Telme GEL 20 Operating Instruction

Z15.013

0198 V02 ING GEL

OPERATING INSTRUCTIONS

GEL 20

Ice cream freezer

English

Ice cream freezer

2

3

Dear customer,

we congratulate you for choosing a high quality product

which will surely satisfy your expectations.

With our thanks for choosing us,

we kindly invite you to examine the present operating

instructions manual before operating your new device.

SUMMARY

WARNING:

GENERAL/MECHANICAL DANGEROUS

DANGER VOLTAGE

A TEXT IN UPPER-CASE, IDENTIFIED BY ONE OF THE SYMBOLS ABOVE, CONTAINS INSTRUCTIONS THAT, IF NOT FOLLOWED, MAY CAUSE HARM TO PEOPLE.

A text in lower-case, identified by this symbol, contains instructions that, if not followed, could cause

damages or malfunctions to the device, or falls in its quality.

1 IMPORTANT SAFETY SUGGESTIONS AND

PRECAUTIONS ...................................................... 4

2 SAFETY DEVICES ................................................. 5

2.1 Lid's magnetic sensor ..................................... 5

2.2 Extraction door's grill ....................................... 5

3 TECHNICAL DATA ................................................. 6

3.1 Technical data plate and EC marking .............. 6

3.2 Acoustic pressure level ................................... 6

4 CARRYING AND UNPACKING .............................. 6

4.1 Transportation of the packed machine

(floor models) .................................................. 7

4.2 Unpacking ...................................................... 7

5 INSTALLATION ...................................................... 8

5.1 Placing and check of the parts ....................... 8

5.2 Machine’s parts reassembling ......................... 8

5.3 Electrical connection ...................................... 9

5.4 Initial functional test ...................................... 10

6 MACHINE’S OPERATION ..................................... 11

6.1 Warnings ....................................................... 11

6.2 Controls and indicators .................................. 11

6.3 Production .................................................... 12

7 WASHING AND SANITIZING ............................... 14

7.1 Rinse only ..................................................... 14

7.2 Disassembling of the parts ............................ 15

7.3 Washing ....................................................... 15

7.4 Reassembly .................................................. 16

7.5 Adjusting blades ............................................ 17

7.6 Sanitization ................................................... 17

8 MAINTENANCE .................................................... 17

8.1 Maintenance during the components

disassembling ............................................... 18

8.2 Check of safety devices ............................... 18

8.3 Yearly maintenance ...................................... 18

9 PERIODS OF INACTIVITY ................................... 19

10 MALFUNCTIONS ................................................. 19

English

Ice cream freezer

4

1IMPORTANT SAFETY SUGGESTIONS AND PRECAUTIONS

CAREFULLY READ THE INSTRUCTIONS CONTAINED IN THE PRESENT OPERATING

INSTRUCTIONS

MANUAL BEFORE INSTALLING AND OPERATING THIS MACHINE. THESE

INSTRUCTIONS

HAVE BEEN DRAFTED FOR THE SAFETY OF INSTALLATION, OPERATION AND

MAINTENANCE OF THIS MACHINE.

»–› The present manual of Operating Instructions, placed on the machine in the packing and supplied with the Technical

Handbook, the EC’s conformity certification and the electrical tests schedule, is an essential part of the ice-cream

freezer (also referred to as, in the present manual of operating instructions, simply with the term, machine) and must

be preserved for any future consultation.

»–› The Technical Handbook must always be given, together with the machine, to the Assistance Service’s personnel or to

the technicians to whom you will eventually request assistance.

»–› In case of selling or transferring to other user, all the above mentioned documentation must be handed to the new user,

so that he can be informed of the operation and relative technical information and safety instructions.

