Page 1

Q II - FOH

Operators Manual

Klark Teknik Building

Walter Nash Road

Kidderminster

Worcestershire

DY11 7HJ

Tel: +44 (0) 1562 741515

Fax: +44 (0) 1562 745371

Email: info@uk.telex.com

Website: www.ddaconsoles.com

Q II - FOH Operators Manual

Telex Communications (UK) Limited

In line with the company’s policy of continual improvement, specifications and function maybe subject

to change without notice. This Operator Manual was correct at the time of writing. E&OE.

Page 2

Contents

3 DECLARATION OF CONFORMITY

4 GENERAL INFORMATION

5 THE Q2 IN USE

7 WARRANTY

9 DIMENSIONS

10 SPECIFICATIONS

12 WIRING CONSIDERATIONS

12 GROUNDING

15 ATTENTION

16 MODULE DESCRIPTIONS

18 THE MATRIX SECTION

19 THE 20DB PAD

20 INPUT MODULE

28 VCA INPUT MODULE

31 STEREO EFFECT RETURN MODULE

36 MONO SUBGROUP OUTPUT MODULE

40 STEREO SUBGROUP OUTPUT MODULE

44 LCR SUBGROUP OUTPUT MODULE

48 FOLDBACK MASTER MODULE

49 AUXILIARY MASTER MODULE

50 STEREO MASTER MODULE

56 MASTER CONNECTOR PANEL

57 VCA MASTER MODULE

62 THE AUDIO MASTER MODULE

62 Q2 TECHNICAL DESCRIPTION

66 THE AUXILIARY MASTER MODULE

67 THE FOLDBACK MASTER MODULE

68 THE INPUT MODULE

76 THE MONO GROUP OUTPUT MODULE

78 THE STEREO GROUP OUTPUT MODULE

79 THE LCR GROUP OUTPUT MODULE

80 Q2 VCA

83 VCA MASTER MODULES

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 2

Page 3

Declaration of Conformity

The Manufacturer of the Products covered by this Declaration is

Klark Teknik Building, Walter Nash Road, Kidderminster, Worcestershire, DY11 7HJ.

The Directives Covered by this Declaration.

89/336/EEC Electromagnetic Compatibility Directive, amended by 92/31/EEC & 93/68/EEC

73/23/EEC Low Voltage Equipment Directive, amended by 93/68/EEC.

The Products Covered by this Declaration.

Equipment type Product Name Variants

Audio Mixing Console Q2 Q2 VCA

Audio Mixing Console Q2 Monitor Meterbridge

Audio Mixing Console QMR Meterbridge

Audio Mixing Console FMR

Audio Mixing Console Forum PA,Matrix,Mute

Audio Mixing Console Forum Monitor Meterbridge

Audio Mixing Console XL200

Audio Mixing Console XL250

The Basis on which Conformity is being Declared

The products identified above comply with the protection requirements of the EMC Directive and with the principal elements of

the safety objectives of the Low Voltage Directive, and the manufacturer has applied the following standards:

EN 55013 : 1990

Limits and methods of measurement of radio disturbance characteristics of Broadcast Receivers and Associated Equipment.

EN 50082-1 : 1992

Electromagnetic Compatibility - Generic Immunity Standard Part 1. Residential, commercial and light industry.

EN 60065 : 1994

Safety requirements for mains operated electronic related apparatus for household and similar general use.

The technical documentation required to demonstrate that the products meet the requirements of the Low Voltage Directive has

been compiled by the signatory below and is available for inspection by the relevant enforcement authorities. The CE mark was

first applied in 1996.

Signed: ................................ G.M.Squires

Authority: Product Support Manager.

Date: 1st, January 1997.

Attention

The attention of the specifier, purchaser, installer, or user is drawn to special measures and limitations to use which must be

observed when these products are taken into service to maintain compliance with the above directive. Details of these special

measures and limitations to use are available on request, and are also contained in product manuals.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 3

Page 4

GENERAL

INFORMATION

Three channel or Left, Centre, Right panning differs from the

normal stereo panning arrangement in that where the conventional

left/right pan moves the signal across the stereo image, LCR

panning moves the mono signal across three distinct positions.

Using LCR panning gives a more spatial effect, offers more control

over vocal and effects positioning, and brings theatre performances

to life in a way that conventional stereo panning cannot.

In the LCR mode, the pan pot acts as follows. When panned hard

left, the signal is only fed to the left channel of the main output (or

sub-group). As the pan is rotated towards the centre, the signal to

the left decreases, and the signal to the centre channel increases

until at dead centre the signal only goes to the centre output. At

this point, no signal is fed to the right channel at all.

LEFT CENTRE RIGHT

Rotating the pan pot further (to the right) decreases the centre feed

while the right feed increases until at full clockwise rotation the

signal is only on the right channel.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 4

Page 5

THE Q2 IN USE

Providing a hard centre image in addition to left and right speaker

clusters improves localisation, as has already been proven in the

cinema industry. Stars and soloists are typically mixed to the centre

channel. Back-up vocals and orchestra or band may be wrapped

around the vocalist in stereo, or panned across the three channels.

In Theatrical performances, LCR panning may be used to follow an

actor around the stage.

Q2's typical use in the theatre maybe as follows.

The main LCR output is used to feed the audience clusters. Further

flexibilty in mixing is provided if the 4 LCR sub-groups are fitted,

as groups can be formed with all signals in place, then simply

fader-controlled as a group to the main output.

Four of the auxiliary sends, labelled foldback, may be used to

provide stage monitoring, as the term foldback suggests. The other

four auxiliaries are then free for effects sends, perhaps using the

dual concentric controls as stereo pairs.

The matrix section has numerous uses. Apart from creating foyer

and backstage feeds, it can be used for distributed loudspeaker

arrays for SPL control further back in the house (see the section on

the Q2 matrix). If the Q2 stereo sub-groups are fitted, the matrix is

fully stereo, so that delayed arrays can be easily set up as distinct

and controllable stereo pairs down each side of the auditorium.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 5

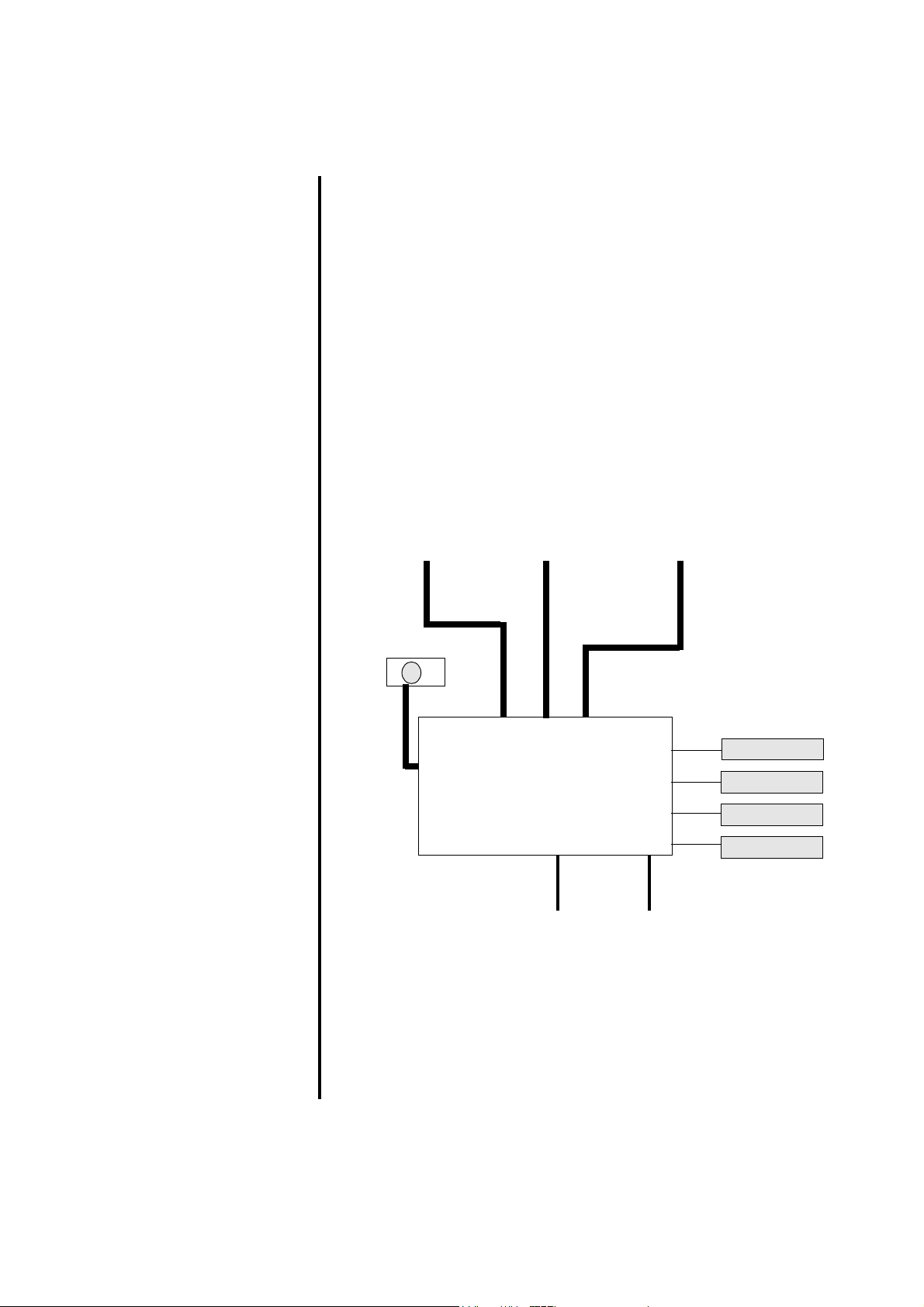

Page 6

Consultants and contractors will be pleased to note that Q2 has

balanced inputs and outputs throughout, including inserts. In

addition, all inputs and outputs (with the obvious exception of the

mic input) operate at a nominal level of +4dBu. This alone means

no catering for special levels on inserts, no compensating for

unbalanced insert sends which combine with balanced returns.

System connection and signal flow is therefore not console

dependant.

LEFT CENTRE RIGHT

F/B

(4)

EFFECTS

Q2

MATRIX OUTPUTS (8)

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 6

Page 7

WARRANTY

If within a period of twelve months from the date of delivery of the

equipment to the End User it shall prove defective by reason only

of faulty materials and/or workmanship (but no faulty design) to

such an extent that the effectiveness and/or the usability thereof is

materially affected, the Equipment or the faulty component shall be

returned to the Distributor or DDA and subject to the following

conditions the Distributor or DDA will repair or at its option replace the defective components. Any components replaced will

become the property of DDA.

Any Equipment or component returned will be at the risk of

the End User whilst in transit (both to and from the Distributor or

DDA) and postage and/or freight charges must be prepaid.

This Warranty shall only be available if:-

i) The Equipment has been properly installed in accordance

with the instructions contained in this manual.

ii) The End User has notified the Distributor or DDA in writing

within 14 days of the defect appearing.

iii) No persons other than authorised representatives of DDA or

the Distributor have effected any replacement of parts,

maintenance adjustments or repairs to the Equipment.

iv) The End User has used the Equipment for such purposes as

DDA recommends with only such operating supplies as meet

DDA’s specifications or approval and otherwise in all

respects in accordance with DDA’s recommendations.

Defects arising as a result of the following are not covered by this

Warranty : -

Faulty or negligent handling, chemical or electro-chemical or

electrical influences, accidental damage, Acts of God, neglect,

defficiency in electrical power , air conditioning or humidity

control.

Benefit of this Warranty may not be assigned by the End User.

