Telwin TECNICAPLASMA18-31 Troubleshooting And Repair Manual

TECNICA 140.1 - 142

cod. 988567

inverter

TECNICA PLASMA 18 -31

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND

REPAIR MANUAL

“reparation no problem !”

CONTENTS PAGE

OPERATION AND WIRING DIAGRAMS................ 2

REPAIR GUIDE.......................................................10

SPARE PARTS LIST...............................................17

REPAIR SHEET......................................................19

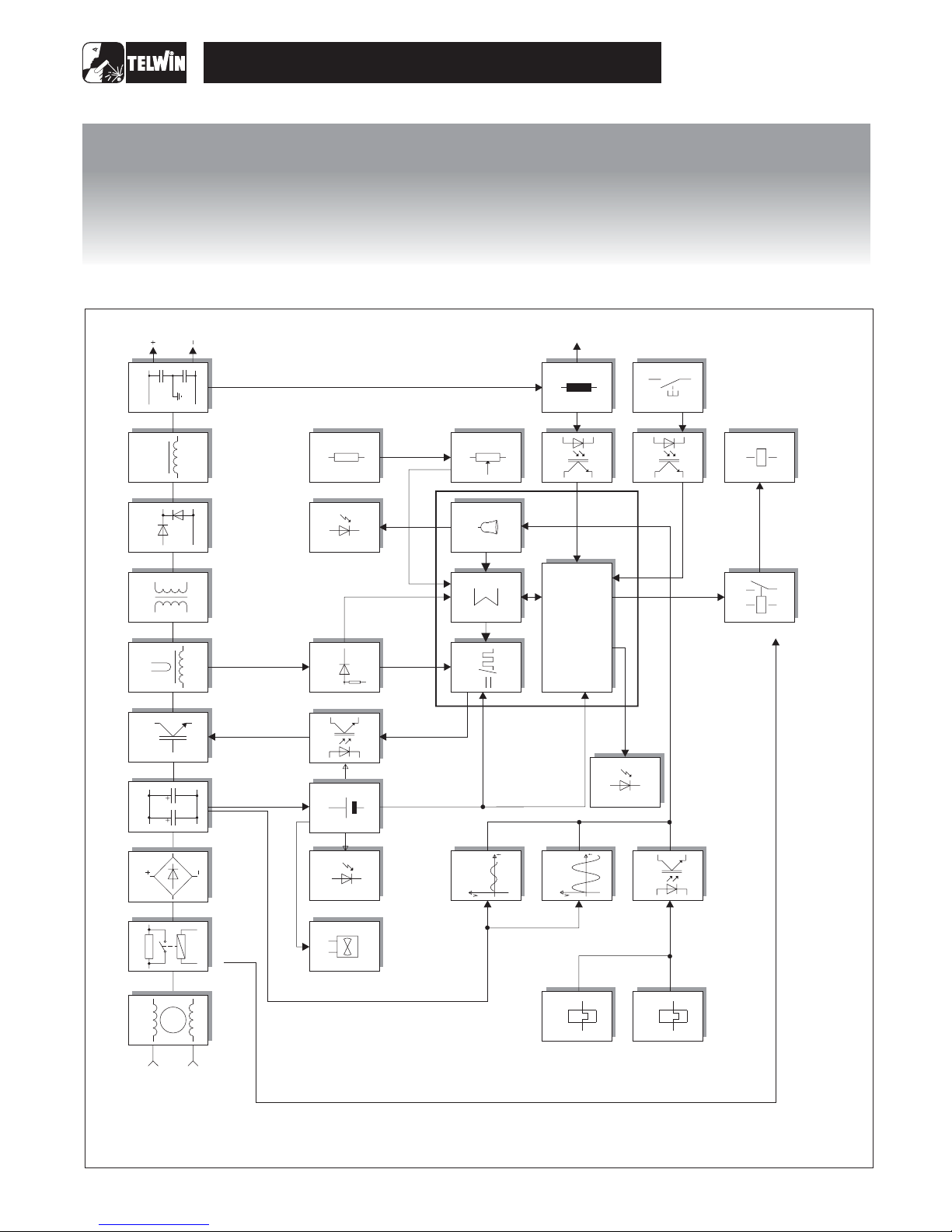

Block diagram 2

Analysis of the block diagram 3

Illustrations 5

Wiring diagrams 6

Equipment required 10

General repair instructions 11

Troubleshooting and remedies 11

Testing the machine 14

Illustrations 16

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND

REPAIR MANUAL

20/09/04

TECNICA PLASMA 18 - 31

-2-

24

25

UNDERVOLTAGE

SAFEGUARD

27

26

11

12

13

17

30

19

21

1

2

3

4

5

6

7

8

9

10

14

15

16

18

FAN

POWER SUPPLY

LED

FLY-BACKPOWER

SUPPLY

DRIVER

OUTPUT

CURRENT

TRANSFORMER

INDUCTANCE

PRIMARY

EMC FILTER

POWER

TRANSFORMER

23

PLASMA

CYCLE

CONTROL

20

TORCH POWER

LED

22

IGBT THERMOSTAT

34

33

29

28

32

31

PILOT ARC

RESISTANCE

OUTPUT

CURRENT

POTENTIOMETER

GALVANIC

SEPARATOR

AIR RALAY

GALVANIC

SEPARATOR

TORCHE BUTTON

AIR SOLENOID

VALVE

AP

BLOCK DIAGRAM

OPERATION AND WIRING DIAGRAMSOPERATION AND WIRING DIAGRAMS

OPERATION AND WIRING DIAGRAMSOPERATION AND WIRING DIAGRAMS

PRE-CHARGE

RECTIFIER BRIDGE

FILTER

CHOPPER

SECONDARY

DIODES

SECONDARY

EMC FILTER

PRIMARY CURRENT

READER AND

LIMITER

DUTY CYCLE

MAKER

ALARM LED

MAXIMUM

CURRENT ADJUST.

OVERVOLATGE

SEFEGUARD

POWERED

TRANSFORMER

THERMOSTAT

ADDER

ALARM BLOCK

GALVANIC

SEPARATOR

INPUT

-3-

ANALYSIS OFTHE BLOCK DIAGRAM

Block 1

Block 2

Block 3

Block 4

Block 5

Block 6

Block 7

Block 8

NOTE:Unlessindicatedotherwise, it should be assumed that

thecomponentsareassembledontheprimaryboard.

Consistingof:C1, L1,C5,C6.

Preventsnoisefromthemachine from being transmittedalong

themain powerline andviceversa.

Consistingof:K1, R1.

Prevents the formation of high transitory currents that could

damage the main power switch, the rectifier bridge and the

