Page 1

User Manual

T3DSO1000 Series Digital

Oscilloscope

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Copyright and Declaration

Copyright

Teledyne LeCroy. All Rights Reserved.

Trademark Information

Teledyne Test Tools is the registered trademark of Teledyne LeCroy.

Declaration

Teledyne Test Tools products are protected by patent law.

Teledyne Test Tools reserves the right to modify or change parts of or all the

specifications or pricing policies at company’s sole decision.

Information in this publication replaces all previously corresponding material.

Any way of copying, extracting or translating the contents of this manual is not allowed

without the permission of Teledyne Test Tools.

Product Certification

Teledyne Test Tools guarantees this product conforms to national and industrial

standards and other international standards.

Contact Us

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual I

Page 3

Safety Information

General Safety Summary

Carefully read the following safety precautions to avoid any personal injury or

damage to the instrument and any products connected to it. To avoid potential

hazards, please use the instrument as specified.

Use Proper Power Line

Only the power cord designed for the instrument and country should be used.

Ground the Instrument

The instrument is grounded through the protective earth conductor of the power line. To

avoid electric shock, please make sure the instrument is grounded correctly before

connecting its input or output terminals.

Connect the Signal Ground Wire Correctly

The potential of the signal ground wire is equal to earth, so do not connect the signal

ground wire to a high voltage.

Look Over All Terminal Ratings

To avoid fire or electric shock, please look over all ratings and sign instructions of the

instrument. Before connecting the instrument, please read the manual carefully to gain

more information about the ratings.

Use Proper Overvoltage Protection

Make sure that no overvoltage (such as that caused by a thunderstorm) can reach the

product, or else the operator might be exposed to the danger of electrical shock.

Electrostatic Prevention

Operate in an electrostatic discharge protective environment to avoid damage induced by

static discharge. Always ground both the internal and external conductors of any cables to

discharge static before connecting.

Keep Ventilated

Inadequate ventilation may cause increasing product temperature, which will eventually

damage the instrument. So keep well ventilated and inspect the intake and fan regularly.

Avoid contact with Exposed Circuit or Components

Do not touch exposed contacts or components when the power is on.

Find Quality Products Online at: sales@GlobalTestSupply.com

II User Manual

www.GlobalTestSupply.com

Page 4

Use proper Fuse

Use only the specified fuse.

Do Not Operate Without Covers

Do not operate the instrument with covers or panels removed.

Do Not Operate With Suspected Failures.

If you suspect damage occurs to the instrument, have it inspected by qualified service

personnel before further operations. Any maintenance, adjustment or replacement

especially to circuits or accessories must be performed by Teledyne Test

Tools authorized personnel.

Do Not Operate in Wet Conditions.

In order to avoid short circuiting the interior of the device or electric shock, please do

not operate in a high humidity environment.

Do Not Operate in an Explosive Atmosphere.

In order to avoid damage to the device or personal injuries, it is important to operate the

device away from an explosive atmosphere.

Keep Product Surfaces Clean and Dry.

To avoid the influence of dust and/or moisture in the air, please keep the surface of the

instrument clean and dry.

Handling Safety

Please handle with care during transportation to avoid damages to buttons, knob

interfaces and other parts on the panels.

Only probe assemblies which meet the manufacturer’s specifications shall be used.

When using 2X/…/10000X probe assemblies, the probe assemblies shall be insulated

from the measured circuits by double or reinforced insulation.

All probe assemblies should meet the requirements of UL 61010-031 and

CAN/CSA-C22.2 No. 61010-031-07.

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual III

Page 5

Safety Terms and Symbols

Terms in this Manual. These terms may appear in this manual:

WARNING

Warning statements indicate the conditions or practices that could

result in injury or loss of life.

CAUTION

Caution statements indicate the conditions or practices that could

result in damage to this product or other property.

Terms on the product. These terms may appear on the product:

DANGER Indicates direct injuries or hazards that may happen.

WARNING Indicates potential injuries or hazards that may happen.

CAUTION Indicates potential damage to the instrument or other property that may

happen.

Symbols on the product. These symbols may appear on the product:

Hazardous protective Earth Warning Test Power Switch

Voltage Terminal Ground

If find such symbols appear on the product, consult the manual to find out the nature

of the potential hazard and the actions which have to be taken.

Find Quality Products Online at: sales@GlobalTestSupply.com

IV User Manual

www.GlobalTestSupply.com

Page 6

Measurement Category

Measurement Categories

This oscilloscope can make measurements in circuits that are not directly connected

to mains.

WARNING

This oscilloscope can only be used for measurements within its specified

measurement categories.

Do not use the product for measurements within other measurement

categories, such as CAT II, CAT III, CAT IV.

Do not use the equipment for measurements on mains circuits

Measurement Category Definitions

Measurement category II is for measurements performed on circuits directly connected to

the low voltage installation. Examples are measurements on household appliances,

portable tools and similar equipment.

Measurement category III is for measurements performed in the building installation.

Examples are measurements on distribution boards, circuit-breakers, wiring, including

cables, bus-bars, junction boxes, switches, socket-outlets in the fixed installation, and

equipment for industrial use and some other equipment, for example. Stationary motors

with permanent connection to the fixed installation.

Measurement category IV is for measurements performed at the source of the low-voltage

installation. Examples are electricity meters and measurements on primary over current

protection devices and ripple control units.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual V

Page 7

Working Environment

Temperature

Operating: 10℃ to +40℃

Non-operation:-20℃ to +70℃

Humidity

Under +35℃:≤90% relative humidity

+35℃ to +40℃: ≤60% relative humidity

WARNING

To avoid short circuit inside the instrument or electric shock, please do not

operate in humid environment.

Altitude

Operating: less than 3 Km

Non-operation: less than 15 Km

Degree of protection

IP20

Installation (over voltage) Category

This product is powered by mains conforming to installation (overvoltage) category II.

WARNING

Make sure that no over voltage (such as that caused by thunderbolt) can reach

the product, or else the operator might expose to the danger of electric shock.

Installation (over voltage) Category Definitions

Installation (over voltage) category I refers to signal level which is applicable to equipment

measurement terminals connected to the source circuit. In these terminals, precautions

are done to limit the transient voltage to the corresponding low level.

Installation (over voltage) category II refers to the local power distribution level which is

applicable to equipment connected to the AC line (AC power).

Find Quality Products Online at: sales@GlobalTestSupply.com

VI User Manual

www.GlobalTestSupply.com

Page 8

Ventilation Requirement

This oscilloscope uses a fan for cooling. Please make sure that the air intake and

exhaust areas are free from obstructions and have free air. When using the oscilloscope

in a bench-top or rack setting, provide at least 10 cm clearance beside, above and behind

the instrument for adequate ventilation.

WARNING

Inadequate ventilation may cause temperature increase which would damage

the instrument. So please keep the instrument well ventilated during operation

and inspect the intake and fan regularly.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual VII

Page 9

General Care and Cleaning

Care

Do not store or leave the instrument in direct sunshine for long periods of time.

WARNING

To avoid damage to the instrument or probe, please do not leave them in fog,

liquid, or solvent.

Cleaning

Please perform the following steps to clean the instrument and probe regularly according

to its operating conditions.

1. Disconnect the instrument from all power sources, and then clean it with a soft wet

cloth.

2. Clean the loose dust on the outside of the instrument and probe with a soft cloth.

When cleaning the LCD, take care to avoid scarifying it.

WARNING

To avoid damage to the surface of the instrument and probe, please do not

use any corrosive liquid or chemical cleanser.

WARNING

Make sure that the instrument is completely dry before restarting it to avoid

short circuits or personal injuries.

Find Quality Products Online at: sales@GlobalTestSupply.com

VIII User Manual

www.GlobalTestSupply.com

Page 10

Document Overview

This manual describes how to use the digital oscilloscope in detail.

Quick Start

Set the Vertical System

Set the Horizontal System

Set the Sampling System

of the oscilloscope.

Trigger the Oscilloscope

Serial Trigger

Save Reference Waveforms

How To Make Math Operations

How To Make Cursor Measurements

How To Use Measurement Functions

to measure the waveform parameters.

Display Settings

display.

Save and Recall

System Settings

Provide information about preparation before

using the instrument and a brief introduction to

the instrument.

Introduce the functions of the vertical system of

the oscilloscope.

Introduce the functions of the horizontal system

of the oscilloscope.

