Tennant 275 II User Manual

r

Home

Find...

Go To..

(Operator Manual)

275 Series II

Sweeper/

Scrubber

r

Home

Find...

Go To..

This manual is furnished with each new TENNANTr Model 275 Series II. It provides necessary operating and

preventive maintenance instructions. Read this manual completely and understand the machine before

operating or servicing it.

This manual covers all machine variations and standard accessories. The tabbed instruction portion of the

manual consists of the Specification, Operation, Maintenance, and Appendix sections. The tabbed parts section

consists of the Low Dump Model Parts; Diesel Parts; Multi-Level Dump Model Parts; Accessories; Hydraulic

Components; Engine Parts, Gasoline, LPG; and Engine Parts, Diesel sections. The tabbed Cross Reference

section identifies the page numbers on which each of the part numbers listed in the manual can be found.

All right side and left side references to the machine are determined by facing the direction of forward travel. All

hardware considered to be of a common nature or locally available has been omitted from the parts sections.

Be aware that this machine may contain metric hardware. Make sure you use equivalent hardware when

replacement becomes necessary.

This machine will provide excellent service. However, the best results will be obtained at minimum costs if:

D The machine is operated with reasonable care.

D The machine is maintained regularly --- per the maintenance instructions provided.

D The machine is maintained with Tennant Company supplied or equivalent parts.

Parts and supplies may be ordered by phone or mail from any Tennant Company parts and service center,

distributor, or from any of the Tennant Company subsidiaries. Before ordering parts or supplies, be sure to have

your machine model number and serial number handy. Fill out the data block below for future reference. The

telephone numbers, telex numbers, mailing addresses, and locations of those outlets are listed in the Customer

Documents section of the manual.

MACHINE DATA

Please fill out at time of installation.

Machine Serial Number ---

Engine Serial Number ---

Sales Representative ---

Date of Installation ---

Manual Number --- MM190

Revision: 05

Published: 6---90

Trademark Registered in: Austria, Benelux, Denmark, England, France, Germany, Italy, Spain, Switzerland,

United States, Argentina, Australia, Canada, Japan, Mexico, Sweden, by TENNANT COMPANY, Minneapolis,

Minnesota, U.S.A.

04632

Acknowledgements: Technical information and/or illustrations supplied by Ford Motor Company; Kubota Ltd.;

Cessna Fluid Power Division; Eaton Corporation, Hydraulics Division.

Copyright 1987, 1988, 1989, 1990 Tennant Company, Printed in U.S.A.

ABOUT THIS MANUAL

Home

Find...

Go To..

ABOUT THIS MANUAL

The machine manual that you received with your

TENNANT machine contains valuable information

about the operation and maintenance, and

numerous sections filled with TENNANT part

numbers for the repair of the machine. Please read

through this section titled ABOUT THIS MANUAL to

become familiar with the contents of the machine

manual, making the information you are looking for

easier to find.

The machine manual consists of several sections of

reference information, and the remainder contain

part number information for ordering repair parts for

the machine. Each section has a shaded bar at the

top of the page with the name of that section. Just as

this section has the title ABOUT THIS MANUAL on

the top of each page. This way you can tell which

section you are in at all times.

REFERENCE SECTIONS

The reference information sections of the manual

are; General Information, Specifications, Operation,

Maintenance, and Appendix.

GENERAL INFORMATION --- The General Information

section of the manual contains the safety

precautions, the location of the safety labels on the

machine, and a table of contents of the entire

manual. The Safety Precautions are an overview of

the safety measures to be observed when operating

and maintaining your machine. The location of the

safety labels show the mounting location of the

safety labels for use in the replacement of the labels.

The table of contents in this section is a list of all the

table of contents that appear in the front of each

section in the manual. This can be used for easy

reference to locate information in a particular section

of the manual.

SPECIFICATIONS --- The Specifications section of the

manual contains machine specification information

useful in the operation and maintenance of the

machine. This section gives you specification

information on the engine, electric motors, brake

system, hydraulics, fluid capacities, and machine

weight to mention a few. The section also has a

illustration of the top and side view of the machine

with the height and width dimensions displayed.

OPERATION --- The Operation section of the manual

contains information needed to operate the machine.

This section will list the controls and instruments on

the machine, overview the machine operation, and

tell you how to transport and store the machine.

MAINTENANCE --- The Maintenance section contains

information on the suggested maintenance

procedures and adjustments to keep your machine

in top operating condition. The section includes a

Maintenance Chart listing the maintenance schedule

and the areas of the machine to be addressed. Each

subject of maintenance is covered in more detail in

such areas as Lubrication, Hydraulics, Engine, and

Electrical System.

APPENDIX --- The Appendix contains hardware and

hydraulic information. Standard hardware torques

and identification information is included, plus

hydraulic torques if your machine is hydraulically

controlled.

PART SECTIONS

The remaining sections of the manual contain part

number information for ordering repair parts for your

machine. The manual contains part number

information on every type of machine model

available in the model size of your particular

machine. Therefore there will be part number

information in your manual you will not need to refer

to when wanting to place an order.

The main thing you need to know about your

machine is what type of model is it. Is the machine

powered by an engine or batteries? If the machine

has an engine, is it fueled from gasoline, LPG, or

gasoline? If it is a mid-sized or larger sweeper, is it

multi-level or low dump? For the scrubbers, is it

SRSr or standard. Determining this information

about your machine will help guide you through the

separate parts sections to find the repair part you

need.

275 SERIES II MM190 (12 ---89)

a

ABOUT THIS MANUAL

Home

Find...

Go To..

The smaller line of sweeper and scrubbers have less

complicated part section arrangement, and are

easier to find your way through the parts sections.

The larger machines can have quite a variety of

model types which significantly increases the size to

the machine manual. Because of this, on the larger

machine we made the first part section, Section 5, a

part section which contains parts common to all type

of the machine. If the machine has an engine, this

section contains parts information on a gasoline

powered machine.

The remaining sections contain only parts

information which is unique to that particular

machine type, such as unique diesel parts on the

machine, or unique SRSr parts. Knowing the

machine model type you have is important when

searching for that part information you need for

ordering repair parts. Start in that unique section first

when looking for a part, then go to the first parts

section, Section 5, if the part can’t be found in the

unique section.

MACHINE SERIAL NUMBERS

When a design change takes place to a machine,

the changes are indicated in the parts sections with

machine serial numbers. Know the serial number of

your machine which can be found on the machine

data plate mounted on the machine. Record this

number on the inside front cover of your manual

along with your customer number.

Machine number usage is recorded in the Machine

Serial Number column of the parts lists in the parts

sections of the manual. If the machine serial number

column lists zeros on the left side of the dash, then

this part is used on all machines; such as (000000---

).

For parts that are used on machines beginning at

and continuing on from a certain serial number, the

column would list a serial number on the left of the

dash and have blank spaces on the right side of the

dash; such as (002346--- ). This part would be

used on machines starting with that machine serial

number and greater.

Finally, parts can be used on machines with serial

numbers in a certain block of numbers. In this

situation there is a serial number on the left and right

side of the dash. The part is then used on a machine

with a serial number starting at the number on the

left and up to and including the number on the right;

such as (002346---008900).

PARTS ASSEMBLIES

A part assembly has parts within the assembly, such

as a parking brake consisting of other smaller parts.

What parts are contained in a part assembly can be

determined by an indentation arrangement in the

description column of the parts lists.

Here is an example of a part assembly, in this case

we will use the parking brake mentioned previously:

Machine

Serial Number Description Qty.

(000000--- ) Parking Brake 1

(000000--- ) Pin, Roll 1

(000000--- ) Link 1

(000000--- ) Spring, Compression 1

(000000--- ) Pin, Roll 1

(000000--- ) Support 1

(000000--- ) Lever, Release 1

(000000--- ) Rod, Parking Brake 1

(000000--- ) Washer, 0.50” 3

If the column lists zeros on the left of the dash and a

number on the right of the dash, then the part is

used on machines up to and including that machine

serial number; such as (00000---002345).

b

In this example, the parts whose descriptions are

indented under the parking brake are all parts of the

parking brake. When you order the parking brake

you will receive all the parts listed under it. You also

can order any of the individual parts listed under the

parking brake if it is the only part you need.

275 SERIES II MM190 (12 ---89)

SUPPLIER COMPONENT BREAKDOWNS

Home

Find...

Go To..

TENNANT purchases certain components of the

machine from suppliers. Some of these components

are engines, hydraulic pumps and motors, electric

motors, and solution pumps.

For those purchased components that are

repairable, lists of parts for them appear in the later

part of the parts sections. These are the supplier

breakdowns. The engine breakdown contains both

supplier and TENNANT parts numbers for repair

parts. Breakdowns for hydraulic and electrical

components have TENNANT part numbers for the

parts TENNANT supplies. The serial numbers listed

in any of the parts lists in these sections is a serial

number the manufacturer uses to identify design

changes in their particular component.

ORDERING REPAIR PARTS

Once you have located a part to order, there are

several things you need to have to place the order.

At the beginning of each parts section is an Ordering

Repair Parts page which lists the information you will

need to place your order. Review this list before

placing the order.

ABOUT THIS MANUAL

275 SERIES II MM190 (12 ---89)

c

ABOUT THIS MANUAL

Home

Find...

Go To..

d

275 SERIES II MM190 (12 ---89)

SAFETY PRECAUTIONS

Home

Find...

Go To..

GENERAL INFORMATION

The following symbols are used throughout this

manual as indicated in their descriptions:

WARNING: To warn of hazards or unsafe

practices which could result in severe

personal injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation.

The following information signals potentially

dangerous conditions to the operator or equipment.

Read this manual carefully. Know when these

conditions can exist. Locate all safety devices on the

machine. Then take necessary steps to train

machine operating personnel. Report machine

damage or faulty operation immediately. Do not use

the machine if it is not in proper operating condition.

FOR SAFETY:

1. Do not operate machine:

-- Unless trained and authorized.

-- Unless operation manual is read and

understood.

-- In flammable or explosive areas unless

modified for use in those areas.

-- In areas with possible falling objects

unless equipped with overhead guard.

2. Before starting machine:

-- Check for fuel leaks (gasoline, LPG,

diesel).

-- Make sure all safety devices are in

place and operate properly. See

Operation section.

-- Check brakes and steering for proper

operation.

5. Before leaving or servicing machine:

-- Stop on level surface.

-- Set parking brake.

-- Turn off machine and remove key.

6. When servicing machine:

-- Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves when working

on machine.

-- Use Tennant Company supplied or

equivalent replacement parts.

WARNING: Machine emits toxic gases.

Severe respiratory damage or asphyxiation

can result. Provide adequate ventilation. Consult

with your regulatory agency for exposure limits.

Keep engine properly tuned.

