Page 1

Copyright Notice

No part of this publication may be copied without the express written permission of Telonics, Inc.,

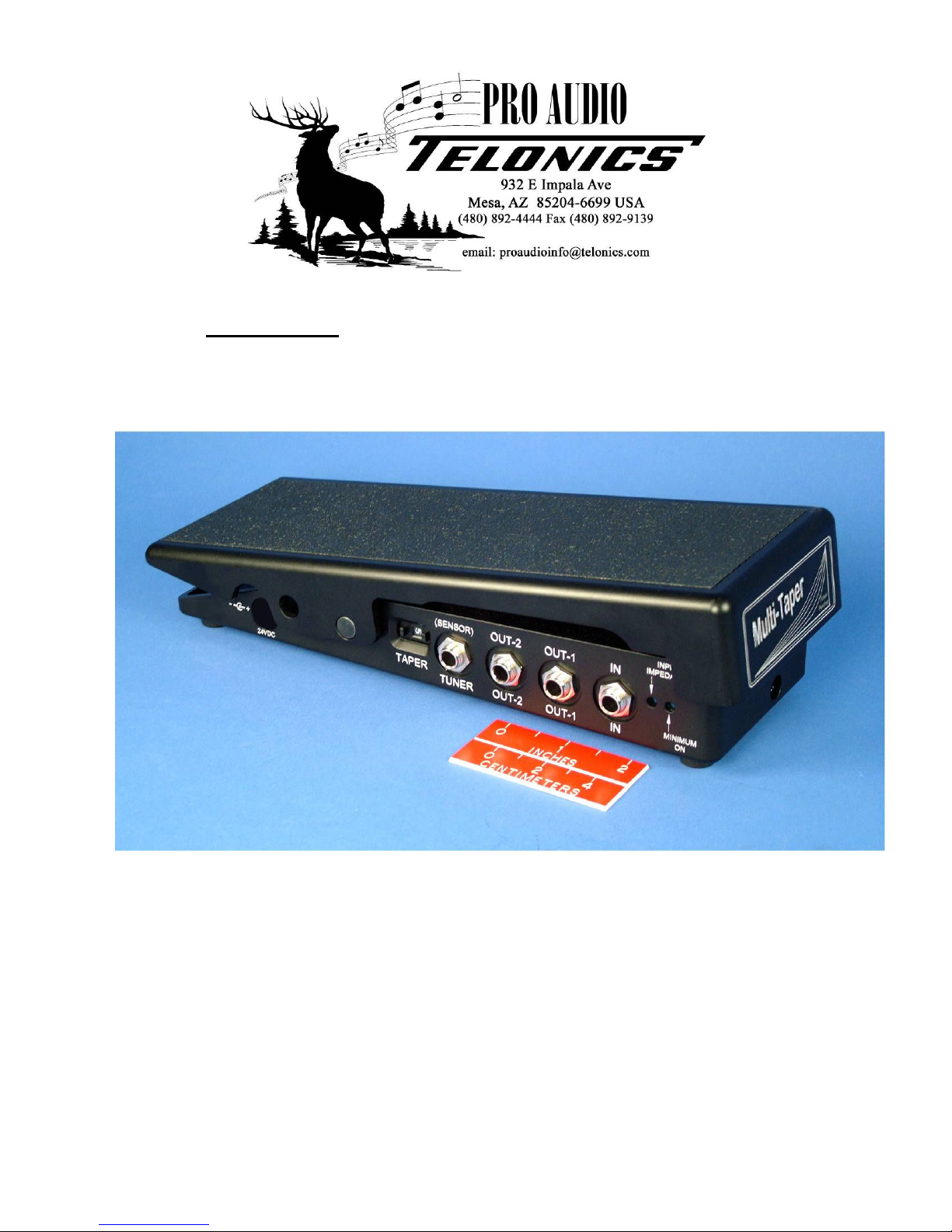

Multi-Taper © “Foot Pedal”Audio Control System

Patented

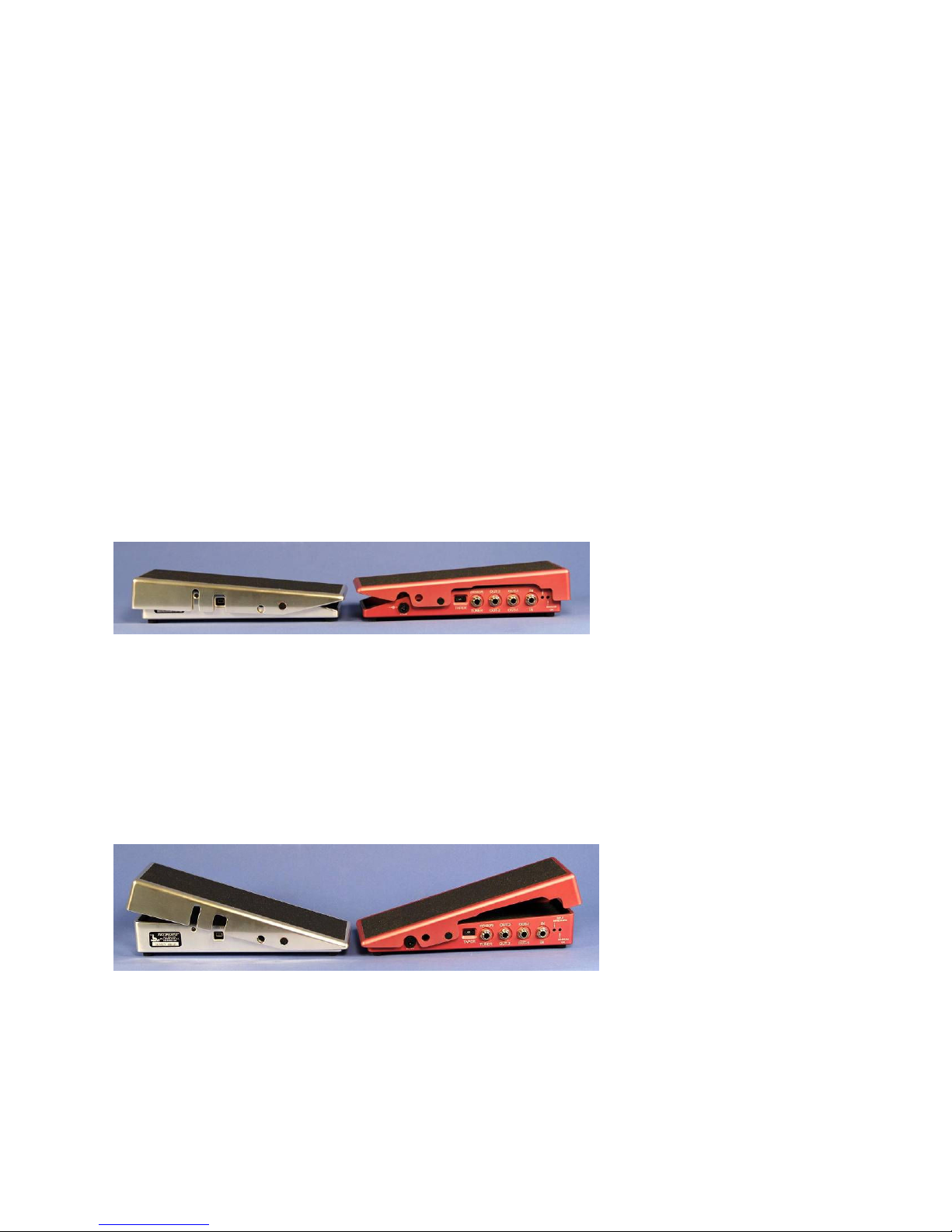

Typical FP-100 Configuration

Copyright 2015 Telonics, Inc.

All Rights Reserved.

This device is fully covered by a multiplicity of patents, both granted and pending.

932 E. Impala Ave., Mesa, AZ 85204.

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 1 of 22

Page 2

Multi-Taper © “Foot Pedal” Audio Control System

General Description:

This “pedal” is actually a family of advanced technology volume and/or audio effects control

systems based upon a series of revolutionary technologies developed by Telonics, Inc. This system

takes the mechanical form of a conventional foot pedal which can be configured with the

axle/pivot point installed in what has historically been called “high” or “low” configuration

(although this historical terminology is still used, the actual physical height is “low” regardless of

the pivot point chosen). It can be used as a foot pedal of the simplest form; however it contains

technical capabilities which far exceed those of any currently available audio dynamics control

device. The basic model includes accurate emulations of virtually all audio tapers of mechanical

potentiometers (“pots”) used in the past, as well as the audio control “taper” of all popular

electronic foot pedals. It also includes one or more recently developed tapers which add

capabilities related such things as gain and sustain – which have not been available to musicians in

the past. (Additional replica tapers or custom tapers can be factory installed via the USB port).

Tapers are selectable by means of a digital switch on the side of the unit near the input and output

jacks. This patented control system does not utilize potentiometers, encoders or light devices of

any type. There are no components to physically wear out.

It incorporates the latest technology in low-noise, analog high headroom amplification - in a class

with the latest exceptional dynamic response studio-grade amplifiers, while preserving the warmth

of vintage tone. Like all Telonics equipment, it is fully analog. The signal chain is never digitized,

therefore A/D or D/A noise is Not added to your signal. The FP-100 system does not modify your

tone (unless you load down your pickup with the Impedance Control). In terms of frequency

response, it is “flat”, or “transparent”. You may “think” it boosts the high frequency response, but

it Does Not. It simply allows you to hear what has always been there, but was attenuated by your

system prior to installing the FP-100. It is fully buffered, preventing noise from externally

connected tuners and other devices from entering the signal chain as well as providing safety from

