Page 1

Model OT-2 System

OPERATING INSTRUCTIONS

FOR

Model OT-2

Oxygen

Transmitter System

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING

SYSTEM. PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/

MANAGER.

Teledyne Analytical Instruments

P/N: M71265

ECO: #99-0000

10/21/1999

i

Page 2

Model OT-2 System

Copyright © 1999 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any other language or computer

language in whole or in part, in any form or by any means, whether it be electronic,

mechanical, magnetic, optical, manual, or otherwise, without the prior written consent of

Teledyne Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free

from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of shipment, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others bear

the warranty of their manufacturer. This warranty does not cover defects caused by wear,

accident, misuse, neglect or repairs other than those performed by Teledyne or an authorized service center. We assume no liability for direct or indirect damages of any kind and

the purchaser by the acceptance of the equipment will assume all liability for any damage

which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts, in

so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by

which valuable data can be gathered. The information provided by the instrument may

assist the user in eliminating potential hazards caused by his process; however, it is

essential that all personnel involved in the use of the instrument or its interface, with the

process being measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The

purchaser is responsible for the training of personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that hazard

warning devices and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments (TAI), the manufacturer of this instrument,

cannot accept responsibility for conditions beyond its knowledge and control. No statement expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control

under the user’s process conditions.

ii

Teledyne Analytical Instruments

Page 3

Model OT-2 System

Table of Contents

1 Introduction

1.1 Overview........................................................................1-1

1.2 Features..........................................................................1-1

1.3 Typical Applications......................................................1-2

1.4 Operator Interface .......................................................1-3

2 Operational Theory

2.1 Introduction ................................................................... 2-1

2.2 Micro-Fuel Cell Sensor ..................................................2-2

2.2.1 Principles of Operation .......................................... 2-2

2.2.2 Anatomy of a Micro-Fuel Cell............................... 2-2

2.2.3 Electrochemical Reactions...................................2-4

2.2.4 The Effect of Pressure .............................................2-5

2.2.5 Calibration Characteristics ...................................2-6

2.3 Electronics and Signal Processing............................... 2-7

2.4 Oxygen Cell Block Heater............................................2-7

2.5 EMI/RFI Protection.........................................................2-7

2.5 Sample System .............................................................. 2-8

3 Operation

3.1 Installation......................................................................3-1

3.1.1 Unpacking the System .........................................3-1

3.1.2 Mounting the System ........................................... 3-2

3.1.3 System Connections.............................................3-3

3.1.3.1 Gas Connections...................................3-3

3.1.3.2 Electrical Connections.......................... 3-4

3.2 Installing the Micro-Fuel Cell........................................3-6

3.3 Calibration ..................................................................... 3-6

3.3.1 Calibration Gas Connections .............................3-6

3.3.2 Setting the Span....................................................3-8

3.3.3 H2S Scrubber .........................................................3-9

3.3.4 Exhaust/Vent Line.................................................. 3-9

3.4 Testing the System.........................................................3-9

4 Maintenance

4.1 Routine Maintenance ..................................................4-1

4.2 Cell Replacement.........................................................4-1

4.2.1 Cell Warranty.........................................................4-2

4.3 Scrubber Replacement ............................................... 4-3

4.4 Filter Servicing................................................................4-3

Teledyne Analytical Instruments

iii

Page 4

Model OT-2 System

Appendix

Specifications ........................................................................A-1

Recommended Spare Parts List ..........................................A-2

Drawing List ............................................................................ A-2

Material Safety Data Sheet .................................................A-3

The following International Symbols are used throughout the

Instruction Manual for your visual and immediate warnings

and when you have to attend CAUTION while operating the

instrument:

GROUND

Protective Earth

CAUTION, The operator needs to refer to the manual

for further information. Failure to do so may

compromise the safe operation of the equipment.

iv

Teledyne Analytical Instruments

Page 5

Model OT-2 System Introduction 1

Introduction

1.1 Overview

The Teledyne Analytical Instruments Model OT-2 System is

designed to accurately monitor the oxygen content in a wide

variety of gases at the ppm level. The Trace Oxygen Transmitter

is equipped with two oxygen analysis ranges, 0–10 ppm and 0–

100 ppm (0-100 ppm and 0-1000 ppm optional). The OT-2

System is acceptable for operation in Class 1, Division 2, Groups

B, C, and D hazardous environments, when used in conjunction

with a non-insendive power source, such as the Elsag Baily Total

Flow TM System.

The heart of the OT-2 System is Teledyne Analytical Instruments' Micro-Fuel Cell oxygen sensor. This cell is a sealed electrochemical device which translates the amount of oxygen

present in a sample into an electrical current. Since it is sealed,

there is no electrolyte to change or electrodes to clean and

therefore, virtually maintenance free.

The transmitter operates from a 12VDC (nominal) power

source and produces a 1-5VDC voltage output that is directly

and linearly proportional to the oxygen concentration. The

output voltage is used to interface with high input impedance

(>10 Kilo ohms) devices such as recorders, alarms, computers or

other voltage driven devices.

1.2 Features

The following features describe the basic model. The exact

configuration depends on the options selected at the time of

purchase.

• Two analysis ranges: 0–10 ppm and 0-100 ppm (0-100

ppm and 0-1000 ppm optional) user selectable

• High sensitivity (0.5% FS)

• Digital O2 concentration display

Teledyne Analytical Instruments

1-1

Page 6

1 Introduction Model OT-2 System

Accurate (±2% of full scale at constant temperature on

•

100 ppm, or 1000 ppm scale; ±1 ppm on 0–10 ppm scale

at constant temperature)

• Insensitive to flow variations

• Fast response and recovery

• Long life, maintenance-free Micro-Fuel Cell oxygen

sensor

• Unaffected by reducing agents (HC's, CO, SO

, etc.)