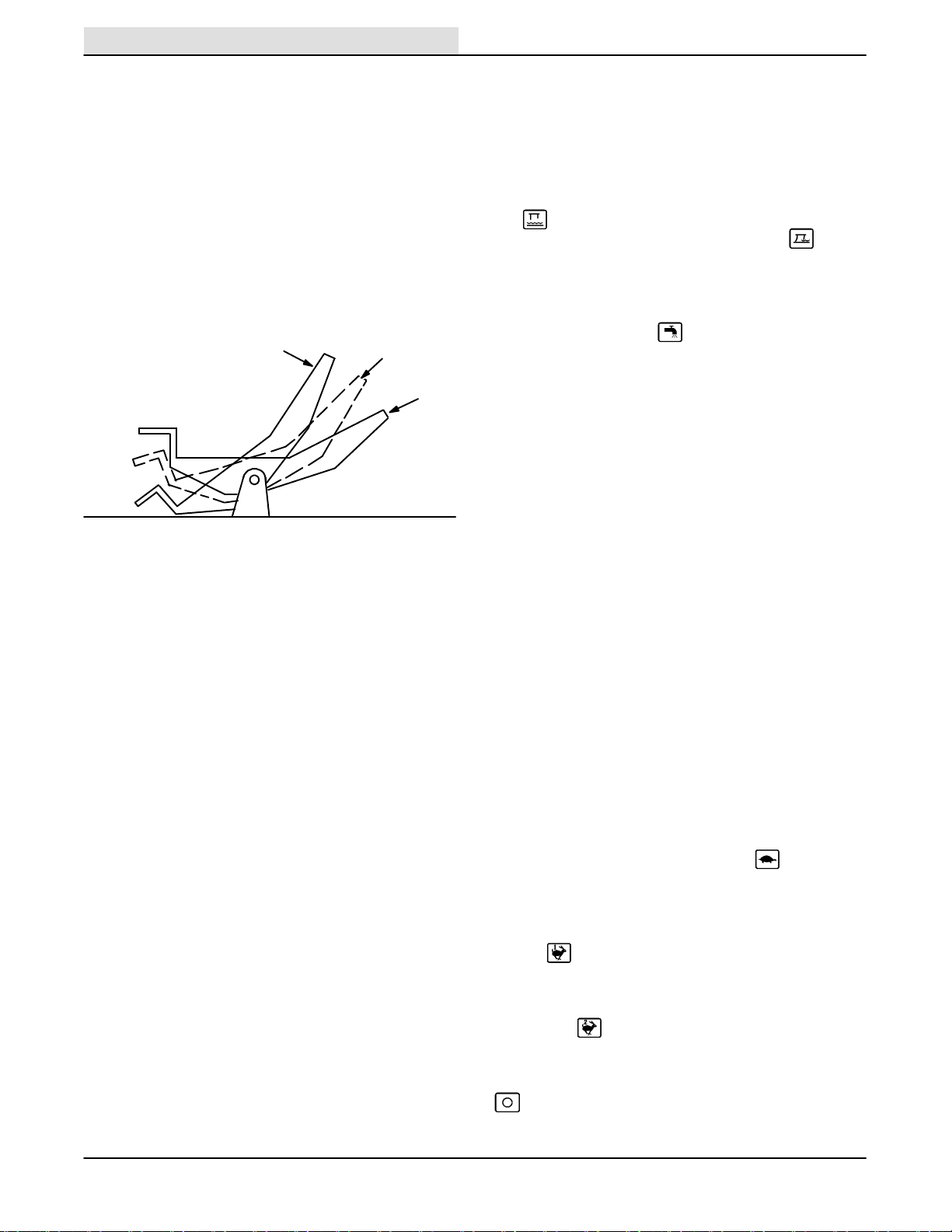

WARNING: Brush throws debris. Severe

personal injury can result. Stop motor

before lifting hopper.

WARNING: Machine can emit excessive

noise. Consult with your regulatory agency

for exposure limits. Hearing loss can result. Wear

hearing protection.

WARNING: Machine hopper lifts to 108 in

(2745 mm) when high dumping. Hopper can

hit overhead wires or object. Electrical shock or

falling debris can result. Be sure adequate

clearance is available before raising hopper.

WARNING: Machine can have static

electricity charge. When pouring fuel, spark

can ignite fuel causing fire or explosion. Connect

wire attached to fuel can to machine to discharge

spark before pouring fuel.

3. When starting machine:

-- Keep foot on brake and directional

pedal in neutral.

4. When using machine:

-- Go slow on grades and slippery

surfaces.

-- Use care when backing machine.

-- Do not carry riders on machine.

-- Always follow safety and traffic rules.

275 SERIES II MM190 (12---89)

WARNING: Machine moves when

directional pedal linkage is out of

adjustment. Severe personal injury or death can

result. If machine creeps when the directional

pedal is in neutral, adjust pedal linkage. Engage

parking brake when stopped.

WARNING: Falling hopper. Engage hopper

support bar before working under hopper.

i

GENERAL INFORMATION

Home

Find...

Go To..

WARNING: Fuel vapor is present when

servicing fuel system. Fire or explosion can

result. Keep flames and sparks away.

WARNING: Hot engine coolant. Scalding

can result. Do not open radiator cap or

service cooling system until radiator and engine

is cool to the touch.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in solution tank.

WARNING: The solution and recovery tanks

must be empty during scrub attachment

installation and removal to avoid personal injury.

WARNING: Machine is unstable on jack.

Jack machine up at designated locations

only. Block machine up with jack stands.

WARNING: Machine is unstable on jack.

Block machine tires before jacking machine

up.

WARNING: Leaking hydraulic fluid under

pressure can penetrate skin. Severe

infection or death can result. Do not use body to

locate leak. Use cardboard to locate leak.

WARNING: Air or water under pressure.

Severe eye or ear injury can result. Wear

eye and ear protection.

WARNING: LPG fuel is very cold. Frostbite

can result. Wear gloves when connecting or

disconnecting LPG hoses.

WARNING: Battery acid causes severe

burns. Avoid contact. Wash immediately

and get medical attention if contact occurs.

WARNING: Stay clear of hopper lift arms

when they are in motion.

WARNING: Keep away from fan.

ii

275 SERIES II MM190 (12---89)

The following safety labels are mounted on the

Home

Find...

Go To..

machine in the locations indicated. If these, or any,

labels become damaged or illegible, install a new

label in its place.

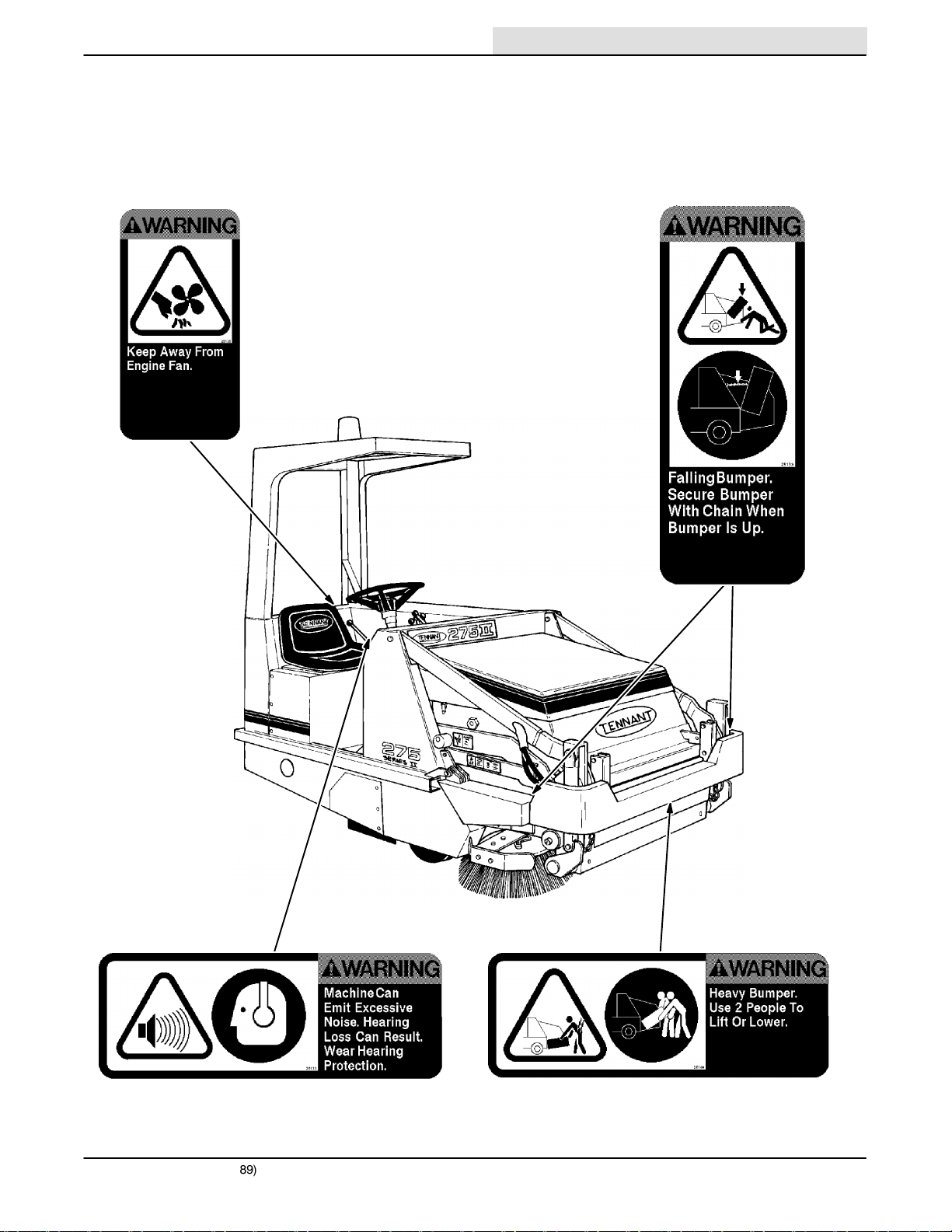

ENGINE FAN LABEL -- LOCATED ON ENGINE

FAN SHROUD.

GENERAL INFORMATION

BUMPER CHAIN LABEL -- LOCATED ON

UNDERSIDE OF BUMPER, LOW DUMP MODEL

ONLY.

NOISE LABEL -- LOCATED ON FRONT RIGHT OF

OPERATOR COMPARTMENT.

275 SERIES II MM190 (12---89)

02745

HEAVY BUMPER LABEL -- LOCATED ON

UNDERSIDE OF BUMPER, LOW DUMP MODEL

ONLY.

iii

GENERAL INFORMATION

Home

Find...

Go To..

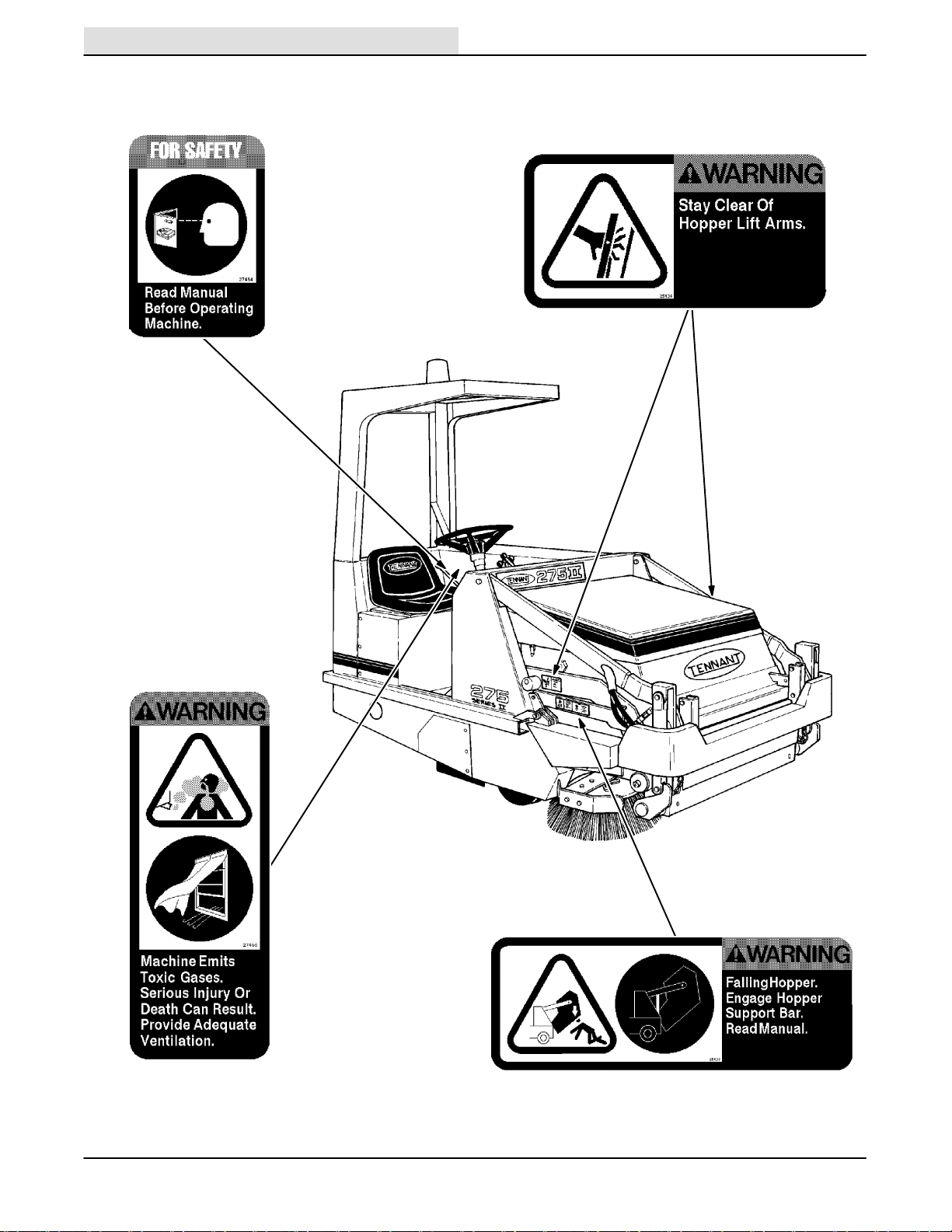

FOR SAFETY LABEL -- LOCATED ON LEFT SIDE

OF OPERATOR COMPARTMENT.