Introduce the functions of the sampling system

Introduce the trigger mode, trigger coupling,

trigger hold off, external trigger and various

trigger types of the oscilloscope.

Introduce how to trigger on serial input signals.

Introduce how to save and display REF

waveforms.

Introduce the math operation function of the

oscilloscope.

Introduce how to use cursors to make

measurements.

Introduce how to use the measurement function

Introduce how to set up the oscilloscope

Introduce how to save and recall the

measurement result and the settings of the

oscilloscope.

Introduce how to adjust the system setup.

Default

Troubleshooting

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Introduce the Default setup of the oscilloscope

Introduce how to deal with common failures of

the oscilloscope.

User Manual IX

Page 11

Table of Content

Copyright and Declaration .............................................................................................................I

Safety Information..........................................................................................................................II

General Safety Summary...........................................................................................................II

Safety Terms and Symbols....................................................................................................... IV

Measurement Category ........................................................................................................... V

Working Environment ............................................................................................................. VI

Ventilation Requirement........................................................................................................ VII

General Care and Cleaning.................................................................................................... VIII

Document Overview......................................................................................................................IX

Quick Start.......................................................................................................................................1

General Inspection....................................................................................................................2

Appearance and Dimensions ....................................................................................................3

To Prepare the Oscilloscope for Use .........................................................................................5

To Adjust the Supporting Legs......................................................................................5

To Connect to Power Supply ........................................................................................6

Power-on Inspection ......................................................................................................7

To Connect the Probe....................................................................................................7

Function Inspection........................................................................................................8

Probe Compensation.....................................................................................................9

Front Panel Overview ..................................................................................................10

Rear Panel Overview...................................................................................................12

Front Panel Function Overview...............................................................................................14

Horizontal.......................................................................................................................14

Vertical ...........................................................................................................................15

Trigger............................................................................................................................16

Run Control ...................................................................................................................17

Universal Knob..............................................................................................................18

Menu...............................................................................................................................19

Help .........................................................................................................................................21

User Interface..........................................................................................................................22

To Use the Security Lock .........................................................................................................24

To Set the Vertical System .........................................................................................................25

To Enable the Channel.............................................................................................................26

To Adjust the Vertical Scale .....................................................................................................27

To Adjust the Vertical Position ................................................................................................27

To Specify Channel Coupling ...................................................................................................28

To Specify Bandwidth Limit.....................................................................................................28

To Specify Probe Attenuation Factor.......................................................................................29

To Specify channel Input Impedance ......................................................................................29

To Specify Amplitude Unit.......................................................................................................30

To Specify Deskew...................................................................................................................30

To Invert a Waveform..............................................................................................................30

Find Quality Products Online at: sales@GlobalTestSupply.com

X User Manual

www.GlobalTestSupply.com

Page 12

Set the Horizontal System ..........................................................................................................31

Adjust the Horizontal Scale .....................................................................................................32

Adjust Trigger Delay ................................................................................................................33

Set the Roll mode....................................................................................................................34

Use the Zoom Function ...........................................................................................................35

To Set the Sample System .........................................................................................................36

Run Control .............................................................................................................................37

Overview of Sampling .............................................................................................................38

Sampling Theory...........................................................................................................38

Sample Rate..................................................................................................................39

Oscilloscope Bandwidth and Sample Rate ..............................................................40

Select Memory Depth .............................................................................................................41

Select Sampling Mode.............................................................................................................42

Select Waveform Interpolation Method .................................................................................43

Select Acquisition Mode .........................................................................................................45

Normal ............................................................................................................................45

Peak Detect .....................................................................................................................46

Average............................................................................................................................47

High Resolution ...............................................................................................................48

Change the Horizontal Format ................................................................................................49

Use Sequence Mode ...............................................................................................................50

To Trigger the Oscilloscope ........................................................................................................52

Trigger Source .........................................................................................................................54

Trigger Mode...........................................................................................................................55

Trigger Level ............................................................................................................................56

Trigger Coupling ......................................................................................................................57

Trigger Holdoff ........................................................................................................................58

Noise Rejection .......................................................................................................................59

Trigger Type.............................................................................................................................61

Edge Trigger..................................................................................................................62

Slope Trigger.................................................................................................................63

Pulse Trigger .................................................................................................................65

Video Trigger.................................................................................................................67

Window Trigger.............................................................................................................70

Interval Trigger..............................................................................................................73

DropOut Trigger............................................................................................................75

Runt Trigger...................................................................................................................77

Pattern Trigger ..............................................................................................................79

Serial trigger and decode............................................................................................................81

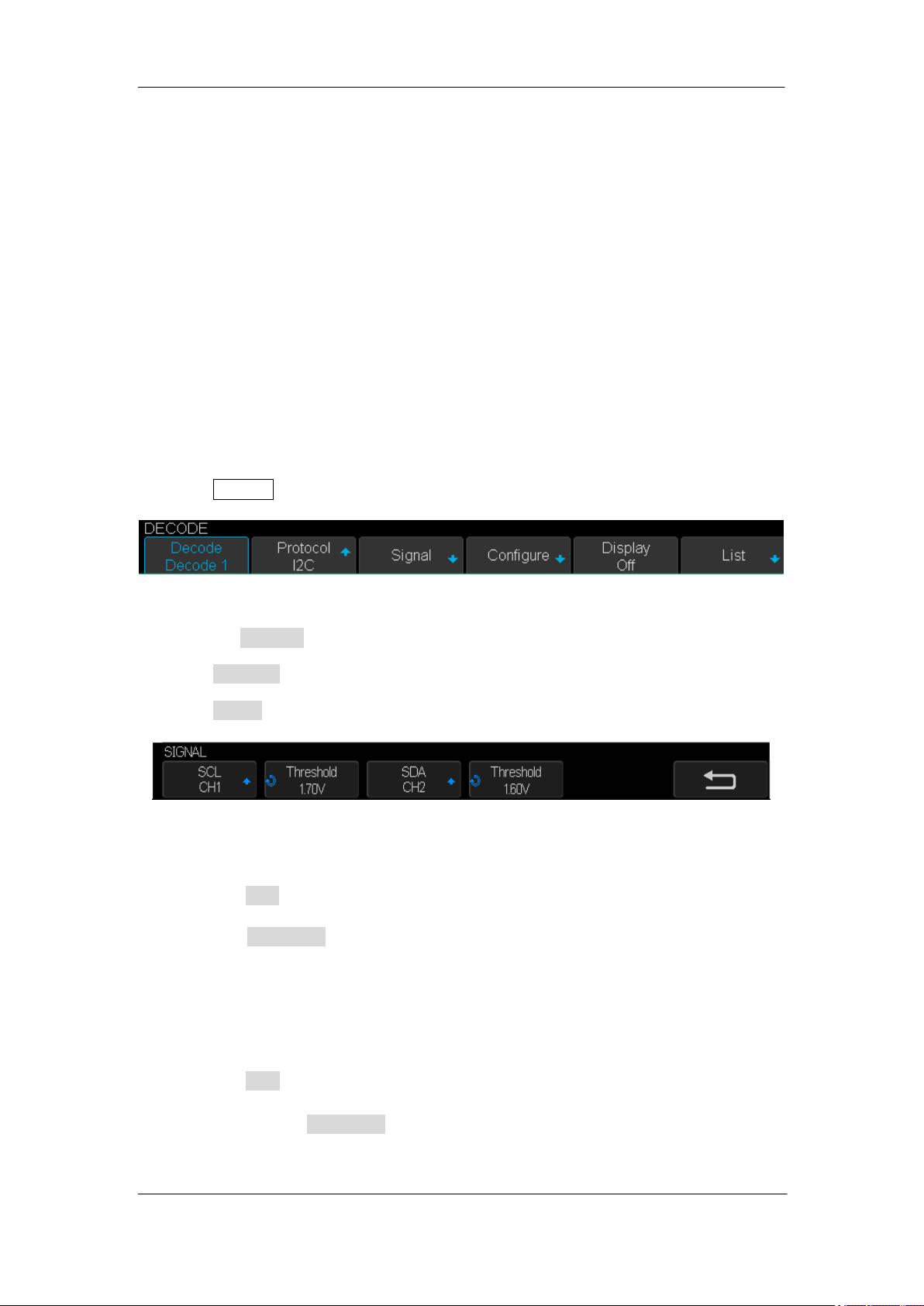

I2C Trigger and Serial Decode .................................................................................................82