system malfunction due to shorted or intermittent cables. A full-time tuner output allows tuning

with the pedal in any position, including the “off”/minimum position. It is factory programmed via

a miniature USB port. Subsequent software updates and additional capabilities may be uploaded

via this USB port. The FP-100 is machined from solid aluminum billet block. It will not skate

around the floor with normal foot movement. It is designed to accept most popular pedal bar

brackets and attachment devices. A patented blue LED pedal-board light also indicates both proper

power and that it is operating within acceptable parameters. The light can also indicate abnormal

operation through an internal error code reporting system.

An optional micro-miniature remote sensor is available which assumes full control of the pedal

in terms of treadle movement when plugged in. This remote control system opens limitless

possibilities, from mechanical control by instruments, to usage by musicians who have a physical

impairment and have been prevented from playing until now. (A remote sensor will be supplied at

no charge to individuals who suffer a physical impairment which can be aided by this remote

control device).

Its internal circuitry is well-behaved in terms of power supply connection, interruption or

disconnection, thereby minimizing noise which might annoy listeners or possibly damage speaker

systems. This is no garage-shop hobbyist toy. It is the culmination of years of research, designed

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 2 of 22

Page 3

and hand-built in the U.S.A. by leading and internationally recognized aerospace engineers,

technicians, assemblers and musicians in a state-of-the-art facility in Mesa, Arizona by Telonics,

Inc., an established leader in scientific instrumentation and communications since the 1970’s.

Dependability, long-term reliability, performance and value are paramount in this pedal/system.

Service, support and advice is always as close as the telephone or e-mail.

Telonics, Inc. is well known by scientists world-wide for the manner in which we stand firmly

behind our products on a personal basis. Please contact us with any questions you might have, we

invite design comments and are open to any and all suggestions:

dave@telonics.com sophie@telonics.com stacy@telonics.com

TEL: 480 892-4444 ext. 122 or ext.102 FAX: 480 892-9139

www.telonics.com

Mechanical

Pedal:

Material: CNC milled 6061-T6 Aluminum with hardened bearing surfaces

Axles are oil-hardened (O1) tool steel, 55-60 C-scale Rockwell

Finish: Heavy hard anodized (Mil-A-8625 Type II, Class 2, 0.002”)

Lettering: Laser-engraved (all markings are burned through the hard

anodize coating. No paints or inks are used on the product,

markings will not smear or wear off.)