HOPPER LIFT ARMS LABEL -- LOCATED ON

HOPPER LIFT ARMS, MULTI-LEVEL DUMP

MODEL ONLY.

EMISIONS LABEL -- LOCATED ON LEFT SIDE OF

OPERATOR COMPARTMENT.

iv

02745

HOPPER SUPPORT BAR LABEL -- LOCATED ON

HOPPER SUPPORT BAR.

275 SERIES II MM190 (12---89)

CONTENTS

Home

Find...

Go To..

GENERAL INFORMATION

Page

GENERAL INFORMATION i. . . . . . . . . . . . . . . . . . . . .

SAFETY PRECAUTIONS i. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 1-1. . . . . . . . . . . . . . . . . . . . . . . . . .

MACHINE SPECIFICATIONS 1-3. . . . . . . . . . . . .

POWER TYPE 1-3. . . . . . . . . . . . . . . . . . . . . . .

POWER TRAIN 1-3. . . . . . . . . . . . . . . . . . . . . .

STEERING 1-3. . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC SYSTEM 1-3. . . . . . . . . . . . . . . .

BRAKING SYSTEM 1-4. . . . . . . . . . . . . . . . . .

SUSPENSION SYSTEM 1-4. . . . . . . . . . . . . . .

SYSTEM FLUID CAPACITIES 1-4. . . . . . . . .

GENERAL MACHINE

DIMENSIONS/CAPACITIES 1-4. . . . . . . . .

MACHINE WEIGHTS 1-4. . . . . . . . . . . . . . . . . .

GENERAL MACHINE PERFORMANCE 1-4. .

MACHINE DIMENSIONS 1-5. . . . . . . . . . . . . . . . .

OPERATION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 2-3. . . . . . . .

AFTER UNLOADING AND BEFORE

OPERATING THE MACHINE: 2-3. . . . . . .

OPERATION OF CONTROLS 2-4. . . . . . . . . . . .

MACHINE COMPONENTS ---

MULTI-LEVEL DUMP

MODEL SHOWN 2-4. . . . . . . . . . . . . . . . .

INSTRUMENT PANEL SYMBOLS 2-5. . . . . .

CONTROLS AND INSTRUMENTS 2-7. . . . .

BRAKE PEDAL 2-8. . . . . . . . . . . . . . . . . . . . . .

DIRECTIONAL PEDAL 2-8. . . . . . . . . . . . . . .

PARKING BRAKE LEVER 2-8. . . . . . . . . . . . .

OPERATOR SEAT 2-8. . . . . . . . . . . . . . . . . . .

SQUEEGEE SWITCH 2-8. . . . . . . . . . . . . . . .

WATER VALVE SWITCH 2-8. . . . . . . . . . . . . .

FUEL LEVEL GAUGE 2-8. . . . . . . . . . . . . . . .

THROTTLE LEVER 2-8. . . . . . . . . . . . . . . . . .

THROTTLE SWITCH 2-9. . . . . . . . . . . . . . . . .

HAZARD LIGHT SWITCH 2-9. . . . . . . . . . . . .

ENGINE CHOKE KNOB 2-9. . . . . . . . . . . . . .

DRIVE LIGHTS SWITCH 2-9. . . . . . . . . . . . . .

DIESEL PREHEAT PUSHBUTTON

AND INDICATOR 2-9. . . . . . . . . . . . . . . . .

HOPPER DUMP LEVER 2-9. . . . . . . . . . . . . .

HOPPER LIFT AND SIDE BRUSH LEVER 2-9

MAIN BRUSH POSITION LEVER 2-10. . . . . .

MAIN BRUSH HEIGHT

ADJUSTMENT KNOB 2-10. . . . . . . . . . . . .

STEERING WHEEL 2-10. . . . . . . . . . . . . . . . . .

Page

MAIN BRUSH, VACUUM FAN

AND FILTER SHAKER SWITCH 2-10. . . . .

CLOGGED FILTER LAMP 2-10. . . . . . . . . . . . .

ENGINE HOUR METER 2-10. . . . . . . . . . . . . .

ENGINE COOLANT

TEMPERATURE GAUGE 2-11. . . . . . . . . . .

ENGINE OIL PRESSURE GAUGE 2-11. . . . .

BATTERY CONDITION GAUGE 2-11. . . . . . . .

IGNITION SWITCH 2-11. . . . . . . . . . . . . . . . . . .

SIDE BRUSH POSITION LEVER 2-11. . . . . . .

HOPPER SUPPORT BAR 2-11. . . . . . . . . . . . .

TO ENGAGE HOPPER

SUPPORT BAR 2-11. . . . . . . . . . . . . . . .

TO DISENGAGE HOPPER

SUPPORT BAR 2-12. . . . . . . . . . . . . . . .

SCRUB BRUSH POSITION LEVER 2-13. . . . .

SOLUTION FLOW KNOB 2-13. . . . . . . . . . . . .

CIRCUIT BREAKERS 2-13. . . . . . . . . . . . . . . .

MACHINE OPERATION 2-14. . . . . . . . . . . . . . . . .

NORMAL SWEEPING OPERATION 2-14. . . .

PRE-START CHECKLIST 2-14. . . . . . . . . .

TO START MACHINE 2-14. . . . . . . . . . . . .

TO SWEEP 2-15. . . . . . . . . . . . . . . . . . . . . .

POST OPERATION CHECKLIST ---

ENGINE OPERATING 2-16. . . . . . . . . .

TO STOP MACHINE 2-16. . . . . . . . . . . . . .

POST OPERATION CHECKLIST ---

ENGINE STOPPED 2-16. . . . . . . . . . . .

NORMAL SCRUBBING OPERATION 2-17. . .

PRE-START CHECKLIST 2-17. . . . . . . . . .

TO START MACHINE 2-17. . . . . . . . . . . . .

TO SCRUB 2-18. . . . . . . . . . . . . . . . . . . . . .

TO DRAIN RECOVERY TANK

AND EMPTY DEBRIS HOPPER 2-18. .

POST OPERATION CHECKLIST ---

ENGINE OPERATING 2-19. . . . . . . . . .

TO STOP MACHINE 2-19. . . . . . . . . . . . . .

POST OPERATION CHECKLIST ---

ENGINE STOPPED 2-19. . . . . . . . . . . .

DOUBLE SCRUBBING OPERATION 2-20. . .

OPERATION ON GRADES 2-20. . . . . . . . . . . .

VACUUM WAND 2-20. . . . . . . . . . . . . . . . . . . .

TO OPERATE VACUUM WAND 2-20. . . . .

HOPPER DOLLY 2-21. . . . . . . . . . . . . . . . . . . . .

TO REMOVE HOPPER WITH DOLLY 2-21

TO INSTALL HOPPER WITH DOLLY 2-22.

SCRUB ATTACHMENT 2-23. . . . . . . . . . . . . . .

TO MOUNT SCRUB ATTACHMENT 2-23.

TO REMOVE SCRUB ATTACHMENT 2-26

SNOW BLADE 2-27. . . . . . . . . . . . . . . . . . . . . .

TO INSTALL SNOW BLADE 2-27. . . . . . . .

TO OPERATE SNOW BLADE 2-28. . . . . . .

275 SERIES II MM190 (12---89)

v

GENERAL INFORMATION

Home

Find...

Go To..

TO REMOVE SNOW BLADE 2-29. . . . . . .

SNOW BROOM 2-30. . . . . . . . . . . . . . . . . . . . .

TO INSTALL SNOW BROOM

ASSEMBLY 2-30. . . . . . . . . . . . . . . . . . .

TO OPERATE SNOW BROOM 2-32. . . . . .

MACHINE TROUBLESHOOTING ---

SWEEPING 2-34. . . . . . . . . . . . . . . . . . . . . .

MACHINE TROUBLESHOOTING ---

SCRUBBING 2-35. . . . . . . . . . . . . . . . . . . . .

TRANSPORTING MACHINE 2-36. . . . . . . . . . . . .

PUSHING OR TOWING MACHINE 2-36. . . . .

MACHINE JACKING 2-36. . . . . . . . . . . . . . . . .

TO JACK UP MACHINE 2-36. . . . . . . . . . .

MACHINE TIE-DOWNS 2-37. . . . . . . . . . . . . . .

MACHINE STORAGE 2-38. . . . . . . . . . . . . . . . . . .

STORING MACHINE 2-38. . . . . . . . . . . . . . . . .

MAINTENANCE 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOMMENDED FIRST 50-HOUR

MACHINE INSPECTION 3-3. . . . . . . . . . . . . .

MAINTENANCE CHART 3-4. . . . . . . . . . . . . . . . .

LUBRICATION 3-6. . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GASOLINE AND LPG POWERED

ENGINES 3-6. . . . . . . . . . . . . . . . . . . . .

DIESEL POWERED ENGINES 3-6. . . . . .

STEERING GEAR 3-6. . . . . . . . . . . . . . . . . . .

REAR WHEEL SUPPORT 3-6. . . . . . . . . . . . .

FRONT WHEEL BEARINGS 3-6. . . . . . . . . . .

HOPPER LIFT ARM PIVOTS 3-7. . . . . . . . . .

HOPPER DOOR LATCHES 3-7. . . . . . . . . . . .

SCRUB ATTACHMENT LEG CASTERS 3-8.

SCRUB ATTACHMENT DEBRIS HOPPER 3-8

HYDRAULICS 3-9. . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC FLUID 3-9. . . . . . . . . . . . . . . . . .

HYDRAULIC FLUID RESERVOIR 3-9. . . . . .

TO DRAIN HYDRAULIC FLUID

RESERVOIR AND REPLACE

FILTER ELEMENT 3-10. . . . . . . . . . . . . .

TO FILL HYDRAULIC FLUID

RESERVOIR 3-11. . . . . . . . . . . . . . . . . .

HYDRAULIC PUMPS 3-11. . . . . . . . . . . . . . . . .

DIRECTIONAL PEDAL 3-11. . . . . . . . . . . . . . .

TO ADJUST DIRECTIONAL PEDAL 3-12.

LIFT ARM SPEED LIMITER 3-13. . . . . . . . . . .

HYDRAULIC FLUID LEAKS 3-13. . . . . . . . . . .

HYDRAULIC SCHEMATIC,

LOW DUMP MODEL 3-14. . . . . . . . . . . . . .

HYDRAULIC SCHEMATIC,

MULTI-LEVEL DUMP MODEL 3-15. . . . . .

HYDRAULIC SYSTEM

TROUBLESHOOTING 3-16. . . . . . . . . . . . .

HYDRAULIC COMPONENTS

TROUBLESHOOTING 3-18. . . . . . . . . . . . .

ENGINE 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE LUBRICATION 3-19. . . . . . . . . . . . . .

Page

Page

GASOLINE AND LPG

POWERED ENGINES 3-19. . . . . . . . . .

DIESEL POWERED ENGINES 3-19. . . . . .

COOLING SYSTEM 3-19. . . . . . . . . . . . . . . . . .

AIR INTAKE SYSTEM 3-20. . . . . . . . . . . . . . . .

AIR FILTER RESTRICTION

INDICATOR 3-20. . . . . . . . . . . . . . . . . . .

AIR FILTER 3-21. . . . . . . . . . . . . . . . . . . . . .

TO REPLACE AIR FILTER ELEMENT 3-21

FUEL SYSTEM --- GASOLINE 3-23. . . . . . . . .

FUEL FILTER 3-23. . . . . . . . . . . . . . . . . . . . .

CARBURETOR 3-23. . . . . . . . . . . . . . . . . . .

FUEL SYSTEM --- LPG 3-23. . . . . . . . . . . . . . .

LPG FUEL SYSTEM 3-23. . . . . . . . . . . . . . .

FUEL TANKS 3-24. . . . . . . . . . . . . . . . . . . . .

TO CHANGE AN LPG FUEL TANK 3-25. .

FUEL FILTER LOCK 3-26. . . . . . . . . . . . . . .

VAPORIZER-REGULATOR 3-26. . . . . . . . .

CARBURETOR 3-26. . . . . . . . . . . . . . . . . . .

OIL PRESSURE SWITCH 3-26. . . . . . . . . .

LPG FUEL TROUBLESHOOTING 3-27. . .

FUEL SYSTEM --- DIESEL 3-28. . . . . . . . . . . .

DIESEL FUEL SYSTEM 3-28. . . . . . . . . . . .

