Telwin TECNICA144-164 Troubleshooting And Repair Manual

TECNICA 140.1 - 142

cod. 988637

inverter

TECNICA 144-164

CONTENTS PAGE

OPERATION AND WIRING DIAGRAMS................ 2

REPAIR GUIDE...................................................... 9

SPARE PARTS LIST...............................................18

REPAIR SHEET......................................................20

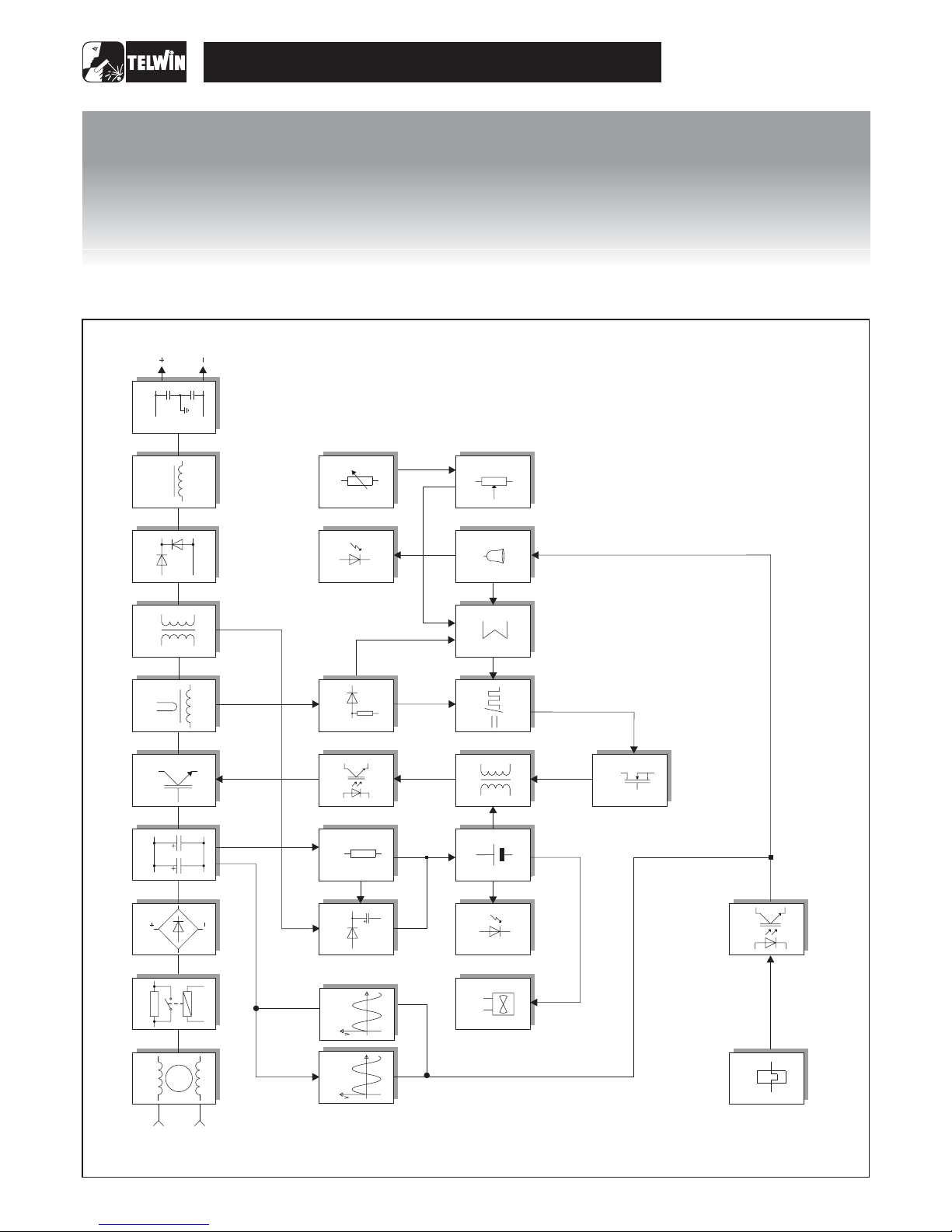

Block diagram 2

Analysis of the block diagram 3

Illustrations 5

Wiring diagrams 6

Equipment required 9

General repair instructions 10

Troubleshooting and remedies 10

Testing the machine 13

Illustrations 15

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND

REPAIR MANUAL

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND

REPAIR MANUAL

“reparation no problem !”

