Teledyne ULTRAFLOW 150 Operation Manual

ULTRAFLOW 150

GAS FLOW AND TEMPERATURE MONITOR

OPERATIONS MANUAL

SERIAL NUMBER: _________________________

DOCUMENT NO.: 1900-0100-01 REV. E

JANUARY 2014

Proprietary Information. All rights reserved by Teledyne Monitor Labs. No part of this

book may be reproduced or copied in any form or by any meansgraphic, electronic, or

mechanical, including photocopying, taping, or information storage and retrieval

systemswithout written permission of the publisher.

Made in the United States of America

TABLE OF CONTENTS

PAGE

1.0 SAFETY ....................................................................................................................................... 1-1

1.1 Internationally Recognized Symbols Used on Teledyne Monitor Labs Equipment ..................... 1-1

2.0 SYSTEM OVERVIEW ................................................................................................................. 2-1

2.1 System Description, Standard Equipment ................................................................................... 2-1

2.1.1 Transducer Interface Enclosure (TIE) ........................................................................... 2-1

2.1.2 Purge Nozzle Assemblies ............................................................................................. 2-1

2.1.3 Protective Purge System ............................................................................................... 2-3

2.1.4 Enhanced Remote Panel .............................................................................................. 2-3

2.2 Specifications (Standard System) ............................................................................................... 2-5

3.0 OPTIONAL EQUIPMENT ............................................................................................................ 3-1

3.1 Protective Purge Air System, (Dual) ............................................................................................ 3-1

3.2 Local User Interface Key Pad and Display .................................................................................. 3-1

3.3 Dual Analog Input Board ............................................................................................................. 3-2

3.3.1 Barometric Pressure Sensor Assembly ........................................................................ 3-2

3.3.2 External Temperature Measurement ............................................................................ 3-3

3.4 Link Rod ....................................................................................................................................... 3-4

3.5 6PT I/O PC Board option for 150DI ............................................................................................. 3-5

4.0 THEORY OF OPERATION ......................................................................................................... 4-1

4.1 Physics of Measurement ............................................................................................................. 4-1

4.1.1 Time of Flight Theory .................................................................................................... 4-1

4.1.2 Flow Volume Measurement .......................................................................................... 4-3

4.1.3 Wet Basis and Dry Basis Measurements ...................................................................... 4-3

4.1.4 Correction to Standard Temperature and Pr essure ...................................................... 4-3

4.2 Monitor Specific Theory ............................................................................................................... 4-4

4.2.1 Box Car Integration ....................................................................................................... 4-4

4.2.2 Operational Modes of the Transducer Interfac e E nclosure .......................................... 4-4

5.0 TRANSDUCER INTERFACE ENCLOSURE (TIE) ...................................................................... 5-1

5.1 Mechanical Description ............................................................................................................... 5-1

5.2 Electrical Description ................................................................................................................... 5-2

5.2.1 External Interface PC Board ......................................................................................... 5-2

5.2.2 Power Supply Board ..................................................................................................... 5-2

5.2.3 Flow Mother Board ........................................................................................................ 5-2

5.2.4 Preamp Boards ............................................................................................................. 5-8

5.2.5 (Optional) Dual Analog Input Board .............................................................................. 5-9

5.2.6 (Optional) Local User Interface Key Pad and Display Assembly .................................. 5-9

5.2.7 Individual Button Function (When Pres sed by Themselves) ...................................... 5-12

5.2.8 Combinations of Buttons ............................................................................................. 5-13

5.2.9 6PT I/O PC Board option for 150DI ............................................................................ 5-13

6.0 ENHANCED REMOTE PANEL W / MULTI I/O MODULE .......................................................... 6-1

6.1 Overview ..................................................................................................................................... 6-1

6.2 Mechanical Description ............................................................................................................... 6-1

6.3 Electrical Description ................................................................................................................... 6-2

6.3.1 Input Power Requirement ............................................................................................. 6-2

6.3.2 Circuit Description (Overview)....................................................................................... 6-2

6.4 Operational Description--Menu Structure and U ser Interface ..................................................... 6-9

6.4.1 Memory Test ................................................................................................................. 6-9

TABLE OF CONTENTS

(Continued)

PAGE

6.4.2 Main Display Screen ................................................................................................... 6-10

6.4.3 Main Menu Screen ...................................................................................................... 6-11

6.4.4 Service Data Menu ...................................................................................................... 6-12

6.4.5 Status Code Help ........................................................................................................ 6-12

6.4.6 Output Cal Tests ......................................................................................................... 6-13

6.4.7 Output Module Configuration Menu ............................................................................ 6-16

6.4.8 Display Properties Menu ............................................................................................. 6-18

6.4.9 Software Versions ....................................................................................................... 6-19

6.4.10 System Properties Menu ........................................................................................... 6-19

6.4.11 View Trending Data ................................................................................................... 6-22

6.4.12 View Numerical Data ................................................................................................. 6-23

6.4.13 View Status History ................................................................................................... 6-23

6.4.14 View Alarms History .................................................................................................. 6-23

6.5 Multi I/O Software ...................................................................................................................... 6-24

6.5.1 Analog Outputs ........................................................................................................... 6-24

6.5.2 Digital Inputs ............................................................................................................... 6-24

6.5.3 Digital Outputs ............................................................................................................. 6-25

7.0 INSTALLATION ........................................................................................................................... 7-1

7.1 Pre-Installation Planning and Preparation ................................................................................... 7-1

7.2 Site Selection ............................................................................................................................... 7-1

7.2.1 Representative Sampling Location ............................................................................... 7-2

7.2.2 Access to Sampling Location ........................................................................................ 7-2

7.2.3 Environmental Conditions at the Sampling L ocation .................................................... 7-2

7.3 Equipment Mounting Considerations .......................................................................................... 7-2

7.3.1 Flange and Mounting Tube Installation ......................................................................... 7-2

7.3.2 Purge System, Reference PURGE ASS’Y MTG., PLUMBING & CLEARANCE

REQUIREMENTS Drawing ...................................................................................... 7-3

7.3.3 Purge Nozzle and Mounting Flange Assembly , Reference PURGE NOZZLE AND

MTG. PLATE INSTALLATION-150 Drawing ............................................................ 7-4

7.3.4 Transducer Interface Enclosure Assembly, Reference XDUCER INTERFACE

ENCLOSURE INSTALLATION Drawing .................................................................. 7-5

7.3.5 Junction Box, Reference JUNCTION BOX MTG. METHODS AND

CLEARANCES Drawing ........................................................................................... 7-5

7.3.6 Enhanced Remote Panel Assembly, Reference ENHANCED REMOTE PANEL

ASSEMBLY Drawing ................................................................................................ 7-5

8.0 SYSTEM CALIBRATION AND ADJUSTMENT ........................................................................... 8-1

8.1 Transducer Interface Enclosure Calibrati on ................................................................................ 8-1

8.1.1 Transducer Interface Enclosure Progra m V ariables ..................................................... 8-1

8.2 Transducer Interface Enclosure Elec tronics Adjustment ............................................................ 8-8

8.2.1 Flow Mother Board ........................................................................................................ 8-8

8.2.2 Preamp Board Adjustment ............................................................................................ 8-8

8.3 Remote Panel Calibration ............................................................................................................ 8-8

8.3.1 Remote Program Variables ........................................................................................... 8-8

8.3.2 Enhanced Remote Panel Analog Adjustments ............................................................. 8-8

9.0 MAINTENANCE .......................................................................................................................... 9-1

9.1 Maintenance Schedule ................................................................................................................ 9-1

9.1.1 After Initial Installation ..................................................................................................... 9-1

9.1.2 Normal Maintenance ....................................................................................................... 9-1

TABLE OF CONTENTS

(Continued)

PAGE

9.2 Troubleshooting Guide ................................................................................................................ 9-2

APPENDIX A Site Specification Data Sheets

APPENDIX B Maintenance Check Sheets

APPENDIX C Spare Parts

1900-0090-01 Ultraflow 150 Spare Parts Location Drawing

APPENDIX D Drawings

Drawing No. Sheet Rev Description

1900-0001-01 1 of 2 D Ultraflow 150 Flange Installation (English)

1900-0001-02 2 of 2 D Ultraflow 150 Flange Installation (Metric)

1900-0002-01 1 of 5 H Ultraflow 150 System Installation, Dual Blowers

1900-0002-02 2 of 5 H Ultraflow 150 System Installation, Single Blower

1900-0002-03 3 of 5 H Ultraflow 150 System Installation, Small Stacks

1900-0002-04 4 of 5 H Ultraflow 150 System Installation, X-Pattern

1900-0004 1 of 12 F Ultraflow 150 50Khz Wiring Diagram (115/230 VAC)

1900-0004 2 of 12 F Ultraflow 150DI 50Khz Direct Interface Wiring Diagram

(115/230 VAC)

1900-0004 3 of 12 F Ultraflow 150 X-Pattern 50Khz Wiring Diagram

(115/230 VAC)

1900-0004 4 of 12 F Ultraflow 150 X-Pattern Wiring Diagram (115/230 VAC)

1900-0004 5 of 12 F Ultraflow 150DI X-Pattern Direct Interface Wiring

Diagram (115/230 VAC)

1900-0004 6 of 12 F Ultraflow 150 Long Range (14/20Khz) Wiring Diagram

(115/230 VAC)

1900-0004 7 of 12 F Ultraflow 150DI Long Range (14/20Khz)

Direct Interface Wiring Diagram (115/230 VAC)

1900-0004 8 of 12 F Ultraflow 150 Long Range (20/14Khz) X-Pattern Wiring

Diagram (115/230 VAC)

1900-0004 9 of 12 F Ultraflow 150 Long Range (20/14Khz) X-Pattern Wiring

Diagram (115/230 VAC)

1900-0004 10 of 12 F Ultraflow 150DI Long Range (14/20Khz) X-Pattern Direct

Interface Wiring Diagram (115/230 VAC)

1900-0004 11 of 12 F Ultraflow 150 50Khz Std. Wiring Diagram (No J-Boxes) –

115/230V

1900-0004 12 of 12 F Ultraflow 150DI 50Khz Direct Interface Wiring Diagram

(No J-Boxes) – 115/230V

1900-0006-01 1 of 1 B Ultraflow 150 Flange Installation X-Pattern

1901-0008-01 1 of 5 B Purge Nozzle and Mtg. Plate Installation-150,

Standard Range, 50Khz

1901-0008-02 2 of 5 B Purge Nozzle and Mtg. Plate Installation-150, Long

Range LR003, 20Khz

1901-0008-04 4 of 5 B Purge Nozzle and Mtg. Plate Installation-150,

Extended Long Range LR006, 14Khz

TABLE OF CONTENTS

(Continued)

Drawing No. Sheet Rev Description

1901-0008-05 5 of 5 B Purge Nozzle and Mtg. Plate Installation-150,

Extended Long Range LR007, 14Khz w/Horn

1903-0000 3 of 4 M Transducer Interface Enclosure Std. Wiring Diagram

1903-0000 4 of 4 M Transducer Interface Enclosure Direct Interface Wiring

Diagram

1903-0010-01 1 of 1 B Transducer Interface Enclosure Installation

1903-0011-02 2 of 2 C Transducer Interface Enclosure Internal Layout

1004-0008-01 1 of 2 J Purge System Assy, Dual 42CFM Blowers

1904-0000-01 1 of 2 A Purge System Assy, Single 110CFM Blower

1904-0000-02 2 of 2 A Purge System Assy, Single 42CFM Blower

1906-0010-01 1 of 2 A Junction Box Mtg. Methods and Clearances, 20/14Khz

1906-0010-02 2 of 2 A Junction Box Mtg. Methods and Clearances, 50Khz

1803-2003-02 2 of 2 H Enhanced Remote Panel Customer Drawing

1903-0012-02 2 of 2 B UF150 Subpanel Assy, Upgrade Installation

1900-0005 1 of 4 C Upgrade Ultraflow 100 to 150 50Khz Wiring, W/New TIE

Subpanel in Existing Stack Elect. Box

1900-0005 2 of 4 C Upgrade Ultraflow 100 to 150 20/14Khz Wiring, w/New

TIE Subpanel and Buffer Boards in Existing J-Boxes

APPENDIX E Enhanced Serial Port Communication Protocol

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

1.0 SAFETY

1.1 INTERNATIONALLY RECOGNIZED SYMBOLS USED ON

TELEDYNE MONITOR LABS EQUIPMENT

This equipment is intended only for the purposes specified in this manual.