FUEL WATER TRAP-FILTER 3-28. . . . . . . .

TO REPLACE FUEL FILTER

ELEMENT 3-28. . . . . . . . . . . . . . . . . . . .

PRIMING FUEL SYSTEM 3-29. . . . . . . . . .

TO PRIME FUEL SYSTEM 3-29. . . . . . . . .

GOVERNOR --- GASOLINE, LPG

(For machines below serial

number 006500) 3-29. . . . . . . . . . . . . . . . . .

TO ADJUST GOVERNOR

(For machines below serial

number 006500) 3-30. . . . . . . . . . . . . . .

GOVERNOR --- GASOLINE, LPG

(For machines serial number

006500 and above) 3-30. . . . . . . . . . . . . . .

IGNITION SYSTEM --- GASOLINE, LPG 3-30.

SPARK PLUGS 3-30. . . . . . . . . . . . . . . . . . .

DISTRIBUTOR

(For machines below serial

number 006500) 3-31. . . . . . . . . . . . . . .

ENGINE IGNITION TIMING

(For machines below serial

number 006500) 3-31. . . . . . . . . . . . . . .

TO CHECK AND ADJUST IGNITION

TIMING (For machines below

serial number 006500) 3-31. . . . . . . . . .

ENGINE IGNITION TIMING

(For machines serial

number 006500 and above) 3-32. . . . .

CYLINDER HEAD --- GASOLINE, LPG 3-32. .

CYLINDER HEAD 3-32. . . . . . . . . . . . . . . . .

VALVE TAPPET CLEARANCE 3-32. . . . . .

CYLINDER HEAD --- DIESEL 3-33. . . . . . . . . .

CYLINDER HEAD 3-33. . . . . . . . . . . . . . . . .

vi

275 SERIES II MM190 (12---89)

GENERAL INFORMATION

Home

Find...

Go To..

VALVE CLEARANCE 3-33. . . . . . . . . . . . . .

CRANKCASE VENTILATION SYSTEM 3-33. .

TUNE-UP CHART --- GASOLINE, LPG 3-33. .

ELECTRICAL SYSTEM 3-34. . . . . . . . . . . . . . . . . .

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-34

ELECTRICAL SCHEMATIC ---

GASOLINE, LPG (For machines

below serial number 006500) 3-35. . . . . .

ELECTRICAL SCHEMATIC --- GASOLINE,

LPG (for machines serial

number 006500 and above) 3-36. . . . . . . .

ELECTRICAL SCHEMATIC --- DIESEL 3-37. .

ELECTRICAL SCHEMATIC ---

ACCESSORIES 3-38. . . . . . . . . . . . . . . . . .

ELECTRICAL SCHEMATIC ---

AUTO SHAKER, RFS 3-39. . . . . . . . . . . . . .

BELTS AND CHAINS 3-41. . . . . . . . . . . . . . . . . . . .

ENGINE FAN BELT 3-41. . . . . . . . . . . . . . . . . .

GOVERNOR BELT --- GASOLINE, LPG

(For machines below serial

number 006500) 3-41. . . . . . . . . . . . . . . . . .

STATIC DRAG CHAIN 3-41. . . . . . . . . . . . . . . .

DEBRIS HOPPER 3-42. . . . . . . . . . . . . . . . . . . . . .

HOPPER DUST FILTER 3-42. . . . . . . . . . . . . .

TO REMOVE HOPPER DUST FILTER 3-42

TO INSTALL HOPPER DUST FILTER 3-43

DEBRIS HOPPER 3-43. . . . . . . . . . . . . . . . . . .

TO ADJUST LOW DUMP

MODEL HOPPER 3-43. . . . . . . . . . . . . .

TO ADJUST MULTI-LEVEL DUMP

MODEL HOPPER 3-44. . . . . . . . . . . . . .

THERMO SENTRYt 3-47. . . . . . . . . . . . . . . . .

BRUSHES 3-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAIN BRUSH 3-48. . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE MAIN BRUSH 3-48. . . . . . .

TO CHECK AND ADJUST

MAIN BRUSH PATTERN 3-49. . . . . . . .

SIDE BRUSH . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-50

TO REPLACE SIDE BRUSH 3-51. . . . . . . .

SKIRTS AND SEALS 3-52. . . . . . . . . . . . . . . . . . . .

HOPPER LIP SKIRTS 3-52. . . . . . . . . . . . . . . .

TO REPLACE HOPPER LIP SKIRTS 3-52.

BRUSH DOOR SKIRTS 3-53. . . . . . . . . . . . . . .

TO REPLACE AND ADJUST

BRUSH DOOR SKIRTS 3-53. . . . . . . . .

REAR SKIRTS 3-54. . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE AND ADJUST

THE REAR SKIRTS 3-54. . . . . . . . . . . .

MAIN BRUSH DOOR SEALS 3-55. . . . . . . . . .

HOPPER SEALS 3-55. . . . . . . . . . . . . . . . . . . .

HOPPER INSPECTION DOOR SEAL 3-55. . .

HOPPER DOOR SEALS 3-56. . . . . . . . . . . . . .

HOPPER COVER SEAL 3-56. . . . . . . . . . . . . .

HOPPER VACUUM FAN SEAL 3-56. . . . . . . .

Page

Page

BRAKES AND TIRES 3-56. . . . . . . . . . . . . . . . . . .

SERVICE BRAKES 3-57. . . . . . . . . . . . . . . . . . .

TO ADJUST BRAKE LINKAGE 3-57. . . . . .

PARKING BRAKES 3-57. . . . . . . . . . . . . . . . . .

TIRES 3-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCRUB ATTACHMENT 3-58. . . . . . . . . . . . . . . . . .

SCRUB ATTACHMENT 3-58. . . . . . . . . . . . . . .

SOLUTION TANKS 3-58. . . . . . . . . . . . . . . . . . .

SOLUTION DISTRIBUTION SYSTEM 3-58. . .

SCRUB BRUSHES 3-58. . . . . . . . . . . . . . . . . . .

TO REPLACE SCRUB BRUSH 3-59. . . . . .

TO CHECK AND ADJUST

SCRUB BRUSH PATTERN 3-59. . . . . .

RECOVERY TANK 3-61. . . . . . . . . . . . . . . . . . .

TO DRAIN THE RECOVERY TANK 3-61. .

TO CLEAN THE RECOVERY TANK 3-61. .

DEBRIS HOPPER 3-62. . . . . . . . . . . . . . . . . . .

SIDE SQUEEGEE 3-63. . . . . . . . . . . . . . . . . . .

TO REPLACE SIDE SQUEEGEE

BLADE 3-63. . . . . . . . . . . . . . . . . . . . . . .

REAR SQUEEGEE 3-64. . . . . . . . . . . . . . . . . . .

TO REPLACE OR ROTATE

REAR BLADE 3-64. . . . . . . . . . . . . . . . .

TO REPLACE OR ROTATE

FRONT BLADE 3-65. . . . . . . . . . . . . . . .

TO CHECK AND ADJUST

REAR SQUEEGEE 3-66. . . . . . . . . . . . .

SNOW BROOM 3-68. . . . . . . . . . . . . . . . . . . . . . . .

SNOW BROOM 3-68. . . . . . . . . . . . . . . . . . . . .

TO REPLACE SNOW BROOM 3-68. . . . . .

APPENDIX 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HARDWARE INFORMATION 4-3. . . . . . . . . . . . . .

STANDARD BOLT TORQUE CHART 4-3. . . .

METRIC BOLT TORQUE CHART 4-3. . . . . . .

BOLT IDENTIFICATION 4-3. . . . . . . . . . . . . . . .

THREAD SEALANT AND LOCKING

COMPOUNDS 4-3. . . . . . . . . . . . . . . . . . . .

HYDRAULIC FITTING INFORMATION 4-4. . . . . .

HYDRAULIC TAPERED SEAT FITTING

(JIC)TORQUE CHART 4-4. . . . . . . . . . . . . .

HYDRAULIC O---RING FITTING TORQUE

CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4

LOW DUMP MODEL PARTS 5-1. . . . . . . . . . . . . . . . .

ORDERING REPAIR PARTS 5-3. . . . . . . . . . . . . . .

Fig. 1 --- Recommended General

Maintenance Items 5-4. . . . . . . . . .

Fig. 2 --- Replacement Brushes 5-6. . . . . . . . . .

Fig. 3 --- Main Frame Group 5-8. . . . . . . . . . . . .

Fig. 4 --- Seat and Radiator Group 5-10. . . . . . .

Fig. 5 --- Seat Group, Distributorless (DIS) 5-12

Fig. 6 --- Radiator Group, Distributorless

(DIS) 5-14. . . . . . . . . . . . . . . . . . . . . .

275 SERIES II MM190 (6---90)

vii

GENERAL INFORMATION

Home

Find...

Go To..

Fig. 7 --- Engine Cover and Side Door

Group 5-16. . . . . . . . . . . . . . . . . . . . .

Fig. 8 --- Hopper Group 5-18. . . . . . . . . . . . . . . . .

Fig. 9 --- Hopper Cover and Filter Group 5-20. .

Fig. 10 --- Hopper Lift Arms Group 5-22. . . . . . . .

Fig. 11 --- Side Brush Group 5-24. . . . . . . . . . . . .

Fig. 12 --- Front Wheel and Brakes Group 5-26.

Fig. 13 --- Steering Control Group 5-28. . . . . . . .

Fig. 14 --- Rear Wheel Drive Group 5-30. . . . . . . .

Fig. 15 --- Main Brush Drive Group 5-32. . . . . . . .

Fig. 16 --- Main Brush Lift Group 5-33. . . . . . . . . .

Fig. 17 --- Access and Kick Panels Group 5-34. .

Fig. 18 --- Vacuum Fan Group 5-35. . . . . . . . . . . .

Fig. 19 --- Instrument and Control

Panels Group 5-36. . . . . . . . . . . . . . .

Fig. 20 --- Battery Group 5-37. . . . . . . . . . . . . . . . .

Fig. 21 --- Wire Harnesses Group 5-38. . . . . . . . .

Fig. 22 --- Hydraulic Hoses Group 5-40. . . . . . . .

Fig. 23 --- Hydraulic Pumps Group 5-42. . . . . . . .

Fig. 24 --- Hydraulic Reservoir 5-43. . . . . . . . . . . .

Fig. 25 --- Hydraulic Control Valve Group 5-44. .

Fig. 26 --- Hydraulic Solenoid Valve Group 5-45.

Fig. 27 --- Hydraulic Filter Group 5-46. . . . . . . . . .

Fig. 28 --- Hydraulic Couplings Group 5-47. . . . .

Fig. 29 --- Engine Group 5-48. . . . . . . . . . . . . . . . .

Fig. 30 --- Engine Group, Distributorless

(DIS) 5-50. . . . . . . . . . . . . . . . . . . . . .

Fig. 31 --- Carburetor Group,

Distributorless (DIS) 5-52. . . . . . . . .

Fig. 32 --- Fuel Tank Bumper Group, LPG 5-54. .

Fig. 33 --- Fuel Tank Bumper Group,

Distributorless (DIS) LPG 5-56. . . .

Fig. 34 --- Sheaves and Belts Group 5-58. . . . . .

Fig. 35 --- Carburetor Group, LPG 5-59. . . . . . . .

Fig. 36 --- Carburetor Group,

Distributorless (DIS) LPG 5-60. . . .

Fig. 37 --- Engine Fan and Alternator

Group, Distributorless (DIS) 5-62. .

Fig. 38 --- Air Cleaner Group 5-63. . . . . . . . . . . . .

Fig. 39 --- Air Cleaner Group,

Distributorless (DIS) 5-64. . . . . . . . .

Fig. 40 --- Directional Control Group 5-65. . . . . .

Fig. 41 --- Directional Control Group,

Distributorless (DIS) 5-66. . . . . . . . .

Fig. 42 --- Flywheel Housing Group 5-68. . . . . . .

Fig. 43 --- Flywheel Housing Group,

Distributorless (DIS) 5-70. . . . . . . . .

Fig. 44 --- Throttle Linkage Group 5-71. . . . . . . . .

Fig. 45 --- Muffler Group 5-72. . . . . . . . . . . . . . . . .

Fig. 46 --- Muffler Group, Distributorless

(DIS) 5-73. . . . . . . . . . . . . . . . . . . . . .

Fig. 47 --- Fuel Tank Group 5-74. . . . . . . . . . . . . .

Fig. 48 --- Clogged Filter Indicator,

Shaker Timer Group 5-75. . . . . . . . .

