Page 1

TELEDYNE

HASTINGS

INSTRUMENTS

INSTRUCTION MANUAL

MODEL NALL

MASS FLOWMETERS

ISO 9001

CERTIFIED

Page 2

Manual Print History

The print history shown below lists the printing dates of all revisions and addenda created for this manual.

The revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda,

which are released between revisions, contain important change information that the user should incorporate

immediately into the manual. Addenda are numbered sequentially. When a new revision is created, all

addenda associated with the previous revision of the manual are incorporated into the new revision of the

manual. Each new revision includes a revised copy of this print history page.

Revision A (Document Number 111-041990) ................................................................... April 1990

Revision B (Document Number 111-102003)............................................................... October 2003

Revision C (Document Number 111-082005) ................................................................August 2005

Revision D (Document Number 111-022006) ............................................................. February 2006

Revision E (Document Number 111-052007).....................................................................May 2007

Revision F (Document Number 111-082010)................................................................. August 2010

Revision G (Document Number 111-122010) ........................................................... December 2010

Visit www.teledyne-hi.com for WEEE disposal guidance.

CAUTION:

CAUTION:

CAUTION:

The instruments des cribed in this manual are av ailable w ith multiple pin-outs .

Ensure that all electrical connections are correct.

The instruments des cribed in this manual are des igned for INDOOR us e only .

The instruments described in this manual are designed for Class 2 installations

in accordance with IAW/IPC standards

Hastings Instruments reserves the right to change or modify the design of its equipment without

any obligation to provide notification of change or intent to change.

Manual 111-082010_Nall Mass Flowmeters Page 2 of 23

Page 3

Table of Contents

1.0

GENERAL INFORMATION....................................................................................................................................... 5

1.1 FEATURES:................................................................................................................................................................... 5

2.0 OPERATING PRINCIPLE.......................................................................................................................................... 6

2.1 OPERATING PRINCIPLE.................................................................................................................................................6

3.0 RECEIVING AND INSPECTION...............................................................................................................................7

3.1 INITIAL INSPECTION:.................................................................................................................................................... 7

3.2 PACKING LIST:.............................................................................................................................................................7

3.3 DECIMAL POINT SETTING: ........................................................................................................................................... 7

3.4 POWER SOURCE:.......................................................................................................................................................... 7

3.5 ELECTRICAL ZERO:...................................................................................................................................................... 7

3.6 INDICATION OF FLOW: ................................................................................................................................................. 7

4.0 INSTALLATION INSTRUCTIONS............................................................................................................................8

4.1 TRANSDUCER.......................................................................................................................................................... 8

4.2 FILTERS:.................................................................................................................................................................... 9

4.3 CABLES.....................................................................................................................................................................9

4.4 POWER SUPPLY:...................................................................................................................................................... 9

5.0 USING THE FLOWMETER......................................................................................................................................11

5.1 WARM-UP TIME: .......................................................................................................................................................11

5.2 RESPONSE TIME:........................................................................................................................................................ 11

5.3 MASS FLOW UNITS:................................................................................................................................................... 11

5.4 SPECIAL FACTORY CALIBRATIONS: ........................................................................................................................... 11

5.5 GAS CONVERSION FACTORS:.....................................................................................................................................11

5.6 OUTPUT SIGNAL: .......................................................................................................................................................12

5.7 ACCURACY:...............................................................................................................................................................13

5.8 REPEATABILITY:........................................................................................................................................................ 13

5.9 OVER-RANGE:............................................................................................................................................................ 13

6.0 PRESSURE EFFECTS................................................................................................................................................14

6.1 STANDARD TRANSDUCERS: .......................................................................................................................................14

6.2 LOW PRESSURE DROP TRANSDUCERS:....................................................................................................................... 14

6.3 HIGH PRESSURE TRANSDUCERS (OPTIONAL):............................................................................................................ 14

7.0 TEMPERATURE EFFECTS......................................................................................................................................15

7.1 AMBIENT TEMPERATURES:........................................................................................................................................15

7.2 GAS TEMPERATURE ...................................................................................................................................................15

8.0 DIFFERENTIAL PRESSURE....................................................................................................................................16

8.1 TYPICAL PRESSURE DROPS................................................................................................................................16

8.2 CHANGES IN DP WITH CHANGES IN LINE PRESSURE................................................................................... 16

8.3 DP INCREASE DUE TO FOULING OF THE TRANSDUCER: ............................................................................................. 17

9.0 CALIBRATION........................................................................................................................................................... 18

9.1 CALIBRATION PROCEDURES.............................................................................................................................18

10.0 MAINTENANCE......................................................................................................................................................... 20

10.1 TRANSDUCERS:.......................................................................................................................................................... 20

10.2 POWER SUPPLY:.........................................................................................................................................................20

11.0 ACCESSORIES...........................................................................................................................................................21

11.1 OPTIONS AND ACCESSORIES............................................................................................................................. 21

11.2 DOUBLE POINT RELAY FLOWMETER/ALARM (DNALL-P):....................................................................................... 21

11.3 TOTALIZERS (TNALL-P):.......................................................................................................................................... 21

11.4 CHASSIS MODEL (NALL-C):..................................................................................................................................... 22

11.5 CURRENT CONVERTER (NALL-P/CC):.......................................................................................................................22

Manual 111-082010_Nall Mass Flowmeters Page 3 of 23

Page 4

11.6 SPECIFICATIONS................................................................................................... ERROR! BOOKMARK NOT DEFINED.

