LE920

Hardware User Guide

1vv0301026 Rev.9 - 2016-03-29

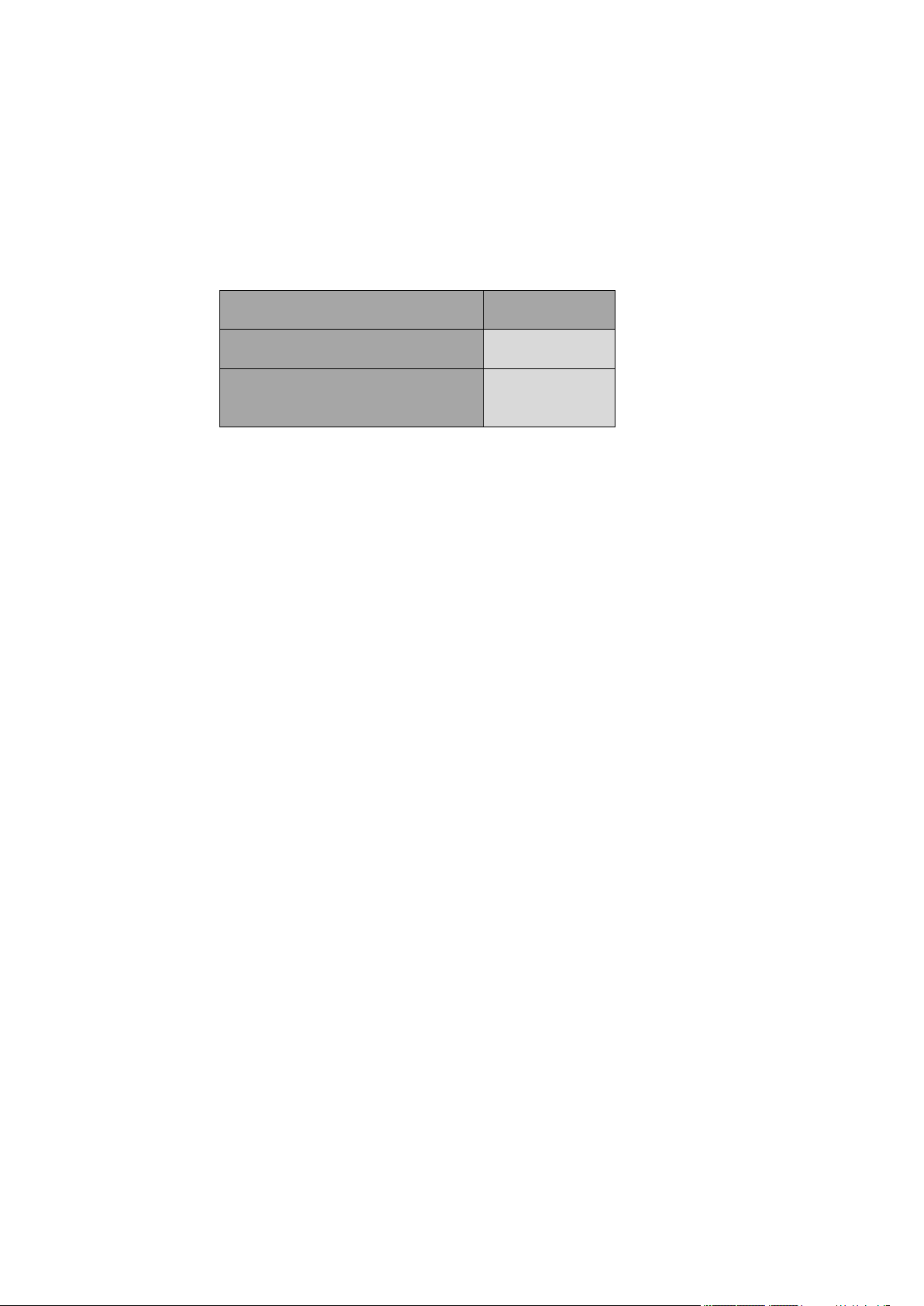

PRODUCT

LE920-EUG (cs1550f-B)

LE920-NAG (cs1550f-A)

LE920-EU (cs1647c)

LE920-NA (cs1701)

LE920-CN (cs1648D)

LE920-NA AUTO S (cs1717)

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

APPLICABILITY TABLE

APPLICABILITY TABLE 1

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 2 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Notice

While reasonable efforts have been made to assure the accuracy of this document, Telit assumes

no liability resulting from any inaccuracies or omissions in this document, or from use of the

information obtained herein. The information in this document has been carefully checked and

is believed to be entirely reliable. However, no responsibility is assumed for inaccuracies or

omissions. Telit reserves the right to make changes to any products described herein and

reserves the right to revise this document and to make changes from time to time in content

hereof with no obligation to notify any person of revisions or changes. Telit does not assume

any liability arising out of the application or use of any product, software, or circuit described

herein; neither does it convey license under its patent rights or the rights of others.

It is possible that this publication may contain references to, or information about Telit products

(machines and programs), programming, or services that are not announced in your country.

Such references or information must not be construed to mean that Telit intends to announce

such Telit products, programming, or services in your country.

Copyrights

This instruction manual and the Telit products described in this instruction manual may be,

include or describe copyrighted Telit material, such as computer programs stored in

semiconductor memories or other media. Laws in the Italy and other countries preserve for Telit

and its licensors certain exclusive rights for copyrighted material, including the exclusive right

to copy, reproduce in any form, distribute and make derivative works of the copyrighted

material. Accordingly, any copyrighted material of Telit and its licensors contained herein or

in the Telit products described in this instruction manual may not be copied, reproduced,

distributed, merged or modified in any manner without the express written permission of Telit.

Furthermore, the purchase of Telit products shall not be deemed to grant either directly or by

implication, estoppel, or otherwise, any license under the copyrights, patents or patent

applications of Telit, as arises by operation of law in the sale of a product.

Computer Software Copyrights

The Telit and 3rd Party supplied Software (SW) products described in this instruction manual

may include copyrighted Telit and other 3rd Party supplied computer programs stored in

semiconductor memories or other media. Laws in the Italy and other countries preserve for Telit

and other 3rd Party supplied SW certain exclusive rights for copyrighted computer programs,

including the exclusive right to copy or reproduce in any form the copyrighted computer

program. Accordingly, any copyrighted Telit or other 3rd Party supplied SW computer

programs contained in the Telit products described in this instruction manual may not be copied

(reverse engineered) or reproduced in any manner without the express written permission of

Telit or the 3rd Party SW supplier. Furthermore, the purchase of Telit products shall not be

deemed to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Telit or other 3rd Party supplied SW, except for

the normal non-exclusive, royalty free license to use that arises by operation of law in the sale

of a product.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 3 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Usage and Disclosure Restrictions

License Agreements

The software described in this document is the property of Telit and its licensors. It is furnished

by express license agreement only and may be used only in accordance with the terms of such

an agreement.

Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is

prohibited by law. No part of the software or documentation may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language or computer language,

in any form or by any means, without prior written permission of Telit

High Risk Materials

Components, units, or third-party products used in the product described herein are NOT faulttolerant and are NOT designed, manufactured, or intended for use as on-line control equipment

in the following hazardous environments requiring fail-safe controls: the operation of Nuclear

Facilities, Aircraft Navigation or Aircraft Communication Systems, Air Traffic Control, Life

Support, or Weapons Systems (“High Risk Activities"). Telit and its supplier(s) specifically

disclaim any expressed or implied warranty of fitness for such High Risk Activities.

Trademarks

TELIT and the Stylized T Logo are registered in Trademark Office. All other product or

service names are the property of their respective owners.

Copyright © Telit Communications S.p.A. 2015.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 4 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Contents

1. Introduction ................................................. 9

1.1. Scope ..................................................... 9

1.2. Audience .................................................. 9

1.3. Contact Information, Support .............................. 9

1.4. Document Organization .................................... 10

1.5. Text Conventions ......................................... 11

1.6. Related Documents ........................................ 11

2. General Product Description ................................. 12

2.1. Overview ................................................. 12

2.2. LE920 Mechanical Dimensions .............................. 13

2.3. Weight ................................................... 13

2.4. Environmental requirements ............................... 14

2.4.1. Temperature range .......................................... 14

2.4.2. RoHS compliance ............................................ 14

2.5. Operating Frequency ...................................... 15

2.5.1. LE920-EUG(cs1550f-B), LE920-EU (cs1647c) ................... 15

2.5.2. LE920-NAG (cs1550f-A) ...................................... 15

2.5.3. LE920-NA (cs1701), LE920-NA AUTO S (cs1717) ................ 16

2.5.4. LE920-CN (cs1648D) ......................................... 17

2.6. Sensitivity .............................................. 18

2.7. Conformity assessment issues .............................. 18

2.7.1. FCC/IC Regulatory notices .................................. 18

2.7.1.1. Modification statement .................................. 18

2.7.1.2. Interference statement .................................. 18

2.7.1.3. RF exposure ............................................. 18

2.7.1.4. FCC Class B digital device notice ....................... 19

2.7.1.5. Labelling Requirements for the Host device .............. 19

3. LE920 Module Connections .................................... 21

3.1. PIN-OUT .................................................. 21

3.1.1. LGA Pads Layout ............................................ 28

4. Hardware Commands ........................................... 29

4.1. Turning ON the LE920 ..................................... 29

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 5 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

4.2. Initialization and Activation state ...................... 29

4.3. Turning OFF the LE920 .................................... 30

4.3.1. Shutdown by Software Command ............................... 31

4.3.2. Hardware Shutdown .......................................... 32

4.3.3. Hardware Unconditional Restart (RESET) ..................... 33

4.3.4. Hardware Unconditional Shutdown ............................ 34

4.4. Summary of Turning ON and OFF the module ................. 35

5. Power Supply ................................................ 36

5.1. Power Supply Requirements ................................ 36

5.2. General Design Rules ..................................... 38

5.2.1. Electrical Design Guidelines ............................... 38

5.2.1.1. + 5V Input Source Power Supply Design Guidelines ........ 38

5.2.1.2. + 12V Input Source Power Supply Design Guidelines ....... 39

5.2.1.3. Battery Source Power Supply Design Guidelines ........... 41

5.2.2. Thermal Design Guidelines .................................. 42

5.2.3. Power Supply PCB Layout Guidelines ......................... 43

6. Antenna(s) .................................................. 45

6.1. GSM/WCDMA/LTE Antenna Requirements ....................... 45

6.2. GSM/WCDMA/LTE Antenna – PCB line Guidelines .............. 46

6.3. GSM/WCDMA/LTE Antenna – Installation Guidelines .......... 47

6.4. Antenna Diversity Requirements ........................... 47

6.5. GPS/GNSS Antenna Requirements ............................ 48

6.5.1. Combined GPS/GNSS Antenna .................................. 49

6.5.2. Linear and Patch GPS/GNSS Antenna .......................... 49

6.5.3. Front End Design Considerations ............................ 49

6.5.4. GPS/GNSS Antenna - PCB Line Guidelines ..................... 50

6.5.5. GPS/GNSS Antenna – Installation Guidelines ................. 50

7. Logic Level Specifications .................................. 51

8. USB Port .................................................... 52

9. Serial Ports ................................................ 53

9.1. Modem Serial Port 1 ...................................... 54

9.2. Modem Serial Port 2 ...................................... 55

9.3. RS232 Level Translation .................................. 55

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 6 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

10. Peripheral Ports ............................................ 57

10.1. SPI – Serial Peripheral Interface ...................... 57

10.2. I2C - Inter-integrated circuit ......................... 58

10.3. SDIO – Secure Digital I/O .............................. 58

10.4. Wi-Fi (SDIO) control Interface ......................... 60

11. Audio Section Overview ...................................... 61

11.1. Analog Audio ........................................... 61

11.2. Digital Audio .......................................... 61

12. General Purpose I/O ......................................... 63

12.1. Logic Level Specifications ............................. 64

12.2. Using a GPIO Pad as Input .............................. 64

12.3. Using a GPIO Pad as Output ............................. 65

12.4. Using the Temperature Monitor Function ................. 65

12.4.1. Short Description ........................................ 65

12.5. Indication of Network Service Availability ............. 66

12.6. RTC Bypass ............................................. 67

12.7. VAUX Power Output ...................................... 67

13. ADC section ................................................. 68

13.1. ADC Converter .......................................... 68

13.1.1. Description .............................................. 68

13.1.2. Using ADC Converter ...................................... 68

14. Mounting the module on your board ........................... 69

14.1. General ................................................ 69

14.2. Finishing & Dimensions ................................. 69

14.3. Recommended foot print for the application ............. 70

14.4. Stencil ................................................ 71

14.5. PCB Pad Design ......................................... 71

14.6. Recommendations for PCB Pad Dimensions (mm) ............ 72

14.7. Solder Paste ........................................... 73

14.7.1. Solder Reflow ............................................ 73

15. Application guide ........................................... 75

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 7 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

15.1. Debug of the LE920 in production ....................... 75

15.2. Bypass capacitor on Power supplies ..................... 76

15.3. SIM interface .......................................... 77

15.3.1. SIM schematic example .................................... 77

15.3.2. eSIM interface guidelines ................................ 78

15.4. EMC recommendations .................................... 80

15.5. Download and Debug Port ................................ 81

16. Packing system .............................................. 82

16.1. Tray Drawing ........................................... 84

16.2. Moisture Sensitivity ................................... 85

17. Safety Recommendations ...................................... 86

18. Document History ............................................ 87

- Adding section 2.7 Conformity assessment issues ............................. 88

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 8 of 88

1. Introduction

1.1. Scope

The aim of this document is to present possible and recommended hardware solutions useful

for developing a product with the Telit LE920 module. All the features and solutions detailed

are applicable to all LE920, where “LE920” refers to the modules listed in the applicability

table.