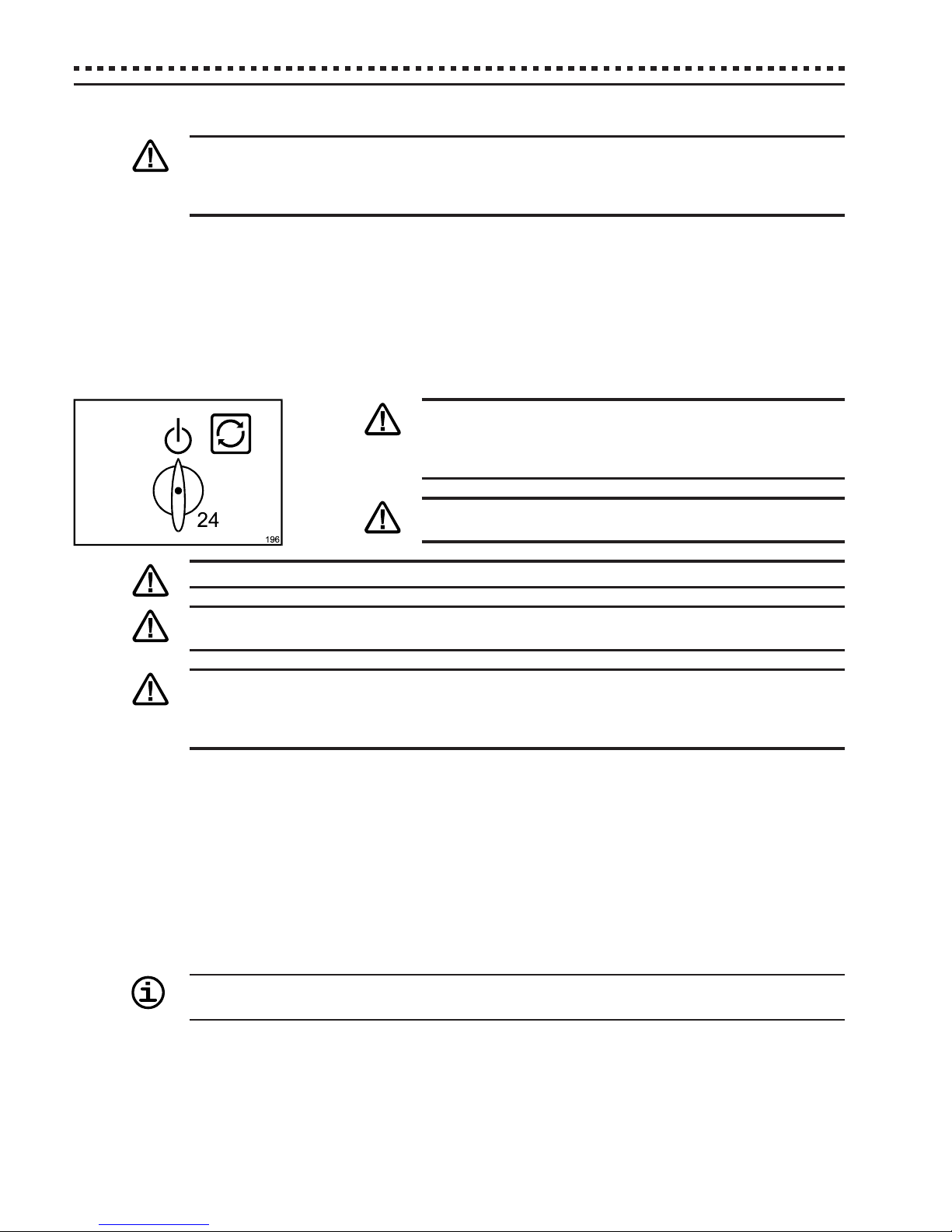

ALWAYS STOP THE MACHINE BY TURNING THE BEATER'S

SWITCH [24] (

AS SHOWN) BEFORE INTRODUCING YOUR

HANDS

OR ANY OBJECT INSIDE THE REFRIGERATING CYLIN-

DER.

DO NOT INSERT YOUR FINGERS OR ANY OBJECT THROUGH

THE GRILLS, LOOPHOLES OR DRAIN HOLES.

DO NOT REMOVE OR HIDE, FOR ANY REASON, ANY LABEL APPLIED ON THE MACHINE.

NEVER OPEN THE PROTECTING PANELS. THE MACHINE DOES NOT CONTAIN, IN ITS INSIDE,

PARTS WHICH CAN BE OPERATED BY THE USER.

