Page 1

GC864 Hardware User Guide

GC864-PY, GC864-QUAD

1vv0300733 Rev. 0 - 12/06/06

Page 2

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

Contents

1 Overview ...........................................................................................................................4

2 Hardware Commands ......................................................................................................5

2.1 Turning ON the GC864 ...........................................................................................................5

2.2 Turning OFF the GC864 ........................................................................................................7

2.2.1 Hardware shutdown..........................................................................................................................7

2.3 Hardware Unconditional Reboot...........................................................................................7

3 Power Supply ...................................................................................................................9

3.1 Power Supply Requirements.................................................................................................9

3.2 General Design Rules ..........................................................................................................10

3.2.1 Electrical design Guidelines........................................................................................................... 10

3.2.1.1 + 5V input Source Power Supply Design Guidelines ................................................................ 10

3.2.1.2 + 12V input Source Power Supply Design Guidelines .............................................................. 12

3.2.1.3 Battery Source Power Supply Design Guidelines ..................................................................... 13

3.2.1.4 Battery Charge control Circuitry Design Guidelines .................................................................. 13

3.2.2 Thermal Design Guidelines ........................................................................................................... 15

3.2.3 Power Supply PCB layout Guidelines ........................................................................................... 16

4 Antenna...........................................................................................................................17

4.1 Antenna Requirements ........................................................................................................17

4.2 GC864 Antenna Connector..................................................................................................17

4.3 Antenna installation Guidelines..........................................................................................18

5 GC864 pins allocation....................................................................................................19

NOTE: RESERVED pins must not be connected.......................................................................... 21

6 Serial Port .......................................................................................................................22

6.1 RS232 level translation ........................................................................................................24

6.2 5V UART level translation....................................................................................................26

7 Audio Section Overview ................................................................................................28

7.1 Microphone paths characteristic and requirements .........................................................30

7.2 General Design Rules ..........................................................................................................33

7.3 Other considerations. ..........................................................................................................33

7.4 Microphone Biasing .............................................................................................................34

7.4.1 Balanced Microphone biasing........................................................................................................ 34

7.4.2 Unbalanced Microphone biasing ...................................................................................................35

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 2 of 68

Page 3

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

7.5 Microphone buffering...........................................................................................................37

7.5.1 Buffered Balanced Mic................................................................................................................... 37

7.5.2 Buffered Unbalanced (Single Ended) Microphone . ...................................................................... 39

8 OUTPUT LINES (Speaker)..............................................................................................42

8.1 Short description..................................................................................................................42

8.2 Output lines characteristics . .............................................................................................43

8.3 General Design rules............................................................................................................44

8.3.1 Noise Filtering................................................................................................................................ 44

8.4 Handset earphone design.................................................................................................... 45

8.5 Hands-free earphone (low power) design ..........................................................................46

8.6 Car Kit speakerphone design..............................................................................................47

9 External SIM Holder .......................................................................................................48

9.1 SIM DESIGN GUIDES............................................................................................................ 48

10 General Purpose I/O.......................................................................................................50

10.1 Using a GPIO pad as INPUT.............................................................................................50

10.2 Using a GPIO pad as OUTPUT.........................................................................................50

10.3 Using the Alarm Output GPIO_06/ALARM......................................................................51

10.4 Using the Buzzer Output GPIO_07/BUZZER...................................................................51

11 Camera ............................................................................................................................52

11.1 Camera characteristics ....................................................................................................52

11.1.1 Camera interface connectors......................................................................................................... 52

11.1.2............................................................................................................................................................. 53

11.1.3............................................................................................................................................................. 53

11.1.4............................................................................................................................................................. 53

11.1.5 EVB for Transchip camera support ............................................................................................... 54

11.1.6 Example usage script for camera .................................................................................................. 55

12 Conformity Assessment Issues....................................................................................56

13 SAFETY RECOMMANDATIONS.....................................................................................57

14 Document Change Log ..................................................................................................58

Annex A – EVK2 schematics ...............................................................................................59

Annex B - Camera EVB schematics ....................................................................................65

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 3 of 68

Page 4

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

1 Overview

The aim of this document is the description of some hardware solutions useful for developing a product with the

Telit GC864 module.

In this document all the basic functions of a mobile phone will be taken into account; for each one of them a

proper hardware solution will be suggested and eventually the wrong solutions and common errors to be

avoided will be evidenced. Obviously this document can not embrace the whole hardware solutions and

products that may be designed. The wrong solutions to be avoided shall be considered as mandatory, while the

suggested hardware configurations shall not be considered mandatory, instead the information given shall be

used as a guide and a starting point for properly developing your product with the Telit GC864 module. For

further hardware details that may not be explained in this document refer to the Telit GC864 Product Description

document where all the hardware information is reported.

NOTICE

(EN) The integration of the GC864 GSM/GPRS cellular module within user application shall be

done according to the design rules described in this manual.

(IT) L’integrazione del modulo cellulare GSM/GPRS GC864 all’interno dell’applicazione

dell’utente dovrà rispettare le indicazioni progettuali descritte in questo manuale.

(DE) Die Integration des GC864 GSM/GPRS Mobilfunk-Moduls in ein Gerät muß gemäß der in

diesem Dokument beschriebenen Konstruktionsregeln erfolgen

(SL) Integracija GSM/GPRS GC864 modula v uporabniški aplikaciji bo morala upoštevati

projektna navodila, opisana v tem priročniku.

(SP) La utilización del modulo GSM/GPRS GC864 debe ser conforme a los usos para los

cuales ha sido diseñado descritos en este manual del usuario

(FR) L'intégration du module cellulaire GC864 GSM/GPRS dans l'application de l'utilisateur

sera faite selon les règles de conception décrites dans ce manuel

(HE)

The information presented in this document is believed to be accurate and reliable. However, Telit

Communication assumes no responsibility for its use, nor any infringement of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent rights of

Telit Communication other than for circuitry embodied in Telit products. This document is subject to change

without notice.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 4 of 68

Page 5

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

2 Hardware Commands

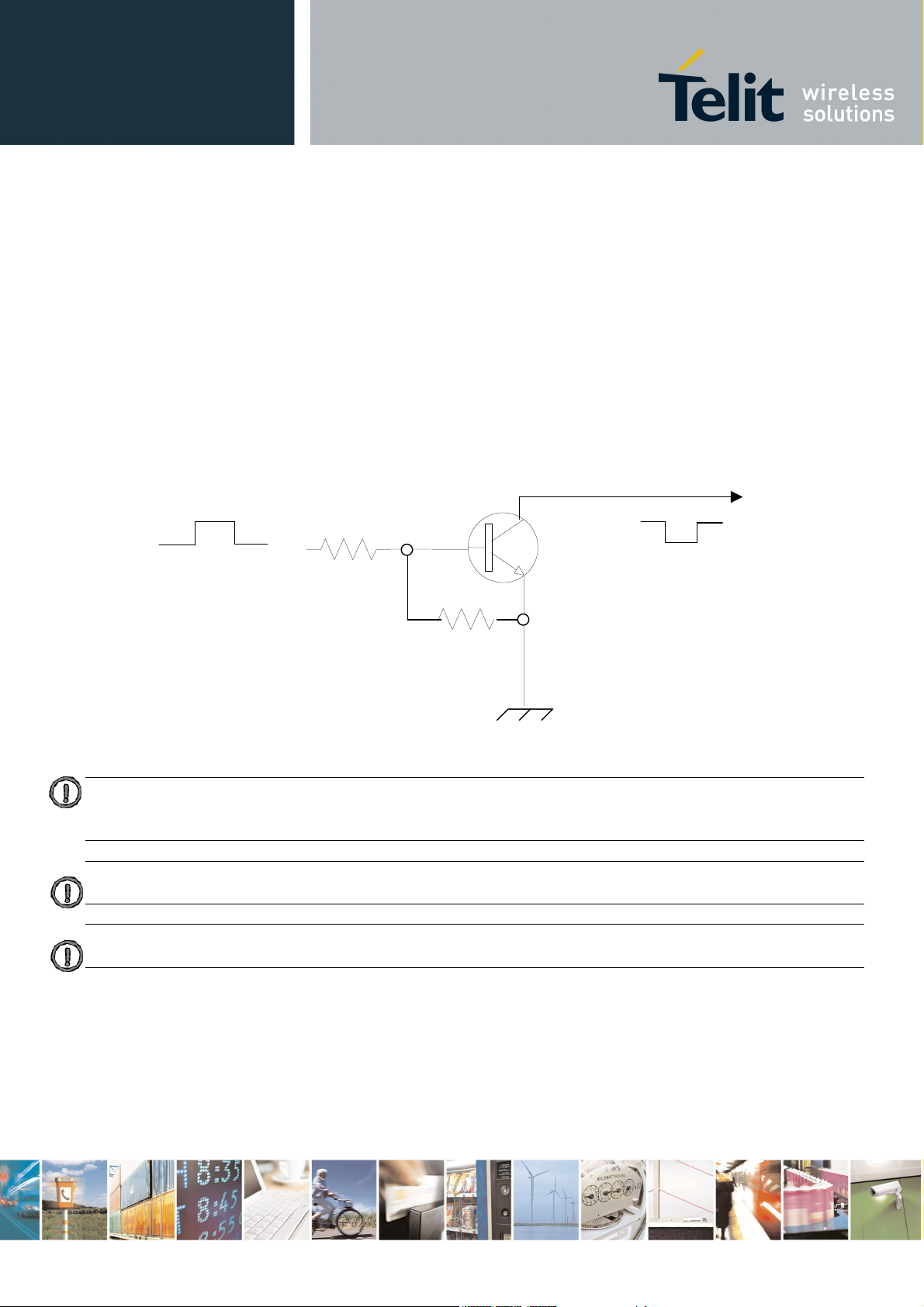

2.1 Turning ON the GC864

To turn on the GC864 the pad ON# must be tied low for at least 1 second and then released.

The maximum current that can be drained from the ON# pad is 0,1 mA.

A simple circuit to do it is:

ON#

R1

Q1

Power ON impulse

R2

GND

NOTE: don't use any pull up resistor on the ON# line, it is internally pulled up. Using pull up

resistor may bring to latch up problems on the GC864 power regulator and improper power

on/off of the module. The line ON# must be connected only in open collector configuration.

NOTE: In this document all the lines that are inverted, hence have active low signals are

labeled with a name that ends with a "#" or with a bar over the name.

NOTE: The GC864 turns fully on also by supplying power to the Charge pad (provided there's

a battery on the VBATT pads).

