Page 1

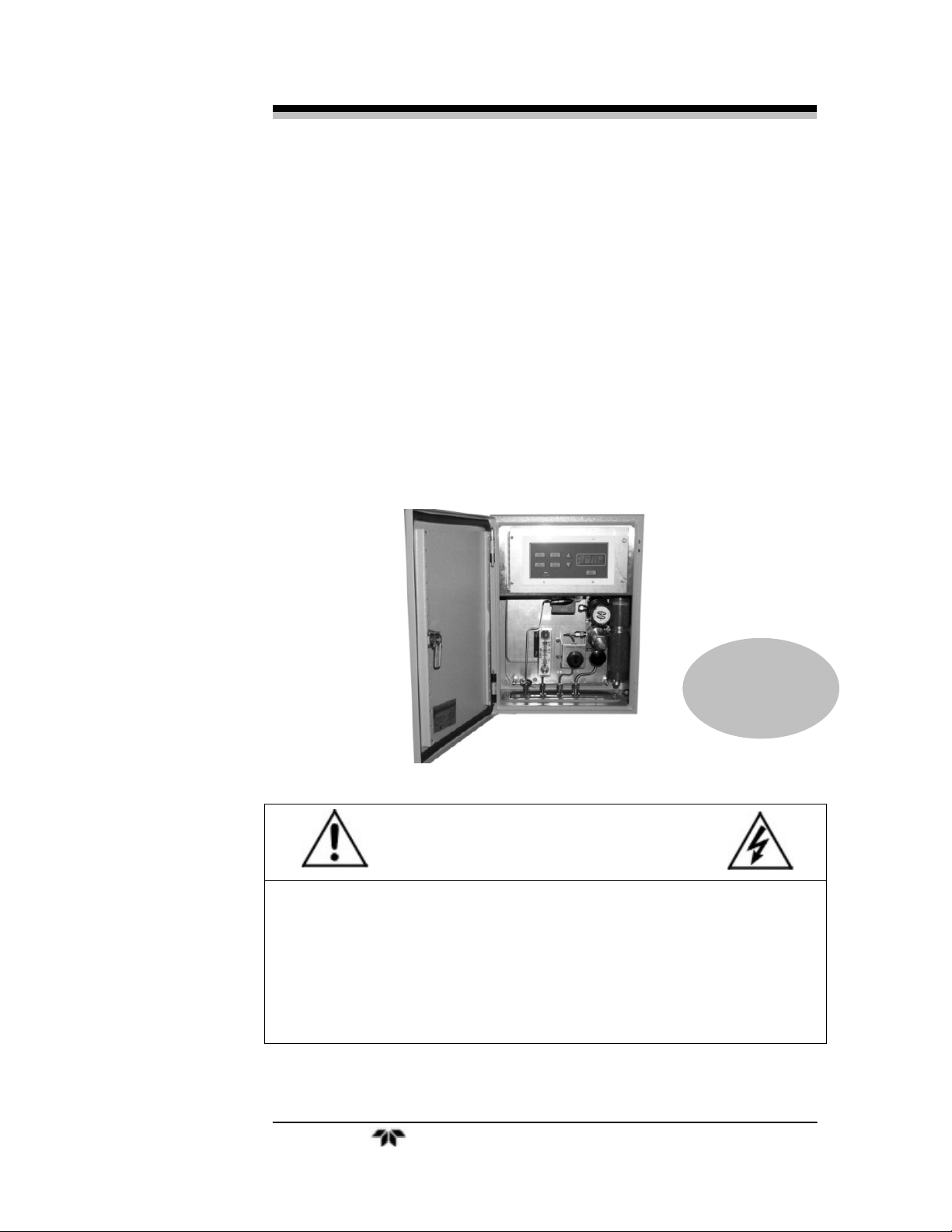

Trace Oxygen Analyzer

OPERATING INSTRUCTIONS FOR

MODEL OT-3MODEL OT-3

Trace Oxygen Analyzer

P/N M74173

10/28/2001

ECO#

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments i

Page 2

Model OT-3

Copyright © 2000 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

Page 3

Trace Oxygen Analyzer

Specific Model Information

The instrument for which this manual was supplied may

incorporate one or more options not supplied in the standard instrument.

Commonly available options are listed below, with check boxes. Any

that are incorporated in the instrument for which this manual is supplied

are indicated by a check mark in the box.

Instrument Serial Number: _______________________

Teledyne Analytical Instruments iii

Page 4

Model OT-3

Important Notice

Model OT-3 complies with all of the requirements of the

Commonwealth of Europe (CE) for Radio Frequency Interference,

Electromagnetic Interference (RFI/EMI), and Low Voltage Directive

(LVD).

The following International Symbols are used throughout the

Instruction Manual for your visual and immediate warnings and when

you have to attend CAUTION while operating the instrument:

No

Symbol

STAND-BY: Instrument is on Stand-by, but circuit is

active

GROUND: Protective Earth

CAUTION: The operator needs to refer to the manual

for further information. Failure to do so may

compromise the safe operation of the equipment.

CAUTION: Risk of Electrical Shock

Note: Additional information in the form of notes are

included which emphasize specific topics regarding the

present discussion.

Teledyne Analytical Instruments iv

Page 5

Trace Oxygen Analyzer

This instrument is designed for CL1 DIV II hazardous locations. It

is the customer's responsibility to ensure safety especially when

combustible gases are being analyzed since the potential of gas

leaks always exist.

The customer should ensure that the principles of operating this

equipment are well understood by the user. Misuse of this product in

any manner, tampering with its components, or unauthorized

substitution of any component may adversely affect the safety of this

instrument.

Since the use of this instrument is beyond the control of Teledyne, no

responsibility by Teledyne, its affiliates, and agents for damage or

injury from misuse or neglect of this equipment is implied or assumed.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration and operation of your new analyzer. Please

read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Page 6

Model OT-3

Table of Contents

List of Figures.............................................................................viii

Introduction....................................................................................1

1.1 Overview 1

1.2 Main Features of the Analyzer 1

1.3 Front Panel Description 2

1.4 Rear Panel Description 4

Operational Theory........................................................................6

2.1 Introduction 6

2.2 Micro-fuel Cell Sensor 6

2.2.1 Principles of Operation 6

2.2.2 Anatomy of a Micro-fuel Cell 7

2.2.3 Electrochemical Reactions 8

2.2.4 The Effect of Pressure 9

2.2.5 Calibration Characteristics 9

2.3 Electronics 10

2.3.1 General 10

2.3.2 Signal Processing 11

Installation ...................................................................................13

3.1 Unpacking the Analyzer 13

3.2 Location and Mounting 14

3.2.2 Installing the Micro-fuel Cell 14

3.3 Electrical Connections 14

3.3.1 Primary Input Power 15

3.3.2 Analog Outputs 15

3.3.3 Alarm Relays 16

3.3.4 Relay Ratings 17

3.3.5 Solid State Relay Output 18

Teledyne Analytical Instruments vi

Page 7

Trace Oxygen Analyzer

3.4 Gas Connections 18

3.5 Sample System 20

3.6 Installation Checklist 21

Operation......................................................................................23

4.1 Introduction 23

4.2 Using the Function and Data Entry Buttons 24

4.3 Setting the Analysis Ranges 24

4.3.1 HI Range 25

4.3.2 LO Range 25

4.4 Setting the Alarm Setpoints 25

4.4.1 Set Alarm 1 25

4.4.2 Set Alarm 2 26

4.4.3 Power Failure Alarm 26

4.5 Alarm Delay 26

4.6 Keypad Lockout 27

4.7 Selecting a Fixed Range or Autoranging 28

4.8 Calibration 28

4.9 Displaying Percent & PPM on the LED Display 29

4.10 Supplementary Information 29

Maintenance.................................................................................31

5.1 Replacing the Fuse 31

5.2 Sensor Installation or Replacement 32

5.2.1 When to Replace a Sensor 32

5.2.2 Ordering and Handling of Spare Sensors 33

5.2.3 Removing the Micro-fuel Cell 33

5.2.4 Installing a Micro-fuel Cell 34

5.2.5 Cell Warranty Conditions 35

Appendix ......................................................................................36

A.1 Specifications 36

A.2 Spare Parts List 37

A.3 Reference Drawing 38

A.4 Miscellaneous 38

Teledyne Analytical Instruments vii

Page 8

Model OT-3

List of Figures

Figure 1-1: Front Panel...................................................................3

Figure 1-2: Rear Panel (AC Version)..............................................5

Figure 1-3: Rear Panel (DC Version)..............................................5

Figure 2-1: Cross Section of a Micro-fuel Cell................................7

Figure 2-2: Characteristic MFC Input/Output Curve .....................10

Figure 2-3: Block Diagram of the Signal Processing Electronics..11

Figure 3-1: Electrical Connectors for AC Control Unit ..................15

Figure 3-2: Contact ID for FAILSAFE Relay Operation ..............166

Figure 3-3: Gas Connections.........................................................19

Figure 3-4: OT-3 Sample System.................................................21

Figure 4-1: Front Panel Control and Indicators.............................23

Figure 5-1: AC Fuse Replacement...............................................32

Teledyne Analytical Instruments viii

Page 9

Trace Oxygen Analyzer Introduction

Introduction

1.1 Overview

The Teledyne Electronic Technologies Analytical Instruments

(TET/AI) Model OT-3 is a microprocessor-based trace oxygen analyzer

for real-time measurement of the parts per million of oxygen in inert

gases, or in a wide variety of gas mixtures. It features simple operation,

fast response, and a compact, rugged construction. Typical applications

of the Model OT-3 include monitoring natural gas pipelines, wellheads,

and compressor/blowers.