Fig. 49 --- Labels Group 5-76. . . . . . . . . . . . . . . . .

Page

Page

DIESEL PARTS 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING REPAIR PARTS 6-3. . . . . . . . . . . . . .

Fig. 1 --- Engine Group, Diesel 6-4. . . . . . . . . . .

Fig. 2 --- Fuel Tank Group, Diesel 6-6. . . . . . . .

Fig. 3 --- Radiator and Shroud

Group, Diesel 6-8. . . . . . . . . . . . . .

Fig. 4 --- Throttle Linkage Group, Diesel 6-9. . .

Fig. 5 --- Muffler Group, Diesel 6-10. . . . . . . . . . .

Fig. 6 --- Directional Control Group, Diesel 6-11

Fig. 7 --- Instrument Panel Group, Diesel 6-12. .

Fig. 8 --- Wire Harness Group, Diesel 6-13. . . . .

Fig. 9 --- Foam Insulation Group, Diesel 6-14. . .

Fig. 10 --- Air Cleaner Group, Diesel 6-15. . . . . .

MULTI---LEVEL DUMP MODEL PARTS 7-1. . . . . . .

ORDERING REPAIR PARTS 7-3. . . . . . . . . . . . . .

Fig. 1 --- Main Frame Group, Multi---Level

Dump 7-4. . . . . . . . . . . . . . . . . . . . .

Fig. 2 --- Hopper Door Assembly,

Multi---Level Dump 7-5. . . . . . . . . .

Fig. 3 --- Hopper Group, Multi---Level

Dump 7-6. . . . . . . . . . . . . . . . . . . . .

Fig. 4 --- Hopper Lift Arms Group,

Multi---Level Dump 7-8. . . . . . . . . .

Fig. 5 --- Hopper Cover and Filter Carrier

Group, Multi---Level Dump 7-10. . .

Fig. 6 --- Hydraulic Lift Cylinder Group,

Multi---Level Dump 7-11. . . . . . . . . .

Fig. 7 --- Stabilizer Leg Group,

Multi---Level Dump 7-12. . . . . . . . . .

Fig. 8 --- Side Brush Group,

Multi---Level Dump 7-13. . . . . . . . . .

Fig. 9 --- Main Brush Lift Group,

Multi---Level Dump 7-14. . . . . . . . . .

Fig. 10 --- Front Wheel and Brake Group,

Multi---Level Dump 7-15. . . . . . . . . .

Fig. 11 --- Hydraulic Hoses Group,

Multi---Level Dump 7-16. . . . . . . . . .

Fig. 12 --- Hydraulic Control Valve Group,

Multi---Level Dump 7-17. . . . . . . . . .

Fig. 13 --- Clogged Filter Indicator, Shaker

Timer Group, Multi---Level

Dump 7-18. . . . . . . . . . . . . . . . . .

Fig. 14 --- Wire Harnesses Group,

Multi---Level Dump 7-19. . . . . . . . . .

ACCESSORIES 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING REPAIR PARTS 8-3. . . . . . . . . . . . . .

Fig. 1 --- Cab Kit 8-4. . . . . . . . . . . . . . . . . . . . . . .

Fig. 2 --- Snow Blade Kit 8-6. . . . . . . . . . . . . . . .

Fig. 3 --- Snow Broom Kit 8-8. . . . . . . . . . . . . . .

Fig. 4 --- Mount Frame Kit 8-10. . . . . . . . . . . . . . .

Fig. 5 --- Tire Chain Kit 8-11. . . . . . . . . . . . . . . . . .

Fig. 6 --- Front Wheel Assembly,

Low Dump 8-11. . . . . . . . . . . . . . . . .

viii

275 SERIES II MM190 (12---89)

GENERAL INFORMATION

Home

Find...

Go To..

Fig. 7 --- Headlight, Taillight, and

Spotlight Kit, Lintel 8-12. . . . . . . . . .

Fig. 8 --- Revolving Light Kit, Overhead

Guard 8-14. . . . . . . . . . . . . . . . . . . . .

Fig. 9 --- Flashing Light Kit, Overhead

Guard 8-15. . . . . . . . . . . . . . . . . . . . .

Fig. 10 --- Revolving Light Kit, Shroud 8-16. . . . .

Fig. 11 --- Flashing Light Kit, Shroud 8-17. . . . . .

Fig. 12 --- Revolving Light Kit, Cab 8-18. . . . . . . .

Fig. 13 --- Flashing Light Kit, Cab 8-19. . . . . . . . .

Fig. 14 --- Rear Squeegee Group 8-20. . . . . . . . .

Fig. 15 --- Side Squeegee Group 8-22. . . . . . . . .

Fig. 16 --- Tire and Wheel Assembly 8-23. . . . . . .

Fig. 17 --- Front Wheel Assembly 8-23. . . . . . . . .

Fig. 18 --- Scrub Brush Drive Group 8-24. . . . . . .

Fig. 19 --- Solution Tanks Group 8-26. . . . . . . . . .

Fig. 20 --- Recovery Tank Group 8-28. . . . . . . . . .

Fig. 21 --- Scrub Attachment Cam Group 8-30. .

Fig. 22 --- Main Scrubber Brush Group 8-31. . . .

Fig. 23 --- Instrument Panel Group 8-31. . . . . . . .

Fig. 24 --- Hopper Dolly Assembly 8-32. . . . . . . .

Fig. 25 --- Scrubber Bumper Group 8-33. . . . . . .

Fig. 26 --- Air Filter Safety Element Kit 8-34. . . . .

Fig. 27 --- Dry Battery Kit 8-35. . . . . . . . . . . . . . . .

Fig. 28 --- Vacuum Wand Kit, Low Dump 8-36. .

Fig. 29 --- Vacuum Wand Group,

Multi---level Dump 8-38. . . . . . . . . . .

Fig. 30 --- Battery Hold Down Kit 8-40. . . . . . . . . .

Fig. 31 --- Overhead Guard Kit 8-41. . . . . . . . . . .

Fig. 32 --- Fire Extinguisher Kit 8-42. . . . . . . . . . .

Fig. 33 --- Alternator Kit 8-42. . . . . . . . . . . . . . . . . .

Fig. 34 --- Suspension Seat Kit 8-43. . . . . . . . . . .

Fig. 35 --- Spark Arresting Muffler Kit 8-43. . . . . .

Fig. 36 --- Hood Latch and Machine

Tie---Down Kit 8-44. . . . . . . . . . . . . .

Fig. 37 --- Protectoseal Fuel Tank Cap Kit 8-45. .

Fig. 38 --- Fuel Tanks Group, LPG 8-45. . . . . . . .

Fig. 39 --- Rear Wheel Assembly,

Steelguard 8-46. . . . . . . . . . . . . . . . .

Fig. 40 --- Rear Wheel Assembly,

Foam Filled 8-47. . . . . . . . . . . . . . . .

Fig. 41 --- Rear Wheel Assembly, Solid 8-47. . . .

Fig. 42 --- Extra Reach Side Brush Group,

Low Dump 8-48. . . . . . . . . . . . . . . . .

Fig. 43 --- Extra Reach Side Brush Group,

Multi---Level Dump 8-49. . . . . . . . . .

Fig. 44 --- Muffler Group, GS, LPS, DS 8-50. . . .

Fig. 45 --- Battery Group, GS, LPS, DS 8-51. . . .

Fig. 46 --- Fuel Tank Group, GS 8-52. . . . . . . . . . .

Fig. 47 --- Instrument Panel Group, GS 8-53. . . .

Fig. 48 --- Alternator Group, GS, LPS 8-54. . . . . .

Fig. 49 --- Instrument Panel Group, LPS 8-55. . .

Fig. 50 --- Instrument Panel Group, DS 8-56. . . .

Fig. 51 --- Alternator Group, DS 8-57. . . . . . . . . .

Fig. 52 --- Fuel System Group, DS 8-58. . . . . . . .

Page

Page

Fig. 53 --- Maximum Path Side

Brush Group 8-60. . . . . . . . . . . . . . .

Fig. 54 --- Hopper and Cover Group, RFS 8-62. .

Fig. 55 --- Filter and Shaker Group, RFS 8-64. . .

Fig. 56 --- Vacuum System Group, RFS 8-66. . . .

Fig. 57 --- Electrical and Hydraulic

Group, RFS 8-68. . . . . . . . . . . . . . . .

Fig. 58 --- Switch and Circuit Group, RFS 8-70. .

Fig. 59 --- Wire Harnesses Group, RFS 8-71. . . .

HYDRAULIC COMPONENTS 9-1. . . . . . . . . . . . . . .

ORDERING REPAIR PARTS 9-3. . . . . . . . . . . . . .

Fig. 1 --- Hydraulic Piston Pump

Breakdown 02704 9-4. . . . . . . . . .

Fig. 2 --- Pump Hydraulic Gear Breakdown 82205

9-6

Fig. 3 --- Hydraulic Motor Breakdown

48663 9-7. . . . . . . . . . . . . . . . . . . . .

Fig. 4 --- Hydraulic Motor Breakdown

13106 9-8. . . . . . . . . . . . . . . . . . . . .

Fig. 5 --- Hydraulic Motor Breakdown

27800 9-9. . . . . . . . . . . . . . . . . . . . .

Fig. 6 --- Hydraulic Motor Breakdown

13105 9-10. . . . . . . . . . . . . . . . . . . . .

Fig. 7 --- Hydraulic Motor Breakdown

28808 9-11. . . . . . . . . . . . . . . . . . . . .

Fig. 8 --- Hydraulic Motor Breakdown

77101 9-12. . . . . . . . . . . . . . . . . . . . .

Fig. 9 --- Hydraulic Motor Breakdown

27796 9-13. . . . . . . . . . . . . . . . . . . . .

Fig. 10 --- Hydraulic Motor Breakdown

27787 9-14. . . . . . . . . . . . . . . . . . . . .

Fig. 11 --- Hydraulic Valve Breakdown

62550 9-15. . . . . . . . . . . . . . . . . . . . .

Fig. 12 --- Hydraulic Valve Breakdown

34319 9-16. . . . . . . . . . . . . . . . . . . . .

Fig. 13 --- Hydraulic Solenoid Valve

Breakdown 82754 9-17. . . . . . . . . .

Fig. 14 --- Hydraulic Cylinder Breakdown

04468 9-18. . . . . . . . . . . . . . . . . . . . .

Fig. 15 --- Hydraulic Cylinder Breakdown

82757 9-19. . . . . . . . . . . . . . . . . . . . .

Fig. 16 --- Hydraulic Cylinder Breakdown

04471 9-20. . . . . . . . . . . . . . . . . . . . .

ENGINE PARTS, GASOLINE, LPG 10-1. . . . . . . . . . .

ORDERING REPAIR PARTS 10-3. . . . . . . . . . . . . .

Fig. 1 --- Cylinder Head Group 10-4. . . . . . . . . . .

Fig. 2 --- Cylinder Block Group 10-6. . . . . . . . . . .

Fig. 3 --- Camshaft Group 10-8. . . . . . . . . . . . . . .

Fig. 4 --- Crankshaft and Piston Group 10-10. . . .

Fig. 5 --- Oil Pump and Oil Pan Group 10-12. . . .

Fig. 6 --- Intake and Exhaust

Manifold Group 10-14. . . . . . . . . . . . .

Fig. 7 --- Front Cover Group 10-15. . . . . . . . . . . . .

Fig. 8 --- Water Pump Group 10-16. . . . . . . . . . . .

Fig. 9 --- Distributor Group 10-18. . . . . . . . . . . . . .

275 SERIES II MM190 (6---90)

ix

GENERAL INFORMATION

Home

Find...

Go To..

Fig. 10 --- Gaskets Group 10-20. . . . . . . . . . . . . . . .

Fig. 11 --- Flywheel Group 10-22. . . . . . . . . . . . . . .

ENGINE PARTS, DIS, GASOLINE, LPG 11-1. . . . . .

ORDERING REPAIR PARTS 11-3. . . . . . . . . . . . . .

Fig. 1 --- Cylinder Head, Valves Group 11-4. . . .

Fig. 2 --- Cylinder Block Group 11-6. . . . . . . . . . .

Fig. 3 --- Camshaft and Valve

Control Group 11-8. . . . . . . . . . . . . .

Fig. 4 --- Crankshaft and Piston Group 11-10. . . .

Fig. 5 --- Oil Pump and Oil Pan Group 11-12. . . .

Fig. 6 --- Intake Manifold Group 11-14. . . . . . . . . .