THE USER MUST NOT EXECUTE OPERATIONS WHICH ARE NOT CLEARLY CONTAINED IN THE

PRESENT

USER’S MANUAL. ANY OPERATION WHICH REQUIRES TOOLS NOT GIVEN IN THE

MACHINE

’S EQUIPMENT IS TO BE CARRIED OUT ONLY BY THE ASSISTANCE SERVICE OR BY

TECHNICALLY AUTHORISED PERSONNEL.

»–› Always turn power supply off before undertaking any operation requiring access to the machine’s moving parts

(beater, cylinder or extracting door).

»–› Any modifying of the electrical supply must be exclusively performed by professionally qualified and certified person-

nel.

»–› Any use of the machine that is not for the production of ice-cream, sorbet, ice-cream cake or crushed-ice, is to be

considered improper.

»–› The machine has been made to be operated by adults, prohibit children to play with it.

»–› Modifying, or attempting to modify this machine, can be dangerous and would void any type of warranty.

»–› Always use original spare parts.

It is important to adopt the following precautions to avoid damages at the cylinder, at the beater

or any other mechanical part:

• Do not drop them and do not expose them to bumps;

• do not operate the machine dry, with a bad quality mixture or in a quantity lower or higher to that recommended: while

inside the cylinder, the ice-cream lubricates the cylinder’s sides as well as cooling down the beater, thus stabilizing its

temperature;

English

Operating instructions

5

• The beater and the cylinder are have been assembled with precision: therefore they are sensitive to changes of

temperature, which could cause breakdowns or damages to the machine's mechanical parts due to thermal dilatation.

NEVER expose to abrupt temperature changes the parts subject to refrigeration: DO NOT pour water in the cylinder

immediately after ice-cream has been produced.

• For the above reason, in the event that you have turned on the refrigerator without inserting the beater in the cylinder

first, wait for the cylinder to reach room temperature, then proceed to install the beater.

»–› In the event of the use of the machine being no longer required, deactivate the machine by severing the electric cable

(after unplugging it from wall socket). In addition, follow these recommendations:

- avoid dispersing the freezing gas and the oil contained in the machine;

- carry out the draining and/or recycling according to the local provisions of the law currently in force on this matter.

2SAFETY DEVICES

DO NOT ALTER THE SAFETY DEVICES AND DO NOT UTILIZE THE MACHINE IF THE SAFETY

DEVICES ARE DAMAGED OR MALFUNCTIONING.

THE MANUFACTURER IS NOT RESPONSIBLE FOR POSSIBLE DAMAGES CAUSED TO PEOPLE

OR OBJECTS BY THE ALTERING OR BYPASSING SUCH DEVICES OR RELATIVE CIRCUITS.