1.2 Main Features of the Analyzer

• The main features of the analyzer include:

• Insta-Trace sensor technology

• Stainless steel sample system (with PVC scrubber and

Nylon cell block)

• Pressure regulator

• Coalescing filter

• Acid gas scrubber (clear, rebuildable )

• Flow control restrictor

• Sample shut off valve

• Bypass/filter drain valve

• Flowmeter

• Viewing window

• Sample/Span selector valve

• NEMA 4 enclosure (15.8” x 11.8” x 8.1”).

• Viewing window 3300/OT-3 Control Unit

Teledyne Analytical Instruments 1

Page 10

Introduction OT-3

The Model 3300/OT-3 Control Unit has its own long list of features

including:

• Keypad lockout feature

• Two user settable fail-safe alarms (with a user settable 0-20

min. time delay )

• Two user settable ranges (from 0-10PPM – 0-9999PPM)

with user selectable auto-ranging.

• Power fail alarm

• SSR power output (Solid State Relay power available on AC

control units)

• Micro processor based electronics 8 bit ADC & 18 bit DAC

• Large 3 ½ digit LED O2 concentration read-out

• 7 button user interface keypad

• Alarm condition indicator LED

• 100-240 VAC 50/60 Hz power (optional 9-36VDC )

• 0-10 VDC output

• 4-20 mA output

• 0-10 VDC range ID output

• Electronic temperature compensation

• Optional RS323 interface

• Accuracy: +/- 2% of range (at constant temp.)

• Response time: 90% in 65 sec of less @ 25 degrees C

• Temperature range (0-50 degrees C)

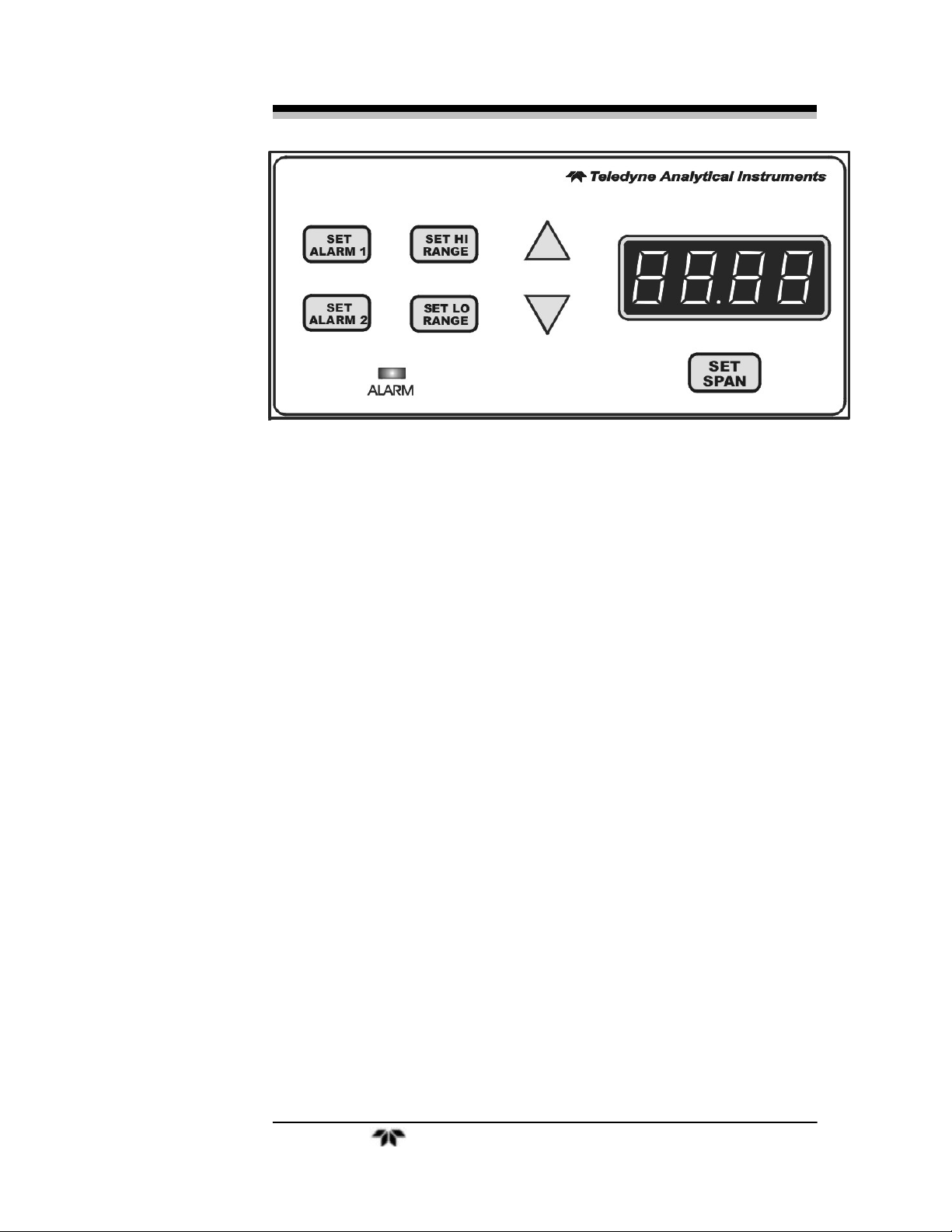

1.3 Front Panel Description

All controls are accessible from the front panel. See Figure 1-1.

The front panel has seven push-button membrane switches, a digital

meter, and an alarm indicator LED for operating the analyzer. These

features are described briefly here and in greater detail in Chapter 4,

Operation.

Teledyne Analytical Instruments 2

Page 11

Trace Oxygen Analyzer Introduction

Figure 1-1: Front Panel

Function Keys:

Seven push-button membrane switches are used to select the function

performed by the analyzer:

Set Alarm 1: Set Alarm 1 Hi or Low, and the concentration at

which alarm 1 activates.

Set Alarm 2: Set the Alarm 2 Hi or Low, and the concentration

to which alarm 2 activates.

Set HI Range: Set the high analysis range for the instrument (up

to 0-9999ppm).

Set LO Range: Set the low analysis range for the instrument

(down to 0-10ppm).

Set Span: Span calibrate the analyzer.

Data Entry Keys: Two push-button membrane switches are used to

manually change measurement parameters of the instrument as they are

displayed on the LED meter readout:

Up Arrow: Increment values of parameters upwards as they are

displayed on the LED readout.

Down Arrow: Increment values of parameters downwards as

they are displayed on the LED readout.

Digital LED Readout: The digital display is a LED device that

produces large, bright, 7-segment numbers that are legible in any

lighting environment. It has two functions:

Teledyne Analytical Instruments 3

Page 12

Introduction OT-3

Meter Readout: As the meter readout, it displays the oxygen

concentration currently being measured.

Measurement Parameters Readout:

It also displays user-definable alarm setpoints, ranges, and span

calibration point when they are being checked or changed.

