Tennant 9007655, 9007471 User Manual

V- WD- 16B

V- WD- 61B

Battery Wet/Dry Vacuum

Batería en asp iración húmeda/seca

Batterie Aspirateur à Sec/humide

バッテリー式ウエットドライ掃除機

Operator Manual EN

Manual del Operario ES

Opérateur Manuel FR

取扱説明書 JP

Model Part No.:

9007471 - V-WD-16B

9007655 - V-WD-61B

www.tennantco.com

www.nobles.com

9007530

Rev. 02 (06-2014)

*9007530*

EN OPERATION

This manual is furnished with each new model.

It provides necessary operation and maintenance

instructions.

Read this manual completely and understand the

machine before operating or servicing it.

This machine will provide excellent service. However,

the best results will be obtained at minimum costs if:

S The machine is operated with reasonable care.

S The machine is maintained regularly - per the

machine maintenance instructions provided.

MACHINE DATA

Please fill out at time of installation

for future reference.

Model No. -

Serial No. -

Machine Options -

S The machine is maintained with

manufacturer- supplied or equivalent parts.

Parts and supplies may be ordered online, by phone,

byfaxorbymail.

UNCRA TING MACHINE: Carefully check carton for

signs of damage. Report damages at once to carrier.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials

and old machine components in an environmentally safe way according to local waste disposal regulations.

Always remember to recycle.

Sales Rep. -

Sales Rep. phone no. -

Customer Number -

Installation Date -

TABLE OF CONTENTS

SAFETY PRECAUTIONS 3....................

SAFETY LABELS 4...........................

MACHINE COMPONENTS 5...................

MACHINE INSTALLATION 6...................

MACHINE SETUP 8..........................

MACHINE OPERATION 8.....................

DRAINING RECOVERY TANK 9................

CHARGING BATTERIES 10....................

MACHINE MAINTENANCE 11..................

TRANSPORTING MACHINE 13.................

STORING MACHINE 13........................

RECOMMENDED STOCK ITEMS 13.............

TROUBLE SHOOTING 14......................

MACHINE SPECIFICATIONS 15................

MACHINE DIMENSIONS 15....................

Tennant Company

PO Box 1452

Minneapolis, MN 55440 USA

Phone: (800) 553- 8033 or (763) 513- 2850

www.tennantco.com

www.nobles.com

Specifications and parts are subject to change without notice.

Copyright E 2010, 2014 TENNANT Company. All rights reserved.

2

V- WD- 16B / V- WD- 61B (06- 2014)

SAFETY PRECAUTIONS

OPERATION EN

The following information signals potentially

dangerous conditions to the operator or

equipment:

This machine is intended for commercial use.

It is designed for wet/dry vacuuming in an indoor

environment and is not constructed for any other

use. Use only recommended accessory tools.

All operators must read, understand and practice

the following safety precautions.

The following warning alert symbol and the “FOR

SAFETY” heading are used throughout this manual as

indicated in their description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

Failure to follow these warnings may result in:

personal injury, electrical shock, fire or explosion.

WARNING: Fire Or Explosion Hazard:

- Do Not Operate Machine In Or Near Flammable

Liquids, Vapors Or Combustible Dusts.

This machine is not equipped with an explosion

proof motor. The electric motor will spark upon start

up and during operation which could cause a flash

fire or explosion if machine is used in an area

where flammable vapors/liquids or combustible

dusts are present.

- Do Not Pick Up Flammable Or Toxic Materials,

Burning Or Smoking Debris.

- Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

WARNING: Electrical Shock Hazard.

Disconnect Battery Cables Before Servicing

Machine.

FOR SAFETY:

1. Do not operate machine:

- With flammable liquids or near flammable

vapors as an explosion or flash fire may

occur.

- Unless trained and authorized.

- Unless operator manual is read and

understood.

- If not in proper operating condition.

- In standing water.

- Without bag and/or filters in place.

2. Before operating machine:

- Make sure all safety devices are in place

and operate properly.

3. When using machine:

- Do not pick up burning or smoking debris,

such as cigarettes, matches or hot ashes.

- Report machine damage or faulty operation

immediately.

- Never allow children to play on or around.

4. Before leaving or servicing machine:

- Stop on level surface.

- Turn machine off.

5. When servicing machine:

- Disconnect battery connections before

working on machine.

- Wear protective gloves and eye protection

when handling batteries or battery cables.

- Avoid contact with battery acid.

- Use manufacturer supplied or approved

replacement parts.

- Allrepairsmustbeperformedbya

qualified service person.

- Do not modify the machine from its original

design.

6. When transporting machine:

- Turn machine off.

- Do not lift machine when batteries are

installed.

- Get assistance when lifting machine.

- Use a recommended ramp when

loading/unloading on/off truck or trailer.

- Use tie- down straps to secure machine to

truck or trailer.

V- WD- 16B / V- WD- 61B (04- 10)

3

EN OPERATION

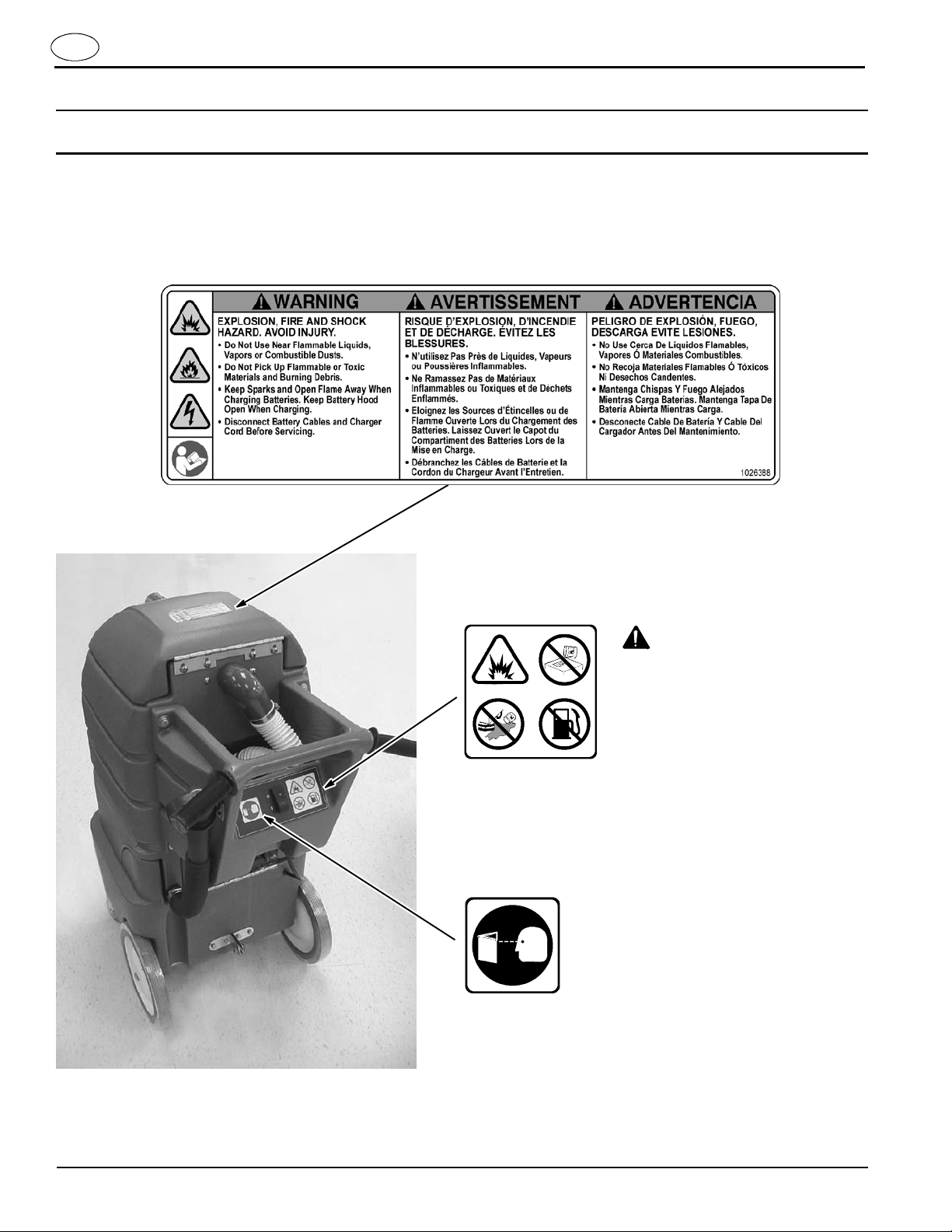

SAFETY LABELS

The safety labels appear on the machine in the locations indicated. Replace labels if they are missing or become

damaged or illegible.

WARNING LABEL - LOCATED ON TOP OF THE MACHINE.

WARNING LABEL -

LOCATED ON BACK SIDE OF MACHINE.

WARNING: FAILURE TO

FOLLOW THESE WARNINGS

MAY RESULT IN: PERSONAL

INJURY, ELECTRICAL SHOCK,

FIRE OR EXPLOSION.

Do Not Operate Machine In Or

Near Flammable Liquids,

Vapors Or Combustible Dusts.

