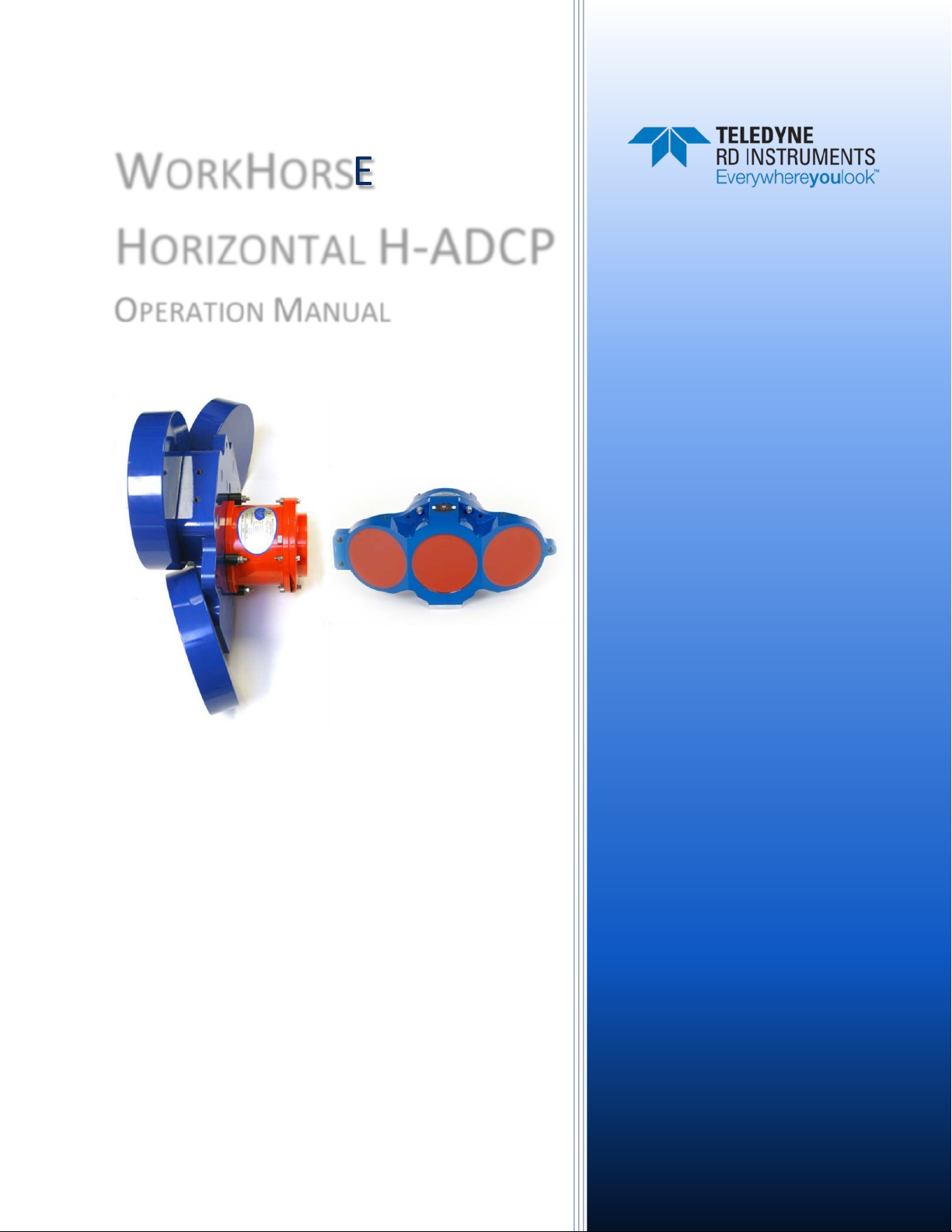

Teledyne WORKHORSE Operation Manual

WORKHORSE

HORIZONTAL H-ADCP

OPERATION MANUAL

Information included herein is controlled by the Export Administration Regulations (EAR) and may

require an export license, license exception or other approval from the appropriate U.S.

Government agency before being exported from the United States or provided to any foreign

person. Diversion contrary to U.S. law is prohibited.

P/N 957-6212-00 (May 2015)

© 2015 Teledyne RD Instruments, Inc. All rights reserved.

Page ii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

TABLE OF CONTENTS

CHAPTER 1 - AT A GLANCE ...................................................................................................................................1

How to Contact Teledyne RD Instruments ................................................................................................... 2

Conventions Used in this Manual................................................................................................................. 2

System Overview .......................................................................................................................................... 3

Inventory List ............................................................................................................................................... 5

Computer Considerations ............................................................................................................................ 6

Power Overview ........................................................................................................................................... 7

Setting up the H-ADCP System ..................................................................................................................... 8

Connecting to the H-ADCP ................................................................................................................... 9

Testing the H-ADCP .............................................................................................................................. 10

Changing the Baud Rate in the H-ADCPs .............................................................................................. 12

Caring for the H-ADCP System ..................................................................................................................... 13

General Handling Guidelines ................................................................................................................ 13

Assembly Guidelines ............................................................................................................................ 13

Deployment Guidelines ........................................................................................................................ 14

CHAPTER 2 - INSTALLATION ..................................................................................................................................15

I/O Cable and Dummy Plug .......................................................................................................................... 16

Routing Cables ............................................................................................................................................. 18

Cable Wiring Diagrams ................................................................................................................................. 19

Installation ................................................................................................................................................... 20

Cathodic Disbondment and Galvanic Corrosion ................................................................................... 21

H-ADCP Orientation ............................................................................................................................. 22

Attaching the H-ADCP to a Structure ................................................................................................... 23

H-ADCP Wave System Installation Checklist ........................................................................................ 25

Testing the Installed H-ADCP................................................................................................................ 27

Periodic Maintenance .................................................................................................................................. 29

CHAPTER 3 – COLLECTING DATA ............................................................................................................................31

Collecting Data with SurfaceView ................................................................................................................ 32

Data Playback with SurfaceView .................................................................................................................. 37

Data Recovery .............................................................................................................................................. 38

Recover a Single File using BBTalk ........................................................................................................ 38

Recover the Entire Recorder using BBTalk ........................................................................................... 38

Recover a Single File Using Direct Commands ..................................................................................... 39

Recover Recorder Using Direct Commands.......................................................................................... 40

CHAPTER 4 - MAINTENANCE .................................................................................................................................41

Parts Location Drawings ............................................................................................................................... 42

Maintenance Schedule ................................................................................................................................. 45

Calibration Items .................................................................................................................................. 45

Maintenance Items .............................................................................................................................. 45

Spare Parts ................................................................................................................................................... 47

Disassembly and Assembly Procedures ....................................................................................................... 49

Housing Assembly Removal ................................................................................................................. 49

End-Cap Removal Procedures .............................................................................................................. 50

H-ADCP Re-assembly ............................................................................................................................ 51

O-ring Inspection and Replacement ..................................................................................................... 51

Housing Assembly Replacement .......................................................................................................... 52

End-Cap Replacement .......................................................................................................................... 53

Periodic Maintenance Items ........................................................................................................................ 54

Replacing the Desiccant Bags ............................................................................................................... 54