Setup for I2C Signals........................................................................................................82

I2C Triggering...................................................................................................................84

I2C Serial Decode ............................................................................................................88

SPI Triggering and Serial Decode.....................................................................................................90

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual XI

Page 13

Setup for SPI Signals...................................................................................................90

SPI Triggering ...............................................................................................................93

SPI Serial Decode........................................................................................................95

UART/RS232 Triggering and Serial Decode .....................................................................................97

Setup for UART/RS232 Signals .................................................................................97

UART/RS232 Triggering....................................................................................................99

UART/RS232 Serial Decode ...........................................................................................101

CAN Trigger and Serial Decode .............................................................................................103

Setup for CAN Signals....................................................................................................103

CAN Triggering...............................................................................................................105

CAN Serial Decode.........................................................................................................107

LIN Triggering and Serial Decode ..........................................................................................109

Setup for LIN Signals.................................................................................................109

LIN Triggering ................................................................................................................110

LIN Serial Decode ..........................................................................................................112

To Save Reference Waveform..................................................................................................114

To Save REF Waveform to Internal Memory .........................................................................115

To Display REF Waveform......................................................................................................115

To Adjust REF Waveform Display...........................................................................................116

To Clear REF Waveform Display.............................................................................................117

To Make Math Operation...........................................................................................................118

Units for Math Waveforms....................................................................................................118

Math Operators.....................................................................................................................119

Addition or Subtraction.................................................................................................119

Multiplication and Division ...........................................................................................120

FFT Operation................................................................................................................121

Math Function Operation......................................................................................................124

Differentiate ..................................................................................................................124

Integrate........................................................................................................................125

Square Root...................................................................................................................126

To Make Cursors Measurements.............................................................................................128

X Cursors ...............................................................................................................................128

Y Cursors................................................................................................................................128

To Make Cursor Measurements ............................................................................................129

To Make Measurements................................................................................................................130

Type of Measurement...........................................................................................................131

Voltage Measurements .................................................................................................131

Time Measurements .....................................................................................................133

Delay Measurements ....................................................................................................134

To Make Automatic Measurement........................................................................................135

To Clear Measurement Parameters.......................................................................................137

To Make All Measurement ....................................................................................................137

Display Setting...............................................................................................................................138

To Set Display Type................................................................................................................139

Find Quality Products Online at: sales@GlobalTestSupply.com

XII User Manual

www.GlobalTestSupply.com

Page 14

To Set Color Display...............................................................................................................140

To Set and Clear Persistence .................................................................................................140

To clear the display................................................................................................................141

To Select Grid Type................................................................................................................142

To Adjust Waveform Intensity...............................................................................................142

To Adjust Grid Brightness......................................................................................................143

To Adjust Transparence .........................................................................................................143

Save and Recall..............................................................................................................................144

Save Type...............................................................................................................................145

Internal Save and Recall ........................................................................................................147

External save and recall.........................................................................................................148

Disk Management .................................................................................................................151

To Create a New File or Folder......................................................................................152

To delete a file or folder ................................................................................................153

Digital Channels(Option) ...........................................................................................................154

To Connect the Digital Probes to the Device-under-test.......................................................155

Acquiring Waveform Using the Digital Channels...................................................................156

To Change the Display Type of the Digital Channels .............................................................156

To Switch a Single Channel On or Off....................................................................................157

To Switch All Digital Channels On or Off................................................................................157

To Change the Logic Threshold for Digital Channels .............................................................158

To Reposition a Digital Channel.............................................................................................158

To Display Digital Channels as a Bus......................................................................................159

System Function Setting................................................................................................................160

To View the System Status ....................................................................................................161

To Do Self Calibration............................................................................................................162

To Enable or Disable the Sound ............................................................................................163

To Specify the Language........................................................................................................163

To Do Pass/Fail Test ...............................................................................................................164

To Set and Perform Pass/Fail Test..................................................................................165

To Save and Recall Test Mask ........................................................................................166

Arbitrary Waveform Generator(Option) ...............................................................................168

Output...........................................................................................................................169

...............................................................................................................................169

Setting ...........................................................................................................................171

Systems .........................................................................................................................173

Remove Device..............................................................................................................174

IO Set.....................................................................................................................................175

To Set the USB Device ...................................................................................................175

To Set the LAN ...............................................................................................................176

To Set the WLAN (Option) .............................................................................................177

To Set Aux Output .........................................................................................................178

To Use the Web Server..........................................................................................................179

To Update Firmware and Configuration................................................................................180

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual XIII

Page 15

Do Self Test............................................................................................................................181

Screen Test ....................................................................................................................181

Keyboard Test................................................................................................................182

LED Test .........................................................................................................................183

To specify Screen Saver Time ................................................................................................184

To Use the Expand Setting.....................................................................................................185

To Use the Power On Line .....................................................................................................185

Option Management.............................................................................................................186

Search............................................................................................................................................188

Setting ...................................................................................................................................188

Results...................................................................................................................................189

Navigate ........................................................................................................................................191

Time navigate........................................................................................................................191

History frame navigate..........................................................................................................191

Search event navigate ...........................................................................................................191

Bode Plot.......................................................................................................................................193

Perform Bode Plot application..............................................................................................193

Setting ...................................................................................................................................193

To Use the History Function..........................................................................................................196

Factory Setup ................................................................................................................................198

Troubleshooting ............................................................................................................................202

Find Quality Products Online at: sales@GlobalTestSupply.com

XIV User Manual

www.GlobalTestSupply.com

Page 16

Content of Figure

Figure 1 Front V iew (2-channel scope) .....................................................................................3

Figure 2 Top View (2-channel scope)........................................................................................3

Figure 3 Front V iew (4-channel scope) .....................................................................................4

Figure 4 Top View (4-channel scope)........................................................................................4

Figure 5 Adjust the Supporting Legs .........................................................................................5

Figure 6 To Connect to Power Supply .......................................................................................6

Figure 7 Function Inspection.....................................................................................................8

Figure 8 2-channel Scope Front Panel Overview......................................................................10

Figure 9 4-channel Scope Front Panel Overview......................................................................11

Figure 10 2-channel Scope Rear panel Overview.....................................................................12

Figure 11 4-channel Scope Rear panel Overview.....................................................................13

Figure 12 Help Message...........................................................................................................21

Figure 13 User Interface...........................................................................................................22

Figure 14 To Use the Security Lock ….......................................................................................24

Figure 15 Display Type Set to Dots................…........................................................................43

Figure 16 x Interpolation...........................................…............................................................44

Figure 17 Sinx/x Interpolation……............................................................................................44

Figure 18 Acquisition System ..................................................................................................45

Figure 19 Pulse With 0.1% Duty, Normal Mode ...…….............................................................46

Figure 20 Pulse With 0.1% Duty, Peak Detect Mode ..............................................................46

Figure 21 With Random Noise, Normal Mode........................................................................47

Figure 22 With Random Noise, Average Mode.......................................................................48

Figure 23 SEQUENCE Function Menu .....................................................................................50

Figure 24 HISTORY Function Menu .........................................................................................50