Do Not Pick Up Flammable Or

Toxic Materials, Burning Or

Smoking Debris.

FOR SAFETY LABEL

- LOCATEDONBACK

SIDE OF MACHINE.

FOR SAFETY:

Read the owner’s manual

before using machine.

4

V- WD- 16B / V- WD- 61B (04- 10)

MACHINE COMPONENTS

OPERATION EN

3

7

6

8

2

1

3

5

11

4

9

10

13

12

1. Bag Compartment Cover

2. Vacuum Hose Snout

3. Control Grips

4. 145 cm (57 in) Vacuum Hose

5. Vacuum Bag Compartment /

Recovery Tank

6. Battery Compartment

7. Compartment Latches

8. Swivel Casters & 300 mm (12 in) Rear Wheels

9. Squeegee Kit (Optional)

14

10. Machine ON/OFF Switch

1 1. Drain Hose

12. Squeegee Kit Lift Pedal (Optional)

13. Charger Plug

14. 3 m (10 ft) Vacuum Hose

V- WD- 16B / V- WD- 61B (04- 10)

5

EN OPERATION

MACHINE INSTALLATION

UNCRA TING MACHINE

Carefully check carton for signs of damage. Report

damages at once to carrier.

Check Machine Contents to ensure package is

complete. Contact distributor for missing items.

Machine Contents:

1 - Battery Cable #130364

4 - Battery Post Caps #45962

4 - Black Battery Boots #611221

1 - 3m (10 ft) Vacuum Hose #160481

1 - 145 cm (57 in) Vacuum Hose #1014026

1 - Paper Bag #1068846

1 - Cloth Bag #900105

2 - 12VDC 105AH Batteries #578426 (included with

machine PAC #9007471)

1 - Battery Charger, 24DC/11A 120V #1073638

(included with machine PAC #9007471)

NOTE: Squeegee and Accessory Tools Kits are

optional, they must be ordered separately (See

OPTIONS section).

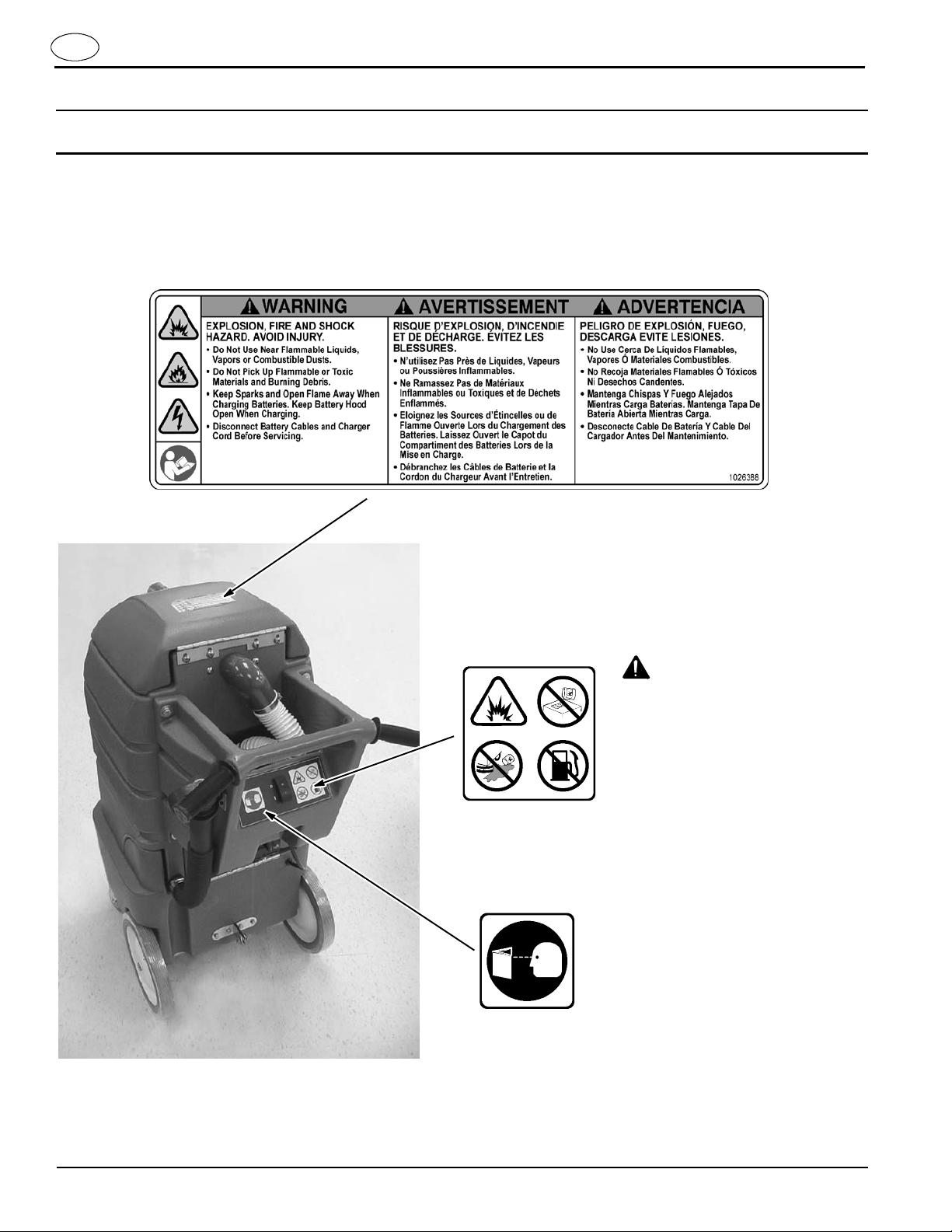

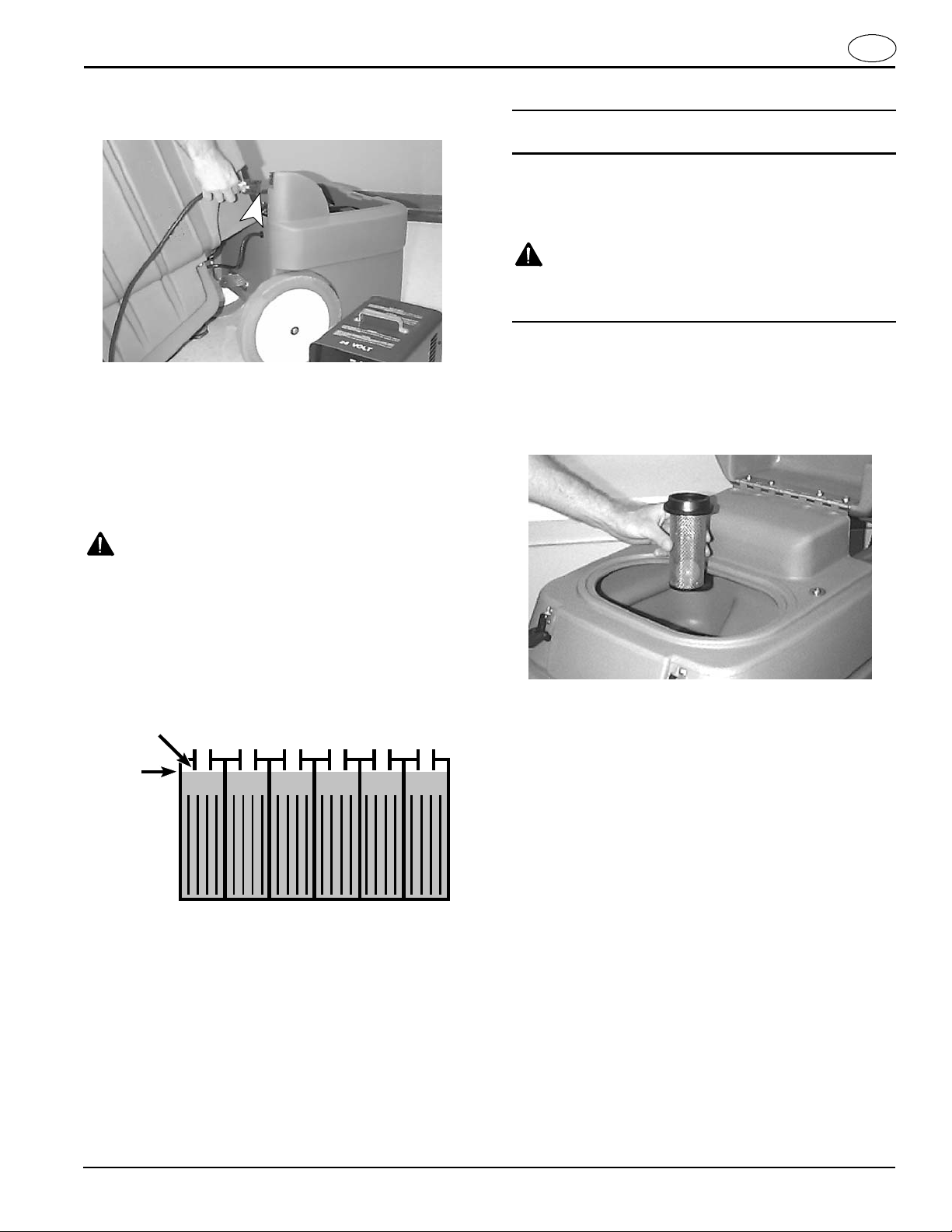

2. Open battery compartment, unlatch lower latches

and carefully tilt upper housing backwards to floor.

