Tennant 510E User Manual

510E

Home

Find...

Go To..

(Operator Manual)

MM239

Rev. 09 (3--95)

This manual is furnished with each new TENNANT Model 510E. It provides necessary operating and

Home

Find...

Go To..

preventive maintenance instructions. Read this manual completely and understand the machine before

operating or servicing it.

This manual covers all machine variations and standard accessories. The instruction portion of the

manual consists of the Specification, Operation, Maintenance, and Appendix sections. The parts portion

consists of the Standard Parts; Options; Breakdowns; and Cross Reference sections.

All right side and left side references to the machine are determined by facing the direction of forward

travel. All hardware considered to be of a common nature or locally available has been omitted from the

parts sections. Be aware that this machine may contain metric hardware. Make sure you use equivalent

hardware when replacement becomes necessary.

This machine will provide excellent service. However, the best results will be obtained at minimum costs if:

D The machine is operated with reasonable care.

D The machine is maintained regularly -- per the maintenance instructions provided.

D The machine is maintained with TENNANT supplied or equivalent parts.

Parts and supplies may be ordered by phone or mail from any TENNANT parts and service center,

distributor, or from any of the TENNANT subsidiaries. Before ordering parts or supplies, be sure to have

your machine model number and serial number handy. Fill out the data block below for future reference.

The telephone numbers, telex numbers, mailing addresses, and locations of those outlets are listed in the

Customer Documents section of the manual.

MACHINE DATA

Please fill out at time of installation.

Machine Serial Number --

Engine Serial Number --

Sales Representative --

Customer Number --

Date of Installation --

Manual Number -- MM239

Revision: 09

Published: 3--95

Trademark Registered in: Austria, Benelux, Denmark, England, France, Germany, Italy, Spain,

Switzerland, United States, Argentina, Australia, Canada, Japan, Mexico, Sweden, by TENNANT

COMPANY, Minneapolis, Minnesota, U.S.A.

Copyright 1990, 1991, 1992, 1993, 1994, 1995 TENNANT, Printed in U.S.A.

SAFETY PRECAUTIONS

Home

Find...

Go To..

GENERAL INFORMATION

The following symbols are used throughout this

manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices which could result in

severe personal injury or death.

FOR SAFETY: To identify actions which must

be followed for safe operation of equipment.

The machine is suited for scrubbing disposable

debris. Do not use the machine other than

described in this manual. The machine is not

designed for use on public roads.

The following information signals potentially

dangerous conditions to the operator or

equipment:

FOR SAFETY:

1. Do Not Operate Machine:

-- Unless Trained And Authorized.

-- Unless Operation Manual Is Read And

Understood.

-- In Flammable Or Explosive Areas

Unless Designed For Use In Those

Areas.

-- In Areas With Possible Falling Objects

Unless Equipped With Overhead

Guard.

6. When Servicing Machine:

-- Avoid Moving Parts. Do Not Wear

Loose Jackets, Shirts, Or Sleeves.

-- Block Machine Tires Before Jacking

Machine Up.

-- Jack Machine Up At Designated

Locations Only. Block Machine Up

With Jack Stands.

-- Use Hoist Or Jack Of Adequate

Capacity To Lift Machine.

-- Wear Eye And Ear Protection When

Using Pressurized Air Or Water.

-- Disconnect Battery Connections

Before Working On Machine.

-- Avoid Contact With Battery Acid.

-- Use TENNANT Supplied Or Approved

Replacement Parts.

WARNING: Batteries Emit Hydrogen

Gas. Explosion Or Fire Can Result.

Keep Sparks And Open Flame Away. Keep

Covers Open When Charging.

WARNING: Flammable Materials Can

Cause An Explosion Or Fire. Do Not

Use Flammable Materials In Tank(s).

WARNING: Flammable Materials Or

Reactive Metals Can Cause Explosion

Or Fire. Do Not Pick Up.

2. Before Starting Machine:

-- Make Sure All Safety Devices Are In

Place And Operate Properly.

-- Check Brakes And Steering For Proper

Operation.

3. When Starting Machine:

-- Keep Foot On Brake And Directional

Pedal In Neutral.

4. When Using Machine:

-- Use Brakes To Stop Machine.

-- Go Slow On Inclines And Slippery

Surfaces.

-- Use Care When Reversing Machine.

-- Do Not Carry Riders On Machine.

-- Always Follow Safety And Traffic

Rules.

-- Report Machine Damage Or Faulty

Operation Immediately.

5. Before Leaving Or Servicing Machine:

-- Stop On Level Surface.

-- Set Parking Brake.

-- Turn Off Machine And Remove Key.

510E MM239 (8--92)

i

GENERAL INFORMATION

Home

Find...

Go To..

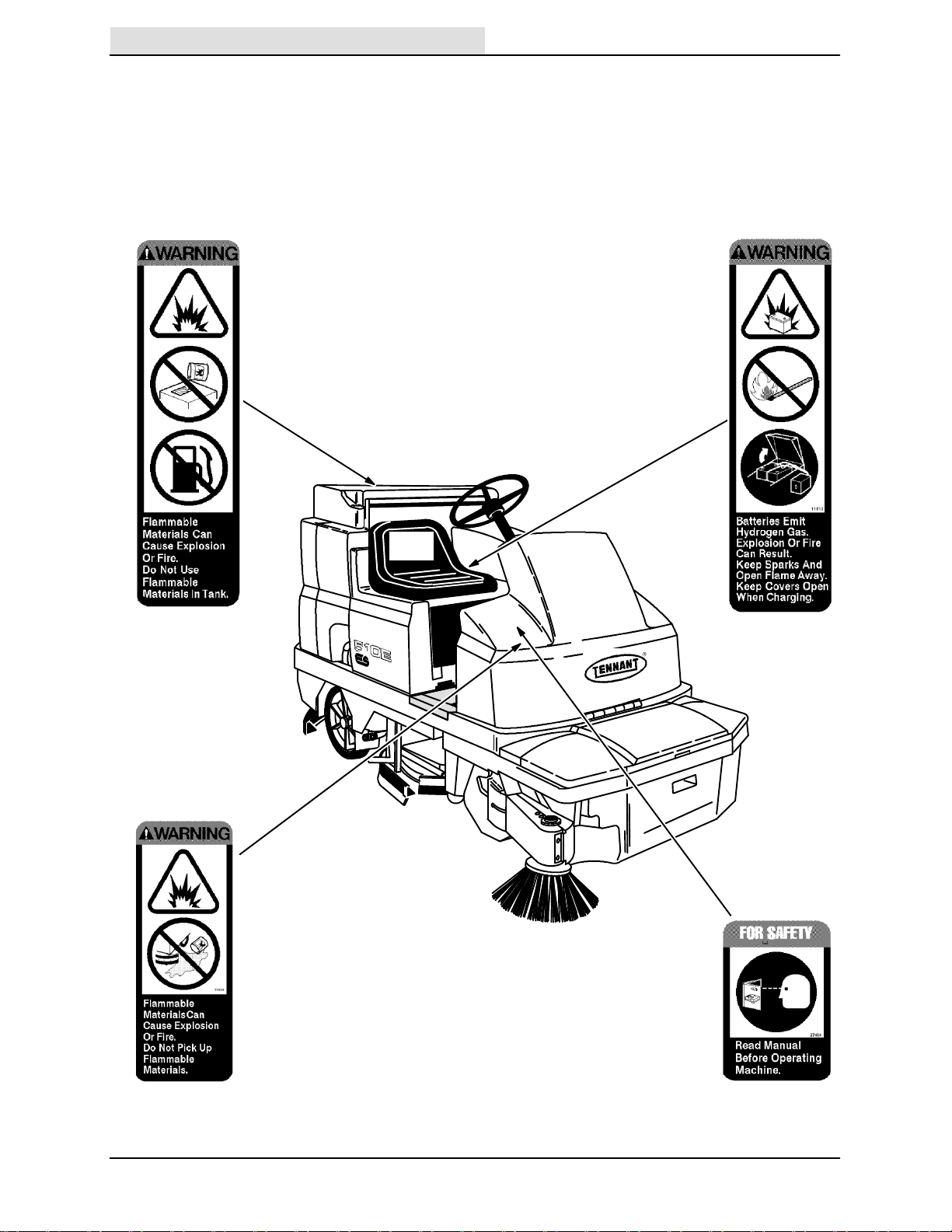

The following safety labels are mounted on the

machine in the locations indicated. If these, or any

labels become damaged or illegible, install a new

label in its place.

CLEANING SOLUTION LABEL -- LOCATED ON

TANKS COVER.

BATTERY CHARGING LABEL -- LOCATED ON

LINTEL.

FLAMMABLE SPILLS LABEL -- LOCATED ON

MOTOR COVER PANEL.

ii

05912

FOR SAFETY LABEL -- LOCATED ON MOTOR

COVER PANEL.

510E MM239 (1--90)

CONTENTS

Home

Find...

Go To..

GENERAL INFORMATION

GENERAL INFORMATION i. . . . . . . . . . . . . . .

SAFETY PRECAUTIONS i. . . . . . . . . . . .

SPECIFICATIONS 1-1. . . . . . . . . . . . . . . . . . . . . . .

MACHINE SPECIFICATIONS 1-3. . . . . . . . .

POWER TYPE 1-3. . . . . . . . . . . . . . . . . . .

POWER TRAIN 1-3. . . . . . . . . . . . . . . . . .

STEERING 1-3. . . . . . . . . . . . . . . . . . . . . .

BRAKING SYSTEM 1-3. . . . . . . . . . . . . .

SUSPENSION SYSTEM 1-3. . . . . . . . . .

SYSTEM FLUID CAPACITIES 1-3. . . . .

GENERAL MACHINE DIMENSIONS --

CAPACITIES 1-3. . . . . . . . . . . . . . .

MACHINE WEIGHTS 1-3. . . . . . . . . . . . .

GENERAL MACHINE

PERFORMANCE 1-3. . . . . . . . . . . . . .

MACHINE DIMENSIONS 1-4. . . . . . . . . . . . .

OPERATION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 2-3. . . .