Fig. 7 --- Front Cover Assembly Group 11-15. . . .

Fig. 8 --- Water Pump Group 11-16. . . . . . . . . . . .

Fig. 9 --- Distributorless Ignition Group 11-17. . . .

Fig. 10 --- Gaskets Group 11-18. . . . . . . . . . . . . . . .

Fig. 11 --- Flywheel Group 11-19. . . . . . . . . . . . . . .

ENGINE PARTS, DIESEL 12-1. . . . . . . . . . . . . . . . . . .

ORDERING REPAIR PARTS 12-3. . . . . . . . . . . . . .

Fig. 1 --- Crankcase Group 12-4. . . . . . . . . . . . . .

Fig. 2 --- Oil Pan Group 12-6. . . . . . . . . . . . . . . . .

Fig. 3 --- Cylinder Head Group 12-7. . . . . . . . . . .

Fig. 4 --- Gear Case Group 12-8. . . . . . . . . . . . . .

Fig. 5 --- Main Bearing Case Group 12-10. . . . . .

Fig. 6 --- Inlet Manifold Group 12-11. . . . . . . . . . . .

Fig. 7 --- Valve, Rocker Arm Group 12-12. . . . . . .

Fig. 8 --- Head Cover Group 12-14. . . . . . . . . . . . .

Fig. 9 --- Piston and Crankshaft Group 12-16. . . .

Fig. 10 --- Camshaft Group 12-18. . . . . . . . . . . . . .

Fig. 11 --- Flywheel Group 12-19. . . . . . . . . . . . . . .

Fig. 12 --- Nozzle Group 12-20. . . . . . . . . . . . . . . . .

Fig. 13 --- Fuel Camshaft Group 12-22. . . . . . . . . .

Fig. 14 --- Governor Group 12-24. . . . . . . . . . . . . . .

Fig. 15 --- Speed Control Plate Group 12-25. . . . .

Fig. 16 --- Stop Lever Group 12-26. . . . . . . . . . . . .

Fig. 17 --- Thermostat Group 12-27. . . . . . . . . . . . .

Fig. 18 --- Water Pump Group 12-28. . . . . . . . . . . .

Fig. 19 --- Starter Breakdown 12-29. . . . . . . . . . . . .

Page

CROSS REFERENCE 13-1. . . . . . . . . . . . . . . . . . . . . .

PART NUMBER TO PAGE NUMBER CROSS

REFERENCE LIST 13-3. . . . . . . . . . . . . . . . . . . . . .

CUSTOMER DOCUMENTS 14-1. . . . . . . . . . . . . . . . .

TENNANT COMPANY LIMITED WARRANTY 14-3

TENNANT COMPANY, TENNANT COMPANY

SUBSIDIARIES, AND MAJOR PARTS AND

SERVICE LOCATIONS DIRECTORY 14-5. . . . . .

x

275 SERIES II MM190 (NIL)

SPECIFICATIONS 1-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Home

Find...

Go To..

MACHINE SPECIFICATIONS 1-3. . . . . . . . . . . . . . . .

POWER TYPE 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER TRAIN 1-3. . . . . . . . . . . . . . . . . . . . . . . . . .

STEERING 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC SYSTEM 1-3. . . . . . . . . . . . . . . . . . . .

BRAKING SYSTEM 1-4. . . . . . . . . . . . . . . . . . . . . .

SUSPENSION SYSTEM 1-4. . . . . . . . . . . . . . . . . .

SYSTEM FLUID CAPACITIES 1-4. . . . . . . . . . . . .

GENERAL MACHINE

DIMENSIONS/CAPACITIES 1-4. . . . . . . . . . . .

MACHINE WEIGHTS 1-4. . . . . . . . . . . . . . . . . . . . .

GENERAL MACHINE PERFORMANCE 1-4. . . . .

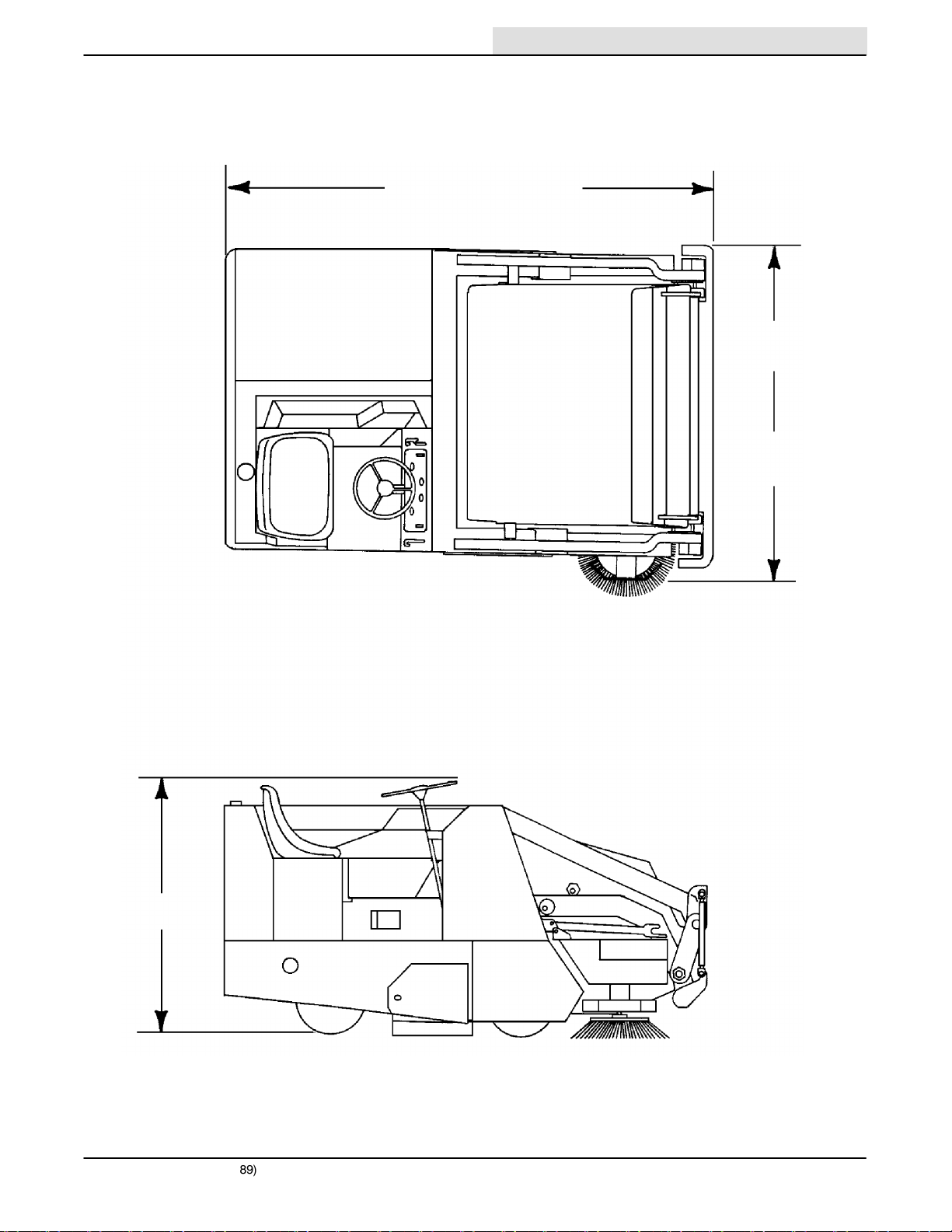

MACHINE DIMENSIONS 1-5. . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

SECTION 1

CONTENTS

Page

275 SERIES II MM190 (12---89)

1-1

SPECIFICATIONS

Home

Find...

Go To..

1-2

275 SERIES II MM190 (12---89)

MACHINE SPECIFICATIONS

Home

Find...

Go To..

SPECIFICATIONS

POWER TYPE

Engine type --- piston

Ignition --- breakerless---type spark

Cycle --- 4

Aspiration --- natural

Cylinders --- 4

Bore --- 2.91 in (74 mm)

Stroke --- 2.97 in (75 mm)

Displacement --- 79 cu in (1300 cc)

Net power --- 28.5 hp (21.2 kw) @ 2200 rpm,

governed

Net power --- 35.5 hp (26.5 kw) @ 2650 rpm,

governed

Net power --- 53.7 hp (40 kw) @ 4000 rpm,

maximum

Fuel --- gasoline, 87 octane minimum, unleaded or

LPG

Cooling system --- water/ethylene glycol antifreeze

Electrical system --- 12 V nominal, 37 A alternator

Engine type --- piston

Ignition --- diesel

Cycle --- 4

Aspiration --- natural

Cylinders --- 3

Bore --- 3.25 in (85 mm)

Stroke --- 3.23 in (82 mm)

Displacement --- 85 cu in (1395 cc)

Net power --- 27 hp (20 kw) @ 2200 rpm, governed

Net power --- 31 hp (23 kw) @ 2650 rpm, governed

Net power --- 32 hp (24 kw) @ 3600 rpm, maximum

Fuel --- diesel, No. 1 or No.2

Cooling system --- water/ethylene glycol antifreeze

Electrical system --- 12 V nominal, 37 A alternator

POWER TRAIN

Propelling --- hydraulic drive motor, rear wheel

Main brush --- hydraulic drive motor

Side brush --- hydraulic drive motor

Vacuum fan --- hydraulic drive motor

STEERING

Type --- rear wheel controlled, automotive worm and

sector gear

Power source --- manual

HYDRAULIC SYSTEM

Function --- operates propelling, hopper lift, hopper

dump, main brush drive, side brush drive, and

vacuum fan drive.

Control valve, low dump model, side brush drive,

hopper lift --- open center type, single spool.

Control valve, multi---level dump model, side brush

drive, hopper lift, hopper dump --- open center

type, two spool.

Control valve, vacuum fan drive, main brush drive ---

open center type, single spool, solenoid

operated.

Pump, propelling --- variable displacement piston

type, 1.24 cu in (20 cc) maximum displacement

per revolution,

11.8 gpm (45 L/min) @ 2200 rpm,

14.2 gpm (54 L/min) @ 2650 rpm

Propelling system relief pressure ---

4000 psi (27,580 kPa)

Pump, accessories --- gear type,

1.02 cu in (14 cc) displacement,

9.5 gpm (36 L/min) @ 2200 rpm,

12.3 gpm (47 L/min) @ 2650 rpm.

Side brush and lift cylinder system relief

pressure --- 1900 psi (13,100 kPa)

Vacuum fan and main brush motor system relief

pressure --- 2150 psi (14,825 kPa)

Motor, propelling --- internal gear type,

19 cu in (310 cc) displacement per revolution,

4500 psi (31,030 kPa) maximum rated

pressure.

Motor, main brush --- internal gear type,

4.5 cu in (75 cc) displacement per revolution,

2500 psi (17,240 kPa) maximum rated pressure

Motor, side brush --- internal gear type,

2.8 cu in (45 cc) displacement per revolution,

1500 psi (10,340 kPa) maximum rated pressure

Motor, vacuum fan --- external gear type,

0.26 cu in (5 cc) displacement per revolution,

3000 psi (20,685 kPa) maximum rated pressure

Cylinder, hopper lift, low dump model --- single

action type, 2.5 in (65 mm) bore x 6 in

(150 mm) stroke, 1.12 in (29 mm) diameter rod,

2500 psi (17,240 kPa) maximum rated pressure

Cylinder, hopper lift, multi---level dump model ---

single action type, 3.5 in (90 mm) bore x

8 in (205 mm) stroke, 1.25 in (32 mm) diameter

rod, 2500 psi (17,240 kPa) maximum rated

pressure

275 SERIES II MM190 (12---89)

1-3

SPECIFICATIONS

Home

Find...

Go To..