12.0 WARRANTY AND REPAIR......................................................................................................................................23

12.1 WARRANTY REPAIR POLICY ...................................................................................................................................... 23

12.2 NON-WARRANTY REPAIR POLICY .............................................................................................................................23

Manual 111-082010_Nall Mass Flowmeters Page 4 of 23

Page 5

1.0 General Information

1.1 Features:

Hastings Linear Mass Flowmeters are designed to accurately measure mass flow without corrections or

compensations for gas pressure and temperature. Due to a linear electrical output signal, the flowmeters are

ideal for use with totalizers and recorders. Hastings Linear Mass Flowmeters do not require any periodic

maintenance under normal operating conditions with clean gases. No damage will occur from the use of

moderate overpressures, overflows, or liquid solvents.

The standard flowmeter calibration is for air. Special calibrations for most other gases such as oxygen,

nitrogen, hydrogen, and carbon monoxide, are available on special order, or by use of a gas multiplier.

Special calibrations are noted by the following options such as OPT-G (special gas) or OPT-R (special

range) and OPT-GR (special gas and range).

Standard HS-Series transducer and L-Series laminar flow elements are available with 300 Series stainless

steel or monel construction. U-Series low pressure drop transducers are constructed of monel.

The basic flowmeter is available in either a cabinet model or a NIM panel. The NIM model can be mounted

side by side in groups of three, in an optional NIM frame. Chassis models are available on special order.

Manual 111-082010_Nall Mass Flowmeters Page 5 of 23

Page 6

2.0 OPERATING PRINCIPLE

2.1 Operating Principle

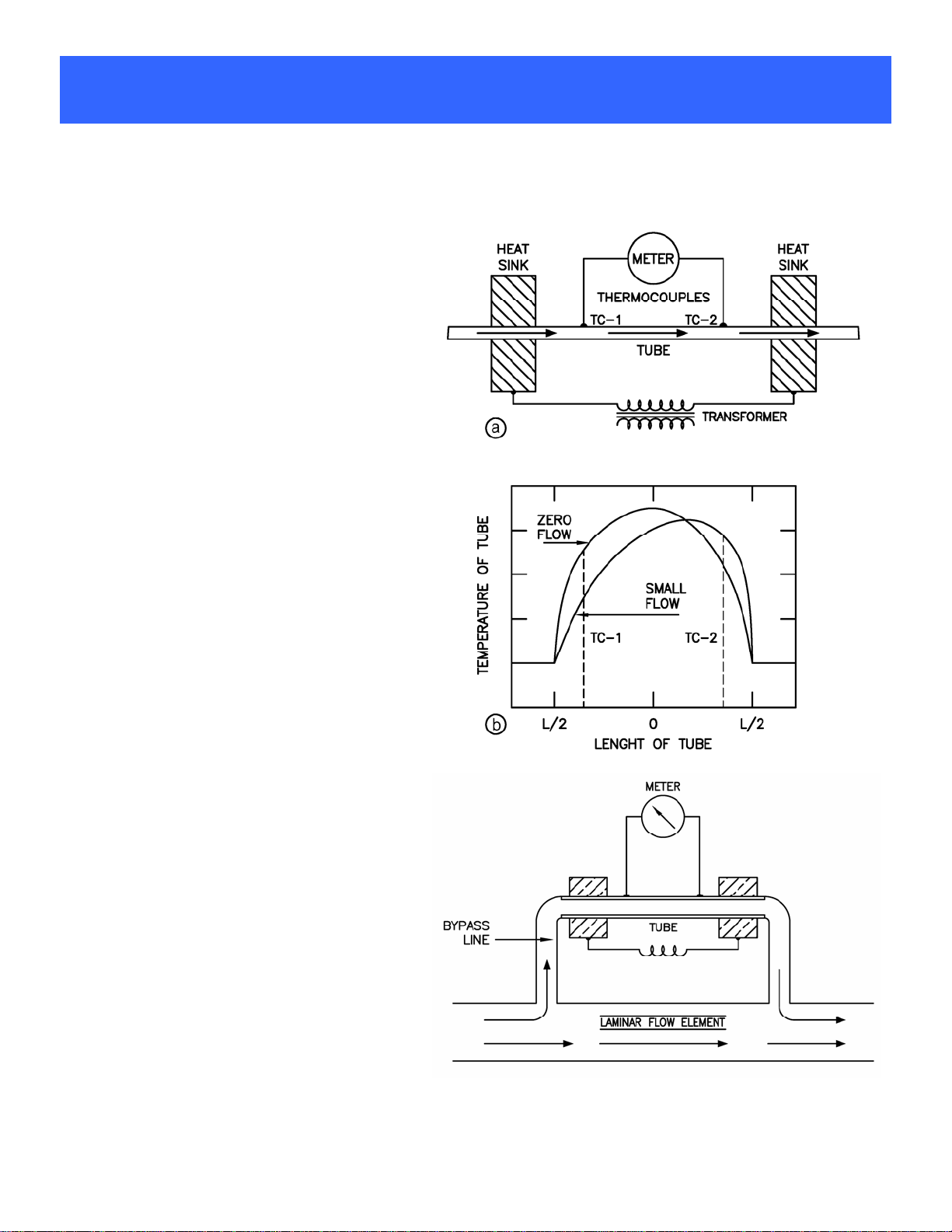

Hastings Linear Mass Flowmeters operate

on a unique electrical principle whereby a

capillary tube is heated uniformly by a

transformer. The temperature distribution

is symmetrical about the midpoint at zero

flow (see Figure 2.1) and external

thermocouples TC-1 and TC-2 develop

equal and opposing outputs.

When flow occurs through the tubing,

heat is transferred to the gas and back

again creating an asymmetrical

temperature distribution. For a constant

power input, the differential thermocouple

output is a function of the mass flow rate

and heat capacity of the gas. Since the

heat capacity is relatively constant over

wide ranges of temperature and pressure,

the flowmeter may be calibrated directly

in mass units for any given gas. Changes

in gas composition only require simple

multiplier applied to the air calibration

(see table, page 19) to account for the

difference in heat capacity, thus the

flowmeter is capable of measuring a wide

variety of gases.