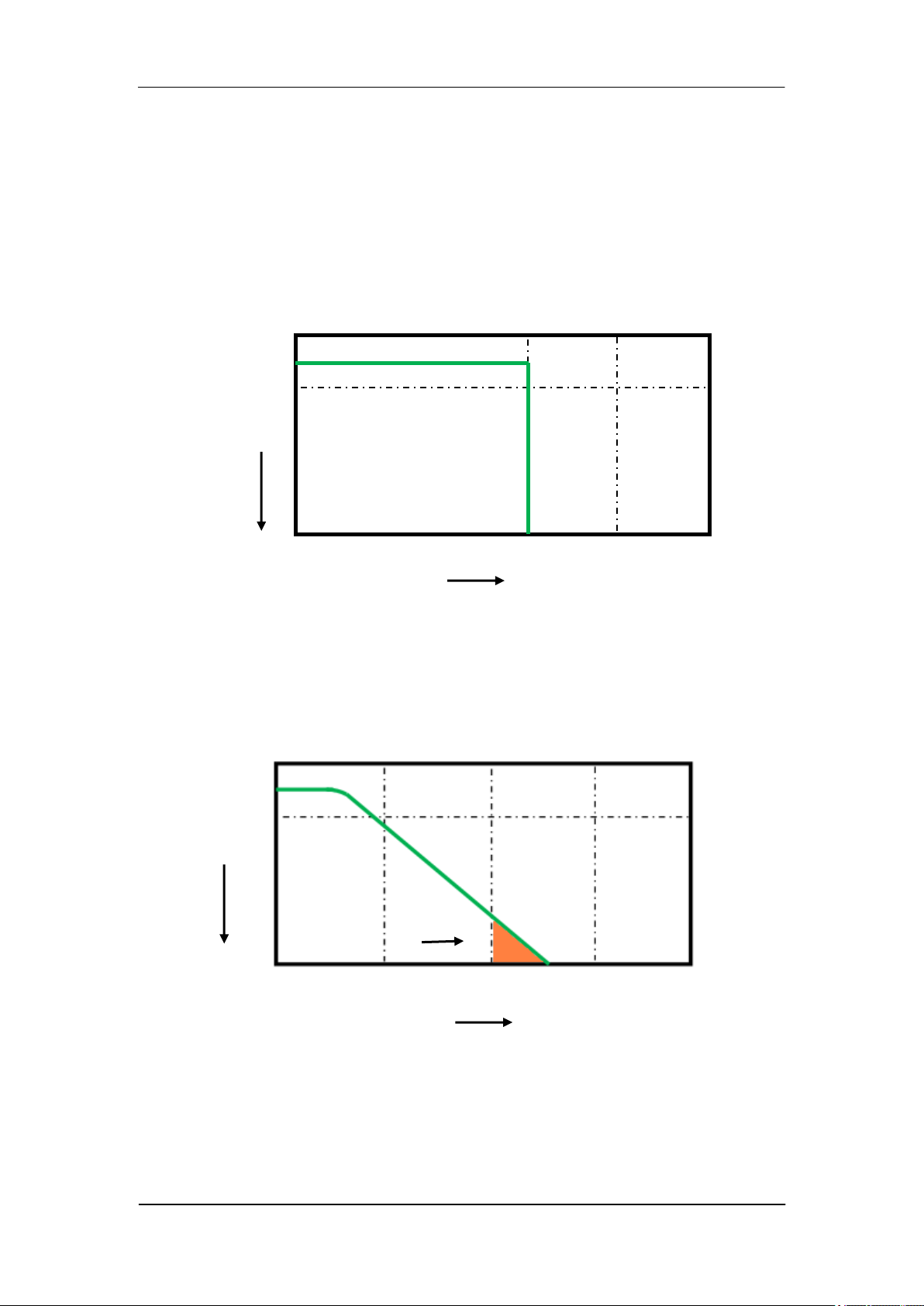

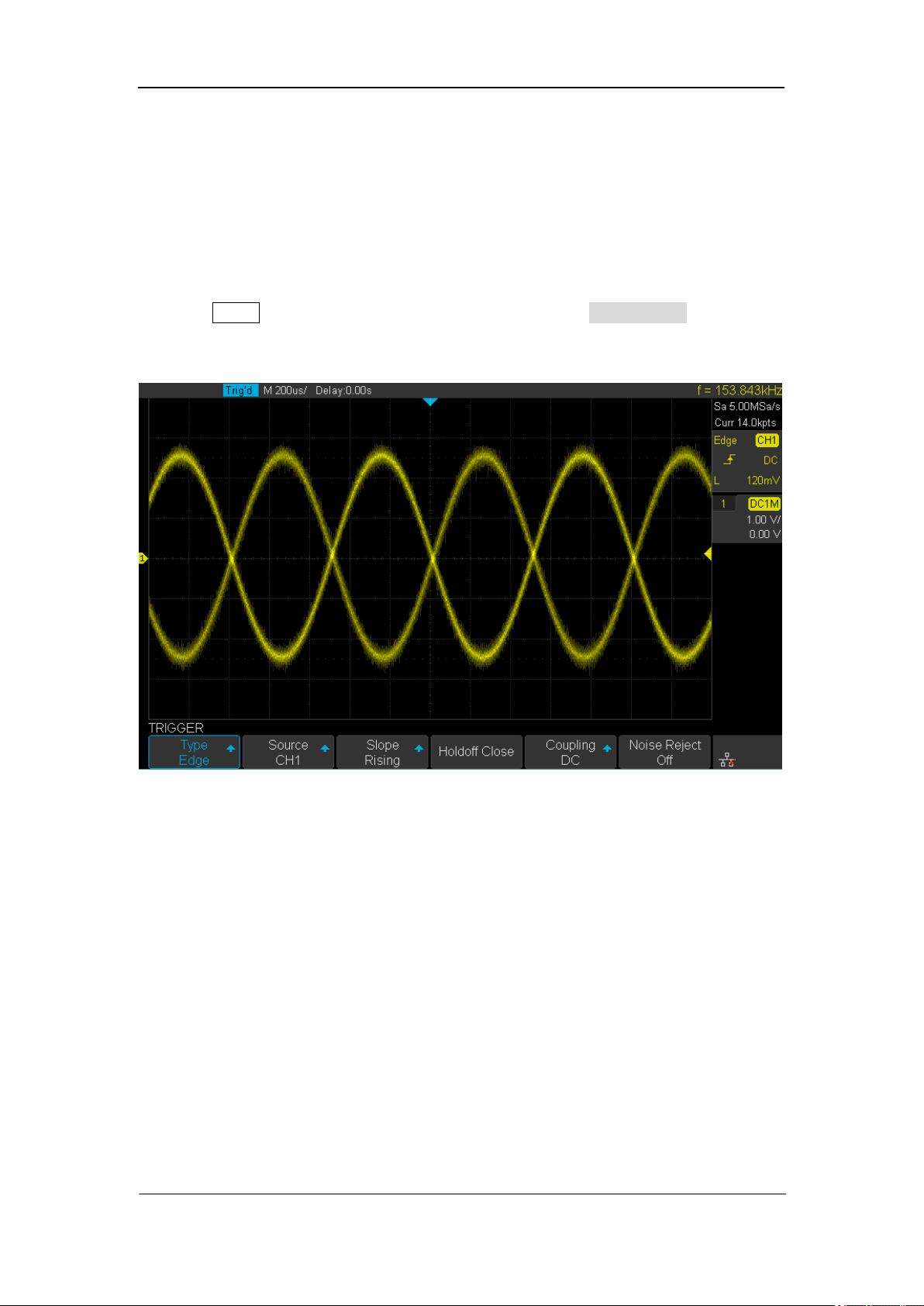

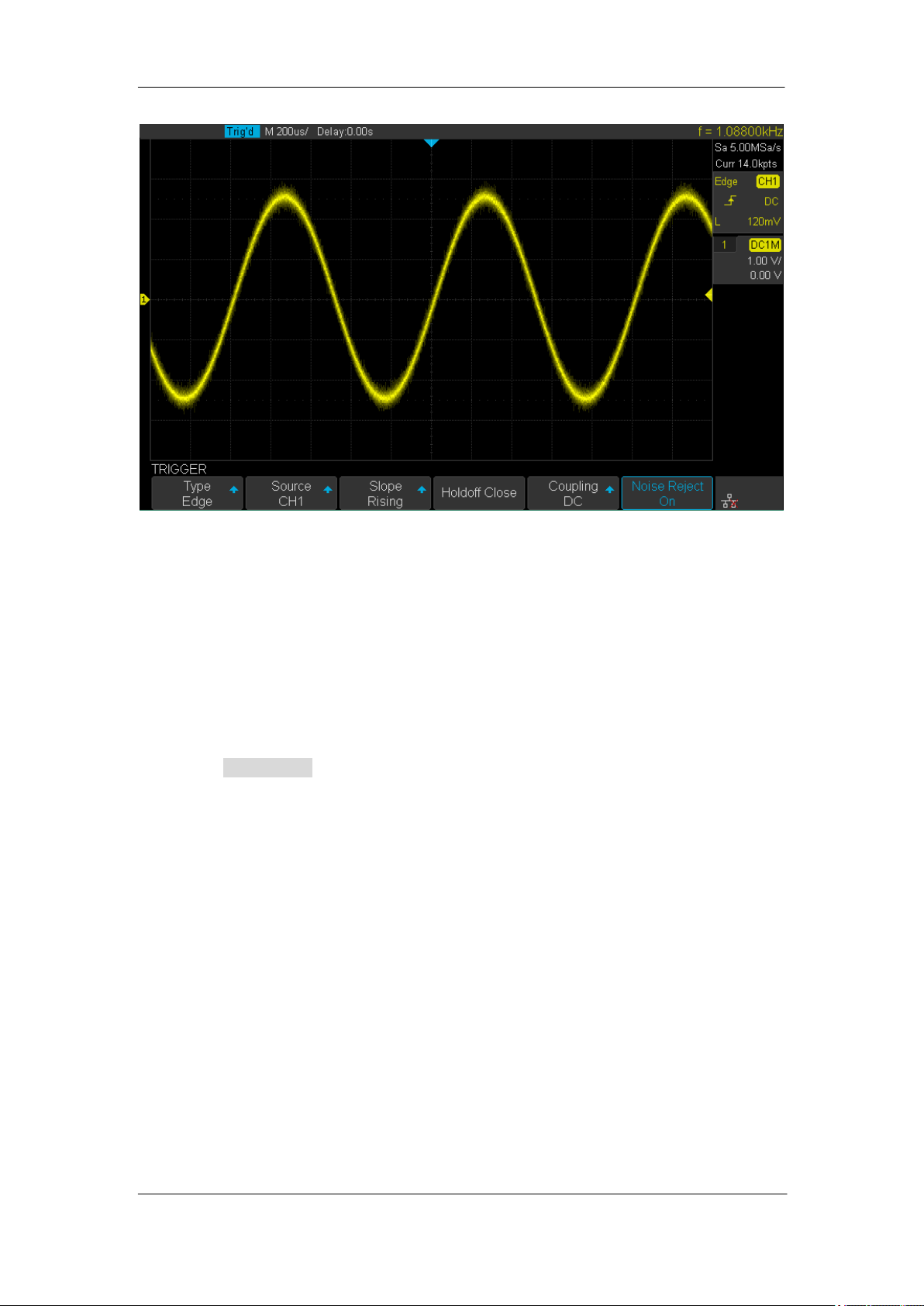

Figure 25 Turn off the Noise Reject.........................................................................................59

Figure 26 Turn on the Noise Reject .........................................................................................60

Figure 27 Edge Trigger.............................................................................................................62

Figure 28 Slope Trigger............................................................................................................64

Figure 29 Pulse Trigger.............................................................................................................66

Figure 30 Video Trigger...........................................................................................................69

Figure 31 Absolute Window Trigger.........................................................................................71

Figure 32 Relative Window Trigger..........................................................................................72

Figure 33 Interval Trigger.........................................................................................................74

Figure 34 Edge DropOut Trigger...............................................................................................76

Figure 35 State DropOut Trigger ..............................................................................................77

Figure 36 Runt Trigger..............................................................................................................78

Figure 37 Pattern Trigger..........................................................................................................80

Figure 38 I2C DECODE Menu ...................................................................................................82

Figure 39 I2C SIGNAL Menu.....................................................................................................82

Figure 40 I2C Trigger Menu .....................................................................................................87

Figure 41 I2C DECODE Menu ...................................................................................................88

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual XV

Page 17

Figure 42 SPI SIGNAL Menu .....................................................................................................91

Figure 43 SPI ClOCK Menu .......................................................................................................91

Figure 44 MISO Menu ..............................................................................................................91

Figure 45 MOSI Menu ..............................................................................................................91

Figure 46 SPI TRIG SET Menu......….……....................................................................................93

Figure 47 UART SIGNAL Menu .................................................................................................97

Figure 48 UART / RS232 Bus Config Menu...............................................................................98

Figure 49 UART TRIG SET Menu...............................................................................................99

Figure 50 UART Trigger..........................................................................................................100

Figure 51 UART / RS232 Decode.............................................................................................101

Figure 52 CAN SIGNAL Menu..................................................................................................103

Figure 53 CAN Trigger.............................................................................................................106

Figure 54 LIN SIGNAL Menu..................................................................................................109

Figure 55 LIN Trigger ..............................................................................................................111

Figure 56 LIN Decode .............................................................................................................112

Figure 57 Reference Waveform .............................................................................................116

Figure 58 Addition .................................................................................................................119

Figure 59 FFT Waveform in Split Mode ...............................................................................123

Figure 60 Differential Function Operation ..............................................................................125

Figure 61 Integral Without Offset ...........................................................................................126

Figure 62 Integral With Offset ...............................................................................................126

Figure 63 Square Root ...........................................................................................................127

Figure 64 Measure Pulse Width .............................................................................................129

Figure 65 Voltage Measurements ..........................................................................................131

Figure 66 Overshoot ..............................................................................................................132

Figure 67 Preshoot ................................................................................................................132

Figure 68 Time Measurements ...........................................................................................133

Figure 69 Select the Measurement Parameter ......................................................................135

Figure 70 Added the Measurements .....................................................................................136

Figure 71 All Parameters Measurement ................................................................................137

Figure 72 Vector Display .......................................................................................................139

Figure 73 Dots Display ...........................................................................................................139