2

• Easy to calibrate, no zero gas required

• 12VDC Battery Powered w/ 1-5 VDC Output

• Rugged NEMA 4, bulkhead mounted enclosure

• Stainless Steel sample system (nylon cell holder)

• H

S scrubber

2

• Pressure regulation with gage

• Sample filter

• Flowmeter

• Heated cell holder assembly

1.3 Typical Applications

Although the OT-2 System is designed in conjunction with the

Elsag Baily Total Flow

capable of monitoring oxygen at the ppm level in a variety of

gases. A few typical applications include:

TM

System for natural gas production, it also is

1-2

• Gas gathering and transportation

• Monitoring inert gas blanketing

• Air separation and liquefaction

• Chemical feedstock analysis

• Petrochemical process control

• Heat treating and bright annealing processes

• Quality assurance

• Gas certification

• Welding applications

Teledyne Analytical Instruments

Page 7

Model OT-2 System Introduction 1

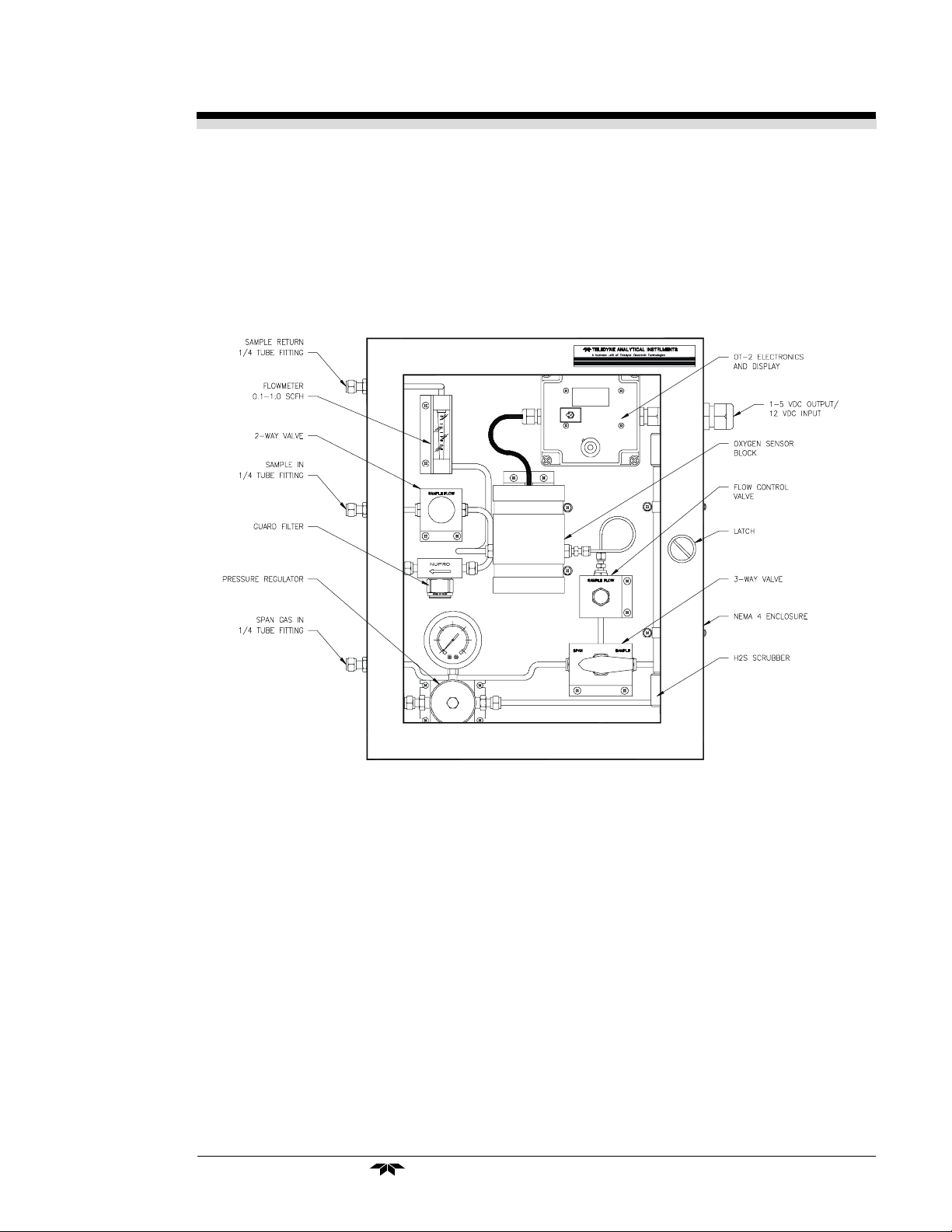

1.4 Operator Interface

The OT-2 System is housed in a rugged metal NEMA-4 case

with the display visible from the front and the controls accessible

from inside the front door. See Figure 1-1. The front door has a

clear Lexan window for viewing the sample system components

and transmitter display.

Figure 1-1 Front View

Access Door: For access to the Micro-Fuel Cell and transmitter controls, the front door swings open when the slotted latch in

the middle right side of the door is turned counter-clockwise. The

replaceable Micro Fuel Cell is housed in a nylon cell block positioned for easy access.

OT-2 Electronics & Display: The OT-2 meter display is a LCD

device that produces 3.5 decimal, 7-segment numbers that are

legible in daylight. It produces a continuous readout of oxygen

cencentration. Accessing the transmitter electronics requires

unfastening the screws of the transparent front cover of the OT-2

and lifting the cover off.

Flowmeter: Monitors the flow of gas past the sensor. Readout

is 0.1-1 standard cubic feet per hour (scfh).

H

S Scrubber: The H2S scrubber prevents H2S gas from affect-

2

ing the oxygen sensor.

Teledyne Analytical Instruments

1-3

Page 8

1 Introduction Model OT-2 System

1-4

Teledyne Analytical Instruments

Page 9

Model OT-2 System Operational Theory 2

Operational Theory

2.1 Introduction

The OT-2 System is composed of three subsystems:

1. Micro-Fuel Cell Sensor

2. Electronic Signal Processing, Display and Control

3. Sample System

The Micro-Fuel Cell is an electrochemical galvanic device

that translates the amount of oxygen present in the sample into an

electrical output.

The electronic signal processing, display and control subsystem provides oxygen concentration information both visually

and electronically.

The sample system accepts the sample gas and removes the

S in the sample prior to introduction to the sensor.

H

2

Teledyne Analytical Instruments

2-1

Page 10

2 Operational Theory Model OT-2 System

2.2 Micro-Fuel Cell Sensor

2.2.1 Principles of Operation

The oxygen sensor used in the Model OT-2 System is a Microfuel Cell designed and manufactured by Analytical Instruments. It

is a sealed plastic disposable electrochemical transducer.