Safety protections inherent in this equipment may be impaired if the

Ultraflow 150 is used in a manner different than specified herein.

The following are internationally recognized symbols used on the

Ultraflow 150 along with specific cautions applicable to the equipment.

Label Standard Number:

ISO 3864 B.3.1

Generic meaning:

CAUTION: RISK OF DANGER. CONSULT MANUFACTURER’S

DOCUMENTATION.

Cautions Invoked By This Label for the Ultraflow 150:

1. The Transducer Interface Enclosure (TIE) and Enhanced Remote

Panel (ERP) power supplies are fused on both grounded (neutral)

and ungrounded (high line) mains supply conductors.

2. The Transducer Interface Enclosure (TIE) and Junction Box Covers

are to be opened only by trained service personnel.

3. This equipment must be installed by a qualified electrician as per

applicable local electrical codes.

4. The Protective Purge System blowers (both Single and Dual) are

permanently connected devices whose overcurrent protection and

supply disconnection must be provided externally and installed by a

qualified electrician in accordance with applicable local electrical

codes. Consult the Ultraflow 150 Wiring Diagrams in Appendix D of

this manual for further guidance of appropriate overcurrent and

supply disconnection requirements.

5. The Transducer Interface Enclosure, Junction Boxes and Protective

Purge System enclosure protection ratings apply only if "liquid tight"

conduit and fittings (such as Appleton Electric type ST, STB or STN

or equivalents) are installed by qualified electricians as per the fitting

manufacturer's documentation.

Label Standard Number:

ISO 3864 B.3.6

Meaning:

CAUTION: RISK OF ELECTRIC SHOCK.

Hazardous AC supply inside. Remove power before servicing.

1-1

SECTION 1.0, SAFETY

Label Standard Number:

ISO 3864, DIN 4844-2 D-W026

Meaning:

CAUTION: HOT SURFACE. DO NOT TOUCH.

This caution refers only to the single blower style of Protective Purge

System.

1-2

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

2.0 SYSTEM OVERVIEW

This manual describes the installation, operation, calibration and routine

maintenance of the Teledyne Monitor Labs Ultraflow 150 Ultrasonic

Stack Flow Measurement System.

2.1 SYSTEM DESCRIPTION, STANDARD EQUIPMENT

The Ultraflow 150 system consists of the following standard equipment.

Transducer Interface Enclosure (TIE)

Purge Nozzle Assemblies

Protective Purge Air System (Single)

Enhanced Remote Panel (ERP)

(Not supplied with a 560DI, see section 3.5)

As shown on the Ultraflow 150 Installation Drawings, the first three above

are located on the stack. The Enhanced Remote Panel Assembly is

typically located in the plant Control Room or CEMS Shelter.

2.1.1 Transducer Interface Enclosure (TIE)

The Transducer Interface Enclosure Assembly contains sophisticated

sampling electronics that control the transmit and receive signals from the

transducers and calculates the flow velocity, flow volume and

temperature. It also provides power for the purge fail sensors. These

measurement data are transmitted to the Enhanced Remote Panel via a

commercial network communication protocol.

Each TIE is capable of controlling and performing analysis of up to two

pairs of Purge Nozzle Assemblies.

2.1.2 Purge Nozzle Assemblies

There are two Purge Nozzle Assemblies located on opposite sides of the

stack or duct. Each houses an ultrasonic transducer and is designed to

conduct the protective purge air around the transducer to prevent

contamination from the effluent gas stream. The Purge Nozzles are

constructed using Teflon, stainless steel, and other corrosion resistant

materials to provide a long service life. The actual transducer element is

housed in the Transducer Housing Subassembly and is located near the

end of the Purge Nozzle Nosepiece.

2-1

The stack geometry, wall thickness, and mounting details determine the

length of the Purge Nozzle Assemblies.

Mounting of the assembly is accomplished using four 1/2-13 threaded rods

and nuts to hold the flange seal and squeeze ring in place. A quick

disconnect latching mechanism secures the assembly to the threaded rods.

Electrical connections include those from the Transducer Housing

Subassembly BNC connector and from the purge sensor switch. Both the

transducer coax cable and the purge air sensor cable are housed in a single

length of 3/4" flexible conduit connected from the rear of the Purge

Nozzle Assembly to the junction box.

2.1.2.1 Transducer Assemblies

The wide variety of user stack geometry, effluent composition and effluent

temperatures require that several different types of ultrasonic transducers

be employed to meet individual user requirements. Decisions on which

transducer type is appropriate for your particular application are made by

the Teledyne Monitor Labs factory based on information supplied by the

user prior to factory configuration and checkout. Documentation of the

transducer type for your particular monitor is included as part of Appendix

A of this manual.

SECTION 2.0, SYSTEM OVERVIEW

2.1.2.1.1 Electrostatic Transducer

The Electrostatic Transducer is used in the majority of all Ultraflow 150

applications. It is typically employed in instrument pathlengths less than

26 feet (8 meters). Its electrostatic characteristics maximize sampling

accuracy at short to moderate pathlengths and in low to moderate acoustic

attenuation conditions.

Consult the Site Specification Data sheet of Appendix A for information on

the transducer type of your individual monitor.

2.1.2.1.2 Long Range Transducer (LR003)

The LR003 Transducer is employed where the instrument pathlengths are

about 30 to 50 feet (9-15 meters). Additional sample medium

characteristics may present acoustic attenuation conditions that reduce the

ultrasonic signal strength of the Standard Transducer below acceptable

levels. This may require the use of the LR003 at some pathlengths less

than 30 feet (9 meters). Long Range Transducers are capable of higher

drive (transmit) energies and have horn designs unique to their operating

frequencies.

Consult the Site Specification Data sheet of Appendix A for information on

the transducer type of your individual monitor.

2-2

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

2.1.2.1.3 Extended Long Range Transducers (LR004 through LR007)

As pathlength, temperature, velocities and medium molecular weight

increase, the acoustic attenuation increases vigorously. As these factors

combine to challenge the signal strength of the Long Range Transducer

LR003, the Extended Long Range Transducers are used to obtain

satisfactory operation in these conditions. This family of transducers

(LR004 through LR007) uses a common transducer element design with

various purging and horn designs. These designs ensure accurate

measurement signals throughout the operating range of the most

challenging acoustic effluent conditions.

Consult the Site Specification Data sheet of Appendix A for information on

the transducer type of your individual monitor.

2.1.3 Protective Purge System

The Standard Purge System for Electrostatic Transducers consists of a

single blower that has a dual outlet and flow restriction device to provide

clean, proportioned purge air to each of the two Purge Nozzle Assemblies.

This configuration can be employed where the effluent pressures are

negative to modestly positive. Use of the single Protective Purge Air may

not be recommended in cases of high positive stack pressures. Long range

uses a dual blower system.

The Purge System provides filtered air to keep the effluent from

contacting the transducers. The air is injected into the stack through the

nozzles of these assemblies by actually having air blow around and in

front of the transducers. Each assembly has a purge air sensor switch that

remains activated as long as the purge air is flowing. If purge air is lost to

either transducer an indication is provided at the Enhanced Remote Panel.

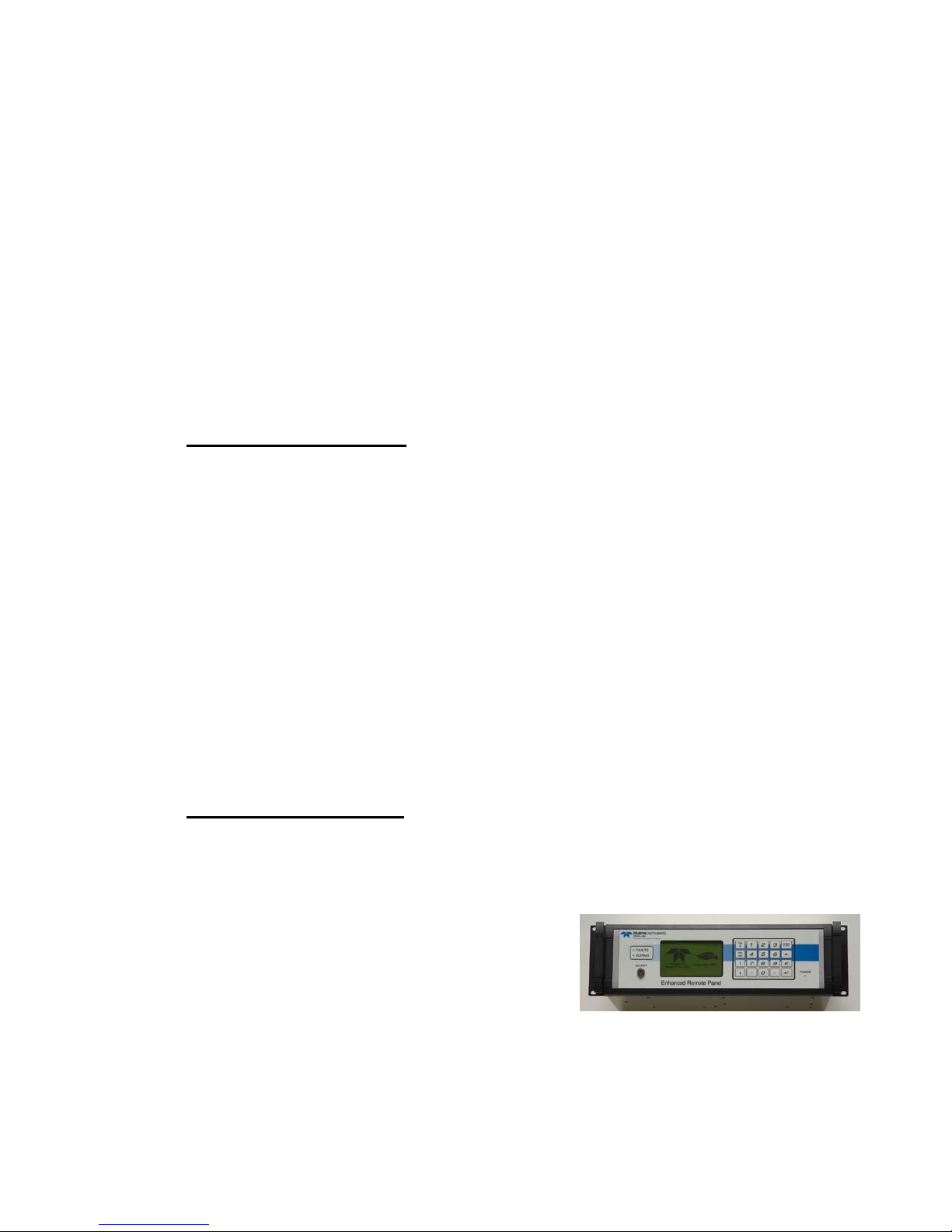

2.1.4 Enhanced Remote Panel

2.1.4.1 Enhanced Remote Display

The Enhanced Remote Display is built with a modular design. It is 19”

rack mountable. The software is menu driven and uses a commercial

network communications platform. It

uses a membrane switch keypad, a 4 ½”

Liquid Crystal Display (LCD) with

graphics capability and a key lockout for

critical functions.

