Page 1

Operator’s Manual

CP150 and CP500

Current Probes

www. .com

information@itm.com1.800.561.8187

Page 2

CP150 and CP500 Current Probes

Operator’s Manual

July, 2017

www. .com

information@itm.com1.800.561.8187

Page 3

CP150 and CP500 Current Probes Operator’s Manual

© 2017 Teledyne LeCroy, Inc. All rights reserved.

Unauthorized duplication of Teledyne LeCroy documentation materials other than for

internal sales and distribution purposes is strictly prohibited. However, clients are

encouraged to duplicate and distribute Teledyne LeCroy documentation for internal

educational purposes.

Teledyne LeCroy is a registered trademark of Teledyne LeCroy, Inc. Windows is a

registered trademark of Microsoft Corporation. Other product or brand names are

trademarks or requested trademarks of their respective holders. Information in this

publication supersedes all earlier versions. Specifications are subject to change

without notice.

928617-00 Rev A

July, 2017

www. .com

information@itm.com1.800.561.8187

Page 4

Operator’s Manual

Contents

Safety Instructions ..................................................................................................................... 1

Symbols .............................................................................................................................................. 1

Precautions ........................................................................................................................................ 1

Introduction ................................................................................................................................ 3

Specifications ............................................................................................................................. 3

Warranted Characteristics ................................................................................................................ 3

Nominal Characteristics .................................................................................................................... 4

Typical Characteristics ...................................................................................................................... 4

Environmental Characteristics ......................................................................................................... 4

Physical Characteristics ................................................................................................................... 5

Safety Ratings .................................................................................................................................... 5

CP150 Derating Curve - Maximum Input Current vs. Frequency * ................................................. 6

CP150 Insertion Impedance vs. Frequency * .................................................................................. 6

CP500 Derating Curve - Maximum Input Current vs. Frequency ................................................... 7

CP500 Insertion Impedance vs. Frequency ..................................................................................... 7

Operation .................................................................................................................................... 8

Precautions ........................................................................................................................................ 8

Connecting to the Test Instrument .................................................................................................. 9

Connecting to the Test Circuit .......................................................................................................... 9

Operating with an Oscilloscope ......................................................................................................10

Performance Verification .......................................................................................................... 12

Test Equipment Required ................................................................................................................13

Preliminary Procedure .....................................................................................................................13

Functional Check .............................................................................................................................14

Check LF Accuracy ..........................................................................................................................14

CPxxx Test Record ...........................................................................................................................16

i

www. .com

information@itm.com1.800.561.8187

Page 5

CP150 and CP500 Current Probes

Care and Maintenance .............................................................................................................. 17

Cleaning ............................................................................................................................................17

Calibration Interval ..........................................................................................................................17

Service Strategy ...............................................................................................................................17

Troubleshooting ...............................................................................................................................17

Returning a Product for Service ................................................................................................ 18

Technical Support ..................................................................................................................... 19

Live Support .....................................................................................................................................19

Resources .........................................................................................................................................19

Service Centers ................................................................................................................................19

Warranty ................................................................................................................................... 20

Certifications ............................................................................................................................ 21

EMC Compliance ..............................................................................................................................21

Safety Compliance ...........................................................................................................................22

Environmental Compliance .............................................................................................................23

ii

www. .com

information@itm.com1.800.561.8187

Page 6

Operator’s Manual

CAUTION, possibility of electric shock.

CAUTION of damage to probe or instrument, or WARNING of hazard to health.

Do not apply around or remove from UNINSULATED HAZARDOUS LIVE

Equipment protected by double insulation or reinforced insulation.

CAUTION, hot surface.

Safety Instructions

Follow these instructions to keep the probe operating in a correct and safe condition.

Observe generally accepted safety procedures in addition to the precautions specified

here. The overall safety of any system incorporating this accessory is the responsibility

of the assembler of the system.

Symbols

These symbols appear on the probe body or in documentation to alert you to important

safety considerations.

Attend to the accompanying information to protect against personal injury or

damage. Do not proceed until conditions are fully understood and met.

conductors which may render electric shock, electric burn, or arc flash.