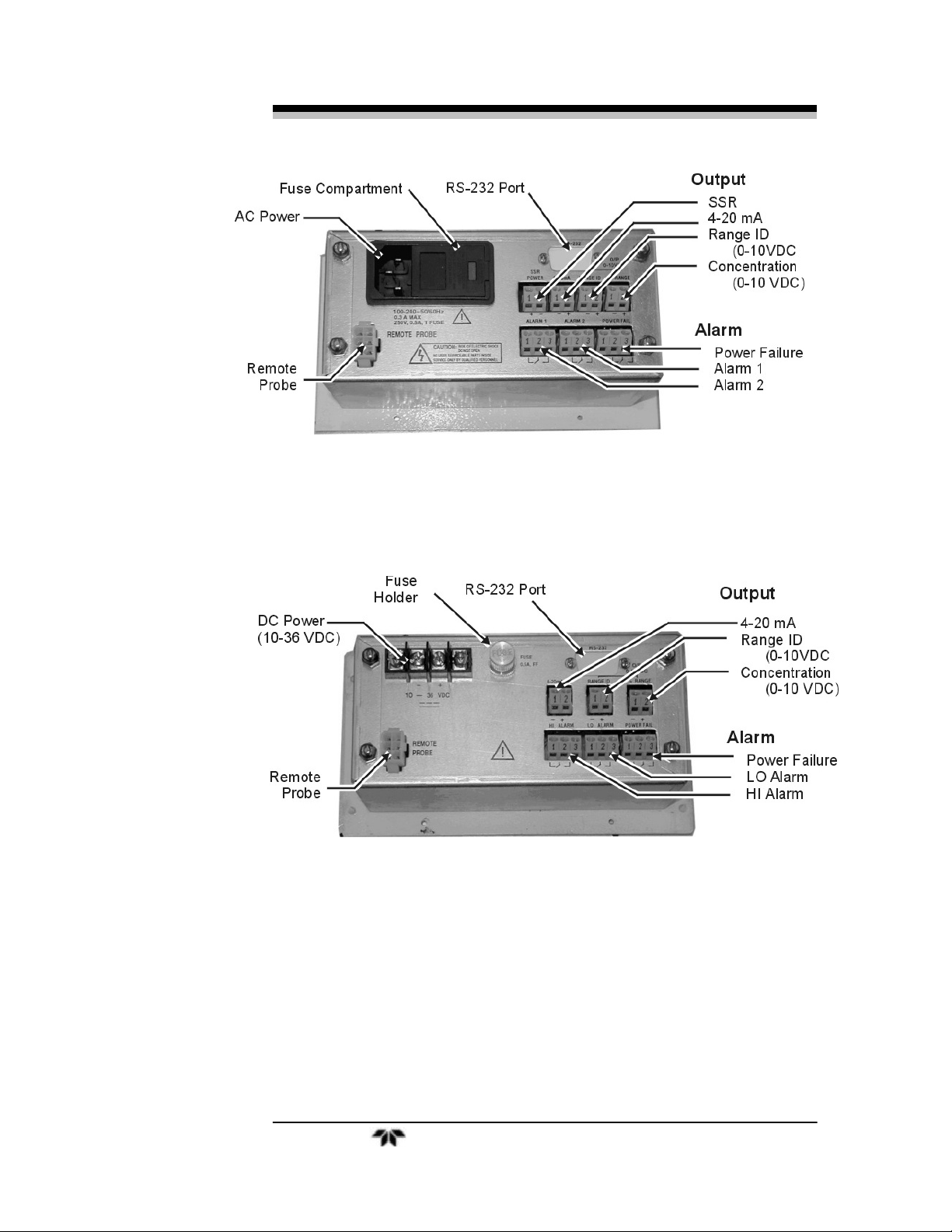

1.4 Rear Panel Description

The rear panel contains the electrical input and output connectors.

The connectors are described briefly here and in detail in the Installation

chapter of this manual. The rear panels for the AC and DC versions are

different. Figure 1-2 shows the AC version while Figure 1-3 shows the

DC version.

Power Connection AC version:

100–240 VAC, at 50/60Hz. The connector housing includes the

fuse holder and AC Power cord receptacle.

Fuse Holder DC version:

Replacing the fuse is described in Chapter 5, Maintenance.

Analog Outputs:

0–10 VDC concentration output.

0–10 VDC range ID (or optional overrange) output.

4–20 mA DC concentration output, negative ground.

Alarm Connections:

Alarm 1, Alarm 2, and Power Failure Alarm connections.

Sensor Connector:

Internal Sampling System, Sensor Connector.

RS-232 Port:

Serial Digital Output of concentration and range signals.

SSR POWER (AC POWER UNITS ONLY):

+15 VDC power output for powering Solid State Relays.

Teledyne Analytical Instruments 4

Page 13

Trace Oxygen Analyzer Introduction

Figure 1-2: Rear Panel (AC Version)

Figure 1-3: Rear Panel (DC Version)

Teledyne Analytical Instruments 5

Page 14

Installation OT-3

Operational Theory

2.1 Introduction

The analyzer is composed of two subsystems:

• 3300/OT-3 control unit

• OT-3 sample sys.

The OT-3 sample system is designed to accept the sample gas and

direct it to the sensitive surface of the Micro-fuel Cell sensor. The

Micro-fuel Cell is an electrochemical galvanic device that translates the

amount of oxygen present in the sample into an electrical current.

The 3300/OT-3 control unit processes the sensor output and

translates it into electrical concentration, range, and alarm outputs, and a

trace oxygen meter readout. It contains a microcontroller that manages

all signal processing, input/output, and display functions for the

analyzer.

2.2 Micro-fuel Cell Sensor

2.2.1 Principles of Operation

The oxygen sensor used in the Model OT-3 is a Micro-fuel Cell

designed and manufactured by TAI. It is a sealed, disposable

electrochemical transducer.

The active components of the Micro-fuel Cell are a cathode, an

anode, and the aqueous electrolyte in which they are immersed. The cell

converts the energy from a chemical reaction into an electrical potential

that can produce a current in an external electrical circuit. Its action is

similar to that of a battery.

There is, however, an important difference in the operation of a

battery as compared to the Micro-fuel Cell: In the battery, all reactants

are stored within the cell, whereas in the Micro-fuel Cell, one of the

reactants (oxygen) comes from outside the device as a constituent of the

sample gas being analyzed. The Micro-fuel Cell is therefore a hybrid

Teledyne Analytical Instruments 6

Page 15

Trace Oxygen Analyzer Installation

between a battery and a true fuel cell. (All of the reactants are stored

externally in a true fuel cell.)

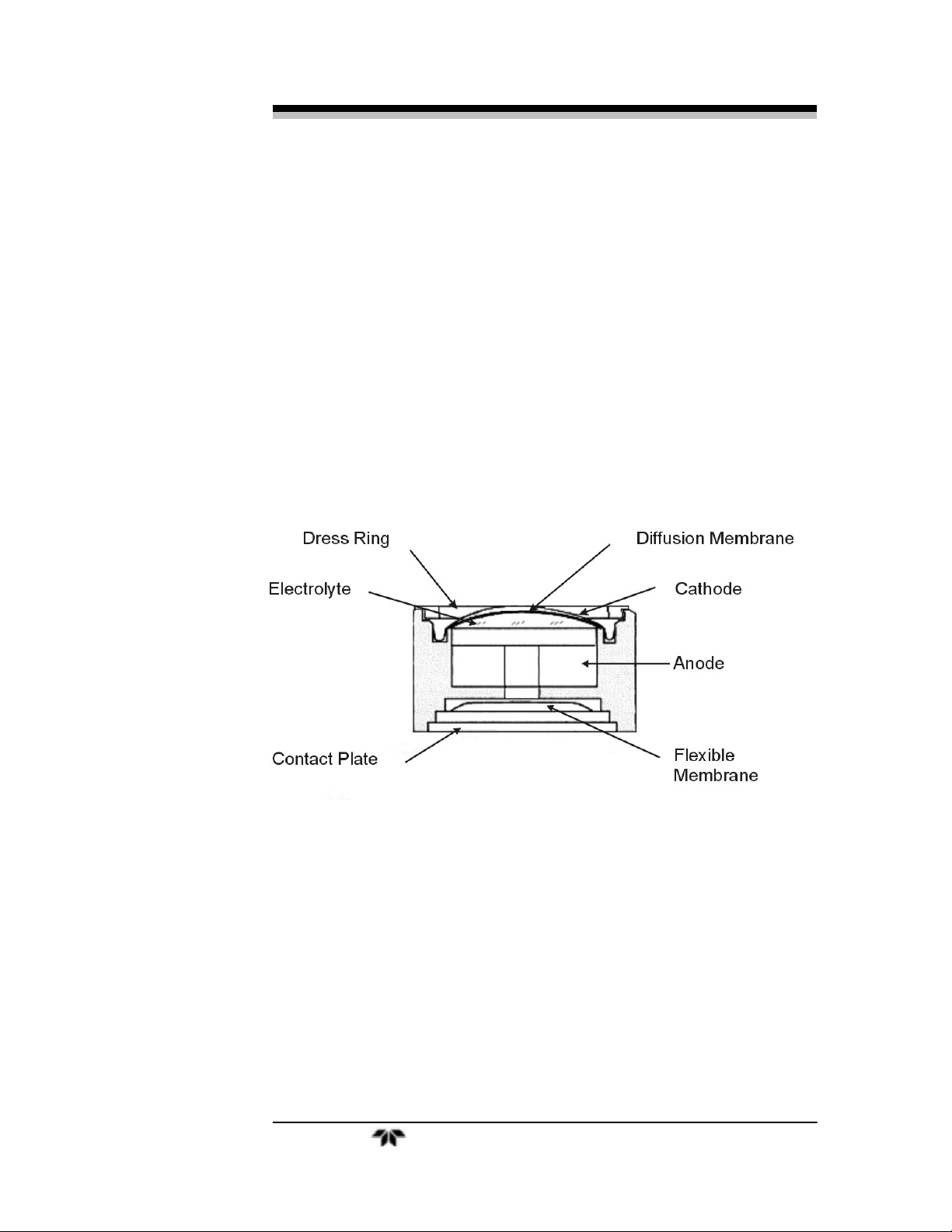

2.2.2 Anatomy of a Micro-fuel Cell

The Micro-fuel Cell is made of extremely inert plastic (which can

be placed confidently in practically any environment or sample stream).

It is effectively sealed, though one end is a gas permeable membrane.

At the permeable end a screen retains a diffusion membrane through

which the oxygen passes into the cell. At the other end of the cell is a

printed circuit board with concentric gold contacts.