The key components of the Micro-Fuel Cell are a diffusion

barrier in the form of a thin membrane, a cathode, an anode, and

an electrolyte in which they are immersed.

Oxygen from the sample gas diffuses through the thin membrane and is reduced at the cathode. As a result, an electrical

current is produced that is proportional to the concentration of

oxygen in the sample gas.

The choice of electrolyte, and hence the sensor type, depends on the exact constituents of the sample gas. For sample

gases that contain a high concentration of CO

acid electrolyte will be the more optimal choice.

, for example, an

2

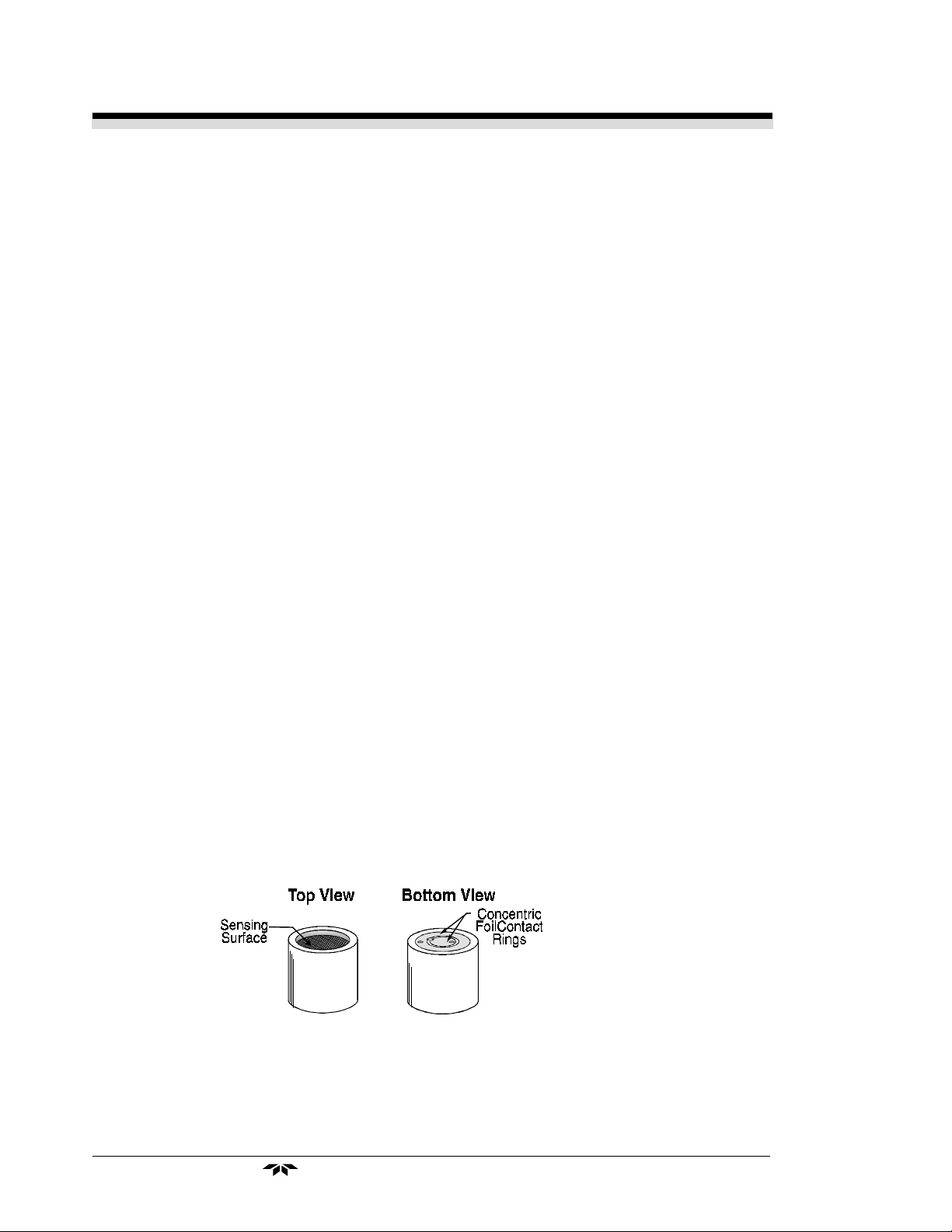

2.2.2 Anatomy of a Micro-Fuel Cell

The Micro-fuel Cell is approximately 1¼ inches in diameter.

The cell body is made of an inert plastic that is compatible with a

wide variety of sample streams. Oxygen from the sample gas

diffuses through a thin membrane located at one end of the

sensor. The other end of the cell is a contact plate consisting of

two concentric foil rings. The rings mate with spring-loaded contacts in the sensor block assembly and provide the electrical

connection to the rest of the analyzer. Figure 2-1 illustrates the

external features.