If a specific feature is applicable to a specific product, it will be clearly highlighted.

NOTICE:

The description text “LE920” refers to all modules listed in the APPLICABILITY TABLE 1.

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

1.2. Audience

This document is intended for Telit customers, especially system integrators, about to

implement their applications using our LE920 module.

1.3. Contact Information, Support

For general contact, technical support, to report documentation errors and to order manuals,

contact Telit’s Technical Support Center (TTSC) at:

TS-EMEA@telit.com

TS-NORTHAMERICA@telit.com

TS-LATINAMERICA@telit.com

TS-APAC@telit.com

Alternatively, use:

http://www.telit.com/en/products/technical-support-center/contact.php

For detailed information about where you can buy the Telit modules or for recommendations

on accessories and components visit:

http://www.telit.com

To register for product news and announcements or for product questions contact Telit’s

Technical Support Center (TTSC).

Our aim is to make this guide as helpful as possible. Keep us informed of your comments and

suggestions for improvements.

Telit appreciates feedback from the users of our information.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 9 of 88

1.4. Document Organization

This document contains the following chapters:

Chapter 1: “Introduction” provides a scope for this document, target audience, contact and

support information, and text conventions.

Chapter 2: “General Product Description” gives an overview of the features of the product.

Chapter 3: “LE920 Module Connections” deals with the pin out configuration and layout.

Chapter 4: “Hardware Commands” instructs how to control the module via hardware

Chapter 5: “Power Supply” deals with supply and consumption.

Chapter 6: “Antenna” The antenna connection and board layout design are the most important

parts in the full product design

Chapter 7: “Logic Level specifications” Specific values adopted in the implementation of

logic levels for this module.

Chapter 8: “USB Port”

Chapter 9: “Serial Ports”

Chapter 10: “Peripheral Ports”

Chapter 11: “Audio Section Overview”

Chapter 12: “General Purpose I/O” How the general purpose I/O pads can be configured.

Chapter 13 “DAC and ADC Section” Deals with these two kind of analog converters.

Chapter 14: “Mounting the module on your board”

Chapter 15: “Application Guides”

Chapter 16: “Packing System”

Chapter 17: “Safety Recommendations”

Chapter 18: “Document History”

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 10 of 88

1.5. Text Conventions

Danger – This information MUST be followed or catastrophic equipment failure or bodily

injury may occur.

Caution or Warning – Alerts the user to important points about integrating the module, if

these points are not followed, the module and end user equipment may fail or malfunction.

Tip or Information – Provides advice and suggestions that may be useful when integrating

the module.

All dates are in ISO 8601 format, i.e. YYYY-MM-DD.

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

1.6. Related Documents

LE920-EUG/NAG Product Description, 80407ST10118A

LE920-EUG/NAG AT command reference guide, 80407ST10116A

Telit EVK2 User Guide, 1vv0300704

Telit xE920 Audio Settings Application Note, 80404NT10095A

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 11 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

2. General Product Description

2.1. Overview

The aim of this document is to present possible and recommended hardware solutions useful

for developing a product with the Telit LE920 module.

In this document all the basic functions of a wireless module will be taken into account; for

each one of them a valid hardware solution will be suggested and usually incorrect solutions

and common errors to be avoided will be highlighted. Obviously this document cannot

embrace every hardware solution or every product that may be designed. Obviously avoiding

invalid solutions must be considered as mandatory. Whereas the suggested hardware

configurations need not be considered mandatory, the information given should be used as a

guide and a starting point for properly developing your product with the Telit LE920 module.

.

NOTICE:

The integration of the GSM/GPRS/EGPRS/WCDMA/HSPA+/LTE LE920 cellular module

within user application must be done according to the design rules described in this manual.

The information presented in this document is believed to be accurate and reliable. However,

no responsibility is assumed by Telit Communication S.p.A. for its use, such as any

infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent rights of Telit Communication

S.p.A. other than for circuitry embodied in Telit products. This document is subject to change

without notice.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 12 of 88

1vv0301026 Rev.8 2015-01-03

2.2. LE920 Mechanical Dimensions

The Telit LE920 module overall dimensions are:

• Length: 34 mm , +/- 0.15 mm Tolerance

• Width: 40 mm , +/- 0.15 mm Tolerance

• Thickness: 2.9 mm , +/- 0.13 mm Tolerance

2.3. Weight

The module weight of LE920 is about 9.0 gram.

LE920 Hardware User Guide

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 13 of 88

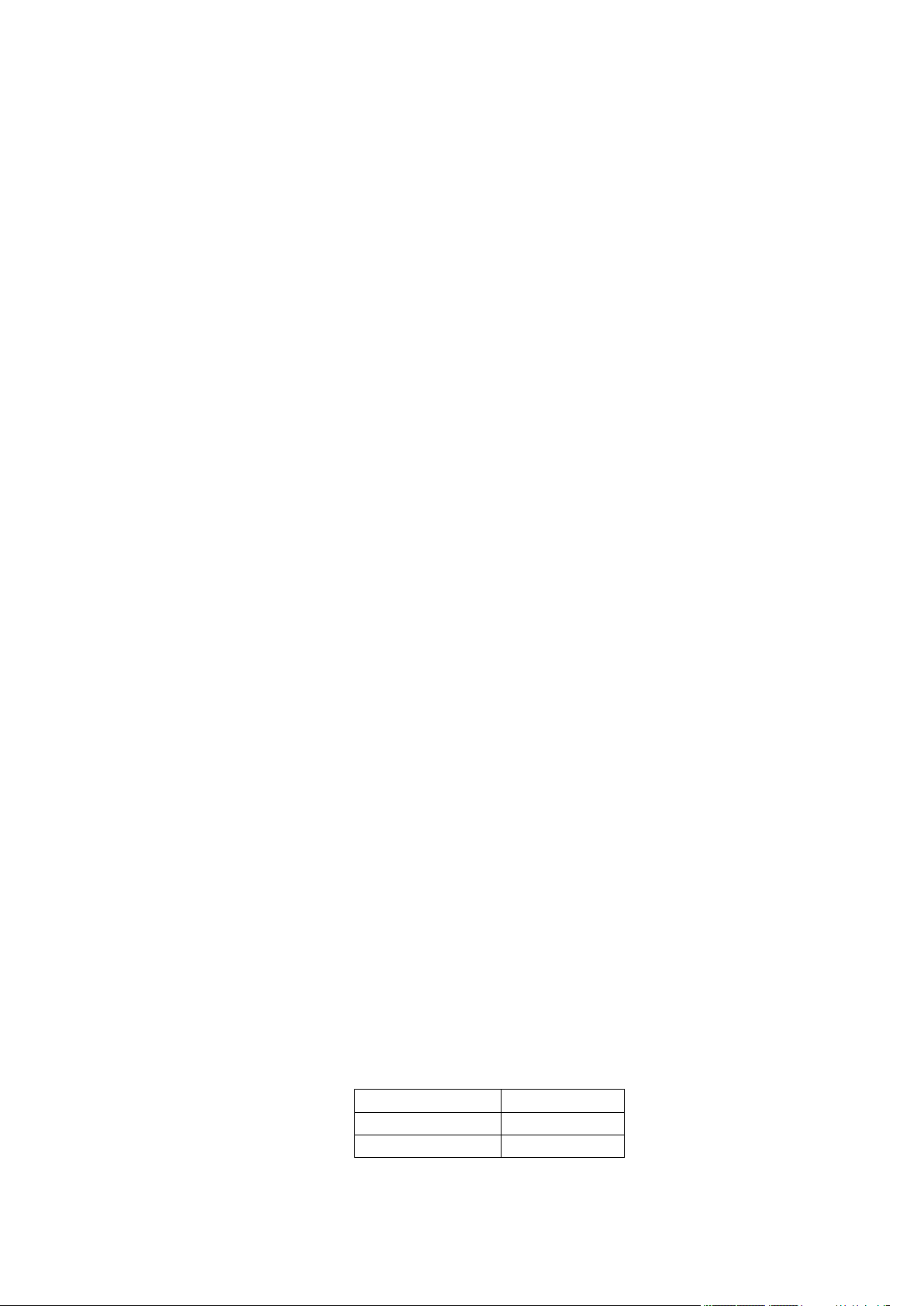

Operating Temperature Range

–40°C ~ +85°C

Storage and non-operating

Temperature Range

–40°C ~ +85°C

1vv0301026 Rev.8 2015-01-03

2.4. Environmental requirements

2.4.1. Temperature range

2.4.2. RoHS compliance

LE920 Hardware User Guide

As a part of Telit corporate policy of environmental protection, the LE920 complies with the

RoHS (Restriction of Hazardous Substances) directive of the European Union (EU directive

2011/65/EU).

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 14 of 88

Mode

Freq. TX (MHz)

Freq. RX (MHz)

Channels

TX - RX offset

GSM850

824 ~ 849

869 ~ 894

128 ~ 251

45 MHz

EGSM900

890 ~ 915

935 ~ 960

0 ~ 124

45 MHz

880 ~ 890

925 ~ 935

975 ~ 1023

45 MHz

DCS1800

1710 ~ 1785

1805 ~ 1880

512 ~ 885

95MHz

PCS1900

1850 ~ 1910

1930 ~ 1990

512 ~ 810

80MHz

WCDMA2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 9612 ~ 9888

Rx: 10562 ~ 10838

190MHz

WCDMA1800 – B3

1710 ~ 1785

1805 ~ 1880

Tx: 937 ~ 1288

Rx: 1162 ~ 1513

95MHz

WCDMA900 – B8

880 ~ 915

925 ~ 960

Tx: 2712 ~ 2863

Rx: 2937 ~ 3088

45MHz

LTE2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 18000 ~ 18599

Rx: 0 ~ 599

190MHz

LTE1800 – B3

1710 ~ 1785

1805 ~ 1880

Tx: 19200 ~ 19949

Rx: 1200 ~ 1949

95MHz

LTE2600 – B7

2500 ~ 2570

2620 ~ 2690

Tx: 20750 ~ 21449

Rx: 2750 ~ 3449

120MHz

LTE900 – B8

880 ~ 915

925 ~ 960

Tx: 21450 ~ 21799

Rx: 3450 ~ 3799

45MHz

LTE800 – B20

832 ~ 862

791 ~ 821

Tx: 24150 ~ 24449

Rx: 6150 ~ 6449

-41MHz

Mode

Freq. TX (MHz)

Freq. RX (MHz)