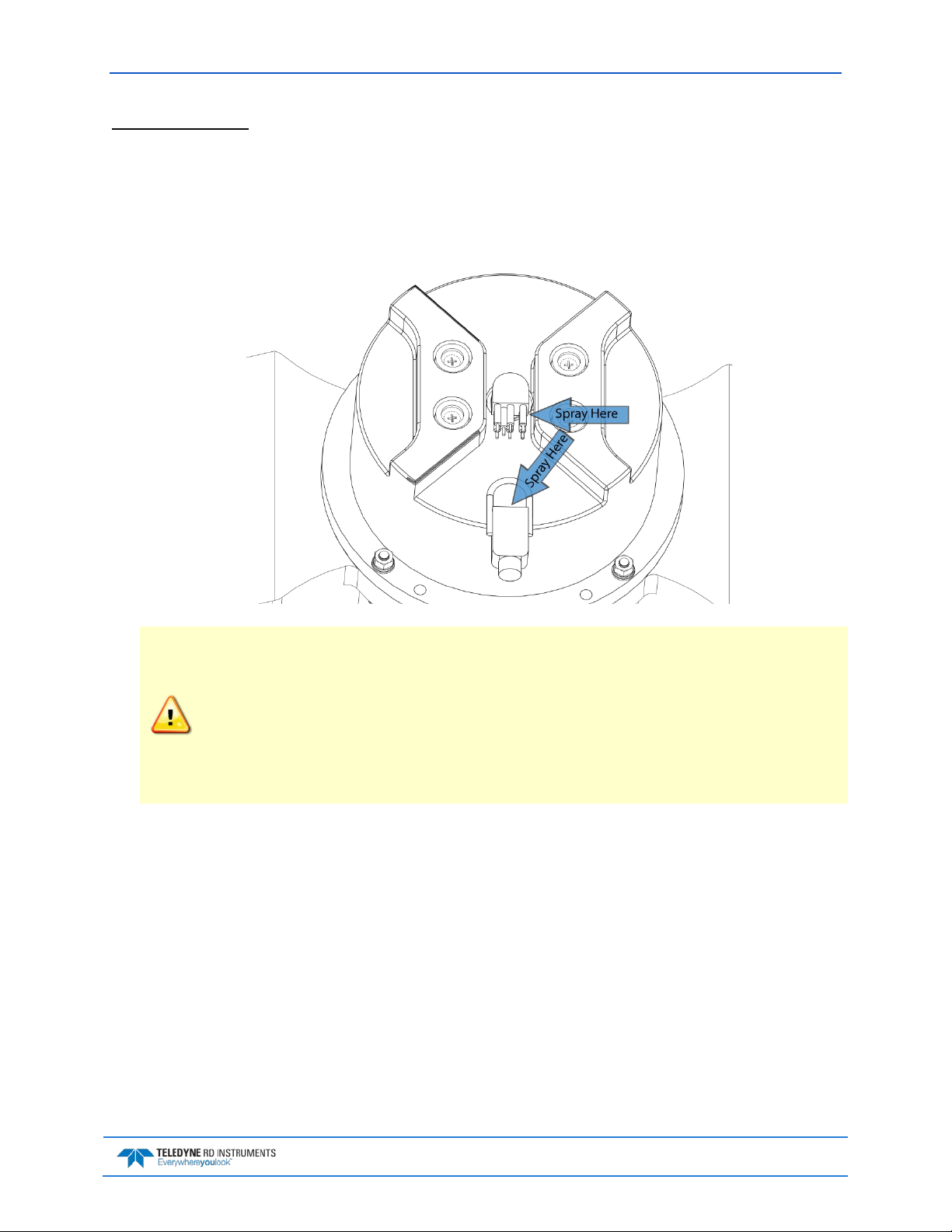

Cleaning the Pressure Sensor Port ....................................................................................................... 55

Preventing Biofouling ........................................................................................................................... 55

Antifouling Paints ........................................................................................................................... 56

Page iii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Applying Antifouling Paints ............................................................................................................ 56

Removing Biofouling ...................................................................................................................... 58

Zinc Anode Inspection and Replacement ............................................................................................. 58

Zinc Anode Inspection .................................................................................................................... 58

Zinc Anode Electrical Continuity Check .......................................................................................... 59

Zinc Anode Replacement ............................................................................................................... 59

Calibrating the Compass....................................................................................................................... 60

Compass Background ..................................................................................................................... 60

Preparing for Calibration................................................................................................................ 61

Compass Calibration Verification ................................................................................................... 61

Compass Calibration ...................................................................................................................... 61

Installing Firmware Upgrades .............................................................................................................. 63

Installing Feature Upgrades ................................................................................................................. 64

Corrective Maintenance Items ..................................................................................................................... 65

Protective Coating Inspection and Repair ............................................................................................ 65

PC Card Recorder ................................................................................................................................. 66

Replacing Fuses .................................................................................................................................... 67

Changing Communications Setting ...................................................................................................... 67

Installing the Spare Boards Kit ............................................................................................................. 68

Remove the Original Set of Boards ................................................................................................ 69

Installing the Spare Board Kit ......................................................................................................... 70

Installing the Beam Cosine Matrix ................................................................................................. 71

Installing the Pressure Sensor Coefficients .................................................................................... 72

Testing the System after Board Replacement ................................................................................ 72

Replacing the End Cap Connector ........................................................................................................ 73

Equipment Provided ...................................................................................................................... 73

Customer Supplied Additional Equipment ..................................................................................... 73

Removing the End-Cap Connector ................................................................................................. 74

Installing the New End-Cap Connector .......................................................................................... 75

Wiring Diagrams ............................................................................................................................ 77

Replacing the H-ADCP Lithium Battery................................................................................................. 78

Testing the Lithium Battery Voltage .............................................................................................. 78

Replacing the Lithium Battery ........................................................................................................ 79

CHAPTER 5- TROUBLESHOOTING ............................................................................................................................81

Equipment Required .................................................................................................................................... 82

Basic Steps in Troubleshooting .................................................................................................................... 83

Troubleshooting the H-ADCP ....................................................................................................................... 83

Troubleshooting Safety ........................................................................................................................ 83

Troubleshooting a Communication Failure .................................................................................................. 84

Incorrect Wakeup Message ........................................................................................................... 84

No Wakeup Message ..................................................................................................................... 85

Check the Power .................................................................................................................................. 85

Check the I/O Cable .............................................................................................................................. 86

H-ADCP Checks ..................................................................................................................................... 86

Troubleshooting a Built-In Test Failure ........................................................................................................ 87

When to use the Spare Boards Kit........................................................................................................ 87

Troubleshooting a Beam Failure .................................................................................................................. 89

Troubleshooting a Sensor Failure ................................................................................................................. 90

Fault Log ............................................................................................................................................... 90

System Overview .......................................................................................................................................... 91

Operating Modes ................................................................................................................................. 91

Command Mode ............................................................................................................................ 91

Ping Mode ...................................................................................................................................... 91

Overview of Normal H-ADCP Operation............................................................................................... 92

Functional Description of Operation .................................................................................................... 92

Input Power ................................................................................................................................... 92

Board Descriptions ......................................................................................................................... 93

Page iv

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Sensors ........................................................................................................................................... 94

CHAPTER 6 - RETURNING SYSTEMS TO TRDI FOR SERVICE ............................................................................................99

Shipping the H-ADCP .................................................................................................................................... 100

Returning Systems to the TRDI Factory ........................................................................................................ 101

Returning Systems to TRDI Europe Factory .................................................................................................. 102

CHAPTER 7 - SPECIFIC ATIONS ................................................................................................................................105

Outline Installation Drawings ....................................................................................................................... 108

CHAPTER 8 - COMMANDS ....................................................................................................................................115

Data Communication and Command Format .............................................................................................. 116

Command Input Processing ................................................................................................................. 116

Data Output Processing........................................................................................................................ 117

Using Direct Commands to Deploy .............................................................................................................. 118

Command Summary ..................................................................................................................................... 119

Command Descriptions ................................................................................................................................ 123

? – Help Menus .............................................................................................................................. 123

Break .............................................................................................................................................. 124

Expert Mode .................................................................................................................................. 125

OL - Features .................................................................................................................................. 125

Compass Commands .................................................................................................................................... 126

Available Compass Commands............................................................................................................. 126

Compass Command Descriptions ......................................................................................................... 126

AC – Output Active Calibration Data .............................................................................................. 126

AD – Display Factory or Active Calibration Data ............................................................................ 127

AF – Field Calibrate Compass ......................................................................................................... 128

AR – Return to Factory Calibration ................................................................................................ 128

AX – Examine Compass Calibration ................................................................................................ 129

AZ – Zero Pressure Sensor ............................................................................................................. 130

Bottom Track Commands ............................................................................................................................. 131

Available Bottom Track Commands ..................................................................................................... 131

Bottom Track Command Descriptions ................................................................................................. 131

BA - Evaluation Amplitude Minimum ............................................................................................. 131

BB – High Bandwidth Maximum Depth.......................................................................................... 132

BC - Correlation Magnitude Minimum ........................................................................................... 132

BE - Error Velocity Maximum ......................................................................................................... 132

BF - Depth Guess ............................................................................................................................ 133

BI - Gain Switch Depth ................................................................................................................... 133

BK – Water-Mass Layer Mode........................................................................................................ 134

BL - Water-Mass Layer Parameters ................................................................................................ 134

BM - Bottom Track Mode .............................................................................................................. 135

BP – Bottom-Track Pings per Ensemble ......................................................................................... 136

BR - Resolution ............................................................................................................................... 136

BS - Clear Distance Traveled .......................................................................................................... 137

BX – Maximum Tracking Depth ...................................................................................................... 137

BZ - Coherent Ambiguity Velocity .................................................................................................. 138

Control System Commands .......................................................................................................................... 139

Available Control System Commands .................................................................................................. 139

Control System Command Descriptions ............................................................................................... 139

CB - Serial Port Control .................................................................................................................. 139

CF - Flow Control ............................................................................................................................ 140

CG – Swap Beams 1 & 2 ................................................................................................................. 141

CK - Keep Parameters .................................................................................................................... 141

CL – Sleep Enable ........................................................................................................................... 141

CM - Master ................................................................................................................................... 142

CN - Save NVRAM to Recorder ....................................................................................................... 142

CP – Polled Mode ........................................................................................................................... 142

CQ – Transmit Power ..................................................................................................................... 143

Page v

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

CR – Retrieve Parameters .............................................................................................................. 144

CS – Start Pinging (Go) ................................................................................................................... 144

CY - Clear Error Status Word .......................................................................................................... 145

CZ – Power Down H-ADCP ............................................................................................................. 146

Environmental Commands ........................................................................................................................... 147

Available Environmental Commands ................................................................................................... 147

Environmental Command Descriptions ................................................................................................ 147

EA - Heading Alignment ................................................................................................................. 147

EB - Heading Bias ........................................................................................................................... 148

EC - Speed of Sound ....................................................................................................................... 148

ED - Depth of Transducer ............................................................................................................... 148

EH - Heading .................................................................................................................................. 149

EP - Pitch (Tilt 1) ............................................................................................................................. 149

ER - Roll (Tilt 2) ............................................................................................................................... 150