Figure 2-1: Micro-Fuel Cell

2-2

Teledyne Analytical Instruments

Page 11

Model OT-2 System Operational Theory 2

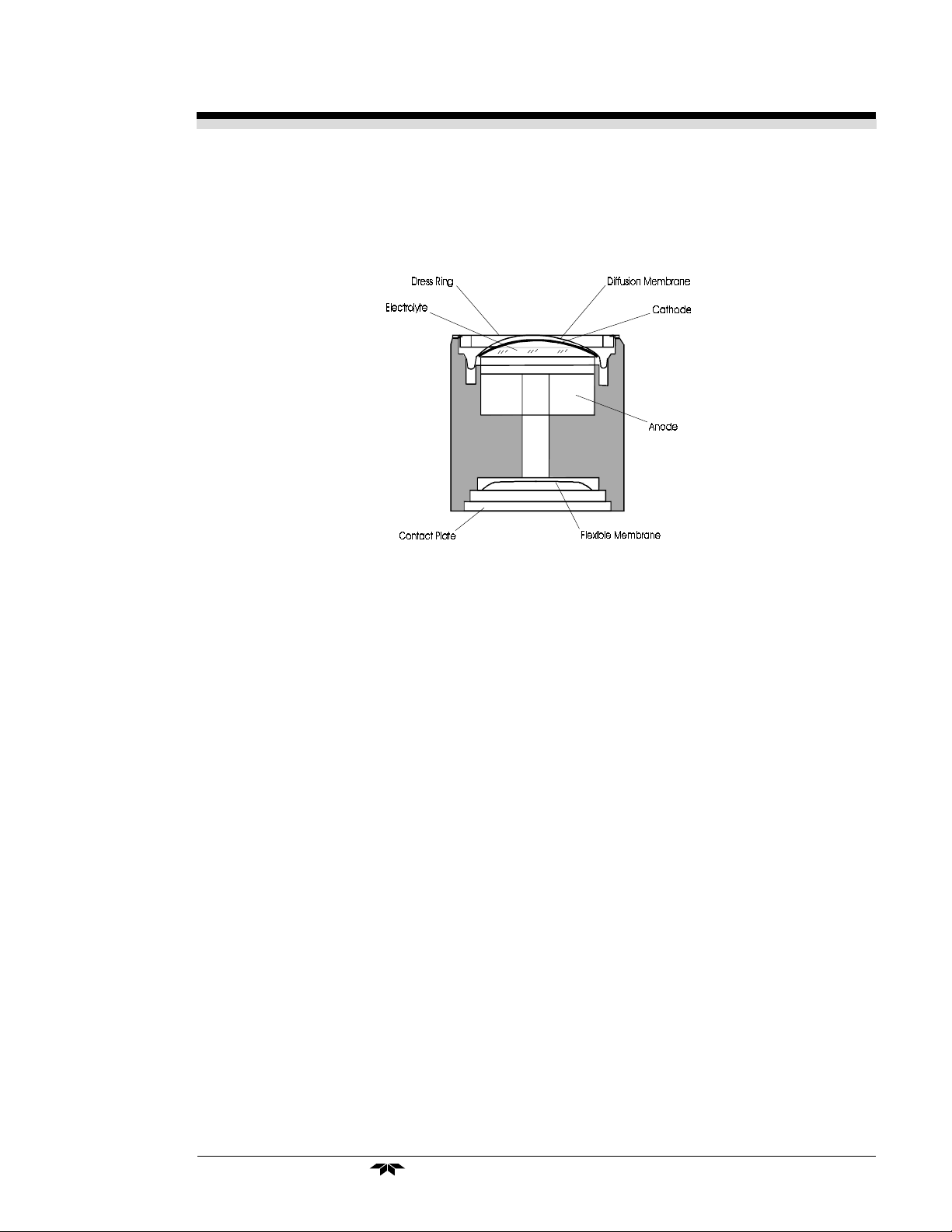

Refer to Figure 2-2,

illustrates the following internal description.

Cross Section of a Micro-Fuel Cell

Figure 2-2. Cross Section of a Micro-Fuel Cell (not to scale)

, which

At the top end of the cell is a diffusion membrane of Teflon.

Beneath the diffusion membrane lies the oxygen sensing element—the cathode.

The anode provides the electrical driving force for the reduction of oxygen at the cathode.

At the rear of the cell, just below the anode structure, is a

flexible membrane designed to accommodate the internal volume changes that occur throughout the life of the cell. This flexibility assures that the sensing membrane remains in its proper position, keeping the electrical output constant.

The entire space between the diffusion membrane, above the

cathode, and the flexible rear membrane, beneath the anode, is

filled with electrolyte. Cathode and anode are submerged in this

common pool. They each have a conductor connecting them to

one of the external contact rings on the contact plate, which is on

the bottom of the cell.

Teledyne Analytical Instruments

2-3

Page 12

2 Operational Theory Model OT-2 System

2.2.3 Electrochemical Reactions

The sample gas diffuses through the Teflon membrane. For a

sensor that employs KOH as electrolyte, oxygen in the sample gas

is reduced on the surface of the cathode according to the following HALF REACTION:

O

+ 2H2O + 4e– ® 4OH

2

(Four electrons combine with one oxygen molecule—in the

presence of water from the electrolyte—to produce four hydroxyl

ions.)

When the oxygen is reduced at the cathode, lead is simultaneously oxidized at the anode by the following HALF REACTION:

Pb + 2OH

–

® Pb+2 + H2O + 2e

(Two electrons are transferred for each atom of lead that is

oxidized. Therefore it takes two of the above anode reactions to

balance one cathode reaction and transfer four electrons.)

–

–

(cathode)

(anode)

The electrons released at the surface of the anode flow to the

cathode surface when an external electrical path is provided. The

current is proportional to the amount of oxygen reaching the

cathode. It is measured and used to determine the oxygen concentration in the gas mixture.

The overall reaction for the fuel cell is the SUM of the half

reactions above, or:

2Pb + O

® 2PbO

2

(These reactions will be the dominant sensor current component as long as no gaseous components capable of oxidizing

lead—such as iodine, bromine, chlorine and fluorine—are present

in the sample.)

In the absence of oxygen, the output of the sensor is approximately zero.

Warning:The sensor used in the Model OT-2 System uses electro-

lytes which contain substances that are harmful if

touched, swallowed, or inhaled. Avoid contact with

ANY fluid or powder in or around the unit. What may

appear to be plain water could contain one of these

harmful substances. In case of eye contact, immediately flush eyes with water for at least 15 minutes. Call

physician. (See Appendix - Material Safety Data Sheet

(MSDS)).

2-4

Teledyne Analytical Instruments

Page 13

Model OT-2 System Operational Theory 2

2.2.4 The Effect of Pressure

The Micro-Fuel Cell responds to the partial pressure of oxygen

present inside the cell holder.

By design, the total gas pressure inside the cell holder is kept

approximately the same as the atmospheric pressure. As the

atmospheric pressure changes, the partial pressure of oxygen in

the cell holder will change accordingly.

The impact due to changes in atmospheric pressure is usually

limited to less than 3% of reading.

Teledyne Analytical Instruments

2-5

Page 14

2 Operational Theory Model OT-2 System

2.2.5 Calibration Characteristics

Given that the total pressure of the sample gas on the surface

of the Micro-Fuel Cell input is constant, a convenient characteristic of the cell is that the current produced in an external circuit is

directly proportional to the rate at which oxygen molecules reach

the cathode, and this rate is directly proportional to the concentration of oxygen in the gaseous mixture. In other words it has a

linear characteristic curve, as shown in Figure 2-3. Measuring

circuits do not have to compensate for nonlinearities.