Outline

Dimensions: 10.6L x 3.7W x 2.4H in. (27L x 9W x 6.1H cm)

Weight: 2.35 lb (1.06 kg)

Optional External Sensor:

Size: 0.8L x 0.9W x 0.125H in. maximum

(20.3L x 22.9W x 3.2H mm) maximum

Connector: ¼” TRS male “Stereo Plug” (Tip-Ring-Shield/Sleeve)

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 3 of 22

Page 4

Mechanical Adjustments:

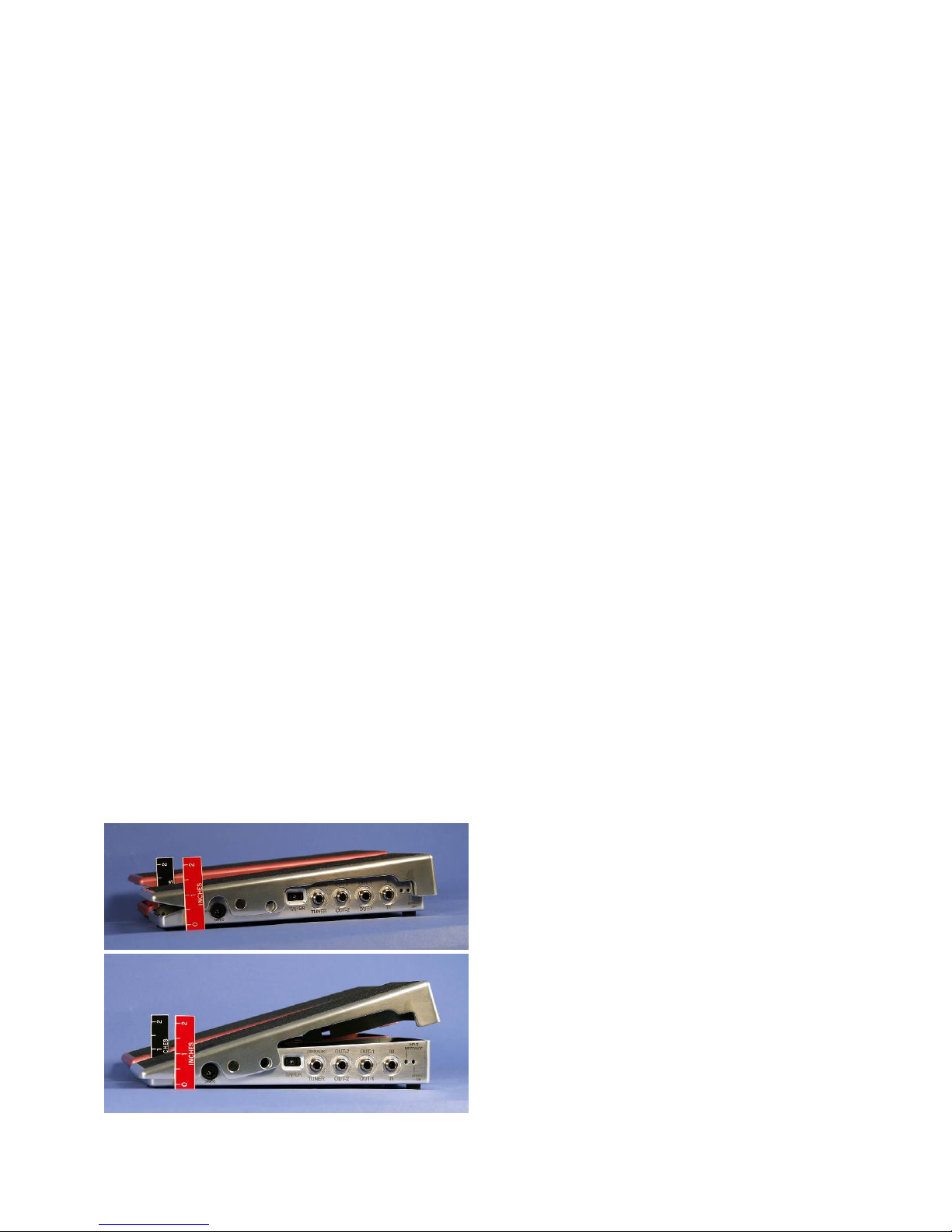

Axle Position – History and Considerations:

In order to discuss the differences between what have been traditionally called

“high” and “low” pedals, one must first define whether we are discussing old,

traditional pot pedals (and some of the very early “light” pedals), or, the newer

generation of electronic pedals.

Historically, the early pedals were, indeed made in a truly “high” and “low”

version, and in fact, the high version was indeed “taller” than low version –

which prompts the discussion regarding longer and shorter legs, brushing the

undercarriage of the steel with a knee, etc.

BUT, often overlooked is the fact that the axle in older “high” pedals was/is

positioned farther forward on the pedal than the “low” models.

Disregarding the actual pedal height factor, and more important to many players,

is that having the axle/pivot point at a different point directly influences the

RANGE of MOTION of the players ankle for the same angle range of the

movable top/treadle on the pedal. As a result, the two types of pedals have a

different feel. Think of it as a children’s teeter-totter. The older “high” pedals are

more like a normal teeter-totter with the pivot point close to the middle.

The older “low” pedals are more like a teeter-totter with the axle moved back

toward the back (or toward your heel on the pedal). Also note that as you move

the axle farther and farther back (toward the heel) with the pedal in the fully

“heel down” condition, two things happen:

1. The heel of your foot gets lower and lower respect to the front of your foot,

and,

2.

You get a leverage effect. Depending upon how far back the axle is placed.

You no longer have a one-to-one relationship, that is, if you move the back of

the pedal 1/8 of an inch, the front of the pedal moves more than 1/8th of an

inch…….

Fast forward to the new generation of electronic pedals.

Because they do not have large pots in them,

there is no need to build a pedal any higher than

the older “low” pedals in order to change the

pivot point of the pedal by moving the axle

forward or backward. As a result, there is very

little difference (only a few millimeters) in what

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 4 of 22

are still sometimes called “low” or “high”

models. This varies by manufacturer between

their two models. In the case of Telonics pedals,

there is no longer a need to produce and stock

two models as one pedal covers both conditions;

the axle can be moved to either position to suit

the player without changing the over-all height to

any appreciable degree.

Page 5

So with Telonics pedals, the aspect of pedal height is no longer applicable with

respect to players having longer or shorter legs. The only significant difference

between the two axle positions in new pedals is therefore the axle placement.

This axle placement becomes important to the player with regard to his or her

comfort with respect to his or her preferred/comfortable range of ankle motion.

This has sometimes boiled down to whether the player is younger or older, and

whether they prefer to wear shoes (or boots) with low or high heels when they

play.

There is a generally accepted common range of motion for the ankle which the

majority of players find to be most comfortable. It is therefore necessary to

choose an axle position which will correspond to a comfortable range of motion

for the type of heel that you prefer to wear while playing, since the heel controls

the angle of your ankle when your shoe is in a given position. People generally

want their foot to be comfortable when the pedal is at full “heel-down”/when the

pedal is at minimum volume. AND, they want their foot to feel comfortable as

they continue the pedal’s range of motion on through to full “toedown”/maximum volume position.

In general we find that people who wear boots to play in (or women with heels)

prefer the axle to be in the

rearward position (closest to the

back of the pedal) – which is

commonly still called a “low”

pedal. A higher boot or shoe

heel raises the back of the

player’s foot, and placing the axle toward the back of the pedal drops the rear of

the treadle a corresponding amount so the foot is not “pointed” as far forward.