Precautions

Comply with the following safety precautions to avoid personal injury or

damage to your equipment:

Use only as specified. The probe is intended to be used only with compatible Teledyne

LeCroy instruments. Using the probe and/or the equipment it is connected to in a

manner other than specified may impair the protection mechanisms.

Do not use the probe for measurements on Mains circuits. The probe should only be

applied around or removed from insulated limited energy circuit conductors that are

not directly connected to the mains.

1

www. .com

information@itm.com1.800.561.8187

Page 7

CP150 and CP500 Current Probes

Do not overload; observe all ratings. To avoid electric shock or fire, do not connect the

current probe to any wire that carries voltages or currents that exceed the ratings of

the probe.

Connect and disconnect properly. Connect the probe to the measurement instrument

before connecting to the circuit/conductor being measured. Avoid damaging the cable

through excessive bending.

Never install or remove the probe on bare conductors which are energized. The

transformer core and shield are grounded but not insulated and may contact the

conductor when the locking lever is open.

Be careful not to damage the insulation surface when making measurements. Before

clamping to the conductor being measured, check that the insulation on the conductor

is undamaged, and take care not to damage the insulation when clamping the

conductor. Any damage to the insulation could cause an electric shock.

Use only indoors and within the operational environment listed. Do not use in wet or

explosive atmospheres.

Do not remove the probe's casing. Touching exposed connections may result in electric

shock.

Keep product surfaces clean and dry.

Comply with the maximum input current vs. frequency derating when measuring

current that includes a high frequency component. Using the probe at high frequencies

or strong magnetic fields may cause the device to become abnormally hot, resulting in

fire, equipment damage or burns.

Do not operate with suspected failures. Before each use, inspect the probe and

accessories for any damage such as tears or other defects in the probe body, cable

jacket, accessories, etc. If any part is damaged, cease operation immediately and

sequester the probe from inadvertent use.

NOTE: Depending on the amplitude and frequency of the current being measured, the

sensor head may emit a resonant sound. This sound may also occur during

demagnetizing operation, but it does not represent a malfunction (device failure).

2

www. .com

information@itm.com1.800.561.8187

Page 8

Operator’s Manual

CP150

CP150-6M

CP500

Amplitude Accuracy

±1.0 % of reading at 0-150 Amp

±2.0% of reading at 150-300 Apeak

±1.0 % of reading at 0-500 Amp

±2.0% of reading at 500-700 Apeak

Bandwidth (probe only)

DC to 10 MHz

DC to 5 MHz

DC to 2 MHz

Introduction

The CP150 and CP500 current probes are designed for easy, highly accurate current

measurements. The compact probes offer wide bandwidth with over-current protection.

The probes utilize a combination of Hall-effect and transformer technology which

enables measurements to be made on DC, AC and impulse currents.

The CP150 has a 10 MHz bandwidth and is designed to measure continuous currents

up to 150 Amps. The CP150-6M has a 5 MHz bandwidth and is designed to measure

continuous currents up to 150 Amps.

NOTE: All CP150 probes, regardless of cable length, will indicate default probe

bandwidth of 10 MHz in the Attributes section of the Probe dialog.

The CP500 has a 2 MHz bandwidth and is designed to measure continuous currents up

to 500 Amp.

The probes can be used with any Teledyne LeCroy instrument with a ProBus interface,

or by using a ProBus interface adapter. With the ProBus interface, the probe becomes

an integral part of the measuring instrument. The bandwidth limit, Auto Zero and

Degauss functions are all controlled from the instrument’s touch screen user interface.

The interface provides power to the probe, so no external power supply is needed.

Specifications

Specifications are subject to change without notice.