High ranges of flow are achieved by

dividing the flow with a fixed ratio

shunting arrangement, as is illustrated in

Figure 2.2. By placing the measuring

tube in parallel with one or more

dimensionally similar channels (laminar

flow elements), viscous restrictions are

created. Therefore, the sensor need heat

only a small portion of the total gas which

results in low power requirements while

retaining mass measuring characteristics.

Fig 2.1

Fig 2.2

Manual 111-082010_Nall Mass Flowmeters Page 6 of 23

Page 7

3.0 RECEIVING AND INSPECTION

3.1 Initial Inspection:

Carefully unpack the Hastings Linear Mass Flowmeter and inspect it for any obvious signs of damage due to

shipment. Immediately advise the carrier who delivered the shipment of any suspected damage.

3.2 Packing List:

The basic flowmeter consist of four separate parts:

1. The power supply (NALL, NALL-P, NALL-P/CC, DNALL-P, TNALL-P, NALL-C, etc.)

2. The transducer (examples: HS-10S, HS-50KM, etc.)

3. The connecting cable (examples: NF-8-NM, NF-25-NM, etc.)

4. The laminar flow element attached to transducer, for ranges higher than 0-100 SLPM (examples: L-5S,

L-100SF, L-200MF, etc.)

Optional equipment or accessories will be listed as part of the model number or listed separately on the

packing list. (See Section 11.0, OPTIONS AND ACCESSORIES.)

3.3 Decimal Point Setting:

The digital flowmeter has a 3-digit LED display. The decimal point is set as shown in the table below:

3.4 Power Source:

Connect the power supply to 115 volt (10%) 50-60 Hz line. (The prefix “E” indicates the power supply is to

be connected to a 230 volt (10%) 50-60 Hz line.) Connect the power supply to the transducer by means of

the connecting cable. When the flowmeter is turned on the readout may fluctuate somewhat, before settling

to a steady indication.

3.5 Electrical Zero:

After allowing a warm-up time of approximately 30 minutes, close off the INLET and OUTLET

connections on the transducer with the protective plastics end caps shipped on the transducer. If the meter

does not indicate zero flow, adjust the “ZERO” potentiometer located on the front panel, until the meter

indicates zero.

3.6 Indication of Flow:

Remove the end plug or end cap from each end of the transducer and blow air into the inlet side. (The

meter readout should increase indicating the flowmeter is in good working order and ready for installation.)

Manual 111-082010_Nall Mass Flowmeters Page 7 of 23

Page 8

4.0 INSTALLATION INSTRUCTIONS.

4.1 TRANSDUCER

4.1.1 Orientation of the Transducer

The transducer may be mounted in any position, as long as the direction of gas flow through the transducer

is from “IN” to “OUT” as marked on the transducer base. (U-Series transducers should be mounted in a

horizontal position only.)

4.1.2 Mounting the Transducer

There are two ¼-20 threaded holes 3/8” deep in the bottom of the transducer that can be used to secure it to

a mounting bracket, if desired. When the transducer is used in combination with an L or LU Series Laminar

Flow Element (LFE), the LFE should be supported instead of the transducer to prevent undue strain on the

connectors between the transducer and the LFE. Standard pipe support rings or pipe hangers are usually

satisfactory for supporting the LFE.

4.1.3 Inlet and Outlet Connections

The table 4.1 describes the inlet and outlet connections for all standard transducers. (If it is necessary to

reduce the pipe size or install an elbow on either side of an L or LU Series Laminar Flow Element, it is

recommended that a straight pipe 12” in length, and of pipe or flange size stated below, be connected

directly to the LFE before connecting a smaller diameter pipe or an elbow.)

4.1.4 Sealing the Threaded Connections

Many users find that Teflon tape is an excellent sealant for most applications, however, any sealant material

compatible with the flow system is acceptable. Caution must be exercised during assembly and disassembly

of the threaded connections to prevent shreds of the Teflon tape, or the sealant from entering the flow line,

where they could block the small passages in the transducer.

Manual 111-082010_Nall Mass Flowmeters Page 8 of 23

Page 9

The use of O-ring seal connectors on the transducers with female threads is often more convenient for many

low pressure applications, such as with U-Series transducers.

4.1.5 Checking for Leaks

Check the transducer connections for leaks by pressurizing the line to the operating pressure (not to exceed

250 psig except on high pressure models), and applying a diluted soap solution to the pipe joints. Any gas

escaping from the pipe joints will cause a continuous stream of bubbles.

4.2 FILTERS:

If the flow stream carries particles large enough to block the small passages inside the transducer

(approximately .02” ID) a filter should be installed in the flow line of the inlet side of the transducer.

4.3 CABLES

4.3.1 Description

A standard 5-conductor 20 gauge shielded 8-foot long cable (NF-8-NM) is normally ordered with each

flowmeter and is used for connecting the power and the transducer. Longer cables are available upon special

request.

4.3.2 Cable Length

The cable length can be extended to 25 feet without changing the calibration of the flowmeter by more than

SP+/-1% of the rated full scale flow. Cables longer than 25 feet will cause the indicated flow rate to be lower

than the actual flow rate and recalibration may be required. (See Section 7.0 for calibration procedures.)

4.3.3 Cable Conductor Size

In the event cable conductors larger than #20 are desired, the connecting cable can be extended to greater

lengths without having to recalibrate the flowmeter. The table below shows the relationship of the conductor

size to the maximum cable length that can be used without changing the calibration by more than 1% of full

scale.