electrolyticcapacitors.

When the power source is switched on the relay K1 is deenergised, capacitors C2, C3, C4 are then charged by R1.

Whenthe capacitorsarecharged therelayisenergised.

Consistingof:D1.

Convertsthemainsalternating voltageinto continuouspulsed

voltage.

Consistingof:C2, C3,C4.

Converts the pulsed voltage from the rectifier bridge into

continuousvoltage.

Consistingof:Q1, Q2.

Converts the continuous voltage from the filter into a high

frequency square wave capable of piloting the power

transformer.

Regulates the power according to the required welding

current/voltage.

Consistingof:T2.

TheC.T.isused tomeasurethe currentcirculatingin thepower

transformer primary and transmit the information to block 14

(primary currentreaderand limiter).

Consistingof:T3.

Adjusts the voltage and current to values required for the

welding procedure. Also forms galvanic separation of the

primary from the secondary (welding circuit from the power

supplyline).

Consistingof:D36, D37,D38.

D36 converts the current circulating in the transformer to a

singledirection, preventingsaturationofthe nucleus.

D37, D38 recirculate the inductance output current (block 9)

when the IGBT's are not conducting, bypassing the power

transformer(block7).

EMC Filter

Pre-charge

Rectifier bridge

Filter

Chopper

Current transformer

Powertransformer

Secondary diodes

Block 9

Block 10

Block 11

Block 12

Block 13

Block 14

Block 15

Block 16

Block 17

Inductance

Secondary EMC Filter

Flyback power supply

Driver

Primary current readerand limiter

Duty cycle maker

Adder

Alarm Block

Alarm LED

Consistingof:L2.

Levels the secondary board diodes’ output current making it

practicallycontinuous.

Consistingof: C50, C51.

Prevents noise from the power source from being transmitted

throughthe weldingcablesandviceversa.

Consistingof:T1,U2.

Uses switching methods to transform and stabilise the voltage

obtained from block 4 (filter) and supplies auxiliary voltage to

powerblock12 (driver)and thecontrolboard correctly.

Consistingof:ISO2, ISO3.

Takes the signal from block 11 (flyback power supply) and,

controlled by block 14 (duty cycle maker), makes the signal

suitableforpiloting block6 (chopper).