Warranted Characteristics

3

www. .com

information@itm.com1.800.561.8187

Page 9

CP150 and CP500 Current Probes

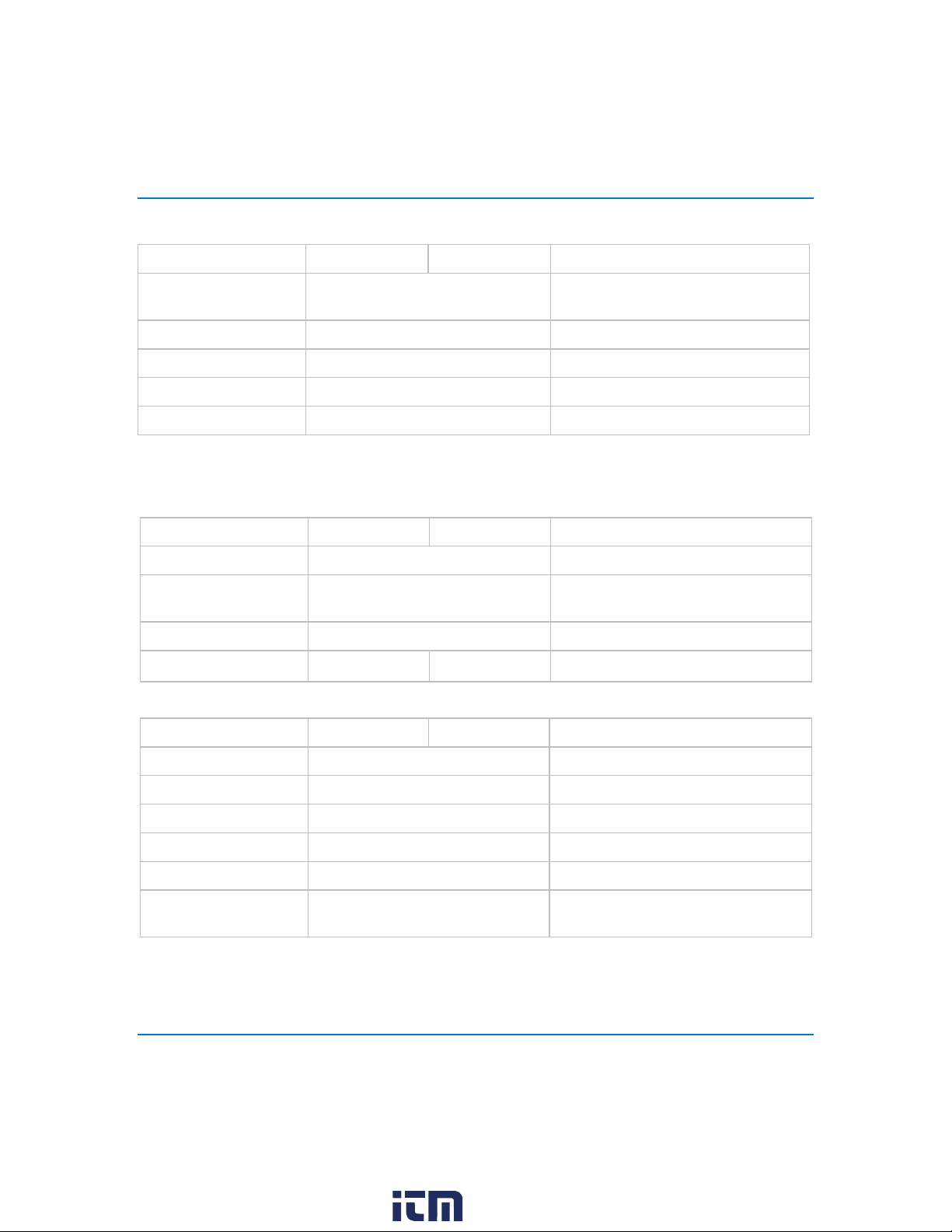

CP150

CP150-6M

CP500

Max Continuous Input

Current

150 Arms

500 Arms

Max Peak Current

300 Apeak non-continuous

700 Apeak non-continuous

Intended Output Load

1 MΩ

1 MΩ

Measured Conductors

Insulated Conductors only

Insulated Conductors only

Sensitivity *

100 mA/div to 100 A/div

100 mA/div to 200 A/div

CP150

CP150-6M

CP500

Output voltage

0.01 V/A

0.01 V/A

Sensitivity Temperature

Coefficient

±2% or less (0⁰C to +40⁰C)

±2% or less (0⁰C to +40⁰C)

Noise (at 20 MHz BW)

6.0 mArms or less

8.0 mArms or less

Rise Time

≤ 35 ns

≤ 70 ns

≤ 175 ns

CP150

CP150-6M

CP500

Operating Temperature

0 ⁰C to 40 ⁰C

0 ⁰C to 40 ⁰C

Operating RH

≤ 80% (non-condensing)