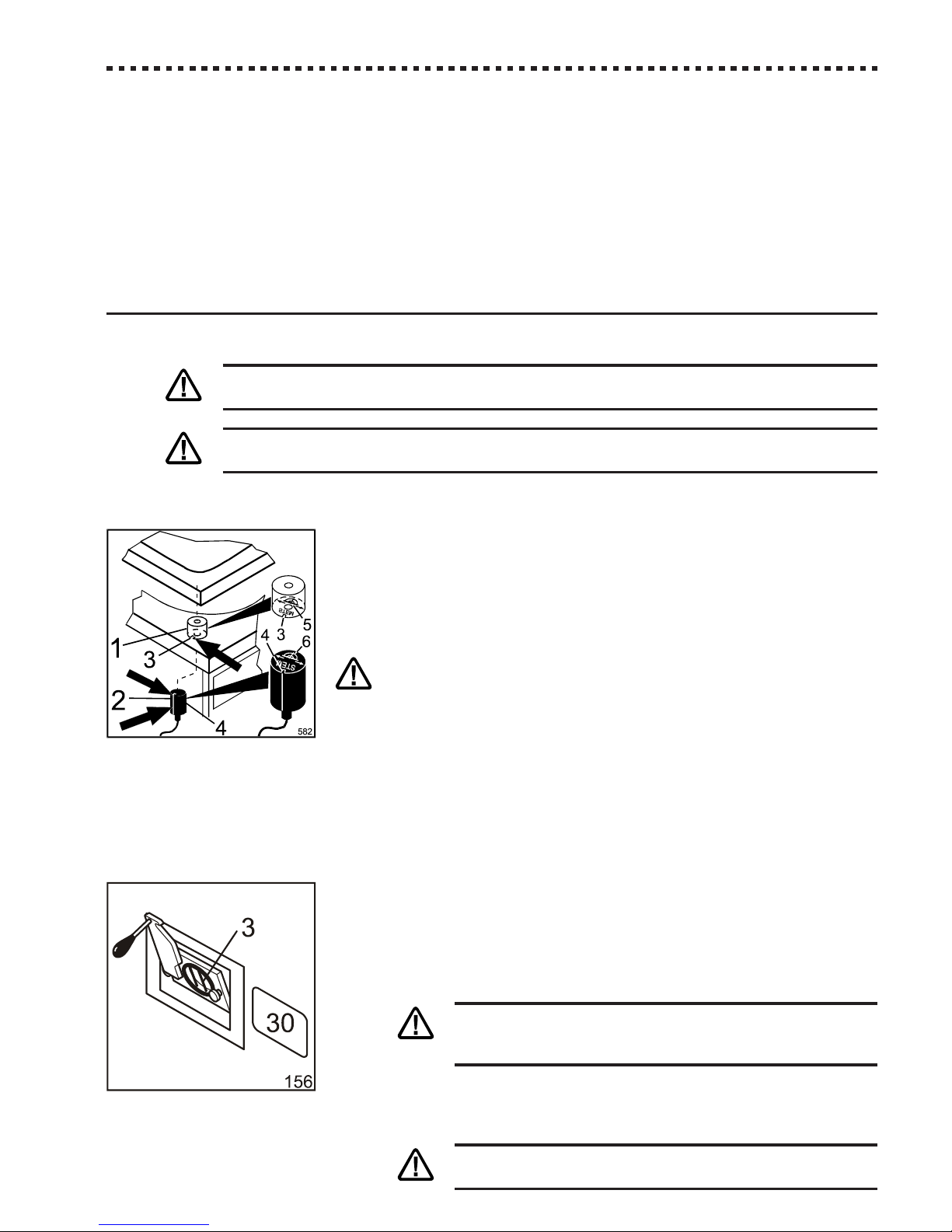

2.1 Lid's magnetic sensor

This safety device, featuring an approved type magnet [1] and a magnetic contact [2]

avoids accidents caused by the accidental starting of the beater when the lid is open.

In consequence the device can't operate when the lid is open, and if it is opened

during its functioning the beater immediately stops.

In any case the lid's magnetic sensor MUST NOT be considered a control to be used

for the normal stop of the device.

DURING THE NORMAL USE, THE DEVICE MUST BE STOPPED ONLY

BY USING THE BUTTONS ON THE CONTROL KEYPAD, AND NOT BY

OPENING THE LID.

The magnet [1] and the magnetic contact [2] must be assembled as follows: the grooves [3] and the stencilled semicircle [5]

on the bottom of the magnet [1] must coincide with the grooves [4] (marked by a white line down the side) and the stencilled

semicircle [6] on top of the magnetic contact [2]. The device will not work unless all parts have been correctly

assembled in accordance with these instructions.

2.2 Extraction door's grill

In large-sized models, supplied with extraction door, a fixed protection grill [3] prevents,

as far as possible, fingers or objects from being ACCIDENTALLY inserted in the chute.

In order to insure normal operation it is not possible to adjust the fixed grill as to prevent

fingers and objects from being VOLUNTARILY inserted through the extraction chute

(according to Machines Directive 89/392/CEE and ensuing modifications, Appendix

I, Art. 1.1.2.b, 3rd paragraph).

RESIDUAL HAZARD: DO NOT FOR ANY REASON INSERT

FINGERS

OR OBJECTS THROUGH THE GRILL OF THE

EXTRACTION DOOR WHEN THE MACHINE IS IN FUNCTION.

The user is warned of the above RESIDUAL HAZARD (89/392/CEE and ensuing

modifications, Appendix. 1, Art. 1.1.2.b, 3rd paragraph and 1.7.2) by a plate [30]

affixed next to the extraction chute.