Channels

TX - RX offset

GSM850

824 ~ 849

869 ~ 894

128 ~ 251

45 MHz

EGSM900

890 ~ 915

935 ~ 960

0 ~ 124

45 MHz

880 ~ 890

925 ~ 935

975 ~ 1023

45 MHz

DCS1800

1710 ~ 1785

1805 ~ 1880

512 ~ 885

95MHz

PCS1900

1850 ~ 1910

1930 ~ 1990

512 ~ 810

80MHz

WCDMA2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 9612 ~ 9888

Rx: 10562 ~ 10838

190MHz

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

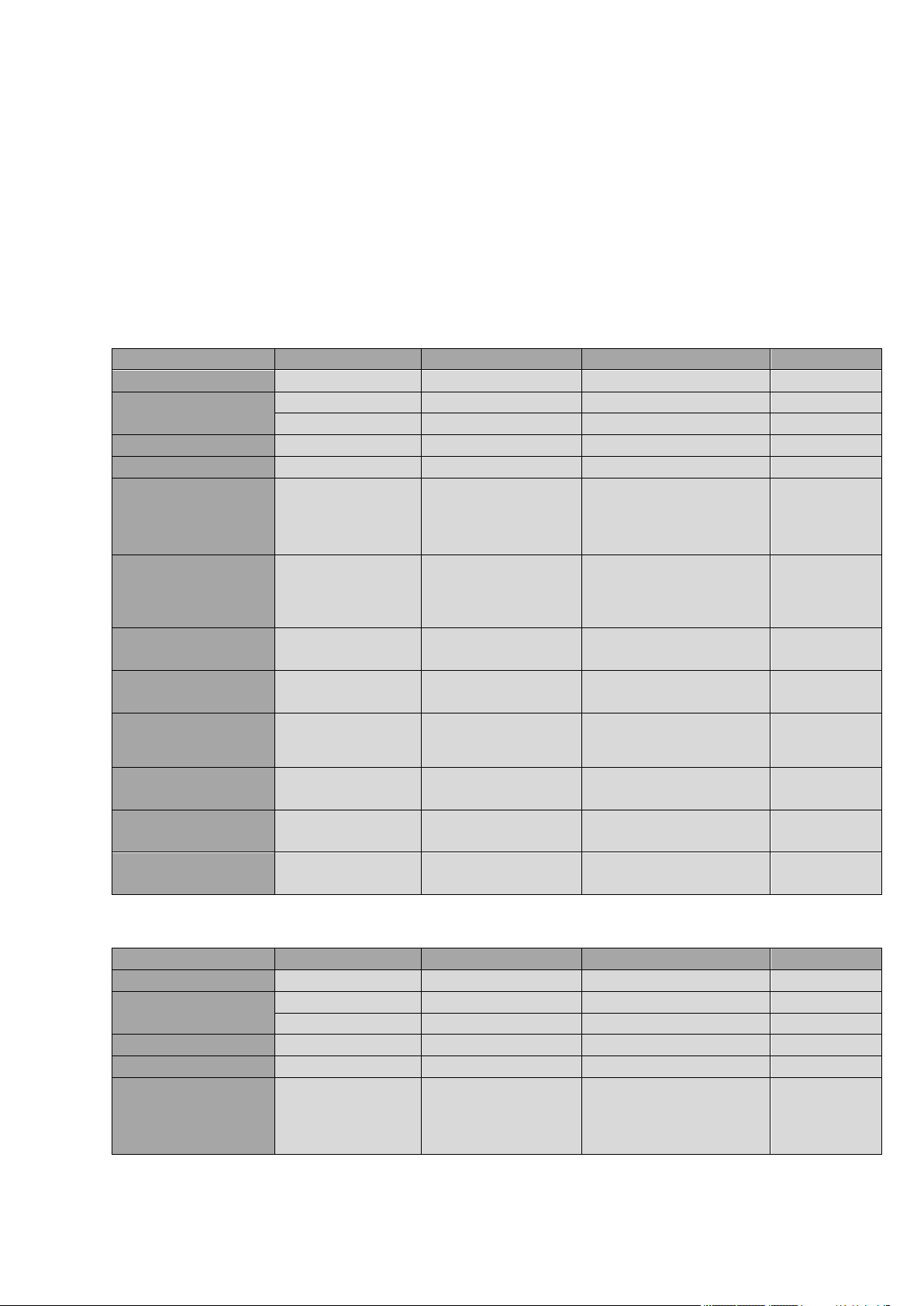

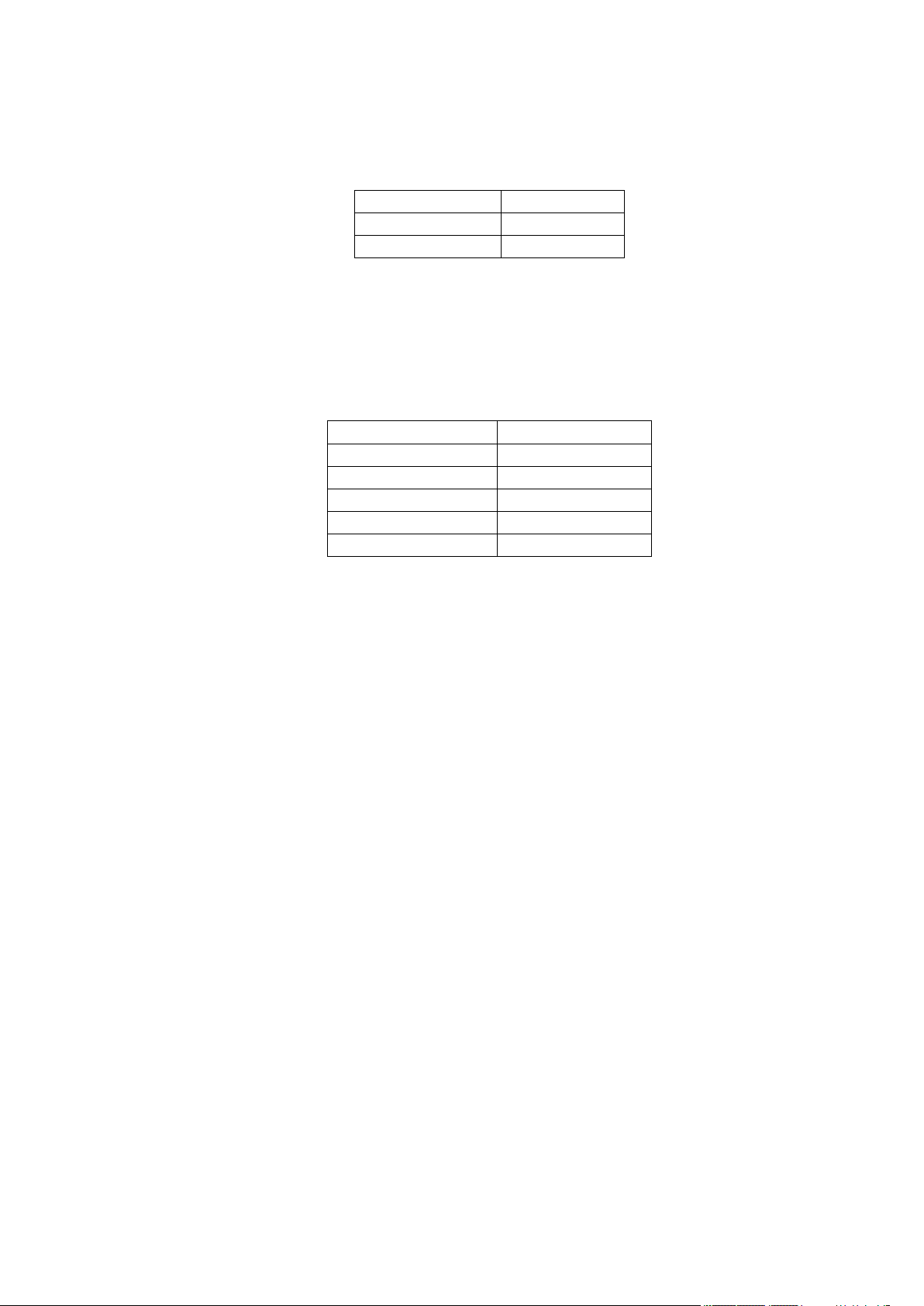

2.5. Operating Frequency

The operating frequencies in GSM850, EGSM900, DCS1800, PCS1900, WCDMA & LTE

modes are conformed to the 3GPP specifications.

2.5.1. LE920-EUG(cs1550f-B), LE920-EU (cs1647c)

2.5.2. LE920-NAG (cs1550f-A)

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 15 of 88

LE920 Hardware User Guide

WCDMA1900 – B2

1850 ~ 1910

1930 ~ 1990

Tx: 9262 ~ 9538

Rx: 9662 ~ 9938

80MHz

WCDMA1700 – B4

1710 ~ 1755

2110 ~ 2155

Tx: 1312 ~ 1513

Rx: 1537 ~ 1738

400 MHz

WCDMA850 – B5

824 ~ 849

869 ~ 894

Tx: 4132 ~ 4233

Rx: 4357 ~ 4458

45MHz

WCDMA800 – B6

830 ~ 840

875 ~ 885

Tx: 4162 ~ 4188

Rx: 4387 ~ 4413

45MHz

LTE2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 18000 ~ 18599

Rx: 0 ~ 599

190MHz

LTE1900 – B2

1850 ~ 1910

1930 ~ 1990

Tx: 18600 ~ 19199

Rx: 600 ~ 1199

80MHz

LTE1700 – B4

1710~ 1755

2110 ~ 2155

Tx: 19950 ~ 20399

Rx: 1950 ~ 2399

400MHz

LTE850 – B5

824 ~ 849

869 ~ 894

Tx: 20400 ~ 20649

Rx: 2400 ~ 2649

45MHz

LTE700 – B17

704 ~ 716

734 ~ 746

Tx: 23730 ~ 23849

Rx: 5730 ~ 5849

30MHz

WCDMA1900 – B2

1850 ~ 1910

1930 ~ 1990

Tx: 9262 ~ 9538

Rx: 9662 ~ 9938

80MHz

WCDMA1700 – B4

1710 ~ 1755

2110 ~ 2155

Tx: 1312 ~ 1513

Rx: 1537 ~ 1738

400 MHz

WCDMA850 – B5

824 ~ 849

869 ~ 894

Tx: 4132 ~ 4233

Rx: 4357 ~ 4458

45MHz

LTE1900 – B2

1850 ~ 1910

1930 ~ 1990

Tx: 18600 ~ 19199

Rx: 600 ~ 1199

80MHz

1vv0301026 Rev.8 2015-01-03

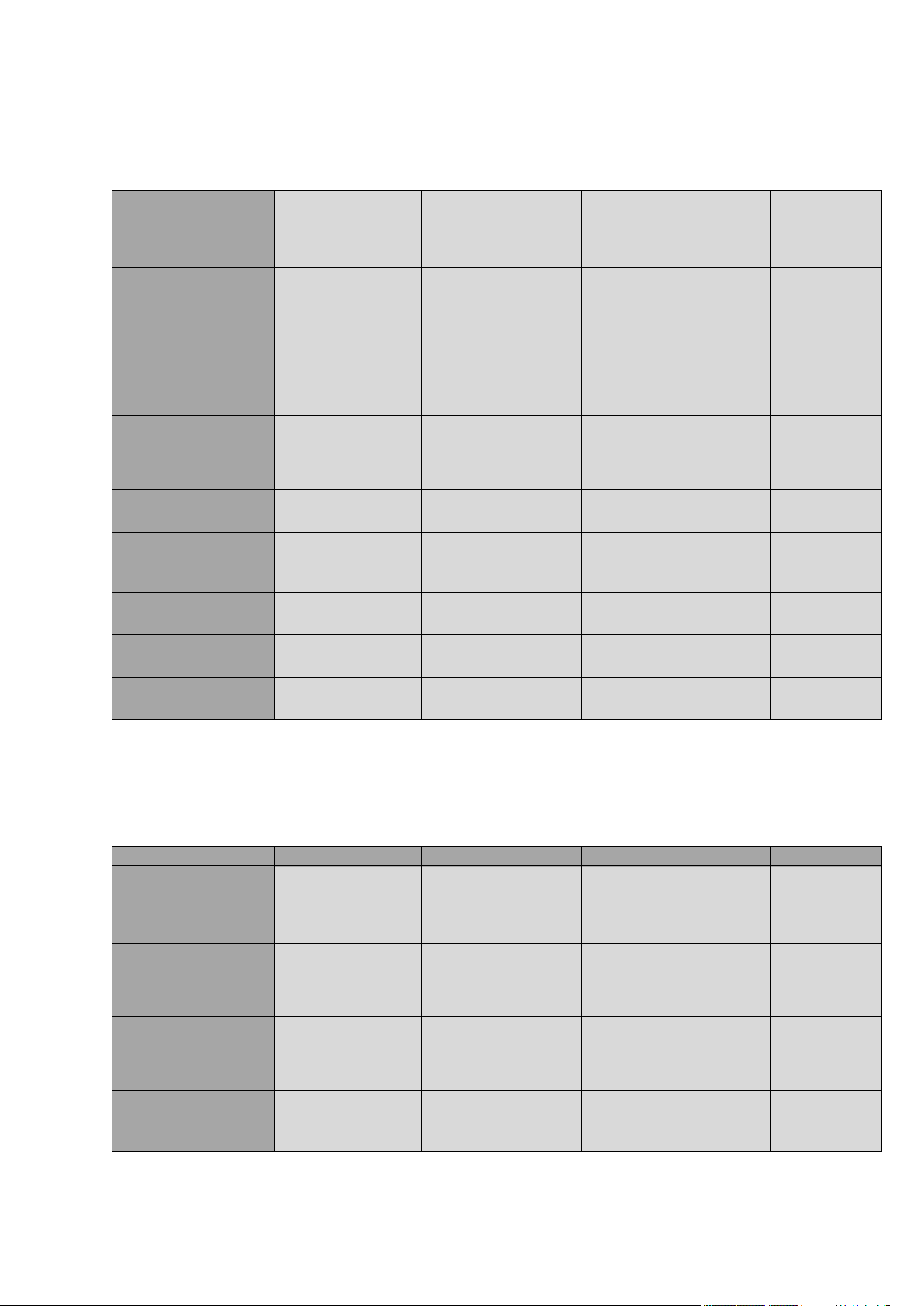

2.5.3. LE920-NA (cs1701), LE920-NA AUTO S (cs1717)

Mode Freq. TX (MHz) Freq. RX (MHz) Channels TX - RX offset

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 16 of 88

LE920 Hardware User Guide

LTE1700 – B4

1710~ 1755

2110 ~ 2155

Tx: 19950 ~ 20399

Rx: 1950 ~ 2399

400MHz

LTE850 – B5

824 ~ 849

869 ~ 894

Tx: 20400 ~ 20649

Rx: 2400 ~ 2649

45MHz

LTE2600 – B7

2500 ~ 2570

2620 ~ 2690

Tx: 20750 ~ 21449

Rx: 2750 ~ 3449

120MHz

30MHz

Mode

Freq. TX (MHz)

Freq. RX (MHz)