AFTER UNCRATING AND BEFORE

OPERATING MACHINE: 2-3. . . . . . .

OPERATION OF CONTROLS 2-4. . . . . . . .

MACHINE COMPONENTS 2-4. . . . . . . .

HOW IT WORKS 2-5. . . . . . . . . . . . . . . . .

INSTRUMENT PANEL SYMBOLS 2-6. .

CONTROLS AND INSTRUMENTS 2-7.

BRAKE PEDAL 2-8. . . . . . . . . . . . . . . . . .

DIRECTIONAL PEDAL 2-8. . . . . . . . . . . .

STEERING WHEEL 2-8. . . . . . . . . . . . . .

SOLUTION FLOW LEVER 2-8. . . . . . . . .

CLOGGED VACUUM INDICATOR 2-8. .

RECOVERY TANK FULL INDICATOR 2-8

HOUR METER 2-8. . . . . . . . . . . . . . . . . . .

BRUSH PRESSURE INDICATOR AND

SWITCH 2-8. . . . . . . . . . . . . . . . . . .

EDGE SCRUB SWITCH 2-9. . . . . . . . . . .

BATTERY DISCHARGE INDICATOR 2-9

ELECTRICAL POWER INDICATOR 2-9

BRUSH CIRCUIT BREAKER

INDICATOR 2-9. . . . . . . . . . . . . . . . . . .

REAR SQUEEGEE AND VACUUM FAN

SWITCH 2-9. . . . . . . . . . . . . . . . . . .

SCRUB BRUSH SWITCH 2-9. . . . . . . . .

HORN BUTTON 2-9. . . . . . . . . . . . . . . . . .

KEY-OPERATED ON-OFF SWITCH 2-9

OPERATING LIGHTS SWITCH 2-10. . . .

REVOLVING LIGHT SWITCH 2-10. . . . . .

PRE-SWEEPt SWITCH 2-10. . . . . . . . . .

ESt SWITCH 2-10. . . . . . . . . . . . . . . . . . .

PARKING BRAKE LEVER 2-10. . . . . . . . .

POWER WAND SWITCH 2-10. . . . . . . . . .

CIRCUIT BREAKERS 2-11. . . . . . . . . . . . .

Page

Page

MACHINE OPERATION 2-12. . . . . . . . . . . . . .

NORMAL SCRUBBING OPERATION 2-12

PRE-START CHECKLIST 2-12. . . . . . .

TO START MACHINE 2-12. . . . . . . . . .

TO FILL SOLUTION TANK 2-12. . . . . .

TO SCRUB 2-14. . . . . . . . . . . . . . . . . . .

TO DRAIN AND CLEAN RECOVERY

TANK 2-15. . . . . . . . . . . . . . . . . . .

POST OPERATION CHECKLIST --

MACHINE ON 2-17. . . . . . . . . . .

TO STOP MACHINE 2-17. . . . . . . . . . .

POST OPERATION CHECKLIST --

MACHINE OFF 2-17. . . . . . . . . .

DOUBLE SCRUBBING OPERATION 2-18

TO RAISE SIDE SQUEEGEES 2-18. .

TO LOWER SIDE SQUEEGEES 2-18

OPERATION ON GRADES 2-18. . . . . . . .

MACHINE TROUBLESHOOTING 2-19. .

OPTIONS OPERATION 2-20. . . . . . . . . . . . . .

VACUUM WAND 2-20. . . . . . . . . . . . . . . . .

TO OPERATE THE VACUUM

WAND 2-20. . . . . . . . . . . . . . . . . . . . .

POWER WAND 2-21. . . . . . . . . . . . . . . . . .

TO OPERATE THE POWER

WAND 2-21. . . . . . . . . . . . . . . . . . . . .

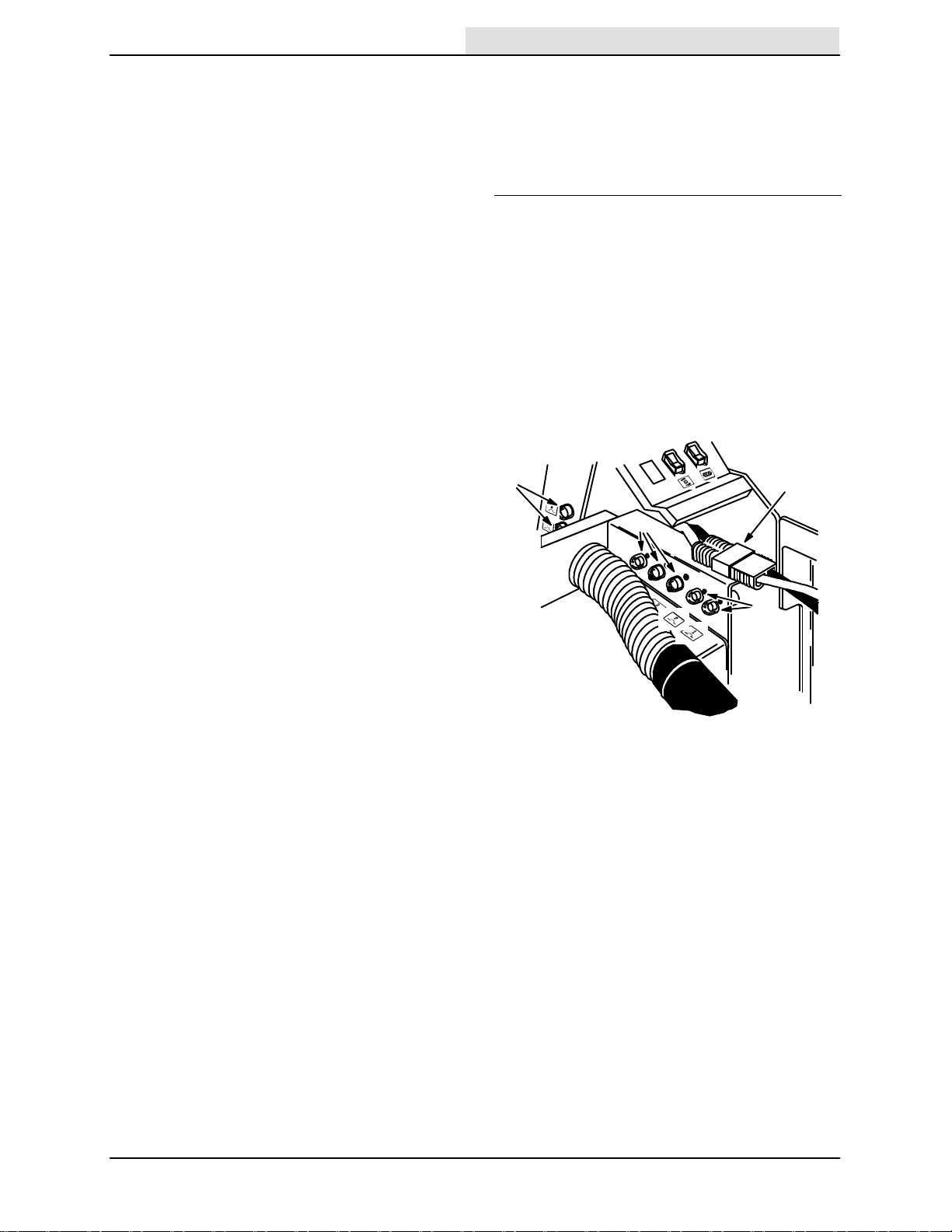

PRE-SWEEPt 2-23. . . . . . . . . . . . . . . . . . .

TO REPLACE THE PRE-SWEEPt

DEBRIS HOPPER LINER 2-23.

TO REMOVE PRE-SWEEPt

ASSEMBLY 2-23. . . . . . . . . . . . . . . .

TO MOUNT PRE-SWEEPt

ASSEMBLY 2-24. . . . . . . . . . . . . . . .

TRANSPORTING MACHINE 2-25. . . . . . . . . .

PUSHING OR TOWING 2-25. . . . . . . . . . .

MACHINE JACKING 2-25. . . . . . . . . . . . . .

TO JACK UP MACHINE 2-25. . . . . . . .

MACHINE TIE DOWNS 2-26. . . . . . . . . . .

MACHINE STORAGE 2-27. . . . . . . . . . . . . . . .

STORING MACHINE 2-27. . . . . . . . . . . . .

MACHINE OPERATION 2-11. . . . . . . . . . . . . .

MAINTENANCE 3-1. . . . . . . . . . . . . . . . . . . . . . . . .

RECOMMENDED FIRST 50-HOUR

MACHINE INSPECTION 3-3. . . . . . . . . .

MAINTENANCE CHART 3-4. . . . . . . . . . . . .

LUBRICATION 3-6. . . . . . . . . . . . . . . . . . . . . .

PROPELLING GEARBOX 3-6. . . . . . . . .

FRONT WHEEL SUPPORT

BEARING 3-6. . . . . . . . . . . . . . . . . . . .

SCRUB HEAD PARALLEL ARMS 3-6. .

ELECTRICAL SYSTEM 3-7. . . . . . . . . . . . . .

BATTERIES 3-7. . . . . . . . . . . . . . . . . . . . .

TO CHARGE BATTERIES 3-8. . . . . .

TO REPLACE 380 A/h

BATTERIES 3-9. . . . . . . . . . . . . . . .

510E MM239 (8--93)

iii

GENERAL INFORMATION

Home

Find...

Go To..

ELECTRICAL SCHEMATIC (For machines

below serial number 001840) 3-11. . . .

ELECTRICAL SCHEMATIC (For machines

serial number 001840 and above) 3-12

BELTS AND CHAINS 3-13. . . . . . . . . . . . . . . .

STEERING GEAR CHAIN 3-13. . . . . . . . .

STATIC DRAG CHAIN 3-13. . . . . . . . . . . .

SCRUB HEAD 3-14. . . . . . . . . . . . . . . . . . . . . .

SCRUB HEAD 3-14. . . . . . . . . . . . . . . . . . .

TO CENTER SCRUB HEAD 3-14. . . .

TO ADJUST EDGE SCRUB

SWITCH 3-15. . . . . . . . . . . . . . . . . . .