2.1.4.2 Multi I/O Board

The Multi I/O Board is installed in the Enhanced Remote Panel chassis

and has eight relay outputs, eight digital inputs, and four individually

2-3

isolated analog outputs. The connections to the user interface devices

from the Multi I/O Board are made via connectors on the back panel of the

Enhanced Remote Display Panel.

2.1.4.3 Ethernet Module

The Ethernet Module is a single printed circuit board located inside of the

ERP chassis. External connection to the Ethernet Module is made via a

standard RJ45 connector socket in the rear panel of the ERP. The module

will provide web browser-based remote access, configuration and control

of the Ultraflow 150. At the same time the Ethernet Module can provide

HTML web pages for user interface and fast Modbus TCP access to

instrument data and parameters.

The details of this powerful ERP feature are described in its own

instruction manual which is provided with the instrument. The customer

supplied network cable may be installed into the socket marked “Ethernet”

at the right hand side of the ERP rear panel.

This option can be supplied in a standalone version for users who

purchased the 560DI.

SECTION 2.0, SYSTEM OVERVIEW

2-4

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

3.0 OPTIONAL EQUIPMENT

The components listed below are optional on the Ultraflow 150 system.

They are not included on a standard system. Please consult the Site

Specification Data sheets in the back of this manual for the details of your

particular system.

Protective Purge Air System, Dual

Local User Interface Key Pad and Display

Dual Analog Input Board

Link Rod

6PT I/O PC Board Option

3.1 PROTECTIVE PURGE AIR SYSTEM, (DUAL)

The Dual Protective Purge Air System consists of two blowers and

weather covers designed to supply purge air to each Purge Nozzle

assembly. This configuration uses separate purge blowers to provide

clean purge air to each of the two Purge Nozzle Assemblies. This option

can be employed where the effluent pressures are very positive and is used

on all standard long range installations.

Consult the Site Specification Data sheet of Appendix A for information on

the configuration of your individual monitor

3.2 LOCAL USER INTERFACE KEY PAD AND DISPLAY

The Local User Interface Key Pad and Display option provides an

operator interface capability at the Transducer Interface Enclosure (TIE)

on the stack. This is a Local User Interface that will provide the ability to

evaluate the operation and setup variables of the system from the TIE

location.

This assembly contains a 6 character, 7 segment display and a keypad. The

two leftmost characters are GREEN while the 4 remaining characters to

the right are RED. The display is organized so that the 2 GREEN

characters indicate the software bank location of data, operational

variables, markers or configuration modifiers. The 4 RED characters to

the right hold the value of the data, status or marker in that bank location.

The locations are organized into different categories or BANKs of data

and parameters. The leftmost GREEN letter character describes the

3-1

BANK or category of display information, while the second GREEN

numeric character identifies the individual memory location within the

BANK.

Consult the Site Specification Data sheet of Appendix A for information on

the configuration of your individual monitor.

3.3 DUAL ANALOG INPUT BOARD

The Dual Analog Input Board option is required when the user wishes to

have the Ultraflow 150 take in external information on stack pressure and

temperature in order to convert the stack flow volume values to standard

conditions.

3.3.1 Barometric Pressure Sensor Assembly

A Barometric Pressure Sensor Assembly is available for the purpose of

correcting flow volume data to standard pressure. The assembly contains

an on-board absolute pressure transducer that reads the ambient pressure

outside the Transducer Interface Enclosure via a sealed vent line. This

approach is recommended only for applications in which the static gage

pressure of the process is not likely to undergo dramatic changes. For

cases where static pressure varies widely, a pressure transducer measuring

the actual process pressure will deliver maximum accuracy. See the

System Properties Menu section (Section 6.0) of this manual for external

pressure transducers.

SECTION 3.0, OPTIONAL EQUIPMENT

The Barometric Pressure Sensor Assembly is inserted into a connector on

the Dual Analog Input Board, a separate option located in the Transducer

Interface Enclosure. The Dual Analog Input Board provides the required

operating power for the assembly and converts the pressure transducer

voltage to 12 bit digital data for use by the Flow Mother Board.

Consult the Enhanced Remote section (Section 6.0) of this manual for

information on calibration of the Barometric Pressure Sensor Assembly.

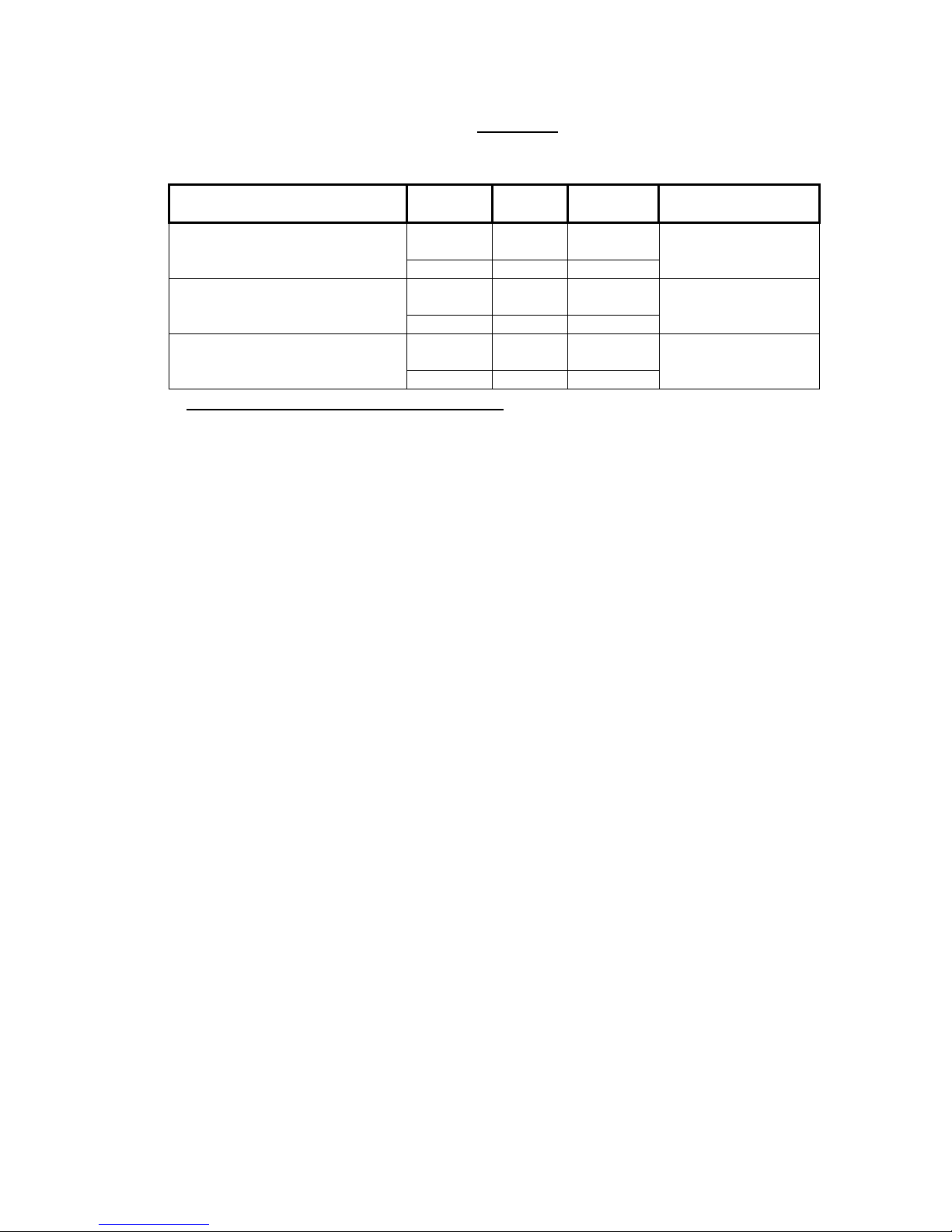

See Table 3-1 below for the Dual Analog Input Board jumper settings for

use of the Barometric Pressure Sensor Assembly.

3-2

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

DESCRIPTION

JUMPER

NUMBER

LABEL

POSITION

WIRING

Barometric Pressure Assembly

JU2

Don’t

Care

Don’t Care

None

JU3

INT

1-2

4-20mA Pressure Transmitter

JU2

CUR

1-2

J4 Terminals

1(+) and 2(-)

JU3

EXT

3-4

0-5VDC Pressure Transmitter

JU2

VOL

3-4

J4 Terminals

3(+) and 2(-)

JU3

EXT

3-4

Table 3-1

Dual Analog Input Board Jumpers for Pressure Input

3.3.2 External Temperature Measurement

The Ultraflow 150 can measure medium temperature in two manners:

INTERNAL MEDIUM TEMPERATURE: This measurement uses the

speed of sound data derived from the time of flights between the

upstream and downstream ultrasonic transducers. Since speed of

sound is directly proportional to the square root of absolute

temperature, a temperature measurement can be made based on this

data provided the concentrations of the major constituent gases

(usually O2, CO2, H20 and N2) are either relatively constant or

change predictably as a function of speed of sound. Examples of

applications where this is true include flow monitoring of single fuel

utility boiler stack gas emissions, cement kiln combustion emissions,

secondary combustion air and process steam boiler emissions.

EXTERNAL MEDIUM TEMPERATURE : This measurement utilizes

external, non-ultrasonic sensors to establish medium temperature.