Channels

TX - RX offset

EGSM900

890 ~ 915

935 ~ 960

0 ~ 124

45 MHz

880 ~ 890

925 ~ 935

975 ~ 1023

45 MHz

DCS1800

1710 ~ 1785

1805 ~ 1880

512 ~ 885

95MHz

WCDMA2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 9612 ~ 9888

Rx: 10562 ~ 10838

190MHz

WCDMA1800 – B3

1710 ~ 1785

1805 ~ 1880

Tx: 937 ~ 1288

Rx: 1162 ~ 1513

95MHz

WCDMA900 – B8

880 ~ 915

925 ~ 960

Tx: 2712 ~ 2863

Rx: 2937 ~ 3088

45MHz

LTE2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 18000 ~ 18599

Rx: 0 ~ 599

190MHz

LTE1800 – B3

1710 ~ 1785

1805 ~ 1880

Tx: 19200 ~ 19949

Rx: 1200 ~ 1949

95MHz

LTE900 – B8

880 ~ 915

925 ~ 960

Tx: 21450 ~ 21799

Rx: 3450 ~ 3799

45MHz

LTE TDD 2600 – B38

2570 ~ 2620

2570 ~ 2620

Tx: 37750 ~ 38250

Rx: 37750 ~ 38250

0MHz

LTE TDD 1900 – B39

1880 ~ 1920

1880 ~ 1920

Tx: 38250 ~ 38650

Rx: 38250 ~ 38650

0MHz

LTE TDD 2300 – B40

2300 ~ 2400

2300 ~ 2400

Tx: 38650 ~ 39650

Rx: 38650 ~ 39650

0MHz

LTE TDD 2500 – B41

2496 ~ 2690

2496 ~ 2690

Tx: 39650 ~ 41590

Rx: 39650 ~ 41590

0MHz

TDSCDMA2000 – B34

2010 ~ 2025

2010 ~ 2025

Tx: 10054 ~ 10121

Rx: 10054 ~ 10121

0MHz

TDSCDMA1900 – B39

1880 ~ 1920

1880 ~ 1920

Tx: 9404 ~ 9596

Rx: 9404 ~ 9596

0MHz

1vv0301026 Rev.8 2015-01-03

LTE700 – B17 704 ~ 716 734 ~ 746

2.5.4. LE920-CN (cs1648D)

Tx: 23730 ~ 23849

Rx: 5730 ~ 5849

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 17 of 88

Frequency band

Antenna gain

700 MHz

5,66 dBi

850 MHz

6,13 dBi

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

2.6. Sensitivity

LE920 maximum sensitivity levels are as follow:

-113 dBm @ 2G

-112 dBm @ 3G

-111 dBm @ TD-SCDMA (BW=1.6MHz)

-102 dBm @ 4G FDD (BW=5MHz)

-101 dBm @ 4G TDD (BW=5MHz)

2.7. Conformity assessment issues

2.7.1. FCC/IC Regulatory notices

2.7.1.1. Modification statement

Telit has not approved any changes or modifications to this device by the user. Any changes or modifications

could void the user’s authority to operate the equipment.

Telit n’approuve aucune modification apportée à l’appareil par l’utilisateur, quelle qu’en soit la nature. Tout

changement ou modification peuvent annuler le droit d’utilisation de l’appareil par l’utilisateur.

2.7.1.2. Interference statement

This device complies with Part 15 of the FCC Rules and Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de

brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

2.7.1.3. RF exposure

This equipment complies with FCC and IC radiation exposure limits set forth for an uncontrolled

environment. The antenna should be installed and operated with minimum distance of 20 cm between

the radiator and your body.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 18 of 88

Antenna gain must be below:

1700 MHz

5,00 dBi

1900 MHz

8,01 dBi

2600 MHz

8,01 dBi

Bande de fréquence

Gain de l'antenne

700 MHz

5,66 dBi

850 MHz

6,13 dBi

1700 MHz

5,00 dBi

1900 MHz

8,01 dBi

2600 MHz

8,01 dBi

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

Cet appareil est conforme aux limites d'exposition aux rayonnements de la IC pour un environnement non

contrôlé. L'antenne doit être installé de façon à garder une distance minimale de 20 centimètres entre la source

de rayonnements et votre corps. Gain de l'antenne doit être ci-dessous:

L'émetteur ne doit pas être colocalisé ni fonctionner conjointement avec à autre antenne ou autre émetteur.

2.7.1.4. FCC Class B digital device notice

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

2.7.1.5. Labelling Requirements for the Host device

The host device shall be properly labelled to identify the modules within the host device. The certification label

of the module shall be clearly visible at all times when installed in the host device, otherwise the host device

must be labelled to display the FCC ID and IC of the module, preceded by the words "Contains transmitter

module", or the word "Contains", or similar wording expressing the same meaning, as follows:

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 19 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Contains FCC ID: RI7LE920NA1

Contains IC: 5131A-LE920NA1

L'appareil hôte doit être étiqueté comme il faut pour permettre l'identification des modules qui s'y trouvent.

L'étiquette de certification du module donné doit être posée sur l'appareil hôte à un endroit bien en vue en tout

temps. En l'absence d'étiquette, l'appareil hôte doit porter une étiquette donnant le FCC ID et le IC du module,

précédé des mots « Contient un module d'émission », du mot « Contient » ou d'une formulation similaire

exprimant le même sens, comme suit:

Contains FCC ID: RI7LE920NA1

Contains IC: 5131A-LE920NA1

CAN ICES-3 (B) / NMB-3 (B)

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de classe B est conforme à la norme canadienne ICES-003.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 20 of 88

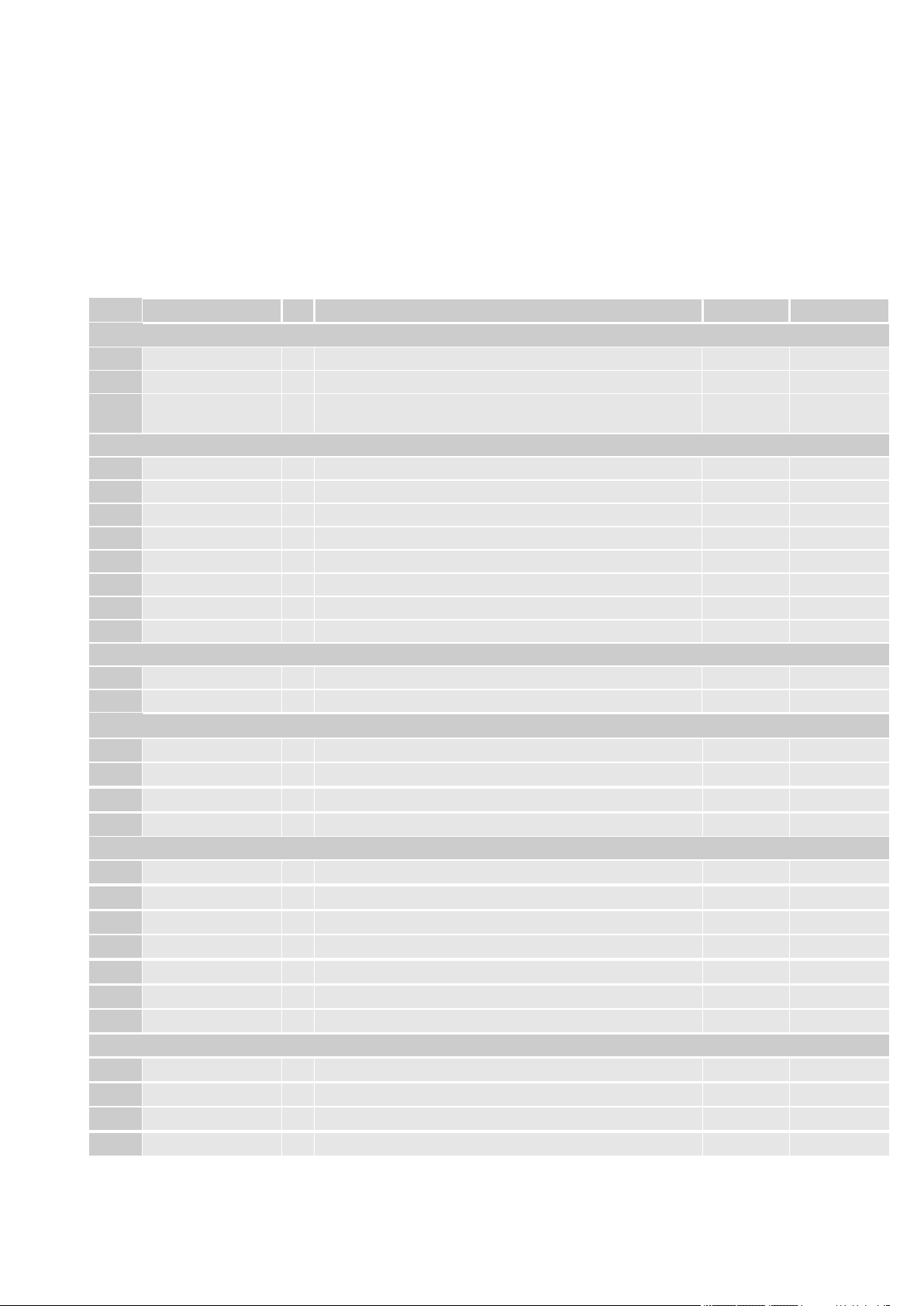

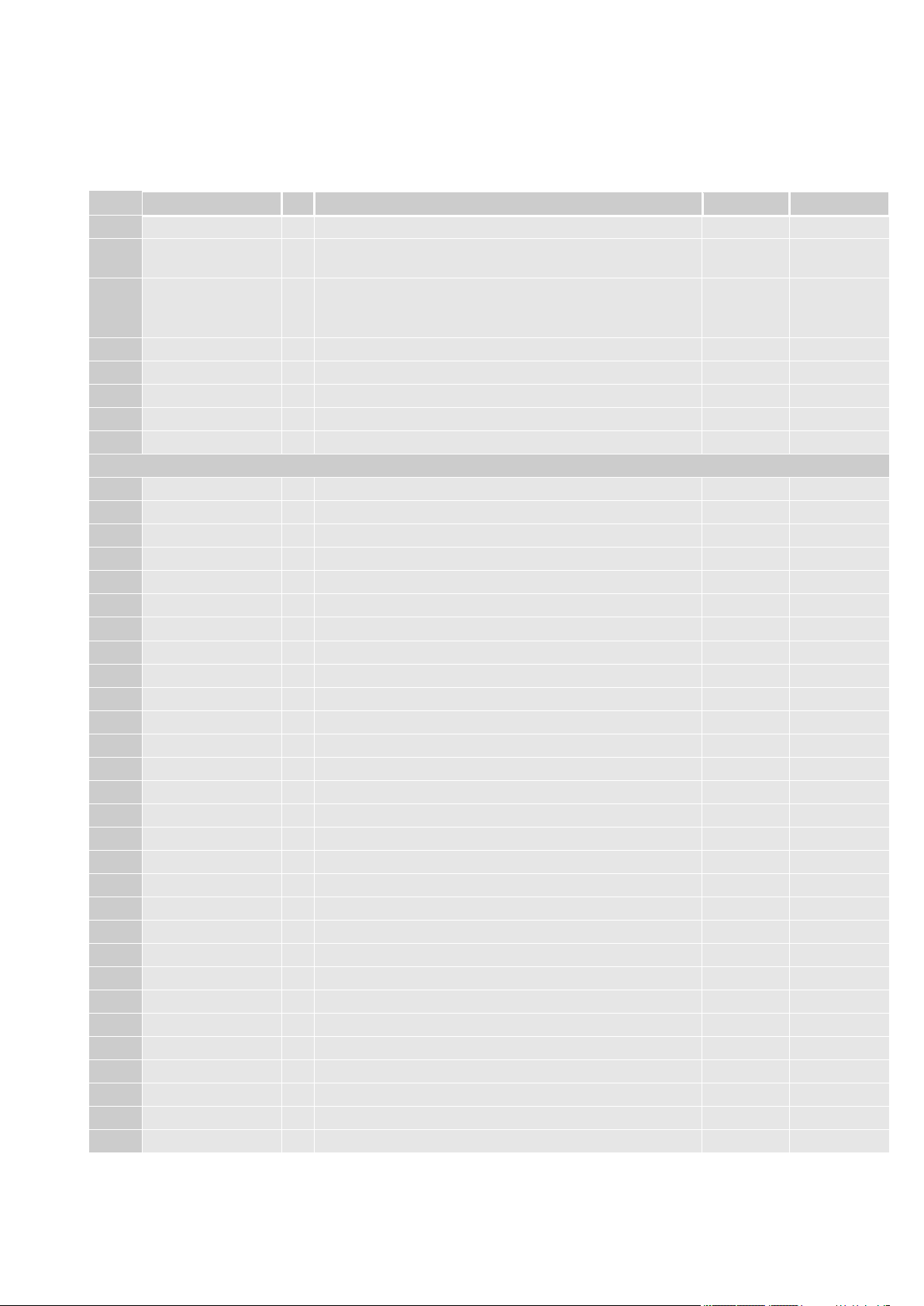

PAD

Signal

I/O

Function

Type

COMMENT

USB HS 2.0 Communication Port

D19

USB_D+

I/O

USB differential Data(+)

F19

USB_D-

I/O

USB differential Data(-)