End Users who are consumers should note that their rights

under this Warranty are in addition to and do not affect any other

rights to which they may be entitled against the seller of the

Equipment.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 7

Page 8

DDA shall not be liable for any damage caused to persons

or property due to :-

i) Incorrect usage of the Equipment

ii) Other equipment attached to the Equipment, which is not

approved by DDA

iii) Modifications made by non-authorised persons, or by using

non-recommended parts, or incorrectly made.

In no circumstances shall DDA be liable for any indirect or

consequential costs, damages or losses (including loss of business

profits, operating time or otherwise) arising out of the use or

inability to use the product, whether or not the likelihood of

damage was advised to DDA or its distributor.

Fuses and filament lamps are specifically excluded from the

warranty

This notice does not affect your statutory rights.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 8

Page 9

DIMENSIONS

Q2 Dimensions

24 Input Frame

Width : 1255mm / 49.4"

Depth : 810mm / 31.9"

Height : 368mm / 14.5"

32 Input Frame

Width : 1505mm / 59.25"

Depth : 810mm / 31.9"

Height : 368mm / 14.5"

40 Input Frame

Width : 1755mm / 69.1"

Depth : 810mm / 31.9"

Height : 368mm / 14.5"

48 Input Frame

Width : 2005mm / 78.9"

Depth : 810mm / 31.9"

Height : 368mm / 14.5"

Floorstand (optional)

Height to underneath of console : 700mm / 27.5"

Q2 Power Supply Dimensions

Height : 134mm / 5.25" (3U rack mounting)

Depth : 265mm / 10.5"

Width : Front panel 483mm / 19"

Housing 438mm / 17.25"

Nett Weight (unpacked): 7.8 Kg / 17.2 lbs

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 9

Page 10

SPECIFICATIONS

Note : All specifications relate to dBu, ie 0dBu = 0.775V RMS

MAXIMUM GAIN

Mic Input to Mix Output: 86dB

Line Input to Mix Output: 40dB

FREQUENCY RESPONSE

Mic Input to Mix Output: 20Hz , -0.50dB

(gain 55dB) 20kHz, -0.20dB

Line Input to Mix Output 20Hz , -0.50dB

(gain 0dB) 20kHz, -0.20dB

NOISE, DIN Audio Weighted

Microphone Input

Gain 55dB, EIN Ref 200 Ohm <-127.5dBu

Line Input to Mix Output

Gain 0dB, 16 inputs routed <-83dBu

DISTORTION

Microphone Input to Mix Output

-50dBu input, +4dBu output <0.005%

Line Input to Mix Output

+4dBu input, +4dBu output <0.005%

CROSSTALK

Adjacent Channel, 1kHz <-100dBu

Group to Mix, 1kHz <-88dBu

Fader Attenuation 1kHz <-95dBu

Panpot Isolation, 1kHz <-72dBu

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 10

Page 11

Q2 Power Supply Specifications

AC Mains Voltage selection :- 110V/120V/220V/240V

Power Consumption (max) : 750VA

AC Mains frequency : 50Hz. - 60Hz

Fuse Ratings: 220/230/240V - 6.3A

90/100/120V - 10A

Cooling Method: Internal fan

DC Power Outputs: +17 Volts, 7A max

-17 Volts, 7A max

+48 Volts, 0.35A max

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 11

Page 12

WIRING

CONSIDERATIONS

To take full advantage of the excellent audio performance of DDA

mixing consoles, it is essential that the installation is carried out

with care and attention. All audio signals are referenced to the

system earth, which must be clean and noise-free, and essentially

equipotential. In addition, the earth system integrity is absolutely

necessary for safety .

Do not disconnect the mains earth wire from each piece of equipment as this could create a hazardous situation.

If in doubt consult a competent engineer and your local electricity

supply company to ensure that safety regulations are not infringed

or negated.

GROUNDING

The console metalwork MUST ALWAYS be connected to the

Mains earth via the PSU lead. However, the user has a choice as

regards the Audio 0V.

The Audio 0V should be taken from the Studio earthing System

which should take the form of a star wired system. Decide on a

central point for the main earth system and starfeed to all mains

outlets and equipment racks from this point. Common electrical

wiring practice is to daisy-chain earth wires from outlet to outlet,

but this is not recommended for audio installations. The location of

the earth system star point should be in a convenient, easily

accessible position, such as the main equipment rack. The star

point must then be connected to the incoming mains earth but

preferably should be connected to a totally separate technical

earth (if local electrical regulations permit).

This should take the form of a large copper plate or stake

buried as deeply as practical into the ground (a 1 metre [39"] copper stake hammered fully into the ground would be suitable).

This should then be fed to the studio star system via heavy gauge,

low impedance cable, with adequate precautions being taken to

prevent excessive corrosion of the cable/earth stake.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 12

Page 13

Do not install other equipment (lighting, vending machines etc) to

the technical earth - only use it for Audio Equipment.

If the star point is derived from mains earth, however, and not from

a ground stake/plate, install separate clean and dirty mains outlets,

wired individually to the mains distribution box. Use the clean

supply for all audio equipment, and the dirty supply for all lighting,

vending machines etc. Do not mix the two systems. It may be

necessary to install an isolating transformer for the clean supply to

ensure adequate isolation from mains-borne interference. The

isolating transformer must be of adequate current capability and

should incorporate a Faraday Shield, connected to the incoming

mains earth.

All audio connecting cables should be good quality twin screened

cable. Do not use single screened cable.

It is very important that the screen is not used as the signal return.

Therefore connect the screen at one end only. Connecting the

screen at both ends will cause an earth loop into which external

hum fields will be induced.

In areas where high levels of radio frequency interference are

present the open end of the screen can be connected to earth

through a 0.01 microfarad capacitor. This will appear as a short

circuit at high frequencies, and lower the effective shield impedance to earth. However at audio frequencies the reactance of the

capacitor will be sufficiently high to not cause an earth loop.

In general, the screen should be connected at the signal source,

and not at the signal destination. The exception to this rule of

thumb is when connecting to an unbalanced input or to an electronically balanced input. In these cases the wires being screened

are referenced to the destination earth.

Electronically balanced outputs which are to be operated in the

unbalanced mode should be unbalanced at the output connector,

not at the signal destination so that the signal current returns to

earth via the shortest, least reactive route.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 13

Page 14

Rack mounted equipment which has unbalanced inputs and outputs

may need to be electrically isolated from the equipment rack and/

or other equipment to avoid earth loops.

DO NOT DISCONNECT THE MAINS EARTH.

Connect all equipment in a logical sequence, starting with the

monitor systems, followed by the multitrack and then the stereo

machines and the peripheral devices and isolate any earth loop

problems as they occur. It is very difficult to rectify a

problematical installation after everything has been connected due

to interaction between the various earth loops.

The Console is supplied with 1 power supply unit 3U high (5.25"),

19" rack mounting. The PSU supplies the console with +18V, 18V, +48V phantom and Audio Ground (0V). Connection

between supplies and console is a cable, terminated at both ends by

polarised Harting multiway connectors. At the console the

connector is located on the rear panel of the console.

The normal length of the PSU-Console cables is 25 feet (8

metres).

The power supply requires the following Mains supplies :-

220-240 Volts AC, 6.3 A (Maximum current ratings)

100-120 Volts AC, 10 A (Maximum current ratings)

and is connected to the AC Mains via standard IEC 3 pin lead.

The PSU has an integral low-noise cooling fan and should be

provided with at least 1U (1.75") of rack space above and below it.

WARNING - ENSURE THAT THE CORRECT VOLTAGE

HAS BEEN SELECTED ON THE PSU BEFORE SWITCHING

ON THE UNIT.

The selection of the mains input voltage is made by removing the

fuse holder from the rear panel of the PSU, and replacing it in the

correct orientation for the local voltage supply. Ensure that the

correct value fuse is fitted to correspond to the supply .

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 14

Page 15

ATTENTION

CABLES

This product should only be used with high quality, screened

twisted pair audio cables, terminated with metal bodied 3-pin XLR

connectors. The cable shield should be connected to Pin 1. Any

other cable type or configuration for the audio signals may result in

degraded performance due to electromagnetic interference.

ELECTRIC FIELDS

Should this product be used in an electromagnetic field that is

amplitude modulated by an audio frequency signal (20Hz - 20Khz),

the signal to noise ratio may be degraded. Degradation of up to

60dB at a frequency corresponding to the modulation signal may be

experienced under extreme conditions (3V/m, 90% modulation).

No permanent damage or degradation of performance will be

caused by these conditions.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 15

Page 16

MODULE

DESCRIPTIONS

Before describing the module functions, it is worth looking at some

of the facilities in some depth which would otherwise be too long to

describe within the module texts.

THE CUE SYSTEM

SOLO MODE

Q2's cue system, smart cue, is as flexible as you want it to be. It

can be operated in several modes, the simplest of which is of course

a regular PFL solo system.

The three modes of cue listening are PFL (pre-fade), AFL (afterfade), and SIP (solo-in-place). The overall level of the cue signal

fed to the monitors is adjustable on the stereo master module, so

PFL signals will not present high level signals to the monitor

outputs.

The solo-in-place mode is different from the normal recording SIP

or other SIP modes in that cueinga channel or group will not

actually mute all the other channels. It would would be useless if

by soloing a group you cut the inputs to that group.

Instead, in SIP mode, any group cue pressed will override and

replace whatever signal is present on the main output, until the cue

is released when the original signal is returned. No channels are

muted, so all active parts of the group remain intact.

As this function could be considered as dangerous in a performance

situation, the SIP mode switch is located at the top of the module

away from all the other cue mode controls.

CUE PRIORITY

CUE BUTTON ACTION

MOMENTARY OR

LATCHING

Q2's smartcue system incorporates a cue priority function. Two

leds on the stereo master module indicate whether an INPUT CUE

or an OUTPUT CUE is active. If an output cue is active, pressing

an input cue will override and replace the output cue until released,

when the output cue signal will be returned. This is an important

facility in live sound production.

The action of the cue buttons is functional in two ways.

If the button is pressed quickly (normally), the channel latches into

cue mode, with a flashing led , and remains in cue mode until the

button is pressed again. This is the "latching" mode, and is the

normal method of cue operation.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 16

Page 17

If the cue button is held depressed for at least one second, the cue

will become momentary , and only active until the cue button is then

released. This allows you to listen to a signal for a short period of

time and only have to press the button once.

CUE INTERLOCK

MODE

MASTER CUE RESET

A further method of operation involves a choice of additive or

exclusive cues.

In normal mode, the cues are additive. That is, any cue button

pressed adds its signal to any cues already pressed, so any number

of cues may be active at one time. To clear all the cues completely,

press the CUE RESET button on the stereo master module.

In the INTERLOCKED mode. pressing a cue button will clear the

previous cue, so only one cue may ever be active at any time. This

prevents cue signals adding.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 17

Page 18

THE MATRIX

SECTION

Nowadays, any console destined for theatre or similar live

performance use must have a matrix. This matrix takes the group

signals, and probably other signals, and allows different sub mixes

to be created for many uses.

Traditionally, matrices have been used to provide backstage mixes,

dressing room and foyer feeds where some elements of the mix are

not required. For example, you may want to send a different mix of

an opera or stage show to the dressing rooms to acentuate certain

points in the peformance.

Now, with demands for sound level control increasing, a matrix is

mandatory for distributing sound throughout an auditorium. Using

the normal front of house stacks, people at the rear of a hall may

need the system power increased for suitable listening levels, while

those at the front will no doubt then be deafened. The answer is to

provide arrays of loudspeakers, with mixes of suitably delayed

signals, stretching from the front of the hall to the back, to provide

more comfortable localised levels for better audience reception.

Here, the matrix increases the potential of creativity of the

performance, as by utilising the mixing facilities of the matrix, a

more surround sound effect may be created by perhaps focusing

vocals to the front, and mixing effects and music around the hall.