≤ 80% (non-condensing)

Storage Temperature

-10 ⁰C to 50 ⁰C

-10 ⁰C to 50 ⁰C

Storage RH

≤ 80% (non-condensing)

≤ 80% (non-condensing)

Max Altitude

2000 m

2000 m

Effect of External

Magnetic Field

Maximum of 150 mA in a DC/60 Hz,

400 A/m magnetic field

Maximum of 800 mA in a DC/60 Hz,

400 A/m magnetic field

Nominal Characteristics

* Values are based on oscilloscopes with 1 mV/div sensitivity. Numbers will be higher on instruments with

lower sensitivity.

Typical Characteristics

Environmental Characteristics

4

www. .com

information@itm.com1.800.561.8187

Page 10

Operator’s Manual

CP150

CP150-6M

CP500

Probe Head Length

175 mm (6.9 inch)

175 mm (6.9 inch)

Probe Head Width

27 mm (1.1 inch)

27 mm (1.1 inch)

Probe Head Height

69 mm (2.6 inch)

69 mm (2.7 inch)

Maximum diameter of

conductors measured

20 mm (0.79 inch)

20 mm (0.79 inch)

Cable Length

2 m (6.5 feet)

6 m (19.6 feet)

6 m (19.6 feet)

Physical Characteristics

Safety Ratings

Probe Designation1 Type D

2

Measurement Category

Safe Voltage Rating

4

Pollution Degree

Definitions (per IEC/EN 61010-2-032:2012)

1. Type D current probe is intended to be applied around or removed from insulated conductors.

2

No rated measurement category

3

Use only on fully insulated conductors

2. No rated measurement category; not intended for measurements on circuits directly connected to the

Mains supply. Not rated for measurements within Measurement Categories II, III, or IV.

3. Not rated for measurements on uninsulated conductors.

4. Pollution Degree 2 refers to operating environment where normally only dry, non-conductive pollution

occurs. Temporary conductivity caused by condensation must be expected.

NOTE: Because of the marking requirements per safety standard EN 61010-2-032:2012 (Third Edition), the

measurement category rating that was on the CPxxx probes originally certified per EN 61010-2-032:2002

(Second Edition) has been removed from the product label. However, this change does not reduce the

measurement capability or the level of protection offered by the new probe design.

5

www. .com

information@itm.com1.800.561.8187

Page 11

CP150 and CP500 Current Probes

CP150 Derating Curve - Maximum Input Current vs. Frequency *

* Does not apply to CP150-6M

CP150 Insertion Impedance vs. Frequency *

* Does not apply to CP150-6M

6

www. .com

information@itm.com1.800.561.8187

Page 12

Operator’s Manual

CP500 Derating Curve - Maximum Input Current vs. Frequency

CP500 Insertion Impedance vs. Frequency

7

www. .com

information@itm.com1.800.561.8187

Page 13

CP150 and CP500 Current Probes

WARNING: Comply with the derating characteristics of the probe when

CAUTION: Do not touch the probe head until it has had sufficient time to

CAUTION: Do not use this probe for making measurements on Mains

Operation

Precautions

The sensor head is a precision assembly consisting of a molded component with a

ferrite core and a Hall effect element. It may be damaged if subjected to sudden

changes in temperature, mechanical strain or shock.

The mating surfaces of the sensor are precision ground and should be treated with

care. If there is any type of dust or dirt on the mating surfaces of the sensor head,

measurements may be impaired.

Accurate measurements may not be possible in locations subject to strong magnetic

fields such as transformers and high-current conductors, or in locations subject to

strong external electric fields.

measuring current that includes a high frequency component, and never

measure any current that exceeds the rated current. Using the probe at high

frequencies or in strong magnetic fields may cause the probe head to

become abnormally hot, resulting in fire, equipment damage or burns.

cool after disconnecting the probe from the circuit. Using the probe near the

current and ambient temperature upper limits for extended lengths of time

may cause the probe head surface to become hot to the touch.

Circuits. Using the probe on uninsulated hazardous live conductors may

result in electric shock, electric burn, or arc flash.

8

www. .com

information@itm.com1.800.561.8187

Page 14

Operator’s Manual

CAUTION: Never use this probe on bare conductors. The core and shield are

probe or the circuit under test.