ES – Salinity .................................................................................................................................... 150

ET - Temperature ........................................................................................................................... 150

EX – Coordinate Transformation .................................................................................................... 151

EZ - Sensor Source .......................................................................................................................... 152

Fault Log Commands .................................................................................................................................... 153

Available Fault Log Commands ............................................................................................................ 153

Fault Log Command Descriptions ......................................................................................................... 153

FC – Clear Fault Log ........................................................................................................................ 153

FD – Display Fault Log .................................................................................................................... 153

Performance and Testing Commands .......................................................................................................... 154

Available Performance and Testing Commands ................................................................................... 154

Performance and Testing Command Descriptions ............................................................................... 154

PA – Pre-deployment Tests ............................................................................................................ 154

PC – User-Interactive Built-In Tests ................................................................................................ 155

PD - Data Stream Select ................................................................................................................. 156

PM - Distance Measurement Facility ............................................................................................. 157

PS – Display System Parameters .................................................................................................... 157

PT - Built-In Tests ........................................................................................................................... 159

PT Test Results Error Codes ........................................................................................................... 159

PT0 - Help ....................................................................................................................................... 159

PT2 - Ancillary System Data ........................................................................................................... 160

PT3 - Receive Path ......................................................................................................................... 160

PT4 - Transmit Path ........................................................................................................................ 161

PT5 - Electronics Wrap Around ...................................................................................................... 162

PT6 - Receive Bandwidth ............................................................................................................... 163

PT7 - RSSI Bandwidth ..................................................................................................................... 163

Recorder Commands .................................................................................................................................... 165

Available Recorder Commands ............................................................................................................ 165

RA - Number of Deployments ........................................................................................................ 165

RB - Recorder Built-In Test ............................................................................................................. 165

RE – Erase Recorder ....................................................................................................................... 166

RF – Recorder Free Space (Bytes) .................................................................................................. 166

RN – Set Deployment Name .......................................................................................................... 166

RR – Show Recorder File Directory ................................................................................................ 167

RS - Recorder Free Space (Megabytes) .......................................................................................... 167

RY – Upload Recorder Files ............................................................................................................ 167

Timing Commands ....................................................................................................................................... 168

Available Timing Commands ................................................................................................................ 168

Timing Command Descriptions ............................................................................................................ 168

TB - Time per Burst ........................................................................................................................ 168

TC - Ensemble per Burst ................................................................................................................. 169

TE – Time per Ensemble ................................................................................................................. 169

TF – Time of First Ping .................................................................................................................... 169

Page vi

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

TG – Time of First Ping (Y2k Compliant) ......................................................................................... 170

TP – Time Between Pings ............................................................................................................... 171

TS – Set Real-Time Clock ................................................................................................................ 171

TT – Set Real-Time Clock (Y2k Compliant)...................................................................................... 172

Water Profiling Commands .......................................................................................................................... 173

Standard Water Profiling Commands ................................................................................................... 173

WA - False Target Threshold Maximum ......................................................................................... 173

WB - Bandwidth Control ................................................................................................................ 174

WC - Low Correlation Threshold .................................................................................................... 174

WD – Data Out ............................................................................................................................... 175

WE - Error Velocity Threshold ........................................................................................................ 175

WF – Blank after Transmit ............................................................................................................. 176

WI - Clip Data Past Bottom ............................................................................................................ 176

WJ - Receiver Gain Select ............................................................................................................... 176

WL - Water Reference Layer .......................................................................................................... 177

WN – Number of Depth Cells ......................................................................................................... 177

WP – Pings Per Ensemble ............................................................................................................... 177

WQ - Sample Ambient Sound ........................................................................................................ 178

WS – Depth Cell Size ...................................................................................................................... 178

WT - Transmit Length ..................................................................................................................... 178

WU - Ping Weight ........................................................................................................................... 179

WV – Ambiguity Velocity ............................................................................................................... 179

WW – Mode 1 Pings before Mode 4 Re-Acquire ........................................................................... 180

WY – Mode 1 Bandwidth ............................................................................................................... 180

Advanced Commands .................................................................................................................................. 181

Sound Velocity Smart Sensor Commands .................................................................................................... 181

Available Sound Velocity Smart Sensor Command .............................................................................. 181

Sound Velocity Smart Sensor Descriptions........................................................................................... 181

DB - RS-485 Port Control ................................................................................................................ 181

DS - Load SpeedOfSound with SVSS Sample (BIT Result) ............................................................... 182

DW - Current ID on RS-485 Bus ...................................................................................................... 182

DX - Set SVSS to RAW Mode .......................................................................................................... 182

DY - Set SVSS to REAL Mode .......................................................................................................... 183

DZ - Get Single SCAN from SVSS ..................................................................................................... 183

Waves Commands ........................................................................................................................................ 184

Available Waves Commands ................................................................................................................ 184

Waves Command Descriptions ............................................................................................................ 184

HA – Waves False Target Threshold ............................................................................................... 184

HB – Automatically Chosen Bins for Wave Processing ................................................................... 185

HD – Waves Data Out .................................................................................................................... 185

HF – Waves Flow Control ............................................................................................................... 185

HP – Waves Pings per Wave Record .............................................................................................. 186

HR – Time Between Wave Records ................................................................................................ 186

HS – Bins for Directional Wave Spectrum ...................................................................................... 187

HT – Time Between Wave Record Pings ........................................................................................ 187

HV – Bins for Velocity Spectrum .................................................................................................... 188

Ping Synchronization Commands ................................................................................................................. 189

Available Ping Synchronization Commands ......................................................................................... 189

Ping Synchronization Command Descriptions ...................................................................................... 189

SA - Synchronize Before/After Ping/Ensemble .............................................................................. 189

SB – Enable Channel B Breaks ........................................................................................................ 190

SI - Synchronization Interval .......................................................................................................... 190

SM - RDS3 Mode Select .................................................................................................................. 191

SS - RDS3 Sleep Mode .................................................................................................................... 191

ST - Slave Timeout .......................................................................................................................... 192

SW - Synchronization Delay ........................................................................................................... 192

Example Master/Slave Setup ............................................................................................................... 193

Page vii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Example Wakeup Banners ............................................................................................................. 194

CHAPTER 9 – OUTPUT DATA FORMAT .....................................................................................................................195

Choosing a Data Format ............................................................................................................................... 196

PD0 Output Data Format ............................................................................................................................. 198

Header Data Format ............................................................................................................................. 199

Fixed Leader Data Format .................................................................................................................... 201

Variable Leader Data Format ............................................................................................................... 206

Converting ADC Channels .............................................................................................................. 211

How Does the H-ADCP Sample Depth and Pressure? .................................................................... 212

Converting kpa to Depth ................................................................................................................ 212

Velocity Data Format............................................................................................................................ 213

Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format ................................ 215

Binary Bottom-Track Data Format ....................................................................................................... 218

Binary Reserved BIT Data Format ......................................................................................................... 222

Binary Checksum Data Format ............................................................................................................. 222

Special Output Data Formats ....................................................................................................................... 223

DVL Binary Data Format (PD3) ............................................................................................................. 224

DVL Output Data Format (PD3) Details ................................................................................................ 225

DVL Binary Data Format (PD4/PD5) ..................................................................................................... 227

DVL Output Data Format (PD4/PD5) Details ........................................................................................ 228

DVL Binary Data Format (PD5) ............................................................................................................. 231

DVL Output Data Format (PD5) Details ................................................................................................ 232

DVL Output Data Format (PD6) ............................................................................................................ 233

PD8 ASCII Output ................................................................................................................................. 235

H-ADCP Condensed 2D Output Format (PD14) .................................................................................... 236

PD14 Format .................................................................................................................................. 236

PD14 Invalid Data ........................................................................................................................... 236

Output Data Format (PD16) ................................................................................................................. 238

Output Data Format (PD18) ................................................................................................................. 238

How to Decode an H-ADCP Ensemble .......................................................................................................... 239

Rules for the BroadBand Data Format PD0 .................................................................................................. 239

Decoding Sequence for PD0 Data ................................................................................................................ 240

Decoding Sequence Example ....................................................................................................................... 240

APPENDIX A - NOTICE OF COMPL IANCE ...................................................................................................................243

Date of Manufacture .................................................................................................................................... 244

Environmental Friendly Use Period (EFUP) .................................................................................................. 244

WEEE ............................................................................................................................................................ 244

CE ................................................................................................................................................................. 244

Material Disclosure Table ............................................................................................................................. 245

LIST OF FIGURES

Figure 1. 300/600 kHz H-ADCP Overview .................................................................................................. 4

Figure 2. 300 kHz NB H-ADCP Overview .................................................................................................... 4

Figure 3. AC Power Adapter ...................................................................................................................... 7

Figure 4. H-ADCP Connections .................................................................................................................. 8

Figure 5. Removing the I/O Cable ........................................................................................................... 16

Figure 6. Do not use Zip-Ties Directly on Cables ..................................................................................... 18

Figure 7. I/O Cable Wiring ....................................................................................................................... 19

Figure 8. RS232-to-RS422 Converter Wiring (25-Pin to 9-Pin) ................................................................ 19

Figure 9. Cathodic Protection and Anodes .............................................................................................. 21