TO ADJUST SCRUB HEAD DOWN

PRESSURE 3-15. . . . . . . . . . . . .

SCRUB BRUSHES 3-16. . . . . . . . . . . . . . .

TO REPLACE SCRUB BRUSHES 3-16

SCRUB HEAD FLOOR SKIRTS 3-17. . . .

SOLUTION AND RECOVERY TANKS 3-18.

SOLUTION TANK 3-18. . . . . . . . . . . . . . . .

SOLUTION VALVE 3-18. . . . . . . . . . . . . . .

RECOVERY TANK 3-19. . . . . . . . . . . . . . .

TO DRAIN AND CLEAN RECOVERY

TANK 3-19. . . . . . . . . . . . . . . . . . . . .

ESt SOLUTION TANKS 3-21. . . . . . . . . .

TO DRAIN AND CLEAN ESt

SOLUTION TANKS 3-21. . . . . . . . .

SQUEEGEES 3-23. . . . . . . . . . . . . . . . . . . . . . .

SIDE SQUEEGEES 3-23. . . . . . . . . . . . . .

TO REPLACE SIDE SQUEEGEE

BLADES 3-23. . . . . . . . . . . . . . . . . . .

SIDE SQUEEGEE ADJUSTMENT 3-23. .

REAR SQUEEGEE 3-24. . . . . . . . . . . . . . .

TO REPLACE OR ROTATE REAR

SQUEEGEE BLADE 3-24. . . . . . . .

TO LEVEL REAR SQUEEGEE 3-25. .

TO ADJUST REAR SQUEEGEE

DEFLECTION (For machines below

serial number 001724) 3-26. . . . . . .

TO ADJUST REAR SQUEEGEE

DEFLECTION (For machines serial

number 001724 and 002669) 3-26.

TO ADJUST REAR SQUEEGEE

DEFLECTION (For machines serial

number 002670 and above) 3-26. .

BRAKES AND TIRES 3-28. . . . . . . . . . . . . . . .

SERVICE BRAKES 3-28. . . . . . . . . . . . . . .

TIRES 3-28. . . . . . . . . . . . . . . . . . . . . . . . . .

OPTIONS 3-29. . . . . . . . . . . . . . . . . . . . . . . . . .

PRE-SWEEPt 3-29. . . . . . . . . . . . . . . . . . .

PRE-SWEEPt MAIN BRUSH 3-29. . . . .

TO REPLACE PRE-SWEEPt MAIN

BRUSH 3-29. . . . . . . . . . . . . . . . . . . .

TO CHECK AND ADJUST

PRE-SWEEPt MAIN BRUSH

PATTERN 3-30. . . . . . . . . . . . . . . . . .

PRE-SWEEPt SIDE BRUSH 3-31. . . . . .

TO REPLACE PRE-SWEEPt SIDE

BRUSH 3-31. . . . . . . . . . . . . . . . . . . .

Page

Page

PRE-SWEEPt BRUSH SIDE

SKIRTS 3-32. . . . . . . . . . . . . . . . . . . . . .

PRE-SWEEPt REAR SKIRT 3-32. . . . . .

DEBRIS HOPPER SLIT SKIRT 3-32. . . . .

PRE-SWEEPt DEBRIS HOPPER

SEALS 3-32. . . . . . . . . . . . . . . . . . . . . . .

PRE-SWEEPt MAIN BRUSH DRIVE

BELT 3-33. . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE THE MAIN BRUSH

DRIVE BELT 3-33. . . . . . . . . . . . . . .

PRE-SWEEPt SIDE BRUSH DRIVE

BELT 3-34. . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE AND ADJUST THE

SIDE BRUSH BELT 3-34. . . . . . . . .

APPENDIX 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HARDWARE INFORMATION 4-3. . . . . . . . .

STANDARD BOLT TORQUE CHART 4-3

METRIC BOLT TORQUE CHART 4-3. .

BOLT IDENTIFICATION 4-3. . . . . . . . . . .

THREAD SEALANT AND LOCKING

COMPOUNDS 4-3. . . . . . . . . . . . . . . .

HOW TO USE THIS MANUAL 5-1. . . . . . . . . . . .

IMPORTANT INFORMATION 5-1. . . . . . . . .

FINDING A TENNANT PART NUMBER 5-2

PLACING AN ORDER 5-3. . . . . . . . . . . . . . .

STANDARD MODEL PARTS 6-1. . . . . . . . . . . . .

Fig. 1 -- Recommended General

Maintenance Items 6-2. . . . . . .

Fig. 2 -- Replacement Brushes 6-2. . . . . . . .

Fig. 3 -- Main Frame and Cover Group 6-4.

Fig. 4 -- Seat Assembly 6-6. . . . . . . . . . . . . .

Fig. 5 -- Steering Group 6-8. . . . . . . . . . . . . .

Fig. 6 -- Drive Wheel Group 6-10. . . . . . . . . .

Fig. 7 -- Front Brake Linkage Group 6-12. . .

Fig. 8 -- Rear Brake Linkage Group 6-13. . . .

Fig. 9 -- Rear Wheel and Brake Group 6-14.

Fig. 10 -- Floor Plate Group 6-15. . . . . . . . . . .

Fig. 11 -- Directional Pedal Group 6-16. . . . . .

Fig. 12 -- Scrub Head Drive Group 6-18. . . . .

Fig. 13 -- Scrub Head Mount Group 6-20. . . .

Fig. 14 -- Scrub Head Lift Group 6-21. . . . . . .

Fig. 15 -- Edge Scrub Group 6-22. . . . . . . . . .

Fig. 16 -- Scrub Head Stops and

Squeegee Mount Group 6-23. . .

Fig. 17 -- Solution Valve Group 6-24. . . . . . . .

Fig. 18 -- Right Side Squeegee Group 6-26. .

Fig. 19 -- Left Side Squeegee Group 6-27. . .

Fig. 20 -- Rear Squeegee Mount Group 6-28.

Fig. 21 -- Left Side Squeegee Group 6-30. . .

Fig. 22 -- Rear Squeegee Linkage Group 6-31

Fig. 23 -- Recovery Tank Group 6-32. . . . . . . .

Fig. 24 -- Solution Tank Group 6-34. . . . . . . . .

Fig. 25 -- Demister and Cover Group 6-36. . .

Fig. 26 -- Vacuum Fan Group 6-38. . . . . . . . . .

Fig. 27 -- Instrument Panel Group 6-40. . . . . .

Fig. 28 -- Electronic Panel Group 6-41. . . . . .

iv

510E MM239 (8--94)

GENERAL INFORMATION

Home

Find...

Go To..

Fig. 29 -- Control Box Group 6-42. . . . . . . . . .

Fig. 30 -- Wire Harness Group 6-44. . . . . . . . .

Fig. 31 -- Label Group 6-50. . . . . . . . . . . . . . . .

OPTIONS 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fig. 1 -- Pre-Sweept Frame Group 7-2. . .

Fig. 2 -- Pre-Sweept Drive Group 7-4. . . .

Fig. 3 -- Pre-Sweept Brush Idler Group 7-6

Fig. 4 -- Pre-Sweept Brush Wrap Group 7-7

Fig. 5 -- Pre-Sweept Side Brush Group 7-8

Fig. 6 -- Pre-Sweept Hopper Group 7-10. . .

Fig. 7 -- Pre-Sweept Cover Group 7-11. . . .

Fig. 8 -- Pre-Sweept Electrical Group 7-12.

Fig. 9 -- Pre-Sweept Dolly Assembly 7-13. .

Fig. 10 -- Extended Scrub Group 7-14. . . . . . .

Fig. 11 -- Auto Water Valve Group 7-16. . . . . .

Fig. 12 -- Light Kit 7-18. . . . . . . . . . . . . . . . . . . .

Fig. 13 -- Revolving Light Kit, Lintel 7-20. . . . .

Fig. 14 -- Revolving Light Kit,

Overhead Guard 7-21. . . . . . . . .

Fig. 15 -- Overhead Guard Kit 7-22. . . . . . . . .

Fig. 16 -- Heavy Duty Bumper Kit 7-23. . . . . .

Fig. 17 -- Suspension Slide Seat Kit 7-24. . . .

Fig. 18 -- Heavy Duty Motor Kit 7-25. . . . . . . .

Fig. 19 -- Vacuum Wand Kit 7-26. . . . . . . . . . .

Fig. 20 -- Demo Kit 7-27. . . . . . . . . . . . . . . . . . .

Fig. 21 -- Grooved Tire Assembly 7-28. . . . . .

Fig. 22 -- Non-Mark, Non-Skid Tires 7-29. . . .

Fig. 23 -- Battery Kit, 380 A/h, Wet 7-30. . . . .

Fig. 24 -- Battery Kit, 420 A/h, Wet 7-31. . . . .

Fig. 25 -- Battery Kit, 570 A/h, Wet 7-32. . . . .

Fig. 26 -- Battery Kit, 570 A/h, Dry,

International Only 7-33. . . . . . . .

Fig. 27 -- Battery Charger Group,

380 A/h Batteries, 60Hz 7-34. . .

Fig. 28 -- Battery Charger Group,

380 A/h Batteries, 50Hz,

International Only 7-35. . . . . . . .

Fig. 29 -- Battery Charger Group,

420 A/h Batteries, 60Hz 7-36. . .

Fig. 30 -- Battery Charger Group,

420 A/h Batteries, 50Hz,

International Only 7-37. . . . . . . .

Fig. 31 -- Battery Charger Group,

570 A/h Batteries, 60Hz 7-38. . .

Fig. 32 -- Battery Charger Group,

570 A/h Batteries, 50Hz,

International Only 7-39. . . . . . . .

Fig. 33 -- Power Wand Mount and

Pump Group 7-40. . . . . . . . . . . .

Fig. 34 -- Power Wand Assembly 7-42. . . . . .

Fig. 35 -- Power Wand Hose Assembly 7-44.

Fig. 36 -- Fire Extinguisher Kit 7-45. . . . . . . . .

Fig. 37 -- Front Squeegee Blade

Group, Tile 7-46. . . . . . . . . . . . . .