Connecting to the Test Instrument

The probe has been designed for use with the Teledyne LeCroy instruments equipped

with the ProBus interface. When you attach the probe output connector to the

instrument’s input connector, the instrument will:

• Recognize the probe model

• Set the input termination to 1 MΩ

• Activate the probe control functions in the touch screen user interface.

Connecting to the Test Circuit

The probe has been designed with a movable split core, eliminating the need to break

the conductor for the core to slip around the conductor. To connect:

1. Pull back the slider so that the clamp opens.

2. Align the sensor so that the current direction indicator corresponds to the

direction of current flow in the conductor.

3. Close the probe jaws around the conductor until the jaws click shut.

4. Close the slider on the sensor head until the "UNLOCK’ indication disappears

and the "LOCK" indication appears.

5. Verify that the opening lever is firmly locked and the clamp is securely closed.

grounded and any voltage applied to the conductor may cause damage the

9

www. .com

information@itm.com1.800.561.8187

Page 15

CP150 and CP500 Current Probes

Operating with an Oscilloscope

When connected to a Teledyne LeCroy oscilloscope, the displayed scale factor and

measurement values will be adjusted to account for the effective gain of the probe.

A/div, Offset, and Coupling, and Bandwidth (BWL) are controlled from the Channel

setup (Cx) dialog.

Channel setup dialog with Probe dialog behind it.

The probe’s attributes are shown on the Probe dialog, which appears behind the

Channel dialog when a probe is detected. The Probe dialog also contains controls for

Auto Zero and Degauss.

Probe dialog.

Probe A/div and Attenuation

The front panel Volts/div knob controls the oscilloscope’s scale factor and the probe’s

internal attenuation to give full available dynamic range from 100mA/div to 200 A/div

for the CP500 and 100mA/div to 100 A/div for the CP150.

Alternatively, A/div may be controlled from the channel setup dialog (Cx).

Bandwidth Limit

The probe is capable of switching from Full (maximum bandwidth) to 20 MHz

bandwidth by changing the Bandwidth setting on the Cx dialog.

10

www. .com

information@itm.com1.800.561.8187

Page 16

Operator’s Manual

AC Coupling

In general, using offset to adjust a DC current on the screen is the preferred method to

measure transient signals in the presence of a larger DC currents. The offset has limits

that will cause a signal that is beyond the linear operating range of the probe to go off

the screen, preventing measurement errors.

There are times, however, when it is convenient to use AC coupling to remove the DC

component of the measured signal from the measurement. Selecting AC uses the

scope AC coupling at the probe output to remove any steady state value from the

displayed voltage.

NOTE: Since this AC coupling is on the probe output, DC current beyond the linear

range of the probe will cause the probe to saturate and make the displayed waveform

inaccurate. It is important not to exceed the maximum linear input values when using

AC coupling.

Auto Zero

The Probe dialog incorporates an Auto Zero function to remove the DC offset from the

current probe. Auto Zero must be invoked by the user. After several minutes of warmup, or when the probe is exposed to a large shift in ambient temperature, some DC

offset drift may occur. Open the Probe dialog and touch AUTO ZERO.

Degauss

If the probe has been magnetized by external magnetic field or by excessive input, the

core can be demagnetized by degaussing. The demagnetizing process takes about 5

seconds and should always be performed before taking a measurement.

Without clamping the probe around a conductor, slide the opening lever to close and

lock the probe. Open the Probe dialog and touch DEGAUSS.

An Auto Zero is automatically performed as part of the degauss cycle.

11

www. .com

information@itm.com1.800.561.8187

Page 17

CP150 and CP500 Current Probes

Performance Verification

This procedure can be used to verify the warranted characteristics of the probe. The

recommended calibration interval for the models CP150 and CP500 Current Probes is

one year. The complete performance verification procedure should be performed as the

first step of annual calibration. Performance verification can be completed without

removing the probe covers or exposing the user to hazardous voltages. Test results

can be recorded on a photocopy of the Test Record provided at the end of the manual.

The warranted characteristics of the probe are valid at any temperature within the

Environmental Characteristics listed in the Specifications. However, some of the other

test equipment used to verify the performance may have environmental limitations

required to meet the accuracy needed for the procedure. Make sure that the ambient

conditions meet the requirements of all the test instruments used in his procedure.