Unless this is done, the ankle may have to be rotated uncomfortably (for some

people) forward when the toe is fully down. As an observation, some players

have also remarked that the leverage of such a “low” pedal can feel a bit

“touchier” simply because of the leverage change when the axle is moved

toward the rear of the pedal.

Players who wear relatively flat soled shoes (or people who play barefoot),

typically prefer having the

axle/pivot point near the center

of the pedal. This type of pedal

is still often called a “high”

pedal through force of habit or

convention. We have also

found that standing 6-string

guitar players, bass players, fiddlers, etc, typically prefer pedals with the axle

placed near the center of the pedal (they also prefer to have and use the Telonics

friction lock/clutch so they can easily move their foot on and off the pedal

without accidentally changing the volume setting, or have the pedal change due

to the stage vibration from woofer vibration or stomping – C6th players also

often prefer this type of clutch so they can move their foot on and off the volume

pedal when using two feet on their guitar pedals).

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 5 of 22

Page 6

There are certainly more axle considerations, but I hope this information is of

some assistance to you. Once you get past "high" or "low" axle placement, you

are actually just scratching the surface of important considerations for a

professional volume/swell control pedal.

Both DRAG (ease of treadle movement) and TENSION (treadle

return tension) are independently adjustable to suit the

user. Please refer to the photos and drawings provided in

this document:

Drag: A 3/16 (0.187) inch “Allen”-type HEX head cap

screw located on the bottom of the pedal provides a

means of customizing the Drag experienced during

pedal movement. A 3/16 inch HEX wrench is supplied

from the factory for this adjustment. Note that this

adjustment is very sensitive. Turning this screw only a

slight amount will greatly change the ease of pedal

movement. A fraction of a turn Clockwise (CW) will increase drag

(make the treadle more difficult to move). Conversely, a small

amount of adjustment in the Counterclockwise (CCW) direction will

decrease the drag, making the treadle easier to move.

Tension: A Phillips-head screw on the front face of the base

adjusts treadle return Tension (lift). It

can only be properly adjusted if the

Drag adjustment is fully relieved (set to

minimum drag). It exhibits a very wide

adjustment range, requiring several

turns in either direction to make an

appreciable difference. It has been

factory adjusted with the drag

adjustment set to minimum. If you

should decide to adjust it, first be sure

the Drag screw is turned CCW to

minimum drag, make any desired

tension adjustment, then re-set the Drag

to complete the process.

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 6 of 22

Page 7

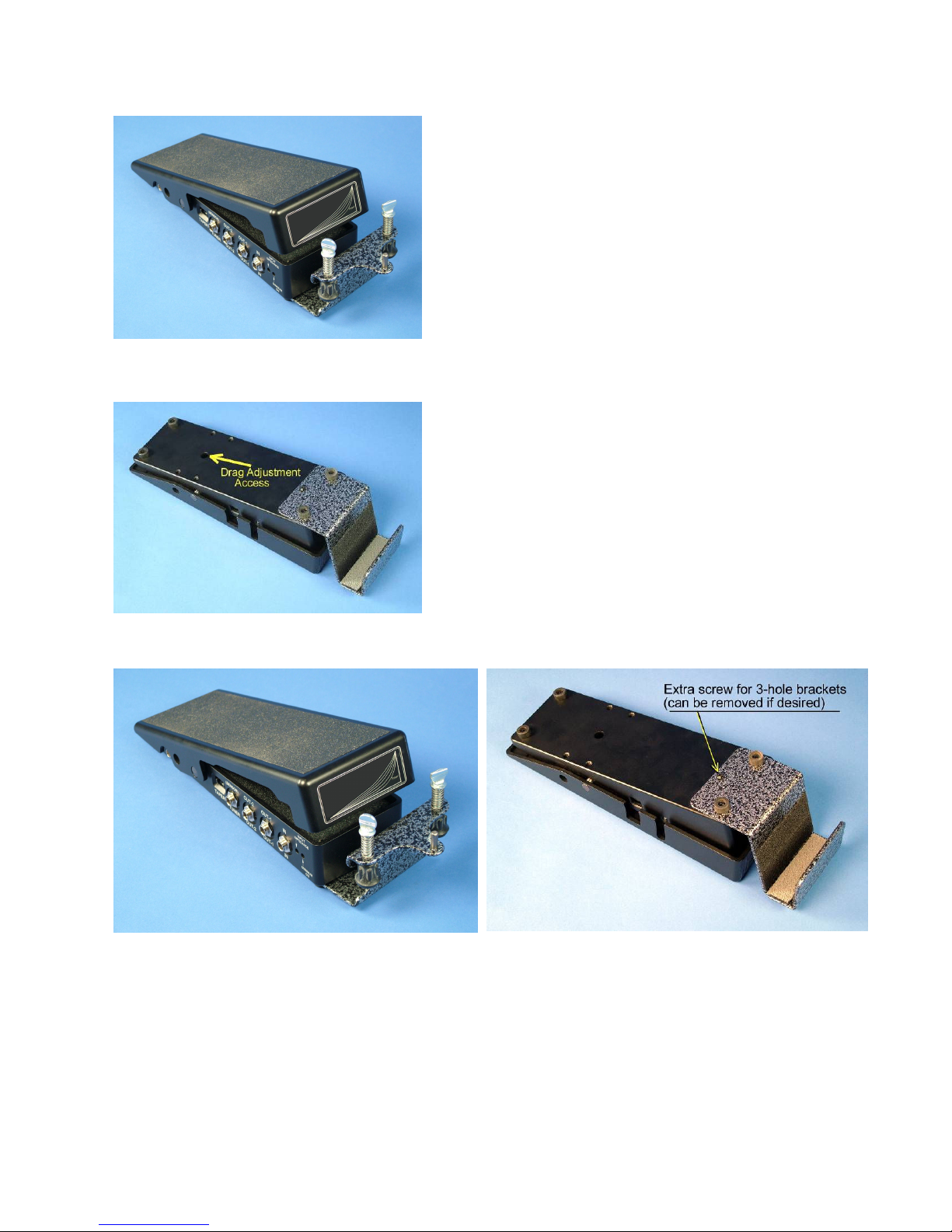

Bracket

Interface: The FP-100 is designed to interface with most popular pedal bar

brackets which utilize either two screws, or a

triangular three hole pattern. The screws which

attach the two front feet are slightly longer in

order to allow for the thickness of a bracket.