In addition, since the sensor output is approximately zero in the

absence of oxygen, the characteristic curve has close to an

absolute zero (within ± 1 ppm oxygen or better, depending on the

sensor type and model). In practical application, zeroing may still

be used to compensate for the combined zero offsets of the cell

and the electronics.

2-6

Figure 2-3. Characteristic Input/Output Curve for a Micro-Fuel Cell

Teledyne Analytical Instruments

Page 15

Model OT-2 System Operational Theory 2

2.3 Electronics and Signal Processing

The OT-2 circuitry consists of three stages: an input stage, a

temperature compensation/gain stage and an output stage.

The input stage consists of a current to voltage converter

producing a voltage signal that is proportional to the oxygen

concentration as detected by the sensor.

The temperature compensation stage contains circuitry that

compensates for the temperature effects on the output current of

the O

the sensor temperature.

ohms corresponding to 0-100% of full scale of the selected range.

range of 9-16 VDC. It is recommended that the output cable be

no longer than 10 feet. A shielded cable should be used whenever possible to minimize electrical noise pickup.

cell. A thermistor mounted in the sensor assembly monitors

2

The output stage provides a 1-5 volt signal into a load >10K

The transmitter circuitry operates with a power supply voltage

2.4 Oxygen Cell Block Heater

The OT-2 system is equipped with an insulated and electrically

heated cell block. The heater is switched on when the enclosure

temperature dips below 1oC. The 3 watt heater is controlled by the

electronic control unit.

Note: The cell block insulation must be in place for the

heater system to be effective.

2.5 EMI/RFI Protection

The OT-2 System is well shielded from EMI/RFI. The transmitter

electronics are mounted within a grounded metallic enclosure,

and the electronics is housed within the main system enclosure. For

optimal transmitter performance, the main system enclosure

should be well grounded.

Teledyne Analytical Instruments

2-7

Page 16

2 Operational Theory Model OT-2 System

2.6 Sample System

The system consists of a shut off valve, particulate filter, pressure regulator, scrubber, calibration selector valve, flow control

valve, O

inch tube fittings for sample inlet and outlet connections at the

side of the enclosure.

leading to the formation of lead sulphide with the anode material.

To eliminate the deleterious effect of H

ber is filled with Purafil

transmitter and a sample flow meter and incorporates ¼

2

S from the sample gas can diffuse into the Micro-Fuel Cell

H

2

S on the sensor, the scrub-

®

.

2

Sample Flow Description

: (See Figure 2-4)

1. The sample enters the transmitter system via the shut off valve

at 6-40 psig and passes through the filter where particulates, to

90 microns, are trapped.

2. A pressure regulator, which has been preset at the factory to

approximately 5 psig ensures a constant gas flow to the sensor.

3. After the pressure regulator, the sample gas passes through the

scrubber to the calibration selector valve.

4. When the sample has been selected, it flows through the flow

control valve to the O

sensor.

2

5. Finally, the sample flows through the flow meter and exits the

system through the vent line to a safe area at atmospheric

pressure.

Note: The flow control valve should be adjusted until the

flow meter indicates a flow rate of 0.4 scfh.

SAMPLE IN

6-40 PSIG

2-8

FILTER

SCRUBBER

Figure 2-4 Flow Diagram

Teledyne Analytical Instruments

H2S

SPAN GAS IN

O2 XMTR

0-10 PPM

FLOWMETER

.1-1.0 SCF H

VENT TO

ATMOSPHERE

PRESSU RE

(SAFE AREA)

Page 17

Model OT-2 System Operational Theory 2

Figure 2-5 Piping Layout

Figure 2-5 is the Piping Layout of the sampling system. In the

standard instrument, calibration gases (zero and span) are connected directly to the Span Gas In port by teeing to the port with

appropriate valves. The sample gas is connected to the Sample

Gas In port in the same manner as the Span Gas.

Teledyne Analytical Instruments

2-9

Page 18

2 Operational Theory Model OT-2 System

2-10

Teledyne Analytical Instruments

Page 19

Model OT-2 System Operation 3

Operation

Operation of the Model OT-2 System involves installing the unit,

making appropriate sample gas connections, and calibration.

3.1 Installation

WARNING: Safe operation of the system requires the user to

properly ground the system, install the wiring and

power the transmitter.

It is the user's responsibility to determine and install, should a safety barrier be required.

Installation of the Model OT-2 System includes:

1. Unpacking

2. Mounting

3. Gas connections

4. Electrical connections

5. Installing the Micro-Fuel Cell

6. Testing the system.

3.1.1 Unpacking the Analyzer

Carefully unpack the analyzer and inspect it for damage.

Immediately report any damage to the shipping agent.

Teledyne Analytical Instruments

3-1

Page 20

3 Operation Model OT-2 System

3.1.2 Mounting the Analyzer

The OT-2 System is designed for bulkhead mounting. Figure 3-1

is an illustration of the OT-2 System and mounting hole dimensions.

There are four mounting holes—one in each of the inside corners

of the rigid enclosure.

3-2

Figure 3-1 Mounting Details

Teledyne Analytical Instruments

Page 21

Model OT-2 System Operation 3

All operator controls are located inside the system enclosure,

which is hinged on the left edge and provides easy access to the

transmitter, sensor and cell block inside the instrument. The main

enclosure door will swing open when the slotted latch at the right

center of the door is turned counter-clockwise. Allow clearance

for the door to open in a 90-degree arc at a radius of 16 inches.

See Figure 3-1.

3.1.3 System Connections

Figure 3-2 shows the Model OT-2 System. There are ports for

gas inlet and outlet, power and analog concentration output.

Figure 3-2 Front View of OT-2 System

3.1.3.1 Gas Connections

The unit is manufactured with

installations.

Teledyne Analytical Instruments

1

/4 inch tube fittings for system

3-3

Page 22

3 Operation Model OT-2 System

To connect gas lines to the Model OT-2 System:

1. Insert the tube into the tube fitting, and finger-tighten the

nut until the tubing cannot be rotated freely, by hand, in

the fitting. (This may require an additional 1/8 turn

beyond finger-tight.)