Figure 10. Galvanic Corrosion ................................................................................................................... 21

Figure 11. Installing the H-ADCP ............................................................................................................... 22

Page viii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Figure 12. Optional Mounting Kit (P/N 757K6085-00) .............................................................................. 23

Figure 13. 300 kHz NB H-ADCP Mounting Holes ....................................................................................... 24

Figure 14. SurfaceView Deployment Screen ............................................................................................. 28

Figure 15. SurfaceView Intensity Profile ................................................................................................... 28

Figure 16. Barnacle Damage to a Urethane Face ...................................................................................... 29

Figure 17. 300 kHz NB Assembly – One Piece Housing ............................................................................. 42

Figure 18. 300 kHz NB Assembly – Two Piece Housing ............................................................................. 43

Figure 19. 300/600 kHz H-ADCP Assembly ................................................................................................ 44

Figure 20. Transducer View ....................................................................................................................... 46

Figure 21. End-Cap View ........................................................................................................................... 46

Figure 22. 300 kHz Narrow Beam Width Backup O-Ring Detail ................................................................ 52

Figure 23. Antifouling Paint Applied to an H-ADCP ................................................................................... 57

Figure 24. Compass Calibration ................................................................................................................. 62

Figure 25. Installing Feature Upgrades ..................................................................................................... 64

Figure 26. PC Card Recorder ..................................................................................................................... 66

Figure 27. Communication Switch and Fuse ............................................................................................. 67

Figure 28. Transmit Cable ......................................................................................................................... 69

Figure 29. PC Board Connectors ................................................................................................................ 70

Figure 30. Ground Jumper......................................................................................................................... 70

Figure 31. Mounting Hardware ................................................................................................................. 71

Figure 32. Modified Dummy Plug .............................................................................................................. 74

Figure 33. Extracting Wrench .................................................................................................................... 74

Figure 34. Lock Nut Removal Socket ......................................................................................................... 74

Figure 35. Removing the Connector .......................................................................................................... 75

Figure 36. End-Cap Connector with Isolation Bushing .............................................................................. 76

Figure 37. End-Cap Connector Wiring – H-ADCP ....................................................................................... 77

Figure 38. Lithium Battery Test Points on the CPU Board ......................................................................... 79

Figure 39. Lithium Battery ......................................................................................................................... 80

Figure 40. H-ADCP Wake-up and Timer Logic ........................................................................................... 95

Figure 41. DC Power Path.......................................................................................................................... 96

Figure 42. H-ADCP Block Diagram ............................................................................................................. 97

Figure 43. Water-Mass Layer Processing ................................................................................................ 135

Figure 44. H-ADCP Coordinate Transformation ...................................................................................... 152

Figure 45. PT7 RSSI Bandwidth Test ........................................................................................................ 164

Figure 46. PD0 Standard Output Data Buffer Format ............................................................................. 198

Figure 47. Binary Header Data Format .................................................................................................... 199

Figure 48. Fixed Leader Data Format ...................................................................................................... 202

Figure 49. Variable Leader Data Format ................................................................................................. 207

Figure 50. Velocity Data Format .............................................................................................................. 213

Figure 51. Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format................... 215

Figure 52. Binary Bottom-Track Data Format ......................................................................................... 220

Figure 53. Binary Reserved BIT Data Format ........................................................................................... 222

Figure 54. Binary Checksum Data Format ............................................................................................... 222

Figure 55. DVL Binary Data Format (PD3) ............................................................................................... 225

Figure 56. DVL Binary Data Format (PD4/PD5) ....................................................................................... 228

Figure 57. DVL Binary Data Format (PD5) ............................................................................................... 232

LIST OF TABLES

Table 1: Horizontal Waves Upper Cutoff Frequency .............................................................................. 27

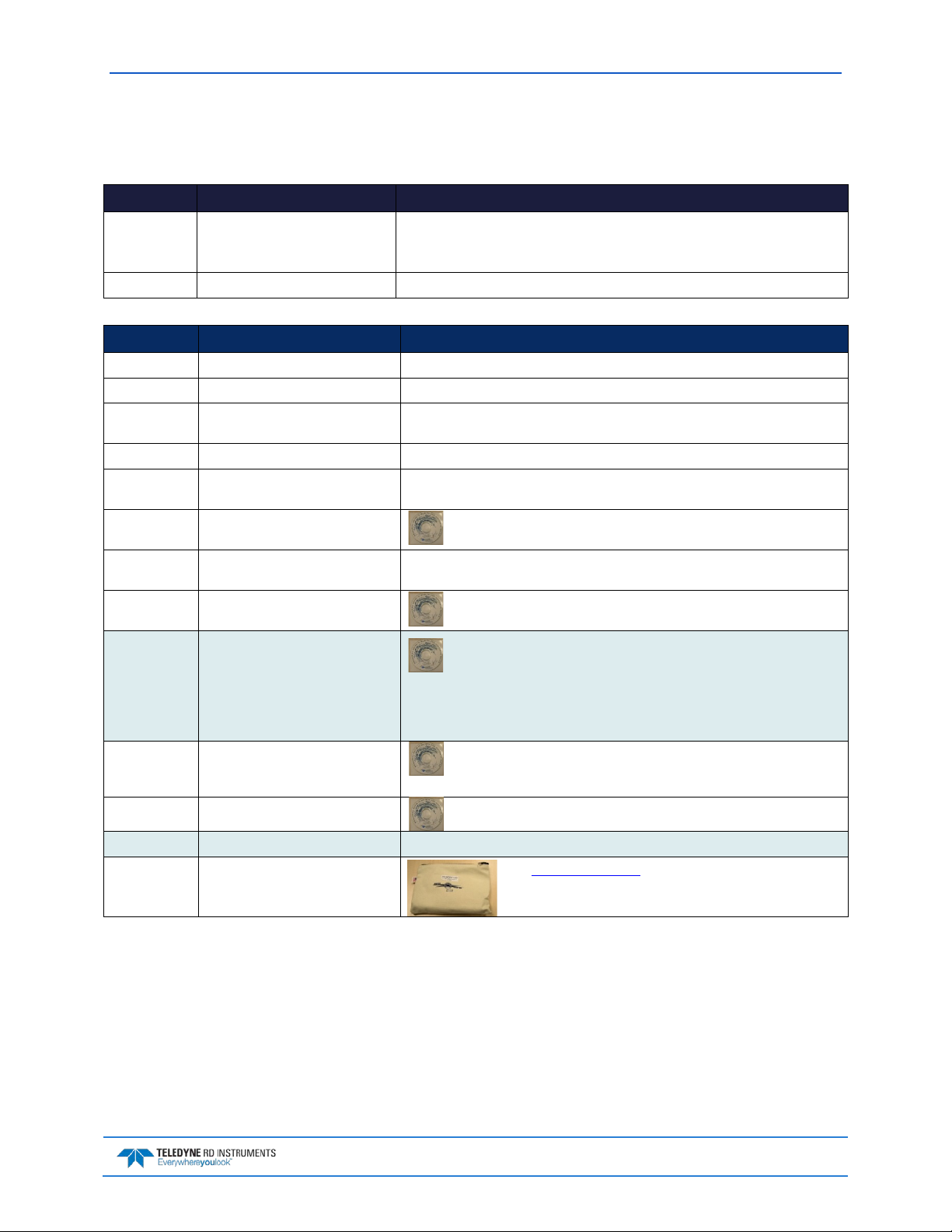

Table 2: H-ADCP 300 Narrow Beam ADCP Spare Parts (P/N 757K6071-00) ........................................... 47

Table 3. H-ADCP 300 and 600 kHz ADCP Spares Parts (P/N 757K6073-00) ............................................ 48

Table 4. Replacement Kits ...................................................................................................................... 48

Table 5: List of Least Replaceable Assemblies ....................................................................................... 82

Table 6: Required Test Equipment ......................................................................................................... 82

Page ix

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Table 7: Pre-deployment Test (PA) Possible Cause of Failures .............................................................. 88

Table 8: Water Profiling Specifications ................................................................................................ 107

Table 9: Specifications ......................................................................................................................... 107

Table 10: Outline Installation Drawings ................................................................................................. 108

Table 11: ADCP Minimum Required Commands for Deployments ........................................................ 118

Table 12: H-ADCP Input Command Summary ........................................................................................ 119

Table 13: H-ADCP Factory Defaults ........................................................................................................ 121

Table 14: Water-Mass Reference-Layer Modes ..................................................................................... 134

Table 15: BM4/BM5 Minimum Tracking Depths .................................................................................... 135

Table 16: Serial Port Control .................................................................................................................. 139

Table 17: Flow Control ........................................................................................................................... 140

Table 18: Polled Mode Commands ........................................................................................................ 143

Table 19: Retrieve Parameters ............................................................................................................... 144

Table 20: Error Status Word................................................................................................................... 145

Table 21: Coordinate Transformation Processing Flags ......................................................................... 151

Table 22: Sensor Source Switch Settings................................................................................................ 152

Table 23: Data Stream Selections .......................................................................................................... 157

Table 24: Error Code Hex to Binary Conversion ..................................................................................... 159

Table 25: PT3 Failure .............................................................................................................................. 161

Table 26: PT4 Failure .............................................................................................................................. 161