4.4 POWER SUPPLY:

4.4.1 Mounting

One type of housing available for the power supply is a small metal cabinet, 7.75” X 5.75”X 5.75”, which

can sit on a table or desk or can be mounted securely on a bracket. The “NIM” style package is 5.41” X

8.71” X 9.68”, and can be housed in an 8.75” X 19.00” relay rack-panel.

4.4.2 Electrical Connections

Connect the power supply to the transducer with the NF-8-NM connecting cable (Section 4.3) and connect

the AC line cord to a suitable power source (Section 3.4).

Manual 111-082010_Nall Mass Flowmeters Page 9 of 23

Page 10

4.4.3 Electrical Zero Check

Turn the power supply “ON” and allow the flowmeter 30 minutes to warm up. Stop all flow through the

transducer and check the electrical zero.

CAUTION: DO NOT ASSUME THAT ALL METERING VALVES WILL COMPLETELY

SHUT OFF FLOW. EVEN A SLIGHT LEAKAGE THROUGH A VALVE WILL CAUSE AN

INDICATION ON THE METER WHICH WILL FALSELY APPEAR TO BE A ZERO SHIFT.

If necessary, adjust the “ZERO” potentiometer located on the front panel of the power supply, until the

meter indicates zero.

Manual 111-082010_Nall Mass Flowmeters Page 10 of 23

Page 11

5.0 USING THE FLOWMETER

USING THE HASTINGS LINEAR MASS FLOWMETER

5.1 Warm-Up Time:

When the flowmeter is first turned on, the meter will fluctuate somewhat before settling to a stable

indication. The flowmeter indicates the mass flow to +/- 3% of full scale in about 5 minutes, but should be

allowed to warm up for 30 minutes to achieve maximum accuracy.

5.2 Response Time:

The response time to a change in flow is logarithmic and is approximately 7 seconds for a 67% change and

30 seconds for a 90% change. Pneumatic imbalance in the associated plumbing will often cause the response

time to appear longer due to additional time required for flow to stabilize in the system. If a faster response

time is desired, consult the factory.

5.3 Mass Flow Units:

The units of mass flow used with the Models NALL, ENALL, NALL-P, and ENALL-P mass flowmeters are

the “standard cubic centimeter per minute” (SCCM) and/or the “standard litre per minute” (SLPM). An

SCCM is the volume occupied by a given mass of gas at a specified temperature and pressure referred to as

standard conditions (STP). These conditions are defined as 0° C (32°F) and 760 Torr (14.7 psia). A one

litre volume of gas is equivalent to 1000 cm³ of the same gas. Those models incorporating a Laminar Flow

Element (LFE) use “standard cubic foot per minute” (SCFM) units, which are equivalent to a flow of

28,300 SCCM or 28.3 SLPM. To convert to other units of mass flow, multiply the mass flow rate of the gas

by the density of the gas at standard conditions.

Example: What is the equivalent mass flow in grams per minute of 100 SCCM of air?

Solution: The density of air at 0° C and 760mm of Hg is .00129 gm/cm³.

Mass Flow = 100 SCCM X .00129 gm/cm³.

= .129 gm/min.

5.4 Special Factory Calibrations:

All Hastings Mass Flowmeters are calibrated for air unless otherwise specified. Calibrations for a special

range or for a gas other than air are clearly indicated on the front panel readout of standard models, or by

special comments or curves in the manual. Calibrations traceable to the National Institute of Standards &

Technology (NIST), can also be made for an extra charge.

5.5 Gas Conversion Factors:

The Hastings Linear Mass Flowmeter can be used for many different gases as long as the gas is compatible

with materials of construction. No electrical adjustments are necessary when using the gas conversion factors

so the original calibration is undisturbed.

5.5.1 Flowmeters Factory Calibration for Air

A flowmeter originally calibrated for air can measure other gases by using the Hastings Gas Conversion

Factors on Page 35 of this manual. Simply multiply the meter indication by the appropriate gas conversion

factor (K).

Example: What is the actual flow rate of Helium through a flowmeter calibrated for Air if the

meter reading is 50 SCCM?

Solution: From the table on page 35, the gas conversion factor for Helium is 1.382.

Manual 111-082010_Nall Mass Flowmeters Page 11 of 23

Page 12

Actual flow = meter reading X (KHe)

= 50 SCCM X 1.382

= 69.1 SCCM of Helium

5.5.2 Flowmeter Factory Calibrated for a Special Gas

If the Hastings Linear Mass Flowmeter is calibrated for a gas other than air, it may also be used to measure

the flow rate of many other gases. The flow rate will be equal to the meter reading multiplied by the ratio of

the gas conversion factors.

Example: What is the actual flow rate of Carbon Dioxide through a flowmeter calibrated for Helium, if

the meter reading is 96 SCCM?

Solution: Flow of CO2‚ = (meter reading) (K for CO2)

K for He

= (96 SCCM) * .6933

1.3820

= 48.2 SCCM

5.5.3 Gas Mixtures

If a mixture of gases is used and the percentage by volume of each gas is reasonable constant, a conversion

factor for the gas mixture can be obtained.

K (mix) = _____________________________1__________________

__ __ __

Va + Vb + Vc + ….

Ka Kb Kc

Where

V (a, b, ….) = percent of gas a, b ….)

K = conversion factor

K can be obtained from the table beginning on page 35 for many gases.

Example: What is the conversion factor for a mixture of 20% Hydrogen, 40% Argon, and 40%

Oxygen?

Solution: = _________________________1______________

__ __ __

Va + Vb + Vc + ….

Ka Kb Kc

=__________________________1______________

.2 + .4 + .4

1.01 1.41 .96

= 1.11

5.6 Output Signal:

The two output terminals on the back of the power supply provide a 0-5 VDC signal for recording or

operating auxiliary equipment such as flow controllers or converters. The output signal is linear with respect

to mass flow and has sensitivity equal to the rated full-scale flow rate divided by 5.00 VDC.