TECNICA 144 - 164

-2-

26

t

OVERVOLTAGE

PROTECTION

BLOCK DIAGRAM

OPERATION AND WIRING DIAGRAMSOPERATION AND WIRING DIAGRAMS

OPERATION AND WIRING DIAGRAMSOPERATION AND WIRING DIAGRAMS

6

1

7

22

CURRENT

POTENTIOMETER

25

11

ALIMENTATORE

FLY-BACK

13

15

SEPARATOR

TRANSFORMER

28

29

24

16

TRANSFORMER

PILOT

18

19

ADDER

20

ALARM CLOCK

2

3

4

5

8

8

9

17

14

10

12

AUXILIARY POWER

SUPPLYTRIGGER

11

VOLTAGE

RECTIFIER

21

27

t

23

OUTPUT

CURRENT

TRANSFORMER

INDUCTANCE

EMC FILTER II°

PRIMARY

EMC FILTER

POWER

TRANSFORMER

SECONDARY

DIODES

FILTER

CHOPPER

RECTIFIER BRIDGE

PRE-CHARGE

INPUT

FAN

POWER SUPPLY

LED

AUXILIARY POWER

SUPPLY

DRIVER

ALARM LED

PRIMARY CURRENT

READER AND LIMITER

MAXIMUM

CURRENT ADJUST.

DUTY CYCLE

MAKER

OVERVOLATGE

SEFEGUARD

THERMOSTATS

GALVANIC

SEPARATOR

POWER

TRANSFORMER

THERMOSTAT

-3-

ANALYSIS OF THE BLOCK DIAGRAM

NOTE: Unless indicated otherwise, it should be assumed that

the components areassembled on thepower board.

Consisting of: C1,T4, C8, C15.

Prevents noise from the machine from being transmitted along

the main powerline and vice versa.

Consisting of: PD1,R4.

Prevents the formation of high transitory currents that could

damage the main power switch, the rectifier bridge and the

electrolytic capacitors.

When the power source is switched on the relay PD1 is deenergised, capacitors C21, C22, C27 are then charged by R4.

When the capacitorsare charged the relayis energised.

Consisting of: PD1.

Converts the mains alternating voltage into continuous pulsed

voltage.

Consisting of: C21,C22, C27.

Converts the pulsed voltage from the rectifier bridge into

continuous voltage.

Consisting of: Q5,Q8.

Converts the continuous voltage from the filter into a high

frequency square wave capable of piloting the power

transformer.

Regulates the power according to the required welding

current/voltage.

Consisting of: T2.

The C.T. is used to measure the current circulating in the

power transformer primary and transmit the information to

block 17 (primarycurrent reader and limiter).

Consisting of: T3.

Adjusts the voltage and current to values required for the

welding procedure. Also forms galvanic separation of the

primary from the secondary (welding circuit from the power

supply line).

Consisting of: D32,D33, D34 .

D34 converts the current circulating in the transformer to a

single direction, preventingsaturation of the nucleus.

D32, D33 recirculate the inductance output current (block 9)

when the IGBT's are not conducting, bypassing the power

transformer (block 7).

Block 1

Block 2

Block 3

Block 4

Block 5

Block 6

Block 7

Block 8

EMC Filter

Pre-charge

Rectifier bridge

Filter

Chopper

Current transformer

Power transformer

Secondary diodes

Block 9

Block 10

Block 17

Block 18

Inductance

Secondary EMC Filter

Primary current readerand limiter

Duty cycle maker

Consisting of: L1.

Levels the secondary board diodes’ output current making it

practically continuous.

Consisting of: C28, C33.

Prevents noise from the power source from being transmitted

through the weldingcables and vice versa.

Consisting of: D2, R25.

Reads the signal from block 6 (current transformer) and scales

it down so it can be processed and compared in blocks 18 and

19.

