Teledyne RIVERPRO, RIOPRO User Manual

RIVERPRO & RIOPRO

ADCP GUIDE

Information included herein is controlled by the Export Administration Regulations (EAR) and may

require an export license, license exception or other approval from the appropriate U.S. Government

agency before being exported from the United States or provided to any foreign person. Diversion

contrary to U.S. law is prohibited.

P/N 95B-6097-00 (October 2017)

© 2017 Teledyne RD Instruments, Inc. All rights reserved.

Page ii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

TABLE OF CONTENTS

CHAPTER 1 - AT A GLANCE ...................................................................................................................................1

RiverPro/RioPro Inventory ........................................................................................................................... 2

RiverPro Overview ....................................................................................................................................... 3

RioPro Overview........................................................................................................................................... 4

Boat Overview .............................................................................................................................................. 5

Computer Overview ..................................................................................................................................... 5

Power Overview ........................................................................................................................................... 6

Auto-Adaptive Water Profiling Mode .......................................................................................................... 6

RiverPro/RioPro Options ...................................................................................................................... 6

Setting up the RiverPro/RioPro System ....................................................................................................... 8

Bluetooth Connection .......................................................................................................................... 8

Serial Connection ................................................................................................................................. 11

Connecting to the RiverPro/RioPro ................................................................................................ 12

Changing the Baud Rate in the ADCPs ........................................................................................... 14

RiverPro/RioPro Recorder ............................................................................................................................ 15

Enabling the Loop Recorder ................................................................................................................. 15

Recovering Data from the Loop Recorder ............................................................................................ 15

Erasing Data from the Loop Recorder .................................................................................................. 16

Caring for the RiverPro/RioPro System ........................................................................................................ 17

General Handling Guidelines ................................................................................................................ 17

Assembly Guidelines ............................................................................................................................ 17

Deployment Guidelines ........................................................................................................................ 17

CHAPTER 2 - INSTALLATION ..................................................................................................................................19

Attaching the Boat Mounting Plate .............................................................................................................. 20

Boat Assembly .............................................................................................................................................. 21

Boat Battery Connection .............................................................................................................................. 22

I/O Cable and Dummy Plug .......................................................................................................................... 23

Using the Cable Clips ............................................................................................................................ 24

Routing Cables...................................................................................................................................... 25

Cable Wiring Diagram .................................................................................................................................. 26

Mounting the Instrument ............................................................................................................................ 27

Over-the-Side Mounting ...................................................................................................................... 28

In-Hull Mounting .................................................................................................................................. 29

CHAPTER 3 – COLLECTING DATA ............................................................................................................................31

RiverPro/RioPro Operation Overview .......................................................................................................... 32

Glossary ................................................................................................................................................ 33

Prepare for Discharge Measurement ................................................................................................... 33

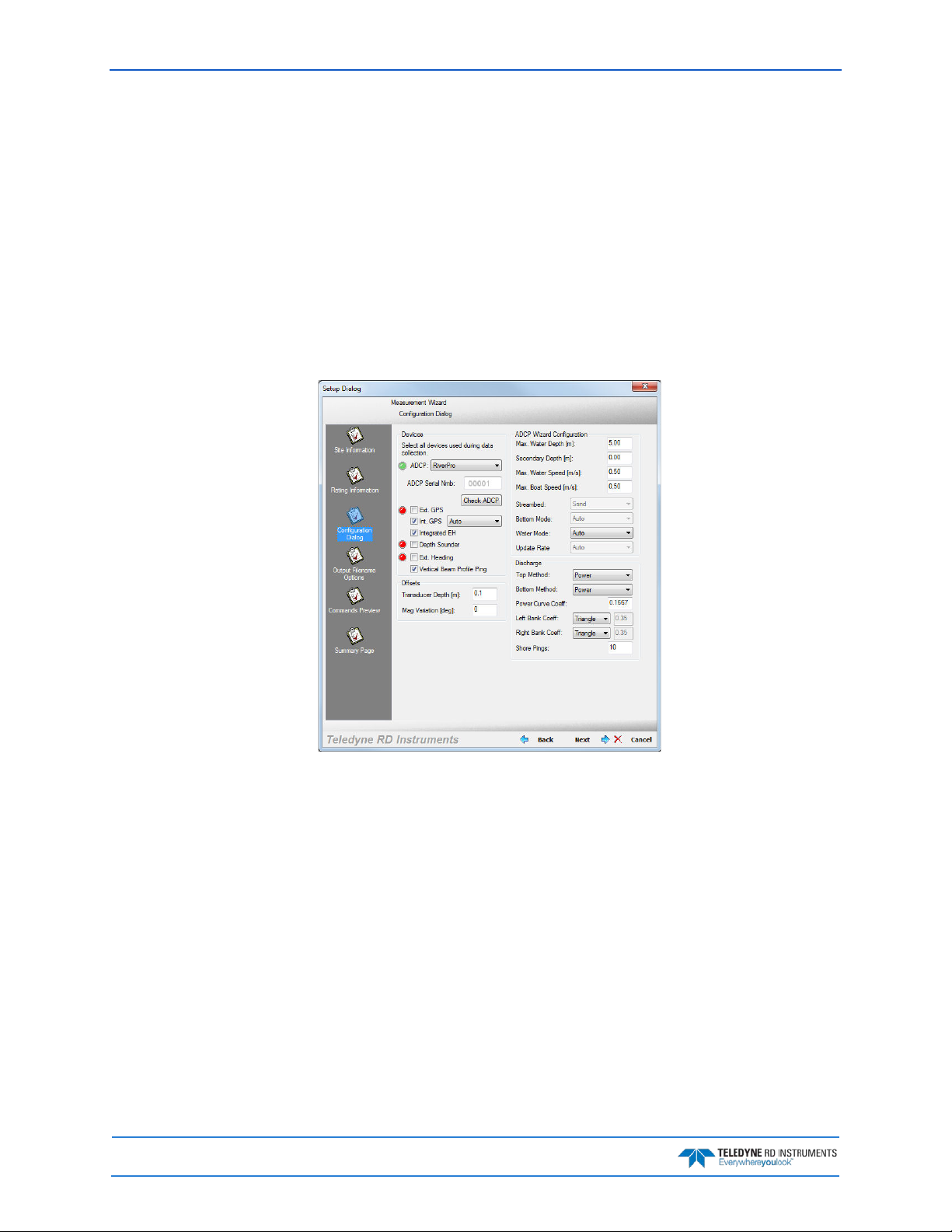

Measurement Wizard .................................................................................................................... 34

Run Built-In Tests ........................................................................................................................... 34

Compass Calibration ...................................................................................................................... 34

Moving Bed Test ............................................................................................................................ 34

Locating the Start and Stop Positions................................................................................................... 35

Discharge Measurement .............................................................................................................................. 35

Moving Boat Discharge Measurement ................................................................................................. 35

Stationary Discharge Measurement ..................................................................................................... 36

CHAPTER 4 - MAINTENANCE .................................................................................................................................37

Parts Location Drawings ............................................................................................................................... 38

Maintenance Schedule ................................................................................................................................. 40

Calibration Items .................................................................................................................................. 40

Maintenance Items .............................................................................................................................. 40

Periodic Maintenance Items ........................................................................................................................ 41

I/O Cable Connector Lubrication .......................................................................................................... 41

Page iii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Cleaning the I/O Cable Connectors ...................................................................................................... 42

Cleaning the Temperature Sensor Cover ............................................................................................. 42

Removing Biofouling ............................................................................................................................ 42

Final Storage or Shipping Preparation .................................................................................................. 43

Calibrating the Compass....................................................................................................................... 43

Calibrating the Compass with WinRiver II ...................................................................................... 43

Yearly Maintenance Items ........................................................................................................................... 45

Maintenance Kit ................................................................................................................................... 45

End-Cap Removal Procedures .............................................................................................................. 49

Transducer Head Assembly Removal ................................................................................................... 49

RiverPro/RioPro Re-assembly ...................................................................................................................... 50

Desiccant Bags ...................................................................................................................................... 50

O-ring Inspection and Replacement ..................................................................................................... 51

Transducer Head Assembly Replacement ............................................................................................ 52

End-cap Replacement .......................................................................................................................... 53

CHAPTER 5 – TESTING TH E RIVERPRO/RIOPRO .........................................................................................................55

Testing the System using WinRiver II ........................................................................................................... 56

Testing the System with SxS Pro .................................................................................................................. 57

Testing the System with BBTalk ................................................................................................................... 57

Test Results .................................................................................................................................................. 58

Display System Parameters .................................................................................................................. 58

Instrument Transformation Matrix ...................................................................................................... 58

Pre-deployment Test ............................................................................................................................ 59

Display Heading, Pitch, Roll, and Voltage ............................................................................................. 59

CHAPTER 6 - TROUBLESHOOTING ...........................................................................................................................61

System Status and LED Behavior .................................................................................................................. 62

Fuse Replacement ........................................................................................................................................ 63

Boat Wiring Diagram .................................................................................................................................... 64

CHAPTER 7 - RETURNING SYSTEMS TO TRDI FOR SERVICE ............................................................................................65

Shipping the RiverPro/RioPro....................................................................................................................... 66

Returning Systems to the TRDI Factory ........................................................................................................ 67

Returning Systems to TRDI Europe Factory .................................................................................................. 68

CHAPTER 8 - SPECIFIC ATIONS ................................................................................................................................71

Outline Installation Drawing ........................................................................................................................ 74

CHAPTER 9 - COMMANDS ....................................................................................................................................77

Data Communication and Command Format .............................................................................................. 78

Command Input Processing ................................................................................................................. 78

Data Output Processing........................................................................................................................ 79

Firmware Updates ........................................................................................................................................ 79

Feature Upgrades ......................................................................................................................................... 80

Command Summary ..................................................................................................................................... 81

Command Descriptions ................................................................................................................................ 84

? – Help Menus .............................................................................................................................. 84

Break .............................................................................................................................................. 85

OL – Display Feature List ................................................................................................................ 86

Y – Display Banner ......................................................................................................................... 86

Bottom Track Commands ............................................................................................................................. 87

Available Bottom Track Commands ..................................................................................................... 87

Bottom Track Command Descriptions ................................................................................................. 87

BP – Number of BT Pings ............................................................................................................... 87

BX – Maximum Tracking Depth ...................................................................................................... 88

Control System Commands .......................................................................................................................... 89

Available Control System Commands .................................................................................................. 89

Control System Command Descriptions ............................................................................................... 89

Page iv

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

CA – Communication Timeout ....................................................................................................... 89

CB – Serial Port Control .................................................................................................................. 90

CF – Set Control Flags..................................................................................................................... 91

CK – Save Command Parameters to Flash ..................................................................................... 92

CR – Restore Command Defaults ................................................................................................... 92

CS – Start Pinging (Go) ................................................................................................................... 93

CState – Pinging State Query ......................................................................................................... 93