Q2's matrix offers all the flexibility that you need. In addition to a

feed from all the group outputs each matrix output may be fed from

the main stereo and mono (or LCR) buses, and any 2 of the four

foldnack mixes. This latter facility is extremely useful when you

consider that you can now set up one mix on a foldback bus, and

feed portions of that mix to any or all of the matrix outputs.

With fader control, CUE and ON/OFF facilities, Q2's matrix is

peraps one of the most powerful systems available on a console.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 18

Page 19

THE 20DB PAD

One trend in modern console design that DDA has chosen not to

follow is the removal of the traditional 20dB pad in favour of a

wide range gain control system.

The reason for this is mostly due to the use of microphone input

transformers. Their position in the circuit is always before the

input amplifier. Without a pad, the risk of saturating the

transformer with high level microphone outputs is extreme, unless

very large transformers are used.

DDA's philosophy places the 20dB pad before the transformer to

eliminate the risk of transformer saturation.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 19

Page 20

INPUT MODULE

The input module is essentially the same for all subgroup versions

of Q2, with links selecting whether the buses feed 8 mono, 8 stereo,

4 LCR or 16 mono subgroups. Dedicated LCR input modules have

4 routing buttons marked A, B, C, and D instead of buttons 1-8.

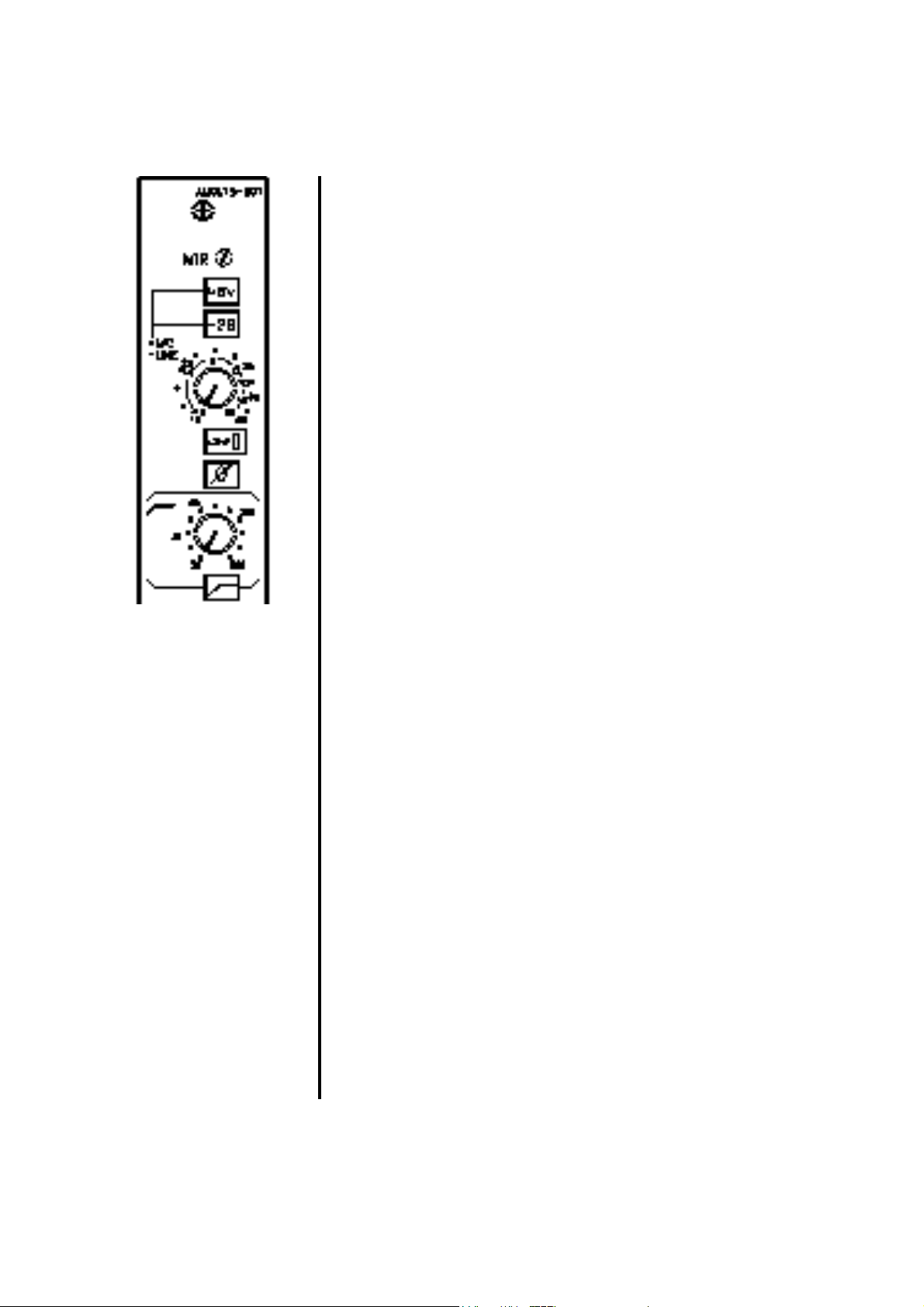

MTR

This sub-panel preset is for calibration of the external meter output

of the module.

48V

Provides phantom power for a condenser microphone, or DI box.

Optional balancing transformers may be fitted on the Mic input.

-20dB (PAD)

This inserts a 20dB attenuator in circuit with the Mic input. It may

be used when high-output microphones are employed, or for the

use of the Mic input for Line-level signals.

GAIN

The gain control is a wide range rotary potentiometer, and is active

on both Mic and Line Inputs. On Mic, the gain can be adjusted

from 12 to 66dB. For Line inputs, the adjustment is from -10 to

+20dB.

LINE

The LINE switch selects the signal on the line input socket to feed

the channel path when it is down. In this case, the Mic signal is

disconnected. The led illuminates when Line is selected.

PHASE

The PHASE REVERSE switch inverts the phase of the selected

input, to allow compensation for different wiring standards.

FILTER

The Filter switch inserts a tuneable highpass filter with a roll-off of

12dB per octave into circuit after the input amplifier. This may be

used to eliminate unwanted low-frequency noises such as rumble,

or camera buzz.

FILTER FREQUENCY CONTROL

The frequency range of the filter is continuously variable between

20Hz to 500Hz.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 20

Page 21

EQUALISER

The Q2 Equaliser is a four-band design, all bands having sweep

frequency adjustment. Each band consists of two dual-concentric

pots. The upper pot is the gain adjustment, the lower control being

the frequency adjustment. The two mid-range sections each have a

switch-selectable Q.

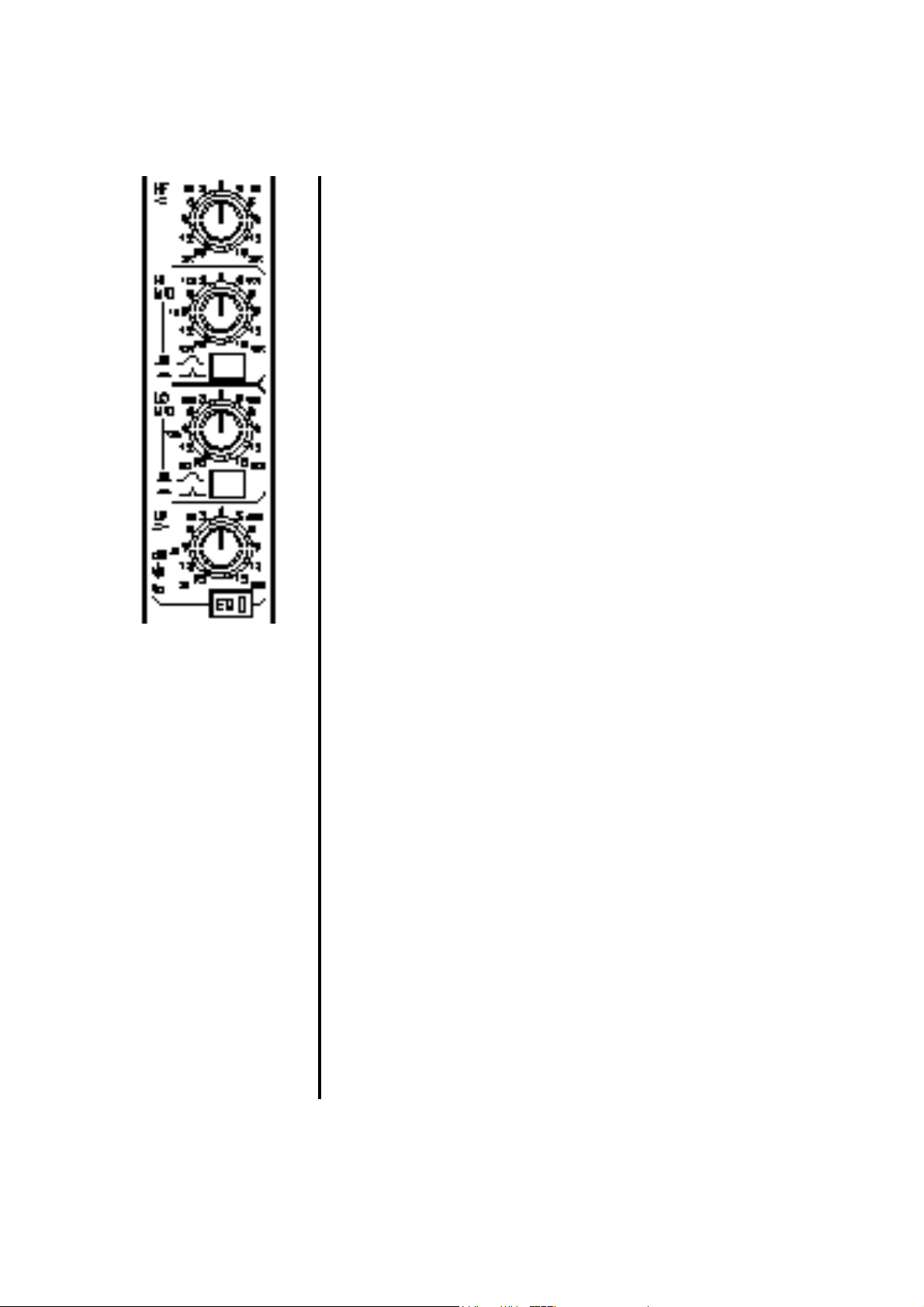

HF

Shelving section, providing +/-15dB of gain with an adjustable

frequency range of 2kHz to 20kHz.

HI MID

Peaking section, providing +/-15dB of gain, at frequencies from

525Hz to 15kHz.

Q

Selects the Q to be 0.9 or 1.8. The Q is 0.9 when the switch is in

the ‘down’ position.

LO MID

Peaking section, providing +/-15dB of gain, at frequencies from

80Hz to 2.2kHz.

Q

Selects the Q to be 0.9 or 1.8. The Q is 0.9 when the switch is in

the ‘down’ position.

LF

Shelving section, providing +/-15dB of gain with an adjustable

frequency range of 20Hz to 500Hz.

EQ IN

The EQ switch inserts the entire equaliser circuit into circuit.

When switched out, the equaliser is totally bypassed, keeping the

signal path to a minimum. The led in the switch illuminates when

the EQ is in circuit. The Insert point is normally located after the

EQ section, but a switch located on the module pcb allows the

insert to be pre-EQ.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 21

Page 22

AUXILIARIES

Q2 has eight auxiliary buses, accessed on the Input module from 4

sets of dual-concentric controls. In addition, the channel direct

output may be controlled via one pot, to provide extended auxiliary

sends. For convenient assignment four of the auxiliary buses are

denoted as foldback buses.