Consisting of: U1.

Processes the information from block 19 (adder) and block 17

(primary current reader and limiter) and produces a square

wave with variable duty cycle limiting the primary current to a

maximum pre-set valueunder all circumstances.

Block 11

Block 12

Block 13

Block 14

Block 15

Block 16

Voltagerectifier

Auxiliary power supplytrigger

Auxiliary power supply

Driver

Separator transformer

TransformerPilot

Consisting of: D11,C18.

Rectifies and filters the voltage from the tertiary winding of the

power transformer (block7).

Consisting of: R18,R35, C20.

Via the resistors, the power source supplies the necessary

voltage to powerblock 13 (power supply).

Consisting of: U3,C17.

Stabilises the voltage at 12Vdc for the power arriving from

block 12 (auxiliary power supply trigger) and from block 11

(voltage rectifier).

Consisting of: Q6,D19, D23, Q7, D27,D26

Picks up the signal arriving from block 15 (separator

transformer) and under the control of block 17 (transformer

pilot) adjusts itto suit piloting ofblock 5 (chopper).

Consisting of: T1.

Supplies two signals, which are separated galvanically from

one another, that will be sent to powerblock 14 (driver).

Consisting of: Q4,D20, D22, D24.

Amplifies the signal arriving from block 18 (duty cycle maker),

needed to pilotblock 15 (separator transformer).

TECNICA 144 - 164

-4-

Block 27

Block 28

Block 29

Power supply LED

Fan

Consisting of: D10.

Indicates when the power source is correctly powered and

ready for use.

Consisting of: V1.

Powered directly by block 13 (flyback transformer) and cools

the power components.

Undervoltage safeguard

Consisting of: R39, R64, U2B .

If the main supply voltage falls below the minimum allowed

value this safeguard triggers (a tolerance of approx. ±15% of

the power supply voltage is allowed: outside this range the

safeguard triggers).

Block 19

Block 20

Block 21

Block 22

Block 23

Block 24

Adder

Alarm Block

Alarm LED

Current potentiometer

Maximum current adjustment

Power transformer thermostat

Overvoltage safeguard

Consisting of: U2C.

Gathers all the information from block 17 (primary current

reader and limiter), from block 20 (alarms) and from block 22

(current potentiometer), and produces a signal with a suitable

voltage for processingby block 18 (duty cycle maker).

Consisting of: Q3,R43, R44, R38, R36

When an alarm is detected the power source output current is

drastically reduced by making direct adjustments to block 18

(duty cycle maker) and directly changing the reference signal

obtained from block22 (current potentiometer).

Consisting of: D12.

It is switchedon by block 20(alarms) in theevent of:

1) Triggering of thermostatic capsule/thermostat on power

transformer.

Triggering due to undervoltage.

3) Triggering due to overvoltage.

4) Short circuit at output (electrode holder clamp and earth

cable connected to one another or electrode stuck to piece

being welded).

Consisting of: R23.

This is used to set the reference voltage needed to adjust the

output current: when the potentiometer knob is turned the

cursor voltage varies, thus varying the current from the

minimum to themaximum value.

Consisting of: JP1,JP2, JP3.

Used to adjust the maximum cutting current to be supplied by

the power source.

Consisting of: ST1.

When the temperature of the power transformer is too high,

this safeguard is triggered. It is reset automatically after the

alarm condition hasceased.

Consisting of: R1,R5, R14, R19, R24,R29, U2A.

If the main supply voltage exceeds the maximum value this

safeguard triggers (a tolerance of approx. ±15% of the power

supply voltage is allowed: outside this range the safeguard

triggers).

2)

Consisting of: ISO1.

The signal arriving from blocks 24 (power transformer

thermostat) is separated galvanically and sent to block 20

(alarms) for detectionof a possible alarmevent.