CStop – Stop Pinging ...................................................................................................................... 93

CT – Turnkey Mode ........................................................................................................................ 93

CW – Output the Last Stored Ensemble ......................................................................................... 94

CZ – Put the system to sleep .......................................................................................................... 94

Environmental Commands ........................................................................................................................... 95

Available Environmental Commands ................................................................................................... 95

Environmental Command Descriptions ................................................................................................ 95

EA – Heading Alignment ................................................................................................................ 95

EB – Heading Bias ........................................................................................................................... 96

EC – Speed of Sound ...................................................................................................................... 96

ED – Depth of Transducer .............................................................................................................. 97

EH – Heading .................................................................................................................................. 97

EP – Pitch (Tilt 1) ............................................................................................................................ 98

ER – Roll (Tilt 2) .............................................................................................................................. 98

ES – Salinity .................................................................................................................................... 98

ET – Temperature .......................................................................................................................... 99

EU – System Orientation ................................................................................................................ 99

EX – Coordinate Transformation .................................................................................................... 100

EZ – Sensor Source ......................................................................................................................... 103

Recorder Commands .................................................................................................................................... 104

Available Recorder Commands ............................................................................................................ 104

Recorder Command Descriptions......................................................................................................... 104

ME – Erase Recorder ...................................................................................................................... 104

MM – Show Memory Usage .......................................................................................................... 105

MN – Set File Name ....................................................................................................................... 105

MR – Set Recorder On/Off ............................................................................................................. 105

MQ – Streaming Download ............................................................................................................ 106

MY – Y-Modem output .................................................................................................................. 106

Performance and Testing Commands .......................................................................................................... 107

Available Performance and Testing Commands ................................................................................... 107

Performance and Testing Command Descriptions ............................................................................... 107

PA – Run Go/No-Go Tests .............................................................................................................. 107

PC – User Interactive Built-In Tests ................................................................................................ 108

PD – Set Output Format ................................................................................................................. 110

PS – Display System Parameters .................................................................................................... 110

PT – Built-In Tests........................................................................................................................... 111

PF – Results from most recent PA tests ......................................................................................... 115

Sensor Control Commands ........................................................................................................................... 116

Available Sensor Control Commands ................................................................................................... 116

Compass Command Descriptions ......................................................................................................... 116

SA – Compass Cal ........................................................................................................................... 116

SF – External NMEA Menu ............................................................................................................. 117

SI – Internal NMEA Menu .............................................................................................................. 119

SZ – Sensors Installed ..................................................................................................................... 119

Timing Commands ....................................................................................................................................... 120

Available Timing Commands ................................................................................................................ 120

Timing Command Descriptions ............................................................................................................ 120

TE – Time Per Ensemble ................................................................................................................. 120

TF – Time of First Ping .................................................................................................................... 121

TP – Time Between Pings ............................................................................................................... 121

Page v

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

TS – Set Real-Time Clock ................................................................................................................ 122

Vertical Beam Range Commands ................................................................................................................. 123

Standard Vertical Beam Range Commands .......................................................................................... 123

VG – Depth Guess .......................................................................................................................... 123

VP – Number of Vertical Beam Pings ............................................................................................. 123

Water Profiling Commands .......................................................................................................................... 124

Standard Water Profiling Commands ................................................................................................... 124

WC – Correlation Threshold ........................................................................................................... 125

WD – Data Out ............................................................................................................................... 125

WF – Blank after Transmit ............................................................................................................. 126

WM – Water Profiling Mode .......................................................................................................... 126

WN – Number of Bins .................................................................................................................... 126

WO – Number of SubPings............................................................................................................. 127

WP – Number of Pings ................................................................................................................... 127

WS – Bin Size .................................................................................................................................. 127

WV – Ambiguity Velocity ............................................................................................................... 128

Vertical Beam Profile Commands ................................................................................................................. 129

Standard Vertical Beam Profile Commands ......................................................................................... 129

ZB – Vertical Beam Bandwidth ....................................................................................................... 129

ZC – Vertical Beam Correlation Threshold ..................................................................................... 129

ZD – Vertical Beam Data Out ......................................................................................................... 130

ZF – Vertical Beam Blanking Distance ............................................................................................ 130

ZG – Vertical Beam Gain ................................................................................................................ 131

ZM – Vertical Beam Profile Mode .................................................................................................. 131

ZN – Vertical Beam Number of Bins ............................................................................................... 132

ZO – Vertical Beam Number of Mode-12 Subpings ....................................................................... 132

ZP – Vertical Beam Number of Pings.............................................................................................. 132

ZS – Vertical Beam Bin Size ............................................................................................................ 133

ZV – Vertical Beam Ambiguity Velocity .......................................................................................... 133

CHAPTER 10 – OUTPUT DATA FORMAT ...................................................................................................................135

PD0 Output Data Format ............................................................................................................................. 136

Header Data Format ..................................................................................................................................... 138

Fixed Leader Data Format ............................................................................................................................ 140

Variable Leader Data Format ....................................................................................................................... 145

Velocity Data Format ................................................................................................................................... 149

Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format ........................................ 151

Bottom-Track Data Format .......................................................................................................................... 154

Surface Layer Velocity Leader Format .......................................................................................................... 158

Surface Layer Velocity Format ..................................................................................................................... 159

Surface Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format ........................... 160

Automatic Mode 3 Setup ............................................................................................................................. 163

Firmware Status Data ................................................................................................................................... 167

Vertical Beam Range Data Format ............................................................................................................... 168

Vertical Beam Profile Leader Format ........................................................................................................... 169

Vertical Beam Profile Velocity Data Format ................................................................................................. 171

Vertical Beam Profile Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format ...... 171

NMEA PD0 Message Format ........................................................................................................................ 173

Beam Correction Matrix Format .................................................................................................................. 174

Reserved BIT Data Format............................................................................................................................ 175

Checksum Data Format ................................................................................................................................ 175

Decoding an RiverPro/RioPro Ensemble ...................................................................................................... 176

Rules for the BroadBand Data Format PD0 .......................................................................................... 176

Recommended Data Decoding Sequence for BroadBand Data Format PD0 ........................................ 177

APPENDIX A - NOTICE OF COMPL IANCE ...................................................................................................................179

Date of Manufacture .................................................................................................................................... 180

Environmental Friendly Use Period (EFUP) .................................................................................................. 180

Page vi

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

WEEE ............................................................................................................................................................ 180

CE ................................................................................................................................................................. 180

Material Disclosure Table ............................................................................................................................. 181

LIST OF FIGURES

Figure 1. RiverRay/RiverPro/RioPro Boat Overview .................................................................................. 5

Figure 2. RiverPro/RioPro Connections – Bluetooth Connection .............................................................. 8

Figure 3. RiverPro/RioPro Serial Connection ........................................................................................... 11

Figure 4. Download Directory ................................................................................................................. 15

Figure 5. Recover Loop Recorder ............................................................................................................ 16

Figure 6. Mounting Plate Installation ...................................................................................................... 20

Figure 7. Removing the I/O Cable ........................................................................................................... 23

Figure 8. Do not use Zip-Ties Directly on Cables ..................................................................................... 25

Figure 9. RiverRay/RiverPro/RioPro I/O Cable Wiring ............................................................................. 26

Figure 10. Rio Grande I/O Cable Wiring .................................................................................................... 26

Figure 11. End-Cap User Mounting Holes ................................................................................................. 28

Figure 12. RiverPro Parts Location ............................................................................................................ 38

Figure 13. RioPro Parts Location ............................................................................................................... 39

Figure 14. I/O Cable Connector Lubrication .............................................................................................. 41

Figure 15. RiverPro/RioPro Compass Calibration Screen .......................................................................... 44

Figure 16. RiverPro/RioPro Compass Calibration Screen – Pitch/Roll ....................................................... 45

Figure 17. RiverPro Assembly .................................................................................................................... 47

Figure 18. RioPro Assembly ....................................................................................................................... 48

Figure 19. Testing the RiverPro/RioPro using WinRiver II ......................................................................... 56

Figure 20. Testing the RiverPro/RioPro using SxS Pro ............................................................................... 57

Figure 21. RiverRay/RiverPro/RioPro Boat Wiring Diagram ...................................................................... 64

Figure 22. 96B-6060 RiverPro Outline Installation Drawing ...................................................................... 75

Figure 23. 967-6150 RioPro 1200 kHz Outline Installation Drawing ......................................................... 76

Figure 24. Installing Feature Upgrades ..................................................................................................... 80

Figure 25. X, Y, and Z Velocities ............................................................................................................... 101

Figure 26. RiverPro/RioPro Coordinate Transformation ......................................................................... 102

Figure 27. RiverPro/RioPro Pitch and Roll ............................................................................................... 102

Figure 28. PD0 Standard Output Data Buffer Format ............................................................................. 137

Figure 29. Header Data Format ............................................................................................................... 138

Figure 30. Fixed Leader Data Format ...................................................................................................... 141

Figure 31. Variable Leader Data Format ................................................................................................. 146

Figure 32. Velocity Data Format .............................................................................................................. 149

Figure 33. Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format................... 151

Figure 34. Bottom-Track Data Format..................................................................................................... 155

Figure 35. Surface Layer Leader Format .................................................................................................. 158

Figure 36. Surface Layer Velocity Format ................................................................................................ 159

Figure 37. Surface Data Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format160

Figure 38. Automatic Mode Setup Data .................................................................................................. 165

Figure 39. Firmware Status Data ............................................................................................................. 167

Figure 40. Vertical Beam Range Format .................................................................................................. 168

Figure 41. Vertical Beam Profile Leader Format ..................................................................................... 169

Figure 42. Vertical Beam Profile Velocity Data Format ........................................................................... 171

Figure 43. Vertical Beam Profile Correlation Magnitude, Echo Intensity, Percent-Good, and Status Data Format

171

Figure 44. NMEA PD0 Data Message....................................................................................................... 173

Figure 45. Beam Correction Matrix Format ............................................................................................ 174

Figure 46. Reserved BIT Data Format ...................................................................................................... 175

Figure 47. Checksum Data Format .......................................................................................................... 175

Page vii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

LIST OF TABLES

Table 1. Mounting Locations .................................................................................................................. 27

Table 2: RiverPro Maintenance Kit......................................................................................................... 45

Table 3: RioPro/Rio Grande Maintenance Kit ........................................................................................ 46

Table 4. Torque Settings ........................................................................................................................ 52

Table 5. LED Behavior ............................................................................................................................ 62

Table 6: Troubleshooting the RiverPro/RioPro ...................................................................................... 63

Table 7: RiverRay/RiverPro/RioPro Boat Wiring .................................................................................... 64

Table 8: RiverPro/RioPro Specifications ................................................................................................. 73

Table 9: Outline Installation Drawings ................................................................................................... 74

Table 10: RiverPro/RioPro Input Command Summary ............................................................................. 81