To mount a two-hole bracket, remove the two

front feet and mount it using the two screws

with the rubber feet still attached (under the

bracket).

To attach three-hole brackets, remove both front

feet AND the single screw just behind them

(slightly toward the center of the pedal). Attach

the bracket using all three screws.

Note: This center screw is provided solely for

bracket use, it serves no other purpose and can

be removed if desired.

Note: The brackets from some manufacturers

are not produced with consistent hole pattern

location and spacing. In some cases it may be

necessary to enlarge a hole or holes, or even

re-drill the odd hole in a bracket.

(Refer to the pictures showing various types of pedal bar mounting brackets, no modifications to

these brackets were necessary.)

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 7 of 22

Page 8

Electrical:

Power Supply: UL and CE approved transformerless switching power supply*

PS-1: 100-120 VAC, 60 Hz (US power)

2.5L x 1.1W x 1.7H in. (63L x 26.6W x 43.3H mm) (typical)

<3.5 oz (<100 g)

PS-2: 90-264 VAC, 47-63 Hz (Worldwide usage)

2.9L x 1.7W x 1.3H in. (74L x 43.5W x 34H mm)

<6 oz (<170 g)

* Note: Two (2) power supply options are available:

1. PS-1 - supplied with a locking plug which firmly

attaches to the pedal’s power jack (J5) and cannot be

pulled out accidentally.

(The PS-1 units plug in 90 degrees to an AC

“mains” power strip and occupy only one outlet slot.

They are very small, lightweight {<3.5 oz., <100g}

and do not emit the 50-60 Hz AC hum-producing

electrical fields normally associated with the older

transformer-type “wall-wart” power supplies.)

2. PS-2 International model, with interchangeable

prongs which snap into place for international use.

Supplied with conventional coaxial DC mini-plug

end which allows the user to plug and unplug the

pedal easily.

(Like the PS-1 units described above, the PS-2

International units do not exhibit the 50-60 Hz AC

hum-producing electrical fields normally associated

with the older transformer-type “wall-wart” power

supplies.)

Still relatively lightweight, the PS-2 power supplies

are slightly larger than the PS-1 power supplies.

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 8 of 22

Page 9

Jacks and Controls:

NOTE: All inputs and outputs are buffered and isolated such that shorted or

Intermittent Cables will not damage the pedal, interfere with other

cable functions or adversely effect signal levels.

Inputs:

*It will ALSO accept standard TRS plugs for BALANCED line inputs

In Stereo models, input jack J1 accepts a conventional ¼” TRS stereo

Monaural models are supplied with a *dual-function input jack (J1,

refer to Outline Drawing on page 18) and associated circuitry which

will accept a conventional ¼” TS plug for conventional unbalanced

pickups.

(for future very low-noise balance-wound pickups.

plug.

Monaural (MONO) Models:

IN-Unbalanced:

audio plug for all conventional unbalanced, high impedance pickups.

The input jack (J1) ALSO accepts BALANCED inputs as follows:

Stereo Models:

Tip = Left Channel

Ring = Right Channel

Shield = Common signal ground

IN-Balanced:

design, Input jack (J1) also accepts standard ¼” TRS-type plugs for

both high and low impedance balanced pickups. Its associated circuitry

automatically detects the type of input (balanced or unbalanced) and

requires no switching or other user intervention.

IN-Stereo, unbalanced:

type INPUT jack for two independent input signal sources using

unbalanced, high impedance pickups. Wiring connections are:

Input jack (J1) accepts standard ¼” TS-type

In anticipation of forthcoming advances in pickup

Input jack (J1) accepts standard ¼” TRS-

24VDC (power):

used with a factory supplied power supply. It will accept either the

standard smooth-barrel DC power plug, or the optional ¼-turn locking

type DC power plug. The non-locking plug makes it easy to remove the

power supply for transport, while the locking tabs prevent the plug

from being accidentally being pulled loose.

The FP-100 is specifically designed such that unpleasant loud pops

which might damage speaker systems are NOT generated when (or if)

J5 is the DC power input jack. It may ONLY be

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 9 of 22

Page 10

the power plug is suddenly pulled out while the amplifier systems are

on/live.

OUTPUTS

OUT-1:

in monaural models, J2 (refer to Outline Drawing on

page 18) is a conventional ¼ inch TS jack with its audio output level

buffered, and controlled by treadle movement. Audio taper selection is

controlled by the taper program preset switch as well as by a userselected “minimum OFF” setting which the user may adjust for each

individual taper.

OUT-2:

in monaural models, J3 (refer to Outline Drawing on page

18)) is also a conventional ¼ inch TS jack. This jack provides an output

which is identical to that of OUT-1, and is normally used to provide a

second identical, phase-coherent signal source for players who wish to

feed their signal to a second preamp, combo amp or special effects

system. (Note: This is Not the case when the expression option is

installed – see below.)

In stereo models, J2 and J3 provide individual buffered, analog signal

chain outputs for Left and Right Channels respectively.

The EXPRESSION option in Telonics mono pedals:

The EXPRESSION option is an added function and costs extra. It must be

installed at the time the pedal is initially built; it cannot be added later! It is

installed only in MONO (monaural) pedals, either the mono PRO or the

standard mono models.

The expression option essentially adds one additional capability to the

pedal: In addition to controlling the normal volume control function, this

added DC-control-voltage-output can be used to control any effects unit

which is designed to accept a control voltage supplied by an external

expression pedal. With the EXPRESSION option installed, as you push the

treadle forward, the volume at the output of the pedal is increased in the

normal manner; simultaneously the DC expression control voltage from

OUT-2 will cause the external effects unit to increase the intensity of its

effect.

Effects units that people currently use are ones like the Fractal-Axe, but the

Telonics pedal also works well with older equipment as well, such as the

Lexicon MPX-1. There are still lots of them around and they can be

programmed to use an effects pedal to control them. Most such EFX units

can also be programmed as to how fast you want the effect to increase

(similar to the way the volume is controlled in all Telonics pedals for

minimum and maximum levels). As an example, with the expression

option installed, a Telonics pedal could be used to control an instrument’s

volume, but could also be connected for EXPRESSION output to an

external effects unit which is set for tremolo effect. With the pedal in the

off position (no volume), the player would have no volume out and no

tremolo effect. But, as the pedal’s treadle is depressed, the volume will

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 10 of 22

Page 11

begin to rise, with a hint of the effect being heard. Then, as the treadle is

depressed more, the volume will increase and the tremolo effect will

become more pronounced. Toward the full toe-down position, the volume

will be nearing maximum and the tremolo will be very pronounced. The

pedal will work the same with any effect or any combination of effects you

might have programmed into an external effects unit which is designed to

be controlled by an external 0-5 VDC control voltage.