Block 25

Block 26

Galvanic separation

TECNICA 144 - 164

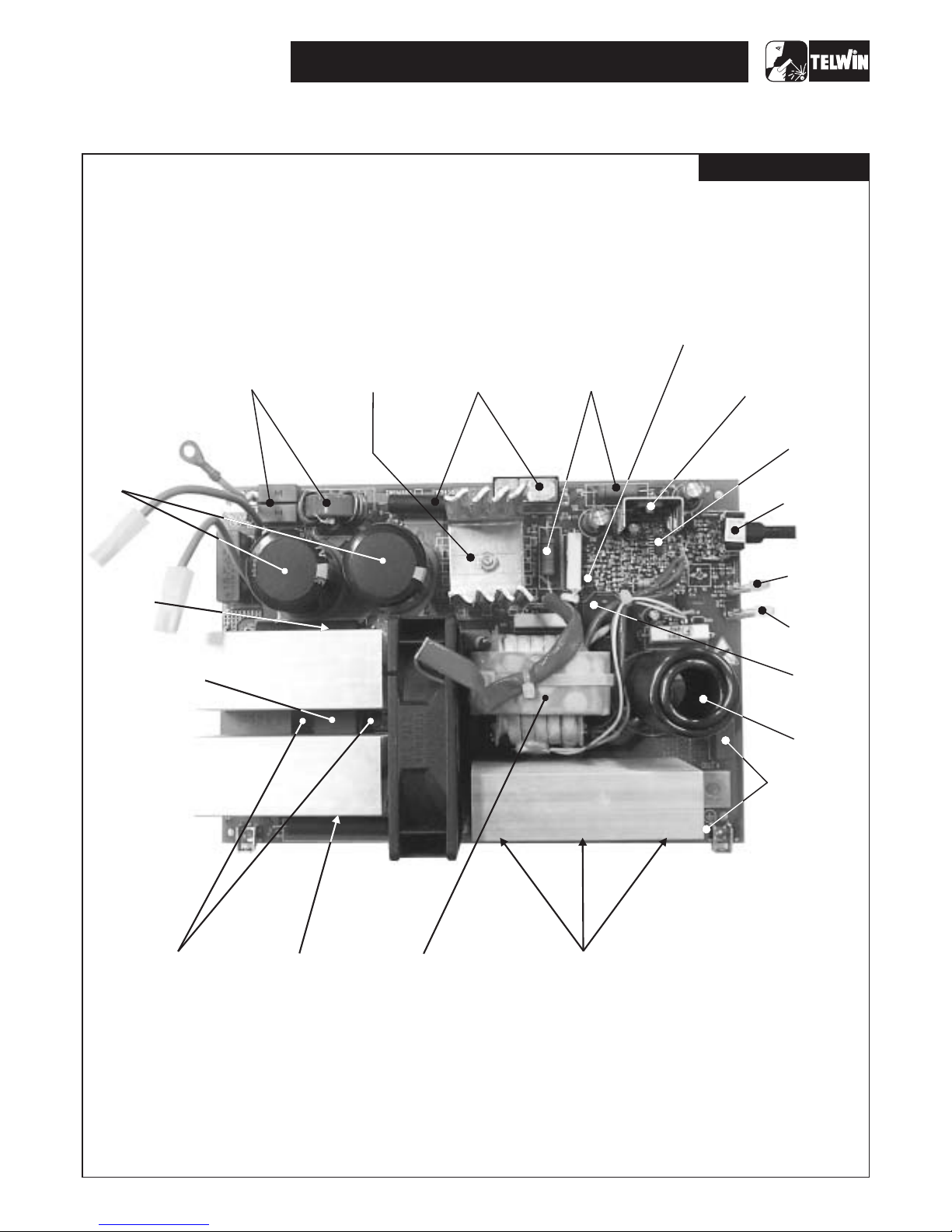

ILLUSTRATIONS

-5-

(5)

CHOPPER

(7)

POWER

TRANSFORMER

TECNICA 144 - 164

Power boad

(1)

PRIMARY EMC

FILTRE

(3)

RECTIFIER

BRIDGE

(2)

PRE-CHARGE

(6)

POWER

TRANSFORMER

(14)

DRIVER

(5)

CHOPPER

(4)

FILTER

(22)

CURRENT

POTENTIOM.