Fig. 38 -- Positive Solution Control Drain

System Kit, Standard 7-47. . . . . .

Page

Page

Fig. 39 -- Positive Solution Control Drain

System Kit, ESt 7-48. . . . . . . . . .

Fig. 40 -- Documentation Group 7-50. . . . . . . .

ELECTRICAL COMPONENTS 8-1. . . . . . . . . . . .

Fig. 1 -- Electric Motor Breakdown,

17363 8-2. . . . . . . . . . . . . . . . . .

Fig. 2 -- Battery Charger Breakdown,

41390 8-4. . . . . . . . . . . . . . . . . .

Fig. 3 -- Electric Motor Breakdown,

16225 8-6. . . . . . . . . . . . . . . . . .

Fig. 4 -- Electric Motor Breakdown,

16224 8-7. . . . . . . . . . . . . . . . . .

Fig. 5 -- Electric Motor Breakdown,

86356 8-8. . . . . . . . . . . . . . . . . .

Fig. 6 -- Electric Motor Breakdown,

60196 8-9. . . . . . . . . . . . . . . . . .

Fig. 7 -- Electric Motor Breakdown,

04922 8-10. . . . . . . . . . . . . . . . . .

Fig. 8 -- Electric Motor Breakdown,

60198 8-11. . . . . . . . . . . . . . . . . .

Fig. 9 -- Water Pump Breakdown,

17333 8-12. . . . . . . . . . . . . . . . . .

Fig. 10 -- Water Pump Breakdown,

65590 8-13. . . . . . . . . . . . . . . . . .

CROSS REFERENCE 9-1. . . . . . . . . . . . . . . . . . .

PART NUMBER TO PAGE NUMBER CROSS

REFERENCE LIST 9-1. . . . . . . . . . . .

510E MM239 (3--95)

v

GENERAL INFORMATION

Home

Find...

Go To..

vi

510E MM239 (1--90)

MACHINE SPECIFICATIONS 1-3. . . . . . . . . . . . .

Home

Find...

Go To..

POWER TYPE 1-3. . . . . . . . . . . . . . . . . . . . . . .

POWER TRAIN 1-3. . . . . . . . . . . . . . . . . . . . . .

STEERING 1-3. . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKING SYSTEM 1-3. . . . . . . . . . . . . . . . . .

SUSPENSION SYSTEM 1-3. . . . . . . . . . . . . .

SYSTEM FLUID CAPACITIES 1-3. . . . . . . . .

GENERAL MACHINE DIMENSIONS --

CAPACITIES 1-3. . . . . . . . . . . . . . . . . . . . . .

MACHINE WEIGHTS 1-3. . . . . . . . . . . . . . . . .

GENERAL MACHINE PERFORMANCE 1-3.

MACHINE DIMENSIONS 1-4. . . . . . . . . . . . . . . . .

SPECIFICATIONS

SECTION 1

CONTENTS

Page

510E MM239 (1--90)

1-1

SPECIFICATIONS

Home

Find...

Go To..

1-2

510E MM239 (1--90)

MACHINE SPECIFICATIONS

Home

Find...

Go To..

SPECIFICATIONS

POWER TYPE

Electric propelling motor -- nominal voltage

36 VDC, 2 hp (1.5 kW) @ 2000 rpm

Electric vacuum fan motor (2) -- nominal voltage

36 VDC, 0.85 hp (0.63 kW) @ 14,000 rpm

Electric brush drive motor (2) -- nominal voltage

36 VDC, 1 hp (0.75 kW) @ 2200 rpm

Electric heavy duty brush drive motor (option) (2)

-- nominal voltage 36 VDC, 1.5 hp

(1.12 kW) @ 2200 rpm

Electric Pre-Sweept motor (option) -- nominal

voltage 36 VDC, 0.8 hp (0.60 kW)

@ 320 rpm

Batteries (3) -- 12 V, 380 A/h @ 6 hour rate

(1) 36 V, 570 A/h @ 6 hour rate

Battery charger (option) -- 36 VDC 120 A,

208--240--480 VAC, 60 Hz, 1 ph

36 VDC 120 A, 208--240--480 VAC, 60 Hz,

3 ph

36 VDC 120 A, 208--240--480 VAC, 50 Hz,

1 ph

36 VDC 120 A, 208--240--480 VAC, 50 Hz,

3 ph

36 VDC 75 A, 208--240--480 VAC, 50 Hz,

3 ph

36 VDC 75 A, 208--240--480 VAC, 60 Hz,

1 ph

36 VDC 75 A, 208--240--480 VAC, 60 Hz,

3 ph

36 VDC 50 A, 240 VAC, 60 Hz, 1 ph

36 VDC 50 A, 230 VAC, 50 Hz, 1 ph

36 VDC 45 A, 200 VAC, 50 & 60 Hz, 1 ph

SYSTEM FLUID CAPACITIES

Gearbox grease capacity, propelling -- 2.7 qt

(2.6 L)

Solution tank capacity -- 55 gal (210 L)

Recovery tank capacity -- 50 gal (190 L)

Tank capacity with ESt option -- 80 gal (303 L)

GENERAL MACHINE DIMENSIONS -CAPACITIES

Length -- 83 in (2110 mm)

Length with Pre-Sweept -- 97 in (2465 mm)

Width -- 42 in (1065 mm)

Width with edge scrub -- 47 in (1195 mm)

Height -- 57 in (1450 mm)

Height with overhead guard -- 80 in (2030 mm)

Track -- rear 34.8 in (885 mm)

Wheel base -- 42.8 in (1085 mm)

Scrub brush diameter -- 20 in (510 mm)

Pre-Sweept main brush (option) diameter --

8 in (205 mm)

Pre-Sweept main brush (option) length --

36 in (915 mm)

Pre-Sweept side brush (option) diameter --

13 in (330 mm)

Scrubbing path width -- 40 in (1015 mm)

Pre-Sweept hopper capacity -- 0.75 cu ft

(0.02 m#) 75 lb (34 kg)

Rear squeegee path width -- 47.5 in (1210 mm)

POWER TRAIN

Propelling -- electric motor to gearbox driven

Scrub brushes -- electric motor to gearbox driven

Vacuum fan -- electric motor direct driven

Pre-Sweept brushes (option) -- electric motor

belt driven

STEERING

Type -- front wheel controlled, universal joint to

gear and chain

Power source -- manual

BRAKING SYSTEM

Service brakes -- mechanical drum brakes (2),

1 per rear wheel, linkage actuated

Parking brake -- utilizes service brakes, linkage

actuated

SUSPENSION SYSTEM

Front -- 16.25 x 6 solid tire (1)

Rear --- 16 x 3.5 solid tire (2)

510E MM239 (8--92)

MACHINE WEIGHTS

GVWR -- 4600 lb (2087 kg)

GENERAL MACHINE PERFORMANCE

Maximum forward speed -- 5 mph (8 km/h)

Maximum reverse speed -- 3 mph (4.8 km/h)

Aisle turnaround width -- 90 in (2290 mm)

Aisle turnaround width with Pre-Sweept --

104 in (2640 mm)

Maximum rated ramp climb with empty tanks --

8.5_

Maximum rated ramp descent angle with empty

tanks -- 8.5_

Maximum rated ramp climb with full tanks -- 5.7_

Maximum rated ramp descent angle with full

tanks -- 5.7_

1-3

SPECIFICATIONS

Home

Find...

Go To..

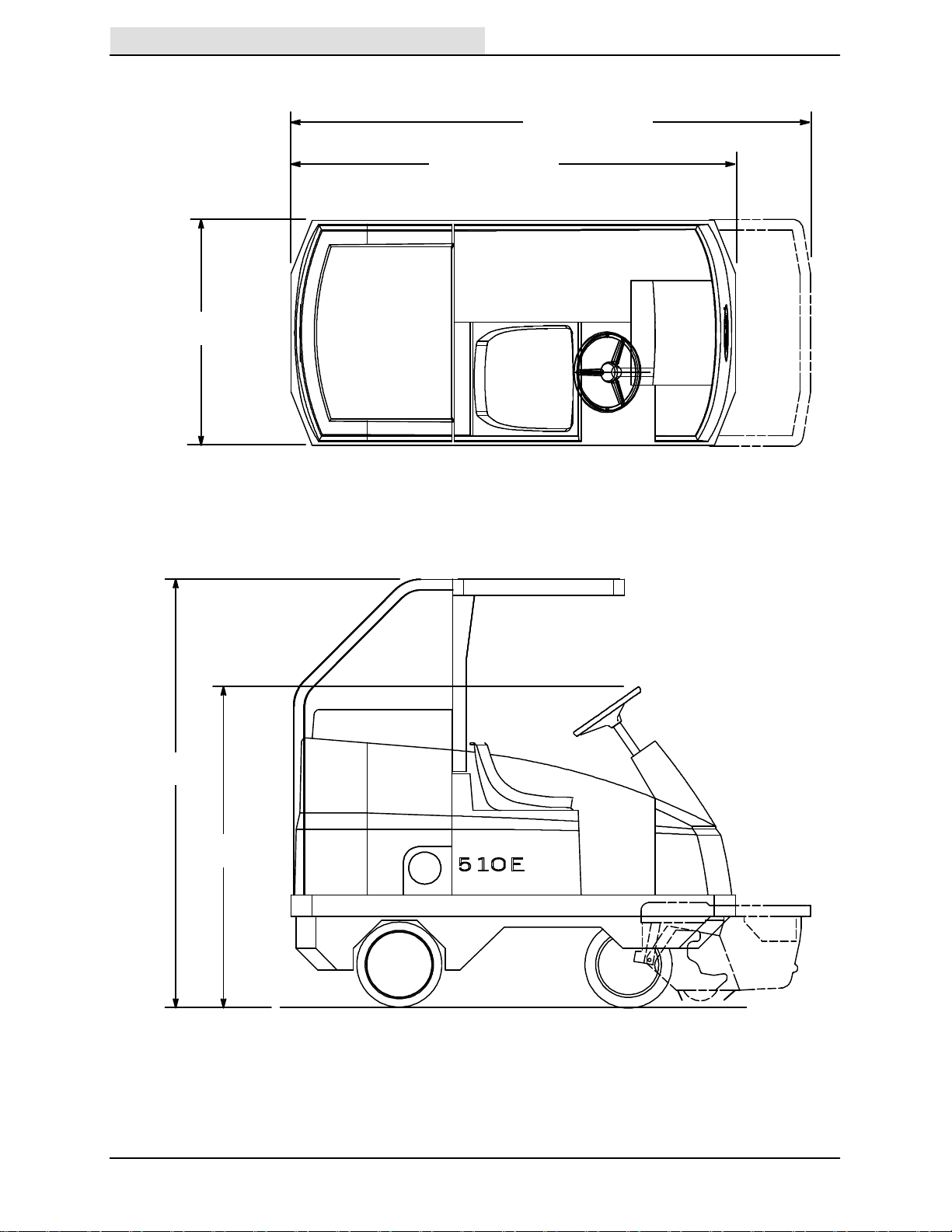

42 in

(1065 mm)

MACHINE DIMENSIONS

97 in (2465 mm)

83 in (2110 mm)

TOP VIEW

(2030 mm)

1-4

80 in

57 in

(1450 mm)

SIDE VIEW

05424

510E MM239 (1--90)

CONTENTS

Home

Find...