Table 27: PT6 Receive Bandwidth Nominal Values ................................................................................ 163

Table 28: Bandwidth Control ................................................................................................................. 174

Table 29: Ping Weights........................................................................................................................... 179

Table 30: WV-command Maximum Setting (20 Degree) ....................................................................... 180

Table 31: Waves Flow Control ............................................................................................................... 186

Table 32: Synchronization Parameters .................................................................................................. 189

Table 33: Sleep Mode Parameters ......................................................................................................... 191

Table 34: Summary of Output Data Formats ......................................................................................... 197

Table 35: Header Data Format ............................................................................................................... 200

Table 36: Fixed Leader Data Format ...................................................................................................... 203

Table 37: Variable Leader Data Format ................................................................................................. 208

Table 38: Velocity Data Format .............................................................................................................. 214

Table 39: Correlation Magnitude Data Format ...................................................................................... 215

Table 40: Echo Intensity Data Format .................................................................................................... 216

Table 41: Percent-Good Data Format .................................................................................................... 217

Table 42: Status Data Format................................................................................................................. 217

Table 43: Bottom-Track Data Format..................................................................................................... 220

Table 44: Reserved for TRDI Format ...................................................................................................... 222

Table 45: Checksum Data Format .......................................................................................................... 222

Table 46: DVL Output Data Format (PD3) Details .................................................................................. 225

Table 47: DVL Output Data Format (PD4/PD5) Details .......................................................................... 228

Table 48: DVL Output Data Format (PD5) Details .................................................................................. 232

Table 49: DVL Output Data Format (PD6) .............................................................................................. 233

Table 50: PD14 Output Data Format ...................................................................................................... 236

Table 51: Common Data Format IDs ...................................................................................................... 239

Table 52. Toxic or Hazardous Substances and Elements Contained in Product ..................................... 245

Page x

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

REVISION HISTORY

May 2015

• Combined Quick Start Guide into the Operation Manual.

• Created new H-ADCP setup card.

• Added corrections for ICN 126 antifouling paint.

• Added corrections for ICN 127 Force Cold Start.

• Added corrections for ICN 130 End Cap Removal.

• Added corrections for ICN 145 I/O Connector Lubricant.

• Added corrections for ICN 153 Converting ADC channels.

• Updated the installation instructions.

• Updated the maintenance procedures and parts location drawings.

• Updated the specifications and outline installation drawings.

• Updated Commands and Output Data Format to firmware version 11.11.

• Updated styles and fonts.

December 2008

• General update to the manual. – Removed add oil to pressure sensor.

• Added more to installation section.

• Incorporated the following corrections: ICN095, ICN106, and ICN114 (oil).

October 2007

• Initial release.

Page xi

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

EXCLUSIONS AND OMISSIONS

1: None

Page xii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

WorkHorse H-ADCP Operation Manual May 2015

Chapter 1

AT A GLANCE

In this chapter, you will learn:

• H-ADCP Models and Options

• System Overview

• Computer Considerations

• Power Overview

• Setting up the H-ADCP

• Caring for your H-ADCP System

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 1

May 2015 WorkHorse H-ADCP Operation Manual

How to Contact Teledyne RD Instruments

If you have technical issues or questions involving a specific application or deployment with your instrument, contact our Field Service group:

Teledyne RD Instruments Teledyne RD Instruments Europe

14020 Stowe Drive

Poway, California 92064

Phone +1 (858) 842-2600 Phone +33(0) 492-110-930

FAX +1 (858) 842-2822 FAX +33(0) 492-110-931

Sales – rdisales@teledyne.com

Field Service – rdifs@teledyne.com

For all your customer service needs including our emergency 24/7 technical support, call +1 (858) 842-2700

Client Services Administration – rdicsadmin@teledyne.com

Web: http://www.rdinstruments.com

2A Les Nertieres

5 Avenue Hector Pintus

06610 La Gaude, France

Sales – rdie@teledyne.com

Field Service – rdiefs@teledyne.com

Conventions Used in this Manual

Conventions used in the WorkHorse Horizontal Acoustic Doppler Current Profiler (H-ADCP) Operation

Manual have been established to help learn how to use the system quickly and easily.

Menu items are printed in bold: click Collect Data. Items that need to be typed by the user or keys to

press will be shown as <F1>. If a key combination were joined with a plus sign (<ALT+F>), press and

hold the first key while pressing the second key. Words printed in italics include program names (BBTalk)

and file names (TestWH.rds).

Code or sample files are printed using a fixed font. Here is an example:

[BREAK Wakeup A]

WorkHorse Horizontal Broadband ADCP Version 11.xx

Teledyne RD Instruments (c) 1996-2004

All Rights Reserved.

>

There are four visual aids to help:

This paragraph format indicates additional information that may help you avoid problems or

that should be considered in using the described features.

This paragraph format warns the reader of hazardous procedures (for example, activities that

may cause loss of data or damage to the H-ADCP).

This paragraph format tells the reader where they may find additional information.

Recommended Setting. This paragraph format indicates additional information that may help

Page 2

you set command parameters.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

WorkHorse H-ADCP Operation Manual May 2015

System Overview

The H-ADCP transducer assembly contains the end-cap, housing, transducer ceramics, and electronics.

The standard acoustic frequencies are 600 and 300 kHz. See the Outline Installation Drawings

sions and weights.

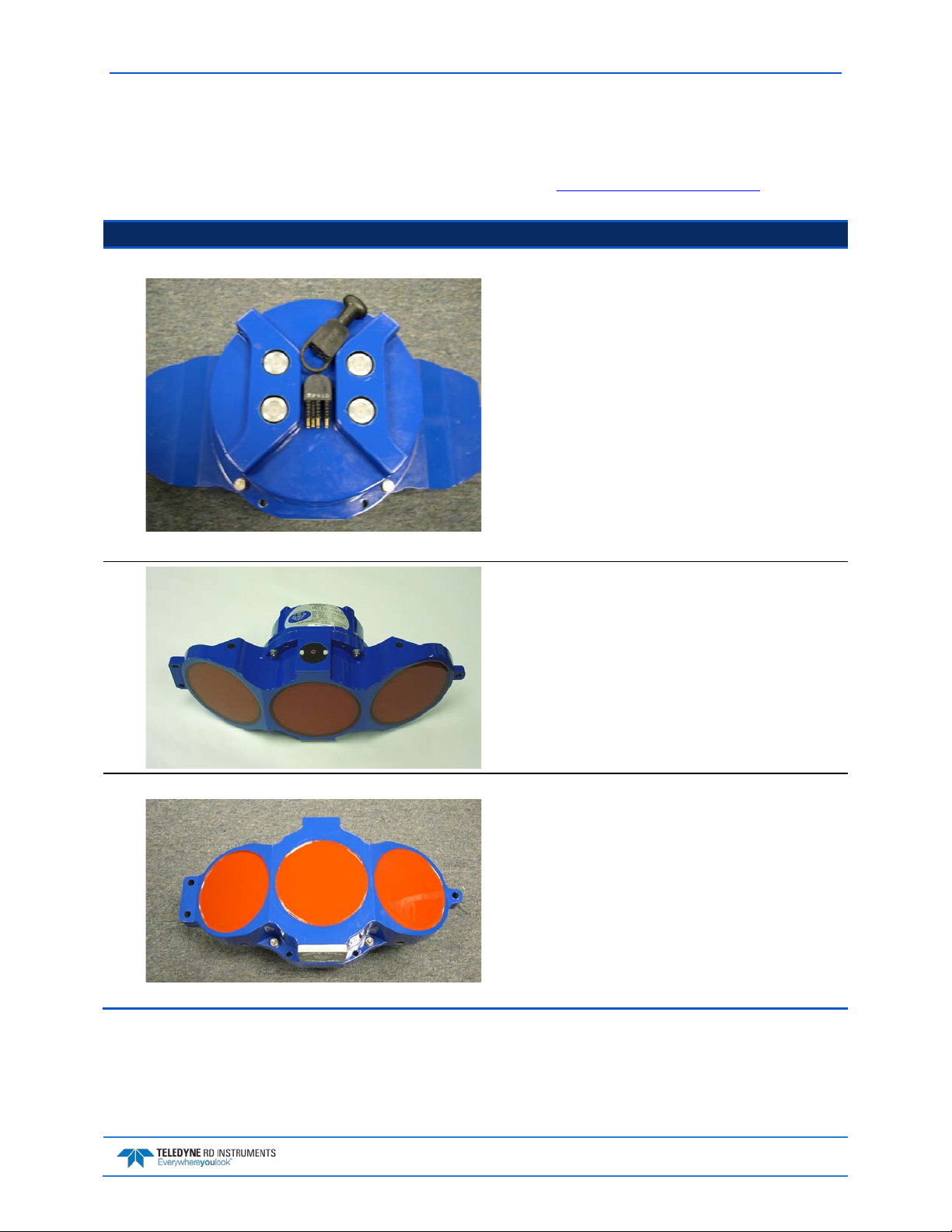

Picture Description

The Input/Output (I/O) cable connects the H-ADCP to the

computer and external power supply. When the cable is not

connected, use the dummy plug to protect the connector.

for dimen-

The optional pressure sensor (standard 200 Bar) measures

water pressure (depth).