Figure 74 Color Temperature .................................................................................................140

Figure 75 Persist Set To Infinite ..............................................................................................141

Figure 76 SAVE / RECALL File System ....................................................................................148

Figure 77 Select Save Location ..............................................................................................149

Figure 78 File Name Dialogue .................................................................................................149

Figure 79 Input Keyboard ........................................................................................................152

Figure 80 Digital Function Menu .............................................................................................156

Figure 81 Digital Channel Height ............................................................................................156

Figure 82 Digital: High Display Type ........................................................................................157

Figure 83 Digital Thresholds Function Menu .........................................................................158

Figure 84 Digtal Bus Function Menu .........................................................................................159

Figure 85 Digital Bus ..............................................................................................................159

Find Quality Products Online at: sales@GlobalTestSupply.com

XVI User Manual

www.GlobalTestSupply.com

Page 18

Figure 86 System Status .........................................................................................................161

Figure 87 Do Self Cal ..............................................................................................................162

Figure 88 Pass / Fail Test ........................................................................................................164

Figure 89 AWG Menu Interface .............................................................................................169

Figure 90 Wave Type Interface ..............................................................................................169

Figure 91 Built-in Arb Interface ..............................................................................................171

Figure 92 AWG Setting Interface .............................................................................................171

Figure 93 AWG System Information Interface ....................................................................173

Figure 94 AWG Update Interface .........................................................................................174

Figure 95 LAN Settings ..........................................................................................................176

Figure 96 WIFI Setting Menu .................................................................................................177

Figure 97 Web Server Interface .............................................................................................179

Figure 98 Screen Test ............................................................................................................181

Figure 99 Keyboard Test ........................................................................................................182

Figure 100 LED Test ...............................................................................................................183

Figure 101 Screen Saver Interface .......................................................................................184

Figure 102 OPTION Function menu.......................................................................................186

Figure 103 LABEL Function Menu ...........................................................................................186

Figure 104 Option Information ...............................................................................................187

Figure 105 Search Menu .........................................................................................................188

Figure 106 Search When Stopped ..........................................................................................190

Figure 107 Search When Running ...........................................................................................190

Figure 108 Bode Plot Menu ...................................................................................................193

Figure 109 Bode Plot Configure Menu ...................................................................................193

Figure 110 Bode Plot Display Menu ......................................................................................194

Figure 111 Bode Plot Data Menu ..........................................................................................195

Figure 112 Bode Plot List On ..................................................................................................195

Figure 113 History ..................................................................................................................196

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual XVII

Page 19

Quick Start

This chapter introduces the preparations when using the oscilloscope for the first time, the

front panel, rear panel and user interface.

The contents of this chapter:

◆ General Inspection

◆ Appearance and Dimensions

◆ To Prepare the Oscilloscope for Use

◆ Front Panel Overview

◆ Rear Panel Overview

◆ Front Panel Function Overview

◆ Back Panel Function Overview

◆ User Interface

◆ To Use the Security Lock

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 1

Page 20

General Inspection

1. Inspect the shipment for damage.

Keep the shipping box and cushioning material until the contents of the shipment

have been checked for completeness and the instrument has passed both electrical

and mechanical tests.

The shipper or carrier shall be liable for the damage to instrument resulting from

shipment. Teledyne Test Tools would not be responsible for free maintenance /

rework or replacement of the unit.

2. Inspect the instrument.

In case of any damage, or defect, or failure, notify your Teledyne Test Tools sales

representative.