Remove loose battery cables at bottom of

compartment (Figure 1).

FIG. 1

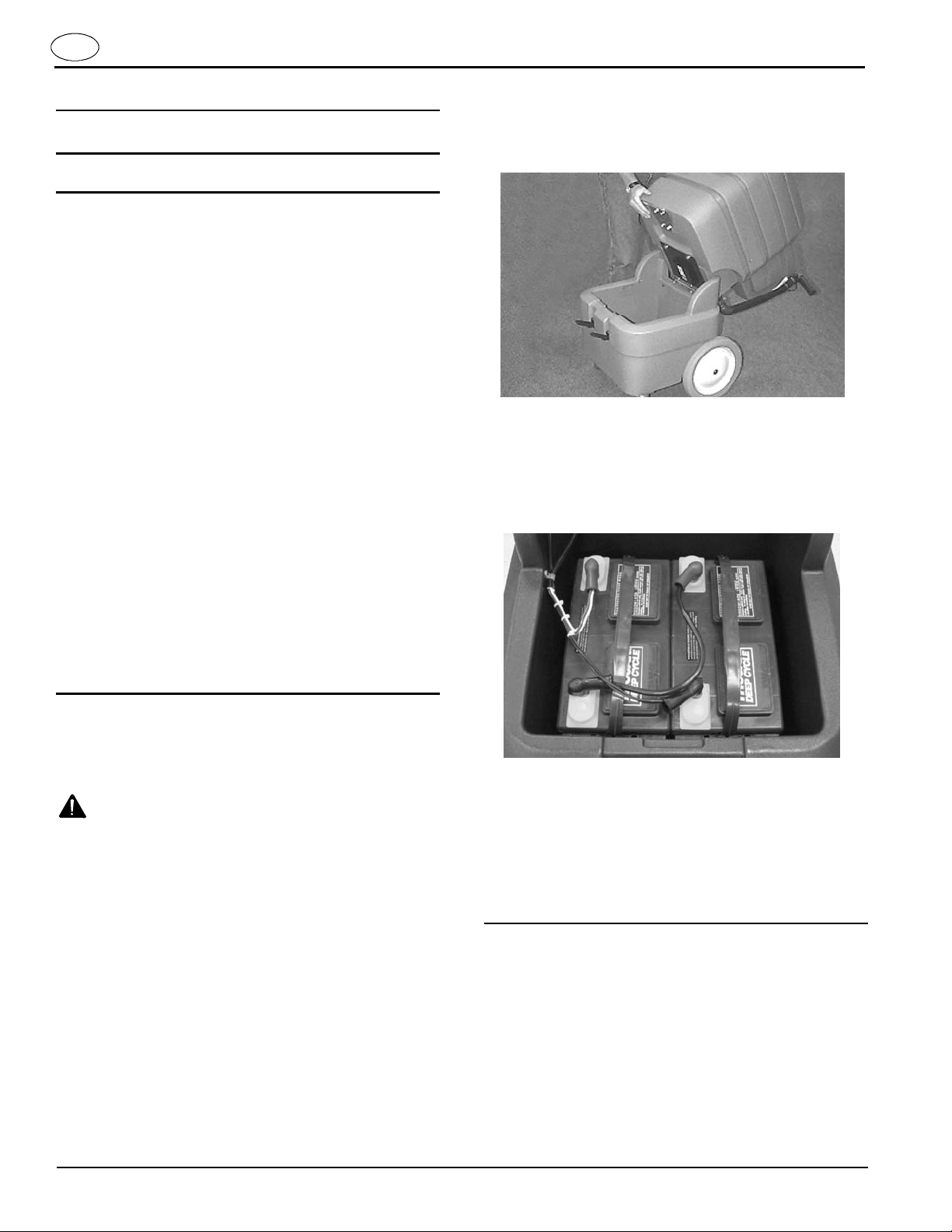

3. Carefully install batteries into compartment and

arrange battery posts as shown. Connect the

battery cables to the battery posts as shown, RED

TO POSITIVE & BLACK TO NEGATIVE. Use the

battery post covers and rubber boots supplied

(Figure 2).

(+)

(- )

(+)

(- )

INSTALLING BATTERIES

NOTE: If planning to install Optional Squeegee Kit, wait

to install the batteries until kit is installed

(See ATTACHING OPTIONAL SQUEEGEE KIT).

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries or battery cables. Avoid contact

with battery acid.

Recommended Battery Specifications:

Two 12 volt 105/130 amp hour deep cycle batteries.

Maximum battery dimensions are 340 mm (13.5 in) L x

180 mm (7 in) W x 250 mm (10 in) H.

1. Turn ON/OFF switch to off.

A TTENTION: Make sure tanks are empty before

opening.

FIG. 2

ATTENTION: Do not drop batteries into

compartment. Battery and machine housing

damage may result.

4. Apply a light coating of non- metallic grease or

protective spray on the cable connections to

prevent battery corrosion.

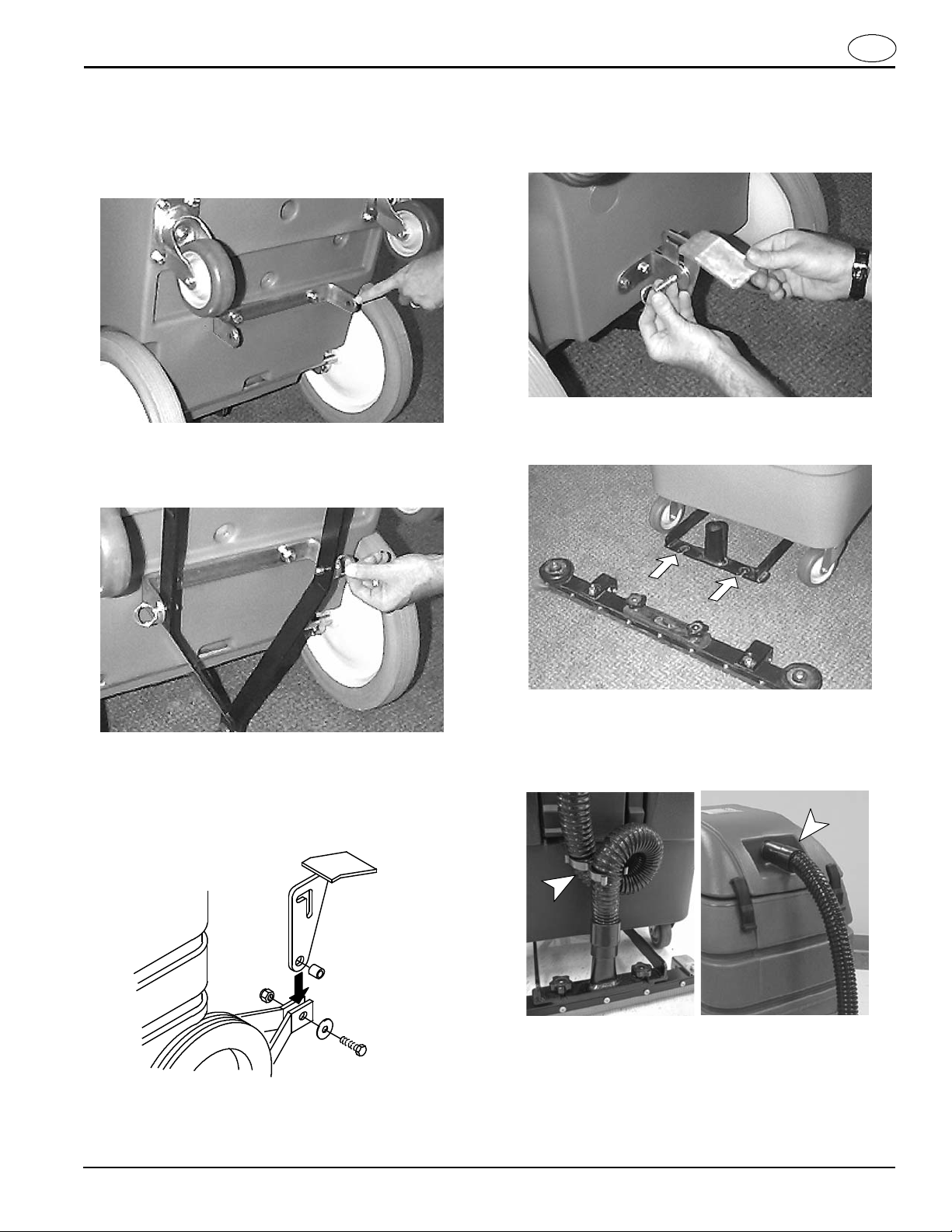

A TTACHING OPTIONAL SQUEEGEE KIT

NOTE: Kit installation is made easy if batteries are not

installed. However, kit can be installed with batteries in

place.