2. Hold the fitting body steady with a wrench, and with

another wrench rotate the nut another 1-1/4 turns.

All gas connections, Sample In, Sample Return and Span Gas

In are made at the connectors located on the left side of the

system enclosure as shown in Figure 3-2.

SAMPLE IN: The gas connection for the sample is made at the

SAMPLE IN connector.

The internal gas pressure regulator is factory preset to approximately 3 psig which will keep the system flowmeter reading in an

acceptable range (0.1-1 scfh). The sample in pressure can be 6-40

psig.

SAMPLE RETURN: Exhaust connections must be consistent with

the hazard level of the constituent gases. Check Local, State, and

Federal laws, and ensure that the exhaust stream vents to an

appropriately controlled area if required.

SPAN GAS IN: This is the port for inputting span gas and zero

gas. The span gas source should be regulated at 3 psig.

3.1.3.2 Electrical Connections

All electrical connections for the OT-2 System are made on a

terminal blocks in the transmitter box located on the inside of the

system enclosure, see Figure 3-3.

1. To access the terminal block remove the four screws

securing the transmitter box cover and remove it.

2. Connect the 4 wires and shield to the terminal block as

shown in Figure 3-4.

3. Replace the cover and screws.

For safe connections, ensure that no uninsulated wire extends

outside of the connectors they are attached to. Stripped wire

ends must insert completely into terminal blocks. No uninsulated

wiring should be able to come in contact with fingers, tools or

clothing during normal operation.

3-4

Teledyne Analytical Instruments

Page 23

Model OT-2 System Operation 3

(4 p

)

Transmitter Cover

Screws

laces

Display

To Sensor

Span

Electrical

Connections

Figure 3-3 Front View of Transmitter

System Power Requirements:

The Model OT-2 System requires a 12 VDC (nominal), reverse

polarity protected power source.

Observe good wiring practices. For hazardous area

applications, the Model OT-2 System must be powered by a source that is consistent with intrinsically

safe operation.

Analog Outputs:

1-5 VDC: Voltage increases linearly with increasing oxygen,

from 1 VDC at 0 ppm to 5 VDC at full scale ppm.

Figure 3-4: Transmitter Electrical Connections

Teledyne Analytical Instruments

3-5

Page 24

3 Operation Model OT-2 System

3.2 Installing the Micro-Fuel Cell

The Micro-Fuel Cell is not installed in the cell block when the

instrument is shipped. Install it before the analyzer is placed in

service.

When the micro-Fuel Cell needs to be installed or replaced,

follow the procedures in chapter 5,

and installing cells.

Recommendation: During installation, minimize the time the

sensor is exposed to atmospheric oxygen, i.e. the time between

removal of the sensor from the sealed bag to installation into the

cell holder.

Maintenance,

for removing

3.3 Calibration

The calibration process consists of:

• Connecting span gas to Span In Port

• Setting the span

Setting the span of the transmitter requires adjustment of the

potentiometer located on the transmitter box.

The sensor will respond to changes in oxygen concentration

immediately after installation. For maximum performance (accuracy and sensitivity) TET/AI recommends that the sensor be purged

with a zero (0% oxygen) gas for about 24 hours after the sensor is

installed and then calibrate with span gas with a value of approx.

80-100% of the analytical range of interest. The following sections

describe the calibration procedure.

3.3.1 Calibration Gas Connections

Prior to installation of the O

taining less than 1 ppm O2, should be connected to the system

and be ready to purge the O2 cell. To facilitate spanning the zero

and span gas source can be connected to a common manifold

via a three way valve. This manifold then connects directly to the

"Span Gas In" port on the system (Fig. 3-5).

cell, a zero gas (purge gas) con-

2

It is important that the

operator bleeds any trapped air in the tubing prior to installation

of the sensor to minimize the amount of atmospheric oxygen

introduced into the system.

NOTE: In order to minimize the time required to purge the cell

after exposure to air, limit the time the cell is exposed to

air to 1 minute or less, if possible.

3-6

Teledyne Analytical Instruments

Page 25

Model OT-2 System Operation 3

The span gas cylinder must be equipped with a pressure

regulator with a metallic diaphragm. The regulator should be set to

approximately 3-5 psig. Rotate the selector valve (a) to the span

position and observe the flow meter (b) which should indicate a

flow of about 0.4 scfh. For calibration purposes the flow can be

increased to as much as 1 scfh in order to reduce the time required to stabilize.

Allow the span gas to pass through the O

reading has stabilized (approx. 10 min.). The O

then be adjusted (see instructions elsewhere in this section) to

match the analyzed content of the span gas. When the calibration

is complete, return the selector valve (a) to the sample position

and readjust the flow valve (c), (if necessary) so that flow meter

(b) reads 0.4 scfh.

sensor until the

2

transmitter can

2

Figure 3-5 Sample System Component Locations

Teledyne Analytical Instruments

3-7

Page 26

3 Operation Model OT-2 System

NOTE: This procedure is more critical on the 0-10 ppm range and

less critical on the 0-100 or 0-1000 ppm range.

3.3.2 Setting the Span Pot

1. Switch the system from zero gas to span gas and allow

time for stabilization.

Display

Span

Span Pot

Figure 3-6: Span Pot Location

NOTE: The span gas should have an O2 concentration of 80% -

100% of full scale. For example, if the range is set at 0-100

ppm, the span gas should be a certified grade gas of

about 90 ppm O2 in N2 or Argon.

2. If 90 ppm gas is used, adjust the span pot (Figure 3-6)

to read 90.0 ppm on the LCD display. The output to

the Elsag Baily Total Flow TM computer will have a

signal of 4.6VDC (into a >10K ohm load).

3-8

The formula for this is:

Span Gas % F.S. x 4

100

Teledyne Analytical Instruments

+=

Output in VDC

1

Page 27

Model OT-2 System Operation 3

3.3.3 H2S Scrubber

The life expectancy of the stainless steel H2S scrubber, included in this system, is determined by the amount of H2S passing

through it.

With the maximum concentration of 200 PPM H

rate of 0.2 scfh the expected scrubber life will be over 6 months

with Purifil® and over 11 months with Purifil® II.