Refer to Figure 2-1, Cross Section of a Micro-fuel Cell, which

illustrates the following internal description.

Figure 2-1: Cross Section of a Micro-fuel Cell

At the sensing end of the cell is a diffusion membrane, whose

thickness is very accurately controlled. Near the diffusion membrane lies

the oxygen sensing element—the cathode.

The anode structure is larger than the cathode. It is made of lead

and is designed to maximize the amount of metal available for chemical

reaction.

The space between the active elements is filled by a structure

saturated with electrolyte. Cathode and anode are wet by this common

pool. They each have a conductor connecting them, through some

Teledyne Analytical Instruments 7

Page 16

Installation OT-3

electrical circuitry, to one of the external contacts in the connector

receptacle, which is on the top of the cell.

2.2.3 Electrochemical Reactions

The sample gas diffuses through the Teflon membrane. Any

oxygen in the sample gas is reduced on the surface of the cathode by the

following half reaction:

O2 +2H2O + 4e- —> 4OH

-

(cathode)

In this reaction, four electrons combine with one oxygen

molecule—in the presence of water from the electrolyte—to produce

four hydroxyl ions.

When the oxygen is reduced at the cathode, lead is simultaneously

oxidized at the anode by the following half reaction:

Pb + 2OH- —> Pb

+2

+ H

O + 2e

2

-

(anode)

In this reaction, two electrons are transferred for each atom of lead

that is oxidized. Therefore it takes two of the above anode reactions to

balance one cathode reaction and transfer four electrons.

The electrons released at the surface of the anode flow to the cathode

surface when an external electrical path is provided. The current is

proportional to the amount of oxygen reaching the cathode. It is measured

and used to determine the oxygen concentration in the gas mixture.

The overall reaction for the fuel cell is the SUM of the half

reactions above, or:

2Pb + O

—> 2PbO

2

These reactions will hold as long as no gaseous components

capable of oxidizing lead—such as iodine, bromine, chlorine and

fluorine—are present in the sample.

The output of the fuel cell is limited by:

(1) the amount of oxygen in the cell at the time and

(2) the amount of stored anode material.

In the absence of oxygen (or any gases capable of oxidizing lead),

no current is generated.

Teledyne Analytical Instruments 8

Page 17

Trace Oxygen Analyzer Installation

2.2.4 The Effect of Pressure

In order to state the amount of oxygen present in the sample as a

percentage of the gas mixture, it is necessary that the sample diffuse into

the cell under constant pressure.

If the total pressure increases, the rate that oxygen reaches the

cathode through the diffusing membrane will also increase. The electron

transfer, and therefore the external current, will increase, even though

the oxygen concentration of the sample has not changed. It is therefore

important that the sample pressure at the fuel cell (usually vent pressure)

remain constant between calibrations.

2.2.5 Calibration Characteristics

Given that the total pressure of the sample gas at the surface of the

Micro-fuel Cell input is constant, a convenient characteristic of the cell

is that the current produced in an external circuit is directly proportional

to the rate at which oxygen molecules reach the cathode. This rate is

directly proportional to the concentration of oxygen in the gaseous

mixture. In other words it has a linear characteristic curve, as shown in

Figure 2-2. Measuring circuits do not have to compensate for

nonlinearity.

In addition, since there is zero output in the absence oxygen, the

characteristic curve is close to an absolute zero. The cell itself does not

need to be zeroed on ranges as sensitive as 0-10 ppm. The electronics

are zeroed to compensate for zero offsets in the electronics. (The

electronics is zeroed automatically when the instrument power is turned

on during the Self-Test.)

As the cell reaches the end of its useful life, the slope seen in

Figure 2-2 decreases. As this occurs, the span adjustments will become

larger.

Teledyne Analytical Instruments 9

Page 18

Installation OT-3

Figure 2-2: Characteristic MFC Input/Output Curve

2.3 Electronics

2.3.1 General

The signal processing uses an Intel microcontroller with on-board

RAM and ROM to control all signal processing, input/output, and

display functions for the analyzer. System power is supplied from a

universal power supply module designed to be compatible with most

international power sources.

The power supply circuitry is on the Power Supply PCB, which is

mounted vertically, just behind the rear panel of the Control Unit.

The signal processing electronics including the sensor amplifier,

microcontroller, analog to digital, and digital to analog converters are

located on the Main PCB, which is mounted vertically, just behind the

front panel of the Control Unit.

Teledyne Analytical Instruments 10

Page 19

Trace Oxygen Analyzer Installation

2.3.2 Signal Processing

Figure 2-3 is a block diagram of the signal processing electronics

described below.

Figure 2-3: Block Diagram of the Signal Processing Electronics

In the presence of oxygen the cell generates a current. The sensor

has an internal thermistor compensation network.

The output of the sensor is converted to voltage millivolt range.

This output is fed to a voltage amplifier. The internal thermistor network

provides temperature compensation of the sensor output. The resistance

of the network changes with temperature, compensating for the changes

of the Micro-fuel Cell output to temperature.

The output from the temperature compensation amplifier is sent to

an analog to digital converter (ADC), and the resulting digital

concentration signal is sent to the microcontroller.

The digital concentration signal along with input from the front

panel buttons (KEYBOARD) is processed by the microcontroller, and

appropriate output signals are directed to the display and alarm relays.

Teledyne Analytical Instruments 11

Page 20

Installation OT-3

The same digital information is also sent to a 12-bit digital to analog

converter (DAC) that produces the 0-10 V dc analog concentration

signal and the 0-10 VDC analog range ID output. A voltage to current

converter (E–I CONV) produces the 4-20 mA DC analog concentration

signal.

Teledyne Analytical Instruments 12

Page 21

Trace Oxygen Analyzer Installation

Installation

Installation of the analyzer includes:

• Unpacking the system.

• Installing the Micro-fuel Cell

• Making the electrical connections.

• Making the gas connections.

• Testing the installation.

CAUTION: READ THIS ENTIRE CHAPTER BEFORE INSTALLING

THE UNITS.

SAMPLE MUST BE FREE OF ENTRAINED SOLIDS

OR WATER. HOWEVER, A HIGH HUMIDITY (NON–

CONDENSING) SAMPLE IS IDEAL, SINCE IT WILL

PREVENT WATER LOSS FROM THE CELL

ELECTROLYTE.

THE MICRO-FUEL CELL SENSOR ELECTROLYTE IS

CAUSTIC. DO NOT ATTEMPT TO OPEN IT. LEAKING

OR EXHAUSTED CELLS SHOULD BE DISPOSED OF

IN ACCORDANCE WITH LOCAL REGULATIONS.

REFER TO THE MATERIAL SAFETY DATA SHEET IN

THE APPENDIX.

ANY DAMAGE OR SCARRING OF THE DELICATE

PERMEABLE MEMBRANE ON THE SENSING END

OF THE CELL WILL REQUIRE CELL REPLACEMENT.

PREVENT CONTACT WITH MEMBRANE BY ANY

SOLID OBJECT.

3.1 Unpacking the Analyzer

As soon as you receive the instrument, carefully unpack and inspect

the Unit, and any included accessories for damage. Immediately report

any damage to the shipping agent. The analyzer is shipped with all the

materials you need to install and prepare the system for operation.

Teledyne Analytical Instruments 13

Page 22

Installation OT-3

CAUTION: DO NOT DISTURB THE INTEGRITY OF THE CELL

PACKAGE UNTIL THE CELL IS TO ACTUALLY BE

USED. IF THE CELL PACKAGE IS PUNCTURED AND

AIR IS PERMITTED TO ENTER, CELL-LIFE WILL BE

COMPROMISED.

3.2 Location and Mounting

This instrument should be installed at viewing level either indoors

or sheltered from the moisture and the elements and mounted so it won’t

be subject to vibration. The ambient temperature should be within the

range of 0-50°C (32-122°F). For the best performance, do not exceed

40°C (104°F).

In choosing a location for the analyzer, select a site that is as close

as possible to the sample extraction point. This will enhance the overall

instrument response time. If the analyzer is to be mounted in direct

sunlight, minimize the solar heating by orienting it in a north or south

facing direction.

3.2.2 Installing the Micro-fuel Cell

A Micro-fuel Cell is included as a separate item. It must be

installed prior to instrument use.

Also, once it is expended, or if the instrument has been idle for a

lengthy period, the Micro-fuel Cell will need to be replaced.

During the Installation and/or Replacement of the MFC, the

membrane surface MUST ALLWAYS FACE DOWNWARD

TOWARD THE CELL CAP. The concentric gold contacts must

face up.

To install or replace the Micro-fuel Cell, follow the procedures in

Chapter 5, Maintenance.

3.3 Electrical Connections

Figure 3-1 shows the Model 3300T/OT-3 rear panel of the control

unit. (See Figure 1-3 for DC version). To gain access to the terminal

blocks, the analyzer door screws must be loosened, and the door opened.

Teledyne Analytical Instruments 14

Page 23

Trace Oxygen Analyzer Installation

Figure 3-1: Electrical Connectors for AC Control Unit

3.3.1 Primary Input Power

A detachable power cord is installed directly into the Control Unit

and connects to a three pin terminal block on the rear panel. The

terminal block is provided for customer AC wiring.