1. Remove vacuum bags and/or empty recovery tank.

2. Tip machine on backside - only if batteries are

removed from machine.

6

V- WD- 16B / V- WD- 61B (06- 2014)

OPERATION EN

3. Remove two unused squeegee mounting screws

from bottom of machine.

4. Install squeegee mounting bracket as shown.

Secure with screw and washers that you removed

(Figure 3).

FIG. 3

5. Fasten squeegee bracket to mounting bracket. Use

two (2) clevis and cotter pins provided

(Figure 4).

8. Slide pedal between the two mounting arms on

back of machine. Align and insert clevis pin through

arms and slot in pedal, secure with cotter pin

(Figure 6).

FIG. 6

9. Attach squeegee assembly to bracket as shown

and secure with two thumb screws (Figure 7).

FIG. 4

6. Stand machine upright.

7. Insert spacer through hole in pedal then position

pedal between two holes in squeegee bracket.

Secure with hardware provided (Figure 5).

FIG. 5

FIG. 7

10. Connect the 145 cm (57 in) vacuum hose to the

squeegee assembly and to cover snout

. Loop the

hose as shown using the hose clip provided (Figure

8).

FIG. 8

V- WD- 16B / V- WD- 61B (04- 10)

7

EN OPERATION

MACHINE SETUP

WET VACUUMING

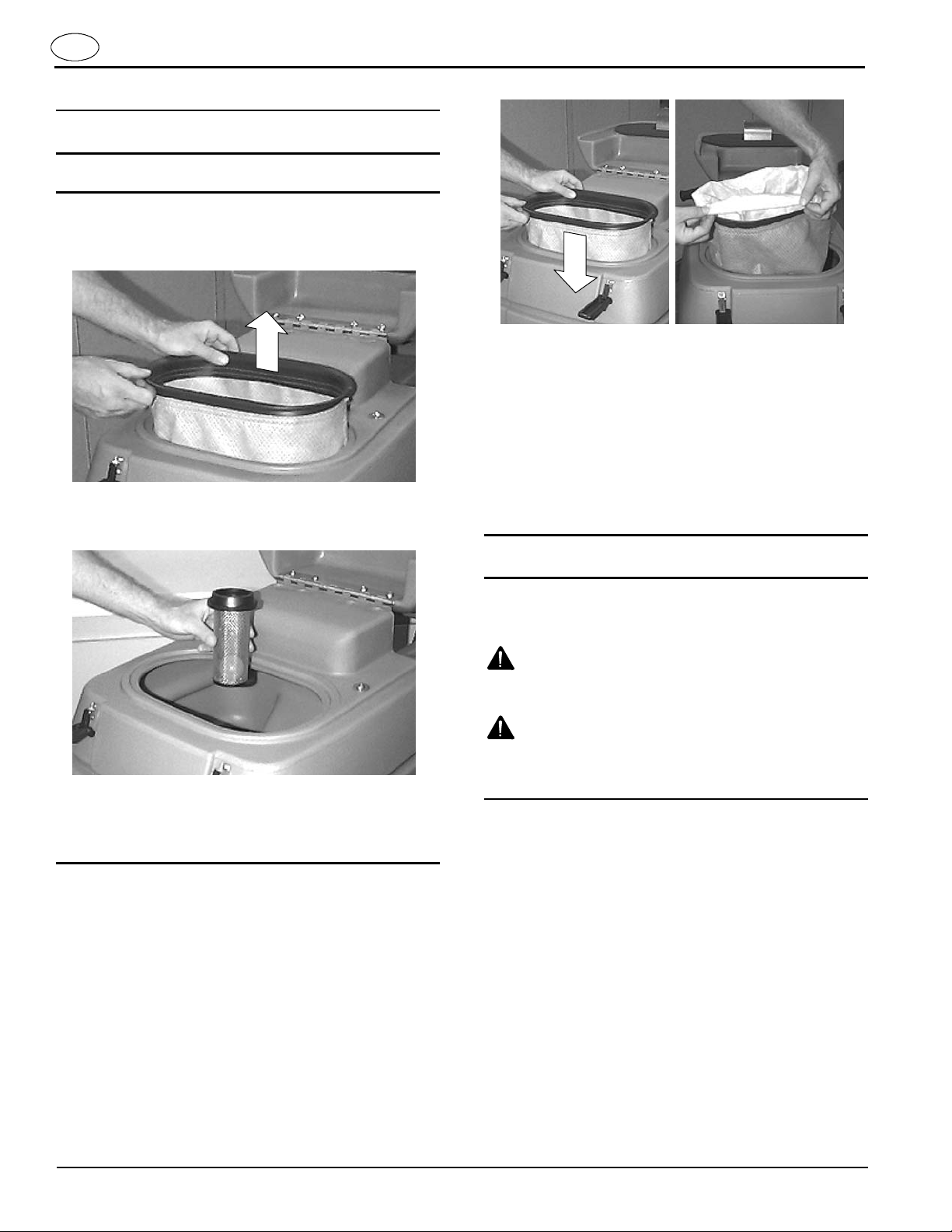

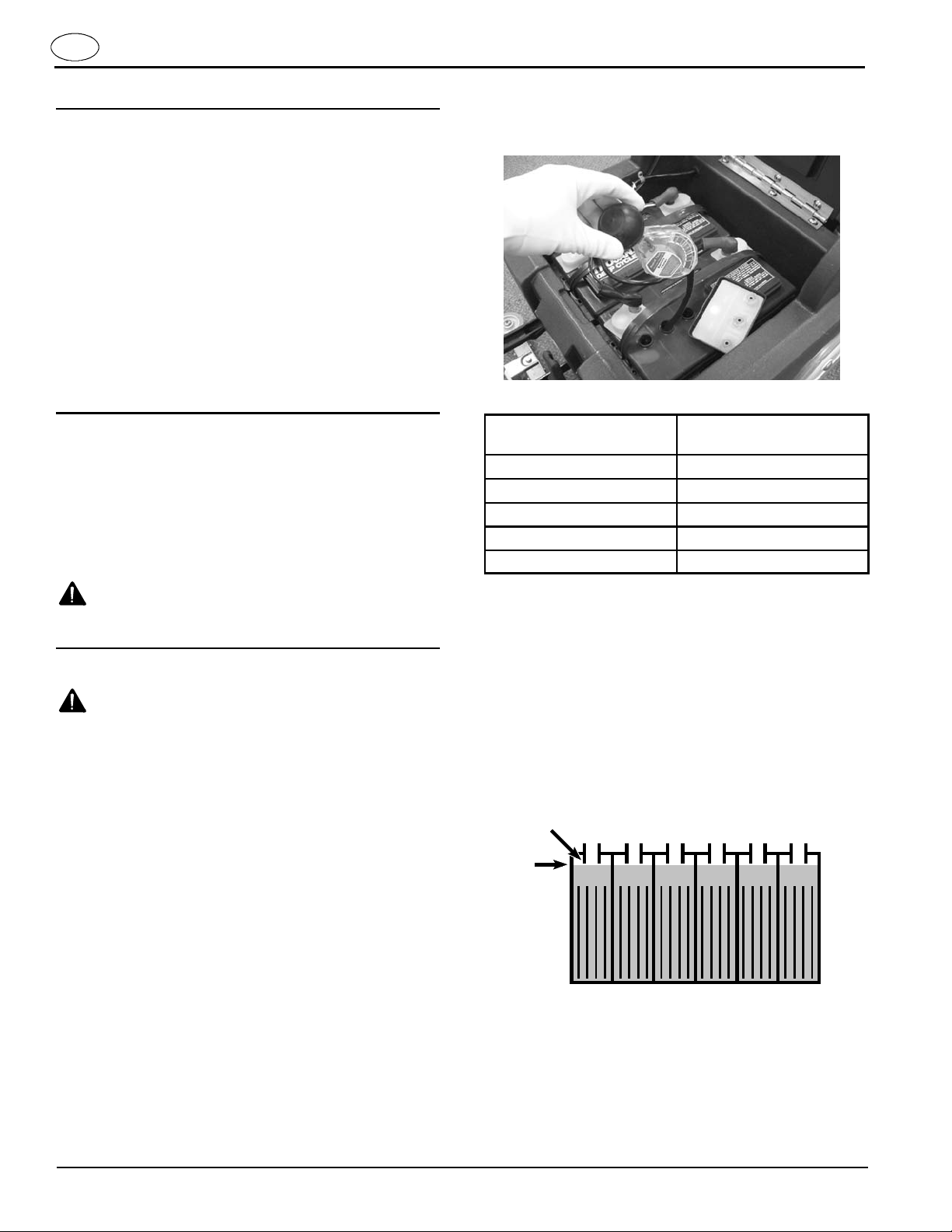

1. Open machine cover and remove vacuum bag from

recovery tank (Figure 9).

FIG. 9

2. Make sure automatic float shut-off screen is in

place (Figure 10).

FIG. 11

A TTENTION: Always make sure that a bag is in

place before dry vacuuming. Operating machine

without bag in place will damage vacuum motor.

This damage is NOT covered by warranty.