Table 11: Serial Port Control .................................................................................................................... 90

Table 12: Set Control Flags ....................................................................................................................... 91

Table 13: Restore Command Defaults ..................................................................................................... 92

Table 14: Coordinate Transformation Processing Flags ......................................................................... 100

Table 15: Sensor Source Switch Settings................................................................................................ 103

Table 16: Water Modes ......................................................................................................................... 126

Table 17: Data ID Codes ......................................................................................................................... 136

Table 18: Header Data Format ............................................................................................................... 139

Table 19: Fixed Leader Data Format ...................................................................................................... 142

Table 20: Variable Leader Data Format ................................................................................................. 147

Table 21: Velocity Data Format .............................................................................................................. 150

Table 22: Correlation Magnitude Data Format ...................................................................................... 151

Table 23: Echo Intensity Data Format .................................................................................................... 152

Table 24: Percent-Good Data Format .................................................................................................... 153

Table 25: Status Data Format................................................................................................................. 153

Table 26: Bottom-Track Data Format..................................................................................................... 156

Table 27: Surface Layer Leader Format .................................................................................................. 158

Table 28: Surface Layer Velocity Data Format ....................................................................................... 160

Table 29: Surface Correlation Magnitude Data Format ......................................................................... 161

Table 30: Surface Echo Intensity Data Format ....................................................................................... 161

Table 31: Surface Percent-Good Data Format ....................................................................................... 162

Table 32: Surface Status Data Format .................................................................................................... 162

Table 33: Automatic Mode Setup Format .............................................................................................. 165

Table 34: Firmware Status Format ......................................................................................................... 167

Table 35: Vertical Beam Range Format .................................................................................................. 168

Table 36: Vertical Beam Profile Leader Format ..................................................................................... 170

Table 37: Vertical Beam Profile Velocity Data Format ........................................................................... 171

Table 38: Vertical Beam Profile Correlation Magnitude Data Format ................................................... 172

Table 39: Vertical Beam Profile Echo Intensity Data Format ................................................................. 172

Table 40: Vertical Beam Profile Percent-Good Data Format .................................................................. 172

Table 41: Vertical Beam Profile Status Data Format .............................................................................. 172

Table 42: NMEA PD0 Data Messages ..................................................................................................... 173

Table 43: Beam Correction Matrix Format ............................................................................................ 175

Table 44: Reserved for TRDI Format ...................................................................................................... 175

Table 45: Checksum Data Format .......................................................................................................... 175

Table 46: Common Data Format IDs ...................................................................................................... 176

Table 47. Toxic or Hazardous Substances and Elements Contained in Product ..................................... 181

Page viii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

REVISION HISTORY

October 2017

• Added a deployment guide to the system documentation

• Replaced the Quick Start Card with Getting Started with the RiverPro/RioPro

• Updated Inventory list

• Added using cable clips

• Updated Bluetooth connection

August 2015

• Added the RioPro ADCP to the RiverPro manual

• Updated the RiverPro/RioPro Inventory

• Updated the LED behavior table

• Added the Boat Wiring Diagram

• Added Beam Coordinate Systems information to the EX command

• Updated the PT3 command

• Updated the GPS specifications

• Updated the outline installation drawings

October 2014

• Initial release

EXCLUSIONS AND OMISSIONS

This manual covers the RiverPro/RioPro ADCP hardware and firmware. For instructions on using a computer running the WinRiver II software, see the WinRiver II User’s Guide. For information on using the

SxS Pro software, see the SxS Software User’s Guide.

Page ix

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

HOW TO CONTACT TELEDYNE RD INSTRUMENTS

If you have technical issues or questions involving a specific application or deployment with your instrument, contact our Field Service group:

Teledyne RD Instruments Teledyne RD Instruments Europe

14020 Stowe Drive

Poway, California 92064

Phone +1 (858) 842-2600 Phone +33(0) 492-110-930

FAX +1 (858) 842-2822 FAX +33(0) 492-110-931

Sales – rdisales@teledyne.com

Field Service – rdifs@teledyne.com

Client Services Administration – rdicsadmin@teledyne.com

Web: http://www.teledynemarine.com/rdi

For all your customer service needs including our emergency 24/7 technical support, call +1 (858) 842-2700

Self-Service Customer Portal

Use our online customer portal at http://www.teledynemarine.com/rdi and click on the Support link to download manuals, firmware

updates, software, or other Teledyne RDI documentation.

2A Les Nertieres

5 Avenue Hector Pintus

06610 La Gaude, France

Sales – rdie@teledyne.com

Field Service – rdiefs@teledyne.com

Page x

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

CONVENTIONS USED IN THIS MANUAL

Conventions used in this documentation have been established to help explain how to use the

RiverPro/RioPro system quickly and easily.

Software menu items are printed in bold: File menu, Collect Data. Items that need to be typed by the

user or keys to press will be shown as F1. If a key combination were joined with a plus sign (ALT+F), press

and hold the first key while pressing the second key. Words printed in italics include program names

(WinRiver II) and file names (default.txt).

Code or sample files are printed using a fixed font. Here is an example:

>break

RioPro

Teledyne RD Instruments (c) 2015

All rights reserved.

Firmware Version: 56.03

>

There are four visual aids to help:

This paragraph format indicates additional information that may help avoid problems or that

should be considered in using the described features.

This paragraph format warns the reader of hazardous procedures (for example, activities that

may cause loss of data or damage to the RiverPro/RioPro ADCP).

This paragraph format tells the reader where they may find additional information.

Recommended Setting. This paragraph format indicates additional information that may help

set command parameters.

Page xi

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

NOTES

Page xii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

1

AT A GLANCE

In this chapter:

• RiverPro/RioPro Inventory

• RiverPro/RioPro Options

• System Overview

• Computer Overview

• Power Overview

• Setting up the RiverPro/RioPro ADCP

• Caring for the RiverPro/RioPro System

Chapter

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 1

October 2017 RiverPro and RioPro ADCP Guide

Section-by-Section (SxS) Pro is a stationary ADCP discharge data collection and pro-

required to collect data).

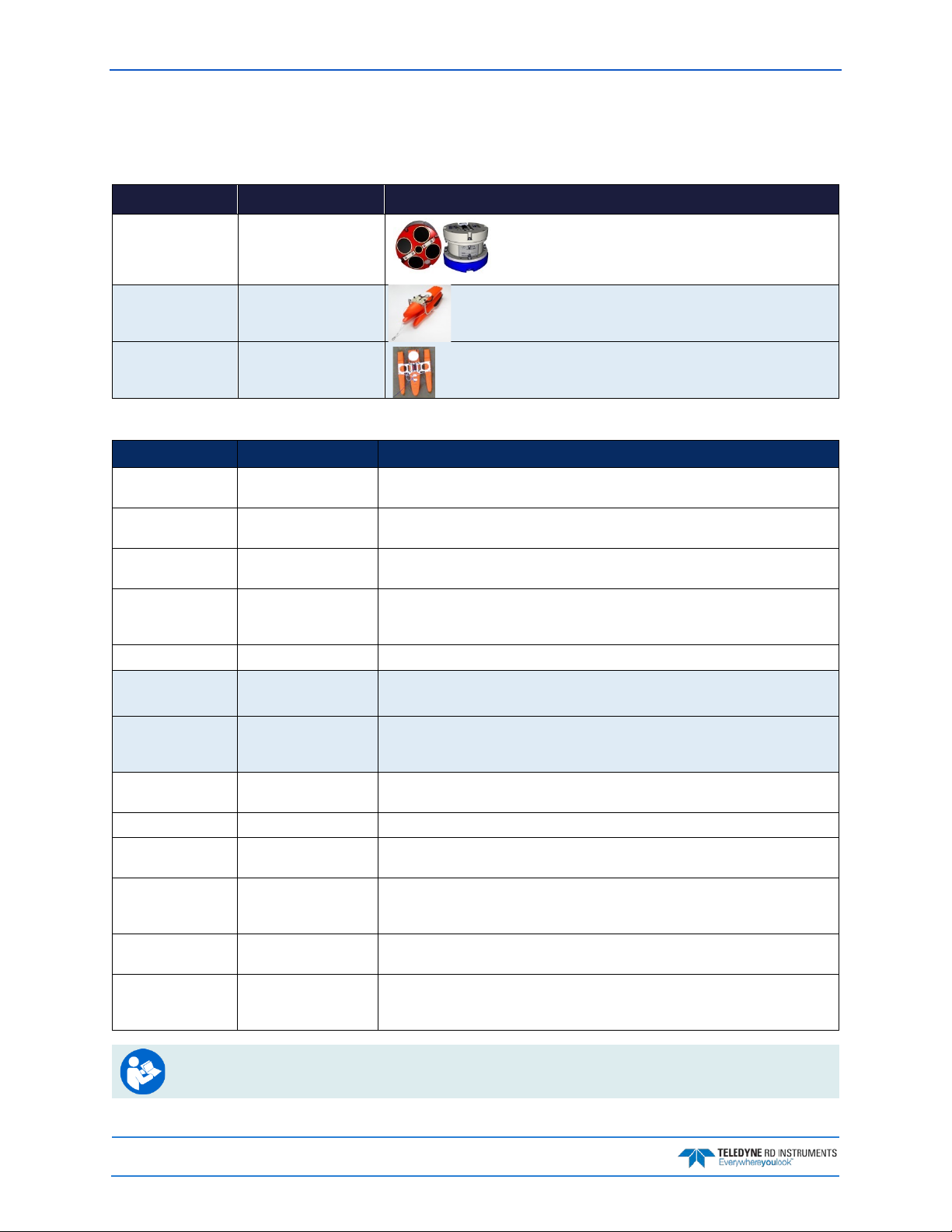

RiverPro/RioPro Inventory

Included with the RiverPro/RioPro system:

Part Number Name Description

RIVPRO1200-I

707-6025-02

71B-7007-xx RiverRay/RiverPro Boat

RiverPro 1200 kHz system

RioPro 1200 kHz system

(optional)

The RiverPro/RioPro system includes the transducer, dummy

plug, and protective cap. When unpacking, use care to prevent

physical damage to the transducer face and connector. Use a

soft pad to protect the transducer.

Tri-hull Boat and mounting plate for tethered deployments (shown

folded). Various GPS wiring optional configurations are available.

RIVERBOAT-xx RioPro Boat (optional) The RioPro requires the Riverboat for tethered deployments. Various GPS

wiring optional configurations are available.

Included with the RiverPro (RIVERPRO1200-A)/RioPro (RIOPRO-A) Accessories Kit:

Part Number Name Description

UK821 (RiverPro)

717-7000-00 (RioPro)

73B-6020-005

(RiverPro Only)

90B-8021-00 RiverPro/RioPro

907-8075-00 WinRiver II Software CD TRDI’s river and coastal data acquisition software package where the primary use is for

907-8040-00 RDI Tools Software CD Utility and testing software package including BBTalk that can be used to test the ADCP.