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 5 of 68

Page 6

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

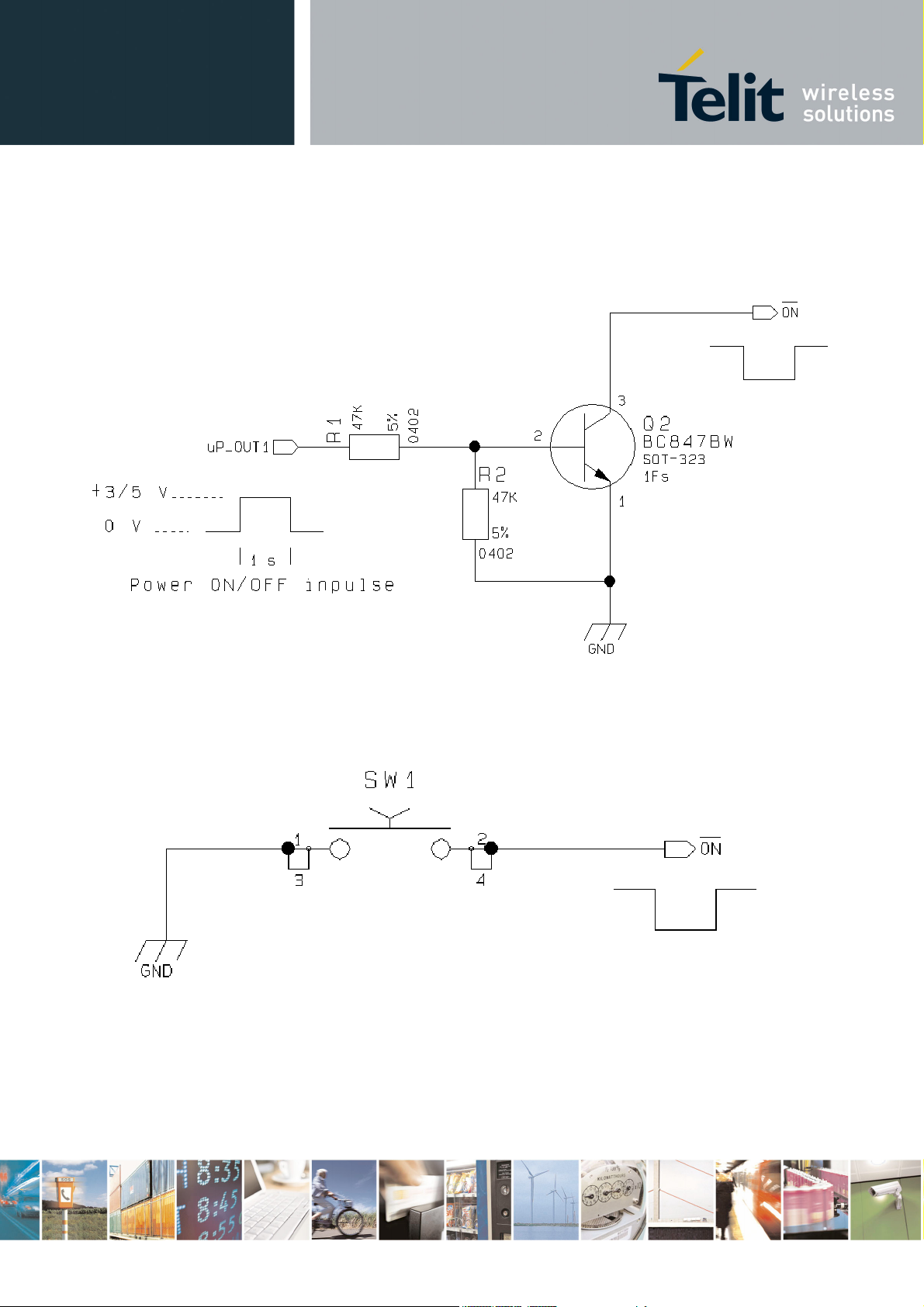

For example:

1- Let's assume you need to drive the ON# pad with a totem pole output of a +3/5 V microcontroller

(uP_OUT1):

2- Let's assume you need to drive the ON# pad directly with an ON/OFF button:

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 6 of 68

Page 7

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

2.2 Turning OFF the GC864

The turning off of the device can be done in three ways:

• by software command (see GC864 Software User Guide)

• by hardware shutdown

When the device is shut down by software command or by hardware shutdown, it issues to the

network a detach request that informs the network that the device will not be reachable any more.

2.2.1 Hardware shutdown

To turn OFF the GC864 the pad ON# must be tied low for at least 1 second and then released.

The same circuitry and timing for the power on shall be used.

The device shuts down after the release of the ON# pad.

TIP: To check if the device has powered off, the hardware line PWRCTL should be monitored.

When PWRCTL goes low, the device has powered off.

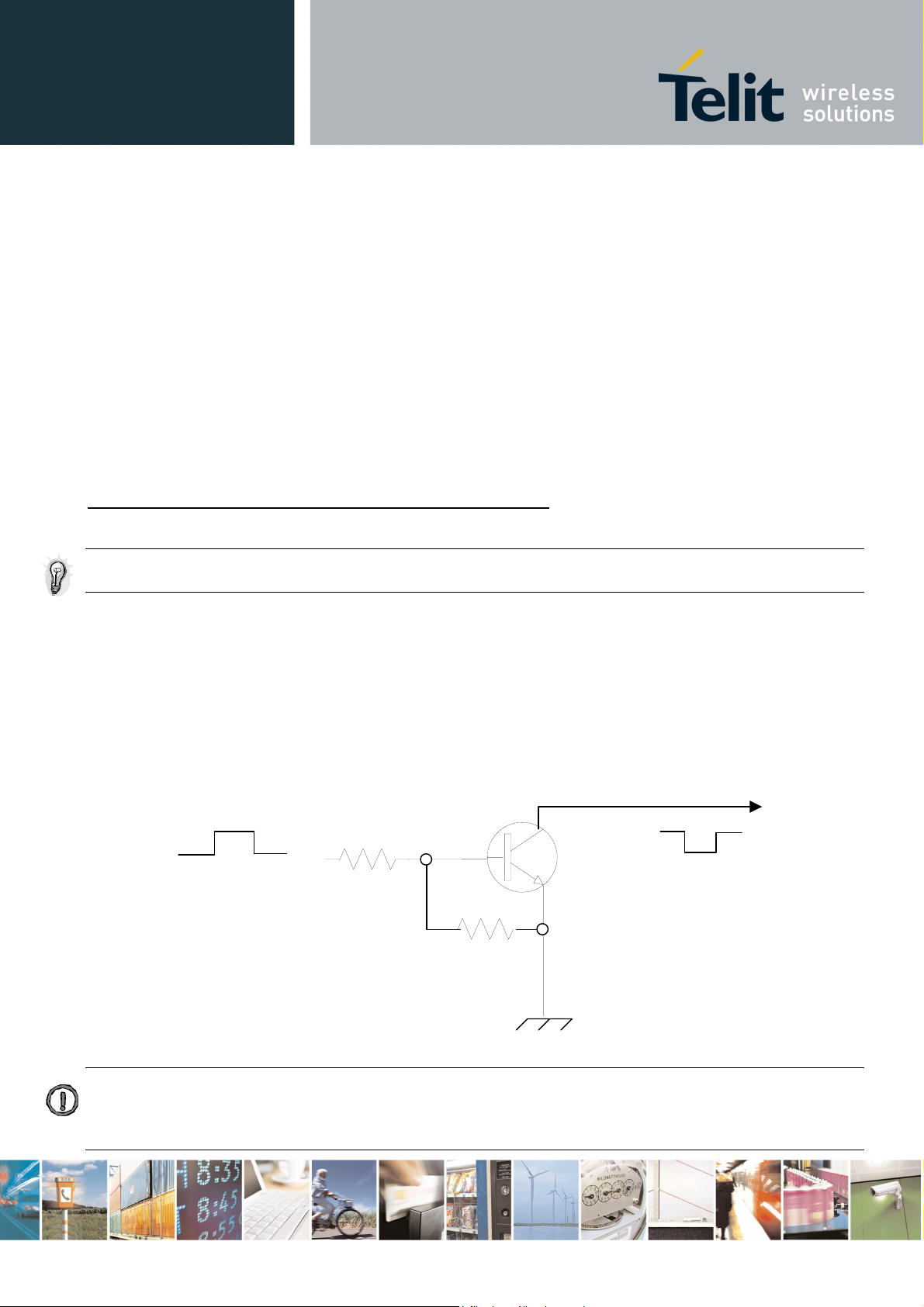

2.3 Hardware Unconditional Reboot

To unconditionally Reboot the GC864, the pad RESET# must be tied low for at least 200 milliseconds

and then released.

The maximum current that can be drained from the ON# pad is 0,15 mA.

A simple circuit to do it is:

NOTE: don't use any pull up resistor on the RESET# line nor any totem pole digital output.

Using pull up resistor may bring to latch up problems on the GC864 power regulator and

improper functioning of the module. The line RESET# must be connected only in open

collector configuration.

Unconditional Reboot

impulse

GND

RESET#

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 7 of 68

Page 8

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

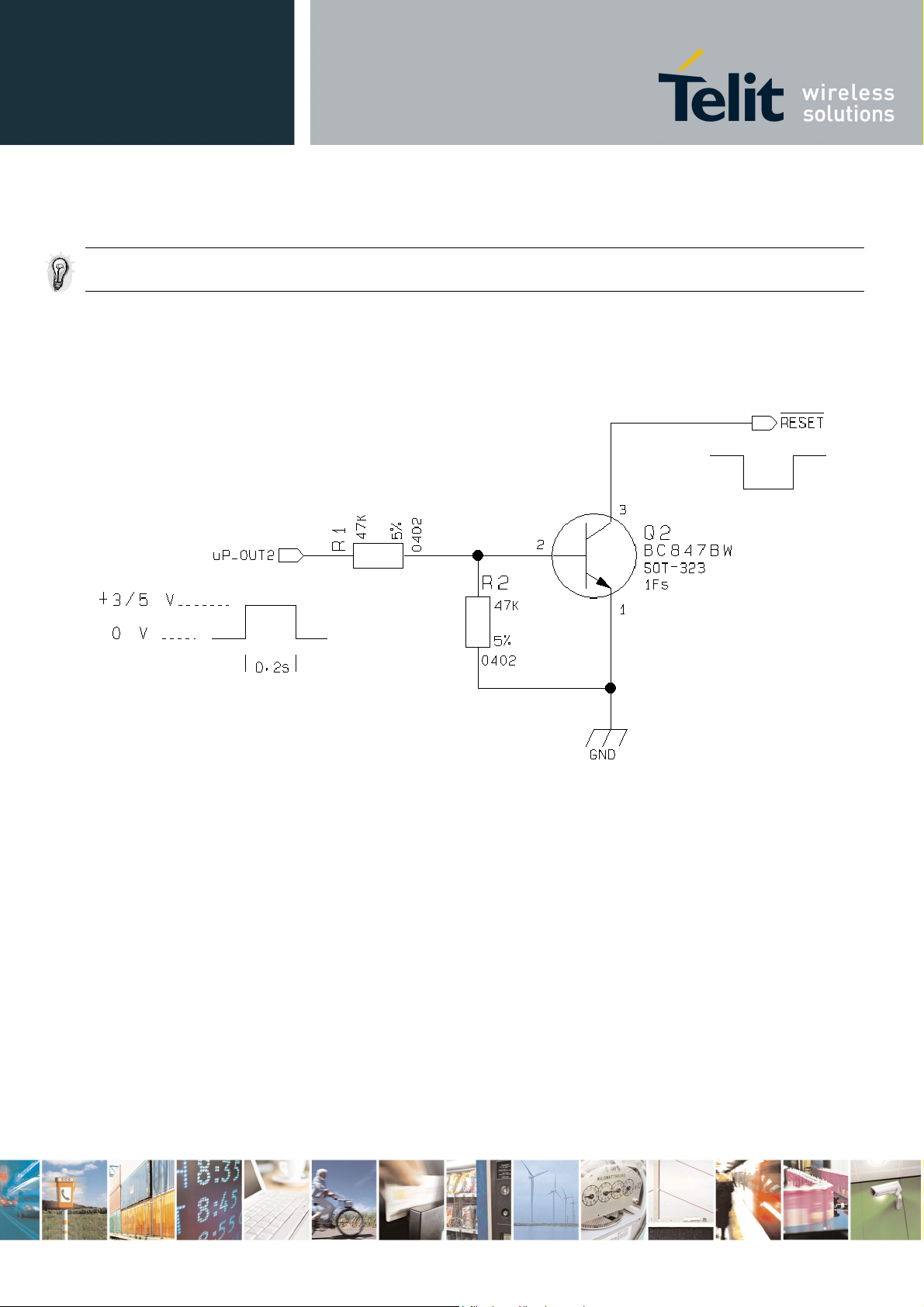

TIP: The unconditional hardware reboot should be always implemented on the boards and

software should use it as an emergency exit procedure.