2. Close cover and fasten latches.

3. Leave automatic float shut- off screen in place

when dry vacuuming. It can provide limited vacuum

motor protection for a faulty bag.

MACHINE OPERATION

FIG. 10

A TTENTION: To prevent vacuum motor damage,

automatic float shut-off screen must be in place.

DRY VACUUMING

1. Open machine cover and install cloth filter bag,

make sure that the bag edge is properly seated on

compartment rim (Figure 11).

For easy debris disposal and to increase the life of

cloth filter bag, use a paper vacuum bag with the

cloth bag. Place the paper bag inside of cloth bag

and tuck the top of paper bag around outside rim of

cloth bag. Never use paper bag without cloth filter

bag in place. Do not reuse paper bags - always

dispose.

FOR SAFETY: Do not operate machine unless

operator manual is read and understood.

WARNING: Fire Or Explosion Hazard. Do Not

Operate Machine In Or Near Flammable Liquids,

Vapors Or Combustible Dusts.

WARNING: Fire Or Explosion Hazard. Do Not

Pick Up Flammable Or Toxic Materials, Burning Or

Smoking Debris.

VACUUM MOTOR THERMAL PROTECTOR

The vacuum motor is thermally protected by a

temperature sensor device. It will trip if motor has an

overload. If motor should quit, wait 20 minutes for

motor to cool and remove obstruction before

continuing.

8

V- WD- 16B / V- WD- 61B (04- 10)

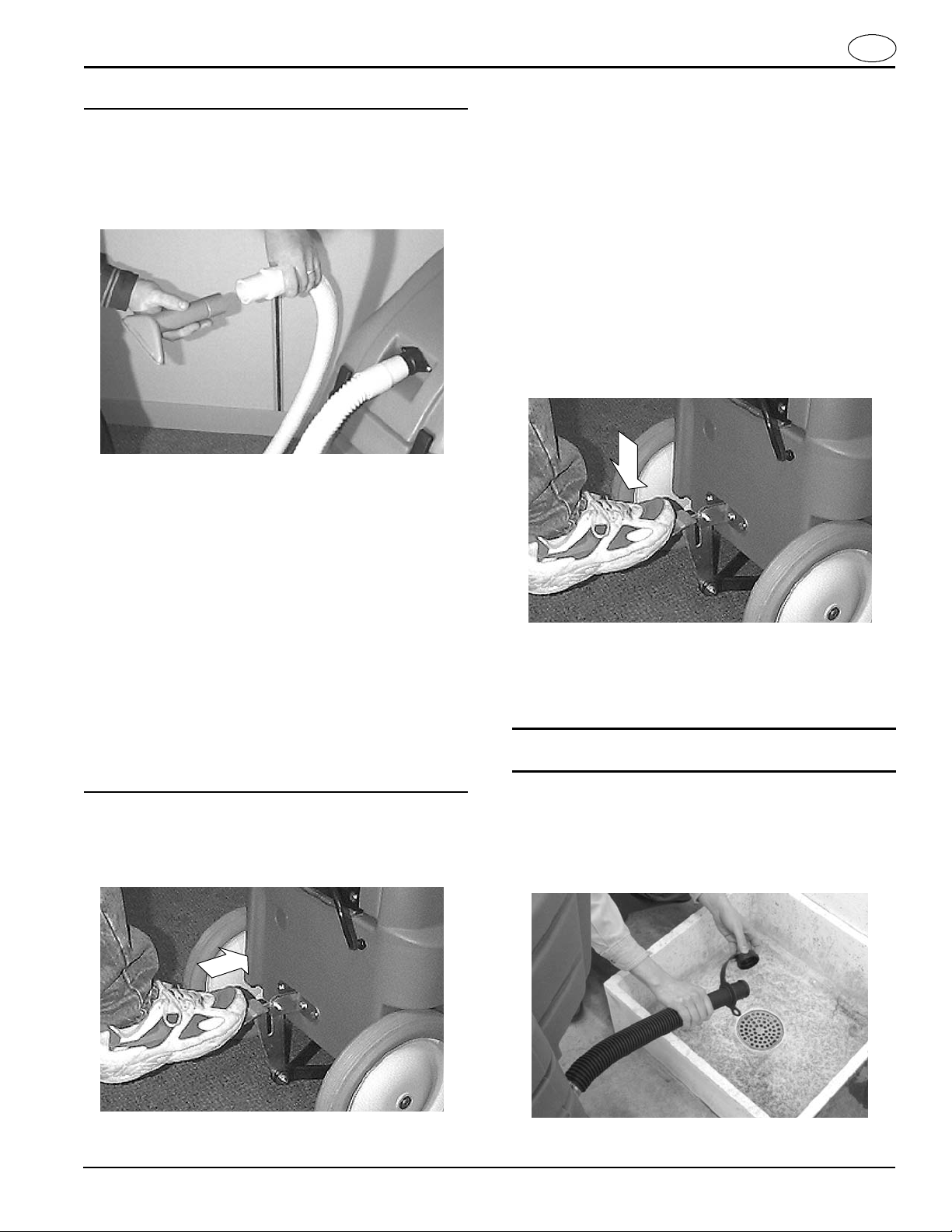

OPERATING ACCESSORY TOOLS

1. Connect 3m (10 ft) vacuum hose to machine cover

snout.

2. Select desired accessory tool and connect to

vacuum hose (Figure 12).

FIG. 12

3. Activate ON/OFF switch and operate accessory

tool as normal.

4. During DRY vacuuming, check bag periodically for

fullness. For best suction performance, empty bag

at 3/4 full.

During WET vacuuming, the float shut-off screen

will automatically stop water intake when recovery

tank becomes full (See DRAINING RECOVERY

TANK).

ATTENTION: If you are vacuuming up liquids that

may cause foaming inside recovery tank, use a

quality defoamer chemical to eliminate the foam.

Foam will NOT shut off automatic float and will

damage vacuum motor. Damage due to foam is

NOT covered by warranty.

OPERATION EN

2. Activate the ON/OFF switch.

3. Begin operating by pushing and pulling machine in

either direction.

4. During operation, the float shut-off screen will

automatically stop water intake when recovery tank

becomes full (See DRAINING RECOVERY TANK).

ATTENTION: If you are vacuuming up liquids that

may cause foaming inside recovery tank, use a

quality defoamer chemical to eliminate the foam.

Foam will NOT shut off automatic float and will

damage vacuum motor. Damage due to foam is

NOT covered by warranty.

5. To raise squeegee, step downward on pedal until

pedal engages in the transport position

(Figure 14).

FIG. 14

NOTE: Squeegee Kit can be used to pick up fine

particles (dust, sand, sawdust, etc...). The squeegee is

not recommended for ordinary dry pick up.

DRAINING RECOVERY TANK

OPERATING SQUEEGEE KIT OPTION

1. Lower squeegee to floor, lightly kick the pedal

forward to release from transport position

(Figure13).

FIG. 13

V- WD- 16B / V- WD- 61B (04- 10)

1. Push machine to nearest floor drain, if not available

use a bucket to drain machine.

2. Remove drain hose from holder and twist off drain

hose cap and drain. Raise hose to stop flow of

water (Figure15).

FIG. 15

9

EN OPERATION

3. After draining recovery tank, open cover and

thoroughly rinse out tank with clean water.

4. Replace drain hose knob securely and return to

holder.

A TTENTION: Be certain drain hose knob is secure

to prevent suction loss.