A18

USB_VBUS

AI

Power sense for the internal USB transceiver

Power

2.2V – 5.25V

@ max 5mA

Asynchronous UART – Prog. / data +HW Flow Control

AH19

C103/TXD

I

Serial data input (TXD) from DTE

1.8V

AF19

C104/RXD

O

Serial data output to DTE

1.8V

AC18

C108/DTR

I

Input for Data terminal ready signal (DTR) from DTE

1.8V

AA18

C105/RTS

I

Input for Request to send signal (RTS) from DTE

1.8V

AK19

C106/CTS

O

Output for Clear to send signal (CTS) to DTE

1.8V

AE18

C109/DCD

O

Output for Data carrier detect signal (DCD) to DTE

1.8V

AG18

C107/DSR

O

Output for Data set ready signal (DSR) to DTE

1.8V

AJ18

C125/RING

O

Output for Ring indicator signal (RI) to DTE

1.8V

Asynchronous Auxiliary UART

AB19

TXD_AUX

O

Auxiliary UART (TX Data to DTE)

1.8V

AD19

RXD_AUX

I

Auxiliary UART (RX Data from DTE)

1.8V

SPI – Serial Peripheral Interface

P19

SPI_CLK

O

SPI Clock output

1.8V

M19

SPI_MISO

I

SPI data Master Input Slave output

1.8V

K19

SPI_MOSI

O

SPI data Master Output Slave input

1.8V

N18

SPI_CS

O

SPI Chip select output

1.8V

SDIO – Secure Digital I/O

AH17

SD/MMC_CMD

O

SD Command

1.8/2.95V

AD17

SD/MMC_CLK

O

SD Card Clock

1.8/2.95V

Y17

SD/MMC_DATA0

I/O

SD Serial Data 0

1.8/2.95V

AF17

SD/MMC_DATA1

I/O

SD Serial Data 1

1.8/2.95V

AB17

SD/MMC_DATA2

I/O

SD Serial Data 2

1.8/2.95V

W17

SD/MMC_DATA3

I/O

SD Serial Data 3

1.8/2.95V

U17

SD/MMC_CD

I

SD card detect input

1.8V

Active Low

Wi-Fi (SDIO) control Interface

AB3

WiFi_SD_CMD

O

Wi-Fi SD Command

1.8V

AM3

WiFi_SD_CLK

O

Wi-Fi SD Clock

1.8V

AD3

WiFi_SD _DATA0

I/O

Wi-Fi SD Serial Data 0

1.8V

AF3

WiFi_SD _DATA1

I/O

Wi-Fi SD Serial Data 1

1.8V

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

3. LE920 Module Connections

3.1. PIN-OUT

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 21 of 88

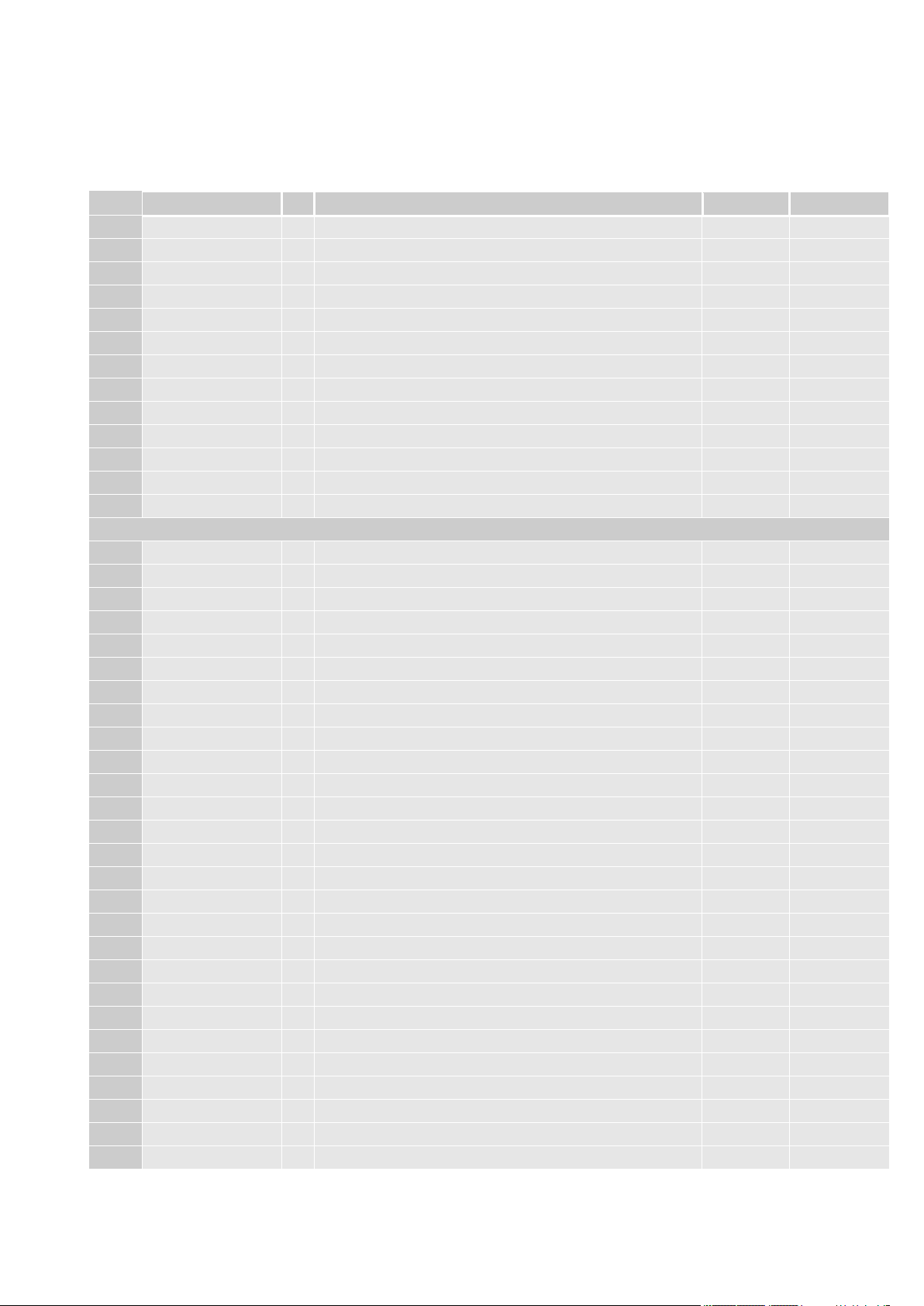

PAD

Signal

I/O

Function

Type

COMMENT

AH3

WiFi_SD _DATA2

I/O

Wi-Fi SD Serial Data 2

1.8V

AK3

WiFi_SD _DATA3

I/O

Wi-Fi SD Serial Data 3

1.8V

Y3

WiFi_RST_Ctr

O

Wi-Fi Reset output control / Power enable control

1.8V

Active Low

SIM Card Interface 1

A10

SIMCLK1

O

External SIM signal – Clock

1.8/2.85V

B11

SIMRST1

O

External SIM signal – Reset

1.8/2.85V

B9

SIMIO1

I/O

External SIM signal - Data I/O

1.8/2.85V

B7

SIMIN1

I

External SIM signal - Presence (active low)

1.8V

A8

SIMVCC1

-

External SIM signal – Power supply for the SIM

1.8/2.85V

E8

ESIM_RST

-

Internal eSIM signal – Reset

1.8/2.85V

Analog Audio interface

B5

EAR1_MT+

AO

Earphone signal output1, phase +

Audio

A4

EAR1_MT-

AO

Earphone signal output1, phase -

Audio

B3

MIC1_MT+

AI

Mic signal input1, phase +

Audio

A2

MIC1_MT-

AI

Mic signal input1, phase -

Audio

Digital Voice interface (DVI)

D11

DVI_WA0

O

Digital Voice interface (WA0 master output)

1.8V

C8

DVI_RX

I

Digital Voice interface (RX)

1.8V

D9

DVI_TX

O

Digital Voice interface (TX)

1.8V

C10

DVI_CLK

O

Digital Voice interface (CLK master output)

1.8V

Digital I/O

F9

GPIO_01

I/O

GPIO_01

1.8V

I2C alternate

E10

GPIO_02

I/O

GPIO_02

1.8V

I2C alternate

F11

GPIO_03

I/O

GPIO_03

1.8V

I2C alternate

E12

GPIO_04

I/O

GPIO_04

1.8V

I2C alternate

F13

GPIO_05

I/O

GPIO_05

1.8V

I2C alternate

E14

GPIO_06

I/O

GPIO_06

1.8V

I2C alternate

R18

GPIO_07

I/O

GPIO_07

1.8V

I2C alternate

S19

GPIO_08

I/O

GPIO_08

1.8V

I2C alternate

U19

GPIO_09

I/O

GPIO_09

1.8V

I2C alternate

W19

GPIO_10

I/O

GPIO_10

1.8V

I2C alternate

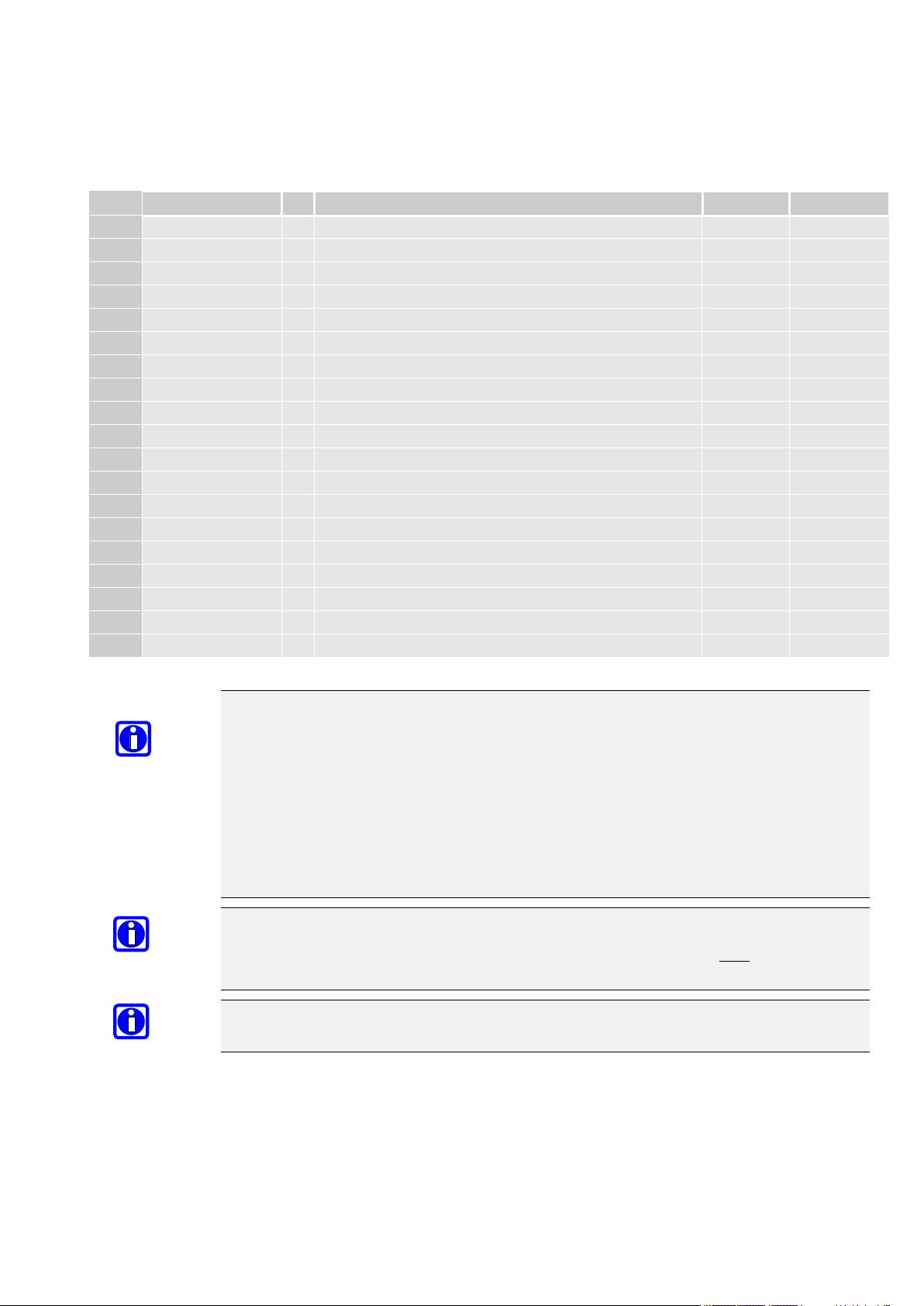

RF Section

AD1

Antenna

I/O

GSM/EDGE/UMTS/LTE Antenna (50 Ohm)

RF

AU9

ANT_DIV

I

UMTS/LTE Antenna Diversity Input (50 Ohm)

RF

GPS Section

S1

ANT_GPS

I

GPS Antenna (50 Ohm)