3. Check the Accessories

Please check the accessories according to the packing lists. If the accessories are

incomplete or damaged, please contact your Teledyne Test Tools sales

representative.

Find Quality Products Online at: sales@GlobalTestSupply.com

2 User Manual

www.GlobalTestSupply.com

Page 21

Appearance and Dimensions

Figure 1 Front View (2-channel scope)

Figure 2 Top View (2-channel scope)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 3

Page 22

Figure 3 Front View (4-channel scope)

Figure 4 Top View (4-channel scope)

Find Quality Products Online at: sales@GlobalTestSupply.com

4 User Manual

www.GlobalTestSupply.com

Page 23

To Prepare the Oscilloscope for Use

To Adjust the Supporting Legs

Adjust the supporting legs properly to use them as stands to tilt the oscilloscope upwards

for stable placement of the oscilloscope as well as better operation and observation.

Figure 5 Adjust the Supporting Legs

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 5

Page 24

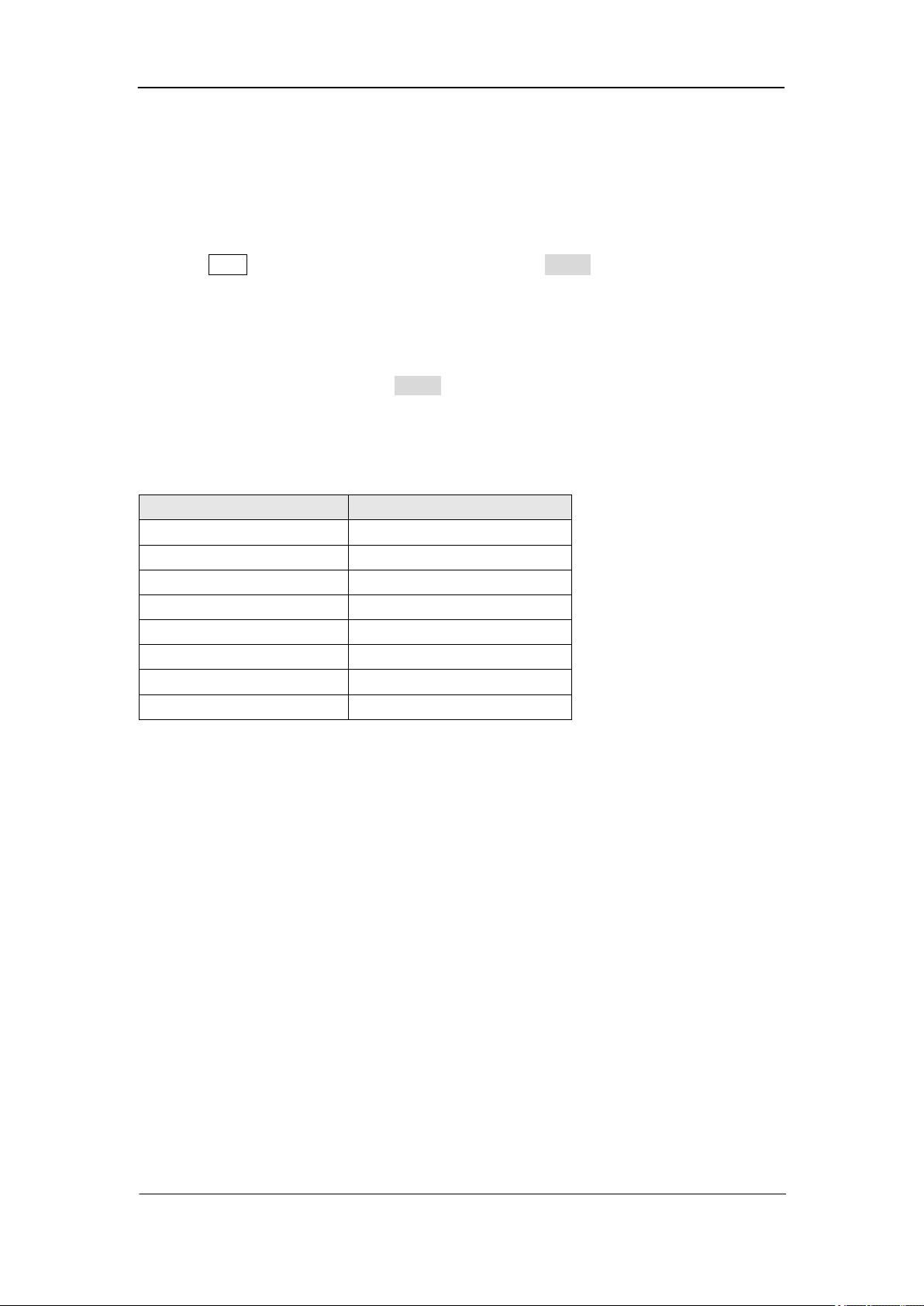

To Connect to the local line Power

The power requirements of the oscilloscope are 100-240 V, 50/60Hz or 100-120 V, 400Hz.

Please use the power cord supplied with the accessories to connect the oscilloscope to

the power source.

Power

socket

2-channel scope 4-channel scope

Figure 6 To Connect to Power Supply

Power

socket

Find Quality Products Online at: sales@GlobalTestSupply.com

6 User Manual

www.GlobalTestSupply.com

Page 25

Power-on Inspection

When the oscilloscope is connected to line power, press the power key at the lower-left

corner of the front panel to start the oscilloscope. During the start-up process, the

oscilloscope performs a series of self-tests and you can hear the sound of relays

switching. After the self-test is finished, the welcome screen is displayed.

To Connect the Probe

Teledyne Test Tools provides passive probes for the oscilloscopes. For detailed

technical information of the probes, please refer to the corresponding Probe User’s Guide.

Connect the Probe:

1. Connect the probe to an oscilloscope front channel BNC.

2. Connect the probe tip to the circuit point to be tested and connect the ground alligator

clip of the probe to the circuit ground terminal.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 7

Page 26

Function Inspection

1. Press the Default button on the front panel to restore the instrument to its default

configuration.

2. Connect the ground alligator clip of the probe to the “Ground Terminal” under the

probe compensation signal output terminal.

Compensation Signal Output Terminal

Ground Terminal

2-channel scope

Ground Terminal

Compensation Signal Output Terminal

4-channel scope

3. Use the probe to connect the input terminal of CH1 of the oscilloscope to the

“Compensation Signal Output Terminal” of the oscilloscope.

4. Press the Auto Setup.

5. Observe the waveform on the display. In normal condition, the display should be a

square waveform as shown in the figure below:

Figure 7 Function Inspection

6. Use the same method to test the other channels. If the square waveforms actually

shown do not match that in the figure above, please perform “Probe Compensation”

Find Quality Products Online at: sales@GlobalTestSupply.com

8 User Manual

www.GlobalTestSupply.com

Page 27

in the next section.

WARNING

To avoid electric shock during the use of a probe, please make sure that the

insulated wire of the probe is in good condition and do not touch the metallic

part of the probe when the probe is connected to a high voltage source

Probe Compensation

When the probes are used for the first time, you should compensate the probes to match

the input channels of the oscilloscope. Non-compensated or poorly compensated probes

may cause measurement inaccuracy or error. The probe compensation procedures are as

follows.