Consistingof: R37, R38andpartof thecontrolsection.

Readsthe signal from block6(current transformer)and scales

it down so it can be processed and compared in blocks 14 and

15.

Consistingof:U2 (controlboard).

Processes the information from block 15 (adder) and block 13

(primary current reader and limiter) and produces a square

wave with variable duty cycle limiting the primary current to a

maximumpre-set valueunder allcircumstances.

Consistingof:U1C,U1D(control board).

Gathers all the information from block 13 (primary current

reader and limiter), from block 16 (alarms) and from block 18

(current potentiometer), and produces a signal with a suitable

voltageforprocessing byblock14(duty cyclemaker).

Consistingof:U1A, U1B(controlboard).

When an alarm is detected the power source output current is

drastically reduced by making direct adjustments to block 14

(duty cycle maker) and directly changing the reference signal

obtainedfrom block18 (currentpotentiometer).

Consistingof:D26.

Itis switchedon byblock16(alarms)intheeventof:

1) Triggering of thermostatic capsule/thermostat on power

transformer.

2) Triggering of thermostatic capsule/thermostat on IGBT

dissipator.

3) Triggeringduetoundervoltage.

4) Triggeringduetoovervoltage.

TECNICA PLASMA 18 - 31

-4-

Block 27

Block 28

Block 29

Block 30

Block 31

Block 32

Block 33

Block 34

Fan

Torch button

Torch button galvanic separator

Torch powered LED

Air relay

Air solenoid valve

Pilot arc resistance

Pilot arc galvanic separator

Consistingof:V1.

Powered directly by block 11 (flyback transformer) and cools

thepowercomponents.

Consistingof:plasma torch.

Pressing the torch button strikes the pilot arc and enables the

air solenoid valve. The signal is re-dimensioned to enable

processingbyblock29.

Consistingof:ISO1A.

The signal from block 28 is separated galvanically and sent to

block 22 (plasma cycle control) which will process the

information.

Consistingof:D35 yellowLED.

This lights up under instruction from block 20 (plasma cycle

control) when the torch button is pressed and it indicates that

thecutting circuitisactivated.

Consistingof:K2.

Thisis energised underinstructionfromblock20(plasmacycle

control) and activates block 32 (air

Consistingof:solenoid valve.

Supplies the compressed air, to permit pilot arc strike, and is

necessaryfortorchoperationand cooling.

Consistingof:R43 andR44.

Allowsthe pilot arc tostrikefor amaximumof2 seconds.Within

this time the electric arc should have been transferred to the

pieceof iron to be cut: if not block 20 (plasma cycle control) will

resetthe completecuttingcycle.

Consistingof:ISOD andISOB.

The signal from block 33 is separated galvanically and sent to

block20 (plasma cycle control) forcorrect management of the

plasmacutting cycle.

solenoid valve) when

thetorchbuttonis pressed.

TECNICA PLASMA 18 - 31

Block 18

Block 19

Block 20

Block 21

Block 22

Block 23

Block 24

Block 25

Block 26

Current potentiometer

Maximum current adjustment

Plasma cycle control (control board)

Powertransformer thermostat

IGBT thermostat

Galvanic separator

Overvoltage safeguard

Undervoltage safeguard

Powersupply LED

Consistingof:R42.

This is used to set the reference voltage needed to adjust the

output current: when the potentiometer knob is turned the

cursor voltage varies, thus varying the current from the

minimumto themaximumvalue.

Consistingof:R32, R33,R42.

Used to adjust the maximum cutting current to be supplied by

thepowersource.

Logiccontrolboardthatmanagestypicaltimingforthe plasma

cuttingcycle withthecontact torch.

Consistingof:ST2.

When the temperature of the power transformer is too high,

this safeguard is triggered. It is reset automatically after the

alarm conditionhas ceased.

Consistingof:ST1.

When the temperature on the IGBT dissipator reaches a preset level the thermostat triggers to indicate an alarm to block

23 (galvanic separator). Reset is automatic when the alarm

conditionceases.

Consistingof:ISO1C.

The signal from blocks 21 and 22 (thermostats) is separated

galvanically and sent to block 16 (alarms) for identification of

possiblealarm condition.

Consistingof:R3, R4andpartof thecontrolsection.

If the main supply voltage exceeds the maximum value this

safeguard triggers (a tolerance of approx.±15% of the power

supply voltage is allowed: outside this range the safeguard

triggers).