The expression voltage supplied by the FP-100 pedal is the industry

standard 0 to 5 Volts DC. Make sure your EFX devices will accept this

voltage range and work properly with it. The Fractal AXE, the Lexicon

MPX-1, and most of the higher-end EFX units are fine with it, but you will

need to check the manuals for the particular units you are using.

When the expression option is built into these pedals, the OUT-2 jack is no

longer available as an audio output jack, but rather becomes the Expression

voltage output jack! As such, it does not perform any other function. In

other words, if you wanted to use this pedal as a “splitter” (by connecting

your guitar or other signal source to the INPUT jack and using the OUT-1

and OUT-2 to feed two different amplifiers), you sacrifice that capability

when you have the Expression option. Thus, if you need a 2nd output jack

more than an Expression output, don’t order the Expression option. You

cannot return a pedal that has the Expression option in it, since the

Expression option cannot be removed once it is installed in the pedal.

In summary, adding the EXPRESSION option essentially makes your one

pedal do the work of two pedals simultaneously: one volume pedal and one

expression pedal. Some players (both steel guitar and 6-string guitar

players), appreciate this capability. There is no other pedal which will do

all these things.

EXPRESSION:

In units with the factory installed Expression option,

“OUT-2” is a fully-functioning expression control jack which requires a

TRS plug. OUT-2 does not provide an audio output when the

expression option is installed; it ONLY functions as an expression

output jack.

Wiring follows industry standard protocol:

Tip = Expression Voltage (Linear) Output (0 - 5 VDC)

Ring = DC Voltage input from external EFX units

(However External Voltage is Not Used by FP-100)

Sleeve = Common DC Ground

NOTE: The DC Expression Control Voltage is at zero volts when the

treadle is at Volume Minimum (normally heel-down) and at +5 VDC

when the treadle is at Volume Maximum (normally toe-down).

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 11 of 22

Page 12

TUNER/sensor:

jack, providing a full-time TUNER OUTPUT signal, regardless of pedal position

(¼” TS-type). This allows the user to continuously monitor tuning with the pedal in

any position, including the full/minimum off position. This output is buffered and

isolated. It will not allow the noise from digital tuners to get back into the system.

This jack (J4) is also used for the optional Telonics Miniature Remote Sensor

(TMRS). It accepts the ¼” TRS-type plug on the TMRS cable and automatically

communicates with the sensor when the user chooses to use the TMRS instead of the

foot pedal to control volume.

When the remote sensor is plugged into J4 it automatically assumes full control of the

pedal, replacing the control function of the moveable foot platform (treadle).

J4 (refer to Outline Drawing on page 18) is a dual-function ¼”

NOTE:

In order for the pedal to recognize the sensor, it must be plugged into the

(SENSOR)/Tuner jack on the pedal (next to the taper selection switch) - without POWER

APPLIED TO THE PEDAL.

The pedal must then be powered up AFTER the sensor cable has been plugged in.

(If you leave the sensor plugged into the pedal after use and the pedal has been powered

down, you may simply apply power to the pedal in the normal manner and the sensor will

function properly).

CONTROLS and INDICATORS:

INPUT IMPEDANCE:

adjustment is provided on the right side of the pedal (near the front, immediately

that can still be done with these pedals, however the practice “swamps” or reduces the

output of the pickup, reduces its resonant characteristics, diminishes its dynamic

characteristics and reduces its frequency response. (Some players are accustomed to

the resultant “muted” or “nasal” sound quality when their pick-ups are impedanceloaded, and they intentionally use this adjustment to subtly color their sound.)

Musicians tend to get together and compare hardware by substitution and often (if not

generally) come to false or unrepeatable and/or confusing conclusions. The

equipment being compared (various instruments with different pickups, different

amplifiers with varying input impedances, different pedals being using with

preamplifiers having impedance controls, etc), will produce differing/inconclusive

results with various models and types of pickups, as they will exhibit different

characteristics when loaded with the same impedance. This is why a given device

may yield wonderful results with one persons’ instrument, but has little effect, no

effect, or even an adverse effect when used with another instrument.

A miniature screwdriver 240 degree rotation

forward of the INput jack J1) which controls the

input impedance of the low-noise, high headroom

input amplifier. Please utilize the miniature

screwdriver adjustment tool provided and take

care to avoid excessive force. This control is set

to maximum (fully clockwise) as supplied from the

factory. In the past, players have unknowingly

(and in a few cases knowingly), employed

impedance controls as a “poor man’s tone control”,

lowering the input impedance to “load” the pickup

and reduce its high frequency response. If desired,

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 12 of 22

Page 13

Its not rocket science, it’s just that there may be a large number of complex

variables. In such cases, very simple tests can be very misleading.

If you are using a studio-quality preamplifier with proper tonal shelving

characteristics such as the Telonics preamps, it is suggested that the user

leave this control at the factory setting (maximum clock-wise, very high

impedance/little or no pickup loading) and allow the preamplifier to provide

control of tonal characteristics without inhibiting the performance of their

pickup.

If conventional amplifiers are used, we suggest that this control be used very

sparingly, and only after all other tonal possibilities on the amplifier are

exhausted. Nonetheless, this control is provided for those players who have

played that way for many years and feel that they cannot achieve their

individual sound any other way.

Note that this control is both small and delicate. Please utilize the

miniature screwdriver adjustment tool provided and take care to avoid

excessive force. The entire range of adjustment occurs over

approximately a 240 degree range. If it were a clock-face, maximum

pickup loading would occur at about 8:00 o’clock (fully CCW) and

minimum loading at 4:00 o’clock (maximum CW). We suggest that you

check and make sure that it is fully clockwise (CW) when not being used.

You can watch the pocket clip on the adjustment tool provided with the

pedal while turning to get an idea of where it is set.