The orange urethane faces covers the transducer ceramics.

Never set the transducer on a hard surface. The urethane

faces may be damaged.

The standard H-ADCP housing allows deployment depths to

200 meters.

The H-ADCP electronics and transducer ceramics are

mounted to the transducer head.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 3

May 2015 WorkHorse H-ADCP Operation Manual

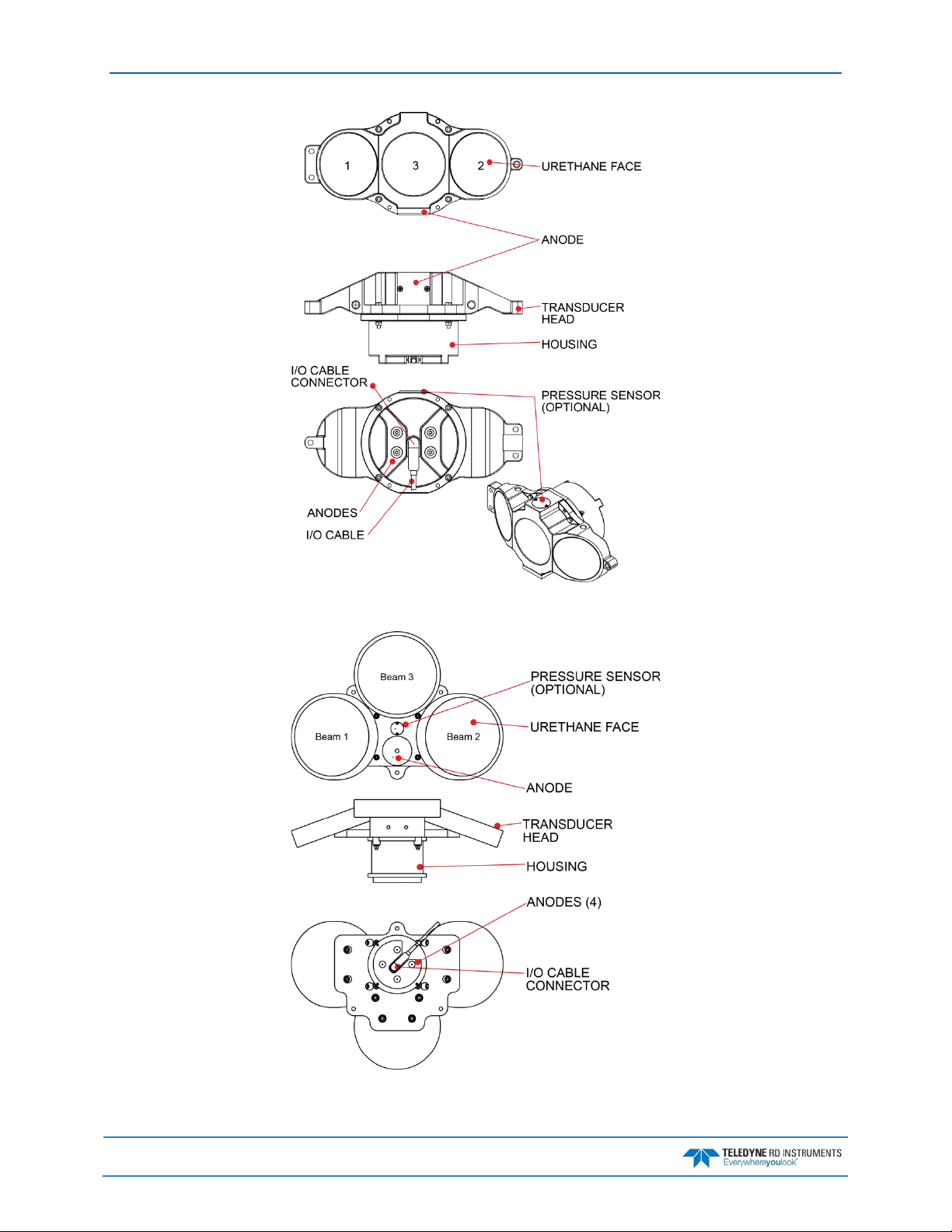

Figure 1. 300/600 kHz H-ADCP Overview

Page 4

Figure 2. 300 kHz NB H-ADCP Overview

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

WorkHorse H-ADCP Operation Manual May 2015

Inventory List

Included with the H-ADCP system:

Part Number Name Description

HADCP-I H-ADCP 600 kHz

H-ADCP Accessories Kit Contains the I/O cable, shipping case, software, and documentation listed below.

H-ADCP 300 kHz

H-ADCP 300 kHz Narrow Beam

Included with the H-ADCP Accessories Kit:

Part Number Name Description

73B-3030-005 I/O cable The I/O cable is used for serial communications.

737-3008-025 Extension Cable 25 meter extension cable

717-3014-00

PO3-6

737-3010-00 RS232/RS422 Converter If you ordered RS-422 communications, a RS-232 to RS-422 adapter will be added.

MRDI1004

305D0550-4

90B-8015-00 H-ADCP Documentation CD This CD has PDF versions of all of the H-ADCP documentation. Please read

957-6276-00 H-ADCP Setup Card A printed reference card showing H-ADCP connection and inventory. A PDF version is

907-8040-00 RDI Tools Software CD Utility and testing software package including BBTalk that can be used to

907-8076-00

907-8082-00

907-8029-00 WinSC WinSC works as a shell program to launch the PlanADCP program.

907-8038-00 WinADCP Use the WinADCP program to view data in real-time or playback data files.

AC Power Adapter

Power cord

Shipping case Shipping case with custom foam cutouts.

Waves Software CD (optional)

WavesView Software CD (optional)

The H-ADCP system includes the transducer and dummy plug.

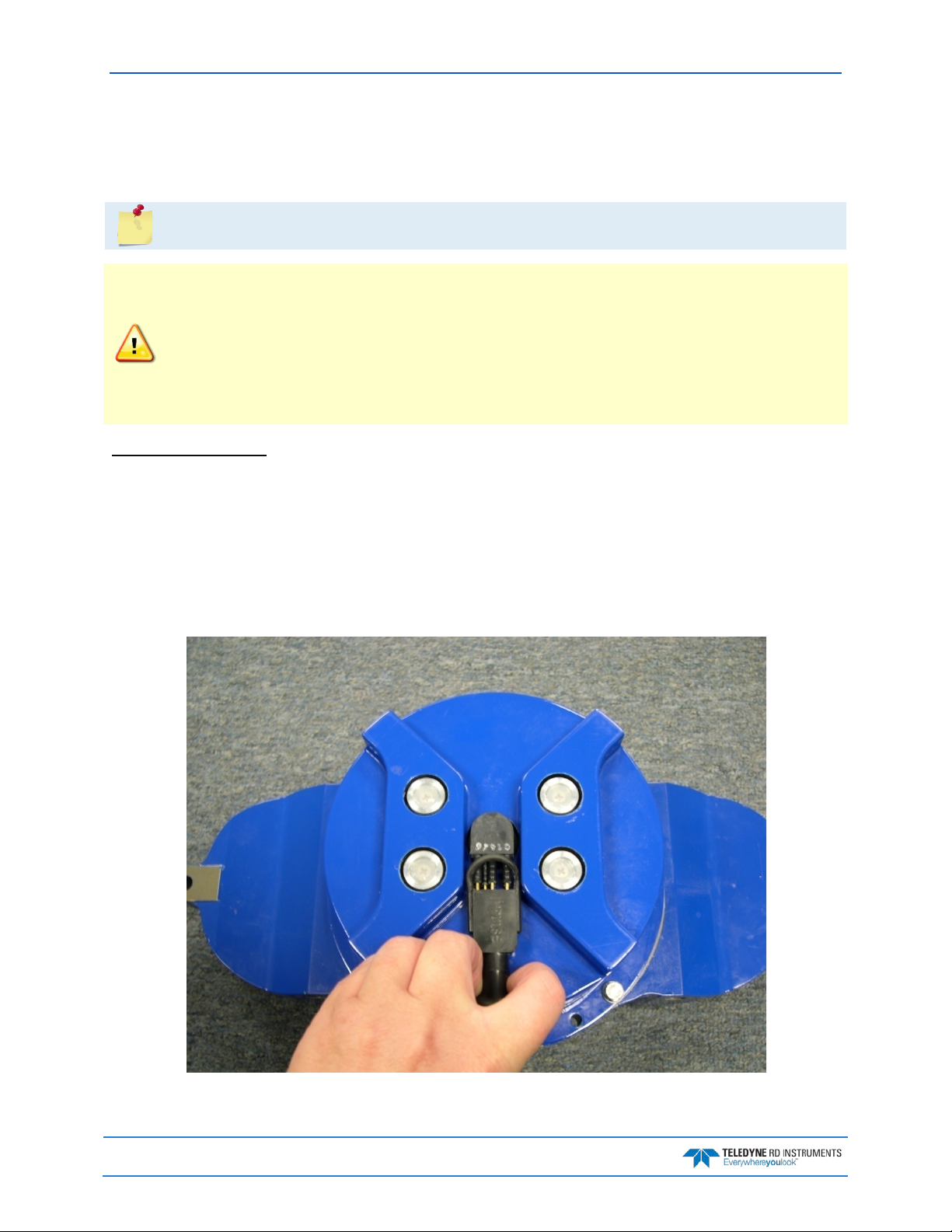

When unpacking, use care to prevent physical damage to the transducer face and

connector. Use a soft pad to protect the transducer.