Go To..

OPERATION

SECTION 2

PREPARATION FOR OPERATION 2-3. . . . . . . .

AFTER UNCRATING AND BEFORE

OPERATING MACHINE: 2-3. . . . . . . . . . .

OPERATION OF CONTROLS 2-4. . . . . . . . . . . .

MACHINE COMPONENTS 2-4. . . . . . . . . . . .

HOW IT WORKS 2-5. . . . . . . . . . . . . . . . . . . . .

INSTRUMENT PANEL SYMBOLS 2-6. . . . . .

CONTROLS AND INSTRUMENTS 2-7. . . . .

BRAKE PEDAL 2-8. . . . . . . . . . . . . . . . . . . . . .

DIRECTIONAL PEDAL 2-8. . . . . . . . . . . . . . . .

STEERING WHEEL 2-8. . . . . . . . . . . . . . . . . .

SOLUTION FLOW LEVER 2-8. . . . . . . . . . . .

CLOGGED VACUUM INDICATOR 2-8. . . . . .

RECOVERY TANK FULL INDICATOR 2-8. .

HOUR METER 2-8. . . . . . . . . . . . . . . . . . . . . . .

BRUSH PRESSURE INDICATOR AND

SWITCH 2-8. . . . . . . . . . . . . . . . . . . . . . . . .

EDGE SCRUB SWITCH 2-9. . . . . . . . . . . . . .

BATTERY DISCHARGE INDICATOR 2-9. . .

ELECTRICAL POWER INDICATOR 2-9. . . .

BRUSH CIRCUIT BREAKER INDICATOR 2-9

REAR SQUEEGEE AND VACUUM FAN

SWITCH 2-9. . . . . . . . . . . . . . . . . . . . . . . . .

SCRUB BRUSH SWITCH 2-9. . . . . . . . . . . . .

HORN BUTTON 2-9. . . . . . . . . . . . . . . . . . . . . .

KEY-OPERATED ON-OFF SWITCH 2-9. . . .

OPERATING LIGHTS SWITCH 2-10. . . . . . . .

REVOLVING LIGHT SWITCH 2-10. . . . . . . . . .

PRE-SWEEPt SWITCH 2-10. . . . . . . . . . . . . .

ESt SWITCH 2-10. . . . . . . . . . . . . . . . . . . . . . .

PARKING BRAKE LEVER 2-10. . . . . . . . . . . . .

POWER WAND SWITCH 2-10. . . . . . . . . . . . . .

CIRCUIT BREAKERS 2-11. . . . . . . . . . . . . . . . .

MACHINE OPERATION 2-12. . . . . . . . . . . . . . . . . .

NORMAL SCRUBBING OPERATION 2-12. . .

PRE-START CHECKLIST 2-12. . . . . . . . . .

TO START MACHINE 2-12. . . . . . . . . . . . . .

TO FILL SOLUTION TANK 2-12. . . . . . . . .

TO SCRUB 2-14. . . . . . . . . . . . . . . . . . . . . . .

TO DRAIN AND CLEAN RECOVERY

TANK 2-15. . . . . . . . . . . . . . . . . . . . . . . . .

POST OPERATION CHECKLIST --

MACHINE ON 2-17. . . . . . . . . . . . . . . . . .

TO STOP MACHINE 2-17. . . . . . . . . . . . . . .

POST OPERATION CHECKLIST --

MACHINE OFF 2-17. . . . . . . . . . . . . . . . .

DOUBLE SCRUBBING OPERATION 2-18. . .

TO RAISE SIDE SQUEEGEES 2-18. . . . . .

TO LOWER SIDE SQUEEGEES 2-18. . . .

OPERATION ON GRADES 2-18. . . . . . . . . . . .

MACHINE TROUBLESHOOTING 2-19. . . . . .

Page

Page

OPTIONS OPERATION 2-20. . . . . . . . . . . . . . . . . .

VACUUM WAND 2-20. . . . . . . . . . . . . . . . . . . . .

TO OPERATE THE VACUUM WAND 2-20

POWER WAND 2-21. . . . . . . . . . . . . . . . . . . . . .

TO OPERATE THE POWER WAND 2-21.

PRE-SWEEPt 2-23. . . . . . . . . . . . . . . . . . . . . .

TO REPLACE THE PRE-SWEEPt

DEBRIS HOPPER LINER 2-23. . . . . . . .

TO REMOVE PRE-SWEEPt

ASSEMBLY 2-23. . . . . . . . . . . . . . . . . . . .

TO MOUNT PRE-SWEEPt

ASSEMBLY 2-24. . . . . . . . . . . . . . . . . . . .

TRANSPORTING MACHINE 2-25. . . . . . . . . . . . .

PUSHING OR TOWING 2-25. . . . . . . . . . . . . . .

MACHINE JACKING 2-25. . . . . . . . . . . . . . . . . .

TO JACK UP MACHINE 2-25. . . . . . . . . . . .

MACHINE TIE DOWNS 2-26. . . . . . . . . . . . . . .

MACHINE STORAGE 2-27. . . . . . . . . . . . . . . . . . .

STORING MACHINE 2-27. . . . . . . . . . . . . . . . .

510E MM239 (8--92)

2-1

OPERATION

Home

Find...

Go To..

2-2

510E MM239 (1--90)

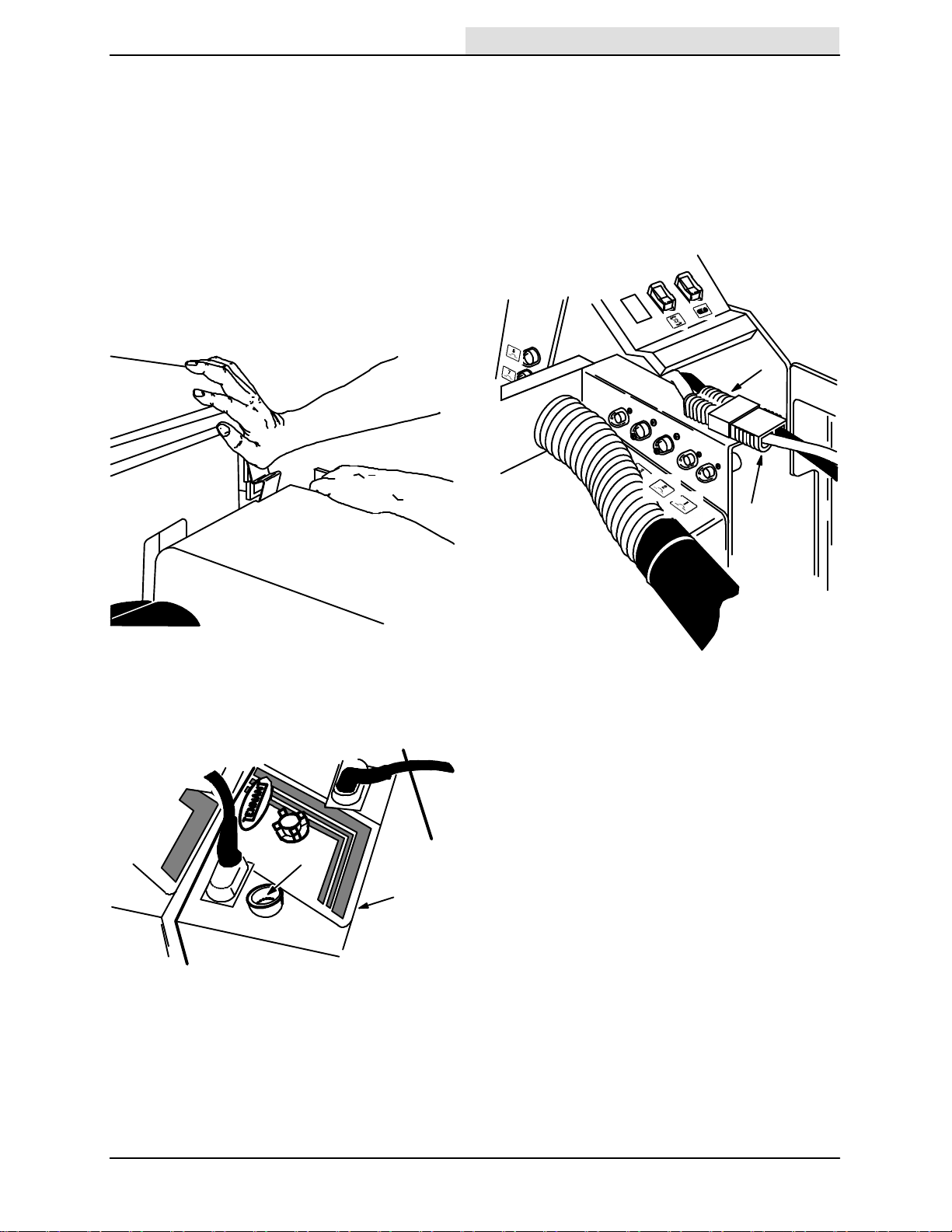

PREPARATION FOR OPERATION

Home

Find...