NOTE: Operation of the probe as described requires software version 4.3.0.0 or higher.

To confirm the version installed, choose Utilities > Utilities Setup from the oscilloscope

menu bar, then open the Status tab.

12

www. .com

information@itm.com1.800.561.8187

Page 18

Operator’s Manual

Wide Band Oscilloscope

200 MHz bandwidth

Teledyne LeCroy WaveRunner 6 Zi

Digital Multimeter (2)

DC: 0.1% Accuracy

Agilent Technologies 34401A

Function Generator

50 Hz sine wave output 3 Vrms

Teledyne LeCroy WaveStation 3082

Calibration Fixture

500 turn loop in series with 0.5Ω

Teledyne LeCroy CP150-CF02

Calibration Fixture

ProBus Extension Cable

Teledyne LeCroy PROBUS-CF01

Banana Plug Adapter

Female BNC to Dual Banana Plug

Pomona 1269

Patch Cables (4)

Male Banana to Male Banana, 12"

Pomona B-12-0 (black)

BNC Adapter

BNC Male to Dual Banana Jack

Pomona 1296

Test Equipment Required

The following table lists the test equipment and accessories (or their equivalents)

which are required for performance verification of the CP150/CP0500 Current Probes.

Because the input and output connector types may vary on different brands and

models of test instruments, additional adapters or cables may be required.

Description Minimum Requirements Example Equipment

ProBus interface equipped

5½ digit resolution

into 50 Ω

±0.1% resistor with sense

terminals

Fluke 8842A-09

Stanford Research Model DS340

Teledyne LeCroy CP500-CF02

Pomona B-12-2 (red)

Preliminary Procedure

1. Connect the probe to the C1 input of the instrument and completely close the

probe slider.

2. Turn on the instrument and allow at least 30 minutes warmup time for the probe

before performing the verification procedure.

3. Turn on the other test equipment and allow these to warm up for the time

recommended by the manufacturer.

4. While the instruments are reaching operating temperature, make a photocopy of

the Performance Verification Test Record and fill in the necessary data.

13

www. .com

information@itm.com1.800.561.8187

Page 19

CP150 and CP500 Current Probes

Functional Check

The functional check will verify the basic operation of the probe functions. It is

recommended to perform the functional check prior to the performance verification

procedure.

1. Open the C1 setup dialog and confirm that the bandwidth is set to Full (BWL

OFF).

2. Verify that the probe is sensed and the probe dialog (CP150 or CP500 tab)

appears behind the C1 setup dialog.

3. Open the probe dialog and degauss the probe by touching DEGAUSS, then OK.

4. Confirm that the message "Performing Degauss on CPxxx...." is displayed in the

message bar and that no error messages are displayed.

Check LF Accuracy

LF Accuracy Test set up.

14

www. .com

information@itm.com1.800.561.8187

Page 20

Operator’s Manual

1. Set the Function generator to 50 Hz sine wave, output voltage at 1.7 Vrms for

CP150 or 3 Vrms for CP500 with 50 Ω output.

2. Remove the probe from the instrument and reconnect using the ProBus

extension cable. Connect the BNC male connector of the ProBus extension to

DMM #1 using a BNC Female to Dual Banana adapter.

3. Using Banana Patch cords and the BNC to Dual Banana Plug adapter, connect

the ’V Source’ and ’V Return’ terminals of the 500 Turn Calibration Loop to the

output of the Function Generator.

4. Connect the Current Sense terminals of the 500 Turn Calibration Loop to the

voltage inputs of DMM #2.

5. Set both DMMs to measure AC Volt.

6. With the probe removed from any signal and the slider returned to the LOCKED

position, degauss the probe by pressing the DEGAUSS button.

7. Open the probe slider and position the probe input around the 500 Turn loop.

Close and LOCK the slider.

8. Adjust the Function generator voltage until the voltage measured at the ’Current

Sense’ terminals (DMM #2) reads 10 mV ±0.01 mV (10 A at the probe head) for

CP150 or 50 mV ±0.05 mV (500 A at the probe head) for CP500.

