occur.

OPERATION

1. Park the machine on a level surface and remove

the key.

2. Lift the operator seat forward until the support arm

bracket engages (Figure 1).

FIG. 1

3. Remove the rear battery access panel from the

machine (Figure 2). Philips screwdriver required.

FIG. 2

4. With adequate assistance carefully install the

batteries into the battery compartment (Figure 3).

Arrange the batteries as shown in Figure 4. Secure

the batteries in place with the battery straps

provided.

BATTERY INSTALLATION

If the machine was shipped without batteries pre--installed

carefully install batteries as described below.

Contact distributor or Tennant for battery

recommendations if machine is not equipped with the

following batteries.

Battery Specifications:

Six 6 volt, deep cycle, 435 AH wet lead acid batteries

(Standard).

Six 6 volt, deep cycle, 390AH AGM sealed batteries

(Optional).

FOR SAFETY: When servicing machine, wear

appropriate personal protection equipment as

needed. Avoid contact with battery acid.

Tennant B10 (01--2013)

FIG. 3

5. Replace the rear battery access panel after

installing batteries.

6. To keep the batteries from moving, position the

supplied foam battery spacers around the batteries

as shown (Figure 4).

9

Loading...

Loading...