AC power adapter provides 48 VDC

the manual!

included on the H-ADCP documentation CD.

test the H-ADCP.

Waves is a feature upgrade for 300 kHz NB H-ADCPs. If you ordered the

directional wave measurement upgrade, WavesMon and WavesView are

included.

WavesMon is the directional wave measurement package for the H-ADCP.

Use WavesView to view wave data. It is an enormously useful tool for turning waves

data into waves information.

PlanADCP is designed to create a command file that will be used to set up

an H-ADCP for collecting data.

757K6085-00 Mounting Kit (optional) Optional mounting kit for 300/600 kHz H-HADCPs

757K6073-00

757K6071-00

Tools and Spare Parts kit See Tools and Spare Parts for a list of parts included in these kits.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 5

May 2015 WorkHorse H-ADCP Operation Manual

Computer Considerations

TRDI designed the H-ADCP to use a Windows® compatible computer. The computer controls the

H-ADCP and displays its data, usually through our SurfaceView program.

TRDI highly recommends downloading and installing all of the critical updates, recommended

updates, and the service releases for the version of Windows® that you are using prior to

Minimum computer hardware requirements:

• Windows XP®, Windows 7®, Windows 8®

• One Serial Port (two or more High Speed UART Serial Port recommended)

• Minimum display resolution of 1024 x 768, 256 color (higher recommended)

The computer configuration varies depending of the number of communication ports and the external

data refresh rate. Serial communications require a lot of processor resources, and the minimum requirements can vary. A good quality video card is required to operate SurfaceView and WavesMon simultaneously. We do not use graphic card 3D functions; however, video memory is needed to display all graphics.

installing any TRDI software.

SurfaceView runs on Windows XP® only; it will not operate on Windows 7® or 8®.

However, with experience we can recommend that:

• If you are using more than two communication ports, you should not use a Celeron processor.

• Intel Pentium III or higher processors work best to operate the H-ADCP and give access to the

display and keyboard without losing ensembles.

Page 6

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

WorkHorse H-ADCP Operation Manual May 2015

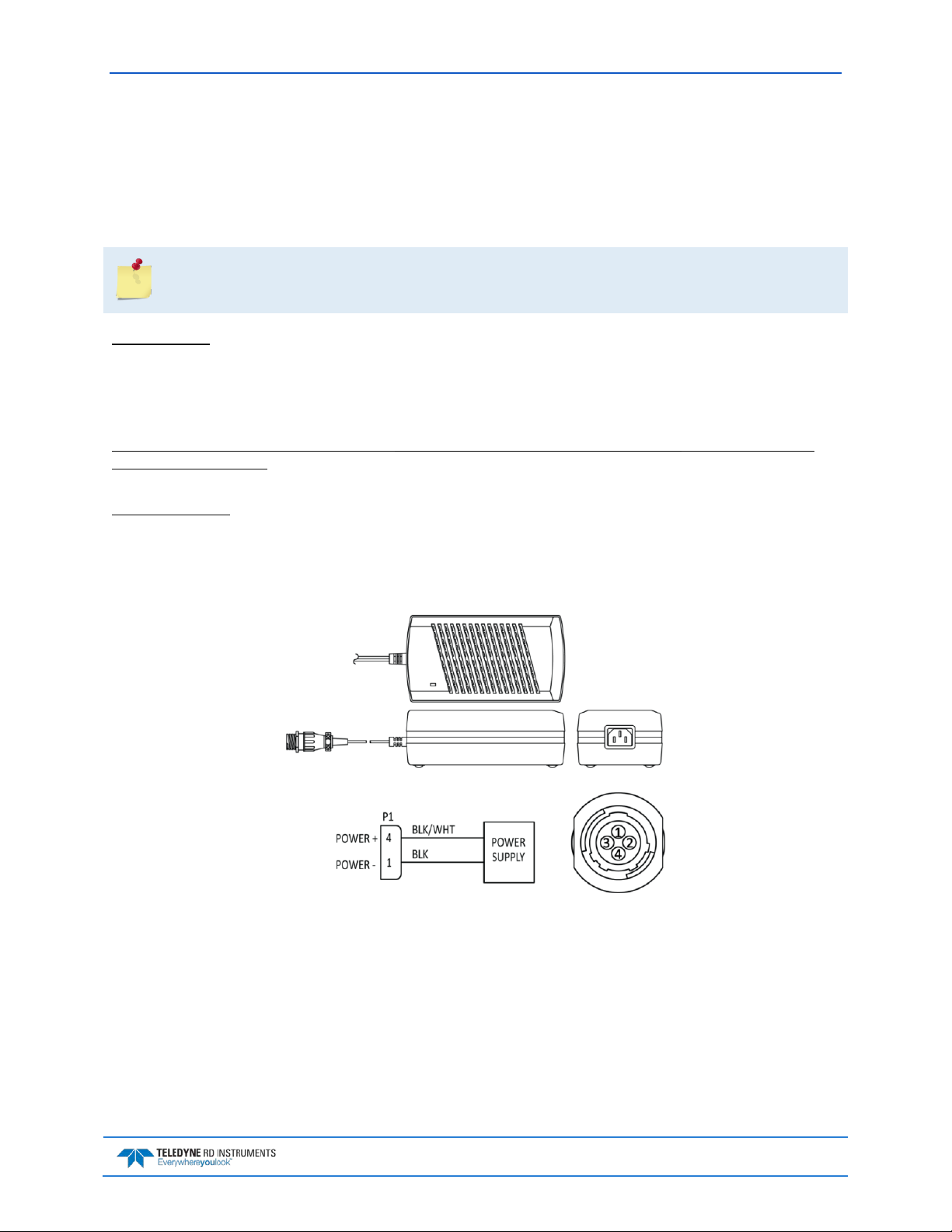

Power Overview

H-ADCP requires +20 to 50 VDC to operate. The AC Adapter runs on any standard AC power and supplies +48 VDC to run the H-ADCP.

Transmitted power increases or decreases depending on the input voltage (within the voltage range of 20

to 50 VDC).

The transmitted power is decreased approximately 1 DB if the input voltage drops from 42 VDC

to 33 VDC. For a 300 kHz H-ADCP, each DB will result in a decrease in range of one default depth

Power on Cycle

The power supply must be able to handle the inrush current as well. Inrush current is the current required

to fully charge up the capacitors when power is applied to the H-ADCP. The capacitors provide a store of

energy for use during transmit. The inrush current is as high as 3 Amps rms. The H-ADCP will draw this

amperage until its capacitors are fully charged.

If the power supply limits the current or the power drop on the cable is significant, then the power on

cycle will take longer. It can take up to one minute. You do not want the power to shut down during the

inrush current draw, as this may not allow the H-ADCP electronics to start.

AC Power Adapter

cell.

The AC power adapter is designed to maintain a 400-ma supply under the H-ADCP’s inrush current. The

adapters are 75-Watt supplies, with 48 VDC, 1.5 amp outputs. They will not fall back to 0 amps, 0 volts

under a load. Customer provided power supplies might shut themselves down under such a load; when

that occurs, the H-ADCP will not wakeup.

Figure 3. AC Power Adapter

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 7

May 2015 WorkHorse H-ADCP Operation Manual

Setting up the H-ADCP System

Use this section to connect the H-ADCP to a computer and establish communications. Install the RDI

Tools software in order to communicate with the H-ADCP.