9. Record the voltage measured by DMM #1 on the Test Record.

10. Verify that the measured voltage is between 99 mV and 101 mV for CP150, or

0.495 V and 0.505 V for CP500.

15

www. .com

information@itm.com1.800.561.8187

Page 21

CP150 and CP500 Current Probes

Model:

_________________________________

Serial Number:

_________

Asset/Tracking Number:

_________________________________

Date:

_________________________________

Technician:

_________

Equipment

Model

Serial Number

Calibration Due Date

Digital Multimeter #1

Digital Multimeter #2

Function Generator*

N/A

Step

Description

Intermediate Data

Test Result

10

Probe Output

Limit

99

0.495 - 0.505 V for CP500

________________ V

CPxxx Test Record

________________________

________________________

* The function generator is used for making relative measurements. The output of the generator is

measured with a DMM or oscilloscope. Thus, the generator is not required to be calibrated.

s:

- 101 mV for CP150

Permission is granted to photocopy this page and record the results of the performance verification

procedure on the copy. File the completed record as required by applicable internal quality procedures.

Results recorded under "Test Result" are the actual specification limit check. The test limits are included in

all of these steps. Record other measurements and intermediate calculations that support the limit check

under "Intermediate Data".

16

www. .com

information@itm.com1.800.561.8187

Page 22

Operator’s Manual

CAUTION: The probe case is not sealed and should never be immersed in any

fluid.

Care and Maintenance

Cleaning

The exterior of the probe and cable should be cleaned only using a soft cloth moistened

with water or isopropyl alcohol. The use of abrasive agent, strong detergents or other

solvents may damage the probe.

Calibration Interval

The recommended calibration interval is one year. Adjustment should only be

performed by qualified personnel. (A performance verification procedure is included in

this manual.)

Service Strategy

Defective probes must be returned to a Teledyne LeCroy service facility for diagnosis

and exchange. A defective probe under warranty will be replaced with a factory

refurbished probe. A probe that is not under warranty can be exchanged for a factory

refurbished probe. A modest fee is charged for this service. A defective probe must be

returned in order to receive credit for the probe core.

Troubleshooting

If the probe is not operating properly the problem may be the way in which it is used.

Before assuming the probe is defective, perform the following troubleshooting

procedures:

1. Verify the test instrument is running the required firmware (4.3.0.0 or higher).

2. If the waveform is inverted, check that the arrow on the slider is in the direction

of the current flow.

3. If there is no signal, check that the slider is closed and locked.

17

www. .com

information@itm.com1.800.561.8187

Page 23

CP150 and CP500 Current Probes

Returning a Product for Service

Contact your regional Teledyne LeCroy service center for calibration or other service. If

the product cannot be serviced on location, the service center will give you a Return

Material Authorization (RMA) code and instruct you where to ship the product. All

products returned to the factory must have an RMA. Return shipments must be

prepaid.

Teledyne LeCroy cannot accept COD or Collect shipments. We recommend airfreighting. Insure the item you’re returning for at least the replacement cost.

1. Remove all accessories from the probe. Do not include the manual.

2. Pack the probe in its case, surrounded by the original packing material (or

equivalent).

3. Label the case with a tag containing:

• The RMA

• Name and address of the owner

• Probe model and serial number

• Description of failure or requisite service

4. Package the probe case in a cardboard shipping box with adequate padding to

avoid damage in transit.

5. Mark the outside of the box with the shipping address given to you by Teledyne

LeCroy; be sure to add the following:

• ATTN: <RMA code assigned by the Teledyne LeCroy>

• FRAGILE

6. Insure the item for the replacement cost of the probe.

7. If returning a probe to a different country:

• Mark the shipment as a “Return of US manufactured goods for warranty

repair/recalibration.”

• If there is a cost for the service, list the cost in the value column and the

original purchase price “For insurance purposes only.”

• Be very specific as to the reason for shipment. Duties may have to be

paid on the value of the service.

18

www. .com

information@itm.com1.800.561.8187

Page 24

CP150 and CP500 Current Probes

Warranty

Teledyne LeCroy warrants this oscilloscope accessory for normal use and operation

within specification for a period of one year from the date of shipment. Spare parts,

replacement parts and repairs are warranted for 90 days.