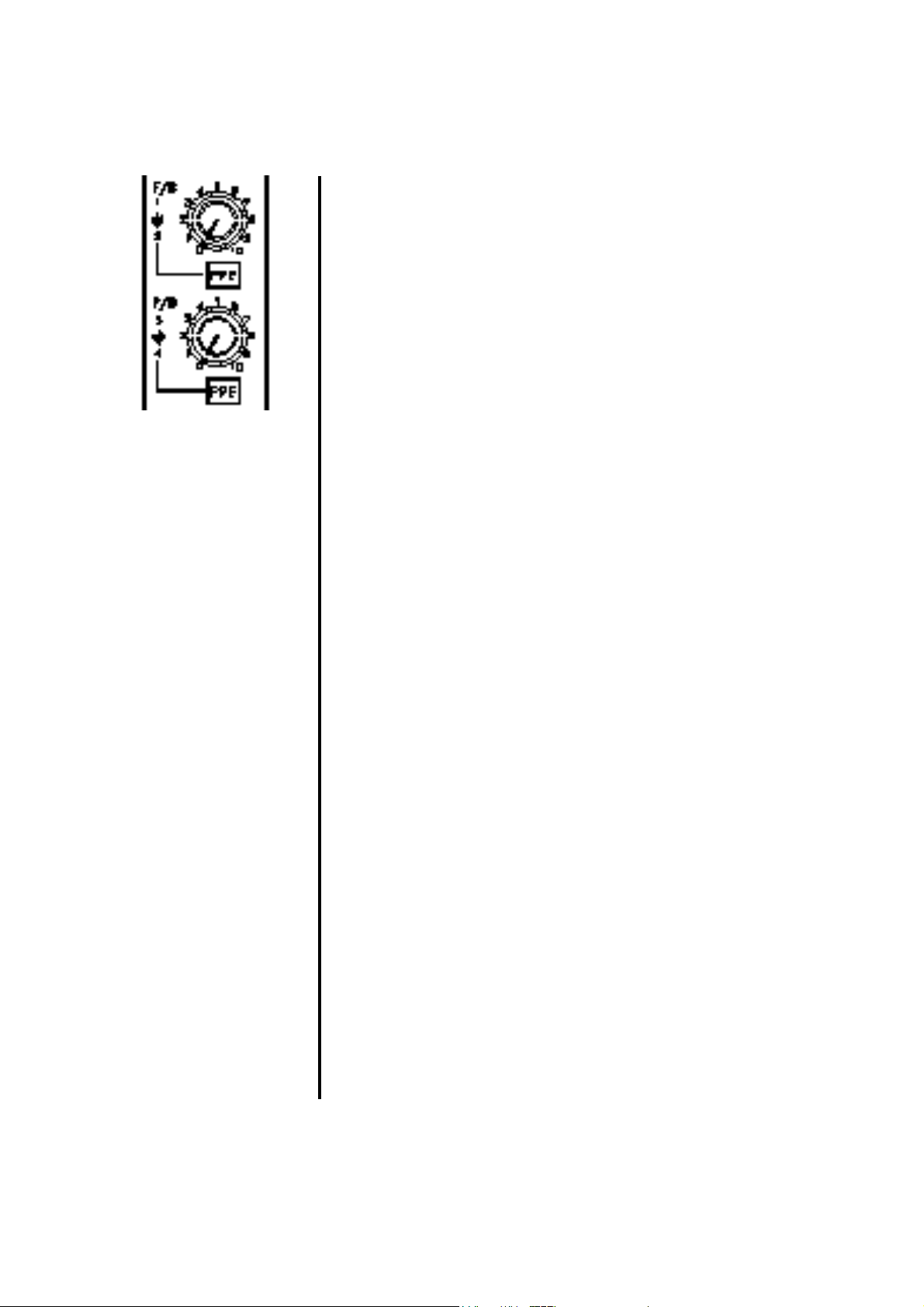

F/B 1 (Foldback 1, upper control)

Controls the level of the channel signal fed to the Foldback 1 bus.

This signal is normally post-fader, unless the PRE button, just

below, is depressed. Internal links on the module pcb allow the

pre-fader feed to be pre or post-EQ (paired with F/B 2).

F/B 2 (Foldback 2, lower control)

Controls the level of the channel signal fed to the Foldback 2 bus.

This signal is normally post-fader, unless the PRE button, just

below, is depressed.

PRE

Selects the signal feed for Foldbacks 1 and 2 to be pre-fader rather

than post-fader.

F/B 3 (Foldback 3, upper control)

Controls the level of the channel signal fed to the Foldback 3 bus.

This signal is normally post-fader, unless the PRE button, just

below, is depressed. Internal links on the module pcb allow the

pre-fader feed to be pre or post-EQ (paired with F/B 4).

F/B 4 (Foldback 4, lower control)

Controls the level of the channel signal fed to the Foldback 4 bus.

This signal is normally post-fader, unless the PRE button, just

below, is depressed.

PRE

Selects the signal feed for Foldbacks 3 and 4 to be pre-fader rather

than post-fader.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 22

Page 23

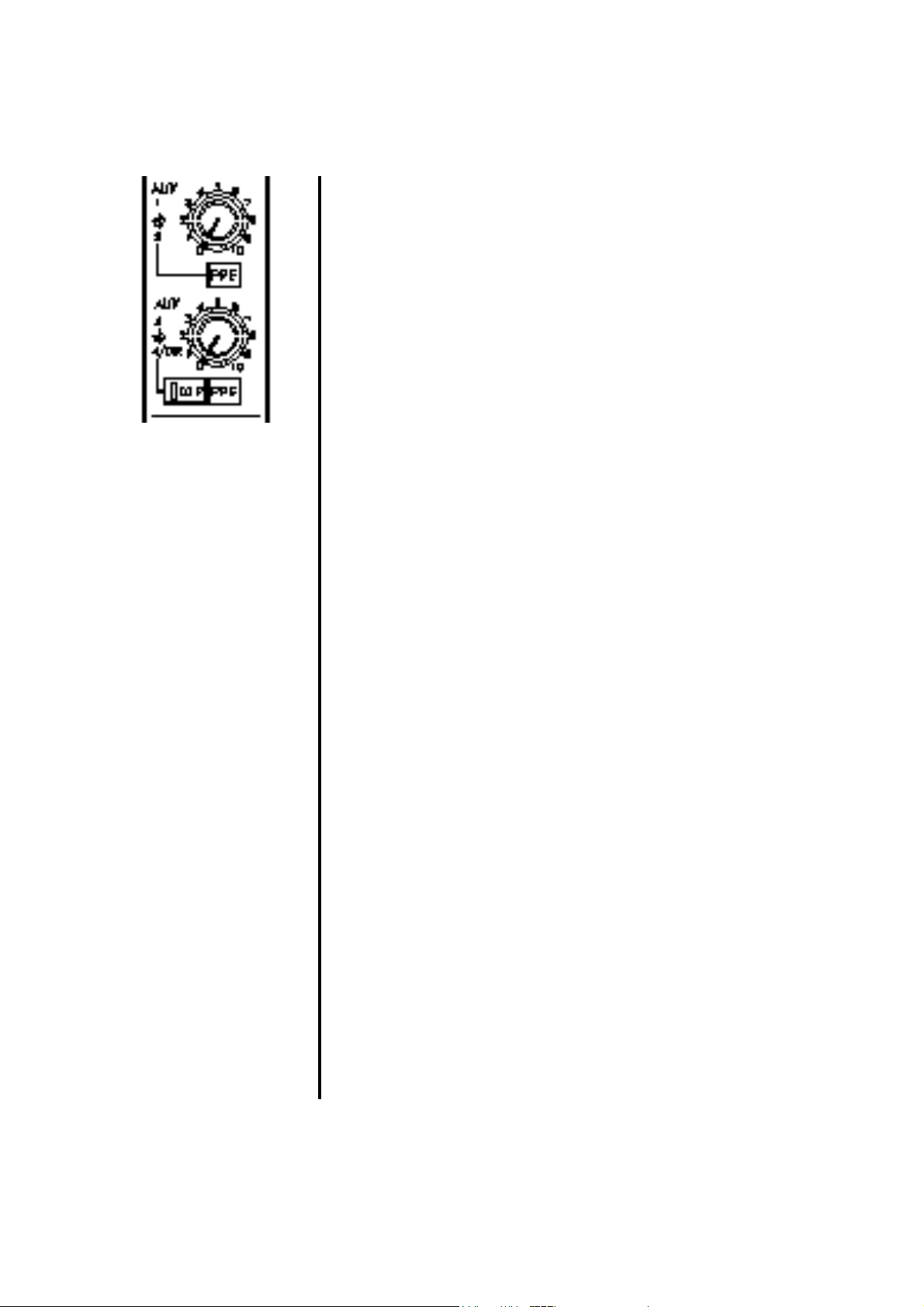

AUX 1 (Upper control)

Controls the level of the channel signal fed to the Aux 1 bus. This

signal is normally post-fader, unless the PRE button, just below, is

depressed. Internal links on the module pcb allow the pre-fader

feed to be pre or post-EQ (paired with Aux 2).

AUX 2 (Lower control)

Controls the level of the channel signal fed to the Aux 2 bus. This

signal is normally post-fader, unless the PRE button, just below, is

depressed.

PRE

Selects the signal feed for Auxes 1 and 2 to be pre-fader rather than

post-fader.

AUX 3 (Upper control)

Controls the level of the channel signal fed to the Aux 3 bus.

This signal is normally post-fader, unless the PRE button, just

below, is depressed. Internal links on the module pcb allow the prefader feed to be pre or post-EQ (paired with Aux 4).

AUX 4 (Lower control)

Controls the level of the channel signal fed to the Aux 4 bus. This

signal is normally post-fader, unless the PRE button, just below, is

depressed.

PRE

Selects the signal feed for Auxes 3 and 4 to be pre-fader rather than

post-fader.

DIR

Re-routes the signal on the Aux 4 control to feed the Channel

Direct output. The signal no longer feeds the Aux 4 bus, and can

be used either as an additional single effects send, or as a feed to a

multitrack for example.