This technique is recommended when the concentrations of the major

constituent gases (usually O2, CO2, H20 and N2) change

unpredictably or are not a function of speed of sound. In these cases,

the absolute values of the Ultraflow 150’s INTERNAL MEDIUM

TEMPERATURE will be inaccurate by magnitudes roughly

proportional to the change in molecular weight. An example of such an

application is a multi-fuel (i.e., one that can run on coal or natural gas

at base load) utility boiler.

The Dual Analog Input Board option is required to implement the

EXTERNAL MEDIUM TEMPERATURE option. The Dual Analog

Input Board is compatible with a variety of external temperature sensors:

1000 ohm 2 wire RTD’s (see the next sub-section of this manual), 4 – 20

mA and 0 to 5 Volt. Thermocouples are not supported. See the System

Properties Menu section (Section 6.0) of this manual for information on

calibration of EXTERNAL MEDIUM TEMPERATURE devices.

3-3

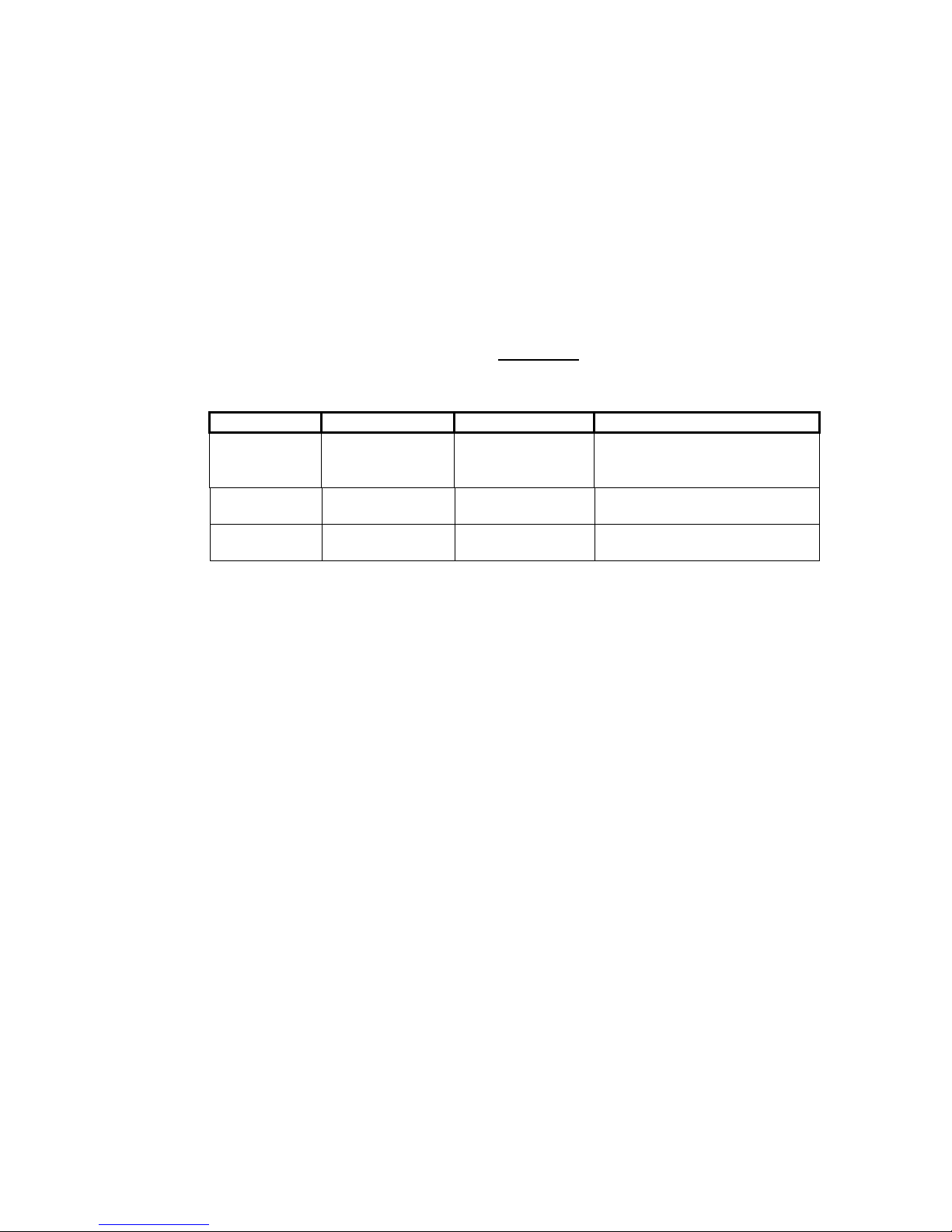

JUMPER

OPTIONS

DEFAULT

FUNCTION

JU1

RTD = 1-2

VOL = 5-6

RTD = 1-2

Selects external input to

RTD, 1-5 volts, or 4-20 mA

JU4

3-4 (1000 ohms)

3-4 (1000 ohms)

Selects the 32°F (0°C) RTD

resistor for calibration

JU7

3-4 (1000 ohms)

3-4 (1000 ohms)

Selects the 1000 ohm RTD

for operations

3.3.2.1 Resistive Temperature Device (RTD)

An optional Resistive Temperature Device (RTD) probe is available for

use as an EXTERNAL MEDIUM TEMPERATURE sensor. The heart of

the assembly is a 1000 ohm 2 wire RTD. Consult the system wiring

diagram for connection of the RTD Assembly to the TIE.

The optional Dual Analog Input Board is required to use the RTD

assembly. See Table 3-2 for the applicable Dual Analog Input Board

jumper settings for the assembly.

Table 3-2

Dual Analog Input Board Jumpers for External Temperature

SECTION 3.0, OPTIONAL EQUIPMENT

3.4 LINK ROD

For stacks with an annulus or thick outer walls that must be bridged by the

Ultraflow 150 Purge Nozzle Assemblies, Teledyne Monitor Labs offers

the Link Rod option whenever the Purge Nozzle Assemblies would exceed

72 inches (183 cm) in length. Beyond this length, the standard assemblies

become unwieldy and are difficult to align in the center of their ports. The

Link Rod Assemblies replace the standard Purge Nozzles. The Link Rod

Assemblies consist of a transducer housing with skids to center it in the

port, and a series of short rods that connect or disconnect as the transducer

housing is inserted or removed from the port. The Link Rod option also

reduces the amount of removal clearance required to extract the

transducers for maintenance and cleaning. This mounting option is

complete with all hardware, flanges and seals.

CUR = 3-4

temperature channel between

Consult the Site Specification Data sheet of Appendix A for information on

the configuration of your individual monitor.

3-4

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

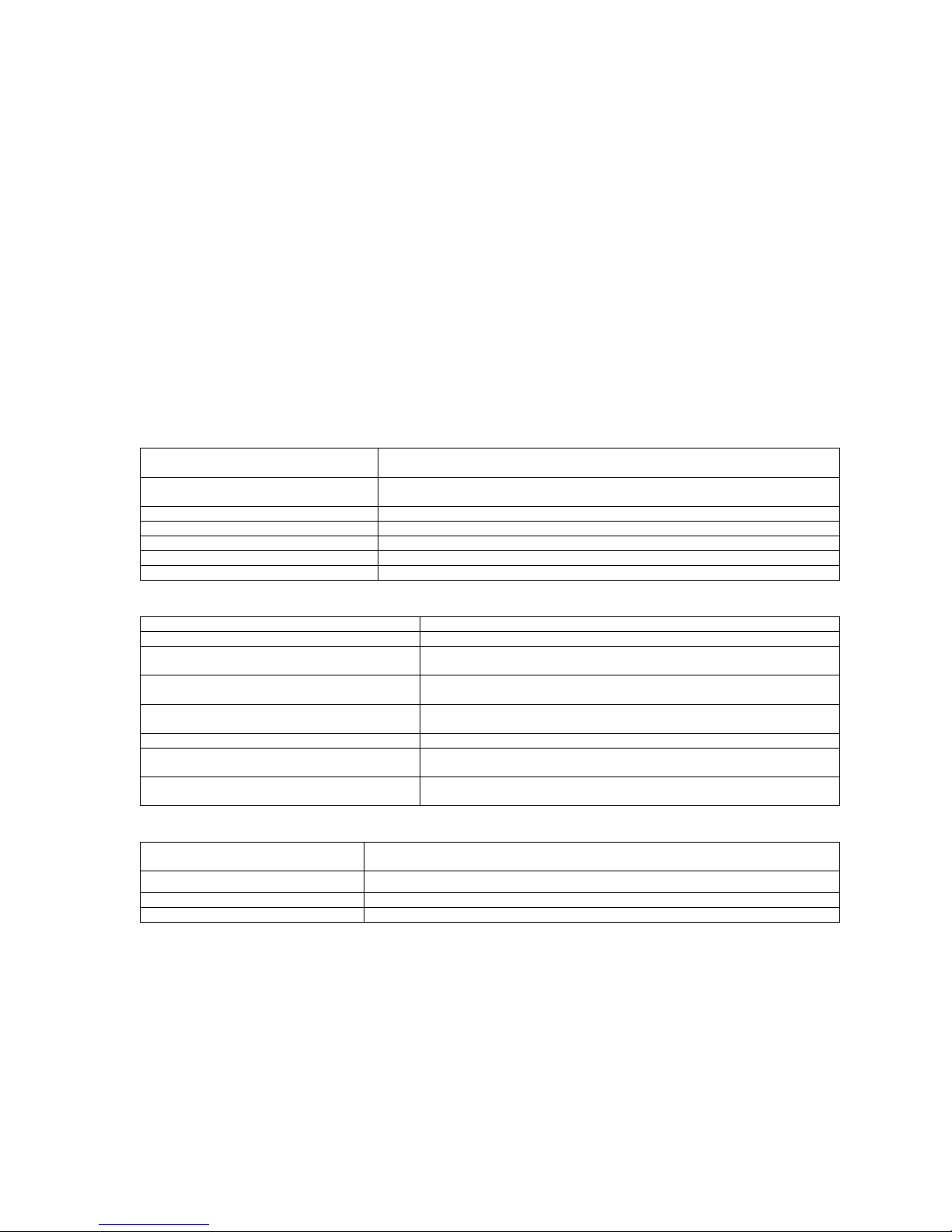

Number

2

Isolation Type

Optical & capacitive barriers; channel to channel, channel

to circuit common & earth

Minimum Isolation Voltage

500Vpeak*, 500VDC*

Output Type

4-20mA with live 4mA zero, OR 0-20mA w/o live zero

Maximum Load Resistance

900 ohms

Maximum Offset

±0.05% of full scale

Total Output Error

±0.30% of full scale

Number

2

Modes

Isolated and Non-isolated

Isolated Mode Minimum Isolation

Voltage

500Vrms*

Isolated Mode Minimum Actuation

Voltage

5VDC (user supplied)

Isolated Mode Maximum Actuation

Voltage

24VDC (user supplied)

Isolated Mode Maximum Input Current

50mA @ 24VDC

Non-Isolated Mode Actuation

Condition

Dry contact closure

Non-Isolated Mode Internal

Operating Voltage

5VDC

Number

2 SPST, N.O. (Single Pole Single Throw, Normally Open or

Normally Closed [jumper selectable])

Minimum Isolation

Maximum Contact Voltage

250VAC

Maximum Contact Current

1Amp AC, 1Amp DC

3.5 6PT I/O PC BOARD OPTION FOR 150DI

The Six Point I/O Board is an optional device intended to provide a low

cost Direct Interface feature to the Ultraflow 150DI where analog output

and control signals are supplied directly from the Transducer Interface

Enclosure (TIE) Assembly. The PC Board has 2 analog outputs, 2 digital

inputs and 2 relay outputs. The Local User Interface Key Pad and Display

option comes standard with the 6PT I/O option. The configuration of the

6PIO Board is software selectable using the PC to Modbus interface

software supplied with the Ultraflow 150DI. Below are the specifications.