DO NOT HANDLE OR REMOVE THE GRILL [3] FROM ITS SET-

TING IN THE EXTRACTION DOOR!

English

Ice cream freezer

6

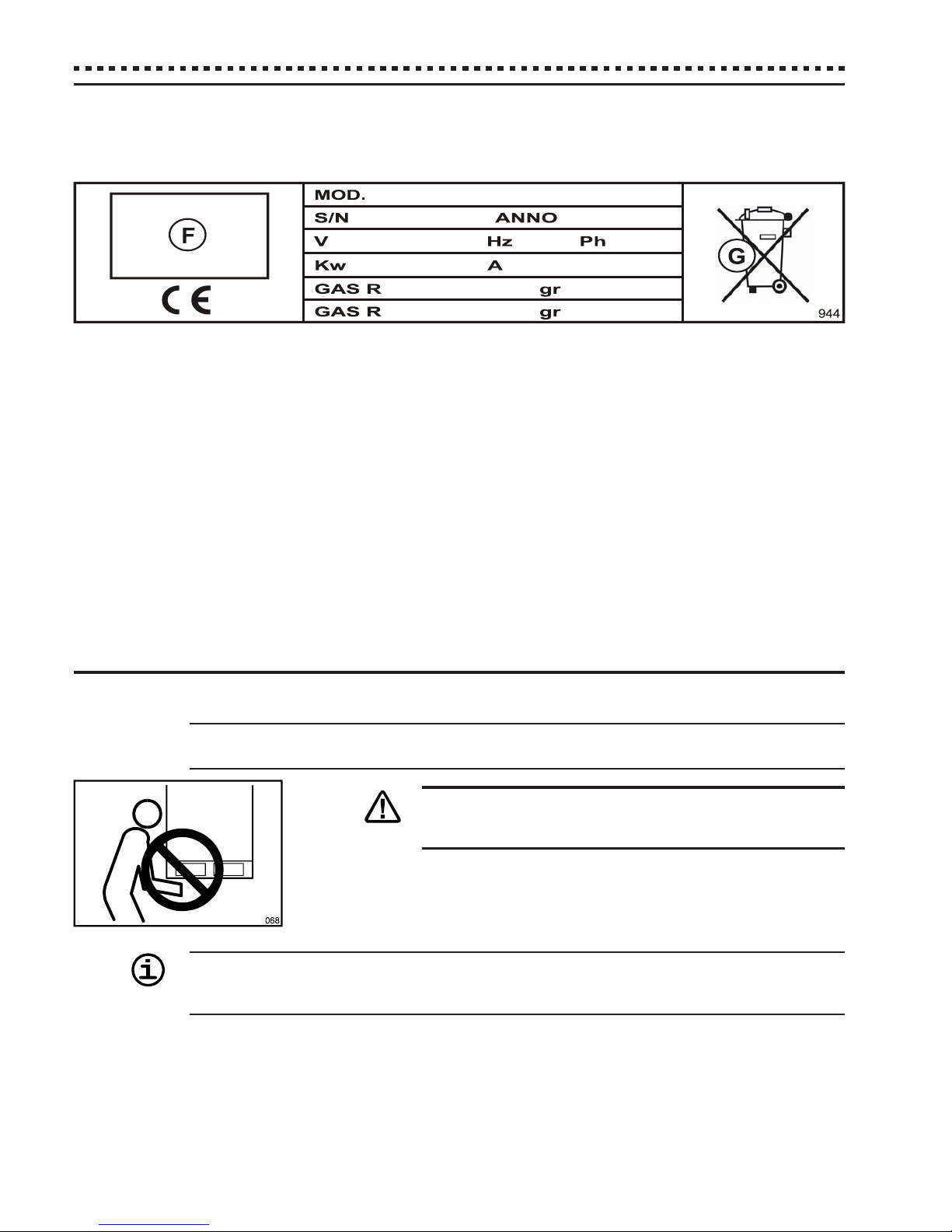

3TECHNICAL DATA

3.1 Technical data plate and EC marking

The technical data plate and CE marking must not be removed. It is located on the back part of the device and identifies:

- the name and address of the manufacturer [F];

- the designation of the model [MOD] and the relative series number [S/N];

- the type and quantity of freezing gas contained [GAS];

- the year of construction [ANNO];

- the values of voltage and frequency [V], and the power [Hz] and current [Ph] consumption;

- the CE marking [9];

- dismantle symbol [G];

3.2 Acoustic pressure level

The average equivalent continuous acoustic pressure level of this machine is quoted in the Technical Handbook (Technical

Data section). This data has been measured at 1 meter from the surface of the machine and at 1.60 meters from groundlevel, during the machine’s functioning.

4CARRYING AND UNPACKING

Note: We suggest you to let the Assistance Service or qualified technicians carry out the transportation,

unpacking and installation.

TO LIFT THE MACHINE ALWAYS USE AN ADEQUATE LIFTING

DEVICE

. ATTEMPTING TO LIFT IT MANUALLY IS DANGEROUS

AND CAN DAMAGE YOUR HEALTH.

The machine’s weight specifications, both inclusive of packaging and net, can be

found in both the supplied documents and on the packaging itself.

To prevent the oil contained in the compressor to flow into the refrigerating circuit, it is necessary to always keep the machine in upright position, both during carrying and during the installation and operation. Always follow the instructions on the packing.

English

Operating instructions

7

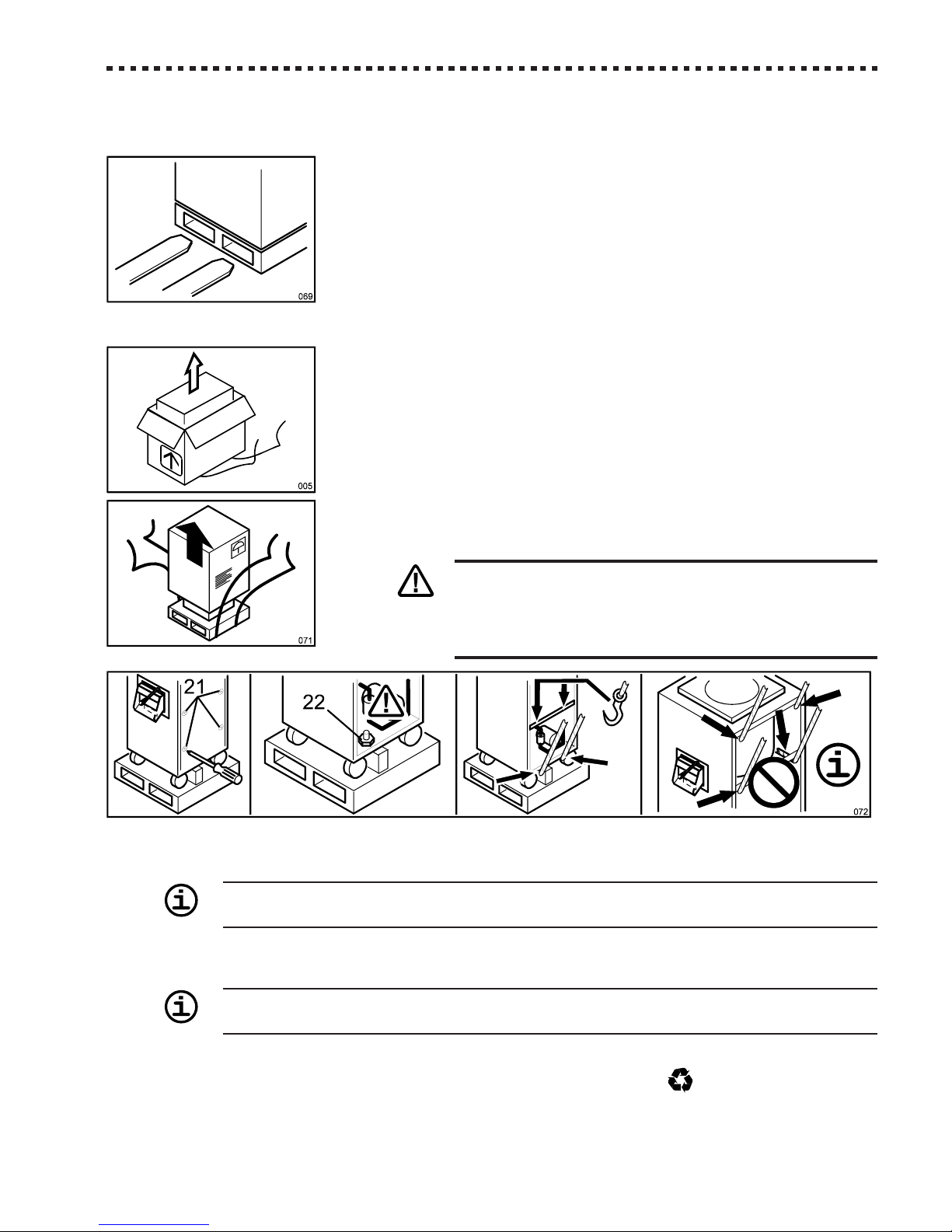

4.1 Transportation of the packed machine

(floor models)

The packing has been projected to assure at the machine the highest protection.

It is therefore suggested to transport the machine while it is packed as near as possible