The universal power supply allows direct connection to any 100-240 VAC,

50/60Hz power source. The fuse block, to the right of the power cord

receptacle, accepts two 5x20mm 0.5 A, 250V, IEC time-lag (T) fuse.

(See Fuse Replacement in chapter 5, Maintenance.)

For DC powered units, the customers DC power wiring is attached

to the two pin terminal block located on the rear of the control unit. See

Figure 1-3.

3.3.2 Analog Outputs

There are three DC (four on AC units) output signal connectors

with screw terminals on the panel. There are two wires per output with

the polarity noted. See Figure 3-1. The outputs are:

• 0–10 V % Range: Voltage rises with increasing oxygen

concentration, from 0 V at 0 percent oxygen to 10 V at full

scale percent oxygen. (Full scale = 100% of programmed

range.)

• 0–10 V Range ID:3.33 V = Low Range, 6.66 V = High

Range, 10 V = Air Cal Range.

Teledyne Analytical Instruments 15

Page 24

Installation OT-3

• 4–20 mA % Range: Current increases with increasing oxygen

concentration, from 4 mA at 0 percent oxygen to 20 mA at

full scale percent oxygen. (Full scale = 100% of programmed

range.)

• SSR POWER (AC units only): Provides 15vdc at 698 ohm

impedance to power external Solid State Relays.

3.3.3 Alarm Relays

The three alarm-circuit connectors are screw terminals for making

connections to internal alarm relay contacts. There is one set of contacts

for each type of alarm. Contacts are Form C, with normally open and

normally closed contact connections capable of switching up to 0.2

ampere at 125 VAC into a resistive load (0.9A for 30 VDC).

The alarm relay circuits are designed for failsafe operation. In

failsafe operation, the relays are energized during normal operation. If

power fails the relays de-energize (alarms activated).

The contact connections are indicated diagrammatically on the rear

panel as Normally Closed, Common, and Normally Open. Figure 3-2

explains how these act in failsafe operation.

Alarm 1 and Alarm 2 can both be configured as either HI or LO. A

HI alarm will activate when concentration is above threshold, while a

LO alarm will activate when concentration is below threshhold.

Figure 3-2: Contact ID for FAILSAFE Relay Operation

Teledyne Analytical Instruments 16

Page 25

Trace Oxygen Analyzer Installation

The specific descriptions for each type of alarm are as follows:

Power Fail Alarm: This alarm changes state when the AC or DC

system power is lost.

Alarm #1: Programmable as high or low alarm (actuates when

concentration is above threshold). Can be set anywhere between 0

and 9999ppm, but must be set ABOVE the threshold set for Alarm 2.

Alarm #2: Programmable as high or low alarm (actuates when

concentration is below threshold). Can be set anywhere from 0 to

9999ppm.

CAUTION: THERE COULD BE HAZARDOUS VOLTAGE AT THE

ALARMS TERMINALS, EVEN WHEN POWER IS

REMOVED FROM THE INSTRUMENT.

3.3.4 Relay Ratings

The 3300/OT-3 has 2 relay ratings.

• Higher rating —established by the manufacturer

DC Rating: 0-30 VDC maximum @ 2.0 Amps

(resistive)

AC Rating: 125 VAC maximum @ 0.5 Amps

minimum reliable switching rating:

10 µA @ 10mV

• Lower rating—maximum safe rating for Cl 1 Div 2 Group

C or D hazardous location

DC Rating: 0-30 VDC maximum @ 0.9 Amps

maximum

AC Rating: 125 VAC maximum @ 0.2 Amps

maximum

minimum reliable switching rating:

10 µA @ 10mV

To safely use the alarm relays in a hazardous location, the

characteristics of both the switched voltage and the components or load

being operated must be known. The alarm relays must not be attached to

Teledyne Analytical Instruments 17

Page 26

Installation OT-3

any unknown power source, or any load or device that may exceed the

safe use ratings for Cl 1 Div 2 Group C & D as listed above. It should

also be understood that that these alarm relays can not be used to operate

any inductive components such as mechanical relays or motors if this

instrument is used in a hazardous location. The higher contact ratings

are applicable only when this system is installed in a general

purpose, non-hazardous location.

It is possible to switch loads that exceed the above ratings by using

an external solid state relay (SSR). This type of relay is a fully potted

semiconductor device with no moving parts. They are non-inductive and

typically require 3-30 VDC at 5 mA to operate. These devices can safely

control loads in excess of 6 amperes in both non-hazardous and

hazardous areas. SSRs are available to handle either AC or DC loads.

3.3.5 Solid State Relay Output

The AC version of the 3300/OT-3 control unit is equipped with a

SSR output on the rear panel. This output provides 15 VDC and ground

through a 689 ohm resistor during an alarm condition. The output as

configured is set for failsafe operation however, it can be set to nonfailsafe by changing an internal jumper.

The output sends a command signal to drive external SSRs (not

provided) during an alarm event. Using external SSRs will allow the

3300/OT-3 Control Unit to operate loads which exceed the safe use

limits listed above for both non-hazardous and hazardous applications.

For DC versions of the 3300/OT-3 Control Unit, the DC service

power can be switched through the alarm relays to operate a DC external

SSR.

3.4 Gas Connections

The standard Model OT-3 incorporates a stainless steel sample

system with a PVC scrubber and nylon cell block. All gas connections

are made using the 1/8” stainless steel tube fittings provided on the

bottom of the enclosure ( ¼” on the drain). There are three separate gas

connections to be made plus a liquid drain connection:

• Sample gas

• Span gas (recommended concentration of 80-90% of the

primary range of interest, balance N2—typically 8-9 ppm or

80-90 ppm O2 in N2)

Teledyne Analytical Instruments 18

Page 27

Trace Oxygen Analyzer Installation

• Vent connection

• Coalescing filter drain

Note: Zero gas is not required however, see Section 5.2.1.

Figure 3-3: Gas Connections

To connect the gas lines, remove the fitting and ferrule and cone at

the bottom panel. Insert the tubing into the fitting then place the ferrule

and cone over the tubing. Mate the assembly back to the connector on

the panel and tighten finger tight. Use a wrench to tighten an additional

1 ¼ turn beyond finger tight. You may have to hold the stationary fitting

with another wrench to keep the entire fitting from turning. Figure 3-3

shows the gas connection panel.

CAUTION: TIE IN ONE LINE AT A TIME. MAKE SURE THAT THE

CORRECT GAS LINE IS MATED TO THE PROPER

FITTING ON THE INSTRUMENT.

For maximum performance, the system should be installed in a

manner to minimize the sample line length.

Teledyne Analytical Instruments 19

Page 28

Installation OT-3

The vent line must be installed in a manner which will prevent dirt

and water from accumulating within the line. It must return sample to

atmospheric pressure. The vent line should be 1/4” diameter tubing or

larger and be at least 24” long. This will help to prevent the back

diffusion of O2 into the sample system.

3.5 Sample System

The sample system used in the OT-3 Trace Oxygen Analyzer is a

robust gas handling and conditioning system designed for low flow rate

trace oxygen analysis in a natural gas or other low-oxygen gas

environment. It uses stainless steel tubing and fittings throughout and a

special 0-10 psig regulator designed to provide stable sample flow at

low volumes over wide temperature extremes. The incoming sample gas

is conditioned using a coalescing filter and an acid scrubber to remove

moisture and contaminants which would otherwise interfere with the

accurate trace analysis and/or reduce the lifetime of the sensor.

Refer to Figure 3-4 for the following discussion.

Note: Check the front of this manual for any additional

information in the form of addenda that may apply to your

custom system.

Sample gas enters the system at 5-2000 psig. A shut off valve is

installed and is used to switch gas flow on or off. The sample gas is

passed through a horizontal coalescing filter to remove moisture and

debris. This filter is designed to handle inlet gas pressure up to 2000

psig. It is important to periodically drain the condensate by opening the

drain valve. If appropriate, the drain line should be connected to a

suitable receptacle for handling contaminated waste liquid.

A 0-10 psig pressure regulator is installed downstream from the filter

and controls the sample pressure through the analyzer. In conjunction with

the flowmeter, it provides a stable mass flow even at low volume over the

rated temperature range of the instrument. Set the pressure regulator to

provide a flow rate of 0.4 SCFH (approximately 4 psig).

A clear PVC acid gas scrubber is installed between the regulator

and the sample/span gas selector switch. The clear housing permits a

visual analysis regarding the condition of the scrubber medium and

allows the user to predict service intervals.

A switching valve is provided to feed the analysis unit with either

sample or span gas.

Teledyne Analytical Instruments 20

Page 29

Trace Oxygen Analyzer Installation

A flowmeter and flow restrictor are parts of the sample system and

assist in setting the flow of the gas. The restrictor is installed upstream

of the analyzer while the flowmeter is installed on the vent side.

Adjust the sample pressure at the regulator to provide a flow rate of

0.4-0.5 SCFH. It is important that the sample vent connection does not

restrict the sample flow. The sensor is designed to operate at

atmospheric pressure. Restricting the sample vent line will pressurize

the sensor, alter the O2 reading, and reduce the sample flow.