Note: Dir and Pre are local to the module, they do not affect the

signal flow on any other module than the one on which they are

located.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 23

Page 24

ROUTING AND STATUS

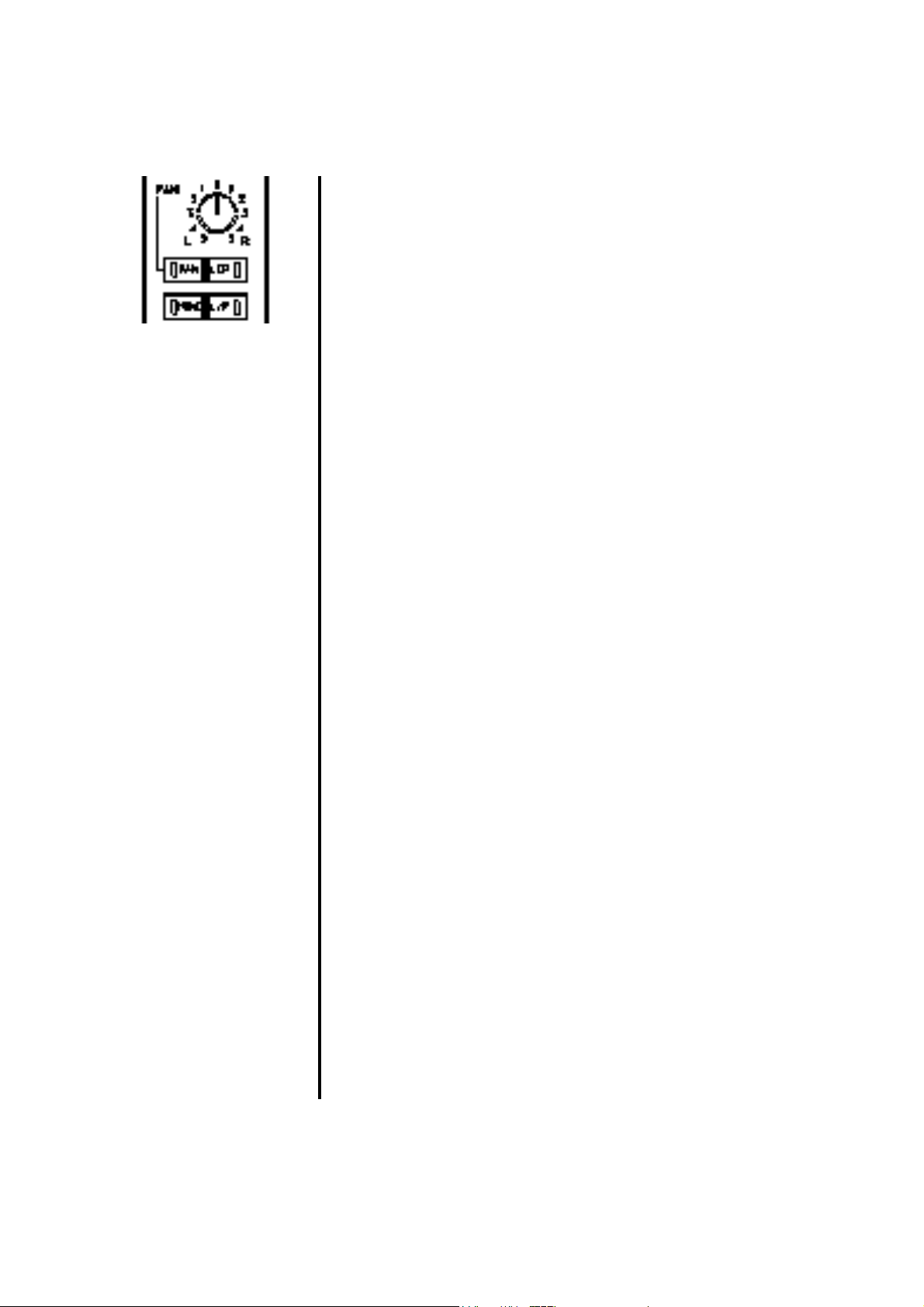

PAN

In normal mode and with the PAN set to centre, equal levels are

sent to both sides of the stereo mix or to ODD and EVEN groups

that are in use, with a 4.5dB drop relative to fully clockwise or anticlockwise. Setting the PAN control fully anticlockwise sends full

level to the Left bus, cutting the send to the Right bus; fully

clockwise rotation sends full level to the Right bus, cutting the

feed to Left.

L/R

Routes the post-fade, post-pan channel signal to the main stereo

mix bus, with led indication. The PAN control is automatically

inserted into circuit.

MONO

Routes the post-fade, post-pan channel signal to the main mono

mix bus, with led indication.

PAN

Switches the PAN control in circuit across odd and even group

buses, with led indication.

LCR

Changes the mode of the pan pot from conventional stereo (L/R

panning as described above to Left-Centre-Right mode. In this

mode, the pan control acts across all three main buses, using the

mono bus as a centre bus. When the pan is fully anti-clockwise,

signal is sent only to the left bus, with no signal to centre or right

buses. In the centre, signal is sent only to the centre (mono) bus,

with no signal to left or right buses. When fully clockwise, signal is

only sent to the right bus, with no signal sent to left or centre buses.

If a pair of groups (eg 1 and 2) is selected, the pan also acts in LCR

mode, but without a centre output from the groups unless the LCR

group modules are fitted.

11

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 24

Page 25

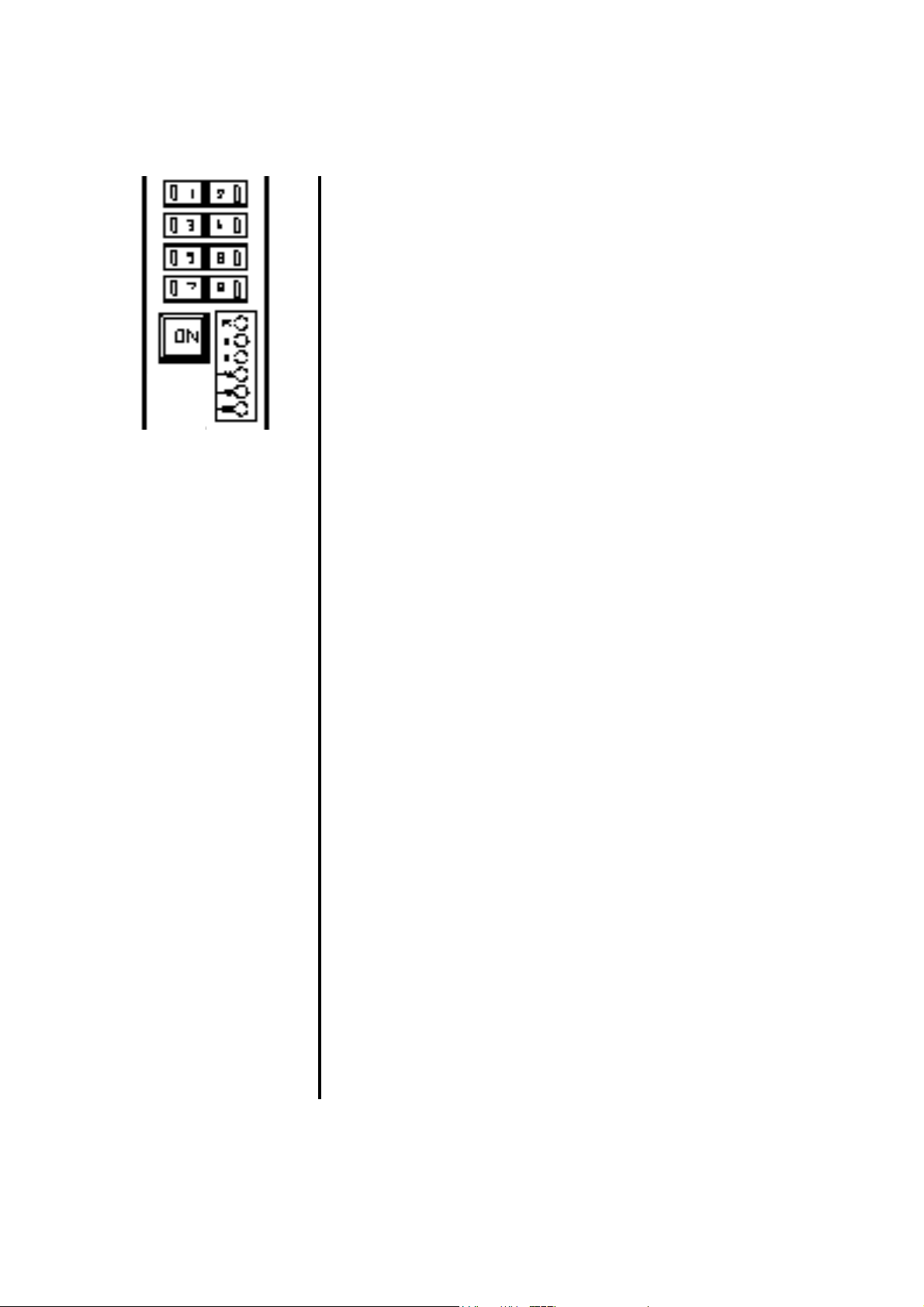

1

Routes the post-fade, post-pan channel signal to output bus 1, with

led indication.

2 ( and 3, 4, 5, 6, 7, 8)

Routes the post-fade, post-pan channel signal to output bus 2 (and

3, 4, 5, 6, 7, and 8 if pressed), with led indication.

ON

The ON switch enables the channel signal path, and is indicated by

an led in the switch when the channel is active. When OFF, all

post-fade auxiliary sends and routing assignments are muted.

Internal links allow the ON switch to be configured as a channel

CUT.

METER

The six segment led meter comprises a five segment meter, fed

from one of three points in the signal chain, and the PEAK led,

which is fed simultaneously from all 3 points, giving a warning of

potential overload signals within the signal path.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 25

Page 26

CUE

The CUE (or SOLO) button feeds a Pre-fader or post-fader signal

(as selected on the master module PFL or AFL) to the Monitor

section (loudspeakers or headphones), replacing the selected

monitor source if one is selected. The main stereo output of the

console is not affected unless SIP (Solo-in-place) mode has been

selected on the master . The yellow led in the CUE switch will flash

when the CUE function is active. CUE signals from different

sources that are active simultaneously in the non-interlocked mode

will be summed.

To latch the CUE function, press the button quickly and release. To

unlatch, repeat. To CUE a signal momentarily, hold down the CUE

button for at least 1 second. On release, the CUE will also be

released.

See THE CUE/SOLO SYSTEM on page 16 for full functional

details.

FADER

The fader is the main signal level control for the channel, and is a

long-throw type which gives smooth control of the channel level.

SAFE

Deselects the return from the VCA/MUTE Group system, without

affecting the mute group assignments. Useful to locally protect

signals, or manually override grouped MUTE ON conditions.

MUTE GROUP 1

Assigns the channel to MUTE Group 1. Similarly for MUTE

Groups 2 through 8.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 26

Page 27

CONNECTORS AND PIN ASSIGNMENTS

MIC INPUT :XLR type 3 pin connectors, Balanced

Nominal level : -56dBu to -8dBu

Pin 1 - Ground

Pin 2 - Signal +ve (hot)

Pin 3 - Signal -ve (cold)

Input impedance : >2k.

LINE INPUT :1/4" TRS Jack Socket, 'A' Guage, Balanced

Nominal Input Level : +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

INSERT SEND :

1/4" TRS Jack socket, ‘A’ Gauge, Balanced

Nominal Output level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Output Impedance: <75 Ohm

INSERT RETURN :

1/4" TRS Jack Socket, ‘A’ Gauge, Balanced

Nominal Input Level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

DIRECT OUTPUT : 1/4" TRS Jack socket, ‘A’ Gauge, Balanced

Nominal Output level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Output Impedance: < 75 Ohm

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 27

Page 28

VCA INPUT MODULE

Q2 may also be supplied with 8 VCA/Mute groups. The input

module is essentially the same as the standard mono input, with the

addition of the 8 VCA/Mute groups, and mutes on most of the

auxiliary sends.

Replacing 4 input modules are the VCA master modules, which are

the fader and mute masters to control the 8 VCA/Mute groups.

Each module has 2 such masters, and a stereo effects return input.

Only the differences from the standard module are described here,

which are in fact all on the lower section of the module.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 28

Page 29

F/B 1/2 ON

Enables the channel feeds to the foldback buses 1 and 2.

F/B 3/4 ON

Enables the channel feeds to the foldback buses 3 and 4.

AUX 1/2 ON

Enables the channel feeds to the foldback buses 1 and 2.

EXT

This led illuminates when the channel is muted via an external

source, for example a noise gate control system using the channel

VCA. The remote control input accepts a DC voltage in the range

0 -10V. This facility is not available on current consoles, unless to

special order, although the led indicator has not been removed.

The wiring diagram overleaf should be followed to minimise noise

on the control lines when using external inputs.

MUTE SAFE (Not active on VCA consoles)

This may not be fitted to future production.

VCA/MUTE GROUP 1 ASSIGN

Assigns the channel mute to VCA/Mute Group 1, with led

indication. The channel level is now dependant on both the

position of the local fader and the position of the VCA master

fader. Similarly for assigns 2, 3, 4, 5, 6, 7 and 8.

Internal links allow the MUTE GROUPS to become SCENE

PRESETS, that is when a MASTER is pressed, all assigned

channels are switched ON, not muted.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 29

Page 30

EXTERNAL VCA

FADER CONTROL

WIRING

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 30

Page 31

STEREO EFFECT RETURN MODULE

As an option, in place of a standard input, a stereo effect return

input may be fitted. The effect return section may be controlled by

the VCA master, if VCA/Mute subgrouping is fitted to the console.