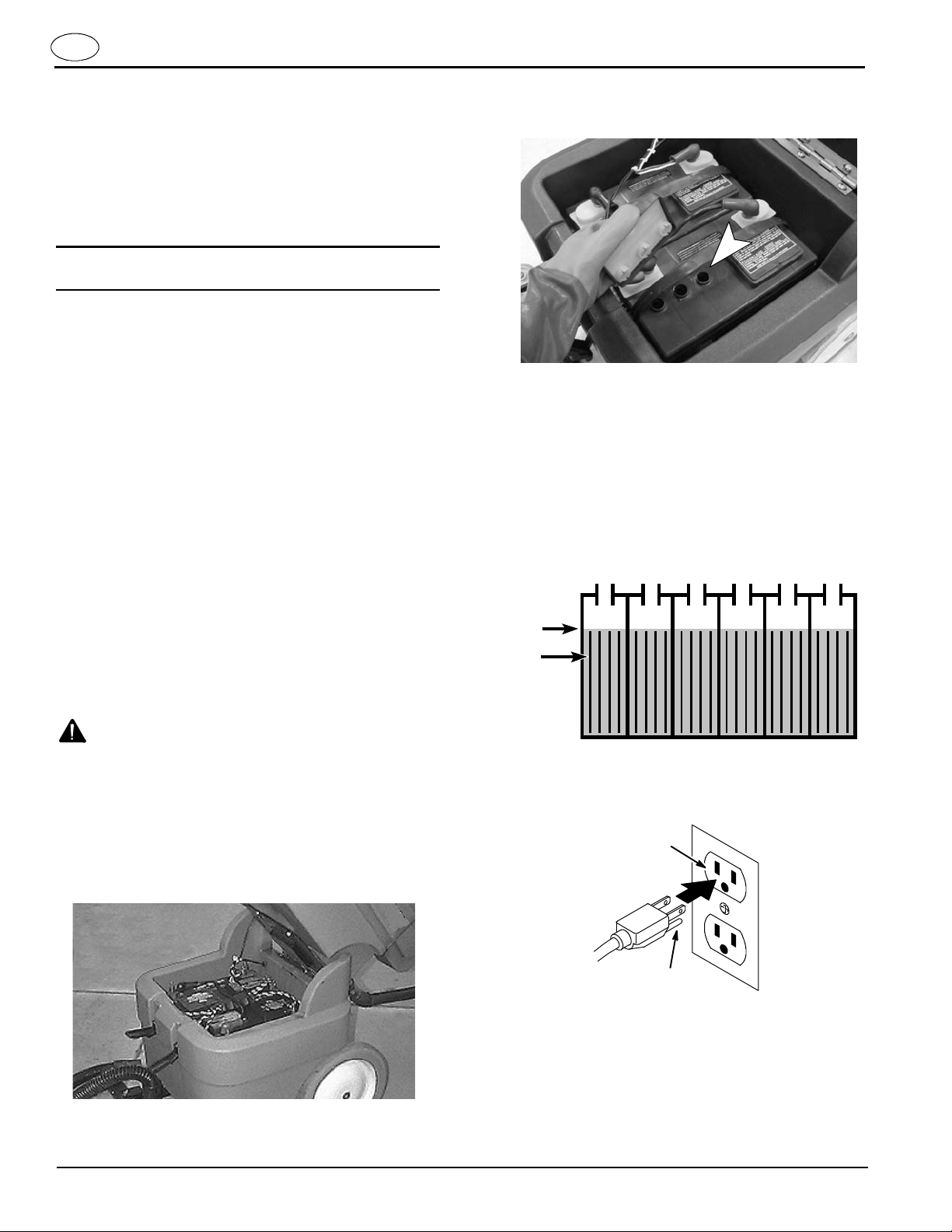

CHARGING BATTERIES

ATTENTION: To prolong the life of the batteries

and to provide optimum machine performance,

ONLY recharge the batteries after a total of 30

minutes of use or more. Do not leave batteries

discharged for lengthy periods.

The following charging instructions are intended for

battery chargers supplied with the machine. Only use a

battery charger with the following specifications to

prevent battery damage.

CHARGER SPECIFICATIONS:

S OUTPUT VOLTAGE - 24 VOLTS

S OUTPUT CURRENT - 15 AMPS

S AUTOMATIC SHUTOFF CIRCUIT

S FOR DEEP CYCLE BATTERY CHARGING

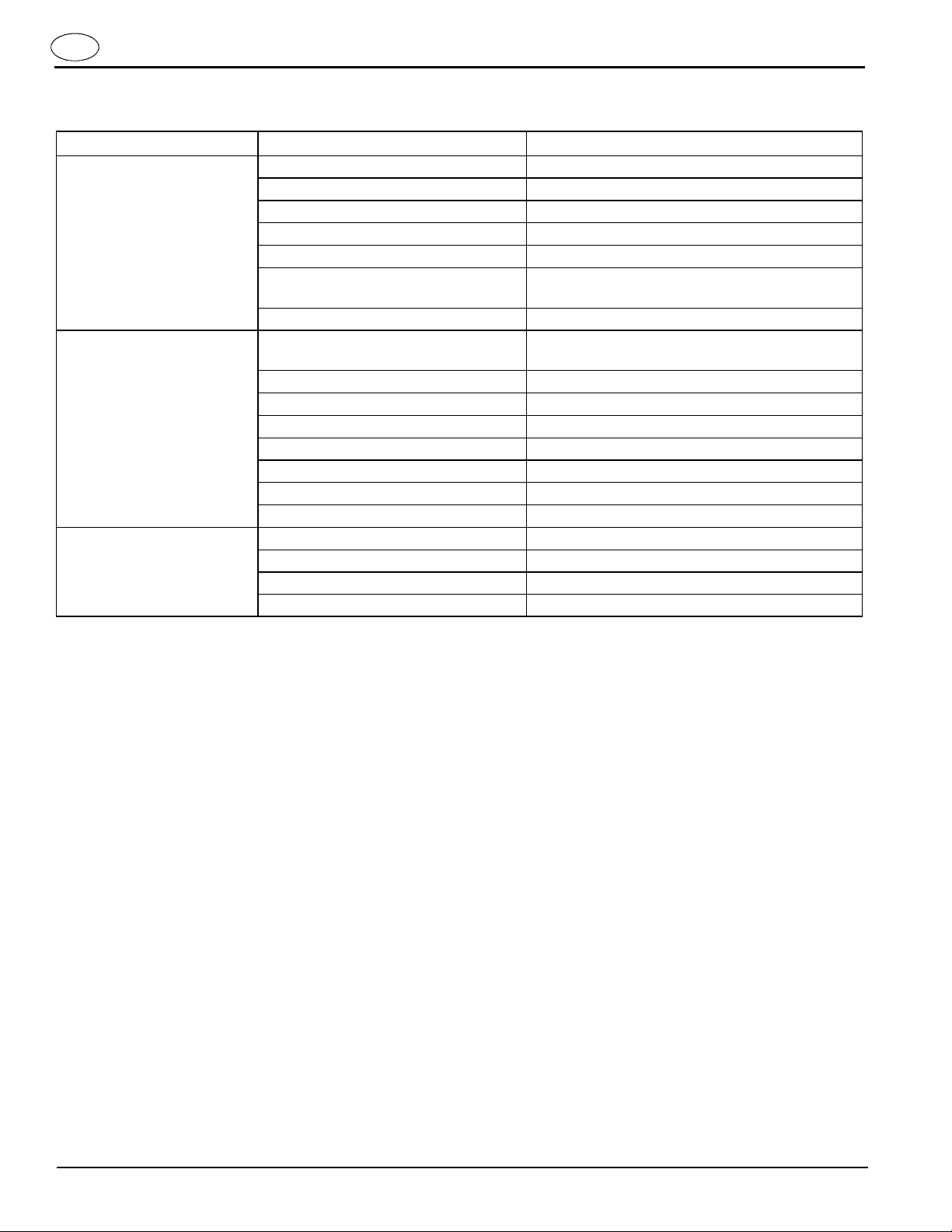

3. Before charging the batteries, check the electrolyte

level in each battery cell (Figure 17).

FIG. 17

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries or battery cables. Avoid contact

with battery acid.

The electrolyte level (A) should slightly cover the

battery plates (B). Add distilled water as needed.

DO NOT OVERFILL, the fluid may expand and

overflow while charging. Replace cell caps before

charging (Figure 18).

A

1. Push the machine to a flat, dry surface in a wellventilated area for charging.

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

2. Open battery compartment. Unlatch lower latches

at front of machine and carefully tilt upper housing

backwards to floor (Figure 16).

NOTE: Make sure to drain the tank prior to accessing

the batteries.

FIG. 16

B

FIG. 18

4. Connect the charger’s AC power supply cord to a

properly grounded receptacle (Figure 19).

Grounded

3HoleOutlet

Ground Pin

FIG. 19

10

V- WD- 16B / V- WD- 61B (04- 10)

5. Connect the battery charger into the machine’s

charging receptacle as shown (Figure 20).

FIG. 20

6. The charger will automatically begin charging and

shut off when fully charged.

ATTENTION: Do not disconnect the charger’s DC

cord from the machine’s receptacle when the

charger is operating. Arcing may result. If the

charger must be interrupted during charging,

disconnect the AC power supply cord first.

OPERATION EN

MACHINE MAINTENANCE

To keep machine in good working condition, simply

follow the daily, monthly and quarterly maintenance

procedures.

WARNING: Electrical Shock Hazard.

Disconnect Battery Cables Before Servicing

Machine.

DAILY MAINTENANCE

(After Every Use)

1. Drain and rinse out recovery tank after wet

vacuuming.

2. Remove and rinse off the float shut-off screen

located in recovery tank (Figure 22).

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

7. After charging, check the electrolyte level (A)

again. The level should be approximately 1 cm

(0.38 in) from the bottom of the fill- port (B)

(Figure 21). Add distilled water if needed.

DO NOT OVERFILL.

B

A

FIG. 21

FIG. 22

A TTENTION: Always have float shut- off screen in

place before operating. During wet operation, the

float shut- off screen protects the vacuum motor

from water. During dry vacuuming, the float

shut-off screen can provide limited protection for

a faulty filter bag.

3. Clean squeegee blades with a cloth. Replace

blades when they become worn.

4. Check bag for fullness, empty bag at 3/4 full.

5. Clean machine with an all purpose cleaner and

damp cloth.

FOR SAFETY: When cleaning machine, do not

power spray or hose off machine. Electrical

malfunction may occur.

V- WD- 16B / V- WD- 61B (04- 10)

6. Recharge the batteries after a total of 30 minutes

of use or more (See CHARGING BATTERIES).

7. Inspect vacuum hose regularly for holes, loose cuff

or clogged debris.