Sample and Span pressure should not exceed 2000 psig (13.8 Mpa)

Figure 3-4: OT-3 Sample System

3.6 Installation Checklist

Before connecting the instrument to the power source and turning it

on, make sure you have:

• Correctly installed the Sample and Exhaust gas lines

• Checked for leaks

• Set the flow

Once the above checks have been made, you can connect to the

power source. The instrument is now ready for operation.

Teledyne Analytical Instruments 21

Page 30

Installation OT-3

Teledyne Analytical Instruments 22

Page 31

Trace Oxygen Analyzer Operation

Operation

4.1 Introduction

Once the analyzer has been mounted, the gas lines connected and

the electrical connections made, the Analyzer can be configured for your

application. This involves setting the system parameters:

• Defining the user selectable analysis ranges.

• Setting alarm setpoints.

• Calibrating the instrument.

All of these functions are performed via the front panel controls,

shown in Figure 4-1.

Analyzing for the trace oxygen level in the gas passing through the

cell block is the default mode of operation. As long as no front panel

buttons are being pressed the unit is analyzing.

Figure 4-1: Front Panel Control and Indicators

Teledyne Analytical Instruments 23

Page 32

Operation OT-3

4.2 Using the Function and Data Entry Buttons

When no buttons on the Analyzer are being pressed, the instrument

is in the Analyze mode. It is monitoring the amount of oxygen in the

sample gas that is flowing through the sampling system.

When one of the Function Buttons is being pressed, the Analyzer is

in the Setup mode or the Calibration mode.

The 4 Setup function buttons on the analyzer are:

• SET ALARM 1

• SET ALARM 2

• SET HI RANGE

• SET LO RANGE

The Calibration mode button is:

• SET SPAN

The Data Entry buttons (∆ and ∇) increment the values displayed

on the TRACE OXYGEN meter while one of the Function buttons is

being held down.

∆ : UP arrow—increments the displayed value upwards.

∇ : DOWN arrow—increments the displayed value downwards.

Any of the functions can be selected at any time by holding down

the appropriate button.

Each function will be described in the following sections. Although

the operator can use any function at any time, the order chosen in this

manual is appropriate for an initial setup.

4.3 Setting the Analysis Ranges

The two user definable analysis ranges are both capable of being

adjusted for from 0-10ppm to 0-9999 ppm oxygen concentration.

Whatever values are selected, the analyzer automatically switches from

the LO range to the HI range when the oxygen concentration reaches the

LO range full-scale value, and it switches back to the LO range when the

oxygen concentration falls below of the LO range full-scale value

Note: The HI Range setpoint MUST be set at a higher

concentration percentage than the LO Range setpoint.

Teledyne Analytical Instruments 24

Page 33

Trace Oxygen Analyzer Operation

4.3.1 HI Range

Setting the HI Range full-scale value defines the LEAST sensitive

analysis range to be used. To set the HI Range:

1. Press the SET HI RANGE Function button once.

2. Immediately (within 5 seconds) press either the ∆ or ∇ button to

raise or lower the displayed value, as required, until the display

reads the desired full-scale percent concentration.

4.3.2 LO Range

Setting the LO Range full-scale value defines the MOST sensitive

range to be used. To set the LO Range:

1. Press the SET LO RANGE Function button once.

2. Immediately (within 5 seconds) press either the UP or DOWN

arrow button to raise or lower the displayed value, as required,

until the display reads the desired full-scale percent

concentration.

4.4 Setting the Alarm Setpoints

The alarm setpoints can be adjusted over the full range of the

analyzer (0-9999 ppm oxygen content). The set point values are

expressed in ppm only.

4.4.1 Set Alarm 1

Alarm 1 can be set either as a high or low alarm. To configure this

alarm to your preferences:

1. Press the SET ALARM 1 function button once.

2. The display will flash either HI or LO depending on what the

alarm was configured in the last time. If the alarm configuration

must be changed, use the Up or Down keys to toggle the alarm

from HI to LO or vice-versa (if within 5 seconds no key is

pressed, the instrument will return to the sample mode and

display oxygen concentration).

3. To change the setting at which the alarm will be actuated, press

the SET ALARM 1 function button once more. The alarm

setpoint will flash on the LED display. Press either the Up or

Down keys to raise or lower the displayed value, as required,

Teledyne Analytical Instruments 25

Page 34

Operation OT-3

until the display reads the desired percent concentration. (if

within 5 seconds no key is pressed, the instrument will return to

the sample mode and display oxygen concentration).

After setting the value wait for the unit to time out of this mode

(approximately 5 seconds) and return to displaying oxygen

concentration.

4.4.2 Set Alarm 2

Alarm 2 can be set either as a high or low alarm. To configure this

alarm to your preferences:

1. Press the SET ALARM 2 function button once.

2. The display will flash either HI or LO depending on how the

alarm was last configured. If the alarm configuration must be

changed, use the Up or Down keys to toggle the alarm from HI

to LO or vice-versa. If within 5 seconds no key is pressed, the

instrument will return to the sample mode and display oxygen

concentration.

3. To change the setting at which the alarm will be actuated, press

the SET ALARM 2 function button once more. The alarm

setpoint will flash on the LED display. Press either the Up or

Down keys to raise or lower the displayed value, as required,

until the display reads the desired percent concentration. If

within 5 seconds no key is pressed, the instrument will return to

the sample mode and display oxygen concentration.

After setting the value wait for the unit to time out of this mode

(approximately 5 seconds) and return to displaying oxygen

concentration.

4.4.3 Power Failure Alarm

The power failure alarm provides a set of form C contacts and are

configured for failsafe operation. The contacts remain energized when

the whenever power is applied to the instrument.

4.5 Alarm Delay

The alarms have a user-settable delay feature which can delay the

onset of an alarm. The delay can be set from 0-20 minutes in 1 minute

increments.

Teledyne Analytical Instruments 26

Page 35

Trace Oxygen Analyzer Operation

When the alarms are set for delay and an alarm condition exists, the

display will alternate between the O2 reading and the time in minutes

and seconds before the alarm will trigger. The alarm indicator on the

front panel will blink on and off. The delay time will continue to count

down until it reaches zero then the alarm relay will close. At this point

the display will stop blinking and the O2 concentration will display

continuously. If a second alarm is reached after the delay time has

elapsed, it will trigger immediately without any delay. If the O2 level

drops to below the alarm condition during the delay, the delay timer will

reset to the full delay.

If the alarm delay is set to 0 and an alarm condition exists, the

alarm indicator will blink and the alarm relay will close immediately.

When the O2 level drops out of the alarm condition, the alarm relay will

drop out accordingly.

The alarm delay can be toggled on or off and the timing set through

the DELAY function. To set the alarm delay:

1. Press the UP and DOWN arrow keys simultaneously. The

display will indicate either PASS CODE or DELAY. If the

display indicates PASS CODE, then to set the delay, press both

arrow keys simultaneously again to toggle to DELAY.

2. While the display is blinking the word PASS DELAY, press the

UP arrow key to increase the delay. To decrease the delay, press

the DOWN arrow key. After three seconds the delay feature will

time-out and return to the analyze mode.

4.6 Keypad Lockout

The Model OT-3 has a keypad lockout feature which is designed to

prevent unauthorized changes to the analyzer. This feature is toggled on

or off via the PASS CODE function. To enable the keypad lockout:

1. Press the UP and DOWN arrow keys simultaneously. The

display will indicate either PASS CODE or DELAY. If the

display indicates DELAY, then to set the lockout feature, press

both arrow keys simultaneously again to toggle to PASS CODE.

2. While the display is blinking the word PASS CODE, press the

up or down arrow key to alter the code number. Any number

except 10 will lock the keypad.

3. After three seconds, the control unit will time-out and return

to analyze mode. With the keypad locked, pressing the keys

Teledyne Analytical Instruments 27

Page 36

Operation OT-3

will cause the display to flash NO PASS and the keys will

have no effect.

4. To unlock the keypad, repeat steps 1 and 2. Enter the number 10

when the word PASS CODE blinks on the display.

4.7 Selecting a Fixed Range or Autoranging

The Model OT-3 can operate in fixed high, fixed low, or

autoranging mode. These modes are user-selectable. To change modes:

1. Press and then release the SET HI RANGE and the SET LO

RANGE buttons simultaneously.

2. Within 5 seconds, press either the ∆ or ∇ button until Auto, Lo,

or Hi displays on the LED, as desired.

After about three seconds, the analyzer resumes monitoring in the

selected range mode.

Note: If the concentration exceeds 9999 ppm oxygen, the

analyzer will automatically switch to the Calibration Range,

EVEN THOUGH INSTRUMENT IS IN THE FIXED RANGE

MODE.

4.8 Calibration

Preliminary—If not already done: Power up the Analyzer and allow

the LED reading to stabilize. Set the Alarm setpoints and the full-scale

ranges to the desired values.

Procedure:

Note: This procedure requires a suitable span gas with pressure

regulation.