RF

V2

GPS_LNA_EN

O

Enable the external regulator for GPS LNA

1.8V

Miscellaneous Function

AP1

RESET#

I

Reset Input

Active Low

AS1

ON_OFF#

I

Input Command for Power ON

Active Low

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 22 of 88

PAD

Signal

I/O

Function

Type

COMMENT

AN12

SHDN_N

I

Unconditional Shut down Input

Active Low

P17

VAUX/PWRMON

O

Supply Output for External Accessories / Power ON

Monitor

1.8V

F17

VRTC

AI/

AO

VRTC Backup Capacitor

Power

To be used to

back up the

RTC section

D5

ADC_IN1

AI

Analog/Digital Converter Input 1

Analog

E6

ADC_IN2

AI

Analog/Digital Converter Input 2

Analog

F7

ADC_IN3

AI

Analog/Digital Converter Input 3

Analog

AU3

STAT_LED

O

Status Indicator LED

1.8V

AN10

SW_RDY

O

Indicates that the boot sequence completed successfully

1.8V

Power Supply

AP17

VBATT

-

Main Power Supply (Digital Section)

Power

AP19

VBATT

-

Main Power Supply (Digital Section)

Power

AR18

VBATT

-

Main Power Supply (Digital Section)

Power

AS17

VBATT_PA

-

Main Power Supply (RF Transmit Power Section)

Power

AS19

VBATT_PA

-

Main Power Supply (RF Transmit Power Section)

Power

AT18

VBATT_PA

-

Main Power Supply (RF Transmit Power Section)

Power

AU17

VBATT_PA

-

Main Power Supply (RF Transmit Power Section)

Power

AU19

VBATT_PA

-

Main Power Supply (RF Transmit Power Section)

Power

A6

GND

-

Ground

A12

GND

-

Ground

B13

GND

-

Ground

B15

GND

-

Ground

B17

GND

-

Ground

C4

GND

-

Ground

C6

GND

-

Ground

D3

GND

-

Ground

D7

GND

-

Ground

E18

GND

-

Ground

F1

GND

-

Ground

G18

GND

-

Ground

H19

GND

-

Ground

M1

GND

-

Ground

N2

GND

-

Ground

P1

GND

-

Ground

P3

GND

-

Ground

R2

GND

Ground

T2

GND

Ground

T18

GND

-

Ground

U1

GND

-

Ground

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 23 of 88

PAD

Signal

I/O

Function

Type

COMMENT

V18

GND

-

Ground

W1

GND

-

Ground

X2

GND

-

Ground

X18

GND

-

Ground

Y1

GND

-

Ground

Y19

GND

Ground

AA2

GND

-

Ground

AB1

GND

-

Ground

AC2

GND

-

Ground

AE2

GND

-

Ground

AF1

GND

-

Ground

AG2

GND

-

Ground

AH1

GND

-

Ground

AJ2

GND

-

Ground

AK1

GND

-

Ground

AK17

GND

-

Ground

AL18

GND

-

Ground

AM17

GND

-

Ground

AM19

GND

-

Ground

AN16

GND

-

Ground

AN18

GND

-

Ground

AP3

GND

-

Ground

AP5

GND

-

Ground

AP7

GND

-

Ground

AP9

GND

-

Ground

AP11

GND

-

Ground

AP13

GND

-

Ground

AP15

GND

-

Ground

AR2

GND

-

Ground

AR4

GND

-

Ground

AR6

GND

-

Ground

AR8

GND

-

Ground

AR10

GND

-

Ground

AR12

GND

-

Ground

AR14

GND

-

Ground

AR16

GND

-

Ground

AS5

GND

-

Ground

AS7

GND

-

Ground

AS9

GND

-

Ground

AS11

GND

-

Ground

AS13

GND

-

Ground

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 24 of 88

PAD

Signal

I/O

Function

Type

COMMENT

AS15

GND

-

Ground

AT4

GND

-

Ground

AT6

GND

-

Ground

AT8

GND

-

Ground

AT10

GND

-

Ground

AT12

GND

-

Ground

AT14

GND

-

Ground

AT16

GND

-

Ground

AU1

GND

-

Ground

AU5

GND

-

Ground

AU7

GND

-

Ground

AU11

GND

-

Ground

AU15

GND

-

Ground

Reserved

C12

Reserved

-

Reserved

A14

Reserved

-

Reserved

A16

Reserved

-

Reserved

M17

Reserved

-

Reserved

AN6

Reserved

-

Reserved

C14

Reserved

-

Reserved

D13

Reserved

-

Reserved

C16

Reserved

-

Reserved

D17

Reserved

-

Reserved

E16

Reserved

-

Reserved

C18

Reserved

-

Reserved

D15

Reserved

-

Reserved

F15

Reserved

-

Reserved

E4

Reserved

-

Reserved

F3

Reserved

-

Reserved

F5

Reserved

-

Reserved

G2

Reserved

-

Reserved

H1

Reserved

-

Reserved

H3

Reserved

-

Reserved

H17

Reserved

-

Reserved

J2

Reserved

-

Reserved

J18

Reserved

-

Reserved

K1

Reserved

-

Reserved

K3

Reserved

-

Reserved

K17

Reserved

-

Reserved

L2

Reserved

-

Reserved

L18

Reserved

-

Reserved

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 25 of 88

PAD

Signal

I/O

Function

Type

COMMENT

M3

Reserved

-

Reserved

S3

Reserved

-

Reserved

S17

Reserved

-

Reserved

U3

Reserved

-

Reserved

W3

Reserved

-

Reserved

AL2

Reserved

-

Reserved

AM1

Reserved

-

Reserved

AN2

Reserved

-

Reserved

AN4

Reserved

-

Reserved

AN8

Reserved

-

Reserved

AN14

Reserved

-

Reserved

AS3

Reserved

-

Reserved

AT2

Reserved

-

Reserved

B19

Reserved

-

Reserved

AU13

Reserved

-

Reserved

E2

Reserved

-

Reserved

D1

Reserved

-

Reserved

C2

Reserved

-

Reserved

B1

Reserved

-

Reserved

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

NOTE:

When the UART signals are used as the communication port between the Host and the

Modem:

- DTR pin must be connected in order to enter LE920’s power saving mode.

- RI pin must be connected in order to wake the host when a call is coming during sleep

mode of host.

- RTS must be connected to GND (on the module side) if flow control is not used

In case UART port isn’t used, all UART signals may be left disconnected

NOTE:

E8 port – eSIM Reset signal is available for LE920-NA AUTO S model only. For other

models, E8 is internally disconnected.

NOTE:

Unless otherwise specified, RESERVED pins must be left unconnected (Floating).

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 26 of 88

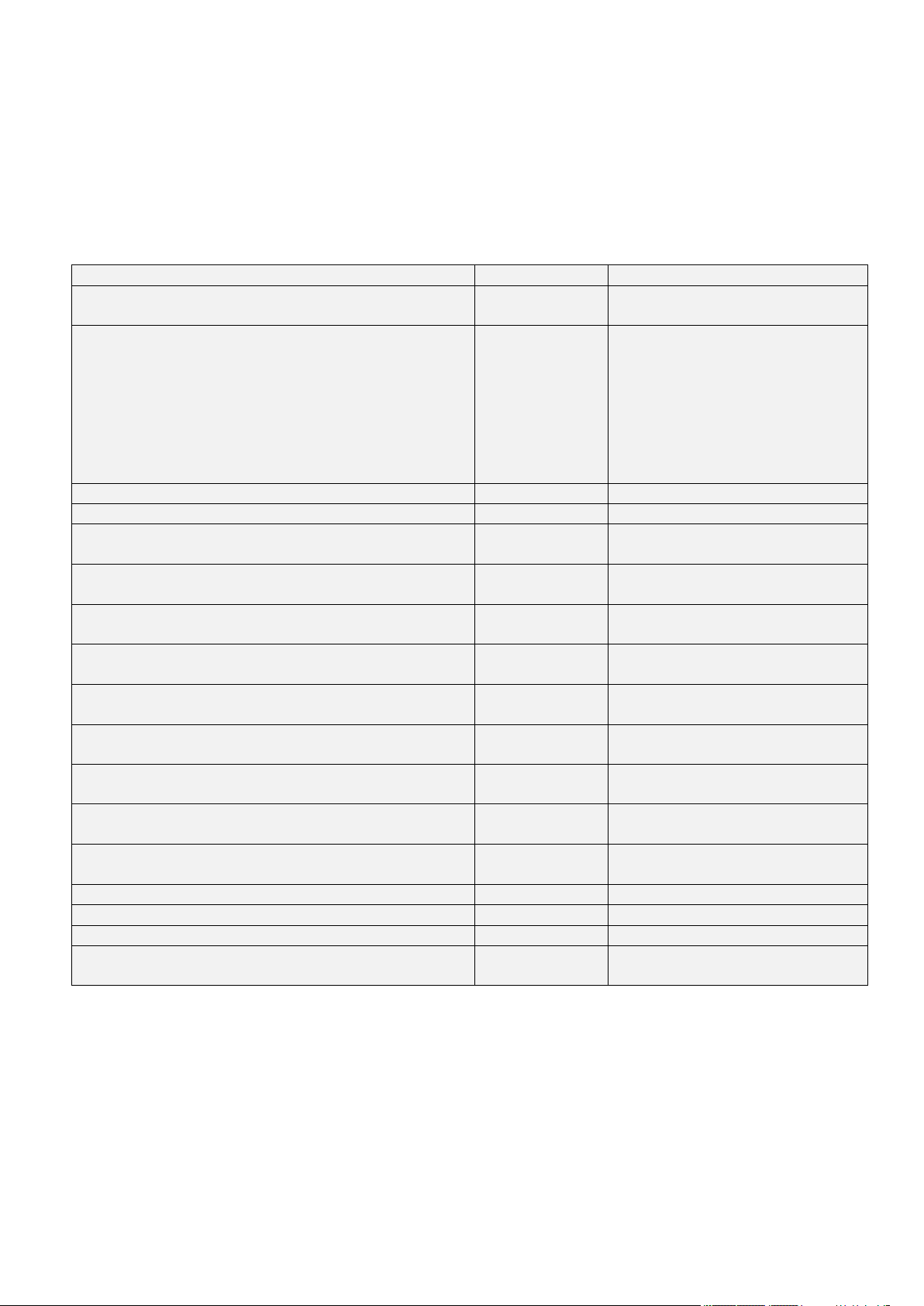

PAD

Signal

Notes

AP17,AP19,AR18,AS17,AS19,AT18,AU17,AU19

VBATT &

VBATT_PA

A6,A12,B13,B15,B17,C4,C6,D3,D7,E18,F1,G18,H19,

M1,N2,P1,P3,R2,T2,T18,U1,V18,W1,X2,X18,Y1,Y19,

AA2,AB1,AC2,AE2,AF1,AG2,AH1,AJ2,AK1,AK17,

AL18,AM17,AM19,AN16,AN18,AP3,AP5,AP7,AP9,

AP11,AP13,AP15,AR2,AR4AR6,AR8,AR10,AR12,

AR14,AR16,AS5,AS7,AS9,AS11,AS13,AS15,AT4,

AT6,AT8,AT10,AT12,AT14,AT16,AU1,AU5,AU7,

AU11,AU15

GND

AS1

ON/OFF*

AN12

SHDN_N

D19

USB_D+

If not used should be connected to

a Test Point or an USB connector

F19

USB_D-

If not used should be connected to

a Test Point or an USB connector

A18

USB_VBUS

If not used should be connected to

a Test Point or an USB connector

AH19

C103/TXD

If not used should be connected to

a Test Point

AF19

C104/RXD

If not used should be connected to

a Test Point

AA18

C105/RTS

If the flow control is not used it

should be connected to GND

AK19

C106/CTS

If not used should be connected to

a Test Point

AB19

TXD_AUX

If not used should be connected to

a Test Point

AD19

RXD_AUX

If not used should be connected to

a Test Point

AD1

Antenna

AU9

ANT_DIV

S1

ANT_GPS

G2, J2, L2, F3, H3, K3, E4, AN14

Reserved

If not used should be connected to

a Test Point

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

The table below specifies the LE920A4 signals that must be connected even if not used by

end application:

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 27 of 88

3.1.1. LGA Pads Layout

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 28 of 88

4. Hardware Commands

4.1. Turning ON the LE920

To turn on LE920, the pad ON# must be tied low for at least 1 second and then released.

The maximum current that can be drained from the ON# pad is 0.1 mA.

A simple circuit to power on the module is illustrated below:

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

4.2. Initialization and Activation state

Upon turning on LE920 module, The LE920 is not activated yet because the boot sequence of

LE920 is still going on internally. It takes about 10 seconds to complete the initializing the

module internally.

For this reason, it would be useless to try to access LE920 during the Initialization state, as

shown below. To reach full stability, The LE920 needs at least 15 seconds after the

PWRMON goes High to become operational by reaching the activation state.

During the Initialization state, any kind of AT-command is not available. DTE must wait for

the Activation state before communicating with LE920.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 29 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

NOTE:

To check if the LE920 has powered on, the hardware line PWRMON must be monitored.

When PWRMON goes high, the module has powered on.

NOTE:

Do not use any pull up resistor on the ON# line, it is internally pulled up. Using pull up

resistor may cause latch-up problems on the LE920 power regulator and improper powering

on/off of the module. The line ON# must be connected only in an open collector

configuration.

NOTE:

In this document all the lines are inverted. Active low signals are labeled with a name that

ends with "#" or with a bar over the name.

NOTE:

In order to avoid a back-powering effect it is recommended to avoid having any HIGH logic

level signal applied to the digital pins of the module when it is powered OFF or during an

ON/OFF transition.