at the place where it will be installed.

To carry the packed machine, use an elevator, or a bench trolley, inserting its forks in

the basement’s holes.

4.2 Unpacking

Unpack the machine and carefully check it. In case of doubt, do not use it, and call the

Seller.

Bench top models:

- cut holding straps, open box from the top, remove protection packaging material

and remove machine from the box.

Floor models:

- cut the straps and remove the cardboard box from the top;

THE OPENING OF THE LATERAL PANEL IS ONLY ALLOWED

TO

THE ASSISTANCE SERVICE OR TO QUALIFIED

TECHNICIANS

AND MUST BE MADE BEFORE CONNECTING

IT

. MAKE SURE NOT TO DAMAGE THE INTERNAL PARTS OF

THE MACHINE.

- Remove both the lateral panels unscrewing the relevant fixing screws [21];

- Find and unscrew the bolts [22] which fix the machine’s frame at the packing’s basement;

The outlet of the supply cable is placed on the machine’s lower side. During the lifting make sure

not to damage it.

- Lift the machine from the basement, possibly working on the lower side, near the wheels, and however, only on the

frame’s carrying parts. Remove the basement, and lean the machine on the floor avoiding bumps;

DO NOT insert objects, ropes or brackets for the lifting THROUGH the machine, since these

could damage the inside parts.

- Re-close the lateral panels;

- Replace or move the packing, which is produced with entirely recyclable materials ( ).

English

Ice cream freezer

8

5INSTALLATION

THE INSTALLATION MUST BE CARRIED OUT ONLY BY THE ASSISTANCE SERVICE OR BY TECH-

NICALLY AUTHORISED PERSONNEL AND IN COMPLIANCE WITH THE LAWS IN FORCE, ALWAYS

FOLLOWING INSTRUCTIONS OF THE MANUFACTURER.