Manual 111-082010_Nall Mass Flowmeters Page 12 of 23

Page 13

Example: (A) What is the output sensitivity of HS-1KS?

(B) What is the flow rate for a 2.71 volt output?

Solution: (A) Sensitivity = rated flow

Rated output

= 1000 SCCM

5.00 VDC

= 200 SCCM/VDC

(B) Mass Flow = output X sensitivity

= 2.71v X 200 SCCM/VDC

= 542 SCCM

5.7 Accuracy:

The accuracy of the flow indication is +/- 1% of full scale, with the exception of the U-Series transducer

where the accuracy is +/- 3% of full scale.

5.8 Repeatability:

The repeatability over a six-month period is +/- ½% of full scale if the flowmeter is operating normally in a

clean, dry system. Under reasonable constant conditions, a repeatability of +/- 1 to +/- 2% of

INDICATION can be expected on a day-to-day basis.

5.9 Over-range:

The flowmeter has an output signal which is directly proportional to mass flow and linear to +/- of full scale

from zero flow to the normal full-scale flow rate.

The flowmeter can be used to measure flow rates higher than the rated maximum flow, but the output signal

normally becomes non-linear above 5 volts d-c. A calibration curve for voltage vs. flow can be made for

outputs up to 10 volts d-c. At some point above 10 volts d-c the output will no longer increase as the flow

increases. The flow rate required to produce this condition is several times the normal full-scale flow rate.

Once flow is reduced to the proper level, the flow meter will again indicate mass flow currectly. The

flowmeter will not be damaged by excessive flow rates as long as the pressure in the line does not exceed the

pressure rating for the transducer.

Manual 111-082010_Nall Mass Flowmeters Page 13 of 23

Page 14

6.0 PRESSURE EFFECTS

6.1 Standard Transducers:

The Hastings Linear Mass Flowmeter can measure mass flow accurately without corrections for a variation

in line pressure from one psia (.068 ATM) to 250 psig (18 ATMS.) Mass flow indications are possible with

downstream pressures as low as .03 psia (.002 ATM), but the upstream must be much higher because of the

increase in pressure drop across the transducer (see Section 8.0).

6.2 Low Pressure Drop Transducers:

The low pressure drop Mass Flowmeter (using U-Series transducers) can measure flow accurately from .03

psia ( .002 ATM) to 15 psig ( 2 ATMS). The transducer is rated for a maximum pressure of 250 psig ( 18

ATMS). Mass flow indications are possible with downstream pressure as low as .1 Torr with upstream

pressures of less than 30 Torr. This flowmeter has been successful for many years in measuring uranium

hexafluoride flow rate under vacuum conditions, and has also been useful in measuring vacuum pumping

speeds and in atmospheric sampling trains.

6.3 High Pressure Transducers (Optional):

Hastings transducers having a P suffix have been pressure tested to 1500 psig using dry nitrogen gas. The

transducer was cycled between 0 and 1500 psig for two periods with a minimum of 5 minutes each, and held

at the pressure for a combined test period of 10 minutes. It was then leak tested on a Helium Leak Detector

where a leak rate of no more than 3 X 10-6 SCCS was required.

The flowmeter has been designed and tested as described above for line pressure up to 1500 psig under

normal usage. High pressure gas is always potentially dangerous and we strongly urge that extreme caution

be taken in locating, installing, and operating this equipment.

Manual 111-082010_Nall Mass Flowmeters Page 14 of 23

Page 15

7.0 TEMPERATURE EFFECTS

7.1 Ambient Temperatures:

7.1.1 Transducer

In order to maintain the accuracy of the flowmeter with changes in ambient temperature, it is necessary to

keep the temperature of the transducer between 10° C and 50° C. (The temperature of the base is normally

about 10° C above ambient due to internal heat.) There are two ¼”-20 bolt holes in the bottom of the

transducer to facilitate mounting the transducer to an external heat sink. Since some of the temperature shift

results in a slight zero offset, better results are obtained if the flowmeter is re-zeroed at the operating

temperature.

7.1.2 Power Supply

The NALL-type power supply can be operated over an ambient temperature range of 0° C to 40° C without

causing a calibration shift of more than +/- 1% of full scale. Since this error is primarily a zero shift, it can be

eliminated by adjusting the flowmeter ZERO potentiometer at the given operating temperature.

7.2 Gas Temperature

No corrections for gas temperature between 0° C and 100° C are necessary for the small ranges, but some

correction may be necessary for higher ranges. Part of the error at high ranges is transitory, and in most

cases will be reduced when the transducer temperature and gas temperature reach an equilibrium condition.

Gas flow at temperatures between -50°C and + 200° C can often be measured, but require recalibration by

the customer at operating conditions. Consult the factory for further details.

When using the NALL – or NALL –P Series flowmeter with a Laminar Flow Element, it is recommended

that both the Laminar Flow Element and the HS-10S (or HS-10M) transducer operate at the same

temperature.

The Hastings Linear Mass flowmeter measures GAS flow. DO NOT let the temperature and/or pressure of

the gas reach a point that would cause the gas to change to a liquid state, or erroneous indications will result.

Manual 111-082010_Nall Mass Flowmeters Page 15 of 23

Page 16

8.0 DIFFERENTIAL PRESSURE

8.1 TYPICAL PRESSURE DROPS

The differential pressure drop (DP) across the Hastings HS-Series Mass Flow Transducer can vary between

0.50” H2O depending upon the transducer’s range. Other pressure drops are listed below and all are based

upon full-scale flow rates of air at 0°C and 760 Torr.

8.2 CHANGES IN DP WITH CHANGES IN LINE PRESSURE

The typical differential pressure drops listed in the table above are for operation at atmospheric pressure. As

the line pressure changes, the differential pressure drop for the same flow rate will also change.