GAIN

Adjusts the gain of the effect return input section. The gain is

adjustable from -15dB to +15dB.

L CUT

Cuts the signal feed to the left channel, with led indication.

R CUT

Cuts the signal feed to the right channel, with led indication.

PHASE REVERSE

Inverts the phase of the signal on the right channel input.

WIDTH

Varies the width of the stereo image from mono through normal

stereo to a wide signal where the left and right signals appear to

come from outside their normal image positions.

M/S DECODING

If the width is set fully anticlockwise to MONO and the PHASE

REVERSE switch is pressed the module will decode line level M/S

(Sum and Difference) signals. This may be the output of a

pre-amp, or recorded material.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 31

Page 32

HF EQ

A shelving equaliser with an adjustable gain of +/-15dB at a

frequency of 12kHz.

LF EQ

A shelving equaliser with an adjustable gain of +/-15dB at a

frequency of 50Hz.

F/B and AUXILIARY SENDS

F/B 1/2

This dual concentric pair of level controls adjusts the amount of

signal fed to foldback buses 1 and 2 (or 3 and 4 if the switch 3-4 is

pressed). The upper control adjusts the level for bus 1 (3), the

lower for bus 2 (4). Internal links allow these feeds to be selected

from a mono sum of the stereo signal, or left to 1, right to 2 (all

selectable pre or post fader by links).

3-4

The switch assigns the level controls to feed foldback buses 3/4

instead of 1/2.

AUX 1/2

This dual concentric pair of level controls adjusts the amount of

signal fed to auxiliary buses 1 and 2 (or 3 and 4 if the switch 3-4 is

pressed). The upper control adjusts the level for bus 1 (3), the

lower for bus 2 (4). Internal links allow these feeds to be selected

from a mono sum of the stereo signal, or left to 1, right to 2 (all

selectable pre or post fader by links).

3-4

The switch assigns the level controls to feed auxiliary buses 3/4

instead of 1/2.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 32

Page 33

BAL

Balances the stereo signal within the stereo bus, or within pairs of

groups if the MONO/STEREO button is set to STEREO.

MONO/STEREO

If set to MONO, a mono sum of the stereo signal is fed to any

selected group. If set to stereo, a stereo signal is sent to pairs of

groups via the BAL control, left to odd, right to even.

MONO

Assigns a MONO sum of the stereo signal to the main MONO

(Centre) bus.

L/R

Assigns the stereo signal to the main STEREO L/R bus.

1

Assigns signal to group 1, either as a mono sum, or the left channel,

depending on the setting of the mono stereo switch. Similarly for

groups 2-8.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 33

Page 34

SAFE (Not active on VCA modules)

Deselects the return from the MUTE Group system, without

affecting the mute group assignments. Useful to locally protect

signals, or manually override grouped MUTE ON conditions.

VCA/MUTE GROUP 1

Assigns the channel to VCA/MUTE Group 1. Similarly for VCA/

MUTE Groups 2 through 8. If the VCA option is fitted then the

post fader level will depend upon the local fader and the VCA

group master fader.

CUE

Assigns the stereo signal to the CUE system, with flashing led

indication when enabled.

ON

Enables the Effect Return signal path.

FADER

Controls the post fader signal level.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 34

Page 35

CONNECTORS AND PIN ASSIGNMENTS

LINE A : 3 Pin XLR type, Balanced

Nominal Input Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Input Impedance : >10 kOhm

LINE B : 1/4" TRS Jack Socket, ‘A’ Gauge, Balanced

Nominal Input Level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 35

Page 36

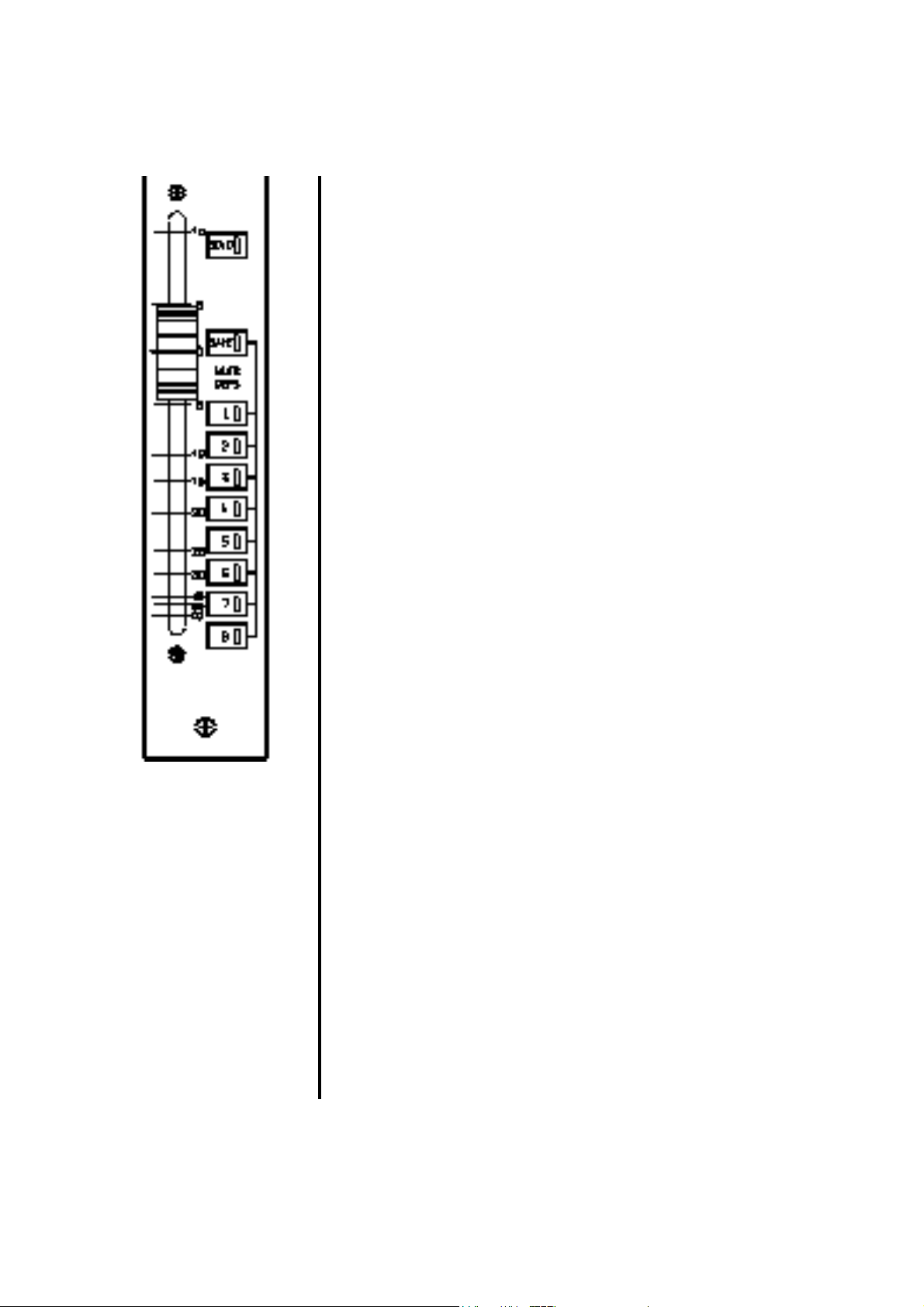

MONO SUBGROUP OUTPUT MODULE

Either 8 or 16 mono subgroup modules may be fitted in Q2. If 16

are fitted, routing is paired, with active pan across the group buses

at all times. For 8 modules, routing is individually selected, with

pan only switched in across odd and even groups as required.

The module comprises the group control and output (lower part of

module) and a matrix mixer section (upper part of module).

Each module has controls for inputs to the Matrix mixer, ie they are

not feeds from that group to the matrix buses, but feeds from the

groups etc to the matrix.

F/B 1/3

Adjusts the level of the Foldback 1 master output (or 3) fed to the

Matrix bus on the module. This may be used to feed a global mix

set-up on the F/B 1 bus to any of the 8 matrix outputs.

F/B 3 (switch)

Selects the Foldback output 3 to the matrix instead of F/B 1.

F/B 2/4

Adjusts the level of the Foldback 2 master output (or 4) fed to the

Matrix bus on the module.

F/B 4 (switch)

Selects the Foldback output 4 to the matrix instead of F/B 2.

L/R

Adjusts the level of the summed (mono) signal from the main

stereo left and right outputs fed to the Matrix on the module.

MONO

Adjusts the level of the main Mono (centre) signal from the main

mono output fed to the Matrix on the module.

1

Adjusts the level of the post-fader Group 1 signal input to the

Matrix. Similarly for Controls 2-8 for Group signals 2 to 8.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 36

Page 37

T/B

Enables talkback signals to be routed to the Matrix output when the

communication system is used, with led indication. This can be

used to prevent talkback signals going to unwanted destinations.

ON

Enables the Matrix output, with led indication.

MATRIX METER

Sub-panel preset used to calibrate the Matrix level meter .

GROUP METER

Sub-panel preset used to calibrate the Group level meter.

CUE/SOLO

Solo’s the Matrix signal to the main monitors (headphones or

loudspeakers), with flashing led indication. See the Input Module

for a functional description of the solo button.

FADER

The 60mm fader controls the level of the Matrix output signal.

PAN

Pans the Group signal across the main Stereo bus, or if in LCR

mode across the Left, Right and Centre (mono) buses. In the

centre, in L/R mode, the signals are 4.5dB below the signals when

hard-panned left or right.

PAN (mode)

In the ‘up’ position the pan mode is conventional Stereo (L/R)

panning. In the ‘down’ position, the group is panned across the

three main outputs in Left-Centre-Right mode.

When the pan is fully anti-clockwise, signal is sent only to the left

bus, with no signal to centre or right buses. In the centre, signal is

sent only to the centre (mono) bus, with no signal to left or right

buses.

When fully clockwise, signal is only sent to the right bus, with no

signal sent to left or centre buses.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 37

Page 38

SUB/LCR

Routes the group signal to the main Stereo (Left/Right) and main

Mono (centre) buses, with led indication.

ON

The ON switch enables the group output, and is indicated by an

led in the switch when the output is active. Internal links allow the

ON switch to be configured as a group CUT.

MATRIX SEND PRE

Allows the Group input to the Matrix to be fed pre-fader, rather

than post-fader.

CUE/SOLO

Solo’s the Group signal to the main monitors (headphones or

loudspeakers), with flashing led indication. See the Input Module

for a functional description of the solo button.

MUTE SAFE (Not active in VCA consoles)

Prevents the Mute Group (or scene preset) master from muting the

channel, and may be used to locally override muted channels.

VCA/MUTE GROUP 1 ASSIGN

Assigns the channel mute to VCA/Mute Group 1, with led

indication. Similarly for assigns 2, 3, 4, 5, 6, 7 and 8. If the VCA

option is fitted then the channel level will depend upon the position

of the channel fader and the VCA group master.

Internal links allow the MUTE GROUPS to become SCENE

PRESETS, that is when a MASTER is pressed, all assigned

channels are switched ON, not muted.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 38

Page 39

CONNECTORS AND PIN ASSIGNMENTS

Group Ouptut : 3 Pin XLR type, Balanced

Nominal Output Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Output Impedance : <75 Ohm

Matrix Ouptut : 3 Pin XLR type, Balanced

Nominal Output Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Output Impedance : <75 Ohm

Insert Send : 1/4" TRS Jack socket, ‘A’ Gauge, Balanced

Nominal Output level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Output Impedance: <75 Ohm

Insert Return : 1/4" TRS Jack Socket, ‘A’ Gauge, Balanced

Nominal Input Level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 39

Page 40

STEREO SUBGROUP OUTPUT MODULE

Eight stereo subgroup modules may be fitted in Q2, and routing is

individually selected.