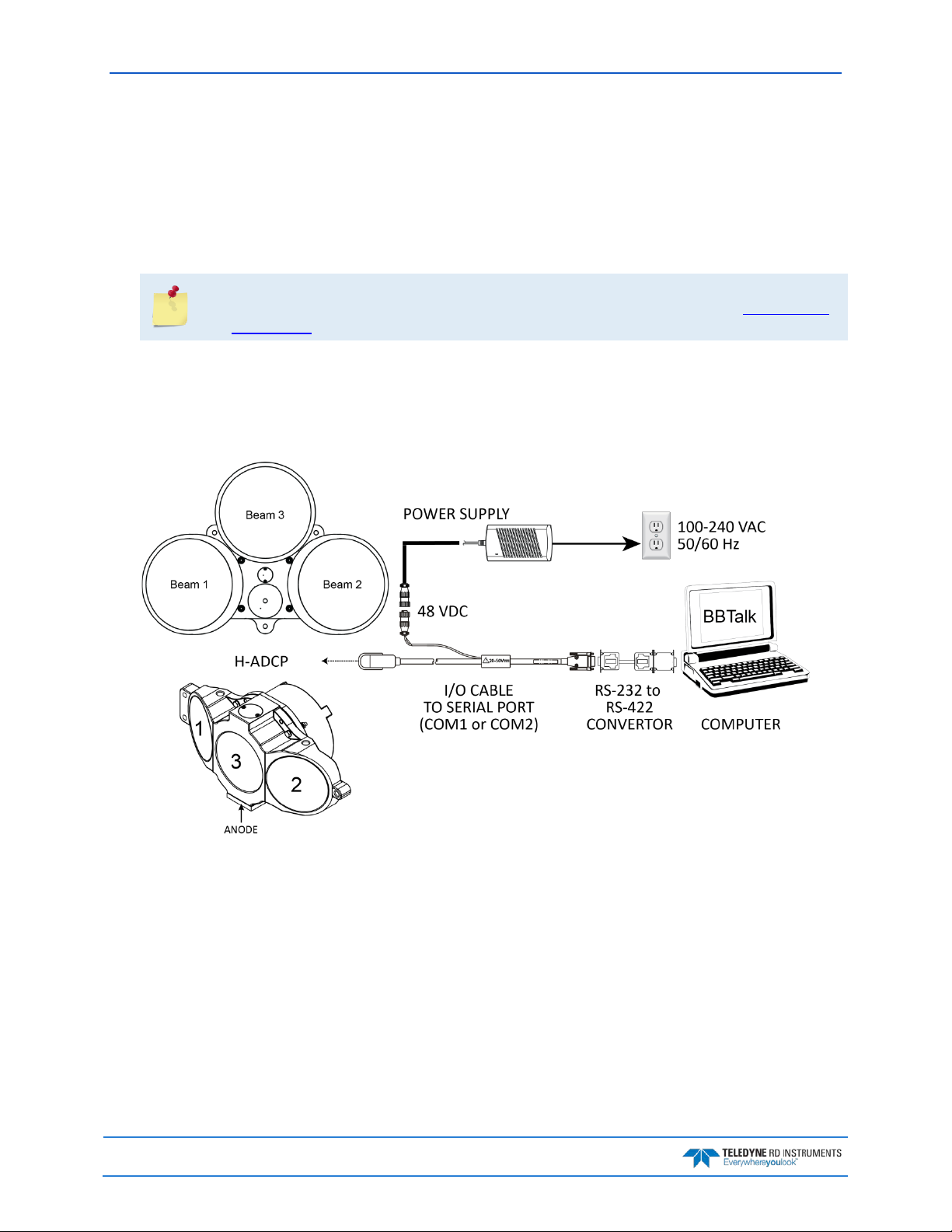

To set up the H-ADCP:

1. Connect the I/O cable to the H-ADCP. Do so by pushing straight in against the connector. Roll the

retaining strap over the connector.

Place a light amount of dry silicone lubricant spray on the connector pins (rubber portion only).

This will make it easier to connect or remove the I/O cable and dummy plug. See I/O Cable and

Dummy Plug for details.

2. Attach the I/O cable to your computer's communication port. The standard communications settings are RS-232, 9600-baud, no parity, 8 data bits and 1 stop bit.

If the computer uses RS-422 communications, connect the RS-232 to RS-422 adapter.

3. Connect the AC power adapter to the I/O cable.

Page 8

Figure 4. H-ADCP Connections

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

WorkHorse H-ADCP Operation Manual May 2015

Connecting to the H-ADCP

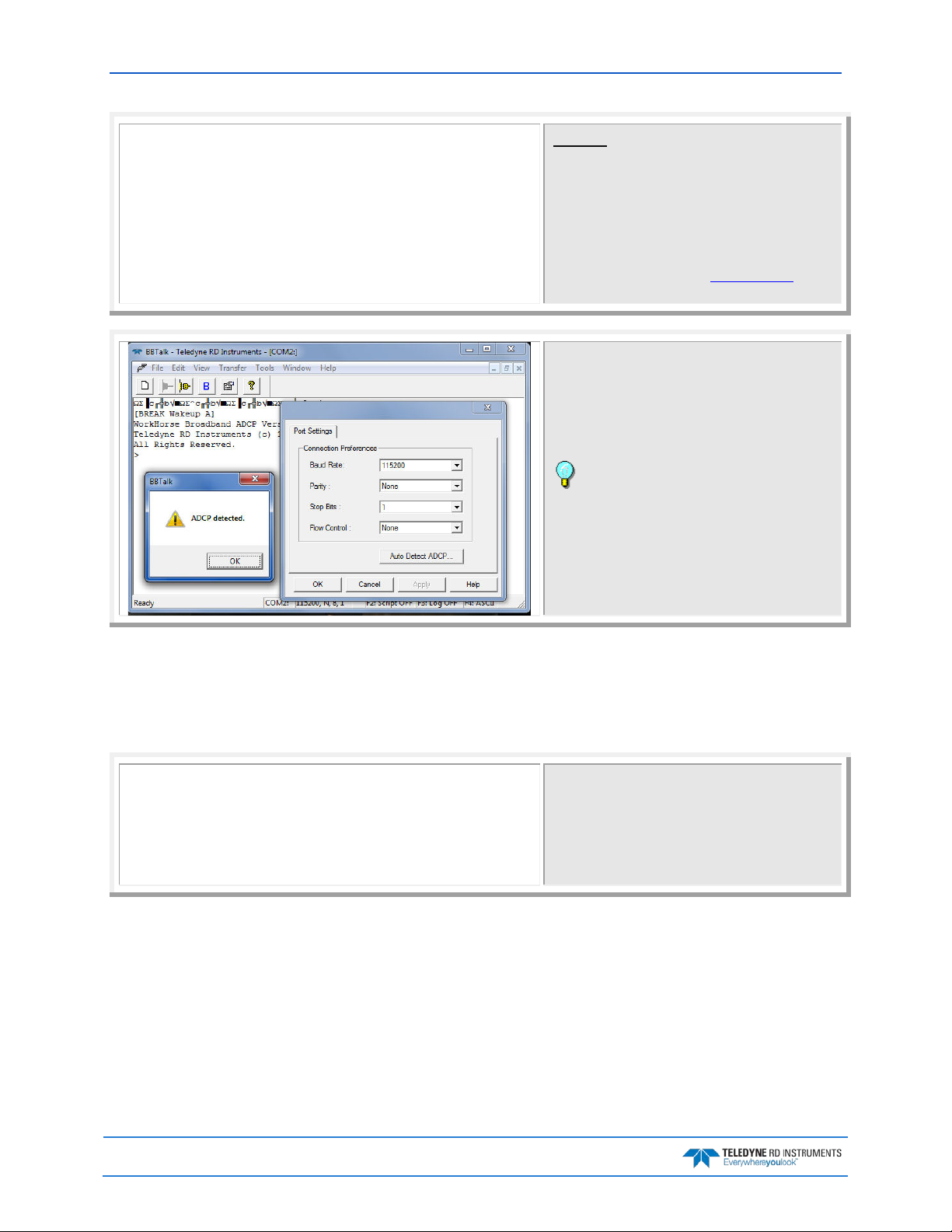

To connect to the H-ADCP:

Start BBTalk

Start the BBTalk program (for help on using BBTalk,

see the RDI Tools User’s Guide).

On the Connect To screen, select WorkHorse.

Select the COM port the H-ADCP cable is connected to.

Click Next.

Enter the Baud Rate, Parity, Stop Bits, and Flow Con-

trol. If you are unsure of the settings, leave them at

the default settings as shown.

Click Next.

Click Finish.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 9

May 2015 WorkHorse H-ADCP Operation Manual

[BREAK Wakeup B]

>cr1

WorkHorse Horizontal Broadband ADCP Version 11.10

Teledyne RD Instruments (c) 1996-2009

All Rights Reserved.

>

Wakeup

On the File menu, click Break (you can also press the

End key to send a break or press the B button on the

Toolbar).

The wakeup message should appear on the log file

window.

If the H-ADCP does not respond, check the serial port,

cables, AC power, and battery connection (Sentinel

only). If necessary, refer to the Troubleshooting section.

If the wakeup message is not readable or visible:

On the File menu, click Properties.

Click the Auto Detect H-ADCP button.

Click OK when the H-ADCP is detected. Try to wake up

the H-ADCP again.

Both BBTalk and the H-ADCP must use the same

Baud rate.

Testing the H-ADCP

These tests checks that the H-ADCP is able to communicate with the computer and runs the H-ADCP PreDeployment tests.

[Parameters set to FACTORY defaults]

>ck

[Parameters saved as USER defaults]

At the ">" prompt in the communication window,

enter CR1 then press the Enter key. This will set the

H-ADCP to the factory default settings.

At the ">" prompt in the communication window,

enter CK then press the Enter key. This will save the

factory default setting as the default power up condition.

Page 10

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

WorkHorse H-ADCP Operation Manual May 2015

>ps0

>

>pa

>

>Pt3

>

Instrument S/N: 3192

Frequency: 307200 HZ

Configuration: 3 BEAM, HORIZONTAL

Beam Angle: 25 DEGREES

Beam Pattern: CONVEX

Orientation: UP

Sensor(s): HEADING TILT 1 TILT 2 DEPTH TEMPERATURE

PRESSURE

Pressure Sens Coefficients: (c3,c2,c1,offset) 0.00,0.00,0.01,-1.15

Temp Sens Offset: -0.22 degrees C

CPU Firmware: 11.07 [0]

Boot Code Ver: Required: 1.13 Actual: 1.13

DEMOD #1 Ver: ad48, Type: 1f

DEMOD #2 Ver: ad48, Type: 1f

PWRTIMG Ver: 85d3, Type: 6