4.3. Turning OFF the LE920

Turning off the device can be done in four different ways:

by Software command AT#SHDN

by Hardware Shutdown using pad ON/OFF#

by Hardware Unconditional Reset using the RESET#

by Hardware Unconditional Shutdown using the SHDN#

When the device is shut down by software command or by hardware shutdown, it issues to

the network a detach request that informs the network that the device will not be reachable

any more.

TIP:

To check if the device has powered off, hardware line PWRMON must be monitored. When

PWRMON goes low it can be considered the device has powered off.

NOTE:

In order to avoid a back-powering effect it is recommended to avoid having any HIGH logic

level signal applied to the digital pins of the module when it is powered OFF or during an

ON/OFF transition.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 30 of 88

1vv0301026 Rev.8 2015-01-03

4.3.1. Shutdown by Software Command

LE920 can be shut down by a software command.

When a shutdown command is sent, LE920 goes into the finalization state and finally will

shut down PWRMON at the end of this state.

The duration of the finalization state can differ according to the situation in which the LE920

is, so a value cannot be defined.

Normally it will be more than15 seconds after sending a shutdown command, DTE should

monitor the status of PWRMON to observe the actual power off.

LE920 Hardware User Guide

TIP:

To check if the device has powered off, hardware line PWRMON must be monitored. When

PWRMON goes low, the device has powered off.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 31 of 88

4.3.2. Hardware Shutdown

To turn OFF LE920 the pad ON/OFF# must be tied low for at least 2 seconds and then

released. The same circuitry and timing for the power on must be used.

When the hold time of ON/OFF# is above 2.5 seconds, LE920 goes into the finalization state

and finally will shut down PWRMON at the end of this state.

The period of the finalization state can differ according to the situation in which the LE920 is,

so it cannot be fixed definitely.

. Normally it will be more than15 seconds after sending a shutdown command ; DTE should

monitor the status of PWRMON to see observe the actual power off.

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

TIP:

To check if the device has powered off, hardware line PWRMON must be monitored. When

PWRMON goes low, the device has powered off.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 32 of 88

NOTE:

Do not use any pull up resistor on the RESET# line or any totem pole digital output. Using

pull up resistor may cause latch-up problems on the LE920 power regulator and improper

functioning of the module. The line RESET# must be connected only in open collector

configuration.

NOTE:

Asserting tRESET low for period greater than 2000 milliseconds will cause the module to

shut down.

TIP:

The unconditional hardware Restart must always be implemented on the boards and the

software must use it only as an emergency exit procedure, and not as a normal power-off

operation

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

4.3.3. Hardware Unconditional Restart (RESET)

To unconditionally restart LE920, the pad RESET# must be tied low for period between 500 2000 milliseconds and then released.

A simple circuit to do it is:

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 33 of 88

NOTE:

Do not use any pull up resistor on the SHDN_N line or any totem pole digital output. Using

pull up resistor may cause latch-up problems on the LE920 power regulator and improper

functioning of the module. The line SHDN_N must be connected only in open collector

configuration.

NOTE:

The unconditional hardware SHDN_N must always be implemented on the boards. The

software must use it as an emergency exit procedure only, and not as a normal power-off

operation.

1vv0301026 Rev.8 2015-01-03

4.3.4. Hardware Unconditional Shutdown

To unconditionally Shutdown LE920, the pad SHDN_N must be tied low for at least 200

milliseconds and then released.

A simple circuit to do it is:

LE920 Hardware User Guide

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 34 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

4.4. Summary of Turning ON and OFF the module

The chart below describes the overall sequences for Turning ON and OFF.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 35 of 88

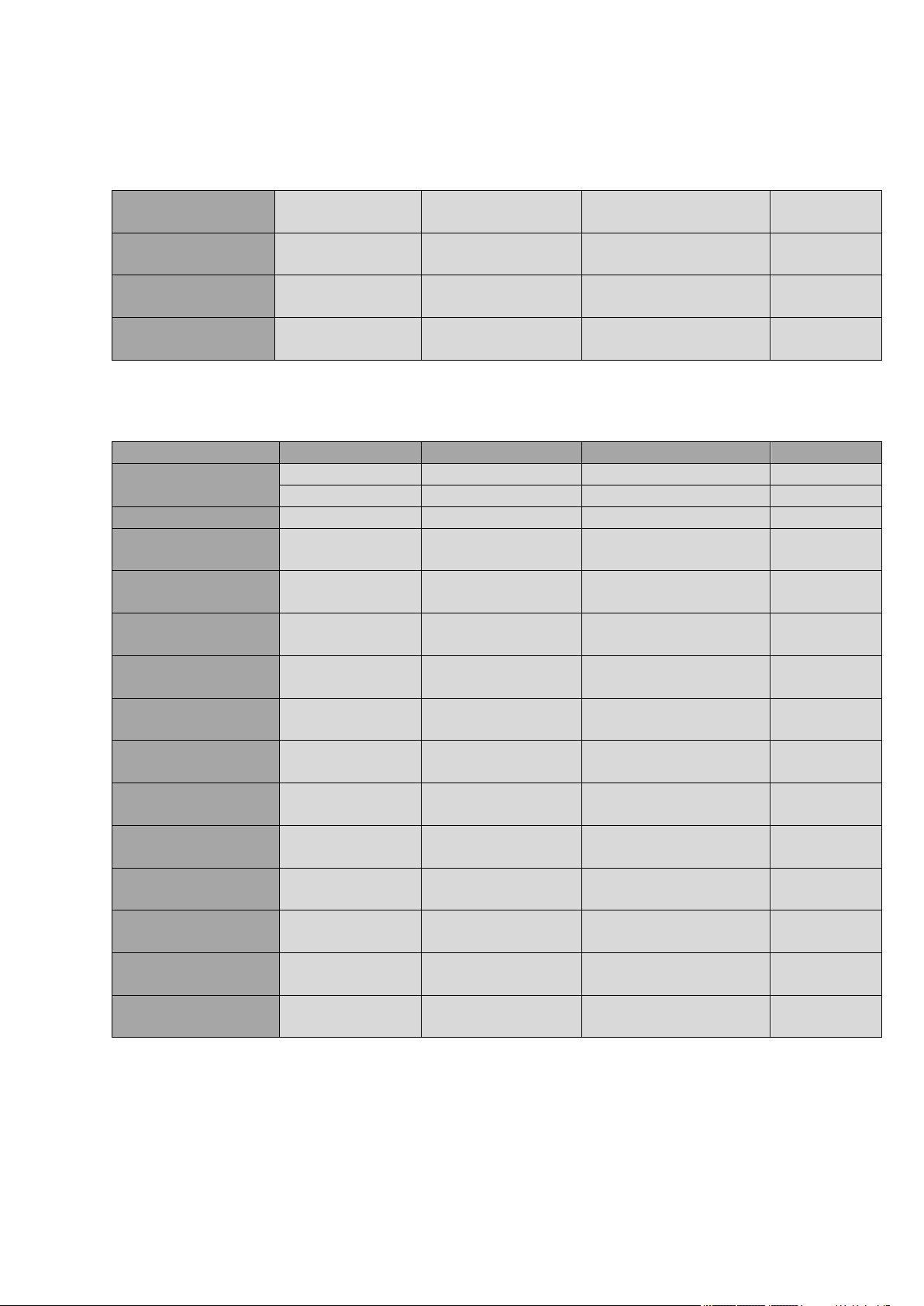

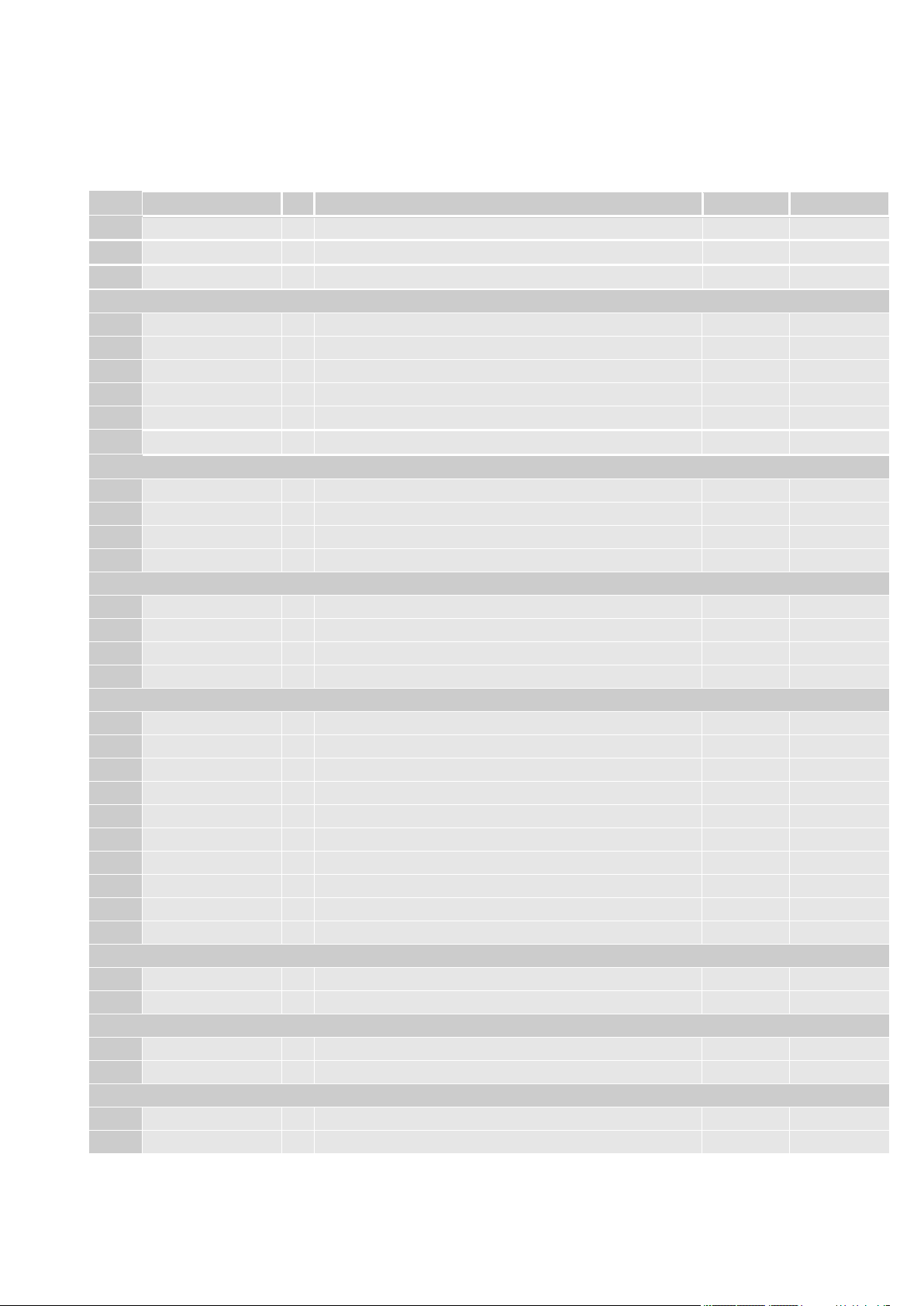

Power Supply

Nominal Supply Voltage

3.8V

Max Supply Voltage

4.2V

Supply Voltage Range

3.3V– 4.2V

LE920 current consumption

Mode

Average(mA)

Mode Description

SWITCHED OFF

Module supplied but switched Off

Switched Off

40 uA

IDLE mode

Standby mode; no call in progress

AT+CFUN=1

WCDMA

16

Normal mode; full functionality of the module

GSM

19

LTE

20

AT+CFUN=4

10

Disabled TX and RX; modules is not registered on the

network

AT+CFUN=5

GSM

4.4

DRx2

3.3

DRx3

2.8

DRx4

2.5

DRx5

2.3

DRx6

2.1

DRx7

2.0

DRx8

1.9

DRx9

WCDMA

3.0

DRx6

2.2

DRx7

1.8

DRx8

1.4

DRx9

LTE

6.3

Paging cycle #32 frames (0.32 sec DRx cycle)

3.8

Paging cycle #64 frames (0.64 sec DRx cycle)

1vv0301026 Rev.8 2015-01-03

5. Power Supply

The power supply circuitry and board layout are a very important part in the full product

design and they strongly reflect on the overall product performance. Reading carefully the

requirements and the guidelines that follow will ensure a good and proper design.