907-8080-00 SxS Pro Software CD

91B-8007-00

90B-8020-00 (CD)

95B-6127-00 Getting Started A printed reference card showing how to get started with the RiverPro/RioPro. A PDF

95B-6123-00 Deployment Guide A Printed guide showing the steps needs for a successful deployment.

957-6274-00 Serial Communications

957-6277-00 SD1000U Bluetooth

SD1000U

DAT5-G01R

N/A Spare parts and tools The RiverPro includes a driver and spare mounting hardware for the Boat mounting

Shipping case Shipping case with custom foam cutouts.

I/O cable The I/O cable is used for serial communications.

Documentation CD

(optional)

Q-View Software

(optional)

Setup Card

Communications Setup

Card

USB Bluetooth device

This CD has PDF versions of all of the RiverPro/RioPro documentation including the

RiverPro/RioPro ADCP Guide. Please read the manual!

discharge calculation. Although this is its primary function, it can be used for general

coastal survey applications.

cessing program. This CD will be included with the SxS Pro upgrade (registration code is

Q-View is designed for customers using WinRiver II software to have easy access to an

evaluation of the quality of collected data while they are still in the field and back in the

office. Once purchased, a download link and activation code is sent.

version is included on the RiverPro/RioPro documentation CD.

A printed quick reference card showing serial communications setup. A PDF version is

included on the WinRiver II CD.

A printed quick reference card showing Bluetooth communications setup using the

SD1000U. A PDF version is included on the WinRiver II CD.

USB Bluetooth device SD1000U and Sena DAT5-G01R antenna.

plate. The RiverPro and RioPro includes a 3mm Allen wrench for removing and connecting the I/O cable strain relief.

For instructions on using the USB Bluetooth device, see the WinRiver II or SxS Pro Software

User’s Guide and the instructions included with the device on the Bluetooth driver CD.

Page 2

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

RiverPro Overview

The RiverPro transducer assembly contains the end-cap, housing, transducer ceramics, and electronics.

The standard acoustic frequencies are four 1200 kHz Janus beams and one 600 kHz vertical beam. See

the Outline Installation Drawings for dimensions and weights.

Picture Description

The Input/Output (I/O) cable connects the RiverPro ADCP to the

computer and external power supply. When the cable is not connected, use the dummy plug to protect the connector.

The LEDs on the end-cap indicates the status of the RiverPro system.

The I/O connector should not be exposed to extended peri-

ods of heat or direct sunlight.

Always apply lubricant before connecting the I/O cable to the

RiverPro.

The RiverPro is intended to be operated as a surface mounted

system only. No depth rating is provided.

The Thermistor measures the water temperature.

The black urethane faces covers the transducer ceramics.

The Vertical Beam allows for depth measurement directly under

the RiverPro.

Never set the transducer on a hard surface. The urethane

faces may be damaged.

The RiverPro electronics and transducer ceramics are mounted to

the transducer head. The numbers embossed on the end-cap and

transducer head indicate the beam number.

The RiverPro ADCP incorporates an internal GPS module intended

for GeoReference purposes. The RiverPro captures the GGA and

VTG NMEA strings from the internal GPS module and reports

them in the PD0 data stream using the general NMEA format.

WinRiver II provides status of this module and displays the data

during both data collection and playback.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 3

October 2017 RiverPro and RioPro ADCP Guide

RioPro Overview

The RioPro is an upgraded 1200 kHz WorkHorse Rio Grande system that contains an updated transducer

head, RiverPro electronics, and new end-cap. The system uses the original Rio Grande housing, shipping

case, and I/O cable. The standard acoustic frequency is four 1200 kHz Janus beams. See the Outline In-

stallation Drawings for dimensions and weights.

Picture Description

The Input/Output (I/O) cable connects the RioPro ADCP to the computer and external power supply. When the cable is not connected,

use the dummy plug to protect the connector.

The LEDs on the end-cap indicates the status of the RioPro system.

The I/O connector should not be exposed to extended periods of

heat or direct sunlight.

Always apply silicone lubricant before connecting the I/O cable

to the RioPro.

The RioPro is intended to be operated as a surface mounted system

only. No depth rating is provided.

The Thermistor measures the water temperature.

The orange urethane faces covers the transducer ceramics.

Never set the transducer on a hard surface. The urethane faces

may be damaged.

The RioPro electronics and transducer ceramics are mounted to the

transducer head. The numbers embossed on the end-cap and transducer head indicate the beam number.

The RioPro ADCP incorporates an internal GPS module intended for

GeoReference purposes. The RiverPro captures the GGA and VTG

NMEA strings from the internal GPS module and reports them in the

PD0 data stream using the general NMEA format. WinRiver II provides status of this module and displays the data during both data

collection and playback.

Page 4

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

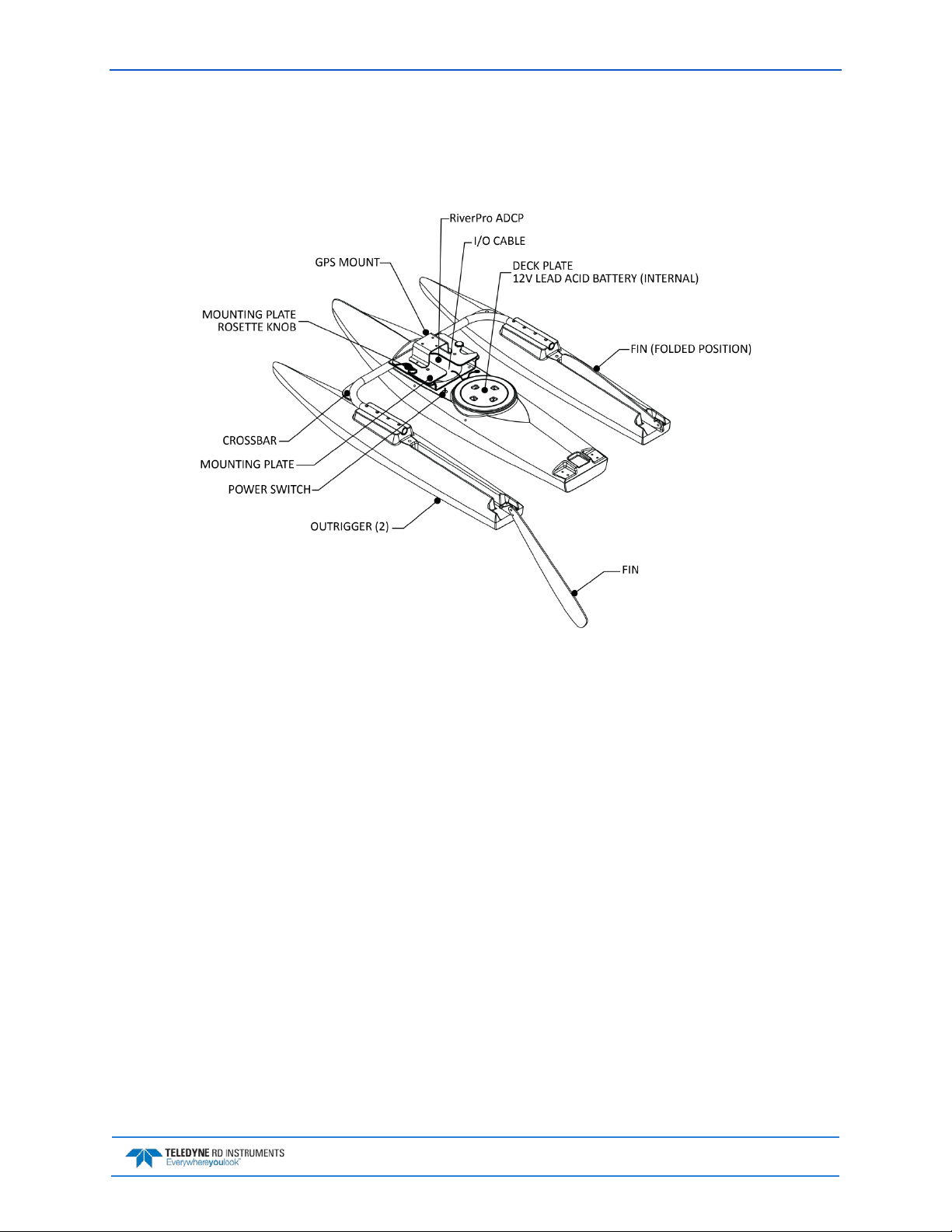

Boat Overview

The RiverRay/RiverPro/RioPro boat is designed to maintain the transducer at a constant depth in the water with minimal water flow disturbance.

Figure 1. RiverRay/RiverPro/RioPro Boat Overview

Computer Overview

TRDI designed the RiverPro/RioPro ADCP to use a Windows® compatible computer. The computer controls the RiverPro/RioPro and displays its data, usually through our WinRiver II or SxS Pro programs.

Minimum Computer Hardware Requirements:

• Windows 10®, Windows 8®, Windows 7® Desktop, Laptop, or Netbook computer

• Screen resolution above 1024x768

• One Serial Port (two or more High Speed UART Serial Port recommended)

• Bluetooth Interface or USB port

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 5

October 2017 RiverPro and RioPro ADCP Guide

Power Overview

The RiverPro/RioPro ADCP requires a DC supply between 10.5 volts and 18 volts. Either an external DC

power supply or battery can provide this power. If using a battery, use the largest rated amp-hour battery

as possible. A car battery should last one to two days powering a 1200 kHz ADCP.

Check that the battery voltage is above 10.5 Volts DC. RiverPro/RioPro ADCPs will work at

10.5 VDC with at least 400 milli amps; however, batteries with voltages below 11 VDC are at

The power supply must be able to handle the inrush current as well. Inrush current is the current required

to fully charge up the capacitors when power is applied to the RiverPro/RioPro. The capacitors provide a

store of energy for use during transmit. The inrush current is as high as 3 Amps rms. The RiverPro/RioPro will draw this amperage until its capacitors are fully charged.

If the power supply limits the current or the power drop on the cable is significant, then the power on cycle will take longer. It can take up to one minute. If the power shuts down during the inrush current draw,

this may not allow the RiverPro/RioPro’s electronics to start.

or near their end of life, and are approaching uselessness.

Auto-Adaptive Water Profiling Mode

The RiverPro/RioPro uses an auto-adaptive water profiling mode which automatically adjusts velocity

profiling parameters every ensemble (reading) based on the water depth and other characteristics to

maintain a balance between velocity precision, spatial resolution, and data storage requirements. This approach allows consistent data quality throughout a transect and discharge measurement regardless of

changes in the water depth or flow characteristics without the need for user intervention.

For more details please refer to the chapter on Water Profiling Modes in the WinRiver II User

Guide.

RiverPro/RioPro Options

• Maintenance Kit – This kit (P/N 75BK6032-00 for RiverPro, 757K6037-00 for RioPro) contains a

complete set of O-Rings and close-up hardware (see Maintenance Kit).