The details on this option are described in its own instruction manual.

Six Point I/O Board Specifications

SIX POINT I/O BOARD ANALOG OUTPUTS

SIX POINT I/O BOARD DIGITAL INPUTS

SIX POINT I/O BOARD RELAY OUTPUTS

500Vrms*

*I/O wires with respect to earth (common mode).

3-5

4.0 THEORY OF OPERATION

Upstream

Transducer

L

θ

(Actual)

Fv

(Nominal)

Fv

Ft

Downstream

Transducer

4.1 PHYSICS OF MEASUREMENT

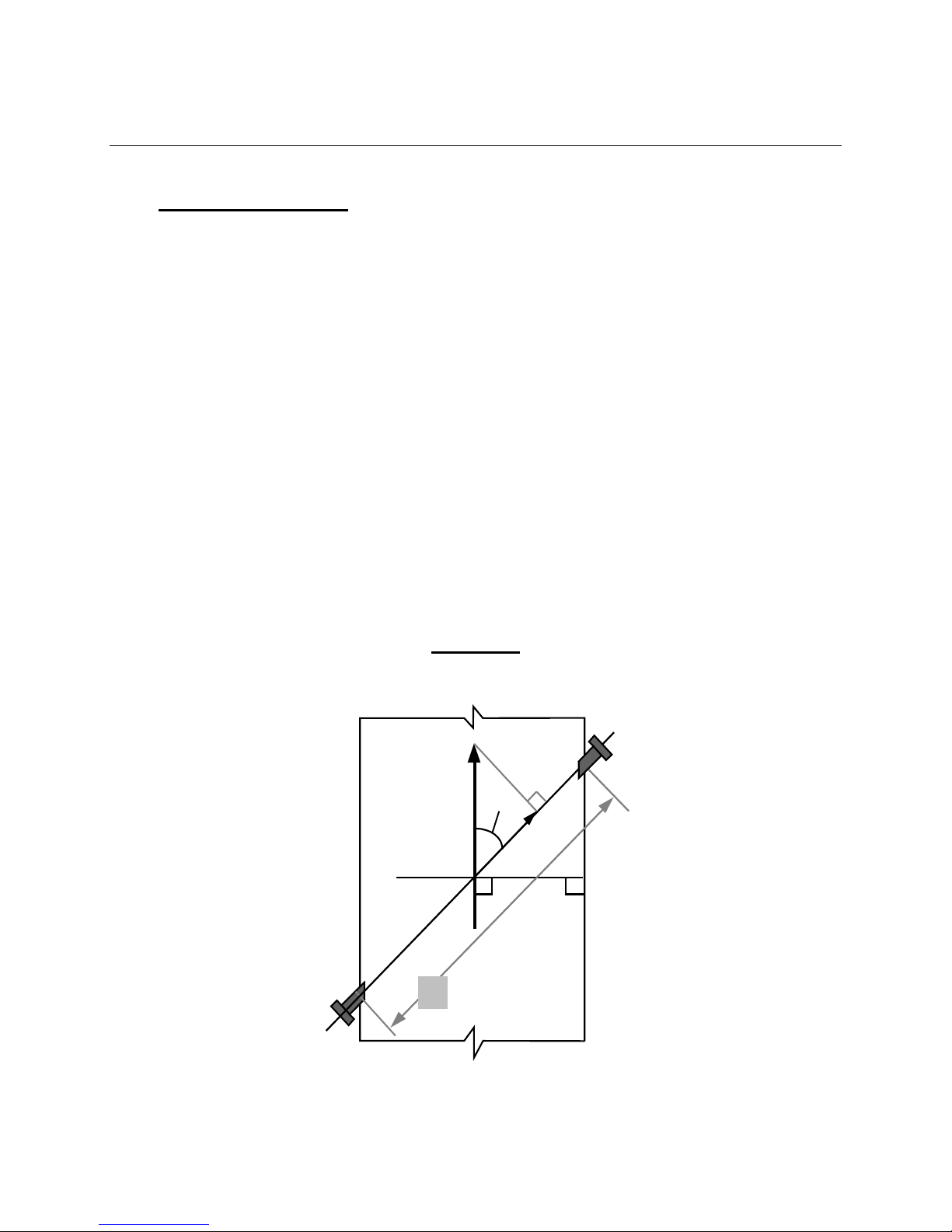

4.1.1 Time of Flight Theory

The Ultraflow 150 system measures the transit times of ultrasonic tone bursts

through the gas stream to determine flow velocity, temperature, and volume.

Each effluent path monitored by the Transducer Interface Enclosure (TIE) uses

two transducers placed on opposite sides of the stack or duct (see Ultraflow 150

System Installation Drawing, Appendix D). The transducers are pointed at each

other with one transducer located diagonally upstream from the other. Each

transducer acts alternately as a transmitter or receiver with the ultrasonic waves

passing through the centroid of the stack or duct to the other transducer. This

makes the measurements a line average of the tone burst path length. When a

tone burst is sent through the gas stream from the upstream transducer to the

downstream transducer the movement of the gas stream reduces the time required

to traverse the distance. When the tone burst is traveling against the gas stream

from the downstream to the upstream transducer, the traverse time is increased.

When there is no gas flow, the time required for the ultrasonic tone bursts to

traverse the gas stream in either direction is the same. Both the upstream and

downstream transit times are measured by the Transducer Interface Enclosure to

an accuracy of 0.5 microseconds.

SECTION 4.0, Theory of operation

Figure 4-1

Transit Time Theory

4-1

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

4.1.1.1 Flow Velocity Measurement

The root measurement of the Ultraflow 150 is transit time. The difference

between upstream and downstream transit times through the gas stream is directly

proportional to the velocity of the gas stream. From transit time and the following

physical equations the TIE calculates flow velocity. This velocity measurement is

inherently independent of the temperature, density, viscosity, and particulate

concentration since these terms drop out of the simplified equations.

1)

Velocity of Sound from Upstream to Downstream Transducer

2)

Velocity of Sound From Downstream to Upstream Transducer

Where:

Cs = The Speed of Sound

Fν = Flue Gas Velocity

θ

= Transducer Angle to Flow

V = Velocity of Respective Tone Bursts

3) Subtract equations 1 & 2:

and solving for Fν:

4)

substituting

5)

Fν is the Line Average Velocity.

And: t = Transit times of sound between the transducers

L = Distance between the transducers

4-2

4.1.1.2 Temperature Measurement

By knowing the precise time required for the tone bursts to traverse the gas stream

the speed of sound is calculated. The influence on the speed of sound resulting

from temperature change is well established. Therefore, the gas stream

temperature measurement may be calculated directly from the speed of sound

determination. This measurement will remain accurate so long as the gas

composition is from a single fuel source or remains relatively consistent in terms

of its molecular weight.

If multi-fuel operation is expected, the Ultraflow 150 should be configured using

an external temperature device that may be facilitated using the optional Dual

Analog Input Board.

Consult the Site Specification Data sheet of Appendix A for information on the

configuration of your individual monitor

4.1.2 Flow Volume Measurement

Once the flow velocity (Fν) has been determined it is multiplied by the crosssectional area of the stack or duct to determine the actual volumetric flow. The

units may be English or Metric, per hour, minute or second, according to a

software selection.

SECTION 4.0, Theory of operation

4.1.3 Wet Basis and Dry Basis Measurements

The Ultraflow 150 gives a wet basis reading only. A wet basis measurement is

one that includes the water vapor component of the effluent in the measurement.

A dry basis measurement is one that removes the water vapor and makes the

measurement on the remaining components of the effluent.

4.1.4 Correction to Standard Temperature and Pressure

Effluent pressure and temperature can vary dramatically from one process to

another. For the sake of uniform reporting most regulatory applications require

the volume and mass flow to be reported in standard pressure and temperature

units. To do this, the monitor’s measurement must be corrected according to the

ideal gas law for the agency specified pressure and temperature. US EPA

standard (reference) conditions are 680 F and 29.92 in. Hg for English units and

200 C and 101.32 Kpa for metric units. The Ultraflow 150 has the ability to take

inputs from an external pressure transducer and a temperature device. The

monitor’s internal temperature measurement may also be used for correction.

Each correction factor can be turned on or off individually to accommodate

systems that do these functions elsewhere.

4-3

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

×=

×

Actual

Ref

Ref

Actual

ActualStandard

T

T

P

P

FlowFlow

To convert actual flow volume to standard flow volume:

NOTE: The temperature must be in absolute terms Eg. 459.69 + deg

4.2 MONITOR SPECIFIC THEORY

4.2.1 Box Car Integration

At the heart of the Ultraflow 150 is a signal conditioning technique known as

“Boxcar Integration”. Each time a tone burst traverses the stack a 16 millisecond

window of interest within the receive signal is digitized by an A/D converter in

0.5 microsecond intervals. This results in a window of interest composed of

32,768 digital values or “boxcars”. For each tone burst during the integration

period the value of each boxcar is added to the sum of all previous boxcars having

the same location in the window. For example on the fourth tone burst of the

integration period, the value of boxcar #100 will be added to the sum of the three

previous boxcar #100s. This technique greatly enhances the signal to noise ratio.

The true receive signals occur at virtually the same time (boxcar) for each tone

burst in the average period and are always positive thus add up faster than the

background noise which is random in time.

At the end of the integration period the resulting window of 32,768 data bits is

sent through the digital signal processing algorithms and the boxcar integrator

reset for the next integration period. The signal processing algorithms determine

the center of the receive signal and thus the exact transit time across the stack.

f

4.2.2 Operational Modes of the Transducer Interface Enclosure

4.2.2.1 NORMAL Mode

During the NORMAL mode the transducers of each transducer pair are alternately

transmitting and receiving signal through the medium and performing the gas

stream velocity calculations. The mode code for NORMAL mode is 1. During

NORMAL mode the TIE cycles the transmit pulses to the transducers on a round

robin basis so there are never any two transducers transmitting or receiving at the

same time. If only one path (transducer pair) is being used, the upstream and

downstream transducers will alternate. The TIE processes and reports the data at

the end of each integration period.