The O2 concentration of the span gas should be 80-90% of the

principle range of use— typically 8-9 ppm or 80-90 ppm.

1. Attach the pressure regulated span gas to the to the span port on

the bottom of the analyzer as described in Section 3.4.

2. Move the gas selector valve to the SPAN position.

3. Adjust the pressure on the span gas to produce a 0.4-0.5 SCFH

flow and allow the analyzer to stabilize before setting the span.

4. The analyzer reading should be stable prior to setting the span.

Teledyne Analytical Instruments 28

Page 37

Trace Oxygen Analyzer Operation

Note: If the analyzer output goes above the high alarm setpoint

or below the low alarm setpoint, the display will go blank

and the front panel ALARM Indicator, beneath the SET

Function buttons, will blink. Hold down the SPAN button

until the ALARM Indicator stops blinking.

To set the span:

1. Press the SPAN button once.

2. Within 5 seconds press either the ∆ or ∇ button until the display

is stable and matches the known span gas concentration.

The unit is now calibrated.

4.9 Displaying Percent & PPM on the LED Display

The analyzer displays the concentration in percent whenever the

reading is over 9999 ppm. When the reading changes to percent, the

LED display will flash the oxygen concentration on and off. On the

other hand, if the instrument is displaying ppm, only the concentration

reading will be shown.

4.10 Supplementary Information

If, during the Span Procedure, you pressed the SPAN button by

mistake, you must wait five minutes for the analyzer to resume analysis

or you can press the UP button and then the DOWN button. (Pressing

the UP and DOWN buttons causes the analyzer to time-out in five

seconds instead of five minutes).

If during the span procedure, you press the RANGE or ALARM

buttons:

- either the range or alarm routine will be activated.

- any changes to span will be rejected.

- the 60 second alarm delay will not occur, i.e., the alarms will

be responsive immediately.

CAUTION: TET/AI CONSIDERS THE ACTION OF PRESSING THE

ALARM OR RANGE BUTTONS TO BE AT YOUR

(THE USER’S) DISCRETION.

BE AWARE THAT THE ALARMS WILL BECOME

ACTIVE WITHIN 5 (FIVE) SECONDS IF THE RANGE

Teledyne Analytical Instruments 29

Page 38

Operation OT-3

OR ALARM BUTTONS ARE PRESSED DURING

SPAN. THIS MAY RESULT IN FALSE ALARMS IF

THE SPAN GAS HAS NOT BEEN FULLY PURGED

FROM THE CELL AND SAMPLE LINES.

Teledyne Analytical Instruments 30

Page 39

Trace Oxygen Analyzer Maintenance

Maintenance

Aside from normal cleaning and checking for leaks at the gas

connections, the Model OT-3 should not require any maintenance

beyond replacement of expended Micro-fuel Cells, and perhaps a blown

fuse. Routine maintenance includes occasional recalibration, as

described in chapter 4, Operation.

5.1 Replacing the Fuse

CAUTION: ON AC UNITS, REMOVE THE POWER TO THE UNIT

BEFORE REPLACING THE FUSE.

When a fuse blows, check first to determine the cause, then replace

the fuse using the following procedure:

AC Units

1. On AC units, disconnect the power. Remove the power cord

from the receptacle.

2. The fuse receptacle is located in the power cord receptacle

assembly in the upper left-hand corner of the rear panel. See

Figure 5-1.

3. Insert a small flat-blade screwdriver into the slot in the receptacle

wall nearest the fuse and gently pry open the fuse receptacle. The

fuse holder will slide out. There are two fuses in use and are

visible in the clip.

4. Remove the bad fuse and replace it with a 5x20mm 0.5 A,

250 VAC, IEC time lag (T) fuse (P/N F1130).

5. Replace the fuse holder into its receptacle, pushing in firmly

until it clicks.

Teledyne Analytical Instruments 31

Page 40

Maintenance OT-3

Figure 5-1: AC Fuse Replacement

DC Units

On DC units, the fuse is located in a fuse holder on the rear panel.

See Figure 1-3. Unscrew the cap on the fuse holder and remove the

blown fuse. Replace the fuse with a 1/2 A micro fuse P/N F91.

5.2 Sensor Installation or Replacement

5.2.1 When to Replace a Sensor

On trace analyzers the Micro-fuel Cell will typically fail due to

excessive zero offset caused by loss of water. Large zero offsets will

result in inaccurate SPAN settings. To test for this condition, purge the

sensor and sample system with ZERO gas (typically nitrogen with less

than 1 ppm O2).

To do this, you should connect a pressure regulated zero gas source

to the instrument at the span gas port. This can be done by either

shutting off the span gas and replacing it with the zero gas supply or by

teeing into the span gas line using a selector valve which can then feed

either span or zero gas to the instrument.

It may take several hours for the sample system and cell to return to

a stable low level of O2 if it has been exposed to higher levels of O2. If

the instrument will not come down to an acceptably low reading on zero

gas, then a depleted cell or a sample system leak should be suspected.

Typically offsets of 1.0 ppm or less are acceptable. A cell failure

may also be indicated by an inability to SPAN, or slow response to

changes in O2 concentration at levels below 100 ppm.

Teledyne Analytical Instruments 32

Page 41

Trace Oxygen Analyzer Maintenance

CAUTION: READ THE SECTION CELL WARRANTY

CONDITIONS, BELOW, BEFORE REPLACING THE

CELL.

After replacing the Micro-fuel Cell, the analyzer must be

recalibrated. See Calibration in Chapter 4.

5.2.2 Ordering and Handling of Spare Sensors

To have a replacement cell available when it is needed, TAI

recommends that one spare cell be purchased when the current cell 's

warranty period is approximately two thirds over.

CAUTION: DO NOT STOCKPILE CELLS. THE WARRANTY

PERIOD STARTS ON THE DAY OF SHIPMENT. FOR

BEST RESULTS, DO NOT ORDER A NEW SPARE

CELL TOO SOON.

The spare cell should be carefully stored in an area that is not

subject to large variations in ambient temperature (75 °F nominal), and

in such a way as to eliminate the possibility of incurring damage.

CAUTION: DO NOT DISTURB THE INTEGRITY OF THE CELL

PACKAGE UNTIL THE CELL IS TO ACTUALLY BE

USED. IF THE CELL PACKAGE IS PUNCTURED AND

AIR IS PERMITTED TO ENTER, CELL-LIFE WILL BE

COMPROMISED.

WARNING: THE SENSOR USED IN THE MODEL OT-3 CONTAINS

AN ELECTROLYTE WHICH INCLUDES SUBSTANCES

THAT ARE EXTREMELY HARMFUL IF TOUCHED,

SWALLOWED, OR INHALED. AVOID CONTACT WITH

ANY FLUID OR POWDER IN OR AROUND THE UNIT.

WHAT MAY APPEAR TO BE PLAIN WATER COULD

CONTAIN ONE OF THESE TOXIC SUBSTANCES. IN

CASE OF EYE CONTACT, IMMEDIATELY FLUSH

EYES WITH WATER FOR AT LEAST 15 MINUTES.

CALL A PHYSICIAN. (SEE APPENDIX, Material Safety

Data Sheet—MSDS).

5.2.3 Removing the Micro-fuel Cell

To remove a spent or damaged Micro-fuel Cell:

1. Disconnect the Power Source from the instrument.

Teledyne Analytical Instruments 33

Page 42

Maintenance OT-3

2. Open the analyzer door.

3. Unscrew the cell-retainer cap from the cell block by turning it

counterclockwise until it is free.

4. Withdraw the cap from the block. The cell should come out

with the cap.

5. Carefully pull the cell off of the cap.

WARNING: DO NOT TOUCH THE SCREENED END OF THE CELL

OR ANY FLUID THAT MAY BE LEAKING FROM IT.

6. Dispose of the cell in a safe manner, in accordance with all

applicable ENVIRONMENTAL AND SAFETY laws.

5.2.4 Installing a Micro-fuel Cell

To install a new Micro-fuel Cell:

CAUTION: DO NOT SCRATCH, PUNCTURE, OR OTHERWISE

DAMAGE THE SENSING MEMBRANE OF THE

MICRO-FUEL CELL. IF THE MEMBRANE IS

DAMAGED, THE CELL MUST BE REPLACED.

1. Examine the O-ring at the base of the cell-retainer cap, and

replace it if it is worn of damaged.

2. Disconnect the Power Source from the Control Unit.

3. Set the flow rate to a high level (.5-1 SCFH).

4. As rapidly as possible complete steps 5-7.

5. Remove the new Micro-fuel Cell from its protective bag.

6. Place the cell on the end of cell-retainer cap with the

concentric gold rings facing up.

7. Careful insert the cap and cell into the block, and screw the

cap clockwise into the cell block until it is fully closed.

8. Reconnect the electrical power.

Teledyne Analytical Instruments 34

Page 43

Trace Oxygen Analyzer Maintenance

5.2.5 Cell Warranty Conditions

The B-2C , A-2C, and Insta-Trace Class Micro-fuel Cells are used

in the Model OT-3. These cells are warranted for 6 months, with an

expected life of 8 months from the date of shipment (under specified

operating conditions—see Appendix). Note any Addenda attached to the

front of this manual for special information applying to your instrument.