Cylinder, hopper dump, multi---level dump model ---

double action type, 2 in (50 mm) bore x

5.38 in (135 mm) stroke, 1 in (25 mm) diameter

rod, 2500 psi (17,240 kPa) maximum rated

pressure

BRAKING SYSTEM

Service brakes --- mechanical drum brakes (2), one

per front wheel, linkage actuated

Parking brakes --- utilize service brakes, linkage

actuated

SUSPENSION SYSTEM

Front, low dump model --- two 4 x 16

semi---pneumatic tires

Front, multi---level dump model --- two 4 x 16 solid

tires

Rear --- one 5.70 x 8 pneumatic tire

Rear --- one 5.00 x 8 solid tire accessory

SYSTEM FLUID CAPACITIES

Engine cooling system, gasoline, LPG radiator ---

4 qt (3.8 L)

Engine cooling system, gasoline, LPG total ---

16 qt (15 L)

Engine cooling system, diesel radiator --- N/A qt

(N/A L)

Engine cooling system, diesel total --- N/A qt

( N/A L)

Engine lubricating oil, gasoline, LPG --- 3.5 qt

(3.3 L) with filter

Engine lubricating oil, diesel --- 7 qt (6.7 L) with filter

Fuel tank, gasoline, diesel --- 7.8 gal (30 L)

Fuel tank, LPG --- 33 lb (15 kg)

Hydraulic system, reservoir --- 5 gal (19 L)

Hydraulic system, total --- 6.3 gal (24 L)

GENERAL MACHINE DIMENSIONS/CAPACITIES

Length, low dump model --- 96 in (2440 mm)

Length, multi---level dump model --- 98 in

(2490 mm)

Width, low dump model --- 56 in (1420 mm)

Width,multi---level dump model --- 59 in (1500 mm)

Height --- 52 in (1320 mm)

Height with overhead guard --- 79 in (2005 mm)

Height with overhead guard and hazard lamp ---

85 in (2160 mm)

Height with cab --- 77 in (1955 mm)

Height with cab and hazard lamp --- 83 in

(2110 mm)

Track --- 46 in (1170 mm)

Wheelbase --- 38 in (965 mm)

Main brush diameter --- 14 in (355 mm)

Main brush length --- 42 in (1065 mm)

Side brush diameter --- 21 in (535 mm)

Sweeping path width --- 42 in (1065 mm)

Sweeping path width with side brush --- 53 in (1345

mm)

Hopper capacity --- 1000 lb (455 kg)

Hopper capacity --- 14 cu ft (0.4 m#)

Dust filter area --- 110 sq ft (10.2 m@)

MACHINE WEIGHTS

Net weight, low dump model --- 2150 lb (975 kg)

Net weight, multi---level dump model --- 2800 lb

(1270 kg)

GVWR, low dump model --- 3200 lb (1450 kg)

GVWR, multi---level dump model --- 3800 lb

(1725 kg)

GENERAL MACHINE PERFORMANCE

Maximum forward speed --- 8.5 mph (13.7 km/h)

Maximum reverse speed --- 4.2 mph (6.8 km/h)

Minimum isle turn width, right, low dump model ---

157 in (3990 mm)

Minimum isle turn width, left, low dump model ---

111 in (2820 mm)

Minimum isle turn width, right, multi---level dump

model --- 161 in (4090 mm)

Minimum isle turn width, left, multi---level dump

model --- 111 in (2820 mm)

Maximum rated climb/descent angle --- 10_ with full

hopper, 15_ with an empty hopper

1-4

275 SERIES II MM190 (12---89)

MACHINE DIMENSIONS

Home

Find...

Go To..

96 in (2440 mm)

Low Dump Model

98 in (2490 mm)

Multi-Level Dump Model

SPECIFICATIONS

56 in (1420 mm)

Low Dump Model

59 in (1500 mm)

Multi-Level Dump

Model

52 in (1320 mm)

275 SERIES II MM190 (12---89)

02452

1-5

SPECIFICATIONS

Home

Find...

Go To..

1-6

275 SERIES II MM190 (12---89)

CONTENTS

Home

Find...

Go To..

OPERATION

SECTION 2

OPERATION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 2-3. . . . . . . . . . .

AFTER UNLOADING AND BEFORE

OPERATING THE MACHINE: 2-3. . . . . . . . .

OPERATION OF CONTROLS 2-4. . . . . . . . . . . . . . .

MACHINE COMPONENTS ---

MULTI-LEVEL DUMP MODEL SHOWN 2-4.

INSTRUMENT PANEL SYMBOLS 2-5. . . . . . . . .

CONTROLS AND INSTRUMENTS 2-7. . . . . . . .

BRAKE PEDAL 2-8. . . . . . . . . . . . . . . . . . . . . . . . .

DIRECTIONAL PEDAL 2-8. . . . . . . . . . . . . . . . . .

PARKING BRAKE LEVER 2-8. . . . . . . . . . . . . . . .

OPERATOR SEAT 2-8. . . . . . . . . . . . . . . . . . . . . .

SQUEEGEE SWITCH 2-8. . . . . . . . . . . . . . . . . . .

WATER VALVE SWITCH 2-8. . . . . . . . . . . . . . . . .

FUEL LEVEL GAUGE 2-8. . . . . . . . . . . . . . . . . . .

THROTTLE LEVER 2-8. . . . . . . . . . . . . . . . . . . . .

THROTTLE SWITCH 2-9. . . . . . . . . . . . . . . . . . . .

HAZARD LIGHT SWITCH 2-9. . . . . . . . . . . . . . . .

ENGINE CHOKE KNOB 2-9. . . . . . . . . . . . . . . . .

DRIVE LIGHTS SWITCH 2-9. . . . . . . . . . . . . . . . .

DIESEL PREHEAT PUSHBUTTON

AND INDICATOR 2-9. . . . . . . . . . . . . . . . . . . .

HOPPER DUMP LEVER 2-9. . . . . . . . . . . . . . . . .

HOPPER LIFT AND SIDE BRUSH LEVER 2-9. .

MAIN BRUSH POSITION LEVER 2-10. . . . . . . . .

MAIN BRUSH HEIGHT

ADJUSTMENT KNOB 2-10. . . . . . . . . . . . . . . .

STEERING WHEEL 2-10. . . . . . . . . . . . . . . . . . . . .

MAIN BRUSH, VACUUM FAN

AND FILTER SHAKER SWITCH 2-10. . . . . . . .

CLOGGED FILTER LAMP 2-10. . . . . . . . . . . . . . . .

ENGINE HOUR METER 2-10. . . . . . . . . . . . . . . . .

ENGINE COOLANT

TEMPERATURE GAUGE 2-11. . . . . . . . . . . . .

ENGINE OIL PRESSURE GAUGE 2-11. . . . . . . .

BATTERY CONDITION GAUGE 2-11. . . . . . . . . .

IGNITION SWITCH 2-11. . . . . . . . . . . . . . . . . . . . .

SIDE BRUSH POSITION LEVER 2-11. . . . . . . . . .

HOPPER SUPPORT BAR 2-11. . . . . . . . . . . . . . . .

TO ENGAGE HOPPER SUPPORT BAR 2-11.

TO DISENGAGE HOPPER

SUPPORT BAR 2-12. . . . . . . . . . . . . . . . . . .

SCRUB BRUSH POSITION LEVER 2-13. . . . . . .

SOLUTION FLOW KNOB 2-13. . . . . . . . . . . . . . . .

CIRCUIT BREAKERS 2-13. . . . . . . . . . . . . . . . . . .

Page

Page

MACHINE OPERATION 2-14. . . . . . . . . . . . . . . . . . . .

NORMAL SWEEPING OPERATION 2-14. . . . . . .

PRE-START CHECKLIST 2-14. . . . . . . . . . . . .

TO START MACHINE 2-14. . . . . . . . . . . . . . . .

TO SWEEP 2-15. . . . . . . . . . . . . . . . . . . . . . . . .

POST OPERATION CHECKLIST ---

ENGINE OPERATING 2-16. . . . . . . . . . . . .

TO STOP MACHINE 2-16. . . . . . . . . . . . . . . . .

POST OPERATION CHECKLIST ---

ENGINE STOPPED 2-16. . . . . . . . . . . . . . .

NORMAL SCRUBBING OPERATION 2-17. . . . . .

PRE-START CHECKLIST 2-17. . . . . . . . . . . . .

TO START MACHINE 2-17. . . . . . . . . . . . . . . .

TO SCRUB 2-18. . . . . . . . . . . . . . . . . . . . . . . . .

TO DRAIN RECOVERY TANK

AND EMPTY DEBRIS HOPPER 2-18. . . . .

POST OPERATION CHECKLIST ---

ENGINE OPERATING 2-19. . . . . . . . . . . . .

TO STOP MACHINE 2-19. . . . . . . . . . . . . . . . .

POST OPERATION CHECKLIST ---

ENGINE STOPPED 2-19. . . . . . . . . . . . . . .

DOUBLE SCRUBBING OPERATION 2-20. . . . . .

OPERATION ON GRADES 2-20. . . . . . . . . . . . . . .

VACUUM WAND 2-20. . . . . . . . . . . . . . . . . . . . . . .

TO OPERATE VACUUM WAND 2-20. . . . . . . .

HOPPER DOLLY 2-21. . . . . . . . . . . . . . . . . . . . . . .

TO REMOVE HOPPER WITH DOLLY 2-21. . .

TO INSTALL HOPPER WITH DOLLY 2-22. . . .

SCRUB ATTACHMENT 2-23. . . . . . . . . . . . . . . . . .

TO MOUNT SCRUB ATTACHMENT 2-23. . . .

TO REMOVE SCRUB ATTACHMENT 2-26. . .

SNOW BLADE 2-27. . . . . . . . . . . . . . . . . . . . . . . . .

TO INSTALL SNOW BLADE 2-27. . . . . . . . . . .

TO OPERATE SNOW BLADE 2-28. . . . . . . . .

TO REMOVE SNOW BLADE 2-29. . . . . . . . . .

SNOW BROOM 2-30. . . . . . . . . . . . . . . . . . . . . . . .

TO INSTALL SNOW BROOM

ASSEMBLY 2-30. . . . . . . . . . . . . . . . . . . . . .

TO OPERATE SNOW BROOM 2-32. . . . . . . .

MACHINE TROUBLESHOOTING ---

SWEEPING 2-34. . . . . . . . . . . . . . . . . . . . . . . . .

MACHINE TROUBLESHOOTING ---

SCRUBBING 2-35. . . . . . . . . . . . . . . . . . . . . . . .

TRANSPORTING MACHINE 2-36. . . . . . . . . . . . . . . .

PUSHING OR TOWING MACHINE 2-36. . . . . . . .

MACHINE JACKING 2-36. . . . . . . . . . . . . . . . . . . .

TO JACK UP MACHINE 2-36. . . . . . . . . . . . . .

MACHINE TIE-DOWNS 2-37. . . . . . . . . . . . . . . . . .

MACHINE STORAGE 2-38. . . . . . . . . . . . . . . . . . . . . .

STORING MACHINE 2-38. . . . . . . . . . . . . . . . . . . .

275 SERIES II MM190 (12---89)

2-1

OPERATION

Home

Find...

Go To..

2-2

275 SERIES II MM190 (12---89)

PREPARATION FOR OPERATION

Home

Find...

Go To..

AFTER UNLOADING AND BEFORE OPERATING

THE MACHINE:

1. Check the machine for shipping damage.

2. Read this manual carefully before operating or

servicing the machine.

FOR SAFETY: Do not operate the machine unless

operation manual is read and understood.

3. Check the hydraulic fluid level in the hydraulic

fluid reservoir, using the dipstick provided.

TENNANTr hydraulic fluid is recommended. If

TENNANTr hydraulic fluid is not available, use

only new, approved hydraulic fluid. See

Hydraulics in the Maintenance section.

4. Check the engine oil level.

5. Check the radiator coolant level.

OPERATION

WARNING: Hot engine coolant. Scalding

can result. Do not open radiator cap or

service cooling system until radiator and engine

is cool to the touch.

6. Check the main brush adjustment, as

described in Brushes in the Maintenance

section.

7. Check the air pressure of the rear tire.

8. Fill the fuel tank, or install an LPG fuel tank on

the machine.

WARNING: Machine can have static

electricity charge. When pouring fuel, spark

can ignite fuel causing fire or explosion. Connect

wire attached to fuel can to machine to discharge

spark before pouring fuel.

275 SERIES II MM190 (12---89)

2-3

OPERATION

Home

Find...

Go To..