4-4

SECTION 4.0, Theory of operation

4.2.2.2 ZERO Calibration

The mode code for ZERO mode is 4. During the ZERO mode the TIE processes

the signals in a slightly different manner. When both a ZERO and SPAN

calibration have been completed, a comprehensive full system evaluation check

has been done. During ZERO, only the upstream transducer transmits and it

transmits at twice the normal rate. The downstream transducer is receiveing only.

The TIE‘s electronics process each pair of signals as though they were typical

upstream and downstream signals. Since all ZERO mode receive signals go

through the gas stream in the same direction, the time required to traverse the gas

stream should be essentially the same. With no difference in the transit times, the

flow should indicate zero velocity. Small fluctuations in the upstream transmit

and downstream receive properties will indicate non-zero flow readings.

4.2.2.3 SPAN HIGH Calibration Mode (Upscale Calibration)

The mode code for SPAN HIGH mode is 2. During SPAN HIGH only the

downstream transducer transmits and it transmits at twice the normal rate. The

upstream transducer is receiving only. The TIE’s electronics process each pair of

signals as though they were upstream and downstream signals. This would be

expected to produce another zero flow indication. However, in the "SPAN

HIGH" mode every other received tone burst is delayed by a predetermined

amount. This means that the TIE sees a difference in the time required for the

upstream and downstream tone bursts to traverse the gas stream. Small

fluctuations in the downstream transmit and upstream receive properties or

electronics shifts will show changes in the expected flow readings.

4.2.2.4 SPAN LOW Calibration Mode

The mode code for SPAN LOW mode is 3. During SPAN LOW mode the TIE

controls the transducers and processes the signals in the same way as in the SPAN

HIGH mode except that the calculated delay for every other receive signal is

shorter. This gives a shorter transit time difference, thus a lower expected flow

volume.

4.2.2.5 Acquire Modes

There are four Acquire Modes, NORMAL Acquire = 5, SPAN HIGH Acquire =6,

SPAN LOW Acquire = 7, and ZERO Acquire = 8. Acquire modes are invoked

during transitions from one mode to another. When the TIE changes modes, the

acquire for the requested mode will be indicated until the number of integration

periods needed for a good average has been reached. For example if the number

of integration periods per normal average is set to 4 and a mode change to ZERO

mode initiated, the TIE will indicate ZERO Acquire mode for 4 integration

periods before switching to ZERO mode for the balance of the calibration periods.

NOTE: The number of periods for a calibration average must be equal to or

larger than the number for a normal average.

4-5

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

(This page intentionally left blank.)

4-6

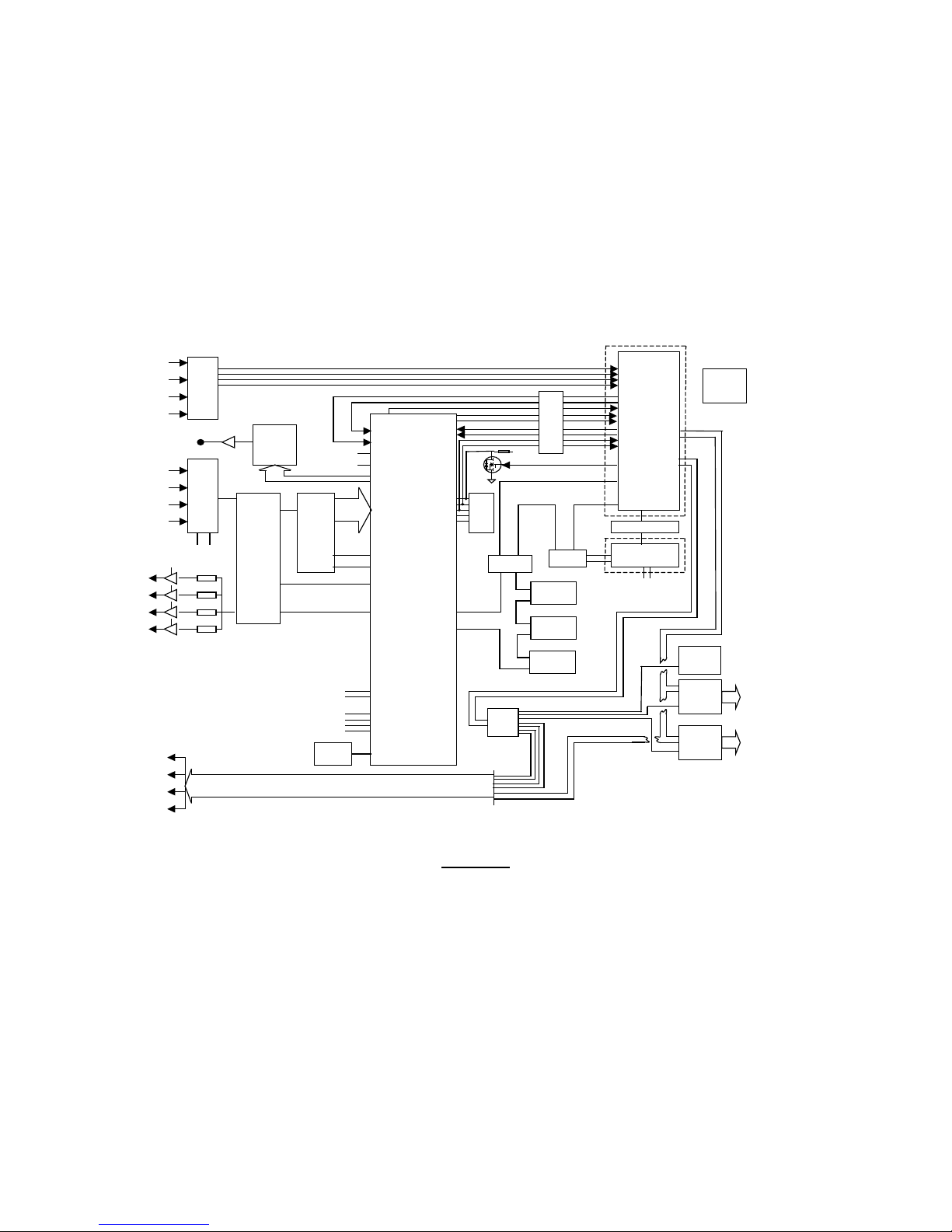

SECTION 5.0, TRANSDUCER INTERFACE ENCLOSURE

Flow

Four DB

Connectors,

SPI

Power

68332

Computer

Module

Optional

Version Only}

2 Discrete Isolator 2 Relay 2 4-20mA

. Inputs Outputs Analog Outputs

Power Supply

Mains

Voltage

Dual

Input Board

{optional}

Preamp /

Board

Purge

Switch

Transducer

Purge

Switch

Transducer

Purge

Switch

Transducer

Purge

Switch

Transducer

Preamp /

Board

Preamp /

Board

Preamp /

Board

Field wiring

Network

remote

RS232 Serial

Port

SPI

SPI

External

Interface Board

Disp

High

Normal

Low

E

Optional Keypad / Display

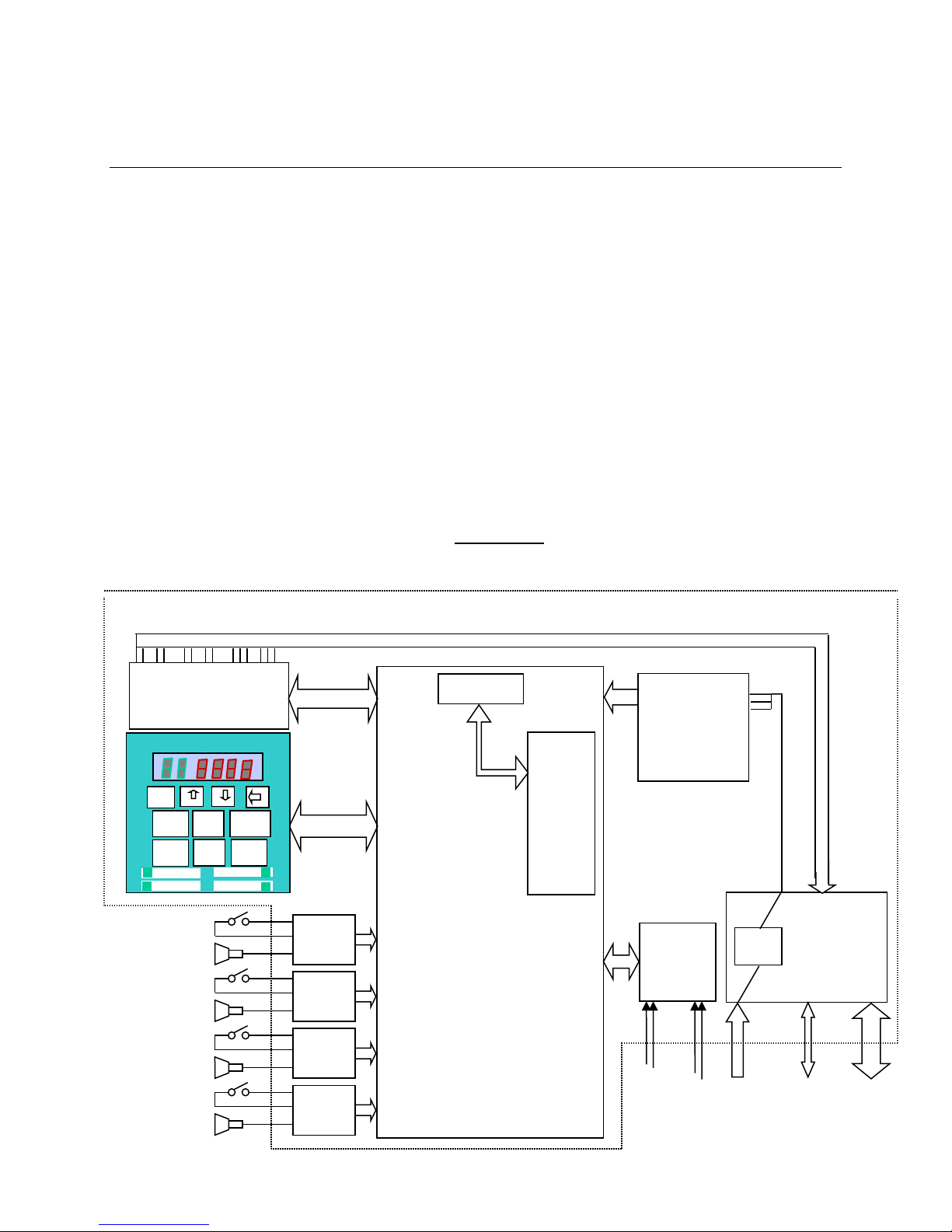

5.0 TRANSDUCER INTERFACE ENCLOSURE (TIE)

The Transducer Interface Enclosure houses the electronics that control the stackmounted portion of the Ultraflow 150. Each Ultraflow 150 TIE has the ability to

monitor two separate paths on the same stack. The TIE will take a full set of

measurements from each path as well as calculate average values of the two paths

combined.