Consistingof:R5, R6andpartof controlboard.

If the main supply voltage falls below the minimum allowed

value this safeguard triggers (a tolerance of approx.±15% of

the power supply voltage is allowed: outside this range the

safeguardtriggers).

Consistingof:D2.

Indicates when the power source is correctly powered and

readyforuse.

-5-

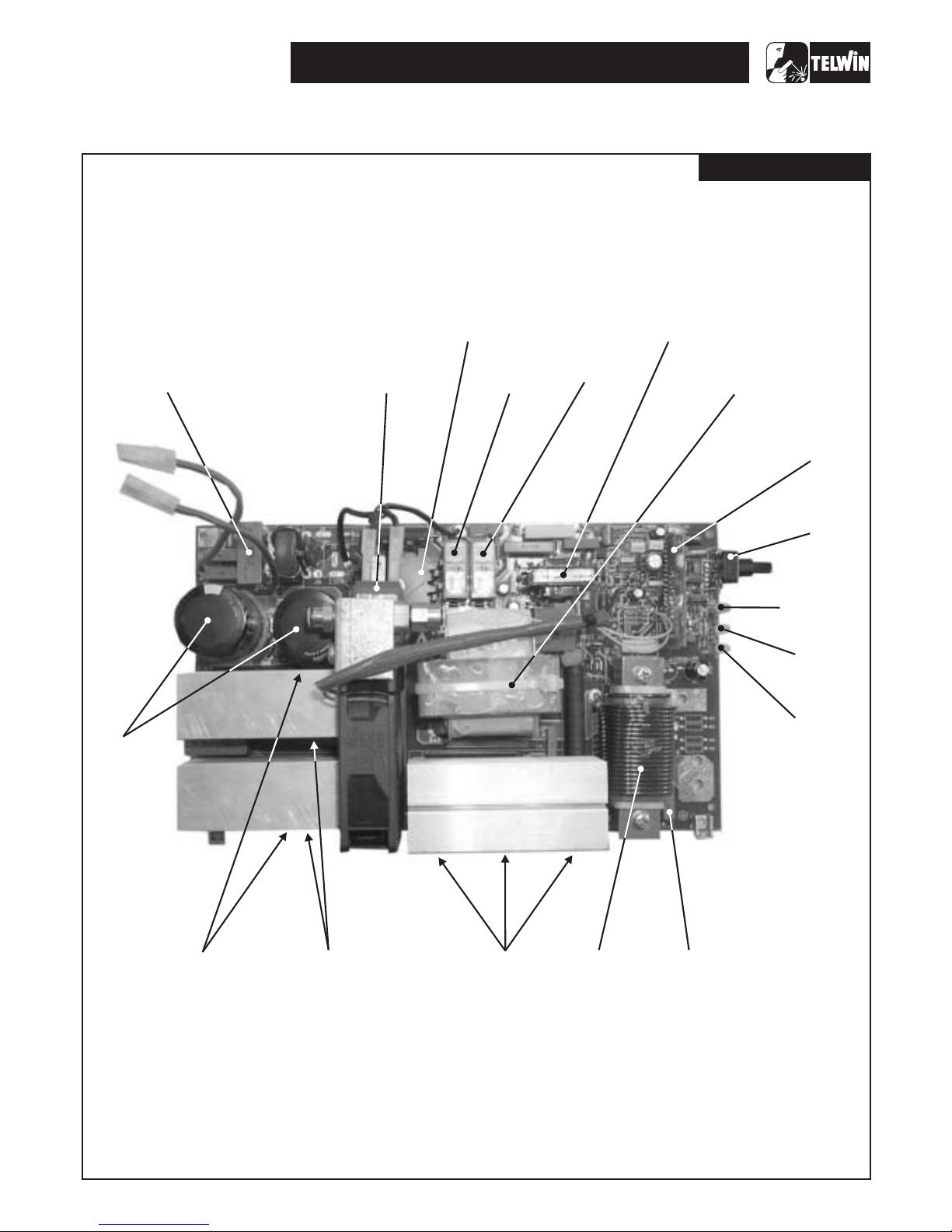

Power board

TECNICA PLASMA 18 - 31

(12)

DRIVER

(5)

CHOPPER

(31)

AIR

RELAY

(32)

AIR SOLENOID

VALV E

(3)

RECTIFIER

BRIDGE

(11)

FLY-BACK

POWER SUPPLY

PLASMA

CONTROL

BOARD

(4)