For example:

1- Let's assume you need to drive the RESET# pad with a totem pole output of a +3/5 V

microcontroller (uP_OUT2):

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 8 of 68

Page 9

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

3 Power Supply

The power supply circuitry and board layout are a very important part in the full product design and

they strongly reflect on the product overall performances, hence read carefully the requirements and

the guidelines that will follow for a proper design.

3.1 Power Supply Requirements

The GC864 power requirements are:

• Nominal Supply Voltage: 3.8 V

• Max Supply Voltage: 4.2 V

• Supply voltage range: 3.4 V - 4.2 V

• Max Peak current consumption (impulsive): 1.9 A

• Max Average current consumption during GPRS transmission (rms): 500 mA

• Max Average current consumption during VOICE/CSD transmission (rms): 270 mA

• Average current during Power Saving: ≈ 4 mA

• Average current during idle (Power Saving disabled) ≈ 19 mA

The GSM system is made in a way that the RF transmission is not continuous, else it is packed into

bursts at a base frequency of about 216 Hz, the relative current peaks can be as high as about 2A.

Therefore the power supply has to be designed in order to withstand with these current peaks without

big voltage drops; this means that both the electrical design and the board layout must be designed for

this current flow.

If the layout of the PCB is not well designed a strong noise floor is generated on the ground and the

supply; this will reflect on all the audio paths producing an audible annoying noise at 216 Hz; if the

voltage drop during the peak current absorption is too much, then the device may even shutdown as a

consequence of the supply voltage drop.

TIP: The electrical design for the Power supply should be made ensuring it will be capable of a

peak current output of at least 2 A.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 9 of 68

Page 10

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

3.2 General Design Rules

The principal guidelines for the Power Supply Design embrace three different design steps:

- the electrical design

- the thermal design.

- the PCB layout.

3.2.1 Electrical design Guidelines

The electrical design of the power supply depends strongly from the power source where this power is

drained. We will distinguish them into three categories:

• +5V input (typically PC internal regulator output)

• +12V input (typically automotive)

• Battery

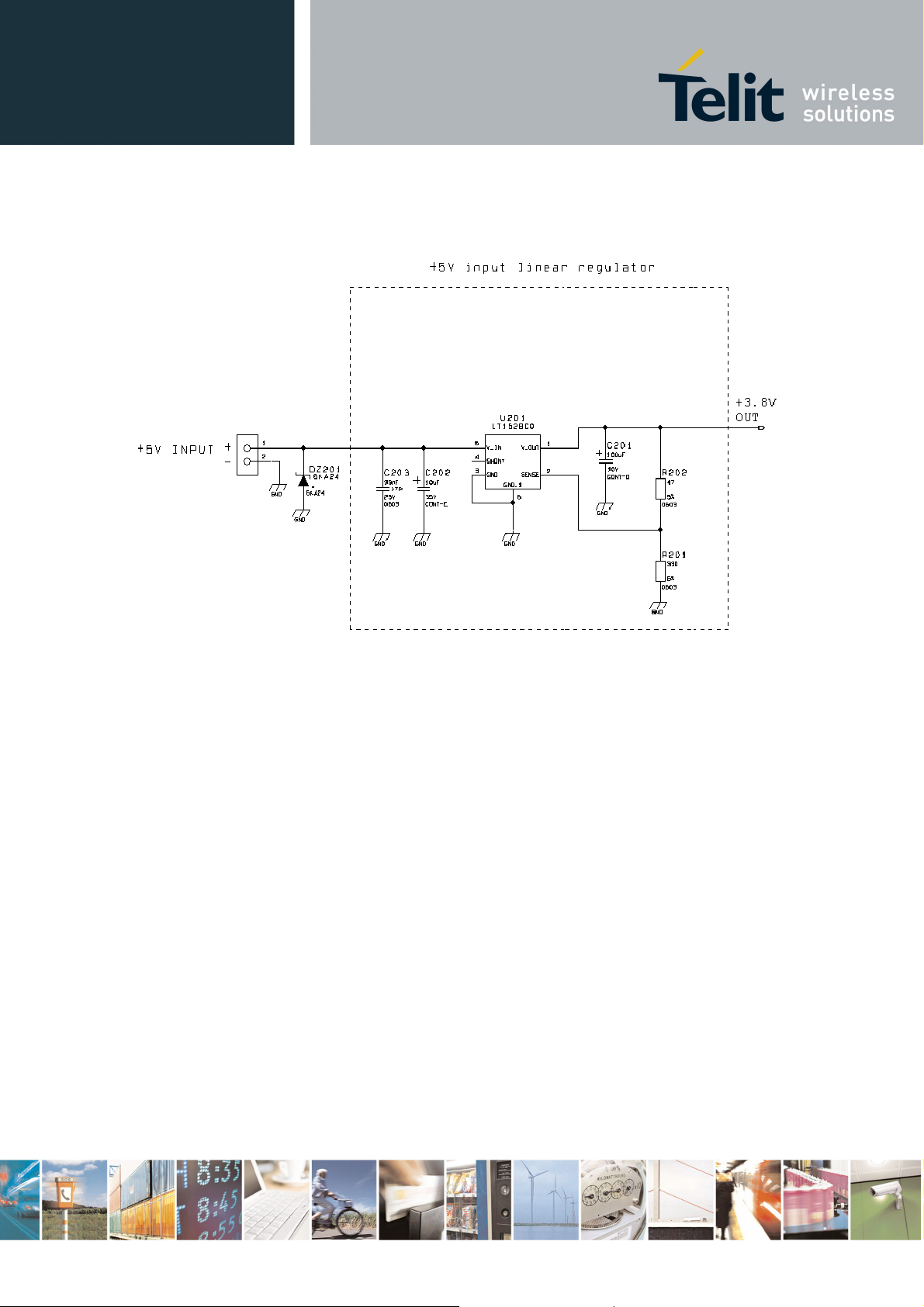

3.2.1.1 + 5V input Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence there's not a big difference between the

input source and the desired output and a linear regulator can be used. A switching power supply

will not be suited because of the low drop out requirements.

• When using a linear regulator, a proper heat sink shall be provided in order to dissipate the power

generated.

• A Bypass low ESR capacitor of adequate capacity must be provided in order to cut the current

absorption peaks close to the GC864, a 100μF tantalum capacitor is usually suited.

• Make sure the low ESR capacitor on the power supply output (usually a tantalum one) is rated at

least 10V.

• A protection diode should be inserted close to the power input, in order to save the GC864 from

power polarity inversion.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 10 of 68

Page 11

An example of linear regulator with 5V input is:

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 11 of 68

Page 12

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

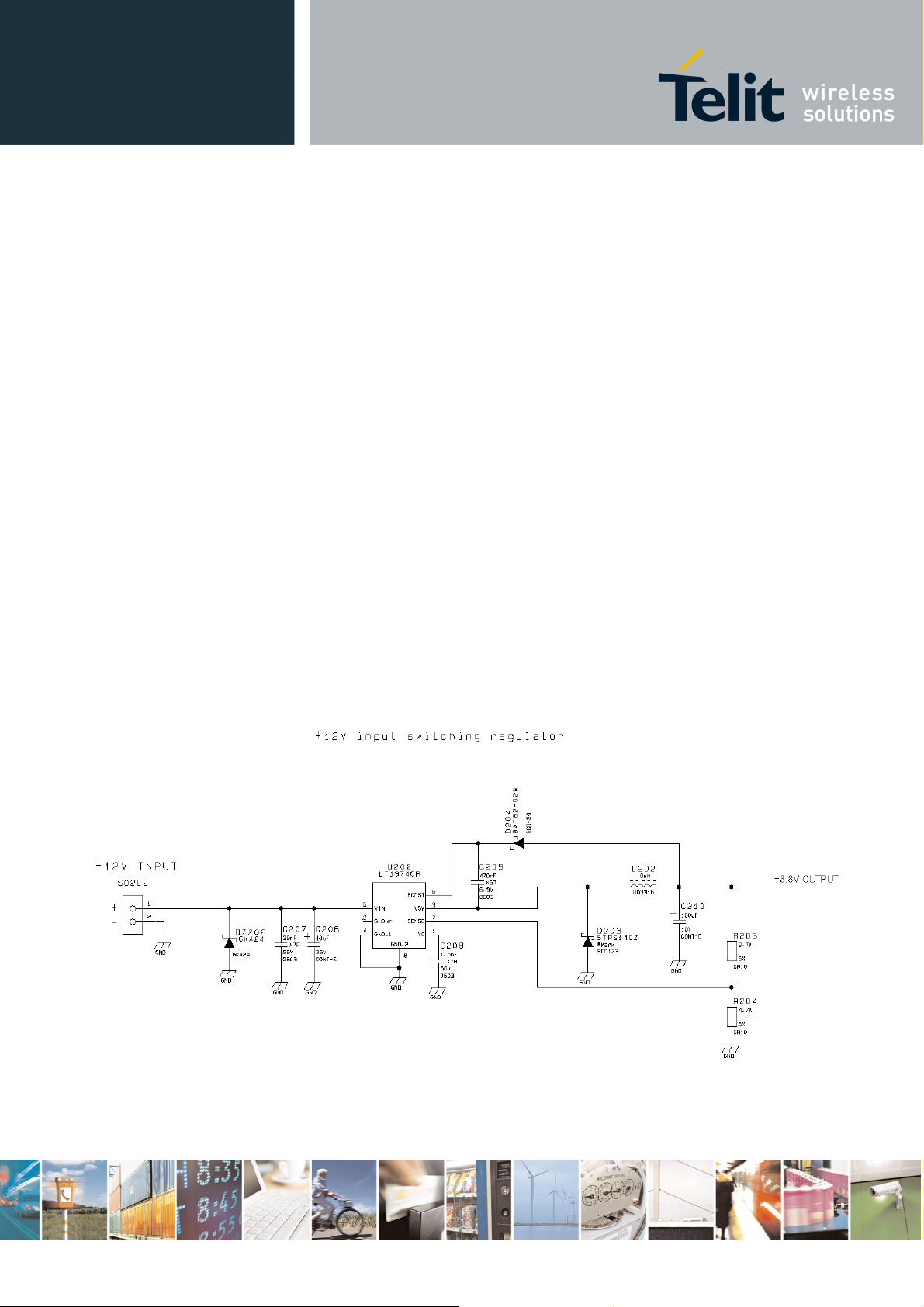

3.2.1.2 + 12V input Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence due to the big difference between the input

source and the desired output, a linear regulator is not suited and shall not be used. A switching

power supply will be preferable because of its better efficiency especially with the 2A peak current

load represented by the GC864.