• Manual Profile Modes – These modes allows the RiverPro/RioPro to override the automatic profil-

ing mode and adds additional water profiling commands (see Water Profiling Commands). To

purchase a feature upgrade, please contact sales.

• Q-View Software – Q-View is designed for customers using TRDI’s discharge measurement prod-

ucts such as the RiverRay, RiverPro/RioPro, StreamPro, and Rio Grande ADCPs with the Win-

River II software to have easy access to an evaluation of the quality of collected data while they

are still in the field and back in the office. To purchase a registration code to enable the software,

please contact sales.

• SxS Pro – The SxS Pro software can be used in place of the Wi n Ri v er II software. To purchase a

registration code to enable the software’s full capability, please contact field service.

SxS Pro software and manuals can be downloaded at http://www.teledynemarine.com/rdi

Page 6

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

• GPS wiring and mounting kits – GPS wiring and mounting kits for the RiverPro/RioPro boat are

available for a variety of GPS systems. GPS wiring and mounting kits are normally ordered in conjunction with new RiverPro/RioPro systems and any required boat modifications are performed

at the factory. Common GPS wiring/mounting kits are shown below; additional kits and custom

configurations are available – consult TRDI for more information.

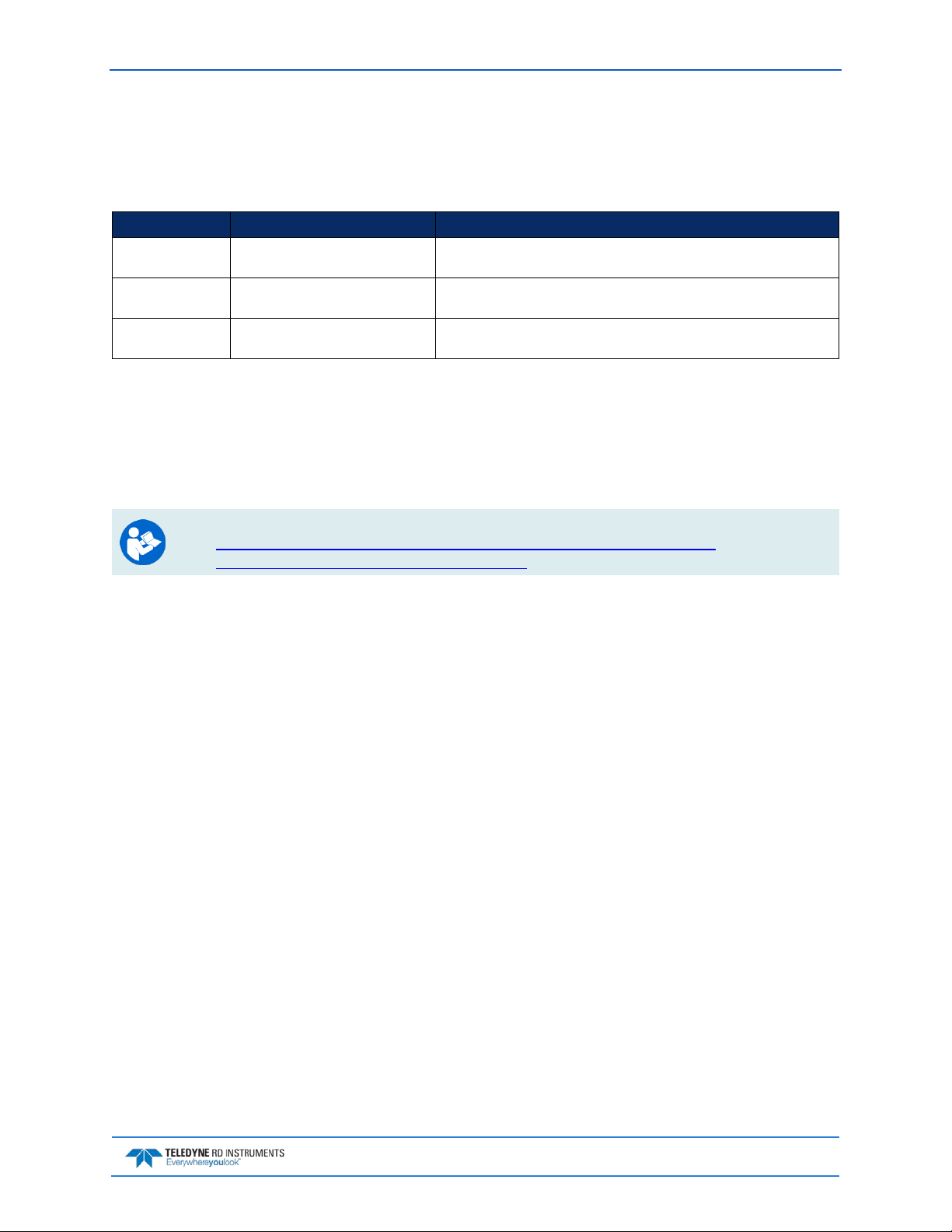

Part Number Supported GPS Systems Notes

GWIR-HA100

GWIR-HS321 Hemisphere S321

GWIR-KTA various

Hemisphere A101, A325, and

AtlasLink

Integrated antenna/receiver. Includes internal cable, external cable, and

GPS mount. GPS powered from battery in boat.

Includes internal cable, external cable, and GPS mount. Powered by internal

battery in GPS.

Includes (2) bulkhead connectors with attached internal cables only. GPS

mount and additional required interconnect cables sold separately.

• Hemisphere A101 DGPS kit –Hemisphere A101 Smart Antenna DGPS & configuration cable.

• Hemisphere Atlaslink DGPS kits – Atlas capable Hemisphere Atlaslink Smart Antenna DGPS with

configuration cable. L1/L2, GLONASS, and RTK support optionally available.

• Hemisphere S321 DGPS kits – Atlas capable Hemisphere S321 Smart Antenna DGPS with configu-

ration cable, integrated batteries, and integrated radio/cellular modem. L1/L2, GLONASS, and

RTK support optionally available.

GPS manuals and software are available for download:

http://www.hemispheregps.com/Support/PrecisionProductSupport/Antennas/

TechnicalDocumentation/tabid/553/Default.aspx

• High Speed Riverboat – For discharge measurements in applications with high water velocities or

challenging surface turbulence conditions where the standard boat does not provide stable operation. Can be used with RiverPro/RioPro, RiverRay, and Rio Grande ADCPs.

• Depth Sounder – General purpose/non survey grade depth sounder for measuring depth directly

under the RiverPro/RioPro or for redundancy with the bottom track depth measurement.

• Carrying Cases – Soft-sided and hard-sided carrying cases for the RiverPro/RioPro boat are availa-

ble. Contact TRDI for more information.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 7

October 2017 RiverPro and RioPro ADCP Guide

Setting up the RiverPro/RioPro System

Use this section to connect the RiverPro/RioPro to a computer and establish communications. Install the

RDI Tools software in order to communicate with the RiverPro/RioPro. For collecting data, install the

WinRiver II, SxS Pro (optional), and Q-View (optional) software.

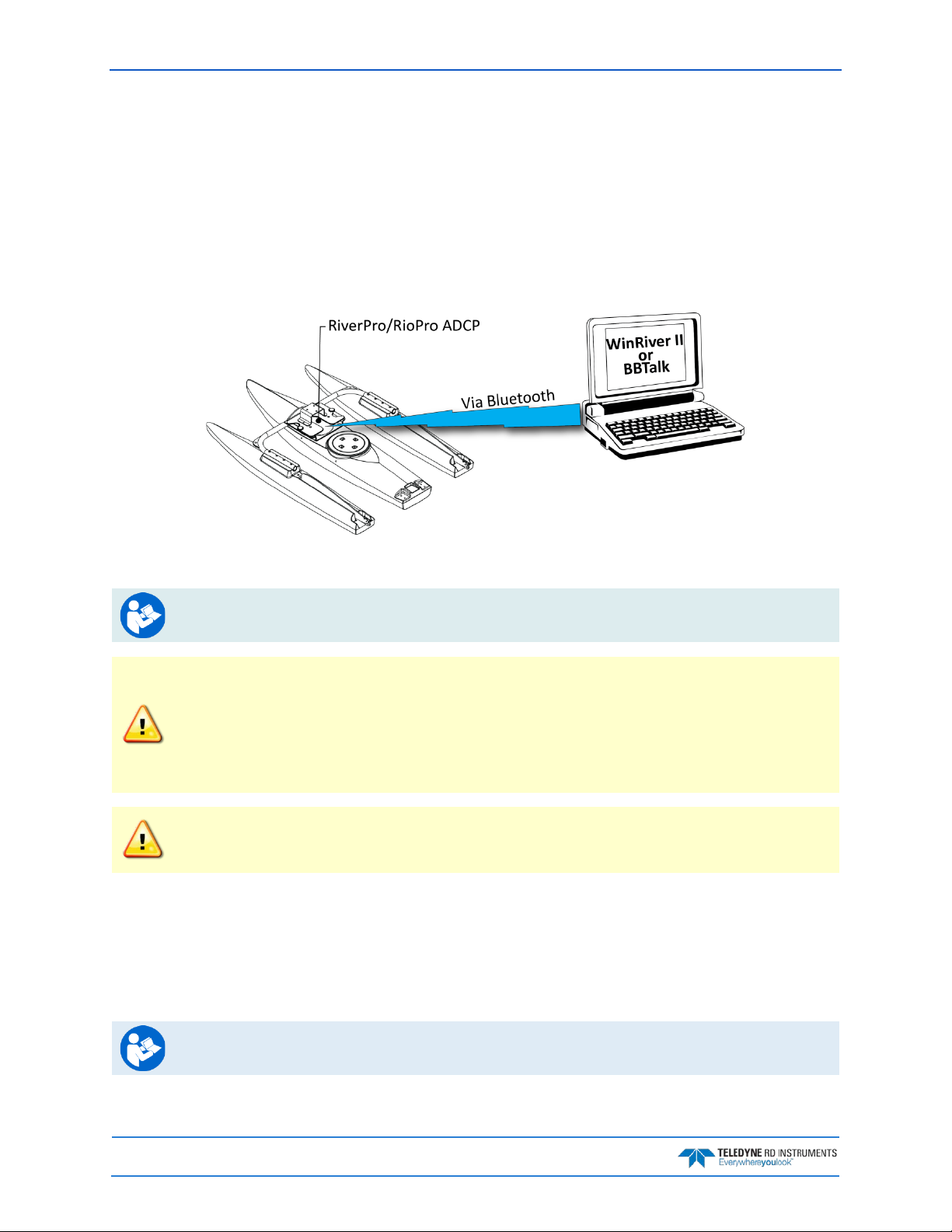

Bluetooth Connection

Use these next steps to setup a Bluetooth connection to the RiverPro/RioPro.