MINIMUM ON:

An adjustment access hole is provided immediately

forward of the Input Impedance access hole on the right front corner of the

pedal. This adjustment controls the minimum level of audio signal which

is allowed to pass through the pedal when

the control platform is fully back, or in the

MINIMUM sound level position (of course

this will reverse if you are using the

Reverse Taper option). Units are factory

adjusted such that the output level appears

OFF to the ear of the average player when

the pedal is fully back (the most popular

adjustment setting for the majority of

musicians). The adjustment range of this

control is determined by software. (It is normally set correctly at the factory

for most users, however it can be easily adjusted by the user using the

miniature black screwdriver tool supplied with the pedal.) Please use the

small screwdriver tool supplied, this is a delicate control and can be

damaged by using large screwdrivers. It turns easily and only rotates a

total of about 240 degrees, DO NOT force it beyond its stops at each end of

its rotation. The adjustment procedure is outlined in the following

paragraphs.

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 13 of 22

Page 14

HOW TO CHANGE the Minimum ON setting for a given taper:

If you first understand a bit about how the system operates when you change the minimum

on adjustment, the operation will go much more smoothly.

When the pedal is first powered up, the “brain” inside the pedal “sees” the last setting that

someone made with this control. When you select a given taper with the selector switch, it

checks its memory for the last setting used with that taper, and implements it. Then it

begins to “look at”, or check the minimum on control to see if you are moving it (It checks

for any movement about 60 times each second). If the control is not moved, the brain is

“happy” and nothing happens.

Now you want to change the setting.

The brain has been given a rule, that it is to record your new setting

10 seconds after you stop moving the control.

The instant you move the adjustment, the brain starts a 10 second countdown – which is

reset to10 each time you move the control. When you finally stop moving the control for a

10 second period, the brain writes (what it now “thinks” is) your “final” setting to a

memory location associated with the taper you are using. It will then recall this setting

each time you select this same taper.

Now that you know the rules for how it works, you may not be so surprised when you

move the control for the first time and the volume suddenly changes initially.

Let’s think about why this might happen; initially the volume is set according to the

position of your pedal, as defined by the taper you have chosen, and modified further by

the last memorized setting of the minimum on control which its “brain” pulled from the

current taper’s memory location. Now you move the control a bit one way or the other. The

system immediately adjusts to the new setting!

If you moved the control up, the sound level jumps to the new increased level. Conversely,

if you happened to move it down, the sound level abruptly drops to the new level.

Of course after that point, you can select any desired level with great precision. Then if

you don’t change the control for 10 seconds, the new setting is written to memory and that

setting will now be the new minimum on setting until you decide to change it.

Note that this control is both small and delicate. Please utilize the adjustment tool

provided and take care to avoid excessive force. The entire range of adjustment

occurs over approximately a 240 degree range. If it were a clock-face, the adjustment

range would occur from about 8:00 o’clock (fully CCW) to about 4:00 o’clock

(maximum CW). You can listen to the audio volume while turning it with the pedal

FULLY BACK, (MINIMUM SOUND position) to determine where it is set.

The FP-100 will “remember” this setting and store it in FLASH memory along with the

particular taper you have it set to - 10 seconds after you stop moving the control. That

way, when you recall any taper using the TAPER switch (described below), your desired

minimum-off setting will be preserved for that taper.

The FP-100 will Also write the setting to memory Immediately if you change the Taper

Switch before the 10 second countdown is reached.

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 14 of 22

Page 15

TAPER:

provided in the form of the taper program preset switch which

2 Goodrich* LED light pedal (green LED model)

3 Goodrich* pot pedal (using Clarostat type EJA1N116P504A)

4 Emmons* factory pot pedal (using classic Allen-Bradley

5 Hilton* LED light pedal (“old type” with large permanently

6 Telonics Special Sustain Taper

7 is like 4, but has added gain at the end of treadle throw.

8 is like 5, but has added gain at the end of treadle throw.

9 Vacant – other taper may be added in this position.

0 is reserved as a programming position and will not respond to

pedal movement.

If a given switch position is unused (currently 9), the output will be

held to a fixed low volume and will not respond to pedal action.

* Note: Hilton, Emmons and Goodrich are fine companies who produce a good product and

stand behind their products in a commendable manner. Their names are included

solely for comparison of an electronic characteristic exhibited by one or more of

their pedal models; in this case, that characteristic is measured audio volume taper.

A means to select the desired audio volume taper is

selects the desired taper by means of

two small buttons on either side of

the display window. One button

advances the number, the other

reduces the number.

The factory-supplied volume tapers

are as follows:

1 Hilton* LED light pedal (“new

type” with small detachable

power supply)

pot, Type J, JAIN200P504AA)

attached Motorola power supply)

Blue Pedal board Light:

The blue light (LED) on the left side of the pedal serves to illuminate the

pedal board, but it also serves as a visible error status reporting interface

between the user and the microprocessors in the pedal. If your pedal

includes error reporting and status capability F2 firmware set version 2.0

or later, it will have a label on the bottom surface which lists the most

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 15 of 22

Page 16

important functions. This label, along with an explanation of these

functions is shown below:

NOTE: The user may choose to have the blue LED either ON or OFF

(other than when it reports a problem by blinking).

The desired condition may be set using the following procedure:

1.

With the power plug removed, set the pedal on a flat surface and

advance or retard the TAPER switch to position “0” (zero).

2.

If you wish the LED to be normally ON, tilt the top of the pedal

fully forward (maximum ON) and insert the power plug. The blue

LED will come ON, and it will normally stay ON from that point

forward.

If you wish the LED to be normally OFF, unplug the power cord,

tilt the top of the pedal fully back (minimum ON) and insert the

power plug. The blue LED will not come on, and it will normally

stay OFF from that point forward (unless an error is encountered).

You may then advance or retard the TAPER switch to the taper you prefer

and use the pedal normally.

Normally, the blue LED indicator is either always

ON, or always OFF as described in the previous

paragraph. However, in later model pedals, it also

serves to notify the user of various conditions.

Error or Fault Reporting: If the internal self-test

routines encounter an internal circuitry fault,

reporting bad power supply condition or other out of

range conditions, the LED will blink rapidly as listed

on the chart attached to the bottom surface of the

pedal. The various conditions are indicated by the number of times the

blue LED flashes.

Groups of two (2) pulses indicate that the taper program preset switch

on the side of the pedal has been left in an invalid state. These states

include Taper 0 (which is used for programming functions and for turning

the LED fully ON or fully OFF), or any switch position which does not

currently have a valid taper program installed. For example, at the time of

this writing, pedals are being shipped from the factory with taper programs

installed in switch positions 1 through 8. If the switch is inadvertently left

in position 9, the LED will begin to flash two times, pause, then flash two

times again, and so on, until the invalid condition is rectified.