• When using a switching regulator, a 500kHz or more switching frequency regulator is preferable

because of its smaller inductor size and its faster transient response. This allows the regulator to

respond quickly to the current peaks absorption.

• For car PB battery the input voltage can rise up to 15,8V and this should be kept in mind when

choosing components: all components in the power supply must withstand this voltage.

• A Bypass low ESR capacitor of adequate capacity must be provided in order to cut the current

absorption peaks, a 100μF tantalum capacitor is usually suited.

• Make sure the low ESR capacitor on the power supply output (usually a tantalum one) is rated at

least 10V.

• For Car applications a spike protection diode should be inserted close to the power input, in order

to clean the supply from spikes.

• A protection diode should be inserted close to the power input, in order to save the GC864 from

power polarity inversion. This can be the same diode as for spike protection.

An example of switching regulator with 12V input is:

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 12 of 68

Page 13

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

3.2.1.3 Battery Source Power Supply Design Guidelines

• The desired nominal output for the power supply is 3.8V and the maximum voltage allowed is

4.2V, hence a single 3.7V Li-Ion cell battery type is suited for supplying the power to the Telit

GC864 module.

The three cells Ni/Cd or Ni/MH 3,6 V Nom. battery types or 4V PB types MUST NOT BE USED

DIRECTLY since their maximum voltage can rise over the absolute maximum voltage for the

GC864 and damage it.

NOTE: DON'T USE any Ni-Cd, Ni-MH, and Pb battery types directly connected with GC864.

Their use can lead to overvoltage on the GC864 and damage it. USE ONLY Li-Ion battery types.

• A Bypass low ESR capacitor of adequate capacity must be provided in order to cut the current

absorption peaks, a 100μF tantalum capacitor is usually suited.

• Make sure the low ESR capacitor (usually a tantalum one) is rated at least 10V.

• A protection diode should be inserted close to the power input, in order to save the GC864 from

power polarity inversion. Otherwise the battery connector should be done in a way to avoid polarity

inversions when connecting the battery.

• The battery capacity must be at least 500mAh in order to withstand the current peaks of 2A; the

suggested capacity is from 500mAh to 1000mAh.

3.2.1.4 Battery Charge control Circuitry Design Guidelines

The charging process for Li-Ion Batteries can be divided into 4 phases:

• Qualification and trickle charging

• Fast charge 1 - constant current

• Final charge - constant voltage or pulsed charging

• Maintenance charge

The qualification process consists in a battery voltage measure, indicating roughly its charge status. If

the battery is deeply discharged, that means its voltage is lower than the trickle charging threshold,

then the charge must start slowly possibly with a current limited pre-charging process where the

current is kept very low with respect to the fast charge value: the trickle charging.

During the trickle charging the voltage across the battery terminals rises; when it reaches the fast

charge threshold level the charging process goes into fast charge phase.

During the fast charge phase the process proceeds with a current limited charging; this current limit

depends on the required time for the complete charge and from the battery pack capacity. During this

phase the voltage across the battery terminals still raises but at a lower rate.

Once the battery voltage reaches its maximum voltage then the process goes into its third state: Final

charging. The voltage measure to change the process status into final charge is very important. It

must be ensured that the maximum battery voltage is never exceeded, otherwise the battery may be

damaged and even explode. Moreover for the constant voltage final chargers, the constant voltage

phase (final charge) must not start before the battery voltage has reached its maximum value,

otherwise the battery capacity will be highly reduced.

The final charge can be of two different types: constant voltage or pulsed. GC864 uses constant

voltage.

The constant voltage charge proceeds with a fixed voltage regulator (very accurately set to the

maximum battery voltage) and hence the current will decrease while the battery is becoming charged.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 13 of 68

Page 14

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

When the charging current falls below a certain fraction of the fast charge current value, then the

battery is considered fully charged, the final charge stops and eventually starts the maintenance.

The pulsed charge process has no voltage regulation, instead the charge continues with pulses.

Usually the pulse charge works in the following manner: the charge is stopped for some time, let's say

few hundreds of ms, then the battery voltage will be measured and when it drops below its maximum

value a fixed time length charging pulse is issued. As the battery approaches its full charge the off

time will become longer, hence the duty-cycle of the pulses will decrease. The battery is considered

fully charged when the pulse duty-cycle is less than a threshold value, typically 10%, the pulse charge

stops and eventually the maintenance starts.

The last phase is not properly a charging phase, since the battery at this point is fully charged and the

process may stop after the final charge. The maintenance charge provides an additional charging

process to compensate for the charge leak typical of a Li-Ion battery. It is done by issuing pulses with

a fixed time length, again few hundreds of ms, and a duty-cycle around 5% or less.

This last phase is not implemented in the GC864 internal charging algorithm, so that the battery once

charged is left discharging down to a certain threshold so that it is cycled from full charge to slight

discharge even if the battery charger is always inserted. This guarantees that anyway the remaining

charge in the battery is a good percentage and that the battery is not damaged by keeping it always

fully charged (Li-Ion rechargeable battery usually deteriorate when kept fully charged).

Last but not least, in some applications it is highly desired that the charging process restarts when the

battery is discharged and its voltage drops below a certain threshold, GC864 internal charger does it.

As you can see, the charging process is not a trivial task to be done; moreover all these operations

should start only if battery temperature is inside a charging range, usually 5°C - 45°C.

The GC864 measures the temperature of its internal component, in order to satisfy this last

requirement, it's not exactly the same as the battery temperature but in common application the two

temperature should not differ too much and the charging temperature range should be guaranteed.

NOTE: For all the threshold voltages, inside the GC864 all threshold are fixed in order to

maximize Li-Ion battery performances and do not need to be changed.

NOTE: In this application the battery charger input current must be limited to less than 400mA.

This can be done by using a current limited wall adapter as the power source.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 14 of 68

Page 15

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

3.2.2 Thermal Design Guidelines

The thermal design for the power supply heat sink should be done with the following specifications:

• Average current consumption during transmission @PWR level max (rms): 500mA

• Average current consumption during transmission @ PWR level min (rms): 100mA

• Average current during Power Saving: 4mA

• Average current during idle (Power Saving disabled) 19mA

NOTE: The average consumption during transmissions depends on the power level at which

the device is requested to transmit by the network. The average current consumption hence

varies significantly.

TIP: The thermal design for the Power supply should be made keeping a average consumption

at the max transmitting level during calls of 500mA rms.

Considering the very low current during idle, especially if Power Saving function is enabled, it is

possible to consider from the thermal point of view that the device absorbs current significantly only

during calls.

If we assume that the device stays into transmission for short periods of time (let's say few minutes)

and then remains for a quite long time in idle (let's say one hour), then the power supply has always

the time to cool down between the calls and the heat sink could be smaller than the calculated one for

500mA maximum RMS current, or even could be the simple chip package (no heat sink).

Moreover in the average network conditions the device is requested to transmit at a lower power level

than the maximum and hence the current consumption will be less than the 500mA, being usually

around 150mA.

For these reasons the thermal design is rarely a concern and the simple ground plane where the

power supply chip is placed can be enough to ensure a good thermal condition and avoid overheating.

For the heat generated by the GC864, you can consider it to be during transmission 1W max during

CSD/VOICE calls and 2W max during class10 GPRS upload.

This generated heat will be mostly conducted to the ground plane under the GC864, you must ensure

that your application can dissipate it.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 15 of 68

Page 16

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

3.2.3 Power Supply PCB layout Guidelines

As seen on the electrical design guidelines the power supply shall have a low ESR capacitor on the

output to cut the current peaks and a protection diode on the input to protect the supply from spikes

and polarity inversion. The placement of these components is crucial for the correct working of the

circuitry. A misplaced component can be useless or can even decrease the power supply

performances.

• The Bypass low ESR capacitor must be placed close to the Telit GC864 power input pads or in the

case the power supply is a switching type it can be placed close to the inductor to cut the ripple

provided the PCB trace from the capacitor to the GC864 is wide enough to ensure a dropless

connection even during the 2A current peaks.

• The protection diode must be placed close to the input connector where the power source is

drained.

• The PCB traces from the input connector to the power regulator IC must be wide enough to ensure

no voltage drops occur when the 2A current peaks are absorbed. Note that this is not made in

order to save power loss but especially to avoid the voltage drops on the power line at the current

peaks frequency of 216 Hz that will reflect on all the components connected to that supply,

introducing the noise floor at the burst base frequency. For this reason while a voltage drop of 300400 mV may be acceptable from the power loss point of view, the same voltage drop may not be

acceptable from the noise point of view. If your application doesn't have audio interface but only

uses the data feature of the Telit GC864, then this noise is not so disturbing and power supply

layout design can be more forgiving.

• The PCB traces to the GC864 and the Bypass capacitor must be wide enough to ensure no

significant voltage drops occur when the 2A current peaks are absorbed. This is for the same

reason as previous point. Try to keep this trace as short as possible.

• The PCB traces connecting the Switching output to the inductor and the switching diode must be

kept as short as possible by placing the inductor and the diode very close to the power switching

IC (only for switching power supply). This is done in order to reduce the radiated field (noise) at the

switching frequency (100-500 kHz usually).

• The use of a good common ground plane is suggested.

• The placement of the power supply on the board should be done in such a way to guarantee that

the high current return paths in the ground plane are not overlapped to any noise sensitive circuitry

as the microphone amplifier/buffer or earphone amplifier.

• The power supply input cables should be kept separate from noise sensitive lines such as

microphone/earphone cables.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 16 of 68

Page 17

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

4 Antenna

The antenna connection and board layout design are the most important part in the full product design

and they strongly reflect on the product overall performances, hence read carefully and follow the

requirements and the guidelines for a proper design.