(15)

TRANSFORMER

SEPARATOR

(18)

DUTY CYCLE

MAKER

(10)

SECONDARY

FILTER EMC

(8)

SECONDARY

DIODES

(21)

ALARM

LED

(9)

INDUCTANCE

(12)

AUXILIARY POWER

SUPPLY TRIGGER

(28)

POWER

SUPPLY

LED

(19)

ADDER

(13)

AUXILIARY POWER

SUPPLY

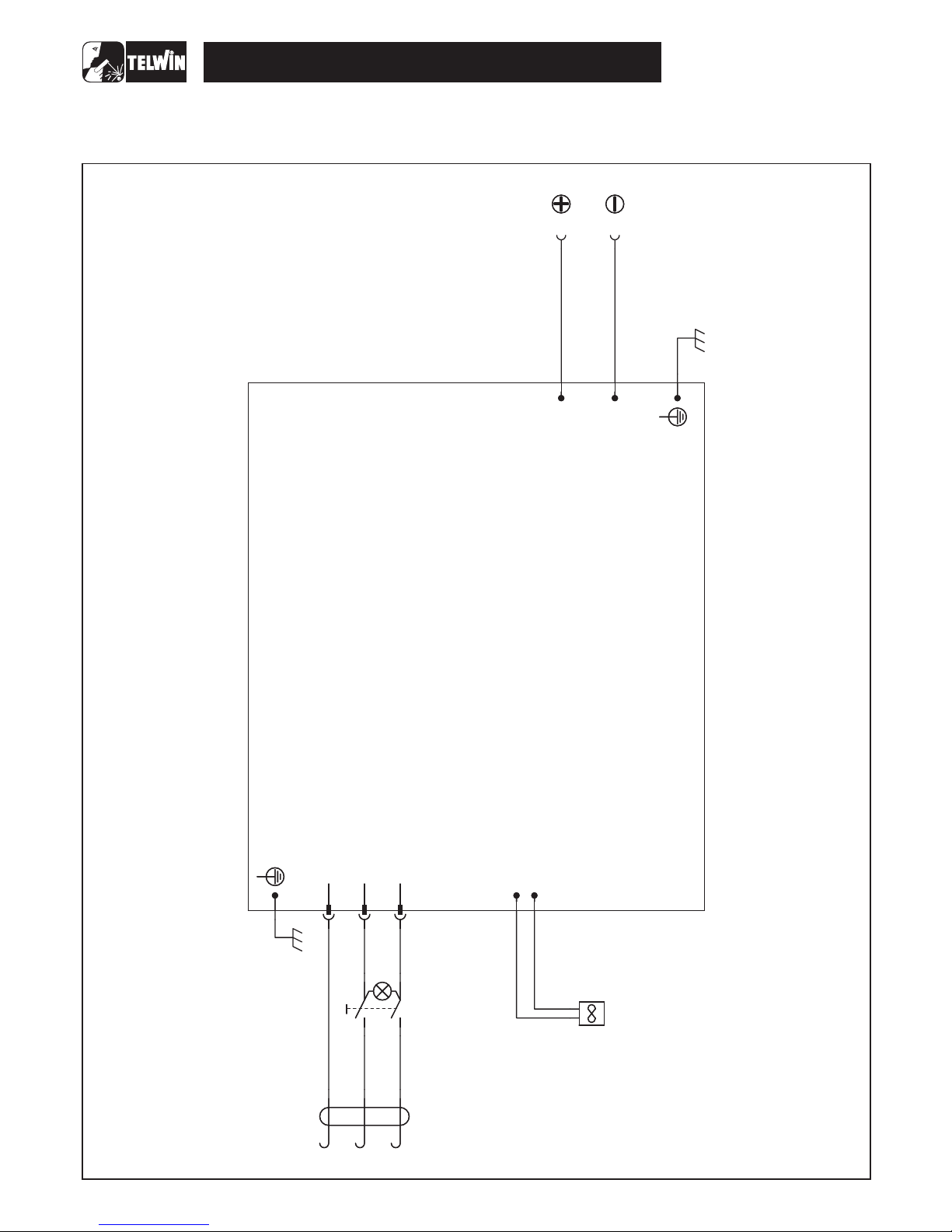

-6-

TECNICA 144 - 164

POWER PCB

J3J3

J4-J4-

J2J2

PE

N (L2)