5.1 MECHANICAL DESCRIPTION

The Transducer Interface Electronics is enclosed in a stainless steel NEMA 4X

type enclosure. All cable entries in the enclosure are located in the bottom for

better seal integrity and are sized for ¾” conduit fittings. The cover is hinged on

the left side with screw down latches on the other three sides. Inside the

enclosure, all the electronics are mounted to a removable back plate. A field wire

terminal block board (External Interface Board) with power ON/OFF switch is

mounted to the right inside of the enclosure. Please see the assembly and

installation drawings in Appendix D.

Figure 5-1

Transducer Interface Enclosure Block Diagram

Six Point I/O Board

{Direct Interface

Zero

Path

Driver

Analog

Power

switch

5-1

Driver

Driver

Driver

SPI and analog

Stack

Pressure

Stack

Temperature

wires to

for optional

I/O

ULTRAFLOW 150 GAS FLOW AND TEM P ER ATURE MONITOR

5.2 ELECTRICAL DESCRIPTION

The TIE can be powered with either 115 VAC or 230 VAC feeds. The power

supply is auto ranging and will function normally with inputs from 85 VAC to

265 VAC, 50-60HZ. The power ON/OFF switch is located inside on the External

Interface Board. This board’s main purpose is to provide a place to land the field

wiring. The terminal blocks are sized to handle 12 – 28 AWG wire.

The data cable to the Enhanced Remote Panel uses shielded two-wire cable to

carry the serial data via a commercial communication protocol. The signals to

and from each of the transducer probes are carried by a RG62 coax cable and a

multi pair, individually shielded, 22 AWG, cable carries the purge on/off signal.

5.2.1 External Interface PC Board

The main purpose of the External Interface PC Board is to provide a connection

point for the field wiring. It has three terminal blocks. TB1 is for landing the AC

mains and TB2 is used to land the data cable network wires. If the optional Direct

Interface (560DI) is incorporated into the system, the unused terminals of TB2

and all of TB3 are used to land the interface wires. A double pole power ON/OFF

switch is also located here. The board has direct connections to the Power Supply

Board, Flow Mother Board, and optional Six Point I/O Board.

Consult the Site Specification Data sheet of Appendix A for information on the

configuration of your individual monitor.

5.2.2 Power Supply Board

The Power Supply Board is located in the upper right corner of the enclosure. It

plugs directly into the Flow Mother Board. The power supply is auto ranging. It

requires 85-265 VAC, 50-60 HZ input power and provides +15 VDC regulated, 15 VDC regulated, and +5 VDC regulated outputs.

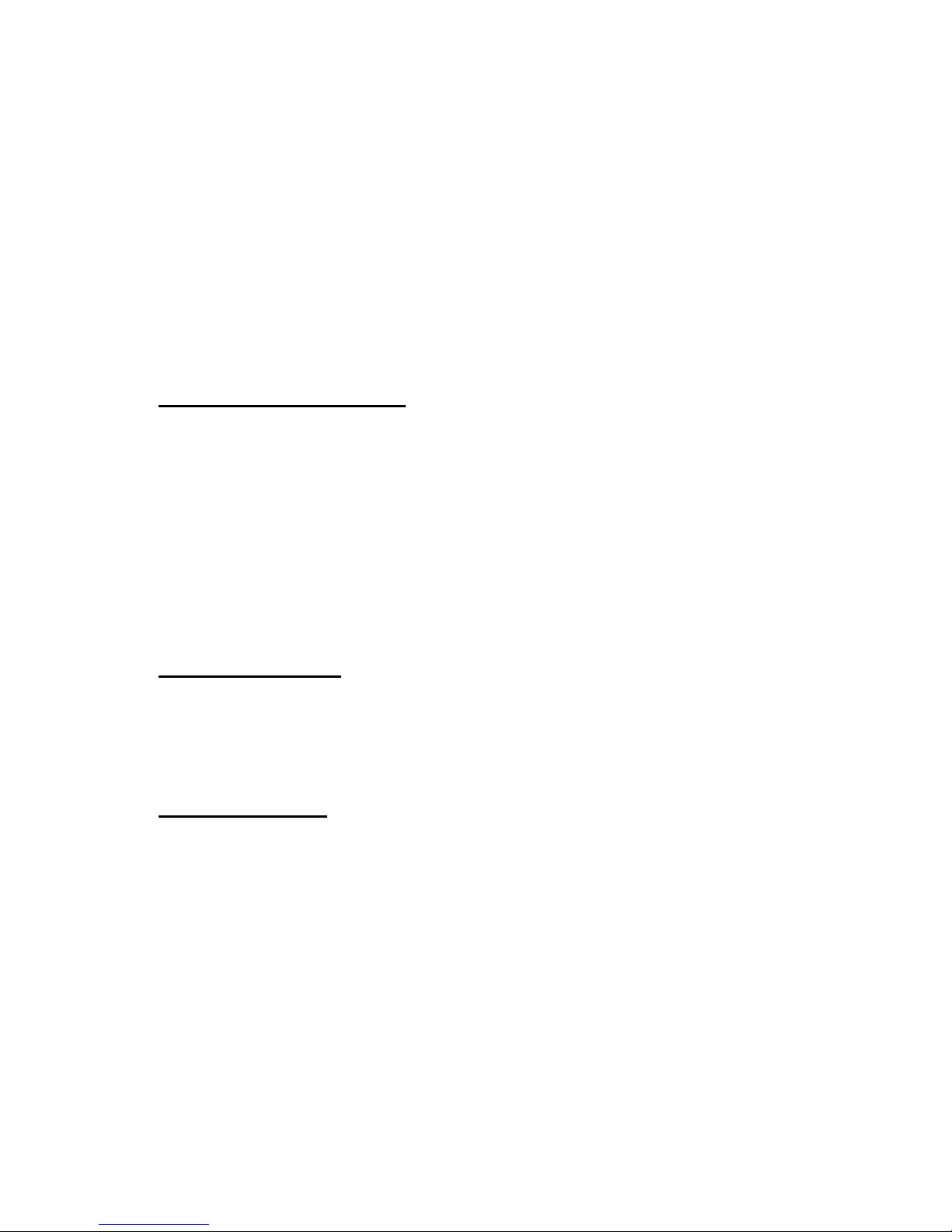

5.2.3 Flow Mother Board

At the heart of the Flow Mother Board are two control devices a Field

Programmable Gate Array (FPGA) and a self-contained computer processor

module. The FPGA performs all of the low-level control functions of the

transducer interface. The computer module is a stand alone, SBC 332 Processor

Board that plugs directly into the Flow Mother Board. The computer module

handles all calculations and higher level control/timing. Please refer to Fig 5-2.

The Flow Motherboard architecture is complex, as is the custom application

software it runs. A detailed description of the board’s electronics and software is

beyond the scope of this manual. For ease of understanding, the Mother Board’s

function is described on a block diagram level.

5-2

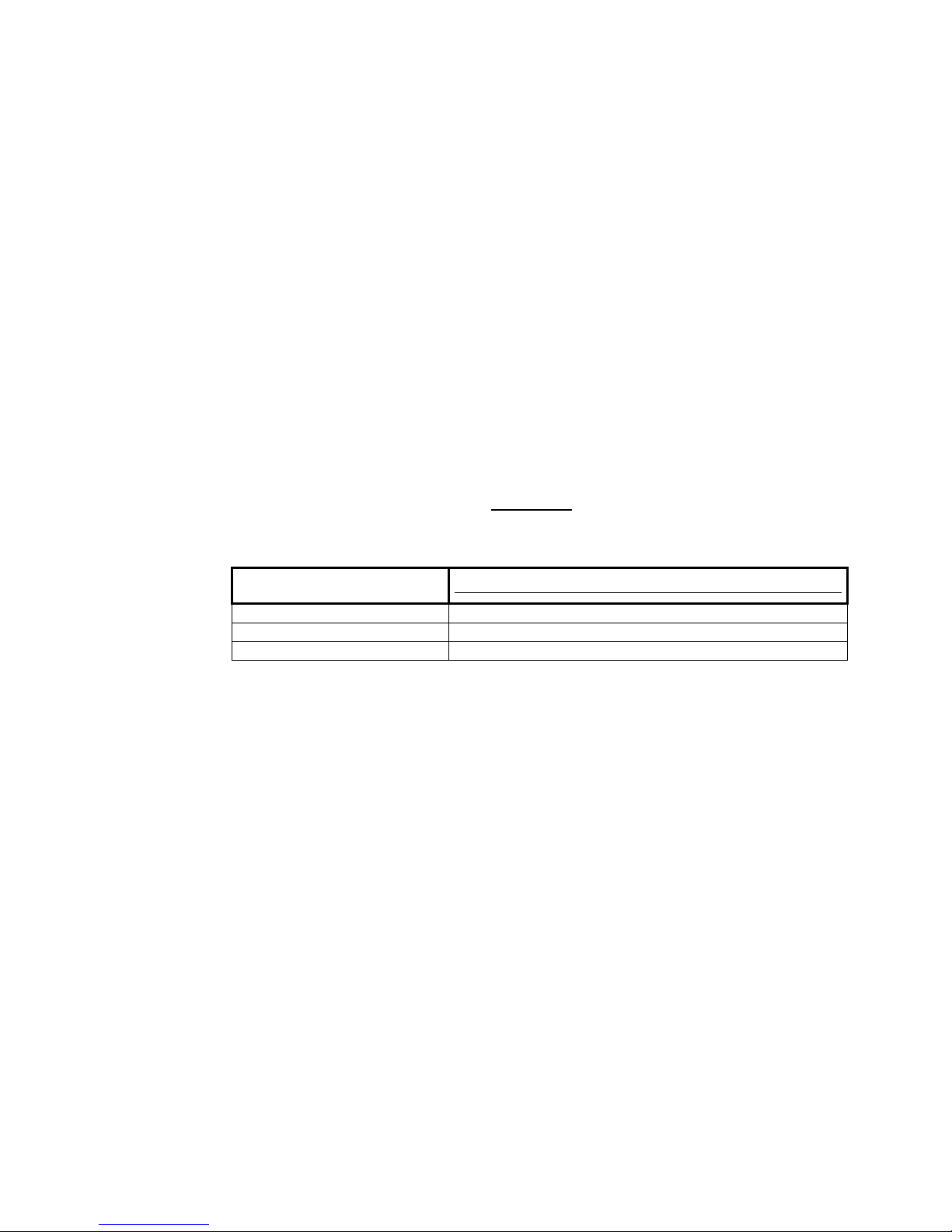

SECTION 5.0, TRANSDUCER INTERFACE ENCLOSURE

150BlockDiagram.ppt

21 Feb. 2001

ELM

FPGA

4

Channel

Mux

12 bit

Parallel

2MSPS

ADC

ADS803

12 MHz

Oscillator

Dual 8 Bit

Parallel

Multiplying

DAC

TLC7528

From P r e a mp

Purge Switch

Circuits

From P r e a mp

Analog

Output

Circuits

To

Prea mp

Transmit

Drive

Input

Circuits

To Preamp

AGC DAC’s

(1 per

Prea mp)