4.1 Antenna Requirements

As suggested on the Product Description the antenna for a Telit GC864 device shall fulfill the following

requirements:

ANTENNA REQUIREMENTS

Frequency range

Bandwidth

Gain

Impedance

Input power

VSWR absolute

max

VSWR

recommended

Standard Dual Band GSM/DCS frequency

range or

Standard Tri Band GSM/DCS/PCS

frequency range if used for all three bands

136 MHz in GSM 850 and 900 & 170 MHz in

DCS & 140 MHz PCS band

Gain < 3dBi

50 ohm

> 2 W peak power

<= 10:1

<= 2:1

4.2 GC864 Antenna Connector

The GC864 module is equipped with a 50 Ohm RF connector from Murata,

GSC type P/N MM9329-2700B.

The counterpart suitable is Murata MXTK92 Type or MXTK88 Type.

Moreover, the GC864 has the antenna pads on the backside of the PCB. This allows the manual

soldering of the coaxial cable directly on the back side of the PCB. However, the soldering is not an

advisable solution for a reliable connection of the antenna.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 17 of 68

Page 18

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

4.3 Antenna installation Guidelines

• Install the antenna in a place covered by the GSM signal.

• The Antenna must be installed to provide a separation distance of at least 20 cm from all persons

and must not be co-located or operating in conjunction with any other antenna or transmitter;

• Antenna shall not be installed inside metal cases

• Antenna shall be installed also according Antenna manufacturer instructions.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 18 of 68

Page 19

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

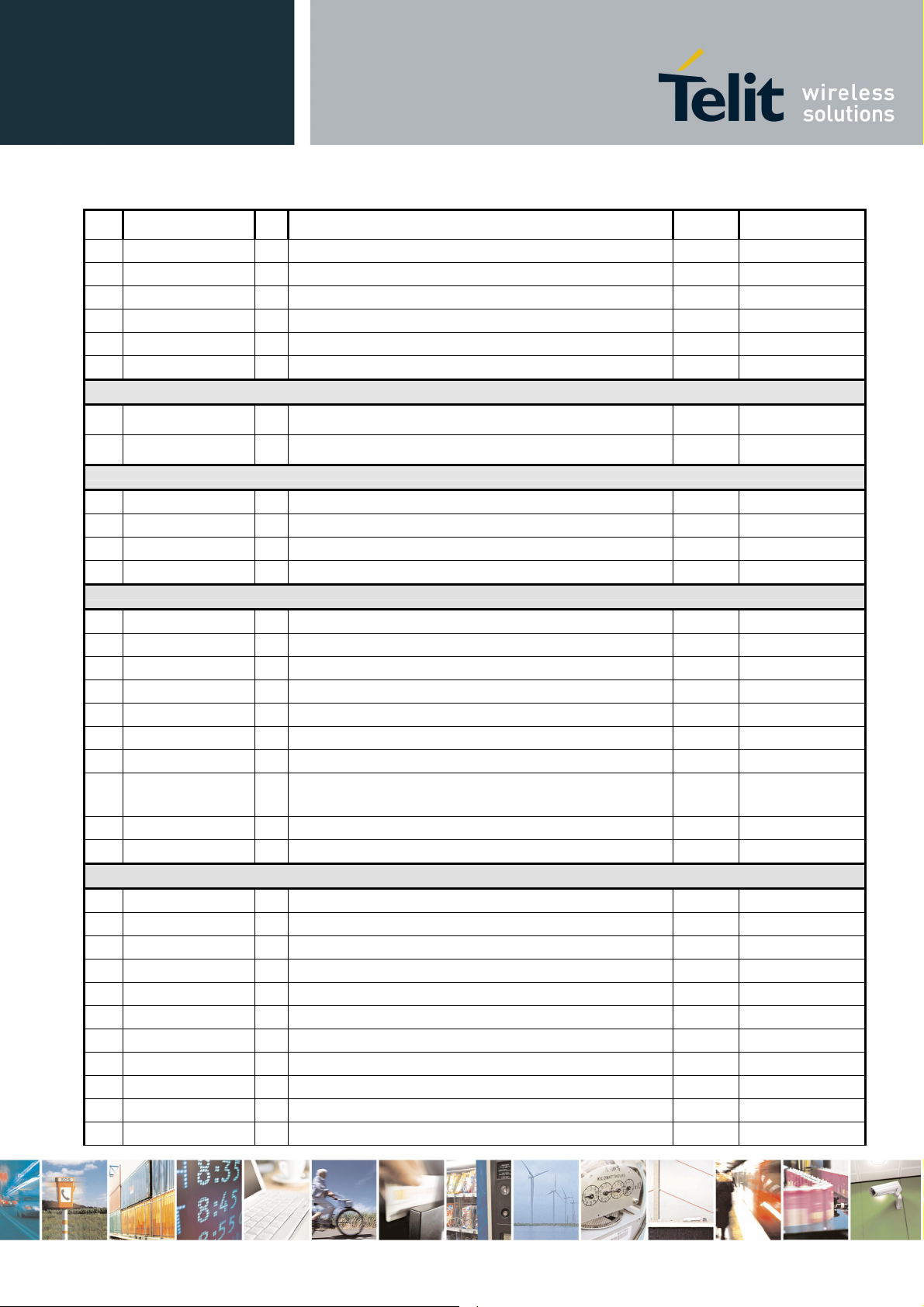

5 GC864 pins allocation

The GC864 uses an 80 pin Molex p.n. 53949-0878 male connector for the connections with the external

applications. This connector matches the 54150-0878 model

Pin Signal I/O Function Internal

Power Supply

1 VBATT - Main power supply Power

2 VBATT - Main power supply Power

3 VBATT - Main power supply Power

4 VBATT - Main power supply Power

5 GND - Ground Power

6 GND - Ground Power

7 GND - Ground Power

Audio

8 AXE I Handsfree switching

9 EAR_HF+ AO Handsfree ear output, phase + Audio

10 EAR_HF- AO Handsfree ear output, phase - Audio

11 EAR_MT+ AO Handset earphone signal output, phase + Audio

12 EAR_MT- AO Handset earphone signal output, phase - Audio

13 MIC_HF+ AI Handsfree microphone input; phase +, nominal level 3mVrms Audio

14 MIC_HF- AI Handsfree microphone input; phase -, nominal level 3mVrms Audio

15 MIC_MT+ AI Handset microphone signal input; phase+, nominal level 50mVrms Audio

16 MIC_MT- AI Handset microphone signal input; phase-, nominal level 50mVrms Audio

SIM Card Interface

18 SIMVCC - External SIM signal – Power supply for the SIM 1.8/3V

19 SIMRST O External SIM signal – Reset 1.8/3V

20 SIMIO I/O External SIM signal - Data I/O 1.8/3V

21 SIMIN I External SIM signal - Presence (active low)

22 SIMCLK O External SIM signal – Clock 1.8/3V

Trace

23 RX_TRACE I RX Data for debug monitor CMOS 2.8V

24 TX_TRACE O TX Data for debug monitor CMOS 2.8V

Prog. / Data + Hw Flow Control

25 C103/TXD I Serial data input (TXD) from DTE CMOS 2.8V

26 C104/RXD O Serial data output to DTE CMOS 2.8V

.

Pull up

100K

Ω

47K

Ω

CMOS 2.8V

1.8/3V

Type

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 19 of 68

Page 20

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

Pin Signal I/O Function Internal

27 C107/DSR O Output for Data set ready signal (DSR) to DTE CMOS 2.8V

28 C106/CTS O Output for Clear to send signal (CTS) to DTE CMOS 2.8V

29 C108/DTR I Input for Data terminal ready signal (DTR) from DTE CMOS 2.8V

30 C125/RING O Output for Ring indicator signal (RI) to DTE CMOS 2.8V

31 C105/RTS I Input for Request to send signal (RTS) from DTE CMOS 2.8V

32 C109/DCD O Output for Data carrier detect signal (DCD) to DTE CMOS 2.8V

IIC

35 CAM_SCL /

IIC_SCL

36 CAM_SDA /

IIC_SDA

37 ADC_IN1 AI Analog/Digital converter input A/D

38 ADC_IN2 AI Analog/Digital converter input A/D

39 ADC_IN3 AI Analog/Digital converter input A/D

40 DAC_OUT AO Digital/Analog converter output D/A

44 MON1_CAM I/O MON1 / Camera interface CMOS 2.8V

45 STAT_LED O Status indicator led CMOS 1.8V

46 GND - Ground Ground

49 PWRMON I Power ON Monitor CMOS 2.8V

50 VAUX1 - Power output for external accessories -

51 CHARGE AI Charger input (*) Power

52 CHARGE AI Charger input (*) Power

53 ON/OFF* I Input command for switching power ON or OFF (toggle command).

54 RESET* I Reset input

55 VRTC AO VRTC Backup capacitor Power

56 TGPIO_19 I/O Telit GPIO19 Configurable GPIO CMOS 2.8V

57 TGPIO_11 I/O Telit GPIO11 Configurable GPIO CMOS 2.8V

58 TGPIO_20 I/O Telit GPIO20 Configurable GPIO CMOS 2.8V

59 TGPIO_04 I/O Telit GPIO4 Configurable GPIO CMOS 2.8V

60 TGPIO_14 I/O Telit GPIO14 Configurable GPIO CMOS 2.8V

61 TGPIO_15 I/O Telit GPIO15 GPIO pin CMOS 2.8V

62 TGPIO_12 I/O Telit GPIO12 Configurable GPIO CMOS 2.8V

63 TGPIO_10 I/O Telit GPIO10 I/O pin CMOS 2.8V

64 TGPIO_22 I/O Telit GPIO22 Configurable GPIO CMOS 1.8V

65 TGPIO_18 I/O Telit GPIO18 I/O pin CMOS 2.8V

66 TGPIO_03 I/O Telit GPIO3 Configurable GPIO CMOS 2.8V

I/O Camera IIC interface / Configurable GPIO CMOS 2.8V

I/O Camera IIC interface / Configurable GPIO CMOS 2.8V

DAC and ADC

Miscellaneous Functions

The pulse to be sent to the GC864 must be equal or greater than 1

second.