Figure 2. RiverPro/RioPro Connections – Bluetooth Connection

For instruction on using the SD1000U USB Bluetooth device, see the WinRiver II or SxS Pro

Software User’s Guide and the instructions and Bluetooth CD included with the device.

Some Bluetooth devices may ask for a passkey, PIN code, Pair code, Pairing code, Security

code, or Bluetooth code.

In all cases, the code is 0 or 0000 (zero, not the letter o).

To connect to a RiverPro/RioPro ADCP using the Bluetooth port:

1. Attach the boat’s cable to the ADCP’s connector and install the battery in the boat. Turn on the

boat power switch. Verify that both the red and green LEDs light. After a few seconds the red LED

should go out and the green LED will blink twice and then stay on. This indicates that the

RiverPro/RioPro self-test has passed.

The pin code is 0 for systems shipped prior to August 2017 and 0000 for systems shipped

after August 2017. If your system is sent in for repair and the Bluetooth module is replaced,

the pin code (if needed) will change from 0 to 0000.

For RiverPro/RioPro systems shipped after August 2017, the Microsoft® Bluetooth drivers

work with WinRiver II. For best results, use the USB Bluetooth device with the driver supplied

with the ADCP for WinRiver II.

2. Plug in the SD1000U device to a USB port and determine the Com port used.

See the WinRiver II SD1000U Bluetooth Communication Setup Card for instructions.

Page 8

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

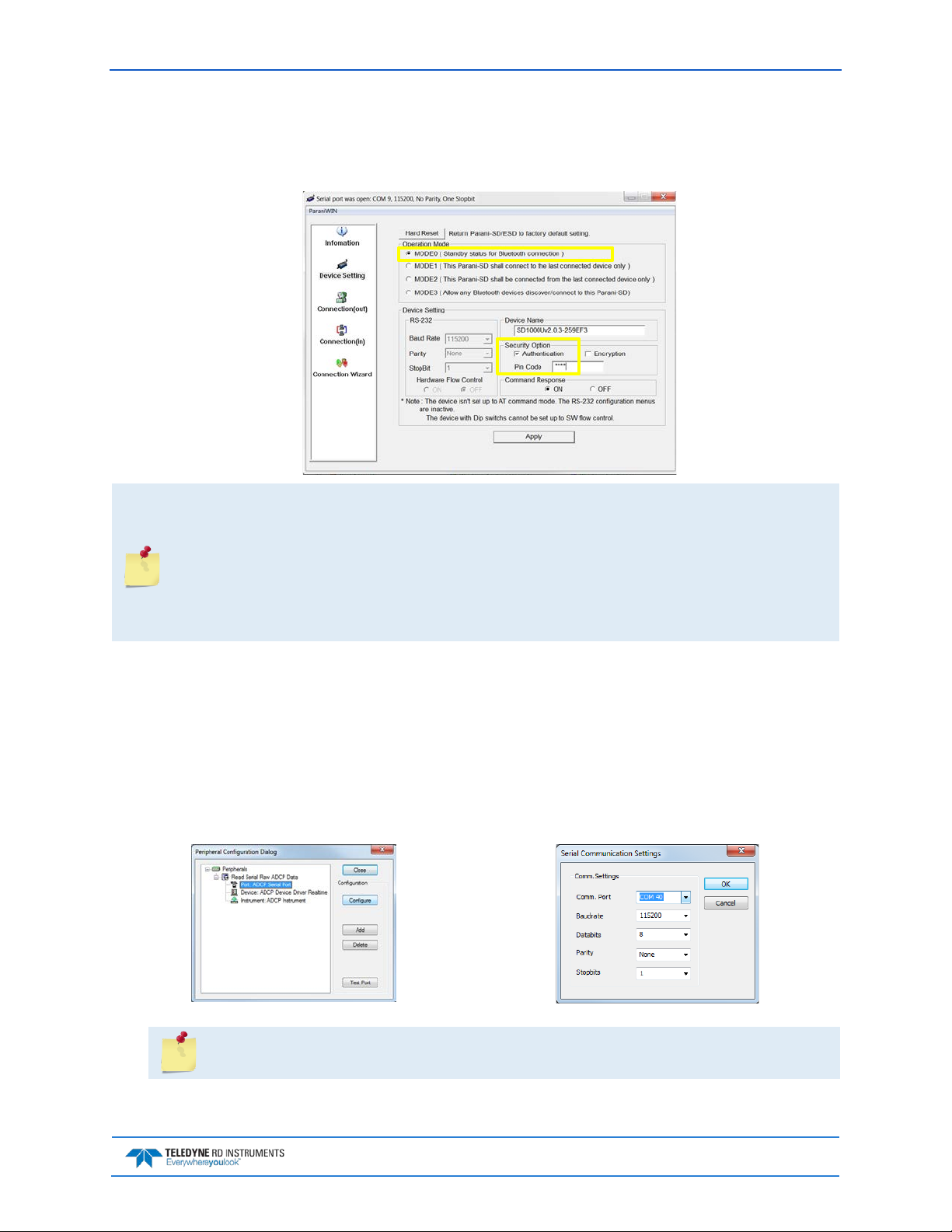

3. Run the ParaniWin program and connect to the ADCP. With the Bluetooth modules used since

August 2017 (or a repaired older unit where the Bluetooth module was replaced) select Mode 0

and you may or may not need to select Authentication (not Encryption). The Pin Code is 0000

(four zeros) and click Apply.

You may need to use either Authentication or no authentication when using ParaniWin with

an SD100U. Try one, and if does not work try the other. Use whichever one works going

forward.

The selection of Mode 0 or Mode 1 is independent of Authentication/no Authentication:

• Mode 1 automatically reconnects to the ADCP, but is otherwise identical to Mode 0.

• You must establish an outgoing connection before you can switch to Mode 1, but once in

Mode 1 you can connect to a different ADCP without switching back to Mode 0.

4. Exit the ParaniWin program.

5. Start WinRiver II.

6. On the Configure menu, select Peripherals.

7. Select Port: ADCP Serial Port and then click the Configure button.

8. Select the Comm. Port number as noted in step 2. The Baudrate must be set to 115200. Leave

the Databits, Parity, and Stopbits as shown.

9. Click OK to close the Serial Communication Settings screen.

Note it may take several seconds to accept the Comm. Port selection.

In this example, the Comm. Port is set to Com Port 40.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 9

October 2017 RiverPro and RioPro ADCP Guide

10. Click the Test Port button. The RiverPro/RioPro banner appears.

>break

RiverPro/RioPro

Teledyne RD Instruments (c) 2015

All rights reserved.

Firmware Version: 56.xx

>

11. Click the Close button to exit the Test Port Dialog.

12. Click the Close button once more to exit the Peripherals Configuration Dialog.

13. Start a new measurement in WinRiver II.

14. On the Configuration D i alo g, ensure the ADCP type matches the RiverPro/RioPro and the

indicator next to the RiverPro/RioPro is green. Verify the blue LED on the RiverPro/RioPro

ADCP is on.

Page 10

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

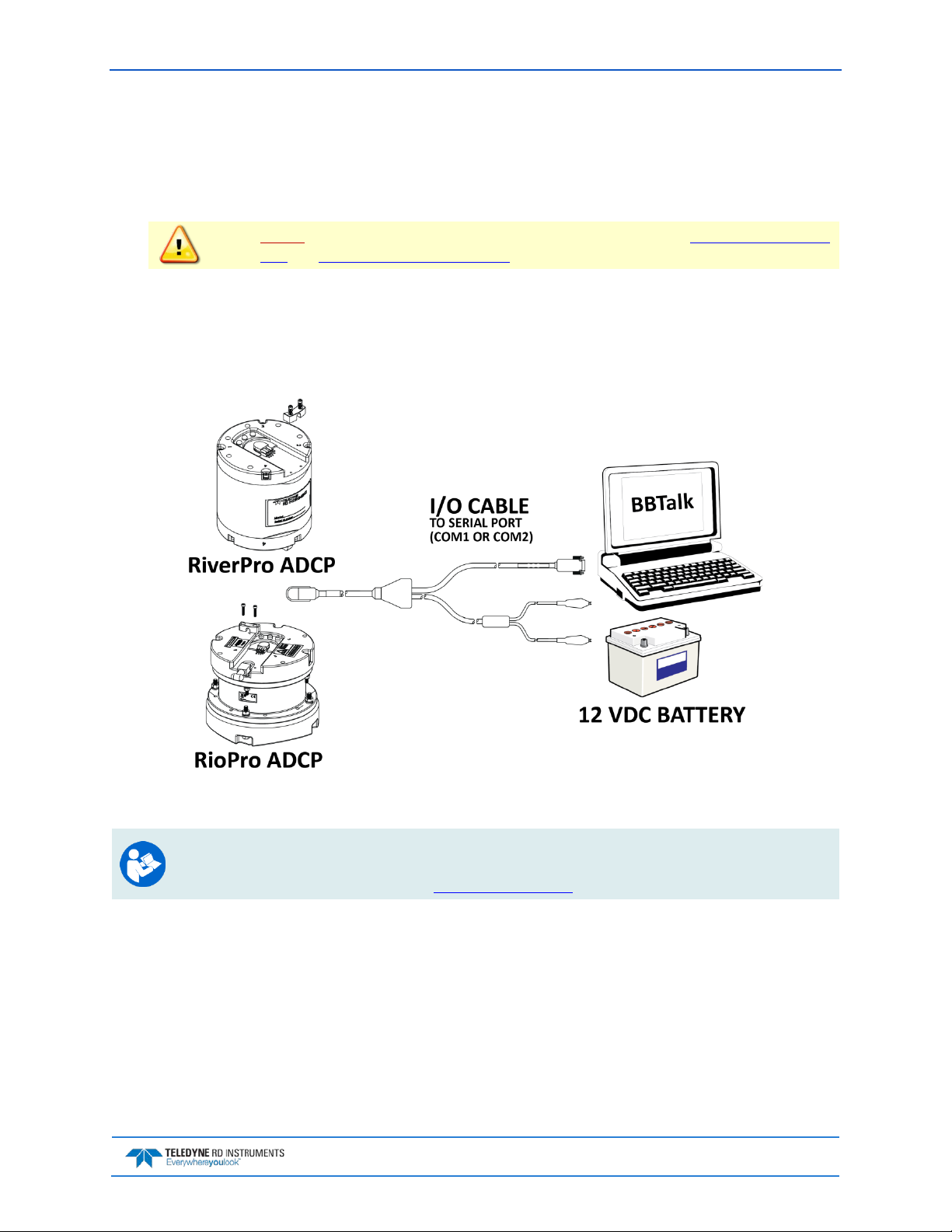

Serial Connection

To set up the RiverPro/RioPro ADCP:

1. The I/O cable connector must be lubricated before connecting. Connect the I/O cable to the

RiverPro/RioPro ADCP.

Always apply silicone lubricant before connecting the I/O cable. See I/O Cable and Dummy

Plug and I/O Cable Connector Lubricant for details.