Note that the warranty period begins on the date of shipment. The

customer should stock only one spare cell per instrument at a time. Do

not attempt to stockpile spare cells.

If a cell was working satisfactorily, but ceases to function before

the warranty period expires, the customer will receive credit toward the

purchase of a new cell.

If you have a warranty claim, you must return the cell in question to

the factory for evaluation.

Note: When returning cells for evaluation, do not install the

shorting pin on the rear of the cell.

If it is determined that failure is due to faulty workmanship or

material, the cell will be replaced at no cost to you.

Note: Evidence of damage due to tampering or mishandling will

render the cell warranty null and void.

Teledyne Analytical Instruments 35

Page 44

Appendix OT-3

Appendix

A.1 Specifications

Ranges: Two user selectable ranges can be set

between 0-10 ppm and 0-9999 ppm

oxygen, and a 0-25 % (nominal) Air

Calibration Range.

Signal Output: Voltage: 0–10 VDC, negative ground

Current: 4-20 mA, negative ground

Range ID: 0-10 VDC.

Display: Light emitting diode (LED) display.

Alarms: Two user-settable non-latching alarms,

with user adjustable programmable 0-20

min.delay; one power failure relay. (All

are failsafe.)

System Operating Temp: 0-50 °C

Accuracy: ±2 % of full scale at constant temperature

±5 % of full scale through operating

temperature range (At 100 ppm and higher

user defined ranges) once temperature

equilibrium is reached.

±1 ppm for 10 ppm range under above

conditions.

Response Time: 90 % in less than 65 seconds at 25°C (68°F).

System Power Requirement:

AC (100-240 VAC, 50/60Hz @ 2.8W), or

DC (10-36 VDC @2.8W )

Weight: 30.9Lbs (14 Kg)

System Enclosure: NEMA 4 enclosure.

40 cm x 30 cm x 20.6 cm

(15.8” x 11.8” x 8.1”)

Teledyne Analytical Instruments 36

Page 45

Trace Oxygen Analyzer Appendix

A.2 Spare Parts List

QTY P/N DESCRIPTION

1 C65220-A PC Board, Main (std.)

1 C70740-A PC Board, Power Supply AC (std.)

1 C6689-B-2C Micro-Fuel Cell, class B-2C, or

1 C6689-A-2C Micro-Fuel Cell, class A-2C, (CO2 type), or

1 B 71875 Micro-fuel Cell Insta-Trace, B-2C type, or

1 B 73016 Micro-fuel Cell Insta-Trace, A-2C (CO2 type)

2 F1130 Fuse (AC), ½A, 250 VAC, IEC Type T, 5 x

20mm

1 C-74162-A PC Board, Power Supply DC (std.)

1 F1605 Filter Elements (5 elements)

1 R2533 Restrictor (0.4 SCFH @ 4 psig)

1 R2588 Regulator

1 O182 O-Ring std. OT-3 Cell Holder

1 C74050A Acid Gas Scrubber

1* C73514A 3300/OT-3 Control Unit, AC, std.

1* C73514B 3300/OT-3 Control Unit, AC, RS232

1* C73514C 3300/OT-3 Control Unit, DC, std

1* C73514C 3300/OT-3 Control Unit, DC, RS232

1 F51 Fuse (DC Units) 1/2 Amp Micro

* Depends on options chosen at time of purchase

IMPORTANT: Orders for replacement parts should include the part

number and the model and serial number of the system for which the

parts are intended.

Send orders to:

TELEDYNE ELECTRONIC TECHNOLOGIES

Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580Telephone: (626) 934-1500

Fax: (626) 961-2538 or your local representative.

Web: www.teledyne-ai.com

Teledyne Analytical Instruments 37

Page 46

Appendix OT-3

A.3 Reference Drawing

D-74110 Outline Diagram

B-74106 Piping Diagram

D-65305 Schematic main PCB

D-70739 Schematic AC Power Supply PCB

D-74161 Schematic DC Power Supply PCB

B-74224 Wiring diagram 3300/OT-3 ext. SSR drive.

A.4 Miscellaneous

The symbol ~ is used on the rear panel of the Model OT-3 to

signify volts alternating current (VAC).

Teledyne Analytical Instruments 38

Page 47

Trace Oxygen Analyzer Index

Index

accuracy, 2, 36

address. See company address

alarm

connection, 16

delay, 26

HI, 16

LO, 16

power failure, 2, 26

SET ALARM 1, 25

SET ALARM 2, 26

specifications, 36

alarm 1, 17

alarm 2, 17

alarm indicator, 27

alarm indicator LED, 2

analog concentration signal, 12

analog to digital converter, 10, 11

analysis mode, 23, 24

analysis range. See range

analysis ranges. See range

anode, 6, 7, 8

autoranging, 28

auto-ranging, 2

back diffusion, 20

blinking alarm indicator, 29

blinking display, 27

concentration, 29

calibration, 9, 28

calibration mode, 24

cathode, 6, 7, 8, 9

cell block, 1, 18

cell failure, 32

cell output, 8

cell warranty, 35

Class 1 Div 1, 18

coalescing filter. See filter

company address, 37

configuring the OT-3, 23

contaminants, 8, 13, 20

control unit, 6

copyright, ii

current generation, 11

current output. See output

data entry buttons, 24

data entry keys, 3

DELAY, 27

DELAY function, 27

diffusion membrane, 7

digital display, 3

digital meter, 2

digital to analog converter, 10, 12

display, 36

drain

filter, 19

drain valve, 20

drawing list, 38

E to I converter. See voltage to current

electrical connections, 14

electrical potential, 6

electrochemical device, 6

electrochemical transducer, 6

electrolyte, 6, 7, 13, 33

electron transfer, 9

failsafe operation, 16, 18

false alarms, 30

features, 1

filter

bypass, 1

coalescing, 1, 19, 20

flow restrictor, 1, 21

flowmeter, 1, 20

forced time-out, 29

front panel, 2, 23

function keys, 3

fuse block, 15

fuse holder, 4, 31

fuse replacement procedure, 31

gas connection, 18

gas selector switch, 20

half reaction. See reaction

hazardous location, 17

HI Range, 25

hydroxyl ion, 8

installation, 13

installation checklist, 21

Insta-Trace, 1

Teledyne Analytical Instruments 39

Page 48

Index OT-3

international power, 10

jumper, 18

keypad lockout, 2, 27

lead, 7, 8

linear curve, 9

LO Range, 25

location, 14

maintenance, 31

manuals, additional, v

membrane, 8, 9, 13, 14

microcontroller, 6, 10, 11

Micro-fuel Cell, 6, 9

anatomy, 7

characteristic curve, 10

contacts, 7, 14

cross section, 7

installation, 14

installing, 34

removing, 33

temperature compensation, 11

model information, iii

NEMA 4, 1, 36

NO PASS, 28

operating temperature, 36

operation, 23

output, 2, 9, 15

analog, 4

connectors, 15

current, 16

range ID, 2, 15

sensor, 11

solid state relay, 18

specifications, 36

oxidization, 8

oxygen concentration, 9, 15

oxygen sensor. See Micro-fuel Cell

packaging, 14, 33

PASS CODE, 27

PCB

main, 10

power supply, 10

percent concentration, 29

permeable membrane, 7

power, 2, 10

power supply, 15

power connection, 4

power cord, 15

power failure alarm. See alarm

power supply module, 10

pressure, 21

pressure effects, 9

pressure regulator, 1

RAM, 10

range, 2, 24, 36

range ID, 36

reaction, 8

rear panel, 4

AC version, 5

DC version, 5

recovery time, 32

reduction, 8

regulator, 20

relay

contacts, 16

DC SSR, 18

failsafe operation, 16

rating, 17

solid state relay (SSR), 18

replacement cell, 33

response time, 2, 14, 36

restrictor. See flow restrictor

ROM, 10

sample pressure, 20

sample system, 18, 20

scrubber, 1, 18, 20

sensor amplifier, 10

sensor connector, 4

sensor installation, 32

serial number, iii

setup function buttons, 24

setup mode, 24

shut off valve, 1, 20

signal output, 36

signal processing, 6, 10

slope, 9

solid state relay, 2, 4. See relay

span, 29

span adjustment, 9

span gas, 18, 20

concentration, 28

flowrate, 28

spare parts listing, 37

specifications, 36

SSR. See solid state relay

stainless steel, 20

stockpiling MFCs, 33

switches

membrane, 2

temperature compensation, 2, 11

temperature range, 2, 14

Teledyne Analytical Instruments 40

Page 49

Trace Oxygen Analyzer Index

terminal block, 14, 15

thermistor, 11

universal power supply. See power

supply module

VAC symbol, 38

vent, 19, 20

voltage amplifier, 11

voltage to current converter, 12

warranty, ii, 35

web address, 37

website address, v

zero

absolute, 9

zero gas, 19, 32

zero offset, 9, 32

Teledyne Analytical Instruments 41

Page 50

Index OT-3

Teledyne Analytical Instruments 42

Loading...

Loading...