J

OPERATION OF CONTROLS

M

L

K

A

B

C

D

E

2-4

I

F

H

G

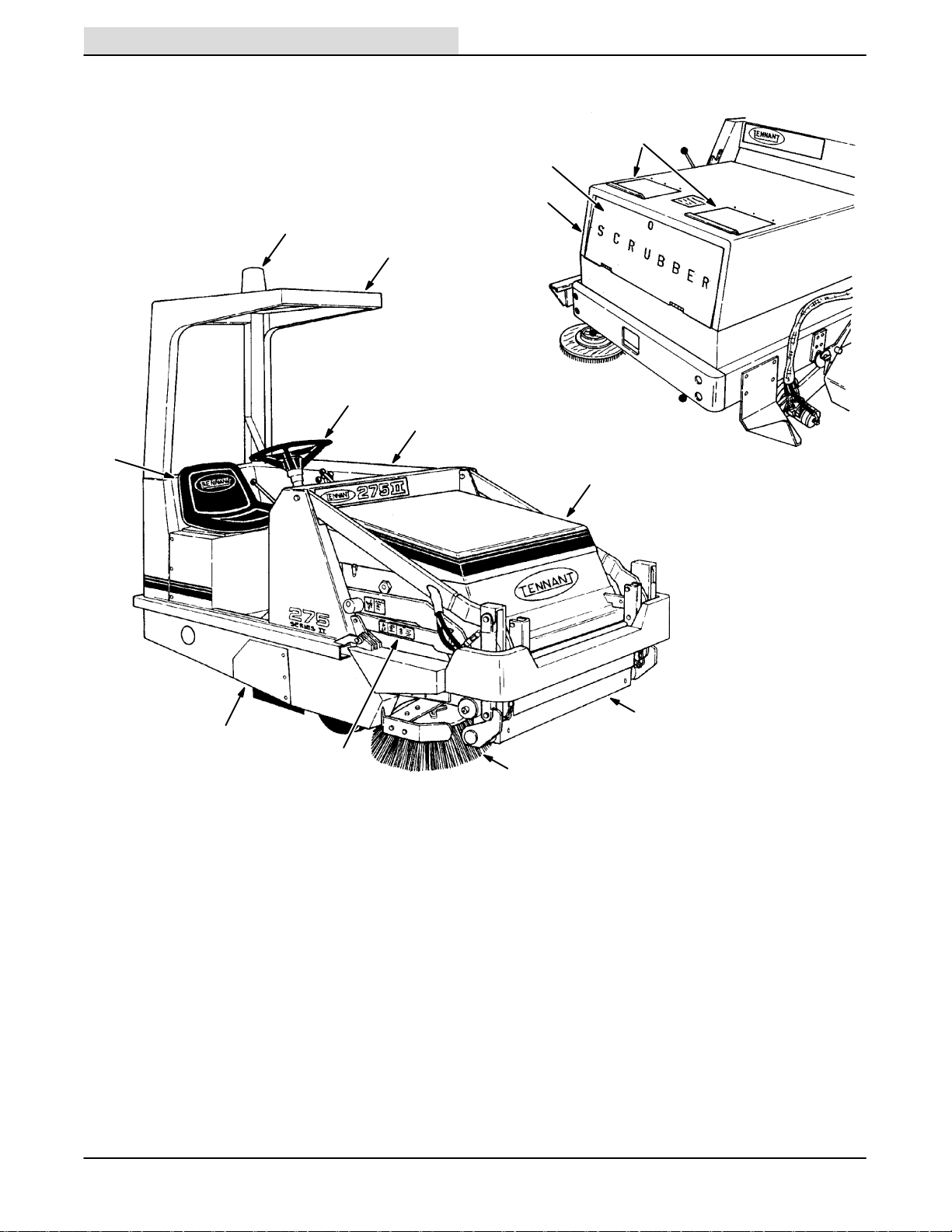

MACHINE COMPONENTS -- MULTI-LEVEL DUMP MODEL SHOWN

A. Hazard Light H. Hopper Support Bar

B. Overhead Guard I. Main Brush Access Door

C. Steering Wheel J. Operator Seat

D. Engine Cover K. Scrub Attachment

E. Hopper Cover L. Front Access Door

F. Hopper Door M. Solution Tank Covers

G. Side Brush

275 SERIES II MM190 (12---89)

02745

02746

INSTRUMENT PANEL SYMBOLS

Home

Find...

Go To..

The symbols are used to identify controls and

displays on the machine:

OPERATION

Squeegee Up

Squeegee Down

Solution Flow

Diesel Off

Idle

Fast 1

Fast 2

Hopper Down

Hopper Hold

Headlights

Hazard Light

Main Brush Free-Float

Main Brush Down

Main Brush Up

Engine Start

Hopper Roll Out

Hopper Roll In/Out Hold

Hopper Roll In

Side Brush On

Hopper Up

Main Brush On

Filter Shaker

Filter Clogged

Key Switch

Side Brush Down

Side Brush Up

275 SERIES II MM190 (12---89)

2-5

OPERATION

Home

Find...

Go To..

INSTRUMENT PANEL SYMBOLS (cont.)

Circuit Breaker 1

Circuit Breaker 2

Circuit Breaker 3

Circuit Breaker 4

Circuit Breaker 5

Circuit Breaker 6

Circuit Breaker 7

2-6

275 SERIES II MM190 (12---89)

OPERATION

Home

Find...

Go To..

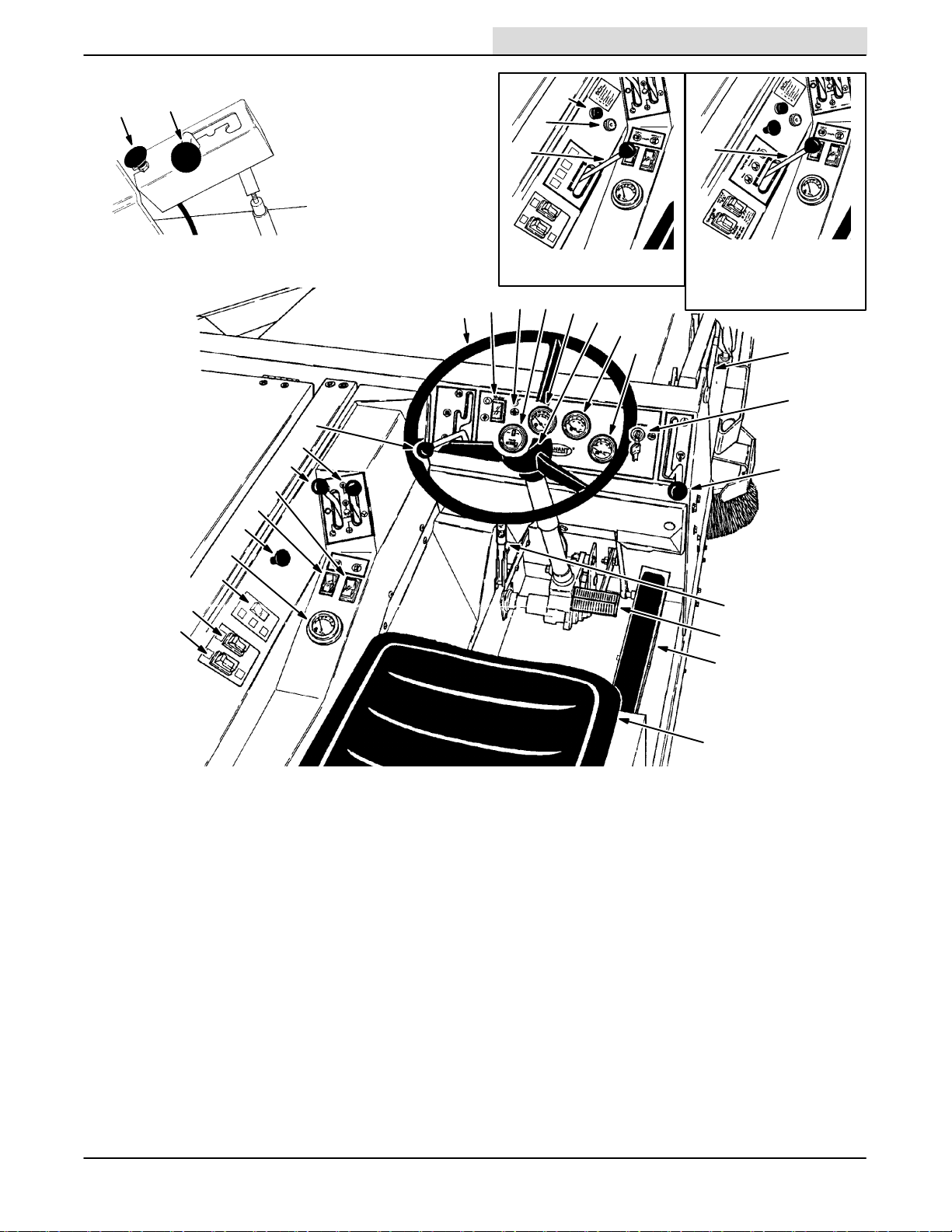

CC

BB

DD

M

L

H

Diesel Powered

Machines

ST

R

Q

U

V

W

X

H

(Gasoline and LPG

powered machines

below serial number

006500)

AA

Y

P

O

N

Z

K

I

J

G

F

E

A. Brake Pedal Q. Steering Wheel

B. Directional Pedal R. Main Brush, Vacuum Fan And

C. Parking Brake Lever Shaker Switch

D. Operator Seat S. Clogged Filter Lamp

E. Squeegee Switch T. Engine Hour Meter

F. Water Valve Switch U. Engine Coolant Temperature Gauge

G. Fuel Level Gauge V. Horn Button

H. Throttle Lever W. Engine Oil Pressure Gauge

I. Hazard Light Switch X. Battery Condition Gauge

J. Engine Choke Knob Y. Ignition Switch

K. Drive Lights Switch Z. Side Brush Position Lever

L. Diesel Preheat Indicator AA.Hopper Support Bar

M. Diesel Preheat Pushbutton BB.Scrub Brush Position Lever

N. Hopper Dump Lever CC.Solution Flow Knob

O. Hopper Lift and Side Brush Lever DD.Throttle Switch

P. Main Brush Position Lever

275 SERIES II MM190 (12---89)

CONTROLS AND INSTRUMENTS

C

A

B

D

05954

02747

05953

04637

2-7

OPERATION

Home

Find...

Go To..

BRAKE PEDAL

The brake pedal operates the mechanical drum

brakes on the two front wheels.

To stop the machine, return the directional pedal to

neutral; then apply pressure to the brake pedal.

DIRECTIONAL PEDAL

The directional pedal controls the propelling drive. It

is used to select the direction of travel and the

propelling speed of the machine.

A

B

C

SQUEEGEE SWITCH

The squeegee switch is present on machines

equipped with the rear squeegee or scrub

attachment accessories. The switch controls the

position of the rear squeegee.

To raise the rear squeegee, place the switch in the

top (Squeegee Up) position. To lower the rear

squeegee, place the switch in the bottom

(Squeegee Down) position.

WATER VALVE SWITCH

The water valve switch is present on machines

equipped with the scrub attachment accessory. The

switch controls solution flow to the floor. The solution

flow knob mounted on the scrub attachment controls

the solution flow rate to the floor.

To start the solution flow to the floor from the scrub

attachment tank, place the switch into the top

position. To stop the solution flow to the floor, place

the switch into the bottom position.

00116

DIRECTIONAL PEDAL

A. “Reverse” Position

B. “Neutral” Position

C. “Forward” Position

To travel forward, press the “toe” portion of the

pedal; to travel backward, press the “heel” portion of

the pedal. The propelling speed of the machine is

regulated by varying the pressure on the pedal.

PARKING BRAKE LEVER

The parking brake lever operates the front wheel

brakes. To engage the parking brake, push the

parking brake handle down. To disengage the

parking brake, pull the brake handle up. Always park

on a level surface, stop the engine, and engage the

parking brake before leaving the machine

unattended and before working on the machine.

OPERATOR SEAT

The operator seat is of a fixed back style with a

forward-backward adjustment. To adjust the seat,

remove the seat mounting bolts, slide the seat to the

position desired, and reinstall and tighten the bolts.

The operator seat also tilts forward to allow access to

the fuel tank.

FUEL LEVEL GAUGE

The fuel level gauge is present on machines with the

fuel level gauge accessory. It indicates how much

fuel is left in the fuel tank. Machines without the

instrument panel mounted gauge have a mechanical

gauge built into the fuel tank cap.

THROTTLE LEVER

The throttle lever controls the engine governed

speed on gasoline and LPG powered machines

below serial number 006500. The throttle lever

controls the engine governed speed and stops the

engine on all diesel powered machines.

When starting the engine and to slow the engine

speed to idle, push the lever into the (Idle)

position.

To pick up normal debris, speed the engine to the

normal governed speed by pulling the lever into the

middle (Fast 1) position.

To pick up light litter, speed the engine to the

maximum governed speed by pulling the lever to the

left into the (Fast 2) position.

To stop the engine on a diesel powered machine,

pull the lever all the way to the right into the

(Diesel Off) position.

2-8

275 SERIES II MM190 (12---89)

Loading...

Loading...