1. Set the switch to 10X on the probe.

2. Perform steps 1, 2, 3 and 4 of “Function Inspection” in the previous section.

3. Check the waveforms displayed and compare them with the following:

Over Perfectly Under

Compensated Compensated Compensated

4. Use a nonmetallic screwdriver to adjust the low-frequency compensation adjustment

hole on the probe until the waveform displayed is as the “Perfectly compensated”

waveform in the figure above.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 9

Page 28

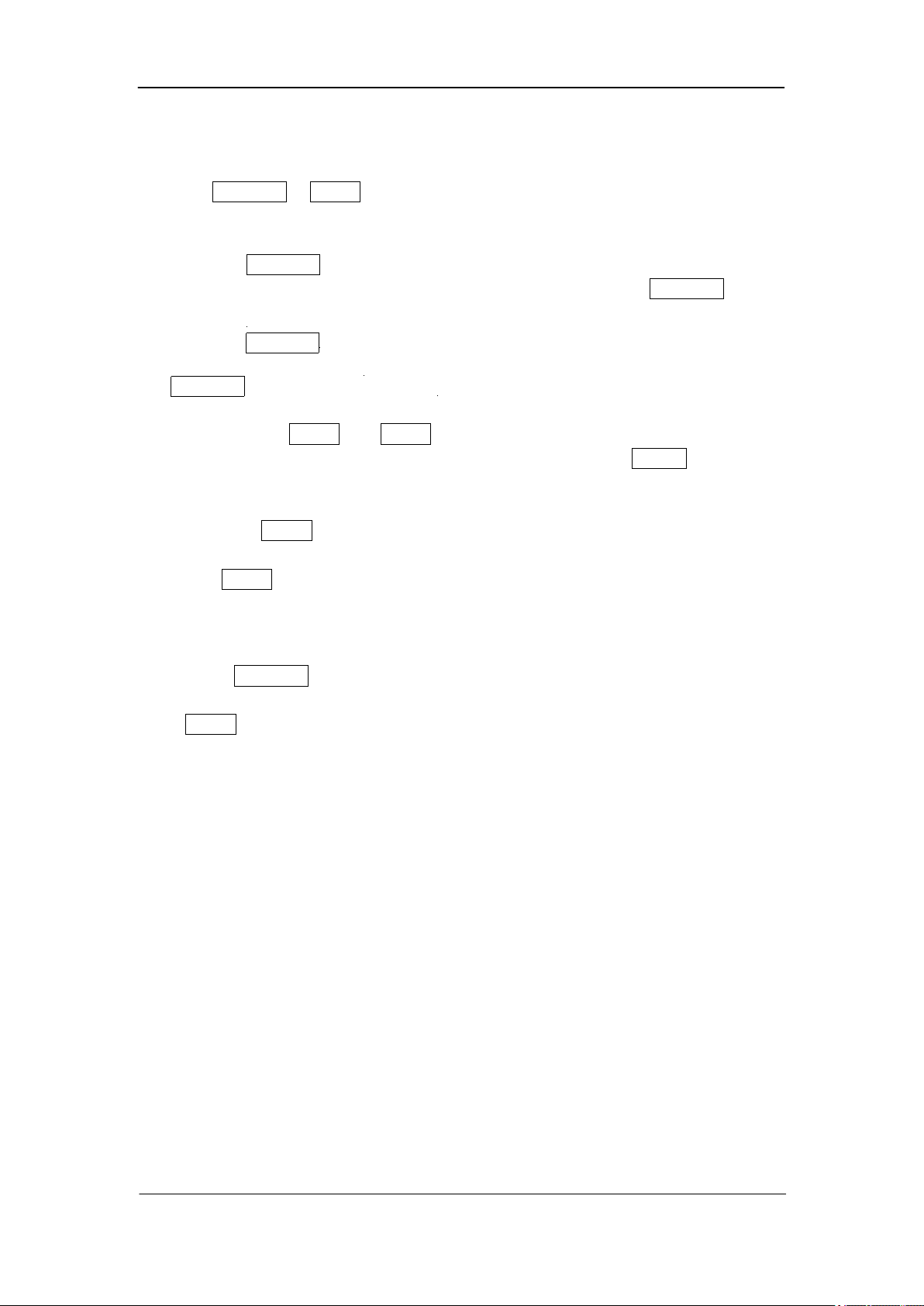

Front Panel Overview

3

7

10

9

13

14

12

2

1

18

11

Figure 8 2-channel Scope Front Panel Overview

NO. Description NO. Description

1 LCD Display 8 Vertical Control

2 Universal Knob 9 Probe Compensation/ Ground Terminal

3 Common Function Menus 10 Analog Channel and Ext Input

4 Run/Stop 11 USB Host

5 Auto Setup 12 Menu Softkey

6 Trigger Control 13 Menu on/off

7 Horizontal Control 14 Power Button

4

5

6

10 User Manual

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

4

2

3

8

1

6

9

5

7

10

13

12

14

18

19

15

20

21

16

11

17

Figure 9 4-channel Scope Front Panel Overview

NO. Description NO. Description

1 LCD Display 12 Horizontal Control

2 Universal Knob 13 Trigger Control

3 Common Function Menus 14 Menu on/off

4 Clear Sweeps 15 Menu Softkey

5 Run/Stop 16 One- Button shortcut for Save

6 Decode 17 Analog Channel

7 Auto Setup 18 Power Button

8 Navigate 19 USB Host

9 History 20 Digital Inputs

10 Default 21 Probe Compensation/ Ground Terminal

Vertical Control, Math, REF and

11

Digital

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 11

Page 30

Rear Panel Overview

Figure 10 2-channel Scope Rear panel Overview

1. Handle

Pull up the handle vertically for easy carrying of the instrument. When you do not need

the handle, press it down.

2. Safety lock Hole

You can lock the instrument to a fixed location using the security lock (not supplied) via

the lock hole.

3. LAN

The instrument can be connected to network via this interface to perform remote

control.

4. Pass/Fail or Trigger Out

The BNC port can output a signal that reflects the current waveform capture rate of

the oscilloscope at each trigger or a pass/fail test pulse.

5. USB Device

The oscilloscope support SCPI remote control commands, user can control the

oscilloscope through this interface.

Find Quality Products Online at: sales@GlobalTestSupply.com

12 User Manual

www.GlobalTestSupply.com

Page 31

Figure 11 4-channel Scope Rear panel Overview

1. Handle

Pull up the handle vertically for easy carrying of the instrument. When you do not need

the handle, press it down.

2. LAN

The instrument can be connected to network via this interface to perform remote

control.

3. USB Device

The oscilloscope support SCPI remote control commands, user can control the

oscilloscope through this interface

4. USB Host

5. Safety lock Hole

You can lock the instrument to a fixed location using the security lock (not supplied) via

the lock hole.

6. AC Power Socket

AC power input connector. The power requirements of this oscilloscope are 100-240

V, 50/60/400 Hz. Use the power cord provided with the instrument to connect it to AC

power.

7. Pass/Fail or Trigger Out

The BNC port can output a signal that reflects the current waveform capture rate of

the oscilloscope at each trigger or a pass/fail test pulse.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 13

Page 32

Front Panel Function Overview

Horizontal

4-channel scope 2-channel scope

: Quickly enter the roll mode. The timebase range is from 50mS/div to

100S/div.

: Enable or disable search function. This function can search for the events

that users specify in the acquired data, the results are displayed with a white

triangle symbol.

Horizontal Position Knob : adjust horizontal position. The trigger point would

move left or right relative to the center of the screen when you turn the knob. During the

modification, waveforms of all the channels would move left or right and the trigger

position message at the upper-right corner of the screen would change accordingly. Press

down this knob to quickly reset the trigger delay to Zero.

Horizontal Scale Knob : adjust the horizontal time base. Turn clockwise to

reduce the time base and turn counterclockwise to increase the time base. During the

modification, waveforms of all the channels will be displayed in expanded or compressed

mode and the time base message at the upper-left side of the screen would change

accordingly. Press down this knob to quickly turn on Zoom function.

Find Quality Products Online at: sales@GlobalTestSupply.com

14 User Manual

www.GlobalTestSupply.com

Page 33

Vertical

2-channel scope 4-channel scope

: Analog input channels. The two channels are marked by different colors which

are also used to mark both the corresponding waveforms on the screen and

the channel input connectors.

Vertical Position Knob : adjust the vertical position of the current channel

waveform. Turn clockwise to increase the position and turn counterclockwise to decrease.

During the modification, the waveform would move up and down and the position

message at the lower-left corner of the screen would change accordingly. Press down this

knob to quickly reset the vertical position to zero.

Vertical Variable Knob : adjust the vertical scale of the current channel. Turn

clockwise to decrease the scale and turn counterclockwise to increase. During the

modification, the amplitude of the waveform would enlarge or reduce and the scale

information at the right side of the screen would change accordingly. Press down this knob

to quickly switch the vertical scale adjustment modes between “Coarse” and “Fine”.

: press the button to enter the MATH function menu. The oscilloscope provides

addition, subtraction, multiplication, FFT, differential, integral and square root

operations.

: press the button to enter the REF function menu. A reference waveform can

be displayed and compared against other waveforms.

Press the button to open the digital channel function menu (Optional function).

The T3DSO1x04 (4-channel scope) supports 16 digital channels.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 15

Page 34

Trigger

2-channel scope 4-channel scope

: press the button to enter the TRIGGER function menu. The oscilloscope

provides abundant advanced trigger functions

: press the button to set the trigger mode to Auto.