This scrubber life expectancy increases with lower H2S concentration or gas sample flow rates. It is recommended that the

flow rate be set

should be increased only if a faster system response time is desired.

It is suggested that a spare scrubber be kept on hand and

replaced every 6 months. When the scrubber needs to be replaced, follow the procedure in section 4,

ber Replacement".

WARNING: IF SCRUBBER IS NOT PROPERLY MAINTAINED THE

no higher than 0.4 scfh initially. The flow rate

Maintenance

O

SENSOR LIFE WILL BE SHORTENED.

2

S and a flow

2

, "Scrub-

3.3.4 Exhaust/Vent Line (Sample Return)

It is recommended that a long vent line (approx. 4 ft.) be

installed to the "Sample Return" connector at the side of the system enclosure. The extended vent line will minimize back diffusion

from the atmosphere back to the sensor. The minimum recommended tubing diameter is 1/4" to minimize back pressure.

3.4 Testing the System

Before connecting the instrument into the power source:

• Check the integrity and accuracy of the gas

connections. Make sure there are no leaks.

• Check the integrity and accuracy of the electrical

connections. Make sure there are no exposed

conductors.

• Check that inlet sample pressure is within the

acceptable range (see section 3.3.1).

• Power up the system, and test it.

Teledyne Analytical Instruments

3-9

Page 28

3 Operation Model OT-2 System

3-10

Teledyne Analytical Instruments

Page 29

Model OT-2 System Maintenance 4

Maintenance

4.1 Routine Maintenance

Aside from normal cleaning and checking for leaks at the gas

connections, routine maintenance includes servicing the filter, the

scrubber, installing replacement Micro-Fuel cells and recalibration.

For recalibration, see section 3.3

Calibration

.

4.2 Cell Replacement

The Micro-Fuel Cell is a sealed electrochemical transducer

with no electrolyte to change or electrodes to clean. When the

cell reaches the end of its useful life, it is replaced. The spent fuel

cell should be discarded according to local regulations.

The characteristics of the Micro-Fuel Cell are similar to those

of a mercury battery in that both provide an almost constant

output (when the sensor is exposed to a constant level of oxygen)

throughout their useful life, and then fall off sharply towards zero at

the end. Cell failure, in the Model OT-2 System, will probably be

indicated by the inability to properly span calibrate the transmitter,

or excessively long response time to changes in oxygen concentration.

To ensure availability, TAI recommends that a spare cell be

purchased shortly after the instrument is placed in service, and

each time the cell is replaced.

The spare cell should be carefully stored in a cool, and near

constant temperature, area if possible.

NOTE: Do not disturb the integrity of the cell package until the

cell is to actually be used. If the cell package is punctured

and has been exposed to atmospheric air over an extended period, the sensor may not function properly.

Power must be removed from the OT-2 prior to removing or

installing the sensor.

Teledyne Analytical Instruments

4-1

Page 30

4 Maintenance4 Maintenance

4 Maintenance Model OT-2 System

4 Maintenance4 Maintenance

To replace the cell: Figure 4-1

1. Open the enclosure door.

2. Undo the velcro straps.

3. Remove the insulation.

4. The cell block is located in the center of the unit.

Unscrew the cap on the bottom of the cell block. The

B-2C sensor should drop down once the cap is

removed.

INSULATION

B-2C

SENSOR

CAP

Figure 4-1 Cell Block

NOTE: Before the cell is removed from its package, a zero gas

with low ppm oxygen flowing at a relative high rate

through the cell block can lessen the time it will take the

newly installed cell to drop to a zero reading.

3. Remove the new cell from its package, and carefully

remove the shorting clip.

WARNING: The sensor used in the Model OT-2 System uses

electrolytes which may contain substances that are

harmful if touched, swallowed, or inhaled. Avoid

contact with ANY fluid or powder in or around the

unit. What may appear to be plain water could

contain one of these toxic substances. In case of

eye contact, immediately flush eyes with water for

at least 15 minutes. Call physician. {See Appendix Material Safety Data Sheet (MSDS)}.

4-2

Teledyne Analytical Instruments

Page 31

Model OT-2 System Maintenance 4

4. Place the new cell on the cap with the sensing surface

face down and the gold contact rings up.

5. Position the cell and cap so that the cell is inside the cell

block. Press up on the cap and rotate. Tighten the cap

screws.

4.2.1 Cell Warranty

The cell warranty is sensor specific. Please contact Teledyne

Electronic Technologies/ Analytical Instruments on explicit warranty on sensors.

NOTE: Evidence of damage due to tampering or mishandling will

render the cell warranty null and void.

4.3 Scrubber Replacement

To ensure proper operation of the OT-2 System, it is recommended to replace the scrubber every 6 months or more frequently if the sensor is reaching end of life prematurely.

It is important that the replacement of the scrubber be completed within one hour of it's removal to prevent back diffusion of

oxygen from the atmosphere to the sensor.

During scrubber replacement, it is recommended that the 3way valve is switched to "Span Gas". This will minimize the system

recovery time.

NOTE: If the sensor is exposed to air through back diffusion, from

the atmosphere it may cause the sensor to re-stabilize

slowly.

4.4 Filter Servicing

To ensure the proper performance and sample flow, it is

recommended that the sample filter be inspected when the cell is

replaced. The filter requires both a 1" and a 11/16" open end

wrench to remove the filter bowl. Turn off the sample flow valve

prior to servicing filter. The filter should be cleaned or replaced as

required.

Teledyne Analytical Instruments

4-3

Page 32

4 Maintenance4 Maintenance

4 Maintenance Model OT-2 System

4 Maintenance4 Maintenance

4-4

Teledyne Analytical Instruments

Page 33

Model OT-2 System Appendix

Appendix

Specifications:

System Enclosure: NEMA 4 Rated, bulkhead mounted

Power Requirements: 9-16 VDC and 16-275mA.

Ranges: 0–10ppm and 0–100ppm Oxygen

or 0-100 ppm and 0-1000 ppm O2.

Accuracy: ± 2% of full scale at constant temperature and

pressure (temperature and pressure of calibration), except ± 1ppm on 0–10ppm range.

± 5% of full scale over operating temperature

range (once thermal equilibrium has been

reached), except ± 1ppm on 0–10ppm range.