2. Attach the I/O cable to the computer’s communication port. The standard communications settings are RS-232, 115200-baud, no parity, 8 data bits and 1 stop bit.

3. Connect a battery or DC power supply to the power connectors. Verify that both the red and green

LEDs light. After a few seconds the red LED should go out and the green LED will blink twice and

then stay on. This indicates that the RiverPro/RioPro self-test has passed.

Figure 3. RiverPro/RioPro Serial Connection

For information on how to set up communications with WinRiver II, see the WinRiver II Serial

Communications Setup Card or see Chapter 2 in the WinRiver II Software User's Guide.

For Bluetooth connection, see Bluetooth Connection.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 11

October 2017 RiverPro and RioPro ADCP Guide

Connecting to the RiverPro/RioPro

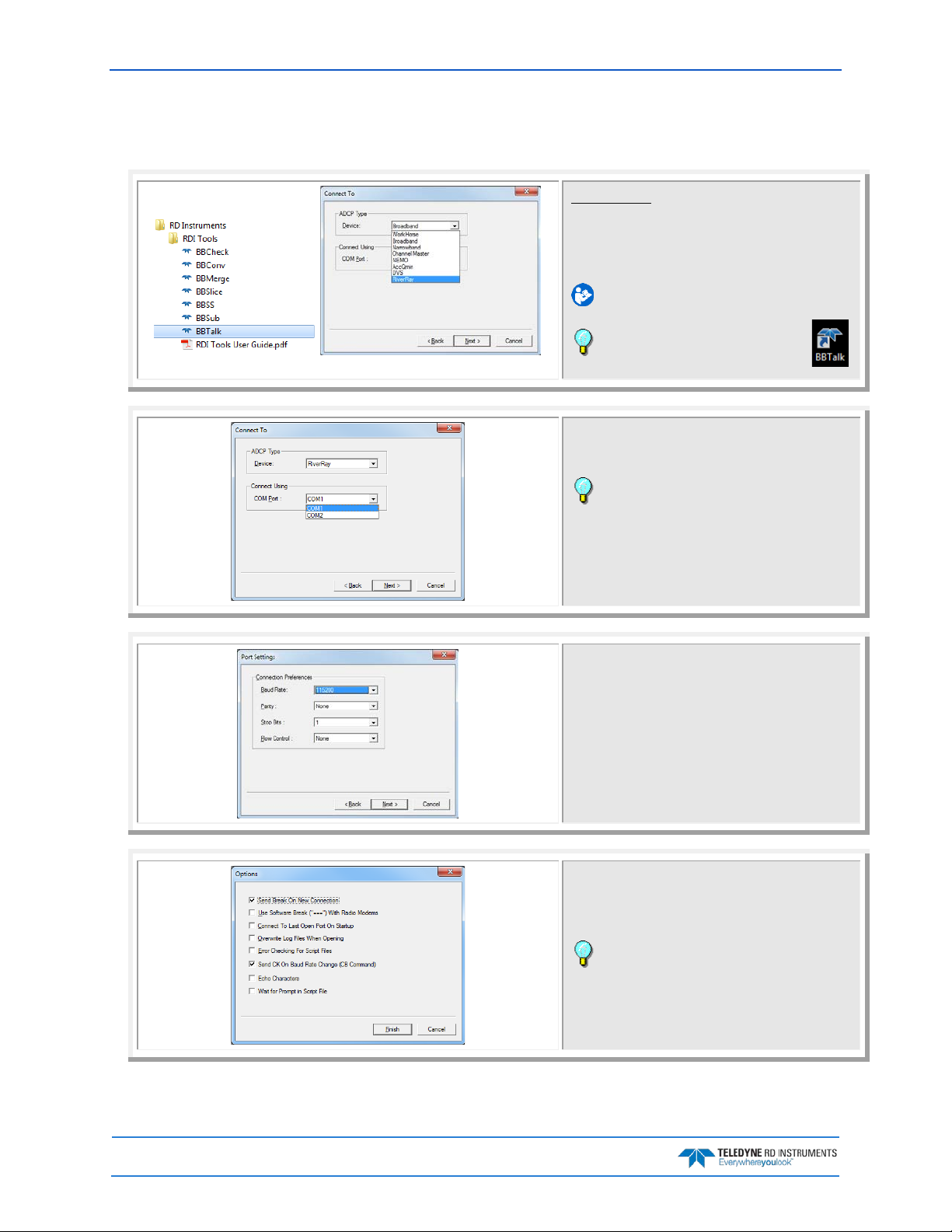

To connect to the RiverPro/RioPro ADCP using the BBTalk software:

Start BBTalk

Start the BBTalk program by clicking Start, All Programs, RD Instruments, RDI Tools, BBTalk.

On the Connect To screen, select RiverRay.

For help on using BBTalk, see the RDI Tools User’s

Guide.

Use the BBTalk desktop icon to start

BBTalk.

Select the COM port the RiverPro/RioPro ADCP cable is

connected to.

Click Next.

BBTalk can be used with Bluetooth communica-

tions. Right-click on the RDI RPro icon in the Bluetooth

management software and make sure that that it is

connected and verify what COM Port is used.

Enter the Baud Rate, Parity, Stop Bits, and Flow Con-

trol. If you are unsure of the settings, leave them at

the default settings as shown.

Click Next.

Page 12

Check Send Break On New Connection and Send CK

on Baud Rate Change (CB Command).

Click Finish.

If a Bluetooth connection is used, check the Use

Software Break (“===”) With Radio Modems box.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

RioPro Banner

RioPro

Teledyne RD Instruments (c) 2015

All rights reserved.

Firmware Version: 56.03

>

RiverPro Banner

RiverPro

Teledyne RD Instruments (c) 2015

All rights reserved.

Firmware Version: 56.03

>

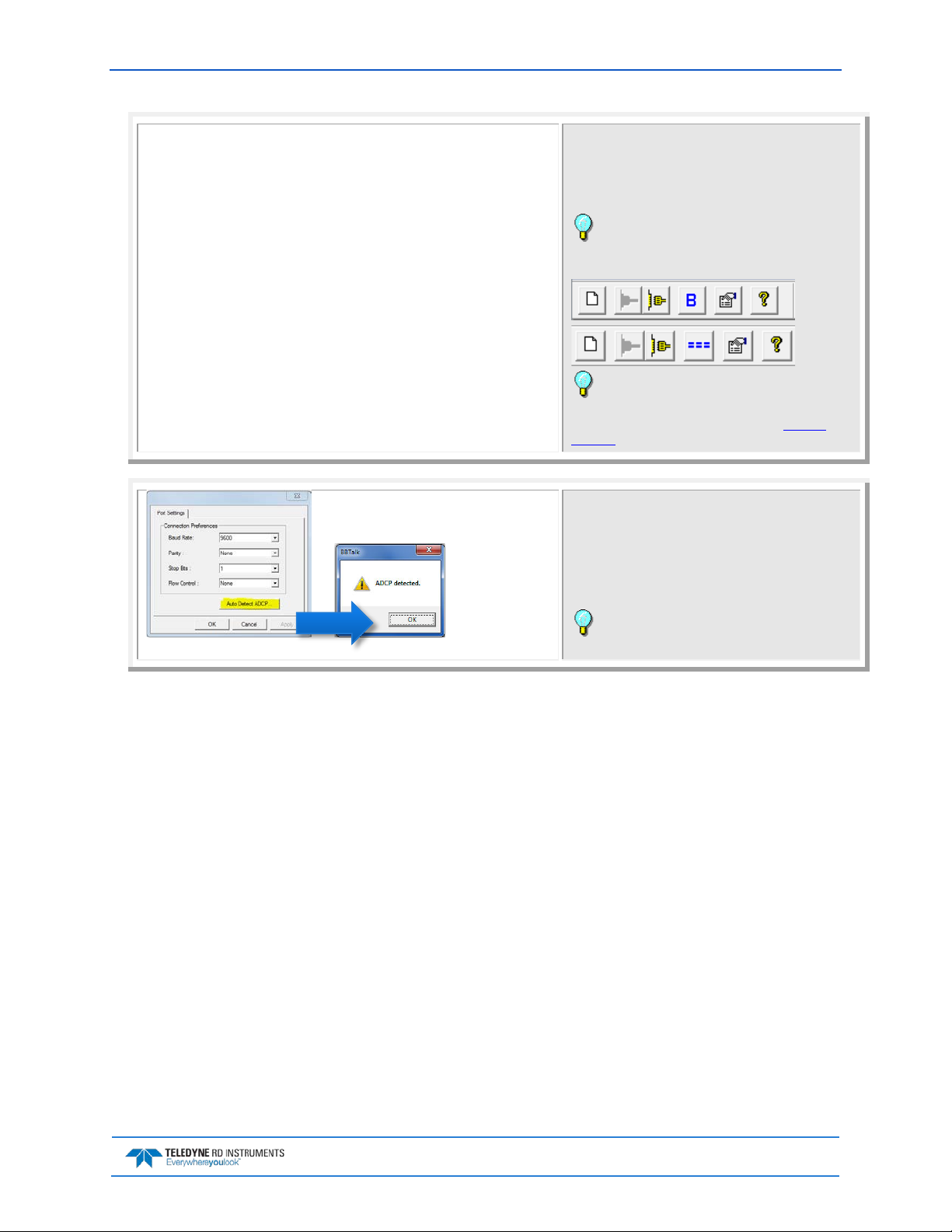

On the File menu, click Send A Break. Pressing the End

key will also send a break or press the === button or B

on the Toolbar.

The banner message should appear on the log file window.

The BBTalk toolbar will display === if it is config-

ured for using Software Breaks or B if it is configured

to send a Hard Break.

If the RiverPro/RioPro ADCP does not respond,

check the serial port, cables, DC power supply or battery connection. If necessary, refer to the Trouble-

shooting section.

If the banner is not readable or visible:

On the File menu, click Properties.

Click the Auto Detect ADCP button.

Click OK when the RiverPro/RioPro is detected. Try to

wake up the RiverPro/RioPro again.

Both BBTalk and the RiverPro/RioPro must use

the same Baud rate.

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 13

October 2017 RiverPro and RioPro ADCP Guide

RiverPro

>cb?

Changing the Baud Rate in the ADCPs

The RiverPro/RioPro can be set to communicate at baud rates from 1200 to 115200. The factory default

baud rate is always 115200 baud. The baud rate is controlled via the CB-command. The following procedure explains how to set the baud rate and save it in the RiverPro/RioPro. This procedure assumes using

the program BBTalk that is supplied by Teledyne RD Instruments.

Teledyne RD Instruments (c) 2015

All rights reserved.