11

EN OPERATION

MONTHLY MAINTENANCE

(Every80HoursofUse)

1. Check the fluid level in each battery cell

(See BATTERY MAINTENANCE).

2. Clean battery tops to prevent corrosion

(See BATTERY MAINTENANCE).

3. Check for loose or corroded battery cables.

4. To maintain maximum performance, wash the cloth

filter bag by hand with a mild detergent. Let bag dry

thoroughly before replacing.

5. Lubricate wheels and front swivel casters with a

water resistant oil.

6. Check machine for loose nuts and bolts.

NOTE: Do not take readings immediately after adding

distilled water. If the water and acid are not thoroughly

mixed, the readings may not be accurate.

FIG. 23

QUARTERLY MAINTENANCE

(Every 250 Hours of Use)

Check the motor for carbon brush wear. Replace

carbon brushes when worn to a length of 10 mm

(0.38 in) or less.

Contact an Authorized Service Center for

machine repairs.

WARNING: Electrical Hazard. Disconnect

Battery Cables Before Servicing Machine.

BA TTER Y MAINTENANCE

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries and battery cables. Avoid

contact with battery acid.

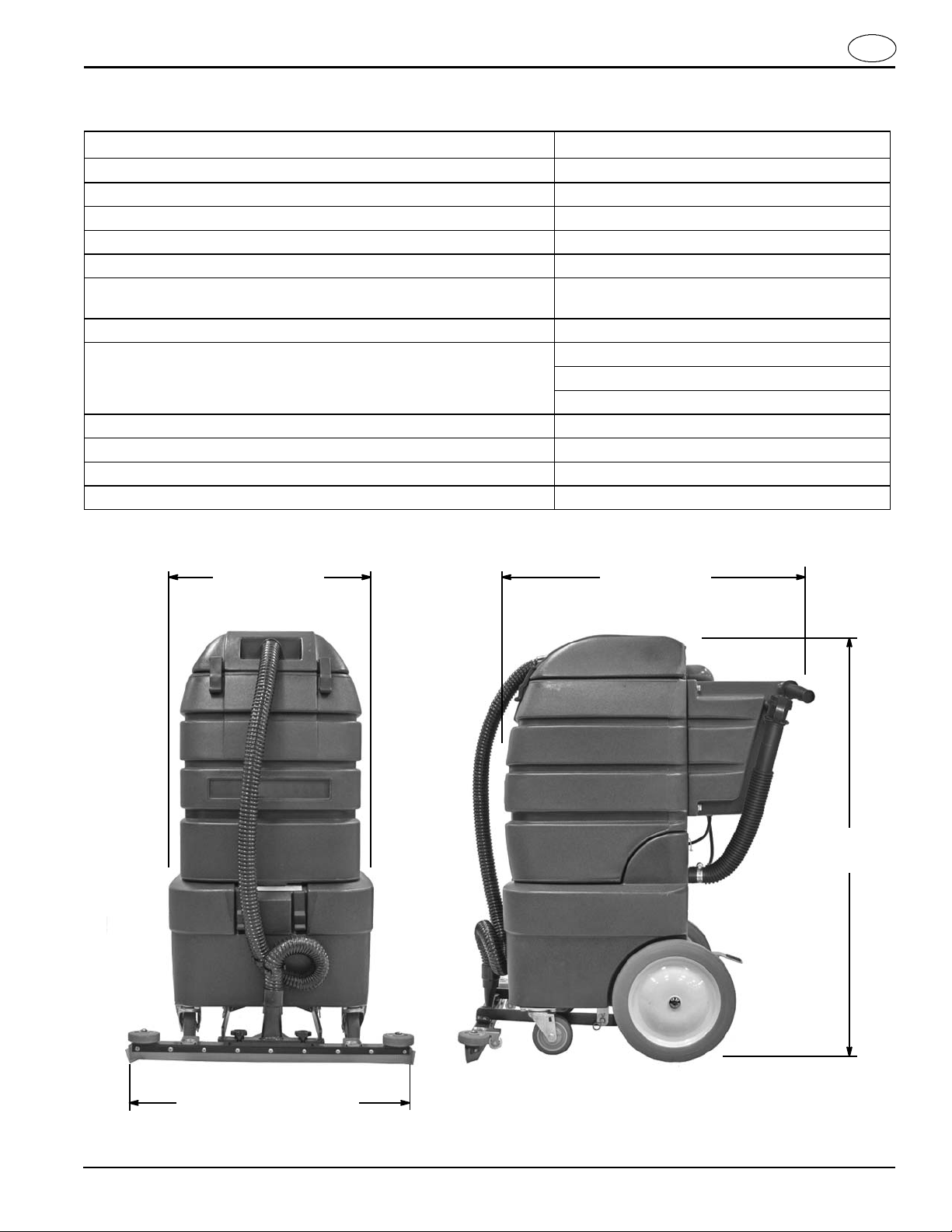

1. Check the specific gravity using a hydrometer to

determine the charge level and the condition of the

batteries (Figure 23). If one or more of the battery

cells read lower than the other battery cells (0.050

or more), the cell is damaged, shorted, or is about

to fail. Check the hydrometer readings against the

following chart to determine the remaining battery

charge level.

SPECIFIC GRAVITY

at 27_C(80_F)

1.265 100% CHARGED

1.223 75% CHARGED

1.185 50% CHARGED

1.148 25% CHARGED

1.110 DISCHARGED

BATTERY

CHARGE

NOTE: If the readings are taken when the battery

electrolyte is any temperature other than 27_C(80_F),

the reading must be temperature corrected. Add or

subtract to the specific gravity reading 0.004, 4 points,

for each 6_C(43_F) above or below 27_C(80_F).

2. Always follow proper charging instructions

(See CHARGING BATTERIES).

3. Check the electrolyte level (A) in each battery cell

after charging batteries. The level should be

approximately 1 cm (0.38 in) from the bottom of the

fill- port (B) (Figure 24). Add distilled water if

needed. DO NOT OVERFILL.

B

A

FIG. 24

12

V- WD- 16B / V- WD- 61B (04- 10)

OPERATION EN

4. Keep the battery tops clean to prevent battery

corrosion.

To clean batteries:

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries and battery cables. Avoid

contact with battery acid.

a. Mix a strong solution of baking soda and water

(Figure 25).

FIG. 25

b. Brush the solution sparingly over the battery

tops and cable connectors.

NOTE: Do not allow baking soda solution to enter

battery cells.

c. Use a wire brush to clean the battery terminals

and cable connectors.

d. After cleaning, apply a coating of clear battery

post protectant to the terminals and cable

connectors.

5. Check for loose or worn cables. Replace if worn.

2. Position the front of machine up against the front of

thetrailerortruck.

3. Place a block behind each rear wheel to prevent

machine from rolling.

4. Place tie- down straps over top of machine to prevent

it from tipping. It may be necessary to install

tie- down brackets to the floor of your trailer or truck.

FOR SAFETY: When transporting machine, use a

recommended ramp when loading/unloading

on/off truck or trailer, use tie - down straps to

secure machine to truck or trailer.

STORING MACHINE

Before storing the machine perform the following

instructions below:

1. Empty and rinse out recovery tank and accessory

tools.

2. Empty or replace vacuum bag.

3. Raise or remove squeegee assembly.

4. Store machine in a dry area in the upright position.

5. Disconnect battery cables if storing for a lengthy

period.

ATTENTION: Do Not Expose Machine To Rain.

Store Indoors.

ATTENTION: If storing machine in freezing

temperatures, be certain to drain machine of all

water. Damage due to freezing is not covered by

warranty.

TRANSPORTING MACHINE

When transporting machine by use of trailer or truck,

be certain to follow tie-down procedures below:

FOR SAFETY: When using machine, go slow on

inclines and slippery surfaces.

1. Load the machine using a recommended loading

ramp.

V- WD- 16B / V- WD- 61B (04- 10)

RECOMMENDED STOCK ITEMS

Refer to the Parts List manual for recommended stock

items. Stock Items are clearly identified with a bullet

preceding the parts description. See example below:

13

EN OPERATION

TROUBLE SHOOTING

PROBLEM CAUSE SOLUTION

No power.

Poor pickup.

Short run time.

Faulty ON/OFF switch. Contact Service Center.

Batteries need charging. See CHARGING BATTERIES.

Faulty battery(s). Replace battery(s).

Loose battery cable. Tighten loose cables.

Improper battery cable connection. See INSTALLING BATTERIES.

Vacuum motor thermal overload

tripped.

Faulty vacuum motor wiring. Contact Service Center.

Air flow obstruction. Remove obstruction from float shut- off screen,

Vacuum bag is full. Empty or replace bag.

Float shut-off screen is activated. Drain recovery tank.

Drain hose plug is loose or off. Secure drain hose plug.

Cover latches are not engaged. Engage cover latches.

Batteries need charging. Charge batteries.

Worn cover gasket. Replace gasket.

Vacuum motor carbon brushes worn. Contact Service Center.

Batteries not fully charged. Charge batteries.

Faulty battery(s). Replace battery(s).

Batteries need maintenance. See BATTERY MAINTENANCE.