L1

PE

N (L2)

L1

OUT+OUT+

V1

Fan

OUT-OUT-

J1J1

J7J7

54

12

S1

ON/OFF

54

12

S1

ON/OFF

J4+J4+

WIRING DIAGRAMS

General wiring diagram

-7-

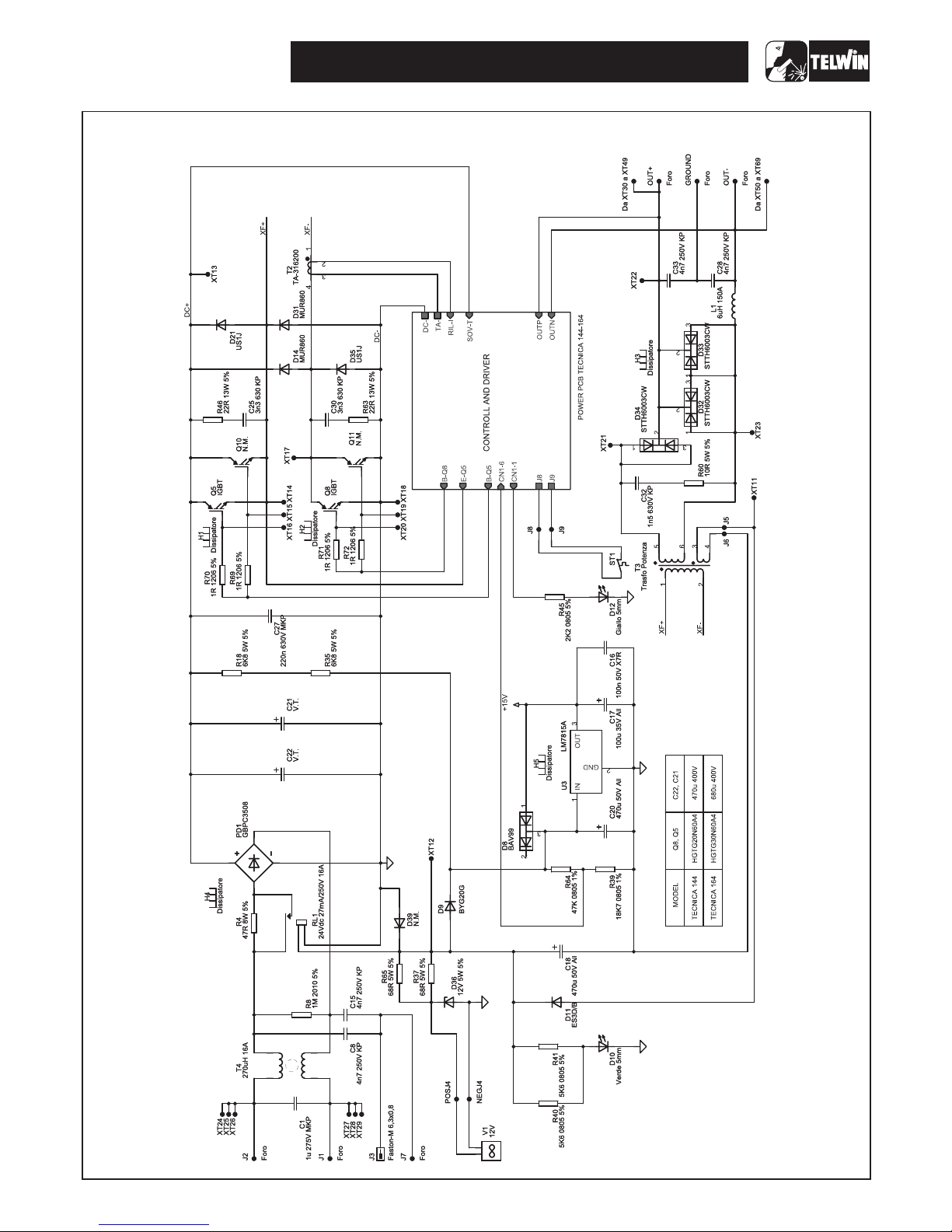

TECNICA 144 - 164

Wiring diagram power board – power supply

Loading...

Loading...