The module comprises the Stereo Group control and output (lower

part of module) and a Stereo Matrix mixer section (upper part of

module). Each module has controls for inputs to the Stereo Matrix

mixer ie they are not feeds from that Group to the Matrix buses, but

feeds from the Groups etc to the Matrix.

F/B 1/3

Adjusts the level of the Foldback 1 master output (or 3) fed to the

Stereo Matrix bus on the module. This may be used to feed a global

mix set-up on the F/B 1 bus to any of the 8 Stereo Matrix outputs.

The control is a dual-concentric pair with Level and Pan adjust

across the Stereo Matrix.

F/B 3 (switch)

Selects the Foldback output 3 to the matrix instead of F/B 1.

F/B 2/4

Adjusts the level of the Foldback 2 master output (or 4) fed to the

Matrix bus on the module. The control is a dual-concentric pair

with Level and Pan adjust across the Stereo Matrix.

F/B 4 (switch)

Selects the Foldback output 4 to the matrix instead of F/B 2.

L/R

Adjusts the level of the main Stereo Left and Right outputs fed to

the Stereo Matrix on the module.

MONO

Adjusts the level of the main Mono (centre) signal from the main

Mono output fed to both sides of the Stereo Matrix on the module.

1

Adjusts the level of the post-fader Stereo Group 1 signal input to

the Stereo Matrix. Similarly for Controls 2-8 for Group signals 2 to

8.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 40

Page 41

T/B

Enables talkback signals to be routed to the Matrix output when the

communication system is used, with led indication. This can be

used to prevent talkback signals going to unwanted destinations.

ON

Enables the Matrix output, with led indication.

MATRIX METER (L and R)

Sub-panel preset used to calibrate the Stereo Matrix level meters.

GROUP METER (L and R)

Sub-panel preset used to calibrate the Stereo Group level meters.

CUE/SOLO

Solo’s the Stereo Matrix signal to the main monitors (headphones

or loudspeakers), with flashing led indication. See the Input

Module for a functional description of the solo button.

FADER

The 60mm fader controls the level of the Stereo Matrix output

signals.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 41

Page 42

BAL

Adjusts the Stereo Group signal within the main Stereo Left and

Right buses. The range of adjustment is +/-3dB.

SUB/LCR

Routes the Stereo Group signal to the main Stereo (Left/Right) bus,

and/or the main Mono (centre) buses, with led indication.

ON

The ON switch enables the group output, and is indicated by an

led in the switch when the output is active. Internal links allow the

ON switch to be configured as a group CUT.

MATRIX SEND PRE

Allows the Stereo Group input to the Stereo Matrix to be fed

pre-fader, rather than post-fader.

CUE/SOLO

Solo’s the Group signal to the main monitors (headphones or

loudspeakers), with flashing led indication. See the Input Module

for a functional description of the solo button.

MUTE SAFE (Not active on VCA consoles)

Prevents the Mute Group (or scene preset) master from muting the

channel, and may be used to locally override muted channels.

VCA/MUTE GROUP 1 ASSIGN

Assigns the channel mute to VCA/Mute Group 1, with led

indication. Similarly for assigns 2, 3, 4, 5, 6, 7 and 8. If the VCA

option is fitted then the channel level will depend upon the position

of the channel fader and the VCA group master.

Internal links allow the MUTE GROUPS to become SCENE

PRESETS, that is when a MASTER is pressed, all assigned

channels are switched ON, not muted.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 42

Page 43

CONNECTORS AND PIN ASSIGNMENTS

Group Output : 3 Pin XLR type, Balanced

Nominal Output Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Output Impedance : <75 Ohm

Matrix Output : 3 Pin XLR type, Balanced

Nominal Output Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Output Impedance : <75 Ohm

Insert Send : 1/4" TRS Jack socket, ‘A’ Gauge, Balanced

Nominal Output level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve : Ground

Output Impedance: <75 Ohm

Insert Return : 1/4" TRS Jack Socket, ‘A’ Gauge, Balanced

Nominal Input Level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 43

Page 44

LCR SUBGROUP OUTPUT MODULE

The LCR Subgroup Output module has three outputs (for the left,

centre and right outputs from each group). It may be used with

either the normal input module or the dedicated LCR input module.

The module comprises the LCR Group control and output (lower

part of module) and a mono Matrix mixer section (upper part of

module). Each module has controls for inputs to the Matrix mixer

ie they are not feeds from that group to the matrix buses, but feeds

from the groups etc to the matrix.

F/B 1/3

Adjusts the level of the Foldback 1 master output (or 3) fed to the

Matrix bus on the module. This may be used to feed a global mix

set-up on the F/B 1 bus to any of the 8 matrix outputs.

F/B 3 (switch)

Selects the Foldback output 3 to the matrix instead of F/B 1.

F/B 2/4

Adjusts the level of the Foldback 2 master output (or 4) fed to the

Matrix bus on the module.

F/B 4 (switch)

Selects the Foldback output 4 to the matrix instead of F/B 2.

L/R

Adjusts the level of the summed (mono) signal from the main

stereo left and right outputs fed to the Matrix on the module.

MONO

Adjusts the level of the main Mono (centre) signal from the main

mono output fed to the Matrix on the module.

1

Adjusts the level a summed mono signal of the post-fader LCR

Group A (1) signal input to the Matrix. Similarly for Controls 2-4

for LCR Group signals B, C and D (2 to 4).

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 44

Page 45

T/B

Enables talkback signals to be routed to the Matrix output when the

communication system is used, with led indication. This can be

used to prevent talkback signals going to unwanted destinations.

ON

Enables the Matrix output, with led indication.

MATRIX METER

Sub-panel preset used to calibrate the Matrix level meter .

GROUP METERS (L, C, R)

Sub-panel presets used to calibrate the LCR Group level meters.

CUE/SOLO

Solo’s the Matrix signal to the main monitors (headphones or

loudspeakers), with flashing led indication. See the Input Module

for a functional description of the solo button.

FADER

The 60mm fader controls the level of the Matrix output signal.

SUB/LCR

Routes the group signal to the main LCR Stereo (Left/Right) and

Centre (mono) buses, with led indication.

ON

The ON switch enables the group output, and is indicated by an

led in the switch when the output is active. Internal links allow the

ON switch to be configured as a group CUT.

MATRIX SEND PRE

Allows the Group input to the Matrix to be fed pre-fader, rather

than post-fader.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 45

Page 46

CUE/SOLO

Solo’s the Group signal to the main monitors (headphones or

loudspeakers), with flashing led indication. See the Input Module

for a functional description of the solo button.

MUTE SAFE (Not active in VCA consoles)

Prevents the Mute Group (or scene preset) master from muting the

channel, and may be used to locally override muted channels.

VCA/MUTE GROUP 1 ASSIGN

Assigns the channel mute to VCA/Mute Group 1, with led

indication. Similarly for assigns 2, 3, 4, 5, 6, 7 and 8. If the VCA

option is fitted then the channel level will depend upon the position

of the channel fader and the VCA group master.

Internal links allow the MUTE GROUPS to become SCENE

PRESETS, that is when a MASTER is pressed, all assigned

channels are switched ON, not muted.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 46

Page 47

CONNECTORS AND PIN ASSIGNMENTS

Group Output : 3 Pin XLR type, Balanced

Nominal Output Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Output Impedance : <75 Ohm

Matrix Output : 3 Pin XLR type, Balanced

Nominal Output Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Output Impedance : <75 Ohm

Insert Send : 1/4" TRS Jack socket, ‘A’ Gauge, Balanced

Nominal Output level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Output Impedance: <75 Ohm

Insert Return : 1/4" TRS Jack Socket, ‘A’ Gauge, Balanced

Nominal Input Level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 47

Page 48

FOLDBACK MASTER MODULE

F/B 1 LEVEL

Adjusts the level of the Foldback 1 Master output signal.

ON

Enables the Foldback 1 Master output signal, with led indication.

CUE/SOLO

Solo’s the Foldback signal to the main monitors (headphones or

loudspeakers), with flashing led indication. See the Input Module

for a functional description of the solo button.

Foldbacks 2-4 are identical to Foldback 1 above.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 48

Page 49

AUXILIARY MASTER MODULE

AUX 1 LEVEL

Adjusts the level of the Auxiliary 1 Master output signal.

ON

Enables the Auxiliary 1 Master output signal, with led indication.

CUE/SOLO

Solo’s the Auxiliary signal to the main monitors (headphones or

loudspeakers), with flashing led indication. See the Input Module

for a functional description of the solo button.

Auxiliaries 2-4 are identical to Auxiliary 1 above.

MUTE GROUP MASTER 1

When pressed, mutes all channels and outputs assigned to MUTE

GROUP 1. MASTER MUTES 2-8 operate in a similar fashion for

MUTE GROUPS 2-8.

HEADPHONES/HEADSET OUTPUTS

Two pairs of headphones (impedance 200-600 Ohms) may be

plugged in to the module. A Clearcom-type headset may also be

connected, complete with boom microphone, on a 4-pin XLR

connector.

HEADPHONES LEVEL

Adjusts the level of the monitor signal in the headphone or headset,

independently of the main monitor level control.

ON

Switches on the headphone/headset outputs.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 49

Page 50

STEREO MASTER MODULE

SOLO METER

Indicates the level of the Solo signal in stereo.

PFL METER

Indicates the level of the PFL signal.

METER CALIBRATIONS

Sub-panel presets to calibrate all module and meterbridge master

meters.

PSU INDICATOR LEDs

Three led’s which indicate all DC voltages are present.

CUE MODE SIP

Selects the CUE mode to be SIP (Solo-in-Place). This mode does

not mute inputs when a channel or output is solo’ed. The main

output signal is replaced by the solo’ed signal, until the cue/solo is

cleared when the original signal is returned to the main outputs.

EXTERNAL TAPE INPUT

An external input is provided, for use as interval playback, or

effects input.

L/R

Assigns the Tape input to the main Stereo Left and Right Outputs.

MONO

Assigns the Tape input to the main Mono (Centre) Output.

TAPE PLAY LEVEL

Adjusts the level of the Tape Input.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 50

Page 51

INTERNAL SINEWAVE/NOISE GENERATOR

Q2 features an integral generator capable of producing a 1kHz

sinewave or pink noise for system testing and alignment.

PINK/1kHz

Selects the type of output from the generator. In the ‘up’ position,

the generator produces PINK noise, in the ‘down’ position a 1kHz

sinewave tone.

ON

Enables the generator, with led indication

OSC

Adjusts the level of the generator output.

GENERATOR/TALKBACK ASSIGN MATRIX

Both the internal generator and talkback system share a matrix of

assign switches to all outputs.

F/B 1-2, 3-4

Assigns the generator and/or talkback to Foldback buses 1 and 2

and 3 and 4 respectively .

AUX 1-2, 3-4

Assigns the generator and/or talkback to Auxiliary buses 1 and 2

and 3 and 4 respectively .

GROUPS

Assigns the generator and/or talkback to all the Group buses.

MTX

Assigns the generator and/or talkback to all the Matrix buses which

have their T/B assign buttons pressed.

L/R

Assigns the generator and/or talkback to the main Left and Right

outputs.

MONO

Assigns the generator and/or talkback to the main Mono (centre)

output.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 51

Page 52

MONITOR SECTION

Any of three sources may be fed to the monitoring section, in

addition to the CUE/SOLO signal. If no source is selected, nothing

is heard on monitors until a CUE/SOLO is pressed.

TAPE

Selects the Tape input as the monitor source.

L/R

Selects the main Stereo Left/Right output as the monitor source.

MONO

Selects the main Mono output as the monitor source.

If both L/R and MONO are pressed, monitoring is in true LCR

mode, ie three channel outputs for simulation of the main speaker

system. This facility is very useful when the console is located in a

screened booth in a Theatre.