Telit GPIO

Pull up

47K

Ω

Pull up to VBATT

Type

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 20 of 68

Page 21

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

Pin Signal I/O Function Internal

67 TGPIO_08 / CAM_ON I/O Telit GPIO8 Configurable GPIO / Camera Interface CMOS 2.8V

68 TGPIO_06 / ALARM I/O Telit GPIO6 Configurable GPIO / ALARM CMOS 2.8V

69 TGPIO_23 I/O Reserved to detect ON/OFF. It is physically connected to pin 49

70 TGPIO_01 I/O Telit GPIO1 Configurable GPIO CMOS 2.8V

71 TGPIO_17 I/O Telit GPIO17 GPIO pin CMOS 2.8V

72 TGPIO_21 I/O Telit GPIO21 Configurable GPIO CMOS 2.8V

73 TGPIO_07 / BUZZER I/O Telit GPIO7 Configurable GPIO / Buzzer CMOS 2.8V

74 TGPIO_02 / JDR I/O Telit GPIO02 I/O pin / Jammer detect report CMOS 2.8V

75 TGPIO_16 I/O Telit GPIO16 Configurable GPIO CMOS 2.8V

76 TGPIO_09 /

CAM_RST

77 TGPIO_13 I/O Telit GPIO13 Configurable GPIO CMOS 2.8V

78 TGPIO_05 /

RFTXMON

17 -

33 -

34 -

41 -

42 -

43 -

47 -

48 -

79 -

80 -

(PWRMON)

I/O Telit GPIO9 GPIO I/O pin 7 Camera Interface CMOS 2.8V

I/O Telit GPIO05 Configurable GPIO / Transmitter ON monitor CMOS 2.8V

RESERVED

Pull up

CMOS 2.8V

Type

NOTE: RESERVED pins must not be connected

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 21 of 68

Page 22

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

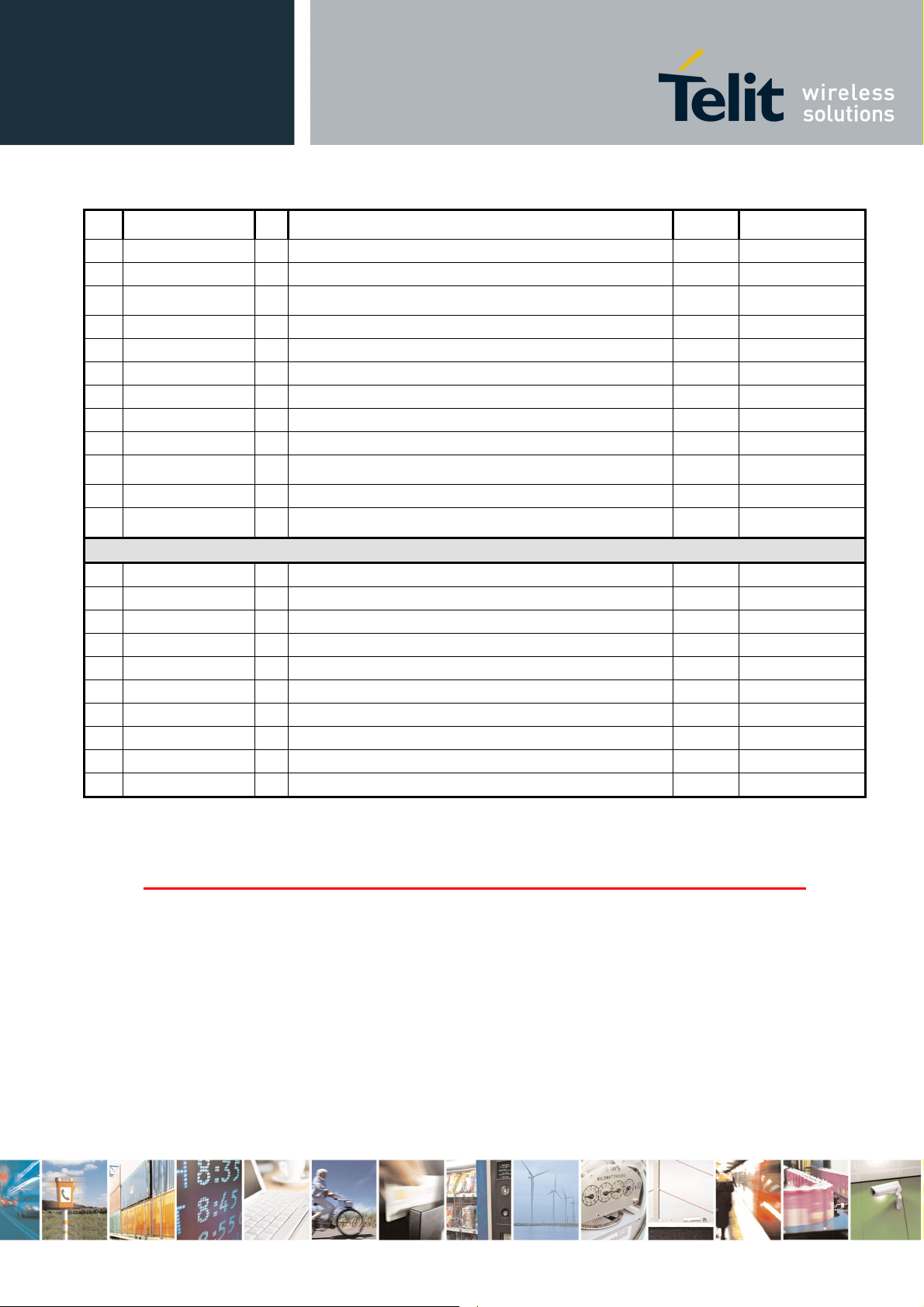

6 Serial Port

The serial port on the Telit GC864 is the core of the interface between the module and OEM

hardware. Several configurations can be designed for the serial port on the OEM hardware, but the

most common are:

- RS232 PC com port

- microcontroller UART @ 2.8V - 3V (Universal Asynchronous Receive Transmit)

- microcontroller UART@ 5V or other voltages different from 2.8V

Depending from the type of serial port on the OEM hardware a level translator circuit may be needed

to make the system work. The only configuration that doesn't need a level translation is the 2.8V

UART.

The serial port on the GC864 is a +2.8V UART with all the 7 RS232 signals. It differs from the PCRS232 in the signal polarity (RS232 is reversed) and levels. The levels for the GC864 UART are the

CMOS levels:

Absolute Maximum Ratings -Not Functional

Parameter Min Max

Input level on any

digital pad when on

Input voltage on

analog pads when on

Operating Range - Interface levels (2.8V CMOS)

Level Min Max

Input high level V

Input low level VIL 0V 0.5V

Output high level VOH 2.2V 3.0V

Output low level VOL 0V 0.35V

-0.3V +3.75V

-0.3V +3.0 V

2.1V 3.3V

IH

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 22 of 68

Page 23

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

The signals of the GC864 serial port are:

RS232 Pin

Number

3 25 C103/TXD I Serial data input (TXD) from DTE Input receive of the GC864 UART

2 26 C104/RXD O Serial data output to DTE Output transmit line of GC864 UART

6 27 C107/DSR O Output for Data set ready signal (DSR) to DTE Output from the GC864 that indicates the

8 28 C106/CTS O Output for Clear to send signal (CTS) to DTE Output from the GC864 that controls the

4 29 C108/DTR I Input for Data terminal ready signal (DTR) from

9 30 C125/RING O Output for Ring indicator signal (RI) to DTE Output from the GC864 that indicates the

7 31 C105/RTS I Input for Request to send signal (RTS) from DTE Input to the GC864 that controls the

1 32 C109/DCD O Output for Data carrier detect signal (DCD) to

5 5,6,7 GND - Ground ground

GC864

Pad

Number

Signal Type Name Usage

module is ready

Hardware flow control

DTE

DTE

Input to the GC864 that controls the DTE

READY condition

incoming call condition

Hardware flow control

Output from the GC864 that indicates the

carrier presence

NOTE: According to V.24, RX/TX signal names are referred to the application side, therefore on

the GC864 side these signal are on the opposite direction: TXD on the application side will be

connected to the receive line (here named TXD/ rx_uart ) of the GC864 serial port and

viceversa for RX.

TIP: For a minimum implementation, only the TXD and RXD lines can be connected, the other

lines can be left open provided a software flow control is implemented.

The signals in the UART connector on the EVK2 are:

DCD RXD

TXD DTR

GND DSR

RTS CTS

RI GND

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 23 of 68

Page 24

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

6.1 RS232 level translation

In order to interface the Telit GC864 with a PC com port or a RS232 (EIA/TIA-232) application a level

translator is required. This level translator must

- invert the electrical signal in both directions

- change the level from 0/3V to +15/-15V

Actually, the RS232 UART 16450, 16550, 16650 & 16750 chipsets accept signals with lower levels on

the RS232 side (EIA/TIA-562) , allowing for a lower voltage-multiplying ratio on the level translator.

Note that the negative signal voltage must be less than 0V and hence some sort of level translation is

always required.

The simplest way to translate the levels and invert the signal is by using a single chip level translator.

There are a multitude of them, differing in the number of driver and receiver and in the levels (be sure

to get a true RS232 level translator not a RS485 or other standards).

By convention the driver is the level translator from the 0-3V UART level to the RS232 level, while the

receiver is the translator from RS232 level to 0-3V UART.

In order to translate the whole set of control lines of the UART you will need:

- 5 driver

- 3 receiver

NOTE: The digital input lines working at 2.8VCMOS have an absolute maximum input voltage

of 3,75V; therefore the level translator IC shall not be powered by the +3.8V supply of the

module. Instead it shall be powered from a +2.8V / +3.0V (dedicated) power supply.

This is because in this way the level translator IC outputs on the module side (i.e. GC864

inputs) will work at +3.8V interface levels, stressing the module inputs at its maximum input

voltage.

This can be acceptable for evaluation purposes, but not on production devices.

NOTE: In order to be able to do in circuit reprogramming of the GC864 firmware, the serial port

on the Telit GC864 shall be available for translation into RS232 and either it's controlling

device shall be placed into tristate, disconnected or as a gateway for the serial data when

module reprogramming occurs.

Only RXD, TXD, GND and the On/off module turn on pad are required to the reprogramming of

the module, the other lines are unused.

All applicator shall include in their design such a way of reprogramming the GC864.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 24 of 68

Page 25

An example of level translation circuitry of this kind is:

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

the RS232 serial port lines are usually connected to a DB9 connector with the following layout:

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 25 of 68

Page 26

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

6.2 5V UART level translation

If the OEM application uses a microcontroller with a serial port (UART) that works at a voltage different

from 2.8 - 3V, then a circuitry has to be provided to adapt the different levels of the two sets of signals.

As for the RS232 translation there are a multitude of single chip translators, but since the translation

requires very few components, then also a discrete design can be suited. For example a possible

inexpensive translator circuit for a 5V driver can be:

and for a 5V receiver:

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 26 of 68

Page 27

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

NOTE: The UART input line TXD (rx_uart) of the GC864 is NOT internally pulled up with a

resistor, so there may be the need to place an external 47KΩ pull-up resistor, either the DTR

(dtr_uart) and RTS (rts_uart) input lines are not pulled up internally, so an external pull-up

resistor of 47KΩ may be required.

A power source of the internal interface voltage corresponding to the 2.8VCMOS high level is

available at the VAUX pad, whose absolute maximum output current is 100mA.

Pull-up resistors can be connected to the VAUX pad provided that the pulled-up lines are GC864 input

lines connected to open collector outputs in order to avoid latch-up problems on the GC864.

Care must be taken to avoid latch-up on the GC864 and the use of this output line to power electronic

devices shall be considered with care, especially for devices that generate spikes and noise such as

level translators, digital ICs or microcontroller, failure in any of these condition can severely

compromise the GC864 functionality.

NOTE: The input lines working at 2.8VCMOS can be pulled-up with 47KΩ resistors that can be

connected directly to the VAUX line.