Go To..

OPERATION

AFTER UNCRATING AND BEFORE

OPERATING MACHINE:

1. Check the machine for shipping damage.

2. Read this manual carefully before operating

or serving the machine.

FOR SAFETY: Do Not Operate Machine,

Unless Operation Manual Is Read And

Understood.

3. Open the machine cover.

5. Check the battery specific gravity to

determine the state of charge as described

in BATTERIES in the MAINTENANCE

section. Charge the batteries if necessary.

6. Connect the battery connector to the

machine connector.

A

B

OPENING MACHINE COVER

05915

4. Check the batteries electrolyte level as

described in BATTERIES in the

MAINTENANCE section.

B

A

00879

CHECKING BATTERY ELECTROLYTE LEVEL

A. Battery

B. Electrolyte Indicator Ring

FOR SAFETY: When Servicing Machine, Avoid

Contact With Battery Acid.

MACHINE TO BATTERY CONNECTOR

05920

A. Machine Connector

B. Battery Connector

7. Install the scrub brushes as described in

SCRUB BRUSHES in the MAINTENANCE

section.

8. Pre-Sweept machines: Install the

Pre-Sweept assembly as described in TO

MOUNT PRE-SWEEPt ASSEMBLY.

510E MM239 (3--91)

2-3

OPERATION

Home

Find...

Go To..

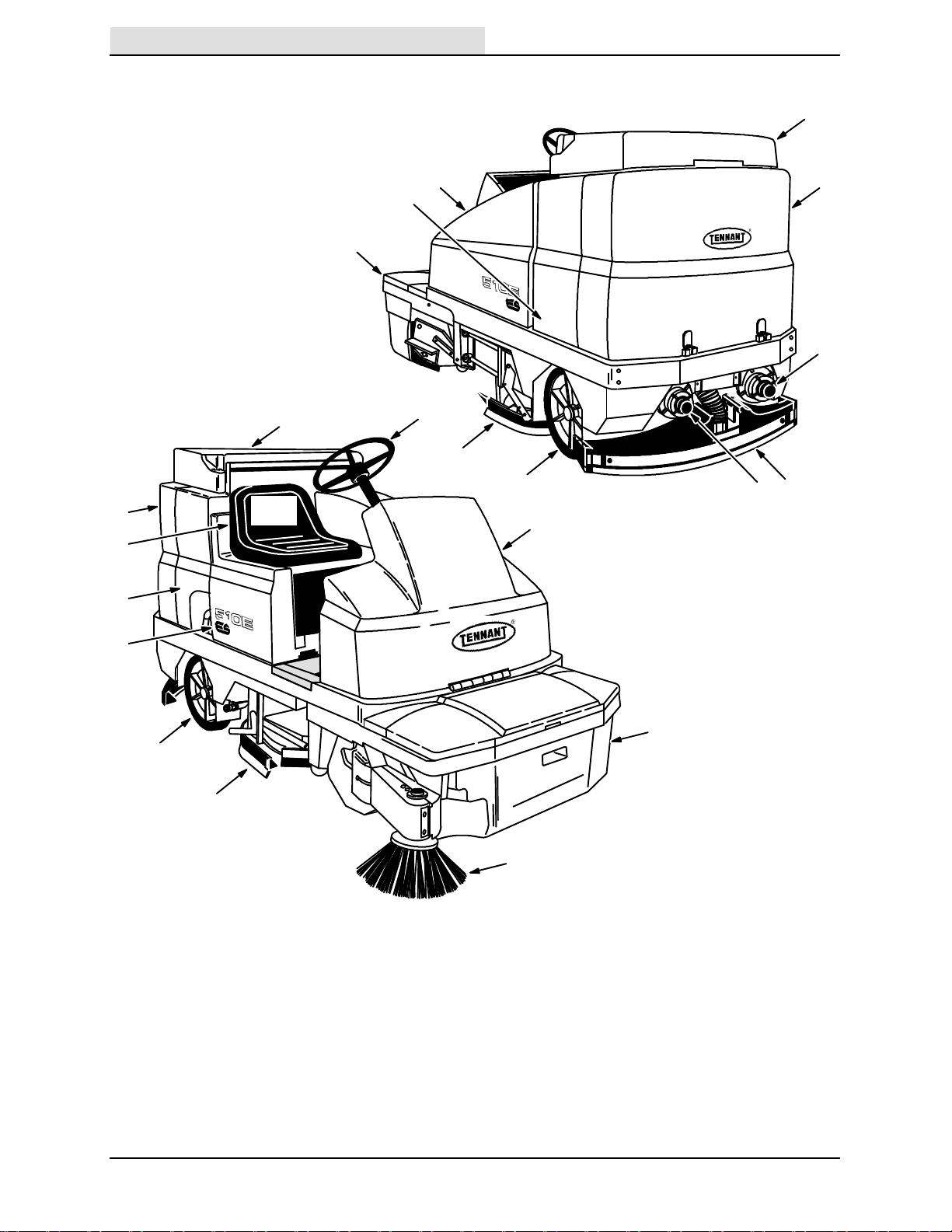

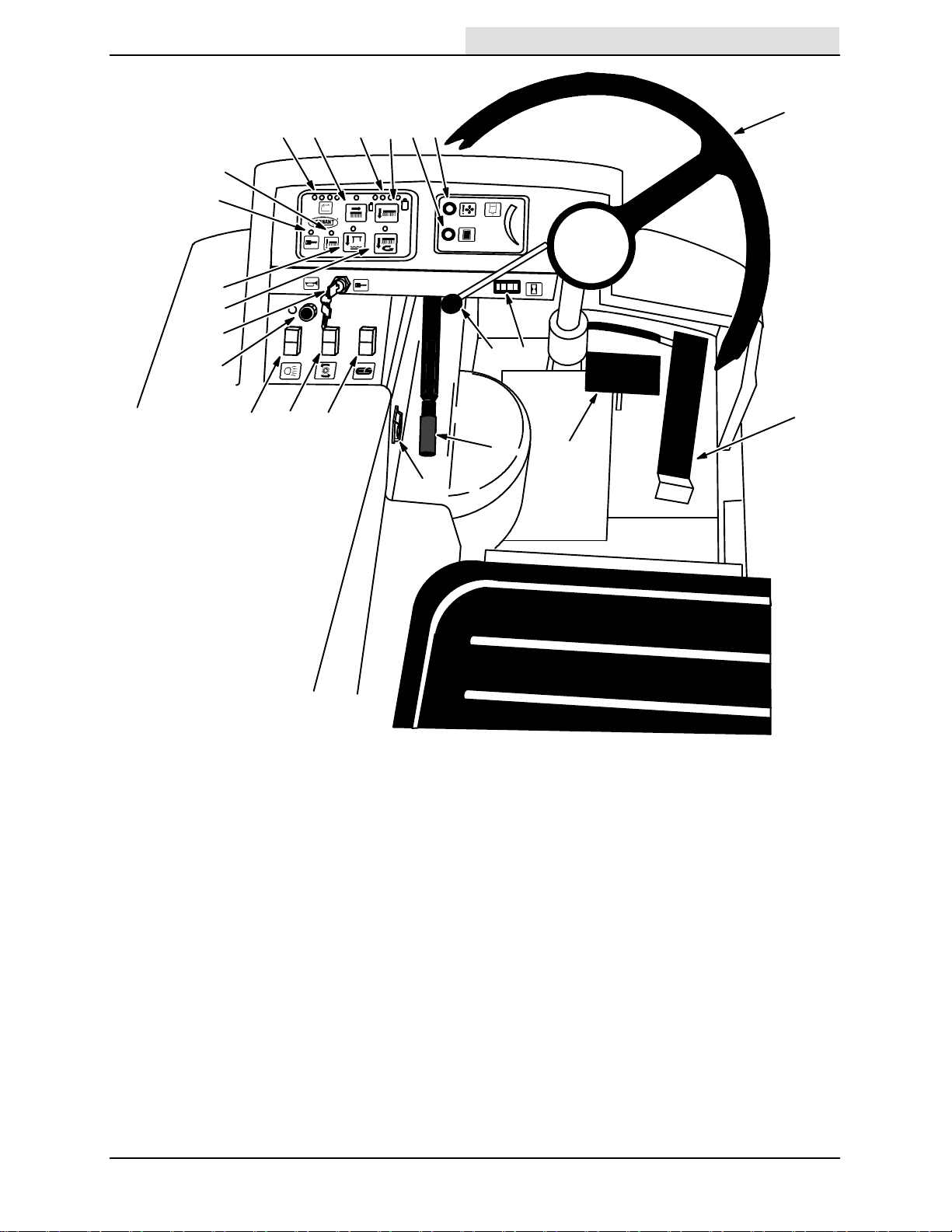

OPERATION OF CONTROLS

F

C

D

K

F

E

A

D

B

H

M

C

I

E

J

G

N

K

M

H

L

05912

MACHINE COMPONENTS

A. Operator Seat H. Side Squeegee

B. Steering Wheel I. Solution Tank Drain

C. Machine Cover J. Recovery Tank Drain

D. Recovery Tank K. Pre-Sweept Assembly

E. Solution Tank L. Side Brush

F. Tanks Cover M. Rear Wheel

G. Rear Squeegee N. Seat Support

05924

2-4

510E MM239 (1--90)

HOW IT WORKS

Home

Find...

Go To..