: press the button to set the trigger mode to Normal.

: press the button to set the trigger mode to Single.

Trigger Level Knob : adjust the trigger level. Turn clockwise to increase the

level and turn counterclockwise to reduce the level. During the modification, the trigger

level line would move up and down and the value in the trigger level message box at the

up-right corner of the screen would change accordingly. Press down the knob to quickly

reset the trigger level to center of the waveform.

Find Quality Products Online at: sales@GlobalTestSupply.com

16 User Manual

www.GlobalTestSupply.com

Page 35

Run Control

: press this key to enable the waveform auto setting function. The

oscilloscope will automatically adjust the vertical scale, horizontal time base

and trigger mode according to the input signal to realize optimum waveform

display.

: press the button to set the acquisition state to Run or Stop.

In RUN state, the key is illuminated in yellow.

In STOP state, the key is illuminated in red.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 17

Page 36

Universal Knob

1. Adjust the waveform intensity.

You can press the Display/Persist button; press the Next Page softkey to go to the

second page of the DISPLAY function menu; press the Intensity softkey and then

turn the Universal Knob to adjust the waveform intensity.

2. Select the desired submenu.

In menu operation, press any menu softkey and turn the Universal Knob to select the

desired submenu under the menu and push down the knob to confirm the current

submenu. Turn clockwise to move up the submenu and counterclockwise to move

down.

3. Modify parameters.

After having chosen a parameter, turn the Universal Knob to modify the value. Turn

clockwise to increase the value and counterclockwise to reduce. In addition, it can

also be used to adjust scale and offset of MATH and REF.

4. Choose file or directory or input filename.

After having entered the file system, turn the Universal Knob to select the desired file

or directory. When inputting filename, turn the Universal Knob to select the desired

character and the push the knob to confirm.

Find Quality Products Online at: sales@GlobalTestSupply.com

18 User Manual

www.GlobalTestSupply.com

Page 37

Menu

2-channel scope common function panel

4-channel scope common function panel

: Press the button to enter the CURSOR function menu. The oscilloscope

provides manual and track cursor mode.

: Press the button to enter the DISPLAY function menu and quickly enable the

persist function. User can set the grid, intensity, graticule, transparence.

: Press the button to enter the UTILITY function menu to look at the system

status, do self calibration, set the sound, language and so on.

: The button is a shortcut key for clear function. When the measurement

statistics is ON, press the button to clear the count and recount it. When

persist is enabled, press the button to clear persist.

: Press the button to enter the MEASURE function menu to set the

measurement parameters, all measurements, statistics and set the gate.

: Press the button to enter the ACQUIRE function menu to set the acquisition

mode, memory depth, wave interpolation and so on.

: Press the button to enter the SAVE/RECALL function menu to save setups,

waveforms, pictures, or CSV files to internal memory or USB flash driver.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 19

Page 38

: Press the button to reset the oscilloscope to user default setup.

: Press the button to enter the history mode. In history mode, it can record up

to 80,000 waveforms. If the sequence function is enabled, it will only record

the waveforms which you set, the most you can set is 80,000.

: Press the button to enter the DECODE function menu. The oscilloscope

supports I2C, SPI, UART/RS232, CAN and LIN serial bus decode.

: Press the button to turn off or turn on the navigate function. T3DSO1x04

(4-channel scope) supports three navigate types: time, search event, history

waveform.

Find Quality Products Online at: sales@GlobalTestSupply.com

20 User Manual

www.GlobalTestSupply.com

Page 39

Help

The oscilloscope has an on line help function that supplies multi-language help

information.

You can access the help function by pressing any button for 2 seconds and a help window

will explain the function. Also all of the submenus include help information.

Figure 12 Help Message

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 21

Page 40

User Interface

Figure 13 User Interface

1. Oscilloscope Display

The oscilloscope display is the main area to see most of the settings and the menus.

2. Channel Label/Waveform

Different channels are marked by different colors and the color of the waveform

complies with the color of the channel.

3. Trigger Status

Available trigger status includes Ready, Auto, Stop, Arm, Trig’d.

4. Horizontal Time Base

● Represent the time per graticule on the horizontal axis on the screen.

● Use the TIMEBASE Knob to adjust the parameter. The available

range is from 1.0 ns to 100 s.

5. Trigger Position

Turn the Horizontal Position Knob to adjust the delay. Push the knob to set the

value to 0 (center of the screen) automatically.

6. Trigger Delay Label

Indicate the trigger zero time position on the waveform.

Find Quality Products Online at: sales@GlobalTestSupply.com

22 User Manual

www.GlobalTestSupply.com

Page 41

7. Frequency Counter

Display the frequency value of the trigger channel.

8. Sampling Rate/ Memory Depth

Display the current sampling rate and memory depth. Sa means the current sampling

rate per second and Curr means the current memory depth.

9. Trigger Setup

Trigger Type : display the current trigger type. The trigger type names display

an abbreviation when the name is too long to display.

Trigger source : displays the currently trigger source. Each channel displays

in a different color.

Trigger condition : display the current trigger condition.

Trigger coupling : display the current trigger coupling. Available trigger coupling

mode: DC, AC, HF Reject, LF Reject.

Trigger level : display the current value of trigger level. Push the knob to

set the trigger to the 50% of the waveform amplitude automatically.

10. Channel Setup

Probe attenuation factor : display the current probe attenuation factor of the

channel. Available probe attenuation factors: 0.1X, 0.2X, 0.5X, 1X, …through to

2000X, 5000X, 10000X.

Input impedance: display the current input impedance of the channel. Available

Input impedance : 1MΩ.

Channel coupling : display the current channel coupling of the channel. Channel

coupling that are available: DC, AC, and GND.

Vertical Scale : display the current vertical scale of the channel per division.

Turn the Vertical Scale Knob to adjust the value.

11. Trigger Level Label

Display the position of trigger level, the trigger level indicator is colored the same as

the channel triggered on. It can move from +4.5div to -4.5div of the screen center.

12. I/O status

Indicate that the USB Host is connected.

Indicate that the LAN port is connected.

Indicate that the LAN port is disconnected.

Indicate that the WLAN port is connected.

Indicate that the WLAN port is disconnected.

13. Menu

Display the corresponding function menu of the selected button. Press the

corresponding softkey to adjust the oscilloscope.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 23

Page 42

To Use the Security Lock

If needed, you can use the security lock (not supplied) to lock the oscilloscope to

a fixed location. The method is as follows, align the lock with the lock hole and plug it into

the lock hole vertically, turn the key clockwise to lock the oscilloscope and then pull the

key out.

Security

lock hole

Figure 14 To Use the Security Lock

Find Quality Products Online at: sales@GlobalTestSupply.com

24 User Manual

www.GlobalTestSupply.com

Page 43

To Set the Vertical System

This chapter introduces how to set the vertical system of the oscilloscope.

The contents of this chapter:

◆ To Enable the Channel

◆ To Adjust the Vertical Scale

◆ To Adjust the Vertical Position

◆ To Specify Channel Coupling

◆ To Specify Bandwidth Limit

◆ To Specify Probe Attenuation Factor

◆ To Specify channel Input Impedance

◆ To Specify Amplitude Unit

◆ To Specify Deskew

◆ To Invert a Waveform

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

User Manual 25

Page 44

To Enable the Channel

The oscilloscope provides 2 or 4 analog input channels and provides independent vertical

controls for each channel. This chapter takes CH1 as an example since all of the vertical

channel setting methods are the same for all other channels.

Connect a signal to the CH1 channel BNC connector; and then press the CH1 button in

the vertical control area (VERTICAL) on the front panel to enable CH1 and illuminate the

CH1 button.

The channel setting menu is displayed at the bottom of the screen and the channel label

at the right side of the screen. The information displayed in the channel label is related to

the current channel setting.

After the channel is turned on, modify the parameters such as the vertical scale, the

horizontal time base and the trigger mode according to the input signal to make the

waveform display easy to observe and measure.

Note: to turn off the channel, press the channel button until

the channel indication light is no longer illuminated.

Find Quality Products Online at: sales@GlobalTestSupply.com

26 User Manual

www.GlobalTestSupply.com

Page 45

To Adjust the Vertical Scale

The vertical scale can be adjusted in Coarse or Fine mode.

● Coarse adjustment (take counterclockwise as an example): set the vertical scale in