NO disturbing devices should be powered with the VAUX line, otherwise the module

functionality may be compromised.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 27 of 68

Page 28

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

7 Audio Section Overview

The Base Band Chip of the GC864 Telit Module provides two different audio blocks; both in transmit

(Uplink) and in receive (Downlink) direction:

“MT lines” should be used for handset function,

“HF lines” is suited for hands -free function (car kit).

These two blocks can be active only one at a time, selectable by AXE hardware line or by AT

command.

The audio characteristics are equivalent in transmit blocks, but are different in the receive ones and

this should be kept in mind when designing.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 28 of 68

Page 29

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

-12dBFS

Differential

8

16

Line-Out Driv ers

EXTERNAL

AMPLIFIER

Fully Differen tial Power Buffers

16

ended

Single

Balance

egolite.sk

Ear_MT+

Ear_MT-

Ear_HF+

Ear_HF-

GC864

Mic_MT+

3,3mV

Mic_MT-

rms

365mV

+20dB

-45dBV/Pa

7cm

Mic_HF+

0,33mV

Mic_HF-

rms

23mV

+10dB

-45dBV/Pa

50cm

GC864 Audio Paths

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 29 of 68

Page 30

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

7.1 Microphone paths characteristic and requirements

TIP: being the microphone circuitry the more noise sensitive , its design and layout must be

done with particular care. Both microphone paths are balanced and the OEM circuitry should

be balanced designed to reduce the common mode noise typically generated on the ground

plane. However also an unbalanced circuitry can be used for particular OEM application needs

.

TIP: due to the difference in the echo canceller type, the “Mic_MT” audio path is suited for

Handset applications, while the “Mic_HF”audio path is suited for hands-free function (car kit).

The Earphone applications should be made using the “Mic_HF” audio path but DISABLING the

echo canceller by software AT command. If the echo canceller is left active with the Earphone,

then some echo might be introduced by the echo cancel algorithm.

“Mic_MT” 1

• line coupling AC

• line type balanced

• coupling capacitor ≥ 100nF

• differential input resistance 50kΩ

• differential input voltage ≤ 1,03V

• microphone nominal sensitivity -45 dBV

• analog g

• echo canceller type handset

“Mic_HF” 2

• line coupling AC

• line type balanced

• coupling capacitor ≥ 100nF

• differential input resistance 50kΩ

• differential input voltage ≤ 65mV

• microphone nominal sensitivity -45 dBV

• analog

• echo canceller type car kit hands-free

st

differential microphone path

(365mV

pp

/Pa

rms

ain suggested + 20dB

nd

differential microphone path

(23mV

pp

/Pa

rms

gain suggested +10dB

rms

rms

)

)

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 30 of 68

Page 31

=

-

-

3

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

TIP: definition of the nominal sensitivity of the microphone lines .

The nominal sensitivity of the microphone lines indicates the voltage level on the GC864 pins present

during "normal spoken" conditions.

For a handset , the "normal spoken” conditions take place when the talker mouth is 7cm far from the

microphone ; under these conditions the voice will produce an acoustic pressure of -4,7dBPa @1kHz

on the microphone membrane .

TIP: electrical equivalent signal and operating voice levels .

At "normal spoken" conditions, a microphone having the suggested nominal sensitivity of -

45dBV

/Pa , will produce

rms

the electrical equivalent signal :

that means :

MicLevel = ( -45) + (-4.7) = -49.7 dB

(

49.7 / 20 )

= 3.3* 10

MicVoltage = 10

Vrms

V

rms

During a call , this level varies according to the volume of the talker voice; usually the following rough

thumb rule for the dynamic range may be used :

1) the talker is screaming . This is the strongest voice level condition : the signal increases by

+20dB ;

2) the talker is whispering. This is the lowest voice level condition: the voice level decreases by

–50dB .

These changes must be considered for designing the external microphone amplifier .

TIP: example of external microphone amplifier calculation .

Let’s suppose to use the 1

voltage to “Mic_MT” lines is 365mV

Now we can calculate the maximum voltage gain of an external microphone amplifier G

()

[]

[]

dBG

A

94,20= you can set G

++

G

A

G−=+− 209,40

A

st

differential microphone path .In this case the maximum differential input

(1,03Vpp) corresponding to –8,76dBV.

rms

:

A

dBVGdBMicLevel

A

76,820 −

76,8207,49 −=++−

= +20dB to use standard resistor values .

A

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 31 of 68

Page 32

-

-

3

-

3

-

3

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

TIP: environment consideration .

For hands-free/car kit microphone, you must take into account the voice attenuation, due to the

distance between the microphone itself and the talker, when designing the external microphone

amplifier.

Not only, you must consider that the microphone will pick up also ambient noise; to overcome this

problem it is preferable to set the gain of the microphone 10dB lower with respect to the calculated

value for a nominal sensitivity. The corresponding reduction in signal level will be compensated by an

increased voice volume of the talker which will speak louder because of the ambient noise.

For a car cabin usually the distance between the microphone itself and the talker is 40/50cm; in these

conditions the attenuation can be considered as a thumb rule around 20dB.

For the earphone we shall distinguish two different types: the earphones having the microphone

sustained close to the mouth and the ones having the microphone on the earpiece cable.

The same considerations for the additional voice attenuation due to the distance from the microphone

and the noise pick up can be made for the earphone having the microphone on the earpiece cable,

while the other kind of earphone shall be threaten as an handset.

TIP: how to compensate the losses in car cabin hands-free condition .

The voice signal , that in the "normal spoken” conditions produces on the microphone membrane an

acoustic pressure of -4,7dBPa at 1kHz , will have a further attenuation of 20dB due the 50cm distance

.

Therefore a microphone having the suggested nominal sensitivity of -45dBV

/Pa,will produce a lower

rms

electrical

equivalent signal :

MicLevel = ( -45) + (-4.7)-20 = -69.7

that means :

MicVoltage = 10

(

49.7 / 20 )

= 0,33* 10

Setting the “microphone gain” at +10dB (3 times), the signal in the nominal conditions on the

“Mic_HF” inputs s of GC864 Telit Module will be :

“Mic_HF” Level = 0,33* 10

* 3=1* 10

Hence in these conditions the signal level on the“Mic_HF” input pads of the GC864 is 10 dB (3 times)

lower than the nominal, as suggested.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 32 of 68

Page 33

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

7.2 General Design Rules

There are several configurations for the audio paths, but the most effective difference is between

balanced and unbalanced microphone configuration.

It is highly recommended to keep the whole microphone path balanced even if this means having 2

wires connecting the microphone instead of one needed (plus ground) in the unbalanced case. The

balanced circuitry is more suited because of its good common mode noise rejection, reducing the 216

Hz burst noise produced during the GSM transmissions.

• Where possible use balanced microphone circuitry

• Keep the microphone traces on the PCB and wires as short as possible.

• If your application requires an unbalanced microphone, then keep the lines on the PCB balanced

and "unbalance" the path close to the microphone wire connector if possible.

• For the microphone biasing voltage use a dedicated voltage regulator and a capacitor multiply

circuit.

• Make sure that the microphone traces in the PCB don't cross or run parallel to noisy traces

(especially the power line)

• If possible put all around to the microphone lines a ground trace connected to the ground plane by

several vias. This is done in order to simulate a shielded trace on the PCB.

• The biasing circuit and eventually the buffer can be designed in the same manner for the internal

and external microphones.

7.3 Other considerations.

If your application is a hands-free/car kit scenario, but you need to put microphone and speaker inside

the same box:

• Try to have the maximum possible distance between them, at least 7cm;

• Because the microphone type is very important, if you use an omni-directional one (and this is the

typical application) please seal it on the rear side (no back cavity) in order not to collect unwanted

signals;

• Try to make divergent the main axes of the two devices.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 33 of 68

Page 34

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

7.4 Microphone Biasing

The electret microphones usually need a biasing voltage to work properly. Refer to your microphone

provider for the characteristics required.

NOTE: The microphones have a hot wire were the positive biasing must be connected. Usually

it is indicated by a + symbol or a red point. If the polarity of the bias is reversed, then the

microphone will not work properly. For this reason be sure to respect the mic. biasing polarity.

7.4.1 Balanced Microphone biasing

The balanced microphone bias voltage should be obtained from a dedicated voltage regulator, in order

to eliminate the noise present on the power lines. This regulator can be the same for all the audio

paths. The microphone should be supplied from a capacitor multiply circuit.

For example a circuit for the balanced microphone biasing can be:

NOTE: In the balanced application the resistors R2 and R3 must have the same value to keep

the circuit balanced.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 34 of 68

Page 35

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

NOTE: The cable to the microphone should not be shielded, instead a twisted pair cable shall

be used.

NOTE: The microphone sensitivity changes with the value of R2 and R3. Usually the

microphones are characterized with 2kΩ biasing resistance, so try to keep the sum of R2 and

R3 around 2kΩ. Refer to your microphone manufacturer for the mic. characteristics.

7.4.2 Unbalanced Microphone biasing

The unbalanced microphone biasing voltage should be obtained from a dedicated voltage regulator, in

order to eliminate the noise present on the power lines. This regulator can be the same for all the

audio paths. The microphone should be supplied from a capacitor multiply circuit.

For example a circuit for the unbalanced microphone biasing can be:

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 35 of 68

Page 36

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

NOTE: In the unbalanced application the capacitor C3 shall be > 200nF otherwise the frequency

response will be cut at low band frequencies (down to 300Hz). This capacitor can be placed

close to the MIC- pad (MIC_HF- or MIC_MT- depending on the audio path chosen) or if

possible it should be placed close to the shielded cable connector. If the ground return path is

well designed, then it is possible to eliminate the C3 capacitor, provided the buffer is close to

the mic. input.

NOTE: The cable to the microphone should be shielded.

NOTE: The microphone changes with the value of R2. Usually the microphone sensitivity is

characterized with 2kΩ biasing resistance, so try to keep the value of R2 around 2kΩ. For mic.

characteristics refer to the manufacturer.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 36 of 68

Page 37

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

7.5 Microphone buffering

As seen previously, a microphone shall be connected to the input pins of the GC864 through a buffer

amplifier that boosts the signal level to the required value.

Again the buffered microphone circuitry can be balanced or unbalanced : where possible it is always

preferable a balanced solution. The buffering circuit shall be placed close to the microphone or close

to the microphone wire connector.

7.5.1 Buffered Balanced Mic.

A sample circuit can be:

270pF

270pF

To

GC864

This circuit has a gain of 10 times (+20 dB), and is therefore suited for the “Mic_MT “ input if you have

a microphone with a sensitivity close to the suggested one (-45 dBV

Pa). If your microphone has a

rms/

different sensitivity or if the buffer is connected to the “Mic_HF “ inputs , then a gain adjustment shall

be done by changing resistors R604 and R606 ( if the required value is not a standard one , you can

change R605 e R607 ) and as a consequence the capacitors C636 and C637 to maintain the

bandwidth 150-4000Hz (at -3dB).