FILTER

(1)

EMC

FILTRE

PRIMARY

(7)

POWER

TRANSFORMER

(10)

SECONDARY

FILTER EMC

(8)

SECONDARY

DIODES

(2)

PRE-CHARGE

(18)

CURRENT

POTENTIOMETER

(26)

POWER

SUPPLY LED

(30)

TORCH

POWERED LED

(17)

ALARM

LED

(9)

INDUCTANCE

ILLUSTRATIONS

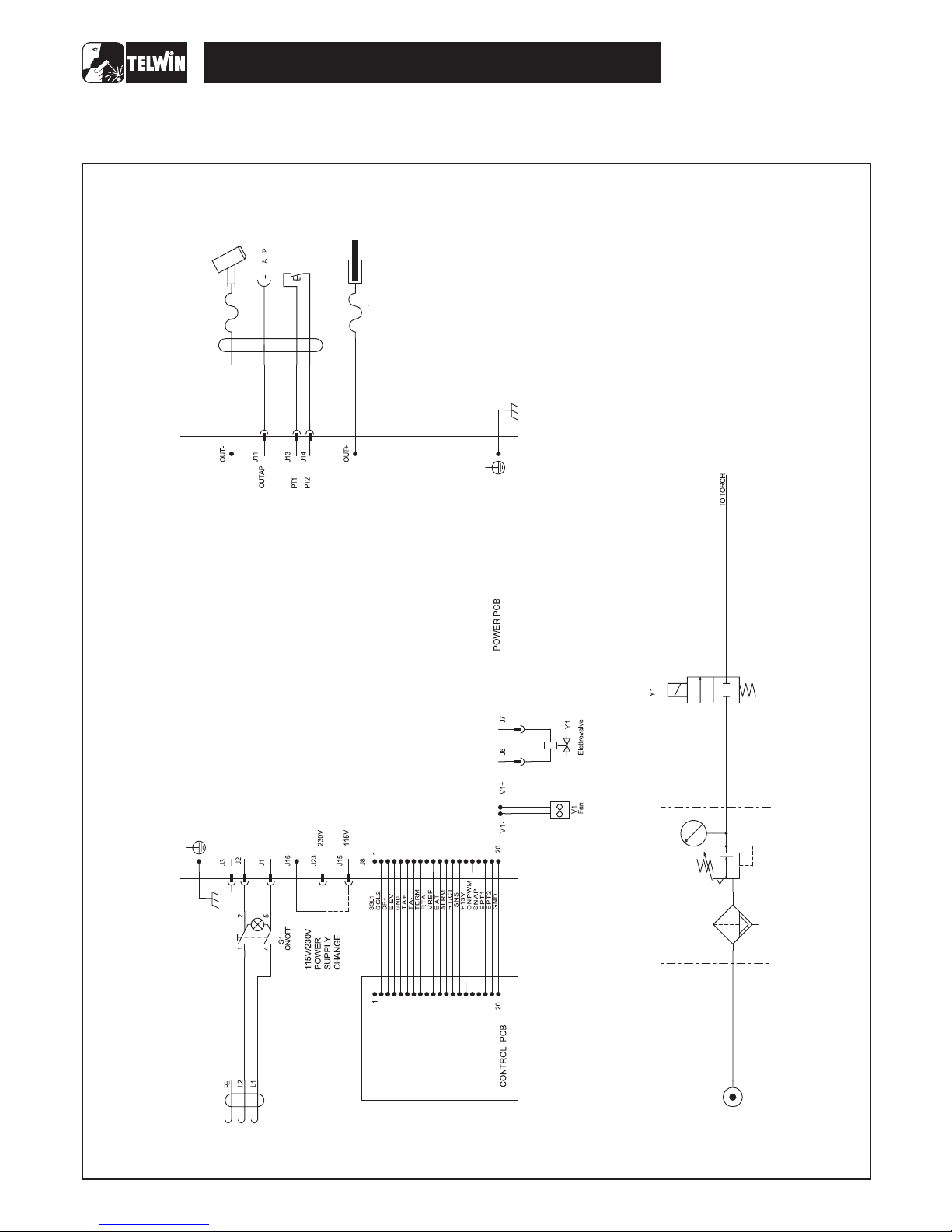

-6-

TECNICA PLASMA 18 - 31

TECNICA PLASMA 18 - 31

WIRING DIAGRAMS

General wiring diagram

Loading...

Loading...