In exercising its warranty, Teledyne LeCroy, at its option, will either repair or replace any

assembly returned within its warranty period to the Customer Service Department or an

authorized service center. However, this will be done only if the product is determined

by Teledyne LeCroy’s examination to be defective due to workmanship or materials,

and the defect is not caused by misuse, neglect, accident, abnormal conditions of

operation, or damage resulting from attempted repair or modifications by a nonauthorized service facility.

The customer will be responsible for the transportation and insurance charges for the

return of products to the service facility. Teledyne LeCroy will return all products under

warranty with transportation charges prepaid.

This warranty replaces all other warranties, expressed or implied, including but not

limited to any implied warranty of merchantability, fitness or adequacy for any

particular purposes or use. Teledyne LeCroy shall not be liable for any special,

incidental, or consequential damages, whether in contract or otherwise.

20

www. .com

information@itm.com1.800.561.8187

Page 25

Operator’s Manual

Certifications

Teledyne LeCroy certifies compliance to the following standards as of the date of

publication. As standards evolve, these may no longer be current. Please see the

Declaration of Conformity certificate shipped with your product.

EMC Compliance

EC Declaration of Conformity - EMC

The probes meet the intent of EC Directive 2014/30/EU for Electromagnetic

Compatibility. Compliance was demonstrated to the following specifications as listed

in the Official Journal of the European Communities:

EN 61326-1:2013 EMC requirements for electrical equipment for measurement, control,

and laboratory use.

ELECTROMAGNETIC EMISSIONS:

EN 55011/A1:2010 Radiated and Conducted Emissions Group 1 Class A

LECTROMAGNETIC IMMUNITY:

E

EN 61000-4-2:2009 Electrostatic Discharge, 4 kV contact, 8 kV air, 4 kV

vertical/horizontal coupling planes

1

2 3

4

EN 61000-4-3/A2:2010 RF Radiated Electromagnetic Field, 3 V/m, 80-1000 MHz; 3 V/m,

1400 MHz - 2 GHz; 1 V/m, 2 GHz - 2.7 GHz

EN 61000-4-8:2010 Power Frequency Magnetic Field, 3 A/m, 50 Hz; 3 A/m, 60 Hz

1 To ensure compliance with the applicable EMC standards, use high quality shielded interface cables.

2 This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic

interference.

3 Emissions which exceed the levels required by this standard may occur when the probe is connected to a test object.

4 Meets Performance Criteria “B” limits of the respective standard: during the disturbance, product undergoes a

temporary degradation or loss of function or performance which is self-recoverable.

21

www. .com

information@itm.com1.800.561.8187

Page 26

CP150 and CP500 Current Probes

Australia & New Zealand Declaration of Conformity - EMC

The probes comply with the EMC provision of the Radio Communications Act per the

following standards, in accordance with requirements imposed by the Australian

Communication and Media Authority (ACMA):

AS/NZS CISPR 11:2011 Radiated and Conducted Emissions, Group 1, Class A.

Safety Compliance

EC Declaration of Conformity – Low Voltage

The probes meet the intent of EC Directive 2014/35/EU for Product Safety. Compliance

was demonstrated to the following specifications as listed in the Official Journal of the

European Communities:

IEC/EN 61010-1:2010 Safety requirements for electrical equipment for measurement,

control, and laboratory use – Part 1: General requirements

IEC/EN 61010-2-032:2012 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 2-032: Particular Requirements for

Hand-Held and Hand Manipulated Current Sensors for Electrical Test and

Measurement.

22

www. .com

information@itm.com1.800.561.8187

Page 27

Operator’s Manual

Environmental Compliance

End-Of-Life Handling

The probe is marked with this symbol to indicate that it complies with the

applicable European Union requirements to Directives 2012/19/EU

2013/56/EU on Waste Electrical and Electronic Equipment (WEEE) and

Batteries.

The probe is subject to disposal and recycling regulations that vary by

country and region. Many countries prohibit the disposal of waste electronic

equipment in standard waste receptacles.

Restriction of Hazardous Substances (RoHS)

The product and its accessories conform to the 2011/65/EU RoHS2 Directive.

and

23

www. .com

information@itm.com1.800.561.8187

Loading...

Loading...