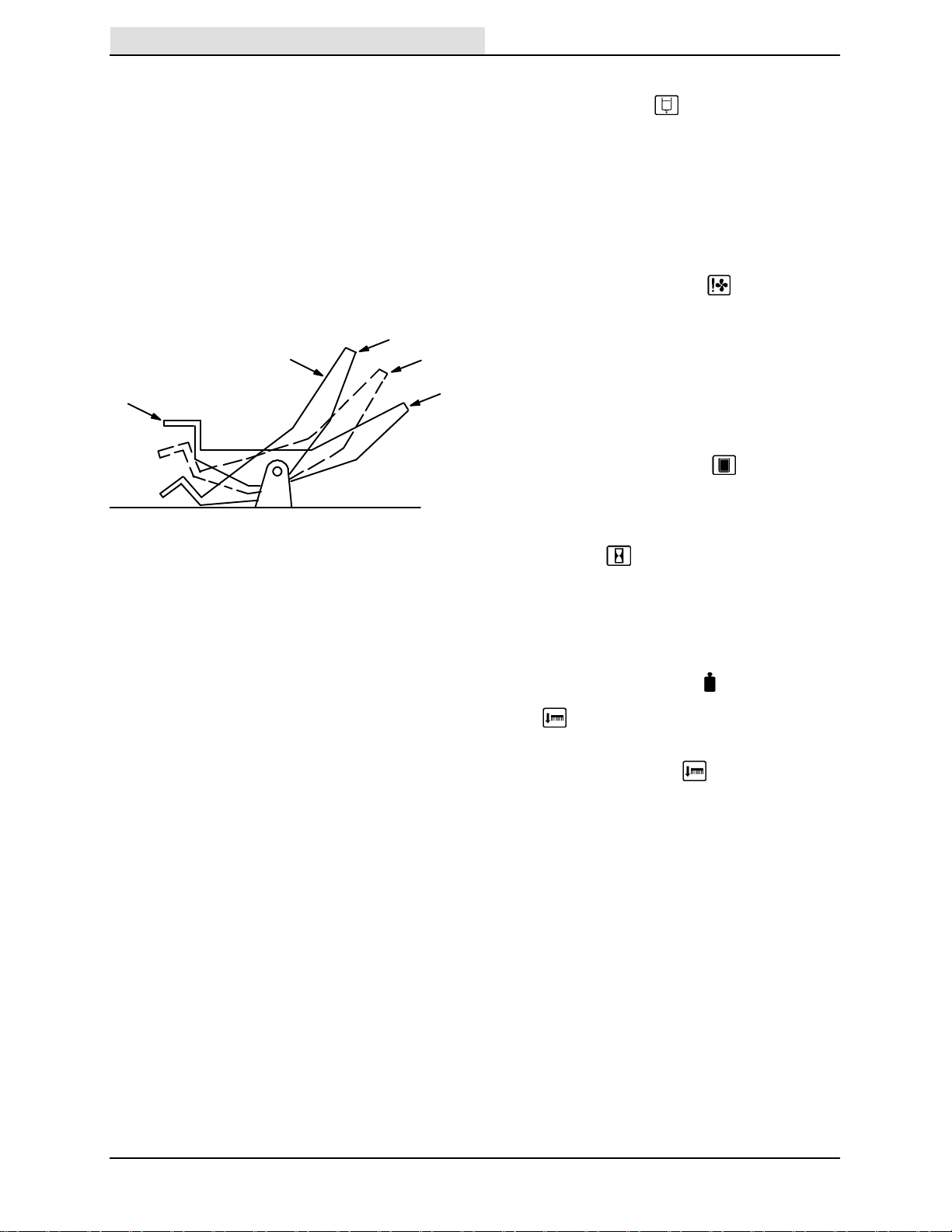

The Model 510E is a rider scrubber. The machine

is propelled by a electric motor via the front wheel.

The machine is steered with the steering wheel

and is very responsive.

The main scrubbing components include a

solution tank, two disc-type brushes, rear and side

squeegees, a vacuum fan, and a recovery tank.

Water and detergent solution flows from the

solution tank through the water control valve to

the scrub brushes. The rotating scrub brushes

scrub the floor. As the machine moves forward,

the squeegees collect the dirty solution and

channel it into the vacuum of the squeegee

pick-up hose. The pick-up hose deposits the dirty

solution in the recovery tank.

Machines with the ESt option filter the dirty

solution in the recovery tank and return it to the

solution tank.

OPERATION

510E MM239 (1--90)

2-5

OPERATION

Home

Find...

Go To..

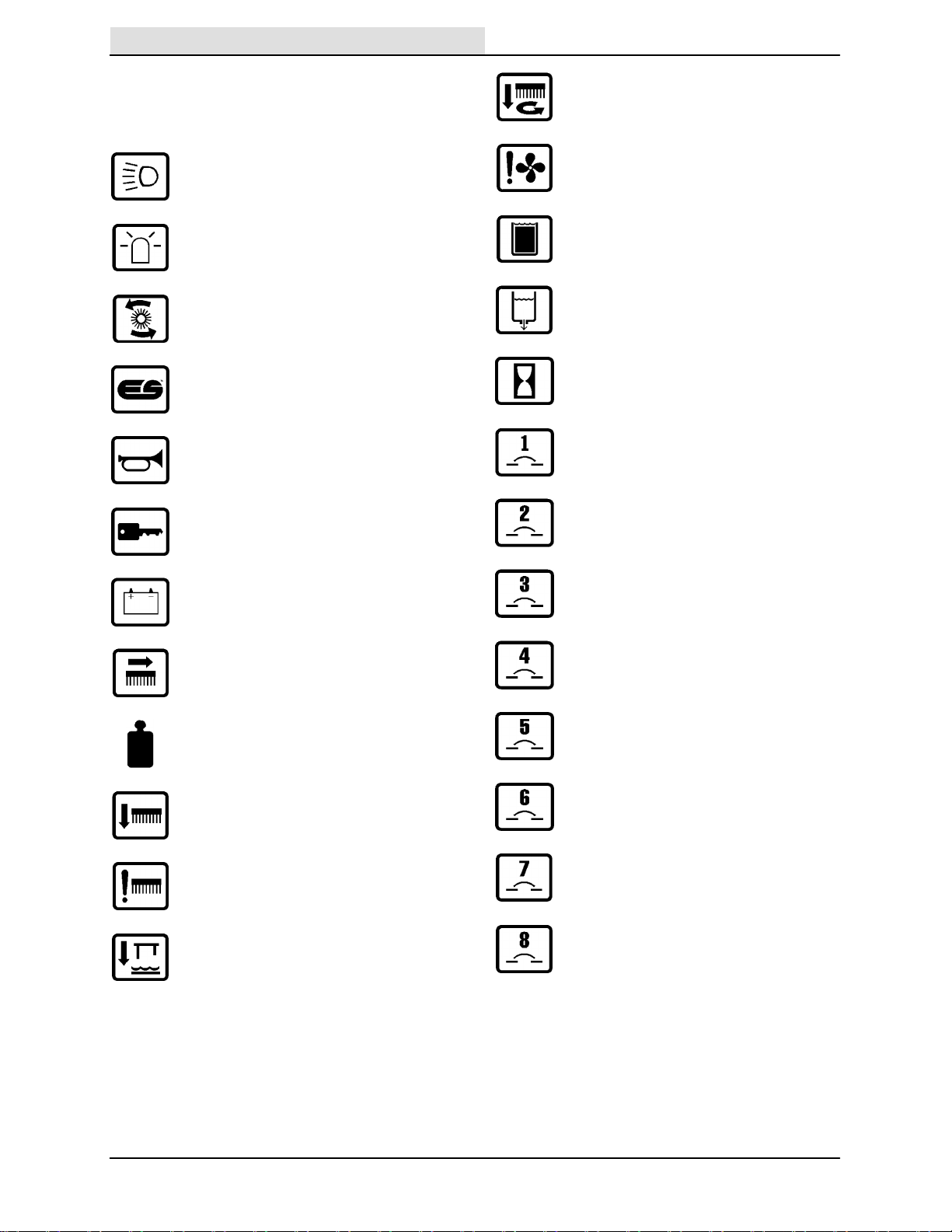

INSTRUMENT PANEL SYMBOLS

These symbols are used to identify controls and

displays on the machine:

Scrub Brush Down and On

Headlights

Revolving Light

Brushes On (Pre-Sweept)

ESt

Horn

Key Switch

Battery Charging System

Vacuum Clogged

Recovery Tank Full

Solution Flow

Hour Meter

Circuit Breaker #1

Circuit Breaker #2

Circuit Breaker #3

Scrub Brush Edge Clean

Down Pressure

Scrub Brush Down

Scrub Brush Shut Down

Squeegee Down

Circuit Breaker #4

Circuit Breaker #5

Circuit Breaker #6

Circuit Breaker #7

Circuit Breaker #8

2-6

510E MM239 (1--90)

M

Home

Find...

Go To..

L

N

O

Q

P

OPERATION

C

H IJK

DEFG

R S T

U

V

CONTROLS AND INSTRUMENTS

A. Brake Pedal M. Brush Circuit Breaker Indicator

B. Directional Pedal N. Rear Squeegee and

C. Steering Wheel Vacuum Fan Switch

D. Solution Flow Lever O. Scrub Brush Switch

E. Clogged Vacuum Indicator P. Horn Button

F. Recovery Tank Full Indicator Q. Key-Operated On-Off Switch

G. Hour Meter R. Operating Lights Switch/Revolving

H. Brush Pressure Indicator Light Switch

I. Brush Pressure Switch S. Pre-Sweept Switch

J. Edge Scrub Switch T. ESt Switch

K. Battery Discharge Indicator U. Parking Brake

L. Electrical Power Indicator V. Power Wand Switch

A

B

05913

510E MM239 (8--92)

2-7

OPERATION

ABC

Home

Find...

Go To..

BRAKE PEDAL

The brake pedal operates the brakes on the two

rear wheels.

To stop the machine, return the direction control

pedal to neutral, then apply pressure to the brake

pedal.

DIRECTIONAL PEDAL

The directional pedal controls the propelling drive.

The pedal is used to select the direction of travel

and the speed of the machine.

E

D

00116

DIRECTIONAL PEDAL POSITIONS

A. “Reverse” Position

B. “Neutral” Position

C. “Forward” Position

D. “Heel” Portion

E. “Toe” Portion

Gradually press the “toe” portion of the pedal for

forward travel or the “heel” portion for reverse

travel. Regulate the machine speed by varying the

pressure on the pedal.