8.2.1 Increase in Line Pressure

The differential pressure drop across the transducer will decrease proportionately as the absolute line

pressure increases as stated in the following equation:

DP = DP (@STP) Pressure (STD)

Pressure (ACT)

Where DP = Transducer differential pressure at 0oC and 760 Torr

Pressure (STD) = 14.7 psia

Pressure (ACT) = 14.7 psia + line pressure

Manual 111-082010_Nall Mass Flowmeters Page 16 of 23

Page 17

8.2.2 Decrease in Line Pressure

The relationship stated in Section 8.2.1 also shows that DP increases proportionally as absolute line pressure

decreases. This situation is true until the DP becomes a significant part of the total absolute line pressure.

When this occurs, the relationship becomes more complex but the effect is still the same. The change in DP

does not affect the accuracy of the mass flow indications, but causes a change in the minimum upstream

pressure necessary to force a given amount of flow through the transducer.

8.3 DP Increase Due to Fouling of the Transducer:

A DP measurement across the transducer can often provide a good indication of fouling inside the

transducer. The values given in the Table on the preceding page are typical and may vary as much as 50%

for any given model. However, an increase in DP of two or three times the typical value is definitely an

indication of fouling. When checking for changes in DP, the flowmeter should be in operation at or near

standard conditions of 0oC and 760 Torr in order to relate the measured DP to those listed in the

Table. If there is an indication of fouling, refer to Section 10.1.

Manual 111-082010_Nall Mass Flowmeters Page 17 of 23

Page 18

9.0 Calibration

9.1 CALIBRATION PROCEDURES

The Hastings Mass Flowmeter has been carefully inspected and calibrated at the factory before shipment and

will give long, reliable service. Calibration is stable, and recalibration is seldom necessary under normal

operating conditions; however, to maintain optimum accuracy it is advisable to check calibration on an

annual basis. The unit may be returned to the factory for this purpose, but if that is undesirable, the

following calibration procedure may be of assistance:

1. Connect the power supply to the proper power source (Section 3.4).

2. Turn the power supply “ON” and allow 30 minutes for warm-up.

3. Set the “electrical zero” (Section 3.5).

4. Connect the inlet side of the transducer through a metering valve, to a well-regulated air source and the

outlet to a reliable flow reference such as the Hastings Mini-Flo Calibrator.

5. Check transducer heating voltage as outlined in Section 10.2.1.

6. During normal calibration, a flowmeter is spanned at 80% of full scale to obtain best average linearity.

Example: A 50 SCCM flowmeter with 0-5 VDC output at the binding posts is to be calibrated. If a

reference flow standard is set at a 40 SCCM flow rate, the flowmeter should indicate 80% (.80 X 50 SCCM

= 40 SCCM) of full scale. At this flow rate, the voltage at the binding posts should read 4 VDC (80% X 5

VDC).

CAUTION: Most flow standards are volumetric devices and must be corrected for temperature and

pressure to standard conditions of 0oC and 760 Torr. This correction amounts to several percent at normal

room temperatures and pressures and should not be neglected.

7. If the flowmeter does not agree with the reference flow standard, it is first necessary to correct the output

at the binding posts. This is done by making a small adjustment to the “GAIN” potentiometer R-30,

located on the circuit board inside the power supply. This adjustment will also produce a change in the

meter indication.

8. If the meter reading (flow) does not correspond with the binding post’s output (voltage), make a small

adjustment to the “METER” trim potentiometer R-32, located on the circuit board inside the power

supply. This correction has no effect on the output voltage.

9. PC-581A Board Only: Refer to Figure 9.1. Do not change the dipswitch (S2) settings. These settings

are factory pre-set and should only need changing if there is a change in the transducer or the units of

calibration. Switches 1, 2, & 3 change gain and 5, 6, 7, & 8 change the meter range to engineering units.

The number 4 position should remain closed.