Response Time (90%): Sensor Response Time = 61 seconds @ 77°F

(25°C).

Overall system response time is flow rate

dependent.

Operating Temperature: 5-113°F (-15–45°C)

Stability: ± 1% in 24 hours (at constant temperature)

Reproducibility: ± 1% of full scale at constant temperature

Sensor Type: Micro-Fuel Cell class B2C

Optional (application dependent): Micro-Fuel

Cell class A2C if CO2 concentration consistently exceeds 1000 ppm.

Signal Output: 1-5 VDC

Teledyne Analytical Instruments

A-1

Page 34

AppendixAppendix

Appendix Model OT-2 System

AppendixAppendix

Recommended Spare Parts List

Qty. Part Number Description

1 C71345A & C71345B Cell Block Insulation Set

1 C70976B PC Board — 1-5V Transmitter (0-100/0-1000 ppm)

1 C70976A PC Board — 1-5V Transmitter (0-10/0-100 ppm)

1 B71343 Scrubber Assembly (complete)

1 P396 Scrubber Material

1 C6689-B2C Micro-Fuel Cell B2C Class

1 C6689-A2C Micro-Fuel Cell A2C Class

1 F688 Filter

1 H517 Heater

1 C71272 Cell Holder Assembly

A minimum charge is applicable to spare parts orders.

NOTE: Orders for replacement parts should include the part number (if available ) and the

model and serial number of the instrument for which the parts are intended.

Orders should be sent to:

Teledyne Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Phone (626) 934-1500, Fax (626) 961-2538

TWX (910) 584-1887 TDYANLY COID

Web: www.teledyne-ai.com

or your local representative

Drawing List

A-2

C71020 Outline Diagram

B71018 Interconnection Diagram

D70975 Schematic — 1-5V Transmitter

B71019 Piping Diagram

Teledyne Analytical Instruments

Page 35

Model OT-2 System Appendix

Material Safety Data SheetMaterial Safety Data Sheet

Material Safety Data Sheet

Material Safety Data SheetMaterial Safety Data Sheet

Section I – Product Identification

Product Name: Micro-Fuel Cells

Mini-Micro-Fuel Cells, all classes

Super Cells, all classes except T–5F

Electrochemical Oxygen Sensors, all classes.

Manufacturer: Teledyne Analytical Instruments

Address: 16830 Chestnut Street, City of Industry, CA

91749

Phone: (626) 934-1500

Date Prepared or Last Revised: 08/08/91

Emergency Phone Number: (626) 934-1500

Section II – Physical and Chemical Data

Chemical and Common Potassium Hydoxide (KOH), 15% (w/v)

Name s: Lead (Pb), pure

CAS Number: KOH 1310–58–3

Pb 7439–92–1

KOH (15%) Pb (pure)

Melting Point/Range: –10 to 0 °C 328 °C

Boiling Point/Range: 100 to 115 °C 1744 °C

Specific Gravity: 1.09 @ 20 °C 11.34

pH: >14 N/A

Solubility in Water: Completely soluble Insoluble

Percent Volatiles by Volume: None N/A

Appearance and Odor: Colorless, odorless solution Grey metal,

odorless

Teledyne Analytical Instruments

A-3

Page 36

AppendixAppendix

Appendix Model OT-2 System

AppendixAppendix

Section III – Physical Hazards

Potential for fire and explosion: The electrolyte in the Micro-Fuel Cells is

not flammable. There are no fire or explosion hazards associated with Micro-Fuel Cells.

Potential for reactivity: The sensors are stable under normal conditions of

use. Avoid contact between the sensor electrolyte and strong acids.

Section IV – Health Hazard Data

Primary route of entry: Ingestion, eye/skin contact

Exposure limits: OSHA PEL: .05 mg./cu.m. (Pb)

ACGIH TLV: 2 mg./cu.m. (KOH)

Effects of overexposure

Ingestion: The electrolyte could be harmful or fatal if

swallowed.

Oral LD50 (RAT) = 3650 mg./kg

Eye: The electrolyte is corrosive; eye contact could

result in permanent loss of vision.

Dermal: The electrolyte is corrosive; skin contact could

result in a chemical burn.

Inhalation: Liquid inhalation is unlikely.

Signs/symptoms of exposure: Contact with skin or eyes will cause a burning

sensation and/or feel soapy or slippery to

touch.

Medical conditions

aggravated by exposure: None

Carcinogenicity: NTP Annual Report on Carcinogens: Not listed

LARC Monographs: Not listed

OSHA: Not listed

Other health hazards: Lead is listed as a chemical known to the State

of California to cause birth defects or other reproductive harm.

A-4

Teledyne Analytical Instruments

Page 37

Model OT-2 System Appendix

Section V – Emergency and First Aid Procedures

Eye Contact: Flush eyes with water for at least 15 minutes and get immedi-

ate medical attention.

Skin Contact: Wash affected area with plenty of water and remove con-

taminated clothing. If burning persists, seek medical attention.

Ingestion: Give plenty of cold water. Do not induce vomiting. Seek

medical attention. Do not administer liquids to an unconscious person.

Inhalation: Liquid inhalation is unlikely.

Section VI – Handling Information

NOTE: The oxygen sensors are sealed, and under normal circumstances,

the contents of the sensors do not present a health hazard. The

following information is given as a guide in the event that a cell

leaks.

Protective clothing: Rubber gloves, chemical splash goggles.

Cleanup procedures: Wipe down the area several times with a wet paper

towel. Use a fresh towel each time.

Protective measures

during cell replacement: Before opening the bag containing the sensor

cell, check the sensor cell for leakage. If the sensor

cell leaks, do not open the bag. If there is liquid

around the cell while in the instrument, put on gloves

and eye protection before removing the cell.

Disposal: Should be in accordance with all applicable state,

local and federal regulations.

NOTE: The above information is derived from the MSDS provided by the

manufacturer. The information is believed to be correct but does not

purport to be all inclusive and shall be used only as a guide.

Teledyne Analytical Instruments shall not be held liable for any

damage resulting from handling or from contact with the above

product.

Teledyne Analytical Instruments

A-5

Page 38

AppendixAppendix

Appendix Model OT-2 System

AppendixAppendix

A-6

Teledyne Analytical Instruments

Loading...

Loading...