SOLUTION FLOW LEVER

The solution flow lever controls the flow of

solution to the floor. To start the solution flow,

push the lever slightly up. To increase the solution

flow to maximum, push the lever all the way up.

To stop the solution flow to the floor, pull the lever

all the way down.

CLOGGED VACUUM INDICATOR

The clogged vacuum indicator lights when

the vacuum system is obstructed and the vacuum

is no longer picking solution from the floor.

When the clogged vacuum indicator lights, check

the vacuum system hoses for obstructions

starting at the rear squeegee pick-up hose.

RECOVERY TANK FULL INDICATOR

The recovery tank full indicator lights when

the recovery tank is full.

HOUR METER

The hour meter records the number of hours

the machine has operated. This information is

useful in determining when to service the

machine.

BRUSH PRESSURE INDICATOR AND SWITCH

The brush pressure indicator shows the

brush pressure selection. The brush pressure

switch controls how aggressive the brushes

are scrubbing the floor.

The machine will coast for a short distance before

changing direction when it is moving and the

directional pedal is reversed. Use the brakes to

stop the machine.

FOR SAFETY: When Using Machine, Use

Brakes To Stop Machine.

STEERING WHEEL

The steering wheel controls the front drive wheel.

The machine is very responsive to the movement

of the steering wheel. The operator should use

care until he or she becomes experienced in

guiding the machine.

2-8

The brush pressure switch has four positions.

Under normal conditions, the brush pressure

should be set in the light zone. Under heavy grime

conditions, the brush pressure should be set in

the heavy zones. Travel speed and floor

conditions will affect the scrubbing performance.

To change the brush pressure, touch the brush

pressure switch. Each time the switch is touched,

it will increase brush pressure until it reaches the

maximum setting. Then it will return to the

minimum setting as shown on the pressure

indicator.

510E MM239 (3--95)

OPERATION

Home

Find...

Go To..

EDGE SCRUB SWITCH

The edge scrub switch extends the scrub

head to the right to allow close edge scrubbing.

To operate the edge scrub, press the edge scrub

switch during normal scrubbing. To turn off the

edge scrub, press the edge scrub switch again.

BATTERY DISCHARGE INDICATOR

The battery discharge indicator indicates the

charge level of the batteries. It displays the

charge level when the scrub brushes are

operating.

The display should be on the 1 mark of the gauge

when the batteries are fully charged. As the

batteries discharge, the display will move near the

0 mark. For best life, the batteries should be

recharged when the display nears the 0 mark. If

the light near the 0 mark starts to blink, the

batteries are fully discharged. At this point, the

brushes will automatically raise to limit current

draw and to alert the operator of the battery

condition. Further operation of the machine could

damage the machine or the batteries.

When the machine is left overnight with less than

a full charge, the display may at first indicate a full

charge. It is reading the surface charge level -- not

the true charge level. After running the machine a

few minutes, the indicator will give the correct

charge level.

NOTE: Do not charge the batteries more often

than is necessary to prolong the life of the

batteries. Do not allow the batteries to become

completely discharged as this will also damage

the batteries. See BATTERIES in the

MAINTENANCE section.

REAR SQUEEGEE AND VACUUM FAN

SWITCH

The rear squeegee and vacuum fan switch ,

along with the direction of machine travel, control

the position of the rear squeegee, and turns on

the vacuum fan.

To start the vacuum fan and lower the rear

squeegee, press the rear squeegee and vacuum

fan switch.

When the machine travels backward, the rear

squeegee lifts. This prevents the rear squeegee

from being damaged when backing the machine.

The rear squeegee will lower again when the

machine travels forward.

To raise the rear squeegee and stop the vacuum

fan, press the rear squeegee and vacuum fan

switch again.

SCRUB BRUSH SWITCH

The scrub brush switch controls the scrub

head position and scrub brush rotation.

To lower the scrub head and start the scrub

brushes rotating, press the scrub brush switch.

When the machine travels forward, the scrub

head will lower and the scrub brushes will start

rotating. If the machine is stopped for more than 6

seconds, the scrub head raises to prevent scrub

brush wear. When the machine travels in reverse,

the scrub head raises. Once the machine starts

traveling forward the scrub brushes start rotating

and the scrub head will lower.

To raise the scrub head and stop the scrub

brushes, press the scrub brush switch again.

ELECTRICAL POWER INDICATOR

The electrical power indicator lights when the

key-operated switch is turned on and the machine

has electrical power.

BRUSH CIRCUIT BREAKER INDICATOR

The brush circuit breaker indicator lights

when one or both of the two brush motor circuit

breakers have tripped. When the circuit breakers

are tripped, the brushes will stop rotating and the

scrub head will raise. The circuit breaker(s) must

be reset before resuming scrubbing.

510E MM239 (3--91)

HORN BUTTON

The horn button operates the horn. To sound

the horn, press the horn button.

KEY-OPERATED ON-OFF SWITCH

The key-operated on-off switch controls all

machine power. To allow the machine to operate,

turn the key clockwise. To turn the machine off,

turn the key counter-clockwise.

2-9

OPERATION

Home

Find...

Go To..

OPERATING LIGHTS SWITCH

The operating lights switch is present on

machines equipped with the operating lights

option. The switch operates the headlights and

taillights; and revolving light if equipped with

revolving light option. To turn the operating lights

on, place the switch in the top position. To turn the

operating lights off, place the switch in the bottom

position.

REVOLVING LIGHT SWITCH

The revolving light switch is present on

machines equipped with the revolving light option.

To turn the revolving light on, place the switch in

the top position. To turn the revolving light off,

place the switch in the bottom position.

PRE-SWEEPt SWITCH

The Pre-Sweept switch is present on

machines equipped with the Pre-Sweept option.

The switch operates the Pre-Sweept assembly.

To lower the Pre-Sweept and turn the brushes

on, press and hold the bottom portion of the

switch until the the Pre-Sweept lowers to the

floor and the actuator ratchets. To raise the

Pre-Sweept and turn off the brushes, press the

top of the switch and hold it until the actuator

ratchets, 3 to 4 seconds.

ESt SWITCH

The ESt switch controls the extended

scrubbing solution system on machines equipped

with the ESt option.

The machine will start with the ESt system on.

The ESt pump may not start right away. The

pump will start as the recovery tank fills up with

solution.

To start the ESt system, place the switch in the

top position. The green light on the switch will

light. To stop the ESt system, place the switch in

the bottom position.

PARKING BRAKE LEVER

The parking brake lever operates the rear wheel

brakes.

To set the parking brake, pull the handle up. To

release the parking brake, push the handle down.

POWER WAND SWITCH

The power wand switch controls the solution to

the power wand option.

To start the solution flow to the power wand, press

the top or ON position of the switch. To stop the

solution flow to the power wand, press the bottom

or OFF position of the switch.

2-10

510E MM239 (8--92)

OPERATION

Home

Find...

Go To..

CIRCUIT BREAKERS

The circuit breakers are resetable circuit

protection devices designed to stop the flow of

current in the event of a circuit overload. Once

tripped, circuit breakers must be manually reset,

after it cools, by pressing the reset button. If the

overload which caused the circuit breaker to trip is

still present in the circuit, the circuit breaker will

continue to stop current flow until the overload is

corrected.

The fuse is a one-time circuit protection device

designed to stop the flow of current in the event of

a circuit overload. Never substitute higher value

fuses then those specified in this manual.

The circuit breakers are located to the left of the

operator’s compartment near the machine and

battery connectors. The fuse is located in the

control box.

The following chart shows the various circuit

breakers, and the electrical components they

protect.

PROTECTIVE

DEVICE RATING CIRCUIT

PROTECTED

CB--1 20 A Vacuum fan motor

CB--2 20 A Vacuum fan motor

CB--3 40 A Scrub brush motor

CB--4 40 A Scrub brush motor

CB--5 30 A Pre-Sweept (option)

CB--6 10 A Control Circuit

CB--7 10 A Horn

CB--8 15 A Revolving and operating

FU--1 100 A Propelling

A

50 A Heavy Duty scrub brush

motor (option)

50 A Heavy Duty scrub brush

motor (option)

lights (option/ESt)

B

A

A

CIRCUIT BREAKERS

A. Circuit Breakers

B. Machine and Battery Connectors

05920

510E MM239 (8--92)

2-11

OPERATION

Home

Find...

Go To..

MACHINE OPERATION

NORMAL SCRUBBING OPERATION

A normal scrubbing operation consists of eight

typical operations; pre-start checklist, starting

machine, filling solution tank, scrubbing, draining

and cleaning recovery tank, post operation

checklist -- machine on, stopping machine, and

post operation checklist -- machine off.

PRE-START CHECKLIST lists the things to check

before starting the machine.

TO START THE MACHINE lists the steps

required to start the machine.

TO FILL SOLUTION TANK lists the steps

required to fill the solution tank.

TO SCRUB lists the things to keep in mind before

and during the scrubbing operation.

TO DRAIN AND CLEAN RECOVERY TANK lists

the steps required to empty and clean the

recovery tank.

POST OPERATION CHECKLIST -- MACHINE

ON lists the things to check before turning off the

machine.

TO STOP MACHINE lists the steps required to

stop the machine.

POST OPERATIONAL CHECKLIST -- MACHINE

OFF lists the things to check after turning off the

machine.

TO START MACHINE

NOTE: Before starting machine, go through the

pre-start checks.

1. The machine operator must be in the

operator’s seat with the directional pedal in

the “neutral” position and with a foot on the

brake pedal or with the parking brake set.

FOR SAFETY: Before Starting Machine Make

Sure All Safety Devices Are In Place And

Operate Properly.

2. Turn the key-operated on-off switch

clockwise to turn on the machine.

3. Release the machine parking brake.

4. Drive the machine to the solution filling site.

TO FILL SOLUTION TANK

1. Turn off the machine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, Turn Off Machine And Remove Key.

2. Pull the solution flow lever all the way down

to shut off the solution flow to the floor.

3. Lift open the tanks cover.

PRE-START CHECKLIST

Check under the machine for leaks.

Check the brakes and controls for proper

operation.

Check the service records to determine service

requirements.

2-12

510E MM239 (8--92)

Loading...

Loading...