Firmware Version: 56.xx

>

>cr1

[Parameters set to FACTORY defaults]

BAUD RATE CB-command

1200 CB111

2400 CB211

4800 CB311

9600 CB411

19200 CB511

38400 CB611

57600 CB711

115200 CB811 (Default)

CB = 411 ----------------- Serial Port Control (Baud

[4=9600]; Par; Stop)

>cb811

>CK

[Parameters saved as USER defaults]

>cb?

CB = 811 ----------------- Serial Port Control (Baud

[8=115200]; Par; Stop)

>

Connect the RiverPro/RioPro to the computer and apply power.

Start the BBTalk program and establish communica-

tions with the RiverPro/RioPro.

Wake up the RiverPro/RioPro by sending a break signal

with the End key.

At the ">" prompt in the communication window, type

CR1 then press the Enter key. This will set the

RiverPro/RioPro to the factory default settings.

Send the CB-command that selects the baud rate you

wish. The table on the left shows the CB-command settings for different baud rates with no parity and 1 stop

bit.

For example, to change the baud rate to 115200, at

the ">" prompt in the communication window, type

cb811 then press the Enter key.

The CB? command will identify the communication setting.

BBTalk will send the command CK to save the new

baud rate setting.

Exit BBTalk.

The RiverPro/RioPro is now set for the new baud rate.

The baud rate will stay at this setting until changed

again with the CB command.

Exit BBTalk so the communication port is available for use with other programs.

Page 14

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

RiverPro and RioPro ADCP Guide October 2017

RiverPro/RioPro Recorder

The recorder contains approximately 16 megabytes of solid-state nonvolatile memory, which can be used

to record data. If more data is collected than fits in the memory, the newest data will not be recorded.

Once the recorder fills up, the recorder MUST be erased before re-deploying the RiverPro/RioPro (start

pinging again).

If the RiverPro/RioPro is set to record data (MR1) and the recorder is full, the RiverPro/RioPro

will not start pinging and will return a RECORDER NOT READY message.

Use BBTalk version 3.08 or greater. Older versions of BBTalk do not have the RiverRay device.

See the RDI Tools User’s Guide for details on using BBTalk.

Enabling the Loop Recorder

The loop recorder is off by default.

To enable the loop recorder:

1. Start BBTalk. Configure BBTalk to connect to a RiverPro/RioPro ADCP type device.

2. Send the MR1 command to enable the recorder.

Using the loop recorder will slow down the RiverPro/RioPro’s ping rate.

3. When done recording data, send the MR0 command to turn the loop recorder off.

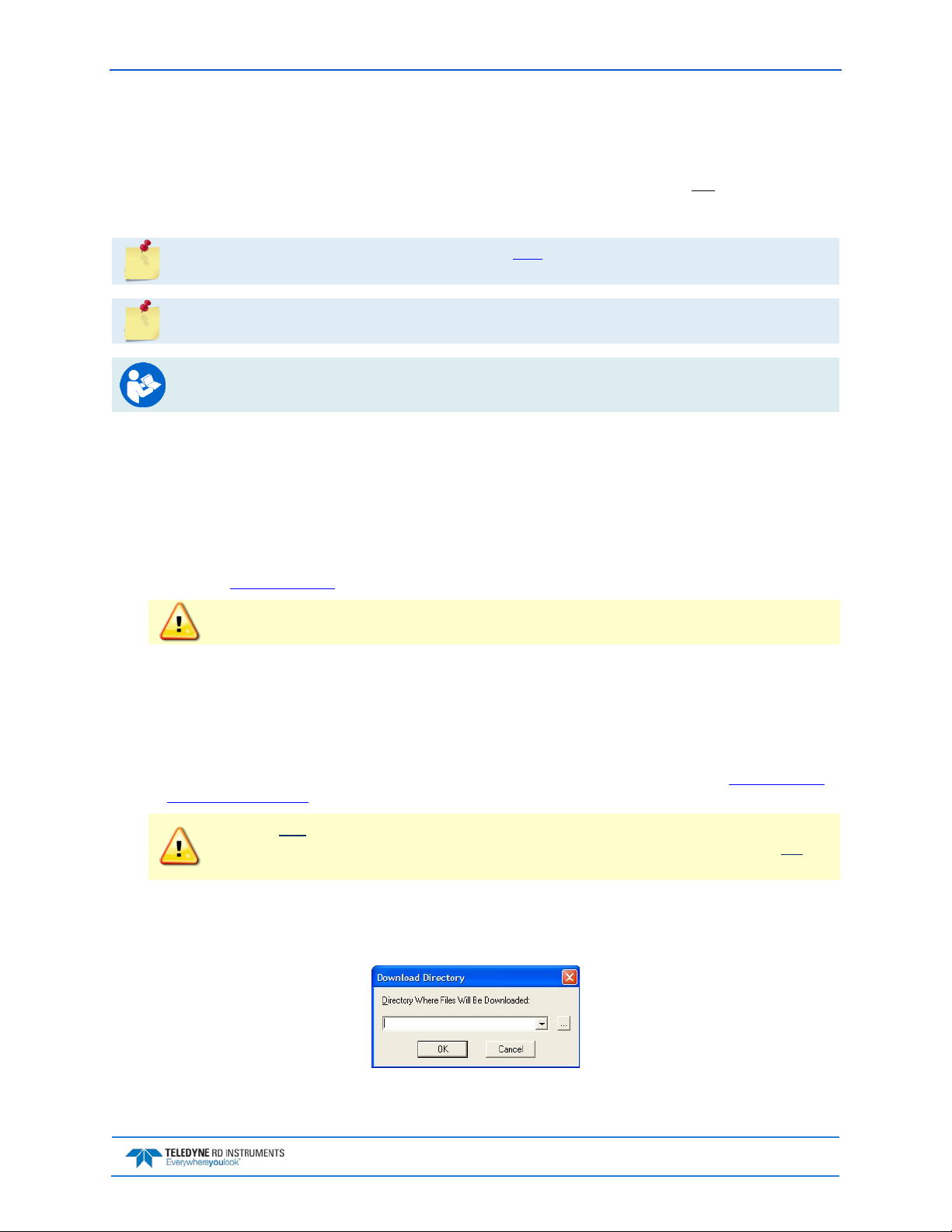

Recovering Data from the Loop Recorder

To recover data:

1. Start BBTalk. Configure BBTalk to connect to a RiverRay ADCP type device (see Connecting to

the RiverPro/RioPro).

Make sure to select RiverRay as the Device. BBTalk will communicate with the

RiverPro/RioPro if Workhorse or another ADCP type is selected as the device, but will not be

able to recover the recorder.

2. On the File menu, click Recover Loop Recorder.

3. Enter the directory where the files will be downloaded. Click the “…” button to browse for the di-

rectory. Click OK.

Figure 4. Download Directory

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 15

October 2017 RiverPro and RioPro ADCP Guide

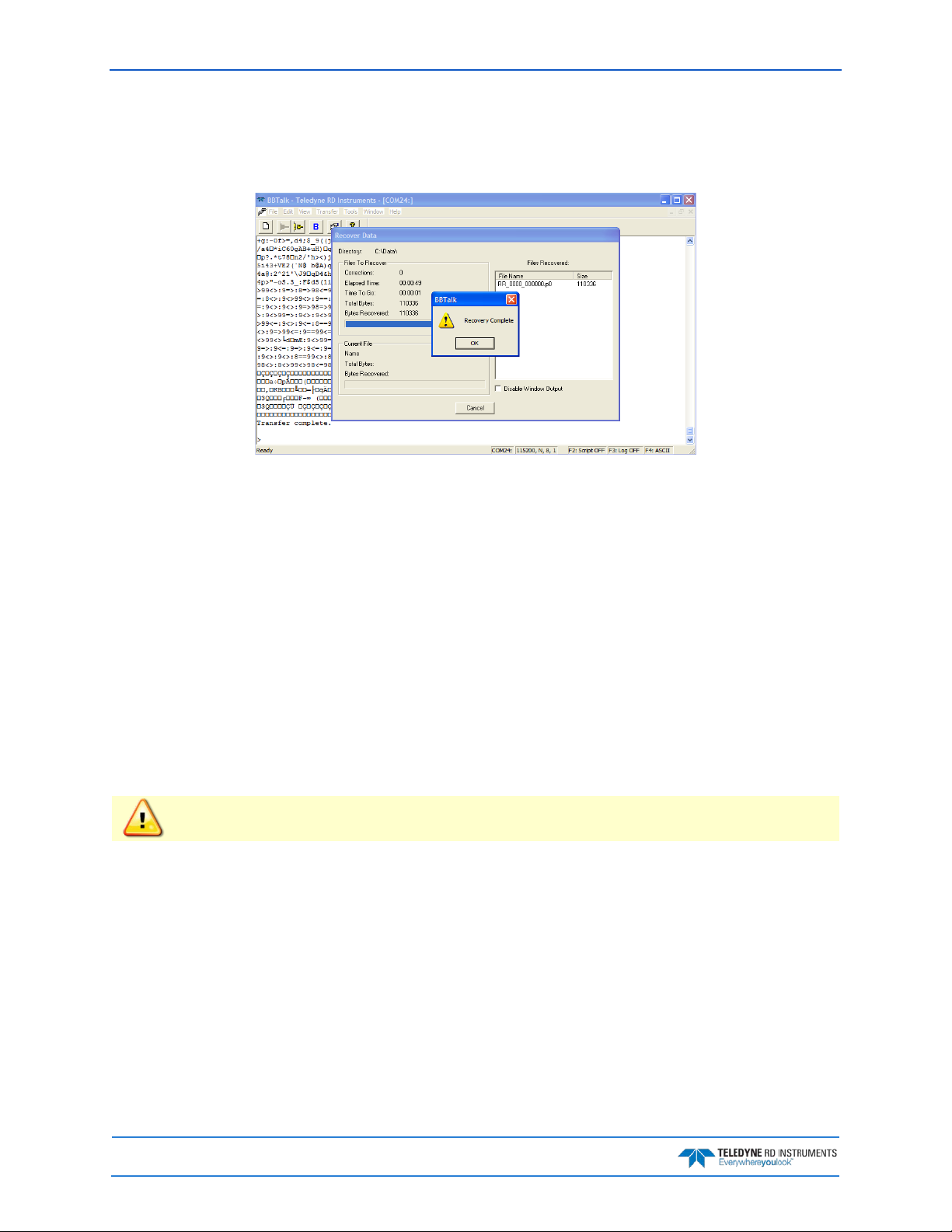

4. BBTalk displays current protocol status, filename being received, total size of receiving file and

current number of bytes received (see Figure 5, page 16).

5. When recovery is complete, click OK.

Figure 5. Recover Loop Recorder

Erasing Data from the Loop Recorder

To erase data:

1. Start BBTalk. Configure BBTalk to connect to a RiverRay ADCP type device.

2. At the “>” prompt, type ME ErAsE. To make it more difficult to accidentally erase the data, the

word “erase” must be typed with exactly one space after the “ME” (which is not case sensitive) and

with alternating upper and lower case letters, as shown.