Manual 111-082010_Nall Mass Flowmeters Page 18 of 23

Page 19

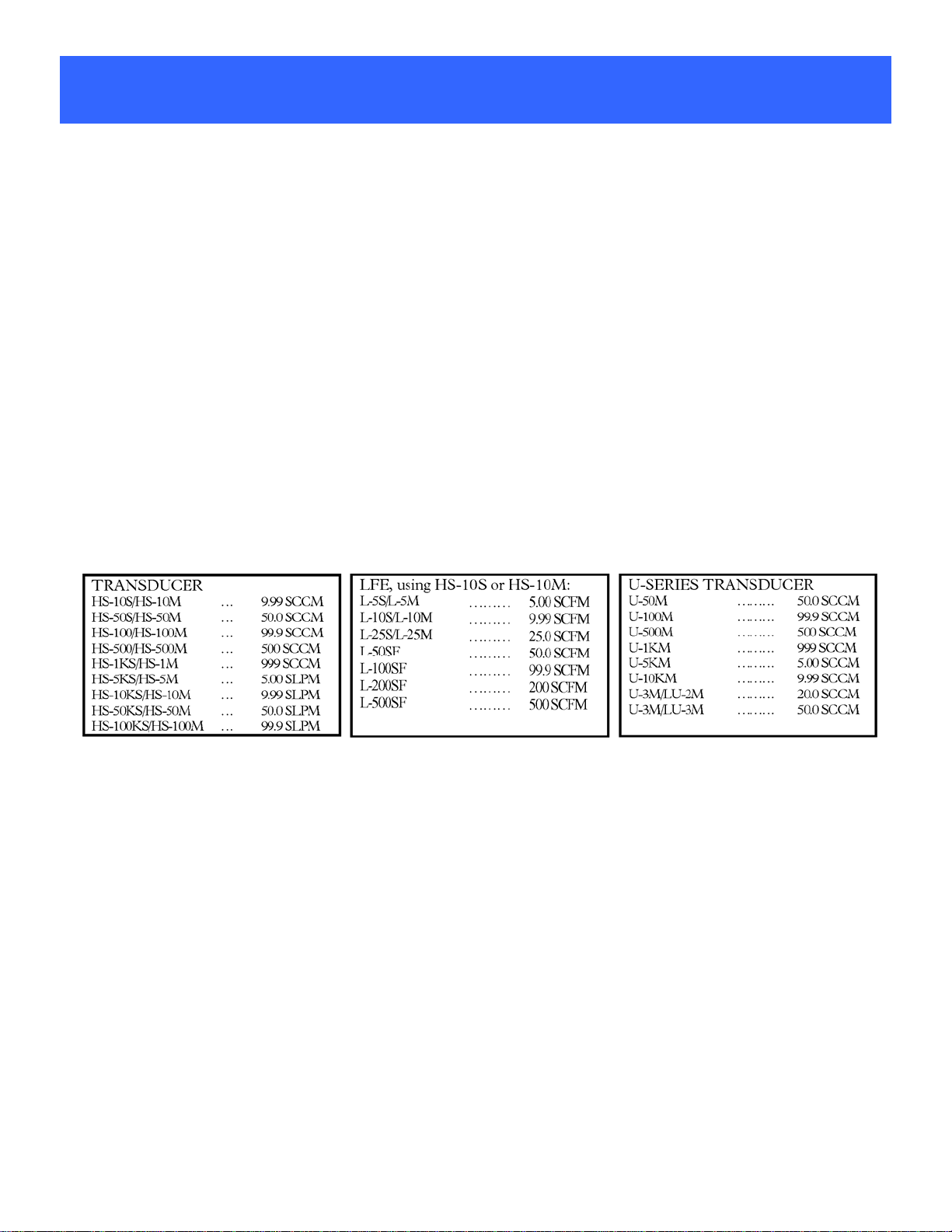

TRANSDUCER

MILLIVOLT

TEST

+5 VDC OUTPUT

BIAS METER GAIN TRMS AC TEST

JUMPER T1

FOR 230V OPERATION

FOR 581A ONLY FIG 9.1

Manual 111-082010_Nall Mass Flowmeters Page 19 of 23

Page 20

10.0 Maintenance

10.1 Transducers:

10.1.1 Cleaning

With proper care in installing and use, the transducer will require little or no maintenance. Should the small

passages in the transducer become partially clogged, they can be cleaned with any suitable solvent such as

acetone, vythene, etc. and/or blown out with clean air under moderate pressure (up to 50 psig).

NOTE: If solvents are used for cleaning the transducer, sporadic indications may occur when it is returned

to service due to residual moisture in the passages of the transducer. Time should be allowed for the liquid

solvent to evaporate.

10.1.2 Damage to the Transducer

The transducer can be checked for internal electrical damage by disconnecting the cable and using an ohmmeter to measure resistances at the 6-pin connector. Internal repairs to the transducer are not recommended

and should only be done at the factory. Attempting to remove the transducer cover or the nut on the

connector may result in irreparable damage to the transducer. The table below is for determining whether or

not some damage has occurred and IS NOT to be used as a guide for repairs.

10.2 Power Supply:

NALL and NALL-P power supplies are very stable and should require little or no maintenance. An

occasional check of the electrical zero is recommended but drift will be small under normal operating

conditions.

10.2.1 Power Supply Troubleshooting

If a problem does occur, the transducer heating voltage and the transducer output can be checked (refer to

Figure 9.1). To check the heating voltage, the flowmeter must be connected to the transducer and a true

R.M.S. voltmeter must be used. With the TRMS voltmeter connected between test points D and A (TRMS

AC test), the voltage should be 16.00 TRMS VAC +/- 0.1 VAC (and can be adjusted by the BIAS pot, R6).

The transducer output is measured between test points BC and E (millivolt test) using a DC millivolt meter.

This output will vary as flow through the transducer varies. At full scale flow for the transducer, the millivolt

meter should read between 0.75 and 7 millivolts DC, depending on the individual transducer. This signal is

amplified to produce the flowmeter output.

If it is necessary to return the flowmeter for repair, please return the transducer, power supply, and cable to

Teledyne Hastings-Raydist with a detailed explanation of the problem. Use the Service Repair form on page

35. This will help to ensure prompt, reliable service.

Manual 111-082010_Nall Mass Flowmeters Page 20 of 23

Page 21

11.0 Accessories

OPTIONS AND ACCESSORIES

11.1 Double Point Relay Flowmeter/Alarm (DNALL-P):

The Hastings Flowmeter/Alarm is a complete Linear Mass Flowmeter with all of its characteristics and

ranges. It also includes two adjustable HI-LO set points which can be read on the digital indicator. When

the flow rate exceeds the pre-set LO alarm point, the LO relay is energized; then its normally closed (NC)

contact opens and the normally open (NO) contact closes. This sequence also occurs when the flow rate

exceeds the pre-set HI alarm point. The SPDT relays de-energize and return to their normal state when the

flow rate drops below the pre-set alarm points. The relays are rated 5 amps @ 115 VAC.

11.2 Totalizers (TNALL-P):

11.2.1 Descriptions

The Hastings Mass Flow Totalizer is an electronic/mechanical device which, when used in conjunction

a. Specifications: (For Totalizer Only)

1 Accuracy: 25BC and 115 K 15 VAC K ½% F. S.

1 Count Rate: 5, 10, 50 & 100 Counts/Min. @ F. S. Flow –selectable by use of the front panel

switch.