Faulty charger. Replace charger.

Check air flow for obstruction, wait 20 minutes

for motor to cool.

vacuum hose, accessary tool or squeegee.

14

V- WD- 16B / V- WD- 61B (04- 10)

OPERATION EN

MACHINE SPECIFICATIONS

Model V - WD- 16B / V-WD- 61B

LENGTH 840 mm (33 in)

WIDTH 530 mm (21 in)

HEIGHT 1090 mm (43 in)

WEIGHT / WEIGHT WITH BATTERIES 41 Kg (90 lbs) / 107 Kg (235 lbs)

RECOVERY TANK CAP ACI TY 60.75 L (16 Gal)

V ACUUM BAG CAPACITY Cloth 15.5 cubic liter s (0.44 bushels)

Paper 22.7 cubic liters (0.65 bushels)

V ACUUM MOTOR 24V , 3-stage, .75hp, 23A, 566W

OPTIONAL SQUEEGEE P ATH WIDTH 685 mm (27 in)

864 mm (34 in)

1016 mm (40 in)

AIRFLOW / SEALED WATER LIFT 70 cfm (1.98 m3/h) / 1780 mm (70 in)

BA TTERI ES 2- 12V deep cycle lead acid, 105AH or 130AH

RUN TIME, CONTINUOUS up to 4 hours

DECIBEL RATING A T OPERATOR’S EAR, INDOORS ON TILE >70dB(A)

MACHINE DIMENSIONS

530 mm (21 in)

840 mm (33 in)

1090 mm

(43 in)

(See Specifications Chart)

Optional Squeegee Kit

V- WD- 16B / V- WD- 61B (04- 10)

15

ES FUNCIONAMIENTO

Este manual acompaña a los modelos nuevos e

incluye las instrucciones necesarias para su utilización

y mantenimiento.

Lea todo el manual para familiarizarse con la

máquina antes de utilizarla o realizar tareas de

mantenimiento.

Esta máquina ofrece un funcionamiento excelente y

puede obtener los mejores resultados con los mínimos

costes si:

DATOS DE LA MÁQUINA

Rellénela c uando realice la instalación para utilizarla

como referencia en el futuro.

Nº modelo:

Nº serie:

S Maneja la máquina con un cuidado razonable.

S Revisa la máquina periódicamente, de acuerdo con

las instrucciones de mantenimiento adjuntas.

S Las operaciones de mantenimiento de la máquina se

realizan con piezas suministradas por el fabricante o

equivalentes.

Puede solicitar las piezas a través de internet, por

teléfono, por fax o por correo.

DESEMBALADO DE LA MÁQUINA: Controle

cuidadosamente si la caja presenta signos de

deterioro. Si detecta desperfectos, informe

inmediatamente al transportista.

PROTECCIÓN DEL MEDIO

AMBIENTE

Deseche el material de embalaje y los

componentes usados de la máquina de

forma segura para el medio ambiente,

de acuerdo con las normativas locales

sobre desecho de residuos.

No olvide reciclar.

Tennant Company

PO Box 1452

Minneapolis, MN 55440 EE.UU.

Teléfono: (800) 553- 8033 o (763) 513- 2850

www.tennantco.com

www.nobles.com

Opciones de la máquina:

Vendedor:

Nº de teléfono del vendedor:

Nº de cliente:

Fecha de instalación:

ÍNDICE

MEDIDAS DE SEGURIDAD 17..................

ADHESIVOS DE SEGURIDAD 18...............

COMPONENTES DE LA MÁQUINA 19...........

INSTALACIÓN DE LA MÁQUINA 20.............

PREPARACIÓN DE LA MÁQUINA 22............

OPERACIÓN DE LA MÁQUINA 23..............

VACIADO DEL DEPÓSITO DE

RECUPERACIÓN 24..........................

CARGA DE LAS BATERÍAS 24.................

MANTENIMIENTO DE LA MÁQUINA 26.........

TRANSPORTE DE LA MÁQUINA 28.............

ALMACENAMIENTO DE LA MÁQUINA 28.......

STOCK RECOMENDADO DE REPUESTOS 28...

LOCALIZACIÓN DE FALLAS 29................

ESPECIFICACIONES DE LA MÁQUINA 30.......

DIMENSIONES DE LA MÁQUINA 30............

Las características técnicas y las piezas están sujetas

a modificaciones sin previo aviso.

opyright E 2010, 2014 TENNANT Company.

C

Todos los derechos reservados.

16

V- WD- 16B / V- WD- 61B (06- 2014)

MEDIDAS DE SEGURIDAD

FUNCIONAMIENTO ES

La información siguiente señala condiciones

potencialmente peligrosas para el operador o el

equipo:

Esta máquina es para el uso comercial. Se ha

diseñado para aspiración húmeda/seca en un

ambiente interior y no se construye para ningún

otro uso. Use sólo las herramientas adicionales

recomendadas.

Todos los operadores deben leer, entender y

practicar las precauciones siguientes de

seguridad.

A lo largo de todo el manual se utilizan los siguientes

símbolos de advertencia y encabezados “PARA SU

SEGURIDAD” descritos a continuación:

ADVERTENCIA: Para advertir de riesgos o

prácticas inseguras que podrían resultar en

lesiones personales graves o la muerte.

PARA SU SEGURIDAD: Para identificar acciones

que deben seguirse para el funcionamiento seguro

del equipo.

El no cumplimiento de estas advertencias puede

causar lesiones personales, descargas eléctricas,

incendios y explosiones.

ADVERTENCIA: Peligro de incendio o

explosión:

- No opere la máquina en o cerca de líquidos,

vapores inflamables o polvos combustibles.

Esta máquina no está equipada con motor a

prueba de explosión. El motor eléctrico emite

chispas al arrancar y durante el funcionamiento lo

que podría causar un fuego explosivo o explosión

si la máquina se usa en una área donde están

presentes vapores/líquidos inflamables o polvos

combustibles.

- No recoja materiales tóxicos o inflamables ni

residuos humeantes o ardiendo.

- Las baterías emiten hidrógeno. Mantenga

chispasyllamasalejadasdelamáquina.

Mantenga el compartimento de la batería

abierto mientras realiza la operación de carga.

ADVERTENCIA: Peligro choque eléctrico.

Desconecte los cables de la batería antes de

realizar reparaciones en la máquina.

PARA SU SEGURIDAD:

1. No opere la máquina:

- Con líquidos inflamables o cerca de los

vapores inflamables ya que puede ocurrir

una explosión o fuego explosivo.

- A menos que está capacitado y autorizado.

- A menos que se haya leído y entendido el

manual del funcionamiento.

- Si no está en condición de ejecutar una

operación apropiada.

- En agua estancada.

- Sin haber colocado los filtros y/o la bolsa.

2. Antes de arrancar la máquina:

- Asegúrese que todos los dispositivos de

seguridad están en su lugar y operando

apropiadamente.

3. Al usar máquina:

- No recoja restos ardiendo o humeantes

como cigarrillos, cerillas o cenizas

calientes.

- Informe inmediatamente acerca de daños o

una operación defectuosa de la máquina.

- Nunca permita que los niños jueguen en o

alrededor de la máquina.

4. Antes de salir de o reparar la máquina:

- Deténgala en una superficie nivelada.

- Apague la máquina.

5. Al prestar servicio a la máquina:

- Desconecte las conexiones de la batería

antes de trabajar en la máquina.

- Utilice guantes y gafas de protección al

trabajar con las baterías o sus cables.

- Evite el contacto con el ácido de la batería.

- Use piezas de repuesto provistas o

aprobadas por el fabricante.

- Todas las reparaciones deben ser

realizadas por una persona de servicio

calificada.

- No modifique la máquina de su diseño

original.

6. Al transportar máquina:

- Apague la máquina.

- No levante la máquina con las baterías

instaladas.

- Obtenga ayuda al alzar la máquina.

- Utilice una rampa al cargar/descargar la

máquina en/de un camión o remolque.

- Use correas de amarre para asegurar la

máquina al camión o remolque.

V- WD- 16B / V- WD- 61B (04- 10)

17

ES FUNCIONAMIENTO

ADHESIVOS DE SEGURIDAD

Los adhesivos de seguridad se encuentran en las posiciones indicadas a continuación. Sustituya los adhesivos si se

han desprendido, están deteriorados o son ilegibles.

ADHESIVO DE ADVERTENCIA - Situado en la parte trasera de la máquina.

ADHESIVO DE ADVERTENCIA –

Situado en la parte trasera de la máquina.

ADVERTENCIA: El no

seguir estas advertencias

puede resultar en: lesiones

personales, electrocución,

choque eléctrico, fuego o

explosión.

No opere la máquina en o

cerca de líquidos, vapores

inflamables o polvos combustibles.

No recoja materiales tóxicos

o inflamables ni residuos

humeantes o ardiendo.

ADHESIVO DE PARA SU SEGURIDAD –

Situado en la parte trasera de la máquina.

PARA SU SEGURIDAD:

Lea el manual antes de utilizar la máquina.

18

V- WD- 16B / V- WD- 61B (04- 10)

Loading...

Loading...