5.1. Power Supply Requirements

The LE920 power requirements are:

LE920 Hardware User Guide

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 36 of 88

2.5

Paging cycle #128 frames (1.28 sec DRx cycle)

1.9

Paging cycle #256 frames (2.56 sec DRx cycle)

Operative mode (LTE)

LTE (0dBm)

203

LTE data call channel BW 5MHz,RB=1, TX = 0dBm)

LTE (22dBm)

540

LTE data call (channel BW 5MHz,RB=1, TX = 22dBm)

Operative mode (WCDMA)

WCDMA Voice

185

WCDMA voice call (TX = 10dBm)

WCDMA HSDPA (0dBm)

170

WCDMA data call (Cat 14, TX = 0dBm, Max Throughput)

WCDMA HSDPA (22dBm)

470

WCDMA data call (Cat 14, TX = 22dBm, Max Throughput)

Operative mode (GSM)

GSM TX and RX mode

GSM900 PL5

290

GSM Voice Call

DCS1800 PL0

170

GPRS 4TX + 1RX

GSM900 PL5

410

GPRS Sending data mode

DCS1800 PL0

320

EDGE 4TX + 1RX

GSM900 PL5

255

EDGE Sending data mode

DCS1800 PL0

240

NOTE:

In GSM/GPRS mode, RF transmission is not continuous and is packed into bursts at a base

frequency of about 216 Hz with relative current peaks as high as about 2A. Therefore the

power supply must be designed to withstand these current peaks without big voltage drops;

this means that both the electrical design and the board layout must be designed for this

current flow. If the layout of the PCB is not well designed, a strong noise floor is generated

on the ground. This will reflect on all the audio paths producing an audible annoying noise at

216 Hz; if the voltage drops during the peaks, current absorption is too high. The device may

even shut down as a consequence of the supply voltage drop.

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

* Worst/best case depends on network configuration and is not under module control.

TIP:

The electrical design for the Power supply must be made ensuring that it will be capable of a

peak current output of at least 2A.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 37 of 88

1vv0301026 Rev.8 2015-01-03

5.2. General Design Rules

The principal guidelines for the Power Supply Design embrace three different design steps:

the electrical design

the thermal design

the PCB layout

5.2.1. Electrical Design Guidelines

The electrical design of the power supply depends strongly on the power source where this

power is drained. We will distinguish them into three categories:

+5V input (typically PC internal regulator output)

+12V input (typically automotive)

battery

LE920 Hardware User Guide

5.2.1.1. + 5V Input Source Power Supply Design Guidelines

The desired output for the power supply is 3.8V, hence there is not a big

difference between the input source and the desired output and a linear regulator

can be used. A switching power supply will not be suitable because of the low

drop-out requirements.

When using a linear regulator, a proper heat sink must be provided in order to

dissipate the power generated.

A Bypass low ESR capacitor of adequate capacity must be provided in order to

cut the current absorption peaks close to LE920, a 100μF tantalum capacitor is

usually suitable (on both VBATT and VBATT_PA together)..

Make sure the low ESR capacitor on the power supply output (usually a tantalum

one) is rated at least 10V.

A protection diode must be inserted close to the power input, in order to protect

LE920 from power polarity inversion.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 38 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

An example of linear regulator with 5V input is:

5.2.1.2. + 12V Input Source Power Supply Design Guidelines

The desired output for the power supply is 3.8V, hence due to the big difference

between the input source and the desired output, a linear regulator is unsuitable

and must not be used. A switching power supply will be preferable because of its

better efficiency especially with the 2A peak current load represented by LE920.

When using a switching regulator, a 500 kHz or more switching frequency

regulator is preferable because of its smaller inductor size and its faster transient

response. This allows the regulator to respond quickly to the current peaks

absorption.

In any case, the frequency and switching design selection is related to the

application to be developed due to the fact the switching frequency could also

generate EMC interference.

For car batteries (lead-acid accumulators) the input voltage can rise up to 15.8V

and this must be kept in mind when choosing components: all components in the

power supply must withstand this voltage.

A bypass low ESR capacitor of adequate capacity must be provided in order to

cut the current absorption peaks. A 100μF tantalum capacitor is usually suitable

(on both VBATT and VBATT_PA together).

Make sure the low ESR capacitor on the power supply output (usually a tantalum

one) is rated at least 10V.

For automotive applications a spike protection diode must be inserted close to the

power input, in order to clean the supply of spikes.

A protection diode must be inserted close to the power input, in order to protect

LE920 from power polarity inversion. This can be the same diode as for spike

protection.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 39 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

An example of switching regulator with 12V input is in the below schematic (it is split in 2

parts):

Switching regulator

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 40 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

5.2.1.3. Battery Source Power Supply Design Guidelines

The desired nominal output for the power supply is 3.8V and the maximum allowed

voltage is 4.2V, hence a single 3.7V Li-Ion cell battery type is suited for supplying

the power to the Telit LE920 module.

NOTE:

Do not use any Ni-Cd, Ni-MH, and Pb battery types directly connected with LE920. Their use

can lead to overvoltage on LE920 and damage it. Use only Li-Ion battery types.

A bypass low ESR capacitor of adequate capacity must be provided in order to

cut the current absorption peaks; a 100μF tantalum capacitor is usually suitable

(on both VBATT and VBATT_PA together).

Make sure the low ESR capacitor (usually a tantalum one) is rated at least 10V.

A protection diode must be inserted close to the power input, in order to protect

LE920 from power polarity inversion. Otherwise the battery connector must be

done in a way to avoid polarity inversions when connecting the battery.

The battery capacity must be at least 900mAh in order to withstand the current

peaks of 2A.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 41 of 88

5.2.2. Thermal Design Guidelines

The thermal design for the power supply heat sink must be done with the following

specifications:

Average current consumption during HSPA transmission @PWR level max in

LE920: 640mA (TBD)

Average current consumption during class12 GPRS transmission @PWR level

max: 680mA (TBD)

Average GPS current during GPS ON (Power Saving disabled) : 65mA (TBD)

NOTE:

The average consumption during transmissions depends on the power level at which the

device is requested to transmit via the network. The average current consumption hence varies

significantly.

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

NOTE:

The thermal design for the Power supply must be made keeping an average consumption at

the max transmitting level during calls of 640mA(HSPA)/680mA(GPRS) rms plus 65mA rms

for GPS in tracking mode.

Considering the very low current during idle, especially if Power Saving function is enabled,

it is possible to consider from the thermal point of view that the device absorbs significant

current only during calls.

If we assume that the device stays in transmission for short periods of time (let us say few

minutes) and then remains for quite a long time in idle (let us say one hour), then the power

supply always has time to cool down between calls and the heat sink could be smaller than the

calculated for 640mA (HSPA)/680mA (GPRS) maximum RMS current. There could even be

a simple chip package (no heat sink).

Moreover in average network conditions the device is requested to transmit at a lower power

level than the maximum and hence the current consumption will be less than 640mA (HSPA)

/680mA (GPRS) (being usually around 250mA).

For these reasons the thermal design is rarely a concern and the simple ground plane where

the power supply chip is placed can be enough to ensure a good thermal condition and avoid

overheating.

For the heat generated by the LE920, you can consider it to be during transmission 2W max

during class12 GPRS upload. This generated heat will be mostly conducted to the ground

plane under the LE920; you must ensure that your application can dissipate heat.

In the WCDMA/HSPA mode, since LE920 emits RF signals continuously during

transmission, you must pay special attention how to dissipate the heat generated.

The current consumption will be up to about 640mA in HSPA (630mA in WCDMA)

continuously at the maximum TX output power (23dBm). Thus you must arrange on the PCB

used to mount LE920, that the area under LE920 is as large as possible. You must mount

LE920 on the large ground area of your application board and make many ground vias to

dissipate the heat.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 42 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Even though peak current consumption in GSM mode is higher than in WCDMA,

consideration for the heat sink is more important in the case of WCDMA.

As mentioned before, a GSM signal is bursty, thus, the temperature drift is more insensitive

than WCDMA. Consequently, if you successfully manage heat dissipation in WCDMA mode,

you don’t need to think more about GSM mode.

5.2.3. Power Supply PCB Layout Guidelines

As seen in the electrical design guidelines, the power supply must have a low ESR capacitor

on the output to cut the current peaks and a protection diode on the input to protect the supply

from spikes and polarity inversion. The placement of these components is crucial for the

correct working of the circuitry. A misplaced component can be useless or can even decrease

the power supply performances.

The bypass low ESR capacitor must be placed close to the Telit LE920 power

input pads, or in the case the power supply is a switching type, it can be placed

close to the inductor to cut the ripple as long as the PCB trace from the capacitor

to LE920 is wide enough to ensure a drop-less connection even during the 2A

current peaks.

The protection diode must be placed close to the input connector where the power

source is drained.

The PCB traces from the input connector to the power regulator IC must be wide

enough to ensure no voltage drops occur during the 2A current peaks. Note that

this is not done to save power loss but especially to avoid the voltage drops on the

power line at the current peaks frequency of 216 Hz that will reflect on all the

components connected to that supply (also introducing the noise floor at the burst

base frequency.) For this reason while a voltage drop of 300-400 mV may be

acceptable from the power loss point of view, the same voltage drop may not be

acceptable from the noise point of view. If your application does not have audio

interface but only uses the data feature of the Telit LE920, then this noise is not

so disturbing and power supply layout design can be more forgiving.

The PCB traces to LE920 and the bypass capacitor must be wide enough to

ensure no significant voltage drops occur when the 2A current peaks are

absorbed. This is needed for the same above-mentioned reasons. Try to keep this

trace as short as possible.

The PCB traces connecting the switching output to the inductor and the switching

diode must be kept as short as possible by placing the inductor and the diode very

close to the power switching IC (only for switching power supply). This is done

in order to reduce the radiated field (noise) at the switching frequency (usually

100-500 kHz).

The use of a good common ground plane is suggested.

The placement of the power supply on the board must be done in a way to

guarantee that the high current return paths in the ground plane are not

overlapping any noise sensitive circuitry such as the microphone amplifier/buffer

or earphone amplifier.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 43 of 88

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

The power supply input cables must be kept separate from noise sensitive lines

such as microphone/earphone cables.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 44 of 88

Antenna Line on PCB Requirements

GSM / WCDMA/ LTE Antenna Requirements

Frequency

range

Depending on frequency band(s) provided by the network operator, the customer must use the most suitable antenna for

that/those band(s)

Bandwidth

LE920-EU

LE920-NAG

LE920-NA

GSM850 : 70 MHz

GSM900 : 80 MHz

GSM1800(DCS) : 170 MHz

GSM1900(PCS) : 140 MHz

WCDMA band I(2100) : 250 MHz

WCDMA band III(1800) : 170 MHz

WCDMA band VIII(900) : 80 MHz

LTE Band I(2100) : 250 MHz

LTE band III(1800) : 170 MHz

LTE Band VII(2600) : 190 MHz

LTE Band VIII(900) : 80 MHz

LTE Band XX(800) : 71 MHz

GSM850 : 70 MHz

GSM900 : 80 MHz

GSM1800(DCS) : 170 MHz

GSM1900(PCS) : 140 MHz

WCDMA band I(2100) : 250 MHz

WCDMA band II(1900) : 140 MHz

WCDMA band IV(1700) : 445 MHz

WCDMA band V(850) : 70 MHz

WDCMA band VI(800): 70MHz

LTE Band I(2100) : 250 MHz

LTE Band II(1900) : 140 MHz

LTE Band IV(1700) : 445 MHz

LTE Band V (850) : 70 MHz

LTE Band XVII(700) : 42 MHz

GSM850 : 70 MHz

GSM1900(PCS) : 140 MHz

WCDMA band II(1900) : 140 MHz

WCDMA band IV(1700) : 445 MHz

WCDMA band V(850) : 70 MHz

LTE Band II(1900) : 140 MHz

LTE Band IV(1700) : 445 MHz

LTE Band V (850) : 70 MHz

LTE Band VII(2600) : 190 MHz

LTE Band XVII(700) : 42 MHz

LTE Band XII(700) : 42 MHz

Gain

Gain < 3dBi

Impedance

50 Ohm

Input power

> 33dBm(2 W) peak power in GSM

> 24dBm Average power in WCDMA & LTE

VSWR

absolute max

<= 10:1

VSWR

recommended

<= 2:1

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

6. Antenna(s)

The antenna connection and board layout design are the most important parts in the full

product design and they strongly reflect on the product’s overall performance. Read carefully

and follow the requirements and the guidelines for a good and proper design.

6.1. GSM/WCDMA/LTE Antenna Requirements

The antenna for a Telit LE920 device must fulfill the following requirements:

When using the Telit LE920, since there’s no antenna connector on the module, the antenna

must be connected to the LE920 antenna pad (AD1) by means of a transmission line

implemented on the PCB.

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 45 of 88

In the case that the antenna is not directly connected to the antenna pad of the LE920, then a

PCB line is required in order to connect with it or with its connector.

This transmission line shall fulfill the following requirements:

Characteristic Impedance

50Ohm

Max Attenuation

0.3dB

Coupling with other signals shall be avoided

Cold End (Ground Plane) of antenna shall be equipotential to the LE920 ground pads

LE920 Hardware User Guide

1vv0301026 Rev.8 2015-01-03

Furthermore if the device is developed for the US and/or Canada market, it must comply with

the FCC and/or IC approval requirements:

This device is to be used only for mobile and fixed application. The antenna(s) used for this

transmitter must be installed to provide a separation distance of at least 20 cm from all

persons and must not be co-located or operating in conjunction with any other antenna or

transmitter. End-Users must be provided with transmitter operation conditions for satisfying

RF exposure compliance. OEM integrators must ensure that the end user has no manual

instructions to remove or install the LE920 module. Antennas used for this OEM module must

not exceed 3dBi gain for mobile and fixed operating configurations.

6.2. GSM/WCDMA/LTE Antenna – PCB line Guidelines

Make sure that the transmission line’s characteristic impedance is 50ohm.