1 Power: 115 volts AC 50-60 Hz, 10 watts.

b. Circuits

The circuit for the Totalizer is a voltage to frequency converter which produces a pulse rate linear

proportional to the 0-5 volts DC input signal. The pulse rate is set by the factory on standard units for 5, 10,

50, and 100 counts/min. Any of the four ranges can be selected with the Range Selector switch on the front

panel or by changing a jumper on the back panel on some models. Normally ranges are 5 cpm or 50 cpm for

a 5, 50, 500, 5K, or 50K SCCM range. 10 cpm are used for a 10, 100, 1K, or 10K SCCM range. Other

count rates up to 1000 counts/min. are available on special order.

Special count rates are optional when the range of the flowmeter does not correspond to the factor of 5 or 10.

c. Counter

The pulses from the Totalizer circuit are accumulated by the six-digit electro-mechanical counter. The

counter recycles automatically at 999,999 or can be manually reset to zero at any time.

11.2.2 Mounting

The Hastings Mass Flow Totalizer is normally built into a NIM style Hastings Mass Flowmeter power

supply. The meter is designated by the prefix T.

11.2.3 Totalizer Sensitivity

The Totalizer count rate varies in direct proportion to flowmeter output variations. Therefore, the total

number of counts over a period of time can be realted to the total flow for that period by determining the

sensitivity of the flowmeter/Totalizer combination. The sensitivity is the full-scale count rate of the

Totalizer.

Example: A TNALL-P Flowmeter with an HS-10S transducer is used with the Range Selector set for 100

cpm over a period of 7 hours, and a total of 13,500 counts accumulate on the counter.

Manual 111-082010_Nall Mass Flowmeters Page 21 of 23

Page 22

a) What is the sensitivity of the totalizer?

b) What is the total flow indicated by the 13,500 count?

c) What is the average flow rate over the 7 hour period?

Solution: a) The full scale flow rate for the TNALL-P/HS-10S is 10 SCCM. The full-scale count rate for the

totalizer is 100 counts per minute.

Sensitivity = F. S. flow rate

F. S. countrate

= 10 std. cm³/min.

100 counts/min.

d) The total flow indicated by 13,500 counts is:

Total flow = total counts X sensitivity

= 13,500 counts X 0.1 std cm³/min.

= 1350 std cm³

c) The average flow rate over the 7 hour period is the total flow divided by the time:

Average Flow Rate = Total Flow

Time

= 1350 std cm³

7 hrs X 60 min/hr

= 1350 std cm³

420 min.

= 3.2 std cm³/min.

If a special gas is used with the flowmeter (other than that for which it was originally calibrated), refer to

Section 5.5 to determine the new full-scale flow rate for the special gas. Once the full-scale rate for the

special gas is obtained, it may be used with the equations above to determine the sensitivity of the totalizer in

std. cm³/count.

11.2.4 Maintenance

The totalizer is all solid-state and is designed for a long life expectancy and no maintenance is normally

required. Should the totalizer or counter need repair, return them to Teledyne Hastings with a statement

describing the problem; use the form on page 35.

11.3 Chassis Model (NALL-C):

Hastings Chassis Linear Mass Flowmeters are designed for installations where the electronic circuits are

remotely mounted from both the transducer and readout. It is particularly useful in applications where the

meter must be located long distances from the transducer. Thus, the transducer cable is kept short, and the

meter may be located long distances from the Chassis without concern for cable losses. Also, panel space is

reduced to that of the meter only. The Chassis is designated by adding the suffix “C” to the Cabinet Model

number; NALL becomes NALL-C.

11.4 Current Converter (NAll-P/CC):

A 4-20 mA current converter is an option available with the Hastings Mass Flowmeter. The Hastings 4-20

mA may be built into a flowmeter package or supplied as a separate unit. The converter produces a 4-20 mA

current signal from the 0-5 VDC output of the flowmeter.

Manual 111-082010_Nall Mass Flowmeters Page 22 of 23

Page 23

12.0 Warranty and Repair

12.1 Warranty Repair Policy

Hastings Instruments warrants this product for a period of one year from the date of shipment to be free

from defects in material and workmanship. This warranty does not apply to defects or failures resulting from

unauthorized modification, misuse or mishandling of the product. This warranty does not apply to batteries

or other expendable parts, or to damage caused by leaking batteries or any similar occurrence. This warranty

does not apply to any instrument which has had a tamper seal removed or broken.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty as to

fitness for a particular use. Hastings Instruments shall not be liable for any indirect or consequential

damages.

Hastings Instruments, will, at its option, repair, replace or refund the selling price of the product if Hastings

Instruments determines, in good faith, that it is defective in materials or workmanship during the warranty

period. Defective instruments should be returned to Hastings Instruments, shipment prepaid, together

with a written statement of the problem and a Return Material Authorization (RMA) number.

Please consult the factory for your RMA number before returning any product for repair. Collect freight will

not be accepted.

12.2 Non-Warranty Repair Policy

Any product returned for a non-warranty repair must be accompanied by a purchase order, RMA form and a

written description of the problem with the instrument. If the repair cost is higher, you will be contacted for

authorization before we proceed with any repairs. If you then choose not to have the product repaired, a

minimum will be charged to cover the processing and inspection. Please consult the factory for your RMA

number before returning any product repair.

TELEDYNE HASTINGS INSTRUMENTS

804 NEWCOMBE AVENUE

HAMPTON, VIRGINIA 23669 U.S.A.

ATTENTION: REPAIR DEPARTMENT

TELEPHONE (757) 723-6531

TOLL FREE 1-800-950-2468

FAX (757) 723-3925

E MAIL hastings_instruments@teledyne.com

INTERNET ADDRESS http://www.teledyne-hi.com

Repair Forms may be obtained from the “Information Request” section of the Hastings Instruments web

site.

Manual 111-082010_Nall Mass Flowmeters Page 23 of 23

Loading...

Loading...