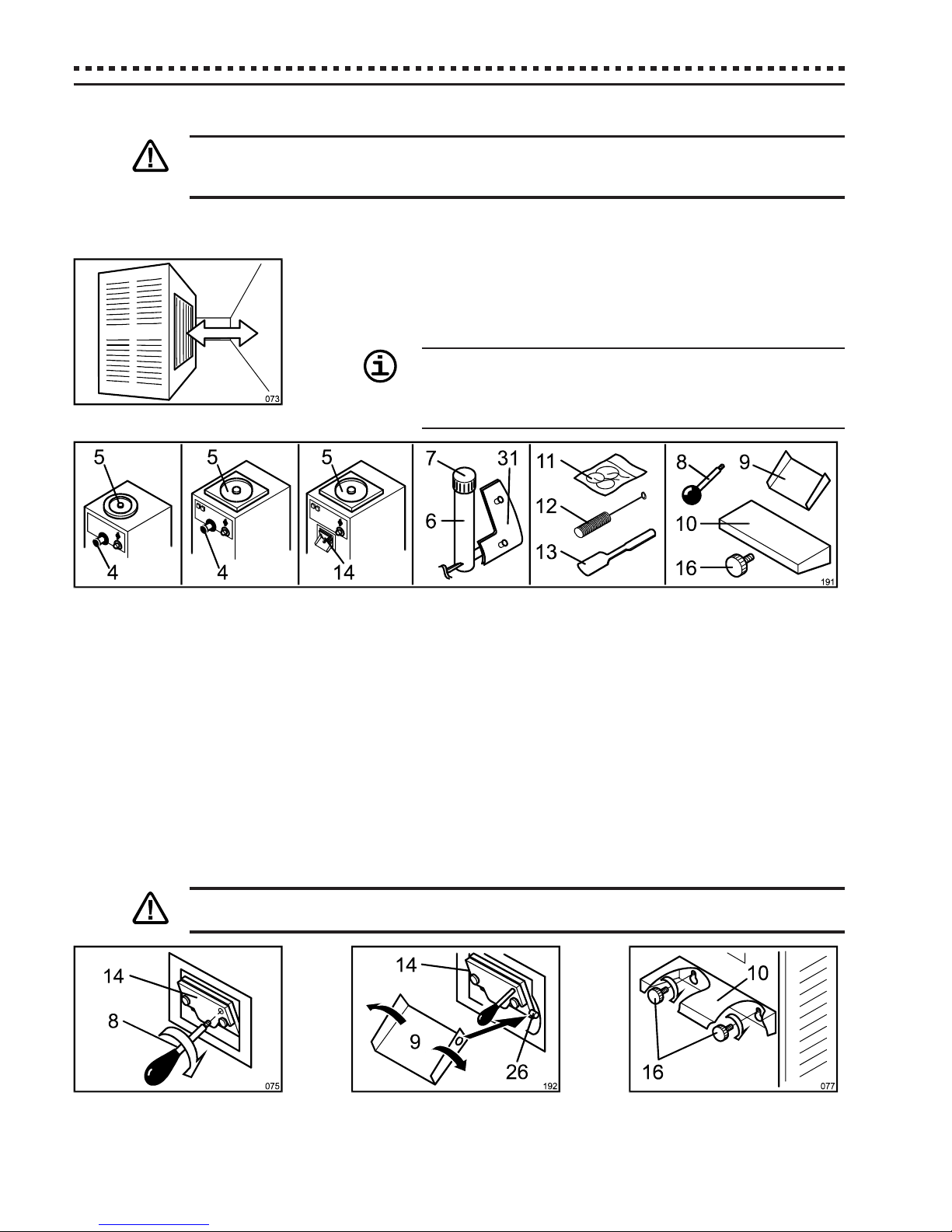

5.1 Placing and check of the parts

Place the machine on a flat and steady surface.

Install the machine away from any source of heat, avoiding a direct exposition to sun

radiation and making sure that air can freely circulate around each side of the machine itself.

The machines with AIR CONDENSING need at least a 50 cm

free space in front of the condenser’s grill, to assure the refrigerating plant correct functioning. Further information are

reported on the Technical Book (Technical Data section).

Check that the following items are all included in the package:

- lid [5];

- beater [6], correctly fixed inside the cylinder with its knob [7] and supplied with adjustable blades [31] (1…3 according

to the model);

- drain plug [4] (not in large-sized models which are supplied with extraction door [14]);

Also check that the following items are included:

- spare part kit [11], tube-brush [12] and ice-cream blade [13];

- only in large-sized models, basin support [10], knobs [16], the lever [8] and the extraction door chute [9];

- all the technical documentation (in addition to this handbook): the Technical Handbook, the EC’s Conformity Certification and Electrical Test’s Schedule.

5.2 Machine’s parts reassembling

THE REASSEMBLING MUST BE MADE BEFORE CONNECTING THE MACHINE TO THE

ELECTRICAL SUPPLY SYSTEM.

- Screw the lever [8] in the extraction door [14];

- if the chute [9] is supplied disassembled, install it under the extraction door [14] by hooking it to the hinges [26];

- install the basin support [10] by fixing it to the front panel with knobs [16].

Loading...

Loading...