MONITOR LEVEL

Adjusts the level of the monitor outputs.

MONO

Assigns the monitor outputs to the mono (centre) monitor output.

DIM

Reduces the level of the monitoring system by 20dB.

ON

Enables the monitoring system.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 52

Page 53

CUE/SOLO MASTER SECTION

PFL/AFL

Selects the Cue/Solo mode to be PFL, or AFL when the switch is

depressed.

TRIM

Adjusts the level of the Cue/Solo signal, most useful in the PFL

mode.

CUE INTLK

Interlock mode selection. In normal mode, Cues are additive. That

is any number of Cue buttons may be pressed and the signals will

be added. In INTERLOCK mode, only one Cue may be active at

any time, so pressing a Cue will automatically cancel the

previously selected Cue.

CUE I/P

Indicates that an input CUE is pressed. Inputs take priority over

outputs in normal mode, so pressing an input CUE will suspend an

output CUE until the input is released.

CUE O/P

Indicates that an output CUE is pressed. This led will extinguish if

an input CUE is pressed while an output CUE is already active.

CUE RESET

Clears all pressed CUE buttons.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 53

Page 54

TALKBACK SYSTEM

In addition to the normal talkback microphone input, Q2 includes a

Clearcom-type communications interface.

S/TONE

Sub-panel preset for adjusting the sidetone of the Clearcom

compatible interface. Sidetone is the level of your own voice that

you will hear in the headphones when speaking into the

communications microphone. Some sidetone is usually preferred

as it gives confidence that the system is working.

T/B LEVEL

Adjusts the level of the talkback microphone system.

COMMS ON

Enables the communication system.

CALL

The led in the switch illuminates when the console is being called.

Alternatively, pressing CALL sends out a call signal to the Master.

TB

Pressing TB (Talkback) routes the talkback signal to all assigned

outputs.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 54

Page 55

MASTER OUTPUT CONTROL

PRE

Allows the signal feed from the main Left/Right outputs to the

Mono (Centre) output to be pre-fader rather than post-fader.

L/R TO MONO

Assigns the post-fader Left/Right Output to the main Mono

(Centre) output.

L/R CUE/SOLO

Solo’s the main Left/Right output to the main monitors

(headphones or loudspeakers), with flashing led indication.

MONO CUE/SOLO

Solo’s the main Mono (Centre) output to the main monitors

(headphones or loudspeakers), with flashing led indication.

FADERS

Three faders control the output level of the main Left, Right and

Centre (mono) signals. The user may determine the configuration

of the faders to be L, C, R or L, R, C.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 55

Page 56

MASTER CONNECTOR PANEL

CONNECTORS AND PIN ASSIGNMENTS

Main Left, Right and Mono Outputs,

Monitor Outputs, Auxiliary Outputs,

and generator output :

3 Pin XLR type, Balanced

Nominal Output Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Output Impedance : <75 Ohm

Mix Insert Send :

1/4" TRS Jack socket, ‘A’ Gauge, Balanced

Nominal Output level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Output Impedance: <75 Ohm

Mix Insert Return :

1/4" TRS Jack Socket, ‘A’ Gauge, Balanced

Nominal Input Level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

Talkback Microphone Input :

3 pin XLR type, Balanced

Nominal Input Level: -62dBu to -8dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Input Impedance : >2 kOhm

+48V Phantom power optional

Tape Play Input :

3 Pin XLR type, Balanced

Nominal Input Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Input Impedance : >10 kOhm

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 56

Page 57

VCA MASTER MODULE

The effect return VCA master is only fitted to consoles with the

optional VCA Grouping inputs. The effects return section may be

controlled by the VCA masters.

GAIN

Adjusts the gain of the effect return input section. The gain is

adjustable from -15dB to +15dB.

L CUT

Cuts the signal feed to the left channel, with led indication.

R CUT

Cuts the signal feed to the right channel, with led indication.

PHASE REVERSE

Inverts the phase of the signal on the right channel input.

WIDTH

Varies the width of the stereo image from mono through normal

stereo to a wide signal where the left and right signals appear to

come from outside their normal image positions.

M/S DECODING

If the width is set fully anticlockwise to MONO and the PHASE

REVERSE switch is pressed the module will decode line level M/S

(Sum and Difference) signals. This may be the output of a

pre-amp, or recorded material.

HF EQ

A shelving equaliser with an adjustable gain of +/-15dB at a

frequency of 12kHz.

LF EQ

A shelving equaliser with an adjustable gain of +/-15dB at a

frequency of 50Hz.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 57

Page 58

F/B and AUXILIARY SENDS

F/B 1/2

This dual concentric pair of level controls adjusts the amount of

signal fed to foldback buses 1 and 2 (or 3 and 4 if the switch 3-4 is

pressed). The upper control adjusts the level for bus 1 (3), the

lower for bus 2 (4). Internal links allow these feeds to be selected

from a mono sum of the stereo signal, or left to 1, right to 2 (all

selectable pre or post fader by links).

3-4

The switch assigns the level controls to feed foldback buses 3/4

instead of 1/2.

AUX 1/2

This dual concentric pair of level controls adjusts the amount of

signal fed to auxiliary buses 1 and 2 (or 3 and 4 if the switch 3-4 is

pressed). The upper control adjusts the level for bus 1 (3), the

lower for bus 2 (4). Internal links allow these feeds to be selected

from a mono sum of the stereo signal, or left to 1, right to 2 (all

selectable pre or post fader by links).

3-4

The switch assigns the level controls to feed auxiliary buses 3/4

instead of 1/2.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 58

Page 59

BAL

Balances the stereo signal within the stereo bus, or within pairs of

groups if the MONO/STEREO button is set to STEREO.

MONO/STEREO

If set to MONO, a mono sum of the stereo signal is fed to any

selected group. If set to stereo, a stereo signal is sent to pairs of

groups via the BAL control, left to odd, right to even, groups.

MONO

Assigns a MONO sum of the stereo signal to the main MONO

(Centre) bus.

L/R

Assigns the stereo signal to the main STEREO L/R bus.

1

Assigns signal to group 1, either as a mono sum, or the left channel,

depending on the setting of the mono stereo switch. Similarly for

groups 2-8.

ON

Enables the Effect Return signal path.

SAFE

Deselects the return from the VCA/MUTE Group system, without

affecting the mute group assignments. Useful to locally protect

signals, or manually override grouped MUTE ON conditions.

VCA/MUTE GROUP 1

Assigns the channel to VCA/MUTE Group 1. Similarly for VCA/

MUTE Groups 2 through 8.

CUE

Assigns the stereo signal to the CUE system, with flashing led

indication when enabled.

FADER

Controls the level of the EFFECT RETURN section of the module.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 59

Page 60

VCA MASTER SECTION

CUT 1

Mutes all channels assigned to VCA/MUTE Group 1. Similarly for

for CUT 2 through 8.

VCA 1

Switches in the VCA master fader to control VCA/Mute Group 1.

If the VCA is not switched in, the VCA control reverts to a fixed

unity gain setting. This is useful for quickly resetting all inputs to

their nominal gains (as set on their individual faders).

VCA MASTER FADER (100mm)

Controls the overall level of all the channels assigned to that group.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 60

Page 61

CONNECTORS AND PIN ASSIGNMENTS

LINE A : 3 Pin XLR type, Balanced

Nominal Input Level: +4dBu

Pin 2 : Signal +ve (Hot)

Pin 3 : Signal -ve (Cold)

Pin 1 : Ground

Input Impedance : >10 kOhm

LINE B : 1/4" TRS Jack Socket, ‘A’ Gauge, Balanced

Nominal Input Level: +4dBu

Tip : Signal +ve (Hot)

Ring : Signal -ve (Cold)

Sleeve: Ground

Input Impedance : >10 kOhm

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 61

Page 62

Q2 TECHNICAL DESCRIPTION

THE AUDIO

MASTER MODULE

This consists of two main boards and one sub board. The sub

board carries the balanced tape inputs, balanced mix outputs,

balanced Left, Centre and Right monitor outputs and the Left AFL

Meter. The tape signals are fed down to the audio master board

while the mix and monitor outputs are fed in to the sub board from

the master board.

The main audio board carries the Right AFL meter and the main

circuitry for the Left, Centre and Right outputs of the console in

addition to the monitoring functions.

Typically the signal path from the left mix bus to the mix output is

as follows. The signal from the LEFT bus is mixed in a virtual

earth amplifier and immediately after this the LMIXPRE signal is

taken to other parts of the circuit. The signal then passes through

an SSM2404 switch which operates as a changeover to allow SIP

signals onto the signal path in place of the mix signal. Following

this an SSM2142 is used to send a balanced insert send signal to the

send jack which is normalled to the return jack. From here the

signal passes through an SSM2143 balanced to unbalanced stage to

the main fader (one each for Left Centre and Right). A fader buffer

stage follows after which the signal is fed up to the sub board to the

main mix outputs of the console. The signal is known as LMIX at

this point. A further buffer stage follows and the signal is then

known as LEFTMIX which goes to the matrix link connector. The

MIXL signal, in addition to going to the sub board connects to the

PRE switch which allows either a mix pre or post fade signal to be

selected as the source for the centre mix when mix left and right are

assigned to it. The combined signal is fed onto the CMIX bus.

The Left Right and Centre PRE signal derived immediately after

the mix amplifiers is used for SOLO and PFL and is fed via

SSM2404s onto the solo buses. A switch selects PFL or AFL

operation while a further switch located towards the top of the

module is used to select SIP operation. The output of the PFL/AFL

switch feeds the AFL meters which are mounted on the module

before entering the monitoring system via an SSM2404. A SOLO

TRIM pot can be used to alter the PFL solo level although it will

not of course change the level shown on the meter. The external

feeds to the meterbridge are permanently tied to the mix outputs of

the console.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 62

Page 63

A rotary pot is used to control the monitor outputs although not

directly. A control voltage is derived from the pot which is fed to

three VCAs on the sub board which control the monitor levels for

Left, Centre and Right. The monitor has associated MONO, DIM

and ON buttons and can be selected to carry CUE, TAPE, L/R and

Centre signals. If both the L/R and CENTRE buttons are depressed

then L C R monitoring will result. If no buttons are depressed then

CUE will be selected. Headphone monitoring is also available and

the left and right headphone feeds have the centre channel mixed in

with them. The headphones receive the same feed as the monitor

outputs of the console.

SIP monitoring uses the main mix outputs of the console in order

that an output solo does not cut the inputs assigned to that group

and the SIP signals enter the signal chain immediately before the

insert send points for the Left, Centre and Right mixes.

A RESET button disables any active cues on the console without

having to locate the soloed channel. The solo function is also

available for the L/R and Mono outputs of the console. A further

section of logic is associated with the solo function and the

operation is as follows.

First of all it is necessary to understand that input priority is the

normal condition in which any input solo will cancel an output solo

for its duration. Multiple input and output solos can be active in

this mode. Interlock mode means that only one solo in the console

can be active at any time. The reset button can be used to clear the

last required solo.

Consider first of all an input solo in the input priority condition.

The solo makes the output of IC44 pin 1 go low causing TR1 to

switch on which in turn causes TR2 to switch on giving INPUT

SOLO indication. Pin 7 of IC44 will go high as it will invert the

low from pin 1 causing TR4 to switch on which in turn switches

TR8 on. The causes the RESET line to stay in a high condition

which disables the solos on the output modules.

Q2 OPERA TION AND MAINTENANCE MANUAL 9601 63

Page 64

Further input solos can be added and the reset button can be used to

cancel them. If a solo is to be cancelled from the master reset

button then a positive voltage is fed to the base of TR9 to switch it

on causing the reset line to go low. Some means must be used to

turn off TR8 as otherwise the Vdd and Vss rails would be shorted

together and TR3 is turned on to prevent this from occurring.