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 16 of 22

Page 17

Groups of three (3) pulses indicate that the angular reporting system in the

pedal “thinks” the pedal is physically upside down. If the pedal is actually

NOT upside down, this could indicate that the angular sensing system is

seeing a fault.

Groups of four (4) pulses indicate that a low power supply output voltage

has been detected. In such case the pedal may not operate properly. This

could indicate that the AC (mains) supply is abnormally low or some other

electrical problem is reducing the internal voltage seen by the electronics

system in the pedal.

Groups of five (5) pulses indicate that the pedal’s physical position is outof-range as determined by the internal angle sensing system. The pedal

can be used at least 30 degrees off-axis. This is common with some

mounting systems such as seen in older Emmons Push-Pull steel guitars.

However if the allowable range is exceeded, this error will be indicated.

If this error code were to be indicated while the pedal is perfectly flat on

the floor, this would mean a possible problem exists in the angular sensing

system.

Groups of six (6) pulses indicate the internal sensing system is providing

out-of-range readings. This would likely indicate a problem in the sensing

system which would require factory service.

Groups of seven (7) pulses indicate that the system is receiving invalid

reading from the taper selection switch. The switch could be possibly be

damaged due to water or wear. It should be moved to other valid taper

positions in order to determine if the problem may be corrected. The

factory should then be consulted.

If your pedal does not have error detection and indication code firmware factory installed, it will

still have basic error detection capability, it will simply be internalized with the exception of

pedal attitude indication as follows:

Pedal attitude invalid : The pedal is designed to be used on a fairly level floor surface (unless

inclined upward and/or cocked slightly sideways when attached to pedal boards or when using an

Emmons pedal-board mount). Its attitude control system allows for such usage, but if the pedal

is placed in an attitude which exceeds those normal limits, two things happen; first the volume is

reduced to a fixed, low volume and secondly, the blue LED will blink rapidly. The unit will

revert to normal operation as soon as it is returned to a valid orientation and attitude.

Error code firmware: If your pedal does not currently have the error code reporting firmware,

you can utilize the Telonics FP-100 Tool Box Software to determine if it can be installed.

Connect the FP-100 to your computer using the Mini-USB Programmable Cable. When you

access the tool box, it will automatically check the hardware revision in your pedal. If it utilizes

the F2 firmware set, it is capable of operating the error/fault reporting code. The toolbox will

automatically check to see if error reporting code is currently installed; if not, it will ask if you

wish to have the F2 firmware added. Select YES and it will be automatically downloaded onto

your computer hard drive. Next, follow the prompts to update the firmware in the FP-100. The

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 17 of 22

Page 18

toolbox will now show that a newer version is available; select NEXT to continue. To program

the new firmware into the FP-100, select the newly available firmware file and select

PROGRAM. Once the update is complete, select FINISH to return to the main FP-100 Toolbox

window.

Signal Path

: Some of the most important aspects of your sound are directly influenced

by the signal path from the pickup in your instrument to the initial

preamplifier in your system.

Be very careful what you insert in your signal path. Unless you have a high

grade preamplifier (such as the Telonics preamp series), a high-quality cable

(low capacitance), as short as possible, should be connected from the output of

your instrument to the input jack (J1) of this pedal. The output of the pedal (J2

or/and J3) should likewise be connected to your amplifier using a short length

of high quality, low capacitance cable. You then have a clean, low-noise,

purely analog signal path with great signal handling characteristics.

If you insert an effects pedal or other device between the pickup of your

instrument and the pedal, you have just prevented yourself from taking

advantage of many of the important capabilities of this pedal.

Such devices will not offer the necessary head-room (instantaneous high

signal level handling characteristics), nor will they offer low-noise

preamplifiers and provide the desired wide-band, airy frequency response.

Additionally, and even worse, many such devices are digital in design.

(While very good digital front ends ‘are’ available, they cost thousands of

dollars and are only found in the highest grade studio recording equipment.)

This means that the lower cost effects units must take the signal from your

pickup and run it through a lower performance A/D, or analog-to-digital

converter. They then process and/or “model” the digital signal to achieve

some desired characteristic (delay, reverb, rotary, chorus, etc). After effect(s)

processing they must convert the processed (and degraded) digital signal

back to analog form in order to feed it to your amplifier using a D/A, or

Digital-to-Analog converter. The A/D and D/A converters do not have the

premium signal handling capabilities of the high-end preamplifier designed

into this pedal. Although set for unity throughput gain, this pedal sets the

stage for everything in your signal chain.

So where “should” you put effect units in your amplifier set-up?

The place for effect hardware devices is in the effects (EFX) loop(s) of your

amplifier, NOT in the direct signal path, and most certainly NOT between

your pickup and the pedal - not even between the pedal and your amplifier.

Additionally, good, high quality effects units are designed to work in

PARALLEL with the analog signal path, this parallel configuration is also

called “FULL WET”. Some of the better effects units (even effects pedals),

are now being designed with a “SERIES/PARALLEL” switch inside the unit

in order to service the old in-line guitar stomp-box/pedal board applications,

while allowing them to work properly in high-end applications such as

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 18 of 22

Page 19

recording-grade preamplifiers and studio boards. The reverb unit called “Mr.

Springgy” (which emulates the old spring reverb units) is a typical example.

The better effects rack units (such as the Lexicon MX-200), are designed

with two (2) sets (or “banks”) of effects, both a serial bank and a parallel

bank. Setting such EFX units to parallel mode and using them in conjunction

with a high quality preamplifier offering parallel EFX loops provides the

highest level of audio performance.

Signal Path Discussion Summary:

In summary, if you have a conventional amplifier, connect your pedal

directly between your instrument and the input of your amplifier. Do not

insert effects units, impedance matching boxes or any type of preamplifier

device between the instrument and the pedal.

If you have a high (studio) quality preamplifier which provides input

circuitry equal to that of this pedal, connect your instrument directly to the

input of the preamplifier, then insert the pedal (using two cables, one IN and

one OUT) in the INSERT/Pre-EQ EFX loop of your preamplifier (this point

inserts the pedal in the signal chain immediately after the first stage of

amplification and prior to the EQ/tone shaping circuitry. The Telonics

preamplifier series provides a pair of IN and OUT jacks specifically for this

purpose as well as providing a separate EFX loop (mono or stereo) for

parallel-mode effects units).

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 19 of 22

Page 20

Outline Drawings

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 20 of 22

Page 21

Quick Connection Diagram

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 21 of 22

Page 22

Model # Selection

FP-100 Foot Pedal PB-008427 Rev G

October 14, 2015 Page 22 of 22

Loading...

Loading...