Start Start ADC

Gain Bus &

Waveform

Data

(8 Data & 3

Control

Lines)

Channel

Selects

SPI Clock, Input and Output Data Lines, 4 SPI Slave Selects

Wait / Measure*

Serial

Configuration

Inpu ts

Measur e ment Co mp l ete

Config

Device

3.3V Bus

Xcvr ’s

D0 to D15, R/W

A0 to A18,

CS6,7,9,10

IRQ5

TPU

I/O

TPU I/O

SBC332 Board

ADC

Data

Input

D0 to D15,

A0 to A18,

CS6,7,9,10,

R/W

NEURON

Circuit

FTT10A

Network Wire s

Bus

Xcvr

Renew*

Real Time

Clock

DB

Connector

DB

Connector

To 6 Point

I/O

To Display

Control

128Kx8

SRAM

Buffer

&

ESD

Network

SPI

Clock

& Data

Sla ve

Selects

12 Bit

Parallel

DAC312

Test Point

(like TP4)

Diagnostic Output

12 lines

RESET Sync

A out

B out

To Channel Selects

128Kx8

SRAM

128Kx8

SRAM

TPU

I/O

1 of 4

Transmit Select

Binary Coded

Receive Select

Mode_1

Mode_2

CONFI G_DO NE

Boxcar Overflow

DIAG_0

DIAG_1

JUx

Logic 0 or 1

JUy

Logic 0 or 1

INIT_DONE

3.3V

Bus

Xcvr ’s

4 to 16

Decoder

Over -

ran ge

OVR

Boxc a r R AM B us y

RECONF IG

+3.3V

RS232

Port

DB

Connector

Figure 5-2

Flow Mother Board Block Diagram

5-3

ULTRAFLOW 150 GAS FLOW AND TEM P ERATURE MONITOR

TRANSDUCER TYPE

REQUIRED CONFIGURATION DEVICE U5

ES

Labeled as X.50

LR003

Labeled as X.20

LR004 through LR007

Labeled as X.14

5.2.3.1 Configuration Devices

The Flow Mother Board FPGA is SRAM-based; therefore its internal memory is

volatile. Consequently, it must be configured each time power is cycled. This is

done automatically with an IC known as a Configuration Device. The

Configuration Device U5 is a flash memory that contains additional circuitry to

control the serial loading of configuration data into the FPGA. The configuration

data in U5 programs the gates and registers inside the FPGA to accomplish the

board’s design functions. It is important to realize this configuration is not the

same as the monitor’s calibration configuration, i.e. parameters such as Geometry

Properties, Calibration Properties, etc., which are usually entered by menu

selections via the Enhanced Remote Panel software.

The FPGA performs digital filtering on the incoming received signals. Since each

transducer type has a different center frequency, a different Configuration Device

is required to properly filter each one. There are three different types of

Configuration Devices, one for each type of transducer. See Table 5-1.

Table 5-1

Configuration Device U5 versus Transducer Type

(where X is number that changes based on the firmwa re v ersion of U5)

In the Enhanced Remote, the System Properties, Intrinsic Properties parameter

Transducer Type can be selected via menu control. This selection must match the

Configuration Device U5 or the monitor will not function. A Filter Mismatch

fault will be generated if the Transducer Type selection does not match

Configuration Device U5.

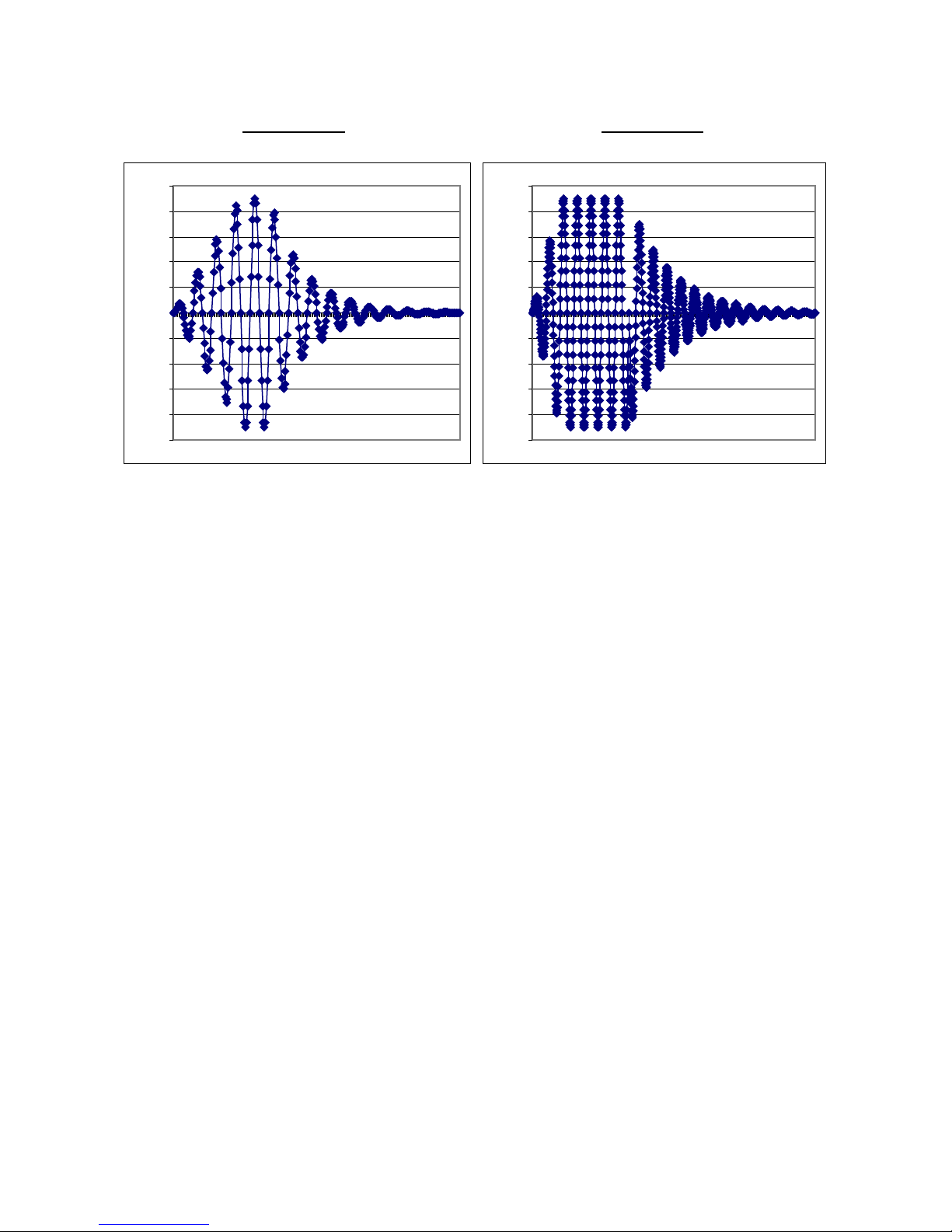

5.2.3.2 Transducer Drive Waveforms

The FPGA produces a digitized version of the ultrasonic tone burst wave packet

required to drive the transducers. The FPGA sends a digital representation of the

wave packet to the “B” half of a dual DAC where it is converted to an analog

signal and steered to the appropriate preamp by the transmit select signals of the

FPGA. Since this waveform is digitally created, it does not require tuning and is

virtually free of temperature drift. Figures 5-3A and 5-3B are examples of typical

waveforms for two different transducer types used in different applications.

Consult the Site Specification Data sheet of Appendix A for information on the

transducer configuration of your individual monitor.

5-4

SECTION 5.0, TRANSDUCER INTERFACE ENCLOSURE

-100

-80

-60

-40

-20

0

20

40

60

80

100

Figure 5-3A Figure 5-3B

100

80

60

40

20

0

-20

-40

-60

-80

-100

Note: The scales of the “X” axes are not the same.

5.2.3.3 Receive Signal Select, Gain, Digitization, Integration and Storage

When the FPGA determines it is time to read the receive signal from a particular

transducer/preamp it sends the appropriate channel select code to the four channel

multiplexer. The multiplexer then places the desired analog receive signal on the

input of the “A” half of a dual DAC. The DAC applies the appropriate gain that

is determined by the FPGA to this signal and places the result on the input of a

twelve bit Analog to Digital converter (ADC). The ADC begins doing a

conversion when it receives a start signal from the FPGA. Each conversion takes

0.5 µsec. At the end of each conversion the digital value is passed to the FPGA

where it is filtered, rectified, and added to the appropriate boxcar in the RAM.

Another start signal is then issued and the ADC starts another conversion cycle.

This continues for 32,384 cycles creating a sixteen millisecond wide window of

0.5 µsec filtered digital averages. The RAM has a separate boxcar window for

each transducer. After the digitized window is complete the FPGA channel select

requests a different transducer/preamp signal from the multiplexer and the ADC

conversions begin forming the digital, (boxcar) window for that transducer. The

channel select continues cycling through the transducers and adding conversions

to the boxcars in the window until the desired integration time is over. This is

typically 30 seconds. At the end of the integration period the FPGA sends a

“Measurement Complete” signal to the 332 Processor. The 332 Board issues a

5-5

“Wait” signal to the FPGA, while it reads the four windows of “Boxcar” data, and

processes the data into time measurements and velocity readings. Then it begins

the next sampling cycle for the duration of the integration period.

ULTRAFLOW 150 GAS FLOW AND TEM P ERATURE MONITOR

DIAG_2

(JU8C)

DIAG_1

(JU8B)

DIAG_0

(JU8A)

0 0 0

A/D Output

0 0 1

Filter ABS

0 1 0

Boxcar (6--17)

0 1 1

Boxcar (7--18)

1 0 0

Boxcar (9--20)

1 0 1

Boxcar (10--21)

1 1 0

Boxcar (11--22)

1 1 1

Boxcar (12--23)

Figure 5

Typical filtered, absol ut e value waveform

Typical A/D output waveform, Normal

5.2.3.4 Diagnostic Waveforms Circuit

The Flow Mother Board has an important built in diagnostic feature. Eight

different signals can be viewed from test point 21 (TP21) depending on the

configuration of the diagnostic jumpers of JU8. The FPGA places the digital data

selected by JU8 (positions A, B or C) on a twelve-bit buss that connects to a

digital to analog converter (DAC). The DAC sends an analog representation of

the data through a buffer to TP21. This gives the user a way to view complex

data such as the filtered and integrated receive data that exists only in the digital

realm.

-4A

Diagnostic Output

Figure 5-4B Figure 5-4C

Note: The sample diagnostic waveforms above were taken from TP21 during normal

mode with the scope triggered on TP34.

5.2.3.5 Bus Transceivers and Logic Level Differences

The digital components of the Flow Mother Board operate with three different

logic levels. The FPGA’s internal logic uses 2.5 VDC. Its I/O logic requires 3.3

VDC. The SBC 332 Processor and Neuron Circuit use conventional 5.0 VDC

5-6

Loading...

Loading...