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 37 of 68

Page 38

-

-

3

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

The buffer gain is given by the formula:

604RR

Gain ==

R

R

605

606

607

The C636 and C637 capacitors are placed in order to cut off the gain at higher frequencies than the

transmitted GSM band, the cutoff frequency (-3dB) should be 3500Hz in order to have -1dB at 3kHz.

The cutoff frequency is given by the formula:

freq

.

1

== [Hz]

637*604*2

ππ

1

636*606*2

CRCR

TIP: example of calculation .

Let's assume you have a microphone with a sensitivity of -45 dBV

/Pa and you want to use it in 1st

rms

differential microphone path (“Mic_MT” inputs) in "normal spoken" conditions at acoustic pressure of

-4.7dBPa.

As reported at page 33 , the electrical level output from the microphone will be :

MicLevel = ( -45) + (-4.7) = -49.7 dB

MicVoltage = 10

(

49.7 / 20 )

= 3.3* 10

Vrms

V

rms

corresponding to:

When the talker is screaming ,we will have a signal of 330 mV

gain G

:

A

on the “Mic_MT “ inputs for a buffer

rms

G

=20 log (AmplifierOutput / MicVoltage) =20 log (330 * 10 -3 )/( 3.3 * 10 -3 ) = 20 log 10=20dB

A

The corresponding values for the resistors on the buffer could be ( if we keep the input resistance

10kΩ )

R604 = R606 = gain* R603= gain* R605 = 10* 15 = 150 kΩ

The commercial values of 150kΩ & 15kΩ are then chosen.

As a consequence the values of the capacitors C636 and C637 shall be:

C636=C637= 1/ (2π*4000*R606)= 265 *10

-12

F

A commercial value of 270pF gives a cutoff frequency of 3931Hz with an errorless than 1,8% .

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 38 of 68

Page 39

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

7.5.2 Buffered Unbalanced (Single Ended) Microphone .

MIC+

2,7nF

6,8nF

To

GC864

MIC+

The above schematic can be used for a single ended (buffered unbalanced) microphone; the required

biasing circuitry is not included. Note also that the capacitor C3 is not needed .

The gains of the two amplifiers are given by the formulas :

719

()

Gain +=

R

1buffer invertingnot

720

R

711

()

Gain =

buffer inverting

R

R

708

Assigning half of overall gain to each amplifier, you will obtain the requested gain because of doubling

the microphone signal path; in fact by the use of two amplifiers (the upper as “inverting” and the lower

as “not inverting”configuration ) we obtain an additional +6dB gain (2 times) .

Remember: the “not inverting “ amplifier section gain shall not be less than 1.

Like for the balanced buffered microphone, the amplifier overall gain can be modify changing the value

of resistor R719/R720 and R711 and as a consequence the capacitors C726 and C727. It is

advisable to change R708 only if you have difficulty to find a commercial value for R711; in this case

change R708 as little as possible.

The -3dB bandwidth is given by the approximated formula (considering C725 >> C726):

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 39 of 68

Page 40

-

-

3

-

3

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

freq

.

1

== [Hz]

726*719*2

ππ

1

727*711*2

CRCR

The buffer bandwidth at -3dB shall be 4KHz.

Note that the biasing of the operational amplifier is given for the inverting amplifier by the series divider

R714-R715. The 100nF capacitor C719 is needed to filter the noise that could be coupled to that

divider. For the not inverting operational amplifier the biasing is given by a different divider R715-R717

with the capacitor C720 and through a series resistor R718 of 470KΩ.

TIP: example of calculation.

Llet's assume you have a microphone with a sensitivity of -45dBV

/Pa and you want to use it in 2nd

rms

differential microphone path (“Mic_HF” inputs) in "normal spoken" conditions at acoustic pressure

of -4.7dBPa.

As reported at page XX , the electrical level output from the microphone will be :

MicLevel = ( -45) + (-4.7) = -49.7 dBV

rms

but we have to consider 20dB loss due to the higher distance from the mouth of the talker ( 50cm ) .

MicLevel = ( -49.7) + (-20) = -69.7 dBV

rms

corresponding to

MicVoltage = 10

(

69.7 / 20 )

= 0,33* 10

In order to have a signal of 1 mV

at the “Mic_HF” inputs , as suggested at TIP “environment

rms

consideration “,

the buffer must have a gain or +10 dB

GA= “Mic_HF /MicVoltage = (1*10

)/(0,33*10

Keeping in mind that “ balancing the line will double the signal”, to calculate the resistor values assign

half of required gain G

to each amplifier section . And therefore GS =1,5times (or +3,52dB) .

A

Choosing as 10kΩ as the input resistance , the corresponding values for the resistors on the buffer will

be :

R711 = G

* R708= 1.5*10 =15 kΩ

S

R719 = (G

-1) * R720 = (1.5 -1)*10 =5 kΩ

S

The commercial values of 15kΩ and 5.6kΩ be accepted .

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 40 of 68

Page 41

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

As a consequence of the assigned values of the resistors, the nominal values of C726 and C727 are

:

C726= 1/ (2π*4000*R719)= 7.10 *10

C727= 1/ (2π*4000*R711)= 2,65 *10

-9

F

-9

F

modified in 6,8nF (f

=4181Hz ) and 2,7nF (fc2=3931Hz) because of commercial values .

c1

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 41 of 68

Page 42

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

8 OUTPUT LINES (Speaker)

8.1 Short description.

The Telit GC864 provides two audio paths in receive section. Only one of the two paths can be active

at a time, selectable by AXE hardware line or by AT command.

You must keep in mind the different audio characteristics of the receive blocks when designing:

the “Ear_MT” lines EPN1 and EPP1 are the Differential Line-Out Drivers ; they can drive an

external amplifier or directly a 16 Ω earpiece at –12dBFS (*) ;

the “Ear_HF” lines EPPA1_2 and EPPA2 are the Fully Differential Power Buffers ; they can directly

drive a 16Ω speaker in differential (balanced) or single ended (unbalanced) operation mode .

(*) FS : acronym of Full Scale. It is equal to 0dB, the maximum Hardware Analog Receive Gain of

BaseBand Chip.

The “Ear_MT” audio path should be used for handset function, while the “Ear_HF” audio path is suited

for hands-free function (car kit).

Both receiver outputs are B.T.L. type (Bridged Tie Load) and the OEM circuitry shall be designed

bridged to reduce the common mode noise typically generated on the ground plane and to get the

maximum power output from the device; however also a single ended circuitry can be designed for

particular OEM application needs.

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 42 of 68

Page 43

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

8.2 Output lines characteristics .

“Ear_MT” Differential Line-out Drivers

• line coupling: DC

• line type: bridged

• output load resistance : ≥ 14 Ω

• internal output resistance: 4 Ω (typical)

• signal bandwidth: 150 - 4000 Hz @ -3 dB

• max. differential output voltage 1310 mV

• differential output voltage 328mVrms /16 Ω @ -12dBFS

• SW volume level step - 2 dB

• number of SW volume steps 10

“Ear_HF” Power Buffers

path

• line coupling: DC

• line type: bridged

• output load resistance : ≥ 14 Ω

• internal output resistance: 4 Ω ( >1,7 Ω )

• signal bandwidth: 150 - 4000 Hz @ -3 dB

• max. differential output voltage 1310 mV

• max. single ended output voltage 656 mV

• SW volume level step - 2 dB

• number of SW volume steps 10

Path

(typ, open circuit)

rms

(typ, open circuit)

rms

(typ, open circuit)

rms

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 43 of 68

Page 44

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

8.3 General Design rules

There are several configurations for the audio output path, but the various design requirements can be

grouped into three different categories:

• handset earphone (low power, typically a handset)

• hands-free earphone (low power, typically a earphone)

• car kit speakerphone (high power, typically a speaker)

The three groups have different power requirements, usually the first two applications need only few

mW of power, which can be directly drained from the GC864 pads, provided a suited speaker is used.

This direct connect design is the cheaper and simpler solution and will be suited for the most of the

earphone design requirements. There's no need to decouple the output ear lines if a suited earpiece is

connected. For the last group, the speakerphone, a power amplifier is required to raise the output

power up to 5-10W required in a car cabin application.

All the designs shall comply with the following guidelines:

• Where possible use a bridged earphone circuitry, to achieve the maximum power output from the

device.

• Keep the earphone traces on the PCB and wires as short as possible.

• If your application requires a single ended earpiece and you want a direct connection, then leave

one of the two output lines open and use only the other referred to ground. Remember that in this

case the power output is 4 times lower than the bridged circuit and may not be enough to ensure

a good voice volume.

• Make sure that the earphone traces in the PCB don't cross or run parallel to noisy traces

(especially the power line)

• The cable to the speaker shall be a twisted pair with both the lines floating for the bridged output

type, shielded with the shield to ground for the single ended output type.

8.3.1 Noise Filtering

The I/O of the PCB should have a noise filter close to the connector, to filter the high frequency GSM

noise. The filter can be a Π formed by 2 capacitor and a inductance, with the one capacitor of 39pF -

0603 case , and the other capacitor of 1nF - 0603; the inductance shall have a value of 39μH .

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 44 of 68

Page 45

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

8.4 Handset earphone design

As seen previously, a 16Ω earpiece can be directly connected to the output pads EAR_MT+ and

EAR_MT- of the GC864.

This solution is often the more cost effective, reducing the components count to a minimum. There are

several limitations to the use of this solution: speaker direct connect imposes the speaker

characteristics to be almost exactly the suggested ones, otherwise the power output may be reduced

(if speaker impedance is bigger than 16Ω) or the GC864 ear port may be damaged (if speaker

impedance is less than 15Ω).

The other limitation of the speaker direct connection is the power output capability of the GC864,

which is limited, and for some particular applications may not be enough.

For these reasons, when the power output of the GC864 is not enough or if the speaker

characteristics are different from the suggested, then it is preferable to use an amplifier to increase the

power and current output capabilities.

Again the output from the GC864 is bridged and both lines should be used, where possible, as inputs

to the power amplifier. This ensures a higher common mode rejection ratio; reducing the GSM current

busts noise on the speaker output.

In this case the “EAR_MT” lines from the GC864 should be AC coupled with a ceramic capacitor of

100nF (or bigger).

It is always desirable to have a mute control on the amplifier, in order to turn it off while the device is

not sending signal to the output, in this manner the amplifier background noise that may be audible

during idle conditions is cut off.

A principle schematic may be:

Reproduction forbidden without Telit Communications S.p.A. written authorization - All Right reserved page 45 of 68

Page 46

The resulting gain and high pass cut can be obtained with the formula:

Gain =

R

23R

.

freq

= [Hz]

And an example of internal Ear amplifier could be:

1

4*3*2

π

CR

+12dB

GC864 Hardware User Guide

1vv0300733 Rev. 0 - 12/06/06

GC864

Some amplifier require a low impedance load at high frequency in order to avoid auto oscillation, this

can be made with a capacitor (100nF) in series with a resistor (15Ω).

When designing your application, remember to provide an adequate bypass capacitor to the amplifier